Page 1

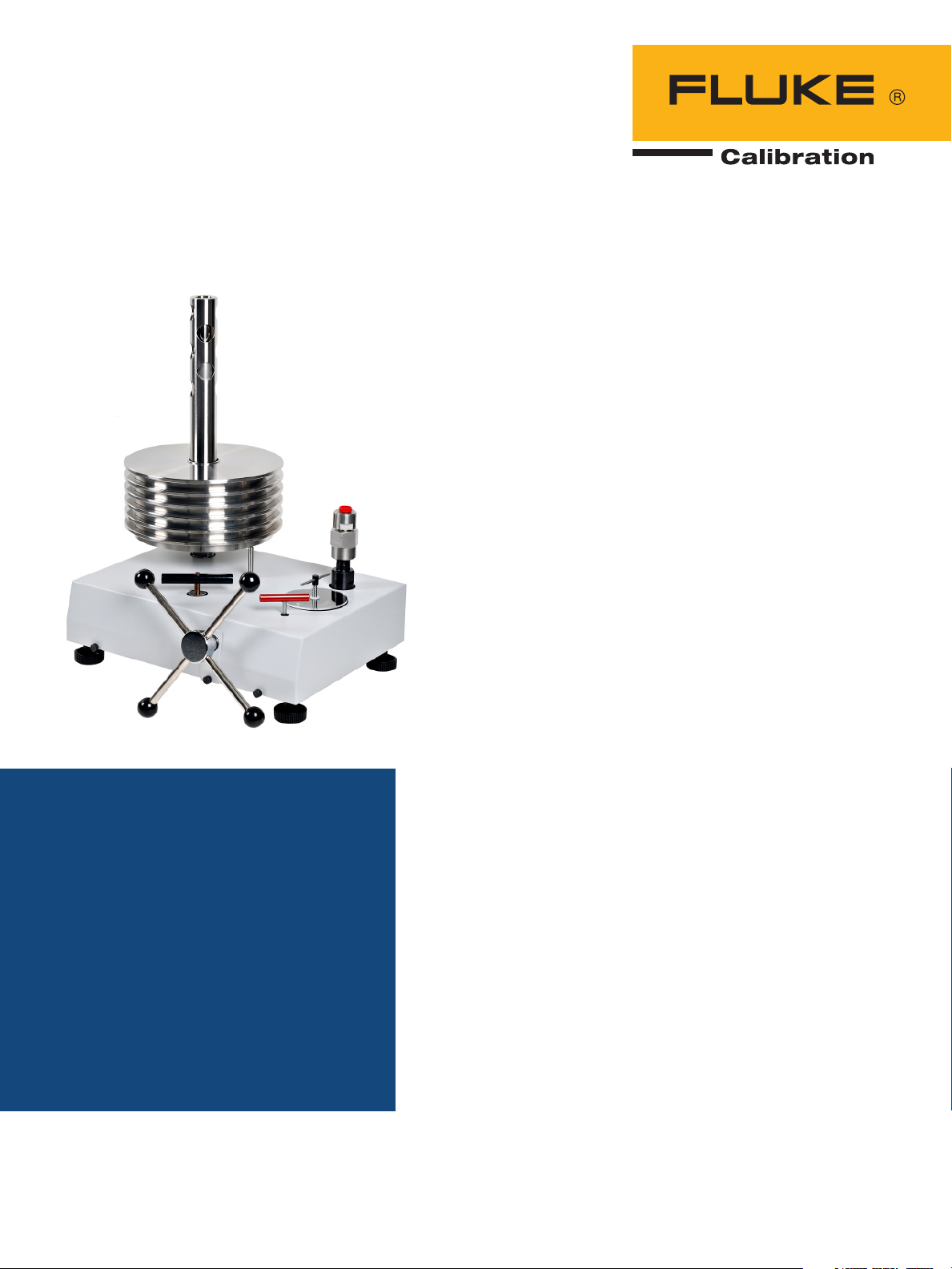

P3800 Series

High Pressure Hydraulic

Deadweight Testers

Models P3830,

P3840 and P3860

Technical Data

Features

• Three models available in ranges from

30 000 psi to 60 000 psi (2 000 bar to

4 000 bar)

• Two accuracy classes available; 0.02 %

or 0.015 % of Reading

• Select nominal increments in psi, bar, or

MPa pressure units

• ISO/IEC 17025 accredited calibration

certificate standard

• PressCal software

• P3000 Series available for pressure/

vacuum ranges and hydraulic pressures

to 20 000 psi (1 400 bar) and below

The Pressurements P3800

Series is the culmination of

over 50 years experience in the

design and manufacture of primary pressure standards. With

features and options designed

to improve accuracy, increase

reliability, and simplify operation, the P3800 Series can be

used to calibrate virtually any

high pressure sensing device

including transducers, transmitters, gauges or pressure

switches.

Instrument base

The Instrument base includes

all items required for operation.

A high quality hand pump is

coupled to a 7 to 1 intensifier,

allowing the operator to easily

generate high pressure in the

system. An oil reservoir is

included so the pump to be recharged when calibrating large

volume devices. A Test Station

is provided for connecting the

Device under Test to the P3800

Series. Adjustable feet and the

level vial allow the operator to

insure the instrument is level

to achieve the ultimate performance. A Piston Float Reference

allows the operator to determine when the piston is in the

ideal, “mid float” position.

Piston/cylinder

The piston/cylinder is the

“heart” of the deadweight

tester. P3800 Series pistons

are manufactured from tungsten carbide which provides

excellent long term stability,

durability, and extremely low

coefficients for temperature and

pressure.

Weight sets

Standard weight masses are

series 3 non-magnetic stainless steel. Each mass is marked

with the serial number of the

instrument and the nominal

pressure value. Select either

psi, bar or MPa pressure units.

PressCal software can be used

to support additional pressure

units.

Gravity correction

Gravity varies significantly with

geographical locations. Each

instrument can be calibrated

to local gravity a no additional

cost. If unspecified, instruments

are calibrated to standard

gravity at 980.665 cm/s2.

Page 2

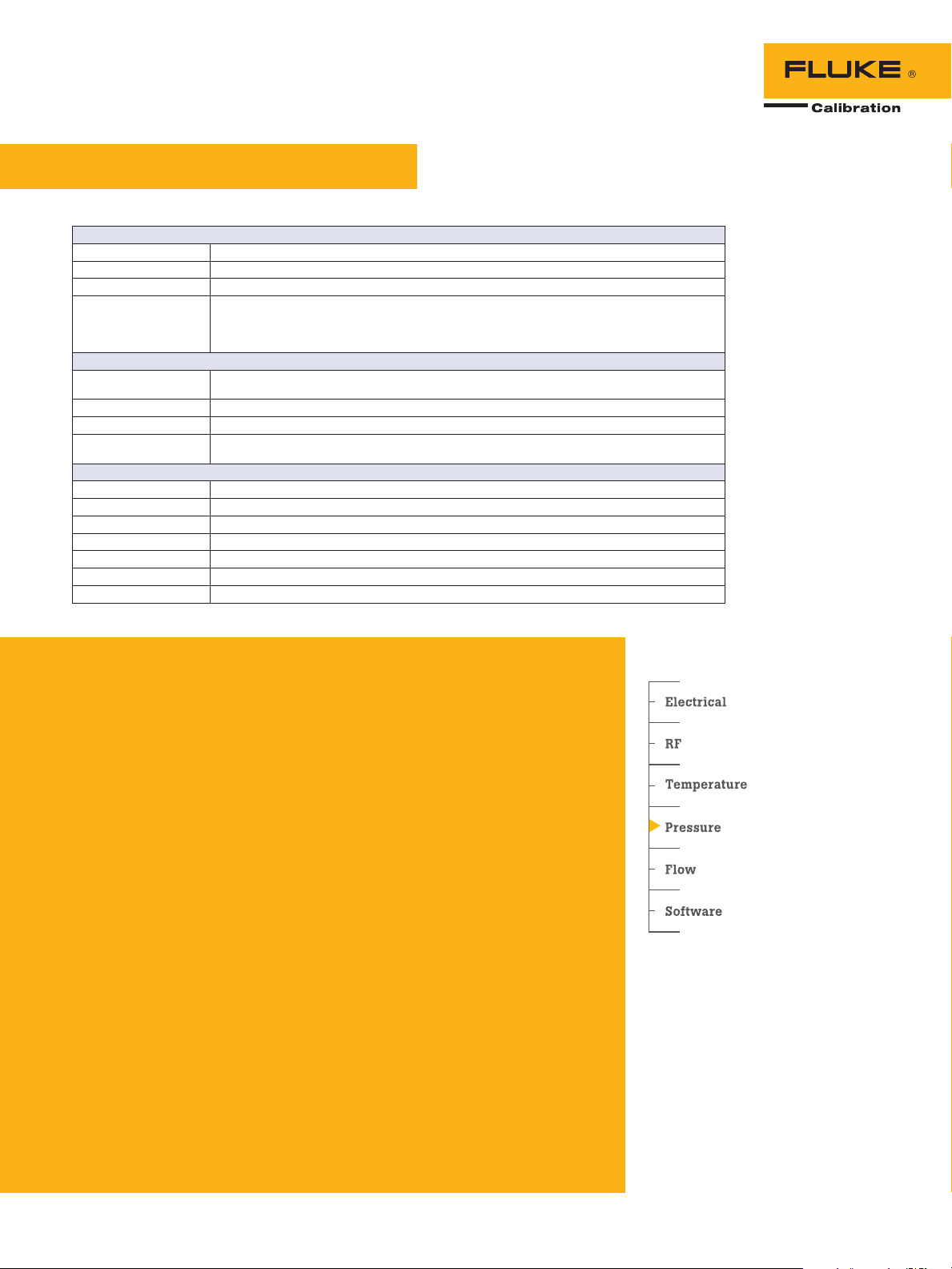

Specications

Pressure ranges

P3830 500 psi to 30 000 psi, or 40 bar to 2 000 bar, or 4 MPa to 200 MPa

P3840 500 psi to 40 000 psi, or 40 bar to 2 600 bar, or 4 MPa to 260 MPa

P3860 500 psi to 60 000 psi or 40 bar to 4 000 bar or 4 MPa to 400 MPa

Accuracy Standard accuracy is 0.02 % of Reading*. Optional accuracy of 0.015 % of Reading is available. ISO/IEC

Materials of construction

Standard weight material Series 3 non-magnetic, austenitic, stainless steel

Piston material Tungsten carbide with nickel binder

Cylinder material Tungsten carbide with cobalt binder

Thermal coefficient of

expansion

General

Test port adaptors 3/4-16 UNF; 9/16 in – 18 UNF (Autoclave); 3/8 in BSP; 1/2 in BSP and 3/4 in BSP

Weight 30 Kg (66 lb) Instrument base only

Dimensions (W x D x H) 455 mm X 340 mm X 478 mm ( 18 in X 13.5 in X 19 in)

Reservoir volume 235 cm

Intensifier ratio 7 to 1

Seal materials Nitrile

Operating fluid Sebacate, our reference 3069551

17025 accredited calibration certificate is standard

*Accuracy is based on % of Reading from 10 % to 100 % of the piston range when used in accordance with

the corrections found on the calibration certificate. Below 10 %, ± (accuracy class) x 10 % of the piston range.

3

(14.3 in3)

3

Density: 7.8 g/cP

11 ppm/°C

Ordering information

Models:

P3830-BAR High Pressure Hydraulic Deadweight Tester, 40 to 2 000 bar

P3830-PSI High Pressure Hydraulic Deadweight Tester, 500 to 30 000 psi

P3830-MPA High Pressure Hydraulic Deadweight Tester, 4 to 200 MPa

P3840-BAR High Pressure Hydraulic Deadweight Tester, 40 to 2 600 bar

P3840-PSI High Pressure Hydraulic Deadweight Tester, 500 to 40 000 psi

P3840 -MPA High Pressure Hydraulic Deadweight Tester, 4 to 260 MPa

P3860-BAR High Pressure Hydraulic Deadweight Tester, 40 to 4 000 bar

P3860-PSI High Pressure Hydraulic Deadweight Tester, 500 to 60 000 psi

P3860-MPA High Pressure Hydraulic Deadweight Tester, 4 to 400 MPa

Options and accessories

A. Improved Accuracy Option with Software - PressCal Software is a

Windows based software program that allows users to easily apply all

necessary corrections, allowing for improved accuracy of 0.015%.

B. Fine Increment Weights - Additional small weights that allow for finer

pressure increments

PPA9159-CAL For use with kPa, MPa, bar, or kgf/cm2 weight sets

PPA9608-CAL For use with psi weight sets

C. Conversion Weights - Allows for an instrument to be used in a pressure

unit other than the pressure unit the instrument was ordered for.

2 Fluke Calibration P3800 Series High Pressure Hydraulic Deadweight Testers

Fluke Calibration.

Precision, performance, confidence.

Fluke Calibration

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (877) 355-3225 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.flukecal.com

©2011-2012 Fluke Calibration.

Specifications subject to change without notice.

Printed in U.S.A. 8/2012 3833630C D-EN-N

Modification of this document is not permitted

without written permission from Fluke Calibration.

™

Loading...

Loading...