RPM3™

Reference Pressure Monitor

Operation and Maintenance Manual

© 1998-2002 DH Instruments, Inc.

High pressure liquids and gases are potentially hazardous. Energy stored in these liquids and gases

can be released unexpectedly and with extreme force. High pressure systems should be assembled

and operated only by personnel who have been instructed in proper safety practices.

© 1998-2002 DH Instruments, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments, Inc.

4765 East Beautiful Lane Phoenix AZ 85044-5318 USA.

DH Instruments makes sincere efforts to ensure accuracy and quality of its’ published materials; however, no warranty, expressed

or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or indirect damages resulting from the

use of the information in this manual or products described in it. Mention of any product or brand does not constitute an

endorsement by DH Instruments of that product or brand. This manual was originally composed in English and was subsequently

translated into other languages. The fidelity of the translation cannot be guaranteed. In case of conflict between the English version

and other language versions, the English version predominates.

Products described in this manual are manufactured under international patents and one or more of the following U.S. patents:

5,142,483, 5,257,640, 5,331,838, 5,445,035. Other U.S. and international patents pending.

DH Instruments, DH, DHI, AutoZ, COMPASS, CalTool, PPC, PPC2+, RPM3 and SDS (Self Defense System) are trademarks,

registered and otherwise, of DH Instruments, Inc.

LabVIEW is a registered trademark of National Instruments Corporation.

Document No. 550094f-01

020909

Printed in the USA.

© 1998-2002 DH Instruments, Inc.

TABLE OF CONTENTS

T

AABBLLEE

T

O

O

FF

C

OONNTTEENNTTS

C

S

TABLE OF CONTENTS ...............................................................I

TABLES .................................................................................IV

FIGURES.................................................................................V

ABOUT THIS MANUAL .............................................................VI

1. INTRODUCTION .................................................................1

1.1 PRODUCT OVERVIEW ...........................................................................................................................1

1.2 SPECIFICATIONS ...................................................................................................................................1

1.2.1 GENERAL SPECIFICATIONS.......................................................................................................................1

1.2.2 PRESSURE MEASUREMENT SPECIFICATIONS........................................................................................2

1.2.2.1 STANDARD REFERENCE PRESSURE TRANSDUCER (RPT) ...............................................................3

1.2.2.2 B TYPE REFERENCE PRESSURE TRANSDUCER (RPT) ......................................................................4

1.2.2.3 ON-BOARD BAROMETER ........................................................................................................................4

1.2.3 CONFIGURATIONS.......................................................................................................................................5

1.2.3.1 ONE OR TWO RPTS: GROUP 1 (< A1500) .............................................................................................6

1.2.3.2 TWO RPTS: ONE GROUP 1 (> A1500) AND ONE GROUP 2 (> A1500 AND < A10000) OR ONE

1.2.3.3 TWO RPTS: BOTH GROUP 2 (> A1500 AND < A10000) OR LIQUID FILLED GROUP 1.......................8

1.2.3.4 ONE RPT: GROUP 2 (> A1500 AND > A10000) OR GROUP 3 (> A10000) OR LIQUID FILLED

LIQUID FILLED GROUP 1 .........................................................................................................................

GROUP 1 ...................................................................................................................................................

7

9

2. INSTALLATION ................................................................ 11

2.1 UNPACKING AND INSPECTION ..........................................................................................................11

2.1.1 REMOVING FROM PACKAGING................................................................................................................11

2.1.2 INSPECTING CONTENTS...........................................................................................................................11

2.2 SITE REQUIREMENTS..........................................................................................................................11

2.3 INITIAL SETUP......................................................................................................................................12

2.3.1 PREPARING FOR OPERATION .................................................................................................................12

2.3.2 FRONT AND REAR PANELS ......................................................................................................................12

2.3.2.1 FRONT PANEL ........................................................................................................................................12

2.3.2.2 REAR PANEL...........................................................................................................................................13

2.3.3 POWER CONNECTION...............................................................................................................................13

2.3.4 TEST PORT CONNECTING ........................................................................................................................13

2.3.4.1 THE ATM AND VENT PORTS .................................................................................................................14

2.4 POWER UP AND VERIFICATION .........................................................................................................15

2.4.1 APPLY POWER...........................................................................................................................................15

2.4.2 CHECK PROPER PRESSURE MEASUREMENT OPERATION ................................................................15

2.4.2.1 CHECKING ABSOLUTE MODE PRESSURE MEASUREMENT.............................................................15

2.4.2.2 CHECKING GAUGE MODE PRESSURE MEASUREMENT...................................................................16

2.5 SHORT TERM STORAGE .....................................................................................................................16

3. OPERATION..................................................................... 17

3.1 GENERAL/MANUAL OPERATION .......................................................................................................17

3.1.1 MAIN RUN SCREEN....................................................................................................................................17

3.1.2 GENERAL OPERATING PRINCIPLES .......................................................................................................18

3.1.2.1 KEYPAD LAYOUT AND PROTOCOL......................................................................................................18

3.1.2.2 SOUNDS ..................................................................................................................................................18

3.1.2.3 SOFT [ON/OFF] KEY ...............................................................................................................................19

3.1.2.4 PRESSURE READY <*>/NOT READY (<↑> OR <↓>)...........................................................................19

3.1.2.5 MULTIPLE PRESSURE RANGES...........................................................................................................19

3.1.2.6 SDS SELF DEFENSE SYSTEM ..............................................................................................................20

Page I © 1998-2002 DH Instruments, Inc.

RPM3™ OPERATION AND MAINTENANCE MANUAL

3.1.2.7 DIRECT FUNCTION KEYS SUMMARY...................................................................................................21

3.2 3.2 DIRECT FUNCTION KEYS ..............................................................................................................22

3.2.1 3.2.1 [RANGE] .............................................................................................................................................22

3.2.2 [UNIT]...........................................................................................................................................................24

3.2.3 [MODE] ........................................................................................................................................................25

3.2.4 [UL] (UPPER LIMIT) ....................................................................................................................................26

3.2.4.1 OVER-PRESSURE FUNCTION (PMAX!) ................................................................................................27

3.2.5 [RES] (RESOLUTION).................................................................................................................................28

3.2.6 [DISPLAY]....................................................................................................................................................29

3.2.6.1 AVG (AVERAGE) .....................................................................................................................................30

3.2.6.2 RATE........................................................................................................................................................31

3.2.6.3 DEV (DEVIATION) ...................................................................................................................................32

3.2.6.4 RPT ..........................................................................................................................................................33

3.2.6.5 HI/LO ........................................................................................................................................................34

3.2.6.6 FREEZE ...................................................................................................................................................35

3.2.6.7 CLEAN .....................................................................................................................................................35

3.2.7 [HEAD].........................................................................................................................................................36

3.2.8 [SDS] (SELF DEFENSE SYSTEM) .............................................................................................................37

3.2.9 [AUTOZ].......................................................................................................................................................40

3.2.9.1 RUNNING AUTOZ IN GAUGE MEASUREMENT MODE ........................................................................40

3.2.9.2 RUNNING AUTOZ IN ABSOLUTE MEASUREMENT MODE..................................................................41

3.3 [SETUP] MENU KEY .............................................................................................................................45

3.3.1 HEAD ...........................................................................................................................................................45

3.3.2 PRESU .........................................................................................................................................................46

3.3.3 READRT (READ RATE)...............................................................................................................................47

3.3.4 STAB (STABILITY)......................................................................................................................................48

3.3.5 LEAK (LEAK CHECK).................................................................................................................................48

3.4 [SPECIAL] MENU KEY..........................................................................................................................50

3.4.1 AUTOZ .........................................................................................................................................................51

3.4.1.1 AUTOZ ON/OFF.......................................................................................................................................53

3.4.1.2 VIEW AUTOZ ...........................................................................................................................................54

3.4.1.3 EDIT AUTOZ ............................................................................................................................................54

3.4.2 SDS ..............................................................................................................................................................55

3.4.3 ATM..............................................................................................................................................................56

3.4.4 REMOTE ......................................................................................................................................................56

3.4.5 RESET..........................................................................................................................................................57

3.4.5.1 RESET - SETS.........................................................................................................................................58

3.4.5.2 RESET - UNITS........................................................................................................................................58

3.4.5.3 RESET - COM..........................................................................................................................................58

3.4.5.4 RESET - CAL ...........................................................................................................................................59

3.4.5.5 RESET - ALL............................................................................................................................................59

3.4.6 CAL ..............................................................................................................................................................59

3.4.7 INTERN ........................................................................................................................................................59

3.4.7.1 SCRSAV...................................................................................................................................................60

3.4.7.2 SOUND.....................................................................................................................................................60

3.4.7.3 TIME.........................................................................................................................................................60

3.4.7.4 ID..............................................................................................................................................................61

3.4.8 LEVEL..........................................................................................................................................................62

3.4.9 LOG..............................................................................................................................................................64

4. REMOTE OPERATION ....................................................... 65

4.1 OVERVIEW ............................................................................................................................................65

4.2 INTERFACING.......................................................................................................................................65

4.2.1 4.2.1 RS-232 INTERFACE...........................................................................................................................65

4.2.1.1 4.2.1.1 COM1 ...........................................................................................................................................65

4.2.1.2 COM2 .......................................................................................................................................................66

4.2.2 IEEE-488 (GPIB)..........................................................................................................................................66

4.3 REMOTE COMMAND SYNTAX AND STYLE .......................................................................................66

4.3.1 LOCAL AND REMOTE SETTING................................................................................................................66

4.3.2 COMMAND SYNTAX...................................................................................................................................66

4.3.3 QUERIES AND REPLIES ............................................................................................................................67

4.3.4 MULTIPLE COMMANDS .............................................................................................................................67

4.3.5 COMMAND PARAMETERS.........................................................................................................................67

4.3.6 SUFFIXES....................................................................................................................................................68

4.3.7 PROGRAMMING TIPS.................................................................................................................................68

4.3.7.1 SCPI AND IEEE-488.2 .............................................................................................................................68

4.3.7.2 PROGRAM TECHNIQUE.........................................................................................................................68

4.4 COMMANDS ..........................................................................................................................................72

4.4.1 ERROR MESSAGES 75

© 1998-2002 DH Instruments, Inc. Page II

TABLE OF CONTENTS

4.4.2 COMMAND DESCRIPTIONS.......................................................................................................................76

4.4.2.1 IEEE STD. 488.2 COMMON AND STATUS COMMANDS ......................................................................76

4.4.2.2 MEASUREMENT SUBSYSTEM ..............................................................................................................78

4.4.2.3 CALCULATE SUBSYSTEM .....................................................................................................................81

4.4.2.4 CALIBRATION SUBSYSTEM ..................................................................................................................82

4.4.2.5 DISPLAY SUBSYSTEM ...........................................................................................................................84

4.4.2.6 SENSE SUBSYSTEM..............................................................................................................................84

4.4.2.7 STATUS SUBSYSTEM ............................................................................................................................86

4.4.2.8 SYSTEM SUBSYSTEM............................................................................................................................90

4.4.2.9 UNIT SUBSYSTEM..................................................................................................................................94

4.5 STATUS SYSTEM .................................................................................................................................96

4.5.1 STATUS REPORTING SYSTEM .................................................................................................................96

4.5.1.1 SCPI STATUS SUBSYSTEM...................................................................................................................96

4.5.1.2 ERROR QUEUE.......................................................................................................................................96

4.5.1.3 STATUS BYTE REGISTER......................................................................................................................97

4.5.1.4 STANDARD EVENT REGISTER .............................................................................................................98

4.5.1.5 RPT READY STATUS REGISTER ..........................................................................................................99

4.5.2 STATUS SUBSYSTEM..............................................................................................................................100

4.5.2.1 OPERATION REGISTER STRUCTURE................................................................................................100

4.5.2.2 QUESTIONABLE REGISTER STRUCTURE.........................................................................................103

5. MAINTENACE, ADJUSTMENTS AND CALIBRATION .............107

5.1 INTRODUCTION ..................................................................................................................................107

5.2 CALIBRATION OF REFERENCE PRESSURE TRANSDUCERS.......................................................107

5.2.1 PRINCIPLE ................................................................................................................................................107

5.2.1.1 PA/PM COEFFICIENTS.........................................................................................................................108

5.2.1.2 SETTING ZNATERR..............................................................................................................................108

5.2.1.3 ORDER OF OPERATIONS....................................................................................................................109

5.2.2 EQUIPMENT REQUIRED ..........................................................................................................................109

5.2.3 SET-UP AND PREPARATION...................................................................................................................110

5.2.4 RPT CALIBRATION USING CALTOOL FOR RPTS SOFTWARE............................................................111

5.2.5 EDITING AND VIEWING RPT CALIBRATION INFORMATION................................................................ 111

5.2.6 SETTING ZNATERR..................................................................................................................................112

5.2.7 RPT CALIBRATION/ADJUSTMENT WITHOUT CALTOOL FOR RPTS SOFTWARE.............................113

5.3 ADJUSTMENT OF ON-BOARD BAROMETER...................................................................................114

5.4 OVERHAUL .........................................................................................................................................114

5.5 RELOADING EMBEDDED SOFTWARE INTO FLASH MEMORY......................................................115

5.6 SUBASSEMBLY DESCRIPTION AND LOCATION ............................................................................116

5.6.1 INTERNAL VIEW .......................................................................................................................................116

5.6.1.1 SDS MODULE........................................................................................................................................116

5.6.1.2 RPTS......................................................................................................................................................117

5.6.1.3 POWER SUPPLY...................................................................................................................................117

5.6.1.4 COOLING FAN.......................................................................................................................................117

5.6.1.5 MICRO BOARD......................................................................................................................................117

5.6.1.6 MAIN BOARD.........................................................................................................................................117

5.6.1.7 ON-BOARD BAROMETER ....................................................................................................................117

5.6.1.8 DISPLAY ................................................................................................................................................117

6. TROUBLESHOOTING .......................................................119

6.1 OVERVIEW ..........................................................................................................................................119

7. APPENDIX ......................................................................123

7.1 PRESSURE UNIT CONVERSIONS .....................................................................................................123

7.2 WARRANTY STATEMENT.................................................................................................................. 124

8. GLOSSARY.....................................................................125

Page III © 1998-2002 DH Instruments, Inc.

RPM3™ OPERATION AND MAINTENANCE MANUAL

T

AABBLLEES

T

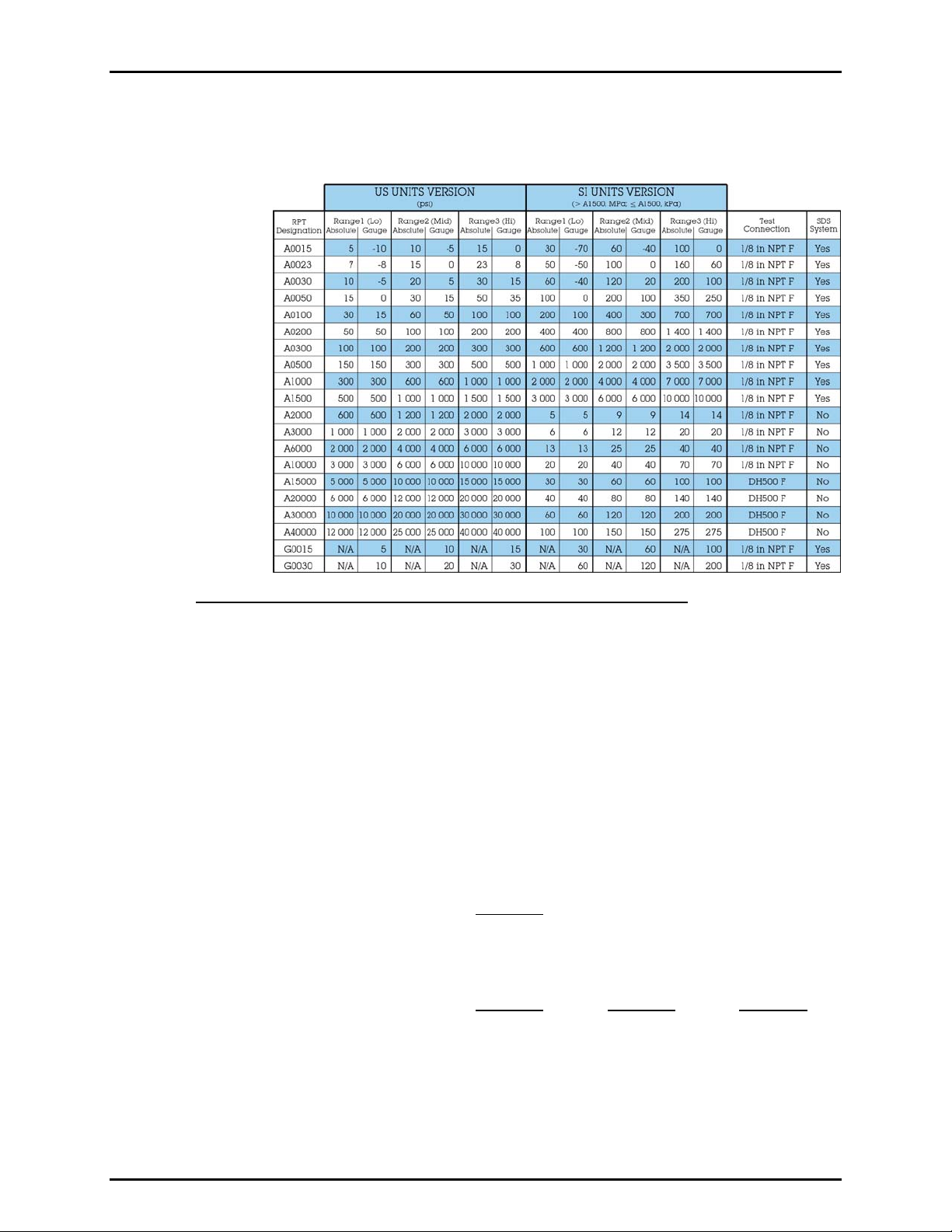

Table 1 Standard RPT Designations and Ranges....................................................................................... 3

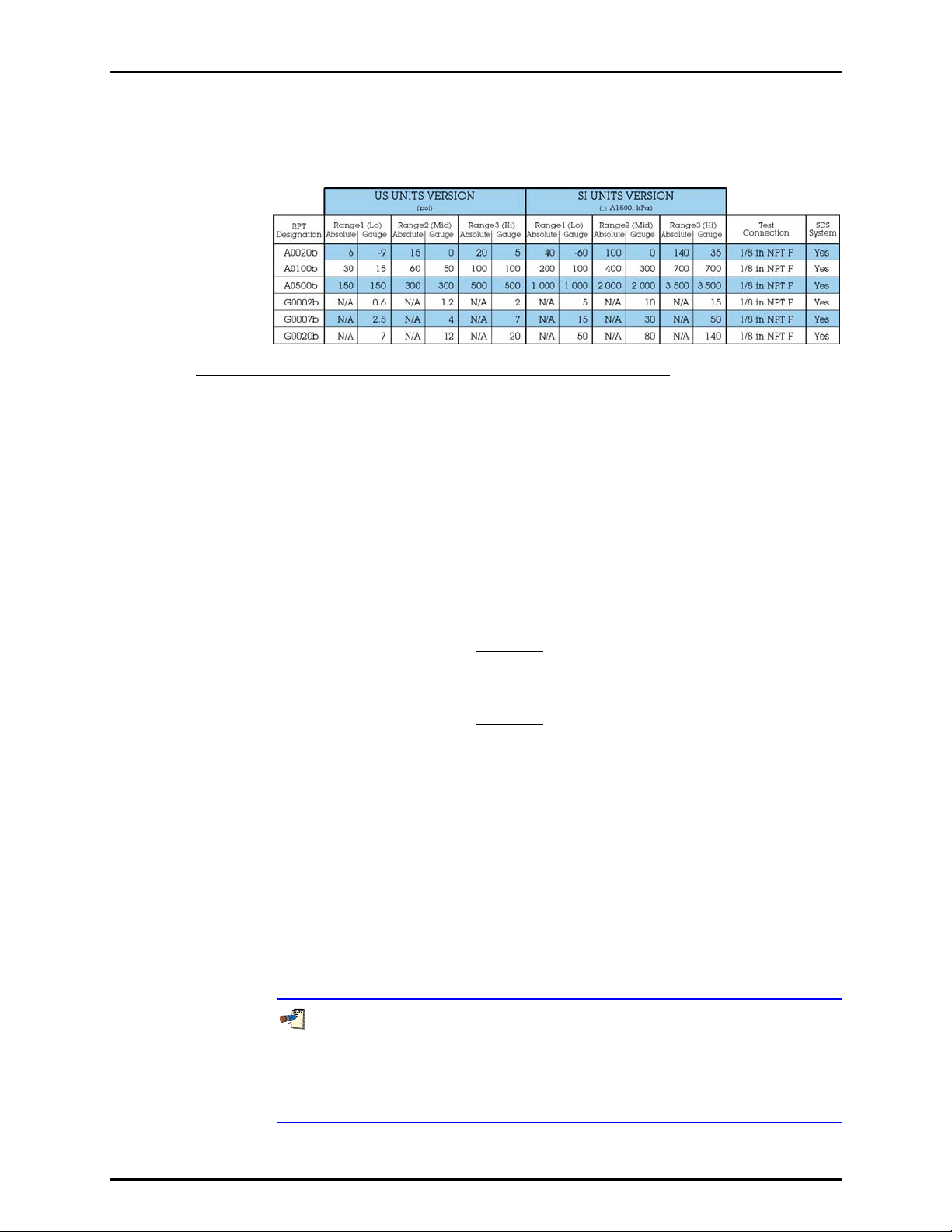

Table 2 b Type RPT Designations and Ranges ..........................................................................................4

Table 3 RPM3 Configurations...................................................................................................................... 5

Table 4 One or Two RPTs: Group 1 (> A1500) Specifications................................................................... 6

Table 5 Two RPTs: One Group 1 (> A1500) and One Group 2 (> A1500 and < A10000)

Table 6 Two RPTs: Both Group 2 (> A1500 and < A10000) or Liquid Filled Group 1 Specifications........ 8

Table 7 One RPT: Group 2 (> A1500 and < A10000) or Group 3 (> A10000) or

Table 8 RPM3 Parts List ............................................................................................................................ 11

Table 9. RPM3 Range Identification Summary.......................................................................................... 20

Table 10 Summary of RPM3 Direct Function Key Operation .................................................................... 22

Table 11 PresU - Available Units ............................................................................................................... 46

Table 12 READRT - Display Update Rates ............................................................................................... 47

Table 13. Functions - Security Levels........................................................................................................63

Table 14 RPM3 COM1 DB-9F Pin Designations ....................................................................................... 65

Table 15 IBM PC/XT DB-9F, DB-9M Connections ....................................................................................65

Table 16 RPM3 COM2 DB-9M Pin Designations ......................................................................................66

Table 17 Quick Tips ...................................................................................................................................71

Table 18 Command Summary ................................................................................................................... 72

Table 19 “SYSTEM:ERROR?” QUERY REPLY ........................................................................................ 75

Table 20 8 Bit Status Byte Register ........................................................................................................... 97

Table 21 Standard Event Register.............................................................................................................98

Table 22 8 Bit RPT Ready Status Register ............................................................................................... 99

Table 23. RPM3 Troubleshooting Symptom / Probable Cause / Solution List ........................................ 119

Table 24 Pa Conversions......................................................................................................................... 123

Table 25. DHI Authorized Service Providers ........................................................................................... 124

S

or One Liquid Filled Group 1 Specifications..............................................................................

Liquid Filled Group 1 Specifications ..........................................................................................

7

9

© 1998-2002 DH Instruments, Inc. Page IV

FIGURES & TABLES

F

IIGGUURREES

F

Figure 1 Rear Panel (Left) One or Two Group 1 RPTs (Right) One or Two Group 1 RPTs with

Figure 2 Schematic (Left) Two Group 1 RPTs (Right) One Group 1 RPT .................................................. 6

Figure 3 Rear Panel (Left) One Group 1 RPT and One Group 2 RPT (Right) One Group 1

Figure 4 Schematic One Group 1 RPT and One Group 2 RPT................................................................... 7

Figure 5 Two Group 2 RPTs (Left) Rear Panel / (Right) Schematic .......................................................... 8

Figure 6 Rear Panel (Left) One Group 2 RPT (Right) One Group 3 RPT ................................................... 9

Figure 7 Schematic (Left) One Group 2 RPT (Right) One Group 3 RPT .................................................... 9

Figure 8. Front Panel .................................................................................................................................12

Figure 9. Test Ports.................................................................................................................................... 13

Figure 10 Keypad.......................................................................................................................................18

Figure 11 SDS Schematic.......................................................................................................................... 21

Figure 12 Status Byte Register .................................................................................................................. 97

Figure 13 Illustration of this Structure Duplicated for Each of the OPERation, INSTrument,

Figure 14 Relationship of the OPERation Register and Its Support Registers .......................................102

Figure 15 Illustration of this Structure Duplicated for Each of the OPERation, INSTrument,

Figure 16 Relationship of the QUEStionable Registers and Its Support Registers................................. 105

Figure 17 RPM3 Internal View ................................................................................................................. 116

S

a GXXXX RPT ...........................................................................................................................

GXXXX RPT and One Group 2 RPT.........................................................................................

and ISUMmary Registers ......................................................................................................

and ISUMmary Registers ......................................................................................................

101

104

6

7

Page V © 1998-2002 DH Instruments, Inc.

RPM3™ OPERATION AND MAINTENANCE MANUAL

A

BBOOUUTT

A

This manual provides the user with the basic information necessary to operate an RPM3, Reference

Pressure Monitor. It also includes a great deal of additional information provided to help you optimize

RPM3 use and take full advantage of its many features and functions.

Before using the manual, take a moment to familiarize yourself with the Table of Contents structure. All first

time RPM3 users should read Sections 1, 2 and 3. Section 3 provides a comprehensive description of

general RPM3 operating principles. Section 4 is for remote operation from an external computer.

Section 5 provides maintenance and calibration information. Section 6 is a quick troubleshooting guide.

Use it to troubleshoot unexpected RPM3 behavior based on the symptoms of that behavior.

Certain words and expressions have specific meaning as they pertain to RPM3. The Glossary is useful

as a quick reference for exact definition of specific words and expressions as they are used in this

manual.

FOR THOSE OF YOU WHO “DON’T READ MANUALS”, GO DIRECTLY TO SECTION 2.3 TO SET UP YOUR

RPM3 AND THEN SECTION 2.4 FOR POWER UP AND VERIFICATION. THIS WILL GET YOU RUNNING

QUICKLY WITH MINIMAL RISK OF CAUSING DAMAGE TO YOURSELF OR YOUR NEW RPM3. THEN…

WHEN YOU HAVE QUESTIONS OR START TO WONDER ABOUT ALL THE GREAT FEATURES YOU MIGHT

BE MISSING, GET INTO THE MANUAL!

T

T

HHIISS

M

AANNUUAAL

M

L

Manual Conventions

(CAUTION) is used in throughout the manual to identify user warnings and cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and

additional explanations.

[ ] indicates direct function keys (e.g., [RANGE]).

< > indicates PG7000 screen displays (e.g., <1yes>).

© 1998-2002 DH Instruments, Inc. Page VI

1. INTRODUCTION

11..

I

NNTTRROODDUUCCTTIIOON

I

N

1.1 PRODUCT OVERVIEW

RPM3 is a stand-alone, microprocessor driven, reference pressure monitor intended to accurately

measure gas or liquid pressure in a wide variety of pressure calibration, measurement and testing

applications. It has been designed to provide very high performance and extensive features combined

with maximum versatility and ease of use.

RPM3 uses one or two high accuracy reference pressure transducers (RPTs) and an on-board barometer

to measure pressure. Various internal configurations exist depending on the RPT ranges.

RPM3 can be controlled locally by the operator using its front panel display and keypad or remotely by a

computer using ASCII character command strings over its RS-232 and IEEE-488 interfaces.

RPM3 models are available to measure pressure in ranges from 0.6 psi (4 kPa) to 40 000 psi (275 MPa)

in gauge, compound and absolute measurement modes.

1.2 SPECIFICATIONS

1.2.1 GENERAL SPECIFICATIONS

Specifications below are specific to PG7307. All other specifications are identical to PG7000

specifications found in the PG7000 Operation and Maintenance Manual (P/N 550099).

Power Requirements

Operating Temperature Range

Storage Temperature Range

Vibration

Weight

Dimensions

Microprocessors

Communication Ports

Overall Pressure Ranges

Operating Media

85 to 264 VAC, 47 to 440 Hz, 18 VA max. consumption

15 to 35 °C

-20 to 70 °C

Meets MIL-T-28800D

3.5 kg (7.7 lb) max depending on RPT configuration

8 cm H x 22.5 cm W x 20 cm D (3.1 in. x 8.9 in. x 7.9 in.) approx.

Motorola 68302

RS-232 (COM1), RS-232 (COM2), IEEE-488

Up to six pressure ranges from 0 to 0.6 psi (4 kPa) to 0 to 40 000 psi

(275 MPa), absolute, gauge and negative gauge, using one or two

reference pressure transducers and a barometer

Any non-corrosive gas or liquid (liquid available only on A0100 or

higher RPTs). RPTs < 10 000 psi (70 MPa) delivered set up for gas

operation, RPTs >

10 000 psi delivered oil filled.

Page 1 © 1998-2002 DH Instruments, Inc.

RPM3™ OPERATION AND MAINTENANCE MANUAL

Pressure Connections

Pressure Limits

Self Defense System (SDS™)

CE Conformance

Test port (RPT ≤ 10 000 psi): 1/8 in. NPT F

Test port (RPT > 10 000 psi): DH500 (gland and collar type for

coned and left hand threaded

tube, equivalent to AE F250C,

HIP HF4, etc.)

Test (-): 1/8 in. NPT F (with gauge RPT

only)

ATM Ref (On-board barometer): 10-32 UNF

Vent (with SDS only): 10-32 UNF

Maximum working pressure: Range 3 of active RPT+ 4 %

Maximum pressure w/o damage: Standard RPT: 125 % of H3

b Type RPT: 150 % of H3

Maximum pressure applied to

SDS protected TEST port

when SDS is active: 2 000 psi (13 MPa)

Included on all gas operated RPTs of 1 500 psi (10 MPa) or lower.

Isolates RPT from TEST port and vents it to atmosphere when NOT

in use. SDS is NOT included with liquid filled RPTs.

Maximum SDS isolation pressure: 2 000 psi (13 MPa)

Available. Must be specified.

1.2.2 PRESSURE MEASUREMENT SPECIFICATIONS

RPM3 can be configured with one or two reference pressure transducers (RPT). Each

transducer has three ranges (see Section 3.1.2.5). The type and designation of the RPM3’s

RPTs determine its measurement specifications and configuration (see Sections 1.2.2 and

1.2.3). Two types of RPTs are available. Standard RPTs are for the highest measurement

specifications and b Type RPTs for lower measurement performance requirements.

All reference pressure transducers (RPTs) with designation greater than G0030 (200 kPa)

are of the absolute pressure type with an evacuated, permanently sealed reference. Absolute

RPTs can measure both absolute and gauge pressure. Gauge pressures with an absolute

RPT are defined by offsetting atmospheric pressure dynamically with compensation for

atmospheric changes by the on-board barometer. Gauge RPTs cannot measure absolute

pressure.

© 1998-2002 DH Instruments, Inc. Page 2

1. INTRODUCTION

1.2.2.1 STANDARD REFERENCE PRESSURE TRANSDUCER (RPT)

Table 1 Standard RPT Designations and Ranges

Standard RPT Measurement Specifications (% FS of Active Range)

Transducer Type

Warm Up Time

Resolution

Overpressure Limits

Without effect on calibration

Without permanent damage

Temperature Effect

Oscillating quartz resonator

≤ 1 500 psi 15 minutes

To 1 ppm, user settable by individual range

115 % of Range 3

125 % of Range 3

Fully compensated with active independent temperature

measurement from -20 to 100 °C

± 0.005 % maximum temperature effect in normal ambient operating

range of 15 to 35 °C

Attitude Affect

Precision

1

± 0.008 % /g maximum, worst axis

≤ 1 500 psi 0.005 %, > 10 500 and ≤ 20 000 psi 0.010 %,

> 20 000 psi 0.015 %

Predicted Stability

Absolute Mode (w/out Autozero)

Measurement Accuracy

Absolute Mode (w/out Autozero)

1

Precision: Combined linearity, hysteresis, repeatability of measurements made by the reference pressure transducer. When using an absolute RPT

2

Stability: Maximum change in zero and span over specified time period for typical transducer used under typical conditions. As stability can only be

3

Accuracy: Maximum deviation of the reference pressure transducer indication from the TRUE value of the applied pressure including precision,

for gauge mode measurement add ± 2.5 Pa (0.00035 psi) to the precision specification to take into account the resolution and short term

stability of the on-board barometer used for dynamic atmospheric pressure compensation.

predicted and varies from transducer to transducer, stability for a specific RPT should be established from experience.

stability, temperature effect and calibration standard accuracy of ± 0.0035 % of reading.

2

Gauge Mode (w/Autozero)

Absolute Mode (w/Autozero)

3

Gauge Mode (w/Autozero)

Absolute Mode (w/Autozero)

All Ranges

90 day / 1 yr

0.003 % / 0.009 %

0.003 % / 0.009 %

0.006 % / 0.0015 %

≤ 1 500 psi

90 day / 1 yr

0.008 / 0.012 %

0.008 / 0.012 %

0.010 / 0.017 %

> 1 500 ≤ 20 000 psi

90 day / 1 yr

0.012 / 0.015 %

0.012 / 0.015 %

0.012 / 0.020 %

> 20 000 psi

90 day / 1 yr

0.020 / 0.022 %

0.020 / 0.022 %

0.022 / 0.025 %

Page 3 © 1998-2002 DH Instruments, Inc.

RPM3™ OPERATION AND MAINTENANCE MANUAL

1.2.2.2 B TYPE REFERENCE PRESSURE TRANSDUCER (RPT)

Table 2 b Type RPT Designations and Ranges

b Type RPT Measurement Specifications (% FS of Active Range)

Transducer Type

Warm Up Time

Resolution

Overpressure Limits

Without effect on calibration

Without permanent damage

Temperature Effect

Micro-machined piezoresistive silicon

None required

10 ppm, user settable by individual range

120 % of Range 3

150 % of Range 3

Fully compensated with active independent temperature

measurement from - 40 to 85 °C

± 0.02 % maximum temperature effect in normal ambient 15 to 35 °C

operating range

Acceleration Affect

Precision

Predicted Stability

1

2

Gauge Mode (w/Autozero)

Absolute Mode (w/Autozero)

Absolute Mode (w/out Autozero)

Measurement Accuracy

3

Gauge Mode (w/Autozero)

Absolute Mode (w/Autozero)

Absolute Mode (w/out Autozero)

1

Precision: Combined linearity, hysteresis, repeatability of measurements made by the reference pressure transducer. When using an absolute RPT

2

Stability: Maximum change in zero and span over specified time period for typical transducer used under typical conditions. As stability can only be

3

Accuracy: Maximum deviation of the reference pressure transducer indication from the TRUE value of the applied pressure including precision,

for gauge mode measurement add ± 2.5 Pa (0.00035 psi) to the precision specification to take into account the resolution and short term

stability of the on-board barometer used for dynamic atmospheric pressure compensation.

predicted and varies from transducer to transducer, stability for a specific RPT should be established from experience.

stability, temperature effect and calibration standard accuracy of ± 0.0035 % of reading.

Insignificant on all axes

0.03 %

90 day / 1 yr

0.02 % / 0.03 %

0.02 % / 0.03 %

0.03 % / 0.05 %

90 day / 1 yr

0.04 % / 0.05 %

0.04 % / 0.05 %

0.05 % / 0.06 %

1.2.2.3 ON-BOARD BAROMETER

Sensor Technology

Warm Up Time

Resolution

The on-board barometer is NOT used as a source of absolute accuracy. It is

used only to measure changes in atmospheric pressure for dynamic

compensation of the atmospheric pressure offset when using an absolute

reference pressure transducer to make gauge pressure measurements (see

Section 3.4.1).

© 1998-2002 DH Instruments, Inc. Page 4

Micro-machined silicon

None required

1.25 Pa (0.00018 psi)

1. INTRODUCTION

1.2.3 CONFIGURATIONS

RPM3 rear panel and internal schematic configurations vary depending on the number (1 or 2)

and pressure ranges of the RPM3’s RPT(s). For configuration purposes, RPTs are divided

into three groups by range designation as in Table 3.

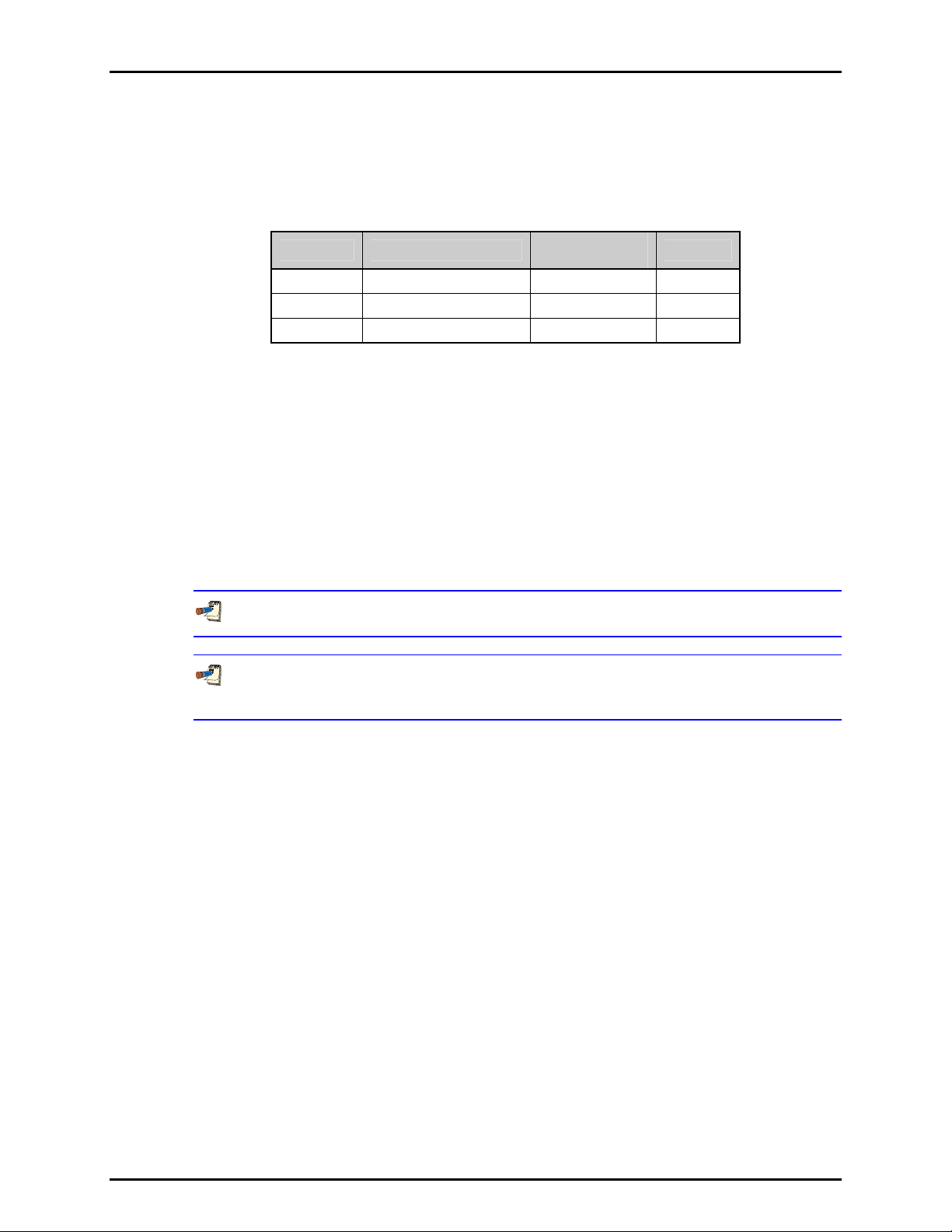

Table 3 RPM3 Configurations

RPT GROUP RPT DESIGNATIONS

1 A1500 or lower 1/8 in. NPT F Yes

2 A2000 to A10000 1/8 in. NPT F No

3 Greater than A10000 DH500 F No

TEST

CONNECTION

SDS

In a single RPT RPM3, the RPT is referred to as the HI RPT.

In a dual RPT RPM3, the higher designation RPT is referred to as the HI RPT and the lower

designation RPT is referred to as the LO RPT.

Identify which RPT or RPTs your RPM3 is equipped with and refer to the corresponding

sections:

• One or two Group 1 (see Section 1.2.3.1)

• One Group 1 and one Group 2 (see Section 1.2.3.2)

• Two Group 2 (see Section 1.2.3.3)

• One Group 2 or one Group 3 (see Section 1.2.3.4)

Liquid filled Group 1 RPTs do NOT have SDS and MUST have their own test port.

The designation of the RPT(s) with which an RPM3 is equipped is given in the label window

just below the front panel display and on the power up introduction screen.

Page 5 © 1998-2002 DH Instruments, Inc.

RPM3™ OPERATION AND MAINTENANCE MANUAL

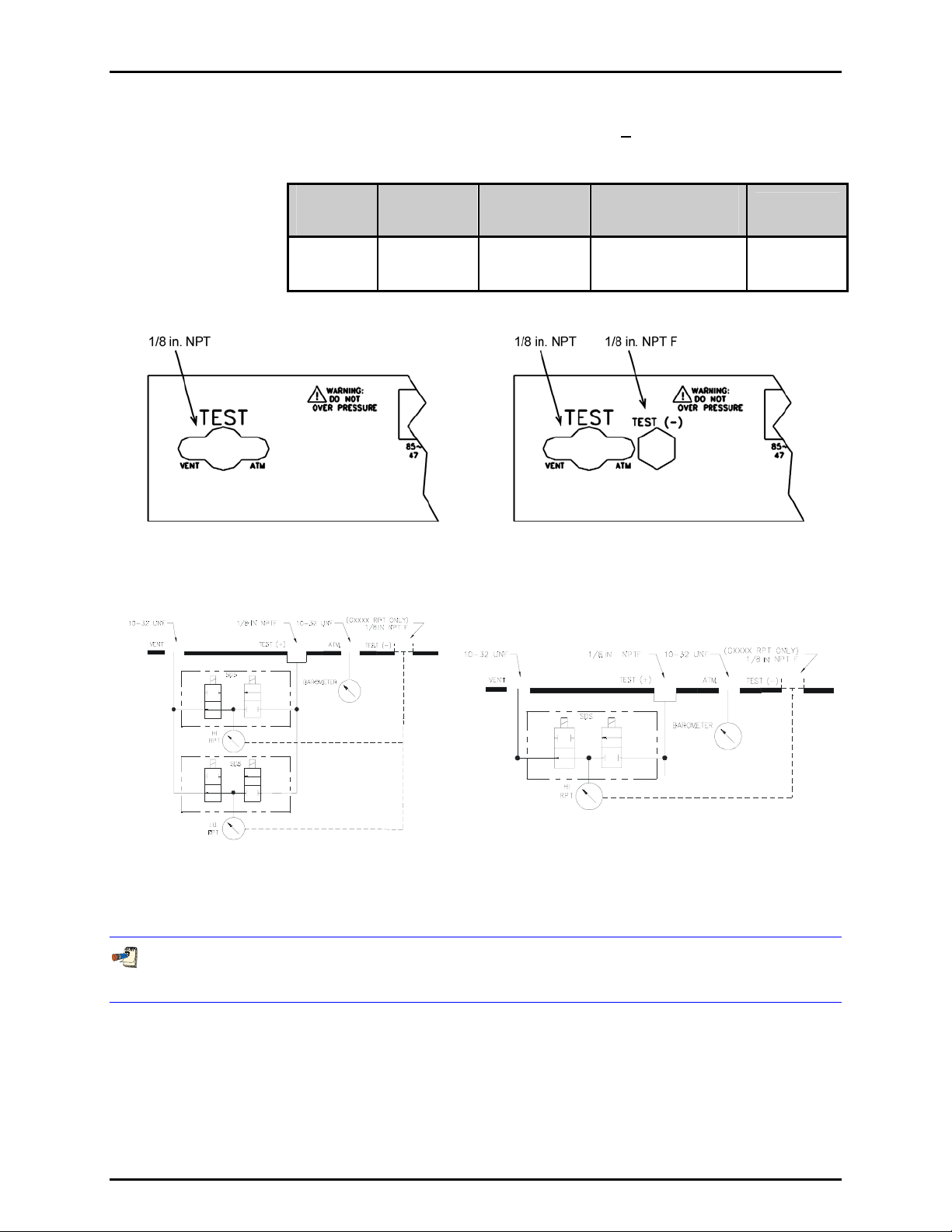

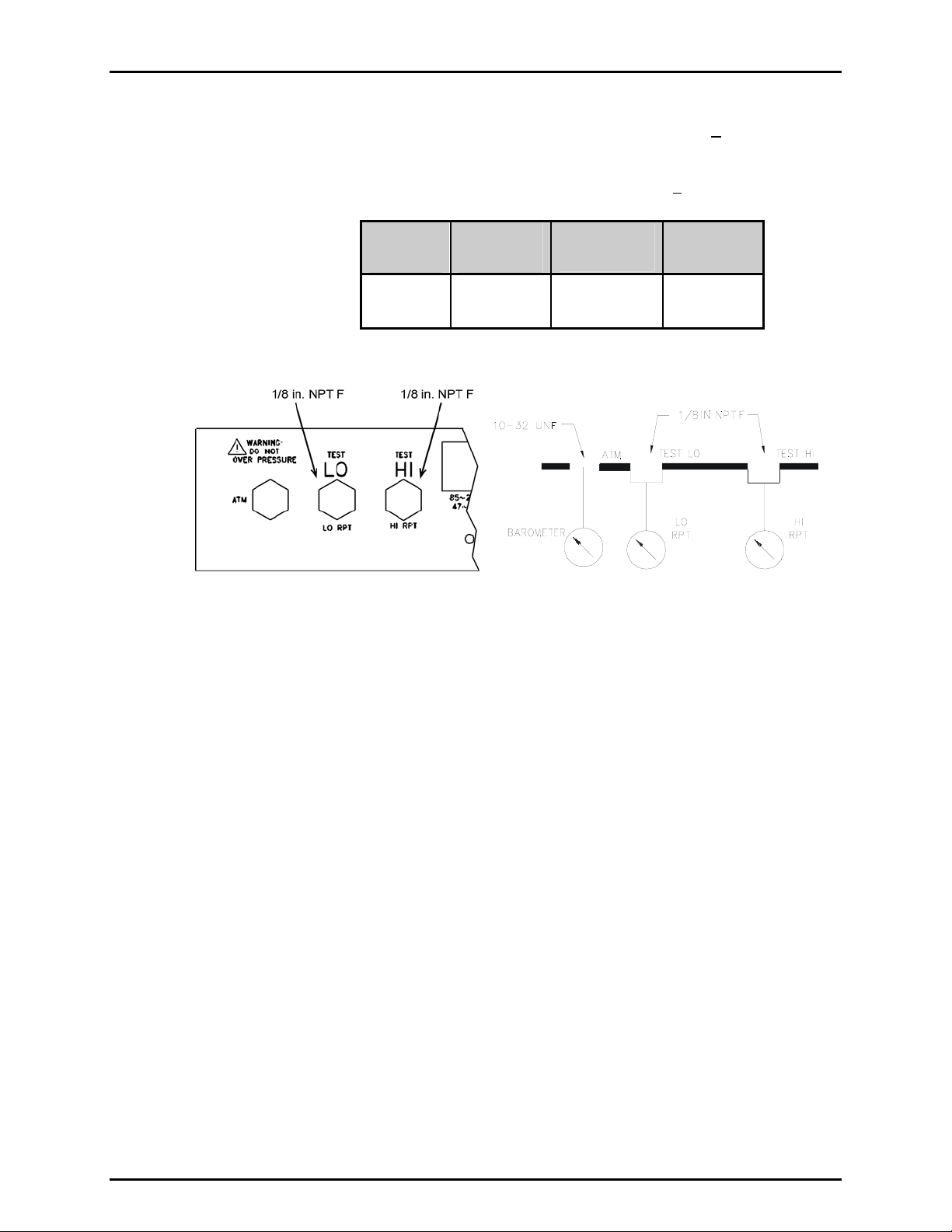

1.2.3.1 ONE OR TWO RPTS: GROUP 1 (< A1500)

Table 4 One or Two RPTs: Group 1 (> A1500) Specifications

NUMBER

OF TEST

PORTS

1 1/8 in. NPT F

HI RPT

TEST PORT

FITTING

LO RPT TEST

PORT FITTING

(IF 2 RPTS)

Uses same

Test Port

as HI RPT

TEST (-) PORT

FITTING

(IF GXXXX RPT PRESENT)

1/8 in. NPT F

SDS

PROTECTION

YES

(On all RPTs)

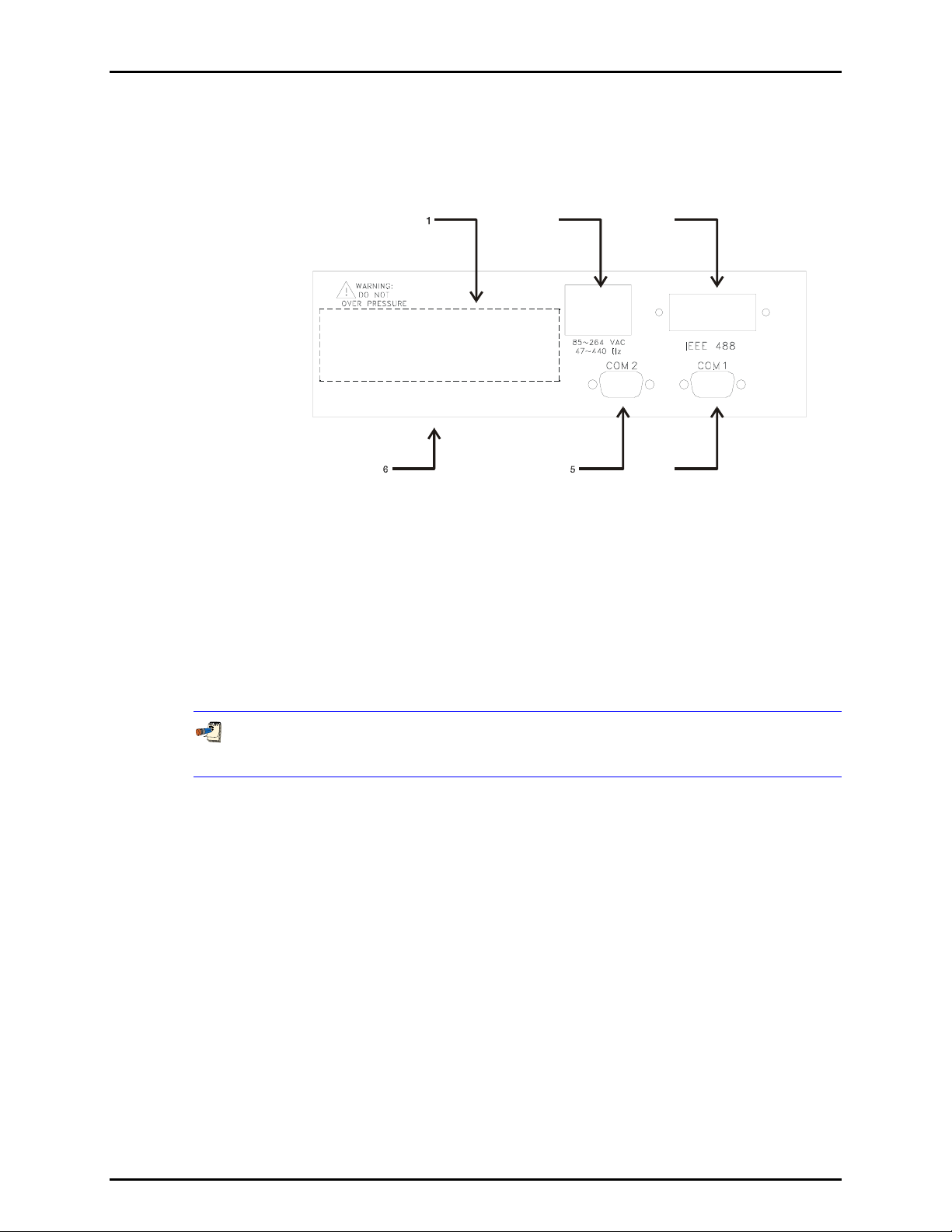

Figure 1 Rear Panel

(Left) One or Two Group 1 RPTs

(Right) One or Two Group 1 RPTs with a GXXXX RPT

Figure 2 Schematic

(Left) Two Group 1 RPTs

(Right) One Group 1 RPT

Group 1 liquid filled RPTs do NOT have SDS and MUST have their own test port. Therefore, liquid filled

Group 1 RPTs are presented in Group 2 format. See Sections 1.2.3.2, 1.2.3.3 and 1.2.3.4.

© 1998-2002 DH Instruments, Inc. Page 6

1. INTRODUCTION

1.2.3.2 TWO RPTS: ONE GROUP 1 (> A1500) AND ONE GROUP 2 (> A1500 AND < A10000) OR ONE LIQUID FILLED GROUP 1

Table 5 Two RPTs: One Group 1 (> A1500) and One Group 2

(> A1500 and <

A10000) or One Liquid Filled Group 1 Specifications

NUMBER

OF TEST

PORTS

2 1/8 in. NPT F 1/8 in. NPT F 1/8 in. NPT F

HI RPT

TEST PORT

FITTING

LO RPT TEST

PORT FITTING

(IF 2 RPTS)

TEST (-) PORT

FITTING

(IF GXXXX RPT PRESENT)

SDS

PROTECTION

YES

(On LO, Group

1 RPTs only)

Figure 3 Rear Panel

(Left) One Group 1 RPT and One Group 2 RPT

(Right) One Group 1 GXXXX RPT and One Group 2 RPT

Figure 4 Schematic

One Group 1 RPT and One Group 2 RPT

Page 7 © 1998-2002 DH Instruments, Inc.

RPM3™ OPERATION AND MAINTENANCE MANUAL

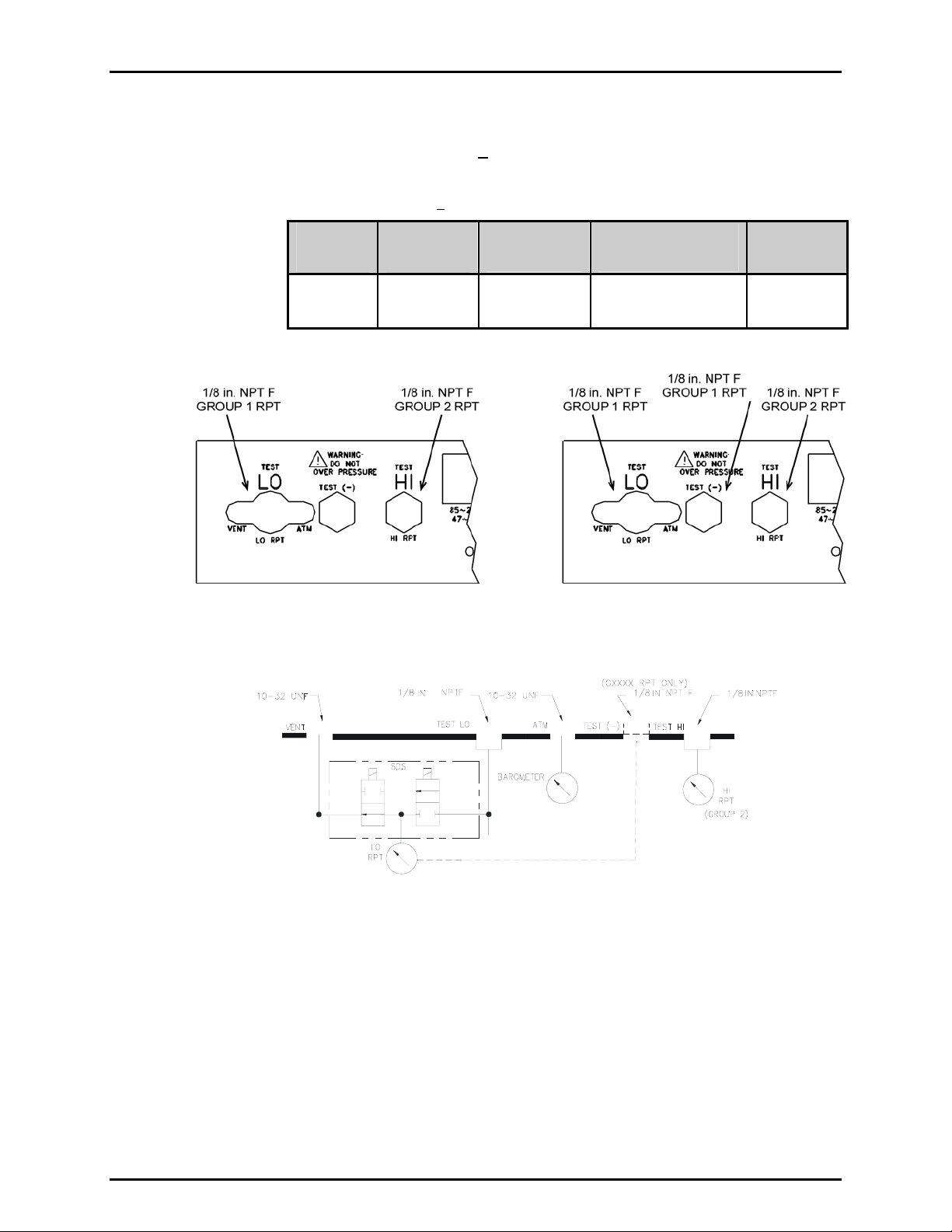

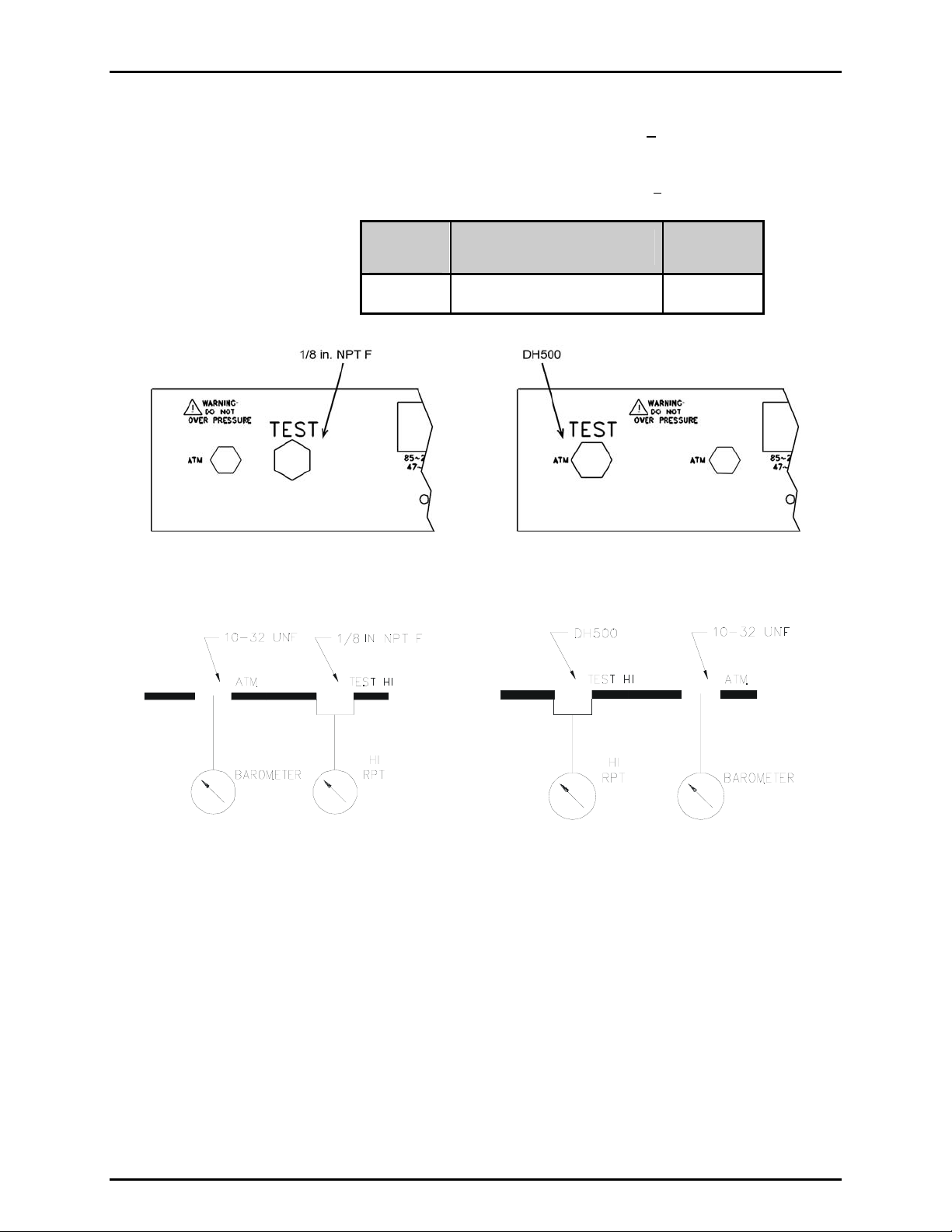

1.2.3.3 TWO RPTS: BOTH GROUP 2 (> A1500 AND < A10000) OR LIQUID FILLED GROUP 1

Table 6 Two RPTs: Both Group 2 (> A1500 and < A10000) or

Liquid Filled Group 1 Specifications

NUMBER

OF TEST

PORTS

2 1/8 in. NPT F 1/8 in. NPT F

HI RPT

TEST PORT

FITTING

LO RPT TEST

PORT FITTING

(IF 2 RPTS)

SDS

PROTECTION

YES

(On LO, Group

1 RPTs only)

Figure 5 Two Group 2 RPTs

(Left) Rear Panel / (Right) Schematic

© 1998-2002 DH Instruments, Inc. Page 8

1. INTRODUCTION

1.2.3.4 ONE RPT: GROUP 2 (> A1500 AND > A10000) OR GROUP 3 (> A10000) OR LIQUID FILLED GROUP 1

Table 7 One RPT: Group 2 (> A1500 and < A10000) or

Group 3 (> A10000) or Liquid Filled Group 1 Specifications

NUMBER

OF TEST

PORTS

1

1/8 in. NPT F (If Group 2)

HI RPT

TEST PORT FITTING

DH500 F (If Group 3)

SDS

PROTECTION

NO

Figure 6 Rear Panel

(Left) One Group 2 RPT

(Right) One Group 3 RPT

Figure 7 Schematic

(Left) One Group 2 RPT

(Right) One Group 3 RPT

Page 9 © 1998-2002 DH Instruments, Inc.

RPM3™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 1998-2002 DH Instruments, Inc. Page 10

2. INSTALLATION

22..

I

NNSSTTAALLLLAATTIIOON

I

N

2.1 UNPACKING AND INSPECTION

2.1.1 REMOVING FROM PACKAGING

RPM3 is delivered, along with its standard accessories, in a custom corrugated container

with polyurethane inserts to hold it in place.

Remove the RPM3 and its accessories from the shipping container and remove each

element from its protective plastic bag.

2.1.2 INSPECTING CONTENTS

Check that all items are present and have NO visible damage.

A standard RPM3 includes all items listed in Table 8.

Table 8 RPM3 Parts List

DESCRIPTION PART #

1 ea. RPM3 Reference Pressure Monitor FAM0003

1 ea. Calibration Certificate 550100

1 ea. Wrench, Open End, 5/8 in. 103044

1 ea. General Accessories Disk (white CD) 102987

ACCESSORIES: 401455

1 ea. User’s Manual 550094

1 ea. Power Cord (7.5 ft.) 100770

1 ea. General Accessories Disk (Important: Includes

system support software and documentation.)

102987

2.2 SITE REQUIREMENTS

Install RPM3 on any stable surface at a convenient height. The front feet are extendible so that the unit

can be inclined for easier viewing.

The RPM3 can also be mounted in a standard 19 in. rack mount using the optional rack mount kit.

Consider ready access to the RPM3 rear panel if TEST port connections may be changed frequently.

Support facilities required include an electrical power source of 85 to 264 VAC, 47 to 440 Hz.

Page 11 © 1998-2002 DH Instruments, Inc.

RPM3™ OPERATION AND MAINTENANCE MANUAL

2.3 INITIAL SETUP

2.3.1 PREPARING FOR OPERATION

To prepare RPM3 for check out and operation:

Remove the plastic caps from the RPM3 rear panel pressure connections.

Remove the protective plastic sheet from the front panel display.

Familiarize yourself briefly with the front and rear panels (see Sections 2.3.2.1 and

2.3.2.2).

2.3.2 FRONT AND REAR PANELS

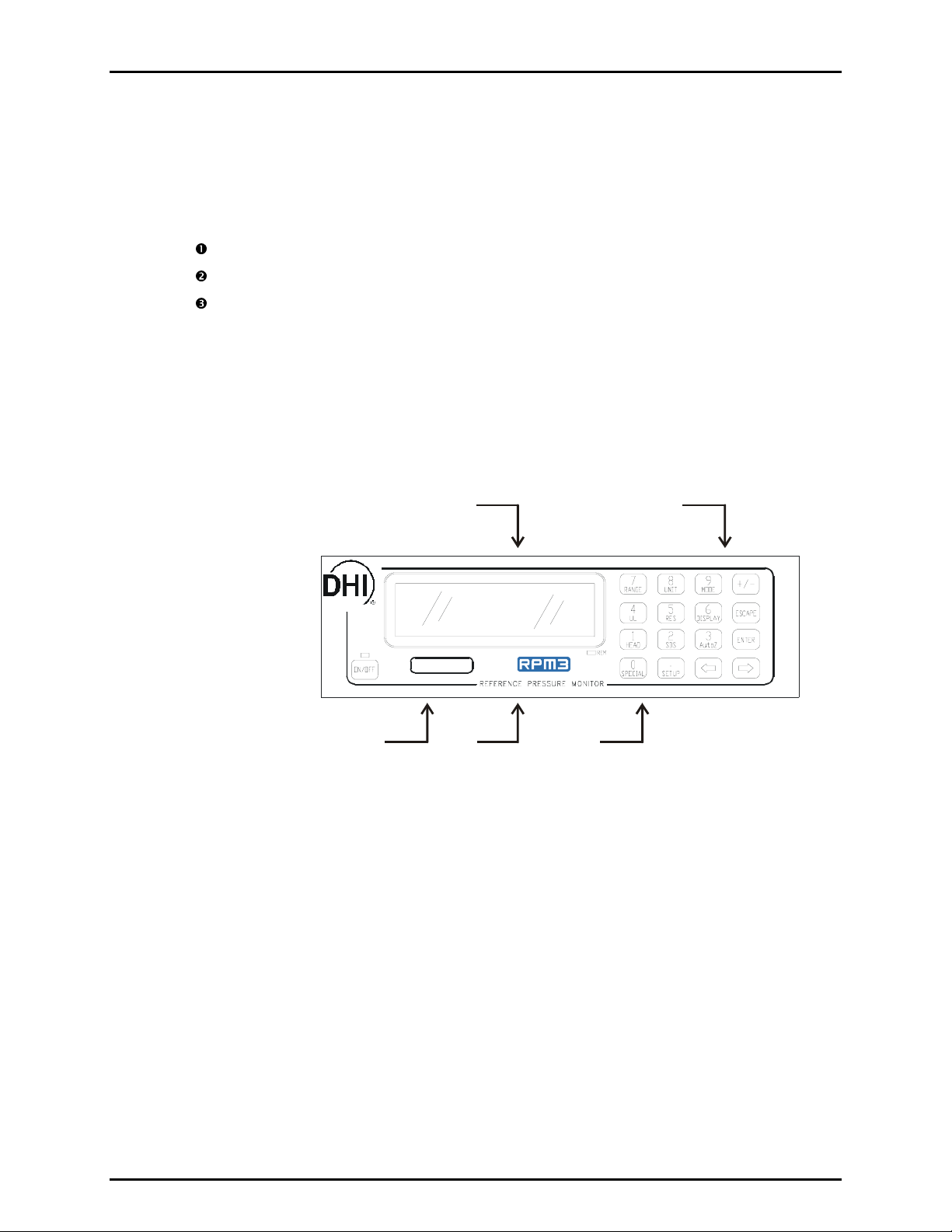

2.3.2.1 FRONT PANEL

The front panel assembly provides a 2 X 20 vacuum fluorescent display of RPM3

operating status, a membrane keypad for local user interface and a soft ON/OFF key.

1

2

1. Display

2. Multi-Function Keypad

3. Remote Indicator

5

4

Figure 8. Front Panel

3

4. RPT Designator Label

5. Soft ON/OFF Key and Indicator

© 1998-2002 DH Instruments, Inc. Page 12

2. INSTALLATION

2.3.2.2 REAR PANEL

The rear panel assembly provides pressure connections, communications

interfaces and the power connection module. Pressure fittings are internally

secured to prevent loosening when making and breaking connections.

2

3

1. Pressure Port(s), layout depending on RPT

Configuration (see Section 1.2.3)

2. Electrical Power Connector Configurations

(IEC320-C13)

Figure 9. Test Ports

3. IEEE-488 (GPIB) Connector

4. COM1 Connector

5. COM2 Connector

6. Label, Product (on bottom of case)

4

2.3.3 POWER CONNECTION

• Connect the power cable to the rear panel power module

• Do NOT connect the other end of the power cable to a power source yet

RPM3 is always powered and active when power is supplied through the rear panel power

connector. The front panel ON/OFF key controls a soft ON/OFF (see Section 3.1.2.3).

2.3.4 TEST PORT CONNECTING

Depending on the reference pressure transducer (RPT) configuration of the specific RPM3,

the TEST port layout, TEST port fittings and acceptable test medium differ (see Sections

1.2.3 and 1.2.1).

Using a pressure hose or tube of appropriate pressure rating, connect the appropriate TEST

port to the test system or supply from which pressure is to be measured. The RPM3 TEST

port is either a 1/8 in. NPT F or a DH500 F, high pressure fitting. Always use compatible

male hardware of the same type. Use Teflon tape or another sealer to make 1/8 in. NPT

connections.

If RPM3 is equipped with a gauge RPT (GXXXX), it has a TEST(-) port. The TEST(-) port is

connected to the low side of the gauge RPT. This connection is normally left open to

atmosphere. It can also be connected to the low side of a differential device that is being

calibrated or tested. When measuring very low pressures, this may enhance the results by

helping assure that the RPM3 and the device under test reference ports are at the same

pressure (see Section 1.2.3).

Page 13 © 1998-2002 DH Instruments, Inc.

RPM3™ OPERATION AND MAINTENANCE MANUAL

USE THE CORRECT TEST PORT: Some RPM3s have more than one TEST port

corresponding to more than one internal RPT. Before connecting an RPM3 TEST port to a

pressure source, familiarize yourself with the RPTs, their pressure limits and their TEST

port fittings (see Section 1.2.3). In most cases, over-pressuring an RPT by more than

25 % will damage it beyond repair.

USE THE CORRECT PRESSURE CONNECTORS: RPM3 TEST port fittings are either 1/8 in.

NPT F or DH500 F (see Section 1.2.1). Never use fittings other than the corresponding

male fittings in these connectors. Damage to the connectors and dangerous failure

under pressure could result from using incorrect fittings.

NEVER connect a pressure source to the TEST(-) port. The pressure applied to this port

should be maintained at standard atmospheric pressure ± 3 psi (20 kPa). Exceeding

these limits may damage the RPT.

USE THE PROPER MEDIUM: b Type RPTs are intended for use only with dry (instrument

grade, non-condensing), non-corrosive gases. Contaminated gases may cause

measurement shifts and offsets. Standard RPTs are delivered for set up for gas

operation (A6000 and lower) or liquid operation (A10000 and higher). Contaminating

gas operated RPTs with liquids may cause aberrant measurements.

SDS Self Defense System: RPTs designated A1500 or lower include the SDS Self Defense

System. SDS, operated properly, allows a Group 1 RPT TEST port (see Section 1.2.3) to

be left connected to a pressure up to 2 000 psi (13 MPa) without damage to the RPT.

Do NOT attempt to use SDS in this manner without first becoming thoroughly familiar

with its operations and limitations (see Sections 3.1.2.6, 3.2.8, and 3.4.2).

2.3.4.1 THE ATM AND VENT PORTS

The ATM pass through is connected to the on-board barometer. This connection

assures that the on-board barometer actually measures ambient atmospheric

pressure rather than the pressure inside the RPM3 case that may vary slightly

from ambient pressure. The ATM port should be left open and unobstructed.

The VENT port is only present on RPM3s equipped with SDS Self Defense

System (Group 1 RPTs only) (see Sections 1.2.3 and 3.1.2.6). The VENT port is

connected to the SDS vent valve to assure that any gases vented through SDS

escape outside the RPM3 case. A connection may be made to the VENT port to

direct these gases if desired but the port must NOT be obstructed. Obstructing

the VENT port may interfere with SDS operation.

NEVER plug or obstruct the ATM pass through as this may adversely affect

gauge mode operation and autozeroing on an absolute transducer.

© 1998-2002 DH Instruments, Inc. Page 14

2. INSTALLATION

NEVER plug or obstruct the VENT pass through as this may interfere with

SDS operation and RPT autozeroing (see Section 3.1.2.6).

2.4 POWER UP AND VERIFICATION

2.4.1 APPLY POWER

Connect the RPM3 power cable to an electric supply of 85 to 264 VAC (47 to 440 Hz).

Observe the front panel display as RPM3 initializes, error checks and goes to the main run

screen (see Section 3.1.1).

RPM3 is always powered and active when power is supplied through the rear panel power

connector. The front panel ON/OFF key controls a soft ON/OFF (see Section 3.1.2.3).

If the RPM3 fails to reach the main run screen, service is required. Record the sequence of

operation and displays observed.

Any SDS present in RPM3 is active at power up. This causes SDS to flash over the

measured pressure (see Section 3.1.2.6).

The active range on power up is the same as the range that was active at the last power

down (see Section 3.1.2.5).

2.4.2 CHECK PROPER PRESSURE MEASUREMENT OPERATION

2.4.2.1 CHECKING ABSOLUTE MODE PRESSURE MEASUREMENT

If the RPM3 has an absolute RPT (designated AXXXX), check that it operates properly in

absolute mode.

Make sure that the TEST port of the RPT is open to atmosphere.

Use [RANGE] to change ranges if necessary (see Section 3.2.1). Select a range of the

absolute RPT.

Press [MODE] and select absolute mode (available on AXXXX RPTs only). Change the

pressure unit if desired (see Section 3.2.2).

If SDS is ON (SDS flashes over the pressure indication on the top display line), turn SDS

OFF. Press [SDS] and select <2 Yes> to defeat SDS (see Section 3.2).

Do NOT defeat SDS with a pressure higher than the active range maximum applied to the

TEST port. Damage to the RPT may result.

Page 15 © 1998-2002 DH Instruments, Inc.

RPM3™ OPERATION AND MAINTENANCE MANUAL

Observe the current value of atmospheric pressure. Check that the value agrees with the

local value of atmospheric pressure within measurement tolerances. Repeat this process for

all the ranges on both RPTs if the RPM3 has two absolute RPTs. Check that the values of

atmospheric pressure measured by the different ranges agree with each other within RPM3

measurement tolerances (see Section 1.2.2). If they do NOT agree within tolerances, RPM3

may need calibration or repair.

2.4.2.2 CHECKING GAUGE MODE PRESSURE MEASUREMENT

Make sure that the TEST port(s) of the RPT(s) is/are open to atmosphere.

Use [RANGE] to change ranges if necessary (see Section 3.2.1). Select a range

of the RPT.

Press [MODE] and select gauge mode. Change the pressure unit if desired

(see Section 3.2.2).

If SDS is ON (SDS flashes over the pressure indication on the top display line),

turn SDS OFF. Press [SDS] and select <2Yes> to defeat SDS (see Section

3.2.8).

Do NOT defeat SDS with a pressure higher than the RPT maximum applied to

the TEST port. Damage to the RPT may result.

The value indicated should be near zero (± 6 psi, 35 kPa). Press [AutoZ]. This

runs AutoZ to zero the range (see Section 3.2.9). Upon return to the main run

screen, observe that the indication of measured pressure has zeroed.

Use [RANGE] to change ranges, repeat the zeroing process for each range.

If a range fails to zero properly, RPM3 may need repair.

It is normal for RPM3 to indicate a value other than zero when vented when

gauge mode is first entered or ranges are changed, especially if AutoZ is OFF

and/or RPM3 has been OFF for some time or its location has changed.

2.5 SHORT TERM STORAGE

The following is recommended for short term storage of RPM3:

Vent the RPM3 TEST port.

Disconnect the power supply.

When RPM3 will NOT be used for some time, it may be left powered, but use the soft ON/OFF key to turn

OFF the display.

© 1998-2002 DH Instruments, Inc. Page 16

3. OPERATION

33..

O

PPEERRAATTIIOON

O

N

3.1 GENERAL/MANUAL OPERATION

RPM3 is designed to offer the optimum balance between simple, straight forward operation and the

availability of a wide variety of functions with a high level of operator discretion if desired. The local

operator interface is through a 2 x 20 character alpha-numeric display and a 4 x 4 multi-function keypad.

3.1.1 MAIN RUN SCREEN

The RPM3 main run screen is its home display that is reached on power up and from which

other functions and menus are accessed. It is the top level of all menu structures.

The main run screen is where the RPM3 is left in normal operation. It displays the current

measured pressure as well as a variety of additional information if desired.

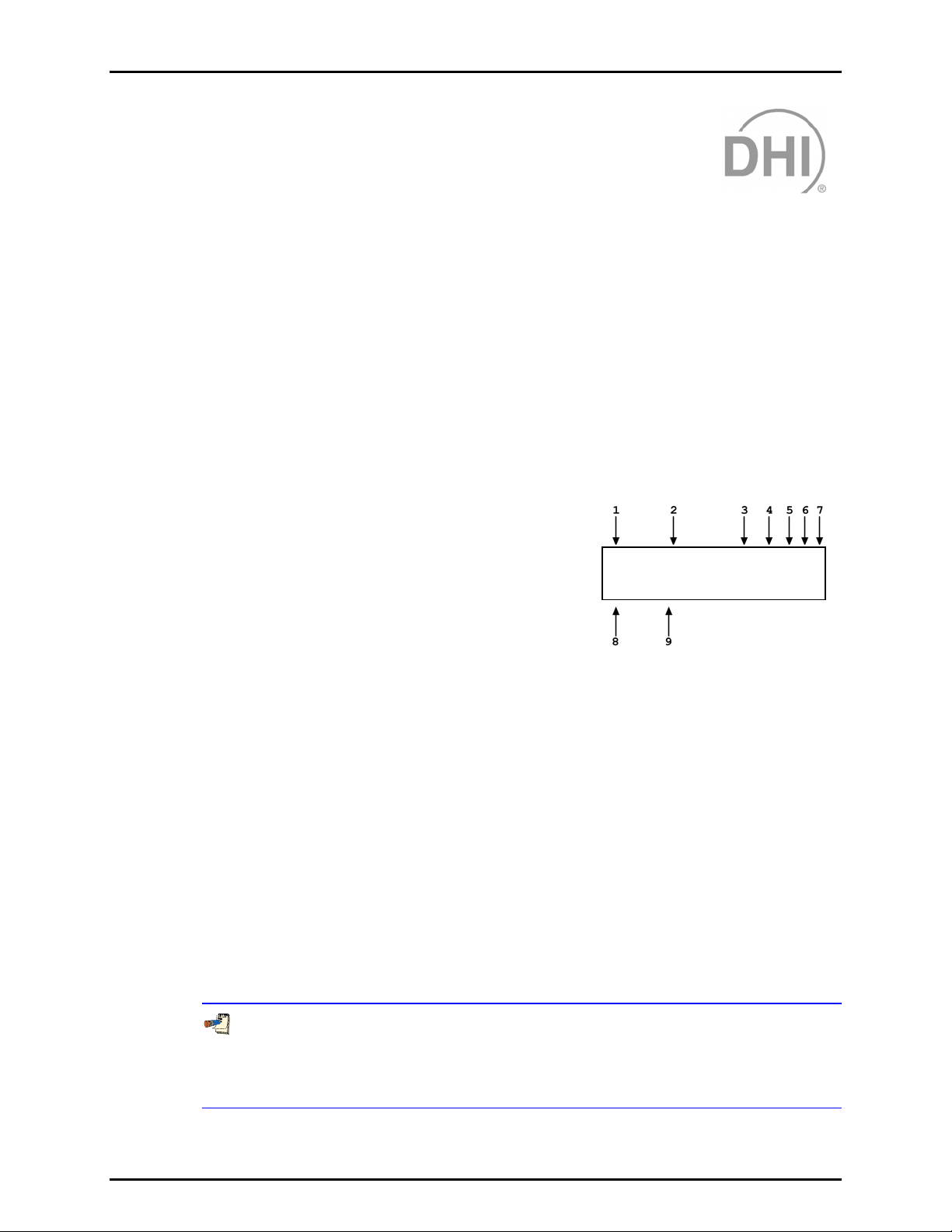

1. <k> Ready/NOT ready indication, <k> when ready, <-> or

<¯> indicating direction of measured pressure evolution when

NOT ready (see Section 3.1.2).

2. <PRESSURE1> Numerical value and sign of pressure

measured by active RPT and range. Shows result of last

average in average display mode (see Section 3.2.6.1).

<**SDS**>: To indicate when SDS is ON (see Section

3.1.2.6) for the active RPT, **SDS** is displayed alternating

with PRESSURE1.

3. <UNIT> Current unit of measure (see Section 3.2.2).

4. <M> Pressure measurement mode: <g> for gauge, <a> for absolute (see Sections 3.2.3 and 3.2.2).

5. <h> Indicates whether a head correction is applied. <h> if applied, blank if NOT (see Section 3.2.7).

6. <z> Indicates whether the autozero function is ON or OFF. <z> if ON; blank if OFF (see Section 3.4.1).

7. <RR> Indicates active RPT (<H> = high, <L> = low) and range (<1> = low, <2> = mid, <3> = hi) (see Section 3.2.1).

8. <DISPLAY FUNCTION> Information displayed depends on current display function.

9. <D> Indication of what is being displayed on the bottom line of the display as set by the DISPLAY function

(see Section 3.2.6). Choices include:

• <s> Current DISPLAY mode is average (see Section 3.2.6.1).

• <R> Current DISPLAY mode is rate (see Section 3.2.6.2); or if <n avg> is in the bottom right hand corner

of the display, current DISPLAY mode is average and this is the instantaneous reading average screen

(see Section 3.2.6.1).

• <H> Current DISPLAY mode is hi/lo (see Section 3.2.6.5).

• <D> Current DISPLAY mode is deviation (see Section 3.2.6.3).

• <S> <-> or <¯> Current DISPLAY mode is RPT (see Section 3.2.6.4).

• <F> Current DISPLAY mode is freeze (see Section 3.2.6.6).

• Blank, NO character Current DISPLAY mode is clean (see Section 3.2.6.7).

* PRESSURE1 UNITM hZRR

D DISPLAY FUNCTION

RPM3 has a screen saver function that causes the display to dim if NO key is pressed

for 10 minutes. Pressing a key restores full power to the display. The screen saver

activation time can be changed or screen saving can be completely suppressed (see

Section 3.4.7.1).

Page 17 © 1998-2002 DH Instruments, Inc.

RPM3™ OPERATION AND MAINTENANCE MANUAL

3.1.2 GENERAL OPERATING PRINCIPLES

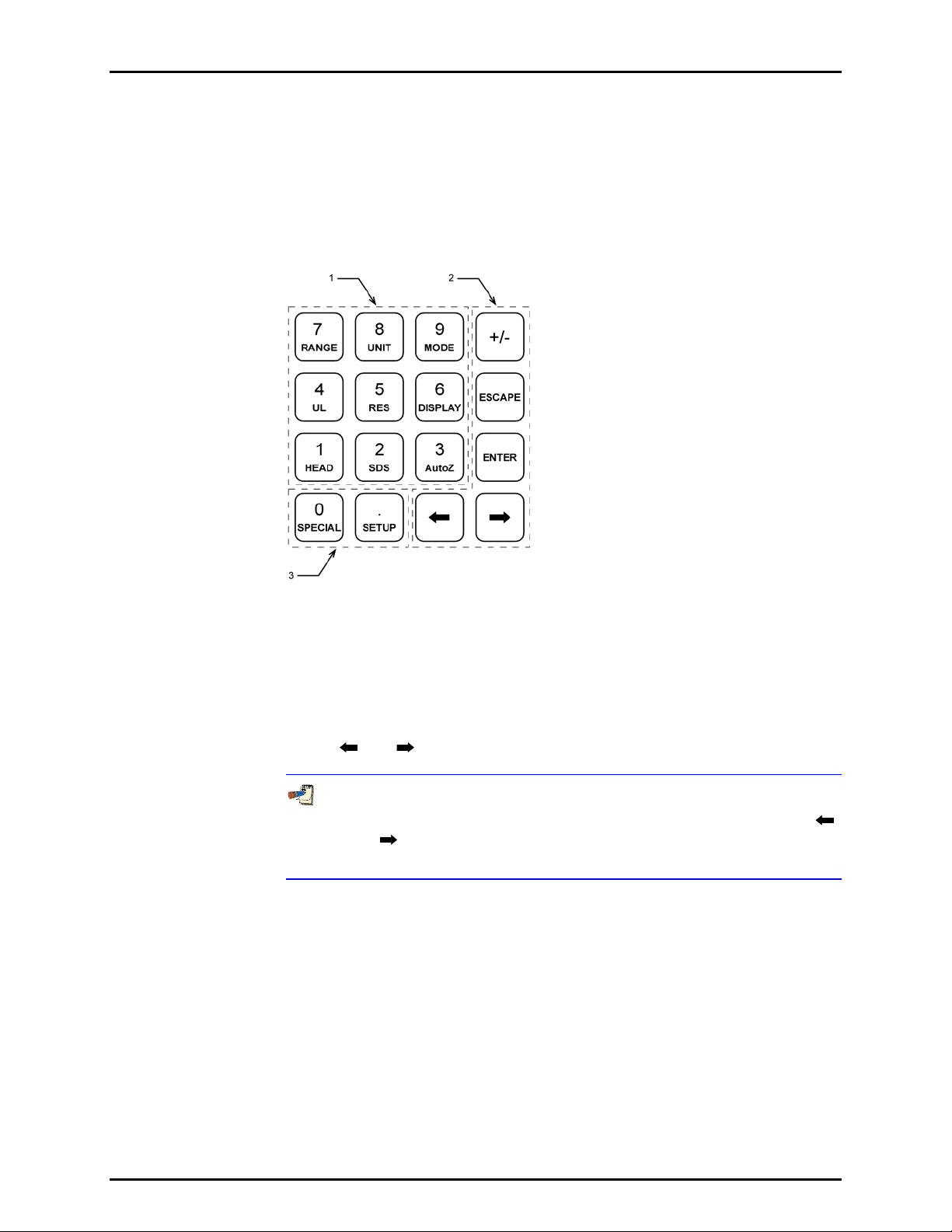

3.1.2.1 KEYPAD LAYOUT AND PROTOCOL

The RPM3 has a 4 x 4 keypad for local operator access to direct functions,

function menus and for data entry.

The [ENTER] key generally causes execution or forward movement in the menu tree.

The [ESCAPE] key moves back in the menu tree and/or causes execution to cease or suspend

without changes being implemented. Pressing [ESCAPE] repeatedly eventually returns to the

main run screen. From the main run screen, pressing [ESCAPE] allows momentary viewing of

the RPM3 introduction screen.

The [+/-] key changes a numerical sign when editing. It also toggles through multiple screens

when available.

The [

They are also used to scroll through choices.

] and [ ]keys allow reverse and forward cursor movement when editing data entry.

Figure 10 Keypad

1. The Function/Data keys allow very commonly

used functions to be accessed directly from the

main run screen by a single keystroke. The

name of the function is on the bottom half of the

key (see Section 3.1.2.7). These keys enter

numerical values when editing.

2. The Editing and Execution keys are for

execution, suspending execution, backing up in

menus and editing entries.

3. The Menu/Data keys provide access to function

menus from the main run screen. The menu

name is on the bottom half of the key. The

SETUP menu is for more frequently used

functions (see Section 3.3). The SPECIAL menu

is for functions that are NOT generally used as a

part of day to day operation (see Section 3.4).

These keys enter numerical values when editing.

Key press confirmation is provided by both tactile

and audible feedback. A single tone confirms a

valid entry, a descending two note tone signals

an invalid entry. The audible valid entry feedback

can be suppressed or modified by pressing

[SPECIAL] and selecting <7Intern>, <2sound>

(see Section 3.4.7.2).

Some screens go beyond the two lines provided by the display. This is

indicated by a flashing arrow in the second line of the display. Use [ ]

and [

] to move the cursor to access the lines that are NOT visible or

directly enter the number of the hidden menu choice if you know it.

3.1.2.2 SOUNDS

RPM3 is equipped with a variable frequency tone device to provide audible

feedback and alarms. The beeper is used for the following indications.

Valid key press - Brief beep, choice between three frequencies or NO sound is

available (see Section 3.4.7.2)

Invalid key press - Descending two tone blurp

Leak check routine completed - Three two second beeps (see Section 3.3.5)

UL (upper limit) exceeded - Intermittent one second beeps (see Section 3.2.4)

Pmax! (overpressure limit) exceeded - Eight second high frequency beep

(see Section 3.2.4.1)

© 1998-2002 DH Instruments, Inc. Page 18

3. OPERATION

3.1.2.3 SOFT [ON/OFF] KEY

RPM3 is equipped with a soft [ON/OFF] key and indicator LED on the bottom left

hand corner of the front panel. The purpose of the soft ON/OFF key is to put

RPM3 into a dormant mode in which the display is turned OFF but power is still

supplied and SDS and overpressure functions are still active. When RPM3 is

ON, the ON/OFF indicator is ON continuously. When RPM3 is soft OFF, the

ON/OFF indicator blinks every five seconds.

The soft [ON/OFF] key can also be used to reset from an overpressure condition

(see Section 3.2.4.1).

When RPM3 is soft OFF, receiving a remote command turns it ON.

Turning RPM3 soft OFF does NOT turn SDS ON. Do NOT assume that SDS

is ON when an RPM3 is soft OFF. Disconnecting power completely turns

SDS ON (see Section 3.1.2.6).

3.1.2.4 PRESSURE READY <*>/NOT READY (<↑> OR <↓>)

The character to the left of the measured pressure on the main run screen

provides a pressure Ready (<*>)/Not Ready (<↑> or <↓>) indication.

This indication is intended to provide the user with a clear and objective

indication of when a stable pressure has been achieved. Ready <*> is indicated

when the current stability (rate of change) of pressure is less than the stability

limit.

The user can set the stability limit (see Section 3.3.4). The ready indication is

often used when comparing the RPM3 and a test device to indicate when a valid

reading can be made.

Ready (<*>)/Not Ready (<↑> or <↓>) character indications are:

<k > Pressure ready (stable)

<↑> Pressure NOT ready (unstable) and decreasing

<↓> Pressure NOT ready (unstable) and increasing

3.1.2.5 MULTIPLE PRESSURE RANGES

RPM3 has one or two reference pressure transducers (RPT) each of which has

three ranges for a total of three or six pressure ranges. This multi-ranging

feature allows accuracy to be optimized for the range of pressure in which you

are working. Generally, the best range to select (see Section 3.2.1) is that

whose full scale is closest to, but greater than, the maximum pressure of the

device or system under test.

RPM3 handles all of the data operations needed to make range changes occur

transparently to the user when the RANGE function is used for range selection.

For a range change to be executed, the current pressure applied to the RPT on

which the range is being selected must be lower than the current upper limit (UL)

of that range (see Section 3.2.4).

When ranges are changed, the upper limit is automatically changed to the default

for that range or to the last upper limit set for that range. In addition, most other

functions and settings are range specific (see Section 3.2.1).

Page 19 © 1998-2002 DH Instruments, Inc.

RPM3™ OPERATION AND MAINTENANCE MANUAL

Each RPM3 has three or six ranges. In general, settings and operational

adjustments are specific to the range currently in use, as if you had six

instruments rather than one. The DISPLAY function, HEAD functions and

AUTO READRT function are NOT range specific. In remote mode, most

settings are RPT specific rather than

RPM3 internal pressure schematics and rear panel TEST port configurations

change depending on the number of RPTs and their ranges. See Section 1.2.3

for details on possible RPM3 configurations.

Ranges and Identification

The currently active RPT and range is continuously indicated in the upper right

hand corner of the main run screen and most other screens (see Section 1.2.2

for complete listing of the RPTs available and their ranges).

Hi RPT The RPT in a single RPT RPM3 or the RPT with the highest

maximum range in a dual RPT RPM3 is referred to as the Hi RPT.

Lo RPT The RPT with the lower maximum range in a dual RPT RPM3

is referred to as the Lo RPT.

Range 1, 2 or 3 The three ranges of an RPT are referred to as 1 = lo range,

2 = mid range, 3 = hi range.

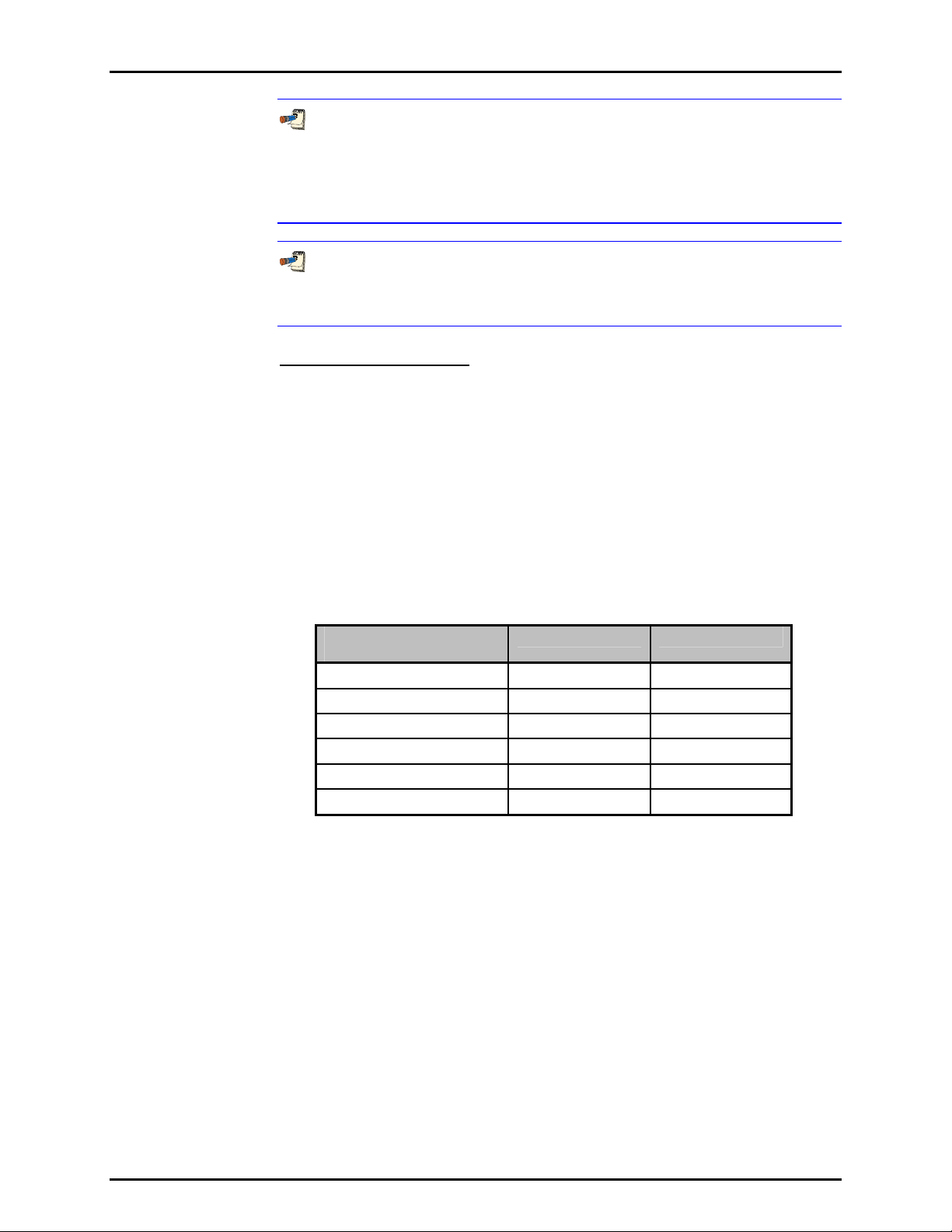

Table 9. RPM3 Range Identification Summary

REFERENCE PRESSURE

TRANSDUCER AND RANGE

Lo RPT, Lo range Lo, 1 L1

Lo RPT, Mid range Lo, 2 L2

Lo RPT, Hi range Lo, 3 L3

Hi RPT, Lo range Hi, 1 H1

Hi RPT, Mid range Hi, 2 H2

Hi RPT, Hi range Hi, 3 H3

* The display symbol is included in the upper, right hand corner of most RPM3 menu displays as a convenient

indicator of active range.

DESIGNATION DISPLAY SYMBOL *

3.1.2.6 SDS SELF DEFENSE SYSTEM

RPTs designated A1500 or lower that are NOT liquid filled are equipped with the

SDS self defense system. The SDS system includes hardware and embedded

software logic to protect RPTs from overpressure. When SDS is ON for an RPT,

that RPT is isolated from the RPM3 TEST port and opened to the VENT port

(See Figure 11 and Sections 1.2.3 and 5.6.1.1).

In dual RPTs with a single TEST port, SDS is used to protect the Lo RPT from

overpressure when the high RPT is in use.

RPM3 internal logic uses SDS to protect against accidental overpressure.

Whenever RPM3 is ON (or in soft OFF mode) it monitors the pressure read by its

RPTs. If the pressure reaches the maximum pressure limit for a range, SDS will

activate automatically to isolate the RPT from the TEST port and vent it to

atmosphere.

© 1998-2002 DH Instruments, Inc. Page 20

3. OPERATION

SDS can also be used to isolate an RPM3 from a test system which may

sometimes be subjected to pressures higher than the RPM3s maximum

pressure. When configuring a multi-range system, this can eliminate the need

for external valving or connecting and disconnecting RPM3s. When used in this

manner, SDS should be activated prior to applying pressure. Automatic SDS

activation should only be used in an emergency overpressure situation.

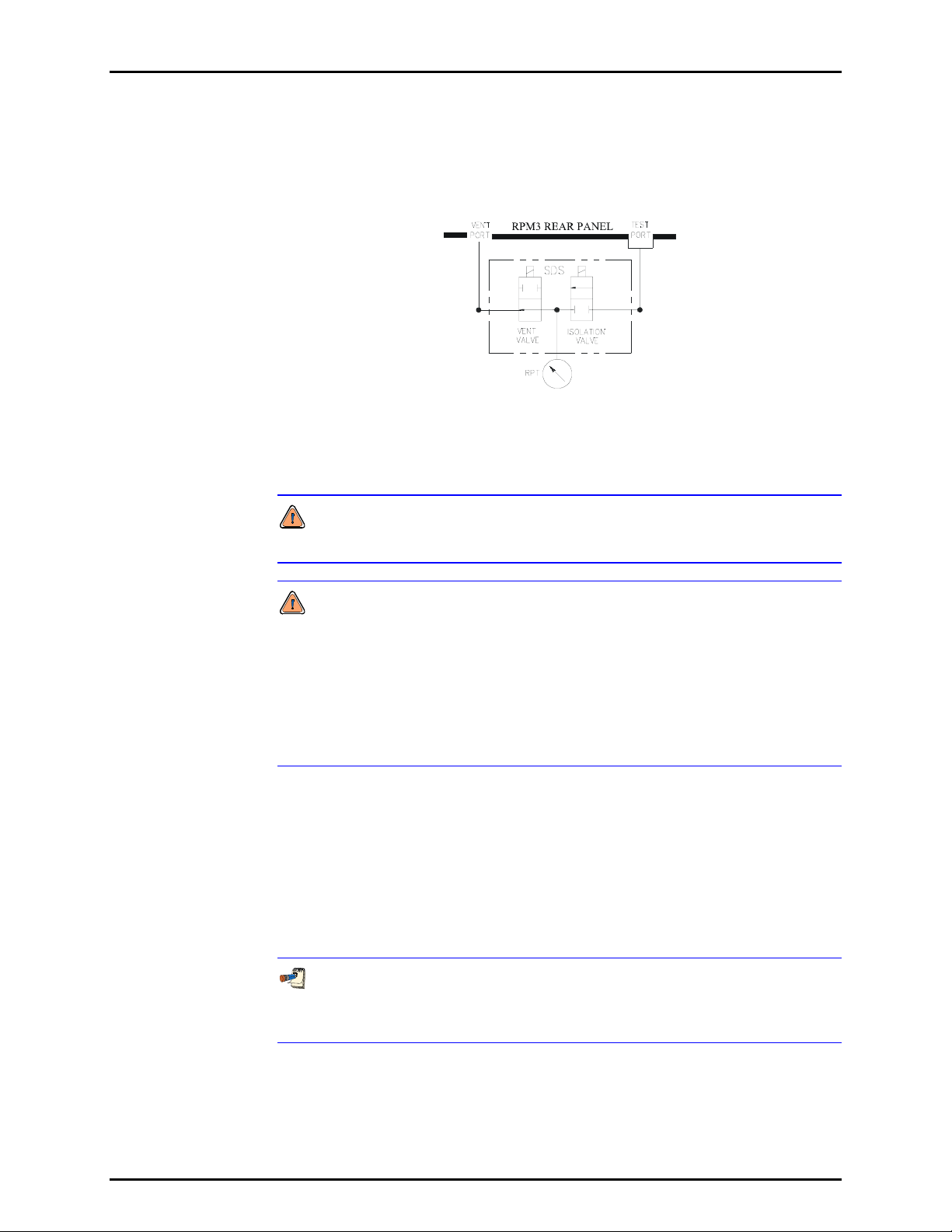

SDS ON - ISOLATION Closed / VENT Open

SDS OFF - (Defeated) ISOLATION Open / VENT Closed

Figure 11 SDS Schematic

The maximum pressure that should be applied to an RPM3 TEST port when

SDS is ON is 2 000 psi (13 MPa).

Though the SDS self defense system includes features to automatically

protect RPTs against accidental overpressure, SDS should NOT be

considered a fail-safe overpressure protection system. SDS cannot

guarantee that overpressure damage will NOT occur. SDS automatic

activation may protect an RPT in case of accidental overpressure but

conventional measures for protecting against overpressure should also

always be followed. Damage to RPTs due to overpressure is NOT covered by

the RPM3 product warranty even when SDS is present.

3.1.2.7 DIRECT FUNCTION KEYS SUMMARY

Local operation of RPM3 is through the 4 x 4 pressure sensitive keypad. To

minimize the use of multi-layered menu structure, the 4 x 4 keypad numerical

keys also provide direct access to the most commonly used functions. The

function accessed is labeled on the bottom half of the keys. Direct function keys

are active whenever RPM3 is in its main run screen. Table 10 summarizes the

operation of the direct function keys.

Table 10 provides a brief summary of direct function key operation. It may be

useful to keep a copy of this summary near the RPM3, especially when first

becoming acquainted with its operation.

Page 21 © 1998-2002 DH Instruments, Inc.

RPM3™ OPERATION AND MAINTENANCE MANUAL

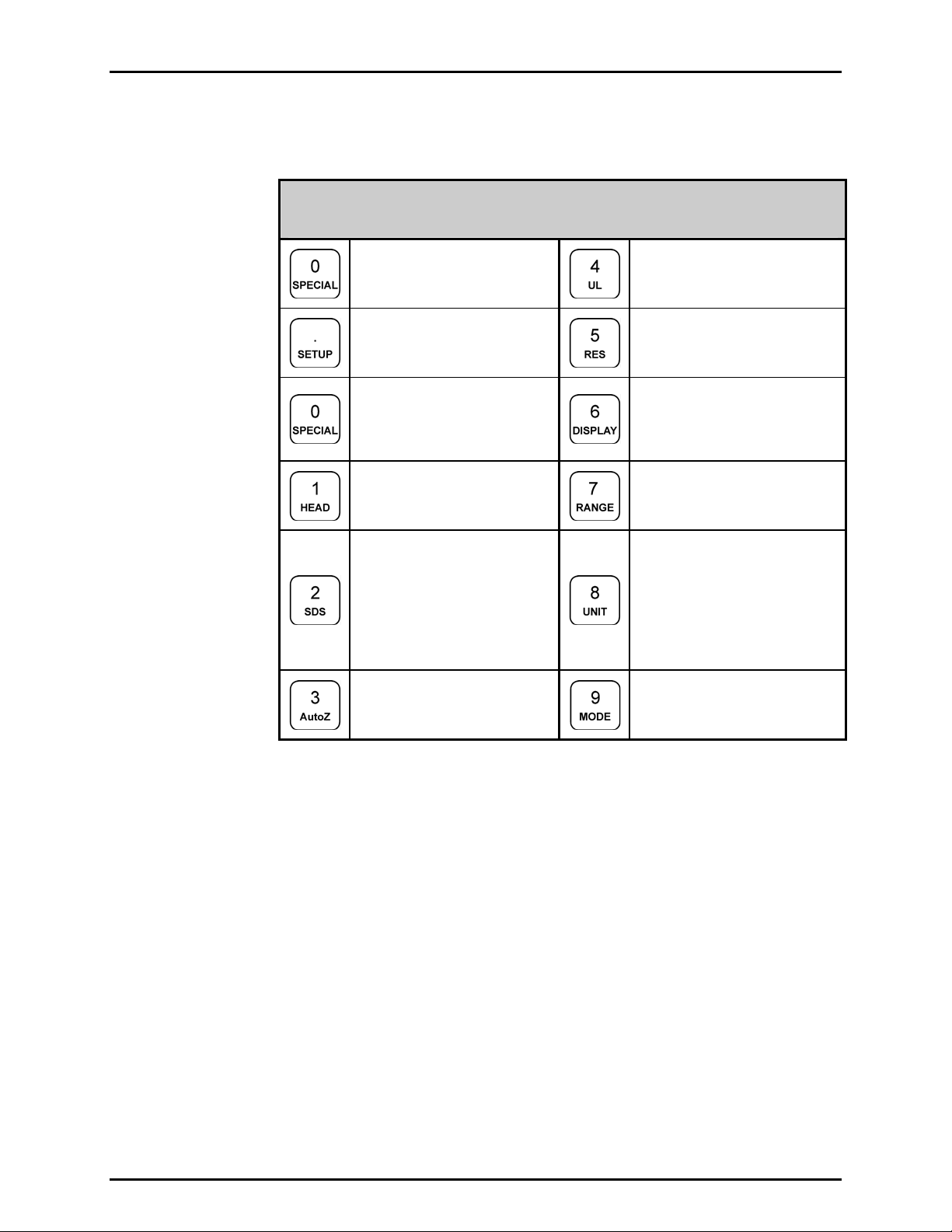

Table 10 Summary of RPM3 Direct Function Key Operation

Direct function keys are active from the main run screen.

See corresponding manual sections for full detail.

DIRECT FUNCTION KEYS ARE ACTIVE FROM ANY RUN SCREEN

See corresponding manual sections for full detail.

Menu of commonly used setup

features including run LEAK

CHECK.

(main, ambient, system).

View/adjust upper limit.

Menu of commonly used setup

features including run LEAK

CHECK.

Menu of less frequently used

internal functions and settings.

Adjust height of fluid head

correction. Set to zero to defeat

head correction.

Turn SDS (Self Defense System)

ON/OFF (if present). SDS ON is

indicated by flashing <***SDS***>.

SDS must be turned OFF to

measure pressures applied to

TEST port. Use with caution as

turning SDS OFF with

overpressure on test port could

damage RPT.

Runs AutoZ to rezero active

range. Should be used in gauge

mode whenever vented.

3.2 DIRECT FUNCTION KEYS

Adjust display resolution of

measured pressure and other

indications and settings.

Select [DISPLAY] function for

second line of RPM3 display.

Choices include <average>,

<rate>, <other RPT>, <Hi/Lo>,

<Deviation>, <Freeze>, <Clean>.

View/Select ranges. Shows active

range and then toggles through

available ranges. Pressing

[ENTER] on a range activates it.

Change pressure measurement

unit. Choice of units can be

customized.

Change pressure measurement

mode (<gauge>, <absolute>).

3.2.1 [RANGE]

PURPOSE

To view and/or change the active pressure measurement range.

PRINCIPLE

Each RPM3 has three or six ranges (see Section 3.1.2.5).

The [RANGE] key allows the range values to be viewed and a range selection to be made.

Most RPM3 settings such as pressure unit of measure (UNIT) and measurement mode

(MODE), are range specific. Changes made while in one range apply to that range only and

do NOT affect the other ranges (see Section 3.2.1).

OPERATION

Pressing [RANGE] activates the range viewing and selecting function. Pressing [RANGE]

key again or [+/-] while in the RANGE function steps through displays of available ranges:

Lo to Hi.

© 1998-2002 DH Instruments, Inc. Page 22

Loading...

Loading...