Page 1

Hart Scientific

1529

Chub-E4 Thermometer Readout

User’s Guide

Rev. 692801

Page 2

Limited Warranty & Limitation of Liability

Each product from Fluke Corporation, Hart Scientific Division ("Hart") is warranted to be free from de

fects in material and workmanship under normal use and service. The warranty period is 2 years for the

Thermometer Readout. The warranty period begins on the date of the shipment. Parts, product repairs,

and services are warranted for 90 days. The warranty extends only to the original buyer or end-user cus

tomer of a Hart authorized reseller, and does not apply to fuses, disposable batteries or to any other prod

uct, which in Hart's opinion, has been misused, altered, neglected, or damaged by accident or abnormal

conditions of operation or handling. Hart warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective me

dia. Hart does not warrant that software will be error free or operate without interruption. Hart does not

warrant calibrations on the Thermometer Readout.

Hart authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Hart. Warranty support is

available if product is purchased through a Hart authorized sales outlet or Buyer has paid the applicable

international price. Hart reserves the right to invoice Buyer for importation costs of repairs/replacement

parts when product purchased in one country is submitted for repair in another country.

Hart's warranty obligation is limited, at Hart's option, to refund of the purchase price, free of charge re

pair, or replacement of a defective product which is returned to a Hart authorized service center within

the warranty period.

To obtain warranty service, contact your nearest Hart authorized service center or send the product, with

a description of the difficulty, postage, and insurance prepaid (FOB Destination), to the nearest Hart authorized service center. Hart assumes no risk for damage in transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Hart determines that the

failure was caused by misuse, alteration, accident or abnormal condition or operation or handling, Hart

will provide an estimate or repair costs and obtain authorization before commencing the work. Following

repair, the product will be returned to the Buyer transportation prepaid and the Buyer will be billed for

the repair and return transportation charges (FOB Shipping Point).

-

-

-

-

-

Rev. 692801

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IM

PLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

HART SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL. OR CONSE

QUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER ARISING FROM

BREACH OF WARRANTY OR BASED ON CONTRACT, TORT, RELIANCE OR ANY OTHER

THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court of com

petent jurisdiction, such holding will not affect the validity or enforceability of any other provision.

Fluke Corporation, Hart Scientific Division

799 E. Utah Valley Drive • American Fork, UT 84003-9775 • USA

Phone: +1.801.763.1600 • Telefax: +1.801.763.1010

E-mail: support@hartscientific.com

www.hartscientific.com

Subject to change without notice. • Copyright © 2005 • Printed in USA

-

-

-

Page 3

Table of Contents

1 Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.2 Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Authorized Service Centers. . . . . . . . . . . . . . . . . . . . . . 4

2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Specifications and Environmental Conditions . . . . . . . . . . 9

3.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . 10

4 Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Use Proper Care . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Learn About the Features and Components . . . . . . . . . . . . . 11

4.4 Connect the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4.1 Using the Clamp-on Ferrites . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5 Connect the Power Source . . . . . . . . . . . . . . . . . . . . . 12

4.6 Switch the Power On . . . . . . . . . . . . . . . . . . . . . . . . 12

4.7 Measure Temperature . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Parts and Controls . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Front Panel Buttons . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Back Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 General Operation . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Changing Units . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.4 Probe Input Modules . . . . . . . . . . . . . . . . . . . . . . . . 20

6.4.1 Connecting a PRT or Thermistor Probe . . . . . . . . . . . . . . . . . . . . 21

6.4.2 Connecting a Thermocouple . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.5 DC Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . 23

i

Page 4

6.6 Power On Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.7 Display Backlight and Contrast . . . . . . . . . . . . . . . . . . . 23

6.8 Taking Measurements . . . . . . . . . . . . . . . . . . . . . . . . 23

6.8.1 Connecting the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.8.2 Enabling the Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.8.3 Selecting Conversion Type and Probe Characterization . . . . . . . . . . . . 24

6.9 Fast Measurement Mode . . . . . . . . . . . . . . . . . . . . . . 24

6.10 Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7 Menu Functions. . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1 Channel Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1.1 Measure Period and Fast Measurement Mode . . . . . . . . . . . . . . . . . 28

7.1.2 Enable Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1.3 Channel Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.1.4 Moving Average. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.1.5 Display Options/Auto-Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.2 Probe Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2.1 Edit Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.2.1.1 ITS-90 Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.2.1.2 ITS-SR5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2.1.3 PT-100 Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.2.1.4 Callendar-Van Dusen (CVD) conversion . . . . . . . . . . . . . . . . . . . . . . . . 38

7.2.1.5 RES Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2.1.6 Thermistor T(R) Conversion [THERM-T] . . . . . . . . . . . . . . . . . . . . . . . 39

7.2.1.7 Thermistor R(T) Conversion [THERM-R] . . . . . . . . . . . . . . . . . . . . . . . 40

7.2.1.8 YSI-400 Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.2.1.9 Thermocouple Volts [Vin[mV]] . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.2.1.10 Standard Thermocouple Conversions. . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.2.1.11 Thermocouple Polynomial Conversion. . . . . . . . . . . . . . . . . . . . . . . . . 41

7.2.2 Copy Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2.3 Test Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.2.4 Print Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.2.5 Default Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.3 Fields Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3.1 Clear Stats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.3.2 Select Fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.3.3 Edit Fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3.4 Default Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3.5 Display Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.4 Logging Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.4.1 Demand Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.4.1.1 Store Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.4.1.2 Log History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.4.1.3 View Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.4.1.4 Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.4.1.5 Delete Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.4.2 Auto Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.4.2.1 Logging Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

7.4.2.2 Start Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.4.2.3 View Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.4.2.4 Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

ii

Page 5

7.4.2.5 Delete Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.4.3 Log Stats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.4.4 Data Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.4.5 Default Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.5 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.5.1 Comm Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.5.1.1 Serial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.5.1.2 GPIB (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

7.5.2 Date Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.5.3 Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.5.4 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.5.5 System Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8 Digital Communications Interface . . . . . . . . . . . . . . . 77

8.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.2 Communications . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.2.1 Serial Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.2.2 GPIB Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.2.2.1 Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.2.2.2 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.2.2.3 Device Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.3 Interface Commands . . . . . . . . . . . . . . . . . . . . . . . . 78

8.3.1 Command Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.3.2 Command Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.4 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.4.1 Measurement Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.4.1.1 CALCulate:AVERage:CLEar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.4.1.2 CALCulate<chn>:AVERage<n>:DATA?. . . . . . . . . . . . . . . . . . . . . . . . 86

8.4.1.3 CALCulate:AVERage<n>:TYPE? . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.4.1.4 FETCh? [<chn>] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.4.1.5 FORMat:STAMp? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

8.4.1.6 FORMat:STAMp <bool> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

8.4.1.7 MEASure? [<chn>] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

8.4.1.8 READ? [<chn>]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

8.4.1.9 SENSe<chn>:DATA? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

8.4.2 Measurement Control Commands . . . . . . . . . . . . . . . . . . . . . . . 88

8.4.2.1 INITiate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

8.4.2.2 INITiate:CONTinuous?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

8.4.2.3 SENSe:AVERage:COUNt? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . . 89

8.4.2.4 SENSe:AVERage:COUNt <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . 89

8.4.2.5 SENSe<chn>:RESistance:RANGe? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . 89

8.4.2.6 SENSe<chn>:RESistance:RANGe <num>|MIN|MAX|DEF . . . . . . . . . . . . . 90

8.4.2.7 SENSe<chn>:RESistance:WIRE? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . 90

8.4.2.8 SENSe<chn>:RESistance:WIRE <num>|MIN|MAX|DEF . . . . . . . . . . . . . . 90

8.4.2.9 TRIGger:TIMer? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.4.2.10 TRIGger:TIMer <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . . . . . . 91

8.4.3 Channel Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.4.3.1 ROUTe:CLOSe? <chn> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.4.3.2 ROUTe:CLOSe <chn> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.4.3.3 ROUTe:OPEN? <chn> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.4.3.4 ROUTe:OPEN <chn> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.4.3.5 ROUTe:SCAN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.4.3.6 ROUTe:SCAN <chn list> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.4.3.7 ROUTe:SCAN:MODE? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . . . 92

8.4.3.8 ROUTe:SCAN:MODE <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . . . 93

iii

Page 6

8.4.4 Probe Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

8.4.4.1 CALCulate<chn>:CONVert:CATalog?. . . . . . . . . . . . . . . . . . . . . . . . . 93

8.4.4.2 CALCulate<chn>:CONVert:COPY <dest chn>|ALL . . . . . . . . . . . . . . . . . 93

8.4.4.3 CALCulate<chn>:CONVert:NAMe? . . . . . . . . . . . . . . . . . . . . . . . . . 94

8.4.4.4 CALCulate<chn>:CONVert:NAMe <conv> . . . . . . . . . . . . . . . . . . . . . . 94

8.4.4.5 CALCulate<chn>:CONVert:PARameter:CATalog? . . . . . . . . . . . . . . . . . . 94

8.4.4.6 CALCulate<chn>:CONVert:PARameter:VALue? [<param>|ALL] . . . . . . . . . . 95

8.4.4.7 CALCulate<chn>:CONVert:PARameter:VALue <param>,<num>[,< param>,<num>...]

95

8.4.4.8 CALCulate:CONVert:PRINt [<chn>|ALL [,<port>]] . . . . . . . . . . . . . . . . . 95

8.4.4.9 CALCulate<chn>:CONVert:SNUMber? . . . . . . . . . . . . . . . . . . . . . . . . 96

8.4.4.10 CALCulate<chn>:CONVert:SNUMber <serl>. . . . . . . . . . . . . . . . . . . . . 96

8.4.4.11 CALCulate<chn>:CONVert:TEST? <res>|<volt> . . . . . . . . . . . . . . . . . . . 96

8.4.5 Calibration Coefficient Commands. . . . . . . . . . . . . . . . . . . . . . . 97

8.4.5.1 CALibrate:AUTo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.4.5.2 CALibrate<chn>:DATE:CALibrate? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . 97

8.4.5.3 CALibrate<chn>:DATE:CALibrate (<year>,<month>,<day>)|MIN|MAX|DEF . . . 97

8.4.5.4 CALibrate<chn>:DATE:DUE? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . 97

8.4.5.5 CALibrate<chn>:DATE:DUE (<year>,<month>,<day>)|MIN|MAX|DEF . . . . . . 98

8.4.5.6 CALibrate<chn>:PARameter:OFFSet<n>? [MIN|MAX|DEF] . . . . . . . . . . . . 98

8.4.5.7 CALibrate<chn>:PARameter:OFFSet<n> <num>|MIN|MAX|DEF. . . . . . . . . . 99

8.4.5.8 CALibrate<chn>:PARameter:SCALe<n>? [MIN|MAX|DEF] . . . . . . . . . . . . 99

8.4.5.9 CALibrate<chn>:PARameter:SCALe<n> <num>|MIN|MAX|DEF . . . . . . . . . . 99

8.4.5.10 CALibrate<chn>:PARameter:LINearity<n>? [MIN|MAX|DEF]. . . . . . . . . . . 100

8.4.5.11 CALibrate<chn>: PARameter:LINearity<n> <num>|MIN|MAX|DEF. . . . . . . . 100

8.4.5.12 CALibrate<chn>:PARameter:RJC? [MIN|MAX|DEF]. . . . . . . . . . . . . . . . 101

8.4.5.13 CALibrate<chn>:PARameter:RJC <num>|MIN|MAX|DEF . . . . . . . . . . . . . 101

8.4.6 Display Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

8.4.6.1 DISPlay:RESolution? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . . . . 101

8.4.6.2 DISPlay:RESolution <num>|AUT|MIN|MAX|DEF . . . . . . . . . . . . . . . . . 101

8.4.6.3 DISPlay:LAMP? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.4.6.4 DISPlay:LAMP <bool>|<num>|MIN|MAX|DEF. . . . . . . . . . . . . . . . . . . 102

8.4.6.5 DISPlay:DECimal:FORMat? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . 102

8.4.6.6 DISPlay:DECimal:FORMat <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . 102

8.4.6.7 DISPlay:WINDow? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . . . . . 103

8.4.6.8 DISPlay:WINDow <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . . . . 103

8.4.6.9 DISPlay:WINDow<n>:FIELd<n>:FEED? . . . . . . . . . . . . . . . . . . . . . . 103

8.4.6.10 DISPlay:WINDow<n>:FIELd<n>:FEED <chn>[,<num>] . . . . . . . . . . . . . . 103

8.4.7 Logging Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.4.7.1 LOGging:AUTomatic:DELete [<num>|ALL] . . . . . . . . . . . . . . . . . . . . 103

8.4.7.2 LOGging:AUTomatic:COUNt? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . 104

8.4.7.3 LOGging:AUTomatic:COUNt <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . 104

8.4.7.4 LOGging:AUTomatic:FREE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8.4.7.5 LOGging:AUTomatic:LABel? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . 104

8.4.7.6 LOGging:AUTomatic:LABel <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . 105

8.4.7.7 LOGging:AUTomatic:POINt? [MAX] . . . . . . . . . . . . . . . . . . . . . . . . 105

8.4.7.8 LOGging:AUTomatic:PRINt [<num>|ALL [,<port>]] . . . . . . . . . . . . . . . . 105

8.4.7.9 LOGging:AUTomatic:STATus? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.4.7.10 LOGging:AUTomatic:STATus <bool> . . . . . . . . . . . . . . . . . . . . . . . . 106

8.4.7.11 LOGging:AUTomatic:TIMe? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . 106

8.4.7.12 LOGging:AUTomatic:TIMe <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . 106

8.4.7.13 LOGging:AUTomatic:VALue? <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . 106

8.4.7.14 LOGging:DEMand:DELete [<num>|ALL] . . . . . . . . . . . . . . . . . . . . . . 107

8.4.7.15 LOGging:DEMand:FREE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8.4.7.16 LOGging:DEMand:LABel? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . 107

8.4.7.17 LOGging:DEMand:LABel <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . 107

8.4.7.18 LOGging:DEMand:POINt? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8.4.7.19 LOGging:DEMand:PRINt [<num>|ALL [,<port>]] . . . . . . . . . . . . . . . . . 108

8.4.7.20 LOGging:DEMand:STORe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

8.4.7.21 LOGging:DEMand:VALue? <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . 108

8.4.7.22 LOGging:LABel<n>:NAME?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

8.4.7.23 LOGging:LABel<n>:NAME <label> . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.4.8 System Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.4.8.1 *IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

iv

Page 7

8.4.8.2 *OPT? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.4.8.3 *RST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.4.8.4 SYSTem:BOOT:VERSion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

8.4.8.5 SYSTem:CODE:VERSion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

8.4.8.6 SYSTem:ERRor? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

8.4.8.7 SYSTem:SNUMber? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

8.4.8.8 SYSTem:VERSion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

8.4.8.9 UNIT:TEMPerature? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

8.4.8.10 UNIT:TEMPerature <unit> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

8.4.9 Communication Interface Commands. . . . . . . . . . . . . . . . . . . . . 111

8.4.9.1 SYSTem:COMMunicate:SERial:BAUD? [MIN|MAX|DEF]. . . . . . . . . . . . . 111

8.4.9.2 SYSTem:COMMunicate:SERial:BAUD <baud>|MIN|MAX|DEF. . . . . . . . . . 111

8.4.9.3 SYSTem:COMMunicate:SERial:FDUPlex? [MIN|MAX|DEF] . . . . . . . . . . . 111

8.4.9.4 SYSTem:COMMunicate:SERial:FDUPlex <bool>|MIN|MAX|DEF. . . . . . . . . 112

8.4.9.5 SYSTem:COMMunicate:SERial:FEED? [MIN|MAX|DEF] . . . . . . . . . . . . . 112

8.4.9.6 SYSTem:COMMunicate:SERial:FEED <bool>|MIN|MAX|DEF . . . . . . . . . . 112

8.4.9.7 SYSTem:COMMunicate:SERial:LINefeed? [MIN|MAX|DEF] . . . . . . . . . . . 112

8.4.9.8 SYSTem:COMMunicate:SERial:LINefeed <bool>|MIN|MAX|DEF . . . . . . . . 113

8.4.9.9 SYSTem:COMMunicate:SERial:TIMe? [MIN|MAX|DEF] . . . . . . . . . . . . . 113

8.4.9.10 SYSTem:COMMunicate:SERial:TIMe <num>MIN|MAX|DEF . . . . . . . . . . . 113

8.4.9.11 SYSTem:KLOCkout? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . . . . 113

8.4.9.12 SYSTem:KLOCkout <bool>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . . . 113

8.4.9.13 SYSTem:POWer:BATTery? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.4.9.14 SYSTem:POWer:SOURce? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.4.10 Date and Time Commands . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.4.10.1 DISPlay:DATE:FORMat? [MIN|MAX|DEF]. . . . . . . . . . . . . . . . . . . . . 114

8.4.10.2 DISPlay:DATE:FORMat <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . 114

8.4.10.3 DISPlay:TIME:FORMat? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . . . 115

8.4.10.4 DISPlay:TIME:FORMat <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . 115

8.4.10.5 SYSTem:DATE? [MIN|MAX|DEF]. . . . . . . . . . . . . . . . . . . . . . . . . . 115

8.4.10.6 SYSTem:DATE <year>,<month>,<day> . . . . . . . . . . . . . . . . . . . . . . . 115

8.4.10.7 SYSTem:TIME? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.4.10.8 SYSTem:TIME <hour>,<minute>,<second> . . . . . . . . . . . . . . . . . . . . . 116

8.4.11 Password Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.4.11.1 SYSTem:PASSword:CDISable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.4.11.2 SYSTem:PASSword:CENable <pass> . . . . . . . . . . . . . . . . . . . . . . . . 116

8.4.11.3 SYSTem:PASSword:CENable:STATe? . . . . . . . . . . . . . . . . . . . . . . . . 116

8.4.11.4 SYSTem:PASSword:CONVersion? [MIN|MAX|DEF] . . . . . . . . . . . . . . . . 117

8.4.11.5 SYSTem:PASSword:CONVersion <bool>|MIN|MAX|DEF . . . . . . . . . . . . . 117

8.4.11.6 SYSTem:PASSword:NEW <pass> . . . . . . . . . . . . . . . . . . . . . . . . . . 117

8.4.12 Status Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8.4.12.1 *CLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8.4.12.2 *ESE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8.4.12.3 *ESE <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8.4.12.4 *ESR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8.4.12.5 *SRE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8.4.12.6 *SRE <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8.4.12.7 *STB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8.4.12.8 *TST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

8.4.12.9 STATus:MEASure? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

8.4.12.10 STATus:MEASure:CONDition? . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

8.4.12.11 STATus:MEASure:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

8.4.12.12 STATus:MEASure:ENABle <num>. . . . . . . . . . . . . . . . . . . . . . . . . . 119

8.4.12.13 STATus:OPERation? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

8.4.12.14 STATus:OPERation:CONDition? . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

8.4.12.15 STATus:OPERation:ENABle?[MIN|MAX|DEF] . . . . . . . . . . . . . . . . . . . 120

8.4.12.16 STATus:OPERation:ENABle <num>|MIN|MAX|DEF . . . . . . . . . . . . . . . . 120

8.4.12.17 STATus:QUEStionable? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

8.4.12.18 STATus:QUEStionable:CONDition? . . . . . . . . . . . . . . . . . . . . . . . . . 121

8.4.12.19 STATus:QUEStionable:ENABle? [MIN|MAX|DEF]. . . . . . . . . . . . . . . . . 121

8.4.12.20 STATus:QUEStionable:ENABle <num>|MIN|MAX|DEF . . . . . . . . . . . . . . 121

8.4.13 Statistical Calculation Types. . . . . . . . . . . . . . . . . . . . . . . . . . 122

8.4.14 Field Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

v

Page 8

8.4.15 Conversion Types and Parameters . . . . . . . . . . . . . . . . . . . . . . . 124

8.4.16 Port Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

8.4.17 Date and Time Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

9 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

9.1 PRT and Thermistor Calibration . . . . . . . . . . . . . . . . . . 127

9.1.1 PRT Calibration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 127

9.1.2 PRT Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 128

9.1.3 Thermistor Calibration Parameters . . . . . . . . . . . . . . . . . . . . . . 129

9.1.4 Thermistor Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . 129

9.2 Thermocouple Calibration . . . . . . . . . . . . . . . . . . . . . 130

9.2.1 Calibration Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

9.2.2 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 135

11.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 135

11.1.1 Self-Test Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

11.1.2 Start-up Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

11.2 Downloading Auto Logged Data . . . . . . . . . . . . . . . . . 137

11.3 CE Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

11.3.1 EMC Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

11.3.1.1 Immunity Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

11.3.1.2 Emission Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

11.3.2 Low Voltage Directive (Safety) . . . . . . . . . . . . . . . . . . . . . . . . 139

11.4 Frequently Asked Questions . . . . . . . . . . . . . . . . . . . . 139

11.4.1 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

11.4.2 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

11.4.3 Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

11.4.4 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

11.4.5 Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

vi

Page 9

Figures

Figure 1 Using the Clamp-on Ferrites . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 2 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 3 Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 4 Thermocouple Connections . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 5 Probe Connection Wiring Diagram . . . . . . . . . . . . . . . . . . . 22

Figure 6 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 7 Measure Period. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 8 Channel Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 9 Enable Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 10 Channel Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 11 Moving Average . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 12 Display Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 13 Probe Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 14 Edit Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 15 Copy Probe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 16 Test Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 17 Print Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 18 Default Probe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 19 Clear Stats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 20 Fields Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 21 Select Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 22 Edit Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 23 Default Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 24 Display Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 25 Logging Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 26 Demand Log Submenu. . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 27 Store Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 28 Log History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 29 Demand Log View Data . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 30 Print Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 31 Delete Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 32 Logging Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 33 Auto Log Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 34 Log Statistics (Auto Log Started) . . . . . . . . . . . . . . . . . . . . 61

Figure 35 Start Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 36 Auto Log View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 37 Print Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 38 Delete Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 39 Log Stats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 40 Data Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

vii

Page 10

Figure 41 Default Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 42 System Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 43 Comm Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 44 Date Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 45 Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 46 Password for Calibration Access. . . . . . . . . . . . . . . . . . . . . 73

Figure 47 Select Calibration Channel. . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 48 Pass Cal Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 49 Serial Cable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 50 Using a Shorting Wire . . . . . . . . . . . . . . . . . . . . . . . . . 128

viii

Page 11

Tables

Table1 International Electrical Symbols . . . . . . . . . . . . . . . . . . . . . 1

Table 2 Conversion Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 3 Alphabetical List of Commands . . . . . . . . . . . . . . . . . . . . . 79

Table 4 Statistical Calculation Types . . . . . . . . . . . . . . . . . . . . . . 122

Table 5 Field Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Table 6 Reference (REF) Keywords. . . . . . . . . . . . . . . . . . . . . . . 123

Table 7 Conversion Types, Mnemonics, and Serial Port Responses . . . . . . 124

Table 8 Conversion Types and Parameters . . . . . . . . . . . . . . . . . . . 124

Table 9 RJC Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Table 10 Port Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Table 11 Date Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Table 12 Time Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Table 13 PRT and Thermistor Calibration Parameter Description . . . . . . . . 127

Table 14 Calibration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 131

ix

Page 12

1 Before You Start

1.1 Symbols Used

Table 1 lists the symbols that may be used on the instrument or in this manual

Tabl e1 International Electrical Symbols

and the meaning of each symbol.

Symbol Description

AC (Alternating Current)

AC-DC

Battery

1 Before You Start

Symbols Used

Complies with European Union Directives

DC (Direct Current)

Double Insulated

Electric Shock

Fuse

PE Ground

Hot Surface (Burn Hazard)

Read the User’s Manual (Important Information)

Off

1

Page 13

1529 Chub-E4 Thermometer Readout

User’s Guide

Symbol Description

On

Canadian Standards Association

OVERVOLTAGE (Installation) CATEGORY II, Pollution Degree 2 per IEC1010-1 re

fers to the level of Impulse Withstand Voltage protection provided. Equipment of

OVERVOLTAGE CATEGORY II is energy-consuming equipment to be supplied from

the fixed installation. Examples include household, office, and laboratory appliances.

C-TIC Australian EMC mark

The European Waste Electrical and Electronic Equipment (WEEE) Directive

(2002/96/EC) mark.

1.2 Safety Information

Use this instrument only as specified in this manual. Otherwise, the protection

provided by the instrument may be impaired. Refer to the safety information in

Sections 1.2.1 and 1.2.2.

The following definitions apply to the terms “Warning” and “Caution”.

• “Warning” identifies conditions and actions that may pose hazards to the

user.

• “Caution” identifies conditions and actions that may damage the instru-

ment being used.

1.2.1 Warnings

•

DO NOT use this unit in environments other than those listed in the

User’s Guide.

•

Follow all safety guidelines listed in the User’s Guide.

•

Calibration equipment should only be used by trained personnel.

•

This instrument can measure extreme temperatures. Precautions must be

taken to prevent personal injury or damage to objects. Probes may be ex

tremely hot or cold. Cautiously handle probes to prevent personal injury.

Carefully place probes on a heat/cold resistant surface or rack until they

reach room temperature.

•

If this equipment is used in a manner not specified by the manufacturer,

the protection provided by the equipment may be impaired.

•

Before initial use, or after transport, or after storage in humid or semi-hu

mid environments, or anytime the instrument has not been energized for

more than 10 days, the instrument needs to be energized for a "dry-out"

period of 2 hours before it can be assumed to meet all of the safety re

-

-

-

-

2

Page 14

1 Before You Start

Safety Information

quirements of the IEC 1010-1. If the product is wet or has been in a wet

environment, take necessary measures to remove moisture prior to apply

ing power such as storage in a low humidity temperature chamber

operating at 50°C for 4 hours or more.

The AC adapter can present safety concerns if misused or damaged. To

•

avoid the risk of electric shock or fire, do not use the AC adapter outdoors

or in a dusty, dirty, or wet environment. If the cord, case, or plug of the

adapter is damaged in any way, discontinue its use immediately and have

it replaced. Never disassemble the AC adapter. Use only the AC adapter

provided with the instrument or equivalent adapter recommended by the

manufacturer of this instrument.

The AC adapter has circuits with high voltage inside that could present

•

danger of electrical shock or fire if exposed. If the AC adapter is damaged

in any way or becomes hot, discontinue its use immediately, disconnect it

from any AC supply, and have it replaced. Do not attempt to open, repair,

or continue using a damaged or defective AC adapter.

• The instrument batteries can present danger if not handled properly. To

avoid the risk of exposure to dangerous substances or explosion, immediately remove the batteries and discontinue use if they leak or become

damaged. Never allow the batteries to be shorted, heated, punctured, or

dropped. If the instrument is physically damaged, immediately remove

the batteries to insure that they do not become shorted. While removed

from the instrument, store the batteries in a location so that they do not

come into contact with metal or fluids that might short circuit the batteries

and where they are safe from excessive temperatures. Used batteries must

be disposed of properly. Check your local regulations for additional information. Never dispose of batteries in fire which may result in explosion

with the possibility of personal injury or property damage.

•

DO NOT use this instrument in combination with any probe ( PRT,

thermistor, or thermocouple) to measure the temperature or resistance of

any device where the probe might come in contact with a conductor that

is electrically energized. Severe electric shock, personal injury, or death

may occur.

-

1.2.2

Cautions

•

If the instrument is dropped, struck, or handled in a way that causes inter

nal or external physical damage, immediately unplug the AC adapter, re

move the batteries, discontinue use, and contact the factory for repair. Do

not attempt to disassemble or repair the instrument, batteries, or AC

adapter. Refer repairs or replacement components to the manufacturer.

•

The instrument and thermometer probes are sensitive and can be easily

damaged. Always handle these devices with care. DO NOT allow them to

be dropped, struck, stressed, or overheated.

•

Probes are fragile devices which can be damaged by mechanical shock,

overheating, and absorption of moisture or fluids in the wires or hub.

-

-

3

Page 15

1529 Chub-E4 Thermometer Readout

User’s Guide

Damage may not be visibly apparent but nevertheless can cause drift, in

stability, and loss of accuracy. Observe the following precautions:

DO NOT allow probes to be dropped, struck, bent, or stressed.

•

DO NOT overheat probes beyond their recommended temperature range.

•

DO NOT allow any part of the probe other than the sheath to be im

•

mersed in fluid.

DO NOT allow the probe hub or wires to be exposed to excessive temper

•

atures.

Keep the probe wires clean and away from fluids.

•

1.3 Authorized Service Centers

Please contact one of the following authorized Service Centers to coordinate

service on your Hart product:

Fluke Corporation, Hart Scientific Division

799 E. Utah Valley Drive

American Fork, UT 84003-9775

USA

Phone: +1.801.763.1600

Telefax: +1.801.763.1010

E-mail: support@hartscientific.com

-

-

-

Fluke Nederland B.V.

Customer Support Services

Science Park Eindhoven 5108

5692 EC Son

NETHERLANDS

Phone: +31-402-675300

Telefax: +31-402-675321

E-mail: ServiceDesk@fluke.nl

Fluke Int'l Corporation

Service Center - Instrimpex

Room 2301 Sciteck Tower

22 Jianguomenwai Dajie

Chao Yang District

4

Page 16

1 Before You Start

Authorized Service Centers

Beijing 100004, PRC

CHINA

Phone: +86-10-6-512-3436

Telefax: +86-10-6-512-3437

E-mail: xingye.han@fluke.com.cn

Fluke South East Asia Pte Ltd.

Fluke ASEAN Regional Office

Service Center

60 Alexandra Terrace #03-16

The Comtech (Lobby D)

118502

SINGAPORE

Phone: +65 6799-5588

Telefax: +65 6799-5588

E-mail: antng@singa.fluke.com

When contacting these Service Centers for support, please have the following

information available:

• Model Number

• Serial Number

•

Voltage

•

Complete description of the problem

5

Page 17

2 Introduction

2 Introduction

The Hart 1529 is a low-cost, high-accuracy, digital thermometer readout de

signed to be used with 25 and 100Ω PRTs, thermistors, and thermocouples. Its

unique combination of features makes it suitable for a wide variety of applica

tions from laboratory measurement to industrial processes. Features of the 1529

include:

Measures 25Ω and 100Ω PRTs, thermistors, and thermocouples

•

Four inputs: two PRT/thermistor and two thermocouple (standard config

•

uration)

Four-wire connection eliminates lead resistance effects in PRTs

•

Three-wire measurement mode for three-wire RTDs

•

Exclusive patented mini-DWF connectors (U.S. Patent No. 5,964,625)

•

Automatic current reversal eliminates thermoelectric EMF errors

•

• Accuracy: PRTs to 0.006°C, thermistors to 0.002°C, and thermocouples

to 0.3°C

• Typical resolution: PRTs 0.001°C, thermistors 0.0001°C, thermocouples

0.01°C

• Measures four sensors simultaneously with a fast one-second measure-

ment cycle

• Measures one sensor at 10 readings per second (limited accuracy)

• Adjustable moving average for extra precision

• Stores over 8,000 measurements internally

•

Accepts ITS-90, PT-100 (ASTM E1137, DIN 43760, or IEC-751), and

Callendar-Van Dusen PRT characterizations

•

Accepts Steinhart-Hart R(T) or T(R) and YSI-400 type thermistor charac

terizations

•

Accepts thermocouple types B, E, J, K, N, R, S, T, Au-Pt, and polynomial

specified

•

Temperature offsets for improved thermocouple accuracy

•

Stores 10 additional sets of probe parameters

•

Eight programmable display sets for display probe information, measure

ment statistical data, or difference between measurements

•

Password protection of settings

•

Large, LCD, user-configurable, display viewable in bright or dim lighting

•

Serial RS-232 interface standard; IEEE-488 GPIB interface optional

•

Powered by external AC supply, 12-15V DC source, or internal recharge

able battery

-

-

-

-

-

-

7

Page 18

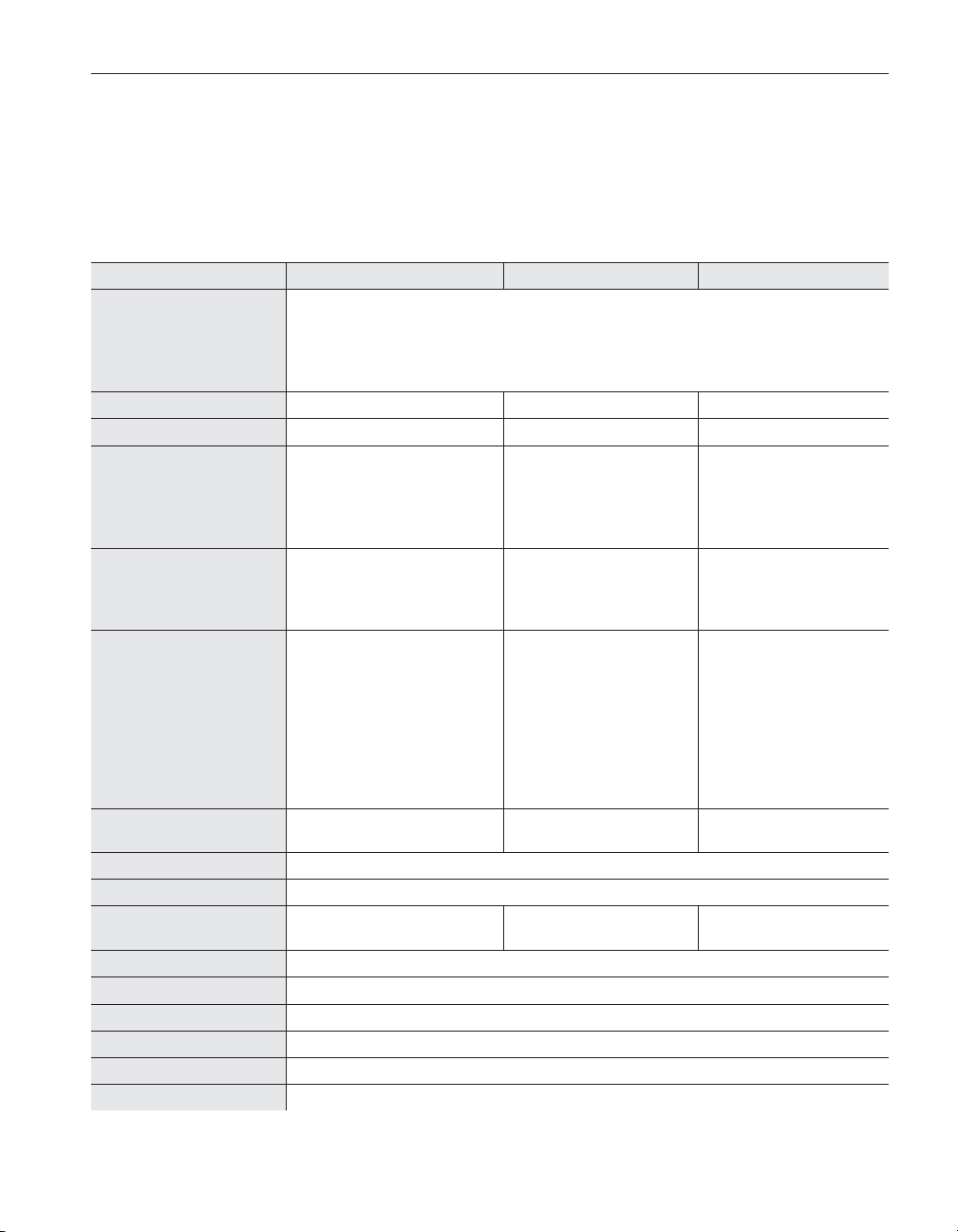

3 Specifications and Environmental Conditions

Specifications

3 Specifications and Environmental

Conditions

3.1 Specifications

PRT Thermistor Thermocouple

Inputs 2 channels PRT/thermistor and 2 channels thermocouple

Temperature Range

Measurement Range

Resistance / Voltage

Accuracy

Characterizations ITS-90,

Temperature Accuracy (meter

only)

Temperature Resolution,

typical

Operating Range

Measurement Interval 0.1 second to 1 hour; inputs may be read sequentially or simultaneously at 1 second or greater interval

Excitation Current 1mA

Display 1.3” x 5" backlit LCD graphical display

Display Units

Data Logging Up to 8,000 time- and date-stamped measurements can be logged

Logging Intervals 0.1, 0.2, 0.5, 1, 2, 5, 10, 30, or 60 seconds; 2, 5, 10, 30, or 60 minutes

Averaging Moving average of most recent 2 to 10 readings, user selectable

Statistical Data Average, standard deviation, minimum, maximum, spread, N, difference (delta)

2

1

3

1

1

or 4 channels PRT/thermistor

or 4 channels thermocouple

PRT/thermistor channels accept 2,3, or 4 wires

Thermocouple channels accept B, E, J, K, N, R, S, T, and Au-Pt thermocouple types

–189 to 960°C –50 to 150°C –270 to 1800°C

Ω

0to400

0to20Ω: ±0.0005

20 to 400Ω: ±25 ppm of reading

PT-100 (ASTM E1137, DIN 43760,

IEC-751),

Callendar-Van Dusen

±0.004°C at –100°C

±0.006°C at 0°C

±0.009°C at 100°C

±0.012°C at 200°C

±0.018°C at 400°C

±0.024°C at 600°C

0.001° 0.0001° 0.01 to 0.001°

16 to 30°C

(reversing)

°C, °F, K,

Ω,KΩ

Ω

,mV

0 to 500k

Ω

Ω

: ±0.0005k

0to5k

5 to 200kΩ: ±100 ppm of

reading

200 to 500 K

reading

Steinhart-Hart, YSI-400 NIST Monograph 175, 3-point

±0.0025°C at 0°C

±0.0025°C at 25°C

±0.004°C at 50°C

±0.010°C at 75°C

±0.025°C at 100°C

μ

2 and 10

selected

Ω

Ω

: ±300 ppm of

A, automatically

–10 to 100 mV

–10 to 50 mV: ±0.005 mV

50 to 100 mV: ±100 ppm of

reading

(Internal RJC: ±0.25°C)

deviation function applied to

NIST 175, 6th-order polynomial

Type Ext./Int.RJC

B ±0.6°C/±0.6°C

E ±0.07°C/±0.25°C

J ±0.1°C/±0.35°C

K ±0.15°C/±0.4°C

N ±0.15°C/±0.3°C

R ±0.4°C/±0.5°C

S ±0.5°C/±0.6°C

T ±0.1°C/±0.3°C

N/A

9

Page 19

1529 Chub-E4 Thermometer Readout

User’s Guide

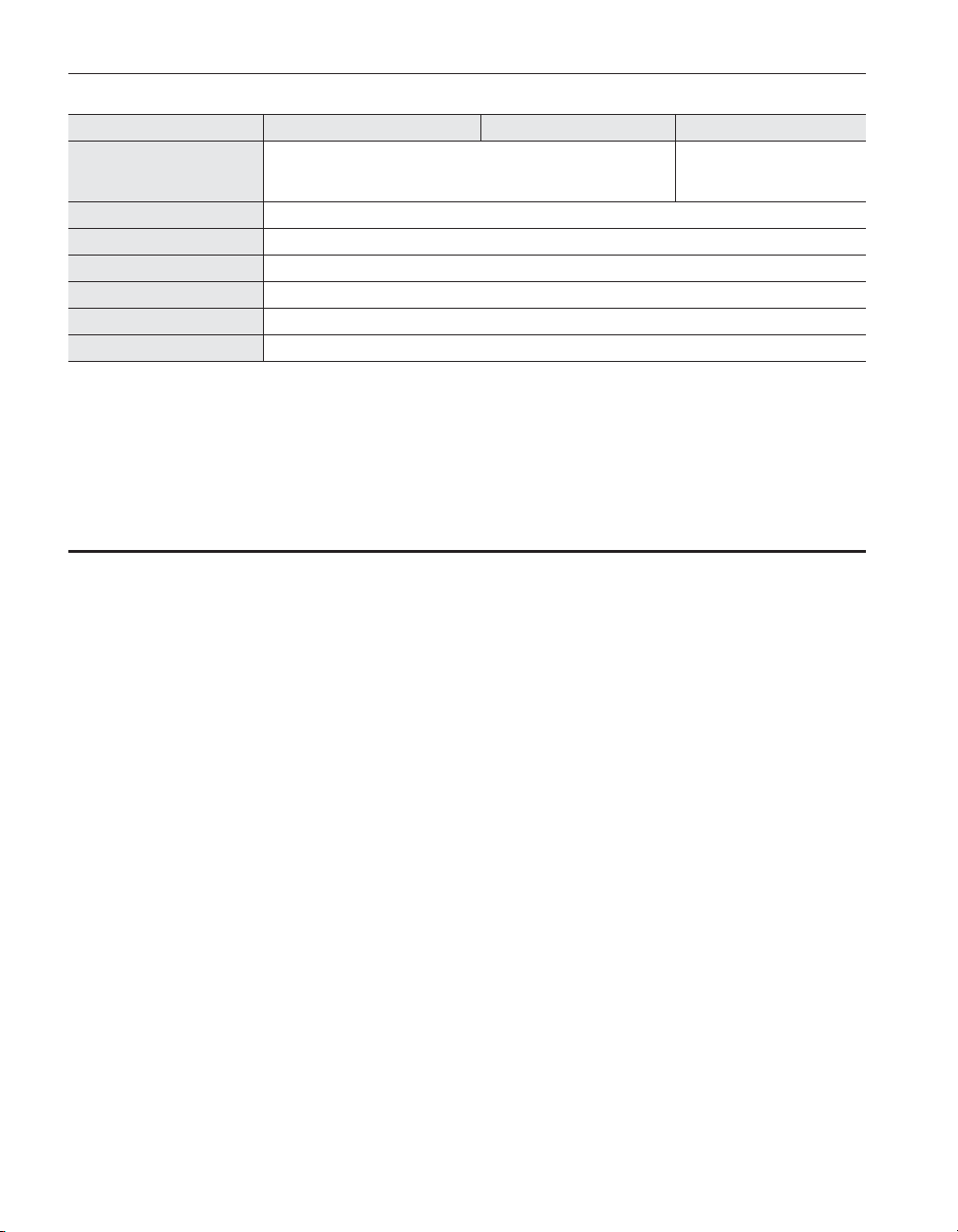

PRT Thermistor Thermocouple

Probe Connection Patented DWF connectors accepts spade lug, bare-wire, or banana

Communications RS-232 port included, IEEE-488 (GPIB) optional

AC Power 100 to 240 VAC, 50-60 Hz, 0.4A

DC Power 12 to 16 VDC, 0.5 A (battery charges during operation from 14.5 to 16 VDC, 1.0A)

Battery NiMH, 8 hours operation typical without backlight, 3 hours to charge, 500 cycles

Size 4.0” H x 7.5” W x 8.2” D (102 x 191 x 208 mm)

Weight 4.5 lbs. (2 kg)

1

The sensor generally limits the actual temperature range. Temperature accuracy specifications do not include sensor accuracy. Thermis

tor temperature accuracy assumes a 10k

improved with external reference junction compensation. Thermocouple temperature accuracies are given for external reference junction

compensation and internal reference junction compensation, respectively.

2

Measurement accuracy specifications apply within the operating temperature range and assume 4-sample averaging and 4 lead wires for

PRTs. With 3-wire RTDs add 0.05

lead wires.

3

Actual resolution can be set greater than typical resolution, but the added digits (0.0001 max.) may not be meaningful to the measurement.

plug terminations

Ω

sensor. Thermocouple accuracy is with internal reference junction compensation; accuracy is

Ω

to the measurement accuracy plus the maximum possible difference between the resistances of the

Universal receptacle accepts

miniature and standard

connectors

-

10

3.2 Environmental Conditions

Although the instrument has been designed for optimum durability and trouble-free operation, it must be handled with care. The instrument should not be

operated in an excessively dusty, dirty, or wet environment. Maintenance and

cleaning recommendations can be found in the Maintenance section of this

manual.

For full accuracy, operate the instrument in ambient temperatures between

16–30°C (61–86°F). The battery may not charge properly at temperatures

above 30°C. Do not operate the instrument in an environment colder than 5°C

(41°F) or warmer than 40°C (104°F).

The instrument operates safely under the following conditions:

•

Ambient temperature range: absolute 5–40°C (41–104°F) [full accuracy

16–30°C (61–86°F)]

•

Ambient relative humidity: maximum 80% for temperature <31°C, de

creasing linearly to 50% at 40°C

•

Pressure: 75 kPa–106 kPa

•

Vibration should be minimized

•

Altitude less than 2,000 meters

•

Indoor use only

-

Page 20

4 Quick Start

This section briefly explains the basics of setting up and operating your 1529

Thermometer Readout.

4.1 Unpacking

Carefully unpack the 1529 thermometer readout. Verify that the following

items are present:

1529 Thermometer Readout (The battery inside the 1529 is completely

•

charged when shipped. Initial charging is not required.)

AC Adapter/Charger and power cord

•

Serial Cable

•

User’s Guide

•

• Report of Calibration with calibration label

• Probe (optional-must be purchased separately)

• Two ferrites (for use with probes as described in Section 4.4.1, Using the

Clamp-on Ferites)

If all items are not present, contact an Authorized Service Center (see Section

1.3)

4 Quick Start

Unpacking

4.2 Use Proper Care

You must understand the safety issues related to the 1529. Be aware that potential hazards exist due to high temperatures and battery chemicals. Carefully

read the Warnings in Section 1.2.1 and Cautions in Section 1.2.2.

The 1529 and any thermometer probes used with it are sensitive instruments

that can be easily damaged. Always handle these devices with care. DO NOT

allow them to be dropped, struck, stressed, or over-heated.

4.3 Learn About the Features and Components

Familiarize yourself with the features and accessories of the 1529 by reading

Section 5, Parts and Controls.

4.4 Connect the Probe

The PRT/thermistor or thermocouple probe connects on the back panel of the

1529 using patented mini-DWF connectors (PRT/thermistor) or the universal

receptacles (thermocouples).

11

Page 21

1529 Chub-E4 Thermometer Readout

User’s Guide

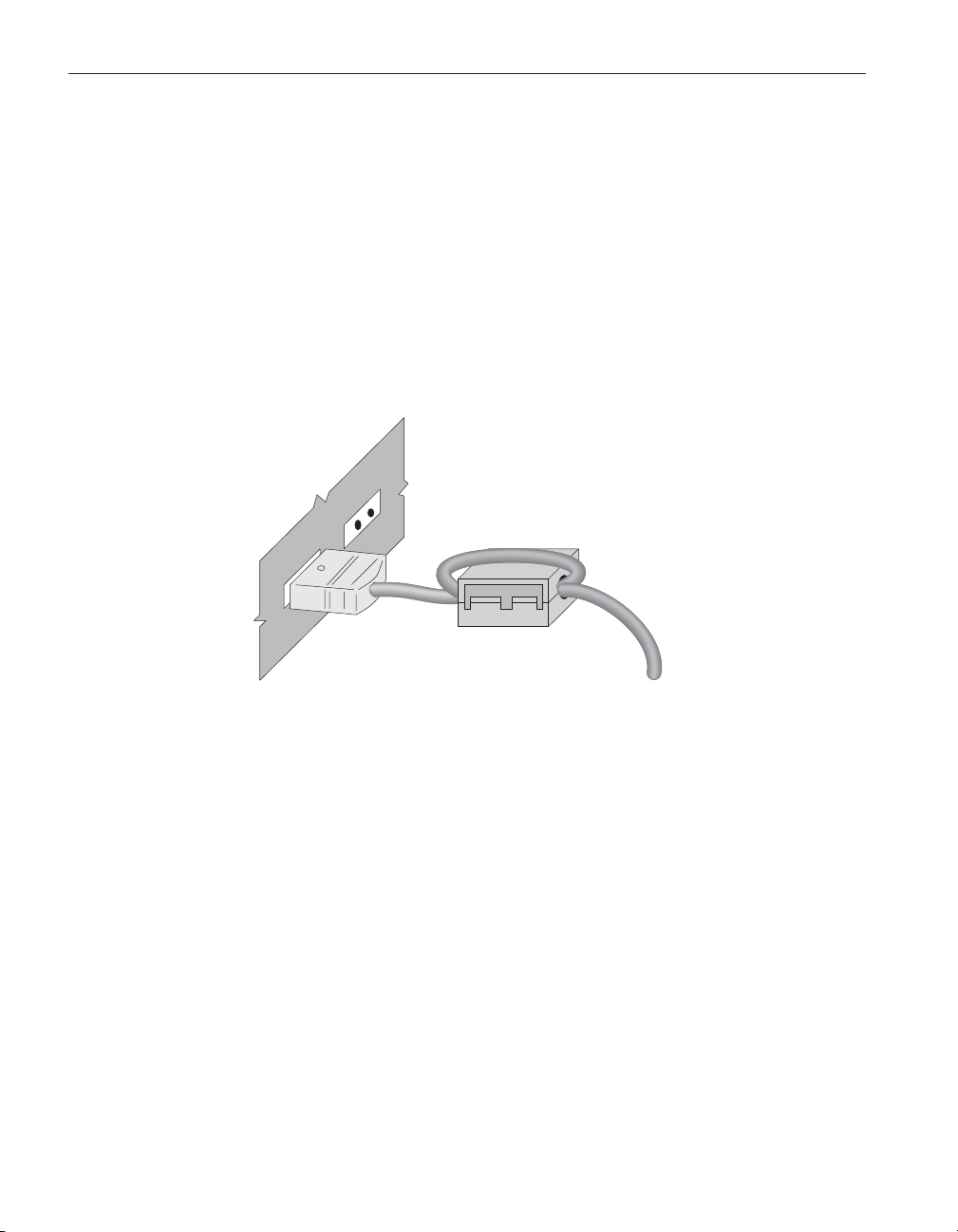

4.4.1 Using the Clamp-on Ferrites

Clamp-on ferrites are provided with this product for the use of improving its

electromagnetic (EM) immunity in environments of excessive EM interference.

During EMC testing we found that ferrites clamped around the probe cables

and power cord reduced the risk that EM interference affects measurements.

Therefore, we recommend that the clamp-on ferrites provided (Steward P/N

28A2025-0A2) be used on the cables of probes attached to this product, espe

cially if it the product is used near sources of EM interference such as heavy in

dustrial equipment.

To attach a ferrite to a probe cable, make a loop in the cable near the connector

and clamp the ferrite around half of the loop as shown in Figure 1. The ferrite

can be easily snapped open and moved to a new probe when needed.

-

-

probe cable

12

clamp-on ferrite

Figure 1 Using the Clamp-on Ferrites

4.5 Connect the Power Source

The 1529 draws power from either a 15-volt DC power supply (the included

AC adapter) connected to the DC input or the internal re-chargeable battery

pack. To use the AC adapter, plug it into a wall outlet of the appropriate voltage

and insert the DC plug into the DC power input of the 1529 (see Figure 3 on

page 16.)

4.6 Switch the Power On

Power is turned on and off with the power switch located on the top right cor

ner of the back panel. To switch the power on, toggle the power switch to the

‘ON’ position. To switch power off, toggle the power switch to the ‘OFF’ posi

tion. The instrument takes a few seconds to power up, initialize, and begin nor

mal operation. A self-test is performed displaying the channel configuration

and status of the system, calibration, GPIB, memory, and buttons. If the ther

mometer readout calibration has expired, the user is notified and must press the

-

-

-

-

Page 22

Enter button to continue initialization. If an error message is displayed on

power up see Section 11.1, Troubleshooting.

4.7 Measure Temperature

After initialization, the temperature measurements for the configured channels

are displayed. The appropriate sensor type must be selected and coefficients en

tered for the measurements to be accurate (see Section 7.2.1, Edit Probe). Place

the sensors of the probe into the object(s) you want to measure. DO NOT force

the probe(s) or otherwise allow them to be bent, stressed, or overheated. Probes

can be easily damaged if misused. For further suggestions on handling the

probe and using the 1529 and probe to measure temperature accurately, see

Section 6, General Operation. For information on the various modes of opera

tion of the 1529 see Section 7, Display Functions.

4 Quick Start

Measure Temperature

-

-

13

Page 23

5 Parts and Controls

The functions of the various features of the 1529 are described below.

5.1 Front Panel Buttons

5 Parts and Controls

Front Panel Buttons

The front panel buttons Enter/Menu, Unit, Contrast,andExit areusedtose

lect and alter the functions of the thermometer readout (see Figure 2).

1

3

1 TYP: CVD

1 SER: 145-560

1 –T1: 0.0000 C

Figure 2 Front Panel

24.159C

24.142C

ALOG: OFF 0%

CHUB E-4 THERMOMETER READOUT

1529

ENTER / MENU UNIT CONTRAST

2

24.634C

4

24.015C

1 AVE: 24.1530 C

1 STD: 0.0038 C

1 SPR: 0.0219 C

TIME: 14:58:43

EXIT

The function of each button is as follows:

Enter/Menu - This button displays and scrolls through the menu options. Use

this button to select the menu to enter and to save changes made to menu

choices.

-

Unit - LR Use these buttons to select the units C, F, or K when not in the

menu structure. In conjunction with the Menu button, use these buttons to

scroll left and right through menu options and choices.

Contrast -UD Use these buttons to lighten or darken the display when not in

the menu structure. In conjunction with the Menu button, use these buttons to

scroll up and down through menu options and choices.

Exit - Use this button to exit any menu. When editing a parameter, if the Exit

button is pressed, the immediate operation is canceled and control skips to the

next parameter. Holding the button down for several seconds, exits to the main

display.

15

Page 24

1529 Chub-E4 Thermometer Readout

User’s Guide

16

Figure 3 Back Panel

Page 25

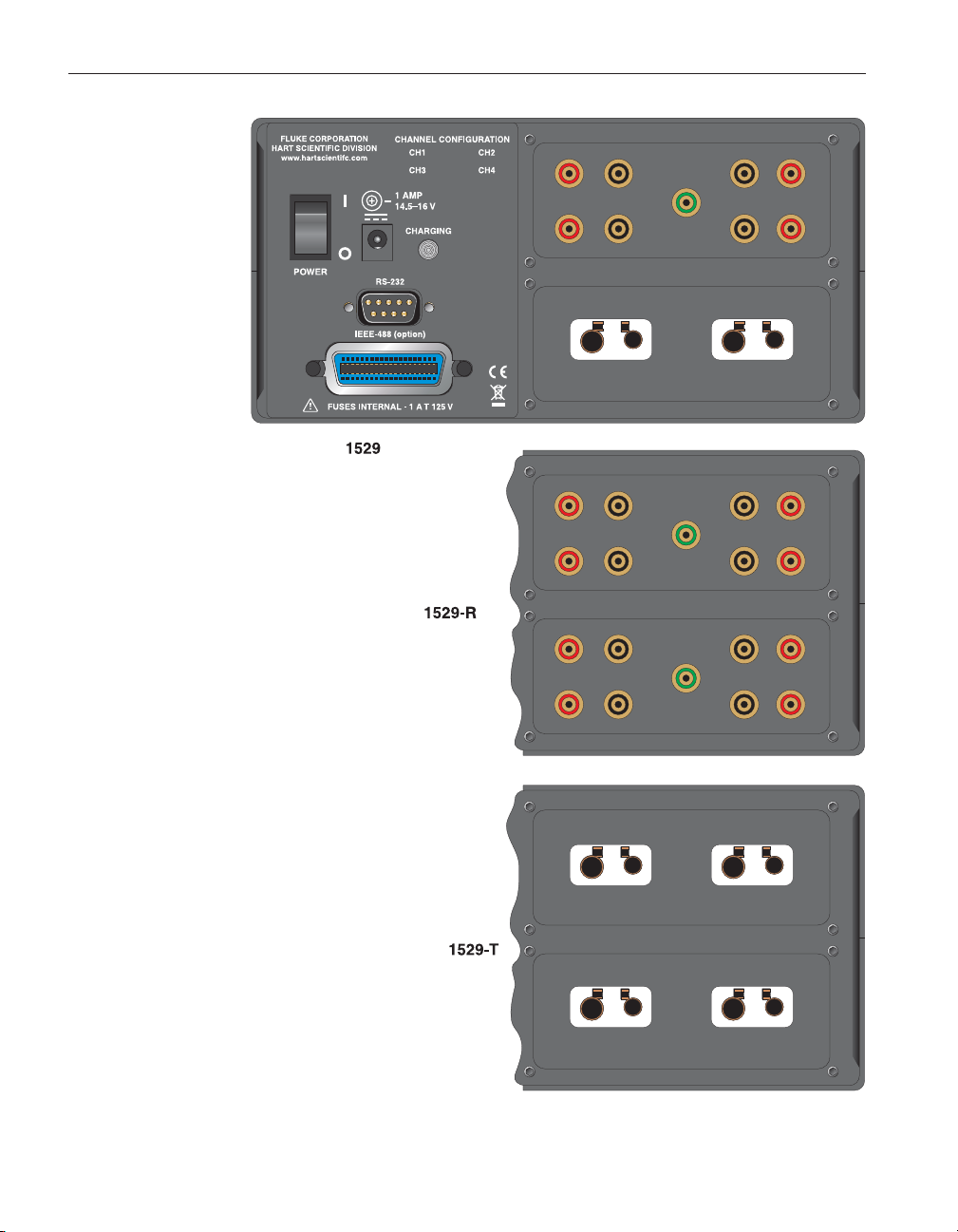

5.2 Back Panel

The back panel consists of the power switch, AC adapter connector, charging

indicator, RS-232 port connector, IEEE-488 port connector (optional), serial la

bel, and probe connectors. The 1529 thermometer readout can be configured in

three different ways. The configuration affects the probe connectors on the

back panel. The Model 1529 is configured with one PRT/thermistor input mod

ule of two channels and one thermocouple input module of two channels. The

Model 1529-R is configured with two PRT/thermistor input modules of four

channels. The Model 1529-T is configured with two thermocouple input mod

ules of four channels. Figure 3 shows the back panel and the three different

configurations.

Power Switch - The power switch turns the thermometer readout on and off.

5 Parts and Controls

Back Panel

-

-

-

AC Adapter Connecor - The AC adapter plugs into the DC power input to re

charge the battery and to power the instrument while the battery is being

charged (see Section 6.3, Battery).

Charging Indicator - The charging indicator lights when the AC adapter is

connected. It glows green when the battery is at full charge and amber when the

battery is being charged.

RS-232 Port Connector - The DB-9 connector is for interfacing the thermometer readout to a computer or terminal with serial RS-232 communications.

IEEE-488 Port (optional) - The GPIB connector is for interfacing the thermometer readout to a computer or terminal with IEEE-488 communications.

Serial Label - The serial label shows the instrument model and serial number.

Probe Connectors - Probe(s) must be connected either to the patented

mini-DWF connectors (PRT/thermistor probes) or to the universal receptacle

(thermocouples) for operation.

5.3 Accessories

The 1529 thermometer readout comes standard with a hand strap on the side

for easy carrying of the instrument. The following accessories are also

available:

•

2513-1529 Rack Mount Kit

•

9323 Soft Carrying Case

•

9322 Hard Carrying Case

•

2380 Small Thermocouple Connector Kit

•

2381 Large Thermocouple Connector Kit

-

17

Page 26

6 General Operation

6 General Operation

Display

This section explains basic operation of the 1529 thermometer readout. De

tailed operation of the 1529 is explained in Sections 7 and 8. Section 7 explains

the menu structure and the functions available in the menu structure and Sec

tion 8 explains the communications interface for operating the 1529 remotely.

6.1 Display

The 1529 display consists of two parts. The top portion of the display is used

for displaying the measurements from one to four inputs. The bottom portion of

the display is reserved for the programmable fields and field display sets. Infor

mation about the channels and measurements can be displayed in greater detail

such as min, max, spread, standard deviation, and many other functions. When

the measure period is 0.1 or 0.2 seconds (fast measurement mode), the pro

grammable fields and field display set information are not displayed.

6.2 Changing Units

The 1529 thermometer readout is capable of displaying temperature in Celsius

(C), Fahrenheit (F), or Kelvin (K). (Displaying in units of Ω,KΩ,ormVisalso

available through the PROBE menu and is channel specific.) Temperature units

are changed on all channels (not individually) by pressing the buttons on the

front panel when not in the menu structure. Press the Unit, LR, buttons to

scroll forward and backward through C, F, or K. All channels or fields that are

displaying temperature on the upper or lower display are updated to the new

units.

-

-

-

-

Channels that are set to Ω,KΩ, or mV in the PROBE menu are left unchanged

when temperature units are modified. Changing the units resets the statistical

calculations (displayed in the bottom portion of the display).

6.3 Battery

The 1529 thermometer readout has a built-in nickel-metal-hydride battery pack

that can power the instrument for about eight hours before needing to be re

charged. The battery discharges more quickly when the display backlight is

used. The percent of battery charge remaining is displayed on the bottom por

tion of the display when the battery power is being used. The battery percent

age is approximate and should only be used as a general guideline when

determining the length of charge remaining. The battery is recharged in situ

(while in place) using the AC adapter that is provided.

Plug the AC adapter into the wall outlet and connect the DC plug of the adapter

into the 1529. The battery is charged as necessary whether or not the instru

ment is switched on. The power control circuit inside the instrument manages

battery charging and stops charging the battery automatically when the battery

-

-

-

-

19

Page 27

1529 Chub-E4 Thermometer Readout

User’s Guide

is fully charged. Only charge the battery when ambient temperature is between

16°C and 30°C (61°F and 86°F) It normally takes about three hours to fully

charge the battery. The instrument can be operated while the battery is being

charged. The charging indicator on the back panel is green when the battery is

fully charged and amber when being charged using the AC adapter.

The battery may self-discharge over several months, especially if the tempera

ture is warm. The battery pack can be used for a minimum of 500 charge-dis

charge cycles before needing to be replaced. Replacement battery packs are

available from the manufacturer. The battery pack can be easily removed and

replaced in the field by following this procedure:

1. Power the 1529 off and unplug the AC adapter from the unit.

2. Turn the 1529 over to expose the battery compartment. Remove the bat

tery cover hex screw. Place the screw in a safe place so it won’t get lost.

Flip open the battery cover to reach the battery pack.

3. Remove the battery pack. Gently disconnect the battery plug connector.

4. Attach the polarized plug of the new battery pack onto the connector.

Note: The battery plug is polarized and can only be plugged in one direction. DO NOT force it. Place the battery pack in the battery

compartment.

5. Close the battery cover and replace the screw. Avoid pinching the battery

wires.

6. Plug in the AC adapter and charge for a minimum of four hours for the

initial charge. Used batteries must be disposed of properly. Check your

local regulations for additional information. You may return used batteries to the manufacturer. Never dispose of batteries in fire as this may result in an explosion with the possibility of personal injury or property

damage.

When the battery charge is not at 100%, the measurement accuracy is not af

fected. If the power is interrupted while the instrument is logging measure

ments (on demand or automatically), the logged data is preserved and logging

resumes when the power is restored.

-

-

-

-

-

20

6.4 Probe Input Modules

The 1529 can be configured in three ways:

•

Two RTD/thermistor input modules.

•

Two thermocouple input modules.

•

One RTD/thermistor and one thermocouple input module.

Each input module supports two channels. Your 1529 thermometer readout is

configured at the factory and is not field changeable. Input modules should

never be removed for any reason.

Page 28

All possible configurations are shown in Figure 3 on page 16.

6.4.1 Connecting a PRT or Thermistor Probe

PRT and thermistor probes are attached to the resistance input module via Hart

Scientific mini-DWF connectors. These patented connectors accept bare wire,

spade, or mini banana plug terminations. The connectors are color coded for

ease in connecting lead-wires.

When using 2- and 3-wire sensors, the accuracy of the 1529 is reduced as

stated in the specifications. Compensation is made for 3-wire PRTs, but the dif

ference in lead resistance affects the measurement accuracy. The 1529 ther

mometer readout is unable to compensate for 2-wire lead resistance.

Attach the lead-wires of the probes as shown in Figure 5 on page 22. The top

termainals sense current and the bottom terminals sense potential.

6.4.2 Connecting a Thermocouple

The 1529 thermocouple input module accepts both standard and sub-miniature

size thermocouple connectors. The connection is made with the positive terminal on the right and the negative terminal on the left. You must use a connector

that matches the thermocouple type for the internal RJC to be accurate. For example, if you are using a type K thermocouple you must also use a type K connector, which is made from the same type of metal. For best results, wait two

minutes before measuring after inserting the thermocouple connector into the

input module.

6 General Operation

Probe Input Modules

-

-

Figure 4 Thermocouple Connections

21

Page 29

1529 Chub-E4 Thermometer Readout

User’s Guide

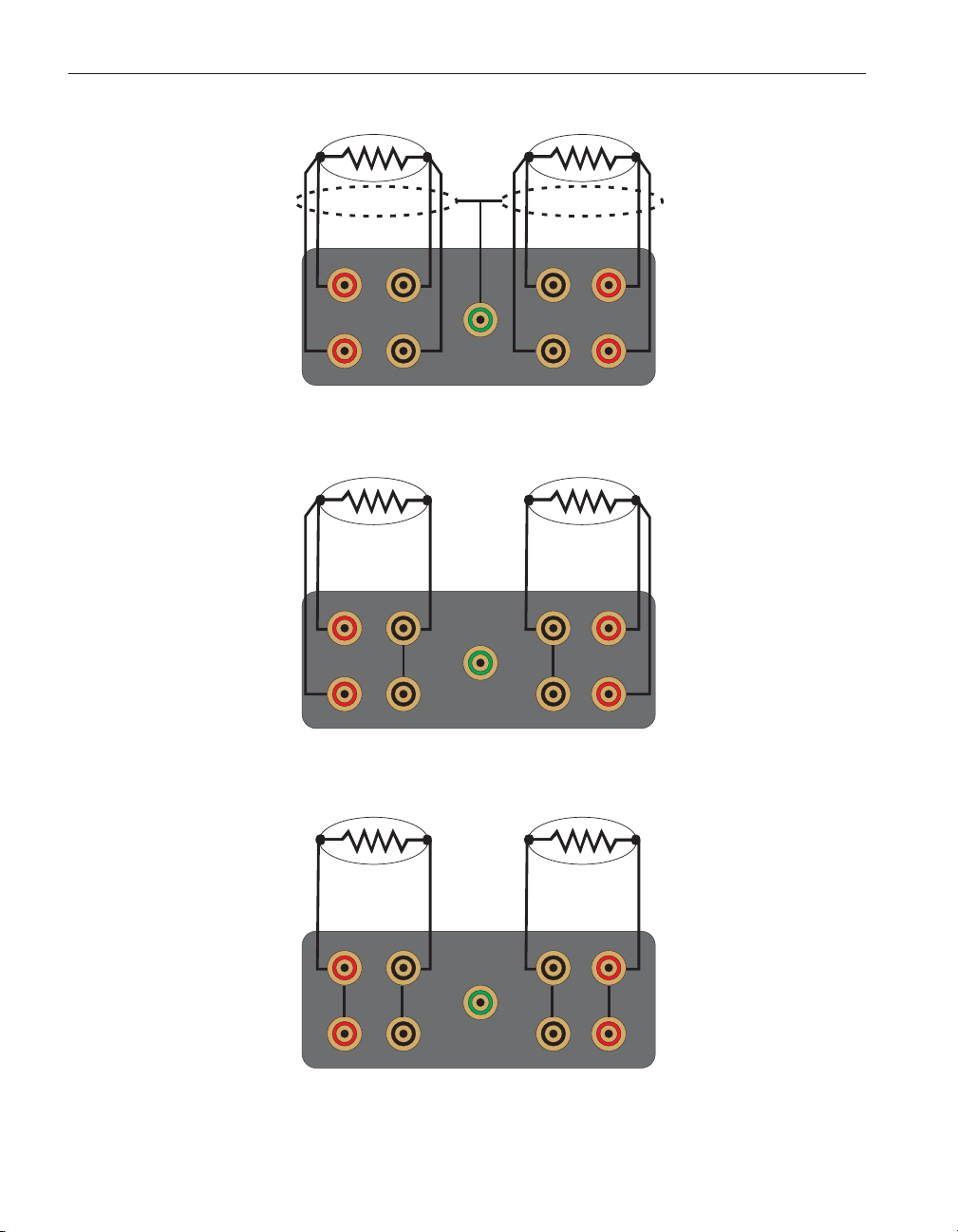

Channel 1 Channel 2

Connecting 4-wire probes

Channel 1 Channel 2

Shield

22

Connecting 3-wire probes

Channel 1 Channel 2

Connecting 2-wire probes

Figure 5 Probe Connection Wiring Diagram

Page 30

6.5 DC Power Source

Caution: For CE compliance and for performance, use only the AC

adapter shipped with the instrument by Hart Scientific. If the AC adapter

needs to be replaced, contact an Authorized Service Center (see Section

1.3).

The DC power source provides power to charge the battery. It can also be used

to power the 1529 while the battery is being charged. The AC adapter provided

with the 1529 is intended for these purposes. The DC power source plugs into

the DC power input on the back panel of the instrument. The AC adapter has

circuits with high voltages inside that could present danger of electric shock or

fire if exposed. If the AC adapter is damaged in any way or becomes hot, dis

continue use immediately, disconnect the adapter from any AC supply, and re

place the adapter. Do not attempt to open, repair, or continue using a damaged

or defective AC adapter.

6.6 Power On Self-Test

When power is turned on, the 1529 performs a self-test checking the system, all

channels, calibration, GPIB, memory, and buttons. If an error occurs, an error

message is displayed. See Section 11.1, Troubleshooting for additional information on error messages.

6 General Operation

DC Power Source

-

-

6.7 Display Backlight and Contrast

The display backlight is adjustable for use in varying lighting conditions. The

four backlight modes are accessible in the CHANNEL menu DISPLAY OP

TIONS function. If the display appears faded, dark, or blank, adjust the con

trast (off, low, medium, high) using the front panel contrast buttons.

6.8 Taking Measurements

The procedure for configuring the 1529 thermometer readout to take measure

ments on a particular input channel requires the following: (1) connecting the

sensor to the appropriate input channel , (2) enabling the channel, and (3) se

lecting the conversion type and probe characterization values.

6.8.1 Connecting the Sensor

Connect the sensor to the RTD/Thermistor channel(s) or thermocouple chan

nel(s) that you want to measure. Refer to Section 7.4, Probe Input Modules, for

additional information.

-

-

-

-

-

23

Page 31

1529 Chub-E4 Thermometer Readout

User’s Guide

6.8.2 Enabling the Channel

Channels are set first by selecting either simultaneous or scan mode in the

CHANNEL menu CHANNEL MODE function. Simultaneous mode shows one

to four channels in the upper display simultaneously. Scan mode shows one

channel at a time (in large digit format) scanning through one to four channels

depending on the channels that are enabled. After the mode has been selected,

use the CHANNEL menu ENABLE CHANNEL function, to select the channel

to be displayed. Any channel set to ‘Off’ is not displayed. See Sections 7.1.3,

Channel Mode, and 7.1.2, Enable Channel, for more information.

6.8.3 Selecting Conversion Type and Probe Characterization

Before the 1529 can accurately measure temperature, it must be configured to

calculate temperature from the resistance or voltage of the sensor. There are

many temperature conversion algorithms available and the one to use depends

on the type of sensor and its calibration. Many conversion algorithms use coef

ficients that characterize the sensor. Coefficients are determined when the sen

sor is calibrated. SPRTs and RTDs often use the ITS-90 algorithms and are

provided with ITS-90 characterization coefficients. Thermistors often use the

Steinhart-Hart algorithms and coefficients. Thermocouples use standard tables

or equations depending on its type. For additional information on conversion

types, see Section 7.2, Probe Menu.

The conversion type and characterization coefficients for a sensor are specified

using the PROBE menu EDIT PROBE function (see Section 7.2.1).

-

-

24

6.9 Fast Measurement Mode

Fast Measurement Mode applies to measure periods of 0.1, 0.2, or 0.5 seconds.

This mode allows measurements to be displayed or logged quickly.

Normally, when each measurement is made a self-calibration of the measure

ment circuit is performed simultaneously during the measurement process to

offset errors from component drift and spurious EMFs. For measure periods of

0.1, 0.2, and 0.5 seconds, the fast measurement rate is achieved by foregoing

the self-calibration. The drawback to this Fast Measurement Mode is the accu

racy of the measurement may be poor and subject to drift. Accuracy can be

temporarily improved using the AUTO-CAL function that appears in the

CHANNEL menu when in this Fast Measurement Mode. The AUTO-CAL

function causes the instrument to perform a single self-calibration of the mea

surement circuit then resume fast measuring (without automatic

self-calibration).

See Section 8.1.1 for detailed information on using the Fast Measurement

Mode.

-

-

-

Page 32

6.10 Data Logging

6 General Operation

Data Logging

Data can be logged either on demand or automatically at a user-selected inter

val. When data is logged, readings are stored to the instrument's memory and

assigned a label for easy recall and organization of data. Up to 100-demand log

and 8,160 auto log readings can be stored. When data is being logged, the left

bottom corner of the main display shows a strip-recorder indicator.

25

Page 33

7 Menu Functions

Selecting the Enter/Menu button from the front panel accesses the main menu

of the 1529 thermometer readout. The main menu consists of the submenus:

CHANNEL, PROBE, FIELDS, LOGGING,andSYSTEM. Each submenu

has its own set of functions. The Enter/Menu buttonisusedtoselectandsave

menu choices. The Unit LR buttons are used to scroll forward or backward

through the functions. The Exit buttonisusedtoreturnfromafunctiontothe

previous menu or step through parameters.

7 Menu Functions

Channel Menu

1

24.159C

3

24.142C

LR to select menu item. Press ENTER.

CHANNEL PROBE FIELDS LOGGING SYSTEM

Figure 6 Main Menu

7.1 Channel Menu

The CHANNEL menu provides functions for setting the measurement period,

selecting channels, setting the channel display mode, and setting measurement

averaging. The functions that appear in the CHANNEL menu are MEASURE

PERIOD, ENABLE CHANNEL, CHANNEL MODE, MOVING AVERAGE,

2

4

CHUB E-4 THERMOMETER READOUT

1529

ENTER / MENU UNIT CONTRAST

24.634C

24.015C

EXIT

27

Page 34

1529 Chub-E4 Thermometer Readout

User’s Guide

and DISPLAY OPTIONS/AUTO-CAL. (The DISPLAY OPTIONS changes to

AUTO-CAL when the measure period is less than 1 second.)

1

3

MEASUREMENT CONTROL FUNCTIONS

MEASURE

PERIOD

Figure 8 Channel Menu

24.159C

24.142C

ENABLE

CHANNEL

CHUB E-4 THERMOMETER READOUT

1529

ENTER / MENU UNIT CONTRAST

2

4

CHANNEL

MODE

24.634C

24.015C

MOVING

AVERAGE

EXIT

DISPLAY

OPTIONS

7.1.1 Measure Period and Fast Measurement Mode

The MEASURE PERIOD function allows you to control the period (time) between measurements. You may select between 0.1, 0.2, 0.5, 1, 2, 5, 10 and 30

seconds, 1, 2, 5, 10, and 30 minutes, or 1 hour. Note: Accuracy may be reduced

in measurement periods less than one second. When this function is selected,

the bottom portion of the display shows the current setting and allows the setting to be changed.

28

1

24.159C

3

24.142C

MEA PER: 1 SEC

Figure 7 Measure Period

2

4

CHUB E-4 THERMOMETER READOUT

1529

ENTER / MENU UNIT CONTRAST

24.634C

24.015C

EXIT

Page 35

7 Menu Functions

Channel Menu

The LR buttons are used to select the period between measurements. Press

the Enter button to save the new setting. Press the Exit button to cancel and to

exit to the menu.

When the measure period is set to less than 1 second (i.e. 0.1, 0.2, 0.5 seconds)

the 1529 enters the Fast Measurement Mode. The menu buttons may seem to be

sluggish in this mode as the processor is making faster measurements. When in

the Fast Measurement Mode, the following changes occur at 0.1, 0.2, and 0.5

seconds.

The channel display is updated quicker.

•

The DISPLAY FUNCTIONS function changes to the AUTO-CAL func

•

-

tion.

The measurement accuracy is reduced and is subject to uncertainty factors

•

that are not typically introduced in a normal full measurement cycle.

With serial port printing (see Section 7.5.1.1) measurements are printed

•

without the time and date and other associated information.