Page 1

TNT 12000

X-Ray Test Tools

FBC 0003

March 2010, Rev. 2, 4/11

© 2010, 2011 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Users Manual

Page 2

Warranty and Product Support

Fluke Biomedical, Radiation Management Services* products are warranted against

defects in material and workmanship.

• Instruments: Warranted for one year from date of shipment. The warranty for instruments that

require calibration may be extended each year by the GCL Extended Warranty

Program.

• Phantoms: Warranted for 6 months from date of shipment. The warranty excludes

disposable phantoms.

• CLEAR-Pb

• Software: Warranted for 90 days that it will perform substantially in accordance with its

• Consumables: Not

During the warranty period, Fluke Biomedical will, at its discretion, either repair or

replace the component or product that proves to be defective upon the company’s

examination. Repairs are limited to those components pertaining to functionality and not

cosmetic appearance.

The limited warranty becomes void if the product is disassembled, modified or repaired

by an unauthorized person or facility, or if the product’s functionality is impaired by

damage, abuse or failure to use and maintain the instrument according to the

manufacturer’s instructions.

®

: Warranted for 6 months from date of shipment against defects in material and

workmanship.

documentation.

covered under warranty.

To exercise this warranty, the owner must write or call a Fluke Biomedical customer

service representative to receive a Service Return Authorization (SRA). The owner must

send the product, transportation prepaid, to a specified service facility. Repairs will then

be made, and the product will be returned to the owner with transportation (normal,

service) prepaid. Repaired or replaced products are warranted for the balance of the

warranty period. For products not covered by warranty, the part repaired has a warranty

of 90 days.

Warranty Limitations: There are no warranties expressed or implied, including without

limitation any implied warranty of merchantability of fitness, which extend beyond that

discretion of the face hereof. This express warranty excludes coverage of and does not

provide relief for incidental or consequential damages of any kind or nature, including

but not limited to loss of use, loss of sales or inconvenience. This exclusive remedy of the

purchaser is limited to repair, recalibration or replacement of the instrument at the

Company’s discretion.

Disclaimer

Please Note: If an instrument is intended for the detection and measurement of ionizing

radiation, it should be used only by persons who have been trained in the appropriate

safety procedures to be followed in the presence of radiation and the proper

interpretation of the instrument’s readings. Instruction and precautions contained in the

manuals must be read before use and strictly followed. Failure to follow these

instructions and precautions may result in inaccurate readings and/or user hazard.

Battery and other preoperational checks should be performed prior to each use to assure

that the instrument is functioning properly.

* Includes products branded Nuclear Associates and Victoreen®. ©

Page 3

Notices

All Rights Reserved

Copyright 2008, Fluke Biomedical. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language without the written permission of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and other printed materials for use in

service training programs and other technical publications. If you would like other reproductions or distributions, submit a written

request to Fluke Biomedical.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for damage. If damage is found, stop

unpacking the instrument. Notify the carrier and ask for an agent to be present while the instrument is unpacked. There are no special

unpacking instructions, but be careful not to damage the instrument when unpacking it. Inspect the instrument for physical damage such

as bent or broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email radtechsupport@flukebiomedical.com or call 1-800- 850-4608 or

1-440-498-2560. Technical support is also available at http://www.flukebiomedical.com/techsupport.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical damage is found, retain all packing

materials in their original condition and contact the carrier immediately to file a claim. If the instrument is delivered in good physical

condition but does not operate within specifications, or if there are any other problems not caused by shipping damage, please contact

Fluke Biomedical or your local sales representative.

Standard Terms and Conditions

Refunds and Credits

Please note that only serialized products and their accessory items (i.e., products and items bearing a distinct serial number

tag) are eligible for partial refund and/or credit. Nonserialized parts and accessory items (e.g., cables, carrying cases,

auxiliary modules, etc.) are not eligible for return or refund. Only products returned within 90 days from the date of original

purchase are eligible for refund/credit. In order to receive a partial refund/credit of a product purchase price on a serialized product, the

product must not have been damaged by the customer or by the carrier chosen by the customer to return the goods, and the product

must be returned complete (meaning with all manuals, cables, accessories, etc.) and in “as new” and resalable condition. Products not

returned within 90 days of purchase, or products which are not in “as new” and resalable condition, are not eligible for credit return and

will be returned to the customer. The Return Procedure (see below) must be followed to assure prompt refund/credit.

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee of 25 %. Products returned in excess of

30 days after purchase, but prior to 90 days, are subject to management approval. Additional charges for damage and/or missing parts

and accessories will be applied to all returns.

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent freight-prepaid to our factory location. When you return

an instrument to Fluke Biomedical, we recommend using United Parcel Service, Federal Express, or Air Parcel Post. We also

recommend that you insure your shipment for its actual replacement cost. Fluke Biomedical will not be responsible for lost shipments

or instruments that are received in damaged condition due to improper packaging or handling.

Use the original carton and packaging material for shipment. If they are not available, we recommend the following guide for

repackaging:

Use a double-walled carton of sufficient strength for the weight being shipped.

Use heavy paper or cardboard to protect all instrument surfaces. Use nonabrasive material around all projecting parts.

Use at least four inches of tightly packed, industry-approved, shock-absorbent material around the instrument.

Returns for partial refund/credit:

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number, obtained from our

Customer Support Group at 1-800-850-4608 or 1-440-498-2564 or email orders@flukebiomedical.com.

Page 4

Repair and calibration:

To find the nearest service center, go to www.flukebiomedical.com/service

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4606 ext. 2564

Email: globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-888-993-5853

Email: service.status@fluke.com

In Europe:

Eindhoven Calibration Lab

Tel: +31-402-675300

Email: ServiceDesk@fluke.com

, or

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke Biomedical’s manufacturing specifications when it

was shipped from the factory. Calibration measurements are traceable to the National Institute of Standards and Technology (NIST).

Devices for which there are no NIST calibration standards are measured against in-house performance standards using accepted test

procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may result in electrical shock hazards or

improper operation. Fluke Biomedical will not be responsible for any injuries sustained due to unauthorized equipment

modifications.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by Fluke Biomedical. Changes made

to the information in this document will be incorporated in new editions of the publication. No responsibility is assumed by

Fluke Biomedical for the use or reliability of software or equipment that is not supplied by Fluke Biomedical, or by its

affiliated dealers.

Manufacturing Location

The TNT 12000 X-Ray Test device is manufactured in Cleveland, Ohio by Fluke

Biomedical, 6045 Cochran Rd., Cleveland, OH, U.S.A.

Page 5

Table of Contents

Chapter Title Page

1 Introduction ......................................................................................... 1-1

Introduction........................................................................................................ 1-3

Unpacking and Inspection.................................................................................. 1-3

Storage ............................................................................................................... 1-3

General Safety Considerations........................................................................... 1-3

Symbols ............................................................................................................. 1-4

RF Certification ................................................................................................. 1-4

United States.................................................................................................. 1-5

Canada ........................................................................................................... 1-5

Europe ........................................................................................................... 1-5

Japan.............................................................................................................. 1-5

Familiarization................................................................................................... 1-6

How to Charge the Battery ................................................................................ 1-9

Accessories ........................................................................................................ 1-10

Specifications..................................................................................................... 1-11

2 Operation ............................................................................................. 2-1

Introduction........................................................................................................ 2-3

Safety Information ............................................................................................. 2-3

How to Set Up the System................................................................................. 2-3

Display to Detector Communications............................................................ 2-3

How to Setup a Wireless Connection........................................................ 2-4

How to Setup a USB Connection.............................................................. 2-4

Multiple Detector Connections ................................................................. 2-4

Communication Settings ........................................................................... 2-4

How to Use the X-ray Detector (TNT 12000WD) ............................................ 2-5

How to Position the X-ray Detector .............................................................. 2-6

Detector Placement with Above Table X-ray Source ............................... 2-6

Detector Placement with Below Table X-ray Source ............................... 2-7

How to Measure X-ray Parameters ............................................................... 2-7

X-ray Display Configuration..................................................................... 2-8

Measurement Mode Setup......................................................................... 2-9

Measurement Mode Profile Parameters .................................................... 2-9

How to Set a Detector Profile ................................................................... 2-10

i

Page 6

TNT 12000

Users Manual

Auto Profiles.................................................................................................. 2-11

Default Profiles.............................................................................................. 2-11

How to Change Profile Parameters ............................................................... 2-12

How to Make a User-Defined Profile............................................................ 2-13

How to Enter a Delay .................................................................................... 2-15

How to Use the Dosimeter Detector (TNT 12000 DoseMate) .......................... 2-15

Ion Chamber Selection and Setup ................................................................. 2-16

Ion Chamber Connection and Placement ...................................................... 2-16

How to Place the Ion Chamber for Over-Table X-ray Sources ................ 2-17

How to Place the Ion Chamber for Under-Table X-ray Sources .............. 2-20

How to Place the Ion Chamber for Horizontal X-ray Beams.................... 2-22

How to Place the Ion Chamber in Limited Access Situations .................. 2-23

How to Make a Dosimeter Measurement ...................................................... 2-24

Ion Chamber Setup.................................................................................... 2-24

Dosimeter Measurements.......................................................................... 2-26

How to Add an Ion Chamber Definition or Cal Factor............................. 2-26

How to Edit an Ion Chamber Definition or Cal Factor ............................. 2-29

How to Delete an Ion Chamber Definition or Cal Factor ......................... 2-30

Measurement Mode Selection................................................................... 2-31

How to Set Units of Measurement ............................................................ 2-32

Air Density Correction.............................................................................. 2-34

How to Adjust the Internal Temperature/Pressure Sensor ........................ 2-36

Dosimeter Status ....................................................................................... 2-37

How to Use the mAs Detector (TNT 12000 mAs) ............................................ 2-38

How to Connect to the X-ray Tube for mAs Measurements ......................... 2-39

Shunt Connections .................................................................................... 2-40

Clamp Connections ................................................................................... 2-43

How to Measure mAs.................................................................................... 2-43

Setup Options..................................................................................................... 2-44

Connection Option......................................................................................... 2-45

How to Set Power Settings ............................................................................ 2-45

Detector Battery Charge Level.................................................................. 2-46

Display Off Time ...................................................................................... 2-46

Low Power Time....................................................................................... 2-46

System Off Time ....................................................................................... 2-47

Brightness.................................................................................................. 2-47

How to Set the Date and Time....................................................................... 2-47

3 Microsoft Excel Add-In Software ....................................................... 3-1

Introduction........................................................................................................ 3-3

System Requirements ........................................................................................ 3-3

How to Install the Add-In .................................................................................. 3-3

How to Install the Excel Add-In Software .................................................... 3-3

How to Install the TNT 12000 Vendor Class Driver..................................... 3-4

How to Uninstall the Add-In.............................................................................. 3-5

How to Uninstall the Excel Add-In Software................................................ 3-5

How to Uninstall the TNT 12000 Vendor Class Driver ................................ 3-6

Communication between a PC and Detector ..................................................... 3-7

How Initialize the TNT 12000 Add-In Software............................................... 3-8

TNT 12000WD Toolbar Options....................................................................... 3-9

DoseMate Toolbar Options................................................................................ 3-11

mAs Toolbar Options......................................................................................... 3-13

ii

Page 7

Contents (continued)

4 Maintenance......................................................................................... 4-1

Introduction........................................................................................................ 4-3

Ion Chamber Care.............................................................................................. 4-3

Cleaning............................................................................................................. 4-3

Firmware Upgrade ............................................................................................. 4-3

Detector ......................................................................................................... 4-3

Display........................................................................................................... 4-4

Service and Calibration...................................................................................... 4-4

Packing .......................................................................................................... 4-4

Shipping......................................................................................................... 4-4

Appendices

A Model 96020C Ion Chamber....................................................................... A-1

B Model 96035B Ion Chamber ....................................................................... B-1

C Model 500-100 CT Probe............................................................................ C-1

D Model 500-200 CT Probe............................................................................ D-1

E TNT 12000WD kVp, Exposure, and Exposure Time Measurement........... E-1

F Warnings and Error Messages..................................................................... F-1

G Troubleshooting .......................................................................................... G-1

H PTB Information ......................................................................................... H-1

iii

Page 8

TNT 12000

Users Manual

iv

Page 9

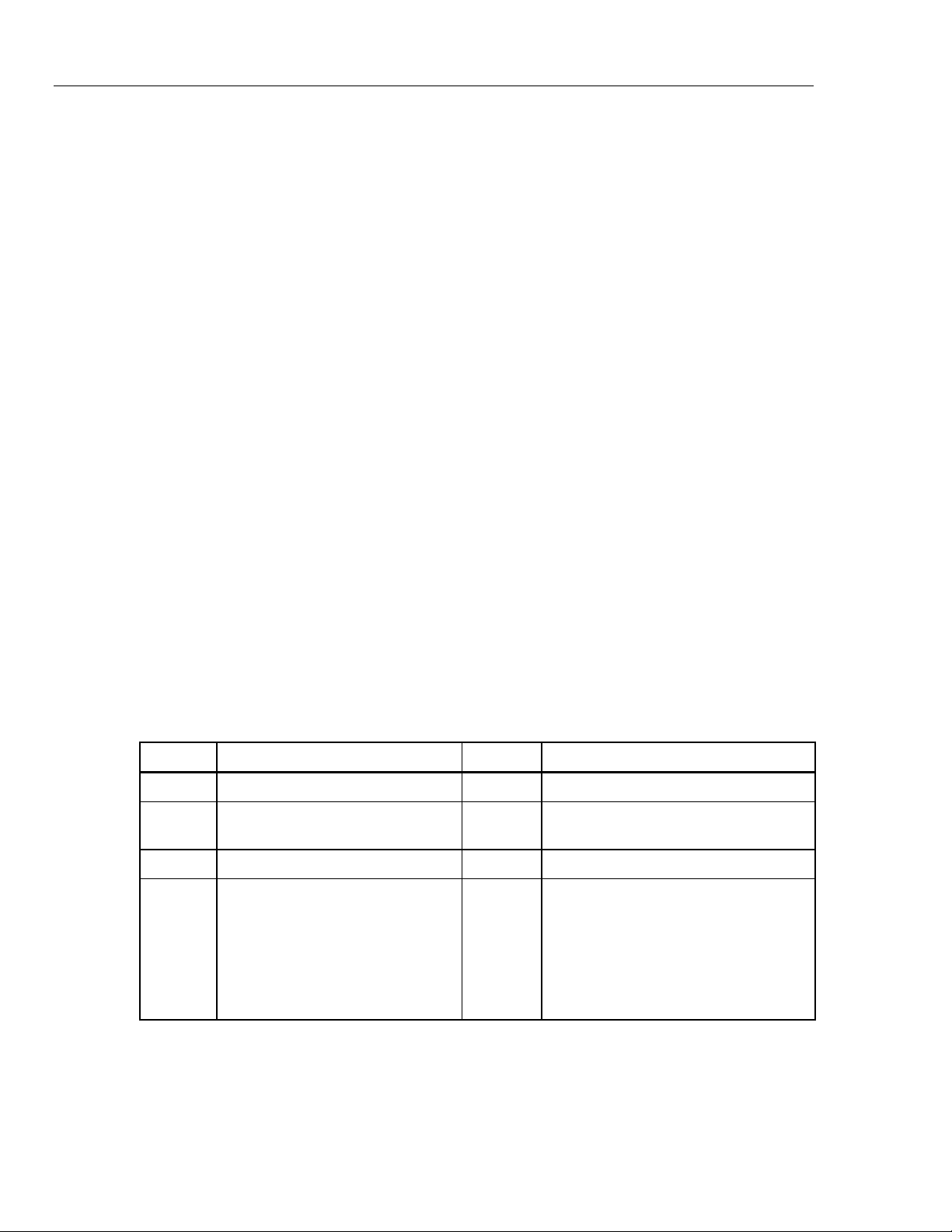

List of Tables

Table Title Page

1-1. Symbols.................................................................................................................. 1-4

1-2. Display Components .............................................................................................. 1-6

1-3. X-ray Detector Components................................................................................... 1-7

1-4. Dose Detector Components.................................................................................... 1-8

1-5. Battery Status Indicator.......................................................................................... 1-10

1-6. Accessories............................................................................................................. 1-10

1-7. Optional Accessories.............................................................................................. 1-11

2-1. Communication Status Indicator............................................................................ 2-3

2-2. Settable Profile Parameters .................................................................................... 2-9

2-3. Default Parameter Values for Each Measurement Mode....................................... 2-12

2-4. Cal Factor Units ..................................................................................................... 2-29

2-5. Dosimeter Measurement Modes............................................................................. 2-31

2-6. Dose Rate Values ................................................................................................... 2-33

2-7. mAs Current Ranges .............................................................................................. 2-39

3-1. TNT 12000WD Excel Add-In Menu and Toolbar Options ................................... 3-10

3-2. DoseMate Excel Add-In Menu and Toolbar Options ............................................ 3-12

3-3. mAs Excel Add-In Menu and Toolbar Options ..................................................... 3-14

v

Page 10

TNT 12000

Users Manual

vi

Page 11

List of Figures

Figure Title Page

1-1. Charging Methods.................................................................................................. 1-9

2-1. Wired (USB) Connection....................................................................................... 2-4

2-2. Connection Screen ................................................................................................. 2-5

2-3. X-ray Detector Alignment Marks .......................................................................... 2-6

2-4. X-ray Detector Setup for Above Table X-ray Source............................................ 2-6

2-5. X-ray Detector Setup for Below Table X-ray Source ............................................ 2-7

2-6. X-ray Detector Measurement Screen ..................................................................... 2-8

2-7. Mode Setup Screen ................................................................................................ 2-9

2-8. Ion Chamber Connection to Dosimeter.................................................................. 2-17

2-9. Test Stand Configuration for Over-Table Tubes.................................................... 2-18

2-10. Test Stand Configuration for Under-Table X-ray Tube ......................................... 2-20

2-11. Test Stand Configuration for Horizontal Tube....................................................... 2-22

2-12. Ion Chamber Cable Stem ....................................................................................... 2-23

2-13. Ion Chamber Notification Screen........................................................................... 2-24

2-14. Ion Chamber Setup Screen ..................................................................................... 2-25

2-15. Dosimeter Measurement Screen............................................................................. 2-26

2-16. mAs Measurement Option Screen.......................................................................... 2-38

2-17. Shunt or Clamp Screen........................................................................................... 2-39

2-18. Direct mAs Shunt Connection to Current Jacks..................................................... 2-41

2-19. mAs Test Leads Connection .................................................................................. 2-42

2-20. mAs Measurement Screen...................................................................................... 2-43

2-21. Setup Screen........................................................................................................... 2-44

2-22. Setup Screen from mAs Measurement ................................................................... 2-44

2-23. Setup Screen with mAs and DoseMater Detectors Connected .............................. 2-45

2-24. Power Setting Screen ............................................................................................. 2-45

2-25. Sleep Mode Display ............................................................................................... 2-46

2-26. Date and Time Setting Screen ................................................................................ 2-47

3-1. InstallShield Wizard............................................................................................... 3-3

3-2. USB Connection between PC and Detector........................................................... 3-4

3-3. Found New Hardware Wizard Window................................................................. 3-5

3-4. Add or Remove Programs Dialog .......................................................................... 3-6

3-5. Computer Management Windows.......................................................................... 3-7

3-6. USB Connection between PC and Detector........................................................... 3-7

3-7. Wireless Connection Between PC and Detector .................................................... 3-8

3-8. Detector Connection Window................................................................................ 3-9

vii

Page 12

TNT 12000

Users Manual

3-9. TNT 12000WD Excel Add-In Menu and Toolbar (Excel 2007) ........................... 3-10

3-10. TNT 12000WD Excel Add-In Menu and Toolbar (Excel 2003) ........................... 3-11

3-11. DoseMate Excel Add-In Menu and Toolbar (Excel 2007) .................................... 3-11

3-12. DoseMate Excel Add-In Menu and Toolbar (Excel 2003) .................................... 3-13

3-13. mAs Excel Add-In Menu and Toolbar (Excel 2007) ............................................. 3-13

3-14. mAs Excel Add-In Menu and Toolbar (Excel 2003) ............................................. 3-14

viii

Page 13

Chapter 1

Introduction

Title Page

Introduction..........................................................................................................1-3

Unpacking and Inspection....................................................................................1-3

Storage .................................................................................................................1-3

General Safety Considerations.............................................................................1-3

Symbols ...............................................................................................................1-4

RF Certification ...................................................................................................1-4

United States....................................................................................................1-5

Canada .............................................................................................................1-5

Europe .............................................................................................................1-5

Japan................................................................................................................1-5

Familiarization.....................................................................................................1-6

How to Charge the Battery ..................................................................................1-9

Accessories ..........................................................................................................1-10

Specifications.......................................................................................................1-11

1-1

Page 14

TNT 12000

Users Manual

1-2

Page 15

Introduction

Introduction 1

Introduction

The Fluke Biomedical TNT 12000 X-ray Test Tools (the TNT 12000) are used to

calibrate and service diagnostic X-ray imaging systems.

The TNT 12000 X-ray Test Tools has these parts:

• TNT 12000WD X-ray Detector option (the X-ray Detector). The X-ray Detector

contains an array of solid-state sensors and filters that measure kV, Dose, Half-Value

Layer (HVL), and exposure time.

• TNT 12000 DoseMate option (the Dosimeter Detector). With its related ion

chambers, the Dosimeter Detector measures dose and rate on all X-ray modalities:

radiographic, mammographic, dental, cine, fluoroscopic, and CT.

• TNT 12000 mAs option (the mAs Detector) to measure X-ray tube current over time.

Use the mAs Detector on radiographic (or Dental or Mammography) and

fluoroscopic X-ray imaging modalities. The mAs option is installed in the X-ray or

Dosimeter Detectors.

• TNT 12000 Display (the Display). The Display contains a 320 x 240 color LCD, four

navigation buttons, an ENTER button, and a power button. The display controls testsystem functions and shows all system measurements.

• TNT 12000/DoseMate/mAs CD that contains an Excel Add-in to control the test

system and import all measurements.

• AC Power Adapter used to charge the rechargeable batteries in the X-ray Detector,

Dosimeter Detector, mAs Detector, and the Display.

The TNT 12000 options communicate between the detectors and the display or computer

through a wireless (ZigBee) or wired (USB) connection.

Unpacking and Inspection

The TNT 12000 is shipped in a container designed to prevent damage during shipment.

Examine the components for damage, and immediately report any damage to the shipper.

Keep the damaged shipping container and packing material for inspection by the carrier.

The shipping container contains foam inserts to prevent damage during

shipment. Keep these and the container for future shipment.

When you unpack the TNT 12000, compare the parts to the packing list. If you ordered

the mAs option, make sure it is installed in a Detector by looking for an mAs input jack

on a Detector. See the Familiarization section later in this chapter. Report any shortage to

the place of purchase.

Storage

To store the TNT 12000, put it in its carrying case. Keep it in an environment free of

corrosive material and within the storage temperature and operating humidity ranges

shown in the specifications. Also prevent vibration and shock to the system.

Note

General Safety Considerations

In this manual, a Warning identifies conditions and actions that pose hazards to the user.

A Caution identifies conditions and actions that may damage the test equipment or the

equipment under test.

Symbols used on the test system or in this manual are explained in Table 1-1.

1-3

Page 16

TNT 12000

Users Manual

To ensure safe operation of the Test System, fully observe all instructions and warnings

contained in this manual.

XW Warning

To avoid possible electrical shock or personal injury, follow

these guidelines:

• Use the TNT 12000 only in the manner specified by the

manufacturer.

• Do not use the product if it operates abnormally.

• Use only the ac adapter provided with the system.

• Ensure that the external power source is properly rated for the

system.

W Caution

To avoid damage to the TNT 12000 or adverse affects on its

performance, follow these guidelines:

• Allow only qualified technical personnel to service the

system.

• Do not expose the system to temperature extremes.

Ambient temperatures should remain between 0 °C and

35 °C. System performance may be adversely affected if

temperatures fluctuate above or below this range.

• Clean the TNT 12000 by gently wiping down with a clean,

lint-free cloth dampened with a mild detergent solution. Do

not immerse the unit in liquid.

Symbols

Table 1-1 describes the symbols associated with the TNT 12000.

Table 1-1. Symbols

Symbol Description Symbol Description

X Hazardous voltage P Conforms to European Union directives

W Important information, refer to manual ;

• Complies with RoHS directives Ž Complies with Part 15 of the FCC rules

Do not dispose of this product as

~

unsorted municipal waste. Go to

Fluke’s website for recycling

information.

´

Conforms to relevant Australian EMC

requirements

This product contains a Lithium-ion

battery. Do not mix with solid waste

stream. Spent batteries should be

disposed of by a qualified recycler or

hazardous materials handler per local

regulations. Contact your authorized Fluke

Service Center for recycling information.

1-4

RF Certification

The TNT 12000 contains radio transceivers that are used for wireless communication

between the Display and the Detectors. The transceivers operate in the 2.4 GHz

frequency band with a maximum transmitting power of 1 mW. The transceivers have

been tested and certified for use in various areas worldwide.

Page 17

Introduction

RF Certification 1

United States

The transceivers used in the TNT 12000 have been approved for use in the United States

by FCC Part 15 certification, FCC ID: OUR-XBEE. The following statement

accompanies the device:

“Contains FCC ID: OUR-XBEE"

The enclosed device complies with Part 15 of the FCC rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference and (2) this

device must accept any interference received, including interference that may cause

undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation.

If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures: Re-orient or relocate

the receiving antenna, increase the separation between the equipment and receiver,

connect equipment and receiver to outlets on different circuits, or consult the dealer or an

experienced radio/television technician for help.

Canada

Europe

Japan

W Warning

To satisfy FCC RF exposure requirements for mobile

transmitting devices, a separation distance of 20 cm or more

should be maintained between the antenna of this device and

persons during device operation. To ensure compliance,

operations at closer than this distance is not recommended.

The antenna used for this transmitter must not be co-located in

conjunction with any other antenna or transmitter.

The transceiver used in the TNT 12000 has been certified for use in Canada, IC

certification number IC: 4214A-XBEE.

The transceiver used in the TNT 12000 conforms to European Union EMC Directive

2004/108/EC, ETSI EN 301 489-1 and EN 301 489-17; and R&TTE Directive

1999/5/EC, ETSI EN300 328.

Japan ID: 005NYCA0378

1-5

Page 18

TNT 12000

Users Manual

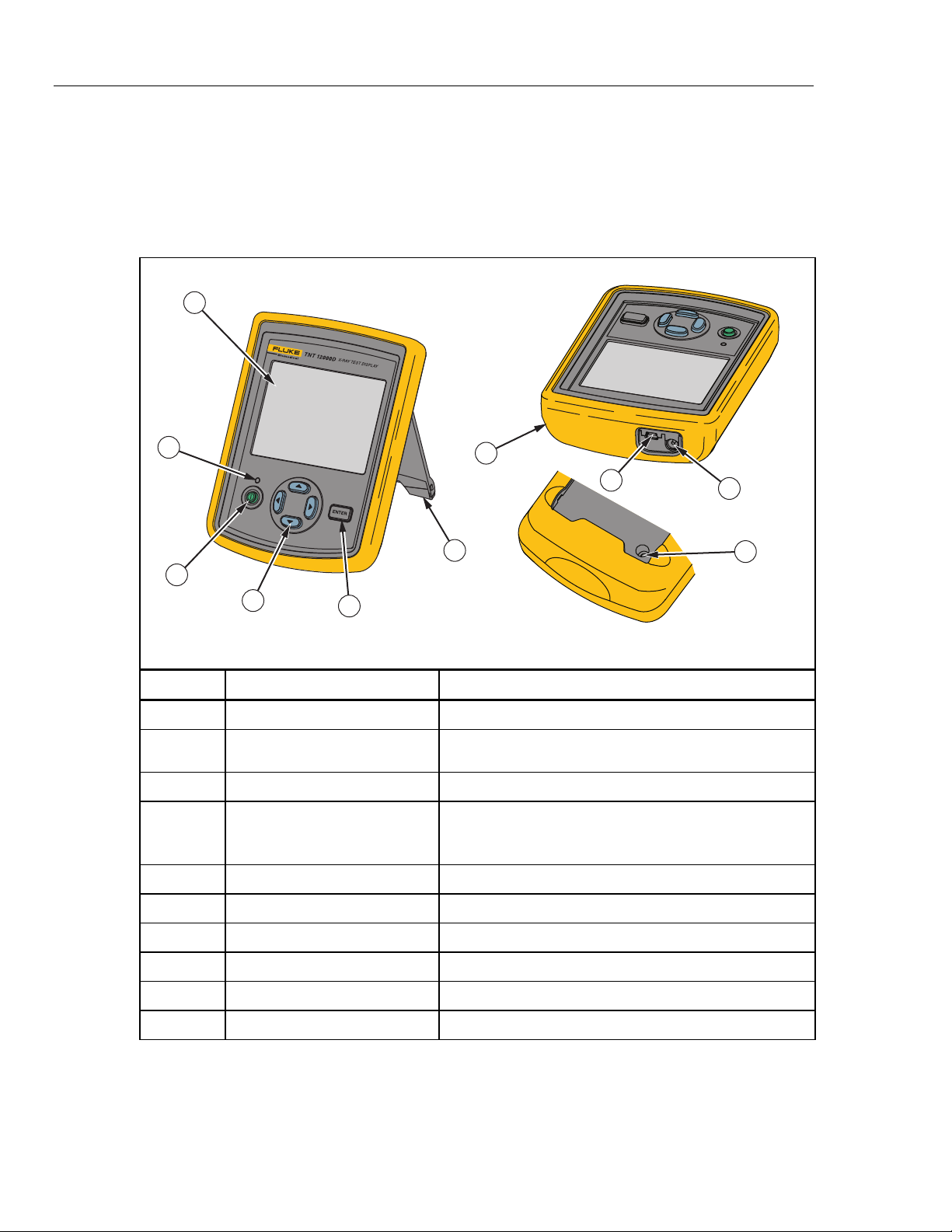

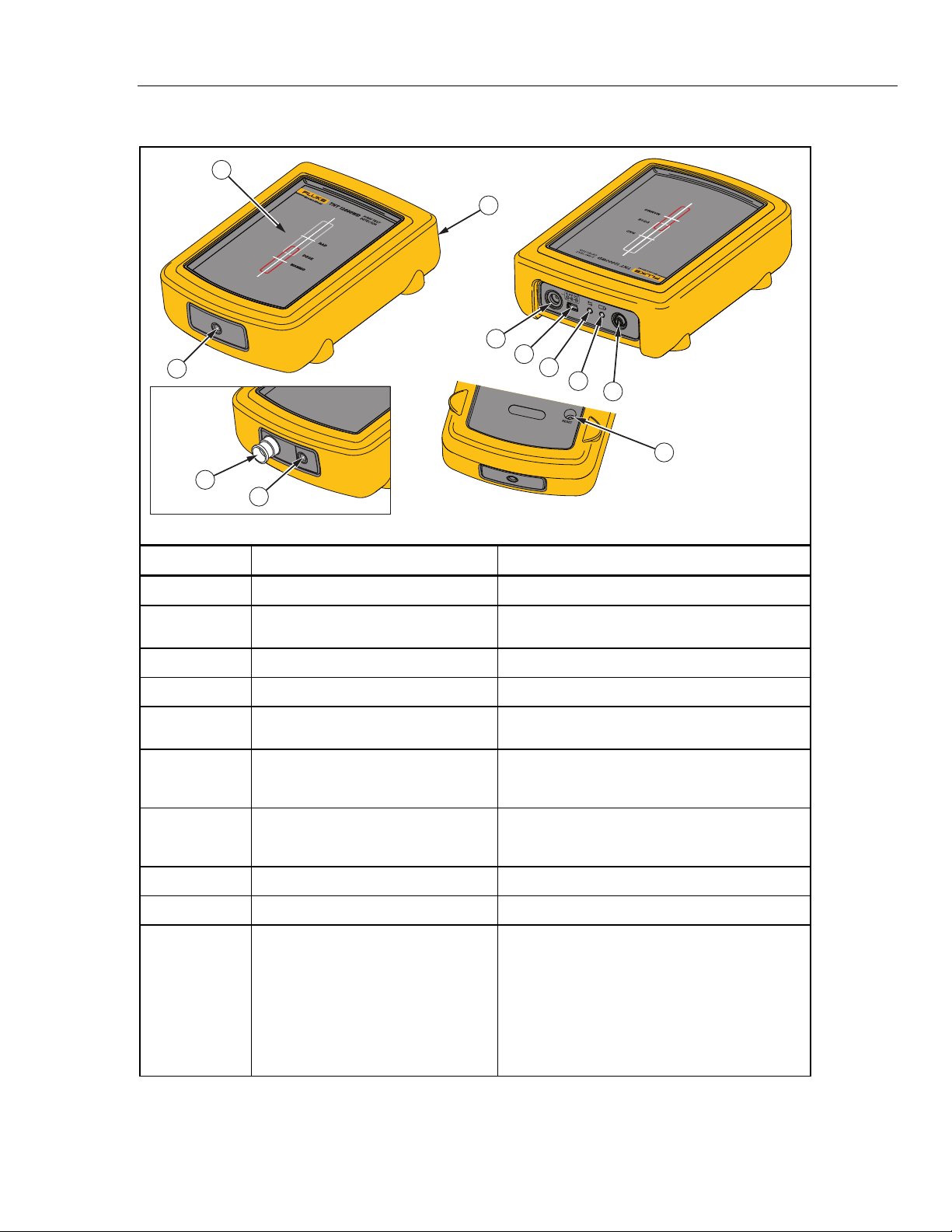

Familiarization

To use the TNT 12000, you must first connect the Display to the X-ray Detector or

Dosimeter Detector. Tables 1-2 through 1-4 shows the controls, indicators, and

connectors of the Display and Detectors.

Table 1-2. Display Components

1

2

3

4

Item Name Description

A

B

C

D

E

LCD Panel 320X240 color display

Battery-status Indicator Tri color LED indicating the battery status of the display.

On/Off Switch Powers the display On/Off

Navigational Keys:

Left, Right, Up, and Down keys

Enter key Selects the menu option on the display screen

5

7

8

RESET

6

Refer to the Battery Charging section for more details.

Moves the cursor through the menu options on the display

screen in various directions.

Note: The cursor movement is circular

9

10

fct02.eps

1-6

F

G

H

I

J

Stand Display support stand

Holster Protective cover for the display

USB Connector To connect the detector or a Computer via USB cable

AC adapter connector Connects the ac adapter

Reset switch Resets the display

Note

A short beep sounds for a valid key press, and a long beep sounds for an

invalid key press.

Page 19

Introduction

Familiarization 1

Table 1-3. X-ray Detector Components

1

3

4

5

2

mAs Option

Installed

10

2

6

7

8

9

fct01.eps

Item Name Description

A

B

C

D

E

F

G

H

I

J

Exposure Surface The surface to be exposed to x-ray radiation

Threaded Insert Secures the detector to a test stand, such as a

camera tripod

Holster Protective cover for the display

AC adapter connector Connects the ac adapter

USB Connector To connect the detector or a Computer via USB

cable

Communication status LED Indicates the communication status (see the

Display to Detector Communications section in

Chapter 1)

Battery-status Indicator Tri color LED indicating the battery status of the

display. Refer to the Battery Charging section

for more details.

On/Off Switch Powers the Detector On/Off

Reset switch Resets the Detector

mAs input jack (when mAs option is

installed)

Male coaxial BNC jack for connection to the

mA/mAs interface cable

WCaution

To avoid damage to the Detector,

never connect to generator mA/mAs

taps without the TNT 12000 mAs

shunt.

1-7

Page 20

TNT 12000

Users Manual

Table 1-4. Dose Detector Components

3

4

5

1

2

6

7

8

9

fct11.eps

Item Name Description

A

mAs input jack (when mAs option is installed) Male coaxial BNC jack for connection to the

mA/mAs interface cable

WCaution

To avoid damage to the Detector,

never connect to generator

mA/mAs taps without the TNT

12000 mAs shunt.

B

C

D

E

F

G

Ion Chamber Connector Triaxial input connection for the Ion Chamber.

Holster Protective cover for Dosimeter

AC adapter connector Connects the ac adapter

USB Connector To connect the Detector or a computer via

USB cable

Communications Status Indicator Indicates the communication status (see the

Display to Detector Communications section

in Chapter 1)

Battery-status Indicator Tri color LED indicating the battery status of

the display. Refer to the Battery Charging

section for more details.

1-8

H

I

On/Off Switch Powers the Detector On and Off.

Reset switch Resets the Dose Detector

Page 21

Introduction

How to Charge the Battery 1

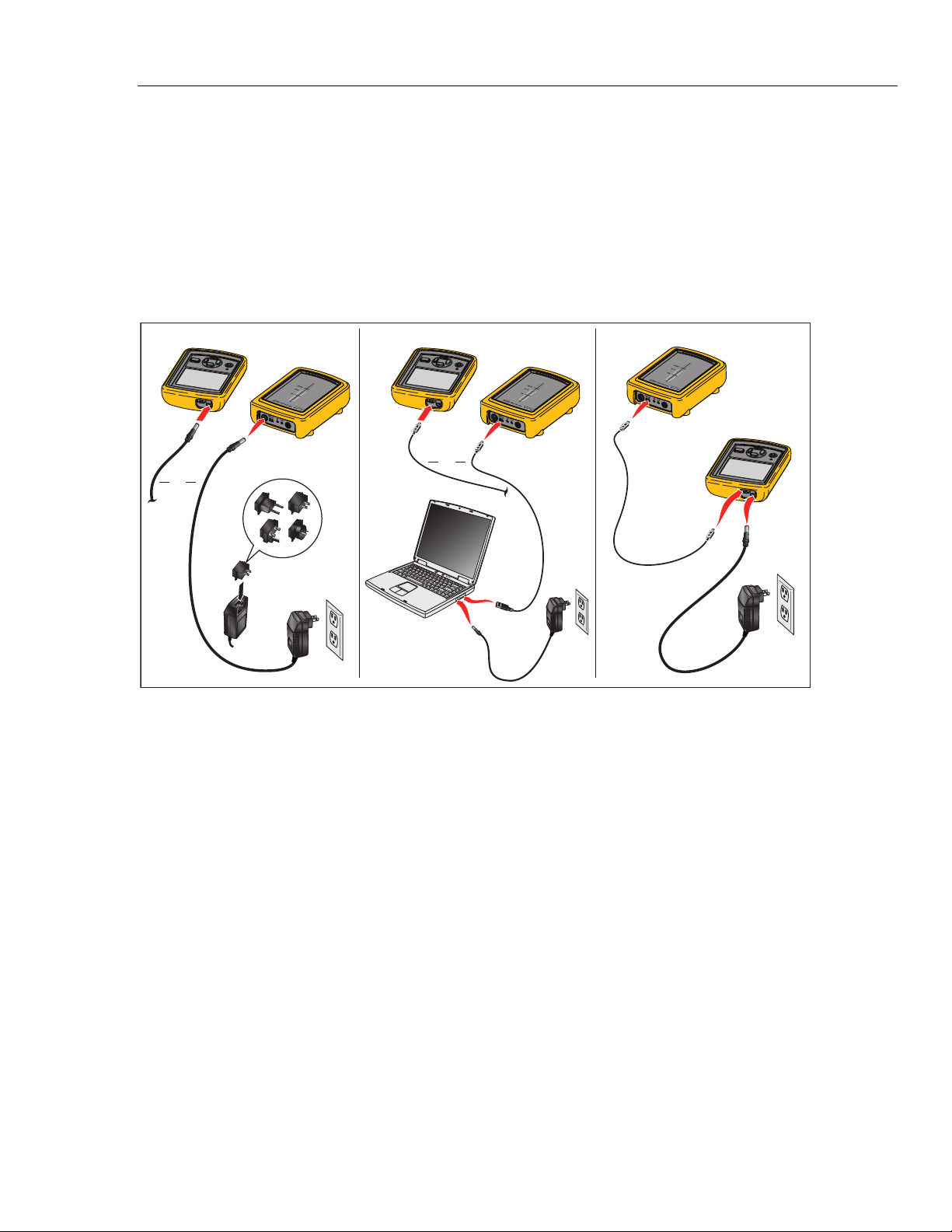

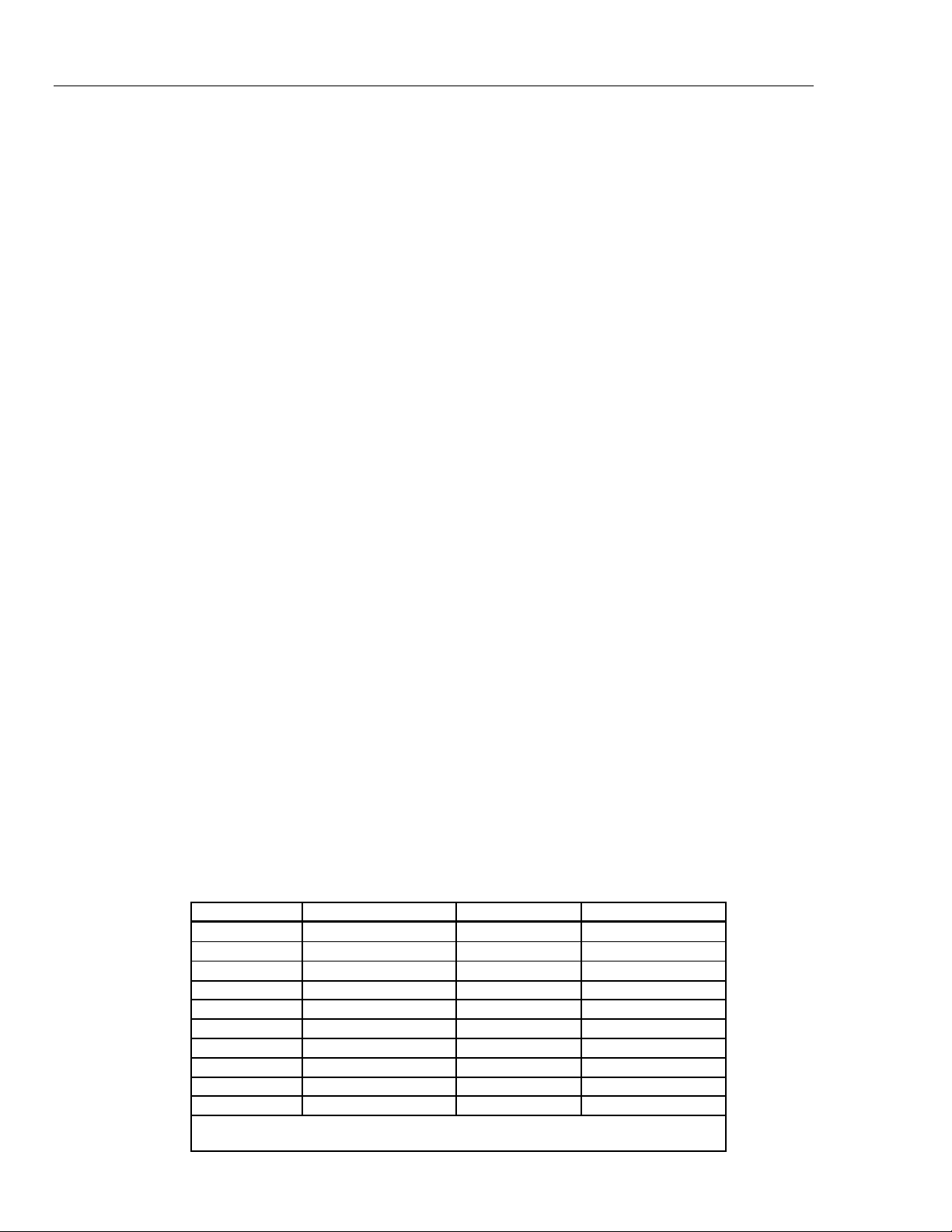

How to Charge the Battery

Charging the internal batteries of the detectors and display from mains power can be done

in three different configurations as shown in Figure 1-1.

WCaution

To prevent damage to the TNT 12000, do not leave batteries

unused for an extended period of time. When a battery has not

been used for six months, check the charge status and charge

if necessary.

Power Source Computer to Power Source Detector to Display to Power Source

OR

OR

Figure 1-1. Charging Methods

fct10.eps

To charge a Detector or the Display directly from mains power, connect the ac-power

adapter directly to the ac adapter connector on a Detector or the Display. To charge a

Detector and the Display simultaneously, connect the ac adapter to the ac adapter

connection on the Display and then, using the Mini-B to Type-A USB cable, connect the

Detector to the Display.

Note

See the markings on the ends of the cable to identify the Mini-A and Mini-B

ends.

A Detector or Display battery can also be charged through a USB connector on a PC.

Connect the Display or Detector to a PC USB port using the Mini-A to Type-A USB

cable.

Both Detectors and the Display have a battery-status indicator to indicate the condition of

the internal battery. The indicator is a tri-color LED that shows the level of charge on the

internal battery. Table 1-5 explains the battery-status indicator levels.

1-9

Page 22

TNT 12000

Users Manual

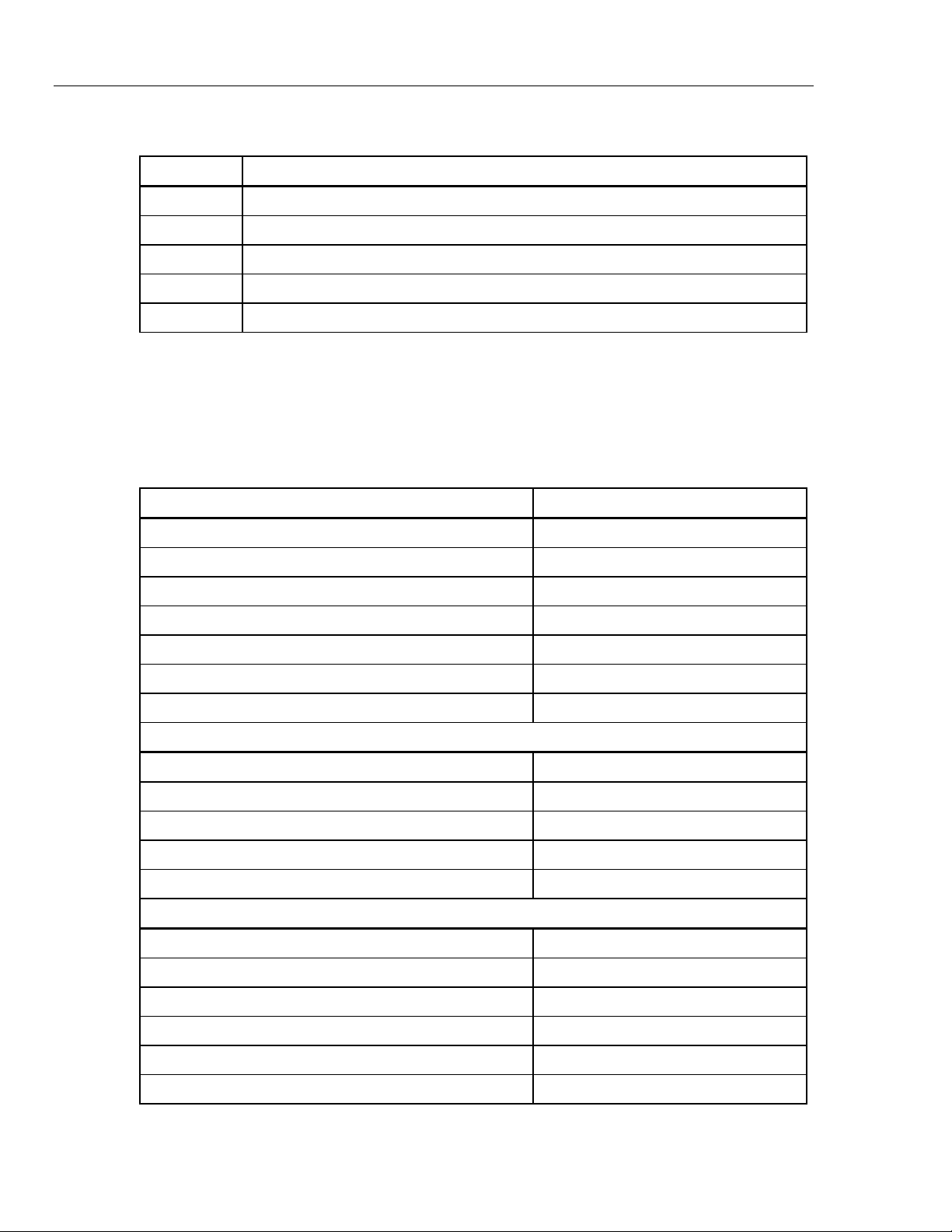

Table 1-5. Battery Status Indicator

Color Description

Blue Battery is fully charged.

Green Battery is charging.

Off Unit is not connected to a charging power source and is operating on battery power.

Yellow Battery is approximately 20 % charged.

Red Battery has 10 % charge and will turn off in two minutes.

Accessories

Items shown in Table 1-6 are standard accessories provided with the TNT 12000. Some

accessories are only associated with specific options. Items in Table 1-7 are optional.

Contact your Fluke Biomedical representative to purchase the accessories shown below.

Table 1-6. Accessories

Accessory Fluke Biomedical Part No

Cable, Type A to Mini B USB 3346027

Cable, Mini A to Mini B USB 3346030

ZigBee Dongle 3341333

AC Power Adapter 3548014

Multi-Prong Adapter 3549414

CD, TNT 12000/DoseMate/mAs 3586667

Ansur Demo CD 2795488

DoseMate Option

Carrying Case, DoseMate/mAs 3586528

Test Stand, DoseMate 3586537

HVL Filter Set 3264115

Adapter Stem 3264091

Tirax Cable, Male to Male, BNC, 1.82 m (6 ft) 3586644

mAs Option

mA Cable Assembly, BNC (male to female) 1918780

mA Shunt Assembly 3586555

1-10

Alligator Clip, Banana Plug (Red) 1942964

Alligator Clip, Banana Plug (Black) 1942920

Connector, BNC (F) to Binding Posts 1938315

Connector, BNC (F) to Double Banana Plug 1633042

Page 23

Introduction

Specifications 1

Table 1-7. Optional Accessories

Accessory Fluke Biomedical Part No

Ansur Plug In, TNT 12000 3337356

Optional Accessories for the DoseMate Option

Diagnostic Ionization Chamber, 150cc, Model 96020C 2549992

Diagnostic Ionization Chamber, 15cc, Model 96035B 2550024

CT Ion Chamber, 3cc, Model 500-100 2549734

CT Ion Chamber, 10cc, Model 500-200 2549741

Triax Cable, Male to Male, BNC, 6.1 m (20 ft) 3265786

Optional Accessories for the mAs Option

Non-Invasive mA/mAs Clamp 3586746

mA Cable Assembly, BNC, 6.1 m (20 ft) (male to female) 2118136

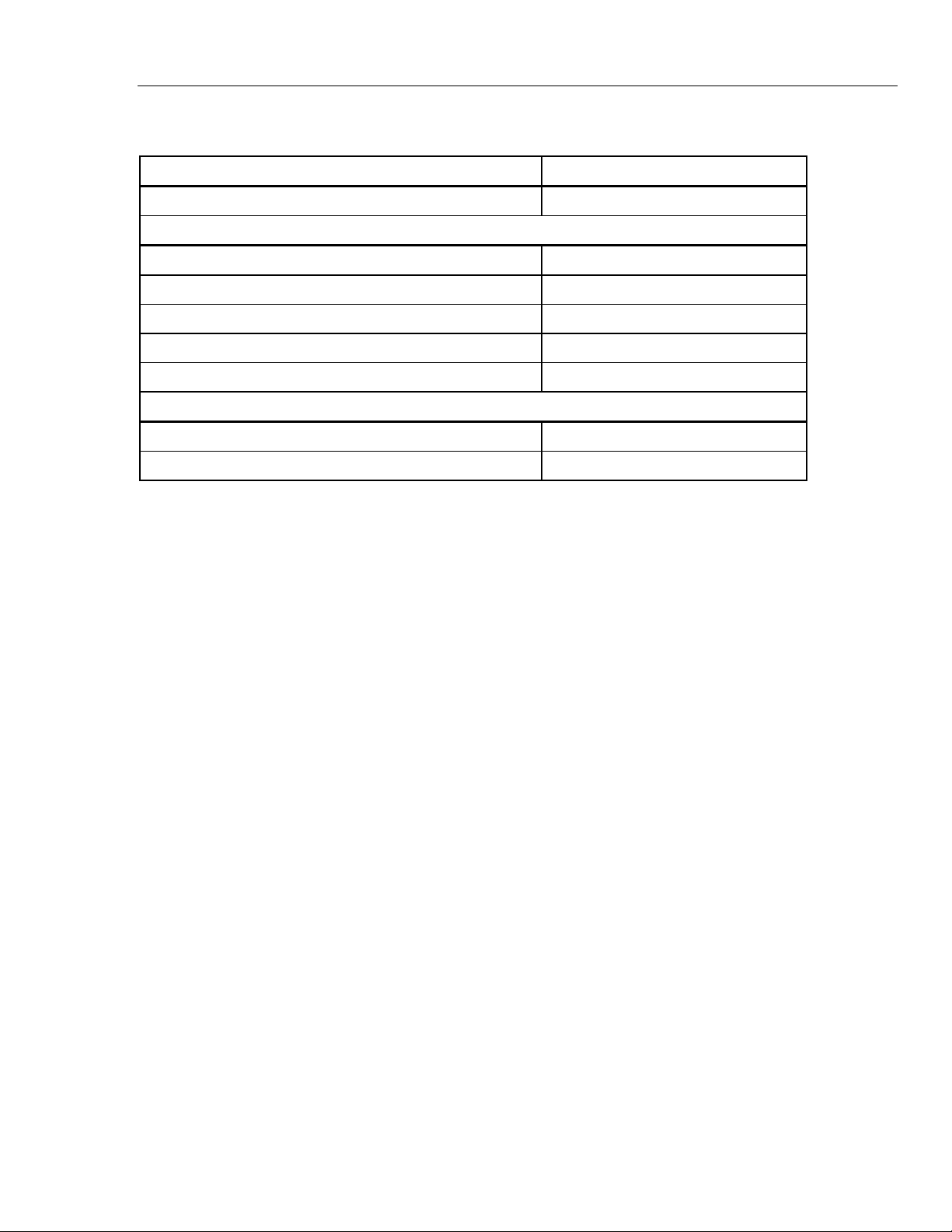

Specifications

Physical

Display Screen........................................................ 320X240 Color LCD

Size

Display ................................................................ 15.24 cm X 11.43 cm X 4.45 cm (6 in X 4.5 in X 1.75 in)

Detector ..............................................................15.24 cm X 11.43 cm X 4.45 cm (6 in X 4.5 in X 1.75 in)

Weight

Display ................................................................ 347 g (0.93 lb)

X-ray Detector w/o mAs...................................... 560 g (1.5 lb)

X-ray Detector with mAs ..................................... 560 g (1.5 lb)

DoseMate w/o mAs............................................. 392 g (1.05 lb)

DoseMate with mAs............................................ 392 g (1.05 lb)

Electrical

Battery

Battery Type ....................................................... Lithium-Ion, 3.7 V, 4000 mAh

Battery Charging time ......................................... Approx. 5 hr

Battery Discharge time ....................................... Approx. 8 hr

Battery Cutoff Voltage......................................... 3.0 V

AC Adapter

Input Voltage....................................................... 100 V ac to 240 V ac

Input Frequency.................................................. 50/60 Hz

Input Current....................................................... 0.5 A (rms)

Output Voltage.................................................... +6 V dc

Output Current .................................................... 2500 mA (max.)

1-11

Page 24

TNT 12000

Users Manual

1-12

Environmental

Operating Temperature........................................... 0 °C to 35 °C (32 °F to 95 °F)

Storage Temperature.............................................. -35 °C to 50 °C (-31 °F to +122 °F)

Operating Humidity ................................................. 20 % to 80 % RH (Non Condensing)

Wireless Range....................................................... 30 m (100 ft)

X-ray Specifications

kVp

Units........................................................................ kVp Average (Average of peaks during a specified interval)

kVp Max (Highest peak during a specified interval)

PPV (Peak Practical Voltage)

Ranges

Radio/Fluoro/Dental Modes (W,Al) ......................... 40 kV–150 kV

Mammo Mode

Mo/Mo................................................................. 22 kV–35 kV

Rh/Rh.................................................................. 25 kV– 49 kV

Mo/Rh ................................................................. 22 kV–40 kV

Mo/Al................................................................... 22 kV– 49 kV

Rh/Al ................................................................... 25 kV–49 kV

W/Rh................................................................... 22 kV–39 kV

W/Ag ................................................................... 22 kV–39 kV

Resolution: .............................................................. 0.1 kV

Accuracy (including calibration uncertainty)

Radio/Fluoro/Dental Modes .................................... ±2 % or ±1 kV, whichever is greater

Mammo Mode ......................................................... ±2 % or ±0.7 kV, whichever is greater

Reproducibility ........................................................ ±1 % (standard deviation % of 5 readings)

Filtration Correction Range

Radio/Fluoro/Dental Modes .................................... 1–10 mm Al or equivalent

Mammo Mode ......................................................... 0–0.4 mm Al or equivalent added filtration (0–0.2 mm AI below 25 kV)

Dose/Exposure

Units........................................................................ Roentgens (R)

Grays (Gy)

Range ..................................................................... 0.5 mR–999 R

5 mGy–999 Gy

Resolution ............................................................... 1 µR

0.01 µGy

Accuracy ................................................................. ±5 %

Reproducibility ........................................................ ±0.5 % (standard deviation % of five readings)

Filtration Correction Range

Radio/Fluoro/Dental Modes ................................ 10 mm Al or equivalent

Mammo Mode..................................................... 0–0.4 mm Al or equivalent added filtration (0– 0.2 mm AI below 25 kV)

kV Correction Ranges

Radio/Fluoro/Dental Modes ................................ 40 kV–150 kV

Mammo Mode: Mo/Mo........................................ 22 kV–35 kV

Dose/Exposure Rate

Units........................................................................ Roentgens per hour, minute, second, pulse (R/hr, R/min, R/sec,

R/Pulse)

Grays per hour, minute, second, pulse (Gy/hr, Gy/min, Gy/sec,

Gy/Pulse)

Range ..................................................................... 8 mR/s–10 R/s

70 µGy/s–100 mGy/s

130 µR/Pulse–160 mR/Pulse (@ 60 PPS)

12 µGy/Pulse–1.4 mGy/Pulse (@ 60 PPS)

Resolution ............................................................... 1 µR/s

0.01 µGy/s

0.02 µR/Pulse (@ 60 PPS)

0.2 nGy/Pulse (@ 60 PPS)

Accuracy ................................................................. ±5 %

Page 25

Introduction

Specifications 1

Filtration Correction Range

Radio/Fluro/Dental Modes .................................. 1-10 mm Al or equivalent

Mammo Mode..................................................... 0–0.4 mm Al or equivalent added filtration (0–0.2 mmAI below 25 kV)

kV Correction Range

Radio/Fluro/Dental Modes .................................. 40 kV–150 kV

Mammo Mode: Mo/Mo........................................ 22 kV-35 kV

Exposure Time–Radiographic Modes

Range @ stated accuracy

Milliseconds ........................................................10–9999 ms

Pulses ................................................................. 1–999 pulses

Resolution

Milliseconds ........................................................0.1 ms

Pulses ................................................................. 1 pulse

Accuracy

Milliseconds ........................................................1 % or 0.5 ms

Pulses ................................................................. ±1 pulse

Reproducibility

Milliseconds ........................................................1 % or 0.5 ms

Pulses ................................................................. ±1 pulse

Elapsed Time–Fluoro Modes

Range ..................................................................... 10–9999 seconds

Resolution ............................................................... 0.1 second

Accuracy ................................................................. 1 % or 0.5 second

Average Pulse Rate – Pulsed Fluoro

Range ..................................................................... 1–999 pps (pulses per second)

Resolution ............................................................... 1 pps

Accuracy ................................................................. 1 pps

Average Pulse Width – Pulsed Fluoro

Range ..................................................................... 10–999 ms

Resolution ............................................................... 0.1 ms

Accuracy ................................................................. 1% or 0.5 ms

HVL (Half Value Layer)

Range

Radio/Fluoro/Dental Modes ................................ 1.2–10 mm Al (equivalent)

Mammo Mode..................................................... 0.2–0.6 mm Al (equivalent)

Resolution

Radio/Fluoro/Dental Modes ................................ 0.1 mm Al (equivalent)

Mammo Mode..................................................... 0.01 mm Al (equivalent)

Accuracy

Radio/Fluoro/Dental Modes ................................ ±10 % or 0.2 mm Al (equivalent)

Mammo Mode: Mo/Mo........................................ ± 5 % or 0.05 mm Al (equivalent)

mAs Specifications

Accuracy

With Invasive Shunt ............................................ ±2 % of rdg ±2 digits

With Non-Invasive Shunt ....................................±3 % ±3 mA

Invasive mA/mAs Range......................................... 0.00 – 99.99 mA/mAs

100.0 – 999.9 mA/mAs

1000 – 1999 mA/mAs

Non-Invasive mA/mAs Ranges............................... 0 – 999.9 mA/mAs

1000 – 3999 mA/mAs

Trigger Levels

Invasive Shunt ....................................................3 mA

Non-Invasive Shunt ............................................ 6 mA

Input Jack................................................................ Male Coaxial BNC

mA/mAs Interface Cable ......................................... 152.4 cm (60 in) BNC Male – Female, 50 Ohm cable with strain relief

1-13

Page 26

TNT 12000

Users Manual

Adapters.................................................................. BNC Female to Binding Posts, BNC Female to Banana Plug

Test Leads .............................................................. 91.4 cm (36 in) safety set with finger guards on probes and shrouded

banana plugs

Invasive Shunt

Shunt Impedance.................................................... 1 Ohm

Sensitivity................................................................ 1 mV per mA

Shunt Signal Input Limit.......................................... 1 A for 30 seconds (Limit set by power dissipation rating of shunt

resistors. Maximum common mode voltage is 500 V).

Input/Output ............................................................ 4 mm Binding posts, 4 mm Banana Plugs

Size ......................................................................... 4.45 cm x 3.66 cm x 1.75 cm (1.75 in x 1.44 in x 0.69 in)

Weight..................................................................... 45 g (0.1 lb)

Non-Invasive Clamp

Range ..................................................................... 0 – 4 Amps

Sensitivity................................................................ 100 mV/A

Power Source ......................................................... 2 x 1.5 V AA UM3 Batteries

Current Consumption.............................................. 10 mA

Operating Condition ................................................ -10 °C to +50 °C at 85 % max. RH

DoseMate Specifications

Accuracy ................................................................. ±1 % of rdg ±2 of range resolution steps (see DoseMate Measurment

Ranges) over the range of 18 to 28 °C and ±2 of reading ±2 range

resolution steps over the full operating temperature range of 0 to

35 °C. This accuracy is exclusive of all ion chamber effects. A 3 %

NIST traceable calibration is provided with each system.

Bias Voltage............................................................ 300 V. The bias voltage is removed from the triaxial input connector at

instrument turnoff.

Ion Chamber Input .................................................. Triaxial-BNC input connector, collector and guard positive-biased

relative to ion chamber body/dosimeter chassis.

Ion Chamber Cable................................................. 1.8 m (6 ft), Triaxial Male to Male cable

Test Stand............................................................... Machined stainless steel upright tool with baseplate, ion chamber

holder, and tray for HVL filters, which includes the ion chamber stem.

HVL Filter Set.......................................................... Set of nine aluminum filters for half-value layer measurements: one

2 mm, two 1 mm, two 0.5 mm, three 0.1 mm, and one 0.2 mm.

Temperature Accuracy............................................ ±2 °C (3.6 °F)

Pressure Accuracy.................................................. ±5 mm Hg

1-14

Note

The measured temperature is the internal temperature of the DoseMate,

which may not be the same temperature as the Ion Chamber that is in use.

Adequate time must be allowed for the DoseMate and Ion Chamber to

reach thermal equilibrium before automatic temperature sensing is used.

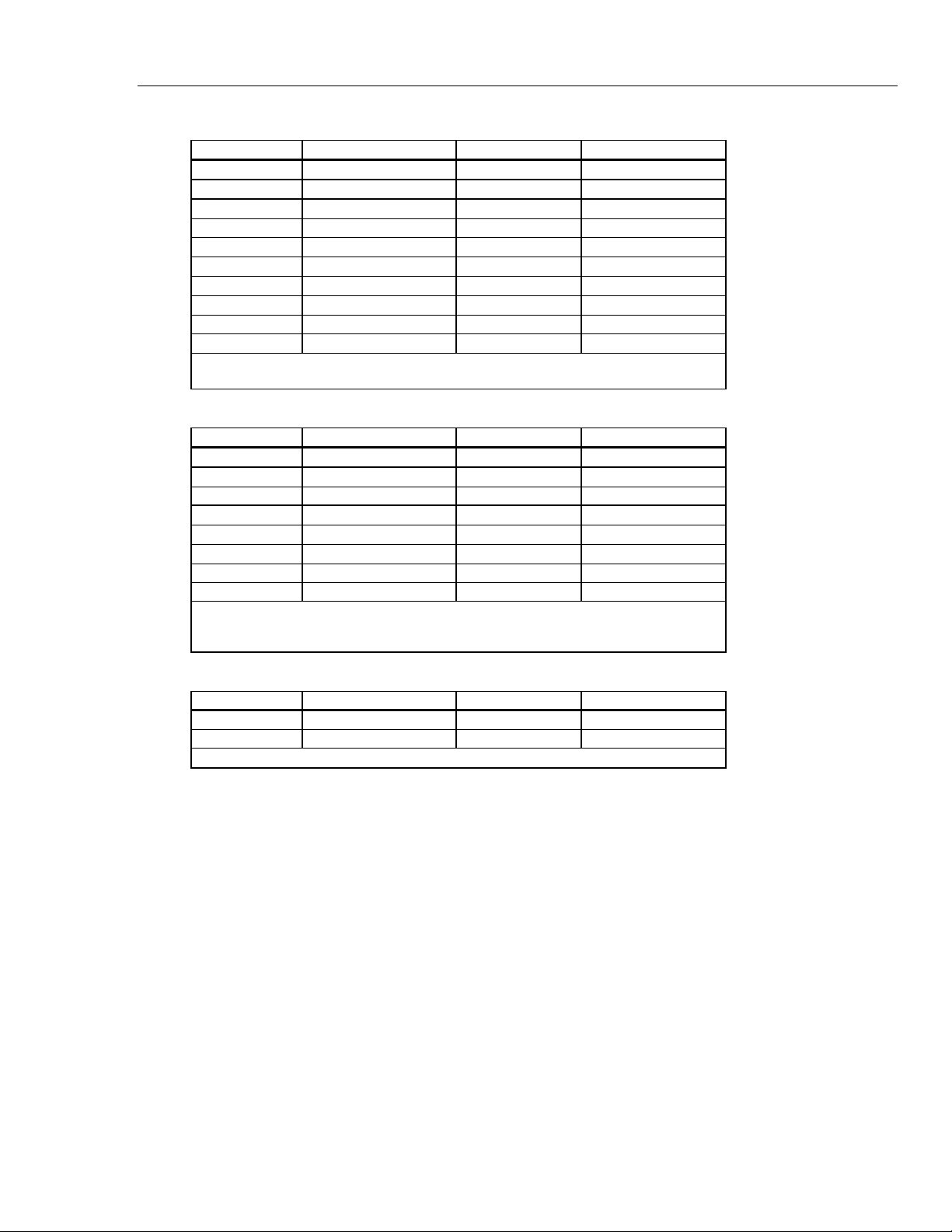

Measurement Ranges

Values for ion chambers are calculated using nominal sensitivities: 15 cc: 2.4 x 108 R/C, 150 CC: 2.4 x 107 R/C.

15 cc Ion Chamber

Units Effective Range

R

R/s

R/min 5 m to 1200 3.6 m

R/hr 100 m to 72 k 216 m 1 m

R/frame

Gy

Gy/s

Gy/min

Gy/hr 1 m to 720 1.89 m 0.01 m

Gy/frame

[1] IEC 61674 effective range at 1 % resolution steps.

[2] At 60 frames/s (1 to 120 frames/selectable).

100 μ to 20 60 μ 1 μ

100 μ to 20 60 μ 1 μ

[2]

[2]

2 μ to 333 m 1 μ 0.02 μ

1 μ to 0.2 0.52 μ 0.01 μ

1 μ to 0.2 0.52 μ 0.01 μ

50 μ to 12 31.5 μ 0.5 μ

0.02 μ to 333 m 0.008 μ

[1]

Threshold Resolution Step Size

50 μ

0.2 n

Page 27

Introduction

Specifications 1

150 cc Ion Chamber

Units Effective Range

R

R/s

R/min 0.5 m to 120 0.36 m

R/hr 10 m to 7.2 k 21.6 m 0.1 m

R/frame

[2]

Gy

Gy/s

Gy/min

Gy/hr 0.1 m to 72 0.189 m 0.001 m

Gy/frame

[1] IEC 61674 effective range at 1 % resolution steps.

[2] At 60 frames/s (1 to 120 frames/selectable).

[2]

150 cc Low Rate Ion Chamber

Units Effective Range

R/s

R/min 0.1 m to 120

R/hr 2 m to 7.2 k

R/frame

[2]

Gy/s

Gy/min

Gy/hr 0.02 m to 72

Gy/frame

[1] IEC 61674 effective range at 1 % resolution steps.

[2] At 60 frames/s (1 to 120 frames/selectable).

[3] Low Rate effective range at 5 % resolution steps.

[2]

0.4 n to 0.33 m

Electrical Units

Units Effective Range

C 1 p to 100 n 0.5 pC 0.01 p

A 1 p to 100 n 250 fA 0.01 p

[1] IEC 61674 effective range at 1 % resolution steps.

[1]

Threshold Resolution Step Size

10 μ to 2 6 μ 0.1 μ

10 μ to 2 6 μ 0.1 μ

0.2 μ to 33 m 0.1 μ 0.002 μ

0.1 μ to 0.02 0.052 μ 0.001 μ

0.1 μ to 0.02 0.052 μ 0.001 μ

5 μ to 1.2 3.15 μ 0.05 μ

0.002 μ to 0.33 m

[3]

2 μ to 2

0.04 μ to 33 m

0.02 μ to 0.02

1 μ to 1.2

[3]

[3]

NA 0.1 m

[3]

[3]

[3]

[3]

[3]

[1]

Threshold Resolution Step Size

NA

NA 0.001 m

NA 0.02 n

[1]

Threshold Resolution Step Size

0.8 n 0.02 n

NA

NA

NA

NA

0.1 μ

0.002 μ

0.001 μ

0.05 μ

5 μ

5 μ

1-15

Page 28

TNT 12000

Users Manual

1-16

Page 29

Chapter 2

Operation

Title Page

Introduction..........................................................................................................2-3

Safety Information ...............................................................................................2-3

How to Set Up the System...................................................................................2-3

Display to Detector Communications..............................................................2-3

How to Setup a Wireless Connection..........................................................2-4

How to Setup a USB Connection................................................................2-4

Multiple Detector Connections ...................................................................2-4

Communication Settings .............................................................................2-4

How to Use the X-ray Detector (TNT 12000WD) ..............................................2-5

How to Position the X-ray Detector ................................................................2-6

Detector Placement with Above Table X-ray Source .................................2-6

Detector Placement with Below Table X-ray Source .................................2-7

How to Measure X-ray Parameters .................................................................2-7

X-ray Display Configuration.......................................................................2-8

Measurement Mode Setup...........................................................................2-9

Measurement Mode Profile Parameters ......................................................2-9

How to Set a Detector Profile .....................................................................2-10

Auto Profiles....................................................................................................2-11

Default Profiles................................................................................................2-11

How to Change Profile Parameters .................................................................2-12

How to Make a User-Defined Profile..............................................................2-13

How to Enter a Delay ......................................................................................2-15

How to Use the Dosimeter Detector (TNT 12000 DoseMate) ............................2-15

Ion Chamber Selection and Setup ...................................................................2-16

Ion Chamber Connection and Placement ........................................................2-16

How to Place the Ion Chamber for Over-Table X-ray Sources ..................2-17

How to Place the Ion Chamber for Under-Table X-ray Sources ................2-20

How to Place the Ion Chamber for Horizontal X-ray Beams......................2-22

How to Place the Ion Chamber in Limited Access Situations ....................2-23

How to Make a Dosimeter Measurement ........................................................2-24

Ion Chamber Setup......................................................................................2-24

Dosimeter Measurements............................................................................2-26

How to Add an Ion Chamber Definition or Cal Factor...............................2-26

How to Edit an Ion Chamber Definition or Cal Factor ............................... 2-29

How to Delete an Ion Chamber Definition or Cal Factor ...........................2-30

Measurement Mode Selection.....................................................................2-31

How to Set Units of Measurement ..............................................................2-32

Air Density Correction................................................................................2-34

2-1

Page 30

TNT 12000

Users Manual

How to Adjust the Internal Temperature/Pressure Sensor ..........................2-36

Dosimeter Status .........................................................................................2-37

How to Use the mAs Detector (TNT 12000 mAs) ..............................................2-38

How to Connect to the X-ray Tube for mAs Measurements ...........................2-39

Shunt Connections ......................................................................................2-40

Clamp Connections .....................................................................................2-43

How to Measure mAs......................................................................................2-43

Setup Options.......................................................................................................2-44

Connection Option...........................................................................................2-45

How to Set Power Settings .............................................................................. 2-45

Detector Battery Charge Level....................................................................2-46

Display Off Time ........................................................................................2-46

Low Power Time......................................................................................... 2-46

System Off Time .........................................................................................2-47

Brightness....................................................................................................2-47

How to Set the Date and Time.........................................................................2-47

2-2

Page 31

Operation

Introduction 2

Introduction

This chapter gives instructions on how to connect, setup, and use the TNT 12000 to

calibrate and service X-ray equipment. It is assumed the reader already read Chapter 1

and understands the Test Tool components.

Safety Information

In this manual, a Warning identifies conditions and actions that pose hazards to the user.

A Caution identifies conditions and actions that may damage the TNT 12000 or the

equipment under test.

XW Warnings

To prevent electric shock:

Use the TNT 12000 as specified in this manual or the protection

provided might be impaired .

Inspect the test leads for damaged insulation or exposed metal.

Check the test leads for continuity. Replace damaged test leads

before using the TNT 12000.

Turn the X-ray generator power off before connecting or

disconnecting the TNT 12000.

W Caution

To prevent damage to the TNT 12000, Do not apply more than

500 V, between the input and earth ground.

How to Set Up the System

The Display controls the detectors and must be set to communicate with a Detector

before you can make a measurement. When connected, all measured values are shown in

the Display.

The subsequent setup step is to prepare the Detector for a measurement. For X-ray

Detector measurements, put the Detector in the X-ray beam. For the Dosimeter, an ion

chamber is connected to the Dosimeter and put in the X-ray beam.

When an mAs Detector is installed in the X-ray Detector or Dosimeter Detector, you

connect the X-ray detector to the X-ray generator. You do this with test leads connected

to an mAs test point or a non-invasive mAs clamp.

Display to Detector Communications

Communication between the Display and a Detector is through a wireless (ZigBee) or

wired (USB) connection. All Test Tool components communicate in these two ways.

The X-ray Detector and Dosimeter Detector have a communication status indicator to

indicate the condition of communications to the Display. See Table 2-1.

Table 2-1. Communication Status Indicator

LED Activity Communication Status

On Detector is connected to the Display/computer

Off Detector is not connected

Blinking Detector is scanning for the Display/computer

2-3

Page 32

TNT 12000

Users Manual

How to Setup a Wireless Connection

To connect the Display to the Detector through a wireless connection:

1. Push O on the Detector.

2. Push O on the Display.

Go to the Communications Settings section to complete the communication setup.

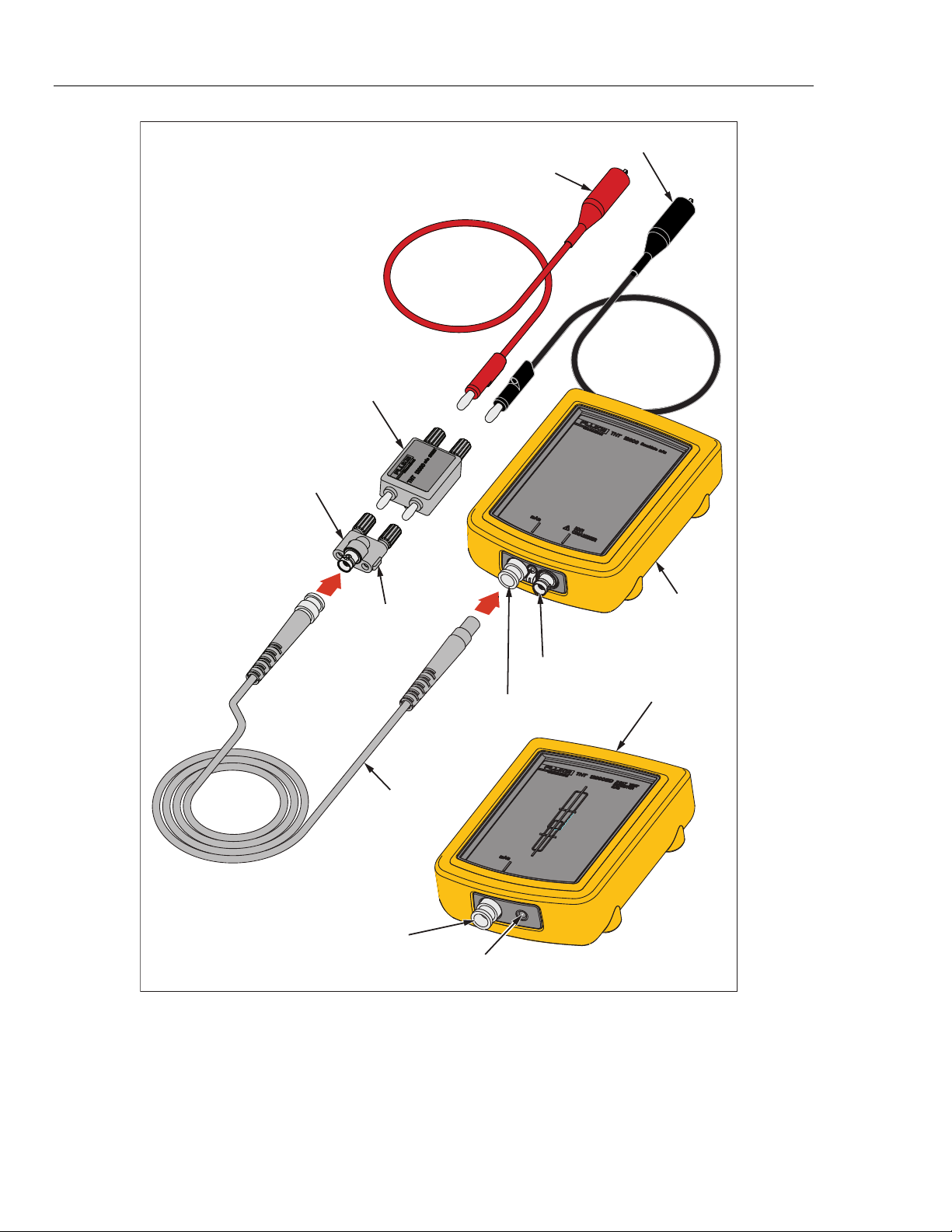

How to Setup a USB Connection

To connect the display to a Detector through a USB connection:

1. Connect the ends of the Mini-A to Mini-B USB cable to the USB port of the Display

and the Detector as shown in Figure 2-1.

Figure 2-1. Wired (USB) Connection

2. Push O on the Detector.

3. Push O on the Display.

Go to the Communications Settings section to complete the communication setup.

Multiple Detector Connections

A maximum of two Detectors can operate with the Display at one time. The X-ray or

Dosimeter Detector can operate with the mAs Detector at the same time. The X-ray

Detector and Dosimeter Detector can not operate with the Display at the same time.

You can make the connections through a combination of USB and/or wireless

connections. With the Display and Detectors turned on, set the combination pair through

the CONNECTION screen in the Communication Settings section.

Communication Settings

When power is applied to the Display, the system does a self-test while a message shows

in the Display. After the self-test, the software and hardware versions show in the

Display.

If the Display senses no Detectors, a No Detector Found screen shows in the Display.

If it senses only one Detector, the communication settings are complete. For the

subsequent step, go to the manual section for the sensed Detector. If it senses more than

one Detector (within rf range and/or connected by wire), the connection screen (see

Figure 2-2) shows in the Display.

fct04.eps

2-4

Page 33

Operation

How to Use the X-ray Detector (TNT 12000WD) 2

Figure 2-2. Connection Screen

1. Use C or D to scroll through the list of detectors.

When you scroll through the detectors, Z or ™ appears in upper-right corner of

the screen if a connection exists between the Display and the highlighted Detector.

Calibration date, calibration due date, software version, and hardware version for the

highlighted Detector shows below the Detector list.

2. With a Detector highlighted, push A or B to highlight the Connect or Always

Connect button.

3. To make a Detector selection, use C or D to highlight the Detector and push

E.

The TNT 12000 automatically goes to the setup or measurement screen for the connected

Detector. For the subsequent step, go to the manual section for the connected Detector.

To connect to a second Detector, highlight the Setup button and push E in the

MEASUREMENT screen. Navigate to the CONNECTION screen shown in Figure 2-2

to make a second selection.

How to Use the X-ray Detector (TNT 12000WD)

The four operation modes of the X-ray Detector are:

• Radio Mode – used to make measurements on radiographic X-ray machines. Radio

mode measures kVp Average, kVp Maximum, kV PPV, Dose, Average Dose Rate,

Exposure Time, and HVL at the same time from one exposure.

fct12.bmp

• Mammo Mode – used to make measurements on mammographic X-ray generators.

Mammo mode measures kVp Average, kVp Maximum, kV PPV, Dose, Average

Dose Rate, Exposure Time, and HVL at the same time from one exposure.

• Fluoro Mode – used to make measurements on fluoroscopic X-ray generators. Fluoro

mode can make Continuous fluoro and Pulsed fluoro measurements. Fluoro Mode

measures kVp Average, kVp Maximum, kV PPV, Dose Rate, Accumulated Dose,

Elapsed Time, Pulse Rate (for Pulsed Fluoro only), Pulse Width (for Pulsed Fluoro

only), and HVL.

• Dental Mode – used to make measurements on Dental X-ray generators. Dental mode

measures kVp Average, kVp Maximum, kV PPV, Dose, Average Dose Rate,

Exposure Time, and HVL at the same time from one exposure.

2-5

Page 34

TNT 12000

Users Manual

How to Position the X-ray Detector

To make measurements, the X-ray Detector must be put into the X-ray beam. The marks

on the face of the Detector help align it in the X-ray beam. See Figure 2-3 for a

description of how to use the marks for an accurate measurement. The distance from the

top surface of the X-ray Detector to the solid state detectors is 0.230 inches or 5.84 mm.

For radiographic and fluoroscopic measurements, center the

beam on the RAD crosshairs and collimate the beam to the grey

outlined area or larger.

For dental measurements, center the cone over the grey

outlined area.

Dose measurement area for all modes.

For mammographic measurements, center the beam on the

MAMMO crosshairs and collimate the beam to the red outlined

area or larger.

Figure 2-3. X-ray Detector Alignment Marks

fct09.eps

Detector Placement with Above Table X-ray Source

For X-ray machines that have the X-ray source above the table, align the Detector face

up, in the middle of the beam, with the long axis of the Detector perpendicular to the axis

of the X-ray tube. See Figure 2-4.

Above Table

X-Ray Tube

X-Ray Table

Tube Axis

TNT 12000WD

2-6

Long Axis of TNT 12000WD

Figure 2-4. X-ray Detector Setup for Above Table X-ray Source

fct05.eps

Page 35

Operation

How to Use the X-ray Detector (TNT 12000WD) 2

Note

Set the Detector so all of the active area of the Detector is exposed to the Xray beam. A 22-inch distance from the focal point to the Detector is

suggested.

Detector Placement with Below Table X-ray Source

For X-ray machines that have the X-ray source below the table, align the Detector face

down, in the middle of the beam, with the long axis of the Detector perpendicular to the

axis of the X-ray tube. See Figure 2-5.

TNT 12000WD

Long Axis of TNT 12000WD

X-Ray Table

Under Table

X-Ray Tube

Figure 2-5. X-ray Detector Setup for Below Table X-ray Source

How to Measure X-ray Parameters

Connect and set up the X-ray Detector for a measurement. See the How to Setup the

System section above for connection and set up instructions. The MEASUREMENT

screen in Figure 2-6 shows in the Display.

If the mAs Detector is already connected, an mAs Measurement Option

screen can show in the display. Go to the How to Use the mAs Detector

manual section to set the mAs measurement options. When done, come back

to this section to continue the X-ray measurement.

Note

Tube Axis

fct06.eps

2-7

Page 36

TNT 12000

Users Manual

Figure 2-6. X-ray Detector Measurement Screen

The buttons at the bottom of the MEASUREMENT screen are used to set the

measurement mode, the measurements to show in the Display, the measurement profile,

the measurement parameters, and set system options. The D in the Display shows there

is a second screen of information. Highlight the icon and push E to reveal the next

screen of information.

X-ray Display Configuration

To set the X-ray measurement parameters that show in the MEASUREMENT screen:

1. In the MEASUREMENT screen, use A or B to highlight the Config button.

2. Push E to open the DISPLAY CONFIGURATION screen.

fct16.bmp

2-8

fct17.bmp

3. Use C, D, A, and B to highlight one of the parameters and push E to toggle the

check box between checked and unchecked.

4. When you complete the measurement selections, highlight the Continue button and

push E to save the configuration and return to the MEASUREMENT screen.

Note

The sequence of values in the Measurement screen is set by the parameters

you set with a check in the Display Configuration screen.

Page 37

Operation

How to Use the X-ray Detector (TNT 12000WD) 2

Measurement Mode Setup

To set the X-ray measurement mode:

1. In the MEASUREMENT screen, use A or B to highlight the 2

nd

button from the left.

The name on this button shows the measurement mode selection. In Figure 2-6, the

button is named Radio which shows the Detector is set to the Radio Measurement

mode. The MODE SETUP screen in Figure 2-7 shows in the Display.

Figure 2-7. Mode Setup Screen

2. Use C or D to highlight one of the measurement mode buttons and push E.

The color of the button name changes to blue.

3. Use C or D to highlight the Continue button and push E to set the

measurement mode and return to the MEASUREMENT screen. The name on the

middle button changed to the name of the new measurement mode.

Note

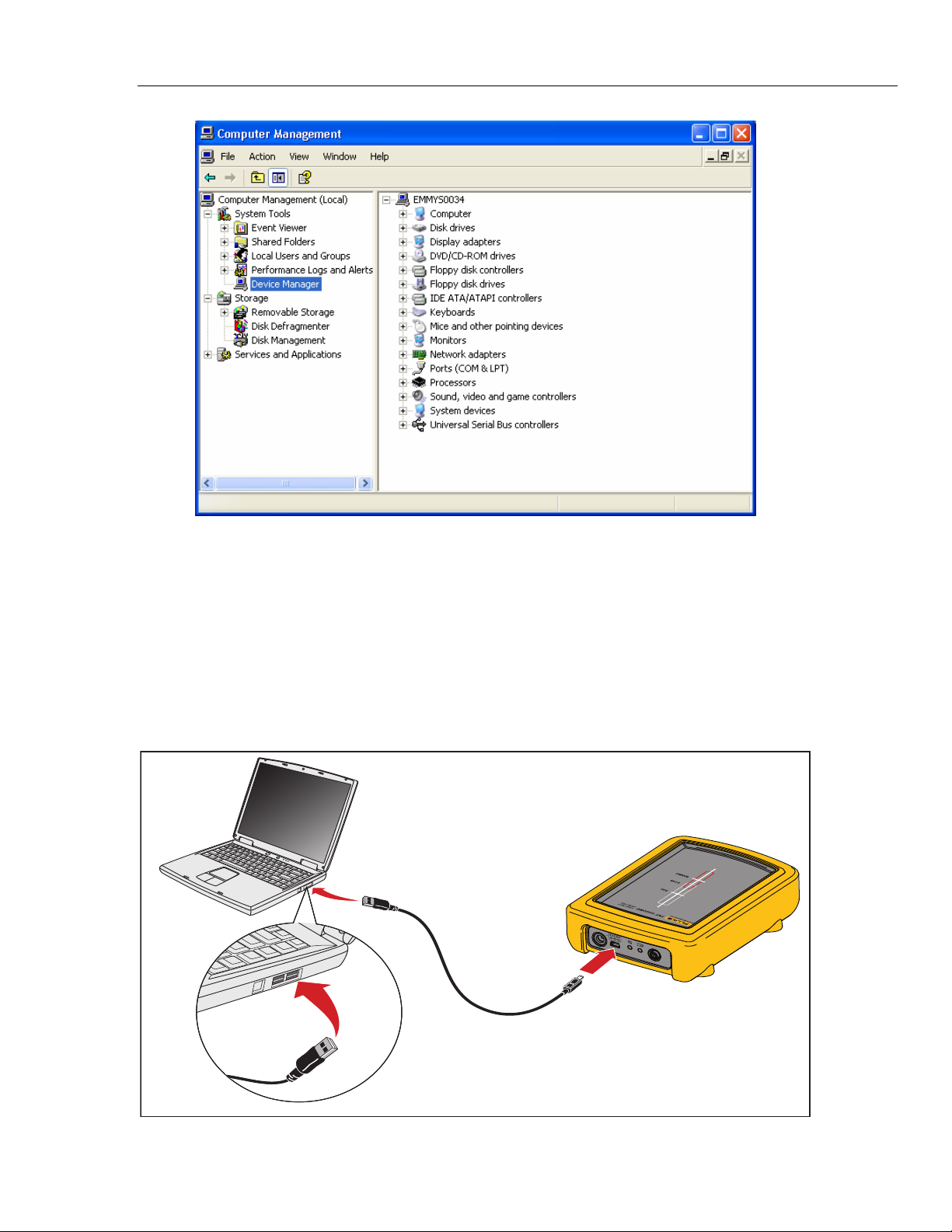

Before the measurement mode is set, move the highlight to the Cancel