Page 1

PN 2716032

October 2006

© 2006 Fluke Corporation, All rights reserved. Printed in USA

All product names are trademarks of their respective companies.

QA-ES II

Electrosurgical Analyzer

Users Manual

Page 2

Warranty and Product Support

Fluke Biomedical warrants this instrument against defects in materials and workmanship for one full year from the date of

original purchase. During the warranty period, we will repair or, at our option, replace at no charge a product that proves to

be defective, provided you return the product, shipping prepaid, to Fluke Biomedical. This warranty does not apply if the

product has been damaged by accident or misuse or as the result of service or modification by other than Fluke Biomedical.

IN NO EVENT SHALL FLUKE BIOMEDICAL BE LIABLE FOR CONSEQUENTIAL DAMAGES.

Only serialized products and their accessory items (those products and items bearing a distinct serial number tag) are covered under this one-year warranty. PHYSICAL DAMAGE CAUSED BY MISUSE OR PHYSICAL ABUSE IS NOT COVERED

UNDER THE WARRANTY. Items such as cables and nonserialized modules are not covered under this warranty.

Recalibration of instruments is not covered under the warranty.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state, province to

province, or country to country. This warranty is limited to repairing the instrument to Fluke Biomedical’s specifications.

Warranty Disclaimer

Should you elect to have your instrument serviced and/or calibrated by someone other than Fluke Biomedical, please be

advised that the original warranty covering your product becomes void when the tamper-resistant Quality Seal is removed or

broken without proper factory authorization. We strongly recommend, therefore, that you send your instrument to Fluke Biomedical for factory service and calibration, especially during the original warranty period.

Page 3

Notices

All Rights Reserved

© Copyright 2006, Fluke Biomedical. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into

any language without the written permission of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and other printed materials for use in service training programs

and other technical publications. If you would like other reproductions or distributions, submit a written request to Fluke Biomedical.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for damage. If damage is found, stop unpacking the instrument.

Notify the carrier and ask for an agent to be present while the instrument is unpacked. There are no special unpacking instructions, but be careful not to damage the instrument when unpacking it. Inspect the instrument for physical damage such as bent or broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email techservices@flukebiomedical.com or call 1-800- 648-7942 or 1-425-446-6945.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical damage is found, retain all packing materials in their original

condition and contact the carrier immediately to file a claim. If the instrument is delivered in good physical condition but does not operate within specifications, or if there are any other problems not caused by shipping damage, please contact Fluke Biomedical or your local sales representative.

Page 4

Standard Terms and Conditions

Refunds and Credits

Please note that only serialized products and their accessory items (i.e., products and items bearing a distinct serial number tag) are eligible for

partial refund and/or credit. Nonserialized parts and accessory items (e.g., cables, carrying cases, auxiliary modules, etc.) are not eligible for return or refund. Only products returned within 90 days from the date of original purchase are eligible for refund/credit. In order to receive a partial refund/credit of a product purchase price on a serialized product, the product must not have been damaged by the customer or by the carrier chosen by the customer to return the goods, and the product must be returned complete (meaning with all manuals, cables, accessories, etc.) and in “as new” and resalable condition. Products not returned within 90 days of purchase, or products which are not in “as new” and resalable condition, are not eligible for credit return and

will be returned to the customer. The Return Procedure (see below) must be followed to assure prompt refund/credit.

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee of 15 %. Products returned in excess of 30 days after purchase, but prior to 90 days, are subject to a minimum restocking fee of 20 %. Additional charges for damage and/or missing parts and accessories will be applied to all returns.

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent freight-prepaid to our factory location. When you return an instrument to

Fluke Biomedical, we recommend using United Parcel Service, Federal Express, or Air Parcel Post. We also recommend that you insure your shipment for its

actual replacement cost. Fluke Biomedical will not be responsible for lost shipments or instruments that are received in damaged condition due to improper

packaging or handling.

Use the original carton and packaging material for shipment. If they are not available, we recommend the following guide for repackaging:

Use a double–walled carton of sufficient strength for the weight being shipped.

Use heavy paper or cardboard to protect all instrument surfaces. Use nonabrasive material around all projecting parts.

Use at least four inches of tightly packed, industry-approved, shock-absorbent material around the instrument.

Page 5

Returns for partial refund/credit:

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number, obtained from our Order Entry Group at

1-800-648-7952 or 1-425-446-6945.

Repair and calibration:

To find the nearest service center, go to www.flukebiomedical.com/service

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4606

Email: globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-888-99 FLUKE (1-888-993-5853)

Email: service.status@fluke.com

In Europe, Middle East, and Africa:

Eindhoven Calibration Lab

Tel: +31-402-675300

Email: ServiceDesk@fluke.com

In Asia:

Everett Calibration Lab

Tel: +425-446-6945

Email: service.international@fluke.com

or

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke Biomedical’s manufacturing specifications when it was shipped from the

factory. Calibration measurements are traceable to the National Institute of Standards and Technology (NIST). Devices for which there are no NIST calibration standards are measured against in-house performance standards using accepted test procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may result in electrical shock hazards or improper operation. Fluke Biomedical will not be responsible for any injuries sustained due to unauthorized equipment modifications.

Page 6

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by Fluke Biomedical. Changes made to the information in

this document will be incorporated in new editions of the publication. No responsibility is assumed by Fluke Biomedical for the use or reliability

of software or equipment that is not supplied by Fluke Biomedical, or by its affiliated dealers.

Manufacturing Location

The QA-ES II Electrosurgical Analyzer is manufactured in Norway for Fluke Biomedical, 6920 Seaway Blvd., Everett, WA, U.S.A.

Page 7

Table of Contents

Title Page

Introduction .................................................................................................................... 1

Safety............................................................................................................................. 2

Specifications ................................................................................................................. 4

General...................................................................................................................... 4

Measurement............................................................................................................. 6

Controls and Connections .............................................................................................. 7

Main Switch On and Off ................................................................................................. 10

Analyzer Menu and Function Keys................................................................................. 10

LCD Display Menu Messages ................................................................................... 11

Start-up Screen..................................................................................................... 11

Main Menu............................................................................................................ 11

SHOW CHOICES (F1).......................................................................................... 12

KNOB PARAM. (F2) ............................................................................................. 12

START (F3) .......................................................................................................... 12

SETUP (F4) .......................................................................................................... 13

QUIT MENU (F5).................................................................................................. 13

PRINT HEADER (F3) ........................................................................................... 13

REMOTE CONTR. (F4) ........................................................................................ 13

i

Page 8

QA-ES II

Users Manual

Printout...................................................................................................................... 13

Foot Switch Output ........................................................................................................ 14

ESU Tests with the Analyzer ......................................................................................... 14

Power Output Tests .................................................................................................. 15

Continuous Operation Test ....................................................................................... 16

Single Operation Test ............................................................................................... 16

Power Distribution Test ............................................................................................. 17

HF Current Leakage Test.......................................................................................... 18

Test Procedure..................................................................................................... 19

Measuring Leakage Current with HF Isolated Equipment .................................... 19

Measuring Leakage Current with Grounded HF Equipment................................. 21

REM Alarm Test........................................................................................................ 21

Foot Switch Control ....................................................................................................... 23

Monopolar Testing .................................................................................................... 24

Cut Activation ....................................................................................................... 24

Coag Activation .................................................................................................... 24

Bipolar Testing .......................................................................................................... 24

Cleaning the Analyzer.................................................................................................... 24

ii

Page 9

List of Tables

Table Title Page

1. Symbols................................................................................................................................. 3

2. Controls and Connectors....................................................................................................... 9

3. Load Resistance.................................................................................................................... 16

4. Leakage Resistance.............................................................................................................. 19

5. Foot Switch Connections....................................................................................................... 23

List of Figures

Figure Title Page

1. Controls and Connectors....................................................................................................... 7

2. Rear Panel ............................................................................................................................ 8

3. Test Results Printout ............................................................................................................. 14

4. ESU Power Output Test ........................................................................................................ 15

5. Power Distribution Test ......................................................................................................... 17

6. Test Setup A.......................................................................................................................... 20

7. Test Setup B.......................................................................................................................... 20

8. Test Setup C ......................................................................................................................... 21

9. Test Setup D ......................................................................................................................... 21

10. REM Alarm Test Setup.......................................................................................................... 22

iii

Page 10

QA-ES II

Users Manual

iv

Page 11

QA-ES II Electrosurgical Analyzer

Introduction

The QA-ES II Electrosurgical Analyzer (hereafter called

the Analyzer) is a precision instrument for use in

performing tests on high-frequency electrosurgical units

(ESU) in accordance with national and international

standards. It is for use by trained service technicians.

Tests include:

• Automatic power distribution measurement

• Crest factor measurement

• RF leak measurement

• Return electrode monitor (REM) test

The Analyzer conducts testing by measuring the ESU

output against test loads set and adjusted in the Analyzer.

The Analyzer can automatically execute a power

distribution test with a load resistance ranging from 10

ohms to 5200 ohms. The Analyzer automatically

measures crest factor with a bandwidth of 2.5 MHz (with

loads), ensuring that the test result is reliable and

reproducible.

Test results shown in the Analyzer’s LCD display can be

printed out directly or transferred to a PC via the Ansur

QA-ES Plug-in test automation software. The Ansur

QA-ES Plug-in software allows you to design test

protocols, remotely control the Analyzer, and store test

results.

Carefully unpack all items from the box and check that

you have the items listed under Standard Accessories.

If you are missing any of these items, or if you find a

damaged item, follow the procedures found in the

Unpacking and Inspection Notices in the front of this

manual.

1

Page 12

QA-ES II

Users Manual

Safety

WXWarning

Read before using the Analyzer.

To avoid possible electric shock or personal

injury, follow these guidelines:

• Do not use the Analyzer in any manner not

specified in the Users Manual. Otherwise, the

protection provided by this product may be

impaired.

• Always press power off on the Analyzer and

unplug the power cord before cleaning the

outer surface.

• Inspect the product. If the Analyzer appears

damaged or appears to operate in a manner

not specified in the manual, DO NOT

CONTINUE USE. Return the product for

service.

• Avoid spilling liquids on the Analyzer; fluid

seepage into internal components creates

corrosion and a potential shock hazard. Do

not operate the instrument if fluid has

contaminated internal components.

• Do not open the Analyzer. There are no user

replaceable parts.

• Do not use the Analyzer in CAT II, III, or IV

environments.

• Retractable end of test leads are for use on

ESU only.

• No probes or accessories supplied with the

Analyzer are intended for handheld use.

Setup and stand clear when activating the

ESU with the footswitch.

2

Page 13

Electrosurgical Analyzer

Safety

WCaution

To avoid damage to the Analyzer:

• Calibrate the Analyzer annually.

• Only qualified technical personnel should

perform troubleshooting and service

procedures on the Analyzer.

• Do not use the Analyzer for anything other

than measuring RF outputs from

electrosurgical units.

• Ensure there is at least six inches of air

space above and behind the Analyzer to

allow air circulation to cool internal load

resistors.

• Do not expose the Analyzer to temperature

extremes. Ambient operating temperatures

should remain between 15 and 35 °C.

Analyzer performance may degrade if

temperatures fluctuate above or below this

range.

Refer to Table 1 for descriptions of symbols found on the

Analyzer.

Table 1. Symbols

Symbol Description

W

X

P

~

CAT I

CAT II

CAT III

T

See Users Manual

Caution, risk of electric shock

Manufacturer’s declaration of product

compliance with applicable EU directives

Do not mix with solid waste stream. Dispose

of using a qualified recycler or hazardous

material handler.

CAT I equipment is designed to protect

against transients from high-voltage lowenergy sources, such as electronic circuits or

a copy machine.

CAT II equipment is designed to protect

against transients from energy-consuming

equipment supplied from the fixed installation,

such as TVs, PCs, portable tools, and other

household appliances.

CAT III equipment is designed to protect

against transients in equipment in fixedequipment installations, such as distribution

panels, feeders, and short branch circuits, and

lighting systems in large buildings.

Double insulated

3

Page 14

QA-ES II

Users Manual

Specifications

General

Temperature, Operating .......................................15 °C to 35 °C (59 °F to 95 °F)

Temperature, Storage ........................................... 0

Humidity.................................................................80% non-condensing

Display

Type ....................................................................LCD graphic display

Alphanumeric format ........................................... 8 lines, 40 characters

Graphics mode.................................................... 240 x 64 point matrix

Controls .................................................................Function keys F1 through F5, ENTER, CANCEL, and an encoder control

Interfaces ...............................................................Parallel printer port; bi-directional RS232 for computer control

Power .....................................................................115/230 VAC, 48 to 66 Hz, 35 VA

Mechanical Specifications

Housing ............................................................... Metal case

Height.................................................................. 13.2 cm (5.2 in)

Width ................................................................... 34.2 cm (13.5 in)

Length .................................................................39.5 cm (15.6 in)

Weight ....................................................................9.8 kg (21.6 lbs)

Models

QA-ES II Electrosurgical Analyzer (115 V) ......... PN 2649769

QA-ES II Electrosurgical Analyzer (230 V).......... PN 2651725

QA-ES II Electrosurgical Analyzer (230 V UK) ... PN 2770445

QA-ES II Electrosurgical Analyzer (230 V AUS) . PN 2770450

°C to 50 °C (32 °F to 122 °F)

4

Page 15

Electrosurgical Analyzer

Specifications

Standard Accessories

Power Cord, country-specific

115 V USA Hospital Grade ............................. PN 2461816

230 V, 10 A Schuko ........................................ PN 2463040

UK ................................................................... PN 769455

Australia .......................................................... PN 658641

Test Lead with Stackable Plugs .......................... PN 2826194

Suregrip Large Alligator Clip set.......................... PN 1610159

Test Lead set with Retractable Sheaths ............. PN 1903307

ESU-Dispersive Safety Lead............................... PN 2772171

ESU-CQM Safety Lead ....................................... PN 2772180

ESU-Jumper Safety Lead.................................... PN 2772209

Users Manual ...................................................... PN 2716032

CD (Users Manual).............................................. PN 2716044

Optional Accessories

Clamp (crocodile style), Grip C, black................. PN 2523266

Clamp (crocodile style), Grip C, red .................... PN 2523275

Carrying Case .................................................... PN 2461794

Calibration Manual .............................................. PN 2716059

Ansur Test Software, QA-ES Plug-in License ..... PN 2461802

Data Transfer Cable, RS232 ............................... PN 2461993

Storage ...................................................................Store in the carrying case in dry surroundings within the temperature range specified.

Periodic Inspection ...............................................Calibrate the Analyzer every 12 months.

5

Page 16

QA-ES II

Users Manual

Measurement

Generator Output ..................................................RF leakage: from active electrode or neutral plate with an open or closed load circuit

Mode of Operation ................................................Manual or user-programmable. Control remotely with PC utilizing accessory Ansur QA-ES

Measurements ....................................................... True RMS value of applied waveform

RMS Bandwidth.....................................................30 Hz to 10 MHz (-3 dB) for instrumentation only; 30 Hz to 2.5 MHz (-3 dB) with loads

Low Frequency Filter ............................................ 100 Hz filter to avoid low frequency disturbance and/or interference

Current ...................................................................20 mA to 2200 mA

Current Accuracy.................................................. 20 to 2200 mA ±2 % of reading

Load Resistance.................................................... 10 to 2500 Ω in steps of 25 Ω (at dc); 2500 to 5200 Ω in steps of 100 Ω (at dc)

Additional Fixed Load...........................................200 Ω, 400 W maximum for 30 seconds, maximum 15 % duty cycle

Crest Factor ........................................................... The Analyzer uses the higher of the two peak measurements for calculation.

Range .....................................................................1.4 to 16 (V peak voltage / V RMS)

Foot Switch Output ...............................................The output triggers the measurement after a programmed delay time, defined as the time

Peak-to-Peak Voltage............................................ 0 to 10 kV (closed load only) Accuracy ±10 %. The Analyzer takes a measurement

Volt-Hertz Product................................................. 10

Oscilloscope Output ............................................. 5 V/A uncalibrated, 100 mA RF current minimum input

Plug-in software and RS232 communication cable connection.

10 Ω at 100 W for 30 seconds, 15 % duty cycle

25 to 50 Ω at 200 W for 30 seconds, 15 % duty cycle

75 to 2975 Ω at 400 W for 30 seconds, 15 % duty cycle

≥3000 Ω at 70 W for 30 seconds, 15 % duty cycle

all load resistances at 500 W for 5 seconds, 10 % duty cycle

from the activation of the foot switch to the beginning of data processing. The delay time

is 200 ms to 4000 ms.

between the active and dispersive electrodes with closed load only.

9

6

Page 17

Electrosurgical Analyzer

Controls and Connections

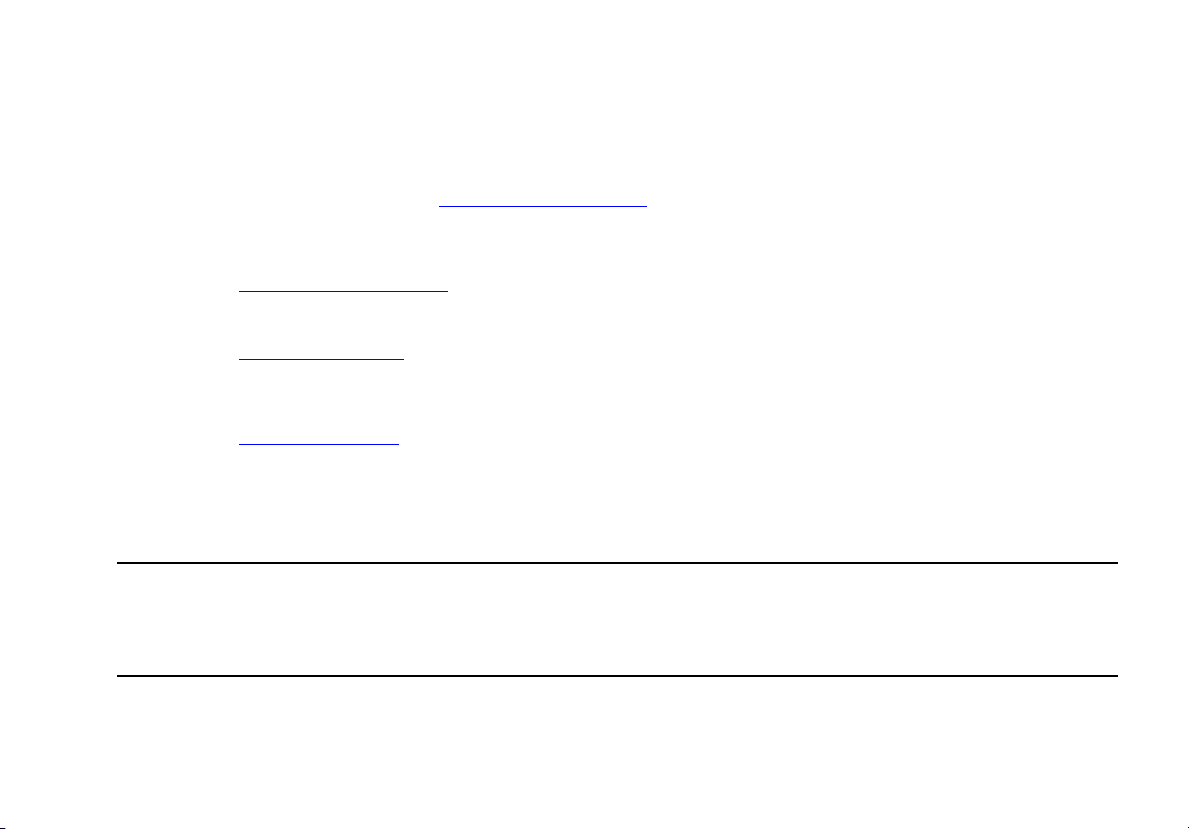

Controls and Connections

Refer to Figures 1 and 2 and Table 2.

2

3

4

1

Q

A

-

E

S

E

L

E

C

T

R

O

S

U

RG

E

R

Y

A

NA

L

Y

Z

E

R

P

O

W

E

F

1

F

2

F

3

F

4

F

5

C

ANC

E

L

E

NT

E

R

R

F

-

D

E

T

E

C

T

R

E

M

O

T

E

R

S

C

O

P

E

O

U

T

P

U

T

5

9

8

7

6

10

11

12

.

R

A

V

D

A

D

O

E

L

X

I

F

D

A

O

T

L

O

O

F

H

C

T

I

W

S

eju011.emf

Figure 1. Controls and Connectors

7

Page 18

QA-ES II

Users Manual

13

1

1

5

V

8

17 16

15

14

Figure 2. Rear Panel

eju010.emf

Page 19

Electrosurgical Analyzer

Controls and Connections

Table 2. Controls and Connectors

Item Name Description

A LCD Display Shows messages, test results, and function menus.

B Cancel Cancels a new value and returns to previously chosen value.

C Encoder Used to set value according to the specified range and chooses between different

operations and measurement ranges.

D Enter Admits newly specified information.

E Power Switch Switches the power on and off.

F Scope Output Connector BNC cable connector for attenuator signal in real time when you require

oscilloscope output.

G Remote Indicates that you have pressed REMOTE CONTR. (F4).

H RF-Detect Indicates an activated ESU.

I Function Keys Fl through F5 each selects the function shown directly above the key on the bottom

line of the LCD display.

J Terminals

GREEN and GREEN

K Terminals

WHITE and WHITE

9

Used for the foot switch output to trigger the ESU. Refer to “Foot Switch Control”

later in this manual.

Used for additional fixed load resistance of 200 • FIXED LOAD, 400 W for serial

connection during leakage test.

Page 20

QA-ES II

Users Manual

Table 2. Controls and Connectors (cont.)

Item Name Description

L Terminals

RED and BLACK

Connection for the electrode outputs of the VAR. LOAD ESU. Attach the active electrode

to the red terminal and neutral electrode to the black terminal.

M Fuses T 200 mA at 230 VAC / T 400 mA at 115 VAC

N Printer Port 25 pin D-sub

O RS232 Serial Port 9-pin D-sub

P Voltage Selector 115 VAC/230 VAC

Q Mains Connector 3-pin connector to power cord

Main Switch On and Off

W Caution

To avoid damaging the Analyzer, ensure the

rear-panel voltage selector switch is set to

the correct mains voltage and the proper

mains fuses are installed for the selected

voltage. Refer to items 16 and 13 in Figure 2

to check the voltage and fuses respectively.

10

The main switch is located on the front panel (see item 5

in Figure 1). When turning the Analyzer off, wait at least

five seconds before turning it on again to allow the reset

circuit to unload.

Analyzer Menu and Function Keys

The Analyzer provides flexibility and control over the

operations with a display, programmable function keys,

and a setting regulator. The upper part of the LCD screen

displays messages, status, and results. The menu bar is

at the bottom of the display. The function keys range from

Fl to F5. Select a function by pressing the key located

directly under the menu bar item.

Page 21

Electrosurgical Analyzer

Analyzer Menu and Function Keys

LCD Display Menu Messages

Start-up Screen

The following screen displays for two seconds after you

switch the Analyzer on:

F1 F2 F3 F4 F5

eju009.eps

eju008.eps

Main Menu

The Analyzer presents the Main menu on the following

two screens. Select a different screen by pressing F5.

F1 F2 F3 F4 F5

eju006.eps

11

Page 22

QA-ES II

Users Manual

SHOW CHOICES (F1)

This function is activated when you see an asterisk (*) in

the status field under ‘Mode’. Choose a test function by

pressing UP (F2) or DOWN (F3). You can also use the

encoder to choose a test function. Press ENTER (F5) to

save the test function under Mode in the STATUS field.

Press CANCEL (F4) to undo the selection.

F1 F2 F3 F4 F5

eju005.eps

KNOB PARAM. (F2)

With this function, you can choose among ‘Mode’, ‘Load’,

and ‘Delay’ in the STATUS field. An asterisk ‘*’ marks the

active item. If you choose ‘Load’, use the encoder to set

the load from 10 ohms to 5200 ohms in the following

increments:

• In increments of 25 ohms from 50 ohms to 2500

ohms.

In increments of 100 ohms from 2500 ohms to 5200

•

ohms.

Save the selected load in ‘Mode’ under the ‘STATUS’

field by pressing ENTER (F5). Press CANCEL (F4) to

undo the selection.

If you choose ‘Delay’, use the setting regulator to set the

delay from 200 ms to 4000 ms in the following

increments:

• In 50 ms increments from 200 ms to 1000 ms

•

In 100 ms increments from 1000 ms to 4000 ms

Save the chosen delay in ‘Delay’ under the ‘STATUS’

field by pressing ENTER (F5). Press CANCEL (F4) to

undo a choice.

START (F3)

Press START (F3) to start a test procedure. The text in

the field ‘Oper.’ changes from ‘Ready’ to ‘Measuring’. If

you have set the Analyzer to the position for a REM test,

this text changes from ‘Ready’ to ‘lncr. res.’ Press

STOP (F3) to stop the test procedure.

12

Page 23

Electrosurgical Analyzer

Analyzer Menu and Function Keys

SETUP (F4)

Here you can set the power distribution level for start,

stop, and step in ohms.

F1 F2 F3 F4 F5

eju007.eps

Choose ‘Start load’ by using KNOB PARAM (F4). Use

the encoder to set the level. Save the level by pressing

ENTER (F5). Press CANCEL (F4) to undo an action. Go

to ‘End load’ and ‘Step Size’ and repeat the same

procedure.

Pwr. distr. Start load is the first load during the

measurements; it can be set from 10 ohms to 2100 ohms,

in increments of 25 ohms beginning at 25 ohms.

Pwr. distr. End load is the last load used in the

measurements; it can be set from 525 ohms to 5200

ohms, in increments of 25 ohms from 525 to 2500

ohms and 100 ohms from 2500 ohms to 5200 ohms.

Pwr. distr. Step Size is the load set with steps of 25, 50,

100, and 200 ohms.

QUIT MENU (F5)

Press this key to return to the main menu.

PRINT HEADER (F3)

Press this key to write a heading for a new test protocol.

REMOTE CONTR. (F4)

This selection enables you to control the Analyzer

through a PC, using the Ansur QA-ES Plug-in software

(optional accessory).

Printout

Press PRINT HEADER (F3) before printing out a page if

you want it to have a new heading. The Analyzer

automatically prints out the test results via the printer

output after every measurement. See Figure 3.

13

Page 24

QA-ES II

Users Manual

Foot Switch Output

Relays (K11) activate a Foot Switch Output, located on

the right side of the Analyzer. Use this output to trigger

the foot switch input on the ESU under test for any of the

Analyzer test modes. Refer to “Foot Switch Control” later

in this manual.

ESU Tests with the Analyzer

This section describes the tests that the Analyzer can

conduct on an ESU, as well as the features available with

the Ansur QA-ES Plug-in software optional accessory.

There are five available test modes with the Analyzer, as

follows:

• Continuous Operation

• Single Operation

• Power Distribution

• RF Leakage

14

Figure 3. Test Results Printout

eju001.eps

• REM Test

Page 25

Electrosurgical Analyzer

ESU Tests with the Analyzer

Access these tests using the following steps:

1. Press F2 until an asterisk (*) symbol appears

following ‘Mode’.

2. Rotate the encoder knob until the required test mode

appears on the screen, and then press the Enter

key.

Power Output Tests

You can conduct power output tests with the Analyzer in

the Continuous Operation, Single Operation, or Power

Distribution mode. These tests check the power output

characteristics of the ESU and provide output current (A),

power (W), peak-to-peak voltage (V), and crest factor

values.

The following standards and setup diagram apply to any

of the power output test modes.

Note

Do not reduce the power output by more than

that specified in IEC 601-2-2, Third edition

1998-09. The power output must be within the

range specified in ANSI/AAMI HF18-2001.

Figure 4 shows a test setup for ESU power output using

the Analyzer foot switch trigger. You can use the same

red and black connections with the ESU triggered by its

foot switch or hand switch. Refer to Table 3 for load

resistance settings.

W Warning

No probes or accessories supplied with the

Analyzer are intended for handheld use.

Setup and stand clear when activating the

ESU with the footswitch.

ESU

Foot Switch

Red

Active

Neutral

The QA-ES II simulates the foot switch in "Singl. Oper.'

Black

Figure 4. ESU Power Output Test

QA-ES

Green

Green

eju012.eps

15

Page 26

QA-ES II

Users Manual

Table 3. Load Resistance

Load Resistance Range Equipment

IEC ANSI/AAMI

Monopolar 100 to 2000 Ω 50 to 2000 Ω

Bipolar 10 to 1000 Ω 10 to 1000 Ω

Continuous Operation Test

In the Continuous Operation mode, the Analyzer

continues to take measurements once you press the

START key. End this test by pressing the STOP key. The

Analyzer acts much like a meter during the test, showing

increasing and decreasing values as received from the

ESU.

To run a test in Continuous Operation mode:

1. Press F2 until an asterisk (*) symbol appears

following ‘Mode’.

2. Rotate the encoder knob until the *Cont. Oper test

mode appears on the screen, and then press the

Enter key.

3. Set the test load as required for the test.

4. Press START (F3) to begin testing.

5. Activate the ESU and verify that the Analyzer is

recording measurements.

6. Press STOP (F3) to end the test.

Single Operation Test

In the Single Operation mode, the Analyzer makes a

single measurement of the ESU output after the set delay

time. When the measurement is complete, the test

automatically stops. Make connections between the

Analyzer and the ESU as shown in Figure 4.

To run a test in Single Operation:

1. Press F2 until an asterisk (*) symbol appears

following ‘Mode’.

2. Rotate the encoder knob until the *Singl. Oper test

mode appears on the screen, and then press the

Enter key.

3. Set the test Load as required for the test.

4. Set the Delay time as required for the test.

5. Set and activate the ESU.

6. Press START (F3) to take a measurement. After the

set delay, the Analyzer records the values and

displays them on the screen.

16

Page 27

Electrosurgical Analyzer

ESU Tests with the Analyzer

7. After taking a measurement, the Analyzer resets

automatically and is then ready for additional testing.

If connected to a printer, the Analyzer writes a line of test

results to the printer following each Single Operation test.

Power Distribution Test

The Power Distribution test allows you to check the power

output performance of the ESU over a range of load

resistances. When using the Analyzer’s footswitch control

ESU

Foot Switch

Active

Neutral (dispersive)

21

Red

Black

QA-ES

Green

Green

during the power distribution test, the ESU output power

automatically powers on and off. The ESU activates, the

Analyzer gets the reading on the first selected load, and

then the ESU turns off while the Analyzer changes the

load to the second selection. Next, the ESU powers on

again and the Analyzer gets the reading. This cycle

Figure 5. Power Distribution Test

eju018.eps

continues throughout the entire range of selected test

loads.

Connect the Analyzer and the ESU as shown in Figure 5

before starting the next series of tests.

17

Page 28

QA-ES II

Users Manual

To run a Power Distribution Test, perform the following

steps:

1. Press F2 until an asterisk (*) symbol appears

following ‘Mode’.

2. Rotate the encoder knob until the *Power Dist test

mode appears on the screen, and then press the

Enter key.

3. Press SETUP (F4) to access the setup menu for this

test.

4. Set the Start Load, End Load, and Step Size for the

test. Use the KNOB PARAM. (F3) key, the encoder

knob, and the Enter key to make and confirm

selections. Press QUIT MENU (F4) when set.

5. Set and activate the ESU using the Analyzer foot

switch control instructions found later in this manual.

WCaution

If you cannot connect to the foot switch

control, you may be able to keep the ESU

activated throughout the test. However,

please check with the ESU manufacturer

prior to triggering for a prolonged period in

this fashion; damage to the ESU could

otherwise result.

6. Press START (F3) to begin the test. The Analyzer

steps through the loads with a delay between each,

as set in the test SETUP screen. The Analyzer

displays values on the screen for each load as it

steps through the test.

(If connected to a printer, the Analyzer writes a line of test

results for each step in the Power Distribution Test.)

HF Current Leakage Test

This test checks whether the active and dispersive

leakage currents are within acceptable limits. There are

four test setups to accomplish this testing.

The ESU must operate at the maximum output setting in

each operating mode per IEC 601-2-2 and ANSI/AAMI

HF18-2001 specifications. The limits for the acceptable

leakage currents depend upon the test configuration as

shown in Table 4.

18

Page 29

Electrosurgical Analyzer

ESU Tests with the Analyzer

Table 4. Leakage Resistance

Test

Configuration

Measured on

electrodes

Bipolar The leakage current should not exceed

Measured at

equipment

terminals

Limits of Acceptable Leakage

Current

The leakage current should not exceed

150 mA.

1 % of the maximum bipolar rated

power output.

The leakage current should not exceed

100 mA.

Test Procedure

To run an HF Leakage Test, perform the following steps:

1. Connect the Analyzer to the ESU to test leakage

from the Active electrode using the appropriate

setup, as shown under “HF Isolated Equipment” or

“Ground HF Equipment.”

2. Press F2 until an asterisk (*) symbol appears

following ‘Mode’.

3. Rotate the encoder knob until the *RF Leakage test

mode appears on the screen, and then press the

Enter key.

4. Set the ESU as prescribed by the manufacturer for

leakage tests and then activate the ESU.

5. With the ESU activated, press START (F3); the

Analyzer takes the leakage measurement.

6. Repeat the leakage test as needed for other ESU

accessories.

If connected to a printer, the Analyzer writes a line of test

results to the printer following each HF Leakage Test.

Measuring Leakage Current with HF Isolated Equipment

Make measurements of the HF current leakage from the

active and neutral electrodes. The test load is 200 ohms,

and the ESU must be operating at maximum power.

19

Page 30

QA-ES II

Users Manual

The Active electrode Test Setup A shown in Figure 6

complies with IEC 601.2.2, sec. 19.101b, fig, 104 and

sec. 19.102, adopted by ANSI/AAMI HF18-2001.

eju015.eps

Figure 6. Test Setup A

The Neutral electrode Test Setup B as shown in Figure 7

complies with IEC 601.2.2, sec. 19.101b, fig, 104 and

Red

Measuring

Load

Black

eju016.eps

sec. 19.102, adopted by ANSI/AAMI HF18-2001.

QA-ES

Earthing

Contact

ESU

Neutral

Figure 7. Test Setup B

20

Page 31

Electrosurgical Analyzer

ESU Tests with the Analyzer

Measuring Leakage Current with Grounded HF Equipment

With the ESU grounded, the test load is 200 ohms, and

the ESU must be operating at maximum power. Test

Setup C as shown in Figure 8 complies with IEC 601.2.2,

sec. 19.101a, test 1, fig. 102, and sec. 19.102, adopted

by ANSI/AAMI HF18-2001.

Red

QA-ES

White

Fixed

Load

White

Measuring

Load

Black

eju013.eps

Earthing

Contact

Active

ESU

Neutral

Figure 8. Test Setup C

Test Setup D shown in Figure 9 complies with IEC

601.2.2, sec. 19.101a, test 2, fig. 103, and sec. 19.102,

adopted by ANSI/AAMI HF18-2001.

White

Earthing

Contact

Active

ESU

Neutral

QA-ES

White

Fixed

Load

Red

Measuring

Load

Black

eju014.eps

Figure 9. Test Setup D

REM Alarm Test

The REM (Return Electrode Monitoring) alarm test

ensures that the ESU sounds an alarm if the resistance

between the two neutral electrodes exceeds its specified

21

Page 32

QA-ES II

Users Manual

limit. The program directs the QA-ES to increase the

resistance gradually, starting at 10 ohms and increasing

through all available load settings. At a certain value, the

ESU should sound an alarm. See Figure 10 for the test

setup for the ESU REM Alarm Test using the Analyzer

foot switch trigger. You can use the same red and black

connections with the ESU triggered by its foot switch or

hand switch.

ESU

Foot Switch

Red

Neutral 1

Neutral 2

The QA-ES II simulates the foot switch in "Singl. Oper.'

Black

QA-ES

Green

Green

eju017.eps

Figure 10. REM Alarm Test Setup

To run a REM test, perform the following steps:

1. Connect the Analyzer to the ESU as shown in

Figure 10.

2. Press F2 until an asterisk (*) symbol appears

following ‘Mode’.

3. Rotate the encoder knob until the REM Test test

mode appears on the screen, and then press the

Enter key. This mode generally tests any of the

monitoring and alarm systems for return, neutral, or

dispersive electrodes.

4. Set the Delay time for the test. Fluke Biomedical

recommends a significant delay time (2000 to

4000 ms) to identify the alarm point more easily.

5. Press START (F3) to begin the REM test.

6. When the ESU alarm sounds, press STOP (F3) to

end the test. The load at which the alarm activated

stays on the screen.

If connected to a printer, the Analyzer writes a line of test

results to the printer following the REM test.

22

Page 33

Electrosurgical Analyzer

Foot Switch Control

Foot Switch Control

There are three sets of two jacks each on the right side of

the Analyzer. The sets are as follows:

1. FOOT SWITCH (green jacks)

2. FIXED LOAD (white jacks)

3. VAR. LOAD, (red and black jacks)

Note

For the following instructions, refer to the ESU

manufacturer’s instructions to determine the

wiring of the ESU monopolar and bipolar foot

switch jacks. Only qualified technicians should

do this, since the technician will be responsible

for making appropriate and safe test cables.

Refer to Figure 5 and Table 5 for connection examples.

Table 5. Foot Switch Connections

Monopolar Cut

A

B

A

B

A

B

Cut activate pin of ESU foot switch

Common

Coag

Coag activate pin of ESU foot switch

Common

Bipolar

Bipolar activate pin of ESU foot switch

Common

23

Page 34

QA-ES II

Users Manual

Monopolar Testing

Cut Activation

1. Connect the red jack on the Analyzer to the active

output on the ESU front panel.

2. Select a proper load for cut output on the ESU.

3. Connect the black jack on the Analyzer to the ESU

front panel via a dispersive return cable.

4. Connect one of the Analyzer green jacks to the cut

activate pin of the ESU foot switch.

5. Connect the other Analyzer green jack to the

common line of the ESU foot switch.

Coag Activation

1. Connect the Analyzer red jack to the active output on

the ESU front panel.

2. Select a proper load for the cut output on the ESU.

3. Connect the Analyzer black jack to the ESU front

panel via a dispersive return cable.

4. Connect one of the green jacks of the Analyzer to the

coag activate pin of the ESU foot switch

5. Connect the other green jack on the Analyzer to the

common line on the ESU foot switch.

Bipolar Testing

1. Connect the Analyzer red jack to the load for the

bipolar cut

2. Select a proper load for the

output

3. Connect the Analyzer black jack to the return of the

bipolar.

4. Leave the dispersive cable connected to the ESU so

that REM does not alarm. Disconnect this single-pin

banana plug from the Analyzer and place it on a nonconductive surface where it cannot contact anyone.

5. Connect one of the Analyzer green jacks to the

activate pin of the ESU bipolar foot switch. Connect

the other Analyzer green jack to the common line on

the ESU bipolar foot switch.

active output on the ESU front panel.

bipolar cut active

on the ESU.

Cleaning the Analyzer

Periodically wipe the Analyzer case with a damp cloth

moistened with a mild detergent. Do not use abrasives or

solvents.

24

Loading...

Loading...