Page 1

APPLICATION NOTE

LED Chip Heat

Dissipation Mapping

The LED chip is the core component of

LED lighting. If the chip temperature is

too high, the LED life and luminous quality

could be severely affected.

What is a heat sink and

why is it important?

A heat sink is a common component in many electronic devices.

It transfers the heat created by

a device, acting to reduce the

device’s temperature to prevent

overheating. Heat sinks are an

important part of LED lighting,

more specifically LED chips. The

heat sink aids in heat dissipation of the chip, ensuring that

the temperature of these chips

stays within the appropriate

range. Testing heat sinks in the

production process of LED chips

is critical to ensuring quality.

Infrared cameras can be used in

the R&D process to check LED

heat sinks. The readings from a

camera can help manufacturers

find potential problems with

materials and designs, to better

analyze and improve heat sink

qualit y.

Relationship between the

LED chip temperature and

the heat sink

To continue operating properly, LED chip temperature

should not exceed 120 °C. As

chip temperature increases,

the unfortunate reality is that

service life decreases. So, if the

chip temperature is very high,

or even worse, exceeds 120 °C,

service life of the chip will be

shortened.

Therefore it is important to

stay below 120 °C to maintain

chip performance and service

capability. This emphasizes the

importance of the heat sink—the

heat sink is what cools the LED

chip. If the heat sink is unavailable, poorly designed, or made

of improper material, the heat

dissipation effect will be seriously affected, thus shortening

the LED service life or resulting

in a change of LED color.

CASE:

We worked with the R&D

department for a large LED manufacturer to understand how LED

chips are tested. The manufacturer stated the importance of

the heat dissipation effect and

heat sink size when designing

a heat dissipation scheme for

the chip. Six types of heat sinks

were designed for research.

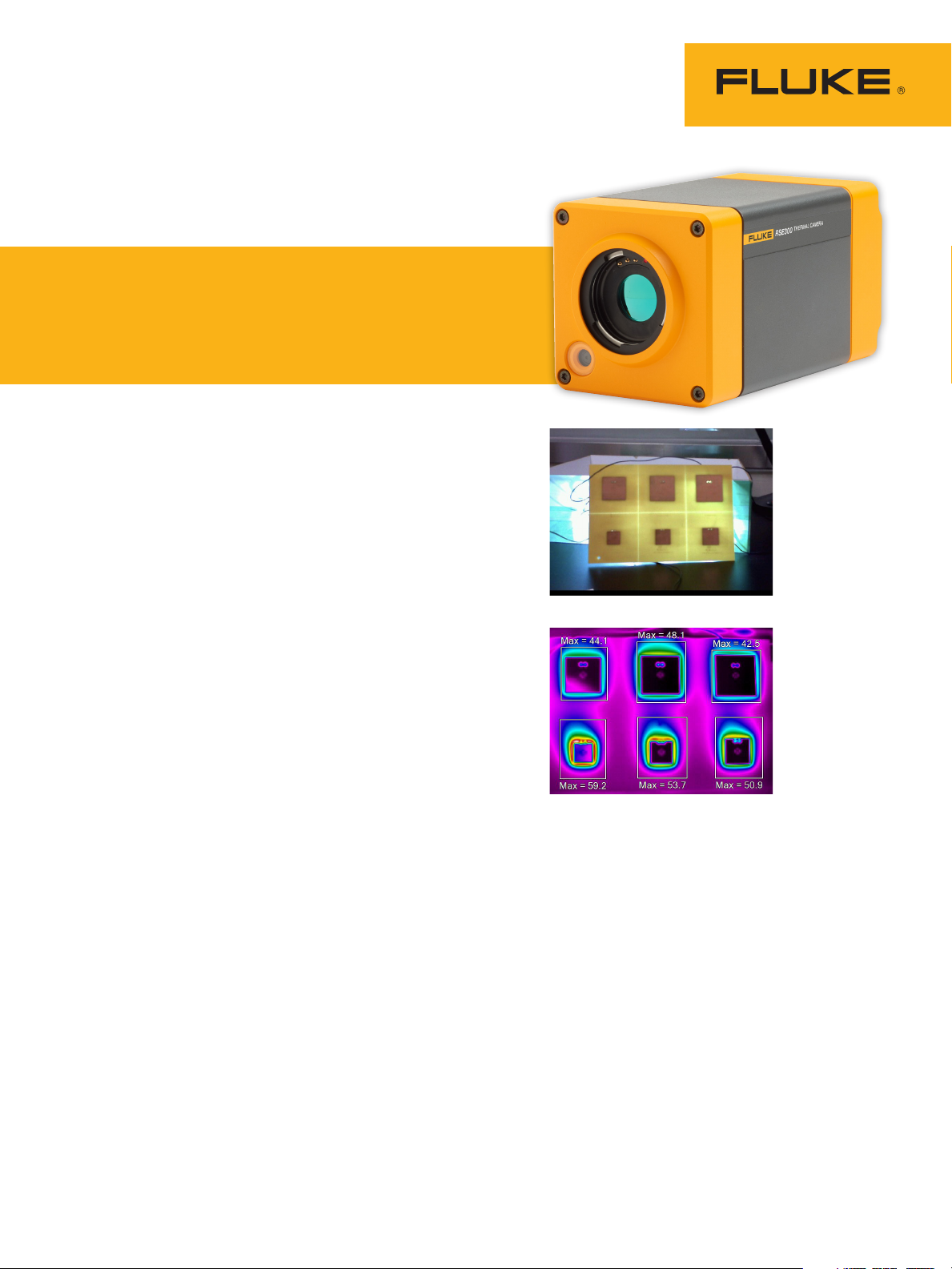

As shown in Figure 1, the heat

sink area increases as you

move from bottom left to top

right. These figures have the

same chip under the same input

voltage, current and the same

lighting time.

In Figure 2, the temperature

at the upper middle position is

48.1 °C, inconsistent with the

temperature trend of heat sink

size. Normally the estimated

value should be in the range of

43 °C to 44 °C. Since we see in

the figure that the temperature

falls outside of this range, it is

likely that the design or material selection of the heat sink

here is flawed. The image can

also be used to calculate the

heat dissipation per unit area by

focusing on the area size and

Figure 1

Figure 2

temperature. In this example, it

is clear that the design at the

lower right corner has the worst

heat dissipation effect, and the

upper right corner shows the

best heat dissipation effect.

Page 2

Before an infrared camera,

what was used to measure

the temperature during

heat dissipation R&D of an

LED chip?

Before the introduction of infrared cameras, a thermocouple

was the most popular way to

measure temperature during

heat dissipation.

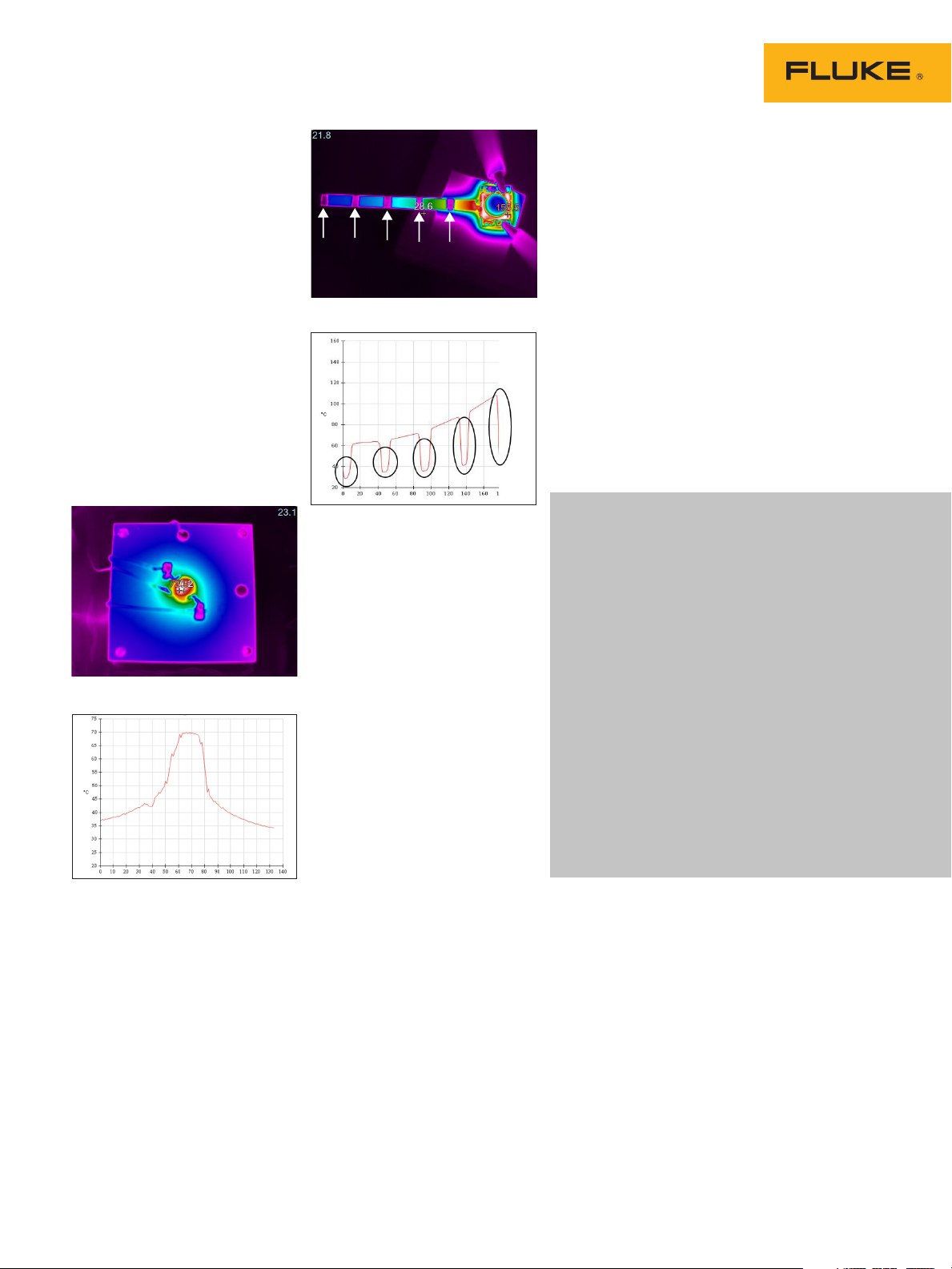

In Figure 3A the LED chip

(circular part) uses a strip-like

heat sink, and Fluke SmartView®

desktop reporting and analysis software is used to perform

linear analysis for the temperature distribution at different

distances as seen in Figure 3B.

In Figure 4A there are metal

bands (purple color on the heat

Metal bands

Figure 4A

What are the advantages of

the infrared camera?

The infrared camera can quickly

test the performance of the radiation fin. The online monitoring

and real-time shooting thermal

map features can be used to

conduct specific temperature

analysis of the fin on a PC. An

infrared camera is a non-contact

form of temperature measurement which decreases the time

it takes to measure the apparent

temperature and is more accurate. The temperature profile of

the heat sink with other related

analysis functions is of major

importance to help optimize the

heat sink design thus prolonging

the LED chip life.

Figure 3A

Figure 3B

Figure 4B

sink) segmented on the striplike heat sink. This is causing

the temperature of these segments to be low due to the low

emissivity. This is seen on the

graph (Figure 4B) where the

temperature drops down, highlighted by the black circles.

What are the disadvantages

of using the thermocouple

for testing?

The thermocouple has a few

limitations. The first disadvantage of using a thermocouple is

that it must make contact with

the surface to take a measurement. To be able to make

contact there must be a surface

placed over the heat sink using

glue which can alter the temperature reading. In addition

when using a thermocouple you

can only take a point measurement. This means that only a

singular point of the heat sink

is tested which does not provide an accurate reading for the

whole heat sink.

When you are performing tests

make sure to keep accuracy as

a priority. Here are three things

to keep in mind for better LED

inspections.

1. The metal material emissivity of

some heat sinks leads to a low temperature reading. To avoid incorrect

measurements, apply silicone grease

or paint to the radiation fin.

2. Given the different sizes of various

LED heat sinks, an add-on macro

lens can help provide more detailed

and accurate readings.

3. When using the camera for LED

inspections look down upon the

items being inspected and not from

an angle.

2 Fluke Corporation LED Chip Heat Dissipation Detection

Page 3

See what you’re missing

Whether you’re designing the next mobile

device, scaling down passenger vehicles,

or developing a new stronger, lighter polymer,

make sure you have the best thermal data you

can get. For accurate and efficient R&D infrared

testing, we recommend the Fluke RSE series—

RSE300 and RSE600 Infrared Cameras. With

down to 40mK thermal sensitivity, and up to

640 x 480 resolution, these mounted cameras

stream data to your PC for R&D and quality

assurance analysis.

To find out more about how these versatile,

high resolution, high accuracy cameras

can help you develop better products faster,

consult your Fluke sales representative or

visit www.fluke.com/infrared for more

information.

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more in formation ca ll:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Afr ica +31 (0)40 267 5100 or

Fax +31 (0)40 267 5222

In Canada (800)-36-FLU KE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2018 Fluke Cor porat ion. A ll trademarks are t he

proper ty of their respective ow ners. Data subject to

change without notice. 3/ 2018 6010 58 2a-e n

Modi ficat ion of th is doc ument is not per mitte d

without wri tten pe rmis sion from Fluk e Corpo ration .

®

3 Fluke Corporation LED Chip Heat Dissipation Detection

Loading...

Loading...