®

Victoreen

Digital Preamplifier, Model 943-227-15,for use with

Model 943-27 Current Mode Beta Detector

February 2008

Manual No. 943-227-15-1, Rev. 3

©2007, 2008 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies

Operator Manual

Fluke Biomedical

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

www.flukebiomedical.com

Table of Contents

Section 1: General Information............................................................................................................. 1-1

1.1 General Description ............................................................................................................... 1-1

1.2 Application.............................................................................................................................. 1-1

1.3 Specifications ......................................................................................................................... 1-2

1.4 Auxiliary Equipment ............................................................................................................... 1-6

1.5 Recommend Spare Parts.......................................................................................................1-6

1.6 Receiving Inspection .............................................................................................................. 1-6

1.7 Storage................................................................................................................................... 1-7

Section 2: Theory of Operation............................................................................................................. 2-1

2.1 Functional Description............................................................................................................ 2-1

2.2 Main Circuit Boards................................................................................................................ 2-1

2.3 977-200-15M Electrometer Board.......................................................................................... 2-1

2.4 977-210-10M Interface Board ................................................................................................ 2-4

2.5 Preamplifier Switch & Jumper Settings.................................................................................. 2-5

Section 3: Operation .............................................................................................................................. 3-1

3.1 Installation .............................................................................................................................. 3-1

3.2 Set-Up .................................................................................................................................... 3-2

3.3 Operation ............................................................................................................................... 3-3

3.4 Configuration Functions ......................................................................................................... 3-4

3.5 Set point Error Codes............................................................................................................. 3-5

3.6 Software Calculations ............................................................................................................ 3-5

Section 4: Maintenance, Calibration and Troubleshooting ............................................................... 4-1

4.1 Maintenance........................................................................................................................... 4-1

4.2 Calibration .............................................................................................................................. 4-1

4.3 Troubleshooting ..................................................................................................................... 4-2

Appendix A: Connector Designations .....................................................................................................A-1

A.1 Connector Designations......................................................................................................... A-1

Appendix B: Applicable Drawings............................................................................................................ B-1

B.1 Applicable Drawings............................................................................................................... B-1

Appendix C: Bill of Materials.....................................................................................................................C-1

C.1 Bill of Materials.......................................................................................................................C-1

Appendix D: Cable Termination Instructions..........................................................................................D-1

D.1 Cable Termination Instructions ..............................................................................................D-1

Appendix E: Modification Sheets/Engineering Instructions............................ .....................................E-1

E.1 Modification Sheets/Engineering Instructions........................................................................ E-1

(Blank page)

General Information

General Description

1

Section 1

General Information

1.1 General Description

The Victoreen® Model 943-227-15 Digital Preamplifier, is designed to operate with the Model 943-27,

Current Mode Beta Scintillation detector and the Model 942A-200C Series Digital Ratemeter (UDR) or the

Model 960 Series Digital Process Control system. When connected to the beta sensitive scintillation

detector, it comprises a monitoring system which operates in the range of 10

Pico amperes). The UDR provides display, control, and annunciator functions for the monitoring system.

The preamplifier contains a microprocessor controlled, auto-zeroing, integrating electrometer, a

programmable gain amplifier, an analog-to-digital converter and an asynchronous serial communications

interface. Communications with the UDR is accomplished via the optically isolated Victoreen Serial

Communication Loop driver/receiver circuitry.

Interconnection of the detector and preamplifier is accomplished utilizing two, six (6) foot coaxial cables.

One cable supplies the high voltage for the detector (negative polarity). The other cable is used for the

detector output signal. Interconnection between the preamplifier and the UDR or 960 system is

accomplished via a six-conductor cable and a high voltage coaxial cable.

The detector operates at a potential of approximately (-) 500 VDC, and produces a nominal DC output

current of 1 x 10

this corresponds to a range of 1 x 10

The preamplifier is a self-contained electronics unit that processes the DC input signal from the detector,

digitizes the signal, and transmits the digitized value to the readout via a modified RS232C compatible

serial data communication port. It contains two printed circuit boards (mounted on the rear of the

enclosure cover, a terminal block for terminating the field cable from its associated controller and two

connectors for terminating the detector Signal and HV coaxial cables. The larger of the two printed circuit

boards is the 977-210-10M Serial Interface board. This board controls the communications with the

controller. The smaller board is the 977-200-15M Electrometer. It contains the microprocessor and

associated circuitry for converting the detector output current into a digital value.

For additional information on the detector or readout device, refer to the instruction manual for the Model

943-27-31 detector, the Model 942A-200C UDR, or the applicable Model 960 System manual.

-12

amperes to 1 x 10

-4

amperes. Depending on sampling geometry and detector set up,

-3

to 1 x 10

+5

uCi/cc.

-3

to 105 uCi/cc (or 1E0 to 1E8

1.2 Application

The Model 943-227-15 Digital Preamplifier is used with the Victoreen 942A-200C or Model 960

microprocessor based radiation monitors. The Model 942A-200C or 960 system provides the +15 VDC

preamplifier electronics power, (-) 500 VDC detector power and the RS232C serial communications

support. The digital preamplifier is available in two serial port configurations. For applications less than

50 feet, the Model 943-227-15, configured for RS232C communications, is used. For applications

requiring signal transmission distances of up to 1 mile, the Model 943-227-15VL, configured for Victoreen

Loop communications is used. Table 1-1 is a list of available configurations and compatible 9XX series

equipment. Please contact Fluke Biomedical Radiation Management Services for additional information.

1-

1

943-227-15 Digital Preamplifier

Operator Manual

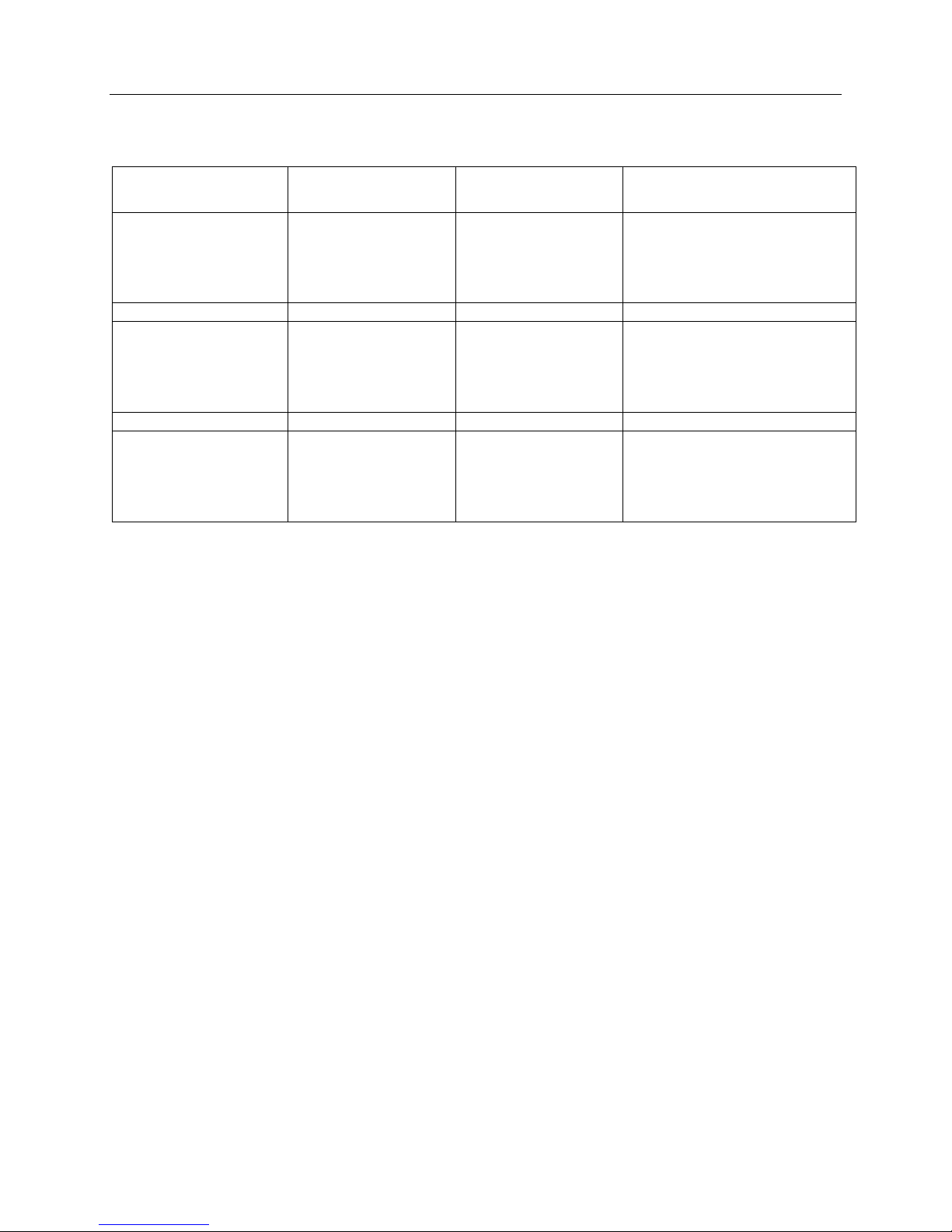

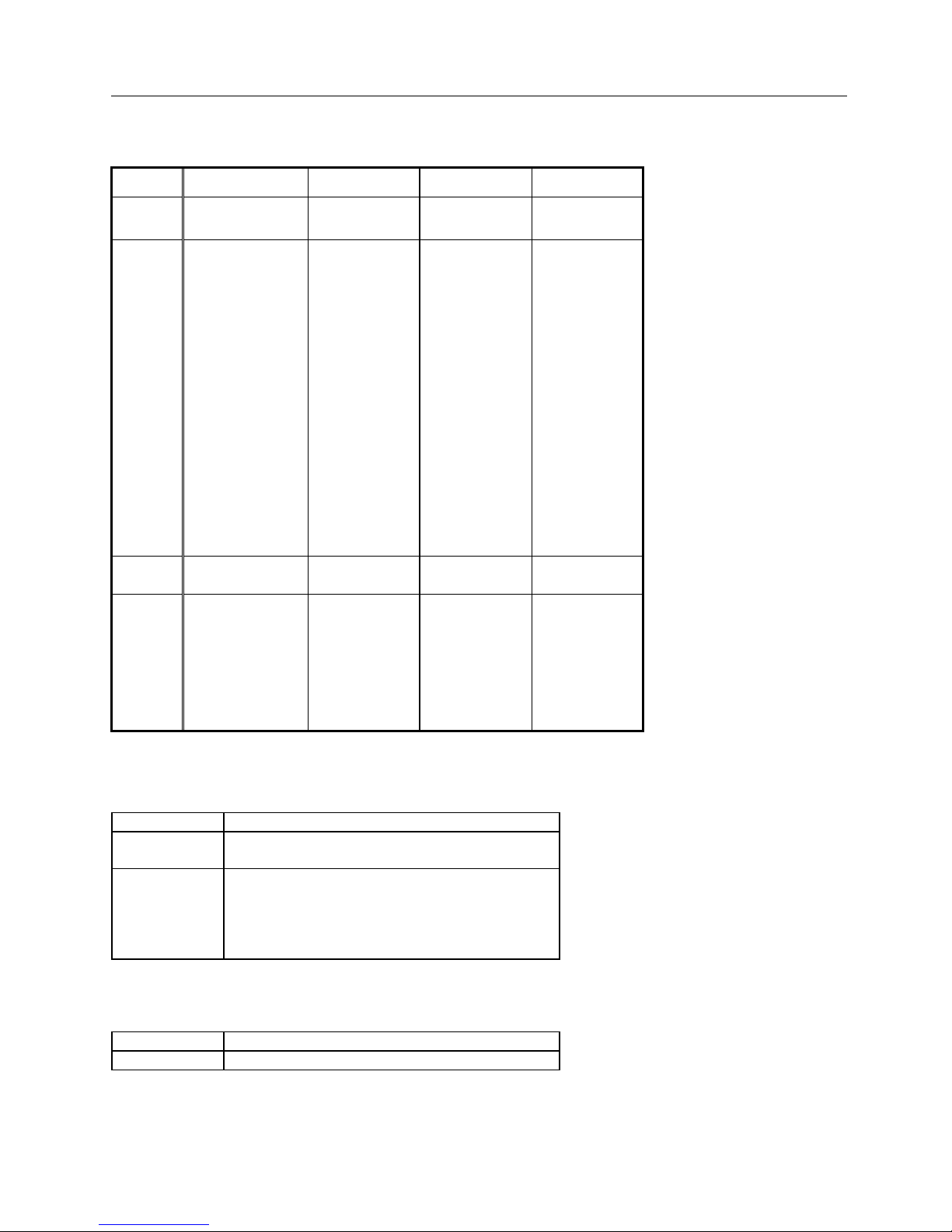

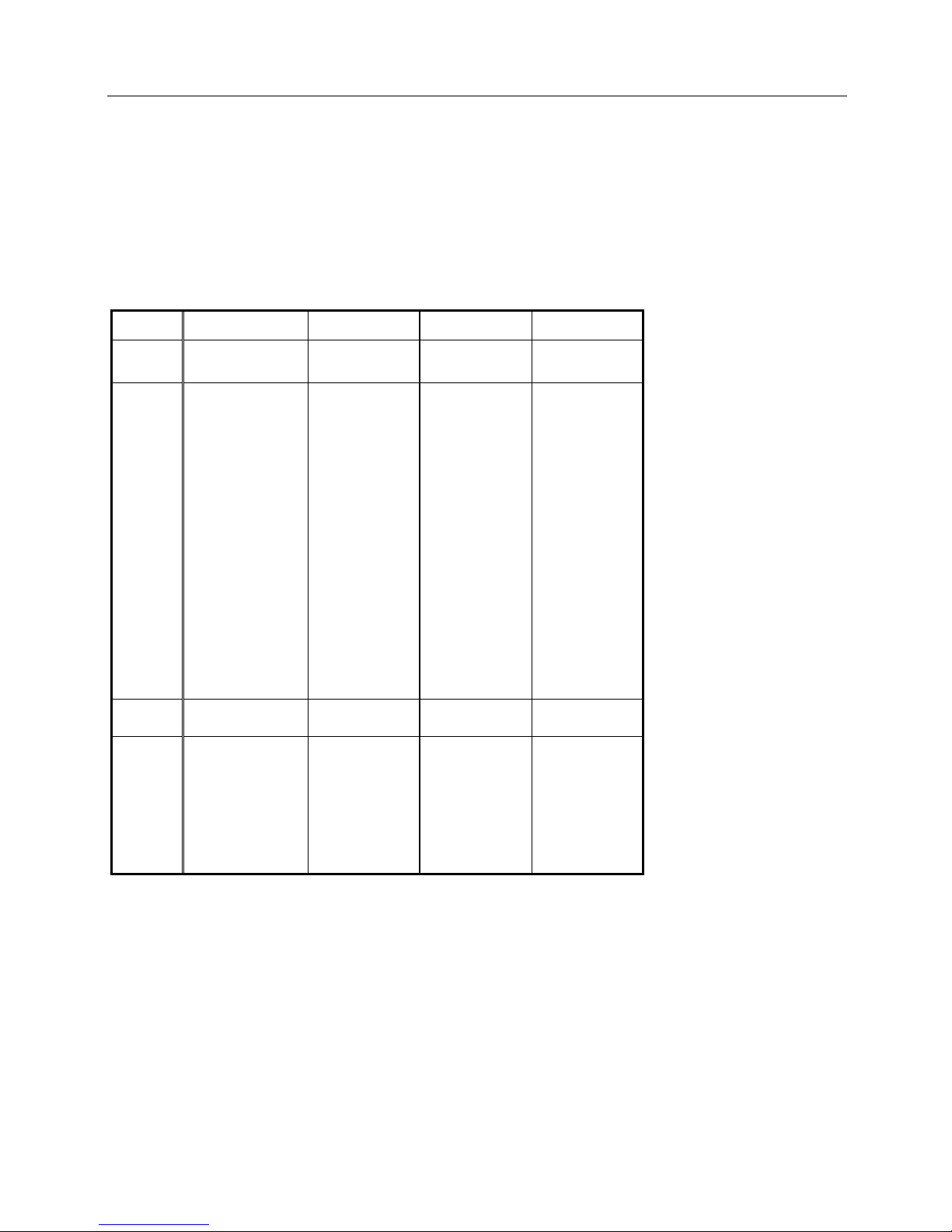

Table 1-1. 943-227-15 Variations and Compatible Equipment

Preamplifier

Variations

943-227-15 Digital

Preamplifier

943-227-15VL Digital

Preamplifier

943-227-15VL-M1

Digital Preamplifier

Application Detector Readout

Transmission

Distances

Less than 50 feet

Transmission

Distances up to 1

mile

Transmission

Distances up to 1

mile; 2.0 inch conduit

field cable interface

943-27-31 Beta

Detector,

Current Mode

Operation

943-27-31 Beta

Detector,

Current Mode

Operation

943-27-31 Beta

Detector,

Current Mode

Operation

942A-200C Digital Ratemeter

or Model 960 Digital Process

Control System

942A-200C Digital Ratemeter

or Model 960 Digital Process

Control System

942A-200C Digital Ratemeter

or Model 960 Digital Process

Control System

1.3 Specifications

General specifications for the Model 943-227-15 Digital Preamplifier are listed below. The 943-227-15

series products are designed for nuclear applications, and any repairs to it by personnel not qualified to

ANSI 45.2.6 1978, Skill Level II may void the nuclear rating.

If a problem develops, the preamplifier may either be returned to the factory for service, or repaired by a

qualified technician.

1-2

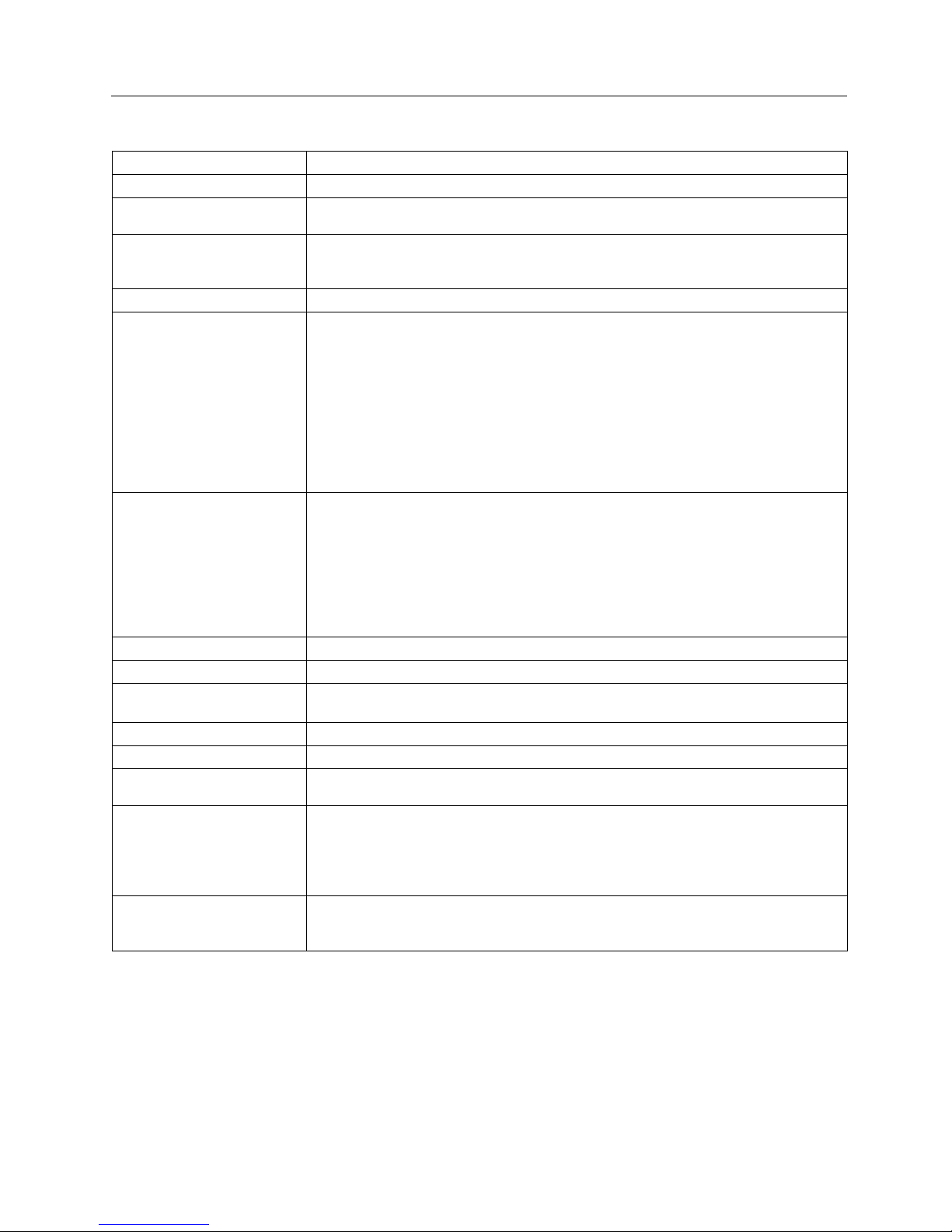

Table 1-2. General Specifications for the 943-227-15 Digital Preamplifier

Feature: Specification:

Preamplifier Power

Preamplifier Input

Preamplifier Output

Electronic Accuracy

Response Time

Dimensions

(H x W x D)

Weight

Housing

Operating Temperature

Relative Humidity

Compatible Detectors

Detector Interface

Cable Requirements

Modification

Information

+ 15 v @ 20 mA

DC current, 1E-12 to 1E-3 amperes from 943-27 Current Mode Beta

Scintillation detector

943-227-15, RS232C;

943-227-15VL, Modified RS232C serial data for transmission distances up

to 5,280 feet.

± 10% of the input current

Decade / Time:

1 / 80 sec

2 / 32 sec

3 / 16 sec

4 / 4 sec

5 / 2 sec

6 / 0.9 sec

7 / 0.2 sec

8 / 0.2 sec

943-227-15 or 943-227-15VL:

8.0 in. x10.0 in. x 4.0 in.

(20.3 cm x 25.4 cm x 10.2 cm)

943-227-15-M1 or 943-227-15VL-M1:

8.0 in. x10.0 in. x 6.0 in.

(20.3 cm x 25.4 cm x 15.2 cm)

Approximately 8 lbs. (3.6 kg)

Gasketed, NEMA 4, Steel enclosure with hinged cover

32 °F to 122 °F

0 °C to + 50 °C

0 to 99 % non-condensing

Victoreen 943-27 Current Mode Beta scintillation detector only

Detector cables enter thru “Seal Grip” fittings; Mating SHV receptacle

provided for HV; Mating BNC receptacle provided for Signal

Victoreen Loop Communications: 6 conductors, 18 AWG (2, TwPr, 2 Single

conductor) with overall shield. For max transmission distance, 16 AWG is

recommended;

RS232C communications: 8 Conductors, 18 AWG (4 TwPr) with overall

shield.

For the Model 943-227-15VL-M1, refer to Modification description provided

in Appendix E

General Information

Application

1

1-3

943-227-15 Digital Preamplifier

Operator Manual

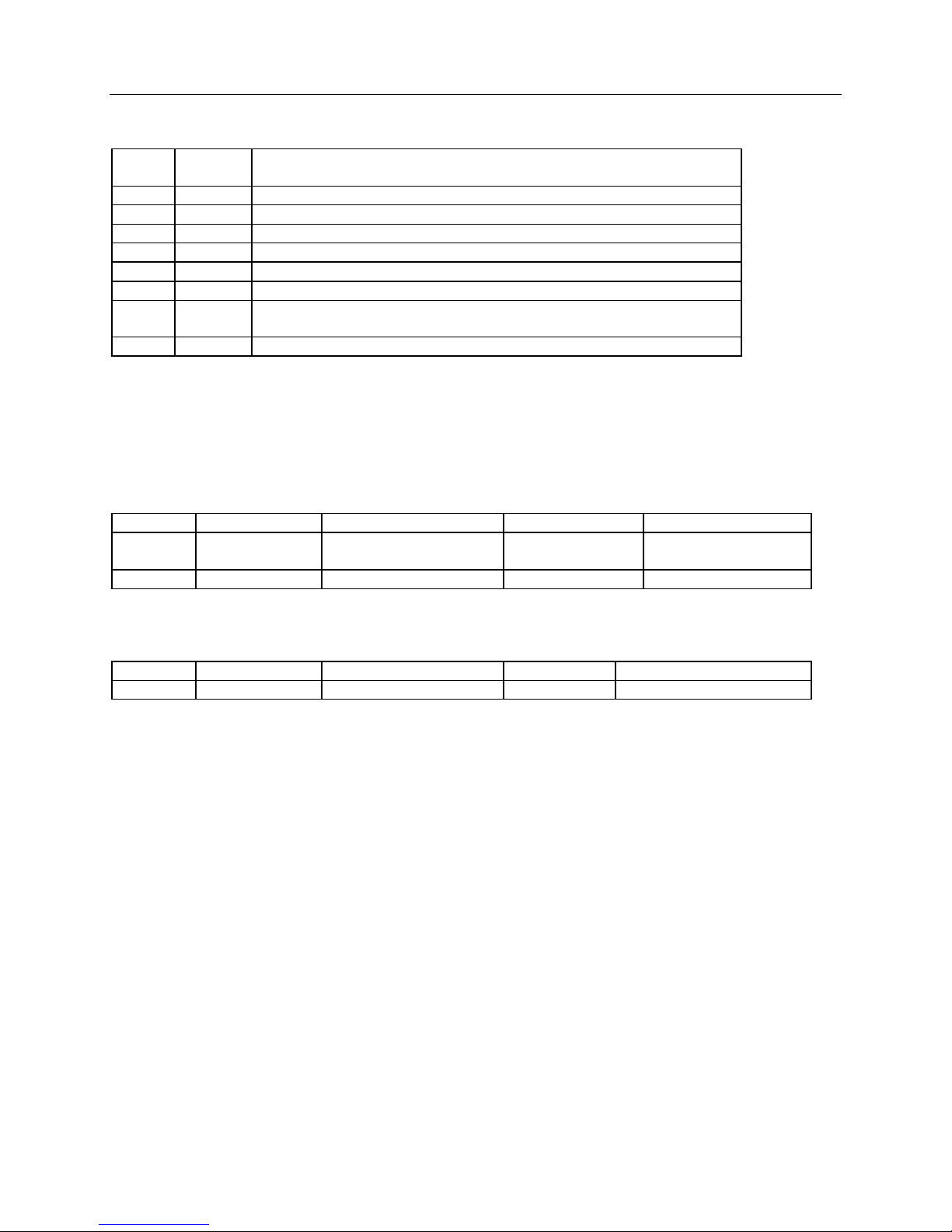

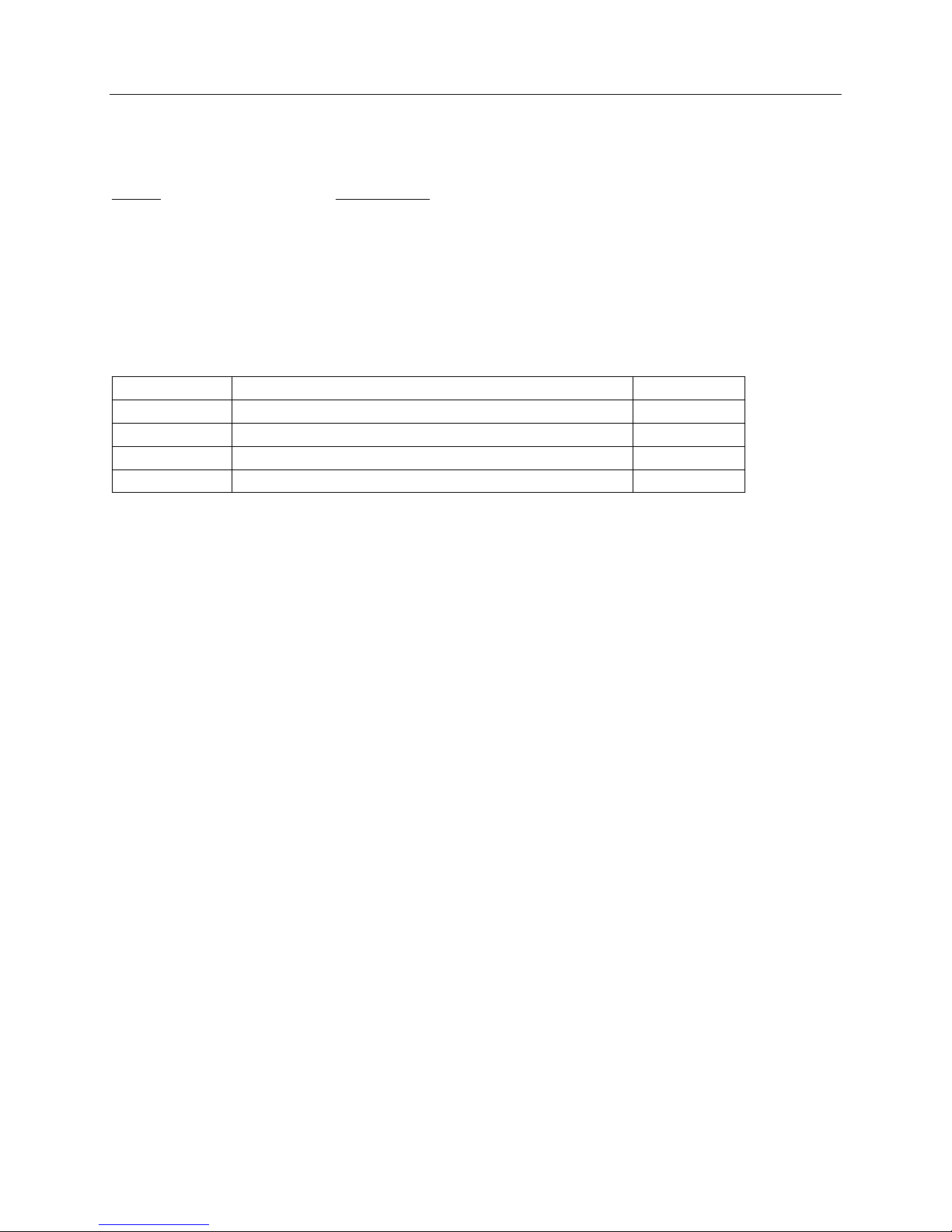

Table 1-3. Preamplifier Serial Interface Board 977-210-10M Switch Settings

Switch Normal

Op.

SW1 Open Microprocessor Reset switch, momentary contact

SW2 N/A Not supplied

SW3-1 ON OFF Selects 300 baud • 1/ON Selects 4800 baud (normal setting)

SW3-2 OFF OFF • (No function is implemented in the 977-210-10M)

SW3-3 OFF OFF Selects Rate Mode (normal) • (Selects Maintenance Mode for

SW3-4 OFF OFF • (No function is implemented in the 977-210-10M)

Switch Function

factory PGA and Auto Zero set-up only)

NOTE

SW3 is a 4-position DIP switch on the 977-210-10M serial

interface board.

Table 1-4. Jumper Positions for Preamplifier Serial Interface Board 977-210-10M

Jumper Normal Setting Function Alternate Setting Function

JMP1 A to B

JMP2 N/A Deleted, Not Used N/A Deleted, Not Used

Table 1-5. Jumper Positions for Preamplifier Electrometer Board 977-200-15M

Jumper Normal Setting Function Cal. Position Function

JMP1 A to B Normal Operation B to C PGA Offset Adjust *

* Programmable Gain Amplifier requires a special test PROM and is a factory adjustment

Enables Victoreen Loop

(normal)

B to C Enables RS232C

1-4

Table 1-6. Field Electrical Connections, 943-227-15 and 943-227-15VL

General Information

Specifications

1

943-227-15

TB1- Description

1 XMIT

2 DTR

3 GND

4 REC

5

6

7 + 15 VDC J3-7 Not Used

8 Ground

9 - 15 VDC J3-4 Not Used Not Used

10 Not Used Not Used Not Used J3-11

HV Detector MHV

SIG Detector BNC

Table 1-7. 977-210-10M LEDs

LED # Indicates

LED1 +15 VDC is being supplied to the circuit board

LED2 Communications – Receive;

Table 1-8. 977-210-10M Test points

Test Point Function

TP2 RS232 Transmit

Not Used

Not Used

Detector

Connections

from the UDR when ON

ON (bright): both + 15 and -15 volt loops

present

ON (dim): Only one loop supply present

OFF: no loop voltage from either supply

Connects To

977-210-10M

J4-1

J4-2

J4-3

J4-4

Not Used

Not Used

J3-8

From Field

coaxial cable

Factory

Terminated,

To 977-200-

15M, R41

943-27-15VL

Description

+ VL, 15

VDC

+ TX

- TX

- VL

+ RX

- RX

Ground

Detector

Connections

Detector

MHV

Detector

BNC

Connects To

977-210-10M

J3-1

J3-2

J3-3

J3-4

J3-5

J3-6

Not Used

J3-8

From Field

coaxial cable

Factory

Terminated,

To 977-200-

15M, R41

1-

5

943-227-15 Digital Preamplifier

Operator Manual

1.4 Auxiliary Equipment

Model Description

None

1.5 Recommended Spare Parts

Table 1-9. Recommended Spare Parts List for the Model 943-227-15 Digital Preamplifier

Part Number Description Used On

977-200-15M Electrometer Circuit Board -

977-210-10M Serial Interface Circuit Board -

92-7072 Fuse, F1, F2, 1Amp, Communication Fuse

450-1-0531 Dryer, Air (5 Grams)

977-210-10M

977-200-15

1.6 Receiving Inspection

Upon receipt of the unit:

1. Inspect the carton(s) and contents for damage. If damage is evident, file a claim with the carrier and

notify the Fluke Biomedical Radiation Management Services Customer Service Department.

Fluke Biomedical

Radiation Management Service

6045 Cochran Road

Cleveland, Ohio 44139

Phone: 440.248.9300

Fax: 440.542.3682

2. Remove the contents from the packing material.

3. Verify that all items listed on the packing list have been received and are in good condition.

NOTE

If any of the listed items are missing or damaged, notify the

Fluke Biomedical Radiation Management Service Customer

Service Department.

1-6

General Information

Spare Parts/Receiving Inspection

1

1.7 Storage

Storage of Fluke Biomedical instruments must comply with Level B storage requirements as outlined in

ANSI N45.2.2 (1972) Section 6.1.2(.2). The storage area shall comply with ANSI N45.2.2 (1972) Section

6.2 Storage Area, Paragraphs 6.2.1 through 6.2.5. Housekeeping shall conform to ANSI N45.2.3 (1972).

Level B components shall be stored within a fire resistant, tear resistant, weather tight enclosure, in a

well-ventilated building or equivalent.

Storage of Fluke Biomedical instruments must comply with the following:

1. Inspection and examination of items in storage must be in accordance with ANSI N45.2.2 (1972)

Section 6.4.1.

2. Requirements for proper storage must be documented and written procedures or instructions must

be established.

3. In the event of fire, post-fire evaluation must be in accordance with ANSI N45.2.2 (1972), Section

6.4.3.

4. Removal of items from storage must be in accordance with ANSI N45.2.2 (1972), Sections 6.5 and

6.6.

1-

7

(Blank Page)

Theory of Operation

Functional Description

2

Section 2

Theory of Operation

2.1 Functional Description

The Model 943-227-15 Digital Preamplifier is an eight-decade, linear reading radiation. The preamplifier

is sensitive to moisture and is mounted in a NEMA 4 sealed enclosure. The preamplifier box contains a

desiccant package to remove moisture from the interior of the preamplifier. The desiccant has a color

indicator to show when it should be replaced when the color changes to blue.

The detector electrometer converts the current from the detector to a voltage which is measured by the

analog to digital converter of the preamplifier. Under program control, this measurement is made every

50 milliseconds on the first five decades and every 100 milliseconds on the upper three decades.

The electrometer is auto-ranging and auto-zeroing. An internal coarse zero control (factory adjusted) is

provided. The microprocessor in the preamplifier performs data collection, integration and multiplication

by a stored calibration factor, range changing and communication with the Model 942A-200C Digital

Ratemeter or Model 960 Digital Process Radiation monitoring system.

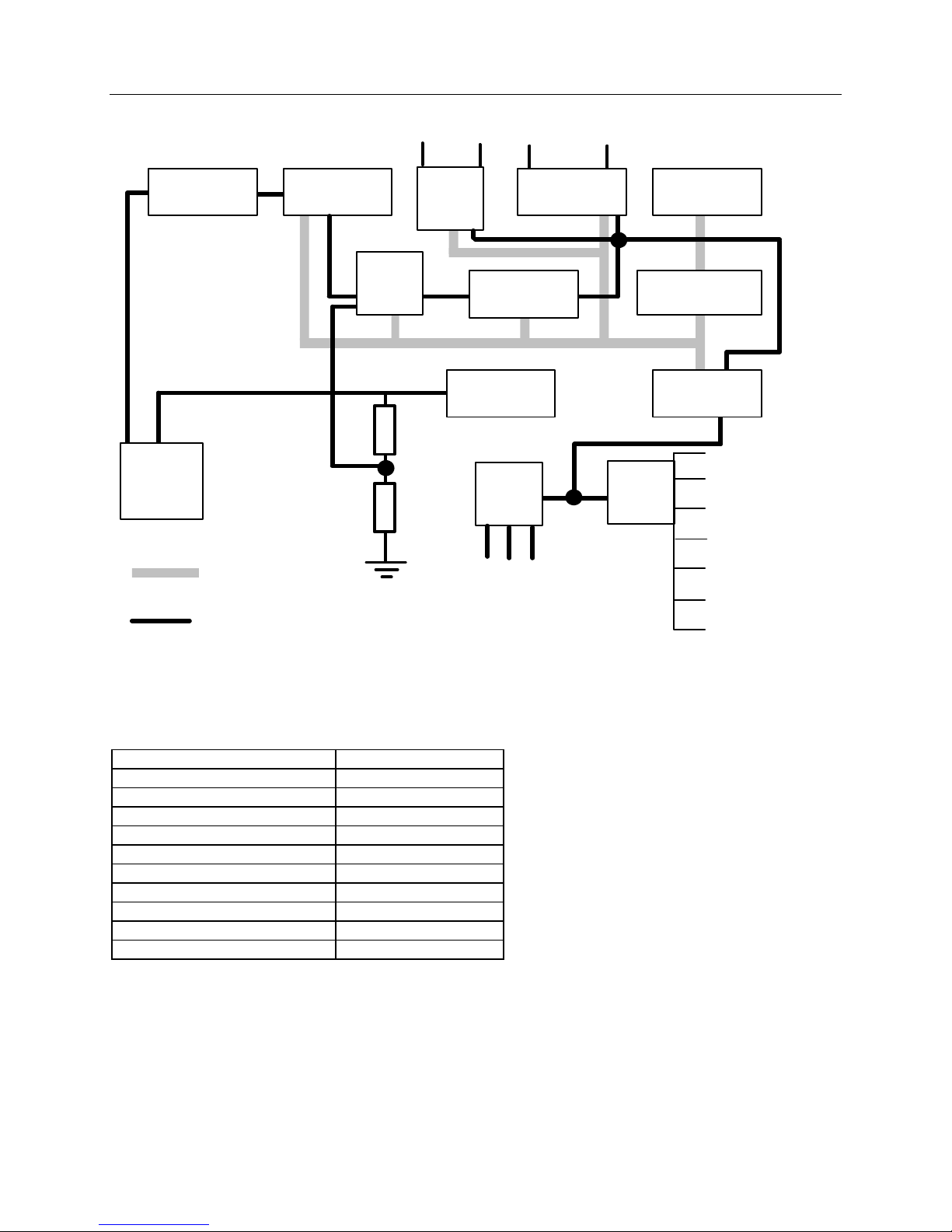

2.2 Main Circuit Boards

The wide range ion chamber detector block diagram is shown in figure 2-1. Detector electronics are

contained within two circuit board assemblies located in the preamplifier enclosure: the 977-210-10 High

Voltage/Communications Interface circuit board assembly and the 977-200-15 Electrometer circuit board

assembly. Schematic diagrams are located in Appendix B.

The 977-200-15M Electrometer circuit board contains the microprocessor, the EPROM, the integrating

electrometer, the programmable gain amplifier, the analog to digital (A/D) converter, and the auto zero

DAC circuit.

The 977-210-10M Communications Interface circuit board contains the dc voltage regulator, the BDC/DC

converter, the asynchronous communication interface adapter (ACIA), the Victoreen communication loop

driver/receiver, the RS232 communications driver/receiver, and the communication loop fuses.

2.3 977-200-15M Electrometer

Refer to the electrometer schematic 977-200-18M located in Appendix B. Z7 is a Texas Instruments TMS

70C00 microprocessor, which is utilized to control detector operation. Z8 latches port C of the

microprocessor to form the lower order bits of memory address. Z10 is a 27C64 EPROM containing the

operational firmware for the detector. Z18 is an optional RAM socket which is not utilized for this model

detector. Z9 is a decoder for the upper order address bits. Z11 is a latch used to store control bits to

select the gain of the programmable gain amplifier formed by the combination of Z5, Z4, and RN2.

Available gains are 1 through 128 in binary increments 1, 2, 4, . . . 128. Z3 is an eight-bit analog to digital

converter used to digitize the output of the programmable gain amplifier. Analog switch Z17 pin 11

selects either the integrating electrometer or the high voltage sense line as the input to the programmable

gain amplifier is not active in this application. Refer to Table 2-1 for preamplifier register addresses and

Table 2-2 for electrometer control bit assignments.

2-1

943-227-15 Digital Preamplifier

Operator Manual

0/-12 Vdc

0 - 10 Vdc

INTEGRATING

ELECTROMETER

SIGNAL

DETECTOR

ASSEMBLY

PGA

ANALOG

SWITCH

HIGH VOLTAGE

MICROPROCESSOR

CONTROL

SIGNAL

ALARM

OUTPUT

Resistor

Resistor

DAC EPROM

ADC

HIGH VOLTAGE

POWER SUPPLY

RS232

Figure 2-1. Typical Detector Electronics Block Diagram

Table 2-1. Preamplifier Register Addresses

Function Hex Address

Electrometer Control 2000

ADC Convert CMD 4000

ADC Read Data 6000

ACIA T/R Data A000

ACIA Status Register A001

ACIA Command Register A002

ACIA Control Register A003

Input SW3 A008

RAM (not used) C000-DFFF

EPROM E000-FFFF

CONTROL

MICROPROCESSOR

+VL

VICO

LOOP

+TX

-TX

+RX

-RX

-VL

ACIA

2-2

Theory of Operation

Main Circuit Boards

2

Table 2-2. Electrometer Control Bit Assignments

Bit Position

7 6 5 4 3 2 1 0 Description

X X X X X 0 0 0 Gain = 1

X X X X X 0 0 1 Gain = 2

X X X X X 0 1 0 Gain = 4

X X X X X 0 1 1 Gain = 8

X X X X X 1 0 0 Gain = 16

X X X X X 1 0 1 Gain = 32

X X X X X 1 1 0 Gain = 64

X X X X X 1 1 1 Gain = 128

X X X X 0 X X X Unshort capacitor

X X X X 1 X X X Short capacitor

X X X 0 X X X X Digitize electrometer

X X X 1 X X X X Digitize high voltage

X = Bit position does not matter (1 or 0)

The integrating electrometer is formed by the combination of current source Z6, dual MOSFET Q4,

operational amplifier Z12, transistor Q3, and analog switch Z17, pin 15.

Counter Z15 and ladder network RN3 form the auto-zero portion of the integrating electrometer. Refer to

section 4 for auto-zero adjustment instructions (note this is a factory only adjustment).

Dual MOSFET Q4 acts as a low leakage input buffer to the electrometer. C17 is an integrating capacitor,

while Z17, pin 15 and Q3 are the shorting elements of the integrator.

There is a hysteresis built into the range changing function of the electrometer. The range change-up

occurs at the decade points whereas the range change-down occurs at 80% of the decade points. This

hysteresis results in the display of only two significant digits when in the upper 20% of a decade.

Whether or not this occurs depends on which direction the radiation level is trending. An increasing trend

will result in three significant digits while a decreasing trend will result in two significant digits.

The response times for a change in reading within the same decade are listed in Table 2-1. If a change

of 100 to 1000 times the current reading occurs, the instrument will range change within a single 50millisecond clock cycle.

Table 2-3. Response Time

DECADE RANGE RESPONSE TIME

1 0.1 to 1.0 mR/h 80 sec.

2 1.0 to 10 mR/h 32 sec.

3 10 to 100 mR/h 16 sec.

4 100 to 1000 mR/h 4 sec.

5 1.0 to 10 R/h 2 sec.

6 10 to 100 R/h 0.9 sec.

7 100 to 1000 R/h 0.2 sec.

8 1.0 k to 10 kR/h 0.2 sec.

2-3

943-227-15 Digital Preamplifier

Operator Manual

The following Test are provided on the 977-200-15M board:

Table 2-4. 977-200-15M Test Points

Test Point Function

TP1 Electrometer Output

TP2 Analog +5 VDC supply

TP3 - 5 VDC supply

TP4 Digital +5 VDC supply (From 977-210-10M)

TP5 High Voltage Sense (Not Used)

TP6 + 12 VDC supply (From 977-210-10M)

TP7 DC Ground

TP8 Programmable Gain Amplifier Output

TP9 Microprocessor Clock Signal

TP10 Chip Enable - EPROM

2.4 977-210-10M Interface Board

Refer to the Communications Interface, P/N 977-210-13M, schematic diagram in Appendix B. U12 is an

asynchronous communications interface adapter (ACIA) which communicates with the UDR or 960

system. U1 is an analog switch used to select either the Victoreen loop or the RS232 driver/receiver for

external communications. Optical isolation U10 isolates data transmitted on the Victoreen loop while the

circuitry comprised of Q6, Q7, Q14, and Q18 are the actual loop drivers. Optical isolator U8 isolates the

receive data from the Victoreen loop.

U2 and U3 are, respectively, the receiver and driver circuits for the RS232 port. U14 decodes address

block A000 to provide chip enables to the ACIA switch input register U6.

Regulated power for the electronics (+/- 12 VDC) is derived from three terminal regulators VR3 and VR4.

The ±5 Vdc logic power is derived from the three terminal regulators VR1 and VR2.

Power for the detector is normally provided by the electronic high voltage power supply in the asso ciated

Model 942A-200C UDR or Model 960 System.

The following LEDs are provided to indicate operation of certain functions of the 977-210-10M board:

Table 2-5. 977-210-10M LEDs

LED # Indicates

LED1 +15 VDC is being supplied to the circuit board

from the UDR when ON

LED2 Communications – Receive;

ON (bright): both + 15 and -15 volt loops

present

ON (dim): Only one loop supply present

OFF: no loop voltage from either supply

The following Test are provided on the 977-210-10M board:

Table 2-6. 977-210-10M Test points

Test Point Function

TP2 RS232 Transmit

2-4

Theory of Operation

Communications

2

Victoreen Communications Loop – 943-227-15VL

Communication between the detector preamplifier and the UDR or 960 controller may be perfo rmed via

Victoreen loop, a serial asynchronous communications interface. The communication utili zes Victoreen

protocol and is intended for use in electrically hostile environments where high noise immunity is required.

Noise immunity is achieved using differential line driving, and electrically isolating the end of each

transmit/receive pair with opto-isolators. Using a ±15 Vdc communications power supply, each 0 to 1

transition is equivalent to a 30-volt swing in loop voltage. Refer to the Model 942-200-80-1

Communications Board instruction manual for further information.

Jumper JP1 controls the communication communications method employed. JP1, A-B selects Victoreen

loop communications.

RS232C Communications – 943-227-15

Communication between the detector preamplifier and the UDR or 960 controller may be perfo rmed via

RS232C serial asynchronous communications interface. Jumper JP1 controls the communication

communications method employed.

JP1, B-C selects RS232C communications.

2.5 Preamplifier Switch & Jumper Settings

Switch and jumper settings for the preamplifier are summarized in Table 2-7, 2-8, and 2-9.

Table 2-7. Preamplifier Serial Interface Board 977-210-10M Switch Settings

Switch Normal

Op.

SW1 Open Microprocessor Reset switch, momentary contact

SW2 N/A Not supplied

SW3-1 ON OFF Selects 300 baud • 1/ON Selects 4800 baud (normal setting)

SW3-2 OFF OFF • (No function is implemented in the 977-210-10M)

SW3-3 OFF OFF Selects Rate Mode (normal) • (Selects Maintenance Mode for

SW3-4 OFF OFF • (No function is implemented in the 977-210-10M)

Switch Function

factory PGA and Auto Zero set-up only)

NOTE

SW3 is a 4-position DIP switch on the 977-210-10M serial

interface board.

2-5

943-227-15 Digital Preamplifier

Operator Manual

Table 2-8. Jumper Positions for Preamplifier Serial Interface Board 977-210-10M

Jumper Normal

Setting

JMP1 A to B

JMP2 N/A Deleted, Not Used N/A Deleted, Not Used

Table 2-9. Jumper Positions for Preamplifier Electrometer Board 977-200-15M

Jumper Normal

Setting

JMP1 A to B Normal Operation B to C PGA Offset Adjust *

* Programmable Gain Amplifier requires a special test PROM and is a factory adjustment

Function Alternate

Setting

Enables Victoreen Loop

(normal)

Function Cal.

B to C Enables RS232C

Position

Function

Function

2-6

Operation

Installation

3

Section 3

Operation

3.1 Installation

Installation consists of mounting the equipment, making the required electrical connections, and entering

the desired set points.

CAUTION

Remove all power prior to installing the

Preamplifier.

Preamplifier Mounting

The preamplifier is a self-contained unit that is designed for mounting on a wall, or structurally sound

surface, within 6 feet of the detector. The preamplifier must be located in an area that is accessible for

future maintenance.

CAUTION

Remove all power prior to connecting field wiring.

Electrical Interface

Electrical connections at the preamplifier include connecting the detector high voltage and sign al coaxial

cables and the field cable from the associated controller.

The detector high voltage and signal cables enter the preamplifier through “Se al Grip” type penetrations

on the enclosure body. The “Seal Grips” contain a rubber gland that is intended to grip the coaxial cables

to prevent moisture entry into the enclosure. The “Seal Grips” are an integral part of the detector cables.

The “Seal Grip” enclosure nut is removed from the fitting. The insulating washer stay with the fitting. The

detector signal and high voltage cables, with connectors and “Seal Grip” fitting nuts are then inserted into

the holes preamplifier enclosure. The “Seal Grip: end fittings are then re-installed securely again st the

wall of the enclosure.

The detector Signal (BNC) and High Voltage (SHV) cables are then terminated on the bulkhead

connectors located on the enclosure inner panel.

On the 943-227-15 or 943-227-15VL, the field cable is terminated on a “MS” type connector. A mating

“MS” style connector supplied with the detector. It is not necessary to open the preamplifier enclosure to

complete the interconnection to the associated controller.

On the 943-227-15VL-M1, a 2.0-inch conduit hub is provided to interface with the field conduit system

and cable. The field conduit is connected to the preamplifier conduit hub and the field cable is routed

through the conduit and into the preamplifier enclosure. The field signal cable is then terminated on the

terminal block in the enclosure. Refer to the applicable wiring diagram or Table 3-1. The high voltage

coax cable is then terminated on the mating SHV connector. Refer to Appendix D for further information.

A desiccant bag is provided in the enclosure to absorb moisture. The desiccant bags should be checked

for moisture absorption prior to placing into service. Each bag contains a color indicator stripe that turns

red when it should be replaced.

3-1

943-227-15 Digital Preamplifier

Operator Manual

NOTE

The electrometer circuitry in the preamplifier is highly sensitive to

moisture and physical damage. Use extreme care when the

preamplifier case is opened as the high impedance electrometer

circuitry is easily damaged. Do not leave the preamplifier

enclosure in the open position for any extended period of time.

The preamplifier terminations are listed below.

Table 3-1. 943-227-15 Preamplifier Electrical Connections

943-227-15

943-27-15VL

TB1- Description

1 XMIT

2 DTR

3 GND

4 REC

5

6

7 + 15 VDC J3-7 Not Used

8 Ground

9 - 15 VDC J3-4 Not Used Not Used

10 Not Used Not Used Not Used J3-11

HV Detector MHV

SIG Detector BNC

Not Used

Not Used

Detector

Connections

Connects To

977-210-10M

J4-1

J4-2

J4-3

J4-4

Not Used

Not Used

J3-8

From Field

coaxial cable

Factory

Terminated,

To 977-200-

15M, R41

Description

+ VL, 15

VDC

+ TX

- TX

- VL

+ RX

- RX

Ground

Detector

Connections

Detector

MHV

Detector

BNC

Connects To

977-210-10M

J3-1

J3-2

J3-3

J3-4

J3-5

J3-6

Not Used

J3-8

From Field

coaxial cable

Factory

Terminated,

To 977-200-

15M, R41

3.2 Set-up

To place the system in operation, the following steps should be performed:

Ensure you have read and fully understand

Section 1, 2 and 3 prior to continuing.

1. Verify that jumpers and DIP switches and jumpers on the preamplifier, are set for the operational

features desired. Refer to Section 1, Table 1-4.

2. Refer to the applicable controller manual prior to powering up the controller.

3-2

NOTE

943-227-15 Digital Preamplifier

Operator Manual

3-3

Operation

Configuration

3

3.3 Operation

Operation of the 943-227-15 Digital Preamplifier is automatic and is controlled by the Model 942A-200C

Digital Ratemeter or Model 960 Digital Process Radiation monitoring system. Once the power to the

controlling device is turned on, the preamplifier begins operation. No operator interaction is required.

Refer to the instruction manual for the applicable controller, detector and the Model 942-200-80

Communications Option Board for further information.

Normal Operation

If the measured radiation field is within the range of the detector during power-up, the uCi/cc value will be

displayed on the controller. The digital display will update once per second.

Alarms

The radiation alarms are initiated by the applicable controller. Refer to the applicable controller manual.

Fail Alarm

There are two equipment failure conditions that can produce a FAIL output or an error display on the

associated controller. The fail condition is true whenever any equipment failure is detected and false

when no equipment failures are detected.

The following are the fail alarms provided by the 943-227-15 Preamplifier:

1. POWER Failure

2. Loop Test Failure

To return the channel to normal operation after a FAIL alarm, the condition, which caused the alarm, must

be located and corrected.

Power Failure

If the power to the controller is lost, the bar graph, alarm indicators, and the display are blanked (turned

off). The HIGH, WARN, and FAIL relay coils will de-energize. If power to the preamplifier only is lost, or if

there is a break in the power cable, operation of the microprocessor will stop. The display on the

controller will then cease to update. If power to the controller is not lost, a break in the interconnecting

wiring or the internal communication power fuses on the 977-210-10M Interface board should be

checked. Loss of power to the preamplifier will also result in a loop communication failure.

Loop Failure

If the UDR or 960 controller does not receive a valid message from the preamplifier in ten seconds, a loop

failure is detected and an E0009 code will normally be displayed. Note the error code displayed is

defined by the controlling device, and not by the preamplifier.

The loop failure can originate from bad seating of the serial communications board in the UDR or 960CD,

bad connections in the preamplifier, bad connections at the P2 connector of the UDR, a baud rate

mismatch between the setting on the serial board and that in the preamplifier, an invalid address setting

on the serial board, or blown communication loop fuses.

The baud rate of the preamplifier may be set to either 300 or 4800 baud. SW3-1 on the 977-interface

board must be in the ON position to select a baud rate of 4800 baud, the normal setting.

3-4

943-227-15 Digital Preamplifier

Operator Manual

For UDR systems, the address of the 942-200-80 Communications board in the UDR must be set 4040

and the baud rate must be set to 4800 baud. If the wiring of the Communications option board to the P2

connector is suspected, a loop test can be performed as described in "Loop Test Mode". The instruction

manual for the Communications option board (P/N 942-200-80-1) contains information on how to set up

the serial board in the UDR.

Firmware Version

This system requires a PROM for operation. For the part number and the latest revision of the PROM,

see the Factory Test Data Sheet. This Manual has been prepared for use with the P/N 227LNK, Rev. 2,

PROM.

3.4 Configuration Functions

The preamplifier configuration jumpers and required settings for this application are listed below:

Table 3-2. Preamplifier Serial Interface Board 977-210-10M Switch Settings

Switch Normal

Op.

SW1 Open Microprocessor Reset switch, momentary contact

SW2 N/A Not supplied

SW3-1 ON

SW3-2

SW3-3

SW3-4

OFF

OFF

OFF

Switch Function

OFF Selects 300 baud • 1/ON Selects 4800 baud (normal setting)

OFF • (No function is implemented in the 977-210-10M)

OFF Selects Rate Mode (normal) • (Selects Maintenance Mode for

factory PGA and Auto Zero set-up only)

OFF • (No function is implemented in the 977-210-10M)

NOTE

SW3 is a 4-position DIP switch on the 977-210-10M serial

interface board.

Table 3-3. Jumper Positions for Preamplifier Serial Interface Board 977-210-10M

Jumper Normal

Setting

JMP1

JMP2 N/A Deleted, Not Used N/A Deleted, Not Used

Table 3-4. Jumper Positions for Preamplifier Electrometer Board 977-200-15M

Jumper Normal

JMP1

* Programmable Gain Amplifier requires a special test PROM and is a factory adjustment

A to B

Setting

A to B

Function Alternate

Setting

Enables Victoreen Loop

(normal)

Function Cal.

Normal Operation B to C PGA Offset Adjust *

B to C Enables RS232C

Position

Function

Function

3-5

Operation

Configuration

3

3.5 Set Point Error Codes

Failure of the 943-227-17 preamplifier may result in the following error codes being displayed on the

controlling device:

Code E0009 is normally used to identify a Loop communication failure. The error code may be due to a

baud rate mismatch between the preamplifier and the UDR or 960 system communication board, a failure

on either the preamplifier or UDR communication board. To clear the error code, the source of the error

must be corrected.

3.6 Software Calculations

The 943-227-17 continuously converts the current output of the detector to a digital value, controls the

gain of the internal amplifier, performs periodic self checks, communicates with the UDR or Model 960

controller and provides a radiation value to the UDR of Model 960. An asynchronous, serial

communication interface, processed through optically isolated drivers/receivers is utilized. The digital

value is transmitted to the associated UDR or 960 System controller for further processing. Refer to the

associated controller manual for further information. .

3-6

(Blank page)

Maintenance, Calibration and Troubleshooting

Maintenance

4

Section 4

Maintenance, Calibration and Troubleshooting

4.1 Maintenance

The 943-227-15 Digital Preamplifier is designed to operate for extended periods of time with no

scheduled maintenance required. Operation may be verified by periodically actuating the check source

(provided with the detector and sampling assembly) and observing the response of the unit. If the

response varies by more than 50% of the normal value, further troubleshooting may be required. If a

problem develops, troubleshoot the unit per Section 4.3 and the drawings in Appendix B.

Whenever the preamplifier enclosure is opened, the condition of the internal desiccant package should be

checked. The desiccant bag is provided in the enclosure to absorb moisture. The desiccant bags should

be checked for moisture absorption prior to placing into service, or whenever the electronics enclosure

cover is opened. Each bag contains a color indicator stripe that turns red when it should b e replaced.

4.2 Electronic Calibration

Electronic Adjustments

There are no user adjustments available on the 943-227-15 Digital Preamplifier. The Programmable Gain

Amplifier and Auto Zero are factory adjustments, requiring the use of a factory test PROM and test fixture.

We strongly recommend the unit be returned to the factory for repair or adjustment.

Table 4-2 lists the electronic adjustments for the 943-227-15 digital preamplifier. The procedures for

making these adjustments are contained in the factory Calibration Procedure listed below. Note that

special test firmware is required to perform the electrical adjustments.

Table 4-1. Electronic Adjustments

Potentiometer Adjustment (943-227-15) Tolerance

R11 Programmable Gain Amplifier Offset Adjustment ± 2 mV

R12 Auto Zero Set-Up Adjustment ± 10 mV

Refer to the drawings in Appendix B to locate adjustment

and/or test points, if required.

The follow factory calibration and test procedures are listed for reference only.

Document Description

TP943-227-15VL Test Procedure, Victoreen Loop Communications

TP943-227-15 Test Procedure, RS232 communications

TP977-200-15M Electrometer PCB Test Procedure

NOTE

4-1

943-227-15 Digital Preamplifier

Operator Manual

4.3 Troubleshooting

WARNING

Extreme care must be used when troubleshooting a

system that has power applied. All standard

troubleshooting precautions apply.

WARNING

Once a problem has been located, remove all power

before continuing with the repair.

CAUTION

Personnel performing the troubleshooting/repair

must be qualified to ANSI 45.2.6, 1978, Skill Level II.

Personnel performing the following procedure must

be familiar with the operation of the monitoring

system and the location of each piece of equipment

used in the system.

If a problem develops, verify that the voltages at connection point inputs and outputs are present and that

all wiring is secure. Refer to Appendix B and C for drawings and parts lists. If a PROM requires

replacement, specify the board revision level when ordering the part.

Troubleshooting / Adjustments

Troubleshooting includes a verification of the LED operation status, the DC voltage levels and the loop

communication loop fuses (Victoreen Loop Communications only).

Specialized test equipment and firmware are required to adjust the auto-zero and PGA subsystems in the

electrometer. If the test equipment and firmware is not available, the unit should be returned to Fluke

Biomedical RMS for re-alignment.

4-2

Connector Designations

A.1 CONNECTOR DESIGNATIONS,

943-227-15 and 943-227-15VL

Table A-1. Field Electrical Connections, 943-227-15 and 943-227-15VL

943-227-15

943-27-15VL

Appendix

Connector Designations

Appendix A

A

TB1- Description

1 XMIT

2 DTR

3 GND

4 REC

5

6

7 + 15 VDC J3-7 Not Used

8 Ground

9 - 15 VDC J3-4 Not Used Not Used

10 Not Used Not Used Not Used J3-11

HV Detector MHV

SIG Detector BNC

Not Used

Not Used

Detector

Connections

Connects To

977-210-10M

J4-1

J4-2

J4-3

J4-4

Not Used

Not Used

J3-8

From Field

coaxial cable

Factory

Terminated,

To 977-200-

15M, R41

Description

+ VL, 15

VDC

+ TX

- TX

- VL

+ RX

- RX

Ground

Detector

Connections

Detector

MHV

Detector

BNC

Connects To

977-210-10M

J3-1

J3-2

J3-3

J3-4

J3-5

J3-6

Not Used

J3-8

From Field

coaxial cable

Factory

Terminated,

To 977-200-

15M, R41

A-1

943-227-15 Digital Preamplifier

Operator Manual

A.2 SWITCH AND JUMPER POSITIONS,

943-227-15 and 943-227-15VL

Table A-2. Preamplifier Serial Interface Board 977-210-10M Switch Settings

Switch Normal

Op.

SW1 Open Microprocessor Reset switch, momentary contact

SW2 N/A Not supplied

SW3-1 ON OFF Selects 300 baud • 1/ON Selects 4800 baud (normal setting)

SW3-2 OFF OFF • (No function is implemented in the 977-210-10M)

SW3-3 OFF OFF Selects Rate Mode (normal) • (Selects Maintenance Mode for

SW3-4 OFF OFF • (No function is implemented in the 977-210-10M)

Switch Function

factory PGA and Auto Zero set-up only)

NOTE

SW3 is a 4-position DIP switch on the 977-210-10M serial

interface board.

Table A-3. Jumper Positions for Preamplifier Serial Interface Board 977-210-10M

Jumper Normal

Setting

JMP1 A to B

JMP2 N/A Deleted, Not Used N/A Deleted, Not Used

Table A-4. Jumper Positions for Preamplifier Electrometer Board 977-200 -15 M

Jumper Normal

Setting

JMP1 A to B Normal Operation B to C PGA Offset Adjust *

* Programmable Gain Amplifier requires a special test PROM and is a factory adjustment

Function Alternate

Setting

Enables Victoreen Loop

(normal)

Function Cal.

B to C Enables RS232C

Position

Function

Function

A-2

Applicable Drawings

Appendix B

Applicable Drawings

B.1 Applicable Drawings

943-227-15 and 943-227-15VL

Drawing No. Description

943-227-15 Preamplifier Assembly, RS232

943-227-15VL Preamplifier Assembly, Victoreen Loop

943-227-15VL-M1 Preamplifier Assembly, Victoreen Loop, w/Conduit Hubs

977-210-10M Preamplifier HV/Interface Printed Circuit Board Assembly

977-210-13M Preamplifier Printed Circuit Board Schematic

977-200-15M Preamplifier Electrometer Board Assembly

977-200-18M Preamplifier Schematic

Appendix

B

B.2 Related Manuals (Not Supplied with this document)

SXXXXXX-1 Applicable 960 Series system Manual

942A-200C-M1 Digital Ratemeter

943-27-31-1 Current Mode Beta Detector

B-1

(Blank page)

Bill of Materials

Appendix C

Bill of Materials

C.1 Bill of Materials- 943-227-15 and 943-227-15VL

Part Number Description

943-227-15 Preamplifier Assembly, RS232

943-227-15VL Preamplifier Assembly, Victoreen Loop

943-227-15VL-M1 Preamplifier Assembly, Victoreen Loop, w/Conduit Hubs

977-210-10M Preamplifier HV/Interface Printed Circuit Board Assembly

977-200-15M Preamplifier Electrometer Board Assembly

Appendix

C

C-1

(Blank page)

Appendix

Cable Termination Instructions

D

Appendix D

Cable Termination Instructions

D.1 Cable Termination Instructions

The procedures and instructions provided in Appendix D are provided for reference in terminating the field

cables to the Digital Preamplifier. A mating SHV connector is provided with the preamplifier. Ring lug

terminals are to be provided by the user. The instructions provided below are based on the use of P/N

50-100 multi-conductor cable. For other customer-supplied cables, the same basic procedures, modified

for the specific cable used, may be utilized.

Detector Cable Termination:

The detector high voltage and signal cables enter the preamplifier through “Seal Grip” type penetrations

on the enclosure body. The “Seal Grips” contain a rubber gland that is intended to grip the coaxial cables

to prevent moisture entry into the enclosure. The “Seal Grips” are an integral part of the detector cables.

The “Seal Grip” enclosure nut is removed from the fitting. The insulating washer stays with the fitting.

The detector signal and high voltage cables, with connectors and “Seal Grip” fitting nuts are then inserted

into the holes preamplifier enclosure. The “Seal Grip: end fittings are then re-installed securely against

the wall of the enclosure.

Detector Field Cable Preparation, “MS” Connector:

Prior to stripping the outer cable jacket, a 4-inch length of 0.75 I.D. shrinkable tubing (provided by the

user) should be slid over the 0.675 in cable jacket. The shrink tubing will be used to seal and protect the

end of the cable after the termination process is completed. To prepare the cable for termination, a

minimum of 7 inches of the cable outer jacket must be stripped off the cable. This will allow for the

stripping of approximately one inch from the various conductors, and provide 6 inches of actual service

loop cable. In addition, for EMI/RFI protection, the drain wire must be terminated to an earth ground

within the enclosure. The length of the drain wire will be based on the distance between the cable entry

and the ground location. The length of cable jacket to be stripped will then be based on the distance to

the drain wire grounding point.

Once the cable outer jacket is stripped to the proper length, the aluminum tape shield and Mylar binder

may be removed, taking care not to damage the No. 20 AWG drain wire. The drain wire may then be

separated from the remaining conductors, for routing and termination at the grounding point.

Next, the HV coaxial cable may be separated from the bundle, followed by the single conductors wires

that are required for the specific application, and the polyester filler cord. Refer to the project specific

detector loop drawing, or the generic detector loop drawing provided in Appendix B for actual conductors

to be used.

The polyester filler cord may now be removed. Cut the cord as close to the outer jacket as possible.

The single conductors may now be stripped and soldered to the appropriate connector pin.

D-1

943-227-15 Digital Preamplifier

Operator Manual

Detector Field Cable Preparation, 943-227-15VL-M1, Conduit Hub:

Prior to terminating the cable, the field conduit must be run to the junction box, and the field cable pulled

into the junction box.

To prepare the cable for termination, a minimum of 7 inches of the cable outer jacket must be stripped off

the cable. This will allow for the stripping of approximately one inch from the various conductors, and

provide 6 inches of actual service loop cable. In addition, for EMI/RFI protection, the drain wire must be

terminated to an earth ground within the enclosure. The length of the drain wire will be based on the

distance between the UDR rear panel and the ground location. The length of cable jacket to be stripped

will then be based on the distance to the drain wire grounding point.

Once the cable outer jacket is stripped to the proper length, the aluminum tape shield and Mylar binder

may be removed, taking care not to damage the No. 20 AWG drain wire. The drain wire may then be

separated from the remaining conductors, for routing and termination at the grounding point.

Next, the HV coaxial cable may be separated from the bundle, followed by the single conductors wires

that are required for the specific application, and the polyester filler cord. Refer to the project specific

detector loop drawing, or the generic detector loop drawing provided in Appendix B for actual conductors

to be used. The ring lug connectors may now be applied to the single conductor cables, and installed in

accordance with the project electrical loop diagram.

Trim each conductor as required to reach its assigned terminal poi nt. Allow a minimum of 1 in. spare

conductor for future re-termination. Because of the unique requirements of each installation, terminal

lugs for the detector single conductor terminations are not included, and are supplied by the user. Ring

terminal, Crimp type lugs, Burndy YAE type, sized for the 18 AWG wire, or equivalent, are recommended.

The terminal block is designed to accept a maximum 14 AWG conductor, and is provided with 6-32

mounting screws. Strip the conductor as required by the lug manufacturer, install the lug, and terminate

the conductor to the appropriate terminal. The screw terminals may now be torqued to 12 in-lbs.

The mating HV connector, P/N 30-92-1 (Kings 1705-14), may now be terminated per the applicable Kings

data sheet attached.

The polyester filler cord may now be removed. Cut the cord as close to the outer jacket as possible

D-2

Appendix

Cable Termination Instructions

D

HV CONNECTOR NOTES (HV)

The mating HV connector, P/N 30-92-1 (Kings 1705-14), may now be terminated per the applicable Kings

data sheet attached

LOCATION P/N DOCUMENT DESCRIPTION

SHV 92-9105-A CP-400, Kings High Voltage Connector,

SHV (1705-1) Cabling SHV, male crimp contact

Procedure, Trim Code pin (Use Tool KTH-100 with

441, 442 KTH-2062)

SHV Alternate AMP Instruction High Voltage Connector,

Connector Sheet SHV, male crimp contact

92-9105-A 408-2187 pin (Use Tool 69710-1 with

(51426-5) 220028-2 Die or Integral

Die Tool 220022-2)

SHV 32-92-1 CP-1001, Kings Cabling High Voltage Connector, SHV,

(1705-14) Procedure, CP-1000, Female solder contact pin

D-3

943-227-15 Digital Preamplifier

Operator Manual

D-4

Appendix

Cable Termination Instructions

D

D-5

943-227-15 Digital Preamplifier

Operator Manual

D-6

Appendix

Cable Termination Instructions

D

D-7

943-227-15 Digital Preamplifier

Operator Manual

D-8

Appendix

Modifications

E

Appendix E

Modification Sheets, Engineering Instructions

E.1 Modification Sheets, Engineering Instructions

P/N Description

943-227-15VL-M1 Modification consists of replacing the standard 8in

H x 10in W x 4in D Enclosure with a 8in H x 10in W

x 6in D Enclosure and replacing the field cable

“Seal Grip” type entry fitting with a 2.0 in diameter

sealed conduit fitting.

E-1

(Blank page)

(Blank page)

Fluke Biomedical

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

www.flukebiomedical.com

Loading...

Loading...