Fluke Ti300, Ti400, 376, 1550C, 721 Brochure

...

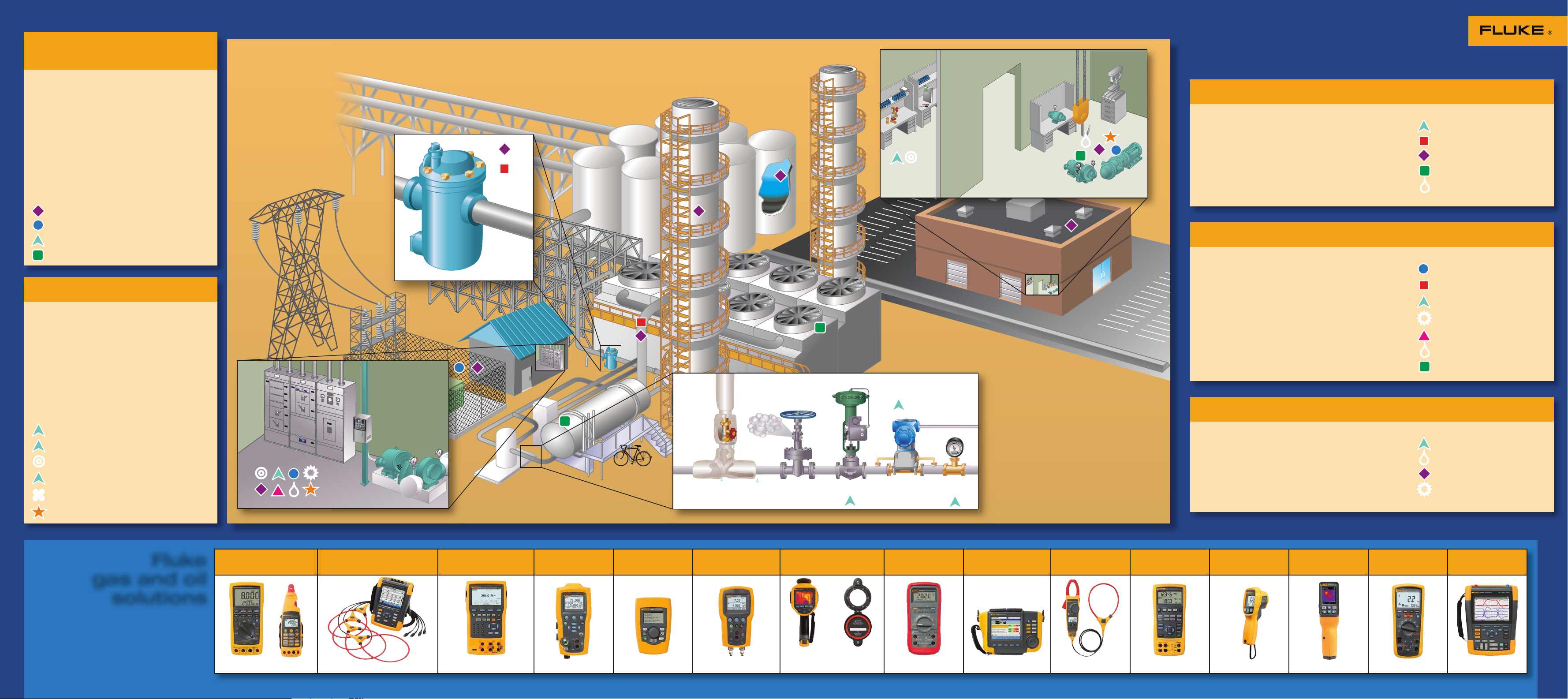

Recommended oil and gas solutions

More recommended oil and gas solutions

Documenting

process calibrators

Best suited for:

• Calibration and

maintenance of process

instrumentation and

control systems.

• Sourcing, measuring and

documenting virtually

any process variable

Oil and gas applications:

Pressure and temperature

transmitter calibration;

calibration and configuration of HART devices;

documenting field

calibrations for recall and

upload

Pressure

calibrators

Best suited for:

• Pressure calibration of

transmitters, gauges,

switches, and custody

transfer meters

• Maintenance of

almost any pressure

device using pressure

sourcing and milliamp

measurements

• Calibrating P/I

instruments with

simultaneous

pressure and current

measurement

Oil and gas applications:

Pressure

measurements

using internal

sensor;

measure mA

while sourcing 24 V loop

power

Thermal imagers

Best suited for:

• Providing non-contact

measurement and display of a visual image of

surface temperatures to

easily and safely identify potential problems

• Reducing the need for

unplanned maintenance

to correct previous

repairs

Oil and gas applications:

Steam trap leakage,

electrical panels,

motors, VFDs,

tank level

and sludge

level

indication,

refractory,

furnaces,

reformers,

transformers,

and pumps

Vibration

testers

Best suited for:

• Diagnosing machine

faults to extend machine

life and reduce costs

• Reducing unexpected

serious failures to help

prevent production

stoppages that cut into

the bottom line

• Giving maintenance

staff time to schedule

repairs and acquire

parts

• Anticipating problem

areas before failure

Oil and gas applications:

Pumps, compressors,

motors, fans, and blowers

Visual IR

thermometers

Best suited for:

• Displaying a visual

heat map of surface

temperatures

• Finding heating and

ventilation problems

• Non-contact monitoring

of pumps, electrical

motors and panels

• Reducing the need for

unplanned maintenance

to correct previous

repairs

Oil and gas applications:

Valve packing leakage,

non-contact

electrical

panel inspection, pump

and motor

inspection

Infrared

thermometers

Best suited for:

• Gathering surface

temperature readings

• Reducing the need for

unplanned maintenance

to correct previous

repairs

Oil and gas applications:

Heating, motors, HVAC,

circuit breaker inspection

Temperature

calibrators

Best suited for:

• Troubleshooting and

calibrating temperature

• Testing temperature

sensors and transmitters

• Measuring and sourc-

ing thermocouples and

RTD’s

Oil and gas applications:

Measure thermocouples,

ohms, and volts to test

sensors and transmitters;

calibrate transmitters by

sourcing/simulating thermocouples, RTDs, volts,

and ohms;

powering

transmitters

during test using loop power

supply with

simultaneous

mA

measurement

Insulation

multimeters

Best suited for:

• Testing a wide range

of insulation resistance

and digital multimeter

tests including simple

spot checks to timed

tests

• Troubleshooting and

preventive maintenance

Oil and gas applications:

Switchgear, motors,

variable speed drives,

generators, electrical

systems and cables;

test voltages from 50 V

to 1000 V

(Insulation

tester to

5000 V also

available)

mA Process

clamp meters

Best suited for:

• Measuring 4 to 20 mA

signals without

breaking the loop

• Sourcing, simulating

and measuring mA

• Sourcing, measuring

DC voltage

Oil and gas applications:

mA sourcing, simulation

and measurement;

loop calibration,

maintenance and repair

Process tools

Power quality

analyzers

Best suited for:

• Finding power quality

problems before

they damage critical

equipment

• Conducting load studies

to reduce energy usage

applications

Oil and gas applications:

Generators, harmonics

(electronics), load studies

Handheld

oscilloscopes

Best suited for:

• Troubleshooting and

installation applications

• Finding fast answers to

problems in machinery,

instrumentation, control

and power systems

• Bus health testing for

industrial bus systems

Oil and gas applications:

Pumps, compressors,

motors, fans, and blowers

Best suited for:

Troubleshooting and calibrating current loop applications using

the functionality of a loop calibrator and digital multimeter built

into one tool.

Oil and gas applications:

Measure, source, and simulate dc loop current

Clamp meters

Best suited for:

• Measure 1000 A ac or

dc with fixed jaw to

measure current in motors, vaults and bus bars

• Clamp around bus bars

or conductors in service

panels to measure loads

and line frequency in

circuits

Oil and gas applications:

Pumps, compressors,

motors, fans, and blowers

Petrochemical professionals can

nd application notes, case studies

and demos of Fluke solutions at

www.uke.com/oilandgas

Intrinsically Safe Test Tools and Standards

Certification Fluke

products

707Ex Loop

Calibrator

718Ex

Pressure

Enabled

Pressure

Calibrator

725Ex

Multifunction

Calibrator

87V-Ex

Industrial Ex

Multimeter

Main

application

Source and

measure mA signals

Calibrate pressure

transmittters

and switches

Calibrate

almost any

process device

True-rms

IEC-1010 CAT IV

600 V rating

North American rating

Division 1 Division 2

Euro pea n ATE x

Zone 0 Zone 1 Zone 2

≥1000 hours/year >10 hours,< 1000

Gas Presence

hours/year

All Gases

Gases

(North American gas groups B,C,D)

(ATEx gas groups IIB)

> 1 hour,

< 10 hours/year

All Gases

All Gases

combination of test tool and

How do you know if the

device under test is safe?

Visit www.fluke.com/ex

and order a free intrinsically

safe training CD

Fluke. The Most Trusted Tools

in the World.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2007-2014 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 1/2014 3106077D_EN

Modification of this document is not permitted

without written permission from Fluke Corporation.

Fluke. Working to keep the

oil and gas industry owing.

Fluke solutions can help you maintain

operational reliability and environmental safety

Fluke understands the petrochemical industry faces a range of challenges from dynamic market fluctuations to multiple stringent regulatory requirements, and downtime and inaccurate measurements can

cost millions. The professionals that work in oil and gas know it is critical to maintain stable, continuous

operations without sacrificing safety.

Onshore or offshore, upstream to downstream, Fluke makes reliable tools that professionals in the oil

and gas industry can count on for accurate and consistent measurements. Tools designed for the demanding oil and gas environment, the people who work there, and the challenges they face every day. With 65

years as the industry leader, they can feel confident that Fluke has the solutions they need to keep the oil

and gas industry flowing.

See our full line of innovative products at www.fluke.com

PORT

MOD

NET A

NET B

VOLTS

AMPS

HERTZ

RUN

FWD

REV

PROGRAM

FAULT

PORT

MOD

NET A

NET B

VOLTS

AMPS

HERTZ

RUN

FWD

REV

PROGRAM FAULT

Maintenance

Superintendent

Focus:

Downtime prevention, safety regulations,

budget goals

Issues faced:

•

Ensuring uptime is continuous and

predictable

•

Safety of personnel and the environment

•

Maintaining high product quality

•

Staying within budget

Fluke solutions:

Thermal imagers

Power quality analyzers

Process tools

Vibration testers

Instrument Technician

Focus:

Equipment and systems testing, maintenance

and repair

Issues faced:

•

Preventing downtimes

•

Safety systems testing

•

Providing immediate response and repair

during process interruptions

Fluke solutions:

Process tools

Documenting process calibrators

Handheld oscilloscopes

Pressure calibrators

Loop calibrators

Digital multimeters

Switch gear

Variable speed drive pump

Steam trap

Leaking pipes

(wet insulation)

Gate valve

(steam leak)

Control

valve

Transmitter

Pressure

guage

Mechanic/Millwright

Focus:

Installation, assembly, and preventive maintenance

Issues faced:

• Meeting equipment standards and specifications

• Effectiveness of repairs (valve repacking)

• Assembling machinery

• Determining optimal machinery placements

Electrician

Focus:

Electrical installation, maintenance and repair

Issues faced:

•

Delivering efficient, consistent and quality power

from utility or generation to process systems

•

Maintaining safety and high energy systems

•

Controlling efficient breakers and motors

Measurement Tech

Focus:

Calibration of flow meters involved in custody

transfer

Issues faced:

• Accurate measurements of flow

• Calibration of flow instruments

• Repair verification

Diagram is not intended to be a n exac t representation . Diag ram components are

Fluke solutions:

Process tools

Infrared thermometers

Thermal imagers

Vibration testers

Visual IR thermometer

Fluke solutions:

Power quality analyzers

Infrared thermometers

Process tools

Insulation multimeters

Clamp meters

Visual IR thermometer

Vibration tester

Fluke solutions:

Process tools

Visual IR thermometer

Thermal imagers

Insulation multimeters

not to scale and are for illustration purposes only.

Fluke

gas and oil

solutions

Learn how Fluke solutions can

save you time and money while

increasing efficiency and safety at

www.fluke.com/gasandoil

Based on you. Built by Fluke.

Process tools Power quality analyzers

789 773 43x Series II 754 719PRO 709H 721

Documenting

process calibrators

Pressure

calibrators

Loop

calibrators

Custody Transfer

Calibrators

Thermal imagers/

IR Windows

Ti1xx/2xx/3xx/4xx

CV Series 28 II Ex 810 376 724 62MAX+ VT04 1587 190 Series II

Digital

multimeters

Vibration tester Clamp meters

Temperature

calibrators

Infrared

thermometers

Visual IR

thermometers

Insulation

multimeters

Handheld

oscilloscopes

Loading...

Loading...