Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

OC3port® Plus

Handheld OC3 / ATM Network Analyzer

Users Manual

PN 686284

June 1996, Rev 1, 5/99

© 1996, 1999 Fluke Corporation, All rights reserved. Printed in USA.

All product names are trademarks of their respective companies

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

Limited Warranty & Limitation of Liability

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs and services

are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of a Fluke

authorized reseller, and does not apply to fuses, disposable batteries or to any product which, in Fluke’s opinion,

has been misused, altered, neglected or damaged by accident or abnormal conditions of operation or handling.

Fluke warrants that software will operate substantially in accordance with its functional specifications for 90 days

and that it has been properly recorded on non-defective media. Fluke does not warrant that software will be error

free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers only but

have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is available if

product is purchased through a Fluke authorized sales outlet or Buyer has paid the applicable international price.

Fluke reserves the right to invoice Buyer for importation costs of repair/replacement parts when product

purchased in one country is submitted for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price, free of charge repair, or

replacement of a defective product which is returned to a Fluke authorized service center within the warranty

period.

To obtain warranty service, contact your nearest Fluke authorized service center or send the product, with a

description of the difficulty, postage and insurance prepaid (FOB Destination), to the nearest Fluke authorized

service center. Fluke assumes no risk for damage in transit. Following warranty repair, the product will be

returned to Buyer, transportation prepaid (FOB Destination). If Fluke determines that the failure was caused by

misuse, alteration, accident or abnormal condition of operation or handling, Fluke will provide an estimate of

repair costs and obtain authorization before commencing the work. Following repair, the product will be returned

to the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR

ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS

OF DATA, WHETHER ARISING FROM BREACH OF WARRANTY OR BASED ON CONTRACT, TORT,

RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation

of incidental or consequential damages, the limitations and exclusions of this warranty may not apply to every

buyer. If any provision of this Warranty is held invalid or unenforceable by a court of competent jurisdiction, such

holding will not affect the validity or enforceability of any other provision.

To locate an authorized service center, visit us on the World Wide Web at:

www.fluke.com

Or call Fluke using the phone numbers listed below:

USA and Canada: 1-888-99-FLUKE (1-888-993-5853)

Europe: +31 402-678-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-356-5500

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

Table of Contents

Chapter Title Page

1 Introduction........................................................................................ 1-1

Introduction .................................................................................................... 1-3

About This Manual......................................................................................... 1-3

Who This Manual Is For .......................................................................... 1-3

What You Should Know.......................................................................... 1-3

How to Use This Manual ......................................................................... 1-3

Notations and Typographical Conventions .............................................. 1-4

OC3port Plus Features and Capabilities ......................................................... 1-4

The OC3port Plus Handheld Tester: at a Glance ..................................... 1-6

Specifications........................................................................................... 1-7

Notices, Warnings, Operating Restrictions..................................................... 1-10

Laser Operation .............................................................................................. 1-11

Checking Your Package ................................................................................. 1-11

Technical Support........................................................................................... 1-11

Service Center Repair..................................................................................... 1-12

2 Getting Started................................................................................... 2-1

Introduction .................................................................................................... 2-3

OC3port Plus Controls and Connections........................................................ 2-3

The Connector Panel................................................................................ 2-3

The Front Panel........................................................................................ 2-4

The LCD.............................................................................................. 2-4

Direct Access Keys.............................................................................. 2-5

Status Section....................................................................................... 2-7

System Control Keys ........................................................................... 2-10

Getting Acquainted with the OC3port Plus Menus......................................... 2-12

Accessing a Menu .................................................................................... 2-13

Using the Directional Arrow Keys........................................................... 2-14

Scrolling through Menu Options.......................................................... 2-14

Changing the Setting for an Option ..................................................... 2-15

i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

OC3port Plus

Users Manual

Editing the Setting for an Option.......................................................... 2-16

Accessing OC3port Plus Submenus.......................................................... 2-17

Exiting OC3port Plus Submenus.............................................................. 2-18

Connecting the OC3port Plus.......................................................................... 2-18

Connecting the OC3port Plus to Network Devices................................... 2-19

Connecting to Remote Devices................................................................. 2-19

Connecting the OC3port Plus to a PC or Laptop.................................. 2-19

Connecting the OC3port Plus to a Modem........................................... 2-20

Connecting to a Printer............................................................................. 2-20

Connecting to an External Power Supply................................................. 2-21

3 Setting Up and Operating the OC3port Plus................................... 3-1

Introduction..................................................................................................... 3-3

Programming the Overall Operation of the OC3port Plus .............................. 3-3

Changing the Default Scrolling Method................................................... 3-4

Turning on the Warning Buzzer ............................................................... 3-5

Setting the System Date and Time............................................................ 3-5

Setting the Communications Speed.......................................................... 3-6

Turning Off the Automatic Diagnostic Tests............................................ 3-7

Parameter Sets .......................................................................................... 3-8

Creating a Parameter Set...................................................................... 3-8

Naming a Parameter Set....................................................................... 3-10

Switching to a Different Parameter Set................................................ 3-11

Editing a Parameter Set........................................................................ 3-11

Performing Basic Operations.......................................................................... 3-12

Turning on the OC3port Plus.................................................................... 3-12

Turning on the Laser Transmitter............................................................. 3-14

Returning to the Introductory Display...................................................... 3-15

Resetting the OC3port Plus ...................................................................... 3-15

Restoring Factory Default Settings........................................................... 3-15

Clearing the Error Counters...................................................................... 3-16

Responding to Low Battery Warnings...................................................... 3-16

Obtaining Information about Your OC3port Plus..................................... 3-17

Storing and Retrieving Test Results ......................................................... 3-17

Manually Storing Test Results ............................................................. 3-18

Automatically Storing Test Results in Memory................................... 3-19

Displaying Stored Test Results ............................................................ 3-22

Deleting Stored Test Results................................................................ 3-24

Deleting a Single Record...................................................................... 3-25

Deleting All Stored Records in a Test Group....................................... 3-25

Printing, Downloading, and Remote Control............................................ 3-26

Connecting to the Serial Port................................................................ 3-26

Printing Reports and Configuration Information.................................. 3-29

Pausing a Print Job............................................................................... 3-30

ii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

Contents

(continued)

Preventing a Report from Being Printed.............................................. 3-30

Controlling the OC3port Plus Remotely .................................................. 3-30

Running the Automatic Diagnostic Tests ....................................................... 3-31

4 SONET/SDH Configuration and Testing.......................................... 4-1

Introduction .................................................................................................... 4-3

Configuring the Framing Format.................................................................... 4-3

Differences between SONET OC3 STS-3c and SDH STM-1.................. 4-3

Changing the Framing Format ................................................................. 4-4

Changing the S-Bit Values (optional) ...................................................... 4-5

Setting Up for Testing STS-3c and STM-1 Signals........................................ 4-7

Generating Automatic Alarms.................................................................. 4-7

Setting the Transmit Clock Source........................................................... 4-9

Scrambling Payloads................................................................................ 4-10

Changing the Threshold Setting for Counters.......................................... 4-11

Enabling/Disabling PATH FERF Support ............................................... 4-12

Monitoring Incoming STS-3c or STM-1 Signals ........................................... 4-13

Inserting Errors............................................................................................... 4-15

Modifying the Value of the Payload Pointer .................................................. 4-17

Generating Alarms.......................................................................................... 4-18

Transmitting an Alarm............................................................................. 4-19

Turning Off an Alarm .............................................................................. 4-20

Viewing Alarms Stored in the Alarm Log ............................................... 4-20

Removing All Alarms from the Alarm Log......................................... 4-22

Responding to an LOS Condition........................................................ 4-23

In-Service Signal Monitoring ......................................................................... 4-23

5 Configuring for ATM Network Testing............................................. 5-1

Introduction .................................................................................................... 5-3

Configuring a Receive Filter........................................................................... 5-3

Configuring an ATM Cell Transmission Stream............................................ 5-7

Some Suggestions for Configuring Multiple Cell Streams ...................... 5-17

Configuring a VBR / Poisson Transmission Source................................. 5-18

Other ATM Configuration Options ................................................................ 5-18

Payload Scrambling Option ..................................................................... 5-19

Coset Polynomial Option......................................................................... 5-20

Correction Algorithm Option................................................................... 5-21

Background Traffic Option...................................................................... 5-22

Header Type Option................................................................................. 5-22

Changing the Form for Expressing the PCR and SCR............................. 5-24

Large Transmit Queue.............................................................................. 5-25

6 Testing ATM Networks...................................................................... 6-1

Introduction .................................................................................................... 6-3

iii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

OC3port Plus

Users Manual

Starting Stream Transmission ......................................................................... 6-4

Monitoring an ATM Network......................................................................... 6-9

Scanning Circuits for ATM Activity............................................................... 6-34

Using the ATM Traffic Templates.................................................................. 6-42

Quality of Service Tests.................................................................................. 6-46

Transmitting OAM Cells on a Single Circuit ........................................... 6-5

Transmitting OAM Cells on Multiple Circuits......................................... 6-7

Monitoring ATM Traffic with a Receive Filter........................................ 6-9

Capturing ATM Cells............................................................................... 6-14

Configuring the OC3port Plus for Capturing ATM Cells .................... 6-15

Starting a Cell Capture......................................................................... 6-19

Looking at the Captured Cells.............................................................. 6-20

Displaying the Results of the Previous Cell Capture............................ 6-22

Capturing ILMI Cells ............................................................................... 6-22

Configuring the OC3port Plus for Capturing ILMI Cells..................... 6-23

Starting an ILMI Cell Capture.............................................................. 6-27

Looking at Captured ILMI Cells.......................................................... 6-27

Capturing OAM Cells............................................................................... 6-28

Configuring the OC3port Plus for Capturing OAM Cells.................... 6-28

Starting an OAM Cell Capture............................................................. 6-29

Looking at Captured OAM Cells ......................................................... 6-30

Searching for AAL Traffic on an ATM Network..................................... 6-31

Setting Up an ATM Activity Scan............................................................ 6-34

Scanning an ATM Circuit......................................................................... 6-38

Printing the Results of an Activity Scan................................................... 6-40

Displaying the Results of the Previous Activity Scan .............................. 6-42

ATM Traffic Templates: a Description .................................................... 6-42

20% SPREAD...................................................................................... 6-43

RAMPDOWN...................................................................................... 6-43

BER Test.............................................................................................. 6-43

POLICE 10MBS .................................................................................. 6-43

Selecting and Loading an ATM Traffic Template.................................... 6-43

Starting Transmission with a Loaded Template ....................................... 6-45

Editing a Template.................................................................................... 6-46

Cell Loss Test........................................................................................... 6-47

Setting Up a Cell Loss Test.................................................................. 6-47

Running a Cell Loss Test ..................................................................... 6-50

Re-running a Cell Loss Test................................................................. 6-51

Remote Cell Loss Test.............................................................................. 6-51

Setting Up a Remote Cell Loss Test..................................................... 6-52

Setting up the Master Unit.................................................................... 6-53

Setting Up the Slave Unit..................................................................... 6-59

Running a Remote Cell Loss Test........................................................ 6-64

Understanding Cell Loss Test Results.................................................. 6-65

Exiting and Returning to a Test in Progress......................................... 6-65

iv

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

Contents

(continued)

Cell Delay Variation Tests....................................................................... 6-66

1-point CDV Test................................................................................. 6-66

Setting Up a 1-point CDV Test............................................................ 6-66

Running a 1-point CDV Test............................................................... 6-68

2-point CDV Test................................................................................. 6-70

Setting Up a 2-point CDV Test............................................................ 6-70

Running a 2-point CDV Test............................................................... 6-71

Cell Transfer Delay Test.......................................................................... 6-72

Setting Up a Cell Transfer Delay Test................................................. 6-73

Running a Cell Transfer Delay Test .................................................... 6-74

Understanding Cell Transfer Delay Test Results................................. 6-75

Exiting a Cell Transfer Delay in Progress Test.................................... 6-75

Bit Error Rate Test (BERT)............................................................................ 6-76

Setting up a BERT Test ....................................................................... 6-76

Creating Your Own BERT Test Pattern............................................... 6-78

Running an ATM BERT Test.............................................................. 6-79

Injecting Individual BERT Errors........................................................ 6-80

IP Ping Test .................................................................................................... 6-81

Setting Up the OC3port Plus to Send an IP Message............................... 6-81

Sending an IP Message ............................................................................ 6-85

Receiving an IP Message ......................................................................... 6-87

Appendices

A Applications............................................................................................. A-1

B OC3port Plus ATM Transmission............................................................ B-1

C Glossary ................................................................................................... C-1

Index

v

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

OC3port Plus

Users Manual

vi

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

List of Tables

Table Title Page

2-1. OC3port Plus Direct Access Keys and their Function.................................... 2-6

2-2. OC3port Plus General Status LEDs................................................................ 2-8

2-3. SONET Alarms Detected by the OC3port Plus on the Status LEDs .............. 2-9

2-4. Description of the System Control Keys on the OC3port Plus....................... 2-11

3-1. Storage Limits for Test Records..................................................................... 3-18

3-2. RJ-11 Pin Descriptions................................................................................... 3-27

3-3. Serial Port 25-pin Computer Connection Pin Descriptions ............................ 3-27

3-4. Serial Port 25-Pin Modem/Printer Connection Pin Descriptions.................... 3-27

3-5. OC3port Plus Diagnostic Test Results for ATM and SONET........................ 3-32

4-1. STS-3c/STM-1 Alarms................................................................................... 4-8

4-2. STS-3c/STM-1 Measurement Results ............................................................ 4-15

4-3. Description of STS-3c/STM-1 Errors............................................................. 4-16

4-4. Alarms Transmitted by the OC3port Plus....................................................... 4-20

5-1. Receive Filter Setup Parameters..................................................................... 5-6

5-2. OC3port Plus Transmission Stream Parameters............................................. 5-15

5-3. Valid Combinations of Traffic Parameter and Traffic Source Selections....... 5-17

6-1. Captured Buffer Size ...................................................................................... 6-15

6-2. BERT Test Patterns ........................................................................................ 6-78

6-3. BERT Error Injection Rates............................................................................ 6-78

vii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

OC3port Plus

Users Manual

viii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

List of Figures

Figure Title Page

1-1. OC3port Plus at a Glance ............................................................................... 1-6

2-1. OC3port Plus Connector Panel....................................................................... 2-3

2-2. OC3port Plus LCD and Direct Access Keys .................................................. 2-5

2-3. OC3port Plus Status LEDs ............................................................................. 2-7

2-4. The System Keys Control the Entire Unit. ..................................................... 2-11

2-5. OC3port Plus Menu System (Version 3.3) ..................................................... 2-14

3-1. OC3port Plus ON/OFF switch........................................................................ 3-12

4-1. In-service Monitoring of Network Performance............................................. 4-24

5-1. UNI and NNI Cell Structure Differences........................................................ 5-23

6-1. Remote Cell Loss test connections................................................................. 6-52

6-2. Remote Cell Loss Testing............................................................................... 6-53

ix

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

OC3port Plus

Users Manual

x

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

Chapter 1

Introduction

Contents Page

Introduction .................................................................................................... 1-3

About This Manual......................................................................................... 1-3

Who This Manual Is For .......................................................................... 1-3

What You Should Know.......................................................................... 1-3

How to Use This Manual ......................................................................... 1-3

Notations and Typographical Conventions .............................................. 1-4

OC3port Plus Features and Capabilities ......................................................... 1-4

The OC3port Plus Handheld Tester: at a Glance ..................................... 1-6

Specifications........................................................................................... 1-7

Notices, Warnings, Operating Restrictions..................................................... 1-10

Laser Operation .............................................................................................. 1-11

Checking Your Package ................................................................................. 1-11

Technical Support........................................................................................... 1-11

Service Center Repair..................................................................................... 1-12

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-1

Page 15

OC3port Plus

Users Manual

1-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

Introduction

The OC3port Plus portable hand-held tester provides an extensive set of OC3

and ATM testing capabilities that address a broad range of test requirements for

OC3- and ATM-based transmission and communications systems. The OC3port

Plus is specifically designed to allow you to test any type of OC3/ATM equipment

for proper operation, configuration, compliance, and interoperability.

This chapter describes the features and capabilities of the OC3port Plus and

provides important information about the operation and use of the tester.

About This Manual

The OC3port Plus Users Manual describes how to operate the OC3port Plus

network analyzer and provides step-by-step instructions on how to perform

network testing and evaluation of ATM networks and equipment.

Who This Manual Is For

This manual provides pertinent technical information and instruction on the

operation and use of the OC3port Plus. It is written for anyone who uses this

product to test and troubleshoot OC3 and ATM network problems, for those

involved in network installation and maintenance, and for individuals who perform

network acceptance testing.

Introduction

Introduction

1

What You Should Know

This manual is not meant to be a SONET or ATM tutorial. A basic familiarity with

wide-area networking, in general, and an in-depth understanding of SONET, OC3

networks and ATM protocols, in particular, are required to effectively understand

and use this manual.

How to Use This Manual

We suggest that the first-time user continue with this chapter, “Introduction”. This

chapter describes the features and capabilities of the OC3port Plus and familiarizes

you with the safety precautions regarding its use.

Next read Chapter 2 “Getting Started”. Before you begin using the OC3port Plus,

you should understand the functions of the keys and status indicators as well as

other elements on the unit’s front panel. You also need to understand the menu

interface and how to navigate through the OC3port Plus menus. This chapter

covers these fundamentals.

After you configure the OC3port Plus, you can go directly to any of the

subsequent chapters that show you how to perform specific tests or operations.

1-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

OC3port Plus

Users Manual

This book also contains a Glossary of terms that are used throughout this manual.

Terms found in the Glossary area highlighted in text when they are first used.

Notations and Typographical Conventions

The following notations and typographical conventions are used in this manual:

Key names The names of keys are in boldface type.

For example, the AUTOTEST key and the Print key.

Key sequences A plus sign, as in SHIFT 1 + M, indicates that you should press and hold down

the SHIFT 1 key and then press the M key.

Screen names The names of screens are in capital letters and boldface type.

For example, the SYSTEM INFORMATION screen.

Options Options are boldface type. For example, the Date option.

Arrow keys The arrow keys are the four keys that encircle the ENTER key.

The name of an individual arrow key refers to the direction in which the arrow

points: the Down Arrow key, the Left Arrow key, the Right Arrow key, and

the Up Arrow key.

Italics Italic type is used for emphasis.

For example: Do

Lists Procedures are shown in sequentially numbered lists.

Monospace Monospace type is used to indicate messages displayed on the tester’s LCD.

For example, INITIALIZING ANALYZER.

Cautions A caution message advises you that failure to take or avoid a specific action

can result in loss of data.

All cautions are preceded by the word Caution.

Warnings A warning message cautions you that failure to take or avoid a specific action

can result in physical harm to you or damage to the tester.

All warnings are preceded by the symbol and the word Warning.

not

operate the unit in the presence of flammable gases.

OC3port Plus Features and Capabilities

The OC3port Plus combines SONET testing features with advanced ATM testing

features, giving you the ability to quickly test and troubleshoot any OC3 circuit as

well as test ATM equipment and services for proper operation and conformance.

At the physical layer, the OC3port Plus can be used to diagnose many common

OC3 network problems. The tester provides complete OC3 Section, Line, and Path

error and alarm transmission and monitoring capabilities that enable you to

1-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

Introduction

OC3port Plus Features and Capabilities

effectively monitor and test OC3 networks from any access point. The OC3port

Plus also provides the following:

• OC3 pointer control and monitoring

• Support for SONET and SDH framing formats

• Date and time stamping of OC3 alarm occurrences

• A passive monitoring mode, which allows for non-intrusive testing

• Automatic testing of OC3 circuits so that you can obtain immediate pass/fail

results and quickly assess problems with SONET networks.

In addition, the OC3port Plus offers a comprehensive set of advanced ATM testing

capabilities, which includes:

• Automatic scanning of active virtual circuits

• Ability to transmit up to eight ATM traffic sources simultaneously

• Quality of Service tests: Cell Delay, Cell Variation, and Cell Loss

• Cell payload capture and viewing

• Various cell transmission modes, including single cell, programmable burst

size, and constant rate

1

• Transmission of ATM traffic that simulates CBR, VBR, and UBR service

categories with programmable random, poisson, or constant traffic distribution

patterns

• AAL type recognition

• OAM cell transmit and monitoring of AIS, RDI, and loopback F4 and F5

flows

• Quality of service measurements: CTD (mean, max), CDV (max), CLR, and

CMR.

In addition to advanced diagnostic and testing capabilities, the OC3port Plus gives

you immediate feedback on the condition of any OC3 circuits under test through

its front-panel LEDs. The tester also lets you store and print test results, making it

possible for you to gather and later examine network statistics.

For long-term monitoring, the OC3port Plus can be connected to a network, which

can be monitored remotely through a modem connected to a PC with Fluke’s

remote control software. This gives you the added advantage of being able to leave

the OC3port Plus connected at a customer premise or central office location and

dial into the tester from a PC or laptop computer from a central monitoring

location.

1-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

OC3port Plus

Users Manual

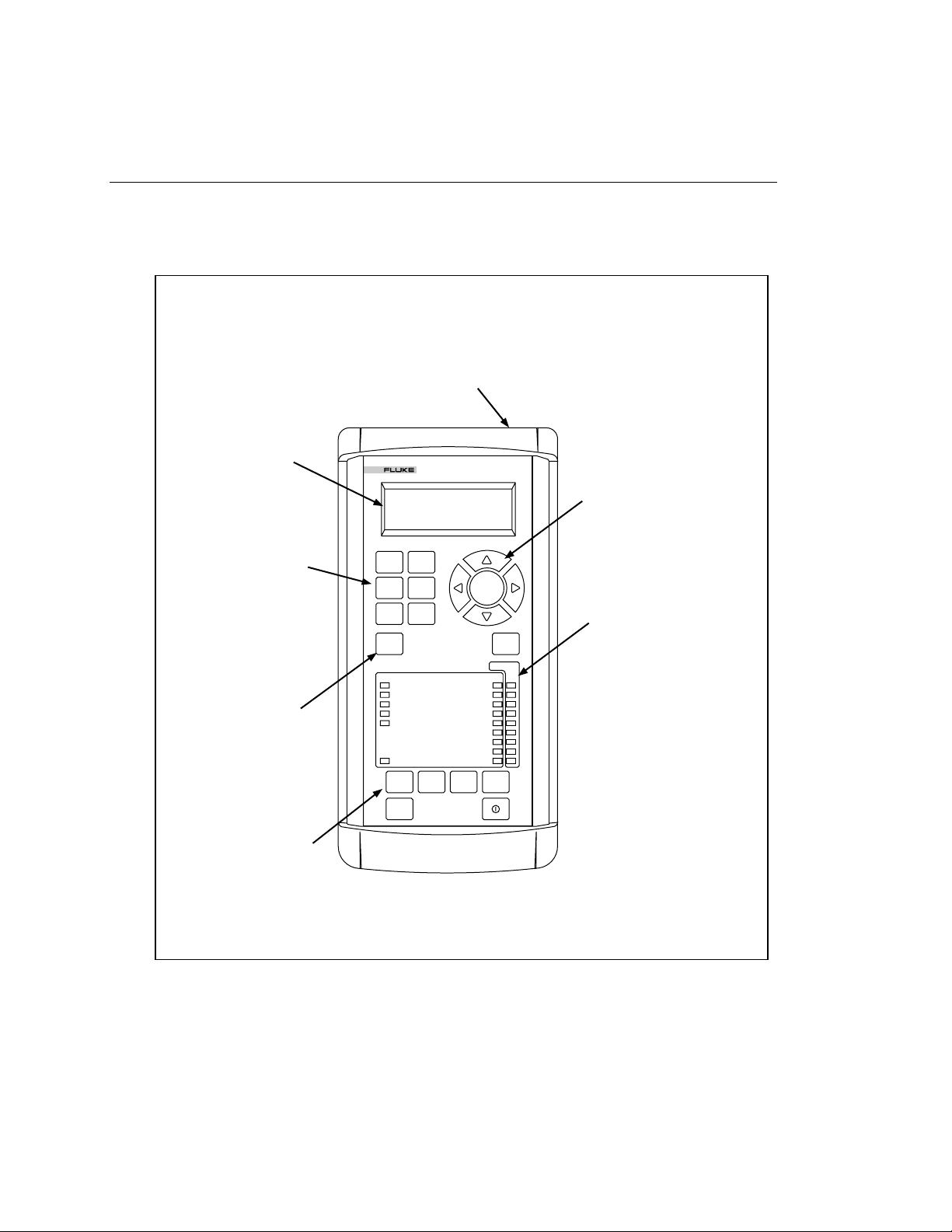

The OC3port Plus Handheld Tester: at a Glance

The OC3port Plus is an easy-to-use handheld tester. It is rugged yet lightweight, so

you can use it anywhere.

RS-232 port provides an interface

for connecting to a printer, remote

control, and downloading test results

For-line by 20-characters

backlit LCD displays test

results and setup

parameters

Six function keys provide

direct access to setup and

configuration options

START/STOP key to

easily control the running

of tests

SONET

BERT

ALARMS

START

STOP

STATUS

STATUS SECTION LOS

ATM CELL LOCK SECTION LOF

ALARMS SECTION OOF

PATTERN / ERROR INSERT LINE FERF

LOOPBACK

POWER

PRINT MEMORY CLEAR DELETE

ESC

OC3port

ATM

AUTO

OPTIONS

PLUS

PATH LOSS OF POINTER

ENTER

CURRENT

LINE AIS

PATH FERF

PATH AIS

PATH YELLOW

EDIT

HISTORY

Arrow keys navigate through

menu items. Up and Down

keys display options. Left

and Right keys choose

settings

Front panel LEDs provide

immediate indications of

OC3 Section, Line, and Path

errors and alarms

1-6

Print stored test results to a

printer or PC

za001f.eps

Figure 1-1. OC3port Plus at a Glance

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

Specifications

This section describes the physical and operational characteristics of the OC3port

Plus.

OC3 Physical

Bit rate: 155.52 Mbps ± 20 ppm

Receiver:

• Single-mode version:

• Multi-mode version:

• UTP-155 version: ATM Forum UTP-155-PMD compliant

Transmit Outputs:

• Single-mode version:

OC3port Plus Features and Capabilities

Maximum input power: -8 dBm

Minimum receive sensitivity: -28 dBm

Maximum input power: -14 dBm

Minimum receive sensitivity: -32.5 dBm

Introduction

1

Average output power: -12.5 dBm (typical)

Range: -15 dBm to -8 dBm

Center wavelength: 1260 to 1360 nm, spectral width: 7.7 nm

• Multi-mode version:

Average output power range: -19 dBm to -14 dBm

Center wavelength: 1270 to 1380 nm, spectral width: 130 nm

• UTP-155 version: ATM Forum UTP-155-PMD compliant

NRZ encoded

Transmit level: 0.90 - 1.10 Vpp

1-7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

OC3port Plus

Users Manual

Physical

Power

Environmental

Size: Approximately 10 in (L) by 6.75 in (W) by 2 in (H)

Weight: 2.50 lbs.

Display: Back-light, 4-line by 20-character text

Connectors:

Single-mode version: FC/PC or SC Duplex

Multi-mode version: SC Duplex

UTP-155 version: RJ-45

AC operations: Operates from an external AC adapter/charger.

Battery type: Operates from internal rechargeable Ni-Cad battery.

Battery life: Minimum battery life is three hours of continuous use.

Recharge time: 12 hours.

Operating temperature: 0 °C to 50 °C

Storage temperature: -20 °C to +60 °C

Humidity: 5 % to 90 % non-condensing

Serial Communications Port

Port: EIA/RS-232

Connector: RJ-11 connector

Baud rates: 1200, 2400, 9600

Flow control: XON/XOFF or RTS/CTS

Standards Compliance

Applicable sections of ATM Forum UNI 3.1

Applicable sections of ANSI T1.105

Applicable sections of BellCore TR-NWT-000253

Applicable sections of ITU I.432, ITU I.610, and ITU I.510

1-8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

Regulatory Compliance

Instrument complies with ETL product category 31

Instrument complies with FCC Part 15, Subpart B, Class A

OC3 Errors Detected

Section, Line, and Path Bit Interleave Parity errors; Line and Path Far-End-Block

errors.

OC3 Alarms Detected

Signal Loss, Loss of Frame, Line FERF, Line AIS, Path FERF, Path AIS, Path

YELLOW, Loss of Pointer alarms.

OC3 Alarms Generated

Signal Loss, Loss of Frame, Line FERF, Line AIS, Path FERF, Path AIS,

Path YELLOW alarms.

SDH-STM-1 Support

SDH option available which provides control and monitoring of S-bits.

Introduction

OC3port Plus Features and Capabilities

1

Pointer Features

Positive and negative pointer adjustment, programmable pointer value, viewable

received pointer value: current, minimum, and maximum.

ATM Layer

Cell mapping: ATM cells carried in the OC3 payload are byte-aligned.

Cell rate adaptation: Provided by the insertion of idle cells.

Cell delineation: Performed using the HEC mechanism as described in ITU I432.

HEC is generated and checked as described in ITU I.432.

1-9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 23

OC3port Plus

Users Manual

Notices, Warnings, Operating Restrictions

This product complies with UL 1950 (2/26/93). This compliance has been certified

for both the United States and Canada by ETL Testing Laboratories and will carry

the ETL listing mark. This product meets the requirements of

FCC Part 15-Subpart A, electronics emission and susceptibility.

Service and adjustment of this unit is to be performed only by trained Fluke

service personnel. The following general safety precautions must be observed

during all phases of operation, service and repair of this instrument. Failure to

comply with these precautions or with specific warnings in this book violate safety

standards of design, manufacture, and intended use of this instrument. Fluke

Corporation assumes no liability for the customer’s failure to comply with these

requirements.

Potential Danger

• Explosion Hazard: Do not operate the system in the presence of flammable

gases.

• Hazardous Material: Should the LCD display become damaged, the liquid

crystal material can leak. Avoid all contact with this material, especially

swallowing. Use soap and water to thoroughly wash all skin and clothing

contaminated with the liquid crystal material.

1-10

• Electric Shock Hazard: Do not remove the system covers. To avoid electric

shock, use only the supplied power module.

• Laser: This product contains a Class 1 Laser Device. Do not look into the

connector labeled "output". Invisible laser energy is emitted from that

connector whenever the laser is on.

Warning

AC adapter/charger:

Only the Fluke-supplied AC adapter/charger may be used

with this equipment. The use of any other AC

adapter/charger is expressly forbidden and will void all

warranty rights.

Outlet:

The AC socket outlet shall be installed near the equipment

and shall be easily accessible. Failure to have this outlet

easily accessible may constitute a safety hazard.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

Laser Operation

The single-mode version of the OC3port Plus contains a laser transmitting device.

As a safety precaution, this transmitter is off when the tester is powered on. For

the tester to function, you must turn on the laser setting. See "Starting the OC3port

Plus" in Chapter 3 for instructions on how to turn on the laser transmitter. The

laser turns on automatically if there is an input signal while you are running the

automatic diagnostic tests.

Checking Your Package

Take time to check your OC3port Plus package. The following items are included:

• 3'TSVX4PYW2IX[SVO%REP]^IV9WIVW1ERYEP

• %'EHETXIVGLEVKIV

• 3'TSVX4PYWRIX[SVOEREP]^IV

• 6.XS6.GEFPI

• 6.XS(&JIQEPIEHETXIV

• (&XS(&JIQEPIEHETXIV

• DB-9 to DB-25 male adapter

If your package does not contain an item from this list contact Fluke at one of the

telephone numbers listed under "Technical Support" below.

Introduction

Laser Operation

1

Technical Support

Fluke Corporation offers a variety of support options to help you get the most from

your OC3port Plus. If you require technical support, please have the following

information available:

• Your name and company.

• OC3port Plus model number and serial number.

• OC3port Plus software revision that appears when you power on the unit.

• Any error messages or flags that appear on the screen.

• Make, model numbers, and configurations of equipment under test.

• A printout of the setup parameters for the OC3port Plus.

For application or operation assistance or information about the OC3port Plus,

call:

USA and Canada: 1-888-993-5853

Europe: +31 402-678-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-356-5500

Or, visit Fluke’s web site at

www.fluke.com.

1-11

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

OC3port Plus

Users Manual

Service Center Repair

If the OC3port Plus requires service, pack it in the original shipping container and

send it, postage paid and insured, to the nearest Fluke Service Center. Include a

written description of the problem. Fluke assumes no responsibility for shipping

damage.

If the OC3port Plus is covered under warranty, it will be properly repaired or

replaced (at Fluke’s option) and returned to you, postage paid, at no charge. See

the registration card for warranty terms. If the warranty has lapsed, Fluke will

repair the unit for a fixed fee and return it to you postage paid. Contact the nearest

Service Center for information and repair prices.

For service information in the USA, call 1-888-99-FLUKE (1-888-993-5853).

Outside the USA, contact the nearest Service Center.

Visit Fluke’s web site at

www.fluke.com.

1-12

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

Chapter 2

Getting Started

Contents Page

Introduction...................................................................................................... 2-3

OC3port Plus Controls and Connections......................................................... 2-3

The Connector Panel................................................................................. 2-3

The Front Panel......................................................................................... 2-4

The LCD............................................................................................... 2-4

Direct Access Keys............................................................................... 2-5

Status Section........................................................................................ 2-7

System Control Keys............................................................................ 2-10

Getting Acquainted with the OC3port Plus Menus......................................... 2-12

Accessing a Menu..................................................................................... 2-13

Using the Directional Arrow Keys............................................................ 2-14

Scrolling through Menu Options .......................................................... 2-14

Changing the Setting for an Option...................................................... 2-15

Editing the Setting for an Option.......................................................... 2-16

Accessing OC3port Plus Submenus.......................................................... 2-17

Exiting OC3port Plus Submenus .............................................................. 2-18

Connecting the OC3port Plus.......................................................................... 2-18

Connecting the OC3port Plus to Network Devices................................... 2-19

Connecting to Remote Devices................................................................. 2-19

Connecting the OC3port Plus to a PC or Laptop.................................. 2-19

Connecting the OC3port Plus to a Modem........................................... 2-20

Connecting to a Printer.............................................................................. 2-20

Connecting to an External Power Supply ................................................. 2-21

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-1

Page 27

OC3port Plus

Users Manual

2-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

Introduction

Chapter 2 first acquaints you with the physical layout of the OC3port Plus so that

you know where the various controls and connections are located and understand

the functions of the keys and general status indicators. Next, it describes the menu

interface and shows you how to access the menus and navigate through them.

Finally, chapter 2 describes how to connect the OC3port Plus to an external power

source and how to connect the tester to the network and to remote devices.

OC3port Plus Controls and Connections

The OC3port Plus has two main panels: a connector panel and a front panel with

status and control sections. Take a moment to become familiar with these two

panels so that you can work more efficiently.

The Connector Panel

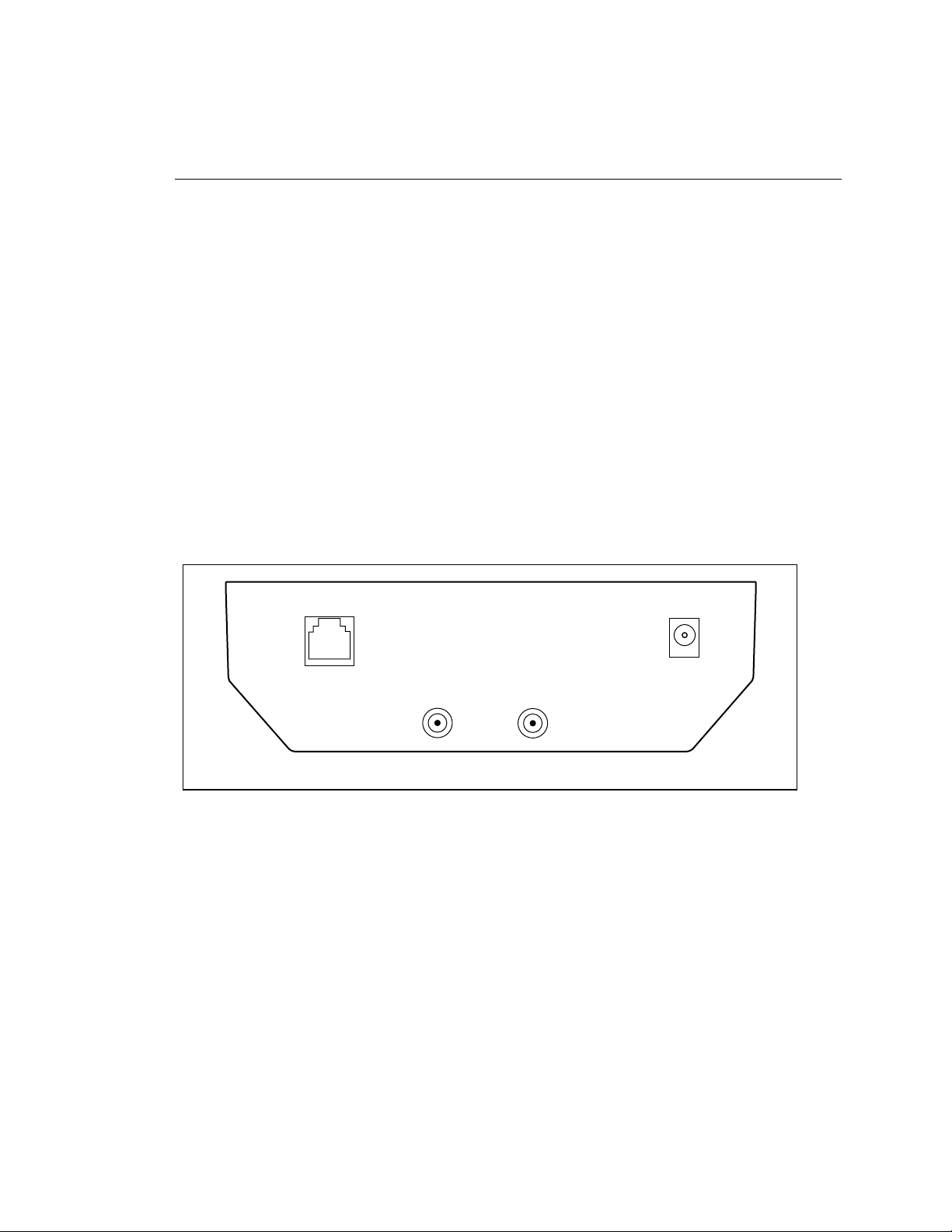

Figure 2-1 is a representation of the OC3port Plus connector panel.

Getting Started

Introduction

2

RS232

IN

Single mode displayed

Figure 2-1. OC3port Plus Connector Panel

The connector panel, which is located on the top of the tester, has a 5V DC input

jack.

Use this jack to attach the AC adapter/charger supplied by Fluke Corporation.

OUT

5VDC

za002f.eps

2-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

OC3port Plus

Users Manual

The Front Panel

Warning

Do not disconnect the AC adapter/charger while the

OC3port Plus is powered on. Doing so can result in the

corruption of current or stored test results.

Only an AC adapter/charger supplied by Fluke can safely

be used with the OC3port Plus. Use of any other adapter

voids your warranty and can damage the tester.

Network connectors. The IN and OUT connector jacks are

attached to the OC3 network. Depending on the type of

interface, you will attach single-mode, multi-mode, or

twisted pair connections to these jacks.

EIA-232 serial port. This is a RJ-11 female jack that

accepts the Fluke-supplied serial conversion cable. Using

this cable, you can download to a PC or a printer and

upload the latest version of OC3port Plus software.

The front panel contains four main sections:

• LCD

2-4

• Direct access keys

• Status section

• System keys

Descriptions of these sections follow.

The LCD

The LCD is located at the top of the tester. It is a four-line by 20-character back-

light display that presents the OC3port Plus menus, test configurations, and results

of specific tests.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

Direct Access Keys

The OC3port Plus has six direct access keys that provide immediate access to tests

and user setup options. These keys are located on the upper left side of the unit

directly across from the

Figure 2-2 is a representation of the LCD and the direct access keys.

ENTER key.

OC3port

Getting Started

OC3port Plus Controls and Connections

PLUS

2

SONET

BERT

ALARMS

START

STOP

ATM

AUTO

OPTIONS

ENTER

EDIT

Figure 2-2. OC3port Plus LCD and Direct Access Keys

za003f.eps

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-5

Page 31

OC3port Plus

Users Manual

Direct Access Key Function

SONET Accesses OC3 and STS-3c setups and tests.

ATM Accesses ATM setups and tests.

BERT Accesses Bit Error Rate test parameters and tests.

AUTO Accesses automatic diagnostic tests and identifies virtual

ALARMS Displays, clears, and controls SONET alarms.

OPTIONS Stores user-defined opt8ions in internal memory.

START/STOP Starts and stops testing.

The Table 2-1 lists the six direct access keys other front panel keys and describes

their function.

Table 2-1. OC3port Plus Direct Access Keys and their Function

paths/channels with ATM activity.

In burst mode, pressing this key initiates a burst of ATM cells.

In transmit mode, pressing this key once pauses transmission;

pressing the key again causes transmission to resume.

EDIT Places the tester in Edit mode for changing the parameters for an

option.

ENTER Accepts user options and editing changes.

2-6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

Status Section

The lower middle section of the front panel on the OC3port Plus contains 24 LEDs

that represent the operating and alarm status of the OC3port Plus and any attached

network.

Figure 2-3 is a representation of the status section.

STATUS

STATUS SECTION LOS

ATM CELL LOCK SECTION LOF

ALARMS SECTION OOF

PATTERN / ERROR INSERT LINE FERF

LOOPBACK

POWER

PATH LOSS OF POINTER

PATH FERF

PATH YELLOW

Getting Started

OC3port Plus Controls and Connections

HISTORY

CURRENT

LINE AIS

PATH AIS

2

Figure 2-3. OC3port Plus Status LEDs

The six general status LEDs appear on the left.

These LEDs provide laser transmitter status, ATM status, and power status

information.

za004f.eps

2-7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 33

OC3port Plus

Users Manual

LED Name LED Condition Meaning

Table 2-2 lists the general status LEDs and their meanings.

Table 2-2. OC3port Plus General Status LEDs

STATUS Slow blinking

Constant Green

Indicates that the laser transmitter is set to

OFF. (for single-mode units only)

Indicates that the laser transmitter is set to

ON. (For single-mode units only).

ATM CELL LOCK On Indicates that ATM cell delineation has been

achieved.

ALARMS On Indicates that alarms are being transmitted

PATTERN / ERROR

INSERT

On Indicates that patterns or errors are being

transmitted.

LOOPBACK On Indicates that the unit is in line loopback or in

cell loopback mode.

POWER ON

Blinking

Indicates adequate AC or battery power.

Indicates that the battery is low on power.

The remaining 18 LEDs, found on the right side of the tester, indicate the status of

the connected SONET network.

The OC3port Plus can detect nine separate alarms.

The red LEDs indicate active or current alarms, while the yellow (History) LEDs

indicate that an alarm occurred at some time in the past but is no longer being

detected.

2-8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 34

Getting Started

OC3port Plus Controls and Connections

Table 2-3 lists the alarms the OC3port Plus can detect and their meanings.

Table 2-3. SONET Alarms Detected by the OC3port Plus on the Status LEDs

SONET Status LED Description

2

SECTION LOS

(Loss of Signal)

SECTION LOF

(Loss of Frame)

SECTION OOF

(Out of Frame)

LINE FERF

(Far End Receive Failure)

LINE AIS

(Line Alarm Indication Signal)

Lights when an incoming optical OC3 signal cannot be

detected.

Declared when a Section OOF condition persists for

three milliseconds.

This three-millisecond timer does not reset until an in-

frame condition also persists for three milliseconds,

prohibiting oscillations and the declaration of an LOF

in the presence of intermittent OOF conditions.

Declared when four consecutive STS-3c frames

containing one or more framing pattern errors are

received.

A Section OOF alarm is removed when two sequential

frames with correct framing patterns are detected (an

in-frame condition).

Detects the presence of a Line FERF in the received

STS-3c stream.

Declared when a “110” pattern is detected in bits 6, 7

and 8 of the K2 framing byte for five consecutive

frames.

A LINE FERF alarm is removed when a pattern other

than “110” is detected for five consecutive frames.

Detects the presence of a Line FERF in the received

STS-3c stream.

Declared when a “111” pattern is detected in bits 6, 7

and 8 of the K2 framing byte for five consecutive

frames.

A Line AIS alarm is removed when a pattern other

than “111” is detected for five consecutive frames.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-9

Page 35

OC3port Plus

Users Manual

Table 2-3. SONET Alarms Detected by the OC3port Plus on the Status LEDs (cont.)

PATH FERF

(Far End Receive Failure)

SONET Status LED Description

Dedicated when the 4

Status Byte (G1) is set to “1001” for two consecutive

frames.

th

bit FEBE field within the Path

If any other pattern is present for two consecutive

frames, a Path FERF alarm is removed.

PATH AIS

(Alarm Indication Signal)

Declared when an all-ones pattern is detected in the

pointer bytes (H1 and H2) for three consecutive STS-3c

frames.

A Path AIS alarm is removed whenever a valid pointer is

detected in H1 and H2 for three consecutive frames.

PATH YELLOW Declared whenever bit 5 of the Path Status Byte (G1) is

set high (1) for five consecutive frames.

A path YELLOW alarm is removed when bit 5 returns

low (0) for five consecutive frames.

PATH LOSS OF POINTER Declared whenever a normal pointer (generally values

within the 0 to 782 range) is not found in eight

consecutive frames.

Path Loss of Pointer is removed when a valid pointer is

detected for three consecutive frames.

A received Path AIS indication does not result in a Path

Loss of pointer alarm.

Negative and Positive stuff indications do not trigger a

Path Loss of Pointer alarm.

System Control Keys

The system control keys are located at the bottom of the tester.

You use these keys to control the entire unit; for example, to turn the OC3port Plus

on and off (

ON/OFF key), to print configuration information and test results (PRINT

key), and to clear counters and delete alarms. (CLEAR key)

2-10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

Getting Started

OC3port Plus Controls and Connections

Figure 2-4 is a representation of the system control keys, which are found on the

bottom part of the front panel.

PRINT MEMORY CLEAR DELETE

ESC

za005f.eps

Figure 2-4. The System Keys Control the Entire Unit.

2

Table 2-4 lists the system control keys and describes their usage.

Table 2-4. Description of the System Control Keys on the OC3port Plus

Key Name Description

ON/OFF Turns the unit on and off.

ESC A single press returns you to the introductory display (see

“Returning to the Introductory Display” in Chapter 3).

A double-press resets the OC3port Plus (see “Resetting the

OC3port Plus” in Chapter 3).

PRINT Prints test results and configuration information.

MEMORY Stores and retrieves test results.

CLEAR Resets the test result counters and deletes individual test

results.

DELETE Clears the alarm history LEDs and deletes stored results.

2-11

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 37

OC3port Plus

Users Manual

Getting Acquainted with the OC3port Plus Menus

The OC3port Plus is a menu driven system. Each time you power on the unit, a

series of self-tests and automatic ATM and SONET diagnostic tests is performed.

Note

The single-mode version of the OC3port Plus contains a laser

transmitting device. As a safety precaution, this transmitter is off

when the unit is powered on. You must turn the laser on each time

you turn on the unit. It remains on until you shut off the unit.

See "Turning on the Laser Transmitter" in this chapter for

instructions on how to turn on the laser transmitter. Note that the

laser comes on automatically if the OC3port Plus detects an input

signal while you are running the automatic diagnostic tests.

While the automatic tests are running, you see displays similar to this:

******************************

ANALYZING

SIGNAL 14

2-12

******************************

za006f.eps

When the tests are completed, you hear a "beep" and see the AUTOTEST SUMMARY

display, which looks like this:

AUTOTEST SUMMARY

- - - - - - - - - - - - - - - - - - - - - - - - -

ATM Detected: OK

Background: UNAS

za007f.eps

From this display, you can access any of the OC3port Plus menus. See "Accessing

a Menu", which follows in this chapter.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 38

Accessing a Menu

You can access any OC3port Plus menu by simply pressing one of the six direct

access keys located under the LCD. For example, press the

OC3port Plus displays the following:

The display has four lines of information:

Getting Acquainted with the OC3port Plus Menus

OPTION SELECTIONS

- - - - - - - - - - - - - - - - - - - - - - -

Parameter Set 1

RS-232 Speed 96

Getting Started

2

OPTIONS key. The

za008f.eps

• Line 1 contains the menu title, which in this example is named

SELECTIONS

.

OPTIONS

• Line 2 is a dashed line. Depending on its location, this line indicates where

you are on a menu. If the line appears directly under the menu title, as it does

in this example, it is the

menu, it is the

end-of-menu bar.

top-of-menu bar. If it appears at the bottom of the

• Line 3 is the selection line. The arrow (È) to the left of the option means that

it can be selected or changed (when you are in edit mode). To the right of the

option is a greater-than symbol ("), which is followed by a . A greater-than

symbol can be followed by a number, a word, or a three-letter abbreviation,

which is the current value of the option. In this example, the current value for

the

Parameter Set option is .

Note

• When you press the

Left or Right Arrow key to change the setting of an option

that has a greater-than symbol (") after it, that new setting takes effect

immediately.

• Line 4 displays the next item on the menu, which in this case is

Speed

option

The OC3port Plus main menus contain a variety of items. These include:

• Options These present choices for you to make when programming

the RS-232

the OC3port Plus

• Actions These let you perform a test or setup function; for example,

Start BERT or Setup RX Filtrs.

• Test items

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

These let you start or monitor test results

2-13

Page 39

OC3port Plus

Users Manual

Figure 2-5 is an illustration of the OC3port Plus menu system. All of the tester’s

functions are accessed through this menu system. On the first level is the

introductory display, which is the display you see when you first turn on or reset

the tester. On the second level are the six direct access keys. These keys control the

operation of the entire tester. When you press any one of these keys, you gain

direct access to the selected function and any of its related subfunctions.

FLUKE CORPORATION

OC3port+ 3.3

03-14-99 7:22:10 PM

SELECT MENU FUNCTION

Press ESC twice

to reset the OS3port+

SONET

SONET

SELECTIONS

Laser

Moniter STS-3c

Insert Errors

Setup STS-3c

Pointer Actions

Loopback STS-3c

ATM BERT AUTO ALARMS OPTIONS

ATM

SELECTIONS

Moniter ATM

Setup RX Filtrs

Setup XMIT Streams

Load XMIT Streams

ATM XMIT Mode

Cell Capture

Quality of Service

OAM Transmit

OAM Moniter

ATM Options

Load Temp Trfc Only

Load Temp Trfc & Hdr

BERT

SELECTIONS

Start BERT

Select BERT Pat

Setup Error Inj

Figure 2-5. OC3port Plus Menu System (Version 3.3)

Using the Directional Arrow Keys

You use the directional arrow keys to scroll through OC3port Plus menus and,

where applicable, to change parameters or edit values for options. There are four

arrow keys, each named for the direction in which they point: the

Down Arrow key, the Left Arrow key, and the Right Arrow key.

the

Scrolling through Menu Options

The Up and Down Arrow keys are used to scroll through the options listed on

OC3port Plus menus.

AUTO

SELECTIONS

IP Ping

AAL Type Detect

Auto Store

ATM Activity Scan

Start Auto Test

Review Auto Test

ALARM

SELECTIONS

Section LOS

Line AIS

Line FERF

Path AIS

Path FERF

Path YELLOW

LOS Action

View Alarm Log

OPTIONS

SELECTIONS

Parameter Set

RS-232 Speed

Scroll Method

Set Buzzer

Factory Defaults

User Info

General Info

Modem Init String

Date Time Editor

Beep Alarm/Err

Auto Test Featre

za009f.eps

Up Arrow key,

2-14

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

The scrolling behavior of the

programmable. The examples in this book assume that you are using

the default scrolling method, which is

this scrolling method, see "Changing the Default Scrolling Method"

in Chapter 3.

When you press the Down Arrow key, the menu selection that was previously on

the fourth line of the display moves up to the selection line. If you continue to

press this key, you eventually reach the end-of-menu bar, and the unit "beeps" if

you try to go past this point. To scroll in the opposite direction, press the Up

Arrow key.

Changing the Setting for an Option

The Left and Right Arrow keys are used to change the settings for options found on

OC3port Plus menus. The following example shows you how to use these keys to

change the setting for an option.

Getting Started

Getting Acquainted with the OC3port Plus Menus

Note

Up

and

Down Arrow

WIN

(for Windows). To change

keys is user-

2

1. Press the

change to the selection line. For example:

Up or Down Arrow key to move the option whose setting you want to

OPTION SELECTIONS

- - - - - - - - - - - - - - - - - - - - - - -

Parameter Set 1

RS-232 Speed 96

Note that the Parameter Set option is on the selection line as indicated by the

arrow to its left.

2. Press the

(in this example, the ) changes to one of the other available settings for this

option. Continue pressing the arrow key until the setting you want is displayed.

The change takes effect immediately. The value you display by pressing the

Left or Right Arrow key becomes the current setting for the option that is on the

selection line.

Left or Right Arrow key. Notice that the value of the current setting

za008f.eps

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-15

Page 41

OC3port Plus

Users Manual

Editing the Setting for an Option

Some settings for an option require you to supply a value rather than select an item

from a menu. You do this by editing the current value of the setting. This example

shows you how to edit a setting.

1. Press the

ATM key. The ATM SELECTIONS menu is displayed:

ATM SELECTIONS:

- - - - - - - - - - - - - - - - - - - - - - -

Monitor ATM

Setup RX Filters

za010f.eps

2. Press the Down Arrow key until the Setup RX Filtrs option is on the selection

line, as in:

ATM SELECTIONS:

Monitor ATM

Setup RX Filtrs

Setup XMIT Streams

za011f.eps

3. Press ENTER. You see the RECEIVE FILTER 1 submenu:

2-16

RECEIVE FILTER: 1

or for Change

NAME:FILTER_1_

LOAD TX HDR TX1

za012f.eps

4. Press the Down Arrow key until the VCI setting is on the selection line (as

indicated by the blue directional arrows located on each side of the LCD).

Then, press the

The first character of the VCI field is flashing. This flashing character

indicates that you are now in Edit mode.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

EDIT key.

Page 42

Getting Started

Getting Acquainted with the OC3port Plus Menus

5. Press the Up or Down Arrow key until the value you want in the first position of

the VCI field is displayed. Then, press the

position.

Right Arrow key to move to the next

2

6. Continue pressing the

the

Right Arrow key to move to the next position in the field.

7. When you are finished making changes, do one of the following:

a. Press the

b. Press the

changes and restores the original value.

Accessing OC3port Plus Submenus

Many options on the OC3port Plus menus have an extended menu or submenu that

you have to access when you need to change their parameters. Some of the

OC3port Plus tests, for example, have many parameters, so to modify these, you

may have to access a submenu.

Typically, any option on a menu that appears by itself (that is, with no setting to its

right) has an additional menu (submenu) associated with it.

The following example shows you how to access an OC3port Plus submenu.

1. Press the

displayed. For example:

ENTER key. You exit Edit mode. The tester saves your changes.

EDIT key. You exit Edit mode. The tester does not save your

SONET direct access key. The SONET SELECTIONS main menu is

SONET SELECTIONS

- - - - - - - - - - - - - - - - - - - - - - -

Up or Down Arrow key to display the desired value and

Monitor STS-3c

Insert Errors

za013f.eps

2. Press the Down Arrow key until the Setup STS-3c option is on the selection line

as in the following:

SONET SELECTIONS

Insert Errors

Setup STS-3c

Pointer Actions

za014f.eps

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-17

Page 43

OC3port Plus

Users Manual

3. Press ENTER. You are now accessing the STS-3c SETUP submenu:

STS-3c SETUP:

- - - - - - - - - - - - - - - - - - - - - - -

Path Auto YEL OFF

Line Auto FERF OFF

This submenu contains all of the STS-3c setup parameters. You navigate

through this and all other submenus by pressing the

move an option to the selection line and then pressing the

key to choose a value for the option.

Exiting OC3port Plus Submenus

To leave a submenu, simply press the ESC key to return to the introductory

display, or press any one of the direct access keys to begin a specific test or

perform a setup.

Connecting the OC3port Plus

Depending on the specific physical interface, the OC3port Plus is designed to be

connected to either intermediate-range, single-mode fiber systems, multi-mode

fiber optic systems, or unshielded twisted pair-155 systems. A single-mode

OC3port Plus uses fiber optic connectors located on the top of the tester.

The multi-mode version of the OC3port Plus is designed to be connected to multi-

mode fiber systems. This version uses the SC Duplex fiber-optic connectors

located on the top of the tester.

za015f.eps

Up or Down Arrow key to

Left or Right Arrow

2-18

The UTP-155 version of the OC3port Plus is designed to be connected to UTP-155

networks.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 44

Connecting the OC3port Plus to Network Devices

You need the appropriate type of cable to connect the OC3port Plus to network

devices. You can contact Fluke to obtain a variety of fiber optic and UTP cables.

Warning

Do not move the fiber connectors from side to side as you

insert them into the receptacles. Doing so can cause the

alignment ferrule to break.

1. To receive signals from network devices, connect the fiber optic cable to the

OC3port Plus

2. To send signals on the line, connect the fiber optic cable to the OC3port Plus

OUT jack.

To create a loopback situation, complete both steps.

IN jack.

Connecting to Remote Devices

The OC3port Plus provides two methods of making remote (RS-232) connections:

direct and modem. The direct method allows you to connect the OC3port Plus to a

PC. You can then use the PC to control the OC3port Plus or to print test results. If

you prefer this type of connection, the PC must have the appropriate software to

control these functions. Contact Fluke Corporation for a programming book or

information about the Testview package.

Getting Started

Connecting the OC3port Plus

2

As an alternative, you can use the RS-232 line to connect the OC3port Plus to a

modem. After these connections are made, you must set the baud rate from the

OC3port Plus and change the communication settings from the receiving device.

Connecting the OC3port Plus to a PC or Laptop

To connect the OC3port Plus to a PC or laptop computer, do the following:

1. Connect the RS-232 line to the OC3port Plus.

2. Connect the other end to the computer serial port. If the computer has a DB-9

connector, use a DB-25-to-DB-9 converter.