Page 1

amprobe.com

ULD-400 Series Ultrasonic Leak Detectors

The ultimate ultrasonic diagnostic tool

HVAC/R, mechanical and electrical inspection and troubleshooting

When equipment begins to fail due to an air or gas leak or vibration, or electrical discharge, the leakage point emits an ultrasonic

sound wave that is above the natural range of human hearing. The ULD-400 Series Ultrasonic Leak Detectors convert this ultrasonic

sound into a signal that can be used to pinpoint the exact location of the equipment failure. See the strength of the leak clearly

on the large LCD display bargraph and identify the source of the leak by listening to the converted audible sound emitted via the

headphones. When working in unpressurized systems, or the pressure is not sufcient enough to detect or verify a leak with the

Receiver alone, use the Transmitter to generate the ultrasonic signal (included with the ULD-420 kit). In extremely noisy environments

where there is strong ultrasonic noise generated by running machinery or equipment, the Receiver’s lter function can lter out up to

three main noise frequencies which would otherwise hide the noise of the fail.

Features

• 2.5” LCD display with

bargraph

• 20 kHz to 90 kHz frequency

range: optimal range for

detecting a variety of leakage

events

• Three filters to remove main

noise frequencies in noisy

environments

• Adjustable Receiver

sensitivity and Three

Transmitter signal strengths

for accurate leak pinpointing

• Quality headphones to help

identify the source of the leak

• Parabola accessory directs the

ultrasound towards the sensor

• Detachable Tubular Extension

provides additional reach in

hard to reach areas

The ULD-400 is

ideal for inspecting:

• Compressed air or other gases*

• Plumbing

• Electrical and mechanical

systems

• Valves, tanks and pipes

• Heat exchangers, boilers and

condensers

• Air conditioning and

refrigeration systems

• Motors and machinery

* Do not use ULD-400 for combustible

gas leak detection. The Amprobe

GSD600 can be used for propane and

methane gas leak detection.

Microphone

Large color

LCD screen

Signal

strength

bar graph

Auto-lter

to lter out

competing

ultrasonic

noise

sensor

ULD-400-R

Receiver

Speaker

Sensitivity

level bar

graph

Sensitivity

level

adjustment

ULD-400-T

Transmitter

LEDs: high/

medium/

low signals

Signal level

adjustment

Safety Certication

All Amprobe tools, including the Amprobe ULD-400 Series, are rigorously

tested for safety, accuracy, reliability, and ruggedness in our state-of-theart test lab. In addition, Amprobe products that measure electricity are listed by a

3rd party safety lab, either UL or CSA. This system assures that Amprobe products

meet or exceed safety regulations and will perform in a tough, professional

environment for many years to come.

©2019 Amprobe® For detailed specications and ordering go to amprobe.com 6012523A-EN Amprobe® | info@amprobe.com | Fluke Corporation, Everett, WA 98203 | Tel: 877-AMPROBE (267-7623)

Page 2

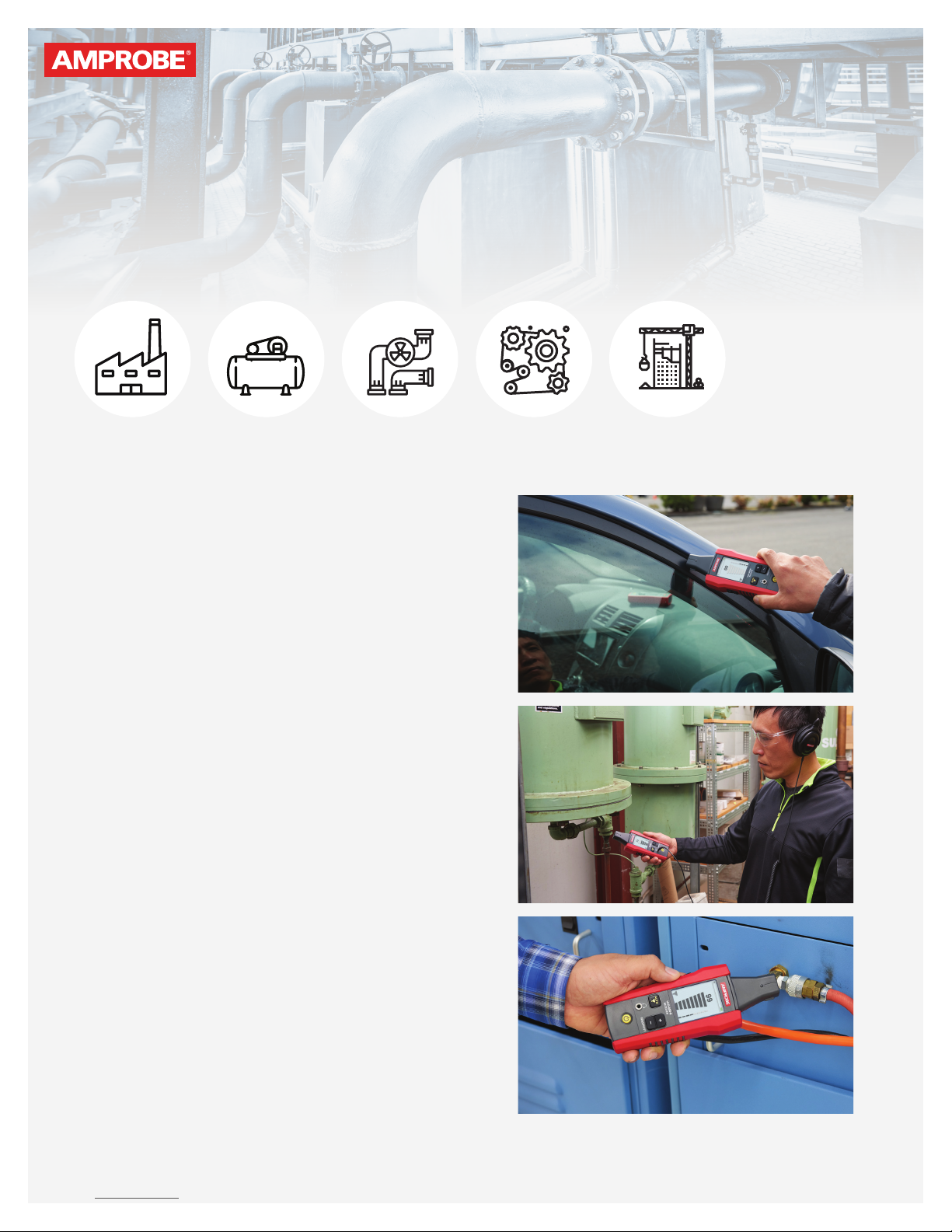

The ULD-400 Series is ideal for

industrial applications.

amprobe.com

Facilities

Maintenance

Air

Compressors

Industrial

Plumbing

Leak not pressurized?

No problem.

When a leak is not pressurized sufciently, or located in an

unpressurized system, it is not emitting enough ultrasonic sound for

the Receiver to detect it. In these circumstances, use the Transmitter to

emit the ultrasonic sound readable by the Receiver. The Transmitter is

programmed with three signal levels for precise pinpointing of leaks.

The Transmitter can be used to nd air and water leaks in:

• Automobile windshields and windows

• Fluid and gas tanks

• Building windows, doors or roofs

Find leaks even in noisy

environments

In some situations, there might be strong ultrasonic noise generated by

running machinery, motion sensors or other equipment. This noise will

cause the Receiver to read the maximum signal strength of this noise

interference on the display regardless of the sensitivity settings and

make it unusable for detecting leaks. The Filter function was designed

for these situations.

Simply press the Filter button and the Receiver will automatically detect

and and lter out up to three main noise frequencies.

Motors and

Machinery

Construction

Visual and audible leak pinpointing

While scanning a target area with the Receiver’s microphone sensor,

the displayed bargraph will indicate proximity to the source of the leak.

Plug the headphones into the Receiver to audibly hear the leak and

verify its source. For example, air leaks will produce more of a hissing

sound while electric discharge manifests in a ticking sound.

©2019 Amprobe® For detailed specications and ordering go to amprobe.com 6012523A-EN Amprobe® | info@amprobe.com | Fluke Corporation, Everett, WA 98203 | Tel: 877-AMPROBE (267-7623)

Page 3

amprobe.com

Features and specications

Features

Sensitivity Adjustment • –

Volume Adjustment • –

Signal Level Adjustment – •

Earphone Jack (3.5 mm) • –

Display Size LCD 2.5 in (6.35 cm) –

Display Dimensions 1.45 x 1.93 in (36.72 x 48.96 mm) –

Display Resolution 240(RGB) x 320 pixels –

Display Type TFT-LCD (262 K) –

Display Color True, 16bit/color –

Frequency Range 20 kHz to 90 kHz Typical 40 kHz squarewave

Filter ±5 KHz of main noise frequency, up to three lters –

Power Supply 4 x 1.5 V AA (LR6) alkaline batteries 2 x 1.5 V AAA (LR03) alkaline batteries

Power Consumption (typical) 75 mA 33 mA

Battery Life (typical) 105 hours (Alkaline) 60 hours (Alkaline)

Low battery indication • Red LED

Weight Approx. 0.518 lb (0.235 kg) Approx. 0.335 lb (0.152 kg)

Dimensions

APO function 60 minutes when in idle

Operating Temperature -4 °F to 122 °F (-20 °C to 50 °C)

Storage Temperature -4 °F to 158 °F (-20 °C to 70 °C)

Operating Humidity <80% RH

Pollution Degree 2

Protection IP40

Certications

Electromagnetic Compatibility (EMC)

ULD-400-R Receiver ULD-400-T Transmitter

7.547 x 2.984 x 1.791 in

(183 x 75 x 43 mm)

EN 61326-1

Korea (KCC): Class A Equipment (Industrial Broadcasting & Communication Equipment) [1]

[1] This product meets requirements for industrial (Class A) electromagnetic wave equipment

and the seller or user should take notice of it. This equipment is intended for use in business

environments and is not to be used in homes.

5.295 x 2.559 x 1.326 in

(137 x 65 x 33 mm)

Included in the ULD-400 Series Kits

ULD-410

ULD-400-R Receiver 1 1

ULD-400-T Transmitter – 1

Headphones 1 1

Earbuds (for use with hard hat) 1 1

PB-1 Power Parabola 1 1

TEA-1 Flexible Tubing Adapter 1 1

TE-1 Tubular Extension 1 1

CC-ULD-400 Hard Carrying Case 1 1

AA Batteries (Receiver) 4 4

AAA Batteries (Transmitter) – 2

User Manual 1 1

ULD-420

ULD-410

ULD-420

©2019 Amprobe® For detailed specications and ordering go to amprobe.com 6012523A-EN Amprobe® | info@amprobe.com | Fluke Corporation, Everett, WA 98203 | Tel: 877-AMPROBE (267-7623)

Loading...

Loading...