Page 1

Programmable

Frequency Counter

PM6685 & PM6685R

Service Manual

Page 2

This is a complementary service manual covering instruments with manufacturing numbers exceeding 840684. The principal

differences are to be found in Chapter 7 and in Chapter 8 due to a major redesign of the main PCB.

Do not dispose of the previous edition, identified by the part number, 4822 872 25012, and the publishing date, June 1996.

You may have to refer to it for information on older instruments as well as options not mentioned here.

4822 872 20106

First Edition (May 2003)

No part of this manual may be copied without the express permission of the copyright owner.

All product names are trademarks of their respective companies.

Ó 2003 Pendulum Instruments AB

All rights reserved. Printed in Sweden.

Page 3

Contents

1 Safety Instructions

2 Performance Check

General Information .........................2-2

Recommended Test Equipment ................2-2

Front Panel Controls .........................2-2

Short Form Specification Test ..................2-3

Rear Input/Output ...........................2-4

Measuring Functions .........................2-4

Options ...................................2-5

3 Disassembly

Removing the Cover .........................3-2

Reinstalling the Cover ........................3-2

PM9624 (HF Input) ..........................3-2

PM9626B (GPIB Interface) ....................3-3

PM9691 or PM9692 (Oven Oscillator) ...........3-3

4 Circuit Descriptions

Block Diagram Description ....................4-2

General ..................................4-2

Hardware Functional Description ...............4-4

Front Unit .................................4-4

Main Board ................................4-5

Rear Panel Unit ............................4-13

Optional Units .............................4-14

Software Functional Description ..............4-15

Test Routines .............................4-16

5 Repair

Preventive Maintenance.......................5-2

Calibration .................................5-2

When to Replace the Fan

(PM6685R only ) ............................5-3

Troubleshooting .............................5-4

General ...................................5-4

Safety Inspection and Test After Repair .........5-9

General Directives...........................5-9

6 Calibration Adjustments

Introduction ................................6-2

Preparation ................................6-2

Power Supply ..............................6-2

Input Amplifier ..............................6-3

Reference Oscillators ........................6-4

Other Options ..............................6-6

7 Replacement Parts

Introduction ................................7-2

Mechanical Parts............................7-3

Main Board ................................7-6

Front Board ...............................7-12

GPIB Interface (PM9626B) ...................7-13

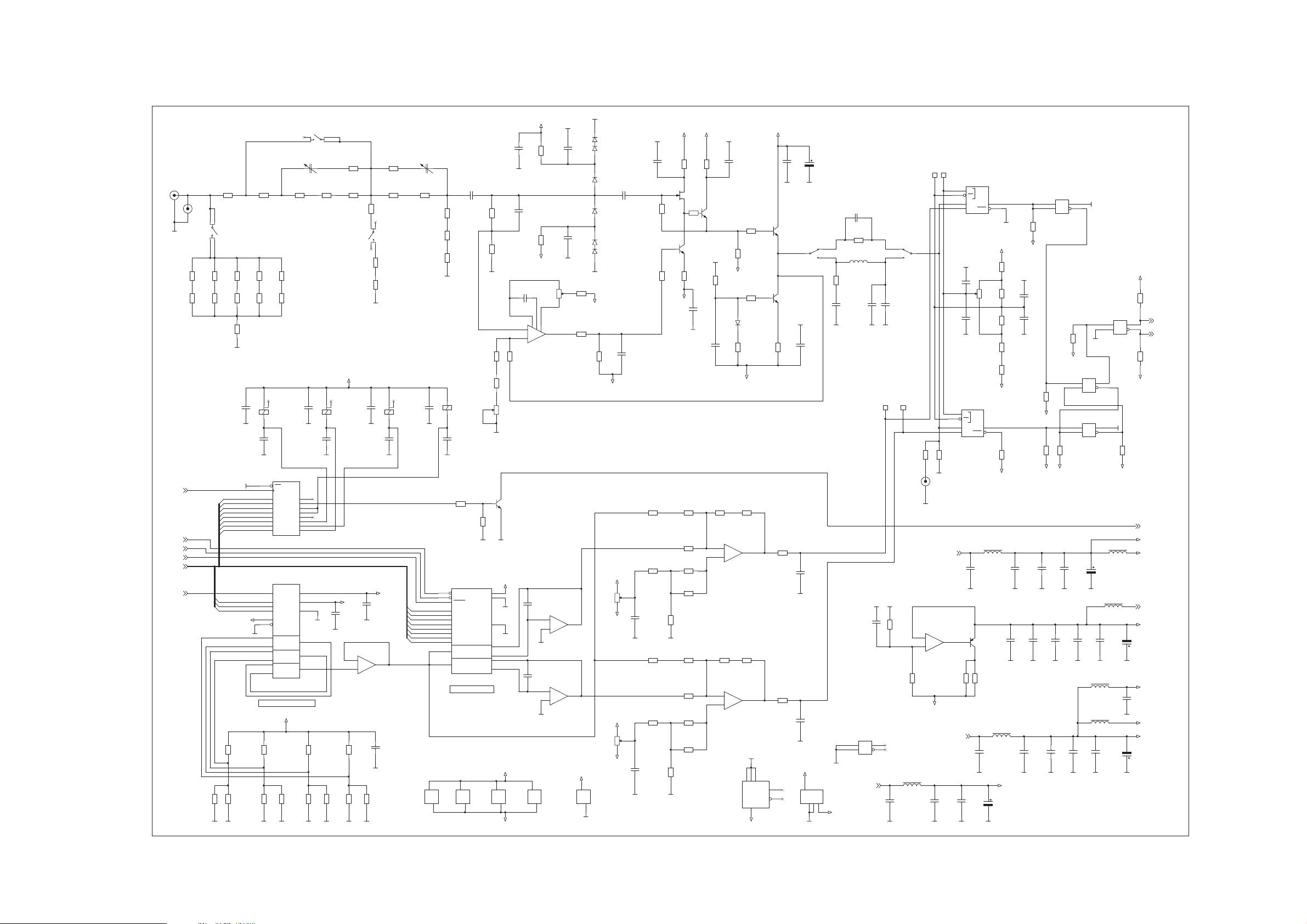

8 Drawings & Diagrams

How to read the diagrams.....................8-2

9 Appendix

How to Replace Surface Mounted Devices........9-2

Electrostatic discharge .......................9-3

Glossary ..................................9-4

Power Supply Switchmode Module .............9-5

Circuit Descriptions ..........................9-5

Repair ....................................9-6

Calibration Adjustments ......................9-7

Replacement Parts..........................9-8

PM6685R ..................................9-12

Introduction ...............................9-12

Performance Check ........................9-12

Functional Description.......................9-12

Calibration Adjustments .....................9-13

Replacement Parts .........................9-14

Page 4

This page is intentionally left blank.

Page 5

Chapter 1

Safety Instructions

Page 6

WARNING: These servicing instructions are for use

by qualified personnel only. To reduce the risk of

electric shock, do not perform any servicing other

than that specified in the Operating Manual unless

you are fully qualified to do so.

Authorized service and calibration of this instrument is available

through your Fluke representative. See address at the end of this

manual.

Read this chapter carefully before you check, adjust, or repair an in

strument.

The ground symbol on the rear panel indicates where the

protective ground lead is connected inside the instrument.

Never remove or loosen this screw.

When the instrument is brought from a cold to a warm environment,

condensation may cause hazardous conditions. Therefore, ensure

that the grounding requirements are strictly met.

Power extension cables must always have a protective ground con

ductor.

-

Indicates that the operator should consult the manual.

-

Caution and Warning Statements

You will find specific warning and caution statements where neces

sary throughout the manual.

CAUTION: Indicates where incorrect operating proce

dures can cause damage to, or destruction of,

equipment or other property.

WARNING: Indicates a potential danger that requires

correct procedures or practices in order to prevent

personal injury.

This Timer/Counter has been designed and tested in accordance with

safety class 1 requirements for Electronic Measuring Apparatus of

IEC (CENELEC) publication EN61010-1, and CSA 22.2

No. 1010-1, and has been supplied in a safe condition.

This manual contains information and warnings that should be fol

lowed by the user and the service technician to ensure safe operation

and repair in order to keep the instrument in a safe condition.

WARNING: Opening instrument covers or removing

parts, except those to which access can be gained

by hand, is likely to expose high voltages which

can cause death.

The instrument must be disconnected from all voltage sources before

it is opened. Remember that the capacitors inside the instrument re

tain their charge even if the instrument has been disconnected from

all voltage sources.

-

Grounding

This instrument is connected to ground via a sealed three-core power

cable, which must be plugged into socket outlets with protective

ground contacts. No other method of grounding is permitted for this

instrument.

WARNING: Any interruption of the protective ground

-

conductor inside or outside the instrument, or dis

connection of the protec- tive ground terminal, is

likely to make the instrument dangerous. Do not in

tentionally disrupt the protective grounding.

-

-

Disposal of Hazardous Materials

WARNING: Disposal of lithium batteries requires spe

cial attention. Do not expose the batteries to heat

or put them under extensive pressure. These mea

sures may cause the batteries to explode.

A lithium battery is used to power the nonvolatile RAM in this in

strument. Our world suffers from pollution, so don’t throw batteries

into your wastebasket. Return used batteries to your supplier or to the

Fluke representative in your country.

-

-

-

-

Line Voltage

The instrument can be powered by any voltage between 90 and

265 V

inal line voltages between 100 and 240 V.

n

Components that are important for the safety of this instrument may

-

only be replaced by components obtained from your local Fluke

representative. After exchange of the primary circuits, perform the

safety inspection and tests, as described in Chapter 5, “Repair”.

n

This instrument is protected by an ordinary 1.6 A slow blow fuse

mounted inside the instrument. NEVER replace this fuse without

first examining the Power Supply Unit.

without range switching. This makes it suitable for all nom

AC

Replacing Components in Primary Circuits

Fuses

-

1-2 Safety Instructions,

Page 7

Chapter 2

Performance Check

Page 8

General Information

Ω

WARNING: Before turning on the instrument, ensure

that it has been installed in accordance with the In

stallation Instructions outlined in Chapter 3 of the

Operators Manual.

This performance procedure is intended to:

Check the instrument’s specification.

–

Be used for incoming inspection to determine the acceptability

–

of newly purchased instruments and recently recalibrated in

struments.

Check the necessity of recalibration after the specified

–

recalibration intervals.

NOTE: The procedure does not check every facet of the in

strument’s calibration; rather, it is concerned primarily

with those parts of the instrument which are essential

for determining the function of the instrument.

It is not necessary to remove the cover of the instrument to perform

this procedure.

If the test is started less than 20 minutes after turning on the instru

ment, results may be out of specification, due to insufficient

warm-up time.

-

-

Preparations

Power up your instruments at least 20 minutes be

fore beginning the tests to let them reach normal

operating temperature. Failure to do so may result

in certain test steps not meeting equipment specifi

cations.

-

-

Front Panel Controls

Power-On Test

At power-on the counter performs an automatic self-test of the fol

-

-

lowing:

Microprocessor

–

–

RAM

ROM

–

Measuring circuits

–

Display

–

If a GPIB interface is installed, the GPIB address is displayed.

If there are any test failures, an error message is shown.

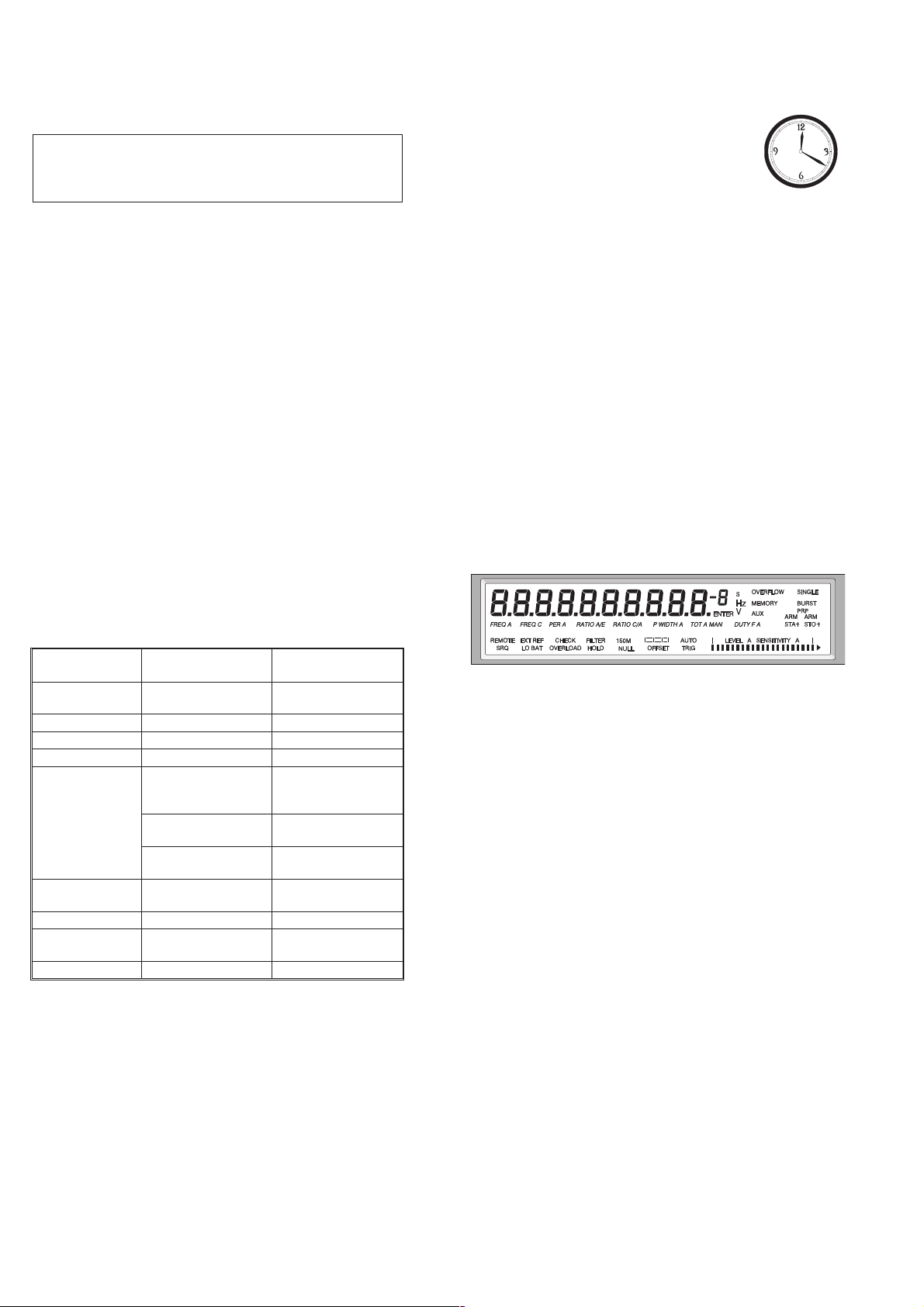

Turn on the counter and check that all segments light up on the

–

display and that no error message appears.

-

Recommended Test

Equipment

Type of instru

ment

LF Synthesizer Square;

Power Splitter 50 W PM9584/02

T-piece

Termination 50 W PM9585

Reference oscilla

tor

HF signal genera

tor

Pulse Generator 125 MHz

Oscilloscope with

probes

BNC cables 5 to 7 cables *

Table 2-1 Recommended Test Equipment.

*) Two of the cables must have 10 ns difference in delay, for ex

ample: 5 ns and 15 ns.

-

-

-

Required

Specifications

Sine up to 10 MHz

10 MHz ±0.1 Hz for

standard oscillator

10 MHz ±0.01 Hz for

PM9691 & PM9692

10 MHz ±0.0001 Hz

for PM6685R

0.5 GHz (no presc.)

3.3 GHz (option 10)

350 MHz

Suggested

Equipment

Fluke counter with

calibrated option

PM9691

Fluke PM6685R or

PM6681R

Fluke 910R or Ce

sium Standard

-

Fig. 2-1 Text on the display.

Internal Self-Tests

The different built-in test routines invoked by the power-on test can

also be activated from the front panel as follows:

Enter the Auxiliary Menu by pressing AUX MENU.

–

Select the test submenu by pressing DATA ENTRY up or

–

down.

Enter the test menu by pressing the ENTER key.

–

Selections for internal self-tests are:

1 TEST ALL (Test 2 to 5 in sequence)

2 TEST RO (ROM)

3 TEST RA (RAM)

4 TEST LOGIC (Measuring Logic)

5 TEST DISP (Display Test)

Use DATA ENTRY up/down to select TEST ALL, then press

–

ENTER.

If any fault is detected, an error message appears on the dis

–

play and the program halts.

If no faults are detected, the program returns to measuring

-

–

mode.

-

2-2 Performance Check, General Information

Page 9

Keyboard Test

The keyboard test verifies that the counter responds when you press

any key. To check the function behind the keys, see the tests further

on in this chapter.

Press the keys as described in the left column and look on the display

for the text, as described in the second column. Some keys change

more text on the display than described here. The display text men

tioned here is the text mainly associated with the selected key.

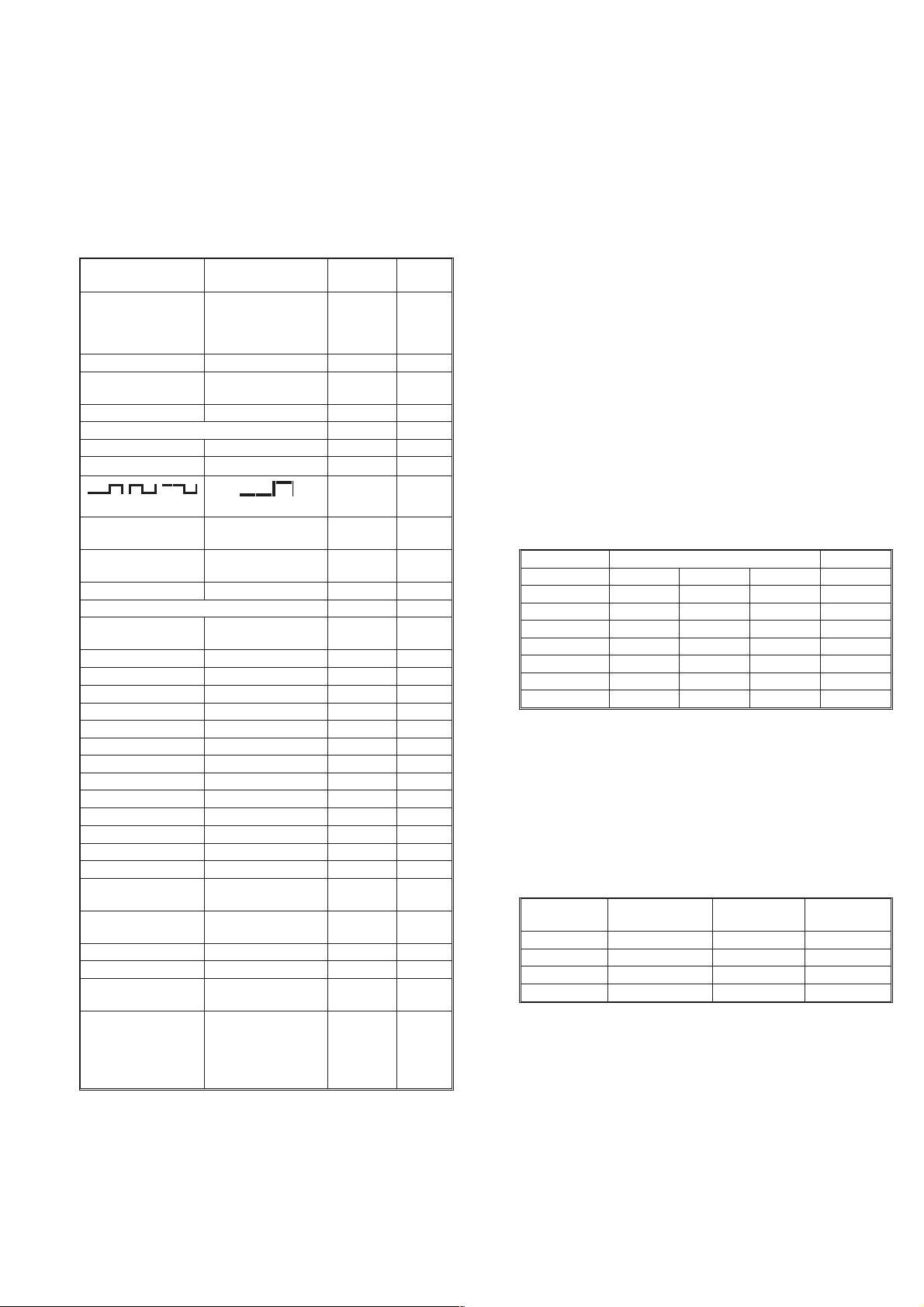

Key(s) Display Note Pass

STAND-BY Display Off Red LED

ON Backlight on

PRESET

ENTER

EXT REF EXT REF

Input A

FILTER FILTER

50 W

(2 times)

SENS

(2 times)

SENS

(2 times)

AUTO AUTO TRIG

PRESET

ENTER

MEAS TIME 200

DATA ENTRY 500

DATA ENTRY 200

ENTER NO SIGNAL

DISPLAY HOLD HOLD

DISPLAY HOLD

SINGLE SINGLE

FUNCTION DUTY F A

FUNCTION TOT A MAN

FUNCTION DUTY F A

FUNCTION FREQ A

AUX MENU RECALL

MEAS RESTART NO SIGNAL

PRESET

ENTER

CHECK 10.00000000

NULL NULL

NULL 10.00000000

BLANK DIGITS

(3 times)

MENU Displays all avail

DEFAULT?

NO SIGNAL

50 W

Bar graph:

zzzzzzzz

Bar graph:

zzzzzzzzzz

Other

DEFAULT?

NO SIGNAL

DEFAULT?

NO SIGNAL

10.00000___

able functions, pro

cesses and input

controls. Selected

items are blinking.

–3

s

–3

s

–3

s

6

Hz* Start

6

Hz*

6

Hz*

counting

-

-

Table 2-2 Keyboard Test.

beside

the key

On

Default

setting

Default

setting

Default

setting

/Fail

NOTE: For the instrument to respond correctly, this test must

be carried out in sequence and you must start with the

preset (power-on) setting.

* The LSD may vary.

** MENU is not disabled by setting DEFAULT; press menu again.

-

Short Form Specification

Test

Sensitivity and Frequency Range

Press the PRESET key to set the counter in the default setting.

–

Then confirm by pressing ENTER.

Turn off AUTO.

–

Select IMP A = 50 W and maximum sensitivity.

–

Connect a signal from a HF generator to a BNC power splitter.

–

Connect the power splitter to your counter and an oscilloscope.

–

Set input impedance to 50 W on the oscilloscope.

–

Adjust the amplitude according to the following table. Read

–

the level on the oscilloscope. The counter should display the

correct frequency.

Frequency Level Pass/Fail

MHz mV

1 30 10 –27

25 30 10 –27

50 30 10 –27

150 60 20 –21

200 90 30 –17

250 150 50 -13

300 150 50 -13

PP

mV

RMS

Table 2-3 Sensitivity of input A at various frequencies.

Reference Oscillators

X-tal oscillators are affected by a number of external conditions,

such as ambient temperature and supply voltage, but they are also af

fected by aging. Therefore, it is hard to give limits for the allowed

frequency deviation. You must decide the limits depending on your

application, and recalibrate the oscillator accordingly. See the Pre

ventive Maintenance in the Repair chapter, Chapter 5.

Oscillator Max. tempera

Standard ±100 Hz ±5 Hz ±50 Hz

PM9691 ±0.05 Hz ±0.1 Hz ±0.75 Hz

PM9692 ±0.025 Hz ±0.03 Hz ±0.2

Rubidium ±0.003 Hz ±0.0005 Hz ±0.002 Hz

ture dependence

Table 2-4 Deviation (for PM9691 and PM9692 after a

warm-up period of 48 hours).

To check the accuracy of the oscillator you must have a calibrated

reference signal that is at least five times as stable as the oscillator

that you are testing, see the following table.

Press the PRESET key, then press the ENTER key to set your

–

counter in the Default setting.

-

dBm Input A

Max. aging

per month

-

-

Max. aging

per year

Performance Check, Short Form Specification Test 2-3

Page 10

Connect the reference to input A.

–

Check the readout against the accuracy requirements of your

–

application.

Acceptance Test

n

As an acceptance test, the following table gives a worst case figure

after a 30 minute warm up time. All deviations that can occur in a

year are added together.

Oscillator Frequency readout Suitable refer

Standard 10.00000000 MHz

±120 Hz

PM9691 10.00000000 MHz

±1 Hz PM6685R

PM9692 10.00000000 MHz

±0.25 Hz

ence

PM9691

PM6681R

Pass

/Fail

Table 2-5 Acceptance test for oscillators.

Acceptance Test, PM6685R

n

To fully test the accuracy of the PM6685R, a reference signal of ex

tremely high stability is needed. Examples of such references are

Cesium Atomic references, or transmitted signals from a nationally

or internationally traceable source, like the GPS satellites.

EXT ARM INPUT

Press the PRESET key, then press the ENTER key to set your

–

counter in the Default setting.

Select 50 W input impedance.

–

Apply 10 MHz 500 mV

–

–

The counter measures and displays 10 MHz.

Press the AUX MENU key.

–

Press the DATA ENTRY UP/DOWN keys until the display

–

shows ‘Ar. Start’, confirm by pressing the ENTER key.

Press DATA ENTRY UP/DOWN keys until the display shows

–

‘POS’, confirm by pressing the ENTER key.

Press the ENTER key once more.

–

The counter does not measure.

–

Connect a pulse generator to Ext Arm input.

–

Settings for pulse generator: single shot pulse, amplitude TTL

–

=0-2V

Apply one single pulse to Ext Arm input.

–

-

The counter measures once and shows 10 MHz on the display.

–

, and duration = 10 ns.

PP

, (1.4 VPP) sine to input A

RMS

Recommended Test Equipment

Type Stability Model

10 MHz refer

ence

-

£ 1x10

-10

910R with satellite contact dur

ing the last 72 hours.

Test Procedure

Connect the counter to the line power.

–

Check that the UNLOCK indicator turns on, and then turns off

–

again within 6 minutes after connecting line power.

Connect the 10 MHz reference signal to input A of the counter.

–

Select FREQUENCY A measurement.

–

Select 2 s measuring time.

–

Check that the displayed frequency is 10.00000000 MHz

–

±0.05 Hz £ 10 minutes after connection to line power.

Rear Input/Output

INT REF Output

Connect an oscilloscope to the 10 MHz output on the rear of

–

the counter. Use coaxial cable and 50 W termination.

The output voltage is sinusoidal and should be above 2.8 VPP.

–

EXT REF Input

Press the PRESET key, then press the ENTER key to set your

–

counter in the Default setting.

Apply 10 MHz sine to input A equipped with a T-piece and to

–

Ext Ref input at the rear, terminated with 50 W. Amplitude on

10 MHz signal; 200 mV

–

Press the Ext Ref key.

The display should show 10.000000006Hz ± 5 LSD.

–

, (560 mVPP)

RMS

Measuring Functions

-

Preparation for Check of Measuring Function is as follows:

Connect a 10 MHz sine wave signal with 2.0 VPPamplitude

–

via a T-piece to Input A.

Connect a cable from the T-piece to Input E (Ext Arm) at the

–

rear.

Select the measuring function as in the ‘Selected Function’ col

–

umn and check that the counter performs the correct measure

ment by displaying the result as shown under the “Display”

column in the following table.

Selected Function Display Pass/ Fail

PRESET

ENTER

IMPA50W 10 MHz

Non AUTO 10 MHz

PER A 100 ns

RATIO A/E 1.0000000

PWIDTH A 50 ns

TOT A MAN

DISPLAY HOLD Start counting

DISPLAY HOLD Stop counting

DUTY FACT 0.500000

AUTO 0.500000

DEFAULT?

10 MHz

2)

1)

2)

2)

2)

1)

1)

Table 2-6 Measuring functions check.

1) Value depends on the symmetry of the signal.

2) Exact value depends on the input signal.

-

-

2-4 Performance Check, Rear Input/Output

Page 11

Options

Prescaler

This extra HF input (PM9624) is easily recognized by its front panel

connector (Input C, type N).

EX T

REF

Fig 2-2 Connect the output of the signal generator to the HF

Required Test Equipment Suggested Specification

HF signal generator 3.3 GHz

Table 2-8 Test equipment for 3.0 GHz HF input.

Connect the output of the signal generator to the HF input of

–

the counter.

Connect the 10 MHz REFERENCE OUT of the generator to

–

the REFERENCE IN at the rear panel of the counter.

Setting for the counter after Preset.

Function = FREQ C.

–

EXT REF.

–

Generate a sine wave in accordance with the following table.

Verify that the counter counts correctly. (The last digit will be

–

unstable).

Table 2-7 Sensitivity of the PM9624 HF input.

input of the counter.

Frequency Amplitude Pass/Fail

MHz mV

100-300 20 –21

-2500 10 –27

-2700 20 –21

-3000 100 –7

RMS

dBm

Performance Check, Options 2-5

Page 12

This page is intentionally left blank.

2-6 Performance Check, Options

Page 13

Chapter 3

Disassembly

Page 14

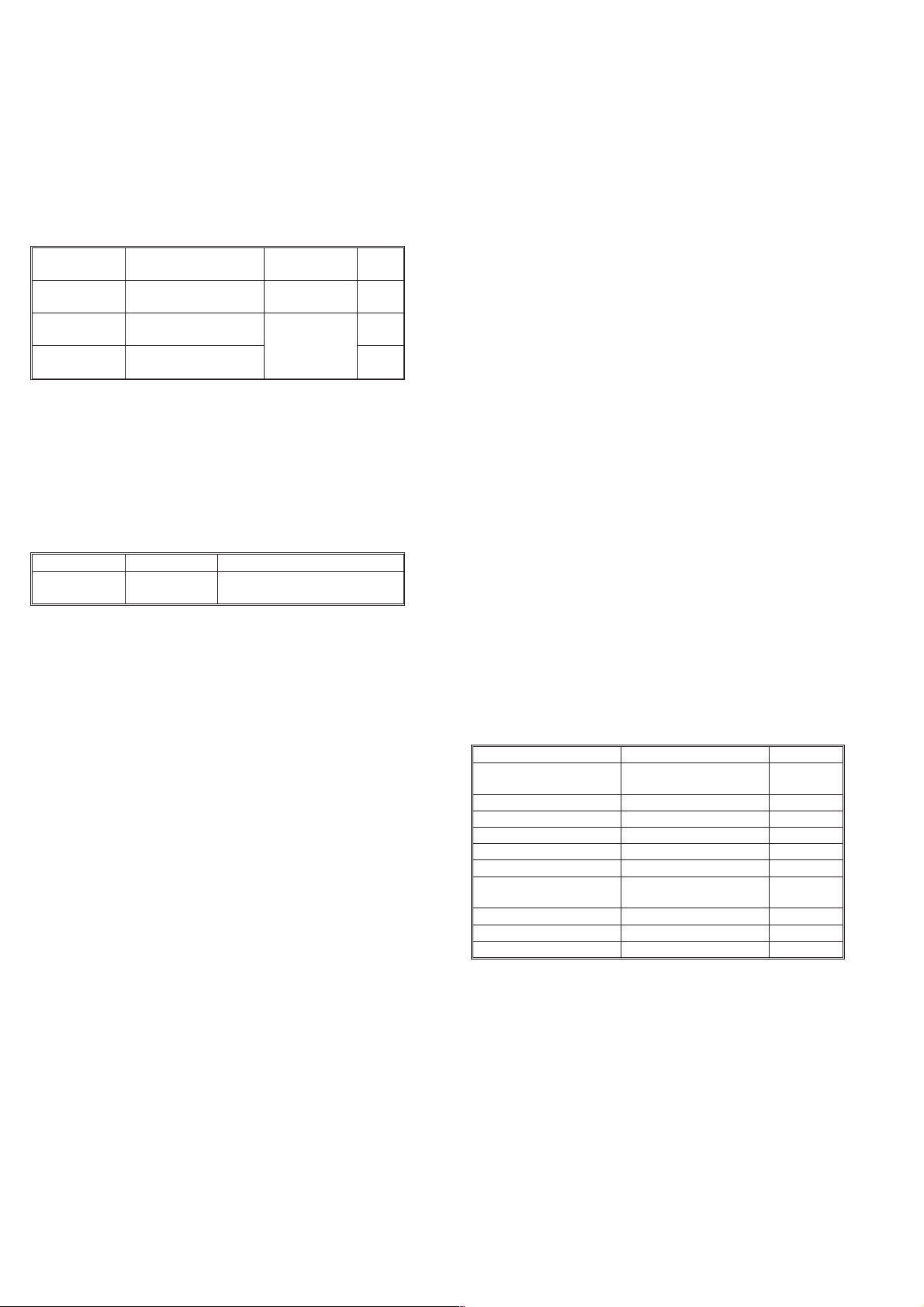

The terms in the following figure are used in all descriptions in this

manual.

To p

Left

Front Bottom

Fig. 3-1 Designations used in this manual.

The PM6685 is available with a number of options and accessories.

The labels on the rear panel of the counter identify the options and

accessories included. If there are no labels, the counter contains an

uncompensated crystal oscillator and no options. The following la

bels exist:

PM9624 3.0 GHz HF input

–

PM9691 High-Stability Oven Oscillator

–

PM9692 Ultra-High-Stability Oven Oscillator

–

PM9626B GPIB Interface

–

The location of these optional parts is illustrated in Fig.3-2.

GPIB interface

Power

Module

G1

Optional

oscillator

Rear

Right

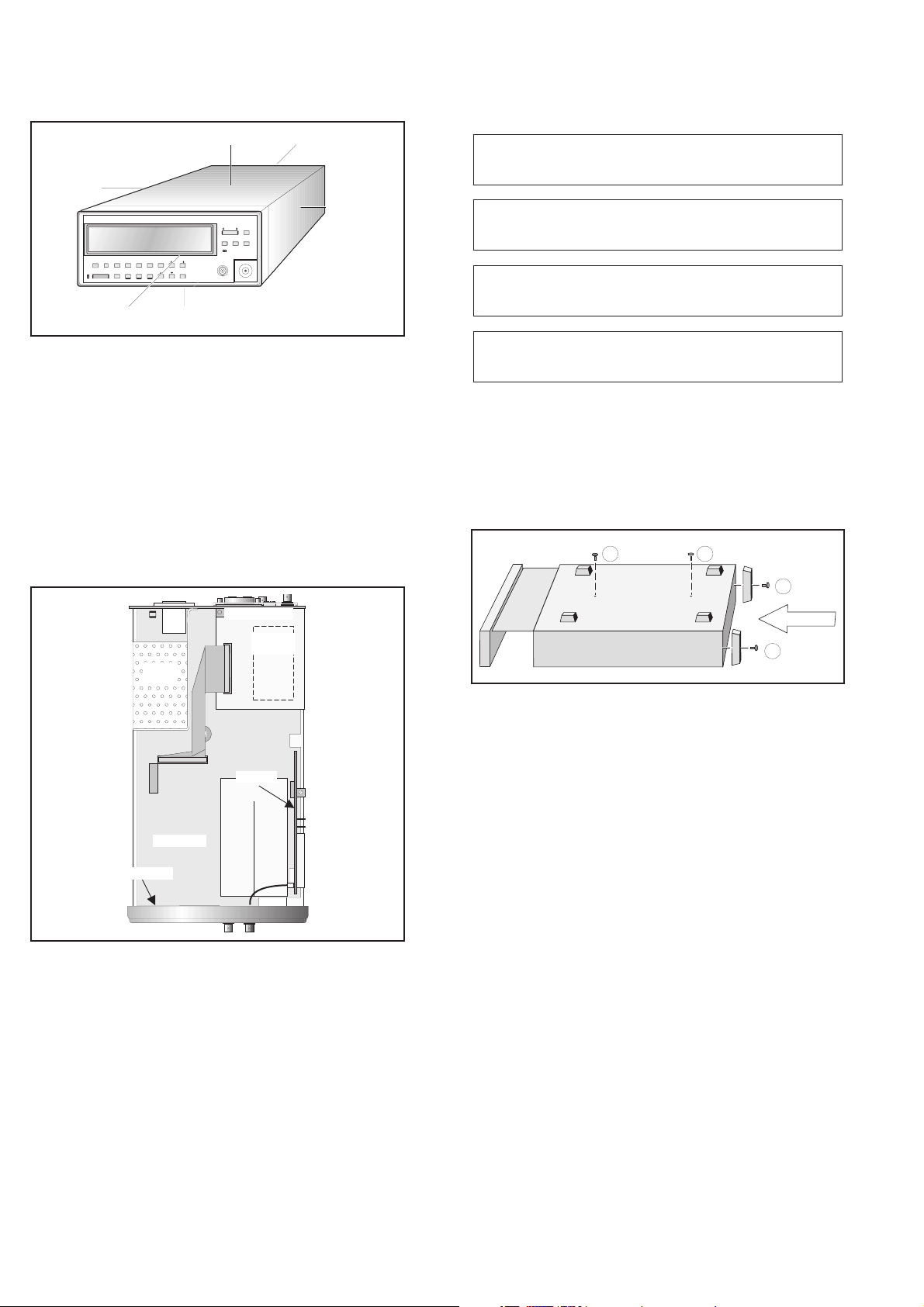

Removing the Cover

WARNING: Do not perform any internal service or ad

justment of this instrument unless you are qualified

to do so.

WARNING: When you remove the cover you will ex

pose high voltage parts and accessible terminals

which can cause death.

WARNING: Although the power switch is in the off

position, line voltage is present on the printed cir

cuit board. Use extreme caution.

WARNING: Capacitors inside the instrument can hold

their charge even if the instrument has been sepa

rated from all voltage sources.

–

Make sure the power cord is disconnected from the counter.

Turn the counter upside down.

-

–

Loosen the two screws (A) at the bottom and the two screws

–

(B) in the rear feet.

Grip the front panel and gently push at the rear.

–

Pull the counter out of the cover.

–

A

Fig. 3-3 Remove the screws and push the counter out of

the cover.

A

B

B

-

-

-

-

HF input

Main board

Front panel

Fig. 3-2 Location of the boards in the counter.

Reinstalling the Cover

Gently push the counter back into the cover.

–

Turn it upside down.

–

Install the two screws (A) at the bottom.

–

Install the two rear feet with the screws (B) to the rear panel.

–

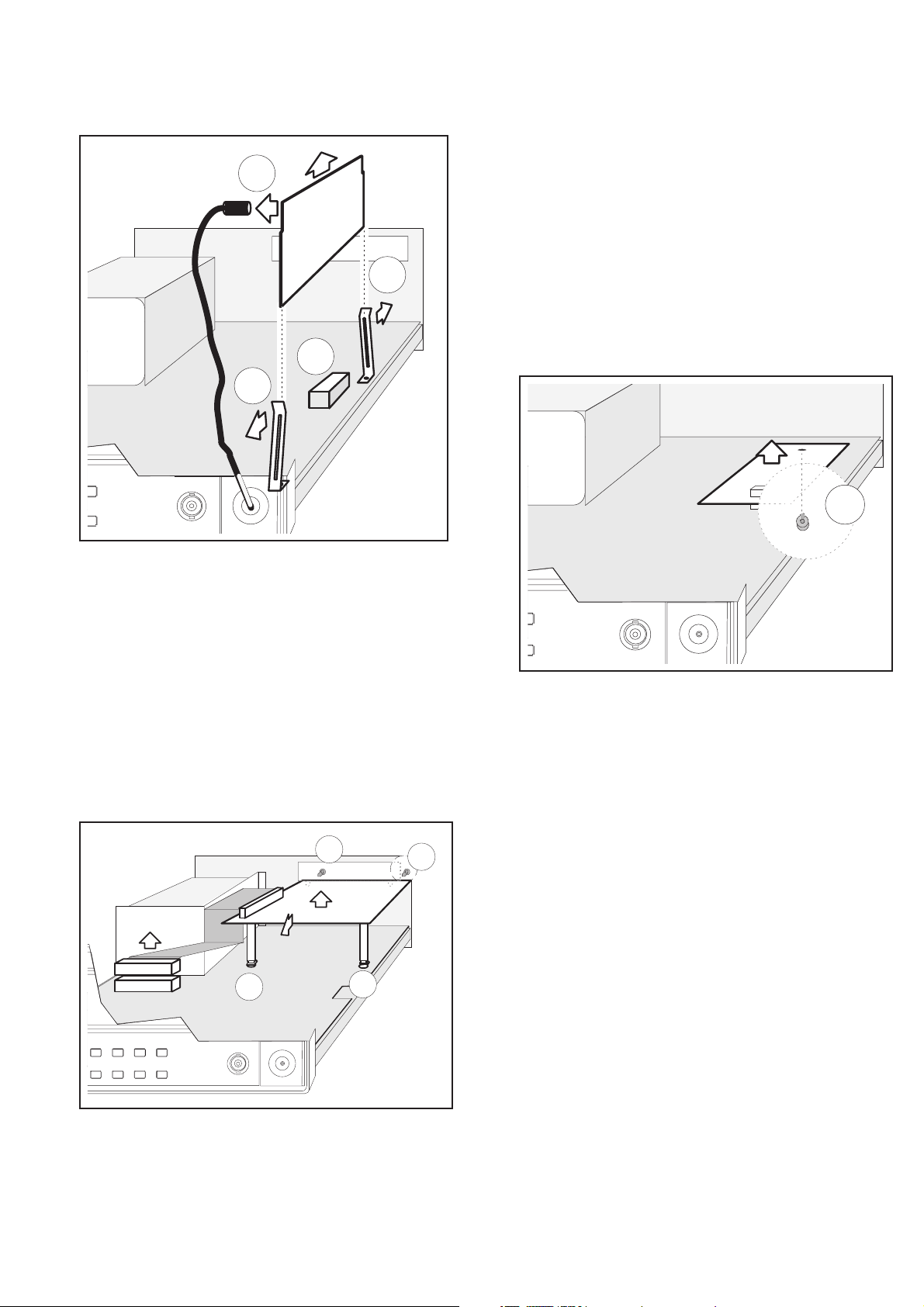

PM9624 (HF Input)

Disconnect the power cable.

–

Remove the cover from the counter.

–

Disconnect the cable from the mini-coax connector (A) on the

–

HF input.

Press the clips (B) apart and lift the HF input pca straight up

–

and out.

3-2 Disassembly, Removing the Cover

Page 15

When installing the HF input, make sure that the connector

–

pins fit exactly in the holes in the connector housing (C).

A

B

C

B

PM9691 or PM9692 (Oven

Oscillator)

Disconnect the power cable.

–

Remove the cover of the counter.

–

Remove the two screws (A) holding the oscillator to the main

–

pca from underneath.

Press the clip (B) gently to the front of the counter and lift the

–

oscillator straight up.

Make sure that jumpers J14 and J15 are set in the correct posi

–

tion.

When fitting the oscillator, make sure that the connector pins

–

fit exactly in the holes in the connector housing.

A

-

Fig. 3-6 Removing the HF Input.

PM9626 (GPIB Interface)

Disconnect the power cable.

–

–

Remove the cover from the counter.

Loosen the two screws (A) holding the GPIB interface to the

–

rear panel.

Disconnect the interface cable from P103.

–

Move the GPIB interface pca toward the front of the counter

–

and lift the pca supports out from the “keyholes” (B) on the

main PCA.

A

B

B

Fig. 3-5 One of the two screws holding the oven oscillator

in place.

A

Fig. 3-4 Loosen the two screws in the rear panel and dis

engage the board from the keyholes.

-

Disassembly, PM9626 (GPIB Interface) 3-3

Page 16

This page is intentionally left blank.

3-4 Disassembly, PM9691 or PM9692 (Oven Oscillator)

Page 17

Chapter 4

Circuit Descriptions

Page 18

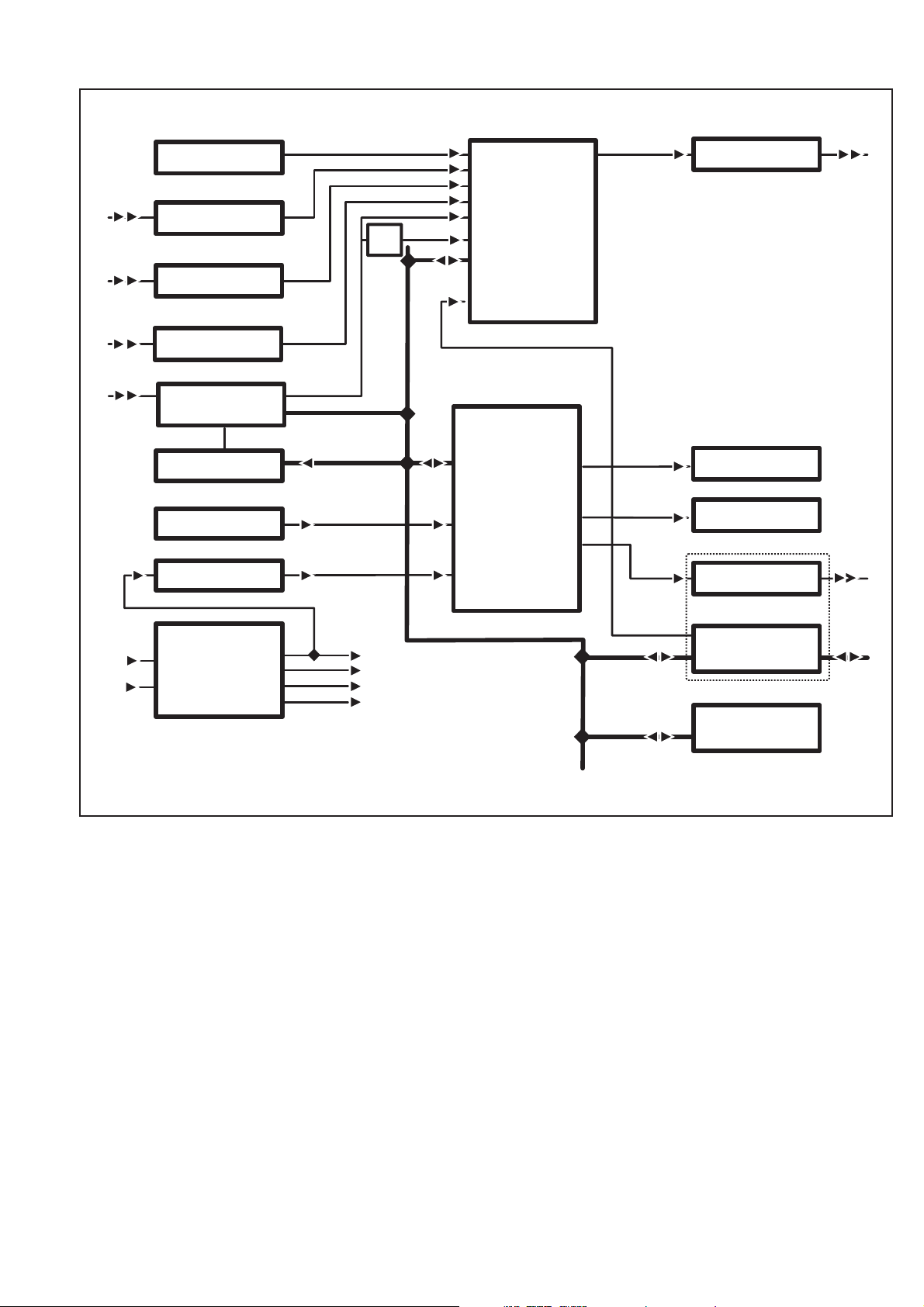

Block Diagram Description

General

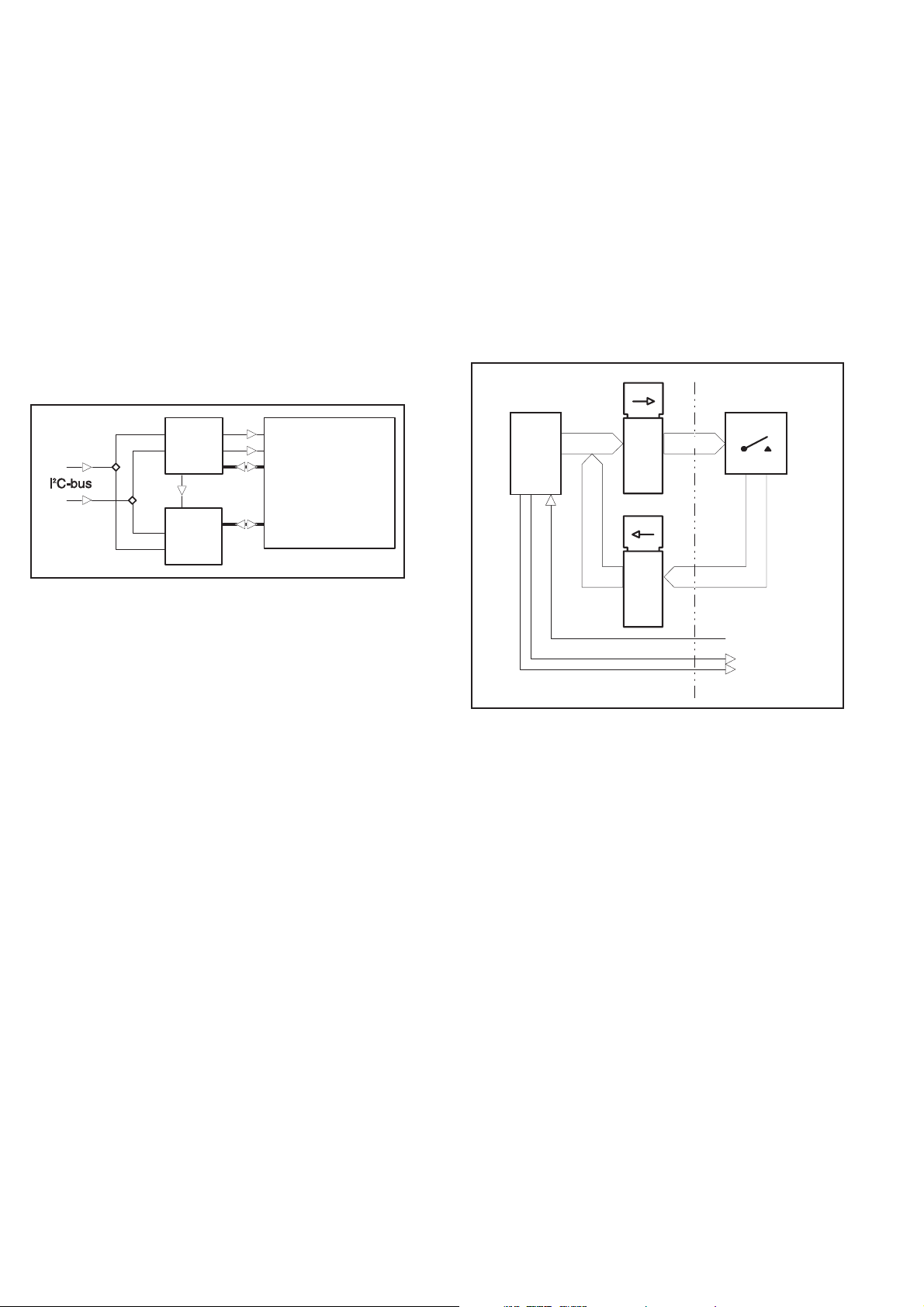

The PM6685 Frequency Counter consists of three main units:

Front unit

–

Main board unit

–

Rear panel unit

–

The following options can be added:

GPIB interface including analog output (PM9626B)

–

–

Prescalers 1.3 GHz (PM9621), 3.0 GHz (PM9624)

Oven-controlled crystal oscillators (PM9691 or PM9692)

–

Rack mount adapter (PM9622/02)

–

Battery option (PM9623)

–

The chassis of the counter consists of a front piece molded in alumi

num, an aluminum rear panel, and two profiled aluminum rods that

hold the front and rear panels together. This unit can be slid into the

aluminum cover of the instrument.

The front unit contains all functions needed for the user communica

tion. It is connected to the main board unit with a flat cable, and the

molded front unit is fixed to the two profiled aluminum rods with

screws.

The main board unit consists of a PCB mounted on two profiled alu

minum rods. Most functions, such as the following, are placed on the

main board:

Input amplifiers with trigger level circuits

–

Power supply

–

–

Measurement logic

Microcomputer circuitry

–

Some outputs, such as the trigger levels and probe compensation

view outputs are directly mounted on the main board.

The rear panel unit is of aluminum with a number of mounted con

-

-

nectors. Most of the connectors are soldered directly to the main

board. The rear panel is fixed to the two profiled aluminum rods with

screws.

-

-

4-2 Block Diagram Description

Page 19

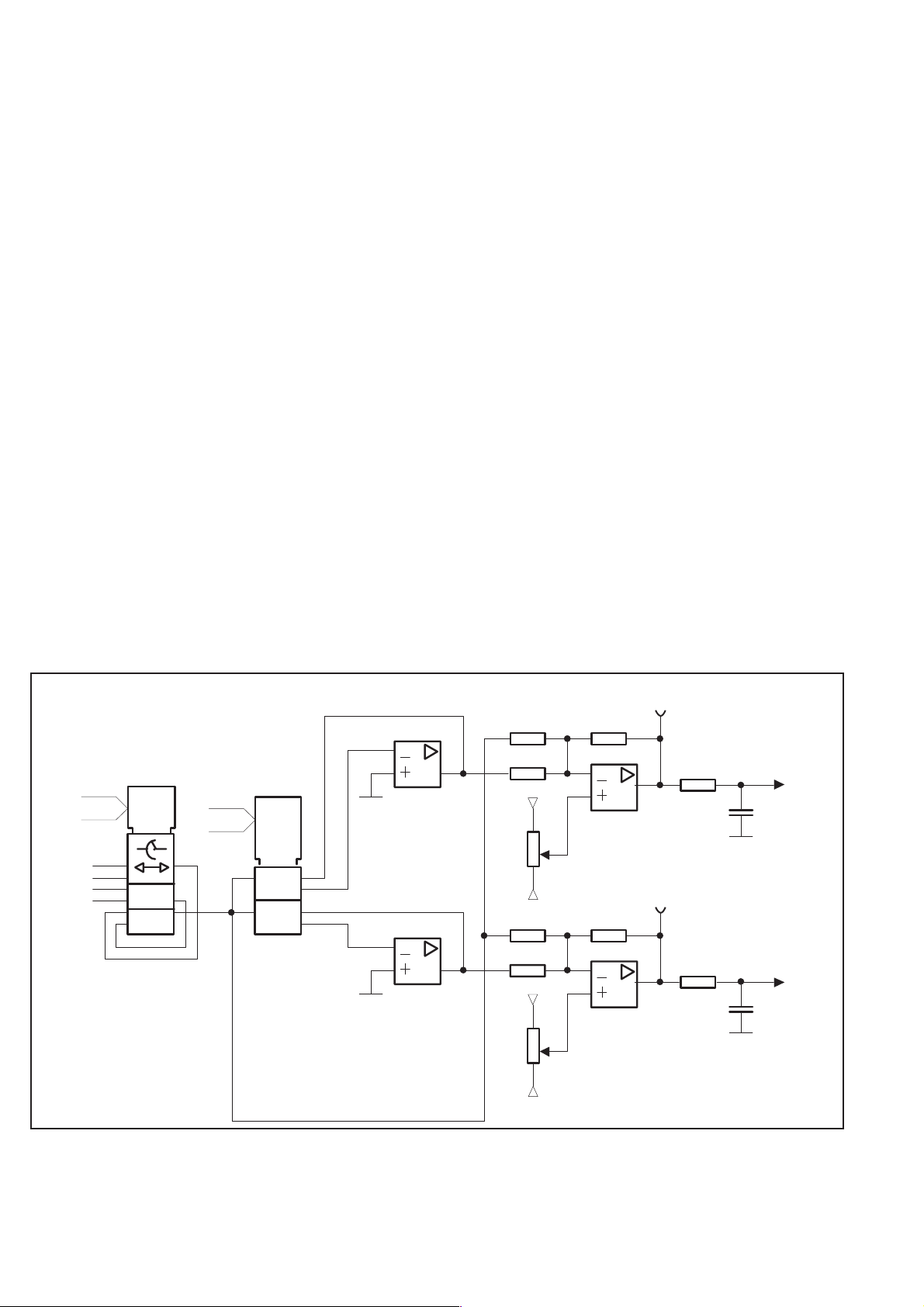

Optional oscillator

A

X2

EXTC

INTREF

10 MHz out

G

B2

E

External arming

÷2

EXTREF

A

A2

C

HF input

GET

D

A

External reference

Input Amplifier

U29

Counter

ASIC

Micro-

computer

Trigger DAC´s

Local preset

Reset circuit

HSI.0

RESET

U11

2

IC

PWM

Gate LED

Display

Analog output

Option 80

Power supply

C

90-265 V

+5V

+12V

GPIB option

+7V

-5.2V

Keyboard

Fig. 4-1 PM6685 block diagram.

Block Diagram Description 4-3

Page 20

Hardware Functional Description

Front Unit

LCD Drivers

U201

Driver 1

SCL

SDA

PC F8 576

Sync.

U2 02

Driver 2

PC F8576

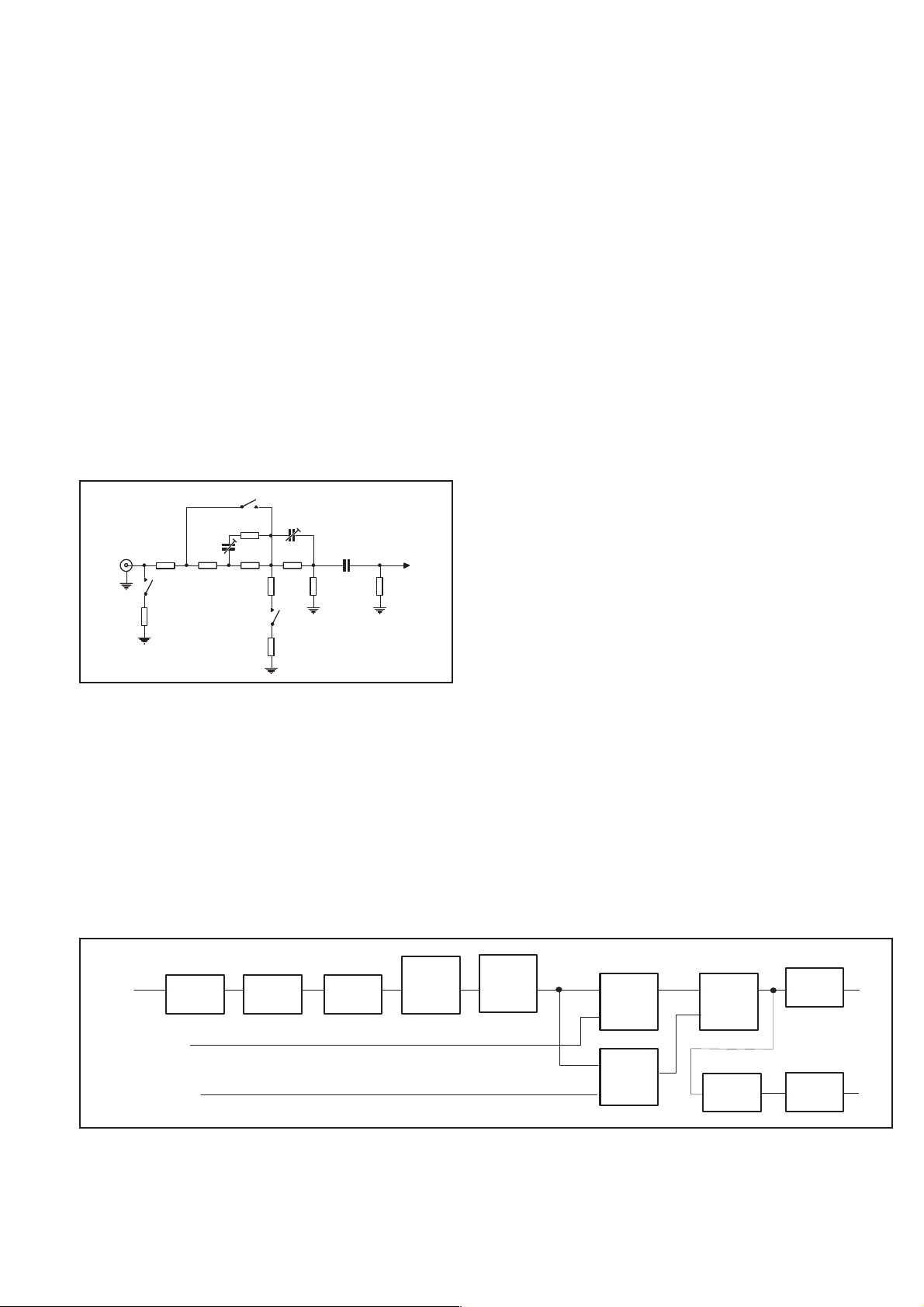

Fig. 4-2 Front panel LCD drivers.

An LCD and two LEDs are used as indicators. The LCD is used to

show both the measurement result and the state indicators of the in

strument setting. The LEDs show standby and gating.

The LCD has 158 segments that are multiplexed with a ratio of 2:1.

Two parallel and synchronized LCD drivers (U201 and U202) are

used. They are connected with a serial I

on the main board. The clock frequency of the drivers is approxi

mately 140 kHz, set by R201. The VLCD pin is connected to GND

on the main board.

The LCD is provided with a backlight, an LED array integrated into

one component. Its current consumption is set by the resistors

R204-R207. The backlight dissipates approximately 1.5 W .

Backpl. 0

Backpl. 1

LC D

1 58 segment s

2:1 Multiplex

2

C bus to the microcomputer

Keyboard

Main Board

U11

AD0-AD7 H0-H3

CPU

HS1.0

P1.1

P1.0

-

Fig. 3 Keyboard scanning.

-

The front panel pushbuttons are connected in a matrix. The scanning

signals H0 to H3 come from the main board. If a push button is

pressed and H0 to H3 is high, one of the output signals V0 to V7 will

be high. The STAND-BY/ON and LOCAL-PRESET buttons are not

part of the scanning but are connected directly to the main board.

The front unit is fixed to the main board unit with three screws. The

electrical connection is made with a 40-lead flat cable to the main

board.

U13A

Latch

U14A

Latch

AD0-AD7

Keyboard & Display

Board

V0-V7

LOCAL/PRESET

SCL

SDA

4-4 Hardware Functional Description

Page 21

Main Board

Introduction

Components not necessary for explaining the function are omitted

from the figures in this chapter. For the complete set of components,

see the circuit diagrams in Chapter 8, Drawings and Diagrams.

Input Amplifier

The input amplifier has 300 MHz bandwidth and is of the split-band

type. It contains four main stages: the signal adaptation stage, the im

pedance converter stage, the comparator stage, and the buffer stage.

Signal Adaptation

n

This part of the amplifier contains:

50 W/1 MW impedance selector

–

x1/x11 attenuator

–

Voltage limiter

–

50 W /1MW Impedance Selector

K2

C2

R6

J1

R1

K1

R7-R17

C1

R2 R3-R5

R22-R23

R18

K3

R19R20

R24R26

C3

To Voltage

li mi te r

R27R28

selected if the relay is open. Depending on selected attenuation, the

1MW input impedance is determined by different combinations of

resistors.

In x1 attenuation mode (K2 is closed and K3 is open) the impedance

is determined by resistor network R22 to R28.

In x11 attenuation mode (K2 is open and K3 is closed) the same net

work as in the x1 case is involved plus the resistors R3 to R5 and R18

to R20.

The input capacitance in parallel with 1 MW is 24 pF at x1 attenua

-

tion and 12 pF at x11 attenuation.

-

The series resistor R1 immediately after the selector serves both as

current limiter together with the voltage limiter (see below) and as

impedance matching resistor. The resistor also improves the Volt

age-Standing-Wave-Ratio (VSWR) of the amplifier input.

x1/x11 Attenuator

The x1 attenuator consists of a resistive low-frequency divider,

which reduces the input signal by a factor of 2, and a capacitive

high-frequency divider. The attenuator is formed by the resistors

R22-R23 andR24-R26 in parallel with R27-R28. The capacitive part

is formed by the variable capacitor C2 in parallel with R22-R23, and

the parasitic capacitance across R24-R26.

The capacitive attenuator is adjusted via variable capacitor C2 to the

same attenuation value as the resistive attenuator.

The x11 attenuator also consists of a resistive low-frequency divider

and a capacitive high-frequency divider. The resistive part is formed

by R1-R5, and R18-R20 in parallel with 1 MW (the x1 attenuator im

pedance). The capacitive divider is formed by the variable capacitor

C1 and the parasitic capacitance at the node where R5, R18 and R22

meet.

-

Fig. 4-4 Impedance selector and 1X/11X attenuator.

The 50 Wor1MW impedance modes are selected by relay K1. 50 W

is selected via the resistors R7 to R17, if the relay is closed. 1 MW is

Input A

Imp. Att. Limiter

Imp.

Conv.

Trigger

level Comp I

Trigger

level Comp II

Resistors R2 and R6 improve the frequency response.

LP

filter

Comp-

arator

FlipFlop

Comp-

arator

÷2

Buffer

Buffer

A

A2

Fig. 4-5 Input amplifier block diagram.

Hardware Functional Description 4-5

Page 22

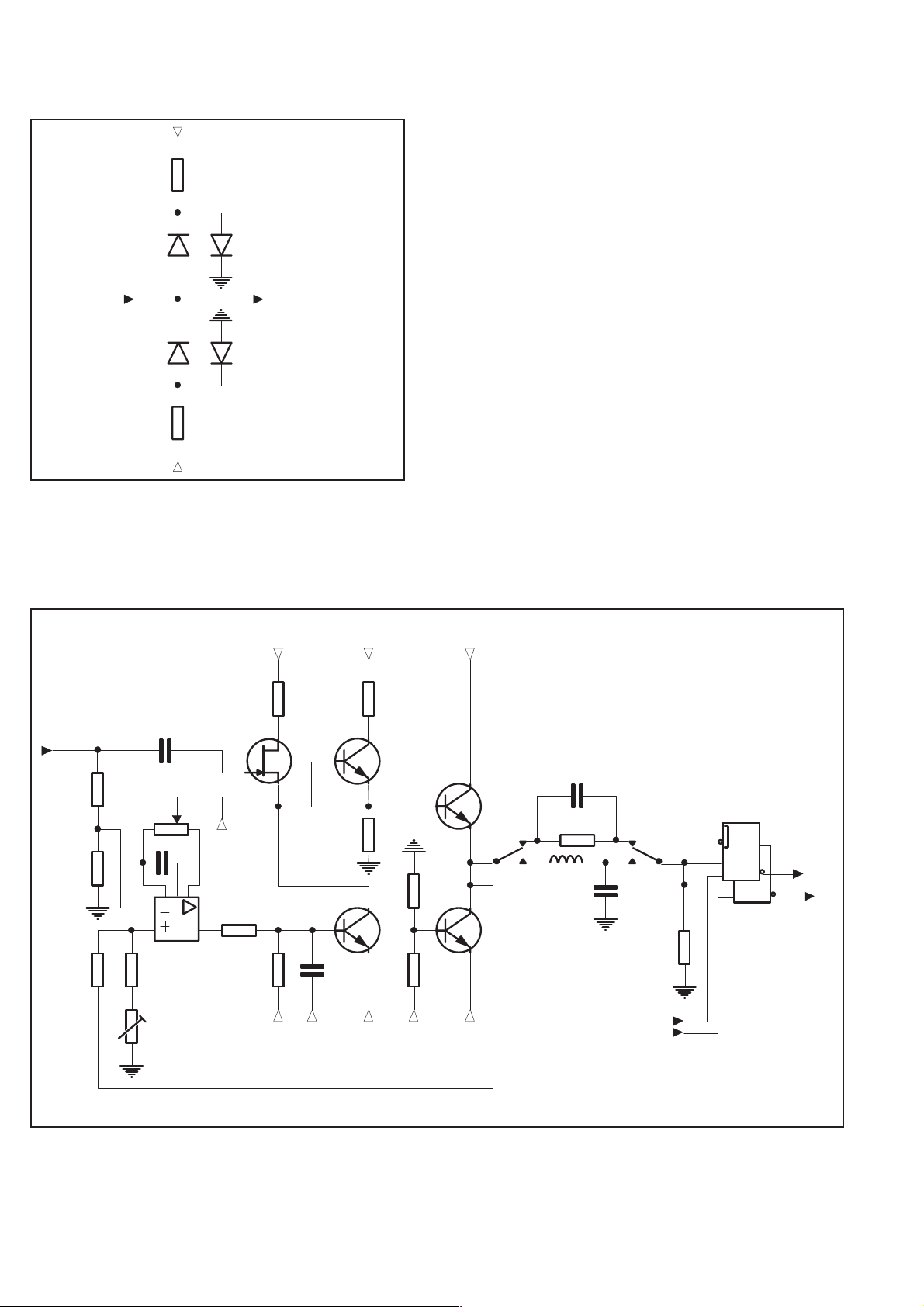

Voltage limiter

p

+5

and D3 to clamp positive voltage and resistor R36 plus the diodes D2

and D4 to clamp negative voltage. The clamp voltage is approxi

mately ±2.1 V for low frequency signals. At high frequency the

clamp voltage rises to approximately ±2.3 V.

-

R35

D3D1

From

Attenuator

D2

R36

-

To Impedance

converter stage

D4

Fig. 4-6 Voltage limiter.

A voltage limiter that protects the impedance converter against

overvoltage is placed between the attenuator and the impedance con

verter. The voltage limiter consists of resistor R35 and the diodes D1

Impedance Converter Stage

n

The analog signal from the input stage is fed to an amplifier stage

where split-band technique is used to get good frequency response

over a wide range. This means that the high-frequency contents of

the signal are fed to a high-impedance AC-coupled FET transistor

stage Q1. The low-frequency contents are fed to a DC-coupled oper

ational amplifier stage with negative feedback from the output of the

converter stage buffer. The low-frequency path handles frequencies

up to approximately 5 kHz.

The high-frequency signal is fed to the gate of Q1. The high imped

ance at the gate is converted to a low impedance at the source. The

source is connected to the base of HF transistor Q2, the summing

point for the two signal paths.

To make the FET work well in its active region within the whole dy

namic range, the FET drain is supplied with +7 V via resistor R42.

The low-frequency signal is divided by the two resistors R27 and

R28 before it is coupled to the input pin #2 of the operational ampli

fier U1. The resistors R37 and R38 at the operational amplifier out

-

put pin #6 center the output swing, and capacitor C6 stabilizes the

operational amplifier stage.

-

The low-frequency path goes from the operational amplifier to the

base of transistor Q3, the collector of which is connected to the base

Fr om Pr o t ec t io n

ci rcu its

R27

R28

R32

C13

R33

R29R30

R31

C5

+7 +5

R42 R43

Q1

-5.2

R37

R38

-5.2 -5.2 -5.2 -5.2 -5.2

Q3

C6

+5

Q2

R105

R46

R47

Q13

C20

R50

K4

L1

C18-

Q4U1

C19

K4

R106

U8

To

+

-

+

-

Flip-Flo

Trig

Level

Fig. 4-7 Impedance converter.

4-6 Hardware Functional Description

Page 23

of transistor Q2. This point is common to the high and low frequency

paths.

A buffer amplifier with high driving capacity is used to get a linear

output in the 100 W load resistor R106 over a swing of 2 V. This am

plifier consists of a driver stage Q2, an output stage Q13, and a cur

rent generator Q4.

From the output of this second amplifier stage, the signal is fed back

to theop amppin 3via thedivider chainR29 toR32. Thetrimmer po

tentiometer R31 sets the gain of the low-frequency path equal to the

high-frequency gain of about 0.9. Capacitor C5 is connected to oper

ational amplifier pins #1 and #8 to achieve stable operation. The

trimmer potentiometer R33 between pins #1 and #5 on the opera

tional amplifier is used for adjusting the offset voltage of the opera

tional amplifier.

The channel A filter connected to the output of the second amplifier

stage isa 100kHz low-pass LC filter. It consists of the coil L1 and the

two capacitors C18 and C19 in parallel. The filter is controlled by the

relay K4. The filter output is connected to the input of the comparator

stage.

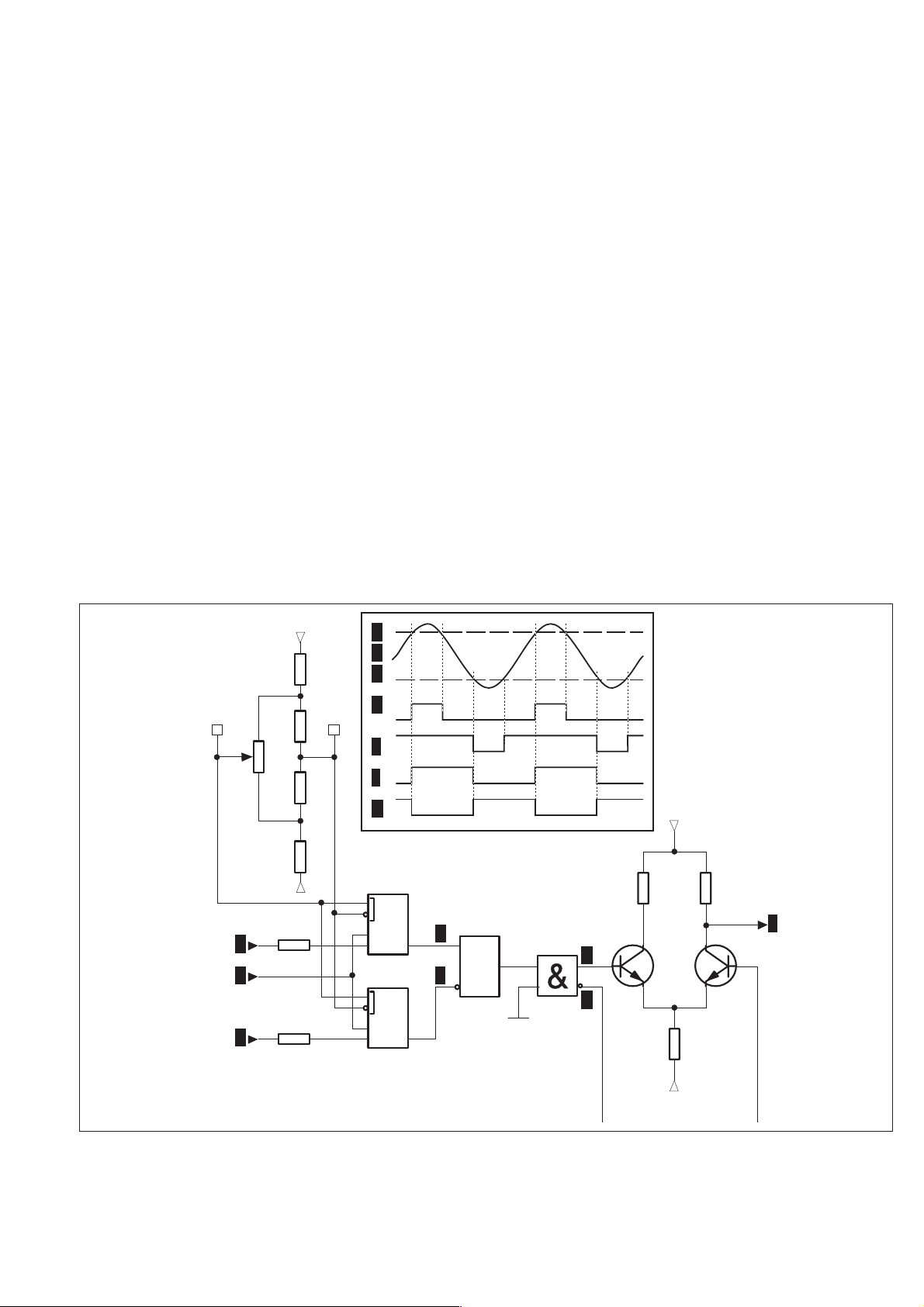

Comparator Stage

n

The comparator stage converts the analog signal from the impedance

converter stage to a square wave. This circuit consists mainly of the

high-speed integrated comparators U8A and U8B plus a separate

trigger level circuit connected to the comparators at pins 9 and 13 via

resistors R87 and R88.

The trigger level circuits, which are described later, generate a DC

level in the range of approximately æ1.6 V. This covers a dynamic

range of 6.4 V since the input signal is divided by a factor of 2 before

-

-

-

-

-

-

it reaches the comparator.

The counter is provided with adjustable hysteresis, i.e., it is control

lable via the front panel or GPIB. The circuitry for setting the hyster

esis consists of the resistor network R91 to R96, supplied with +5 V

and –5.2 V. It is connected to the latch enable inputs of the compara

tor, pin 5 and 7 for Comparator I and pin 17 and 15 for Comparator II.

The input signal is fed to both comparators, the outputs of which are

used for setting/resetting the Flip-Flop U9.

Buffer Stage

n

Before the signal is fed further into the ASIC U29, it has to be

level-shifted by a buffer stage. The negative ECL logic levels

(~ –0.9 V to ~ –1.7 V) from U9 pins 17 and 18, are converted to a

single-ended signal with CMOS logic levels ( ~ 5 V to~0V).

The buffer is a differential amplifier consisting of the two transistors

Q32 and Q33 whose bases are fed differentially from the two com

parator outputs. Resistor R304 serves as a current generator that is

switched alternately to the two collector resistors R296 and R297.

-

-

-

-

Trigger Level Circuits

The trigger level circuits generate the trigger voltage levels to the in

put comparators. The trigger level range is –3.2 V to + 3.2 V with a

maximum resolution of 0.6 mV. The input amplifier attenuation is

-

TP27 TP26

Trig ger Level I

Input signal

Tri gger Level II

+5

B

A

R92

C

D

R93

E

R91

F

R94

R96

-5.2

R87

B

A

G

U8A

+

-

U8B

+5

R296

U9

D

Flip Flop

E

U9

Q32

F

R297

Q33

F

To

Counter

circuits

G

R88

C

+

-

R304

Fig. 4-8 Comparator flip-flop and buffer stages.

-5.2

Hardware Functional Description 4-7

Page 24

approximately 2 times. The trigger level circuits generate a DC level

that has the same attenuation. This means that the output of this cir

cuit has a range of –1.6 V to +1.6 V with a resolution of maximum

0.3 mV. Adual 8-bit DAC is used. The DACs only generate voltages

between 0 and +1.6 V, but by using a X2 amplifier and an offset shift

of 50%,the voltagerange of –1.6 Vto +1.6V is achieved. The supply

voltages to the trigger level circuits are filtered by R and C to prevent

noise originating in the digital circuitry from influencing the trigger

levels. The ground plane under the trigger level circuits is separated

from the rest of the ground plane, and the planes are connected only

at the front of the counter.

The trigger level circuits consist of the following:

Resistor network R57 to R68 for generating the reference volt

–

-

ages 0.04 V, 0.22 V, 0.59 V, and 1.6 V.

Three multiplexers (U3) to select one of the levels. With this

–

arrangement there is a total trigger level range of

–1.6 V to +1.6 V.

A double DAC (U4).

–

Two current-to-voltage converters U6. These circuits convert

–

the current at the IOUT pins of the DACs to a voltage. This

signal has a range of 0 V to approximately 1.6 V.

Two amplifiers, U7, with an amplification of X2, to generate a

–

signal with a range of 0 V to 3.2 V. Resistors R69 and R70 set

the reference voltage to the amplifier to get the 50 % offset

shift. To get exact voltages, 0.5 % precision resistors are used:

R73-R75, R78-R79 and R80-R82, R85-R86.

The zero adjust of the trigger levels is done with trimmer po

–

-

tentiometers R69 and R70 connected to the amplifiers in U7.

Two low-pass filters R87-C29 and R88-C30.

–

AD0-AD2

1.6V

0 .59V

0 .22V

0 .04V

U3

AD0- A D8

U4

D0- D7

+DACA

VREFR FB

IOUT

VREFR FB

IOUT

U6

U6

R73-R74

R75

R69

R80-R81

R82

R70

+5

-5.2

+5

-5.2

Trig ger lev el Comp I

R78-R79

U7

R87

C29

Trig ger l evel

Comp II

R85-R86

U7

R88

C30

Compar ator I

Comparator II

Fig. 4-9 Trigger level circuits.

4-8 Hardware Functional Description

Page 25

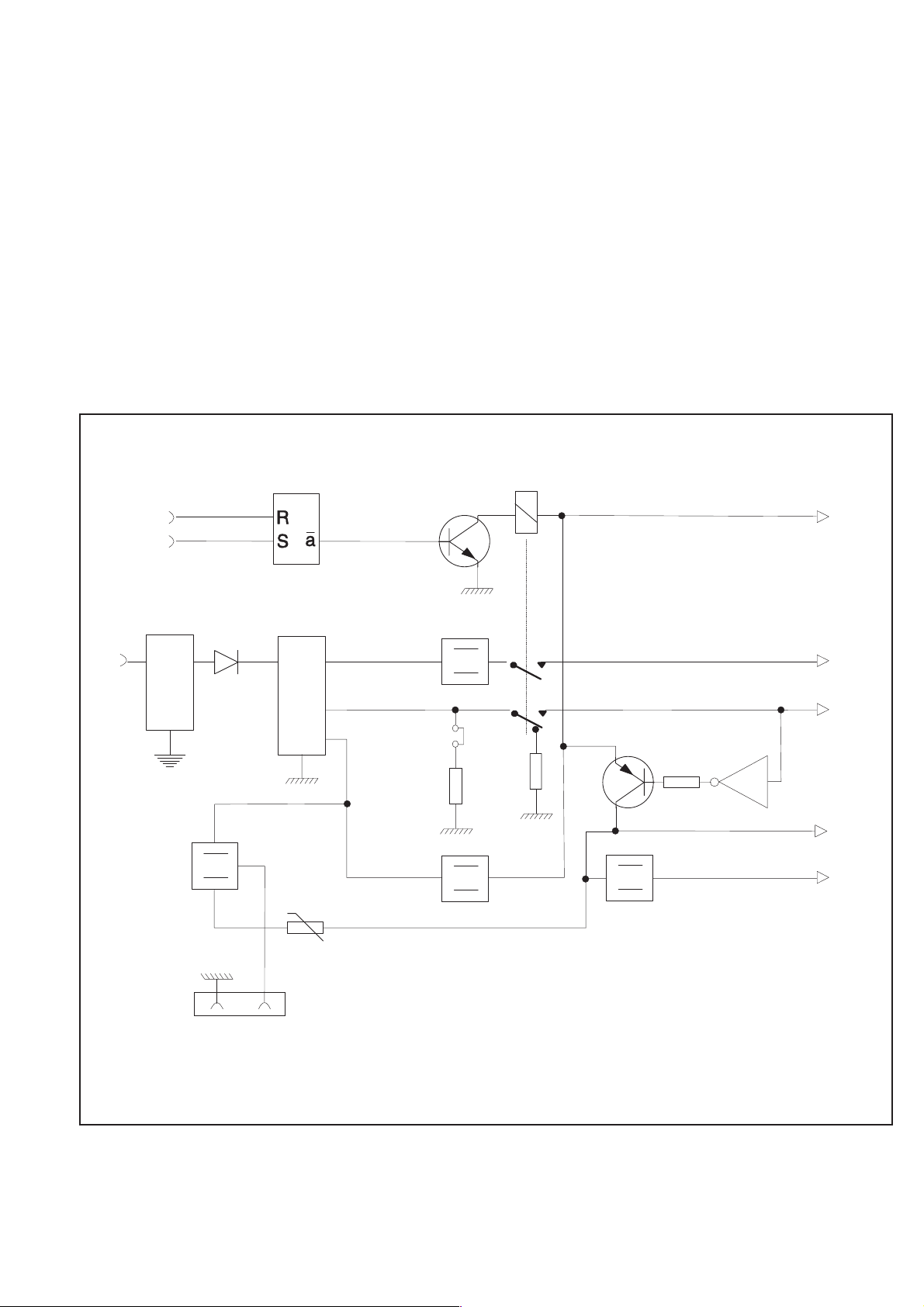

Power Supply

General survey

n

The power supply generates four regulated DC supply voltages to the

counter, as well as some other supply voltages for special purposes.

The power supply block also contains the ON/STANDBY logic.

The main building block of the power supply is a primary switch

mode power module (U39). The line power AC voltage (90 V to

265 V) is rectified to a DC voltage before it is fed to the power mod

ule.

After a line power filter in the power inlet, a fuse of 1.6 AT and an

NTC resistor protect the power supply. The fuse F1 should only blow

if a catastrophic error occurs on the primary side of the power supply.

A short-circuit on the secondary side should not affect the primary

side. To minimize the inrush current to the capacitors at the connec

tion of the power cord, an NTC resistor (R148) is used. The resis

tance is 15 Wwhen the resistor is cold but decreases to a few ohms as

it is warmed up by the steady-state current.

The AC voltage is rectified in the bridge rectifier D9 and filtered in

C64. C65 suppresses noise from D9. L6 and C82-C83 serve as a fil

ter at the input of U39.

All inputs and outputs of the power module have HF chokes. The

module is mounted with distance washers on the main board.

-

-

-

From the module there are three DC voltages outputs. One of those is

regulated (+ 5 V) and the others are unregulated. These voltages will

vary with input line voltage, the current at+5V,andattheunregu

lated voltages. The output marked +15 will be approximately +18 V,

and the output marked –7 will be approximately –8 V. The outputs

are filtered; HF is filtered by C70-C73, and LF is filtered by L7-L9

and C74-C76.

-

-

On

Stand by

ains Inlet

M

D9

Filter&Fuse

U42

U

U40B

U39

R156

-7

+5

+15

Power Module

Q14

U43

U

R149-R155

U

U41

J15

K5

R130-R145

K5

U

U21A&Q17

+12 V*

-5.2 V

+5 V

Q5-Q6

+12 V

+7 V

Fan

PM6685R

only

Fig. 4-10 Power Supply.

J31

+-

*) for ON/STBY control & OCXO

Hardware Functional Description 4-9

Page 26

Function

n

The three DC voltages from the power module are used for

generating the following four supply voltages in the counter:

+5 V

Regulated +5 V from the power module is used directly.

–5.2 V

–7 V is used, with regulator U43.

+12 V

+15 V is used, with regulator U41.

+7 V

Stabilized +12 V is used, with regulator U21A and Q17.

temperature sensor, controls the speed by applying a variable refer

ence voltage to the fan voltage regulator U42.

Counter ASIC

The main part of the counting logic is integrated in a CMOS ASIC

specially designedfor theFluke MultiFunctionCounter series.There

are also analog blocks included in the 100 pin QPF package.

MUX

The MUX block is a switchboard for incoming and internal signals

involved in the measuring process. Some signals are divided by 2 to

make it possible to measure higher frequencies. The trigger slope is

controlled by the MUX block as well. Atrigger edge detector senses

the presence or absence of comparator pulses and controls the trigger

level DAC’s in the TLDAC block. These functional units form an es

sential part of the Auto Trigger System.

-

-

The following supply voltage is used for a special purpose:

+12 V*

This voltage comes directly from the +12 V regulator U41and will be

present as soon as the power cord is connected, regardless of the po

sition ofthe ON/STANDBY switch. It is used for the ON/STANDBY

control logic and for supplying an optional OCXO in STANDBY to

avoid the long warm-up time otherwise needed to obtain maximum

accuracy.

At stand-by, the four main supply voltages are switched off, but as

described above, some parts of the instrument should not be

diconnected. Therefore the power module will never be switched off.

The PM6685 has consequently only a secondary power switch.

A relay (K5) disconnects the load on the +5 V and –5.2 V at stand-by.

Because the power module must always have a load on the regulated

voltage, seven bleeder resistors R149-R155 are always connected to

+5 V via J15. At stand-by the counter only needs +15 V, so a dummy

load consisting of R130-R145 is connected to the power module by

means of the relay K5 in order to stabilize the operation of the

switchmode converter.

+5 V controls the switching on/off of +12 V and +7 V. When +5 V is

on, Q6 and Q5 will conduct, i.e. +12 V will be on. If there is no +5 V,

Q6 and Q5 will be off, thus blocking the +12 V.

The ON/STANDBY logic controls relay K5, which operates as de

scribed above. It is also possible to open the relay by changing the

position of J16.

The ON/STANDBY logic consists of the RS (set-reset) flip-flop

U40B that is controlled by the ON/STANDBY button on the front

panel. Pressing STANDBY will apply a high voltage (+12 V) to the

set input. The inverting output of the flip-flop will be low, discon

necting K5 via Q14. Pressing ON will give a high voltage (+12 V) on

the reset input. The inverting output of the flip-flop will be high,

engaging K5. Inserting the power cord into the power inlet will cause

a pulse on the reset input, via C35. The microcomputer can disable

the ON/STAND-BY button via Q12 and Q7. This is done in remote

mode and during RAM-testing. A high level on the base of Q12 en

ables STAND-BY, a low level disables it.

The STAND-BY indicator on the front panel is controlled by the

+5 V via Q16. +5 V off lights the STAND-BY LED that is fed by the

uninterruptible +12 V*.

+5 V also indirectly controls the fan in the PM6685R. It is a 12 V DC

fan that operates only if +12 V is on. An NTC resistor, serving as a

OSC

The oscillator block generates, selects, and distributes the reference

clock for the circuit. The active semiconductors of the standard oscil

-

lator are included in this block. The crystal is connected to pins X1

and X2. A TCXO or OCXO is connected to X2 only. An external ref

erence clock is connected to EXTREF. The PWM signal generated at

OTRIM controls the frequency of the reference oscillator after exter

nal integration.

-

-

-

PG

A built-in pulse generator having the 10 MHz clock as a reference

can generate pulses with controllable duration and repetition rate at

the OUTPUT connector. The level is fixed TTL.

RTC

A real time clock not used at present.

TLDAC

This block contains two 10-bit DAC’s generating the trigger levels

for the input comparators, VOUTA for channel A and VOUTB for

channel B. An external reference voltage is connected to V+REFA

and V+REFB.

HO

The Hold Off block can manipulate the internal measuring signal X

-

-

-

in several ways. One operating mode simulates a low pass filter (nor

mal hold off), another mode is used in burst measurements.

The following blocks (SYNC, STST, CNTS and MCTRL) form the

actual measuring logic in the ASIC. Three types of measurements

can be made in this MEAS block:

Continuous measurements (frequency, ratio and period average).

Not used at present.

Controlled measurements (time interval, period single, pulse width,

frequency, totalize gated, totalize start-stop, and ratio).

Totalize manual.

SYNC

The SYNC block synchronizes the actual measurement with certain

internal or external events like measuring time and arming signals.

-

STST

The start and/or the stop of the measurements are controlled by this

block. External events can be used to define the exact moments.

4-10 Hardware Functional Description

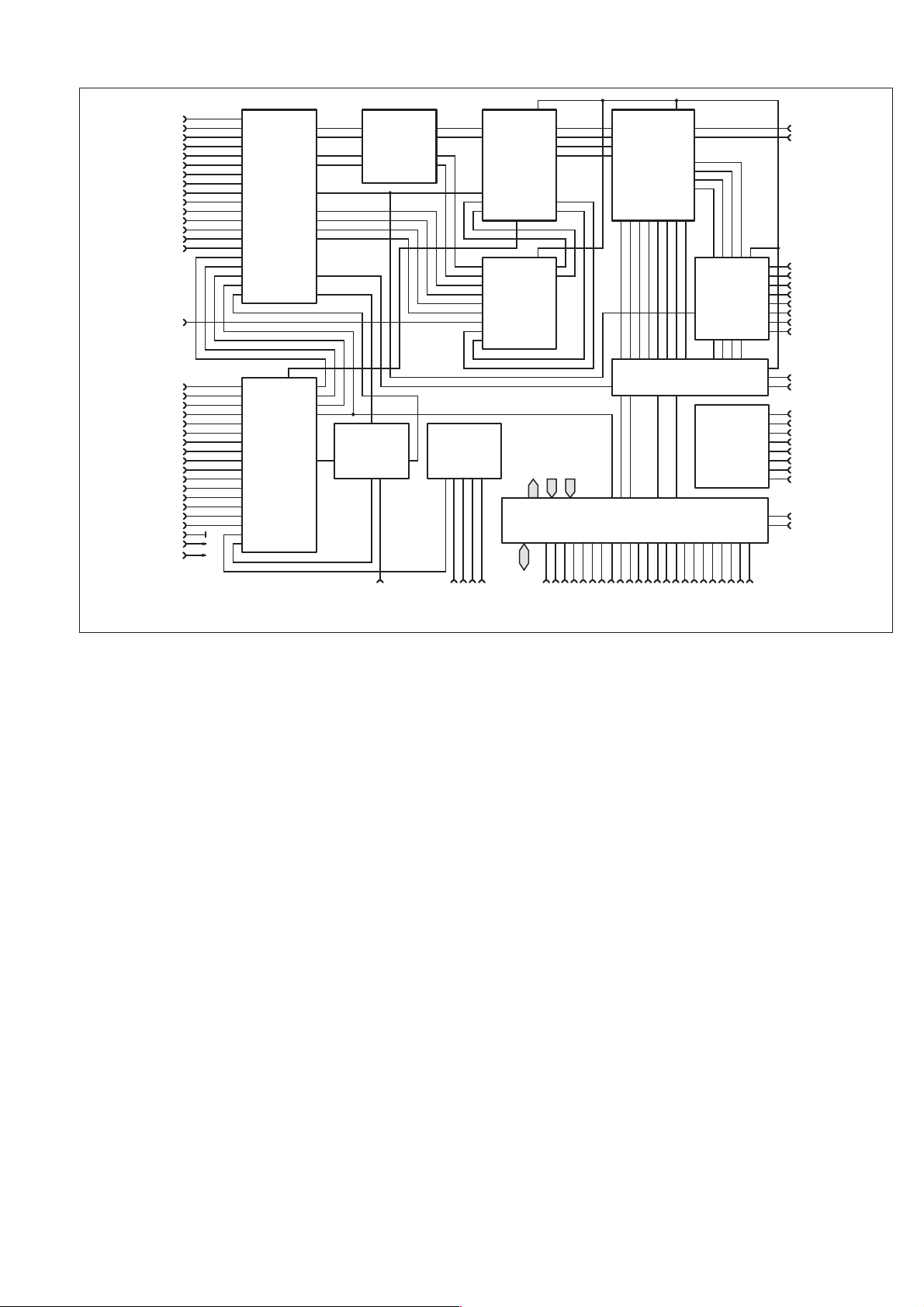

Page 27

EXTC

BURST

TRA

TRB

VCCO

GNDD1

GNDD2

GNDD3

GNDD4

GET

SB

SA

OKD

CLOCK

RE S ET

Inter-

polator

FNb

FNa

I

I

CY 1

CY 2

VC CG

GNDG

VR EFA D

IR ES

IN TP1

IN TP2

IN TS1

OK a

OKb

IN TS2

A2

A

SR

B

B2

P

MUX HO SYNC CNTS

X

Y

HODLYX

HODLYY

CL O C K

S TAAR M

STO ARM

STAD LY

STO DL Y

TI ME

MREF

FREQC

MCLK

PGARM

PCL

PGT RIG

X

Y

HODLYX

HODLYY

HO S X

HO S Y

XH

YH

XH

YH

CLOCK

ST O P

ST AR T

HO S X

HO S Y

STA AR M

STO A RM

STA DLY

STO DL Y

GET

TOTSTA

STA

TOTSTA

GATEO

STOP

STAR T

STST

STA

R1

R2

L1

L2

R1

R2

L1

L2

I

INTB

INTA

NB

FND

F

OKA

FNC

OKB

FNA

I

OK C

I

I

X1

X2

V+R EFO

OTRIM

V- REF O

EXTREF

MTC XO

IN TR EF

OUTMUX

MPCL K

PH1

PH2

VCCB

GNDB

VCCC

GNDC

GNDA

VCCA

VCCX +5

OSC

RTC

+5

PGOUT

TI ME

MREF

FREQC

MCL K

PGR EF

PG

PGR EF

PGT RIG

PGA RM

PGOUT

PG

Fig. 4-11 Counter ASIC, block diagram.

CNTS

Two 32-bit binary counters count external events or keep track of the

time.

Interpolator

This block is not used at present.

MCTRL

The different events in the measurement cycle of the ASIC are timed

by this block.

MPI

This is the microprocessor interface block. The bus width is 16 bits,

AD0 toAD15. Interruptsto themicroprocessor are generated at INT.

GET

The GET signal from an optional GPIB interface can control the start

of a measurement.

External Interpolator

n

The X-POLATOR unit is connected directly to the internal

interpolator in the ASIC. It is used for increasing the time resolution

beyond the limits set by the reference clock period of 100 ns. An er

ror pulse is generated in the SYNC block. Its width is determined by

the difference between an external event on an input channel and the

next clock pulse. This pulse controls a current generator charging a

capacitor. When the pulse has expired the voltage across the capaci

tor is A/D converted and the value is added to the result. There are

two interpolators, one for the start event and one for the stop event.

RTC

RTC

RTCX1

-

-

MCTRL

FI N1

DMAR

TLDAC

DMABR

CS RS SS

PCL

OK

MCL K

MPI

C1

C3

CS

A16

A18

ALE

VBAT

RTCX2

LARMN

RDN

AD0-AD15

A17

WR L N

WRHN

INT

A19

S1N

HO L D N

S2N

HLDAN

QDM AN

C2

S4N

S5N

S3N

FIN

MTIM E

V+R EFA

VOU TA

V- REF A

V+R EFB

VOU TB

V- REF B

VC CE

GNDE

VC CF

GNDF

C4

They are calibrated over the possible error pulse range to allow for

any aberrations from the theoretical linear behavior.

Oscillator Circuits

CPU Oscillator

n

The microcontroller U11 is clocked at 12 MHz. The crystal B1 is

connected to the XTAL inputs of the microcontroller.

n

Reference Oscillators

A 10 MHz crystal oscillator is used as the reference for the measur

ing logic. If a stable external 10 MHz reference is available, it can be

connected to REF IN on the rear panel and selected by means of the

EXT REF button on the front panel.

In addition to the standard crystal oscillator there are two optional

oven-controlled crystal oscillators (OCXO) to choose from.

Standard

The uncompensated standard oscillator consists of the crystal B2,

C109, C113-C115, R209 and R211. C115 is used for manual adjust

ment of the frequency when the calibration tolerance has been ex

ceeded. Theactive circuitryis builtinto theASIC U29and is accessi

ble via the pins marked X1 and X2.

OCXO

If one of the OCXOs is mounted, the standard oscillator has to be in

activated by moving the jumpers J23 and J25 to their alternative po

sition. These oscillators are connected to J24 and are self-contained

-

-

-

-

-

-

Hardware Functional Description 4-11

Page 28

units with facilities for coarse and fine adjustment. They are fixed to

the main PCB with two screws. The output signal is AC-coupled to

the X2 pin on U29 via C107.

External

This input consists of an AC-coupled line receiver with Schmitt trig

ger function (U28) and is protected against excessive voltage

excursions by a resistor-diode network. The output signal from U28

has CMOS logic levels and is connected to the EXTREF pin on the

counter ASIC U29.

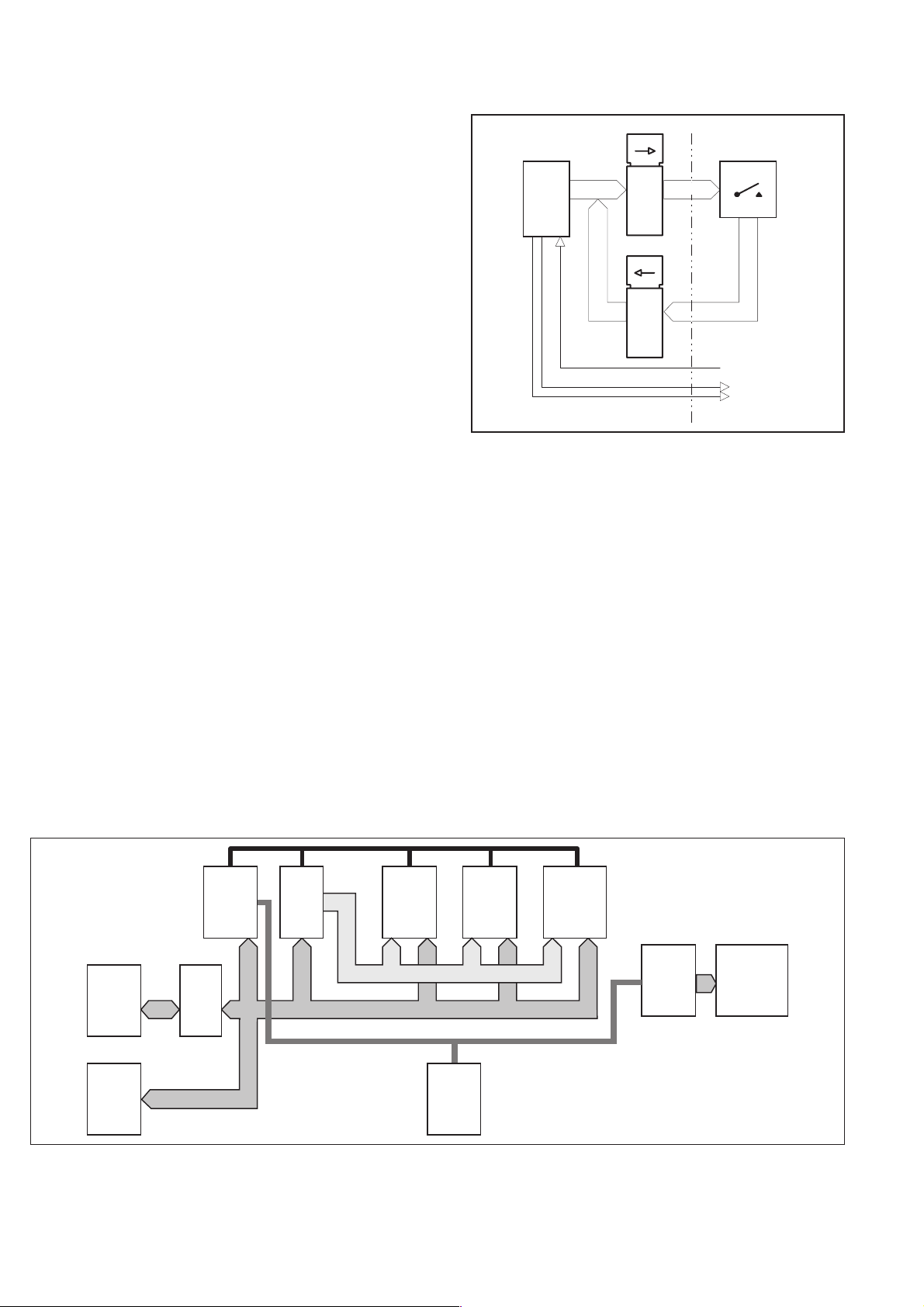

Logic

Microcomputer Circuits

n

Microcontroller

The microcomputer circuitry consists mainly of the microcontroller

U11, an Intel 16-bit CMOS 80C196, RAM (U22A), and EPROM

(U23A). The microcontroller is clocked at 12MHz. The data and ad

dress lines AD0 to AD15 are shared by means of multiplexing.

Therefore the addresses are stored in the latches U16A and U17A.

The ALE signal (Address Latch Enable) enables the latches.

UVEPROM

The main program is stored in U23A that is mounted in an IC socket,

making it easy to update and customize the instrument firmware by

changing the EPROM.

EEPROM

Front panel settings, GPIB address and certain other data that are not

changed frequently, e.g. information in the Protected User Data

Area, are stored in U12A which does not need battery backup.

Reset Circuit

A special reset circuit, the power supply supervisor U10, is included

in the design. If the +5 V supply line becomes lower than 4.5 V, the

reset output pin 5 goes low and the microcontroller will start over.

The length of the reset pulse is set by C88; 2.2 µF gives a pulse of ap

proximately 30 ms. U10 also controls the reset pulse during

power-up so that the microcontroller will be initiated correctly.

Keyboard Scanning

n

Main Board Keyboard & Display

U11

-

AD0-AD7 H0-H3

CPU

P1.0

HS1.0

P1.1

-

U13A

Latch

U14A

Latch

AD0-AD7

Board

V0-V7

LOCAL/PRESET

SCL

SDA

Fig. 4-13 Keyboard scanning.

The keyboard scanning is done in two modes. The first mode is ac

tive aslong asno buttonhas beendetected asdepressed. Then all out

-

puts of U13A are set high, and the latch U14A is read. If no button

has been depressed, all outputs are low. This check is done at every

timer interrupt in the microcontroller, every 25 ms. If a button is

depressed, one of the output bits is high. When this event is detected,

mode two is entered. The outputs of U13A must be set high one after

the other to find the specific button. When found, only this button

will be checked, so other simultaneously depressed buttons will not

be recognized. The depressed button must stay down for several

timer interrupts before action is taken. After the button has been rec

ognized, the timer interrupt SW will be waiting for the button to be

released. The button must be released for several timer interrupts be

-

fore the keyboard scanning returns to mode 1. Then the search for

-

other activated buttons can be resumed.

The following three buttons are not scanned in this way:

The ON button is connected to the ON/STANDBY logic in the

–

power supply.

CPU Latch

Key-

board

Latch

rd

GPIB

Fig. 4-12 Microcomputer circuits, block diagram.

4-12 Hardware Functional Description

RAM

Address Bus

UV

EPROM

OM

Address & Data Bus

2

ICBus

EE

PROM

Counter

ASIC

LCD

Drivers

LCD

Page 29

The STAND-BY button is connected to the ON/STANDBY

–

logic in the power supply.

The LOCAL/PRESET button is connected directly to input pin

–

24 on the microcontroller U11. Pressing this button sends an

interrupt to a special handler in the SW.

Rear Panel Unit

The rear panel contains the following connectors

INPUTS:

External reference input D - REF IN (BNC)

–

External arming input E - EXT ARM (BNC)

–

Power supply inlet including EMI filter

–

OUTPUTS:

Internal reference output G - 10 MHz OUT (BNC)

–

If a GPIB interface is installed in the device, it is mounted on the rear

panel and connected to the main board with a flat cable.

Besides the normal standard GPIB connector, this optional unit also

has a BNC connector capable of outputting an analog representation

of any three consecutive digits on the display.

There is also a 6 SPST DIP switch on this unit for setting the default

GPIB address.

ON

ANALOG OUT

P M962 1

P M962 3

P M962 4

P M962 5

OF F

168 421

A DDRE S S

I E E E 4 88 / I E C 62 5 IN T ER F A C E

SH 1, AH1, T 5, L4, SR1,

RL1, DC1, DT 1, E 2

PM9626

PM9678

PM9690

PM9691

10M Hz O UT RE F I N E XT AR M

GDE

PM9628 /85

P M9697

_______

_______

EXT SUPPLY

12-24V DC

-I NT -S T BY

BAT T ERY

-EX T /L I NE

POWE R

90 V - 26 5V

PRIMARY FUSE

1.6AT

INSIDE

Fig. 4-14 Rear panel.

Hardware Functional Description 4-13

Page 30

Optional Units

B

i

b

d

GPIB Interface Including Analog Output

GPIB, PM9626B

n

IC101/106/117

Analog Out

n

The result on the display can be converted to an analog signal by

means of a pulse-width-modulated (PWM) signal from the micro

processor. The signal is filtered, attenuated, offset-adjusted, inte

grated and buffered by IC103 and supporting passive components to

give an analog DC level between 0 and 4.98 V with a resolution of

20 mV. The analog output has a separate analog ground connected to

the cabinet.

-

-

oar

IC107/108

c

as

A0-15

AD0-15

IC111/

112

IC109/

110

IC113

IC114/115

GPIB

connector

IC116

+5V

Fig. 4-15 GPIB interface.

The GPIB interface controls the communication between the internal

microprocessor and the external GPIB bus. A 32K extension of the

ROM and RAM is placed on the interface board. An analog output is

also included. The PCB is connected to J18 on the main board with a

ribbon cable and fixed to the rear panel with two screws. Two metal

studs at the rear edge of the PCB are inserted in slots on the main

board in order to relieve mechanical stress.

The GPIB control circuit, IC113, communicates with the external

GPIB bus via the bidirectional bus drivers IC114 and IC115. IC113 is

controlled from the microprocessor by writing and reading in the in

ternal control registers. If IC113 has a message for the microproces

sor, it uses the GPIB interrupt signal. The address switch setting is

read by the microprocessor via IC116.

A 32K extension of both ROM (IC109 and IC110) and RAM (IC111

and IC112) is placed on the interface board. The circuit board is pre

pared for a 16-bit extension, but only 8 bits are used. IC110 (ROM),

IC112 (RAM) and R118 are not mounted. IC107, IC108 are address

latches andIC101, IC106and IC117 use the latched address to gener

ate chip select and chip enable signals for internal use on the GPIB

board.

HF Input

You can add an optional prescaler. This HF input is mounted on the

main board, to the right of the input amplifier. It is connected to J19

where there are three pins reserved for ID coding. Preparations have

thus beenmade forother prescalerswith different prescaling factors.

Prescaler 3.0 GHz, PM9624

n

This prescaler cannot be repaired at a local workshop. It must be sent

to the factory for repair.

The prescaler consists of the following parts:

Limiter

The limiter consists ofa6dBattenuator and a PIN diode at

–

tenuator to achieve constant input amplitude to the amplifiers.

Amplifier

–

Five amplifier stages are divided into three blocks. One block

consists of one amplifier. Two blocks consist of two amplifiers

each and an AGC control.

Automatic Gain Control (AGC)

Helps the amplifiers retain a constant output amplitude.

–

-

-

Dividers

Two dividers divide the input signal frequency by 16.

–

Detector

Detects whether the level of the input signal is high enough to

–

ensure correct measurement and, if not, blocks the output sig

-

nal from the prescaler.

Positive Voltage Regulator

–

-

Supplies a well-regulated voltage to the HF amplifiers.

-

-

-5.2V

Zero

IC103

PWM

Full scale

Fig. 4-16 Analog output.

4-14 Hardware Functional Description

IC103

+7V

Analog

Out

Page 31

Software Functional Description

General

The PM 6685 software is divided into two main modules: the GPIB

and DEVICE modules. The GPIB fully implements the Message Ex

change protocol as described in the IEEE 488.2 - 1987 standard.

The DEVICE module is a real-time measurement executive that can

be interrupted to do other tasks, such as handling the keyboard, per

forming bus commands etc.

The basic structure of the main module is as follows:

main PM6685()

{

Initialize();

while (TRUE)

{

if (BREAKFLAG_KEYBOARD)

{

HandleKeyboard();

}

if (BREAKFLAG_PRESET)

{

PresetDevice();

}

if (BREAKFLAG_GPIBCOMMAND)

{

ExecuteGpibCommands();

}

if (BREAKFLAG_RESTART)

{

RestartMeasurement();

}

while (not any BREAKFLAG)

{

Measure( );

}

}

}

All break flags are set by interrupt-driven events, either from exter

-

nal functions (the GPIB interface) or from internal functions (timers

-

etc.).

The Initialize procedure does all necessary initialization at power

up. It also does the power up tests. See Power-On test in chapter 2.

-

The Handlekeyboard procedure controls all user input/output via

the front panel, except displaying the measurement results.

The PresetDevice procedure reprograms the complete device when

the PRESET key has been pressed (in local mode). It aborts pending

measurements.

The ExecuteGpibCommands procedure executes GPIB commands

and, if a query is received, it starts the response formatter and sends

the requested data to the GPIB interface. If the display is switched

on, the results are also displayed.

The RestartMeasurement procedure aborts pending measure

ments; the measure loop will later continue to measure. This is

mainly used when the RESTART key is pressed.

The Measure procedure is the measurement control loop that is used

in local mode. It sends its result to the display.

The ParseGpibInputData procedure parses the GPIB messages

found in the input buffer and sends executable statements to the

ExeceuteGpibCommands procedure. The input of data to the input

buffer from the external GPIB interface is fully controlled in inter

rupts. These interrupts are always enabled so the new data bytes can

be stored in the input buffer while parsing commands. This

ParseGpibInputDat is also executed in interrupt.

Software Functional Description 4-15

Page 32

Test Routines

Test Routines via AUX MENU Key

The testroutines arethe routinesaccessible via the AUX MENU key.

Refer to the PM6685 Operators Manual.

Power-On Tests

At power-on some tests are automatically performed. If any of these

tests fails, an error message is displayed and the instrument is halted.

Pressing the LOCAL/PRESET key makes the device continue inde

pendently of the detected error, but without performing the next tests

in the start-up sequence.The following tests/actions are performed:

Write 001 to internal test pins

–

Pulse all microcomputer i/o ports twice

–

Write 0.1 on display

–

Write 0.1.2. on display and 010 on test pins

–

Test mC internal RAM ( error = Err mC & halt)

–

Write 0.1.2.3 to display and 011 on test pins

–

Test mC timer ( error = Err mC & halt)

–

Write 0.1.2.3.4. on display and 100 on test pins

–

Test main board RAM ( error = Err ra. & halt )

–

Write 0.1.2.3.4.5. to display and 101 to test pins

–

Test ASIC ( error = Err. 5xx & halt)

–

Write 110 on test pins

–

Check display (light all segments for 2 s)

–

Clear Display

–

Perform GPIB RAM test if GPIB is installed

–

(error = Err ra. & halt)

Write 111 on test pins ( final value)

–

Clear display and start normal measurement procedure

–

-

4-16 Software Functional Description

Page 33

Chapter 5

Repair

Page 34

Preventive Maintenance

Calibration

To maintain the performance of your counter we recommend that

you calibrate your instrument every year, or more often, if greater

time base accuracy is required. Calibration should be performed with

traceable references and instruments at a certified calibration labora

tory. Contact your local Fluke representative for calibration.

To know the present status of your instrument, test your timer/coun

ter from time to time. The test can be made according to the informa

tion in Chapter 2, Performance Check.

Oscillators

The frequency of the reference crystal oscillator is the main parame

ter affecting accuracy in a counter. The frequency is affected by ex

ternal conditions like the ambient temperature and supply voltage,

but also by aging. When recalibrating, the reference crystal oscillator

is compensated only for deviation in frequency due to aging.

Some important points:

n

The high stability oscillators have been built into an oven in

–

order to keep the oscillator temperature as stable as possible.

Continuous operation is also important for stability. After a

power interruption, the oscillator restarts at a slightly different

frequency. It will then, as time goes on, age at an equal rate.

The stability indicated for the oscillators is valid within a tem

–

perature range of 0 to +50 °C, with a reference temperature of

+23 °C. If the timer/counter is used in a room temperature of

20 to 30 °C, the temperature stability of an OCXO will be in

-

creased by a factor of 3.

-

-

-

The temperature stability indicated for the standard oscillator is

–

mainly dependent on the ambient temperature. When the coun

ter is operating there is always an internal temperature increase

that will influence the oscillator.

Recalibration intervals

n

-

The Mean Time Between ReCalibration, MTBRC, is defined as:

-

MTBRC

Acceptable error Temperature stability

=

-

−()( )

Agi

(

ng)

MTBRC can be calculated when the total acceptable error and the

oscillator specifications are known.

The total acceptable error is defined as:

()

()

Acceptable error

Deviation of reference frequency

=

(

Nominal reference frequency)

Model PM6685 PM6685R

Option:

Timebase type:

Total uncertainty,

0°Cto50°C,at2

- 1 month after calibration

- 3 months after calibration

- 1 year after calibration

- 2 years after calibration

Typical total uncertainty, for operating

temperature 20°C to 26°C, at 2

dence interval:

- 1 month after calibration

- 3 months after calibration

- 1 year after calibration

- 2 years after calibration

*

After 1styear of operation. For 1styear add: < 3x10

for operating temperature

s (95%) confidence interval:

s (95%) confi

Standard

UCXO

< 1.2 x 10

<1.2x10

<1.2x10

<1.5x10

-

<4x10

<4x10

<7x10

<1.2x10

Table 5-1 Stability of timebase oscillators.

5-2 Preventive Maintenance

PM9691

OCXO

-5

-5

-5

-5

-6

-6

-6

-5

-10

<3x10

<4x10

<1x10

<2x10

<3x10

<4x10

<1x10

<2x10

-8

-8

-7

-7

-8

-8

-7

-7

PM9692

OCXO Rubidium

-9

<8x10

<1.2x10

<2.5x10

-8

<5x10

-9

<8x10

<1.2x10

<2.5x10

-8

<5x10

-8

-8

-5

-8

<4x10

<4x10

<4x10

<6x10

<1x10

<2x10

<2.5x10

<5x10

-10

-10

-10 *

-10 *

-10

-10

-10 *

-10 *

Page 35

Example:

A user can accept a maximum of 3 Hz deviation on the

–

10 MHz frequency of the oscillator. This results in:

()Acceptable error =

3

×

10 10

6

=×

310

−

7

The aging and temperature factors can be selected from the table on

page 5-2.

The value of the aging factor is correctly selected from the table

when the calculation of MTBRC results in 1 to 30 days (use /24h), 1

to 12 months (use /month) or over 1 year (use /year) (not, e.g., 43

days or 17 months or 0.8 years).

Example:

The user has the same requirements as in the example above.

–

The counter has a PM9691 oscillator.

Look up information about PM9691 in the table on page 5-2.

–

The results will be the following:

Relative Frequency deviation caused by:

Ambient temperature deviation

–

(within 0 to 50 °C; reference point at 23 °C): Less than

–8

3*10

Aging/year: Less than 1.5 * 10

–

Use the MTBRC formula with the above values. This gives a

–

–7

MTBRC of maximum:

78

−−

310 310

×−×

−

15 10

×

.

18

=

7

. year

NOTE: When recalibrating, the reference crystal oscillator will be

compensated only for frequency deviation caused by aging.

When to Replace the Fan

(PM6685R only )

To maintain the high reliability of a counter used in

around-the-clock’ applications, you must replace the fan every sec

ond year. For part time and low ambient temperature use, you can ex

tend this service interval to 6-10 years or more. Additional informa

tion can be found in Chapter 9, Appendix.

-

-

-

Preventive Maintenance 5-3

Page 36

Troubleshooting

General

Quick Troubleshooting

The PM6685is ahighly integratedFrequency counterwith dedicated

LSI counter circuits and microcontrollers that control the complete

units. The microcontroller can help you locate faulty parts by run

ning test programs and generating stable signal patterns on t

he bus. If the microcontroller does not work or the fault is in a part of

the counter that cannot be accessed by the microcontroller, tradi

tional troubleshooting must be performed.

Where to Start

After reading the safety instructions, continue with this chapter for

troubleshooting and repair instructions. When you have fixed the in

strument, always do the Safety Inspection and Test after Repair, as

described later in this Chapter. Then do the checks in Chapter 2, Per

formance Check. Recalibrate if required by following the adjustment

instructions in chapter 6, Calibration Adjustments.

Logic Levels

The PM6685 contains logic of four families. The levels for these

families are listed in the following table.

Positive

ECL

Supply voltage +5 V -5.2 V +5 V +5 V

Signal ground 0 V 0 V 0 V 0 V

Input voltage

High, V

IH >+3.9 V >-1.1 V >+4 V >+2 V

Low, V

IL <+3.5 V <-1.5 V <+1 V <+0.8 V

Output voltage

High, V

OH >+4 V >-1 V >+4.9 V >+2.7 V

Low, V

OL <+3.3 V <-1.7 V <+0.05 V <+0.4 V

Bias ref. voltage, V

BB +3.7 V -1.3 V - -

Table 5-2 Logic levels.

Negative

ECL

CMOS TTL

Required Test Equipment

To test the instrument properly using this manual, you will need the

equipment listed below. The list contains specifications for the criti

-

cal parameters.

-

-

DMM

Oscilloscope 300 MHz 2-channel

Signal generator 3300 MHz