Page 1

$XWRUDQJLQJ

&RPEL6FRSH

,QVWUXPHQW

30%30%30%

30%30%

I

SCPI Users Manual

02/- Nov-1998

®

Page 2

II

TRADEMARKS

Microsoft, and Microsoft QuickBASIC are trademarks of Microsoft Corporation.

IBM is a registered trademark of International Business Machines Corporation.

CombiScope

PCIIA is a trademark of National Instruments Corporation.

HPGL is a trademark of Hewlett-Packard Company.

is a trademark of Fluke Corporation.

Copyright 1996, 1998 Fluke Corporation

All rights reserved. No part of this manual may be reproduced by any means or in

any form without written permission of the copyright owner.

Printed in the Netherlands

Page 3

CONTENTS Page

III

1 ABOUT THIS MANUAL

1.1 What this Manual Contains

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2 GETTING STARTED WITH SCPI PROGRAMMING

2.1 Preparations for SCPI Programming

2.1.1 System setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Programming environment . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Initializing the CombiScope Instrument

2.2.1 How to reset the CombiScope instrument . . . . . . . . . . . . . . 2-4

2.2.2 How to identify the CombiScope instrument . . . . . . . . . . . . 2-4

2.2.3 How to switch between digital and analog mode . . . . . . . . . 2-4

2.3 Error Reporting

2.4 Acquiring Traces

2.4.1 How to acquire a single shot trace . . . . . . . . . . . . . . . . . . . . 2-7

2.4.2 How to acquire repetitive traces . . . . . . . . . . . . . . . . . . . . . . 2-8

2.5 Measuring Signal Characteristics

2.5.1 How to make a single shot measurement . . . . . . . . . . . . . 2-10

2.5.2 How to make repeated measurements . . . . . . . . . . . . . . . 2-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

. . . . . . . . . . . . . . . . . . . . . . 2-1

. . . . . . . . . . . . . . . . . . . . 2-4

. . . . . . . . . . . . . . . . . . . . . . . . . 2-9

. . 2-1

3 USING THE COMBISCOPE INSTRUMENTS

3.1 Introduction

3.2 Fundamental Programming Concepts

3.2.1 Measurement instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.2 Single function progra mming using the instrument model . . 3-5

3.2.3 Instrument setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.2.4 Front panel simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

. . . . . . . . . . . . . . . . . . . . . 3-3

. . . . . . . . . 3-1

Page 4

IV

3.3 Measuring Signal Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.1 The MEASure? query . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.2 Benefits of using parameters . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.3.3 Waveform measurements . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.3.4 Customizing settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.3.5 Multiple measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.3.6 Multiple characteristics from a single acquisition. . . . . . . . 3-15

3.3.7 Trigger control via GPIB . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.3.8 Fetching characteristics from memory traces . . . . . . . . . . 3-17

3.4 Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.4.1 Acquisition control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.4.1.1 Triggering

3.4.1.2 Video triggering

3.4.1.3 The trigger modes

3.4.1.4 Pre- and post-triggering

3.4.1.5 External triggering

3.4.2 Reading trace acquisitions . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

3.4.2.1 Single-shot acquisition

3.4.2.2 Repetitive acquisitions

3.4.3 Conversion of trace data . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

3.4.3.1 Conversion of 8-bit samples to integer

3.4.3.2 Conversion of 16-bit samples to integer

3.4.3.3 Conversion to voltage values

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

. . . . . . . . . . . . . . . . . . . . . . . . 3-27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

. . . . . . . . . . . . . . . . . . . . . . . . . 3-30

. . . . . . . . . . . . . . . . . . . . . . . . . 3-30

. . . . . . . . . . . . . 3-32

. . . . . . . . . . . . 3-33

. . . . . . . . . . . . . . . . . . . . 3-34

3.5 Averaging Acquisition Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

3.6 Channel Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

3.7 Signal Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

3.7.1 AC/DC/ground coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

3.7.2 Input filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

3.7.3 Input impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

3.7.4 Input polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

3.7.5 Vertical range and offset . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

3.7.6 Autoranging attenuators . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

3.8 Time Base Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

3.8.1 Number of samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

3.8.2 Time base speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

3.8.3 Real time acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

3.8.4 Autoranging time base . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

Page 5

3.9 Post Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

3.9.1 How to do post processing . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

3.9.1.1 Select the source for the post processing function.

3.9.1.2 Specify the settings of the post processing function.

3.9.1.3 Enable the post processing function.

. . . . . . . . . . . . . . 3-46

3.9.1.4 Check the result of the post processing function.

3.9.2 Mathematical calculations . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

3.9.3 Differentiating and integrating traces . . . . . . . . . . . . . . . . . 3-48

3.9.4 Frequency domain transformations . . . . . . . . . . . . . . . . . . 3-49

3.9.5 Histogram functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

3.9.6 Frequency filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

3.10 Trace Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

3.10.1 Trace formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

3.10.2 Copying traces to memory . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

3.10.3 Writing data to trace memory . . . . . . . . . . . . . . . . . . . . . . . 3-59

3.10.4 Reading data from trace memory . . . . . . . . . . . . . . . . . . . . 3-60

3.11 Screen/Display Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

3.11.1 Brightness control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

3.11.2 Display functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

3.11.2.1 Readout of measurement data

3.11.2.2 Display of user-defined text

3.11.2.3 Selection of softkey menus

. . . . . . . . . . . . . . . . . . . 3-62

. . . . . . . . . . . . . . . . . . . . . 3-65

. . . . . . . . . . . . . . . . . . . . . . 3-65

. . . 3-45

. . 3-46

. . . . . 3-47

V

3.12 Print/Plot Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-66

3.13 Real-Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-68

3.14 Auto Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-68

3.15 Status Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-70

3.15.1 Status data for the CombiScope instruments . . . . . . . . . . . 3-70

3.15.1.1 Operation status data

3.15.1.2 Questionable status data

3.15.2 How to reset the status data . . . . . . . . . . . . . . . . . . . . . . . 3-73

3.15.3 How to enable status reporting . . . . . . . . . . . . . . . . . . . . . 3-74

3.15.3.1 Program example using the status byte (STB)

3.15.3.2 Program example using a service request (SRQ)

3.15.4 How to report errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-76

3.15.4.1 Error-reporting routine

3.15.4.2 Error-reporting using th e SRQ me ch an ism

. . . . . . . . . . . . . . . . . . . . . . . . . . 3-71

. . . . . . . . . . . . . . . . . . . . . . . 3-72

. . . . . . . 3-74

. . . . 3-75

. . . . . . . . . . . . . . . . . . . . . . . . . 3-76

. . . . . . . . . 3-77

Page 6

VI

3.16 Saving/Restoring Instrument Setups . . . . . . . . . . . . . . . . . . . . . 3-78

3.16.1 How to restore initial settings . . . . . . . . . . . . . . . . . . . . . . . 3-78

3.16.2 How to save/restore a setup via instrument memory . . . . . 3-78

3.16.3 How to save/restore a setup via the GPIB controller . . . . . 3-78

3.17 Front Panel Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-79

3.17.1 How to simulate the pressing of a front panel key . . . . . . . 3-79

3.17.2 How to simulate the operation of a softkey menu . . . . . . . 3-80

3.18 Functions not Directly Programmable . . . . . . . . . . . . . . . . . . . . 3-81

4 COMMAND REFERENCE

4.1 Notation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Syntax specification notations . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.2 Data types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2 Command Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3 Command Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

A APPLICATION PROGRAM EXAMPLES

A.1 Measuring Signal Characteristics . . . . . . . . . . . . . . . . . . . . . . . A-2

A.1.1 Making automatic measurements . . . . . . . . . . . . . . . . . . . A-2

A.1.2 Making programmed measurements . . . . . . . . . . . . . . . . A-4

A.1.3 Reading measurement values . . . . . . . . . . . . . . . . . . . . . A-5

A.2 Acquiring Waveform Traces . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

A.3 Saving/Recalling Instrument Setups . . . . . . . . . . . . . . . . . . . . A-6

A.3.1 Save/recall settings to/from internal memory . . . . . . . . . . A-6

A.3.2 Save/recall settings to/from computer disk memory . . . . . A-7

A.4 Making a Hardcopy of the Screen . . . . . . . . . . . . . . . . . . . . . . . A-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

. . . . . . . . . . . . . A-1

A.5 Pass/Fail Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

A.5.1 Saving a pass/fail test setup . . . . . . . . . . . . . . . . . . . . . . A-10

A.5.2 Restoring a pass/fail test setup . . . . . . . . . . . . . . . . . . . . A-11

A.5.3 Running a pass/fail test . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Page 7

VII

B CROSS REFERENCES

B.1 Cross Reference Front Panel Keys / Commands

B.2 Cross Reference Softkey Menus / Commands

B.2.1 ACQUIRE menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B.2.2 CURSORS menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

B.2.3 DISPLAY menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

B.2.4 MATHPLUS MATH menu . . . . . . . . . . . . . . . . . . . . . . . . . B-6

B.2.5 MEASURE menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

B.2.6 DTB (DEL’D TB) menu . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

B.2.7 SAVE/RECALL menu . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

B.2.8 SETUPS menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

B.2.9 TB MODE menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

B.2.10 TRIGGER menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

B.2.11 UTILITY menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

B.2.12 VERTICAL menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-16

B.3 Cross Reference Functions / Commands

C MANUAL CONVENTIONS

C.1 Abbreviations Used

C.2 Glossary of Symbols Used

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

. . . . . . . . . . B-1

. . . . . . . . . . . . B-3

. . . . . . . . . . . . . . . B-17

C.3 List of Tables

C.4 List of Figures

C.5 Documents Referenced

D STANDARDS INFORMATION

D.1 SCPI Conformance Information

D.2 List of Implemented IEEE-488.2 Syntactical Elements

E SUMMARY OF SYSTEM SETTINGS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

. . . . . . . . . . . . . . . . . . . . . . . . D-1

. . . . . . . . . . . . . . . . . . . . . . . . D-1

. . . . . . . . . . . . . . . . . E-1

. . . . . . D-2

Page 8

ABOUT THIS MANUAL 1 - 1

1 ABOUT THIS MANUAL

The SCPI Programming Manual for the CombiScope instruments describes

how to program your CombiScope instrument via the IEEE bus using SCPI

commands.

1.1 What this Manual Contains

A complete table of contents is given at the beginning of the manual.

Chapter 1 ABOUT THIS MANUAL

Explains what the SCPI programming manual for the CombiScopes

instruments contains.

Chapter 2 GETTING STARTED WITH SCPI PROGRAMMING

T ells you how to get started quickly with your CombiScope instrument.

You can execute the program examples per (sub)section or from the

beginning until the end.

Chapter 3 USING THE COMBISCOPE INSTRUMENTS

Explains how SCPI works for your CombiScope instrument from

the functional point of view. Section 3.1 is an introduction and

section 3.2 explains the fundamental programming concepts. The

other sections and subsections represent the functional use of your

CombiScope instrument.

Chapter 4 COMMAND REFERENCE

Is a complete alphabetical reference of all implemented SCPI

commands. In the beginning a command summary is given to

provide you with a quick reference.

Page 9

1 - 2 ABOUT THIS MANUAL

Appendix A APPLICATION PROGRAM EXAMPLES

Appendix A describes some application program examples. The

application programs are supplied on floppy.

Appendix B CROSS REFERENCES

Appendix B gives cross references between SCPI commands and

front panel keys, softkey menu options, and instrument functions.

Appendix C MANUAL CONVENTIONS

Appendix C explains which abbreviations and symbols ar e used i n

the manual. It also gives a list of the tables, figures, and documents

referenced.

Appendix D STANDARDS INFORMATION

Appendix D gives information regarding SCPI and IEEE-488.2

standards.

Appendix E SUMMARY OF SYSTEM SETTINGS

Appendix E lists the system settings per functional group (node),

plus the applicable instrument settings per node.

A full alphabetical index is given at the end of the manual.

Page 10

GETTING STARTED WITH SCPI PROGRAMMING 2 - 1

2 GETTING STARTED WITH SCPI

PROGRAMMING

2.1 Preparations for SCPI Programming

To program your CombiScope instrument, you need a system setup and a

programming environment. Various program examples (refer to PROGRAM

EXAMPLE:) are given in the following sections. These progra m examples can be

executed one at a time or chained together for a complete tutorial. The program

examples are based on the system and programming environment as described

below.

Note: All PROGRAM EXAMPLE's in this chapter are supplied on floppy under

the file name EXGETSTA.BAS. They are chained together in order of

appearance.

2.1.1 System setup

The CombiScope instrument contains a factory-installed IEEE option.

•

A PC is used as controller. In the PC an IEEE-488.2 interface (GPIB) board

•

must be installed to turn the PC into a GPIB controller. The GPIB controller

must be connected to the CombiScope instrument via an IEEE cable.

Note: The program examples throughout this manual have bee n executed

on an IBM-compatible PC with the GPIB interface board and

software of the product PM2201/03 installed. The PM2201 board is

equivalent to the PCIIA board from National Instruments.

2.1.2 Programming environment

MS-QuickBASIC is used as the programming language.

•

A number of standard IEEE-488.2 drivers are used to control the CombiScope

•

instrument via the GPIB. These drivers must be included in the application

program. Therefore, the first statement of an application program must be as

follows:

REM $INCLUDE: ’<path>QBDECL.BAS’

Note: The program examples throughout this manual have bee n executed

using the IEEE-488.2 drivers and the device handler GPIB.COM of

the product PM2201/03.

Page 11

2 - 2 GETTING STARTED WITH SCPI PROGRAMMING

The parameters of these drivers are defined by the device handler GPIB.COM

and by the QuickBASIC program code. The following drivers a nd param eters ar e

used in the program examples:

The IEEE-488.2 driver "Send" is used to send a command or query to an

•

instrument.

CALL Send (<board>, <address>, <command>, <eot>)

The IEEE-488.2 driver "SendSetup" is used to prepare one or more devices

•

to receive data bytes. The controller becomes talker and the device b ecomes

listener.

CALL SendSetup (<board>, <addresslist>)

The IEEE-488.2 driver "SendDataBytes" is used to send data bytes from a

•

talking controller to a listening device.

CALL SendDataBytes (<board>, <data>, <eot>)

The IEEE-488.2 driver "Receive" is used to read a response string from an

•

instrument.

CALL Receive (<board>, <address>, <response>, <term>)

The IEEE-488.2 driver "SendIFC" is used to clear the GPIB interface.

•

CALL SendIFC (<board>)

The IEEE-488.2 driver "IbTMO" is used to specify a time out period for the

•

interface board.

CALL IbTMO (<board>, <timeout>)

Explanation of the parameters used in the IEEE-488.2 drivers:

<board> IEEE board identification inside the PC (default board

•

<address> IEEE instrument address (default CombiScope instrument

•

<addresslist> Array containing GPIB device addresses, terminated by the

•

<command> A command or query string to be sent to the instrument. The

•

<data> One or more data characters to be sent to the listener device.

•

address =0).

address = 8).

constant -1 (FFFF hex.).

"short form" commands are specified in UPPER CASE. The

additional characters in lower case complete the "long form"

commands.

Page 12

GETTING STARTED WITH SCPI PROGRAMMING 2 - 3

Includes GPIB drivers

Clears text from PC screen

Clears the GPIB interface

Sets time out at 10 seconds

<response> A response string sent by the instrument as a response to a

•

<eot> An "end of text" indication:

•

<term> A "terminate" indication:

•

<timeout> A time out indication, e.g., 11 = 1 second, 12 = 3 seconds,

•

PROGRAM EXAMPLE:

’

*****

’Initial program statements:

’

*****

REM $INCLUDE:’c:\pc-gpib\488driv\QBDECL.BAS’ ’

CLS ’

CALL SendIFC(0) ’

CALL IbTMO(0, 13) ’

query .

0 = program message to be continued (no action)

1 = end of program message (sends End-message + EOI

true)

0 = response message to be continued (no detection of EOL

character)

256 = end of response message (stops reading after EOL

character)

13 = 10 seconds.

PROGRAMMING NOTE:

The variable IBCNT% contains the number of response bytes (including NL

after reading a response message using the Receiv e dr iver.

)

Page 13

2 - 4 GETTING STARTED WITH SCPI PROGRAMMING

Resets the instrument

Clears the status data

Requests for identification

Reads the ident string

Prints the ident string

Requests for options

Reads the options string

Prints the options string

Switches to analog mode

Switches back to digital mode

2.2 Initializing the CombiScope Instrument

2.2.1 How to reset the CombiScope instrument

The instrument itself can be reset by sending the

instrument to a fixed setup optimized for remote operation. The status and error

data of the instrument can be cleared by sending the

RST command. This sets the

*

CLS command.

*

PROGRAM EXAMPLE:

’

*****

’Reset the instrument and clear the status data:

’

*****

CALL Send(0, 8, "*RST", 1) ’

CALL Send(0, 8, "*CLS", 1) ’

2.2.2 How to identify the CombiScope instrument

The identity of the instrument can be queried by sending the

followed by reading the instrument response message. The options of the

instrument can be queried by sending the

instrument response message.

OPT? query, followed by reading the

*

IDN? query,

*

PROGRAM EXAMPLE:

’

*****

’Read and print the identity and options of the instrument:

’

*****

response$ = SPACE$(65)

CALL Send (0, 8, "*IDN?", 1) ’

CALL Receive (0, 8, response$, 256) ’

PRINT "Ident: "; LEFT$(response$, IBCNT%) ’

CALL Send (0, 8, "*OPT?", 1) ’

CALL Receive (0, 8, response$, 256) ’

PRINT "Options: "; LEFT$(response$, IBCNT%) ’

2.2.3 How to switch between digital and analog mode

After power on, a CombiScope instrument can be either in the digital or analog

mode. After a

system allows you to switch between the two modes. This can be done by specifying a predefined name (DIGital, ANALog) or the corresponding number

(1 = digital, 2 = analog).

PROGRAM EXAMPLE:

’

*****

’Initialize and change the operating mode of the CombiScope instrument:

’

*****

CALL Send (0, 8, "INSTrument ANALog", 1) ’

CALL Send (0, 8, "INSTrument:NSELect 1", 1) ’

RST command the digital mode is selected. The INSTrument sub-

*

Page 14

GETTING STARTED WITH SCPI PROGRAMMING 2 - 5

Requests for error

Reads error message

Displays error message

2.3 Error Reporting

Instrument errors are usually caused by programming or setting err ors. They are

reported by the instrument during the execution of each command. To make sure

that a program is running properly, you must query the instrument for possible errors after every functional command. This is done by sending the

SYST em:ERR or? query or the STAT us:QUEue? qu ery to the instrument, followed

by reading the response message. However , through this practice the same "error

reporting" statements must be repeated after sending each SCPI command . This

is not always practical. Therefore, one of the following approaches is advised:

1) Send the SYST em:ERRor? or ST ATus:QUEue? query and read the instrument

response message after every group of commands that functionally belong to

each other.

2) Program an error-reporting routine and call this routine after each command

or group of commands. For an example of an error-reporting routine, refer to

section 3.14.4.1.

3) Program an error-reporting routine and use the "Service Request (SRQ)

Generation" mechanism to interrupt the execution of the program and to

execute the error-reporting routine. Therefore, refer to section 3.14.4.2.

PROGRAM EXAMPLE:

’

*****

’Read error message:

’

*****

er$ = SPACE$(60)

CALL Send(0, 8, "SYSTem:ERRor?", 1) ’

CALL Receive(0, 8, er$, 256) ’

PRINT "Response to error query = ";

PRINT LEFT$(er$, IBCNT%-1) ’

Page 15

2 - 6 GETTING STARTED WITH SCPI PROGRAMMING

2.4 Acquiring Traces

Trace acquisitions are started via the INITiate commands. A single acquisition is

done by sending a single INITiate command . Continuous acquisitions are done by

sending the INITiate:CONTinuous ON command.

The TRACe? query allows you to acquire a trace of signal samples from one of

the following sources:

An input channel, e.g., CH2 (input channel 2).

•

A trace area in a memory register, e.g., M2_3 (Memory register 2, trace 3).

•

The number of trace samples (acquisition length) can be specified using the

TRACe:POINts command. If your instrument has standard memory, you can

specify 512, 2048, 4096, or 8192 trace samples. If your instrument has extended

memory, you can specify 512, 8192, 16384, or 32768 trace samples. A

TRACe:POINts command specifies the acquisition length for all channels and

memory registers.

Example: Send --> TRACe:POINts CH1,8192 ’Selects 8192 sample points

for all traces

The number of trace sample bits can be specified using the FORMat command.

This gives you the possibility to define samples of 8 bits (1 byte) or 16 bits

(2 bytes). A FORMat command specifies the number of sample bits for all

channels and memory registers.

Example: Send --> FORMat INT,16 ’Formats 16-bits samples

The format of the trace response data is as follows:

# n x . . x f b . . . . . b s <NL>

NewLine code (10 decimal)

checksum byte over all trace bytes

trace sample data bytes (see Note)

trace data format byte (see Note)

number of trace bytes (fbb...bbs)

number of digits of x..x

Note: If f=8 decimal, each trace sample is one byte (8 bits).

Example:

# 4 1 0 2 6 <16> <msb 1> <lsb 1> . . . <msb 512> <lsb 512> <checksum> <10>

If f=16 decimal, each trace sample is two bytes (16 bits), i.e., most significant byte

(msb) + least significant byte (lsb).

trace sample 512

trace sample 1

decimal 16

number of trace bytes (N)

number of digits of N

Page 16

GETTING STARTED WITH SCPI PROGRAMMING 2 - 7

Formats 8-bits sample

Formats 8192 sample points

Trigger-source = channel 1

Trigger-level = 0.1

Single shot initiation

Waits for previous commands

to finish

Queries for channel 1trace

Reads channel 1 trace

The contents of the tracebuf$ string is as follows:

# 4 8194 <8> <byte 1> ... <byte 8192> <sum> <10>

IBCNT% = number of bytes

2.4.1 How to acquire a single shot trace

In the program example, a single shot trace acquisition of 8192 8-bit samples is

done with a probe connected to input channel 1. The trace sample byte s are read

from the GPIB as string characters. The number of response bytes and the

number of samples are printed.

The TRIGger:SOURce command is used to specify input channel 1 as a trigger

source. The TRIGger:LEV el command is used to reset the trigg er level to e.g., 0.1

volts.

PREPARATIONS:

Connect a probe to channel 1. After start up of the program you will be asked

•

to trigger the acquisition with the open end of the probe, i.e., touch the probe

or strike the probe on the table.

PROGRAM EXAMPLE:

’

*****

’Acquire a single shot trace:

’

*****

DIM tracebuf AS STRING * 16500

CALL Send(0, 8, "FORMat INTeger,8", 1) ’

CALL Send(0, 8, "TRACe:POINts CH1,8192", 1) ’

CALL Send(0, 8, "TRIGger:SOURce INTernal1", 1) ’

CALL Send(0, 8, "TRIGger:LEVel 0.1", 1) ’

CALL Send(0, 8, "INITiate", 1) ’

PRINT "Trigger the CombiScope instrument by touching the probe tip."

PRINT ">>> Press any key when finished."

WHILE INKEY$ = "": WEND

CALL Send(0, 8, "*WAI", 1) ’

CALL Send(0, 8, "TRACe? CH1", 1) ’

CALL Receive(0, 8, tracebuf$, 256) ’

’

’

’

’

nr.of.digits = VAL(MID$(tracebuf$, 2, 1))

nr.of.bytes = VAL(MID$(tracebuf$, 3, nr.of.digits)) - 2

sample.length = ASC(MID$(tracebuf$, 3 + nr.of.digits, 1)) / 8

nr.of.samples = nr.of.bytes / sample.length

PRINT "Number of bytes received ="; IBCNT% ’

PRINT "Number of trace samples ="; nr.of.samples

Note: Refer to section 3.4.3 "Conversion of trace data" about how to convert

this string data.

Page 17

2 - 8 GETTING STARTED WITH SCPI PROGRAMMING

Resets the instrument

Configures channel 2

Switches channel 2 on

Opens file TRACE5.DAT

Single initiation

Queries for channel 2 trace

Notice the

*

WAI; before TRACe?. The

*

WAI command takes care that the TRACe? CH2 command is

executed when the INITiate command is finished.

Reads channel 2 trace

Writes trace header to file

Writes trace buffer to file

Closes file TRACE5.DAT

2.4.2 How to acquire repetitive traces

In the program example, 5 trace acquisitions of 512 16-bit samples are done via

a probe connected to channel 2. The trace sample bytes are read from the GPIB

as string characters and written to the file TRACE5.DAT on the hard disk.

PREPARATIONS:

Connect a probe from the Probe Adjust signal to channel 2.

•

PROGRAM EXAMPLE:

’

*****

’Acquire 5 sequential traces and store in file TRACE5.DAT:

’

*****

DIM tracebuf AS STRING * 1050

CALL Send(0, 8, "*RST", 1) ’

’

’After *RST a trace acquisition is defined at 512 samples of 16 bits

’(2 bytes).

’

CALL Send(0, 8, "CONFigure:AC (@2)", 1) ’

CALL Send(0, 8, "SENSe:FUNCtion ’XTIMe:VOLTage2’", 1)’

OPEN "O",#1,"TRACE5.DAT" ’

FOR i=1 TO 5

CALL Send(0, 8, "INITiate", 1) ’

CALL Send(0, 8, "*WAI;TRACe? CH2", 1) ’

’

’

’

’

CALL Receive(0, 8, tracebuf$, 256) ’

PRINT #1, "Trace buffer:"; i ’

PRINT #1, LEFT$(tracebuf$, IBCNT%) ’

NEXT i

CLOSE ’

Note: Refer to section 3.4.3 "Conversion of trace data" about how to convert

this string data.

Page 18

GETTING STARTED WITH SCPI PROGRAMMING 2 - 9

MEASure?

CONFigure

READ?

INITiate

FETCh?

2.5 Measuring Signal Characteristics

The measurement instructions allow you to make a complete measurement. This

includes the configuration of the instrument, the initiation of the trigger system,

and the fetching of the acquisition data. The measurement instructions can be

used at different levels, varying in processing time. The highest level is the most

easy to use, but takes more time to complete than the lowest level. The following

levels of measurement instructions can be used:

The highest level:

(easy to use)

The middle level:

(gives more programming flexibility)

The lowest level:

(to acquire more signal characteristics)

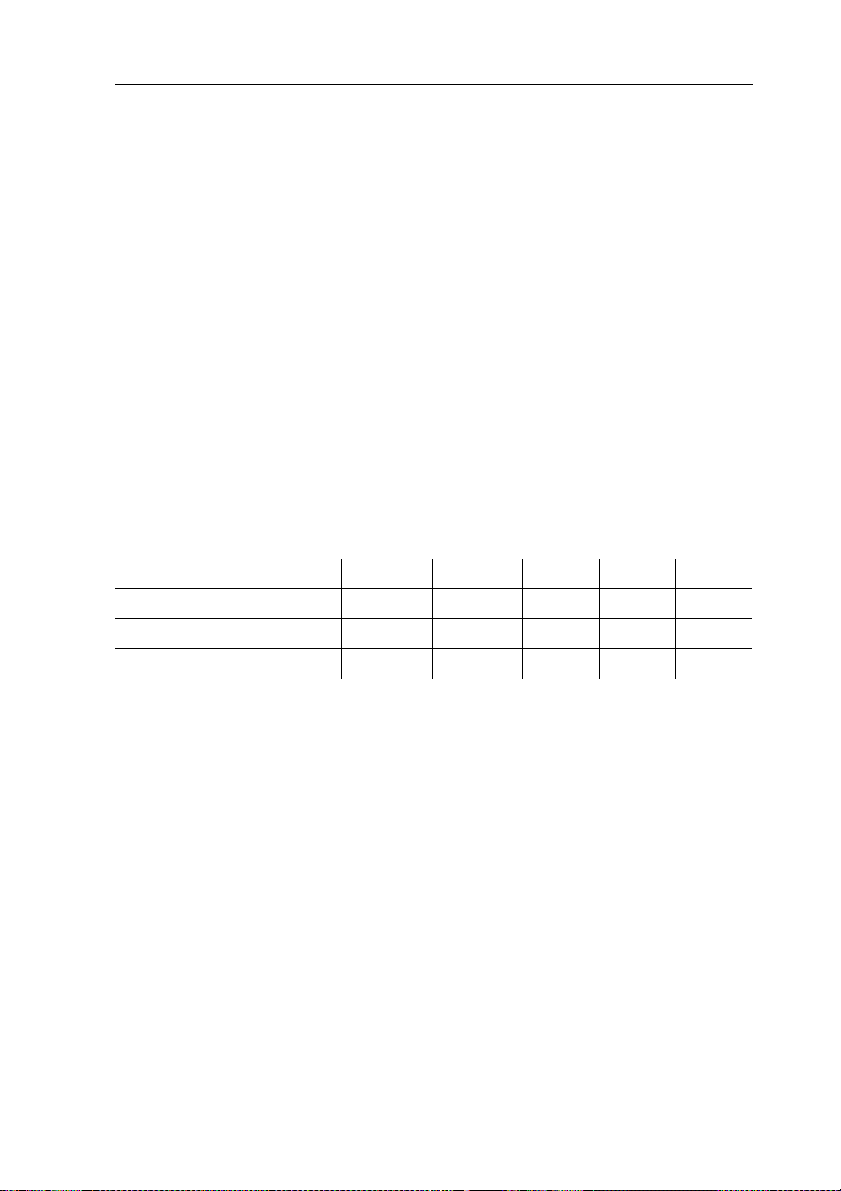

The following table shows which measurement tasks are executed by the

measurement instructions:

Configures the instrument: YES YES

Initiates the trigger system: YES YES YES

Fetches the acquired data: YES YES YES

MEASure?

CONFigure

INITiate

+

+

READ?

FETCh?

(equivalent to MEASure?)

(equivalent to READ?)

Page 19

2 - 10 GETTING STARTED WITH SCPI PROGRAMMING

Measures the AC-RMS value

Reads the AC-RMS value

Fetches the Peak-To-Peak value

Reads the PTP value

Fetches the amplitude value

Reads the amplitude value

Configures for AC-RMS

Performs 5 measurements

Initiates AC-RMS reading

Reads the AC-RMS value

Fetches the Peak-T o-Peak value

Reads the PTP value

Fetches the amplitudevalue

Reads the amplitude value

2.5.1 How to make a single shot measurement

The MEASure? query allows you to make a single-shot measurement, and the

FETCh? query allows you to fetch more signal characteristics.

PROGRAM EXAMPLE:

’

*****

’Measure and print the AC-RMS, peak to peak, and amplitude of

’the signal on channel 1.

’

*****

response$ = SPACE$(30)

CALL Send (0, 8, "MEASure:AC? (@1)", 1) ’

CALL Receive (0, 8, response$, 256) ’

PRINT "AC-RMS value : "; LEFT$(response$, IBCNT% -1)

CALL Send (0, 8, "FETCh:PTPeak?", 1) ’

CALL Receive (0, 8, response$, 256) ’

PRINT "Peak-To-Peak value: "; LEFT$(response$, IBCNT% - 1)

CALL Send (0, 8, "FETCh:AMPLitude?", 1) ’

CALL Receive (0, 8, response$, 256) ’

PRINT "Amplitude value : "; LEFT$(response$, IBCNT% - 1)

2.5.2 How to make repeated measurements

The measurement instructions allow you to make repeated measuremen ts. The

CONFigure command allows you to configure the instrument, the READ? query

allows you to make a measurement, and the FETCh? query allo ws you to fetch

more signal characteristics.

PROGRAM EXAMPLE:

’

*****

’Measure and print 5x the AC-RMS, peak to peak, and

’amplitude of the signal on channel 1.

’

*****

response$ = SPACE$(30)

CALL Send (0, 8, "CONFigure:AC (@1)", 1) ’

FOR i = 1 TO 5 ’

CALL Send (0, 8, "READ:AC?", 1) ’

CALL Receive (0, 8, response$, 256) ’

PRINT "AC-RMS: "; LEFT$(response$, IBCNT%-1);

CALL Send (0, 8, "FETCh:PTPeak?", 1) ’

CALL Receive (0, 8, response$, 256) ’

PRINT " / Peak-To-Peak: "; LEFT$(response$, IBCNT%-1);

CALL Send (0, 8, "FETCh:AMPLitude?", 1) ’

CALL Receive (0, 8, response$, 256) ’

PRINT " / Amplitude: "; LEFT$(response$, IBCNT%-1)

NEXT i

Page 20

USING THE COMBISCOPE INSTRUMENTS 3 - 1

3 USING THE COMBISCOPE

INSTRUMENTS

3.1 Introduction

This chapter explains how to access the functions of the CombiScope instruments

family in a remote programming environm ent. Fo r tha t purp os e, the Comb iScope

instrument is equipped with an IEEE-488 compatible GPIB interface and

implements a full SCPI compatible command set which provides an extensive

range of remote control facilities.

Traditionally, ther e was no standard for the remote operation of instruments. A

wide range of different command sets existed. Each set had its own te rminology

and trade-offs, based upon the implementations and corresponding limitations of

the instrument. Similar functions in different instruments were controlled by

different commands. And, vice versa, identical commands could easily exist in

another instrument to control a different function. With new technologies and

increasing complexity , other prog ramming concepts were introd uced. This caused

programs with identical functions to look different when written for another

instrument.

The remote control of instruments became a cumbersome process, which

required a high learning curve for each new instrument and each additional

instrument. The time and costs to create and maintain application programs were

unnecessarily high due to the lack of standardization.

With the introduction of the Standard Comm ands for Pr ogra mma ble Instr umen ts,

commonly called SCPI, a lot of progress has been made in this area. The

development time of an application program for SCPI-compatible instruments, like

the CombiScope instrument, is considerably reduced. This is mainly achieved by

the consistent programming environment for instrument control and data usage

across all types of instruments that, regardless of the manufacturer , is provided by

SCPI.

The standardized commands allow the same functions in different types of

instruments to be controlled by the same commands. For example, the que ry

MEASure:FREQuency? acquires the frequency characteristic of the input signal,

regardless of whether the instrument is a frequency counter, an oscilloscope, or

any other measuring instrument.

Page 21

3 - 2 USING THE COMBISCOPE INSTRUMENTS

As the example already shows, the commands are easy to learn and selfexplanatory to both novice and expert users. The learning curve is considerably

decreased for new instruments or instrument functions with which the

programmer is not familiar.

Efficiency is not only gained when creating or debugging new application

programs. The easily understandable programs greatly simplify maintenance and

modification of existing application programs that have been written by other

persons or for other instrument functions.

All major CombiScope instrument functions are controlled by standard SCPI

commands. Although the functionality provided is the same, the way the

oscilloscope is controlled via the remote interface dif fers in some aspects from the

front panel operation. This is because the local fr ont pan el opera tion is d esigned

to allow you to take maximum advantage of the interactive communication

possibilities offered by the display screen. This allows for additional information

and guidance during the process of local operation.

The remote command set is based upon an instrument model that is easy to

understand. This model provides a structured survey of the implemented

instrument functions and serves as a guide towards t he commands that control

these functions. This other view allows for optimal and easy access of the

instrument functions when operated from the remote interface. Additionally, a

measurement instruction set allows for easy programm ing of measur ement tas ks

for a wide variety of signal characteristics.

Page 22

USING THE COMBISCOPE INSTRUMENTS 3 - 3

3.2 Fundamental Programming Concepts

The remote operation of your CombiScope instrumen t can be accessed using

different programming concepts. The concept to be cho sen depends upon the

application of the instrument in the remote programming environment. Each of the

four concepts has it own benefits and trade-offs.

1) Using measurement instructions

Advantage: Easy to program. No instrument knowledge required to make

measurements. So, you can start programming quickly and get

measurement results rightaway.

Trade-off: A measurement takes some time to complete, because the

instrument automatically searches for optimal settings.

Example:

2) Single function programming using the instrument model

Advantage: Allows you to program individual functions separately throug h

Trade-off: Requires understanding of the remote operation of the instrument

Example:

MEASure:FREQuency?

single commands. The instrument model gives the relation

between the commands and the functions of the CombiScope

instrument.

functions.

TRACe? CH1

Measures the frequency of the

signal at channel 1.

Returns the acquisition trace of

the signal at channel 1.

3) Programming the complete instrument setup

Advantage: Simple to program. No worry about individual settings. This

method can also be used to save and recall settings, which are

not individually programmable.

Trade-off: Processes complete instrument setups. Individual settings

must be set or programmed separately.

Example:

4) Programming through front panel simulation

Advantage: Gives the possibility to program settings for which no remote

SAV 3

*

RCL 3

*

commands are available, i.e., to match a front panel setup.

Saves actual instrument settings

to internal memory 3.

Recalls instrument settings from

internal memory 3.

Page 23

3 - 4 USING THE COMBISCOPE INSTRUMENTS

Trade-off: This way of programming is cumbersome and tricky, because

additional information on the front panel display is not always

available remotely.

Example: DISPlay:MENU TRIGger Activates the TRIGGER softkey

menu.

SYSTem:KEY 4 Simulates the pressing of softkey 4.

The effect is that TRIGGER menu

option "noise" is switched on or

off.

3.2.1 Measurement instructions

This is a completely new approach in the remote operation of programmable

instruments, which provides a set of task-oriented measurement instructions.

Rather than programming every instrument setting separately with starting the

acquisition and calculating the result, just specify the desired signal characteristic,

and the CombiScope instrument returns the requested re sult. Depending upon

the actual available signal, your CombiScope instrument automatically

determines the optimal settings to acquire and calculate the requested result.

An example of such a command is the MEASure:FREQuency? query, which not

only works on oscilloscopes, but also on different types of SCPI-compatible

instruments, such as counters and multimeters.

With traditional oscilloscopes you had to do the following:

- set up all function s of the oscilloscope separately.

- start the acquisition of the data.

- position the cursor markers.

- calculate the frequency from the acquired data.

- read the calculat ed frequency from the instrument.

A single, simple SCPI query replaces all of the above, namely the

MEASure:FREQuency? query which does the following:

- auto configures the oscilloscope to the best possible setting for the requested

measurement task.

Note: This process is different from the traditional AUTOSET process in

that the autoset function determines the instrument settings based

on the input signal only, whereas, the auto configure algorithm also

takes the desired measurement task into account.

- starts the acquisition process.

- takes care that the measurement is triggered.

- calculates the desired characteristic from the acquired data.

- returns the calculated value.

Page 24

USING THE COMBISCOPE INSTRUMENTS 3 - 5

The measurement instructions are easy to use and do not require any special

knowledge of the instrument. The programming concept reduces simple

measurement tasks with complex instruments to simple instructions, leaving the

setup complexity to the instrument. The measurement instructions are extremely

useful when the application does not require the precise setting of instrume nt

functions. The concept is extendible with separate control of parameters that are

vital to the application.

3.2.2 Single function programming using the instrument model

All major instrument functions such as time base, input impedance, etc, are

separately programmable using "single parameter" commands. The easy to

understand command set is comparable with the way instruments are traditiona lly

controlled. This concept gives you full control over all functions and power of a

modern oscilloscope. However , for maximum b enefit of all the advanced fe atures

of your CombiScope instrument, you need some understanding of their remote

operation.

Functions of the CombiScope instrument th at belong together are grouped into

subsystems. There are several subsystems, each representing a particular

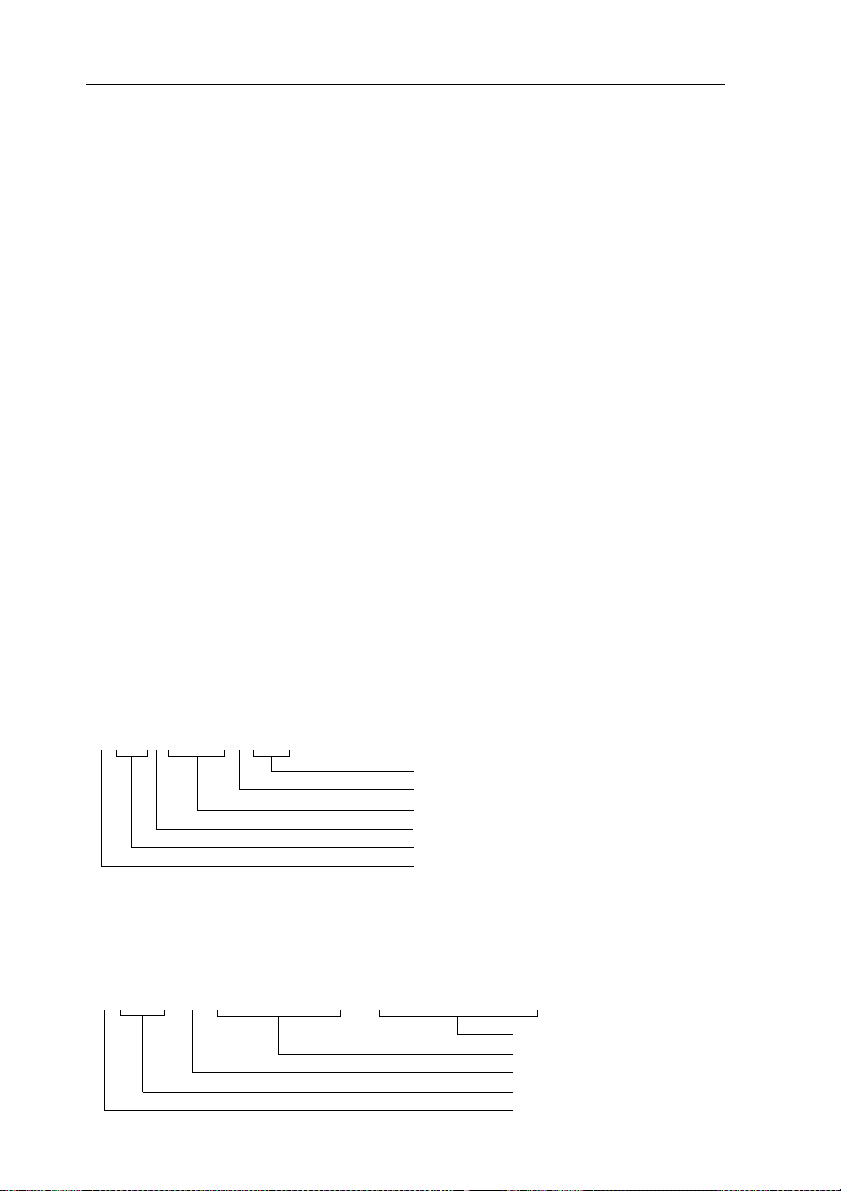

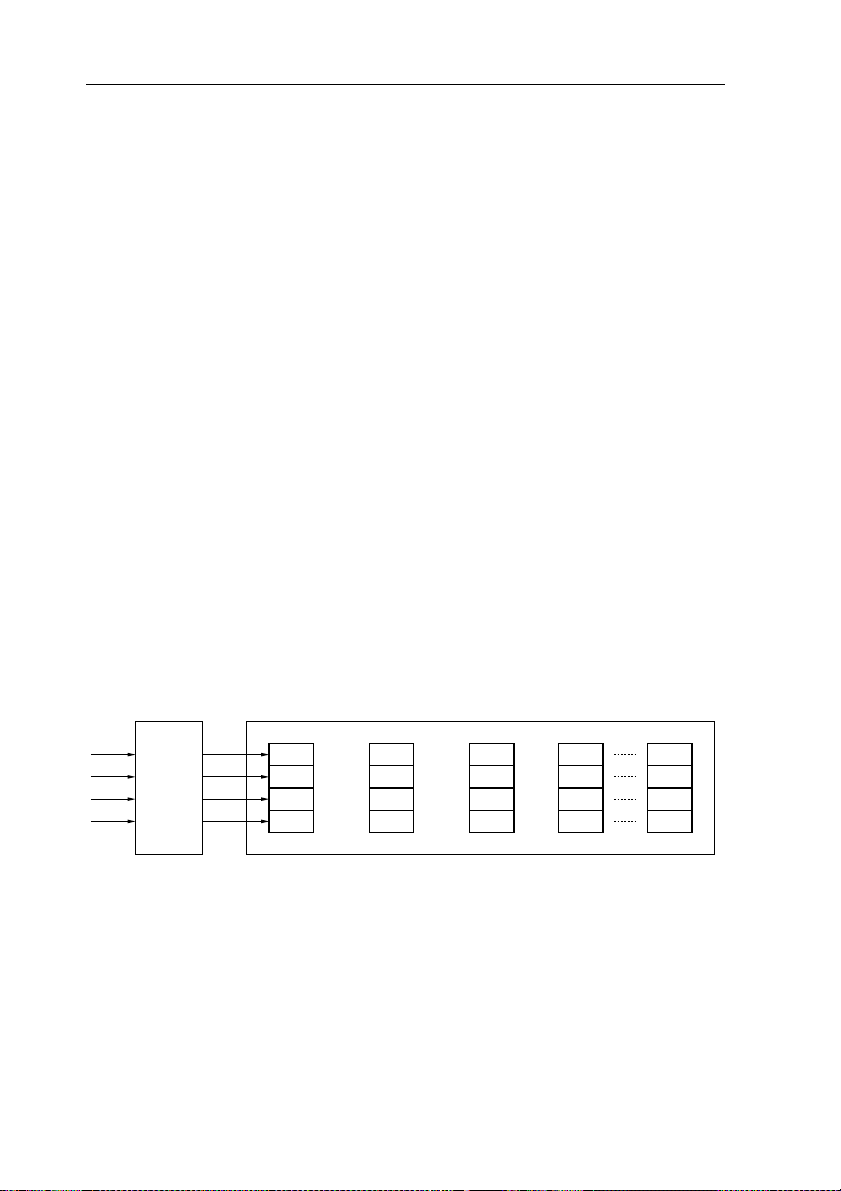

function. The instrument model in the following figure gives an overview of the

most important subsystems.

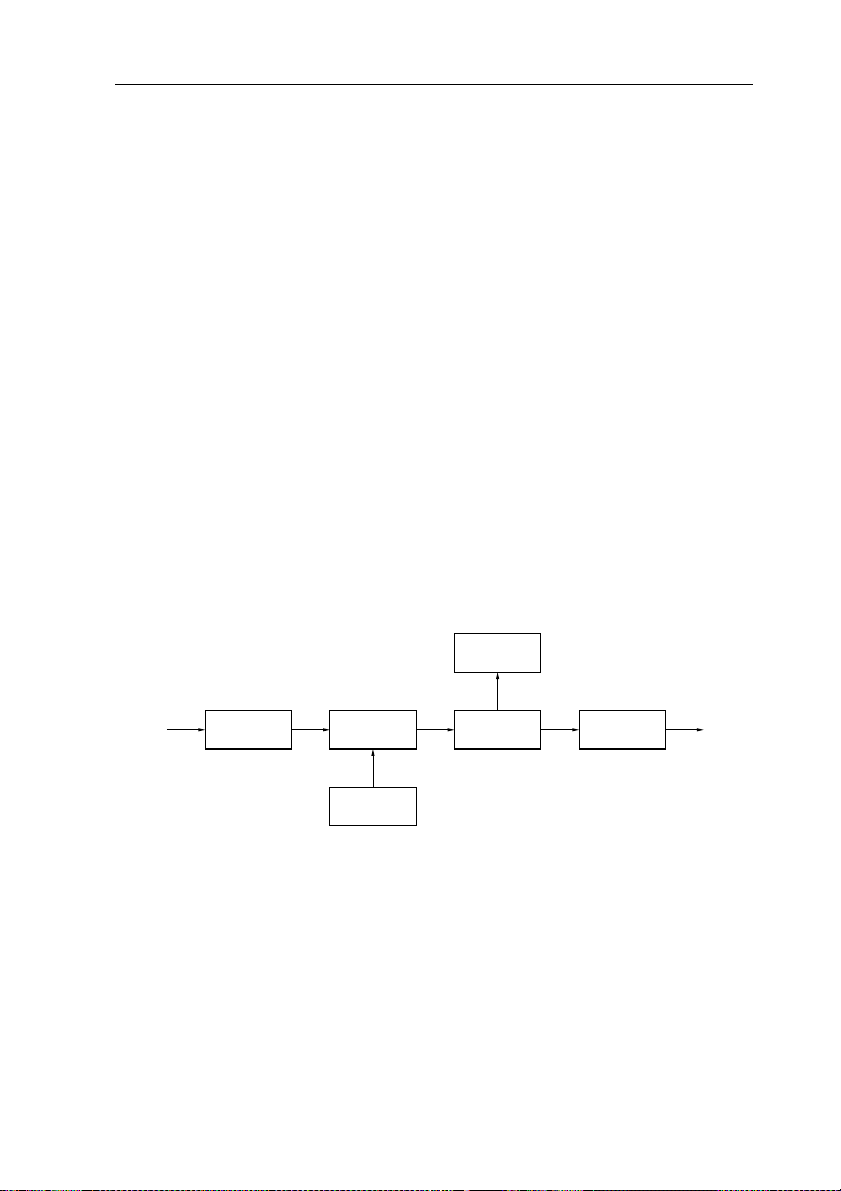

DISPlay

INPut SENSe

TRIGger

Figure 3.1 The Instrument Model for CombiScope instruments

EXPLANATION OF THE INSTRUMENT MODEL:

All functions that deal with signal conditioning are part of the INPut subsystem.

•

In a similar way the SENSe subsystem contains the data acquisition part

•

where the analog signal is converted into a digital value.

The results of the acquisition are stored in a TRACe subsystem memory.

•

Post-processing functions on the acquired data are available in the

•

CALCulate subsystem.

The TRIGger subsystem deals with the control of the acquisition process.

•

The DISPlay subsystem handles the front panel display functions.

•

TRACe CALCulate

ST7155

Page 25

3 - 6 USING THE COMBISCOPE INSTRUMENTS

Functions in a particular subsystem are always controlled by commands that

begin with the name of that subsystem. For example, a command that programs

the input coupling is INPut:COUPling DC.

All programmable settings can be queried easily. The query form is obtained from

the command by simply removing the parameter and adding a question mark. For

example, the command to program the input impedance of your oscilloscope is

INPut:IMPedance 50. This impedance value can be queried by sending

INPut:IMPedance? which returns 50.

3.2.3 Instrument setup

This concept allows you to program instrument settings with a single command.

Several instrument setups can be saved, either created by remote programming

or by front panel control. This concept can also be use d to program instrument

functions that cannot be directly accessed using individual pr ogram instructions.

Complete instrument setups can be saved either in the internal memory of the

oscilloscope or externally in the remote controller. A part of the instrument setup

can also be saved externally.

The oscilloscope is equipped with a number of internal memories in which the

complete instrument set up can be saved and from which it can be restored.

→

Send

Send

Instead of using an internal oscilloscope memory, the instrument setup can be

queried using the SYSTem:SET? query. The result of this query is that the

oscilloscope sends a part or the complete setup in a compact block data format.

Sending this data back as a parameter with the SYSTem:SET command

reprograms the oscilloscope to the same settings.

SAV 3 Saves the current set up into memory 3.

*

→

RCL 3 Recalls the instrument set up that was saved in memory 3.

*

Example for the complete instrument settings:

→ SYSTem:SET? Queries the oscilloscope for the complete

Send

instrument setup.

← <block_data> Reads the <block_data> response, which

Read

contains the requested instrument setup,

from the oscilloscope.

→ SYSTem:SET <block_data> Sends the previously read instrument

Send

setup back to the oscilloscope in the

same <block_data> format.

Page 26

USING THE COMBISCOPE INSTRUMENTS 3 - 7

Example for the instrument cursor settings:

Send

→ SYSTem:SET? 32 Queries the oscilloscope for the

instrument settings of node 32, which are

the cursor settings.

← <settings> Reads the cursor settings.

Read

.

.

Send

→ SYSTem:SET <settings> Restores the cursor settings.

3.2.4 Front panel simulation

This concept allows you to send commands that simulate the pressing of a front

panel key. This method allows the remote operation to precisely match a front

panel setup. In particular, this method can be used to access instrument functions

that cannot be programmed directly by remote commands.

As described in the beginning of this section, there is a difference between the

front panel operation and the remote control of an instrument. If you use the front

panel simulation commands via the remote interface, be aware that no use can

be made of the additional information that is presented on the screen of the

oscilloscope. As this causes the front panel simulation method to be a tedious

process, it is certainly not recommended as a common programming practice.

For example, the SYSTem:KEY 507 command switches the AVERAGE function

on when it was switched off before. When this function was switched on before,

the AVERAGE function is switched off. The effect of the SYSTem:KEY command

completely depends upon the state of the instrument at the moment the command

is received. In a remote programming environment it is not immediately clear

whether a state is on or off. For that reason the command SENSe:AVERage ON

is much better.

To select functions that cannot b e programmed directly, you might use the front

panel simulation commands. For example, the command SYSTem:KEY 4

switches the "noise suppression" option in the TRIGGER menu of the front panel

ON or OFF.

Page 27

3 - 8 USING THE COMBISCOPE INSTRUMENTS

3.3 Measuring Signal Characteristics

As explained in section 3.2.1 "Measurement instructions", the measurement

instruction set is a new approach in the remote operation of programmable

instruments. This instruction set allows you to request a particular characteristic

of the input signal. The CombiScope instrument th en chooses the best possible

settings, executes the requested task, and returns the desired result.

Within the measurement instruction set, different programming levels can be

distinguished. The highest level is the easiest to use, but the trade-off is less

flexibility. Lower levels provide more flexibility by offering more control over the

instrument functionality. This requires more knowledge about the remote

operation of your instrument.

The measurement instructions specify a particular task in terms of the expected

signal and the desired result. The instructions refer to the sig nal characteristics of

the signal being measured. This makes them independent from the

implementation of the instrument functions. For example, when the instruction

MEASure:FREQuency? is executed, it is not important whether t his frequency is

measured by precisely counting the signal period, or if it is calculated from a

sampled waveform. For this reason, the measurement instru ctions provide the

best compatibility among different types of instruments. But, as a trade-off, the

compatibility decreases when more flexibility is needed and lower measurement

instruction levels are used.

3.3.1 The MEASure? query

This is the easiest instruction to use and provides the best compatibility. However,

it does not offer access to the full capability of the CombiScope instrument. The

MEASure? query configures the instrument for optimal settings, starts the data

acquisition, and returns the result in one operation. The signal characteristics that

can be acquired in this way are shown in figure 3.2.

Example:

MEASure:AC?

This query measures the RMS voltage of the AC component at the default

input channel 1. After the acquisition, the result is sent to the controller. The

instrument itself selects an optimal setting for this purpose and carries out the

requested measurement as "well" as possible. Moreover, it automatically

starts the measurement.

Page 28

USING THE COMBISCOPE INSTRUMENTS 3 - 9

3.3.2 Benefits of using parameters

The generic form of a measurement instruction is as follows:

MEASure[:VOLTage]:<measure_function>?

[[<voltage_parameters>,]<measure_parameters>][,<channel_list>]

The :VOL Tage keyword is a default node, which specifies the signal characteristic

to be measured, relates to the voltage component of the signal. The

<measure_function> specifies the desired signal characteristic.

The parameters can be used to provide additional information to the instrument

about the expected signal and the desired result. The oscilloscope uses this

information to determine the best settings for the requested task. As the syntax

shows, the parameters can be left out (defaulted). In that case, the oscilloscope

chooses it own settings based upon the actual available input signal and its own

trade-offs. The result of defaulting parameters is that the measurement needs

more time to complete.

The VOLTage parameters relate to the :VOLTage node in the header. These

parameters specify the expected voltage and the desired resolution:

<voltage_parameters> = [<expected_voltage>[,<resolution>]]

The expected voltage in the parameter specification is assumed to be the value

at the BNC input of the oscilloscope. When a detectable probe is attached, it is

assumed to be the value at the probe tip.

When the <expected voltage> parameter is defaulted, the oscilloscope performs

an autorange, which needs some additional time. When a particular value was

specified instead, the oscilloscope immediately selects the range next higher to

the specified voltage, omitting the relative time-consuming autoranging.

Notice that when voltage parameters are used, the :VOLtage node must be sent

explicitly in the command header . Or, in other words, when the :VOLTage node is

defaulted, the voltage parameters must also be defaulted.

Page 29

3 - 10 USING THE COMBISCOPE INSTRUMENTS

Examples:

MEASure:AMPLitude?

This query measures the amplitude of a waveform at the default input

channel 1. After the acquisition, the resulting amplitude is returned.

MEASure:VOLTage:AMPLitude? 10, (@2)

This query measures the amplitude of a signal at channel 2 (@2). But, since

it specifies the expected voltage value (10 volts), it will complete the

measurement faster.

In a similar way the measure function parameters provide the oscilloscope with

information about the signal characteristic to be measured. The parameters that

are allowed depend upon the requested signal char acteristic (mea sure function).

The measure function parameters that specify a voltage characteristic, such as

:AC, :AMPLitude, :HIGH, :MINimum, etc, use the voltage parameters for that

purpose. Measure functions, such as fall and rise tim e, frequency and period, use

time units. Their expected value and desired resolution are specified in seconds

or Hertz as separate measure parameters.

Examples:

MEASure:VOLTage:FREQuency? 10E6, (@3)

This query measures the frequency of the signal at input channel 3. The

expected frequency is 10 MHz, whereas, the expected voltage is defaulted.

Notice that this command is equivalent to the MEASure:FREQuency? 10E6,

(@3) command.

MEASure:VOLTage:FREQuency? 5, 10E6, (@3)

This query does the same as the previous example, except that the expected

voltage is 5 volts.

Page 30

USING THE COMBISCOPE INSTRUMENTS 3 - 11

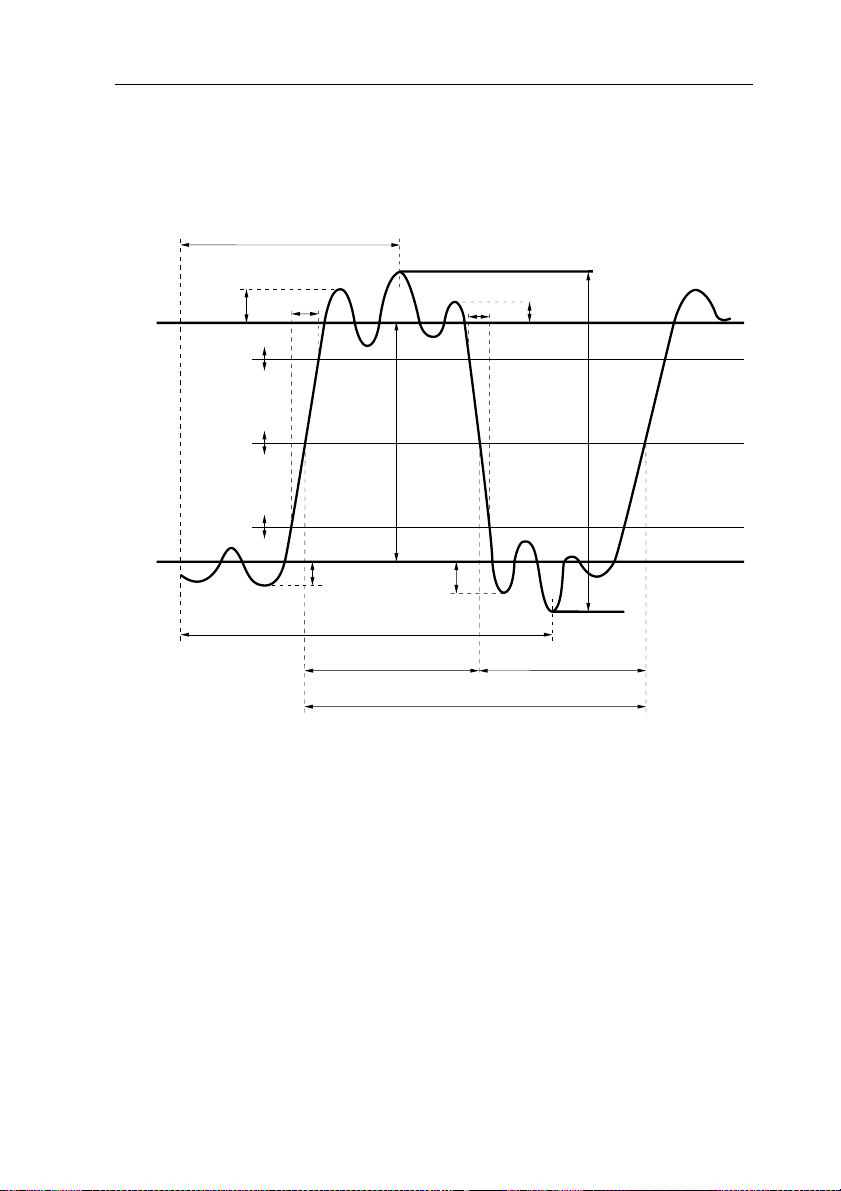

3.3.3 Waveform measurements

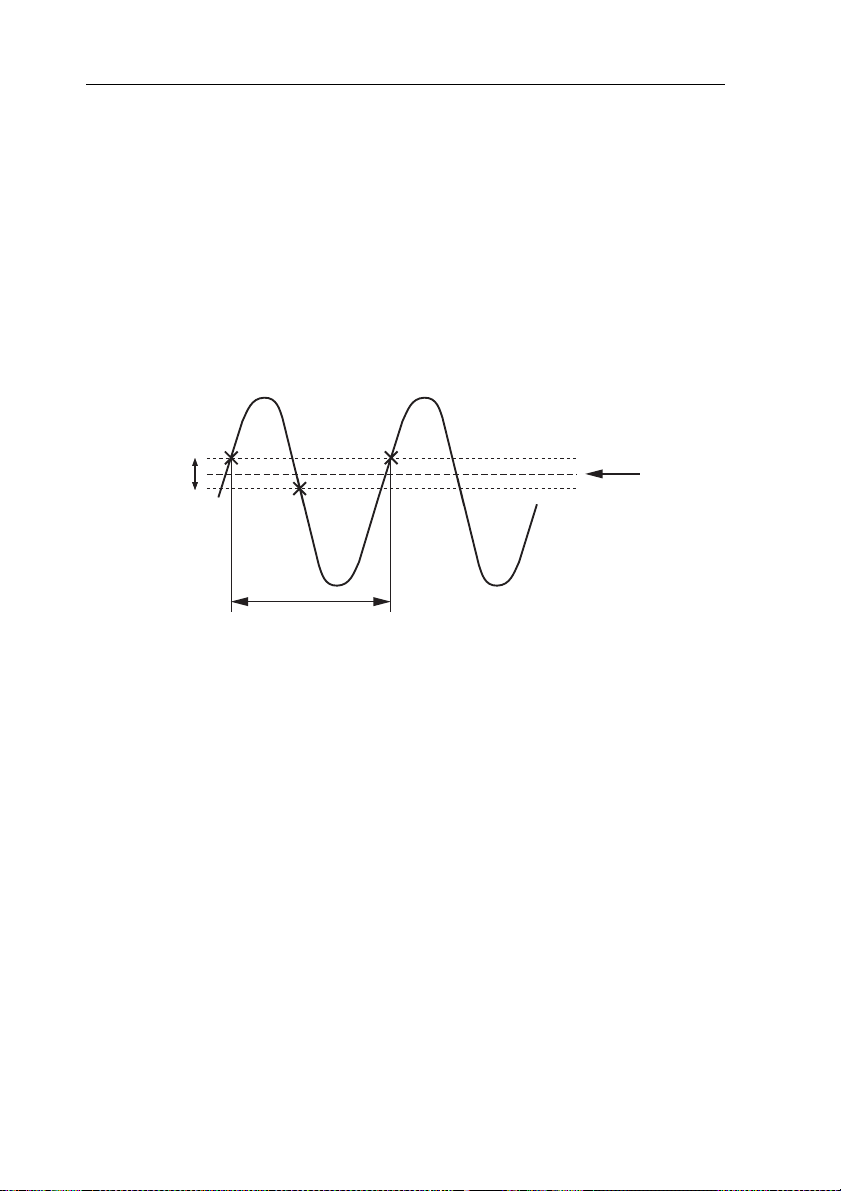

The following figure shows the terms used for pulse measurements and the key

words that are used as header nodes in the measurement instructions.

TMAXimum

MAXimum

HIGH

LOW

RISE

OVERshoot

REFerence

HIGH

REFerence

MIDDle

REFerence

LOW

RISE TIME

RISE

PREShoot

TMINimum

AMPLitude

FALL

OVERshoot

FALL TIME

PERiod

FALL

PREShoot

NWIDthPWIDth

PTPeak

MINimum

ST7154

Figure 3.2 Pulse characteristics

The reference high and low parameters determine the desired interval for rise

time and fall time measurements. The default low and high references are 10%

and 90% of the pulse amplitude (= HIGH - LOW).

Default REFerence LOW =LOW + 0.1

Default REFerence HIGH =LOW + 0.9

(HIGH - LOW)

*

(HIGH - LOW)

*

In a similar way, the reference middle parameter determines the desired interval

for pulse width (PWIDth, NWIDth) and duty cycle (PDUTycycle, NDUTycycle)

measurements. When defaulted, the reference middle value is assumed to be at

50% of the amplitude.

Default REFerence MIDDle =LOW + 0.5

(HIGH - LOW)

*

Page 31

3 - 12 USING THE COMBISCOPE INSTRUMENTS

Examples:

MEASure:FALL:TIME? (@3)

Measures the time interval during which the pulse at channel 3 decreases

from 90% to 10% of its amplitude.

MEASure:RISE:TIME? 20,80

Measures the time interval during which the pulse at the default channel 1

increases from 20% to 80% of its amplitude.

The following measure functions and parameters can be programmed:

<measure_function><measure_parameters>

:AC

:AMPLitude

[:DC]

:FALL

:OVERshoot

:PREShoot

:TIME [<reference_low> [,<reference_high> [,<expected_time>

[,<time_resolution>]]]]

:FREQuency [<expected_frequency> [,<frequency_resolution>]]

:HIGH

:LOW

:MAXimum

:MINimum

:NDUTycycle <reference_middle>

:NWIDth <reference_middle>

:PDUTycycle <reference_middle>

:PERiod [<expected_period> [,<period_resolution>]]

:PTPeak

:PWIDth <reference_middle>

:TMAXimum

:TMINimum

:RISE

:OVERshoot

:PREShoot

:TIME [<reference_low> [,<reference_high> [,<expected_time>

[,<time_resolution>]]]]

Notes: - :DCYCle = alias for :PDUTycycle

- :F TIMe = alias for :FALL:TIME

- :RTIMe = alias for :RISE:TIME

Page 32

USING THE COMBISCOPE INSTRUMENTS 3 - 13

3.3.4 Customizing settings

Often, you need more precise control of the measur ements than possible with the

MEASure? query. The combination of CONFigure and READ? is provided to

allow you to program one or more settings that are vital to your application.

Executing this sequence of instructions is equivalent to sending MEASure? For

setting up the instrument, CONFigure uses the same measure functions and

parameters as MEASure?. The CONFigure command does the instrument setup

portion of MEASure?. The READ? query initiates the acquisition, performs the

needed calculations, and returns the desired result.

Since READ? no longer changes instrument settings, commands that are

executed after CONFigure, but before READ?, are taken into effect by the

acquisition. This concept allows you to perform a generic configuration through

CONFigure and then customize the measurement by programming the settings

that are vital to your application. Next the READ? completes the measurement

process.

Example:

CONFigure:AC Configures the instrument to perform an RMS

measurement of the AC component at the default

input channel 1.

SENSe:AVERage ON Sets averaging on.

SENSe:AVERage:COUNT 4 Sets averaging factor at four .

READ:AC? Starts the measurement and returns the averaged

AC-RMS value.

READ? uses the same measure functions and parameters as CONFigure. After

the instrument has been set up for a particular measure function by the

CONFigure command, the same measure function key words can be repeated by

the READ? query header. Moreover, it is allowed to request for another signal

characteristic by specifying a measure function other than that for which the

instrument was configured. However , keep in mind that the instrumen t was set up

by CONFigure for another task. As these settings are not affected by READ?, it

is not guaranteed that the instrument is able to acquire the signal characteristic

that is requested by READ?

Example:

CONFigure:AC Sets up the instrument to perform an RMS

measurement of the AC component.

Page 33

3 - 14 USING THE COMBISCOPE INSTRUMENTS

READ? Requests to execute the default DC measurement.

Since this is not possible with the chosen

configuration, an execution error is generated and

no result is returned.

CONFigure:RISE:TIME Configures the CombiScope instrument to perform a

rise time measurement.

READ:RISE:OVERshoot? Requests to read the rise time overshoot. Because the

CombiScope instrument is able to calculate the rise

overshoot value when it is set up for a rise time

measurement, the desired result is calculated and

returned.

A READ? also allows the same parameter sets as the correspondin g CONFigure

instructions. But, these sets only serve to specify the desired result. They are

ignored as far as they affect instrument settings. The parameters can be sent for

compatibility with the preceding CONFigure command.

Example:

CONFigure:RISE:TIME Configures the oscilloscope to perform a default rise

time measurement (10% to 90% increase of the

signal amplitude).

READ:RISE:TIME? 20,80 Requests for the rise time of the 20 to 80% increase

of the signal amplitude. As the CombiScope

instrument is able to respond to this request, the

desired rise time is calculated and returned.

3.3.5 Multiple measurements

Sometimes it is necessary to perform multiple measurements of the same signal

characteristic. This can be realized by executing multiple MEASure? queries.

However, this implies that the relative time-consuming configuration portion of

MEASure? is unnecessarily repeated. This can be easily avoided by using the

CONFigure and READ? concept as described in the preceding chapter. This

concept allows you to do the configuration only once by sending the CONFigure

command one time. Sending multiple READ? q ueries next, causes the instrument

to repeatedly execute the desired measurement.

Example:

CONFigure:FREQuency Configures the instrument to perform a frequency

measurement.

Page 34

USING THE COMBISCOPE INSTRUMENTS 3 - 15

READ:FREQuency? Starts the acquisition and returns the measured

frequency.

READ:FREQuency? Starts a next acquisition and returns the new

frequency result.

READ:FREQuency? Etc.

3.3.6 Multiple characteristics from a single acquisition.

It is often necessary to determine several signal characteristics from the last

acquired waveform. Starting a new acquisition, as READ? and MEASure? do, is

undesired. For that purpose, READ? is broken down into two additional

instructions, which are the INIT iate[:IMMediate] command and the FETCh ? query .

Executing this sequence of instructions is equivalent to READ?. The

INITiate[:IMMediate] command starts the acquisition. FETCh? determines the

requested signal characteristic and returns the re sult. This concept allows you to

perform several different FETCh? queries on a single set of acquisition data .

Example:

MEASure:AC? Configures the instrument to measure the RMS value

of the AC component of the signal at input channel 1,

starts the acquisition, and returns the desired result.

FETCh:FREQuency? Determines and returns the frequency of the signal

that is acquired by the preceding MEASure? query .

FETCh:RISE:TIME? Uses default parameters to determine and return the

rise time of the first pulse.

As distinct from the READ? query, defaulting the measure function part of the

FETCh? query, causes the CombiScope instrument to return the characteristic

that was requested with the last executed FETCh?, READ? or MEASure? query.

For this reason, the measure function should always be exp licitly specified in the

header of the FETCh? query.

Page 35

3 - 16 USING THE COMBISCOPE INSTRUMENTS

3.3.7 Trigger control via GPIB

You need a separate GPIB command to start a measurement synchronized with

other instruments. This is done by sending the

(Group Execute Trigger) code. The MEASure? and READ? queries do not allow

you to do so, because such a setup causes a query error. With the

INITiate[:IMMediate] and FETCh? concept, it is possib le to meet the requirements

of such applications.

Example:

CONFigure:AC Configures the instrument to measure the AC-RMS

voltage.

TRIGger:SOURce BUS Specifies that the acquisition is to be triggered by

GET or

INITiate Starts the measurement process.

TRG Triggers the acquisition.

*

FETCh:AC? Determines and returns the AC-RMS value.

TRG.

*

TRG command or the GET

*

Page 36

USING THE COMBISCOPE INSTRUMENTS 3 - 17

Configures for channel 2

Switches channel 2 on

Single initiation

Copies CH2-trace to M1_2

Now trace area 2 of memory register 1 is filled with the channel 2 trace.

Fetches AC-RMS of M1_2

Enters AC-RMS value

Prints AC-RMS value

Fetches Peak-To- Peak of M1_2

Enters Peak-To-Peak value

Prints Peak_to_peak value

Fetches amplitude of M1_2

Enters amplitude value

Prints amplitude value

3.3.8 Fetching characteristics from memory traces

The FETCh? query not only allows you to determine a characteristic from the last

acquired waveform, it also allows you to calculate a signal characteristic from a

waveform that is stored in a trace memory element.

Example:

FETCh:RISE:TIME? (@M3_4) Calculates and returns the default rise time

from a waveform that is stored in trace memory

M3_4.

FETCh:PERiod? (@M4_1) Determines and returns the period of the

waveform that is stored in trace memory M4_1.

Notice that such a FETCh? query operates properly only when there is valid

waveform data stored in the trace memory.

PROGRAM EXAMPLE:

In this example the signal acquired via channel 2 is stored in memory register 1.

The AC-RMS, peak-to-peak, and amplitude values of the stored signal are

fetched and printed.

DIM response AS STRING * 10

CALL Send(0, 8, "CONFigure:AC (@2)", 1) ’

CALL Send(0, 8, "SENSe:FUNCtion ’XTIMe:VOLTage2’", 1)’

CALL Send(0, 8, "INITiate", 1) ’

CALL Send(0, 8, "TRACe:COPY M1_2,CH2", 1) ’

’

’

’

CALL Send(0, 8, "FETCh:AC? (@M1_2)", 1) ’

CALL Receive(0, 8, response$, 256) ’

PRINT "AC-RMS value : "; response$ ’

CALL Send(0, 8, "FETCh:PTPeak? (@M1_2)", 1) ’

CALL Receive(0, 8, response$, 256) ’

PRINT "Peak-To-Peak value: "; response$ ’

CALL Send(0, 8, "FETCh:AMPLitude? (@M1_2)", 1) ’

CALL Receive(0, 8, response$, 256) ’

PRINT "Amplitude value : "; response$ ’

Page 37

3 - 18 USING THE COMBISCOPE INSTRUMENTS

3.4 Acquisition

3.4.1 Acquisition control

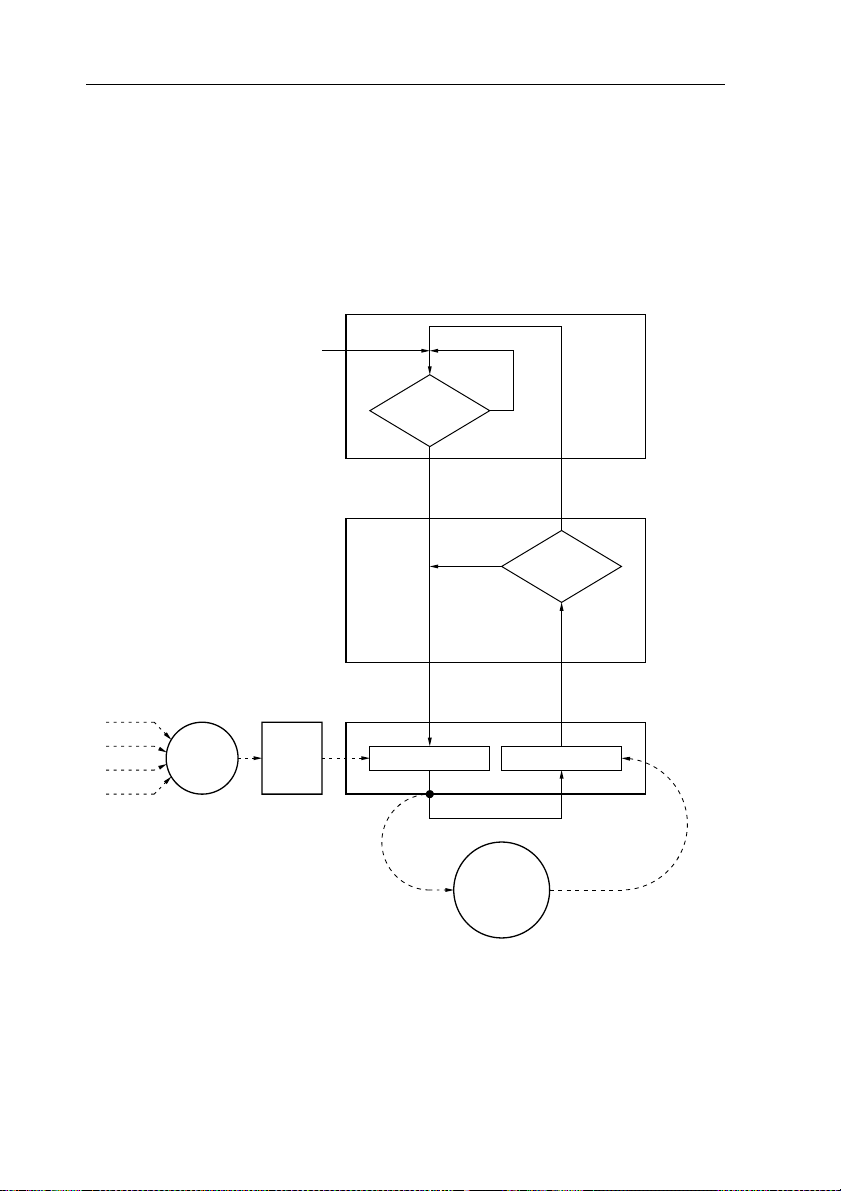

Several commands exist to control the acquisition process. The following diagram

shows the possible states of the acquisition process, and the way they are

affected by commands.

IDLE state

*RST

ABORt

power on

INIT

or

INIT:CONT ON

Yes

No

Yes

INITiated state

No

INIT:CONT ON

BUS

IMMediate

INTernal

LINE

TRIGger

:SOURce

TRIGger

:LEVel

:SLOPe

Start acquisition

Wait for trigger

Acquisition

Wait for TRIGger state

Wait for complete

Acquisition completed

ST7186

Figure 3.3 The Trigger Model for acquisitions

The trigger model shows that after a

IDLE state. An acquisition doesn’t start until an INITiate command is received.

RST command, the instrument is in the

*

Initiation of the oscilloscope occurs by sending the INITiate[:IMMediate] command

Page 38

USING THE COMBISCOPE INSTRUMENTS 3 - 19

or by setting INITiate:CONTinuous to ON. The INITiate[:IMMediate] command

causes the CombiScope instrument to perform one complete acquisition cycle.

Upon completion of the cycle the instrument returns to the IDLE state.

The INItiate:CONTinuous command is used to select whether the instrument is

continuously initiated or not. When INItiate:CONTinuous is set to ON, the

instrument immediately exits IDLE and starts an acquisition cycle. On completion

of each cycle, the instrument does not return to the IDLE state, but immediately

starts another acquisition cycle.

Before the acquisition takes place, the trigger conditions must be satisfied. These

conditions are programmable to suit the needs of your application, as described in

the next section. After a

So, an INITiate command causes the CombiScope instrument to immediately

trigger the acquisition.

Executing the measurement instructions MEASure? and READ? causes the

acquisition to become initiated automatically . No separate INIT iate commands are

needed. When the FETCh? instruction is used, the instrument must have been

initiated either by a preceding INITiate[:IMMediate] command, or implicitly by a

READ? or MEASure? instruction.

When the CombiScope instrument receives the ABORt command, any

acquisition that is in progress is aborted immediately, and the instrument returns

to the IDLE state. The same occurs when

command distinguishes from

settings, whereas, ABORt does not. For example, when INITiate:CONTinuous is

set to ON, a

the instrument to the IDLE state, but it also sets INITiate:CONTinuous to OFF,

preventing the acquisition to initiate again. Since ABORt does not affect the

instrument settings, an aborted acquisition cycle is immediately initiated again.

RST command not only aborts the pending acquisition and forces

*

RST command, there are no trigger conditions to be met.

*

RST is received. The ABORt

RST in that *RST also resets the instrument

*

*

When the instrument is in the IDLE state, the "no-pending operation" flag that is

associated with the acquisition is set True. The

this flag to signal their "Operation Completed" response. Notice that if

INITiate:CONTinuous is set to ON, the instrument does not return to the IDLE

state when an acquisition cycle has completed. This means that no "Operation

Completed" response is generated after the

OPC and *OPC? commands use

*

OPC and *OPC? commands.

*

Page 39

3 - 20 USING THE COMBISCOPE INSTRUMENTS

3.4.1.1 Triggering

After the measurement is initiated, the CombiScope instrument starts the real

acquisition when the trigger conditions are satisfied, e.g., when the selected

trigger event occurs. The trigger conditions can be ignored during a specific h oldoff time, which can be programmed using the TRIGger:HOLDoff command.

During the hold-off time the event detector is inhibited from acting on any trigger.

Trigger Type

The TRIGger:TYPE command selects the type of triggering, which can be

programmed to EDGE triggering (normal trigger mode) , VIDeo triggering (refer to

section 3.4.1.2 "Video triggering"), LOGic, or GLITch triggering. After a

command, the trigger type is EDGE.

Note: Logic state, pattern, or glitch settings cannot be programmed using SCPI

commands.

Trigger Source

The TRIGger:SOURce command selects the source for the trigger event. The

receipt of the GPIB interface message GET (Group Execute Trigger) or the

common command

trigger source.

TRG serves as the trigger event when BUS is selected as

*

RST

*

The trigger event is determined by the AC line voltage when LINE is selected, and

is derived from the input signal when INTernal is programmed as trigger source.

For the 2-channel CombiScope instruments, EXT e rnal can be programmed as the

trigger source. In that case, channel 4 is selected as external trigger input.

A numeric suffix is used to specify the channel number. For example,

TRIGger:SOURce INT2 selects the signal at input channel 2 to trigger the

acquisition.

When IMMediate is selected, an acquisition d oes not wait for a trigger event. So,

an INITiate command causes the acquisition to begin immediately. After a

command, the trigger source is IMMediate, which means no trigger is required.

Trigger Level

The TRIGger:LEVel command allows you to set the trigger level for all input

channels. Programming the trigger level automatically switches off level peakpeak. The trigger level can be programmed only when the TRIGger:SOURce is

INTernal. The TRIGger:LEVel:AUTO command allows you to switch level peakpeak on or off. Switching on level peak-peak, deactivates the trigger level. After a

RST command the TRIGger:LEVel is set to its maximum value and level peak-

*

peak is switched off.

RST

*

Page 40

USING THE COMBISCOPE INSTRUMENTS 3 - 21

Configures channel 2

Sets channel 2 ON

Trigger source = channel 2

Trigger level = 0.2 V

'The TRIGger:LEVel command also switches level peak-peak off.

Trigger slope = negative

Single initiation

Queries for peak-to-peak

Enters peak-to-peak

Prints peak-to-peak

Trigger Slope

The TRIGger:SLOPe command allows you to define the trigger ed ge for all input

channels, which can be POSitive, NEGative, or EITHer. After a

the TRIGger:SLOPe is set to POSitive.

RST command

*

PROGRAM EXAMPLE:

CALL Send(0, 8, "CONFigure:PTPeak (@2)", 1) ’

CALL Send(0, 8, "SENSe:FUNCtion 'XTIMe:VOLTage2'", 1)’

CALL Send(0, 8, "TRIGger:SOURce INTernal2", 1) ’

CALL Send(0, 8, "TRIGger:LEVel 0.2", 1) ’

CALL Send(0, 8, "TRIGger:SLOPe NEGative", 1) ’

CALL Send(0, 8, "INITiate", 1) ’

CALL Send(0, 8, "FETCh:PTPeak? (@2)", 1) ’

response$ = " "

CALL Receive(0, 8, response$, 256) ’

PRINT "Measured peak-to-peak = "; response$ ’

Trigger Coupling

The TRIGger:LPASs and TRIGger:HPASs commands allow you to select the

Main Time Base (MTB) trigger coup ling by pro gramming a fixed cutoff frequency.

The possible trigger coupling options

reject

High Frequency reject

, and

AC coupling, DC coupling, Low Frequency

are mutually exclusive. The TRIGger:LPASs

and TRIGger:HPASs commands are also mutually exclusive. So, activating the

Low-Pass filter will switch off the High-Pass filter, and vice versa. After a

command, the cutoff frequency is 10 Hertz, which selects trigger coupling AC.

RST

*

Note: When the trigger source is INTernal<n>, signal coupling for one input

channel (n) can be programmed to AC, DC, or GROund using the

INPut<n>:COUPling command.

Page 41

3 - 22 USING THE COMBISCOPE INSTRUMENTS

Sets CH2 on.

Sets CH2 input signal DC coupled.

Sets trigger source = CH2.

Sets Low-Pass filter on + cutoff frequency = 0 Hz;

this selects MTB trigger DC coupling.

Sets CH3 on.

Sets CH3 input signal AC coupled.

Sets trigger source = CH3.

Sets Low-Pass filter on + cutoff frequency = 0 Hz;

this selects MTB trigger DC coupling.

Sets cutoff frequency = 10 Hz; this selects

MTB trigger AC coupling.

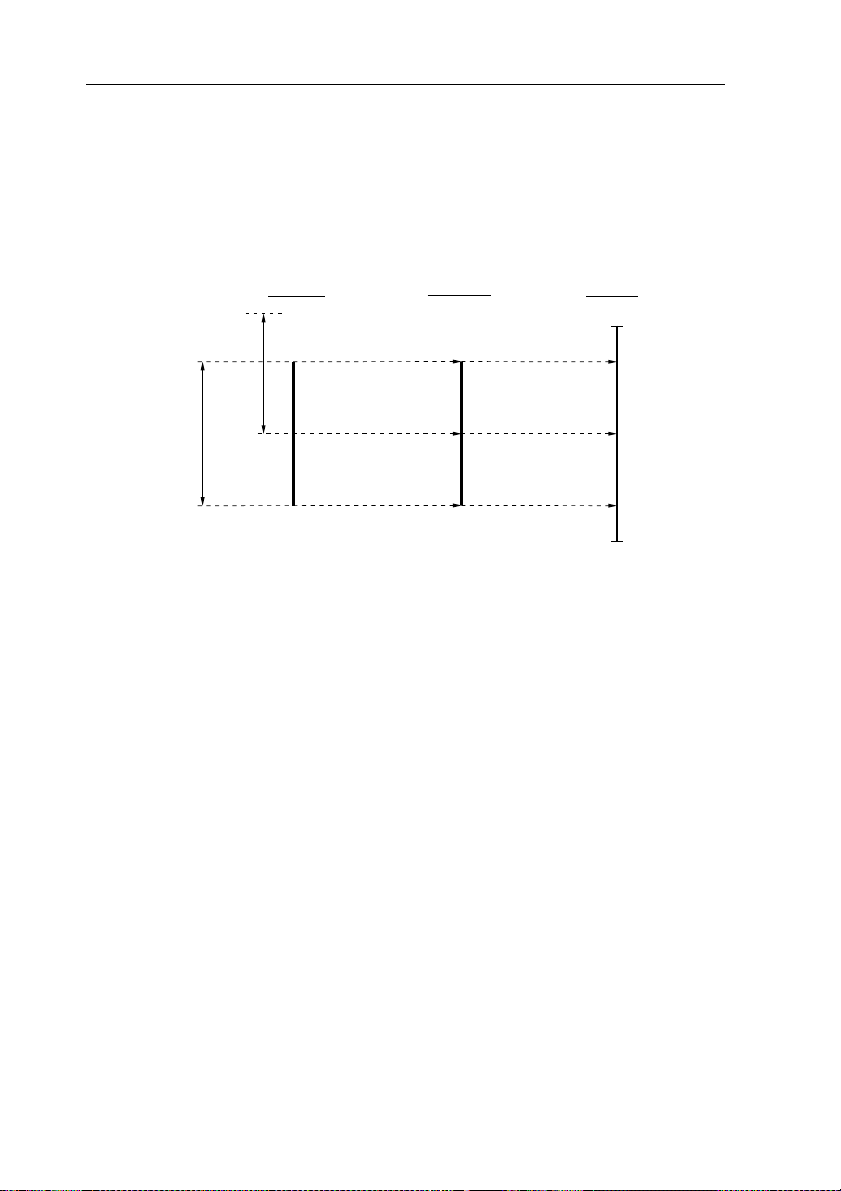

DC COUPLING (0 Hz cutoff frequency):

DC coupling causes the signal to be passed over

0dB

DC COUPLING-3dB

FULL BANDWIDTHDC

FREQ.

the full bandwidth (from 0 Hz to 60/100/200 MHz).

T7427

Figure 3.4 DC Coupling

PROGRAM EXAMPLE:

***

*** Select DC coupling on input signal channel 2.

SENSe:FUNCtion:ON "XTIMe:VOLTage2"

INPut2:COUPling DC

TRIGger:SOURce INTernal2

***

*** Select DC coupling on MTB triggering.

TRIGger:FILTer:LPASs:STATe ON

AC COUPLING (10 Hz cutoff frequency):

AC coupling causes the signal to be passed from

0dB

AC COUPLING-3dB

10 Hz to the full bandwidth frequency

(60/100/200 MHz).

FULL BANDWIDTH10Hz

FREQ.

Figure 3.5 AC Coupling

PROGRAM EXAMPLE:

***

*** Select AC coupling on input signal channel 3.

SENSe:FUNCtion:ON "XTIMe:VOLTage3"

INPut3:COUPling AC

TRIGger:SOURce INTernal3