Page 1

®

NORMA 4000/5000

Power Analyzer

Operators Manual

PN 2842188

June 2007 Rev.2, 5/12

© 2007-2012 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is two years and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

To register your product online, visit http://register.fluke.com.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Page 3

BEGRENZTE GEWÄHRLEISTUNG UND HAFTUNGSBESCHRÄNKUNG

Fluke gewährleistet, daß jedes Fluke-Produkt unter normalem Gebrauch und Service frei von Material- und

Fertigungsdefekten ist. Die Garantiedauer beträgt 2 Jahre ab Versanddatum. Die Garantiedauer für Teile,

Produktreparaturen und Service beträgt 90 Tage. Diese Garantie wird ausschließlich dem Ersterwerber bzw.

dem Endverbraucher geleistet, der das betreffende Produkt von einer von Fluke autorisierten Verkaufsstelle

erworben hat, und erstreckt sich nicht auf Sicherungen, Einwegbatterien oder andere Produkte, die nach

dem Ermessen von Fluke unsachgemäß verwendet, verändert, verschmutzt, vernachlässigt, durch Unfälle

beschädigt oder abnormalen Betriebsbedingungen oder einer unsachgemäßen Handhabung ausgesetzt

wurden. Fluke garantiert für einen Zeitraum von 90 Tagen, daß die Software im wesentlichen in

Übereinstimmung mit den einschlägigen Funktionsbeschreibungen funktioniert und daß diese Software auf

fehlerfreien Datenträgern gespeichert wurde. Fluke übernimmt jedoch keine Garantie dafür, daß die

Software fehlerfrei ist und störungsfrei arbeitet.

Von Fluke autorisierte Verkaufsstellen werden diese Garantie ausschließlich für neue und nicht benutzte, an

Endverbraucher verkaufte Produkte leisten. Die Verkaufsstellen sind jedoch nicht dazu berechtigt, diese

Garantie im Namen von Fluke zu verlängern, auszudehnen oder in irgendeiner anderen Weise abzuändern.

Der Erwerber hat nur dann das Recht, aus der Garantie abgeleitete Unterstützungsleistungen in Anspruch

zu nehmen, wenn er das Produkt bei einer von Fluke autorisierten Vertriebsstelle gekauft oder den jeweils

geltenden internationalen Preis gezahlt hat. Fluke behält sich das Recht vor, dem Erwerber Einfuhrgebühren

für Ersatzteile in Rechnung zu stellen, wenn dieser das Produkt in einem anderen Land zur Reparatur

anbietet, als dem Land, in dem er das Produkt ursprünglich erworben hat.

Flukes Garantieverpflichtung beschränkt sich darauf, daß Fluke nach eigenem Ermessen den Kaufpreis

ersetzt oder aber das defekte Produkt unentgeltlich repariert oder austauscht, wenn dieses Produkt

innerhalb der Garantiefrist einem von Fluke autorisierten Servicezentrum zur Reparatur übergeben wird.

Um die Garantieleistung in Anspruch zu nehmen, wenden Sie sich bitte an das nächstgelegene und von

Fluke autorisierte Servicezentrum, um Rücknahmeinformationen zu erhalten, und senden Sie dann das

Produkt mit einer Beschreibung des Problems und unter Vorauszahlung von Fracht- und

Versicherungskosten (FOB Bestimmungsort) an das nächstgelegene und von Fluke autorisierte

Servicezentrum. Fluke übernimmt keine Haftung für Transportschäden. Im Anschluß an die Reparatur wird

das Produkt unter Vorauszahlung von Frachtkosten (FOB Bestimmungsort) an den Erwerber

zurückgesandt.Wenn Fluke jedoch feststellt, daß der Defekt auf Vernachlässigung, unsachgemäße

Handhabung, Verschmutzung, Veränderungen am Gerät, einen Unfall oder auf anormale

Betriebsbedingungen, einschließlich durch außerhalb der für das Produkt spezifizierten Belastbarkeit

verursachten Überspannungsfehlern, zurückzuführen ist, wird Fluke dem Erwerber einen Voranschlag der

Reparaturkosten zukommen lassen und erst die Zustimmung des Erwerbers einholen, bevor die Arbeiten

begonnen werden. Nach der Reparatur wird das Produkt unter Vorauszahlung der Frachtkosten an den

Erwerber zurückgeschickt, und es werden dem Erwerber die Reparaturkosten und die Versandkosten (FOB

Versandort) in Rechnung gestellt.

DIE VORSTEHENDEN GARANTIEBESTIMMUNGEN STELLEN DEN EINZIGEN UND ALLEINIGEN

RECHTSANSPRUCH AUF SCHADENERSATZ DES ERWERBERS DAR UND GELTEN

AUSSCHLIESSLICH UND AN STELLE VON ALLEN ANDEREN VERTRAGLICHEN ODER

GESETZLICHEN GEWÄHRLEISTUNGSPFLICHTEN, EINSCHLIESSLICH - JEDOCH NICHT DARAUF

BESCHRÄNKT - DER GESETZLICHEN GEWÄHRLEISTUNG DER MARKTFÄHIGKEIT, DER

GEBRAUCHSEIGNUNG UND DER ZWECKDIENLICHKEIT FÜR EINEN BESTIMMTEN EINSATZ.FLUKE

HAFTET NICHT FÜR SPEZIELLE, UNMITTELBARE, MITTELBARE, BEGLEIT- ODER FOLGESCHÄDEN

ODER VERLUSTE, EINSCHLIESSLICH VERLUST VON DATEN, UNABHÄNGIG VON DER URSACHE

ODER THEORIE.

Angesichts der Tatsache, daß in einigen Ländern die Begrenzung einer gesetzlichen Gewährleistung sowie

der Ausschluß oder die Begrenzung von Begleit- oder Folgeschäden nicht zulässig ist, kann es sein, daß die

obengenannten Einschränkungen und Ausschlüsse nicht für jeden Erwerber gelten.Sollte eine Klausel

dieser Garantiebestimmungen von einem zuständigen Gericht oder einer anderen Entscheidungsinstanz für

unwirksam oder nicht durchsetzbar befunden werden, so bleiben die Wirksamkeit oder Durchsetzbarkeit

irgendeiner anderen Klausel dieser Garantiebestimmungen von einem solchen Spruch unberührt.

11/99

Page 4

LIMITES DE GARANTIE ET DE RESPONSABILITE

La société Fluke garantit l’absence de vices de matériaux et de fabrication de ses produits dans des

conditions normales d’utilisation et d’entretien. La période de garantie est de deux ans et prend effet à la

date d’expédition. Les pièces, les réparations de produit et les services sont garantis pour une période de

90 jours. Cette garantie ne s’applique qu’à l’acheteur d’origine ou à l’utilisateur final s’il est client d’un

distributeur agréé par Fluke, et ne couvre pas les fusibles, les batteries/piles interchangeables ni aucun

produit qui, de l’avis de Fluke, a été malmené, modifié, négligé, contaminé ou endommagé par accident

ou soumis à des conditions anormales d’utilisation et de manipulation. Fluke garantit que le logiciel

fonctionnera en grande partie conformément à ses spécifications fonctionnelles pour une période de

90 jours et qu’il a été correctement enregistré sur des supports non défectueux. Fluke ne garantit pas

que le logiciel est exempt d’erreurs ou qu’il fonctionnera sans interruption.

Les distributeurs agréés par Fluke appliqueront cette garantie à des produits vendus neufs et qui n’ont pas

servi, mais ils ne sont pas autorisés à offrir une garantie plus étendue ou différente au nom de Fluke. Le

support de garantie est offert uniquement si le produit a été acheté à un point de vente agréé par Fluke ou

bien si l’acheteur a payé le prix international applicable. Fluke se réserve le droit de facturer à l’acheteur les

frais d’importation des pièces de réparation ou de remplacement si le produit acheté dans un pays a été

expédié dans un autre pays pour y être réparé.

L’obligation de garantie de Fluke est limitée, au choix de Fluke, au remboursement du prix d’achat, ou à la

réparation/remplacement gratuit d’un produit défectueux retourné dans le délai de garantie à un centre de

service agréé par Fluke.

Pour avoir recours au service de la garantie, mettez-vous en rapport avec le centre de service agréé Fluke le

plus proche pour recevoir les références d’autorisation de renvoi, puis envoyez le produit, accompagné d’une

description du problème, port et assurance payés (franco lieu de destination), à ce centre de service. Fluke

décline toute responsabilité en cas de dégradations survenues au cours du transport. Après une réparation

sous garantie, le produit sera retourné à l’acheteur, en port payé (franco lieu de destination). Si Fluke estime

que le problème a été causé par une négligence, un mauvais traitement, une contamination, une modification,

un accident ou des conditions de fonctionnement ou de manipulation anormales, notamment de surtensions

liées à une utilisation du produit en dehors des spécifications nominales, ou de l’usure normale des

composants mécaniques, Fluke fournira un devis des frais de réparation et ne commencera la réparation

qu’après en avoir reçu l’autorisation. Après la réparation, le produit sera renvoyé à l’acheteur, en port payé

(franco point d’expédition) et les frais de réparation et de transport lui seront facturés.

LA PRÉSENTE GARANTIE EST EXCLUSIVE ET TIENT LIEU DE TOUTES AUTRES GARANTIES,

EXPRESSES OU IMPLICITES, Y COMPRIS, MAIS NON EXCLUSIVEMENT, TOUTE GARANTIE

IMPLICITE DE VALEUR MARCHANDE OU D’ADÉQUATION À UN USAGE PARTICULIER. FLUKE NE

POURRA ETRE TENU RESPONSABLE D’AUCUN DOMMAGE PARTICULIER, INDIRECT, ACCIDENTEL

OU CONSECUTIF, NI D’AUCUN DEGAT OU PERTE, DE DONNEES NOTAMMENT, SUR UNE BASE

CONTRACTUELLE, EXTRA-CONTRACTUELLE OU AUTRE.

Etant donné que certains pays ou états n’admettent pas les limitations d’une condition de garantie implicite,

ou l’exclusion ou la limitation de dégâts accidentels ou consécutifs, il se peut que les limitations et les

exclusions de cette garantie ne s’appliquent pas à chaque acheteur. Si une disposition quelconque de cette

garantie est jugée non valide ou inapplicable par un tribunal ou un autre pouvoir décisionnel compétent, une

telle décision n’affectera en rien la validité ou le caractère exécutoire de toute autre disposition.

11/99

Page 5

有限保证和责任限制

在正常使用和维护条件下,Fluke 公司保证每一个产品都没有材料缺陷和制造工艺问题。保证期为从产品发货

之日起二年。部件、产品修理和服务的保证期限为 90 天。本项保证仅向授权零售商的原始买方或最终用户 提

供,并且不适用于保险丝和一次性电池或者任何被 Fluke 公司认定由于误用、改变、疏忽、意外、非正 常操

作和使用所造成的产品损坏。Fluke 公司保证软件能够在完全符合性能指标的条件下至少操作 90 天, 而且软

件是正确地记录在无缺陷的媒体上。Fluke 公司并不保证软件没有错误或无操作中断。

Fluke 公司仅授权零售商为最终客户提供新产品或未使用过产品的保证。但并未授权他们代表 Fluke 公司提供

范围更广或内容不同的保证。只有通过 Fluke 授权的销售商购买的产品,或者买方已经按适 当的国际价格 付

款的产品,才能享受 Fluke 的保证支持。在一个国家购买的产品被送往另一个国家维修时,Fluke 公司保 留

向买方收取修理/更换零部件的进口费用的权利。

Fluke 公司的保证责任是有限的,Fluke 公司可以选择是否将依购买价退款、免费维修或更换在保证期内退回

到 Fluke 公司委托服务中心的有缺陷产品。

要求保修服务时,请与就近的 Fluke 授权服务中心联系,获得退还授权信息;然后将产品连同问题描述寄至

该服务中心,并预付邮资和保险费用(目的地离岸价格)。Fluke 对运送途中发生的损坏不承担责任。在保

修之后,产品将被寄回给买方并提前支付运输费(目的地交货)。如果 Fluke 认定产品故障是由于疏忽、 滥

用、污染、修改、意外或不当操作或处理状况而产生,包含使用超出产品特的特定额定值而导致过电压故

障,或是由于机件日常使用耗损,则 Fluke 会估计修理费用,在实际修理之前先获得买方同意。在修理之后,

产品将被寄回给买方并预付运输费;买方将收到修理和返程运输费用(寄发地交货)的帐单。

本保证为买方唯一能获得的全部赔偿内容,并且取代所有其它明示或隐含的保证,包括但不限于适销性或适用

于特殊目的的任何隐含保证。FLUKE 不应对由于任何原因或推理所发生的任何特殊、间接、偶发或后续的 损

坏或损失承担赔偿责任,包括数据丢失。

由于某些国家或州不允许对隐含保证的期限加以限制、或者排除和限制意外或后续损坏,本保证的限制和排除

责任条款可能并不对每一个买方都适用。如果本保证的某些条款被法院或其它具有适当管辖权的裁决机构判定

为无效或不可执行,则此类判决将不影响任何其它条款的有效性或可执行性。

11/99

Page 6

Page 7

Table of Contents

Chapter Title Page

1 About this Document .......................................................................... 1-1

Signs and Symbols ............................................................................................. 1-3

Transport and Storage ........................................................................................ 1-3

Transport ....................................................................................................... 1-3

Storage ........................................................................................................... 1-3

Recalibration ...................................................................................................... 1-3

Maintenance ....................................................................................................... 1-3

Decommissioning and Disposal ......................................................................... 1-4

Shutting Down ............................................................................................... 1-4

Recycling and Disposal ................................................................................. 1-4

Housing ......................................................................................................... 1-4

Electronic Components ................................................................................. 1-4

2 General Safety Instructions ................................................................ 2-1

Introduction ........................................................................................................ 2-3

Protection Class ................................................................................................. 2-3

Qualified Personnel ............................................................................................ 2-3

Safe Operation ................................................................................................... 2-3

Proper Use.......................................................................................................... 2-3

Warranty ............................................................................................................ 2-3

Electrical Connections ....................................................................................... 2-4

Binding Post ....................................................................................................... 2-4

Risks During Operation ..................................................................................... 2-5

Maintenance and Repairs ................................................................................... 2-5

Accessories ........................................................................................................ 2-5

Shutting Down ................................................................................................... 2-5

Safety Instructions on the Device Housing ........................................................ 2-5

Mains Connection .......................................................................................... 2-5

Input Voltage and Current ............................................................................. 2-5

Maintenance .................................................................................................. 2-6

Indoor Use ..................................................................................................... 2-6

3 Design and Functions ......................................................................... 3-1

About this Chapter ............................................................................................. 3-3

i

Page 8

NORMA 4000/5000

Operators Manual

4 Startup .................................................................................................. 4-1

5 Connection to Circuits ........................................................................ 5-1

Terminals (Back) ............................................................................................... 3-3

Operating Controls and Display ......................................................................... 3-4

Navigation and Measuring Keys ................................................................... 3-5

Navigation through Display .......................................................................... 3-6

Overview of Function Keys ........................................................................... 3-6

Functions ............................................................................................................ 3-7

Taking Inventory ................................................................................................ 4-3

Installation and Switching On ............................................................................ 4-3

Installation ..................................................................................................... 4-3

Switching Device On ..................................................................................... 4-3

Switching Device Off .................................................................................... 4-4

Before You Begin .............................................................................................. 5-3

Connecting Sequence ......................................................................................... 5-3

Overview ............................................................................................................ 5-4

1-Phase Measurement ........................................................................................ 5-4

Direct Connection .......................................................................................... 5-4

Measurement with Shunt ............................................................................... 5-6

Measurement with Voltage and Current Transducer ..................................... 5-7

Aron Circuit (2-Wattmeter Method, W2) .......................................................... 5-8

Direct Connection .......................................................................................... 5-8

Measurement with Shunt ............................................................................... 5-10

Measurement with Voltage and Current Transducer ..................................... 5-11

3-Phase Measurement (W3) ............................................................................... 5-13

Direct Connection .......................................................................................... 5-13

Measurement with Shunt ............................................................................... 5-14

Measurement with Voltage and Current Transducer ..................................... 5-15

Measurement with Star Point Adapter ........................................................... 5-17

6 Simple Measurement .......................................................................... 6-1

About this Chapter ............................................................................................. 6-3

Connection to Circuits ....................................................................................... 6-3

Configuration ..................................................................................................... 6-3

Measuring .......................................................................................................... 6-4

7 Configuration ....................................................................................... 7-1

Set Up for Measuring ......................................................................................... 7-3

Configuration ..................................................................................................... 7-3

Five Steps ........................................................................................................... 7-4

Call up General Setup and System Information Screen ..................................... 7-4

General Setup ................................................................................................ 7-4

System Information Screen ........................................................................... 7-4

Load Configuration ............................................................................................ 7-5

Load Configuration (Optional) ...................................................................... 7-5

Modify Loaded Configurations ..................................................................... 7-5

Configure Method .............................................................................................. 7-5

Configure Data Transfer to Printer and PC ........................................................ 7-5

Configure External Printer ............................................................................ 7-6

Configure Interface to PC .............................................................................. 7-7

Configure RS 232 .......................................................................................... 7-7

ii

Page 9

Contents (continued)

Configure GPIB Address ............................................................................... 7-8

Configure Ethernet ........................................................................................ 7-8

Configure Average Time and Synchronization ................................................. 7-9

Timing & Sync Setup .................................................................................... 7-9

Set Average Time .......................................................................................... 7-10

Select Synchronization Source ...................................................................... 7-11

Set Trigger Level ........................................................................................... 7-11

Select Slope Direction ................................................................................... 7-12

Select Low-Pass Filter ................................................................................... 7-12

Configure Signal Output ................................................................................ 7-12

Adjust Date and Time ........................................................................................ 7-13

Configure Current and Voltage Channels .......................................................... 7-13

Current Channel Setup .................................................................................. 7-14

Configure Input Range .................................................................................. 7-15

Automatic Range Adjustment (Auto) ....................................................... 7-15

Manual Range Adjustment (Range) .......................................................... 7-15

Configure Scale ............................................................................................. 7-15

Configure Coupling ....................................................................................... 7-16

Configure Filter ............................................................................................. 7-17

Voltage Channel Setup .................................................................................. 7-17

Switch Current Input to External Input (BNC) .................................................. 7-18

Switch Current Input ..................................................................................... 7-18

Configure Auto-Range Selection ................................................................... 7-18

Configure Scale ............................................................................................. 7-18

Integration Function Configuration ................................................................... 7-19

Integration Setup ........................................................................................... 7-19

Select Integration Value ................................................................................ 7-21

Configure Status ............................................................................................ 7-21

Configure Start .............................................................................................. 7-22

Configure Stop ............................................................................................... 7-23

Save Configuration ............................................................................................ 7-23

Delete Configuration .......................................................................................... 7-24

Undersampling and Aliasing.............................................................................. 7-24

8 Measuring Process ............................................................................. 8-1

Introduction ........................................................................................................ 8-3

Prior to Measuring ............................................................................................. 8-3

Measuring with Default Configuration .......................................................... 8-3

Measuring with User-Defined Configuration ................................................ 8-3

Measure Voltage, Current and Power ................................................................ 8-4

Measured Values for Individual Channels .................................................... 8-4

View the Values of One Channel .............................................................. 8-4

View Detailed Values of One Channel ..................................................... 8-4

View Totals of all Measured Values ............................................................. 8-7

View Totals ............................................................................................... 8-7

View Efficiency ........................................................................................ 8-8

Compare Measured Values ............................................................................ 8-9

View Fundamental Values ............................................................................ 8-11

View Fundamental Value Details .................................................................. 8-11

User-Defined Screen View ............................................................................ 8-13

View User-Defined Screen ....................................................................... 8-13

Select Numeric Values .............................................................................. 8-14

Change User-Defined Display Size........................................................... 8-15

Save User Defined Screen ......................................................................... 8-15

iii

Page 10

NORMA 4000/5000

Operators Manual

Back to Common Numeric Screen ............................................................ 8-15

Change View Mode ........................................................................................... 8-15

Numerical Display ......................................................................................... 8-16

Vector Graphs ................................................................................................ 8-16

View Vector Graphs .................................................................................. 8-16

Adjust Scale .............................................................................................. 8-16

Oscilloscope Curves ...................................................................................... 8-17

View Oscilloscope Display ....................................................................... 8-17

Adjust Scale of Axes ................................................................................. 8-18

Adjust Zero ............................................................................................... 8-18

Recorder View ............................................................................................... 8-18

Harmonic Analysis ............................................................................................ 8-19

FFT Mode ...................................................................................................... 8-21

Adjust Scale .............................................................................................. 8-21

View Details of a Measured Value ........................................................... 8-22

Set Frequency Range ................................................................................. 8-22

Set View Mode .......................................................................................... 8-24

Harmonic Order Mode .................................................................................. 8-24

View Harmonics ........................................................................................ 8-24

View Harmonics Spectrum Relative to Fundamental in % ....................... 8-26

STD Harmonic Mode (EN 61000-4-7 Ed 2.1 compliant) ............................. 8-28

View Harmonics ........................................................................................ 8-28

Integration Function/Electrical Work ................................................................ 8-31

Save and Print Measurements ............................................................................ 8-33

Save Measurements ....................................................................................... 8-33

Print Measurements ....................................................................................... 8-33

VNC Remote Operation ..................................................................................... 8-33

Introduction ................................................................................................... 8-33

VNC Device Support ..................................................................................... 8-33

9 NORMA Process Interface (Optional) ................................................ 9-1

Process Interface ................................................................................................ 9-3

Pin Assignment .................................................................................................. 9-3

Measured Values ................................................................................................ 9-4

Torque ........................................................................................................... 9-4

Rotational Speed ............................................................................................ 9-4

Sense of Direction ......................................................................................... 9-4

Configuring the Process Interface ...................................................................... 9-4

Call Up Motor/Generator Setup .................................................................... 9-4

Select Motor .................................................................................................. 9-5

Configure Torque Sensor .............................................................................. 9-6

Configure Speed Sensor ................................................................................ 9-6

Configure Motor or Generator ....................................................................... 9-6

Configure Other Motors ................................................................................ 9-7

Configure Analog Output .............................................................................. 9-7

Measuring with the Process Interface ................................................................ 9-8

View Measured Electric Values .................................................................... 9-8

View Mechanical Values ............................................................................... 9-9

View Raw Values .......................................................................................... 9-10

View Torque – All Motors ............................................................................ 9-10

View Speed – All Motors .............................................................................. 9-11

Process Interface - Technical Data .................................................................... 9-12

Eight Inputs (Analog/Digital) ........................................................................ 9-12

Input Configured as Analog Input ............................................................. 9-12

iv

Page 11

Contents (continued)

Input Configured as Digital Input ............................................................. 9-12

Four Digital Inputs for the Detection of the Sense of Rotation ..................... 9-12

Four Outputs (Analog) .................................................................................. 9-12

10 Measured Values Computation .......................................................... 10-1

Measured values per phase x (channel x – values are indexed x) ...................... 10-3

Total values (sum or average) ............................................................................ 10-4

Frequency Analysis ............................................................................................ 10-6

Optional Process Interface Formulas ................................................................. 10-7

11 Technical Data ..................................................................................... 11-1

Technical Data Fluke NORMA 4000/5000 ....................................................... 11-3

General Technical Data ................................................................................. 11-3

Reference Conditions .................................................................................... 11-3

Ambient Conditions ....................................................................................... 11-3

Standards ....................................................................................................... 11-3

Interfaces ....................................................................................................... 11-4

Data Memory ................................................................................................. 11-4

Configuration Memory .................................................................................. 11-4

Channel Specifications .................................................................................. 11-4

Voltage ...................................................................................................... 11-4

Current ...................................................................................................... 11-4

Frequency and Synchronization .................................................................... 11-5

Intrinsic Uncertainty (Reference Conditions) Voltage and Current .............. 11-5

Intrinsic Uncertainty (Reference Conditions) Active Power ......................... 11-5

Block Diagrams ................................................................................................. 11-9

Overview ....................................................................................................... 11-9

Voltage Channels ........................................................................................... 11-10

Current Channels ........................................................................................... 11-10

12 Service and Accessories .................................................................... 12-1

Instrument .......................................................................................................... 12-3

Analyzer ........................................................................................................ 12-3

Optional Equipment ....................................................................................... 12-3

Standard Equipment ...................................................................................... 12-3

Accessories ........................................................................................................ 12-11

Accessories .................................................................................................... 12-11

Software ......................................................................................................... 12-11

Service ............................................................................................................... 12-12

General .......................................................................................................... 12-12

v

Page 12

NORMA 4000/5000

Operators Manual

vi

Page 13

List of Tables

Table Title Page

1-1. Symbols .................................................................................................................. 1-3

3-1. Terminal Descriptions ............................................................................................ 3-3

3-2. Display Descriptions .............................................................................................. 3-4

3-3. Status Symbols ....................................................................................................... 3-5

3-4. Navigation Control Descriptions ............................................................................ 3-5

3-5. Function Keys ........................................................................................................ 3-6

7-1. Configuration Menus ............................................................................................. 7-3

vii

Page 14

NORMA 4000/5000

Operators Manual

viii

Page 15

List of Figures

Figure Title Page

2-1. Binding Post Connection ........................................................................................ 2-4

3-1. Terminals ................................................................................................................ 3-3

3-2. Display ................................................................................................................... 3-4

3-3. Navigation .............................................................................................................. 3-5

5-1. Phase Measurement-Current Input and Mains ....................................................... 5-5

5-2. Phase Measurement-Current Input and Load ......................................................... 5-5

5-3. Measurement with Shunt ........................................................................................ 5-6

5-4. Voltage and Current Transducer Measurement ...................................................... 5-7

5-5. Aron Circuit-Direct Measurement ......................................................................... 5-9

5-6. Aron Circuit-Shunt Measurement .......................................................................... 5-10

5-7. Aron Circuit-Voltage and Current Transducer Measurement ................................ 5-12

5-8. 3-Phase Measurement-Direct Connection .............................................................. 5-13

5-9. 3-Phase Measurement with Shunt .......................................................................... 5-14

5-10. 3-Phase (W3) Voltage and Current Transducer Measurement............................... 5-16

5-11. 3-Phase Measurement with Star Point Adapter ...................................................... 5-17

9-1. Process Interface Pin Assignment .......................................................................... 9-3

11-1. Active Power (PP64 – AAF on 45 to 65 Hz) ......................................................... 11-7

11-2. Active Power (AAF off - 45 to 65 Hz - V=100%) ................................................. 11-7

11-3. Active Power (AAF on - Magnitude V & I 100%) ................................................ 11-7

11-4. Linearity of U & I in % vs. rdg/rng in % (50/60 Hz) ............................................. 11-8

11-5. Uncertainty in % of U & I vs. Frequency (rdg/rng = 100%,

antialiasing filter off) .............................................................................................. 11-8

ix

Page 16

NORMA 4000/5000

Operators Manual

x

Page 17

Chapter 1

About this Document

Title Page

Signs and Symbols .................................................................................................... 1-3

Transport and Storage ............................................................................................... 1-3

Transport .............................................................................................................. 1-3

Storage .................................................................................................................. 1-3

Recalibration ............................................................................................................. 1-3

Maintenance .............................................................................................................. 1-3

Decommissioning and Disposal ................................................................................ 1-4

Shutting Down ...................................................................................................... 1-4

Recycling and Disposal ........................................................................................ 1-4

Housing ................................................................................................................ 1-4

Electronic Components ........................................................................................ 1-4

1-1

Page 18

NORMA 4000/5000

Operators Manual

1-2

Page 19

About this Document

Signs and Symbols 1

Signs and Symbols

Table 1-1 is a list of symbols used in this document.

Table 1-1. Symbols

Symbol Description

W Risk of danger. Important information.

X Hazardous voltage. Risk of electrical shock.

Conformité Européenne.

P

) Conforms to relevant North American Safety Standards.

Conforms to relevant Australian Standards.

Conforms to requirements of European Union and European Free Trade Association

(EFTA).

~

Do not dispose of this product as unsorted municipal waste. Go to Fluke’s website for

recycling information.

. Earth ground.

Transport and Storage

Transport

• Transport the device in its original packaging.

• Protect the device during transport against heat and moisture; do not exceed

temperature range of −20 °C to +50 °C (−4 °F to +122 °F) and maximum

humidity of 85 %.

• Protect the device against impacts and loads.

Storage

• Keep original packaging, as it might be required at a later stage for transport

purposes or to return the device for repairs. Only the original packaging

guarantees proper protection against mechanical impacts.

• Store the device in a dry room; the temperature range of −20 °C to +50 °C (−4 °F

to +122 °F) and maximum humidity of 85 % may not be exceeded.

• Protect the device against direct sunlight, heat, moisture, and mechanical

impacts.

Recalibration

The manufacturer recommends recalibrating the device every 2 years. For information

about how to obtain service and calibration, check the Fluke website: www.fluke.com.

Maintenance

Ensure that the ventilation slots are not blocked. Otherwise, the device is maintenance

free.

1-3

Page 20

NORMA 4000/5000

Operators Manual

Decommissioning and Disposal

Shutting Down

Recycling and Disposal

Housing

• Ensure that all connected devices are switched off and disconnected from the

power supply.

• Switch off the Power Analyzer.

• Disconnect the plug from the mains (power) socket.

• Remove all connected devices.

• Secure the unit against inadvertent switching on.

• Keep the Operators Manual near the device.

Always adhere to the applicable statutory regulations for recycling and waste disposal.

The housing is made of metal and can be recycled.

Electronic Components

The electronic components including the power adapter, filter, plug-in modules, and

wires have a weight of approximately 1500 g (3.3 lb) and a volume of approximately

3000 cm

3

(183 in3).

1-4

Page 21

Chapter 2

General Safety Instructions

Title Page

Introduction ............................................................................................................... 2-3

Protection Class ........................................................................................................ 2-3

Qualified Personnel ................................................................................................... 2-3

Safe Operation .......................................................................................................... 2-3

Proper Use................................................................................................................. 2-3

Warranty ................................................................................................................... 2-3

Electrical Connections .............................................................................................. 2-4

Binding Post .............................................................................................................. 2-4

Risks During Operation ............................................................................................ 2-5

Maintenance and Repairs .......................................................................................... 2-5

Accessories ............................................................................................................... 2-5

Shutting Down .......................................................................................................... 2-5

Safety Instructions on the Device Housing ............................................................... 2-5

Mains Connection ................................................................................................. 2-5

Input Voltage and Current .................................................................................... 2-5

Maintenance ......................................................................................................... 2-6

Indoor Use ............................................................................................................ 2-6

2-1

Page 22

NORMA 4000/5000

Operators Manual

2-2

Page 23

General Safety Instructions

Introduction 2

Introduction

The design and manufacture of this device conform to the latest state of technology and

the safety standards defined in IEC 61010-1/ 2nd edition. If used improperly, there is a

risk of damage to persons and property.

Protection Class

The device is assigned to protection class I according to IEC 61010-1 and is equipped

with a protective earth connector.

Qualified Personnel

The device may be operated only by qualified personnel.

This means only persons who are familiar with the installation, assembly, connection,

inspection of connections, and operation of the analyzer and who have completed training

in at least one of the following areas:

• Switching on/off, enabling, earth-grounding and identification of electrical

circuits and devices/systems according to the applicable safety standards.

• Maintenance and operation of appropriate safety gear, in accordance with the

applicable safety standards.

• First aid.

Safe Operation

• Ensure that all persons using the device have read and fully understood the

Operators Manual and safety instructions.

• The device may only be used under certain ambient conditions. Ensure that the

actual ambient conditions conform to the admissible conditions laid down in the

chapter "Technical Data".

• During operation, ensure that the cooling vents are not obstructed.

• Always comply with the instructions in Chapter 1, "Transport and Storage".

Proper Use

Do not use the device for any other purpose than the measuring of voltages and currents

that are within the measuring ranges and categories, including voltage to earth ground,

detailed in the "Technical Data" chapter.

Improper use shall void all warranty.

Warranty

• The warranty period for fault-free operation is limited to 2 years from the date of

purchase.

• The warranty period for accuracy is 2 years.

2-3

Page 24

NORMA 4000/5000

Operators Manual

Electrical Connections

Binding Post

• Ensure that the power and connecting cables used with the device are in proper

working order.

• Ensure that the protective earth ground connector of the power lead is connected

according to the instructions of the low-resistance unit earth ground cable.

• Ensure that the power and connecting cables as well as all accessories used in

conjunction with the device are in proper working order and clean.

• Install the device in such a way that its power cable is accessible at all times and

can easily be disconnected.

• For connection work, work in teams of at least two persons.

• Do not use the device if the housing or an operating element is damaged.

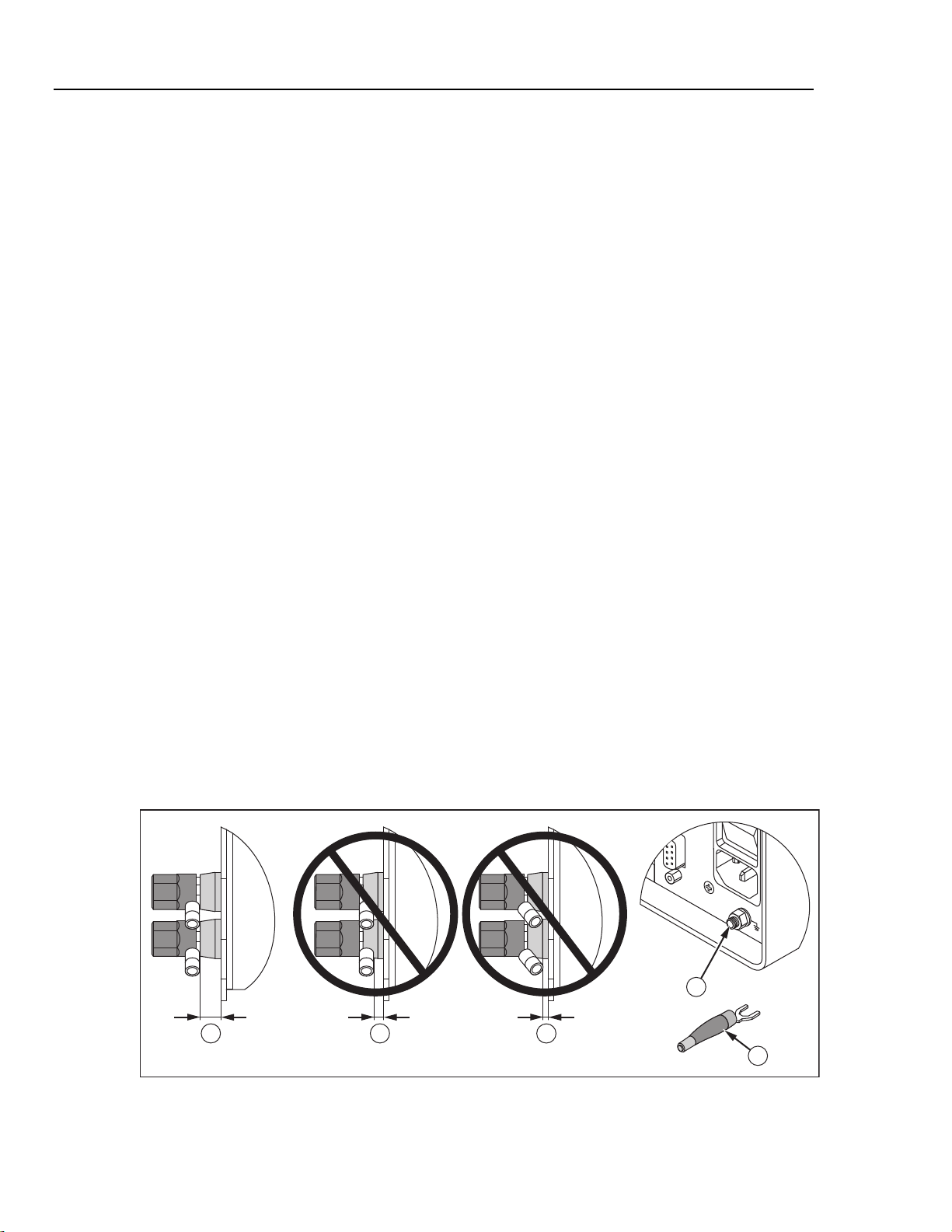

To maintain proper clearance distances, the lug must be correctly connected to the

connection terminal (binding post).

XW Warning

To avoid possible electric shock or personal injury from

flashover caused by CAT III transients between the housing and

the lug, see Figure 2-1:

• The minimum clearance distance must comply with at least

the distance illustrated in

.

• Do not reverse or bend the lug towards the housing.

• Use only insulated lugs preferably assembled with shrinking

tube as illustrated in

.

• If the connection leads exceed a cross section of 0.75 mm²,

an additional external-protective conductor with the same

cross section must be installed between the protective earth

terminal and the protective earth of the measuring circuit.

SERIAL

5

OK

1 2 3

Figure 2-1. Binding Post Connection

4

esn070.eps

2-4

Page 25

General Safety Instructions

Risks During Operation 2

Risks During Operation

• Ensure that the connected devices work properly.

• In the case of a direct connection to current circuits (without transformer or

shunt), ensure that the circuit is protected to maximum 16 A.

• Shunts and conductors generate heat when in use and surfaces may burn the skin.

Maintenance and Repairs

• Do not open the housing. Do not carry out any repairs and do not replace any

component parts of the device.

• Damaged connecting and power leads must be repaired or replaced by an

authorized service technician.

• Damaged or defective devices may only be repaired by authorized technicians.

Accessories

• Only use the accessories supplied with the device or specifically available as

optional equipment for your model.

• Ensure that any third-party accessories used in conjunction with the device

conform to the IEC 61010-031/61010-2-032 standard and are suitable for the

respective measuring voltage range.

Shutting Down

• If you detect any damage to the housing, controls, power cable, connecting leads,

or connected devices, immediately disconnect the unit from the power supply.

• If you are in doubt as regards the safe operation of the device, immediately shut

down the unit and the respective accessories, secure them against inadvertent

switching on, and bring them to an authorized service agent.

Safety Instructions on the Device Housing

Mains Connection

MAINS 85 - 264 V / 47 – 440Hz / 120 – 300 V

Mains connection must conform to these ranges/values

40 VA (NORMA 4000) and 65 VA (NORMA 5000)

Maximum power consumption

Input Voltage and Current

XW Warning

To avoid possible electric shock or personal injury:

VOLTAGE INPUTS MAX 1000 V CAT II to .

CURRENT INPUTS MAX 1000 V CAT II to .

If the measuring circuit is used to measure MAINS, the voltage

to earth . may not exceed 1000 V in a CAT II Overvoltage

Category environment.

2-5

Page 26

NORMA 4000/5000

Operators Manual

Maintenance

Indoor Use

The device may only be used indoors.

No internal parts are user serviceable. Always use a qualified service center for service.

2-6

Page 27

Chapter 3

Design and Functions

Title Page

About this Chapter .................................................................................................... 3-3

Terminals (Back) ...................................................................................................... 3-3

Operating Controls and Display ................................................................................ 3-4

Navigation and Measuring Keys .......................................................................... 3-5

Navigation through Display ................................................................................. 3-6

Overview of Function Keys .................................................................................. 3-6

Functions ................................................................................................................... 3-7

3-1

Page 28

NORMA 4000/5000

Operators Manual

3-2

Page 29

Design and Functions

About this Chapter 3

About this Chapter

This chapter provides an overview of the terminals, ports and interfaces of the Fluke

NORMA 4000/5000 Power Analyzer (referred to throughout as “the Power Analyzer”). It

also includes a list of display and operating devices and a brief introduction to the basic

functions of the unit.

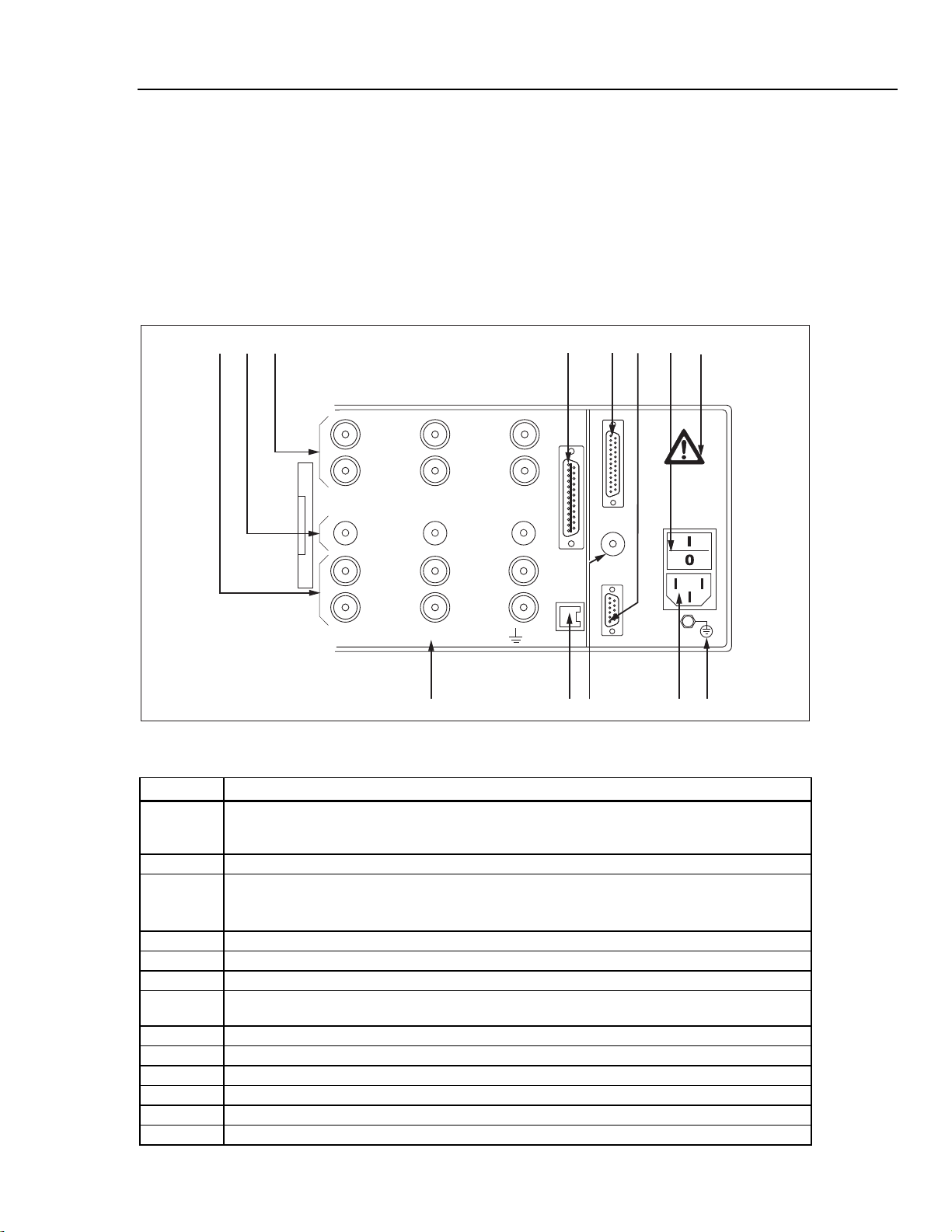

Terminals (Back)

Figure 3-1 illustrates the terminals on the back of the Power Analyzer. Table 3-1 is a list

of the terminal descriptions.

123 4

23

HI

VOLTAGE

1000 V max

LO

PROBE

EXT.SHUNT

10 V max

HI

CURRENT

10 A max

LO

1

HI

VOLTAGE

1000 V max

LO

PROBE

EXT.SHUNT

10 V max

HI

CURRENT

10 A max

LO

ALL INPUTS MAX 1000V CATII TO

56 7 12

891011

13

esn005.eps

Figure 3-1. Terminals

Table 3-1. Terminal Descriptions

Item Description

Measuring inputs for current (channels 1 to 6)

1

HI: Conductor, positive

LO: Conductor, negative

2 Measuring inputs for shunts (channels 1 to 6)

Measuring inputs for voltage (channels 1 to 6)

3

HI: Conductor, positive

LO: Conductor, negative

4 IEEE488 interface (optional)

5 Port for Analog Interface

6 Serial interface (RS232)

7

Power switch

I (on) and O (off)

8 Mains (power) connection

9 Input for external synchronization signal

10 IF1 network adapter (LAN) (optional)

11 Warning regarding maximum voltage to earth ground

12 Warning symbol: danger, observe operating instructions

13 Earth Ground

3-3

Page 30

NORMA 4000/5000

Operators Manual

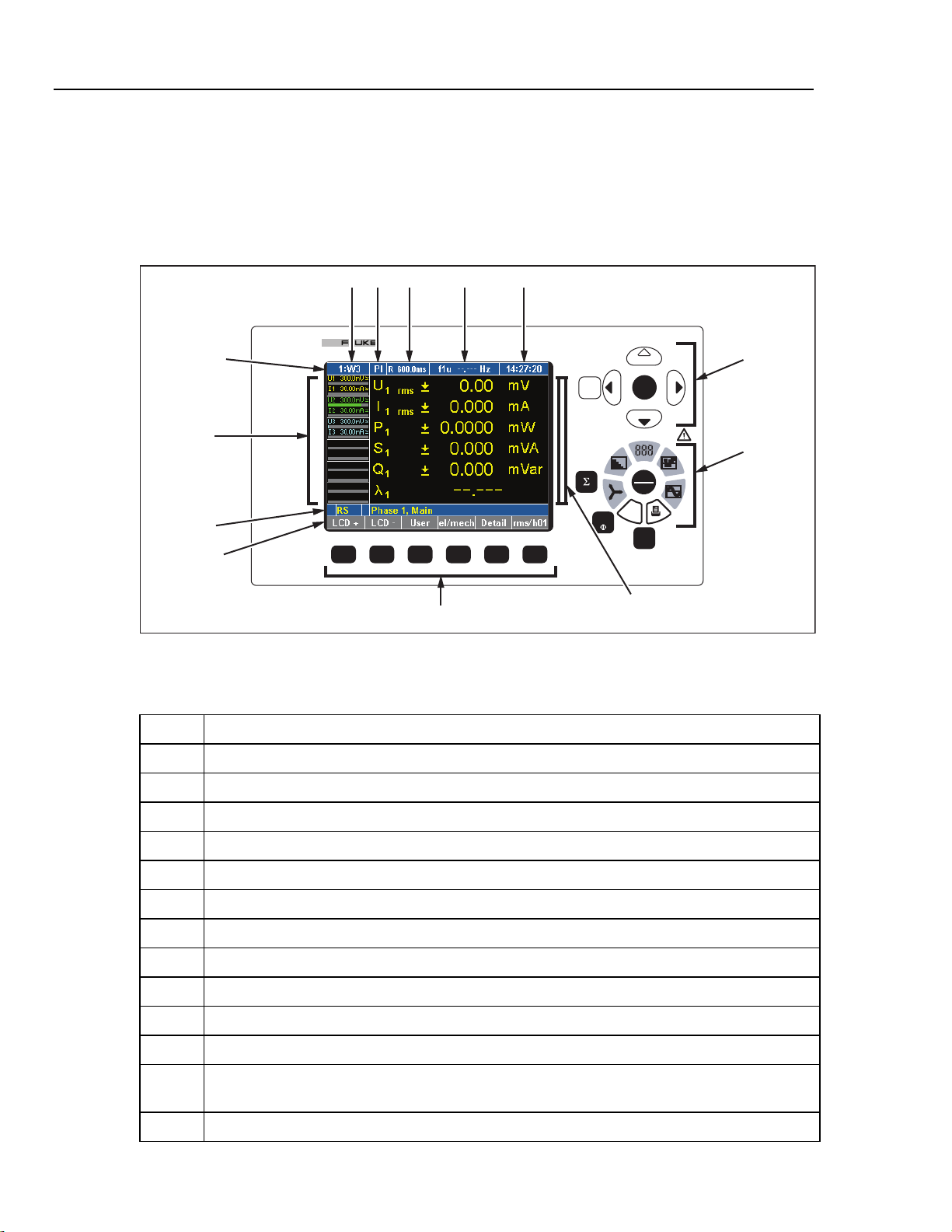

Operating Controls and Display

The display, operating controls, and function keys are located at the front of the Power

Analyzer. The display consists of a menu bar, a section in which the measured values and

the channel settings are shown, and the assignment bar for the function keys. Figure 3-2

illustrates the location of the operating controls on the display and Table 3-2 is a list of

control descriptions.

1

2 3 4 5

POWER ANALYZER

NORMA 5000

12

11

13

10

1...n

MEM

ENTERESC

HOLD

RUN

WAV

6

7

9

8

esn006.eps

Figure 3-2. Display

Table 3-2. Display Descriptions

Item Description

1 Display of configuration; menu item General Setup

2 Menu item Integration Setup/Motor-Generator Setup

3 Measurement status/display of average time

4 Display of synchronization source frequency; menu item Timing & Sync Setup

5 Display of time; menu item Clock Setup

6 Navigation keys

7 Measuring keys

8 Display for measured values

9 Function keys

10 Assignment bar for function keys

11 Information row

3-4

12 Status display for channels 1 to 6 (including measuring range, coupling, and modulation bar);

menu items Current Channel Setup and Voltage Channel Setup

13 Menu bar with menu items

Page 31

Design and Functions

Operating Controls and Display 3

Table 3-3 is an explanation of the status symbols.

Table 3-3. Status Symbols

Status Description

M Memory record active

T Wait for Trigger start condition (memory)

R Measurement active (Run mode)

H Measurement stopped (Hold mode)

Integration of selected values active

Navigation and Measuring Keys

Figure 3-3 illustrates the navigation and measuring keys on the Power Analyzer. Table 34 is a list of the descriptions for the navigation and measuring keys.

26 27

ENTERESC

14

16

17

18

19

27

15

esn007.eps

24

25

23

22

1...n

21

HOLD

RUN

MEM

WAV

20

Figure 3-3. Navigation

Table 3-4. Navigation Control Descriptions

Item Description

14 Enter: confirm; call up menu

15 Numerical display

16 Recorder

17 Hold/Run: start and stop measurement

18 Oscilloscope diagrams

19 Print

20 Show power, current, voltage

21 Save

22 Select channel

23 Vector display

24 Show totals of all channels

25 Frequency analysis

26 Esc: cancel, up one menu level

27 Cursor keys: up, down, left, and right

3-5

Page 32

NORMA 4000/5000

Operators Manual

Navigation through Display

Overview of Function Keys

1. Use the navigation keys (6) and (27) to navigate through the display and the

menus.

The active menu item, display, or entry field in which your cursor is located is

backlit.

2. Press Esc (26) to cancel an entry without saving or to go to the next higher menu

level.

3. Press Enter (14) to call up a menu or to confirm an entry made in a menu.

4. Press the measuring keys (7) and (15) to (25) to select the display mode and the

save or output functions for measured values.

The assignment of the function keys (9) varies, depending on the current menu.

The current key assignment is shown on the assignment bar (10) located above

the function keys.

Table 3-5 is a list of the function keys. The assignment of the function keys varies

depending on the display or menu you have selected.

Table 3-5. Function Keys

Name Function

Default Scale axes automatically

DELETE Delete configuration

Detail View details of a measured value

Freq Set frequency analysis filter

Info… View system information and version number of unit firmware

LCD - Reduce brightness of display

LCD + Increase brightness of display

lin/log View linear/logarithmic scale

LOAD Load configuration

mode View table with harmonics

Offset Adjust zero (with cursor keys)

rms/h01 View rms values or H01 fundamental

SAVE Save configuration

Scale Adjust scales of axes (with cursor keys)

scroll Scroll through display

Set all Adopt configuration or set value for all channels

tab/gra View measured values in table/graph

U/I Switch between voltage channel configuration and current channel

configuration (in General Setup)

zoom Adjust scales of axes (with cursor keys)

View electrical work reference power or recuperated power

Clear Set electrical work integration to zero

∫ Start Start electrical work integration

Stop Stop electrical work integration

3-6

Page 33

Design and Functions

Functions 3

Functions

The Power Analyzer allows for the analysis of currents from dc to several MHz. Voltage

values up to 1000 V and currents up to 20 A (depending on measurement modules

installed in the instrument) are measured accurately, and the respective real, reactive, and

apparent power is calculated. The limit of error is between 0.03 % and 0.3 %, depending

on the model. See the technical specifications for detailed information. For dc and ac up

to a few MHz, it is not affected by the wave shape, frequency, or phase position. The

measuring range can be extended by connecting shunts or clamps. When extending the

range using third-party shunts or clamp, the extra errors due to these devices should be

considered. The device allows for simultaneous measuring in up to six channels.

3-7

Page 34

NORMA 4000/5000

Operators Manual

3-8 4-1

Page 35

Chapter 4

Startup

Title Page

Taking Inventory ....................................................................................................... 4-3

Installation and Switching On ................................................................................... 4-3

Installation ............................................................................................................ 4-3

Switching Device On ............................................................................................ 4-3

Switching Device Off ........................................................................................... 4-4

Page 36

NORMA 4000/5000

Operators Manual

4-2

Page 37

Startup

Taking Inventory 4

Taking Inventory

Before you work with the analyzer, check the delivery to ensure that it is compete, using

the following list and the delivery specifications:

• 1 Power Analyzer

• 1 Operators Manual

• 1 mains (power) cable

• 1 calibration certificate

• 1 built-in printer (if ordered)

• 1 to 6 voltage and current channel modules, according to the delivery

specifications

Installation and Switching On

Installation

XW Warning

To avoid possible electric shock or personal injury:

• The device is connected to the power mains with a number

of internal components live with dangerous voltage levels.

• The device must be equipped with a low-resistance

connection to earth ground.

• Carefully check the mains socket and its wiring.

To install:

1. Follow the safety instructions regarding ambient conditions and location of

installation.

2. Place the device on a clean and stable surface.

3. If necessary, adjust the feet at the base of the unit to improve the view of the

display.

Switching Device On

To turn the Analyzer on:

1. Connect the Analyzer to the power (mains) socket, using the power cable.

2. Set the power switch on the back of the housing to I (on). The Analyzer is now

ready for operation. The following start screen displays.

4-3

Page 38

NORMA 4000/5000

Operators Manual

Switching Device Off

1. Toggle the power switch in the back of the housing to O (off).

2. If the Analyzer is not to be used for a prolonged period of time, disconnect the

plug from the mains (power) socket.

esn008.gif

4-4

Page 39

Chapter 5

Connection to Circuits

Title Page

Before You Begin ..................................................................................................... 5-3

Connecting Sequence ................................................................................................ 5-3

Overview ................................................................................................................... 5-4

1-Phase Measurement ............................................................................................... 5-4

Direct Connection ................................................................................................. 5-4

Measurement with Shunt ...................................................................................... 5-6

Measurement with Voltage and Current Transducer ............................................ 5-7

Aron Circuit (2-Wattmeter Method, W2) ................................................................. 5-8

Direct Connection ................................................................................................. 5-8

Measurement with Shunt .................................................................................... 5-10

Measurement with Voltage and Current Transducer .......................................... 5-11

3-Phase Measurement (W3) .................................................................................... 5-13

Direct Connection ............................................................................................... 5-13

Measurement with Shunt .................................................................................... 5-14

Measurement with Voltage and Current Transducer .......................................... 5-15

Measurement with Star Point Adapter ................................................................ 5-17

5-1

Page 40

NORMA 4000/5000

Operators Manual

5-2

Page 41

Connection to Circuits

Before You Begin 5

Before You Begin

Carefully read and adhere to the following warning statements before you connect the

Power Analyzer.

XW Warning

To avoid possible electric shock or personal injury:

• By connecting the Power Analyzer to active circuits, the

terminals and certain parts inside the Power Analyzer

are live.

• To ensure safe operation, first connect the Power

Analyzer to the power supply.

• If possible, open the circuit before establishing a

connection to the Power Analyzer.

• Before connecting the circuits, ensure that the maximum

measuring voltage and maximum voltage to earth

ground (1000 V CATII and 600 V CATIII respectively) are

not exceeded.

• Do not use leads and accessories that do not comply

with relevant safety standards, as this could lead to

serious injury or death from electric shock.

• To avoid damage to the instrument, never apply voltage

to the current shunt inputs (lower set of input jacks,

blue).

Connecting Sequence

For safety reasons, when connecting a circuit to the Power Analyzer, proceed in the

sequence outlined as follows:

1. Connect the Power Analyzer to the mains (power) socket.

The Power Analyzer is now connected to the protective earth ground wire.

2. Switch on the Power Analyzer.

3. Connect the measuring circuit as shown in the connection diagrams later in this

Operators Manual.

To ensure that the measured values are indicated correctly, connect the phase to

HI so that the energy flow is from HI to LO.

4. Connect the circuit to the power supply.

5-3

Page 42

NORMA 4000/5000

Operators Manual

Overview

1-Phase Measurement

Direct Connection

The Fluke NORMA 4000/5000 Power Analyzer offers the following options for

connection:

• 1-phase measurement

• Aron circuit (W2)

• 3-phase measurement (W3)

Note

When connecting a 4-channel device for electrical efficiency analysis, the

3-phase power cables for this measurement should be connected to the

measuring channels 1 to 3, so that the efficiency can be calculated and

displayed directly on the Power Analyzer.

• Ensure that there is no overload at the current input of the Power Analyzer.

• If necessary, install appropriate fuses.

XW Warning

To avoid possible electric shock or personal injury:

• Risk of injury when touching connections, internal circuits

and measuring devices that are not connected to earth

ground.

• Always adhere to the instructions regarding the sequence

of connection (see Chapter 5, “Connecting Sequence”).

The difference between the connection of the voltage input between the current input and

the mains (Figure 5-1) or between the current input and the load (Figure 5-2) is that, in

the first case, the leakage power of the current input, and in the second, the leakage

power of the voltage input is added to the measuring result. As the leakage power of the

current input may increase up to ~2 W at 10 amp versus a leakage power of the voltage

input of 0.5 W at 1000 V, it is preferable to use the second method. It is used for the

further diagrams, also in Aron and 3-phase measurements. For special applications such

as active current sensors without power loss or higher leakage power at the voltage input

with the “star point adapter,” method 1 is preferable.

5-4

Page 43

Connection to Circuits

V

1-Phase Measurement 5

Load

Max. 10m

HI

VOLTAGE

1000 V max

LO

HI

VOLTAGE

1000 V max

LO

123

PROBE

EXT.SHUNT

10 V max

HI

CURRENT

10 A max

LO

ALL INPUTS MAX 1000V CATII TO

PROBE

EXT.SHUNT

10 V max

HI

CURRENT

10 A max

LO

Figure 5-1. Phase Measurement-Current Input and Mains

Max. 10m

V

I

O

esn009.eps

Load

HI

VOLTAGE

1000 V max

LO

HI

VOLTAGE

1000 V max

LO

123

PROBE

EXT.SHUNT

10 V max

HI

CURRENT

10 A max

LO

ALL INPUTS MAX 1000V CATII TO

PROBE

EXT.SHUNT

10 V max

HI

CURRENT

10 A max

LO

I

O

esn009a.eps

Figure 5-2. Phase Measurement-Current Input and Load

5-5

Page 44

NORMA 4000/5000

Operators Manual

Measurement with Shunt

The connecting leads to the shunts should be as short as possible in order to prevent

interference and noise voltages.

XW Warning

To avoid possible electric shock or personal injury:

• Do not touch sensing terminals. The sense terminals at the

shunts are powered with the same voltage as the power

connections.

• Shunts are not isolated. Never touch the sense terminals at

the shunts.

• Risk of injury when touching connections, internal circuits,

and measuring devices that are not earthed.

• Always adhere to the instructions regarding the connection

sequence (see Chapter 5, “Connecting Sequence”).

Where the current to be measured exceeds the rating of the direct current connection, an

external triaxial shunt should be used, see Figure 5-3. Fluke triaxial shunts are

recommended as they provide high accuracy across the full frequency range. Standard

linear shunts may produce excessive errors due to the possible presence of high

frequency that components experience with electronic loads. The NORMA internal shunt

is optimized for such loads.

L1

N

HILO

Guard

*1

HI

VOLTAGE

1000 V max

LO

PROBE

EXT.SHUNT

10 V max

HI

CURRENT

10 A max

LO

ALL INPUTS MAX 1000V CATII TO

HI

VOLTAGE

1000 V max

LO

PROBE

EXT.SHUNT

10 V max

HI

CURRENT

10 A max

LO

Load

Max. 10 m

V

123

5-6

Figure 5-3. Measurement with Shunt

esn010.eps

Page 45

Connection to Circuits

1-Phase Measurement 5

Note

In Figures 5-3, 5-6, and 5-9, Fluke recommends using MCS measuring

leads for triaxial shunts and MCP leads for planar shunts. Triaxial shunts

are equipped with guard connectors in the plugs and planar shunts are

equipped with guard sockets.

Measurement with Voltage and Current Transducer

Figure 5-4 shows the connections for measurements with a voltage and current

transducer.

W Caution

To prevent damage to the transducer due to overload, check

transducer rating.

Note

Transducer errors limit the measuring bandwidth and reduce the intrinsic

uncertainty.

XW Warning

To avoid possible electric shock or personal injury:

• Risk of injury when touching connections, internal circuits,

and measuring devices that are not connected to earth

ground.

• Always adhere to the instructions regarding the sequence of

connection (see Chapter 5, “Connecting Sequence”).

L1

P

N

2

S

2

HI

VOLTAGE

1000 V max

LO

PROBE

EXT.SHUNT

10 V max

P

1

S

1

N

n

A

a

Load

Max. 10 m

V

HI

VOLTAGE

1000 V max

LO

123

PROBE

EXT.SHUNT

10 V max

HI

CURRENT

10 A max

LO

ALL INPUTS MAX 1000V CATII TO

HI

CURRENT

10 A max

LO

esn011.eps

Figure 5-4. Voltage and Current Transducer Measurement

5-7

Page 46

NORMA 4000/5000

Operators Manual

Aron Circuit (2-Wattmeter Method, W2)

Direct Connection

The Aron circuit is only available for 3-wire networks, see Figure 5-5. It is only required

to measure two phases (currents I1 and I2 in the following connection diagrams), as

I1+I2+I3 must be 0.

Note