Page 1

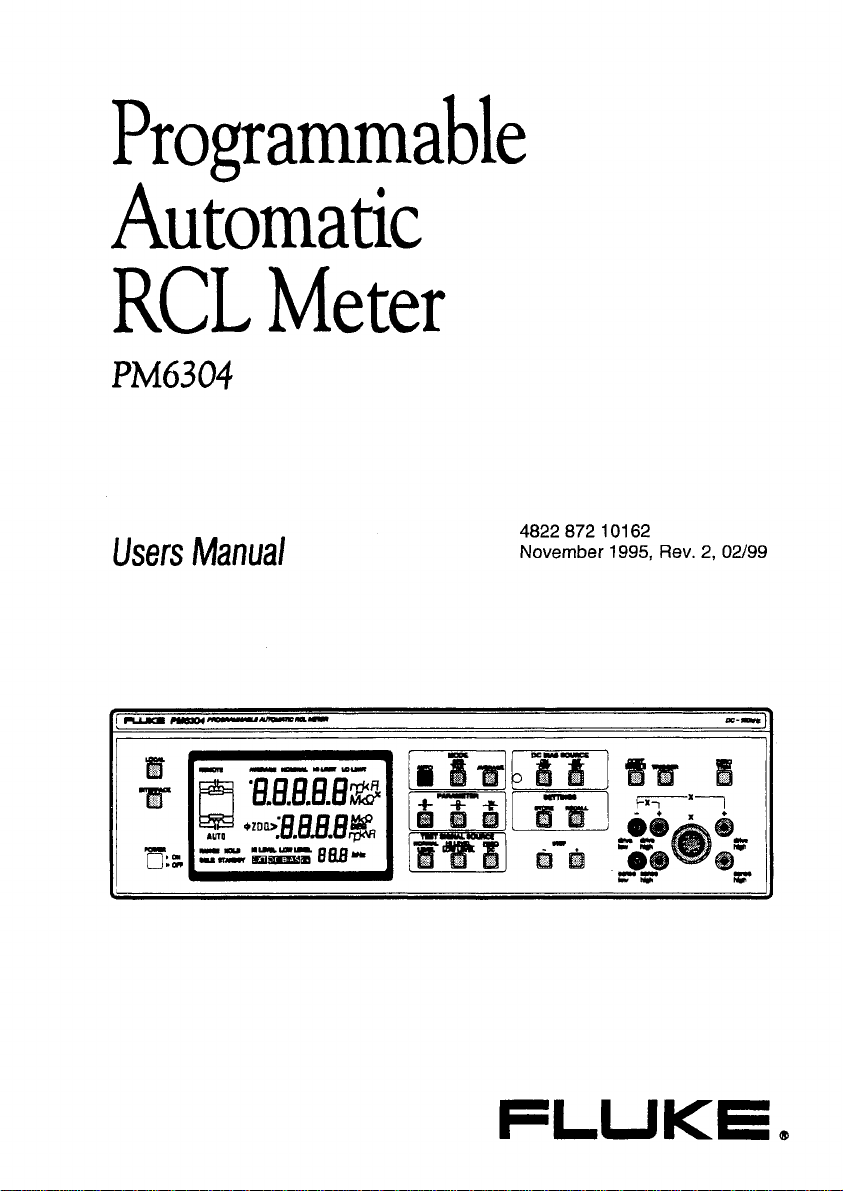

Programmable

Automatic

RCL

Users

Manual

Meter

4822 872

November 1995, Rev.

101

62

2,

02/99

Page 2

Please note

In correspondence concerning this instrument, please quote the type number

and serial number as given on the type plate.

Bitte

beachten

Bei Schriftwechsel uber dieses Gerat wird gebeten, die Typennummer und die

Geratenurnmer anzugeben. Diese befinden sich auf dem Typenschild an der

Riickseite des Gerates.

Noter s.v.p.

Dans votre correspondance et dans vos reclamations se rapportant a cet

appareil, veuillez toujours indiquer le numero de type et le numero de serie qui

sont marques sur la plaquette de caracteristiques.

lmportant

As the instrument is an electrical apparatus,

it

may be operated only by trained

personnel. Maintenance and repairs may also be carried out only by qualified personnel.

Wichtig

Da das Gerat ein eelktrisches Betriebsrnittel ist, darf die Bedienung nur durch eingewiesenes Personal erfolgen. Wartung und Reparatur dorfen nur von geschultern, fach- und sachkundigem Personal durchgefijhrt werden.

lmportant

Comme I'instrument est un equipement electrique, le service doit etre assure par

du personnel qualifie. De mhe, I'entretien et les reparations sont

a

confier aux

personnes suffisamment qualifiees.

O

Fluke Corporation. All rights reserved. Printed in Germany

All product names are trademarks of their respective companies.

Page 3

CONTENTS

Users Manual

CONTENTS

PM6304

lnstrucciones de instalacion y de seguridad

lstruzioni per la messa in funzione e norme di sicureua

lnstructies met betrekking tot de installatie en veiligheid

lnledande anvisningar och sakerhetsanvisningar

Figures

Appendix

Diagrams and Formulas

Table for Storage Register Contents

&

Limited Warranty

Declaration of Conformity

Limitation of Liability

@

a

@

@

Service Centers

Page 4

Page 5

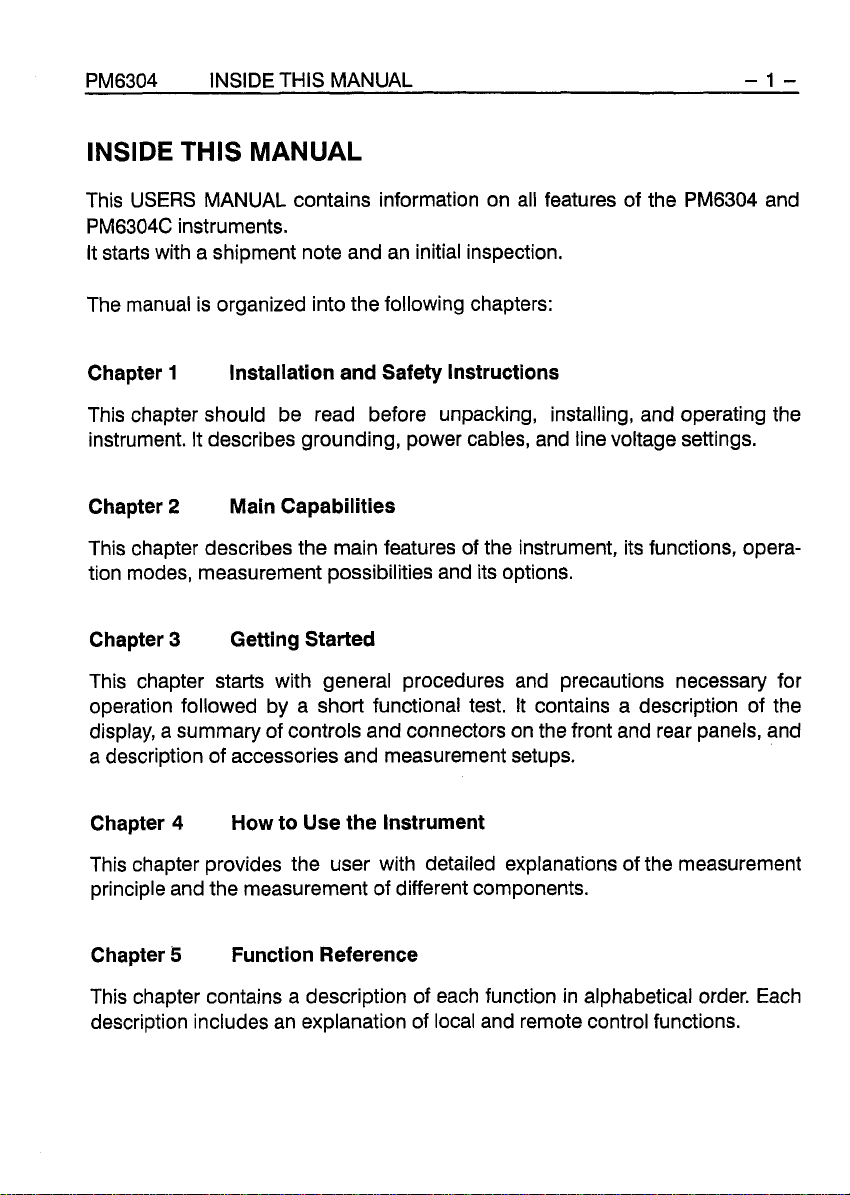

PM6304 INSIDE THIS MANUAL

-1-

INSIDE THlS MANUAL

This USERS MANUAL contains information on all features of the PM6304 and

PM6304C instruments.

It starts with a shipment note and an initial inspection.

The manual is organized into the following chapters:

Chapter

1

Installation and Safety Instructions

This chapter should be read before unpacking, installing, and operating the

instrument. It describes grounding, power cables, and line voltage settings.

Chapter

2

Main Capabilities

This chapter describes the main features of the instrument, its functions, operation modes, measurement possibilities and its options.

Chapter

3

Getting Started

This chapter starts with general procedures and precautions necessary for

operation followed by a short functional test. It contains a description of the

display, a summary of controls and connectors on the front and rear panels, and

a description of accessories and measurement setups.

Chapter

How to Use the Instrument

4

This chapter provides the user with detailed explanations of the measurement

principle and the measurement of different components.

Chapter

5

Function Reference

This chapter contains a description of each function in alphabetical order. Each

description includes an explanation of local and remote control functions.

Page 6

-

2

-

INSIDE THIS MANUAL PM6304

Included in the shipment

The

REFERENCE

CHARACTERISTICS

PRINCIPLE OF OPERATION

BRIEF CHECKING PROCEDURE

PERFORMANCE TEST

PREVENTIVE MAINTENANCE

APPENDIX

SERVICE CENTERS

you

find an additional REFERENCE MANUAL.

MANUAL

contains:

Page 7

PM6304 CONTENTS -1-

CONTENTS

Page

SHIPMENT NOTE AND INITIAL INSPECTION

1

1.1 SAFETY INSTRUCTIONS

1.2 OPERATING POSITION OF THE INSTRUMENT

1.3 RADIO INTERFERENCE SUPPRESSION

2

3

3.1 GENERAL INFORMATION

3.2 TURNING THE INSTRUMENT ON

3.3 SELF-TEST ROUTINE

3.4 OPERATION AND APPLICATION

4

4.1 THE PRINCIPLE OF MEASUREMENT

4.2 MEASURING COMPONENTS

4.3 AUTOMATIC ZERO TRIM

INSTALLATION AND SAFETY INSTRUCTIONS

1.1.1 Maintenance and Repair

.I

.2 Grounding (Earthing)

1

1.1.3 Connections

1.1.4 Line Voltage Setting and Fuses

MAIN FEATURES

GETTING STARTED

3.4.1 Control Elements, Display and Connections

3.4.2 Measurement Setup and Accessories

3.4.3 Example of a Measurement

HOW TO USE THE INSTRUMENT

4.2.1 Test Signal Frequency and Voltage

4.2.2 Resistors

4.2.3 Capacitors

Foil Capacitor

Electrolytic Capacitor

4.2.4 Inductances

Page 8

-2- CONTENTS PM6304

4.4 MEASURING MODES

4.4.1 Automatic (AUTO)

4.4.2 Manual

4.4.3 Accuracy

4.5

4.6 BINNING

4.7 OUT-OF-RANGE AND ERROR MESSAGES

STOREIRECALL OF INSTRUMENT SETTINGS

4.6.1 Introduction

4.6.2 PM 9559 Bin Programmer

(Infrared Remote Control)

4.6.3 PM 9566 Handler Interface

5

5.1

5.2

INSTALLATION AND SAFETY INSTRUCTIONS IN FOREIGN LANGUAGES

FIGURES

Fig.

Fig. 2 Rear view

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7 PM 9542SMD, SMD Adapter

Fig.

Fig. 9

APPENDIX:

DIAGRAMS AND FORMULAS

TABLE FOR STORAGE REGISTER CONTENTS

LIMITED WARRANTY

DECLARATION OF CONFORMITY

SERVICE CENTERS

FUNCTION REFERENCE

FUNCTIONS OF THE FRONT PANEL OF THE INSTRUMENT

FUNCTIONS OF THE PM 9559 BIN PROGRAMMER

1

Front view

PM 9540/TWE, SMD Tweezers

PM 9540/BAN, 4-wire test cable with banana plugs

PM

9541A, 4-wire test cable

Single and double test posts

PM 9542A, RCL Adapter

8

PM 9559 Bin Programmer, Infrared remote control

&

LIMITATION OF LIABILITY

5-1

-

5

-

5

1

20

Page 9

PM6304 SHIPMENT NOTE

-1-

SHIPMENT

The following

1

PM6304 / PM6304C Progammable Automatic

1

Users Manual

1

Reference Manual

1

Programmers Manual

1

Power Cable

2

Fuses

2

Single Test Posts

NOTE

parts

should be included in the shipment:

RCL

Meter

DC

-

100

kHz

Page 10

- 2 -

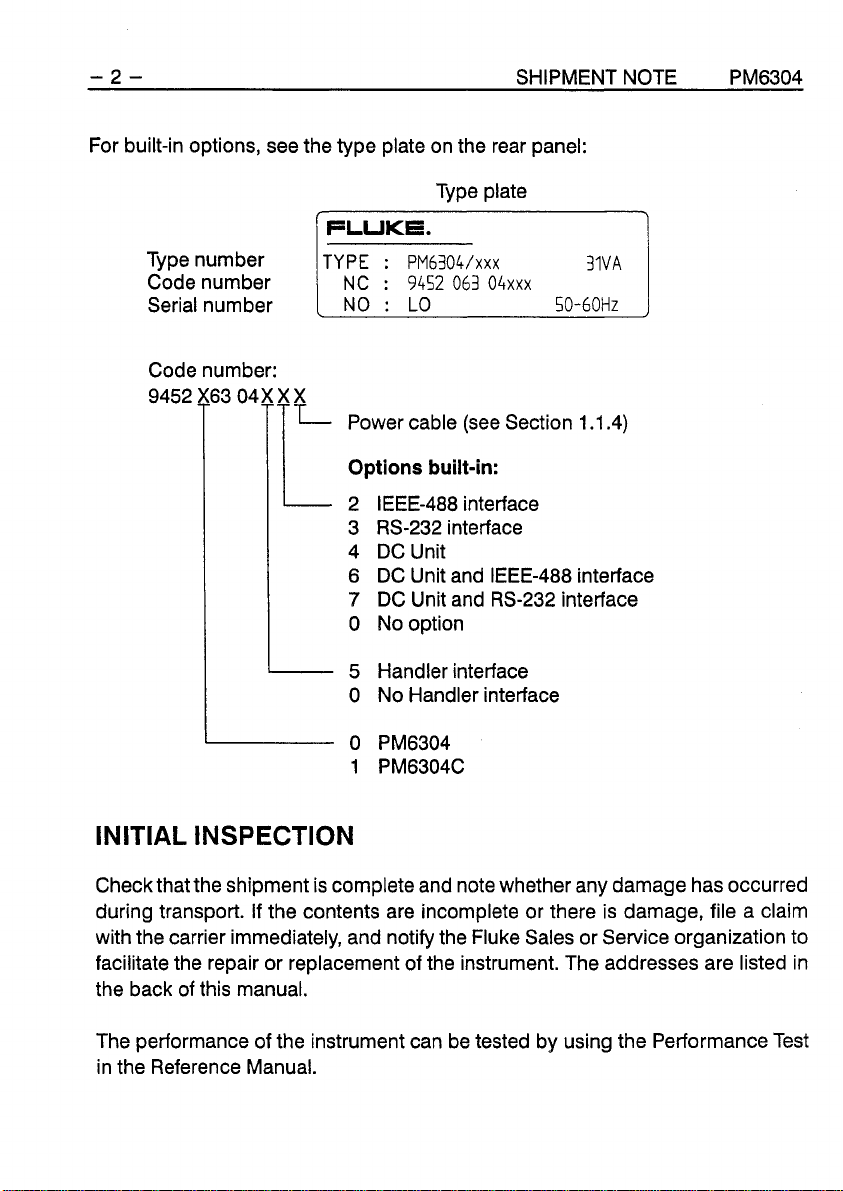

For built-in options, see the type plate on the rear panel:

Type plate

[

FLUKE.

Type number

Code number

Serial number

Code 9452 13 number: 041L

TYPE : PM6304/xxx 31VA

1

NC

:

9452 063 04xxx

NO : LO

Power cable (see Section 1.1.4)

SHIPMENT NOTE PM6304

50-60Hz

Options built-in:

2 IEEE-488 interface

3 RS-232 interface

4 DC Unit

6 DC Unit and IEEE-488 interface

7

DC Unit and RS-232 interface

0

No option

1

5 Handler interface

0 No Handler interface

INITIAL INSPECTION

Check that the shipment is complete and note whether any damage has occurred

during transport. if the contents are incomplete or there is damage, file a claim

with the carrier immediately, and notify the Fluke Sales or Service organization to

facilitate the repair or replacement of the instrument. The addresses are listed in

the back of this manual.

The performance of the instrument can be tested by using the Performance Test

in the Reference Manual.

Page 11

Chapter

INSTALLATION AND SAFETY INSTRUCTIONS

1

Page 12

Page 13

PM6304

INSTALLATION AND SAFETY INSTRUCTIONS

1-1

1

1

.I

Upon delivery from the factory the instrument complies with the required safety

regulations (see Reference Manual, Chapter

ensure safe operation, the instructions below must be followed carefully.

1.1.1

Failure and excessive stress:

If the instrument is suspected of being unsafe, remove it from operation immediately and secure it against any unintended operation. The instrument is considered to be unsafe when any of the following conditions exist:

It shows physical damage.

It does not function anymore.

It is stressed beyond the tolerable limits

(e.g., during storage and transportation).

Disassembling the Instrument:

INSTALLATION AND SAFEN INSTRUCTIONS

SAFETY INSTRUCTIONS

1).

To maintain this condition and to

Maintenance and Repair

WARNING

Calibration, maintenance, and repair of the instrument must be performed only by trained personnel who are aware of the hazards involved.

To avoid electric shock, do not remove the cover unless you are quali-

fied to do so.

Before removing the cover, disconnect the instrument from all power

sources. The capacitors in the instrument may remain charged for

several seconds after all power has been disconnected.

Page 14

1-2

1

.I

.2

Grounding (Earthing)

INSTALLATION AND SAFETY INSTRUCTIONS

PM6304

Before any other connection is made the instrument must be connected to a

protective earth conductor via the three-wire power cable.

The power plug shall be inserted only into a grounded outlet.

Do not defeat the protective action by using an extension cord without a grounded

conductor.

Do not connect a protective ground conductor into the measurement contacts

on the front panel, the four contacts of the connector to which the circuit ground

is applied, or the external contact of the connector plug.

WARNING

Any interruption of the protective ground conductor inside or outside

the instrument or disconnection of the protective ground terminal, is

likely to make the instrument dangerous. Intentional interruption is

prohibited.

1

.I

.3

Connections

The circuit ground potential is applied to four of the eight contacts of the front

panel connector and is connected to the instrument case via parallel-connected

capacitors and a resistor. The external contact of the connector is connected to

the instrument case. This avoids ac ground loops while providing good RF

grounding.

If the circuit ground potential in a measurement setup is different from the protective ground potential, make sure that the four contacts of the front panel connector

are not live.

Page 15

PM6304

1

.I

.4

INSTALLATION AND SAFETY INSTRUCTIONS

Line Voltage Setting and Fuses

1-3

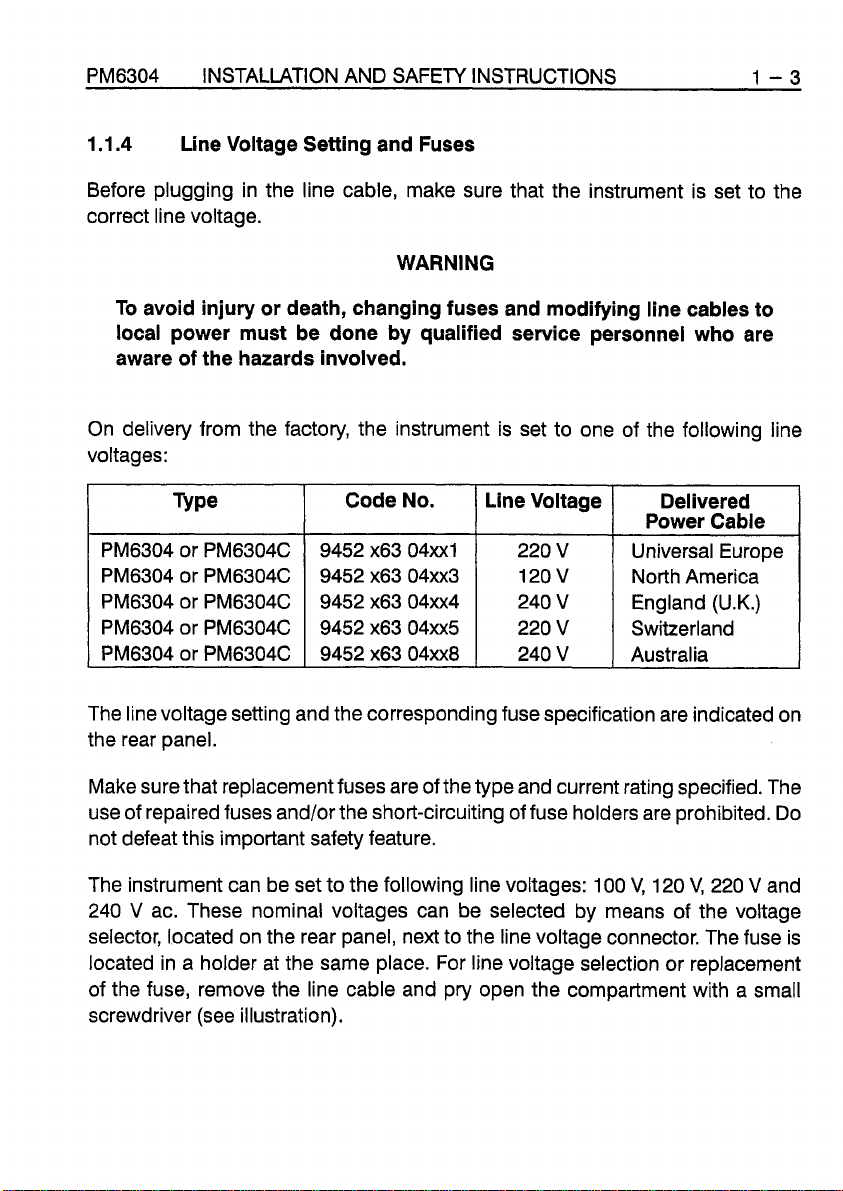

Before plugging in the line cable, make sure that the instrument is set to the

correct line voltage.

WARNING

To avoid injury or death, changing fuses and modifying line cables to

local power must be done by qualified service personnel who are

aware of the hazards involved.

On delivery from the factory, the instrument is set to one of the following line

voltages:

Code No.

Line Voltage

Delivered

Power Cable

9452 x63 04~x1

9452 x63 04~x3

9452 x63 04~x4

9452 x63 04~x5

9452 x63 04~x8

220

120

240

220

240

V

V

V

V

V

Universal Europe

North America

England (U.K.)

Switzerland

Australia

The line voltage setting and the corresponding fuse specification are indicated on

the rear panel.

Make sure that replacement fuses are of the type and current rating specified. The

use of repaired fuses

and/or the short-circuiting of fuse holders are prohibited. Do

not defeat this important safety feature.

The instrument can be set to the following line voltages:

240

V ac. These nominal voltages can be selected by means of the voltage

100

V,

120

V,

220

V and

selector, located on the rear panel, next to the line voltage connector. The fuse is

located in a holder at the same place. For line voltage selection or replacement

of the fuse, remove the line cable and pry open the compartment with a small

screwdriver (see illustration).

Page 16

1-4 INSTALLATION AND

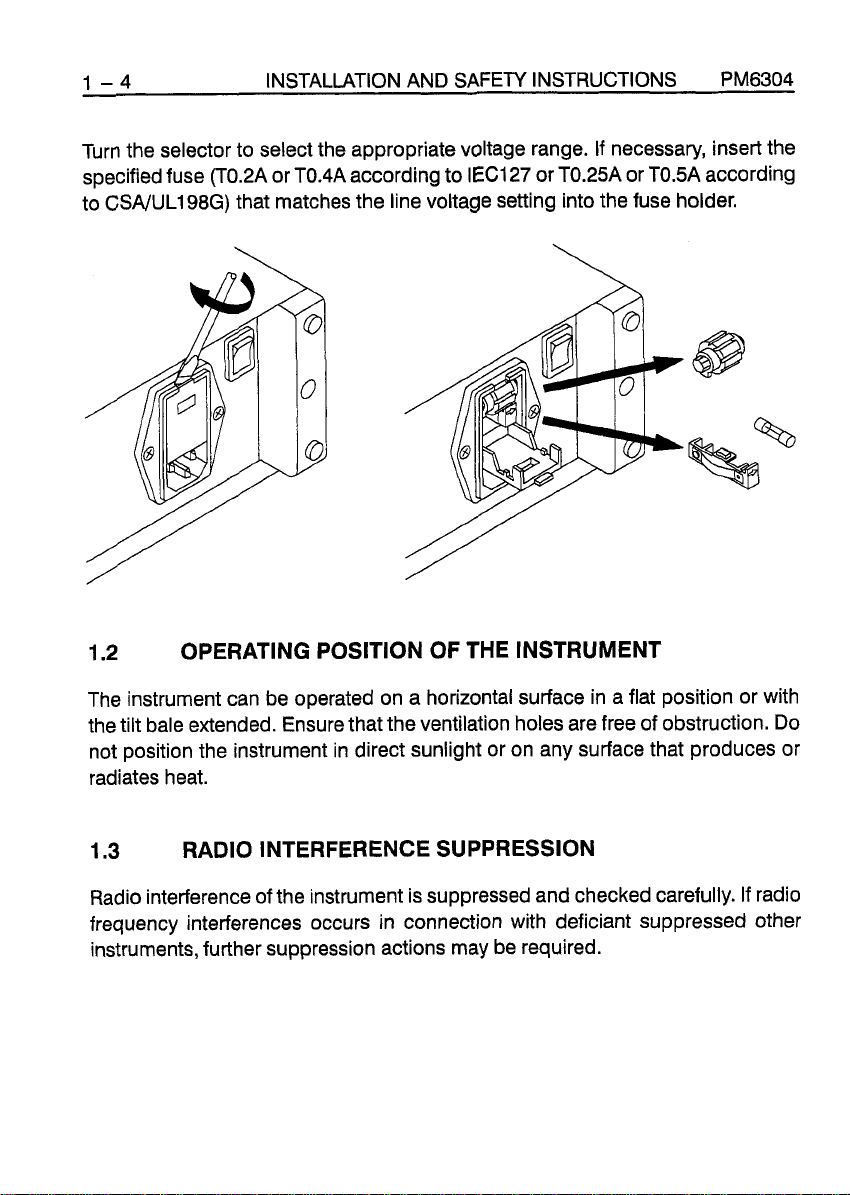

Turn the selector to select the appropriate voltage range. If necessary, insert the

specified fuse

to CSAJUL198G) that matches the line voltage setting into the fuse holder.

(T0.2A

or TOAA according to IEC127 or TOZA or T0.5A according

SAFETY

INSTRUCTIONS PM6304

1.2

The instrument can be operated on a horizontal surface in a flat position or with

the tilt bale extended. Ensure that the ventilation holes are free of obstruction. Do

not position the instrument in direct sunlight or on any surface that produces or

radiates heat.

1.3

Radio interference of the instrument is suppressed and checked carefully. If radio

frequency interferences occurs in connection with deficiant suppressed other

instruments, further suppression actions may be required.

OPERATING POSITION OF THE INSTRUMENT

RADIO INTERFERENCE SUPPRESSION

Page 17

Chapter

2

MAIN

FEATURES

Page 18

Page 19

PM6304 MAIN FEATURES 2-1

2

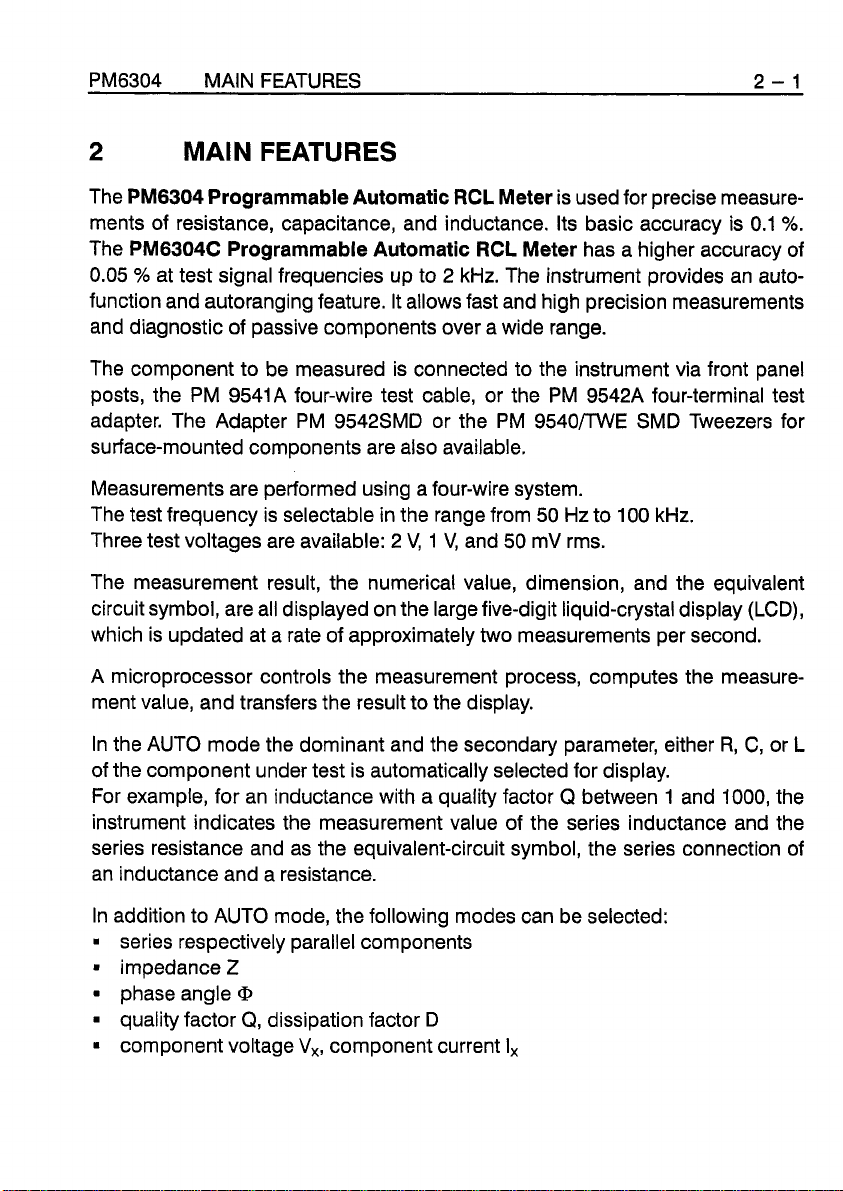

The

ments of resistance, capacitance, and inductance. Its basic accuracy is 0.1

The

0.05

function and autoranging feature. It allows fast and high precision measurements

and diagnostic of passive components over a wide range.

The component to be measured is connected to the instrument via front panel

posts, the PM 9541A four-wire test cable, or the PM 9542A four-terminal test

adapter. The Adapter PM

surface-mounted components are also available.

Measurements are performed using a four-wire system.

The test frequency is selectable in the range from 50 Hz to 100 kHz.

Three test voltages are available:

The measurement result, the numerical value, dimension, and the equivalent

circuit symbol, are all displayed on the large five-digit liquid-crystal display (LCD),

which is updated at a rate of approximately two measurements per second.

A

microprocessor controls the measurement process, computes the measure-

ment value, and transfers the result to the display.

MAIN

PM6304 Programmable Automatic RCL Meter

PM6304C Programmable Automatic RCL Meter

%

at test signal frequencies up to 2 kHz. The instrument provides an auto-

FEATURES

9542SMD or the PM 9540/TWE SMD Tweezers for

is used for precise measure-

2

V, 1 V, and 50 mV rms.

has a higher accuracy of

%.

In the AUTO mode the dominant and the secondary parameter, either

of the component under test is automatically selected for display.

For example, for an inductance with a quality factor

instrument indicates the measurement value of the series inductance and the

series resistance and as the equivalent-circuit symbol, the series connection of

an inductance and a resistance.

In addition to AUTO mode, the following modes can be selected:

series respectively parallel components

impedance

phase angle

quality factor

component voltage V,, component current I,

Z

Q

Q,

dissipation factor D

Q

between 1 and 1000, the

R,

C,

or L

Page 20

2-2 MAIN FEATURES PM6304

(2

V

An internal DC BlAS voltage

dc) can be added to the measurement voltage

for electrolytic capacitors.

An external DC BlAS voltage can also be selected, up to 40

V

dc.

DC resistance measurements without an ac test signal can be made by using the

optional PM 9565 DC Unit.

The instrument can be programmed and can transfer its measurement data via

the optional PM 9548 lnterface for IEEE-488, or via the PM 9549 lnterface for

RS-232. Ten measurements per second are also possible. The RS-232 lnterface

also allows output of measurement results directly to a printer with no controller

needed.

For sorting and binning of components, the optional infrared remote control, the

PM 9559 Bin Programmer, and the PM 9566 Handler lnterface are available.

Nine complete instrument settings can be stored and recalled for fast and convenient setup.

Page 21

Chapter

GETTING STARTED

3

Page 22

Page 23

PM6304 GETTING STARTED 3-1

GETTING STARTED

3.1

This section outlines the procedure and precautions necessary for operation. It

identifies and briefly describes the functions of the front and rear panel controls

and the display.

3.2

After the instrument has been connected to the line voltage in accordance with

Section

to

ON.

The specifications given in the Reference Manual, Chapter

instrument is installed in accordance with the instructions in Chapter

manual and a warm-up period of

After turning the power off, wait at least

allows all power to completely discharge and the instrument to reset.

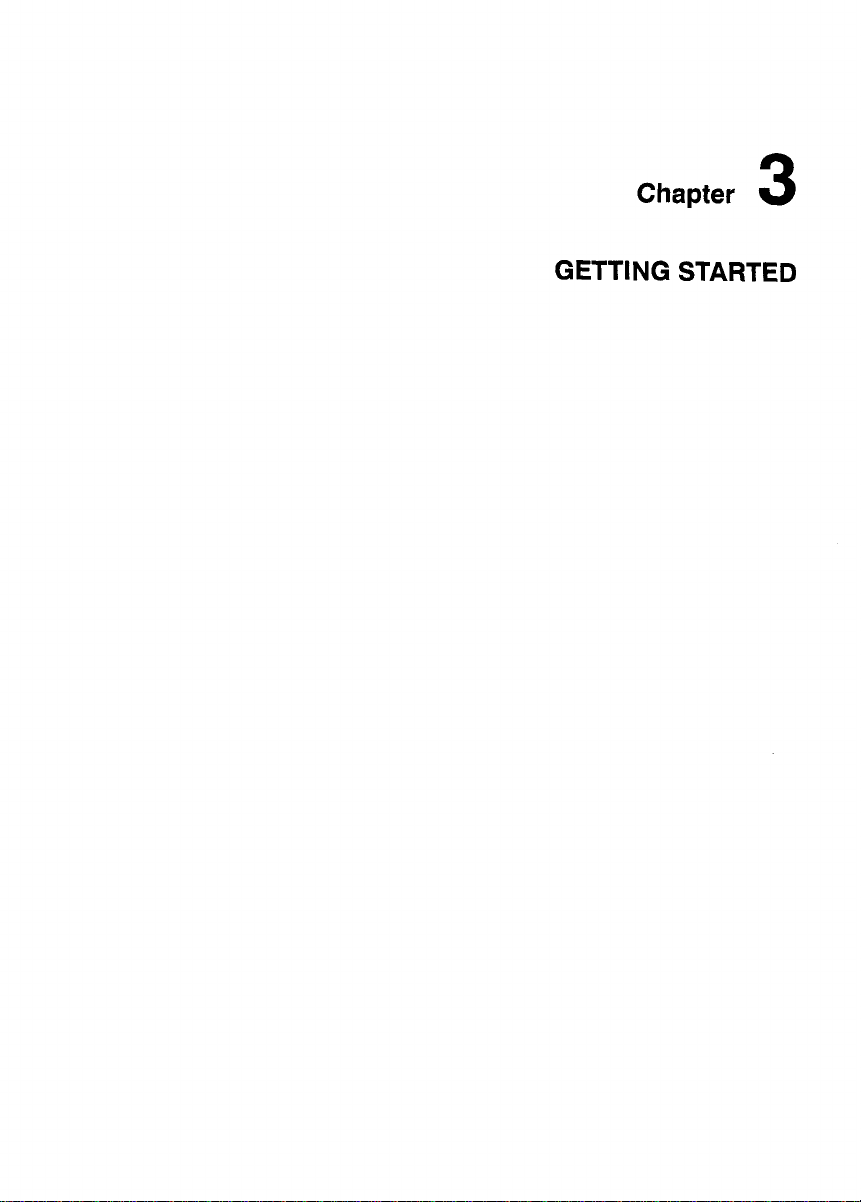

3.3

After power on, the instrument performs a self-test of the PROM, processor RAM,

and external RAM. After this, the software version is indicated in the upper line of

the display for approximately

shown for approximately

instrument state before power off.

GENERAL INFORMATION

TURNING THE INSTRUMENT ON

1.1.4, it can be turned on by setting the

5

minutes is allowed.

5

seconds before turning it on again. This

SELF-TEST ROUTINE

1

second. All segments of the display field are

2

seconds, and the instrument automatically recalls its

POWER

switch on the front panel

1,

are valid when the

1

of this

If a fault is found during self-test, this fault is indicated as follows,

-

for example:

For detailed information see Section 4.7.

r,TT

C

r,

J

Page 24

3-2 GETTING STARTED PM6304

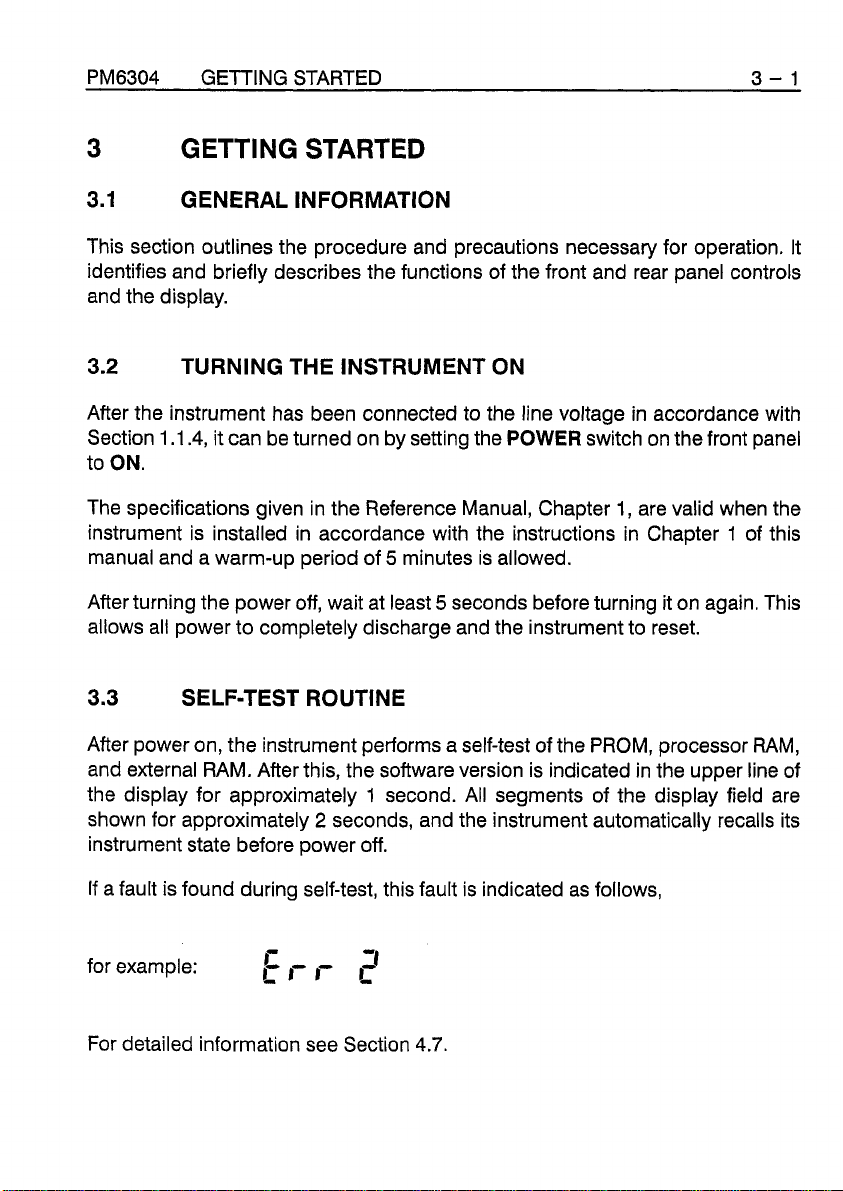

3.4

3.4.1

3.4.1.1

OPERATION AND APPLICATION

Control Elements, Display and Connections

Front Panel

Keyboard:

Descri~tion

LOCAL

INTERFACE

0

POWER

;

:;F

Function

Key used to switch from remote control to keyboard

operation.

Key used to display and to select

Instrument address for remote control via

IEEE-488 interface

Setup for remote control via

RS-232 interface.

Power switch

Keys used to select

the required measurement function

f

MODE

1

AUTO

Automatic measurement mode: the

dominant and secondary para-

meters are automatically determined

SEE

Select series

PAR or parallel mode

AVERAGE Alteration of averaging function

to reduce fluctuation of

measured value

PARAMETER

0

-

L

-

vx

-

Z

9

D

!b!

Phase angle or impedance

(complex impedance)

Quality factor (tan

Dissipation factor (tan

$;

6;

Q

D

Test voltage or current at the

=

=

1

ID)

1

IQ)

0

Ix component terminals.

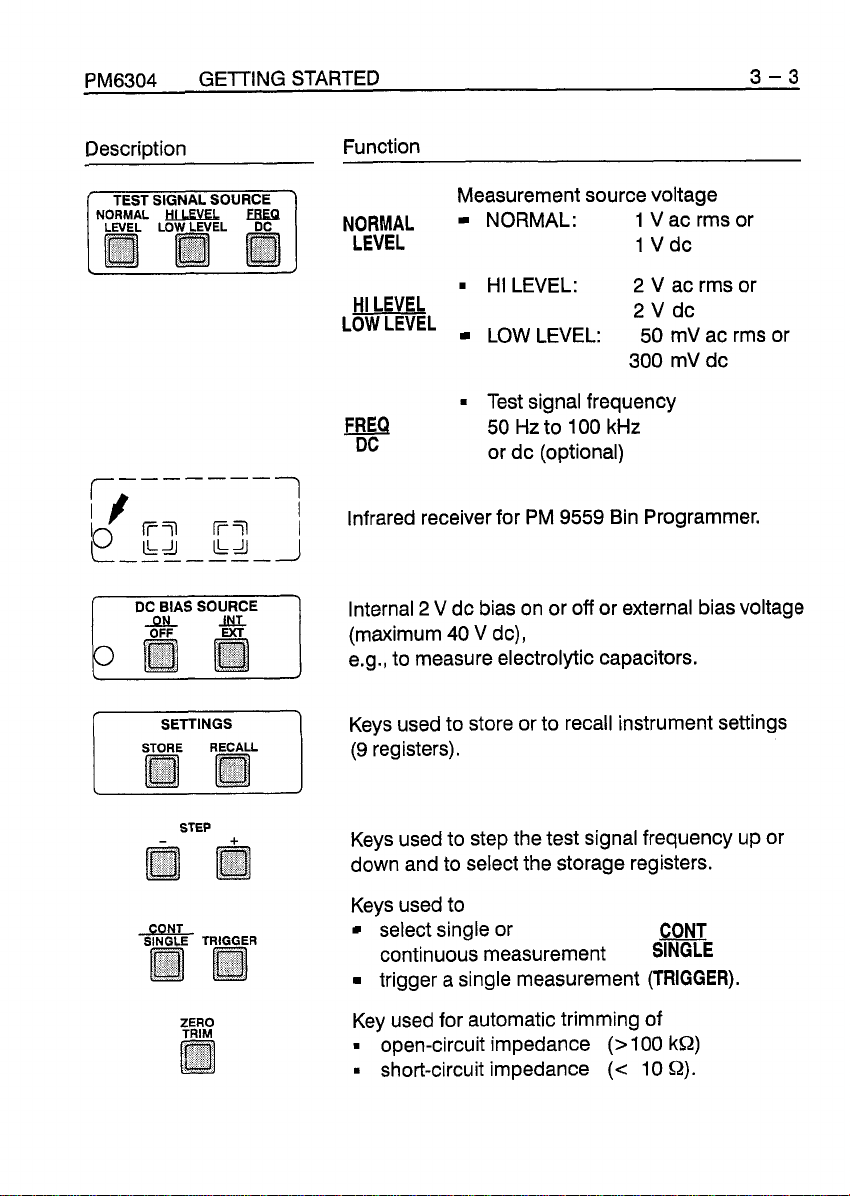

Page 25

PM6304 GETTING STARTED 3

Description Function

SIGNAL

SOURCE

NORMAL

Measurement source voltage

NORMAL:

1

V

ac rms or

LEVEL 1 Vdc

-

3

f

DC

BIAS SOURCE

SETTINGS

STEP

HI LEVEL

LEVEL

HI LEVEL:

~

-

LOW LEVEL: 50 mV ac rms or

2

2

V

V

ac rms or

dc

Test signal frequency

FREa

DC

50 Hz to 100 kHz

or dc (optional)

Infrared receiver for PM 9559 Bin Programmer.

Internal

(maximum 40

2

V

dc bias on or off or external bias voltage

V

dc),

e.g., to measure electrolytic capacitors.

Keys used to store or to recall instrument settings

'I

(9 registers).

I

Keys used to step the test signal frequency

up

or

down and to select the storage registers.

Keys used to

select single or CONT

continuous measurement

S~E

trigger a single measurement (TRIGGER).

Key used for automatic trimming of

open-circuit impedance

short-circuit impedance

(>

(c

100

10

k!2)

Q).

Page 26

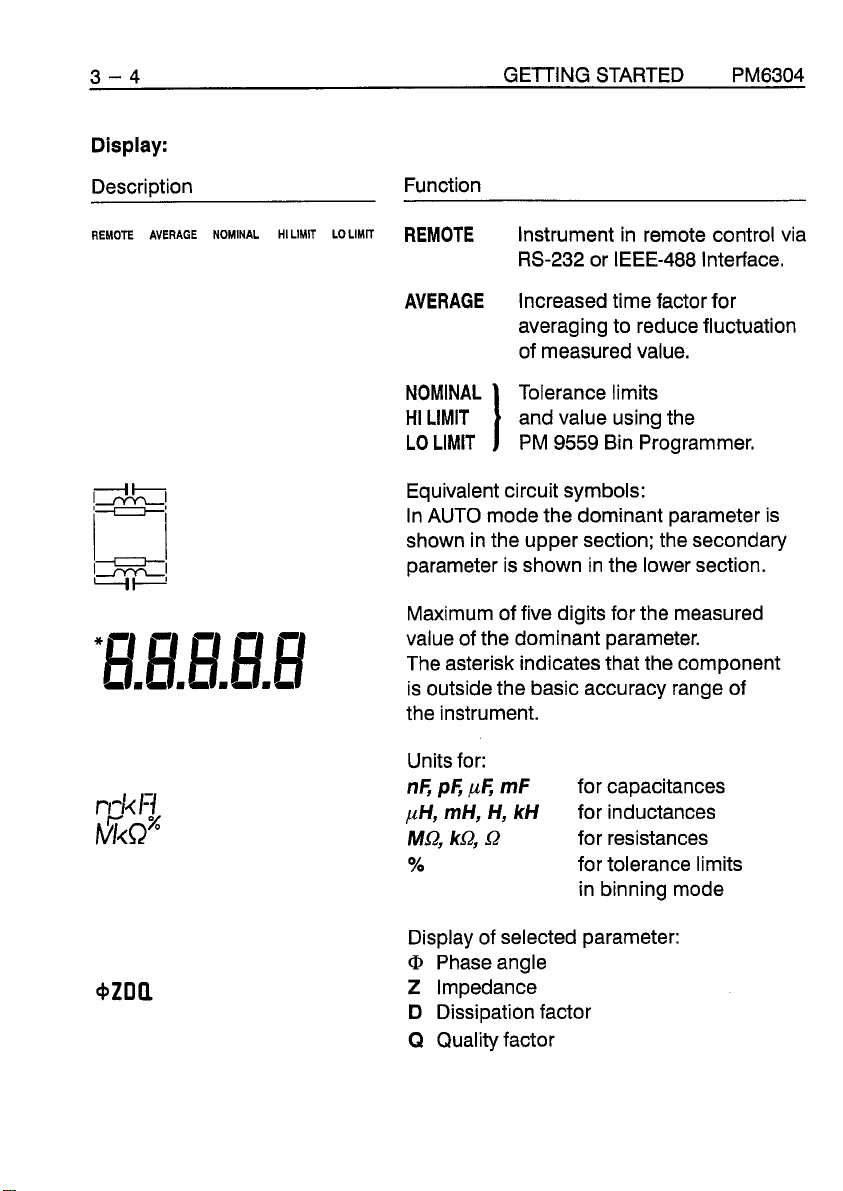

3 - 4 GETTING STARTED PM6304

Display:

Description Function

REMOTE

AVERAGE

NOMINAL

HILIMIT LOLIMIT

REMOTE

Instrument in remote control via

RS-232 or IEEE-488 Interface.

AVERAGE

Increased time factor for

averaging to reduce fluctuation

of measured value.

Tolerance limits

and value using the

PM

9559 Bin Programmer.

Equivalent circuit symbols:

In AUTO mode the dominant parameter is

shown in the upper section; the secondary

parameter is shown in the lower section.

Maximum of five digits for the measured

value of the dominant parameter.

The asterisk indicates that the component

is outside the basic accuracy range of

the instrument.

Units for:

nF,

pF,

pe

pH, mH, H,

MQ,

kQ,

Q

%

mF

kH

for capacitances

for inductances

for resistances

for tolerance limits

in binning mode

Display of selected parameter:

@

Phaseangle

Z

Impedance

D Dissipation factor

Q

Quality factor

Page 27

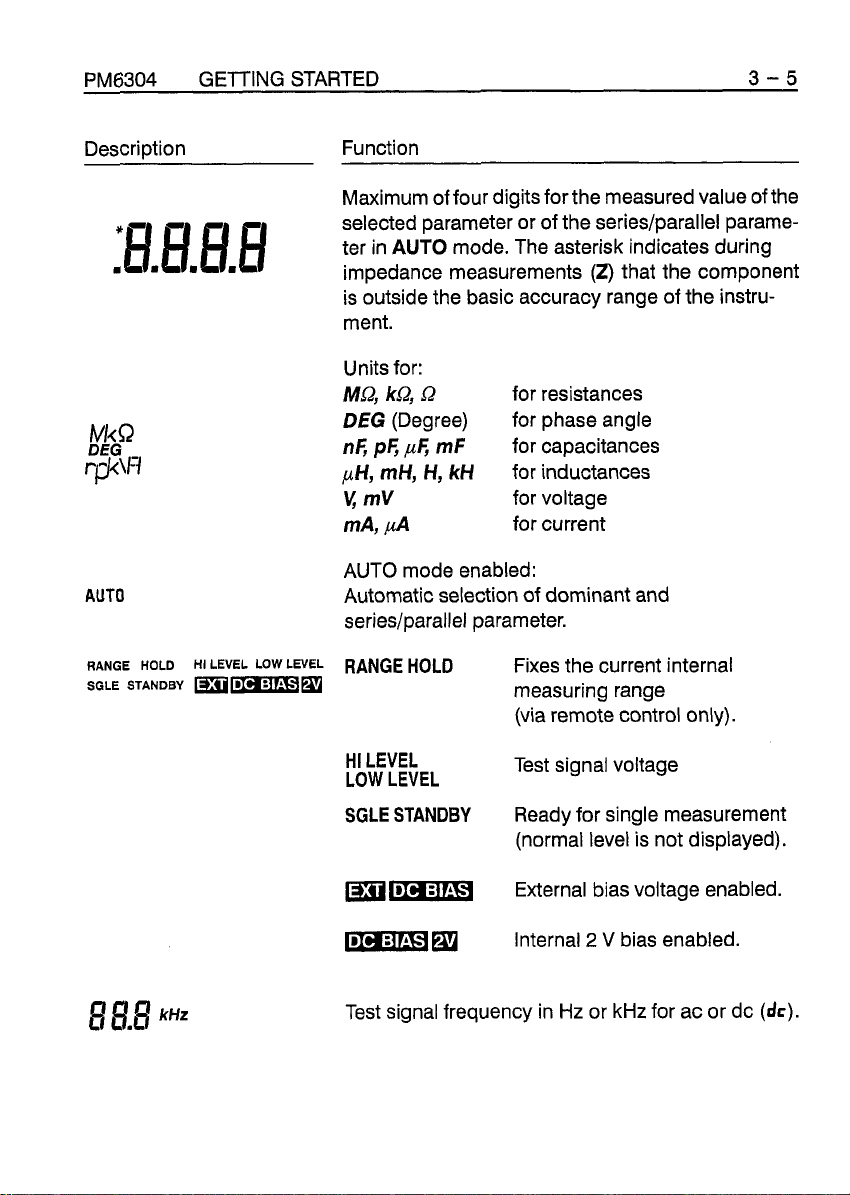

PM6304

Description Function

:BmEI.EI.EI

AUTO

GETTING STARTED

Maximum of four digits for the measured value of the

selected parameter or of the

ter in

impedance measurements

is outside the basic accuracy range of the instru-

ment.

Units for:

Ma, kQ,

DEG

n6

pH, mH, H, kH

v;

mV

mA,

AUTO mode enabled:

Automatic selection of dominant and

series/parallel parameter.

AUTO

(Degree) for phase angle

p6

,uF,

series/parallel parame-

mode. The asterisk indicates during

(2)

that the component

a

mF

for resistances

for capacitances

for inductances

for voltage

for current

3-5

RANGE

HOLD

SGLE STANDBY

HI

LEVEL

LOW

LEVEL

RANGE

mmm

HI LEVEL

LOW LEVEL

SGLE STANDBY

mEipl

Test signal frequency in Hz or kHz for ac or dc

HOLD

Fixes the current internal

measuring range

(via remote control only).

Test signal voltage

Ready for single measurement

(normal level is not displayed).

External bias voltage enabled.

Internal

2

V

bias enabled.

(dc).

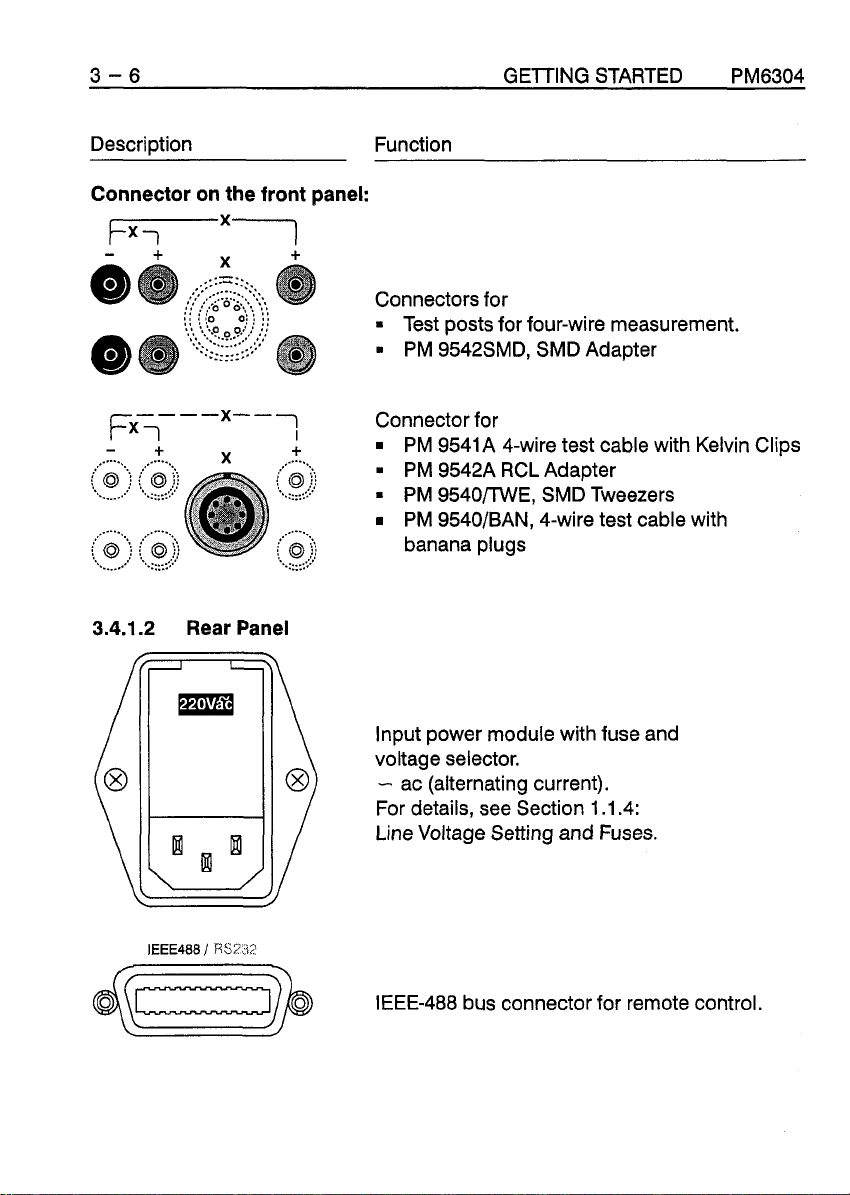

Page 28

3-6 GETTING STARTED PM6304

Description Function

Connector on the front panel:

rx1

+

X

+

Connectors for

=

Test posts for four-wire measurement.

PM 9542SMD, SMD Adapter

Fx7---"--7

-

+

3.4.1.2

Rear Panel

Connector for

PM 9541A 4-wire test cable with Kelvin Clips

PM 9542A RCL Adapter

=

PM 9540/lWE, SMD Tweezers

PM 9540/BAN, 4-wire test cable with

banana plugs

Input power module with fuse and

voltage selector.

-

ac (alternating current).

For details, see Section 1.1.4:

Line Voltage Setting and Fuses.

@Ezzz$

IEEE-488 bus connector for remote control.

Page 29

PM6304 GElllNG STARTED 3-7

Description Function

RS-232 connector.

HANDLER INTERFACE

Component handler interface connector.

EXT

DC

-

BIAS

+

External dc bias voltage input

MAX

(maximum 40

40V

V

dc).

3.4.2

For best accuracy, you should perform ZERO TRIM (see Section

Measurement Setup and Accessories

4.3)

when

you change the measurement setup, the test signal frequency, or the test

signal voltage when test signal frequency is

r

10

kHz.

You should not change the setup after trimming if you use test signal frequencies

r

10

kHz

with the PM 9541A Test Cable with Kelvin Clips, the PM 9542A RCL

Adapter, the PM 9540m/VE SMD Tweezers, or the PM 9540/BAN Test Cable.

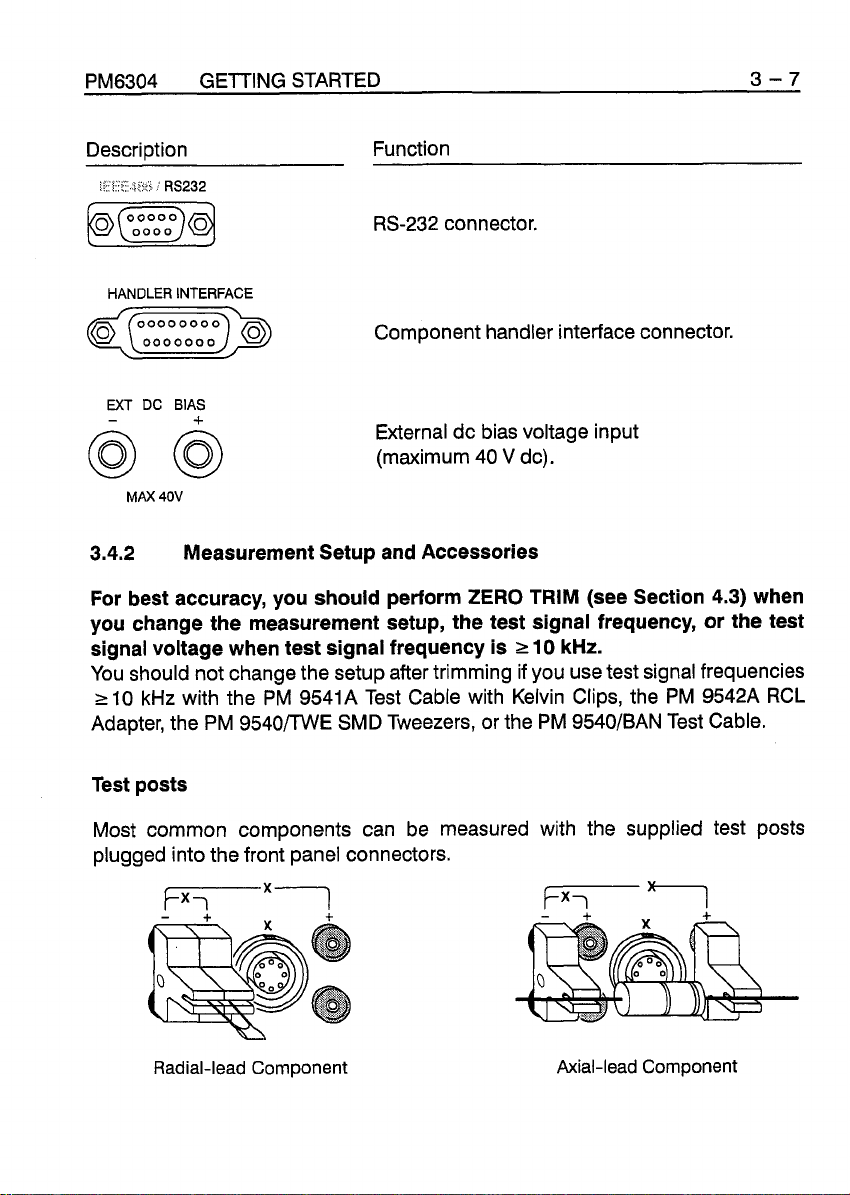

Test posts

Most common components can be measured with the supplied test posts

plugged into the front panel connectors.

Radial-lead Component Axial-lead Component

Page 30

3 - 8 GETTING STARTED

PM6304

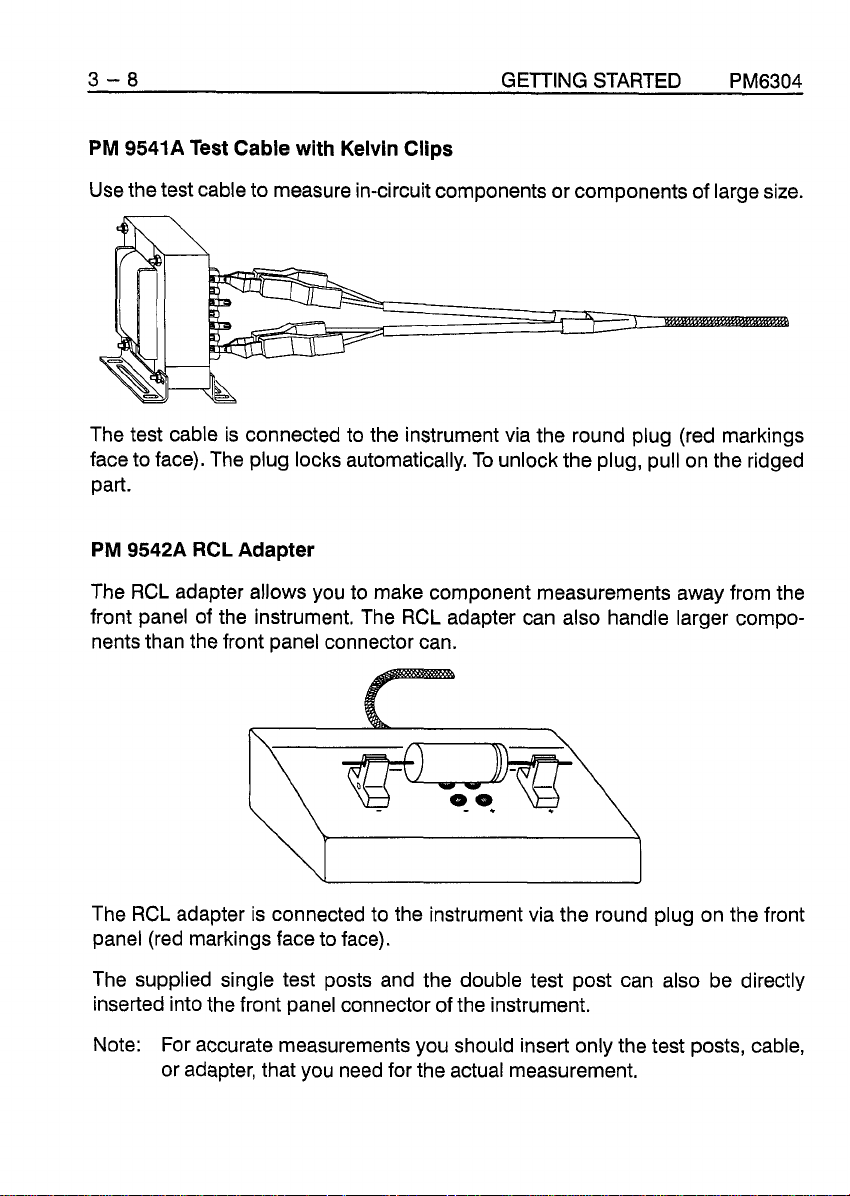

PM 9541A Test Cable with Kelvin Clips

Use the test cable to measure in-circuit components or components of large size.

The test cable is connected to the instrument via the round plug (red markings

face to face). The plug locks automatically. To unlock the plug, pull on the ridged

part.

PM 9542A RCL Adapter

The RCL adapter allows you to make component measurements away from the

front panel of the instrument. The RCL adapter can also handle larger compo-

nents than the front panel connector can.

The RCL adapter is connected to the instrument via the round plug on the front

panel (red markings face to face).

The supplied single test posts and the double test post can also be directly

inserted into the front panel connector of the instrument.

Note: For accurate measurements you should insert only the test posts, cable,

or adapter, that you need for the actual measurement.

Page 31

PM6304 GETTING STARTED 3-9

SMD

Adapter

PM 9542SMD

The SMD adapter can be used to measure SMD components with a length of 2 to

10 mm, depth

>1

mm, height >0.5 mm, or a diameter

>I

mm.

For easy and quick insertion and removal of components, insert the SMD adapter

into the PM 9542 RCL adapter.

You can also insert the SMD adapter directly into the front panel connector of the

instrument. To ease insertion of components, set the instrument in a sloping posi-

tion (handle folded down)

When you use the SMD adapter to measure very small capacitances especially

below 100 pF, you must take into account the alteration of the stray fixture capaci-

tances, depending on the separation of the contacts.

Page 32

3

-

10

Fixture Capacitance (pF)

4

1.4

--

GETTING STARTED

PM6304

Additional capacitance alter

ZERO

TRIM depending on

contact opening of the SMD adapter.

0

-1

--

PM

9540llWE

SMD

Tweezers

contact opening width

(rnm)

Use the SMD Tweezers to measure single SMD components or in-circuit SMD

components.

The SMD Tweezers are connected to the instrument via the round plug on the

front panel (red marking face to face).

Page 33

PM6304 GETTING STARTED 3-11

For open-circuit trimming when you are measuring small capacitances, set the

opening of the tweezers to the size of the component.

The two-wire measuring technique and the pressure applied by the tips of the

tweezers can cause a measuring error in addition to the basic error of the RCL

GI).

Meter, due to the additional serial resistance (typical 0.02

or contaminants on the tips of the tweezers can also affect measurements. The

tips may be periodically cleaned with alcohol and a non-abrasive cloth.

The presence of dirt

PM 9540/BAN

Use the test cable if you need banana plugs for your own special applications.

The test cable is connected to the instrument via the round plug on the front panel

(red marking face to face).

When you perform ZERO TRIM short-circuit DRIVE+ with SENSE+ and DRIVEwith SENSE- for the open-circuit trimming. Short-circuit all four plugs for the

short-circuit trimming.

Test Cable with Banana

Plugs

Page 34

3-

12

GElTING STARTED

PM6304

Two-Wire Measurements

You can measure components with two test leads in two-wire mode by using the

plus and minus connectors. For this, it is necessary to short-circuit the drive and

sense lines at the instrument. To reduce stray capacitances and interferences,

use short leads.

You also can use the eight-pole round connector.

test leads test leads

or

drive - sense

+

The technical specifications given in Chapter 1 of the REFERENCE MANUAL are

valid for four-wire measurements. Four-wire measurements are particularly important for high impedance components at high test signal frequencies and for low

impedance components.

Page 35

PM6304 GETTING STARTED 3- 13

3.4.3

Example of a Measurement

WARNING

Before turning the instrument on, ensure that it has been installed in

accordance with the instruction in Chapter

1.

Immediately after power on a self-test routine is performed. Then the instrument

automatically recalls measurement settings prior to the last power off.

(see Section 3.3).

FX1

Insert the test posts supplied into

the connector on the front panel

(Logos face to face).

If the display shows

press the

EBEQ

DC

key.

dr

,

Select an appropriate measurement

1

frequency, for example,

kHz.

Press the green AUTO key.

The display shows:

Press the ZERO TRIM key for 2 seconds.

STEP

AUTO

Page 36

3

-

14 GElTING STARTED PM6304

For open-circuit trimming

the display shows:

For short-circuit trimming short circuit

the test posts with a short wire or

similar object and press the ZERO TRlM key;

the display shows:

If the ZERO TRlM operation is

unsuccessful, the

Refer to Section 4.7.

If the ZERO TRlM operation was

successful, the diplay shows:

Insert a known component

into the test posts,

e.g., a

1

kS2

diplay shows:

resistor.

bUSY

Cct

The display shows:

The test is finished.

See Chapter

information about measurement

of components and

measurement principles.

4 for detailed

AUTO

[t

kHz

Page 37

Chapter

HOW TO USE THE INSTRUMENT

4

Page 38

Page 39

PM6304 HOW TO USE THE INSTRUMENT 4-1

4 HOW TO USE THE INSTRUMENT

4.1

THE PRINCIPLE

OF

MEASUREMENT

The component measurement is based on the current and voltage technique. The

component voltage and the component current are measured and converted into

binary values. From these values the CPU calculates the electrical parameters of

the component. According to the front panel parameter selection different para-

meters are displayed. Via AUTO mode or by pressing the SERIPAR key when

AUTO mode was selected, the dominant and secondary parameters (resistance,

capacitance, or inductance) are displayed. In addition manually selected para-

meter can be displayed

(Q,

D,

2,

@,

V,, or

I,).

Each measurement cycle lasts approximately 0.5 seconds. For AC measurements one cycle consists of seven single measurements, the results of which are

stored and arithmetically evaluated. Finally the result is transferred to the display.

The seven single measurements are as follows:

1.

Voltage Measurement:

O0

and internal gain factor setting

2.

3.

Gain factor

4.

Reference Measurement:

5.

Current Measurement:

6.

Current Measurement:

7.

Reference Measurement:

>1

Voltage Measurement:

Reference Measurement:

Gain factor

90°

O0

90°

O0

Current Measurement:

Current Measurement:

ReferenceMeasurement:

Reference Measurement:

90°

00

=

1

O0

90°

O0

90°

Page 40

4-2 HOW TO USE THE INSTRUMENT PM6304

The seven measured values are stored at the end of the single measurements.

The microprocessor uses the measured values to calculate the equivalent series

resistance Rs, the equivalent series reactance Xs, and the quality factor

Q = XsIRs of the component. In AUTO mode the microprocessor determines the

dominant and secondary parameter, calculates its value, and displays it together

with the equivalent circuit symbol. If one of the other parameters is manually

selected, this parameter is calculated and displayed. After that

measurement cycle starts with the seven single measurements.

The display shows:

Inn-

r

u.u

The following phase diagrams and formulas show the mathematic basics for internal calculation of the component value.

b

I I-l

r

the next

I=

V2A

Vqr------

vp Ip v1

In the diagram the phase relation between I and V happens to be a lossy inductance.

In each measurement cycle, the following components are determined:

V: voltage

I: current

V1, V2: 0"-voltage, 90"-voltage

I

The phase angle between

The phase angle between I and V1 is

VP, vq, IP, Iq.

and V is

4.

a.

Page 41

PM6304

The series resistance and reactance are calculated from these components.

HOW

TO

USE THE INSTRUMENT 4-3

The following equivalent circuit is valid:

Quality factor:

Dissipation factor:

The magnitude of Q and the sign of Xs determine which parameter of the component is dominant.

The formulas for the various parameters are as follows:

Q=-

lXs'

see equation (3)

Rs

=

tan@ = 1

Q

D = tan6 = 1/Q

Xs positive

Xs negative

/D

=

=

~xt

=

-

I

xs

(3)

Rs

lRs'

=

-

inductive

capacitive

Xs

(4)

z=mTG

Cp

=

w(1

+

1

1/Q2)1XsI

ifXs

ifXs

<

>

0

0

Rs see equation

(1)

Impedance

Admittance

Z = R + jX

Y

=

1

/Z

<

ifXs

ifXs > 0

0

Page 42

4-4 HOW TO USE THE INSTRUMENT PM6304

Example:

By using the seven measurements, the instrument has calculated Rs and Xs in

2,

accordance with formulas 1 and

for example,

From this the instrument calculated:

The instrument displays the corresponding equivalent circuit symbol with the

dominant and the secondary parameter, according to the criteria of the Auto

Mode Decision Diagram (see Section 4.4.1); in this case, as Xs is negative and

1

<Q<

1000:

The display shows:

The calculation of the dominant parameter Cp was done according to the fol-

lowing formula:

Cp

=

1

2n

x

1 kHz (1 + 1 /4.9542) x 15.199

kS2

=

10.061 nF

The maximum display is five digits 21 digit tolerance.

Page 43

PM6304

HOW

TO USE

THE

INSTRUMENT 4-5

Calculation of the other selectable parameters are performed as follows:

1

D=-=--

Q

4.954

-

0.202

Rs

(calculated by the instrument according to formula 1)

Q,

:

The instrument calculates

tan

and gets

lXsl 15.199

Q,

=

-

Rs 3.068

Q,

=

from an internal tangent table similar to a calculator

=

(1

+

4.9542) x 3.068

kR

=

4.954

kSZ

kS2

=

78.36

kR

Q

=

-

78.6 DEG

Page 44

4-6 HOW TO USE THE INSTRUMENT PM6304

For accurate measurement, you should select an appropriate test signal frequen-

cy; see Section 4.2.

If you measure the same component mentioned in the preceding example, with

a

test signal frequency that is too low, the resistive part of the capacitive component dominates.

So the instrument determines a resistor as the dominant parameter.

Example:

Test signal frequency 100 Hz

The display shows:

The instrument determined:

Rs

=

63.248

XS = -31.680

kS2

kQ

and calculated:

Qe

Because

1, the display shows a resistor as the dominant parameter.

Page 45

PM6304

HOW

TO USE THE INSTRUMENT

4-7

Calculation of the other parameter is performed

1

D

=

-

=

2.00

Q

Rp = (1

Cp

Rs

Cs

tan

iP

+

Q2)

x

RS = 79.123 kQ

=

w(l

=

63.248 kQ (calculated according to formula 1)

=

-

wlXsl

iP

=

=

-

+

1

-

lXs

Rs

26.6

1

1

/Q2)

=

50.23 nF

'

=

DEG

1XsI

0.501

=

10.08 nF

by

the same formulas:

If you are interested in mathematics, the appendix of this guide shows the phasor

diagrams and formulas for the various components.

Page 46

4-8 HOW TO USE THE INSTRUMENT PM6304

4.2

4.2.1

Resistors, inductors, and capacitors are not ideal electrical components. They all

have secondary effects that limit their performance. Understanding the effects is

important in understanding the results displayed on the RCL meter. For example,

a resistor has shunt capacitance and lead inductance. Inductors have shunt

capacitance and resistance in their windings.

The differing reaction of these components, which depends on the frequency and

test signal voltage, requires methods of measurement adapted to each situation.

To this end, the PM6304

Resolution: 50, 60, 100, 120, 200, 300, 400

The analog-to-digital converter (ADC), used for digitizing the measured values,

is basically insensitive to hum interfered into the measurement setup. Hum inter-

ference may degrade measurement accuracy using test frequencies of 60 Hz or

120 Hz at 50 Hz AC power or 50 Hz test frequency at 60 Hz AC power.

The following can be selected as the test signal voltage:

AC

voltage:

2 V, 400 Q internal resistance

1 V, 100 Q internal resistance

50 mV, 100 Q internal resistance 300 mV, 100

MEASURING COMPONENTS

Test Signal Frequency and Voltage

/

PM6304C has afrequency range from 50 Hz to 100 kHz.

Hz

DC

to 19.9 kHz, 20 kHz, 100 kHz

voltage (option):

2 V, 400

V,

1

D

internal resistance

100 Q internal resistance

D

internal resistance

An internal

added to the AC voltage signal. The external voltage must be free of hums, partic-

ularly if test signal frequency is 50 Hz or 60 Hz (line frequencies).

If you measure components with

with an impedance >50 Q, perform open-circuit trimming with bias voltage

applied.

A

that it can cause injury if it is accidentally discharged. Verify that polarized capacitors are installed with the correct polarity before applying

a bias voltage.

2

V dc bias voltage or an external bias of maximum 40 V dc can be

Z

>

10 kQ and if you use an external bias source

WARNING

40

volt external bias can charge a capacitor to a high enough voltage

Page 47

PM6304 HOW

TO

USE THE INSTRUMENT

4-9

4.2.2

In principle in addition to its purely resistive component, a resistor has capacitive

and inductive components.

R

=

Ls

=

Cp

=

In the case of wire-wound resistors, C and

In the case of film resistors, these values are considerably smaller.

With low-valued resistors

With high-valued resistors

Resistors

DC resistance.

Inductance of any windinglcoiling and of the components leads.

Shunt capacitance across the resistive component.

L

are relatively high due to the winding.

(<I

kQ),

the series inductive component dominates.

(>I

kQ),

C predominates.

The effect of C and

Measurement Conditions:

Select a low test signal frequency, i.e., 1 kHz or measure with DC voltage (option).

In the case of resistors in the megohm range, the instrument might recognize the

shunt capacitor as the dominant component if the measurement frequency is too

high.

L

limits the high frequency performance of the component.

Page 48

4

-

10

HOW

TO USE THE INSTRUMENT PM6304

4.2.3

Capacitors

Several components, which depend on the type of capacitor, determine the electrical characteristics of a capacitor.

Foil Capacitor:

L

=

lnductance of the lead wires, the bonding and the winding

(mainly in the nH area).

R1

=

R2

Rp

C

Resistance of the bonding

=

Resistance of the foils, which increases as frequency increases.

=

Dissipation in dielectric, which can be ignored as frequency increases.

=

Capacitance.

(5

to

10

ohms in unfavorable cases).

Electrolytic Capacitors:

With AC voltage

L

ESR

C

=

lnductance of the connections and of the winding.

=

Equivalent series resistance:

Resistance of the electrolytes, the dielectric, DC resistance

of the mechanical structure. The ESR depends on the frequency.

=

Overall capacitance.

Page 49

PM6304 HOW TO USE

With DC voltage

=

C

RlsoL

Electrolytic capacitors operate at lower frequencies (usually

Measurement Conditions:

The frequency for the test signal should not be selected too high as otherwise a

capacitance that is too high is measured when the resonant

approached.

Overall capacitance.

=

Insulating resistance, it determines the leakage current of the component.

THE

INSTRUMENT 4-11

c

10 kHz).

frequency is

f,

=

self-resonant frequency

If the frequency is too low, the ohmic and inductive components falsify the result.

A

test frequency lower than f,/30 should be taken as the approximate value.

For example:

Typical self-resonant frequency for a 100 yF capacitor is 50 kHz; select test signal

frequency less than 1.6 kHz.

Electrolytic capacitors used for smoothing in power supplies should be measured

at their operating frequency (1 00

In order to determine the real dissipation components, a high test frequency is

selected for the serial losses and a low one for the parallel losses.

Use DC voltage for measuring the insulating resistance.

Hz

or 120

Hz).

Page 50

4

-

12

HOW

TO

USE THE INSTRUMENT PM6304

4.2.4

Coil with iron core

Rs

=

RE

=

Cp

=

L

=

Measurement Conditions:

As in the case of the capacitor, the test frequency (fTEST) should lie far below

the self-resonant frequency (fo). The fo frequency can be very low because of

the relatively high capacitance of the winding.

Inductances

DC resistance of the copper winding

Core loss

Capacitance of the winding

Inductance

=

1

-

2n

JLC

f,

f,

=

self-resonant frequency

Approximate value: fTEsT = f,/30

It is advisable to measure the coil close to its operating frequency if the reaction

of the coil under operating conditions is to be determined.

Avoltage level that is not too high must be selected for coils because of the saturation effect caused by the iron core. For this purpose, the PM6304 offers a voltage

50

reduced to

Use DC voltage to measure the resistance of the winding.

mV.

Page 51

PM6304 HOW TO USE THE INSTRUMENT

4-

13

4.3

When pressing the

AUTOMATIC ZERO TRIM

ZERO TRlM

key for approximately 2 seconds the instrument

performs an impedance measurement of the measurement setup and stores the

value determined. The display shows

value will be taken into consideration.

PASS.

To ensure best measuring accuracy you

For all further measurements this

should perform ZERO TRlM when you change the measurement setup, the

test signal frequency, or the test signal voltage when the test signal

1

10

frequency is

If you press the

of <10

Q

or >I00 kQ, the value of the component will be taken into consider-

kHz.

ZERO TRlM

key with a component connected with an impedance

ation. At open or short-circuited contacts of the measurement setup the instru-

ment now indicates a negative resistance value, for instance, or an inductance

in case of a connected capacitance (or a capacitor in case of a an inductance.)

Please perform ZERO TRlM once again without any component connected in order to obtain correct values.

The TRIM data are stored in a memory and will persist even if the instrument is

switched off.

Note: If you use the test cable with PM

Adapter, or the PM

9540TTWE, SMD Tweezer for test signal frequencies

9541A Kelvin Clips, the PM 9542A RCL

210 kHz, you should not change the setup after trimming.

To avoid measurement errors, do not touch the contacts during measuring.

Short-circuit Trimming

For measuring low impedances, below 100 Q in particular, please short-circuit

the contacts of the measurement setup and press the

bUSY

and

imately 2 seconds. The display shows

Sct

ZERO TRlM

(short-circuit). The instru-

key for approx-

ment now performs a measurement and stores the value determined, which is the

short circuit impedance. The display shows

PASS.

For all further measurements

this value is taken into consideration, including the line and contact impedances.

If during short circuit trimming the measured impedance is >10

Q,

FAIL

will be

displayed.

Page 52

4 - 14 HOW TO USE THE INSTRUMENT PM6304

Open-Circuit Trimming

When you measure low capacitances with high test signal frequency the opencircuit impedance of the measurement setup may affect the result. Remove any

and

ZERO

Oct

connected component and press the

conds. The display shows

a measurement considering the value determined, which is the open-circuit im-

pedance, for all following measurements. The display shows

If the impedance measured during open-circuit trimming is c 100 kS2, the diplsay

shows

For the ZERO TRIM the contacts DRIVE+ and SENSE+ as well as DRIVE- and

SENSE- should be connected. As far as the adapters available from Fluke are

concerned, this is normally ensured automatically, except for the PM 9540lBAN

cable and for the PM 9542SMD SMD Adapter.

If you use the PM 9540lBAN cable in your own special application short-circuit

DRIVE+ with SENSE+ and DRIVE- with SENSE- for the open-circuit trimming.

Short-circuit all four plugs for the short-circuit trimming.

As far as the SMD Adapter is concerned the contacts are insulated from each

other. The contacts are only closed when a component is inserted.

FAIL.

bUSY

TRIM

key for approximately 2 se-

(open-circuit). The instrument performs

PASS.

Drive- Drive+

m(=e

Contacts of the PM 9542SMD, SMD Adapter

Sense- Sense+

Page 53

PM6304 HOW TO USE THE INSTRUMENT 4- 15

To perform ZERO TRIM at an open adapter with the DRIVEISENSE contacts connected, the SMD Adapter is equipped with SMD components with an impedance

-.

m.

of Z

trimming you can use one of the attached components with an impedance of

Z

+

take into account this value if you measure low impedances.

If you need spare sets you can order them via your Service Organization with the

following number: 5322 31 0 32275.

Please use this component for open-circuit trimming. For short-circuit

0

Q. These components have a real resistance of typical 4 mQ. You should

,

---

black

blue

'

white

blue

4.4

After power on, the instrument automatically recalls the mode that was set before

power off.

Select a suitable measurement setup.

Select the matching test signal frequency and voltage

(refer to Sections 3.4.2 and 4.2).

Execute ZERO

Insert the component.

Galvanic nonconducting components, e.g., electrolytic capacitors, should be

measured with the internal bias voltage activated. To do this

Press the

The display shows

4.4.1

In most cases, you will be interested in the dominant parameter of the component.

This is automatically determined and displayed in the AUTO mode. Press the

green

in the upper line, the value of the secondary parameter in the lower line, and the

appropriate equivalent circuit symbol.

MEASURING MODES

TRIM if necessary.

DC

BIAS

ONIOFF

Automatic

AUTO

key. The display showsAUT0, the value of the dominant parameter

(AUTO)

key.

a.

Page 54

4-

16

HOW TO USE THE INSTRUMENT PM6304

Function and Key Operation Display

I-'

AUTO

The decision criterion for selecting the dominant parameter is

to Section

4.1.

The values Q and D not only depend on the component but also

on the test signal frequency used.

Reactance

D

=

1000

Q = 0.001

cl+R

Resistance

D

=

1000

Q

=

D

=

1.

Refer

AUTO MODE DECISION DIAGRAM

Page 55

PM6304

HOW

TO USE

THE

INSTRUMENT 4-

17

4.4.2

Manual

If you want to determine a parameter that differs from the one automatically calcu-

lated by the instrument, press the appropriate function key:

Function and Key Operation Display

1

n

1.U

kHz

Series or parallel parameter

tn

1.U

kHz

Impedance

Phase angle

Page 56

4-

18

Function and Key Operation Display

Dissipation factor

Quality factor

HOW TO USE THE

INSTRUMENT

PM6304

rnn

3.u

w

I

Current measured

Voltage measured

A

Current or voltage is displayed for approximately 3 seconds. The instrument

then returns automatically to the parameter you selected beforehand.

The values displayed for the selected parameter are calculated by the instrument.

They are based on the values measured for the series reactance and the series

resistance (refer to Section

A

A

4.1).

Page 57

PM6304

HOW TO USE THE INSTRUMENT

4-

19

4.4.3

Accuracy

The following diagrams show the measuring range and accuracy of the instru-

ment as a function of test signal frequency and voltage.

I

I

z

g

$

zz

L.

$2

,&

55:s

I

E*6&jrh

zz

--

zz

LL.

$C

ILa.cDI~

zz

1

SLL.

zz

r%

zz

lL

5:

N

ST

Page 58

Page 59

..I

R

'0'

100M

1 OM

1 M

look

10k

Ik

100

10

1

100m

1

Om

lrn

n

I-

1

OkH

1 kH

1

OOH

0.0lpF

1

OH

0.lpF

1H

1

PF

1

OOmH

1

OpF

1

OmH

100pF

1mH

1 nF

lOOuH

lOnF

1

OuH

1

OOnF

1

uH

1

UF

1

OOnH

1

OuF

1 OnH

1

OOuF

1 nH

1

mF

I

I

I

I I I

--..

1

OmF

Accuracy

with

50

mV (LOW LEVEL)

Page 60

Page 61

PM6304 HOW TO USE THE INSTRUMENT 4

-

23

4.5

Nine complete instrument settings including trim data can be stored in memory

registers

ries are buffered by battery so that the data are retained even after the instrument

is turned off.

After power on, the instrument runs through its start routine, and then goes to the

mode that was last set.

Store

Data are stored by pressing the STORE key. The display shows

from

are to be stored can now be selected by using the

values are not stored.

Pressing STORE once again saves the settings under the register number

selected. Any values that may exist there already are overwritten and lost in the

process.

Recall

STOREIRECALL OF INSTRUMENT SETTINGS

1

to

9.

The current mode is automatically saved separately. The memo-

Sto

and a digit

1

to 9 for the memory register number. This number under which the settings

+/-

step keys; the measured

Stored settings are called up by pressing the RECALL key. The display shows

and a memory register number. The display panel starts to flash. The data from

this memory register are only displayed but not yet called up.

You can use the

display their contents. When you press the RECALL key again, the stored setting

displayed is called up.

+/-

step keys to select memory register numbers 1 to 9 to

rCL

Page 62

4 - 24 HOW TO USE THE INSTRUMENT PM6304

4.6

4.6.1

BINNING

Introduction

Binning means sorting components by their measured value into boxes or similar

containers.

During the binning process with the

PM6304, similar component values are allocated to defined sorting fields known as bins to obtain better tolerances, closer

matching or passlfail sorting.

You can define a maximum of 10 bins. For this purpose, you can use an interface

for remote control with a PC (IEEE-488 or RS-232 as an option) or an infrared

remote control, the PM

9559

Bin Programmer (option).

The instructions for programming with the PC are described in detail in the

5.

PROGRAMMERS MANUAL and in brief form in Chapter

9559

binning using the PM

infrared remote control.

The PM6304 checks the component according to the criteria of bins 1 to

This section describes

9,

last

of all according to bin 0, and displays the bin the component is allocated to. If none

of these requirements are met, the display shows

FAIL.

Values and limits (tolerances) for 10 complete bin records, each record for a maxi-

mum of ten bins (bins 0 to

9),

including the selected instrument settings can be

stored in registers of the PM 6304. These registers are independent of those that

contain the instrument settings typed in at the front panel.

The limits of the bins can be defined in the following ways according to the various

demands:

Binning components can be defined with a certain value according to different

tolerance classes, for example, for quality control or incoming inspection.

-5

%

Nested limits

+

-2%

with

reference to a nominal value.

-1% 1kQ +1%

bin

2

r--

bin

I

nominal value

I

I

-

b

+2%

+5

%

Page 63

PM6304 HOW TO USE THE INSTRUMENT 4

-

25

The instrument checks in the sequence bin

If the greatest tolerance is programmed for bin 1, then

within this tolerance are immediately allocated to bin 1.

A different parameter than that for bin 1 to 9 can be defined for bin 0.

For example, bins 1 to 9 check the tolerance of a capacitor and bin 0 checks at

last the quality factor of the capacitor.

The display is as follows:

I

Component meets tolerance defined in:

I

Binning components can be defined according to certain values, e.g. resistors

according to the series E12, here with

-bin 1

-5%

bin 1 to9

I

1

I

nominal

YES

NO

YES

-+

I

I

1kQ +5% -5% 1.2kQ +5% -5% 1.5kQ +5% -5% 1.8kQ +5%

+--bin2

nominal

1

1

I

I

I

I

bin 0

do not care

-t

YES

NO

rt5

1,

%.

+--bin

bin 2

1

I

1

1

I

3

nominal

I

I

...

to bin 9 and then bin 0.

all

components

Display

binit09

FA1

L

bin 0

-+

I

-bin4

nominal

I

I

lying

I

I

1

I

I

-+

Sequential limits with reference to nominal values.

If limits overlap, a component lying within this overlapping area is always allocated

to the bin with the lower number.

bin

4

nominal nominal

-10

%

1.35 kQ 1.62 kQ

-10%

+lo% +10

1.65 kQ 1.98 kQ

%

Page 64

4

-

26

HOW TO USE THE INSTRUMENT PM6304

Nested and sequential limits can be combined.

4

Sequential and nested limits.

bin

4

-4

bin

2

t-

bin

1

nominal value

I

I

m4

-+

bin

3

b

The limits can be programmed directly as absolute values instead of a nominal

value with an upper and lower limit in percent:

0.950

LOW

I

kQ

1.050

HIGH

I

kQ

When storing, the instrument checks the values entered for plausibility. A nominal

value with an upper limit of

would not be accepted. The instrument displays

+5

%

and a lower limit of

+5%

or avalue without limits

Error

and the number of the bin

concerned.

No check is made whether the tolerances selected lie in the accuracy range of

the instrument. This accuracy depends on the type and the value of the com-

ponent to be measured and on the test signal frequency and voltage. Refer to

Section 4.4.3.

Page 65

PM6304 HOW

TO

USE

THE

INSTRUMENT

4

-

27

4.6.2

PM 9559 Bin Programmer (Infrared Remote Control)

4.6.2.1 Keyboard

Normal

measuring

Binning

Data input for

binning criterias

Tolerance

Keypad for

numerical values

Sign key

Storing of

data sets

Call-up of

data sets

limits

Infrared transmitter

I

mmm

RCLQD

111 111 111 111 1.11

7892Q

DII

n3

un

I111 111

Page 66

4

-

28

HOW TO USE THE INSTRUMENT

PM6304

4.6.2.2

Battery Replacement

The remote control is supplied with power by means of the accompanying

block battery.

Inserting the battery:

Pry open the battery

compartment at the back

of the remote control.

Attach battery terminals

and insert the battery.

The battery is protected

from falling out by a

retaining clip.

Close the compartment.

9

V

Operational check:

NOTE:

CAUTION:

Press any key; the pilot light must flicker.

If necessary, check the battery.

Remove dead batteries and dispose of them

according to local regulations.

To prevent the remote control from being damaged, use

only leak-proof batteries of the type

6F22G

or similar for

replacement.

Page 67

PM6304 HOW TO USE THE INSTRUMENT

4

-

29

4.6.2.3

Programming with the Infrared Remote Control

You can define a set of bins by using the following steps.

The examples are based on empty memory locations. If values are contained

there, delete the old values with the

Pressing the

all values

of the bin.

RUBOUT

and the

Function and Key Operation

RUBOUT

ENTER

key before entering new ones.

key after selecting a bin number deletes

Display

Set the instrument to data input.

DATAINPUT

Select the bin.

B&

N

0

Set to nominal value.

NOMINAL

1

NOMINAL

fggi@@

Define the parameter and

set the value.

/

1

kHz

NOMINAL

kHz

Page 68

4 - 30

Function and Key Operation Display

HOW

TO

USE THE INSTRUMENT PM6304

Set the upper limit

HIGH

Set the lower limit

LOW

Dm

enter

ENTER

A.

*.

5

5

+/-

The instrument automatically

selects the next bin.

I

kHz

I

Page 69

PM6304 HOW TO USE THE INSTRUMENT 4

-

31

If the nominal values selected for the next bins are to remain the same as in

bin

I,

then the tolerances for these bins refer to this nominal value.

Function and Key Operation

Set the upper limit

HIGH

Set the lower limit

LOW

A.

1

A.

1

+/-

nD

Enter

ENTER

Display

The instrument automatically

selects the next bin.

It is also possible to set only the upper or lower limit. The instrument automatically inserts the same

*

value with the appropriate sign for the other limit. However, if values are already stored here, these

remain unchanged.

A

maximum of

10

bins can be defined.

Page 70

4

-

32

HOW TO USE THE INSTRUMENT PM6304

This example referred to nested bins with tolerances in percent.

Other input types, as described in Section 4.6.1, are possible as follows.

Function and Key Operation Display

Input as an absolute value:

Set the instrument to data input.

Select the bin.

DATA INPUT

Select the upper limit.

Define the parameter.

Set the absolute value.

Select the lower limit.

Define the parameter

(the same as for the upper limit).

Set the absolute value.

LOW

R

I1

Page 71

PM6304 HOW TO

USE

THE INSTRUMENT

4

-

33

Function and

Key

Operation Display

Enter

ENTER

The instrument automatically

selects the next bin.

If

Error

appears when pressing the

ENTER

key, please check to see whether the

data record contains a nominal value programmed at an earlier stage

key).

a

Note: The data for

(ENTER).

leaving bin programming by pressing

bin are stored in a buffer after every acknowledgment

These data are lost when the instrument is turned off or when

a

front panel key. After the

function the data are stored in memories buffered by battery (memory

locations

0

to

9).

kHz

(NOMINAL

STORE

Page 72

4 - 34 HOW TO USE THE INSTRUMENT PM6304

Function and Key Operation Display

Store

STORE

1

I1

Enter

In addition to the data of the bin set, the instrument settings selected, such as

DC

test signal frequency and voltage, measuring mode,

stored. Any data found in the storage register are overwritten.

Stored sets are called up by pressing the

register number

(1 to

9)

and the

ENTER

RECALL

key.

If some programmed bins from a set are not to be taken into account during

binning, they can be deactivated by pressing the

1).

Pressing the

activated again by pressing the

ENTER

key now shows only the active bins. A deactivated bin is

BIN NO

key and the relevant number.

DISABLE

bias etc. are also

key, the desired storage

key (except for bin

A

table in the appendix has been provided for your notes on assignment

of

the

storage register contents. You can make a copy of the table and fill in the programmed values.

Page 73

PM6304

HOW

TO

USE THE INSTRUMENT 4 - 35

4.6.2.4

Select the measurement setup and, if necessary, execute trimming

Binning

(ZERO

TRIM).

Press the

record desired by pressing

DATA INPUT

key on the infrared remote control and call up the bin

RECALL.

If

no data have been stored yet, enter the

parameters and tolerances according to which binning is to take place. Refer to

Section 4.6.2.3.

Storage Registers

DATA INPUT

I

BINNING

4

0

If BINNING

has been pressed

NORMAL

RECALLalso calls up stored instrument

settings. If you want to alter the settings

press the NORMAL key, select new set-

RCL

tings via the keyboard of the

press the DATA INPUT key, and press

the BINNING key to start binning.

meter,

Page 74

4 - 36 HOW TO USE THE INSTRUMENT PM6304

The instrument is set to the bin mode by pressing the

BINNING

key. The

instrument settings stored in the memory are adopted. The instrument switches

automatically to single measurement to avoid measuring errors when inserting

or removing the components to be measured.

The display shows maximum five digits. The instrument calculates with a higher

resolution. For example, the upper limit for bin 1 is 100

100.004 S2; in this case the display shows 100.00

rectly allocated to bin

2.

Insert the component and start measuring by pressing the

52,

the instrument measures

S2,

but the component is cor-

TRIGGER

key.

The PM6304 checks the component according to the criteria of the individual bins

and shows in what bin the component is and its value. If none of the criteria of bin

1 to

9

are met, the display shows

FAIL,

see table on Page 4

-

25.

Example:

Function and Key Operation Display

Set the instrument to data input.

DATA

INPUT

Call up the stored data.

RECALL

II

1

D

Page 75

PM6304 HOW TO USE THE INSTRUMENT 4

Function and Key Operation Display

Enter

ENTER

Set the instrument to binning.

BINNING

I

SOLE STANDBY

LCkM

Insert the component.

Start the measurement.

-

37

I

TRIGGER

Remove the component and

insert the next one.

Start the measurement.

TRIGGER

Press the

NORMAL

key to switch back to normal mode.

AUTO

SGLE STANDBY

SOLE STANDBY

1.0

Lo

kHz

kHz

Page 76

4

-

38

HOW TO USE

THE

INSTRUMENT

PM6304

4.6.3

PM

9566

Handler Interface

To make further handling of the checked components easier, you can connect

appropriate control lines to the bin numbers by means of the

FACE

(option). For example, LEDs that can identify the bin where the component

HANDLER INTER-

is placed can be connected by means of these control lines. This process can also

be automated by means of the appropriate application (conveyor and electromagnetic flaps).

Identification by LEDs (principle)

Bin 1 Bin

2

...

Bin 8 Bin 9 Bin 0 FAIL

Automatic handling (principle)

Measurement trigger

Page 77

PM6304 HOW TO USE THE INSTRUMENT

Connection Example:

8

7

bin9

LED

600

8

0

+5v

external

The internal driver stages have open collector outputs.

External operating voltage max.

Maximum collector current 200 mA.

DC

I0

,

.....

,.,..

+24

1 0 FAIL instrument

ZZ

b

V

DC voltage.

-I-

Socket

>-

)--

I-

*3

*2

12

l1

10

9

at

4

the

-

39

Pin assignment:

HANDLER INTERFACE

q=p

8

15

View of the rear

9

1

=

Bin 9

2

=

Bin

8

3 = Bin

4

=

5

=

6 = Bin

7

=

8

=

1

9 = Bin

10 = Bin0

11

=

12

=

13

=

14

=

15

=

7

Bin 6

Bin

5

4

Bin 3

Bin

2

1

FAIL

+DC

TRIGGER

Ground

Shielding (screen)

Page 78

4 - 40 HOW TO USE THE INSTRUMENT PM6304

4.7

The middle segments of the digits are displayed when the following limits are

exceeded:

Resistance >200 MB at AC,

Capacitance

Inductance >637 kH at 50 Hz, >318H at100kHz

The asterisk in front of the upper digits indicates that the measured component

is outside the measurement range of the basic error limit.

Select a different appropriate test signal frequency and check that the

measurement is within the basic accuracy; see tables in Section 4.4.3.

The asterisk in front of the lower digits only indicates when impedance is being

measured that the value is outside the basic error limit. Other parameter values

displayed by this digits are secondary parameters and generally not within the

basic accuracy range of 0.1

After power on, the instrument checks the PROM, the processor RAM, and the

external RAM. Additionally the instrument generates error messages if there are

faults during measurements or trimming or if there is a fault during data transfer

to a printer.

OUT-OF-RANGE AND ERROR MESSAGES

>

50 MSZ at DC

>

32 F at 50 Hz,

%;

for these no asterisk is displayed.

>

16 mF at 100 kHz

Errors are indicated as follows:

Err

Err

2

Err

3

Err

Err

5

Err

6

Program memory checksum error

Processor RAM defective

External RAM defective

External RAM, backup (current instrument settings) destroyed

External RAM, stored instrument settings 1 to 9 destroyed

Error during analog to digital conversion of the test signal

Page 79

PM6304 HOW TO USE THE INSTRUMENT 4 - 41

E

r r

1

Err

0

Err

3

Err

I0

Err

I

Err

Iq

Err

q0

Errors

A

detailed description is given in the Service Manual, Chapter

EEPROM defective

Error in trim data (EEPROM)

Error in calibration data (EEPROM)

Error in binning data (EEPROM)

Error during line frequency detection

I

Test signal out of limits during trimming

Communication error to the printer (time-out)

19 to 41 are errors during recalibration.

9.

During measurement with the bias voltage activated, the display shows

there is excessive

If the values entered for binning do not match each other, the instrument displays

Error

when an attempt is made to store them.

If the instrument cannot compensate the short-circuit or open-circuit impedance

during trimming, it displays

DC

current flow from the bias source.

FAIL.

Check the contacts and try it again.

over

if

Page 80

Page 81

Chapter

FUNCTION REFERENCE

3

Page 82

Page 83

PM6304 FUNCTION REFERENCE, FRONT PANEL 5-1

FUNCTION REFERENCE

In Section

are described in alphabetical order. Each function description contains:

A

The key sequence for setting or calling up via the keyboard and the relevant

display.

The commands for remote control.

The Programmers Manual contains detailed information about the interfaces for

the remote control, the program message syntax, and thi'e complete set of remote

control commands.

Some functions are possible only with the appropriate options:

For example, binning components according to tolerance class requires the

PM 9559 Bin Programmer or an interface for remote control. Measuring compo-

nents with DC voltage only requires an integrated DC unit.

These functions are identified in the description by 'option'

Section 5.2 describes the functions of the PM 9559 Bin Programmer for program-

ming tolerance ranges for binning components.

5.1

5.1,

all functions of the instrument that can be called up at the key panel

detailed explanation of the function.

FUNCTIONS

OF

THE FRONT PANEL

OF

THE INSTRUMENT

-

AUTO

In this mode, the instrument automatically determines the dominant parameter

of the component measured and'displays the appropriate equivalent circuit sym-

bol. The value of the dominant component is displayed in the upper line, and the

value of the secondary parameter is displayed

Mode

in

the line below.

Page 84

5-2

FUNCTION REFERENCE, FRONT PANEL

PM6304

The decision criterion for defining the dominant component is

Q=D=1,

with

Q

and D not only dependent on the features of the component but also on the test

4.1

and

signal frequency used (see Sections

4.2).

Decision criteria for defining the dominant parameter and for the equivalent circuit

symbol in the sectors of the phase level:

Reactance

Q

=

ix'

9

5

-0

c

.-

D

=

1000

0.001

-+R

Resistance

a,

>

.-

C

.-

0

ia

a

8

Q

=

-jX'

AUTO MODE DECISION DIAGRAM

D

=

1000

0.001

Page 85

PM6304

FUNCTION REFERENCE, FRONT PANEL

Remote control commands:

I I

I

l---lw

AUTO

5-3

I

Setting:

AUTO

Query for dominant and

secondary component:

COM?

AVERAGE

With continuous measurement, the instrument performs an exponential average

from the individual measurements before the value is shown in the display. The

time factor of the average is increased by pressing the

AVERAGE

key. This

reduces fluctuations in the display.

The original time factor reappears when the key is pressed again.

I

AVERAGE

Remote control commands:

Activate: AVG ON

Deactivate:

Query:

AVG OFF

AVG?

Page 86

5-4

FUNCTION REFERENCE, FRONT PANEL

PM6304

CONTISINGLE Continuous/Single Measurement

Press this key to select either continuous or single measurements. For single

measurement, the instrument is in a standby status. Press the TRIGGER key to

start the measurement. This function is mainly used for binning in the bin mode.

In this way, components can be inserted or removed without the instrument

executing a measurement.

Insert component and take a measurement:

Remote control commands:

Setting:

Start of a single measurement:

Query:

SOLE STANDBY

SGLE STANDBY

CON or SIN