Page 1

Applications for Thermal Imagers

Moisture in

building envelopes

The presence of moisture in building envelopes, whether from leakage or condensation, can have serious consequences. For example,

moisture in insulation reduces its insulating capability, causing heating

and/or cooling losses and wasting energy. Moisture can also cause

structural deterioration and foster the growth of mold, while a serious

roof leak can damage or destroy a building’s contents.

Application Note

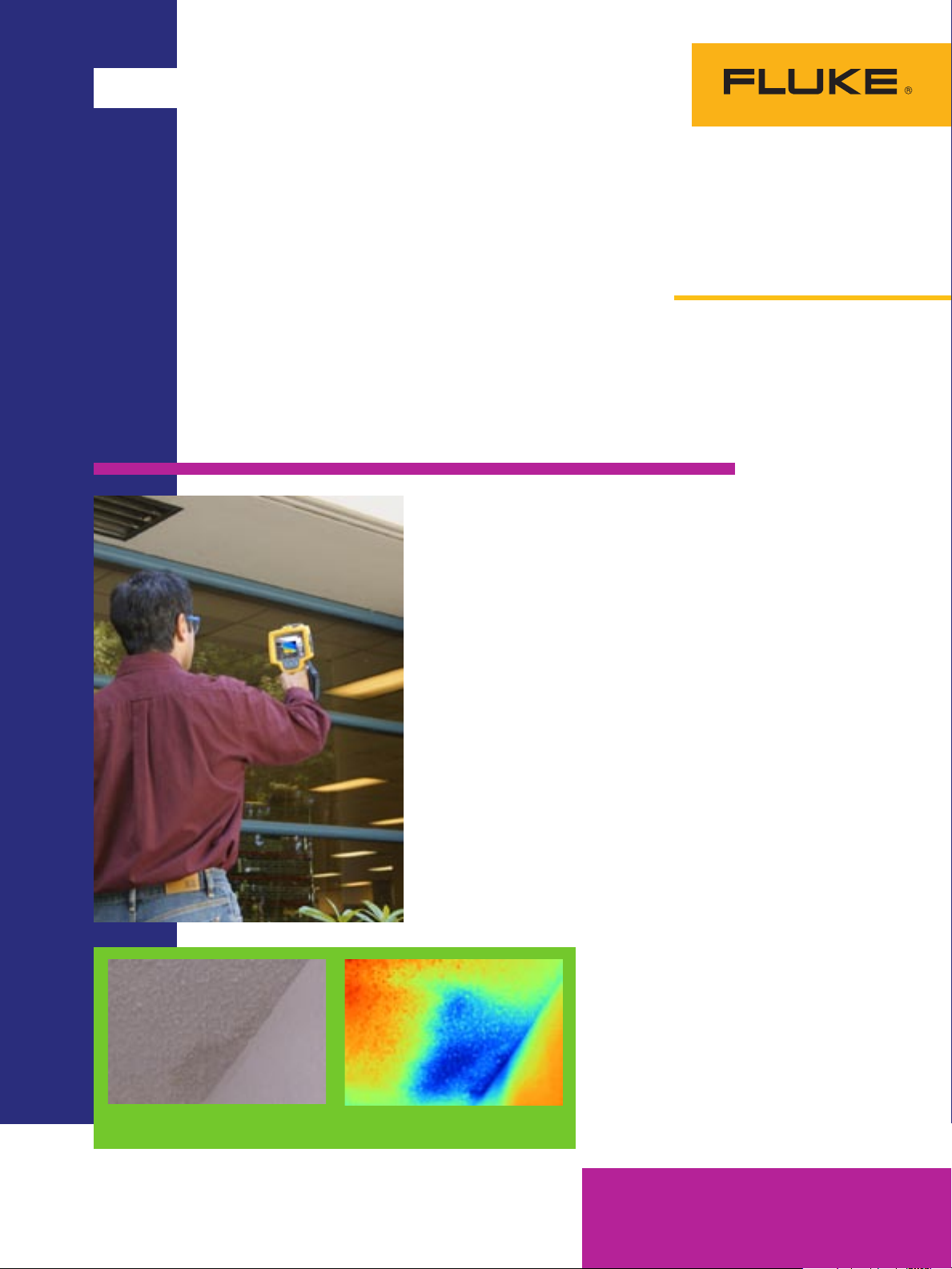

Unexpected moisture intrusion in a ceiling.

Thermography, also known as

thermal imaging, is well suited to

identifying wet spots in building

envelopes. As a diagnostic technique, thermography captures

two-dimensional images of the

apparent temperatures of equipment and structures. Thermal

images can reveal anomalies in

roofs and walls that can indicate the presence of moisture as

buildings cool after having been

under a thermal load. This happens because water conducts

and stores heat better than most

building materials. So, when a

roof or wall cools, wet or damp

areas cool slower than dry areas

and show up as “hot spots” on

thermal images.

The following discussion

focuses on using thermal or

infrared (IR) imaging to check

for moisture in the envelopes of

industrial, commercial and

institutional buildings, including

moisture in roofs, walls and

insulation.

What to check?

Check the outside walls and

roofs of buildings after they have

experienced a thermal load, e.g. a

solar load on a hot, dry day. Eastfacing walls might be checked

in the afternoon and (in the

Northern Hemisphere) south- and

west-facing walls and roofs after

sundown. A significant thermal

gradient (15 or 20 %) between

the inside and outside is essential

in order detect thermal anomalies

attributable to the difference in

heat capacity between the

materials of construction and

the additional moisture load.

When potential wet spots in

exterior walls and roofs are

identified, follow up with an

inspection inside the building,

to further refine the outdoor findings. Inside inspections can also

independently pinpoint moisture

in ceilings and walls caused by

leaks, water pipe breaks, firesprinkler discharges or other

water-producing events. Fast

action with a thermal imager following a water-producing accident can identify which materials

must be dried or replaced.

For more information on Thermal Imagers

go to www.fluke.com/thermography

Page 2

What to look for?

Collecting thermal images is a

good first step in analyzing a

structure and identifying suspected problem areas. Unlike

other moisture-detecting technologies, such as meters, thermography requires no physical contact

with roofs, ceilings, walls or

floors. In addition, you can check

inaccessible areas and cover a

large area in a single image.

Regular building-envelope

inspections are key to prolonging

the lives of industrial, commercial and institutional buildings.

easier to spot where further

investigation is needed.

*The Fluke Ti20 comes with InSideIR™

analysis and reporting software with free

updates for the life of the product.

What represents a

“red alert?”

Give any building-envelope

condition that poses a safety or

health risk the highest repair

priority. Next, any roof leaks or

moisture conditions that threaten

production, electronic data, electronic equipment or the integrity of the building itself should

receive immediate attention.

New construction and especially

new roofs should by thoroughly

inspected 6 to 9 months after

construction, while the structure

is still under warranty. That time

lag allows the structure to experience the elements, hopefully

a rainy season. Then, perform

additional building-envelope

scans every two to five years.

Compare them to the original,

baseline images to establish

trends and determine remedies

to any deterioration. Experts

estimate that preventive maintenance of this kind will double

the life your facility’s roof. Roof

inspections should be conducted

with the imager mounted on a

tripod, so that the technician can

concentrate on properly adjusting the camera to maximize the

thermal resolution and analyzing

the image.

Fluke thermal imagers now

include IR-Fusion®*, a technology that fuses a visual, or visible

light, image with an infrared

image for better identification,

analysis and image management.

The dual images are accurately

aligned at any distance heightening details, making it much

What’s the potential cost

of failure?

Flat roofs are the parts of commercial, industrial and institutional buildings that are the

most likely to fail, and they are

expensive to replace. Factors vary

so much from facility to facility

that it’s difficult to put a price on

roof replacements, but one expert

writing in 1989 came up with

a range of weighted averages

between $4.50 per square foot

for mechanically attached singleply roofs and $8.00 per square

foot for coal-tar built-up roofs.*

Follow-up actions

Before checking your building

for moisture, be aware that this

kind of inspection constitutes

one of the most challenging uses

for IR thermography. Buildings

vary with respect to kind, use,

construction techniques, building

materials, size and so on.

*Source: Benchmark, Inc., Roof & Pavement

Consultants at 6065 Huntington Ct. NE, Cedar

Rapids, IA 52402 — 319-393-9100. The

figures are from an article, “Factors Affecting

Roof System Costs,” by Kent Mattison, P.E.

Safety tip:

Before starting a roof inspection, review the OSHA safety guidelines.

Then, whenever you’re up on a roof doing an inspection, have a

partner with you—day or night. Some people count on their radios.

A radio alone is not good enough. People have died on roofs right

next to their radios! Besides, your partner can mark the edges of

areas of wet insulation while you scan the roof and make images.

2 Fluke Corporation Thermal Applications: Moisture in building envelopes

Conducting effective thermal

building surveys requires understanding construction methods

and the thermal characteristics

of building components, as well

as how to account for changing

thermal conditions within and

around buildings. Then, following the IR inspection, determine

where inside heat sources are

and whether they affected the

exterior images. Finally, perform

further analysis to confirm the

findings. Infrared inspections

provide the most cost effective means of ensuring that the

roof is properly sealed, but the

presence of a thermal anomaly

does not indicate the presence

of moisture in the roof. It is

essential to follow up with core

samples and other techniques.

Reference ASTM C1153 Standard

practice for location of wet insulation in roofing systems using

infrared thermography.

When you have accurately

identified moisture in a building’s

envelope, targeted maintenance

work can be performed. If you

discovered the problem using a

thermal imager, use the software

that came with the instrument

to document your findings in a

report. Include a thermal image

and a digital image of the relevant area of the building. Such

reports are the best way to communicate the problems you find

and to suggest repairs.

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2005-2008 Fluke Corporation. Specifications

subject to change without notice. Printed in U.S.A.

10/2008 2519615 A-EN-N Rev C

Modification of this document is not permitted

without written permission from Fluke Corporation.

®

Loading...

Loading...