Page 1

$XWRUDQJLQJ

&RPEL6FRSH

,QVWUXPHQW

30%30%30%

30%30%

I

Users Manual

2/1- Nov-1998

®

Page 2

II

IMPORTANT

In correspondence concerning this instrument plea se give the model number and

serial number as located on the type plate on the rear of the instrument.

NOTE: The design of this instrument is subject to continuous development and

improvement. Consequently, this instrument may incorporate minor

changes in detail from the information provided in this manual.

Fluke Corporation Fluke Industrial B.V.

P.O. Box 9090 P.O. Box 680

Everett WA 7600 AR Almelo

98206-9090, USA The Netherlands

Copyright 1997, 1998 Fluke Corporation

All rights reserved. No part of this manual may be reproduced by any means or in

any form without written permission of the copyright owner.

Printed in the Netherlands

Page 3

Thank you for purchasing this FLUKE oscilloscope. It has been designed and

manufactured to the highest quality standards to give you many yea rs of trouble

free and accurate measurements.

The powerful measuring functions listed below have been combined with an easy

and logical operation to let you use the full power of this instrument each and

every day.

If you have any comments on how this product could be improved, ple ase contact

your local FLUKE organization. FLUKE addresses are listed in the back of the

REFERENCE MANUAL.

III

The REFERENCE MANUAL also contains:

- CHARACTERISTICS AND SPECIFICA TIONS

- PRINCIPLES OF OPERATION

- BRIEF CHECKING PROCEDURE

- PERFORMANCE TEST PROCEDURES

- PREVENTIVE MAINTENANCE PROCEDURES

Page 4

IV

MAIN FEATURES

There are five models in this family of FLUKE oscilloscopes. Each of these

models is a combination of an analog real-time oscilloscope and a fully featured

digital storage oscilloscope. By pressing a single key , you can switch the

instrument from the analog mode to the digital mode and back. This allows each

of the units to be used in an optimum operating mode for all kinds of signal

conditions. Complex data streams, modulated waveforms, and video signals can

often best be seen in the analog mode of oper ation. The digital mode of operation

is more suited for single events, signals with low repetition freque ncies, and when

automatic measurements need to be performed.

In this family there is a choice of five models. Two models have a ban dwidth of

200 MHz, two have a bandwidth of 100 MHz and one has a bandwidth of 60 MHz.

Beside the 2 channel models with EXT TRIG input, there is a choice of two mode ls

with four fully featured channels, all shown in the following table:

Type Number Bandwidth Sample rate Number of

Channels

PM3370B

PM3380B

PM3384B

PM3390B

PM3394B

In the same instrument family, there are two 200-MHz and two 100-MHz analog

oscilloscopes that have specifications similar to the above-mentioned analog/

digital combination oscilloscopes operating in analog mode.

All analog/digital combination oscilloscopes listed above have the following features:

- Autoranging attenuators.

- Realtime clock.

- 32K sample acquisition memory in 4 channel versions.

- 8K sample acquisition memory, expandable to 32K in 2 channel versions.

- Up to 40 waveforms stored in memory or 204 waveforms with optional

memory extension.

- Autoset function for an instant optimized signal display at the touch of a button.

- Autoranging timebase.

- Cursor measurements with 1% accuracies.

- Extensive set of fully automated voltmeter and time measurement functions.

- Probe operated ’Touch Hold and Measure’ function freezes the display and

instantly displays the signal frequency, amplitude and dc voltage level.

60 MHz

100 MHz

100 MHz

200 MHz

200 MHz

200 MS/s

200 MS/s

200 MS/s

200 MS/s

200 MS/s

2

2

4

2

4

Input

Impedance

1 MΩ

1 MΩ

1 MΩ

1 MΩ/50Ω

1 MΩ/50Ω

Page 5

- Peak detection for the capture of glitches as narrow as 5 ns.

- Pattern, State and Glitch triggering (2 ns) (2 channel models; 4ns Glitch

triggering only)

- Event delay and pretriggering and posttriggering.

- TV triggering including HDTV and TV line selection.

- Serial interface for printing and plotting.

- Averaging to reduce signal noise and to increase the vertical resolution from

8 to 16 bits.

- Advanced mathematics, including digital low-pass filtering. A Math+ option

adds integration, differentiation, histogramming, and FFT.

- Sine interpolation and magnification which enables true to life four cha nnel

single shot acquisitions with a timebase up to 625 ns/div (32x magnified)

- A delayed timebase with full trigger features.

- An RS-232 (EIA-232-D) interface (standard) and an GPIB/IEEE-488 interface

(optional).

- Autocal for automatic fine tuning of all circuitry to achieve maximu m accuracy

under all user conditions.

- Closed case calibration for efficient maintenance of traceable calibration at

minimum cost.

The following options are available:

- A MATH+ option with more automated measurement functions including

envelope and measurement pass/fail testing. Also in cluded in this option are

Integration, Differentiation, Histogramming, and FFT.

- Memory extension offering 32K acquisition length and the ability to store 156

traces (of 512 samples each) in memory for 2 channel versions.

- IEEE-488.2 interface using the new SCPI (Standard Commands for

Programmable Instruments) industry standard for remote control of test and

measurement equipment.

V

Page 6

VI

INITIAL INSPECTION

Check the contents of the shipment for completeness and note whether any

damage has occurred during transport. When the conte nts are incomplete or

there is damage, file a claim with the carrier immediately. Then notify the FLUKE

Sales or Service organization to arrange for the repair or replacement of the

instrument or other parts. FLUKE addresses are listed in the back of the

REFERENCE MANUAL.

The following parts should be included in the shipment:

Service ordering number

or model number

1 Oscilloscope PM3370B, PM3380B or

PM3390B, PM3384B or

PM3394B

1 Front cover 5322 447 70121

1 Users Manual

1 Reference Manual

1 Line cord (European type) or 5322 321 21616

1 Line cord (North American type) or 5322 321 10446

1 Line cord (British type) or 5322 321 21617

1 Line cord (Swiss type) or 5322 321 21618

1 Line cord (Australian type) 5322 321 21781

2 Probes 10:1

2 Batteries AA (LR6)

1 Spare fuse 3.15 AT 4822 070 33152

(located inside fuse holder)

The performance of the instrument can be teste d by us ing the PERFORMANCE

TESTS in the REFERENCE MANUAL.

Page 7

VII

INSIDE THIS MANUAL

This operating guide contains information on all of the oscilloscope’s features. It

starts with a general introduction, a summary of main capabilities, initial

inspection note and a front and rear view.

Operators safety Chapter 1 should be read before unpacking,

installing, and operating the instrument.

Installation instructions Chapter 2 describes grounding, line cord, fuses,

and backup batteries.

Getting started Chapter 3 provides a 10-minute tutorial intended

for those who are not familiar with Fluke

oscilloscopes.

How to use more advanced Chapter 4 provides the more experienced user

functions of the instrument with a detailed explanation of the major functions

of the oscilloscope.

Function reference Chapter 5 contains an alphabetized description of

each function. Each description includes an

explanation of local and remote control functions.

CPL protocol Chapter 6 provides the CPL commands with an

example of each.

Function index The Function Index lists all implemented

functions in alphabetical order.

Index The overall index contains all function names

and reference words in alphabetical order. It

includes the relevant chapter and page number

where more detailed information can be found.

IN THE APPENDICES

Menu structures

RS-232 Cable configurations

Page 8

VIII CONTENTS

CONTENTS

1 OPERATORS SAFETY

1.1 INTRODUCTION

1.2 SAFETY PRECAUTIONS

1.3 CAUTION AND WARNING STATEMENTS

1.4 SYMBOLS

1.5 IMPAIRED SAFETY PROTECTION

1.6 MEASURING EARTH

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

. . . . . . . . . . . . . . . . . . . . . . . . 1-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 INSTALLATION INSTRUCTIONS

2.1 SAFETY INSTRUCTIONS

2.1.1 Protective earthing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Mains voltage cord, mains voltage range and fuses . . . . . 2-1

2.2 MEMORY BACK-UP BATTERIES

2.2.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.2 Installation of batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 THE FRONT COVER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

. . . . . . . . . . . . . . . . . . . . . . . . . 2-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Page

. . . . . . . . . . . . . . . . . . 1-1

. . . . . . . . . . . . . . . . . . . . . 2-1

2.4 HANDLE ADJUSTMENT AND OPERATING

POSITIONS OF THE INSTRUMENT

2.5 IEEE 488.2/IEC 625 BUS INTERFACE OPTION

2.6 RS-232-C SERIAL INTERFACE

2.7 RACK MOUNTING

2.8 VERSIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

. . . . . . . . . . . . . . . . . . . . . . . . 2-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

. . . . . . . . . . . . . . 2-4

Page 9

CONTENTS IX

3 GETTING STARTED

3.1 FRONT-PANEL LAYOUT

3.2 SWITCHING ON THE INSTRUMENT

3.3 SCREEN CONTROLS

3.4 AUTO SETUP

3.5 MODE SWITCHING BETWEEN ANALOG AND

DIGITAL OPERATING MODES

3.6 VERTICAL SETUP

3.7 TIMEBASE SETUP

3.8 MAGNIFY (EXPAND)

3.9 DIRECT TRIGGER SETUP

3.10 PRE-TRIGGER VIEW

3.11 MORE ADVANCED FEATURES

3.12 CURSOR OPERATION

3.13 MORE ADVANCED TRIGGER FUNCTIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

. . . . . . . . . . . . . . . . . . . . . . . 3-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

. . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

. . . . . . . . . . . . . . . . 3-19

3.14 MORE SIGNAL DETAIL WITH THE DELAYED TIMEBASE

3.15 TRACE STORAGE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

4 H OW TO USE MORE ADVANCED FUNCTIONS

OF THE INSTRUMENT

4.1 INTRODUCTION

4.2 DISPLAY AND PROBE ADJUSTMENTS

4.3 ANALOG AND DIGITAL MODES

4.4 VERTICAL DEFLECTION

4.5 HORIZONTAL DEFLECTION AND TRIGGERING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

. . . . . . . . . . . . . . . . . . . . 4-5

. . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

. . . . . . . . . . . . 4-22

. . . . 3-20

Page 10

XCONTENTS

4.6 DIGITAL ACQUISITION AND STORAGE . . . . . . . . . . . . . . . . . . . 4-30

4.7 ADVANCED VERTICAL FUNCTIONS . . . . . . . . . . . . . . . . . . . . . 4-31

4.8 ADVANCED HORIZONTAL AND TRIGGER FUNCTIONS . . . . . 4-34

4.9 MEMORY FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

4.10 CURSORS FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

4.11 MEASUREMENT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

4.12 PROCESSING FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

4.13 DISPLAY FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

4.14 DELAYED TIMEBASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

4.15 HARD COPY FACILITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-68

4.16 AUTOSET AND SETUP UTILITIES . . . . . . . . . . . . . . . . . . . . . . . 4-71

4.17 OTHER FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

5 FUNCTION REFERENCE

6 THE CPL PROTOCOL

6.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 EXAMPLE PROGRAM FRAME . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3 COMMANDS IN FUNCTIONAL ORDER . . . . . . . . . . . . . . . . . . . . . 6-4

6.4 COMMANDS IN ALPHABETICAL ORDER . . . . . . . . . . . . . . . . . . 6-5

6.5 COMMAND REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.6 ACKNOWLEDGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-47

6.7 STATUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-48

6.8 SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-50

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Page 11

CONTENTS XI

Appendix A ACQUIRE menu structure . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B CURSORS menu structure . . . . . . . . . . . . . . . . . . . . . B-1

Appendix C DISPLAY menu structured . . . . . . . . . . . . . . . . . . . . C-11

Appendix D MATHEMATICS menu structure . . . . . . . . . . . . . . . . . D-1

Appendix E MEASURE menu structure . . . . . . . . . . . . . . . . . . . . . E-1

Appendix F DTB (DEL’D TB) menu structure . . . . . . . . . . . . . . . . F-1

Appendix G SAVE/RECALL menu structure . . . . . . . . . . . . . . . . . G-1

Appendix H SETUPS menu structure . . . . . . . . . . . . . . . . . . . . . . . H-1

Appendix J TB MODE menu structure . . . . . . . . . . . . . . . . . . . . . . . J-1

Appendix K TRIGGER menu structure . . . . . . . . . . . . . . . . . . . . . . K-1

Appendix L UTILITY menu structure . . . . . . . . . . . . . . . . . . . . . . . . L-1

Appendix M VERTICAL menu structure . . . . . . . . . . . . . . . . . . . . . M-1

Appendix N RS-232 Cable configurations . . . . . . . . . . . . . . . . . . . N-1

Appendix P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

FUNCTION INDEX (see Chapter 5)

INDEX

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-3

. . . . . . . . . . . . . . . . . . . . . . I-1

Page 12

XII

FRONT VIEW

REAR VIEW

Page 13

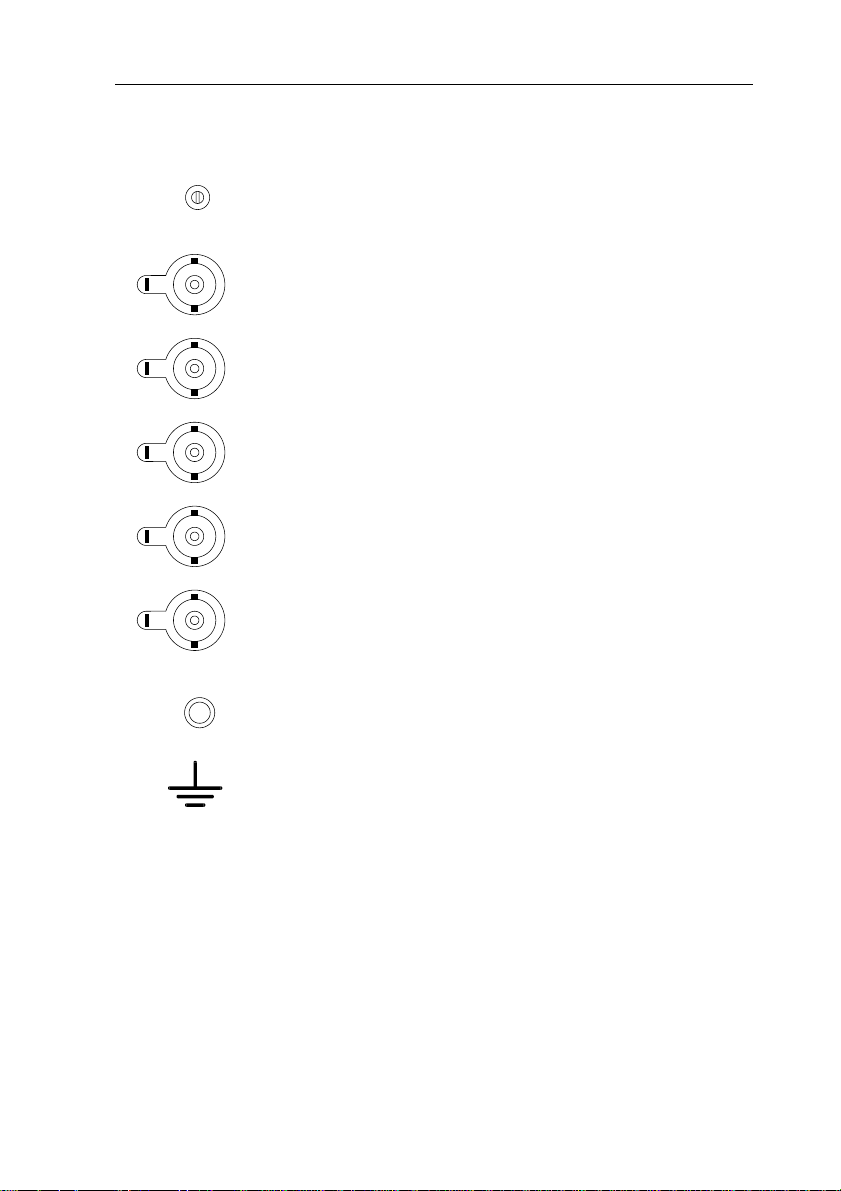

FRONT PANEL CONNECTIONS

Probe Adjust

Squarewave output signal for e.g. probe calibration.

Amplitude is calibrated.

CH1

BNC input socket for vertical channel 1 with probe

indication contact.

CH2

BNC input socket for vertical channel 2 with probe

indication contact.

CH3

BNC input socket for vertical channel 1 with probe

indication contact. (only in 4 channel models)

CH4

BNC input socket for vertical channel 1 with probe

indication contact. (only in 4 channel models)

EXT TRIG

BNC input socket used as an extra external trigger

input with probe indication contact (only in 2 channel

models)

XIII

Ground socket (banana): same potential as safety

ground.

The measuring ground socket and the external

conductor of the BNC sockets are internally

connected to the protective earth conductor of the

three-core mains cable. The measuring ground

socket or the external conductor of the BNC-sockets

must not be used as a protective conductor terminal.

Page 14

XIV

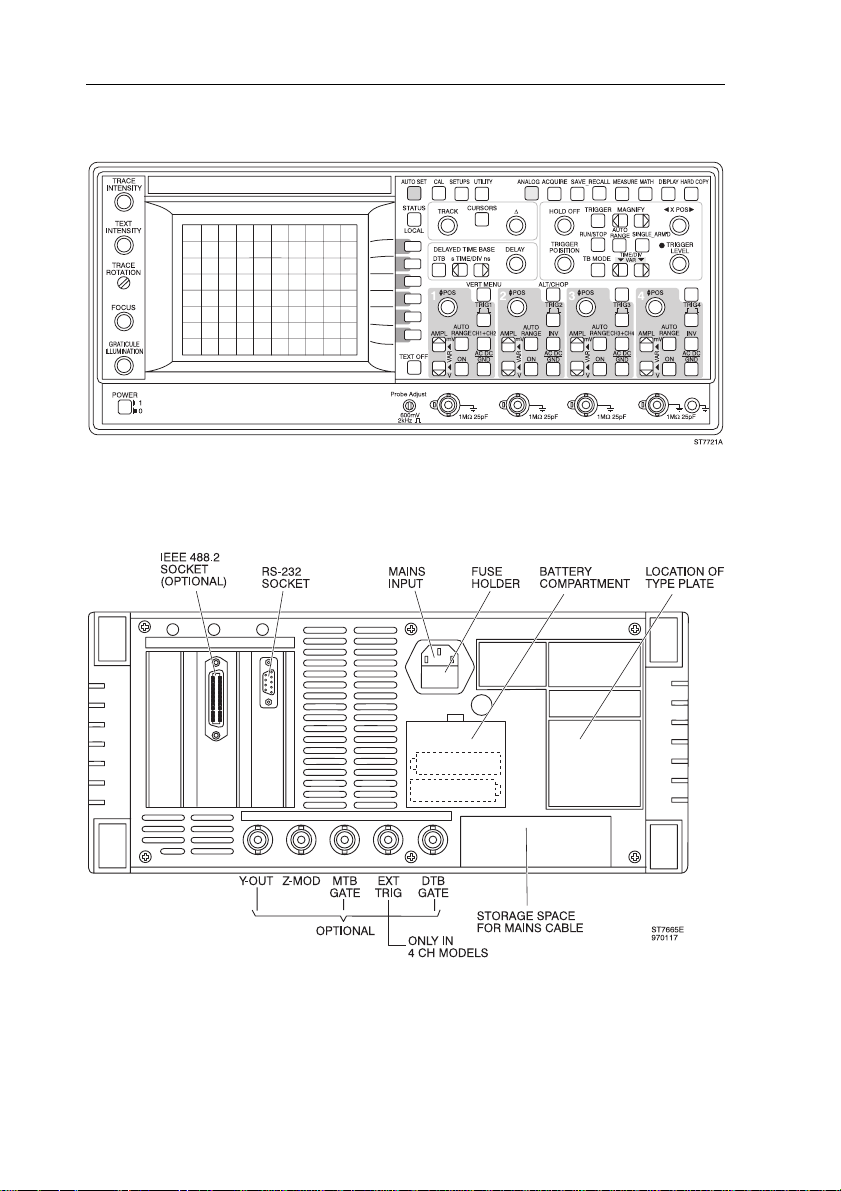

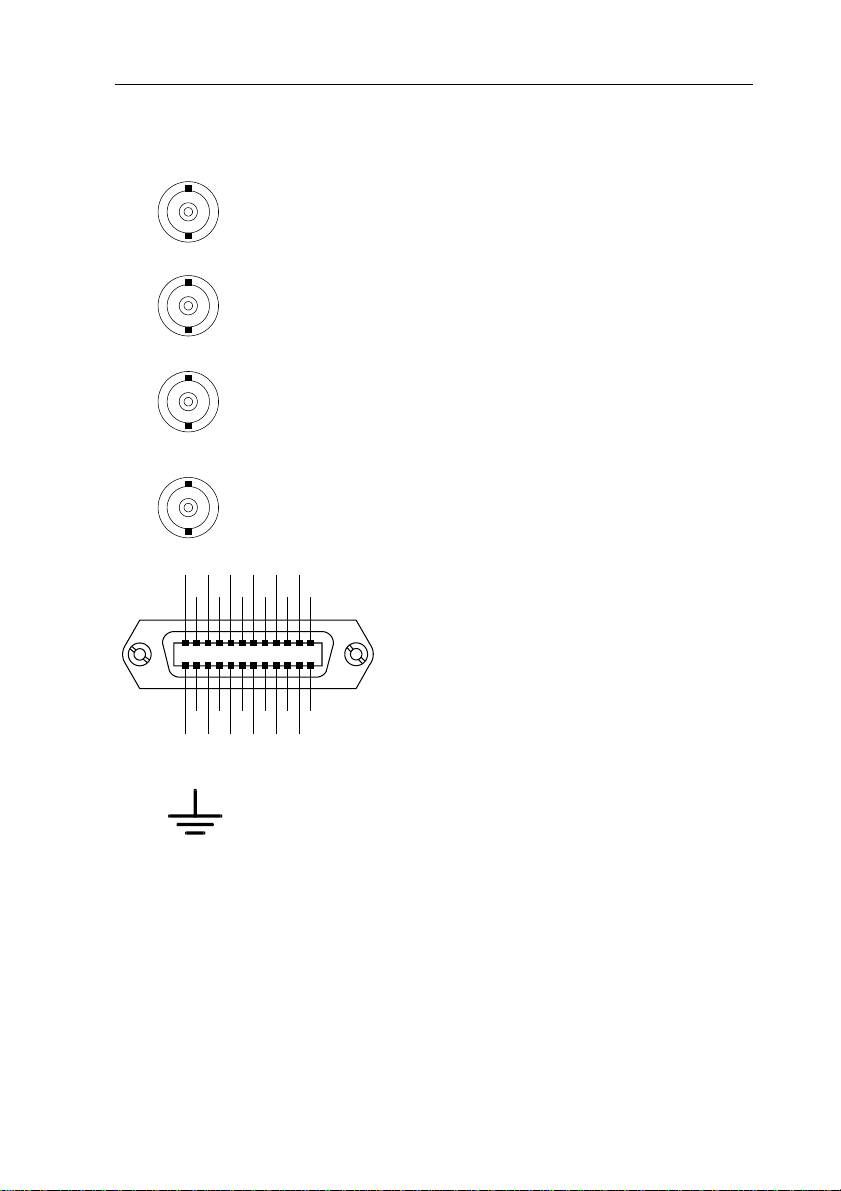

REAR PANEL CONNECTIONS

Z-MOD

BNC input socket for external intensity-modulation

of the CRT trace.

NC

TXD

RXD

DTR

RS-232 BUS (EIA-232-D)

Input/output socket to connect the oscilloscope to an

RS-232 Interface.

LINE IN

Line input socket. Fuse holder is built in.

RTS

5

9

NC

CTS

ST6065

1

6

DSR

NC=NOT CONNECTED

FUSE

Page 15

OPTIONAL REAR PANEL CONN ECTIONS

CH1 Y-OUT

BNC output socket with a signal derived from the

Channel 1 input signal.

MAIN TB GATE

BNC output socket with a signal that is "high" when

the Main Timebase i s running and "low" for the other

conditions.

DTB GATE

BNC output socket with a signal that is "high" when

the Delayed Timebase is running and "low" for the

other conditions.

EXT TRIG (only in 4 channel models)

BNC input socket used as an extra external trigger

input for the Main Timebase

DIO4

SHIELD

12

24

LOGIC

GND

SRQ

IFC

ATN

GND11GND

GND

10

NDAC

GND

9

GND8GND

DIO2

DAV

NR

EO1

DIO3

FD

DIO1

1

13

IEEE 488.2 BUS OPTION

If installed you will find here the input/output

socket to connect the oscilloscope to an

IEEE 488 interface.

DIO7

REN

7

DIO5

DIO6

DIO8

6

ST6064

XV

The external conductor of the BNC sockets

and the screening of the interface bus

connectors are internally connected to the

protective earth conductor of the three-core

mains cable. The external conductor of the

BNC sockets and the screening of the

interface bus connectors must not be used as

a protective conductor terminal.

Page 16

OPERATORS SAFETY 1 - 1

1 OPERATORS SAFETY

ATTENTION: The instrument is designed for indoor use only.

Read this page carefully before installation and use of the

instrument.

1.1 INTRODUCTION

The instrument described in this manual is designed to be used by proper-lytrained personnel only. Adjustment, maintenance and repair of the exposed

equipment shall be carried out only by qualified personnel.

1.2 SAFETY PRECAUTIONS

For the correct and safe use of this instrument it is essential that both operating

and service personnel follow generally-accepted safe ty procedures in addition to

the safety precautions specified in this manual. Specific warning and caution

statements, where they apply, will be found throughout the manual. Where

necessary, the warning and caution statements and/or symbols are marked on

the apparatus.

1.3 CAUTION AND WARNING STATEMENTS

CAUTION: Is used to indicate correct operating or maintenance

procedures in order to prevent damage to or destruction of the

equipment or other property.

WARNING: Calls attention to a potential danger that requires correct

procedures or practices in order to prevent personal injury.

Page 17

1 - 2 OPERATORS SAFETY

1.4 SYMBOLS

Read the safety information in the manual.

Earth.

Conformité Européenne.

Recycling information.

1.5 IMPAIRED SAFETY PROTECTION

The use of the instrument in a manner not specified may impair the protection

provided by the equipment. Before use, inspect the instrument and accessories

for mechanical damage!

Whenever it is likely that safety-protection has been impaired, the instrument

must be made inoperative and be secured against any unintended op eration. The

matter should then be referred to qualified technicians. Safe ty prote ction i s likely

to be impaired when, for example, the instrument fails to perform the intended

measurements or shows visible damage.

1.6 MEASURING EARTH

The measuring earth socket and the external conductor of the BNC sockets are

internally connected to the protective earth conductor of the three-core mains

cable. The measuring earth socket or the external condu ctor of the BNC-sockets

must not be used to connect a protective conductor.

Page 18

INSTALLATION INSTRUCTIONS 2 - 1

2 INSTALLATION INSTRUCTIONS

Attention: You are strongly advised to read this chapter thoroughly before

installing your oscilloscope.

2.1 SAFETY INSTRUCTIONS

2.1.1 Protective earthing

Before any connection to the input connectors is made, the instrument shall be

connected to a protective earth conductor via the three-core mains cable; the

mains plug shall be inserted only into a socket outlet provided with a protective

earth contact. The protective action shall not be negated by the use of an

extension cord without protective conductor.

WARNING: Any interruption of the protective conductor inside or outside

the instrument is likely to make the instrument dangerous.

Intentional interruption is prohibited.

WARNING: When an instrument is brought from a cold into a warm

environment, condensation may cause a hazardous

condition. Therefore, make sure that the grounding

requirements are strictly adhered to.

2.1.2 Mains voltage cord, mains voltage range and fuses

Before inserting the mains plug into the mains socket, make sure that the

instrument is suitable for the local mains voltage.

NOTE: When the mains plug has to be adapted to the local situat io n , such

adaption should be done by a qualified technician only.

WARNING: The instrument shall be disconnected from all voltage

sources when a fuse is to be renewed.

The oscilloscope has a tapless switched-mode power supply that covers most

nominal voltage ranges in use: ac voltages from 100 ... 240 V (r.m.s.). This

obviates the need to adapt to the local mains (line) voltage. The nominal mains

(line) frequency range is 50 Hz ... 400 Hz.

Line fuse rating: 3.15 A T dela yed action, 250 V ( for ordering code see

"INITIAL INSPECTION").

Page 19

2 - 2 INSTALLATION INSTRUCTIONS

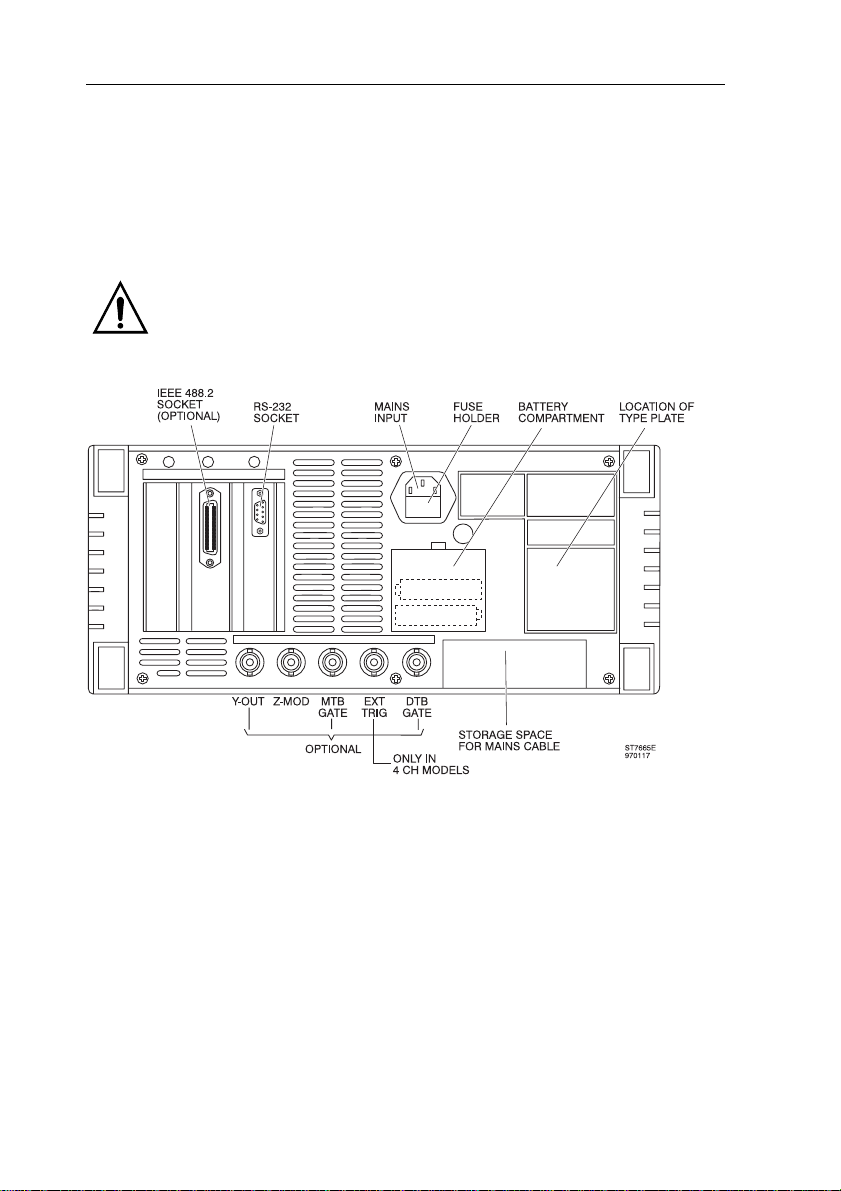

The mains (line) fuseholder is located on the rear panel in the mains (line) input

socket. When the mains (line) fuse needs replacing, proceed as follows:

- disconnect the oscilloscope from the mains (line).

- remove the cover of the fuseholder by means of a small screwdriver.

- fit a new fuse of the correct rating and refit the cover of the fuseholder.

WARNING: Make sure that only fuses with the required rated current and

of the specified type are used for replacement. The use of

makeshift fuses and the short-circuiting of fuse holders are

prohibited.

REAR VIEW

Figure 2.1 Rear view of the instrument showing the mains input/fuse-holder

and back-up battery compartment.

When the apparatus is connected to its supply, terminals may be live, and the

opening of covers or removal of parts (except those to which access can be

gained by hand) is likely to expose live parts.

The apparatus shall be disconnected from all voltage so urces before it is opened

for any replacement, maintenance or repair.

Capacitors inside the apparatus may still be charged even when the apparatus

has been disconnected from all voltage sources.

Any maintenance and repair of the opened apparatus under voltage shall be

avoided as far as possible and, when inevitable, shall be carried out only by a

skilled person who is aware of the hazard involved.

Page 20

INSTALLATION INSTRUCTIONS 2 - 3

2.2 MEMORY BACK-UP BATTERIES

2.2.1 General information

Memory backup is provided to store the oscilloscope’ s settings when switched off

so that the instrument returns to the same settings when turned on. T wo AA (LR6)

Alkaline batteries are used.

Note: The batteries are not factory installed and must be installed at the

customer’s site.

Note: This instrument contains batteries. Do not dispose of these batteries with

other solid waste. Used batteries should be disposed of by a qualified

recycler or hazardous materials handler. Contact your authorized Fluke

Service Center for recycling information.

2.2.2 Installation of batteries

Proceed as follows:

- Remove all input signals and disconnect the instrument line power.

- Remove the plastic cover of the battery compartment so that the battery

holder becomes accessible.

- Install two penlight batteries (AA) in the battery holder as indicated on the

battery holder.

- Reinstall the cover of the battery compartment.

Note: Frontsettings and autocalibration data disappear after exchange of the

batteries with the instrument disconnected from the line power. After

battery exchange, it is necessery to press the CAL key after the

recommended warming up time.

CAUTION: Never leave the batteries in the oscilloscope at ambient temper-

atures outside the rated range of the battery specifications because of possible damage that may be caused to the

instrument. T o avoid batt ery damage, do not leave the bat teries

in the oscilloscope when it is stored longer than 30 days.

2.3 THE FRONT COVER

For ease of removal and reinstallation, the front cover has been designed to snap

on to the front of the instrument.

The front can be removed as follows:

- Fold the carrying handle down so that the oscilloscope occupies a sloping

position (refer to Chapter 2.4 for how to proceed).

- Pull the clamping lip at the top side of the cover slightly outwards.

- Lift the cover off the instrument.

Page 21

2 - 4 INSTALLATION INSTRUCTIONS

2.4 HANDLE ADJUSTMENT AND OPERATING

POSITIONS OF THE INSTRUMENT

By pulling both handle ends outwards away from the instrument, the handle can

be rotated to allow the following instrument positions:

- vertical position on its rear feet;

- horizontal position on its bottom feet;

- in three sloping positions on its handle.

The characteristics mentioned in the REFERENCE MANUAL are guaran teed for

the specified positions or when the handle is folded down.

CAUTION: To avoid overheating, ensure that the ventilation holes in the

covers are free of obstruction. Do not position the instrument

in direct sunlight or on any surface that produces or radiates

heat.

In the rear panel of the instrument there is storage space for the mains cable.

There is also a clamping device to fix the end of the mains cable to the re ar panel.

The mains plug then fits in the area where the RS232 co nnector is present. In this

way the instrument can also stand on its rear feet.

MAT4221

Figure 2.2 Instrument positions

2.5 IEEE 488.2/IEC 625 BUS INTERFACE OPTION

If your oscilloscope is equipped with the IEEE 488.2 interface, it can be used in a

bus system configuration. The protocol used is SCPI (Standard Commands for

Programmable Instruments). For setup information, refer to the function

REMOTE CONTROL IEEE 488.2 in Chapter 5.

The IEEE 488.2 interface is a factory-installed op tio n.

Page 22

INSTALLATION INSTRUCTIONS 2 - 5

2.6 RS-232-C SERIAL INTERFACE

Your oscilloscope is equipped with an RS-232-C interface as standard. The

interface can be used in a system for serial communication. The protocol used is

CPL (Compact Programming Language). CPL is a small set of very powerful

commands that can be used for full remote control. Detailed information about this

interface and the CPL protocol is given in Chapter 6 in this manual. For setup

information, refer to the REMOTE CONTROL RS-232 function in Chapter 5

’Function Reference’.

2.7 RACK MOUNTING

The rackmount kit (PM 8960/04) allows you to install the oscilloscope in a

standard 19 inch rack.

It is not necessary to open the oscilloscope itself to mount the rackmount kit.

Installation can be done easily by the user.

2.8 VERSIONS

The model number of your oscilloscope (e.g. PM33...) is indicated on the text strip

above the CRT. This model number is also represented by the digits 6, 7, 8 and 9

of the 12- digit code on the type plate on the rear panel. The ’A’ or ’B’ series is

indicated by a 1 or 2 on the 5th digit.

The instrument’s serial number is also given on the type plate. This numbe r

consists of a six digit code preceeded by the characters ’DM’.

The instrument version can also be displayed on the CRT after having pressed

menu key UTILITY and then softkey MAINTENANCE.

Page 23

GETTING STARTED 3 - 1

3 GETTING STARTED

This chapter provides a 10-minute tutorial intended for those who are not familiar

with Fluke oscilloscopes. Those who are already fami liar can skip this chapter and

continue to Chapter 4.

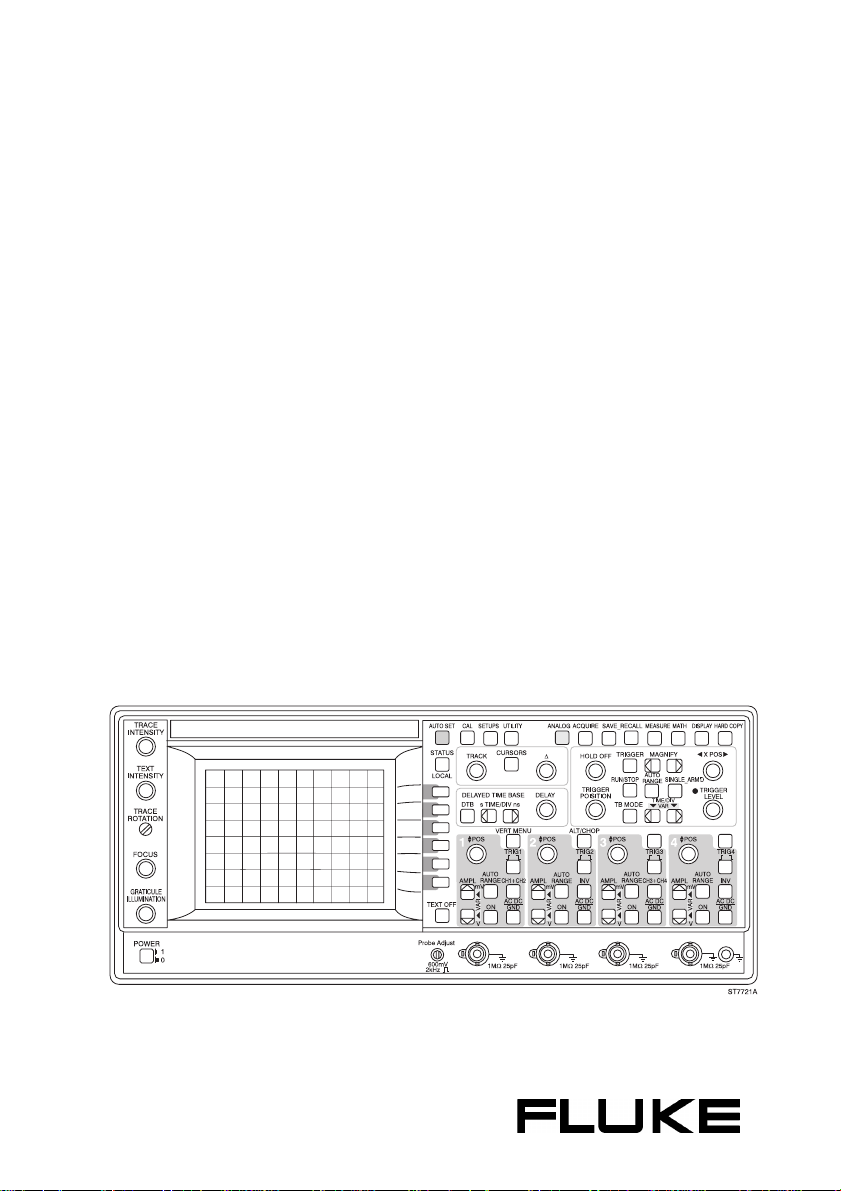

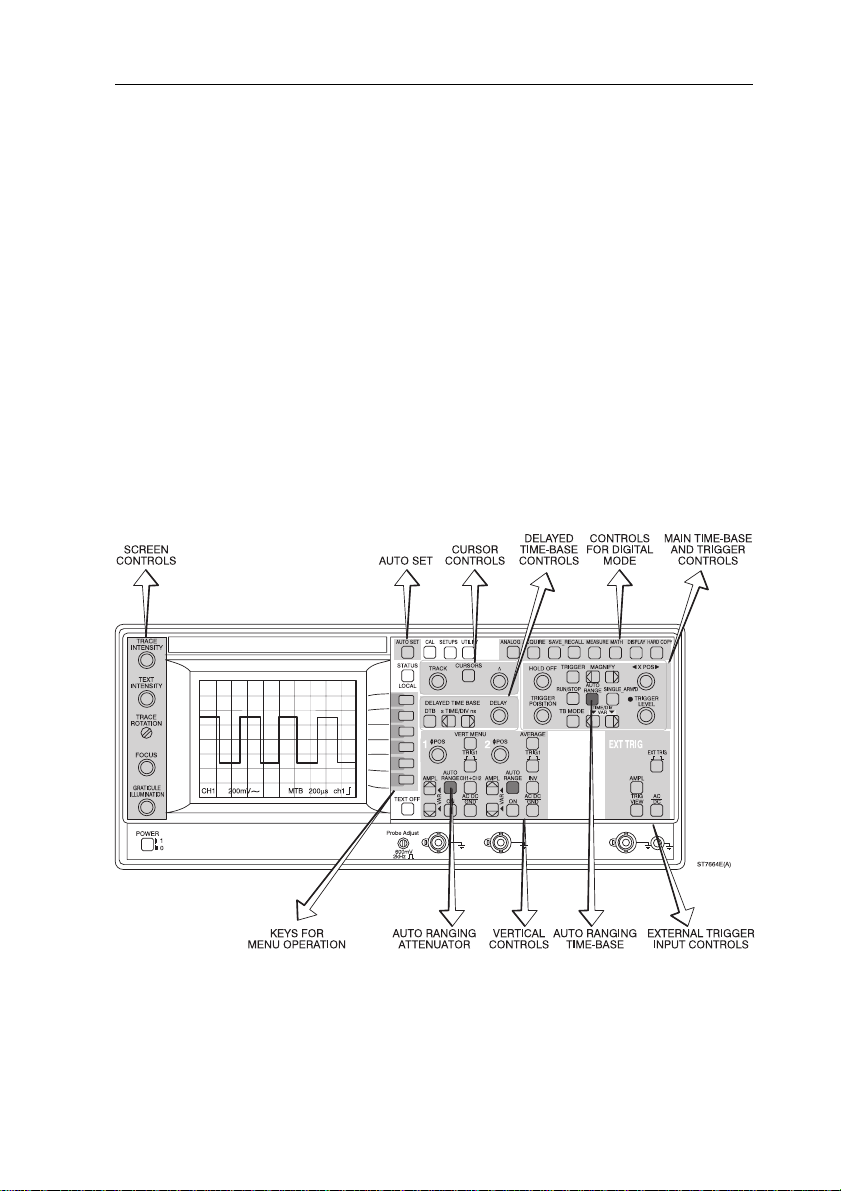

3.1 FRONT-PANEL LAYOUT

This oscilloscope is a combination of an analog oscilloscope and a digital storage

oscilloscope in the same instrument. The basic signal acquisition and display

functions are identical in both operating modes. Differences will be explained in

the text. Switching between the two operating modes is done with the yellow

ANALOG key.

The front panel of the oscilloscope is organized into functional areas. The areas

are discussed in order of typical operation.

Figure 3.1 Front panel layout

Note that the front panel shown is that with the most functions. Differences are

explained in Section 4.1. For this getting started procedure, only CH1 and CH2

are used. These are identical for all models.

Page 24

3 - 2 GETTING STARTED

Typical operation of your instrument will be:

- Switching on the instrument (see Section 3.2)

- Initial standard setup (see Section 3.2)

- Screen controls (see Section 3.3)

- Auto setup (see Section 3.4)

- Analog-Digital mode switching (see Section 3.5)

- Vertical setup (see Section 3.6)

- Timebase setup (see Section 3.7)

- Magnify (Expand) (see Section 3.8)

- Direct trigger setup (see Section 3.9)

- Pretrigger view (see Section 3.10)

- More advanced features (see Section 3.11)

- Cursor operation (see Section 3.12)

- More advanced trigger functions (see Section 3.13)

- More signal detail with the DTB (see Section 3.14)

- Trace storage (see Section 3.15)

3.2 SWITCHING ON THE INSTRUMENT

Connect the power cord and set the front panel power switch to ON. For any line

source between 100V to 240V nominal, 50/400 Hz, the instrument auto matically

turns on. After performing the built-in power-up routine, the instrument is

immediately ready for use. The instrument’s settings will be identical to those

when the oscilloscope was switched off (with the batteries installed).

To ensure that you will get the same setup in all cases, press the

and

TEXT OFF

default condition (STANDARD SETUP) and a trace will appear on the screen.

Text is also displayed at the bottom of the screen.

key simultaneously. This will set the instrument in a predefined

STATUS

key

Page 25

GETTING STARTED 3 - 3

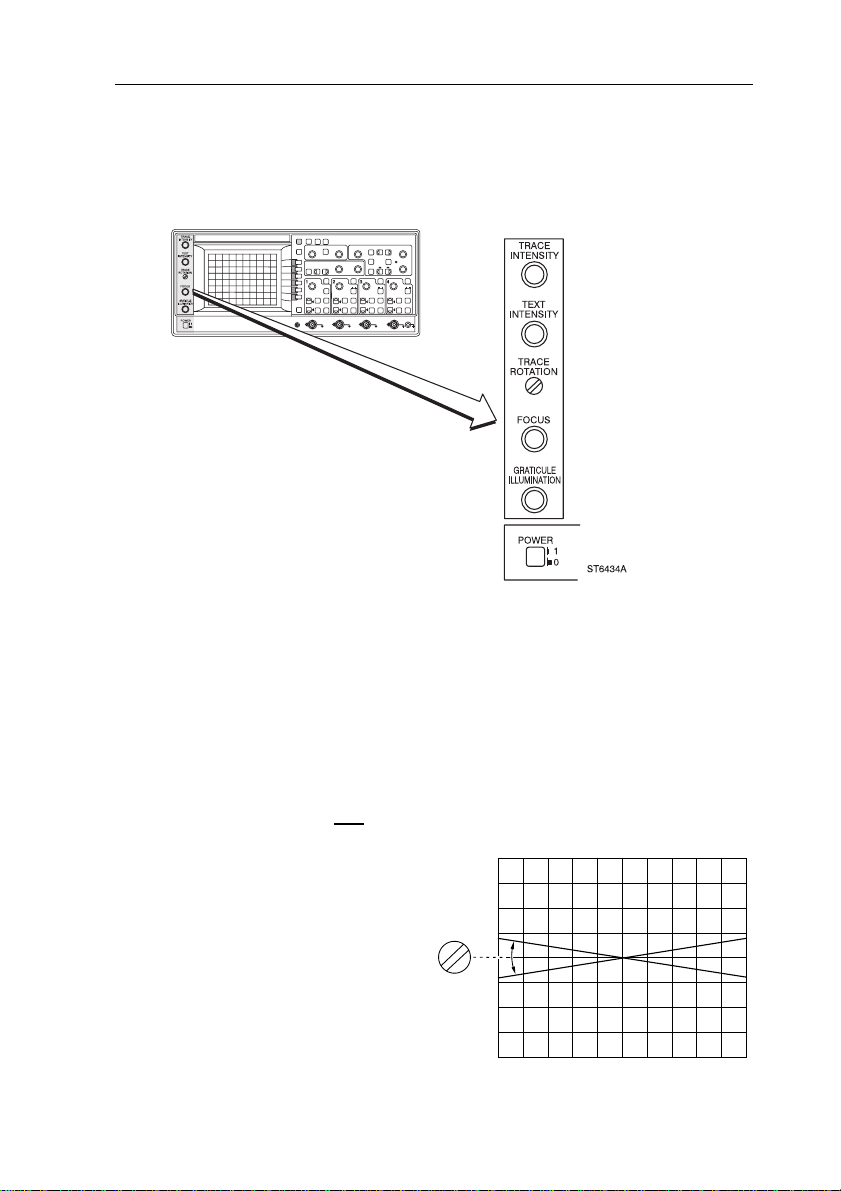

3.3 SCREEN CONTROLS

The screen controls can be adjusted for optimum trace, text and spot quality by

the controls to the left of the screen.

Figure 3.2 Screen control area

The brightness on the screen is adjusted by two controls, one for the trace and

one for the text.

• Turn the

TRACE INTENSITY

control clockwise and verify that only the

brightness of the trace increases.

• Turn the

TEXT INTENSITY

control clockwise and verify that only the

brightness of the text increases.

The sharpness of the trace and

text is optimized by the

When you are making photographs

or are in a dark environment, you

can use the

ILLUMINATION

control

to illuminate the graticule of the

screen.

The trace is adjusted in parallel with

the horizontal graticule lines by the

screwdriver-controlled

ROTATION

control.

TRACE

TRACE

ROTATION

FOCUS

control.

ST5975

9303

Page 26

3 - 4 GETTING STARTED

3.4 AUTO SETUP

The best way to start each measurement is by using the AUTOSET key. This

automatically

finds and scales all relevant parameters on all channels.

AUTO SET

1

23

4

ST6659

9303

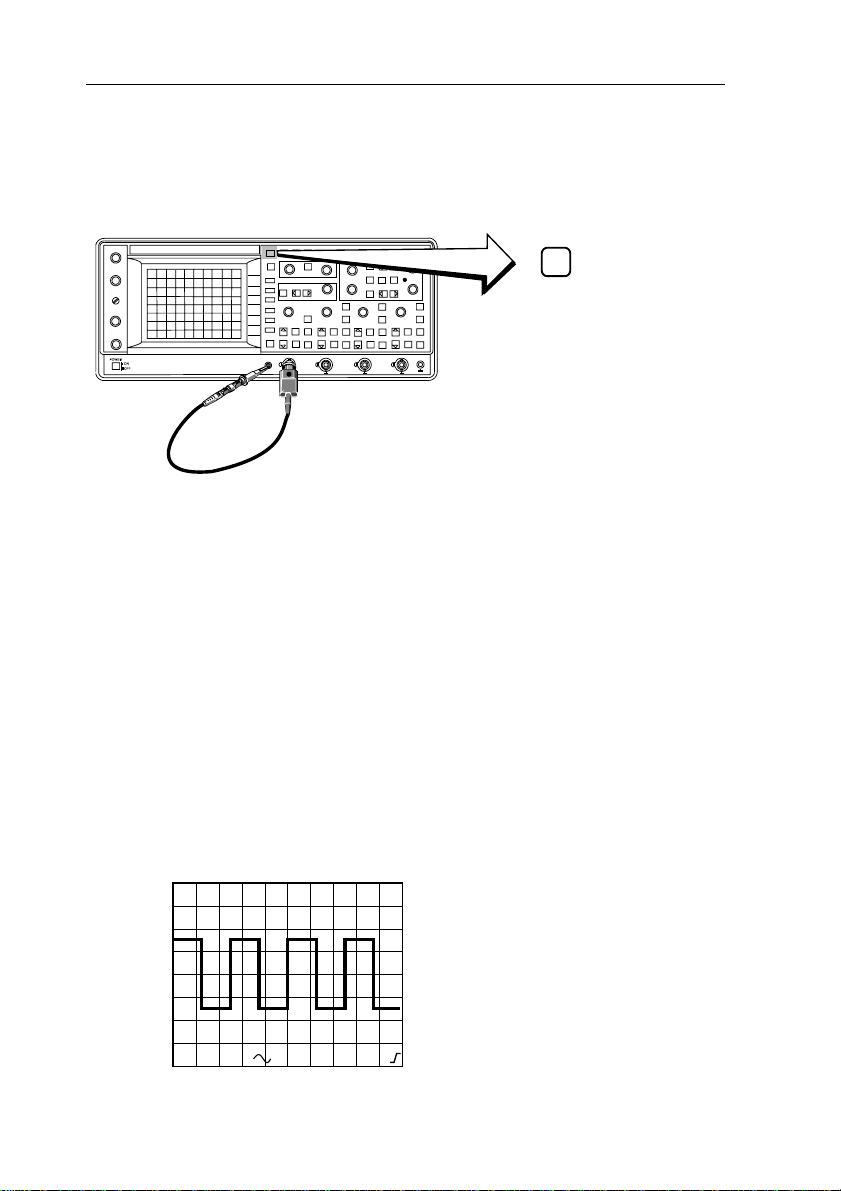

Figure 3.3 Measuring setup

Step 1 Connect the probe as shown in figure 3.3.

NOTE: AUTOSET is programmable. Because you have set the instrument in the

"standard setup" before (see Section 3.2), all programmable features are

set to a predefined condition an d the instrument is set in the analog mode .

Programming of AUTOSET is explained in Chapte rs 4 and 5.

Step 2 Press the

AUTOSET

key.

The scope flashes the message ’AUTO SETTING...’ on the screen. In

a few seconds the front-panel settings are adjusted for an optimized

display of the applied signal in the analog mode.

Step 3 The calibration signal is clearly displayed.

The parameters of the channel and the timebase settings are

displayed at the bottom of the screen.

CH1

200mV

MTB 200µs

CH1

ST6704

Page 27

GETTING STARTED 3 - 5

Step 4 To prevent measurement errors, check the pulse response before any

measurement. If the pulse shows overshoot or undershoot, you can

correct this by using the trimmer in the probe’s body. Chapter 4

describes how to adjust the pulse response.

ST5952

In most cases, using AUTO SETUP is sufficient for a good initial display of the

signal(s). After the initial AUTOSET, and to optimize the signal for a more detailed

view, continue with the paragraphs below.

NOTE: If you get lost when adjusting your instrument, just press AUTOSET.

Page 28

3 - 6 GETTING STARTED

3.5 MODE SWITCHING BETWEEN ANALOG AND

DIGITAL OPERATING MODES

Y ou can use the yellow ANALOG key to switch from the analog mode to the digital

mode and back at any time. The signal acquisition and display functions of both

operating modes are very similar. However, the nature of the signals you are

using may determine which operating mode you prefer to use. For more

information, refer to the following table:

SIGNAL CRITERIA ANALOG MODE DIGITAL MODE

Repetitive signals of Usable Usable

30 Hz and higher

Repetitive signals Causes display Preferred

below 30 Hz flickering

Single events Displayed for the Can capture and

duration of display for long

the event term display

Repetitive signals that are Preferred May cause alaising

amplitude modulated Use Peak detect or

Envelope mode

Repetitive signals that Preferred May cause aliasing.

are modulated in frequency Use Envelope mode.

Long serial data streams Preferred when When using delayed

Delayed sweep sweep to observe

is not used. details, Digital mode

provides better

light output.

Video signals Preferred when When using delayed

Delayed sweep sweep to observe

is not used. details, Digital mode

provides better

light output.

OTHER CRITERIA

Need to see pretrigger Not possible Up to full acq uisition

information length

Page 29

GETTING STARTED 3 - 7

SIGNAL CRITERIA ANALOG MODE DIGITAL MODE

You need to make adjustments Fastest Slower

to the circuitry and watch display display

the signal change update update

Automatic measurements Can’t use Fully implemented

Signal Math Add, Subtract All functions

Add, Subtract, Multiply

Signal Analysis Not available Full analysis

Integration, (optional)

Differentiation, FFT

Automatic Pass/Fail test Not available Fully implemented

(optional)

Autorange attenuator Not available Results in a displayed

signal with an amplitude of 2 to 6.4 divisions

Autorange timebase Not available Results in a signal

display of 2 to 6

waveform periods

ANALOG

1

23

4

RUN/STOP

ST6680

9312

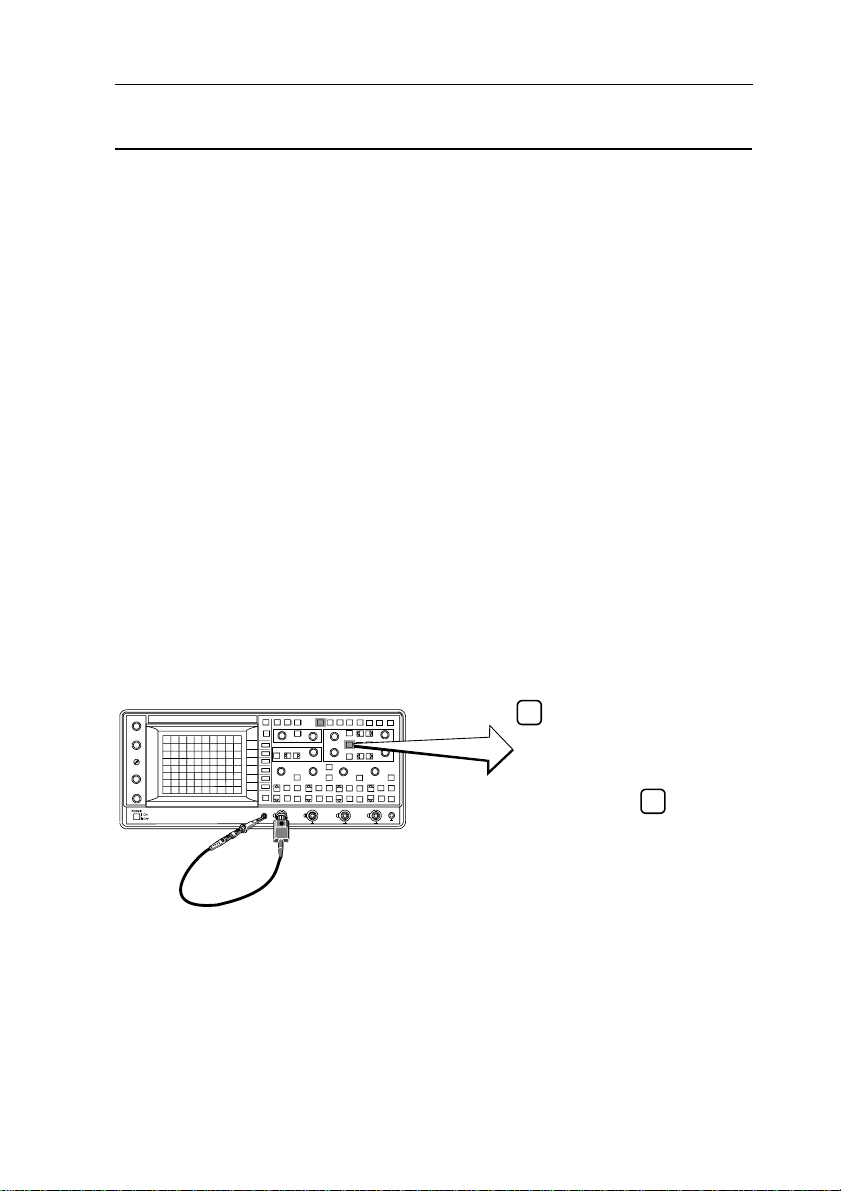

Figure 3.4 Analog-Digital switching setup

Step 1 Press AUTOSET. The scope performs an AUTOSET in analog mode.

Step 2 Press the ANALOG key to change over to the digital mode. Check that

the picture is identical to the one in the analog mode. The text ’DIGIT AL

MODE’ is displayed briefly at the bottom of the screen.

Page 30

3 - 8 GETTING STARTED

Step 3 Press AUTOSET again. This time the scope performs the autoset in

digital mode.

Step 4 Press the RUN/STOP key and observe that the trace is frozen and

stays on screen even after removing the probe.

Step 5 Press the RUN/STOP key to display the actual input signal again.

Reconnect the probe to display the Probe Adjust signal again.

Step 6 Press the ANALOG button once again to return to the analog mode. In

the bottom of the screen, the text ’ANALOG MODE‘ is briefly displa yed.

3.6 VERTICAL SETUP

This section deals with setting of the input circui ts of the four channels. The ma in

adjustments are AMPLitude, POSition, and the channel input coupling selection

for GND, DC, and AC.

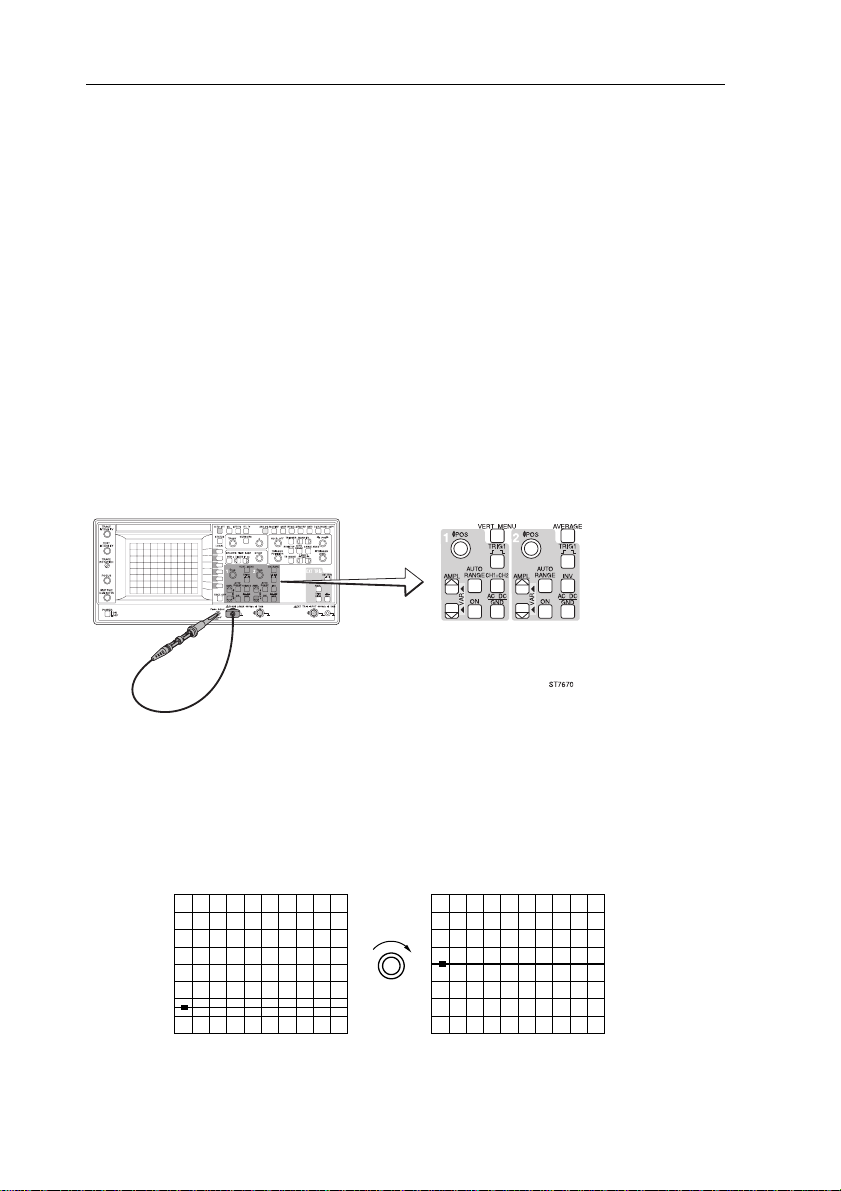

Figure 3.5 Vertical setup

Step 1 Adjust the absolute ground level by disconnecting the signal and using

the POS control to position the trace in the middle of the screen. A

marker with the channel number (’1-’) at the left of the screen indicates

the ground reference.

POS

1

1

MAT4191

Step 2 Reconnect the probe to the Probe Adjust signal for display.

Page 31

GETTING STARTED 3 - 9

CH1

100mV

CH1

500mV

ST6681

Step 3 You can change the amplitude of the signal in a 1, 2, 5 sequence by

pressing one of the AMPL keys. Note that the bottom of the screen

shows the AMPL/DIV setting of CH1.

Step 4 Press the ON button of CH2 and observe that a second trace is now

visible. The position and amplitude of this channel can be adjusted

similar to the adjustment of CH1. The channel settings are also

displayed in the bottom of the screen.

Press the ON key of CH2 once again to turn this channel off.

Step 5 Press the AC DC/GND key of CH1 so that a ’⊥’ sign is displayed in the

bottom text line. This interrupts the input sig nal and connects the inpu t

to the ground. In this case, only the ’base’ line is visible.

Press the AC DC/GND key once again for ac input coupling; the

bottom text line now displays ’~’.

In most cases, dc input coupling is used to show ac as well as dc components of

the signal. However, in some case s where a small ac sign al is superimp osed on

a large dc voltage, ac input coupling must be used. Then only the ac component

is visible on the screen. The text line shows a ’=’ or ’~’ sign to indicate dc or ac

coupling. Because the calibration signal is a square wave with a low level of 0V

and a high level of +600 mV , the screen sh ows either of the following two displays:

AC INPUT COUPLING

ZERO

1

LEVEL

CH1

200mV

MTB 200µs

CH1

DC INPUT COUPLING

ZERO

1

LEVEL

CH1

200mV

MTB 200µs

CH1

ST6682

Page 32

3 - 10 GETTING STARTED

Step 6 Press the ANALOG key to enter the digital mode

Step 7 Press the top one (mV) of the AMPL keys, so that the signal has

maximum amplitude.

Press AUTO RANGE and see the signal change to a suitable

attenuator value. When AUTO RANGE is active, the attenuators

automatically adjust when the signal amplitude changes, to keep the

trace on screen.

Step 8 Press the key labeled AVERAGE. Noise in the input signal can be

reduced by using the average function. The random noise is reduced

by calculating the average over the last n scans (average factor ca n be

set between 2 and 4096)

NOTE: Refer to Chapter 4 for an explanation of the CH1+CH2, TRIG1, and

INV keys.

Page 33

GETTING STARTED 3 - 11

ST6683

MTB 100µsMTB 500µs

TIME/DIV

3.7 TIMEBASE SETUP

The next step is the adjustment of the main timebase controls (

POS

ition, and

MAGNIFY

keys).

MAGNIFY

AUTO

3

2

1

4

RANGE

TIME/DIV

sns

Figure 3.6 Timebase setup

Step 1 Press the

Step 2 Use the

AUTOSET

TIME/DIV

key.

keys on the right hand side of the instrument to

decrease or increase the number of periods of the signal on the

screen.

TIME/DIV, X

VAR

XPOS

ST6435

9312

Step 3 Select a timebase of 1 ms/div.

Step 4 Press

AUTO RANGE

and see the signal display change to a more

suitable timebase. The AUTO RANGE function au tomatically selects a

timebase that displays 2 to 6 signal periods.

Step 5 Press the

Step 6 Turn the

ANALOG

X POS

key to switch the scope to the analog mode.

control to shift the signal horizontally (left or right)

across the screen.

Page 34

3 - 12 GETTING STARTED

3.8 MAGNIFY (EXPAND)

Step 1 You can use the

MAGNIFY

keys to expand the signal on the screen.

The ’MGN’ indication and the corrected timebase settin g are displayed

in the text line.

In the analog mode, magnification is limited to

activate the magnification. The left key will turn off the MAGNIFY

10. The right key will

*

function. On or off is indicated by ’MGN’ in the bottom of the screen.

Step 2 Press the

ANALOG

Step 3 In the digital mode, pressing the right

signal in

left

operate the

1, *2, *4 ...steps to a maximum of *32 times. Pressing the

*

MAGNIFY

MAGNIFY

key to switch the scope to the digital mode.

MAGNIFY

key compresses the signal to

buttons, or when you turn the X

key expands the

1 again. When you

*

POS

ition

control, a bargraph is displayed showing whic h part of the digital trace

is expanded.

NOTE: The MAGNIFY key and X POS control can also be used after the

oscilloscope is STOPped.

5.00µs

10 DIV

1.25µs

4

*

10 DIV

START OF TIME WINDOW CAN BE VARIED WITH

XPOSOVER THE WHOLE SWEEP RANGE.

1.00ms

40 DIV

ST6684

Page 35

GETTING STARTED 3 - 13

3.9 DIRECT TRIGGER SETUP

Now you are ready to set your trigger conditions. Y ou will use one of the channel

selection keys (

control.

LEVEL

TRIG1, TRIG2, TRIG3, TRIG4 or EXT TRIG

Figure 3.7 Direct trigger setup

) and the

TRIGGER

Step 1 Press the

output is now displayed on channel 1. Turn chann el 2 on to display a

second horizontal trace (channel 2 has no input signal).

Step 2 Press the

source. The result is that the signal on channel 1 is no longer triggered

(not stable). The

not triggered. Check also that the right side of the bottom text line

indicates the trigger source (’ch2’).

Step 3 Only in 2 channel models

Press

source. Check that the rightside of the bottom textline indicates the

trigger source ’EXT’.

Step 4 Press the

The ’ch1’ symbol is displayed in the bottom text line. Triggering

resumes. Turn channel 2 off, by pressing ON again.

Step 5 Press the ns key of the MainTB

set to ’2 µs/div’.

AUTOSET

TRIG2

EXT TRIG

TRIG1

key. The square-wave signal of the Probe Adjust

key so that channel 2 is selected as the trigger

LED is on, to indicate that the oscilloscope is

ARM’D

key to select External Trigger input as the trigger

key. Channel 1 is now selected as the trigger source.

TIME/DIV

keys until the timebase is

Page 36

3 - 14 GETTING STARTED

Step 6 The same TRIG1 key that was used to select the trigger source is also

used to select the trigger slope. Repeatedly pressing the TRIG1 button

changes the triggering so that it occurs on the leadin g o r tr aili ng edge

of the input signal. Note that the slope is also displayed in the bottom

text line.

TRIG1

MTB 2µs

CH1

200mV

CH1

CH1

200mV

MTB 2µs

CH1

ST6685

Step 7 For repetitive signals, you obtain a stable display when each

successive timebase sweep is triggered at the same stable level of the

input signal. You use the TRIGGER LEVEL control to adjust the level.

Turn the control. The precise positio n in relation to the maximum signal

amplitude (between +100 % and -100 %) is displayed on the screen.

SUMMARY

The previous steps covered the basic adjustments. Now you are ready to look

at the special features of the oscilloscope. This includes the use of the cursors,

advanced trigger functions and using the second (delayed) timebase for signal

details.

Page 37

GETTING STARTED 3 - 15

3.10 PRE-TRIGGER VIEW

One of the powerful features in the digital mode is the ability to capture and view

signal contents prior to the actual trigger. The amount of pretrigger information

can be as long as one full acquisition/record. The trigger position is ad justed with

the

TRIGGER POSITION

control.

Step 1 Turn the

triggering edge shifts to the center of the screen. A trigger point marker

(s) indicates the trigger point. The part to the left o f the marker is called

pretrigger view. The pretrigger view is indicated in the bottom of the

screen (in divisions)

1

Step 2 The

TRIGGER POSITION

delay. Rotate the

readout displays "0". When you continue to turn the TRIGGER

POSITION control clockwise, a positive delay between trigger point

and acquisition is set. The delay is no longer read out in divisions of

pretrigger information, but in seconds, or fractions of seconds to

indicate how much delay is used.

TRIGGER POSITION

TRIGGER

POSITION

control can also be used to adjust time

TRIGGER POSITION

control counter clockwise. Now the

1

DELAY=−5.00dV

PRE-TRIGGER

VIEW

ST6686

control clockwise until the

Page 38

3 - 16 GETTING STARTED

3.11 MORE ADVANCED FEATURES

All basic functions are accessed by dedicated keys for fast and easy operation.

Some of the more advanced features are menu operated. Menu s are called up by

pressing one of the keys identified with

press one of these keys, a menu is displayed on the right side of th e screen. This

menu gives you access to the more advanced functions of the oscilloscope. Use

the blue softkeys to the right of the screen to select the desired functions; the

selected function is indicated by the highlighted text.

3

2

1

4

SOFTKEYS

Figure 3.8 Menu keys and softkeys

text on the front panel. After you

blue

TRIGGER WITH

MENUKEY

TRIGGER

ST6433

9303

Step 1 Press the key marked

TRIGGER

.

Check that the ’TRIGGER MAINTB’ menu is displayed at the right side

of the screen.

After changing the setting, you can deactivate the menu again to use

the full screen for the signal.

There are two ways to do this:

- Press the

- Press the

TRIGGER

TEXT OFF

key once again.

key.

The TEXT OFF key operates in a 1-2-3 cycle, and allows you to blank

the bottom text line as well.

TRIGGER

MAIN TB

edge tv

logic

ch1

line

TEXT OFF

CH1

MTB 200µs

200mV

CH1

CH1

200mV

MTB 200µs

TEXT OFF

TEXT OFF

CH1

Step 2 Use both methods to familiarize yourself with turning the menus and

the bottom text line on and off.

ST6679

Page 39

GETTING STARTED 3 - 17

3.12 CURSOR OPERATION

Cursors are used for accurate amplitude or time measurements of the signal.

1

23

4

TRACK

CURSORS

∆

ST6431

9303

Figure 3.9 Cursor setup

Step 1 Before you continue, reset the instrument with the STANDARD

SETUP. To do this, press the

STATUS

key and

TEXT OFF

key

simultaneously. Now the instrument is set in the default condition and

operates in analog mode.

Step 2 Press the

Step 3 Press the

AUTOSET

CURSORS

key.

key to enter the cursors menu.

CURSORS

The menu is now displayed on the screen and the

cursors are turned on.

on off

Step 4 Use the second blue softkey from the top to select

one of the three cursor modes:

- Amplitude cursor measurements, indicated by ’=’.

- Time cursor measurements, indicated by ’||’ for

measuring time or frequency.

- Amplitude

’#’. The top text line displays the result of the

time measurements, indicated by

and

READ OUT

measurements (∆V or ∆T).

Step 5 Press the second bluesoft key until ’||’ is highlighted.

#

ST6430

Step 6 The

TRACK

control moves both cursors at the same time. For

example, to measure the period time of the input signal, set the left

(reference) cursor to a rising edge of the signal.

Step 7 The ∆ contro l moves the right cursor only . Set this cursor the next rising

edge of the signal.

Page 40

3 - 18 GETTING STARTED

Step 8 The top text line now shows the pulse repetition time of the signal

(e.g., ch1: ∆T= 500 µs).

200µs

CURSORS

on off

READ OUT

CH1

#

ST6687

ch1:

∆T= 500µs

CH1 200mV

MTB

Step 9 Press the second blue softkey until ’=’ is highlighted. Now perform a

peak-to-peak measurement and check that th e amplitude of the signal

(’∆V’) is 600 mV.

NOTE: When you select ’#’, the fifth blue softkey is automatically activated so

that you can choose between using the controls for positioning the

vertical cursors (’||’) or the horizontal cursors (’=’).

The ’READOUT’ submenu is explained in Chapter 4.

Step 10 Select the vertical cursors again.

Step 1 1 Now switch to the digital mode. Notice the changing readout and the

’X’ indicating where the trace and the cursors intersec t. Since the trace

is digitized, the cursors can be really smart. In the digital mode you can

measure time differences (∆T) and amplitude differences (∆V) at the

same time.

200µs

CURSORS

on off

ch1

-

READ OUT

CH1

ST6688

#

9303

ch1:

∆T= 500µs

CH1 200mV

∆V= 600mV

MTB

Step 12 Use the first blue softkey to turn the cursors off. The cursor menu

disappears.

Page 41

GETTING STARTED 3 - 19

3.13 MORE ADVANCED TRIGGER FUNCTIONS

Most of the trigger functions (source, slope, and level) can be controlled with

direct access to the functions (see Section 3.9). A CRT menu is used for more

advanced trigger functions.

TRIGGER

1

23

4

TB MODE

ARM’D

TRIGGER

LEVEL

ST6432

9303

Figure 3.10 More advanced trigger setup

Press the menu key

TRIGGER

. This

turns the menu on. An extensive set of

functions is now displayed.

All functions are explained in Chapter 4. For most applications, this menu is not

needed.

Page 42

3 - 20 GETTING STARTED

3.14 MORE SIGNAL DETAIL WITH THE DELAYED

TIMEBASE

When you need to study a part of a signal in more detail, a second (delayed)

timebase is available. This timebase has its own timebase settings and trigger

level adjustment. Additional selections are made in the DELAYED TIMEBASE

menu.

DISPLAY

MAGNIFY

23

1

4

Figure 3.11 Delayed timebase setup

Step 1 Press the

STATUS

key and

STANDARD SETUP.

Then shift to trace to the upper half of the screen as indicated.

50mV

CH1

MTB 1.00ms

DELAYED TIMEBASE

DTB

sns

TIME/DIV

TEXT OFF

ch1

ST6690

TRIGGER

DELAY

POSITION

TB MODE

key at the same time for

ST6439

9303

Page 43

GETTING STARTED 3 - 21

Step 2 Press the DTB key . The DELA YED TIME BASE menu is now displayed

on screen. Turn the delayed time base on with the first softkey.

DELAYED

TIME BASE

DEL’D TB

on off

MAIN TB

on off

starts

trig’d

TRACE

T

SEP

CH1

50mV

MTB1.00ms

DTB 100µs4.882ms

ch1

ST6689

The upper trace is the main timebase trace. This first trace shows an intensified

part. Adjust the TRACE INTENSITY with the control as necessary. The lower

trace is the delayed timebase trace and is an expanded representation of the

intensified part in the upper trace.

Step 3 Turn the DELAY knob to shift the intensified part and to select which

part of the main timebase you want to magnify.

Step 4 The delayed timebase TIME/DIV keys are used to select the

’magnification factor’. Notice the changing delayed timebase ’TIME/

DIV’ readout at the bottom of the screen.

Step 5 The ’T’ symbol at the fourth blue softkey indicates that the cursor

TRACK control can be used to make adjustments. In this menu the

cursor TRACK control is used to change the TRACE SEParation, which

is the distance between the main timebase and the delayed timebase.

The delayed timebase can be used in the triggered mode. The trigger ed mode is

selected with the STARTS/TRIG’D softkey . The function of the triggered mode will

be explained in Chapter 4. For this part of "Getting Started", remain in the

STARTS mode.

Step 6 Switch the menu off with the TEXT OFF key. Notice that the delayed

timebase is still active and that the most important functions (DELAY

control and TIME/DIV key pair) still allow you to operate the delayed

timebase.

Page 44

3 - 22 GETTING STARTED

3.15 TRACE STORAGE

In the digital mode you not only have the ability to store traces on the screen

(using the

RUN/STOP

key), but also to store traces in memory for later use.

ANALOG

3

2

1

4

SAVE

RECALL

RUN/STOP

ST6691

9312

Figure 3.12 Digital memory setup

Store traces on screen:

Step 1 Press

AUTOSET

.

Step 2 Make sure that the scope is in the digital mode. If not, press the

ANALOG

Step 3 With the

key to enter the digital mode.

RUN/STOP

key , new acquisitions are stopped and the display

is frozen. Removing the input signal or pressing a key has no ef fect on

the display . Stopping the acquisition is very useful to do me asurements

on the signal or to make a hard copy.

Step 4 Press the

RUN/STOP

key to reactivate the acquisition.

Store traces in memory:

Step 5 For this step-by-step introduction you will first clear all memory

locations so that all unnecessary traces are removed.

- press the

- select

- select

CLEAR & PROTECT

CLEAR ALL

- in the confirm menu, select

Sometimes there will be a second confirm menu. Select

SAVE

menu key.

.

.

YES

.

again to

YES

clear protected traces as well.

Press the

TEXT OFF

key to turn the menu off.

Page 45

GETTING STARTED 3 - 23

Here is how traces are stored in memory:

Step 6 Use the TRACK control to select an empty memo ry

location such as m1, m2, or m3. Empty locations are

marked with a circle in front of the memory location

number (e.g., m3).

Step 7 Press the second blue softkey (’save’). You have

now saved the acquisition signal into memory

’register’ m3. A single register can contain a set of up

to three traces (e.g., CH1, CH2, and EXT (trigger

view)). In this case only one input channel was

SAVE ACQ

TO

MEMORY

m2

m3

m4

save

clear

copy

turned on, so that only one was stored.

Step 8 Remove the probe from CH1. Now recall the stored

trace.

Step 9 Press the RECALL key.

CLEAR &

PROTECT

ST6705

Step 10 Select the previously filled memory register m3 with the TRACK

control. A memory register with trace information is indicated with

Step 11 Press the second blue softkey to turn on the display of this register.

Indicated by

Step 12 Turn the ∆ control to separate the acquisition (live signal) and the trace

recalled from memory.

NOTE: You are now able to operate nearly all the oscilloscope’s functions in

most routine applications. Please continue with Chapter 4 for a more

detailed description of the oscilloscope’s many advanced features.

Memory indications:

Empty register

Filled register

Displayed register

Page 46

HOW TO USE THE INSTRUMENT 4 - 1

4 HOW TO USE MORE ADVANCED

FUNCTIONS OF THE INSTRUMENT

This chapter allows more experienced oscilloscope users to learn more about the

advanced features of this instrument and how to use them. For a complete

description of each function, refer to the next chapter in this manual: "Function

Reference".

This chapter explains the basics of each function and gives examples are given

in a step by step sequence.

Less experienced oscilloscope users should read Chapter 3 before beginning this

chapter.

4.1 INTRODUCTION

All of the oscilloscope models in the PM337xB, PM338xB and PM339xB family

combine the features and operation of an analog oscilloscope with that of a fullfeatured Digital Storage Oscilloscope (DSO). Switching between one mode of

operation to the other is done by pressing one (yellow) push button.

Most signal acquisition functions are identical for both modes of operation, even

though the digital mode allows for pretrigger acquisition and display, plus more

powerful logic triggering.

Delayed sweep operation is available in both operating modes.

Cursors operate in both modes.

The digital mode provides access to many powerful calcul ated measurement and

signal analysis functions.

It also has a completely new feature called AUTO RANGE.

AUTO RANGE automatically adjusts the attenuator or the timebase setting when

the amplitude or the frequency of the signal has changed.

This family of oscilloscopes is available with a 60 MHz, 100 MHz or 200 MHz

bandwidth. There are full four-channel instruments as well as 2+2 channel

models.

The economy version have 2 full channels and an external trigger channel.

PM3394B 200 MHz Full Four Channel Oscilloscope.

The PM3394B offers a 200 MHz bandwidth. Four channels provide equal

bandwidth, and sensitivity ranges. Each channel has full AC/DC/GND coupling

capabilities.

In VERTMENU each channel is set to 50Ω or 1 MΩ input impedance.

Page 47

4 - 2 HOW TO USE THE INSTRUMENT

PM3390B 200 MHz 2 Channel Oscilloscope

The PM3390B has the same capabilities as the PM3394B on the channels 1 and

2. The channels 3 and 4 are replaced by an externa l trigger channel. This channel

can only be used as an additional trigger input channel. Signal manipulation as in

the full channels 1 and 2 is not possible. The external trigger signal can be

displayed by using the function TRIG VIEW.

PM3384B 100 MHz Full Four-Channel Oscilloscope

Bandwidth is 100 MHz.

The PM3384B has the same capabilities as the PM3394B. VERT MENU only

offers BW LIMIT selection.

PM3380B 100 MHz 2 Channel Oscilloscope

The PM3380B has the same capabilities as the PM3384B on the channels 1 and

2. The channels 3 and 4 are replaced by an external trigger channel as in the

PM3390B. VERT Menu offers only BWLIMIT selection.

PM3370B 60 MHz 2 Channel Oscilloscope

The PM3370B has a bandwidth of 60 MHz. All other features are equal to those

of the PM3380B.

Page 48

HOW TO USE THE INSTRUMENT 4 - 3

FRONT PANEL LAYOUT

The controls on the front panel are grouped by function. In this chapter, a

description for each group of controls is given in the following sequence:

- Display and probe adjustment (see section 4.2)

- Analog and digital modes (see section 4.3)

- Vertical deflection ( see section 4. 4)

- Horizontal deflection and triggering (see section 4.5)

- Digital acquisition and storage (see section 4.6)

- Advanced vertical functions (see section 4.7)

- Advanced horizontal and trigger functions (see section 4.8)

- Memory functions (see section 4.9)

- Cursor functions (see section 4.10)

- Measurement functions (see section 4.11)

- Processing functions (see section 4.12)

- Display functions (see section 4.13)

- Delayed timebase (see section 4.14)

- Hard copy facilities (see section 4.15)

- AUTOSET and other utilities (see section 4.16)

Page 49

4 - 4 HOW TO USE THE INSTRUMENT

Study the front panel of your oscilloscope and observe what functions the different

controls and push buttons (keys) perform. There are three differ ent styles of push

buttons, plus the blue softkeys adjacent to the screen. The push button functions

are as follows:

Direct function key. These keys provide direct access to specific

functions as labeled on the front panel. Examples include

AUTOSET for automatic setup of the oscilloscope and AC DC

(GND) for selection of the instrument’s input coupling.

Menu initialization key, with blue text. Press to produce a menu on

the screen from which you can select functions that are related to

the function name of this key.

Key pair. These pair s serve as up/down controls. They a re used to

select a value from a range.

Softkey. Press to select a function from the menu that has been

initialized by pressing one of the menu initialization keys.

Rotary control. Used for continuously variable contr ol of a function.

Page 50

HOW TO USE THE INSTRUMENT 4 - 5

4.2 DISPLAY AND PROBE ADJUSTMENTS

T o help you follow the step-by-step descriptions, each section begi ns by recalling

the standard setting as outlined below.

If you get "lost", you can return to the beginning of each section, because all

functions are set to a predefined state to create a correct start situation.

RECALL STANDARD SETTING

- Simultaneously press the STA TUS and TEXT OFF keys.

Recalling the standard setting always results in a trace on the display, even with

no signal applied to the oscilloscope inputs. Refer for a list of the standard setting

to the section "STA NDARD SETUP/FRONT PANEL RESET" of Chapter 5.

DISPLAY ADJUSTMENT

Before going through the examples that introduce you to

features of this oscilloscope, adjust the display as follows:

- Turn the TRACE INTENSITY control for optimum trace

brightness.

- Turn the TEXT INTENSITY control for optimum

display brightness of the text.

- Adjust trace alignment with the graticule by using the

screwdriver control TRACE ROTATION.

- Turn the FOCUS control until a sharp trace is

obtained.

- You can turn the GRATICULE ILLUMINATION control

to illuminate the graticule lines as desired.

Page 51

4 - 6 HOW TO USE THE INSTRUMENT

DISPLAY LAYOUT

The following illustration shows the layout of th e display with a maximum amou nt

of text.

Most text is active only when specific functions are activated.

Page 52

HOW TO USE THE INSTRUMENT 4 - 7

MENUS TEXT OFF

A menu appears when a key with blue text is pressed.

The menu functions can be selected by pressing the blue softkeys to the right side

of the screen.

- Press the ANALOG key to select the digital mode.

- Press the DISPLAY key to activate the menu.

DISPLAY

Each menu starts with a menu name, which

corresponds with the key that was used to select the

menu. This is sometimes followed by a second name of

the softkey that initialized a submenu.

WINDOWS

on off

VERT

MAGNIFY

off

T

XvsY

The windows function can be switched on and off by

pressing the corresponding blue softkey.

T

indicates that a selection must be made with the

TRACK control.

The arrow ( ) behind TEXT indicates that there is a

TEXT

submenu.

dots

linear

sine

ST7415

9312

The bottom softkey switches (toggles) between the

three functions.

Y ou can turn of f the text by pressing the TEXT OFF key. This can be done to free

up the display area.

- Press the TEXT OFF key three times.

Observe that the text mode follows the following sequence: menu off, settings of f,

both on.

Page 53

4 - 8 HOW TO USE THE INSTRUMENT

CAL SIGNAL AND PROBE ADJUSTMENT

Each measuring probe has been checked and adjusted before delivery. However,

to match the probe to your oscilloscope, you must perform the following

procedure to optimize the pulse response of the combination of oscilloscope input

and probes.

- Connect the probe body to channel 1.

- Connect the probe tip to the Probe Adjust output of the oscilloscope.

- Press the AUTOSET key.

If the display looks like one of the two displays shown on the left, you must adjust

your probe to get the display shown on the right.

The probe output impedance can be adjusted through a hole in the compensation

box of the probe to obtain optimum pulse response. Refer to the following figure.

ST6024

9303

- Adjust the probe until the screen shows the correct compensation.

The probe is now adjusted for optimum pulse response with this oscilloscope. If

you connect the probe to another channel or oscilloscope, it must be adjusted

again to that oscilloscope input.

- Repeat this adjustment for the second probe.

Page 54

HOW TO USE THE INSTRUMENT 4 - 9

4.3 ANALOG AND DIGITAL MODES

ANALOG

This instrument is a combination of an analog real-time oscilloscope and

a digital storage oscilloscope, which offers a variety of additional features.

The combination of analog and digital modes in one instrument gives

you the advantages of both modes.

In the

ANALOG MODE

the signal is directly written on the screen. The result is

the "traditional" real-time signal representation. Because of the high update rate

and infinite resolution, this image gives signal details that are vi sible on ly on tr ue

analog oscilloscopes.

In the

DIGITAL MODE

the input signal is sampled. These samples are stored in

memory so that mathematics, calculated measurements, printing, and other

memory functions can be performed on the trace.

You can use the yellow ANALOG push button to switch from the analog mode to

the digital mode and back at any time. The signal acquisition and displa y functions

of both operating modes are very similar. However, the nature of the signals you

are using may determine which operating mode you prefer to use. For more

information, refer to the following table:

SIGNAL CRITERIA ANALOG MODE DIGITAL MODE

Repetitive signals of Usable Usable

30 Hz and higher

Repetitive signals Causes display Preferred

below 30 Hz flickering

Single events Display for Can capture and

duration of display for long

the event term

Repetitive signals that Preferred May cause aliasing.

are amplitude modulated Use Peak detect or

Envelope mode

Repetitive signals that Preferred May cause aliasing.

are modulated in frequency Use Envelope mode.

Long serial data streams Preferred when When using delayed

Delayed sweep sweep to observe

is not used. details, Digital mode

provides better

light output.

Page 55

4 - 10 HOW TO USE THE INSTRUMENT

SIGNAL CRITERIA ANALOG MODE DIGITAL MODE

Video signals Preferred when When using delayed

Delayed sweep sweep to observe

is not used. details, Digital mode

provides better light

output.

OTHER CRITERIA

Need to see pretrigger Not possible Up to one screen

information

You need to make adjustments Fastest Slower display

to the circuitry and watch display update update

the signal change

Automatic measurements Can’t use Fully implemented

Signal Math Add, Subtract only All functions

Add, Subtract, Multiply

Signal Analysis Not available Full analysis, with

Integration, Math Plus option

Differentiation, FFT installed

Automatic Pass/Fail test Not available Fully implemented,

with Math Plus option

installed

Autorange attenuator Not available Results in a

displayed signal with

an amplitude of 2 to

6.4 divisions

Autorange timebase Not Available Results in a signal

display of 2 to 6

waveform periods

Page 56

HOW TO USE THE INSTRUMENT 4 - 11

STANDARD SETTING

- Simultaneously press the STA TUS and TEXT OFF keys.

- Connect the Probe Adjust signal to channel 1.

The Probe Adjust signal, now supplied to the input, is a square wave with a lower

level of 0V and a top level of 600 mV . The osci lloscope always operates in analog

mode after a recall of the standard setting.

- Press the AUTOSET key for optimum signal display.

ANALOG TO DIGITAL MODE SWITCHING

Switching from analog to digital mode and vice-versa can be done by pressing the

yellow

ANALOG

switch between the modes with no changes in the display.

- Press the ANALOG key again.

The oscilloscope is automatically set in the digital mode. This is indicated by a

message ’DIGITAL MODE’ that appears briefly on the screen.

key. If no Digita l mode-only features were activated, you can

Page 57

4 - 12 HOW TO USE THE INSTRUMENT

TRACE STORAGE RUN/STOP

The digital mode offers a set of powerful features. One of the most importa nt

advantages is that you can store one or more traces in memory or on screen.

- Press the RUN/STOP key to stop the signal acquisition and freeze the

display on the screen.

The trace is frozen and stays on the screen. Observe that the signal stays stored

even when you remove the probe.

Now the instrument has been STOPped, and most keys have been disabled. The

only keys that continue to function are those directly relate d to di spla y functio ns.

This includes trace shift using the

operable.

A frozen trace can be used for comparisons with other traces, mathematics,

cursor measurements, automatic measurements and more.

The

RUN/STOP

key is used to end the STOP mode and start the aquisition a gain.

- Press the RUN/STOP key.

This starts the acquisition again so that the actual input signal is displayed. You

can use the RUN/STOP key at any time.

control. All measurement functions are still

POS

RUN/STOP

RUNNING

FROZEN

ST6482

NOTE: The following section explains the basic functions regardless of

operating mode. The oscilloscope will react almost identically in either

mode. Where necessary, different behavior will be explained.

9312

Page 58

HOW TO USE THE INSTRUMENT 4 - 13

4.4 VERTICAL DEFLECTION

1

AMPL

POS

RANGE

mV

VAR

V

AUTO

ON

VERT MENU

TRIG1

CH1+CH2

AC DC

GND

2

AMPL

POS

RANGE

mV

VAR

V

AUTO

ON

AVERAGE

TRIG2

INV

AC DC

GND

ST6437

9312

The section shown on the left contains all

direct vertical deflection controlls for the input

channels 1 and 2.

Refer to Section 4.1 for the differences

between model numbers.

To start this section with the settings in a

predefined state, you must recall the

standard setting.

STANDARD SETTING

- Simultaneously press the STA TUS and TEXT OFF keys.

- Connect the Probe Adjust signal to channel 1.

The Probe Adjust signal, now supplied to the input, is a square wave with a lower

level of 0V and a top level of 600 mV.

- Press the AUTOSET key.

Page 59

4 - 14 HOW TO USE THE INSTRUMENT

VERTICAL COUPLING AC, DC, GND

The input coupling after AUTOSET is ac. Since the Probe Adjust signal is a pulse

type signal with a 50% duty cycle, its mean value is at the signal’s 50% amplitude

level. When the input is ac coupled, the mean value will be displayed at the

ground level of the oscilloscope. As a result of this, the displayed waveform is

centered on the screen.

AC coupling can be used to examine small ac components that are su perimposed

on large dc voltages.

- Press the AC DC GND key once for DC input coupling.

Since the Probe Adjust signal is a pulse-type signal with a lower level of 0V, and

a higher level of 600 mV, and since the oscilloscope adjusts the display position

of the ground level to coincide with the screen center , switchin g from ac coupling

to dc coupling results in an upward shift of the display position of the signal.

The coupling sign in the lower left hand corner of the scr een changes from ∼(ac)

to = (dc).

The ground level for each of the channels is indica ted by a dash after the ch annel

identifier, i.e., ’1-’ for the ground level of channel 1.

0.5ms

600mV

0V

AC DC

GND

1-

200mV

CH1

GND Coupled

ST6708

AUTO SET

AC DC

GND

Input Signal

AC DC

1-

200mV

CH1

AC Coupled

GND

1-

200mV

CH1

DC Coupled

- Press the AC DC GND key to obtain ground coupling.

A straight line is now displayed. This is the 0V (ground) level of the input. This

level serves as the 0 volt reference for amplitude measurements.

The coupling sign ’⊥’ now indicates ground coupling.

Page 60

HOW TO USE THE INSTRUMENT 4 - 15

VERTICAL POSITION

POS

Use the POS control to adjust the ground level to any desired vertical

position on the screen.

ST6158

9303

1

POS

1

MAT4171

- Use the position control to position the line in the middle of the screen.

Observe that the channel identifier ’1-’ shifts with the trace.

- Press the AC DC GND key again to obtain ac input coupling.