Page 1

ULT800

TEE Transducer Leakage Current Tester

Users Guide

PN 2461434

August 2005, Rev.2, 11/13

© 2006, 2013 Fluke Corporation, All rights reserved. Printed in USA

All product names are trademarks of their respective companies.

Page 2

Warranty and Product Support

Fluke Biomedical warrants this instrument against defects in materials and

workmanship for one full year from the date of original purchase. During the

warranty period, we will repair or, at our option, replace at no charge a product

that proves to be defective, provided you return the product, shipping prepaid,

to Fluke Biomedical. This warranty does not apply if the product has been

damaged by accident or misuse or as the result of service or modification by

other than Fluke Biomedical. IN NO EVENT SHALL FLUKE BIOMEDICAL BE

LIABLE FOR CONSEQUENTIAL DAMAGES.

Only serialized products and their accessory items (those products and items

bearing a distinct serial number tag) are covered under this one–year warranty.

PHYSICAL DAMAGE CAUSED BY MISUSE OR PHYSICAL ABUSE IS NOT

COVERED UNDER THE WARRANTY. Items such as cables and nonserialized

modules are not covered under this warranty.

Recalibration of instruments is not covered under the warranty.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state, province to province, or country to country.

This warranty is limited to repairing the instrument to Fluke Biomedical’s specifications.

Warranty Disclaimer

Should you elect to have your instrument serviced and/or calibrated by someone other than Fluke Biomedical, please be advised that the original warranty

covering your product becomes void when the tamper-resistant Quality Seal is

removed or broken without proper factory authorization. We strongly recommend, therefore, that you send your instrument to Fluke Biomedical for factory

service and calibration, especially during the original warranty period.

Page 3

Notices

All Rights Reserved

Copyright 2013, Fluke Biomedical. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into

any language without the written permission of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and other printed materials for use in service training programs

and other technical publications. If you would like other reproductions or distributions, submit a written request to Fluke Biomedical.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the

shipping carton for damage. If damage is found, stop unpacking the instrument.

Notify the carrier and ask for an agent to be present while the instrument is unpacked. There are no special unpacking instructions, but be careful not to damage the instrument when unpacking it. Inspect the instrument for physical damage such as bent or broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email

techservices@flukebiomedical.com or call 1-800- 850-4608 or 1-440-248-9300.

In Europe, email: techsupport.emea@flukebiomedical.com or call

+31-40-2965314.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical damage is found, retain all packing materials in their original condition and contact the carrier immediately to file a claim. If the instrument is delivered in good physical condition but does not operate within specifications, or if

there are any other problems not caused by shipping damage, please contact

Fluke Biomedical or your local sales representative.

Page 4

Returns and Repairs

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent

freight-prepaid to our factory location. When you return an instrument to Fluke

Biomedical, we recommend using United Parcel Service, Federal Express, or Air

Parcel Post. We also recommend that you insure your shipment for its actual replacement cost. Fluke Biomedical will not be responsible for lost shipments or instruments that are received in damaged condition due to improper packaging or

handling.

Use the original carton and packaging material for shipment. If they are not available, we recommend the following guide for repackaging:

• Use a double–walled carton of sufficient strength for the weight being

shipped.

• Use heavy paper or cardboard to protect all instrument surfaces. Use nona-

brasive material around all projecting parts.

• Use at least four inches of tightly packed, industry-approved, shock-

absorbent material around the instrument.

Returns for partial refund/credit:

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number, obtained from our Order Entry Group at 1-800648-7952 or 1-425-446-6945.

Repair and calibration:

To find the nearest service center, goto www.flukebiomedical.com/service or

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4606 x2564

Email:

globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-888-99 FLUKE

(1-888-993-5853)

Email: service.status@fluke.com

To ensure the accuracy of the Product is maintained at a high level, Fluke Biomedical recommends the product be calibrated at least once every 12 months.

Calibration must be done by qualified personnel. Contact your local Fluke Biomedical representative for calibration.

In Europe, Middle East, and Africa:

Eindhoven Calibration Lab

Tel: +31-40-2675300

Email: ServiceDesk@fluke.com

In Asia:

Everett Calibration Lab

Tel: +425-446-6945

Email:

service.international@fluke.com

Page 5

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke

Biomedical’s manufacturing specifications when it was shipped from the factory.

Calibration measurements are traceable to the National Institute of Standards

and Technology (NIST). Devices for which there are no NIST calibration standards are measured against in-house performance standards using accepted test

procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may result in electrical shock hazards or improper operation. Fluke Biomedical will not be responsible for any injuries sustained due to unauthorized equipment modifications.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by Fluke Biomedical. Changes made to the information in this document

will be incorporated in new editions of the publication. No responsibility is assumed by Fluke Biomedical for the use or reliability of software or equipment that

is not supplied by Fluke Biomedical, or by its affiliated dealers.

Manufacturing Location

The ULT800 Ultrasound Transducer Leakage Current Tester is manufactured in

Everett, WA, U.S.A.

Page 6

Page 7

Table of Contents

Title Page

Introduction ................................................................................ 1

Safety Information ...................................................................... 1

Symbols ..................................................................................... 2

Key Features .............................................................................. 3

Controls and Indicators .............................................................. 4

Specifications ............................................................................. 6

Using the ULT800 ...................................................................... 7

Checking the Battery .................................................................. 11

Checking Solution Conductivity .................................................. 11

Testing for Transducer Leakage Current .................................... 12

Maintenance ............................................................................... 12

Cleaning ................................................................................. 13

Battery .................................................................................... 14

Calibration .............................................................................. 15

Accessories ................................................................................ 16

i

Page 8

ULT800

Users Guide

ii

Page 9

List of Tables

Table Title Page

1. Symbols ..................................................................................... 2

2. Controls and Indicators .............................................................. 5

3. Accessories ................................................................................ 16

List of Figures

Figure Title Page

1. Controls and Indicators .............................................................. 4

2. Disinfection Basin Test Setup .................................................... 9

3. Disinfection/Storage Tube Setup ................................................ 10

iii

Page 10

ULT800

Users Guide

iv

Page 11

Introduction

The ULT800 TEE Transducer Leakage Current Tester measures

the leakage current of ultrasound transducers independent of their

ultrasound systems. Use the hand-held, battery-operated

instrument during the routine transducer cleaning procedure

conducted between patients.

Safety Information

A Warning identifies conditions and procedures that are dangerous

to the user. A Caution identifies conditions and procedures that

can cause damage to the Product or the equipment under test.

Warning

To prevent possible electric shock, fire, or personal injury:

• Read all safety Information before you use the Product.

• Use the Product only as specified, or the protection

supplied by the Product can be compromised.

• Remove the batteries if the Product is not used for an

extended period of time, or if stored in temperatures

above 50 °C. If the batteries are not removed, battery

leakage can damage the Product.

• The battery door must be closed and locked before you

operate the Product.

• Replace the batteries when the low battery indicator

shows to prevent incorrect measurements.

• Carefully read all instructions.

• Do not touch voltages >30 V ac rms, 42 V ac peak, or

60 V dc.

• Do not use and disable the Product if it is damaged.

• Do not use the Product if it operates incorrectly.

• Examine the case before you use the Product. Look for

cracks or missing plastic. Carefully look at the

insulation around the terminals.

• Use this Product indoors only.

1

Page 12

ULT800

Users Guide

• Do not use the Product around explosive gas, vapor, or

in damp or wet environments.

Symbols

Table 1 is a list of symbols used on the Product and in this Users

Guide.

Table 1. Symbols

Symbol Description

Important information. Refer to manual.

Hazardous Voltage

Conforms to European Union directives

Conforms to relevant North American Safety Standards.

Conforms to relevant Australian EMC requirements

Conforms to relevant Australian EMC standards

Standby - On

Battery

Conforms to relevant South Korean EMC Standards.

This product complies with the WEEE Directive (2002/96/EC)

marking requirements. The affixed label indicates that you must

not discard this electrical/electronic product in domestic

In addition to verifying that the ultrasound transducers are safe for

patient use, the ULT800 makes it possible to reduce expensive

repairs. Identifying transducers that exceed safe leakage currents

early may allow for repairs to be made before a transducer

becomes non-repairable.

2

household waste. Product Category: With reference to the

equipment types in the WEEE Directive Annex I, this product is

classed as category 9 "Monitoring and Control Instrumentation"

product. Do not dispose of this product as unsorted municipal

waste. Go to Fluke’s website for recycling information.

Page 13

Ultrasound Transducer Leakage Current Tester

Key Features

Key Features

• Hand-held instrument

• Stand-alone operation

• Direct measurement of leakage current

• Pass/Fail display of test results

• Battery operation for safety

• Independent of 120 or 240 V ac systems

• Built-in self-test circuit

• Auto shut off to conserve battery

3

Page 14

ULT800

Users Guide

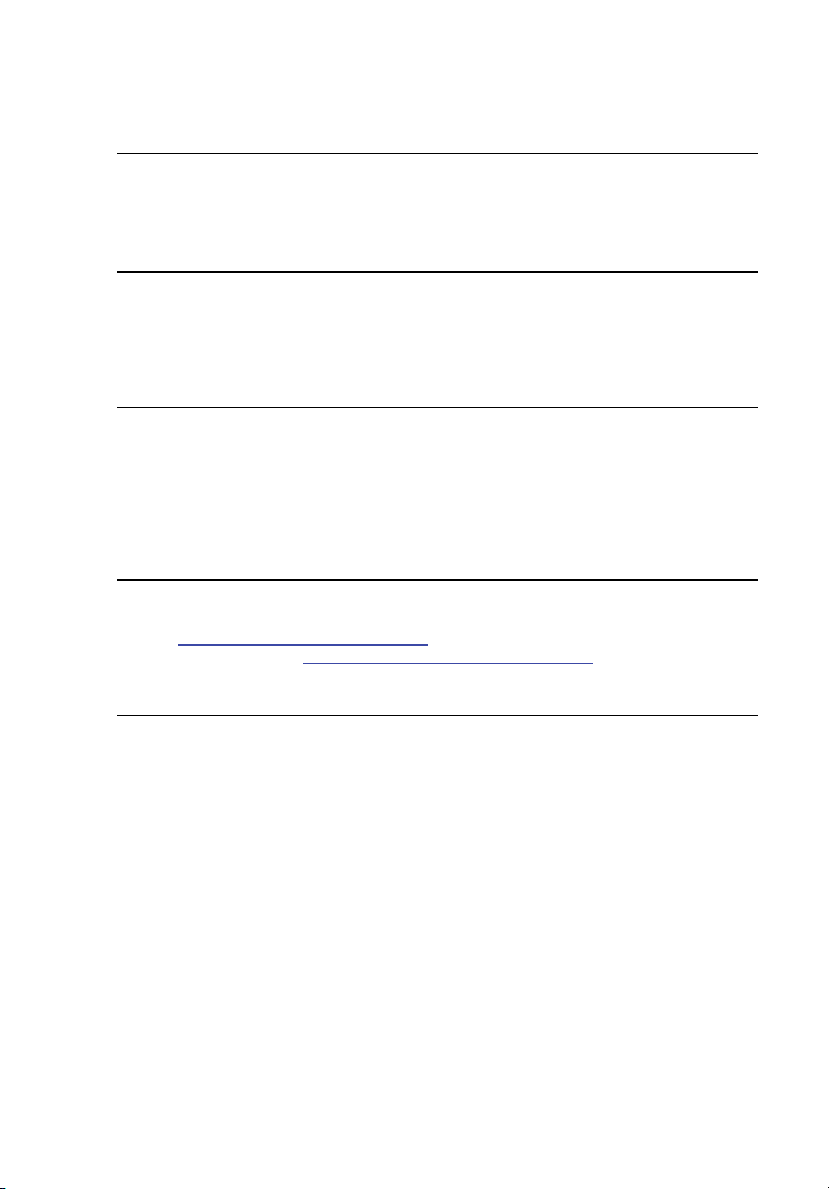

Controls and Indicators

Input connectors are interchangeable and provide for inputting an

ultrasound transducer adapter and the dual conductivity electrode.

Refer to Figure 1 and Table 2 for complete control and indicator

descriptions.

Biomedical

READY

LEAKAGE

CONDUCTIVITY

INSTRUCTIONS:

1. Connect the transducer and the adapters to the ULT 800.

2. Press the ON/TEST button and wait for the READY light.

3. Select CONDUCTIVITY and press the ON/TEST Button-

W

ait for the PASS light.

4. Select LEAKAGE and press the ON/TEST button again-

observe PASS or FAIL light. If test fails, DO NOT USE

TRANSDUCER. Refer to the user’s m

ULT800

TEE TRANSDUCER

LEAKAGE CURRENT TESTER

PASS

FAI L

anual.

LOW BAT

ON

TEST

Figure 1. Controls and Indicators

ecy10f.eps

4

Page 15

Ultrasound Transducer Leakage Current Tester

Controls and Indicators

Table 2. Controls and Indicators

Item Description

READY Glows amber when the self-test procedure

completes (approx. 8 sec.). The ULT800 is

then ready for testing.

PASS Glows green when either the Conductivity

Test or Leakage Test passes.

FAIL Glows red when either the Conductivity Test

or the Leakage Test fails. Pulses red when

the Leakage Test results in less than 20 μA,

indicating a possible open circuit condition

with invalid test results.

LOW BAT Flashes red to indicate that the battery

requires replacement.

LEAKAGE/CONDUCTIVITY

SWITCH

ON/TEST BUTTON Turns the ULT800 on and initiates the

BATTERY COMPARTMENT (not shown): Holds a 9-volt alkaline battery.

Selects the test to perform.

selected test.

The instrument automatically powers off if

you do not perform a test within

12 seconds.

5

Page 16

ULT800

Users Guide

Specifications

Power ...................................................................... 9 V Alkaline Battery

No. of Measurements ............................................ Approx. 1000 measurements on a

Conductivity ........................................................... Pass limit is >250 μA ±5 %

Leakage .................................................................. Pass limit is <185 μA ±5 % and

Dimensions ............................................................ 6.6 in x 3.7 in x 1.5 in

Weight ..................................................................... 12 oz (340 g)

Temperature

Operation ............................................................. 15 °C to 40 °C

Storage ................................................................ 15 °C to 65 °C

Relative Humidity ................................................... 90 % max.

Altitude ................................................................... 2000 m

IP Rating ................................................................. IEC 60529: IP20

Safety ...................................................................... IEC 61010-1: Pollution Degree 2

Electromagnetic Environment .............................. IEC 61326-1: Basic

Emissions Classification ...................................... IEC CISPR 11: Group 1, Class A.

Electromagnetic Compatibility ............................. Applies to use in Korea only.Class A:

[1] This product meets requirements for industrial (Class A) electromagnetic wave

equipment and the seller or user should take notice of it. This equipment is intended

for use in business environments and is not to be used in homes.

single battery

>20 μA ±5 μA

(17 cm x 19 cm 4 cm)

Group 1 have intentionally generated

and/or use conductively coupled radiofrequency energy which is necessary

for the internal functioning of the

equipment itself. Class A equipment is

suitable for use in non-domestic

locations and/or directly connected to

a low-voltage power supply network.

Equipment (Industrial Broadcasting &

Communication Equipment)

[1]

6

Page 17

Ultrasound Transducer Leakage Current Tester

Using the ULT800

Using the ULT800

Warning

To avoid personal injury, do not touch the dual

conductivity electrode rods. Voltage is present on the rods

during a test.

Inspect the conductivity probe for damaged insulation or

exposed metal. To avoid personal injury, replace a

damaged conductivity probe before using.

Caution

To avoid damage to the transducer, observe the immersion

levels. Do not immerse or allow the cable or connector of a

transducer to become wet.

The ULT800 TEE Transducer Leakage Current Tester is a

portable, self-contained, battery-operated device. It measures the

leakage current of the devices attached to its connectors. The

ULT800 applies 120 V ac, 60 Hz to devices placed in a conductive

bath (basin or storage tube). The ULT800 measures the current

and compares the results to an internal threshold. The instrument

displays the results as a PASS or FAIL indication. It also performs

an internal self-calibration on each measurement cycle.

Connect the transducer to be tested to the ULT800 via a unique

adapter. The ULT800 performs the measurement with the

transducer immersed in either the cleaning solution or saline. To

insure that the leakage current test is accurate, first test the

conductivity of the fluid. A special dual element probe also

connected to the ULT800 tests the conductivity of the fluid. A green

PASS light or a red FAIL light indicates the results of the

conductivity and leakage current tests.

The ULT800 makes two types of measurements. The Leakage

Test measures the current between the probe and the electrode.

The Conductivity Test measures the conductivity of the bath

solution between the two electrodes.

7

Page 18

ULT800

Users Guide

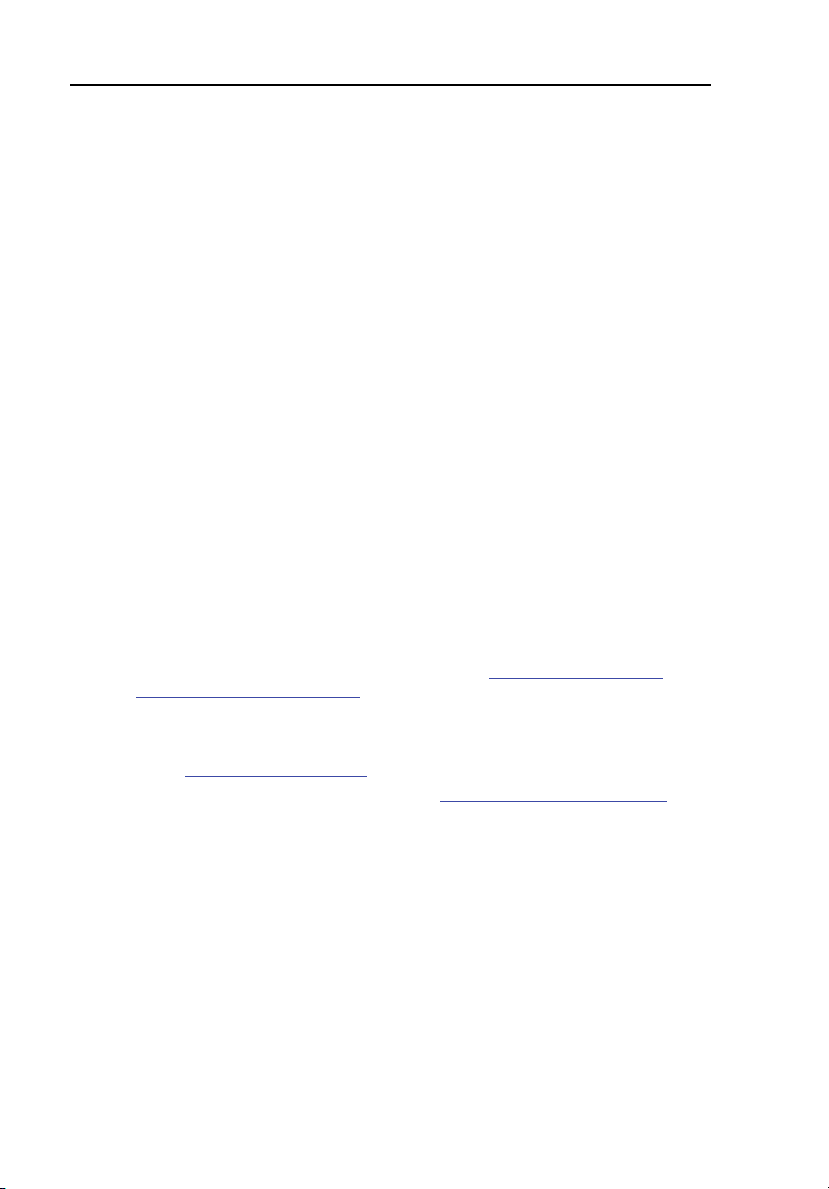

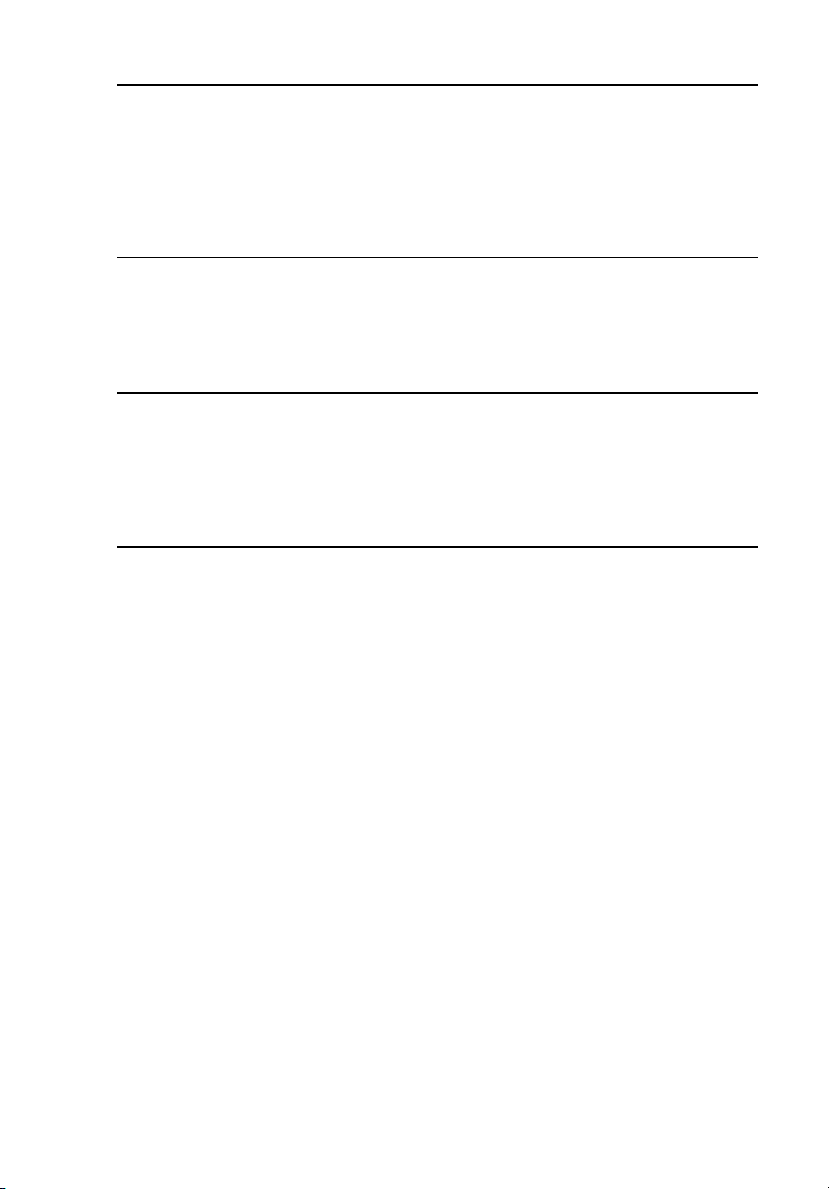

Figures 2 and 3 show some typical test setups. You can use other

setups, as long as you observe the following rules:

1. Connect the ultrasound probe you are testing to the probe

adapter. See the list of available adapters under

Accessories.

2. Place the probe you are testing in a saline bath with the

entire critical area of the probe fully immersed.

3. Place the dual electrode (Part No. 2392502 or 2392569) in

the saline bath to a depth of at least one inch.

4. Plug the probe adapter and the electrode wire connectors

into the ULT800. The connections are fully

interchangeable.

8

Page 19

Ultrasound Transducer Leakage Current Tester

Using the ULT800

Dual Conductivity

Electrodes

X

ULT800

Biomedical

TEE TRANSDUCER

LEAKAGE CURRENT TESTER

READY PASS FAIL LOW BAT

LEAKAGE

CONDUCTIVITY

INSTRUCTIONS:

1. Connect the transducer and the adapters to the ULT 800.

2. Press the ON/TEST button and wait for the READY light.

3. Select CONDUCTIVITY and press the ON/TEST ButtonWait for the PASS light.

4. Select LEAKAGE and press the ON/TEST button again-

observe PASS or FAIL light. If test fails, DO NOT USE

TRANSDUCER. Refer to the user’s manual.

ON

TEST

Fluke

ULT800

Transducer-Specific

Adapter

Figure 2. Disinfection Basin Test Setup

ecy02f.eps

9

Page 20

ULT800

Users Guide

Transducer-Specific Adapter

ULT800

Biomedical

TEE TRANSDUCER

LEAKAGE CURRENT TESTER

READY PASS FAIL LOW BAT

LEAKAGE

CONDUCTIVITY

INSTRUCTIONS:

1. Connect the transducer and the adapters to the ULT 800.

2. Press the ON/TEST button and wait for the READY light.

3. Select CONDUCTIVITY and press the ON/TEST ButtonWait for the PASS light.

4. Select LEAKAGE and press the ON/TEST button again-

observe PASS or FAIL light. If test fails, DO NOT USE

TRANSDUCER. Refer to the user’s manual.

ON

TEST

Fluke

ULT800

X

Dual Conductivity

Electrode with

600/213 Extenders

Figure 3. Disinfection/Storage Tube Setup

Disinfection

and Storage

Tube

ecy03f.eps

10

Page 21

Ultrasound Transducer Leakage Current Tester

Checking the Battery

Checking the Battery

Note

The LOW BAT light flashes red to indicate that the battery

needs replacement.

1. Use the LEAKAGE/CONDUCTIVITY switch to select

CONDUCTIVITY.

2. Press the ON/TEST button to turn on the ULT800.

The self-check routine starts, calibrating the unit. All four LED

indicators flash in sequence, continuing for five cycles. The READY

light glows amber when the self-test routine completes with a

successful battery test.

Checking Solution Conductivity

Note

The LED indicating a test result remains on for 12 seconds.

The ULT800 then powers off to conserve the battery. To

resume testing, power on the ULT800, allow the selfcheck/battery test to complete, and then reinitiate the test.

1. Select CONDUCTIVITY.

2. Press the ON/TEST button to perform a measurement

cycle.

3. At the end of the measurement cycle (two seconds), the

LED indicates the results of the test.

The green PASS light illuminates if the solution passed the

Conductivity Test. The red FAIL light illuminates if the solution

failed the Conductivity Test. Check that you have immersed the

electrodes to a depth of at least 25 mm (1 inch) and that they are

firmly connected to the ULT800, then retest. If the failure repeats,

replace the solution and then retest.

11

Page 22

ULT800

Users Guide

Testing for Transducer Leakage Current

Note

Perform the Leakage Test only if the Conductivity Test passes.

1. Select LEAKAGE.

2. Press the ON/TEST button to perform a leakage

measurement.

The green PASS light illuminates if the transducer passed the

leakage current test. The red FAIL light illuminates if the transducer

failed the leakage current test. If there is less than 20 μA of leakage

current, the red light pulses, indicating a possible open circuit

condition with invalid test results.

Maintenance

Your ULT800 needs little maintenance or special care. However,

treat it as a calibrated measuring instrument. Avoid dropping or

other mechanical abuse that could cause a shift in the calibrated

settings.

Warning

To prevent possible electrical shock, fire, or personal

injury:

• Batteries contain hazardous chemicals that can cause

burns or explode. If exposure to chemicals occurs,

clean with water and get medical aid.

• Do not disassemble the battery.

• Do not disassemble or crush battery cells and battery

packs.

• Do not keep cells or batteries in a container where the

terminals can be shorted.

• Do not put battery cells and battery packs near heat or

fire. Do not put in sunlight.

12

Page 23

Ultrasound Transducer Leakage Current Tester

Maintenance

• Do not operate the Product with covers removed or the

case open. Hazardous voltage exposure is possible.

• Use only specified replacement parts.

• Have an approved technician repair the Product.

For safe operation and maintenance of the Product:

• Repair the Product before use if the battery leaks.

• Do not short the battery terminals together.

• Keep cells and battery packs clean and dry. Clean dirty

connectors with a dry, clean cloth.

Cleaning

Caution

Do not put fluid on the Product surface. Fluid leakage into

the electrical circuitry may cause the Product to fail.

Caution

Do not use spray cleaners on the Product. This can push

fluid into the Product and cause electronic component

damage.

Clean the ULT800 occasionally; use a damp cloth and mild

detergent. Take care to prevent the entrance of liquids.

Wipe down the adapter cables with the same care. Inspect them for

damage to and deterioration of the insulation. Check the

connections for integrity. Keep transducer adapter clean and dry.

13

Page 24

ULT800

Users Guide

Battery

Warning

The 9-volt alkaline battery provided with the ULT800 may

explode or leak if recharged, inserted improperly, disposed

of in a fire, or mixed with different battery types. Dispose

of the battery in accordance with any applicable state or

local regulations.

The ULT800 uses a standard 9-volt alkaline battery. The battery

has a life expectancy of approximately 1000 measurements.

Replace the battery yearly, regardless of its condition.

14

Page 25

Ultrasound Transducer Leakage Current Tester

Maintenance

Calibration

Warning

Examine the calibration label on the back of the ULT800

prior to each use. Do not use a ULT800 with an expired

calibration label. A ULT800 without a calibration label or

with the anti-tamper case label broken is out of calibration.

A ULT800 that is out of calibration can cause excessive

leakage current exposure to the patient; risk of injury to

the patient could result.

Caution

Avoid dropping the ULT800 or allowing other mechanical

abuse that could cause a shift in the ULT800’s calibrated

settings.

The ULT800 requires yearly Fluke factory calibration, which uses

appropriate tools and reference instruments that are traceable to

the National Institute of Standards and Technology (NIST). Factory

calibration provides a calibration sticker on the back of the ULT800

to verify that the calibration was performed.

To locate a service center, visit the Fluke web site at

www.fluke.com, or contact Fluke at service@fluke.com. Call from

anywhere in the world at +1-425-446-5500 or call for service in the

USA at 1-888-99-FLUKE (1-888-993-5853.)

15

Page 26

ULT800

Users Guide

Accessories

Refer to Table 3 for a list of accessories for the ULT800. Available

transducer-specific adapters are listed on Fluke Biomedical’s web

site. www.flukebiomedical.com/electrical safety analyzers/ULT800.

Table 3. Accessories

Part

Number

2392427 600/102FG Chassis ground probe, 8-foot coiled cord

2392502 600/212FG Dual conductivity electrode

2392525 600/214FG Hard-sided carrying case

2392533 600/215FG Conductivity cable

2392569 600/220FG Dual conductivity probe – for use with

Model

Number

Description

Cidex 2032 tray.

16

Loading...

Loading...