Page 1

2640A/2645A

®

PN 942623

May 1994, Rev 2 11/96

© 1994, 1995, 1996 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

NetDAQ

Networked Data Acquisition Unit

Users Manual

Page 2

Page 3

LIMITED WARRANTY & LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under

normal use and service. The warranty period is one year and begins on the date of

shipment. Parts, product repairs and services are warranted for 90 days. This warranty

extends only to the original buyer or end-user customer of a Fluke authorized reseller, and

does not apply to fuses, disposable batteries or to any product which, in Fluke’s opinion,

has been misused, altered, neglected or damaged by accident or abnormal conditions of

operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on nondefective media. Fluke does not warrant that software will be error free or operate without

interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to enduser customers only but have no authority to extend a greater or different warranty on

behalf of Fluke. Warranty support is available if product is purchased through a Fluke

authorized sales outlet or Buyer has paid the applicable international price. Fluke reserves

the right to invoice Buyer for importation costs of repair/replacement parts when product

purchased in one country is submitted for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price, free

of charge repair, or replacement of a defective product which is returned to a Fluke

authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center or send

the product, with a description of the difficulty, postage and insurance prepaid (FOB

Destination), to the nearest Fluke authorized service center. Fluke assumes no risk for

damage in transit. Following warranty repair, the product will be returned to Buyer,

transportation prepaid (FOB Destination). If Fluke determines that the failure was caused

by misuse, alteration, accident or abnormal condition of operation or handling, Fluke will

provide an estimate of repair costs and obtain authorization before commencing the work.

Following repair, the product will be returned to the Buyer transportation prepaid and the

Buyer will be billed for the repair and return transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF

DATA, WHETHER ARISING FROM BREACH OF WARRANTY OR BASED ON

CONTRACT, TORT, RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or

exclusion or limitation of incidental or consequential damages, the limitations and

exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is

held invalid or unenforceable by a court of competent jurisdiction, such holding will not

affect the validity or enforceability of any other provision.

5/94

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett WA 5602 B.D.

98206-9090 Eindhoven

The Netherlands

Page 4

PCaution

This is an IEC safety Class 1 product. Before usi ng, the

ground wire in the line cord or rear panel binding post

must be connect to an earth ground for safety.

Interference Information

This equipment generates and uses radio frequency energy and if not installed and used in strict

accordance with the manufacturer’s instructions, may cause interference to radio and television

reception. It has been type tested and found to comply with the limits for a Class B computing device

in accordance with the specifications of Part 15 of FCC Rules, which are designed to provide

reasonable protection against such interference in a residential installation.

Operation is subject to the following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference received, including interference that may cause

undesired operation.

There is no guarantee that interference will not occur in a particular installation. If this equipment

does cause interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one of more of the

following measures:

• Reorient the receiving antenna

• Relocate the equipment with respect to the receiver

• Move the equipment away from the receiver

• Plug the equipment into a different outlet so that the computer and receiver are on different

branch circuits

If necessary, the user should consult the dealer or an experienced radio/television technician for

additional suggestions. The user may find the following booklet prepared by the Federal

Communications Commission helpful: How to Identify and Resolve Radio-TV Interference Problems.

This booklet is available from the U.S. Government Printing Office, Washington, D.C. 20402. Stock

No. 004-000-00345-4.

Declaration of the Manufacturer or Importer

We hereby certify that the Fluke Model 2640A/2645A Networked Data Acquisition Unit is in

compliance with BMPT Vfg 243/1991 and is RFI suppressed. The normal operation of some

equipment (e.g. signal generators) may be subject to specific restrictions. Please observe the

notices in the users manual. The marketing and sales of the equipment was reported to the Central

Office for Telecommunication Permits (BZT). The right to retest this equipment to verify compliance

with the regulation was given to the BZT.

Bescheinigung des Herstellers/Importeurs

Hiermit wird bescheinigt, daβ Fluke Models 2640A/2645A Networked Data Acquisition Unit in

Übereinstimung mit den Bestimmungen der BMPT-AmtsblVfg 243/1991 funk-entstört ist. Der

vorschriftsmäßige Betrieb mancher Geräte (z.B. Meßsender) kann allerdings gewissen

Einschränkungen unterliegen. Beachten Sie deshalb die Hinweise in der Bedienungsanleitung. Dem

Bundesamt für Zulassungen in der Telekcommunikation wurde das Inverkehrbringen dieses Gerätes

angezeigt und die Berechtigung zur Überprüfung der Seire auf Einhaltung der Bestimmungen

eingeräumt.

Fluke Corporation

Page 5

SAFETY TERMS IN THIS MANUAL

This instrument has been designed and tested in accordance with IEC publicat ion

1010-1,

Equipment

of this equipment in a manner not specified herein m ay impair the protection

provided by the equipment.

This instrument is designed for IEC 1010-1 Inst allation Category II use.

WARNING statements ident ify conditions or practices that could result in personal

injury or loss of life.

CAUTION statements identify condit ions or pr actices that could result in damage

to equipment.

SYMBOLS MARKED ON EQUIPMENT:

Safety Requirements for Electr ical M easur ing, Control and Laboratory

. This Users Manual contains information, war nings and caut ions. Use

WARNING Risk of electric shock.

Ground (earth) terminal.

Protective ground (earth) ter m inal. M ust be connected to safety earth

ground when the power cord is used.

Attention. Refer to the m anual ( see the Index for references). This

symbol indicates that information about usage of a feature is contained

in the manual. This symbol appears on the Universal Input M odule and

in the following three places on the instrument rear panel:

1. Ground Binding Post (to the left of t he line power connector).

2. Ground Binding Post (to the left of t he 10Base2 connect or).

3. ALARM/TRIGGER I/O and DIGITAL I/O connectors.

AC POWER SOURCE

The instrument is intended to operate from an ac power source that will not apply

more than 264V ac rms between the supply conductors or bet ween either supply

conductor and ground. A protective ground connection by way of the grounding

conductor in the power cord is required for saf e oper ation.

Page 6

DC POWER SOURCE

The instrument may also be operated from a 9V to 16V dc power source when

either the rear panel ground binding post or the power cor d grounding conductor

is connected properly.

USE THE PROPER FUSE

To avoid fire hazard, for fuse replacement use only a 1/ 4 am pere, 250V non-time

delay line fuse.

GROUNDING THE INSTRUMENT

The instrument utilizes controlled overvoltage techniques that require the

instrument to be grounded whenever normal m ode or com mon mode ac voltages

or transient voltages may occur. The enclosure m ust be grounded through the

grounding conductor of the power cord, or if operated on battery with the power

cord unplugged, through the rear panel ground binding post.

USE THE PROPER POWER CORD

Use only the power cord and connector appropriate for the voltage and plug

configuration in your country.

Use only a power cord that is in good condition.

Refer power cord and connector changes to qualified service personnel.

WARNING!

DO NOT OPERATE IN EXPLOSIVE ATM O SPHERES

To avoid personal injury or death, do not remove the instrument cover without first

removing the power source connected to the rear panel. Do not operate the

instrument without the cover proper ly installed. Normal calibration is accomplished

with the cover closed. There is no need for the operator to remove the cover

except to replace the fuse. Access procedures and the warnings for such

procedures are contained both in this manual and in the Service Manual. Service

procedures are for qualified service personnel only.

DO NOT ATTEMPT TO OPERATE IF PROTECTION MAY BE IMPAIRED

If the instrument appears damaged or operates abnormally, protection may be

impaired. Do not attempt to operate the instrument under these condit ions. Refer

all question of proper instrument operat ion t o qualified service personnel.

Page 7

Table of Contents

Chapter Title Page

1 Overview........................................................................................... 1-1

1-1. Introduction.......................................................................................... 1-3

1-2. Instrument Features and Capabilities................................................... 1-4

1-3. Analog Channels.............................................................................. 1-7

1-4 Computed Channels......................................................................... 1-7

1-5. Channel Numbering......................................................................... 1-7

1-6. Mx+B Scaling.................................................................................. 1-7

1-7. Alarms.............................................................................................. 1-8

1-8. Channel Monitoring......................................................................... 1-8

1-9. Digital I/O........................................................................................ 1-8

1-10. Totalizer........................................................................................... 1-8

1-11. Trigger Input .................................................................................... 1-9

1-12. Trigger Output.................................................................................. 1-9

1-13. Master Alarm ................................................................................... 1-10

1-14. Interval Trigger................................................................................ 1-10

1-15. External Trigger............................................................................... 1-10

1-16. Alarm Trigger................................................................................... 1-10

1-17. NetDAQ Logger Features and Capabilities.......................................... 1-11

1-18. Operating a NetDAQ Data Acquisition System................................... 1-11

1-19. Isolated Networks............................................................................. 1-12

1-20. General Networks............................................................................. 1-12

1-21. Ethernet Port Selection .................................................................... 1-12

1-22. Asynchronous Instrument Operations.............................................. 1-12

1-23. Group Instrument Operations........................................................... 1-12

1-24. Scanning and Logging...................................................................... 1-13

1-25. RS-232 Interface .............................................................................. 1-13

1-26. Host Computer Requirements .............................................................. 1-14

1-27. Options and Accessories ...................................................................... 1-14

1-28. Instrument Connector Set................................................................. 1-15

1-29. Host Computer Ethernet Adapters................................................... 1-15

i

Page 8

2640A/2645A NetDAQ

Users Manual

2 Preparing for Operation .................................................................. 2-1

2-1. Introduction.......................................................................................... 2-3

2-2. Instrument Preparation......................................................................... 2-3

2-3. Unpacking and Inspecting the Instrument....................................... 2-5

2-4. Positioning and Rack Mounting...................................................... 2-5

2-5. Connecting to a Power Source and Grounding ............................... 2-5

2-6. AC Power.................................................................................... 2-6

2-7. DC Power.................................................................................... 2-7

2-8. Grounding and Common Mode Voltage..................................... 2-7

2-9. Universal Input Module Connections.............................................. 2-7

2-10. Shielded Wiring........................................................................... 2-11

2-11. Crosstalk Considerations............................................................. 2-11

2-12. Digital I/O Connections................................................................... 2-11

2-13. Digital I/O.................................................................................... 2-12

2-14. Totalizer ...................................................................................... 2-12

2-15. Alarm/Trigger I/O Connections....................................................... 2-12

2-16. Trigger Input................................................................................ 2-13

2-17. Trigger Output............................................................................. 2-14

2-18. Master Alarm............................................................................... 2-14

2-19. External Trigger Wiring for a Group Instrument ............................ 2-15

2-20. Controls and Indicators.................................................................... 2-15

2-21. Front Panel Controls ................................................................... 2-17

2-22. Front Panel Indicators................................................................. 2-18

2-23. Rear Panel Controls..................................................................... 2-20

2-24. Rear Panel Indicators .................................................................. 2-20

2-25. Front Panel Operating Procedures................................................... 2-21

2-26. Power-On Options....................................................................... 2-21

2-27. Displaying a Monitor Channel.................................................... 2-22

2-28. Displaying the Digital I/O Status................................................ 2-24

2-29. Displaying the Totalizer Status................................................... 2-26

2-30. Reviewing and Setting the Base Channel Number ..................... 2-27

2-31. Reviewing and Setting the Line Frequency................................ 2-29

2-32. Reviewing and Setting the Network Type .................................. 2-31

2-33. Reviewing and Setting the General Network Socket Port .......... 2-36

2-34. Reviewing and Setting the General Network IP Address........... 2-37

2-35. Reviewing and Setting the Subnet Mask and Default Gateway.. 2-38

2-36. Viewing the Instrument Ethernet Address.................................. 2-41

2-37. Host Computer and Network Preparation............................................ 2-43

2-38. Installing Host Computer Ethernet Adapter.................................... 2-43

2-39. Instrument and Host Computer Interconnection.............................. 2-45

2-40. Host Computer/Instrument Direct Connection........................... 2-45

2-41. Interconnection Using 10Base2 (Coaxial) Wiring...................... 2-48

2-42. Interconnection Using 10BaseT (Twisted-Pair) Ethernet Wiring 2-48

2-43. Installing Host Computer Networking Software............................. 2-50

ii

Page 9

Contents

(continued)

2-44. Setting Host Computer Networking Parameters.............................. 2-51

2-45. Installing NetDAQ Logger............................................................... 2-52

2-46. Installing NetDAQ Logger with Trumpet.................................... 2-53

2-47. Changing from an Isolated Network to a General Network........ 2-54

2-48. Installing Trend Link for Fluke (Optional)...................................... 2-55

2-49. Testing and Troubleshooting................................................................ 2-55

2-50. Testing the Installation..................................................................... 2-55

2-51. Troubleshooting Network Problems................................................ 2-58

3 Configuring NetDAQ Logger for Windows..................................... 3-1

3-1. Introduction.......................................................................................... 3-3

3-2. Starting NetDAQ Logger................................................................. 3-3

3-3. The Main Window........................................................................... 3-3

3-4. Accessing NetDAQ Logger Commands.......................................... 3-3

3-5. Configuring Network Communications ............................................... 3-4

3-6. The Communications Configuration Dialog Box............................ 3-5

3-7. Adding an Instrument to the Network.............................................. 3-5

3-8. Deleting an Instrument from the Network....................................... 3-7

3-9. Verifying Network Communications............................................... 3-7

3-10. Configuring the Current Setup............................................................. 3-8

3-11. Creating an Instrument Icon............................................................. 3-8

3-12. Deleting an Instrument Icon............................................................. 3-9

3-13. Designating Instruments as Group or Asynchronous....................... 3-9

3-14. Setup Files............................................................................................ 3-11

3-15. Saving the Current Setup in a File................................................... 3-11

3-16. Opening a Setup File........................................................................ 3-12

3-17. Starting NetDAQ Logger with a Setup File..................................... 3-13

3-18. Starting Logging Automatically....................................................... 3-14

3-19. NetDAQ Logger Command Line..................................................... 3-14

3-20. Configuring an Instrument.................................................................... 3-15

3-21. Dimmed Configuration Commands ................................................. 3-15

3-22. The Instrument Configuration Dialog Box...................................... 3-15

3-23. Configuring Channels........................................................................... 3-18

3-24. The Channels Configuration Dialog Box......................................... 3-18

3-25. Configuring Analog Channel Functions.......................................... 3-19

3-26. Configuring Computed Channel Functions ..................................... 3-20

3-27. Defining a Computed Channel Equation..................................... 3-20

3-28. Equation Syntax........................................................................... 3-21

3-29. Configuring Mx+B Scaling.............................................................. 3-22

3-30. Configuring Alarms ......................................................................... 3-23

3-31. Assigning Channel Labels................................................................ 3-24

3-32. Configuring Mx+B Scaling From a File .............................................. 3-24

3-33. Entering an Instrument’s Description................................................... 3-25

3-34. Copying a Channels Configuration...................................................... 3-26

iii

Page 10

2640A/2645A NetDAQ

Users Manual

3-35. Default Configuration Settings............................................................ 3-27

3-36. Using Configuration Lockout.............................................................. 3-28

3-37. Saving an Instrument’s Configuration as a Text File.......................... 3-28

3-38. Configuring the netdaq.ini File............................................................ 3-29

4 Operating NetDAQ Logger for Windows........................................ 4-1

4-1. Introduction.......................................................................................... 4-3

4-2. Starting and Stopping Logging............................................................ 4-3

4-3. Starting or Stopping all Instruments at Once................................... 4-4

4-4. Starting or Stopping a Group Instrument......................................... 4-4

4-5. Clearing an Instrument’s Totalizer Value....................................... 4-5

4-6. Simulated Logging........................................................................... 4-5

4-7. Selecting an Instrument’s Scanning Duration ................................. 4-5

4-8. Real-Time Displays.............................................................................. 4-6

4-9. The Logging Status Window........................................................... 4-7

4-10. The Readings Table Window.......................................................... 4-8

4-11. The Spy Window............................................................................. 4-9

4-12. Quick Plot........................................................................................ 4-11

4-13. Dynamic Data Exchange (DDE) Operations................................... 4-12

4-14. Data Files ............................................................................................. 4-13

4-15. Configuring a Data File4-15............................................................ 4-14

4-16. Converting Data Files...................................................................... 4-18

4-17. Viewing and Printing a Data File.................................................... 4-18

4-18. Optimizing Performance...................................................................... 4-20

4-19. Optimizing Performance for Speed................................................. 4-20

4-20. Increasing Scanning Rate............................................................ 4-20

4-21. Increasing Data Transmission and Storage Rate......................... 4-20

4-22. Increasing Network Speed........................................................... 4-21

4-23. Optimizing Performance for Precision............................................ 4-21

4-24. Using Online Help ............................................................................... 4-21

5 Using Trend Link for Fluke.............................................................. 5-1

5-1. Introduction.......................................................................................... 5-3

5-2. Displaying a Trend Link Chart During Logging............................. 5-3

5-3. Playing Back a Trend Link File in Trend Link ............................... 5-4

5-4. Playing Back a Fast Binary File in Trend Link............................... 5-5

5-5. Playing Back an ASCII (CSV) File in Trend Link.......................... 5-6

5-6. Importing Trend Link Data Files..................................................... 5-6

5-7. Create a New Trend Link Data Set Directory............................. 5-6

5-8. Add the New Folder to the Trend Link infolink.ini File ... 5-6

5-9. Import the NetDAQ ASCII (CSV) File into Trend Link ............ 5-7

5-10. Display the Trend Link Chart for the Imported File................... 5-7

5-11. Title the Trend Link Chart .......................................................... 5-8

5-12. Save the Trend Link Chart.......................................................... 5-9

iv

Page 11

Contents

(continued)

5-13. Exporting Trend Link Data Files..................................................... 5-9

5-14. Deleting Old Trend Link Files......................................................... 5-11

5-15. Getting the Right Look for Your Trend Link Chart............................. 5-12

5-16. Using the Trend Link Control Bar................................................... 5-12

5-17. Using the Trend Link Menus........................................................... 5-15

5-18. Adjusting the Curve Time Scale (X-axis) ................................... 5-15

5-19. Adjusting the Curve Amplitude Scale (Y-axis)........................... 5-16

5-20. Configuring the Curve Status Display......................................... 5-17

5-21. Curve Preferences........................................................................ 5-18

5-22. Background Preferences.............................................................. 5-21

5-23. Real Time Frequency Update...................................................... 5-23

5-24. Adding or Changing the Chart Title............................................ 5-23

5-25. Using the Note System ................................................................ 5-24

5-26. Printing a Chart............................................................................ 5-24

6 Maintenance ..................................................................................... 6-1

6-1. Introduction.......................................................................................... 6-3

6-2. Self-Test Diagnostics and Error Codes................................................ 6-3

6-3. Cleaning................................................................................................ 6-4

6-4. Fuse Replacement................................................................................. 6-4

6-5. Performance Test.................................................................................. 6-6

6-6. Configuring the Performance Test Setup......................................... 6-6

6-7. Initializing the Performance Test Setup........................................... 6-9

6-8. Accuracy Performance Tests ........................................................... 6-11

6-9. Volts DC Accuracy Test (2640A) ............................................... 6-11

6-10. Volts DC Accuracy Test (2645A) ............................................... 6-12

6-11. Volts AC Accuracy Test.............................................................. 6-13

6-12. Frequency Accuracy Test............................................................ 6-14

6-13. Analog Channel Integrity Test..................................................... 6-15

6-14. Computed Channel Integrity Test................................................ 6-15

6-15. Thermocouple Temperature Accuracy Test................................ 6-16

6-16. Open Thermocouple Response Test............................................ 6-16

6-17. 2-Wire Resistance Accuracy Test (2640A)................................. 6-17

6-18. 2-Wire Resistance Accuracy Test (2645A)................................. 6-18

6-19. 4-Wire Resistance Accuracy Test (2640A)................................. 6-20

6-20. 4-Wire Resistance Accuracy Test (2645A)................................. 6-23

6-21. RTD Temperature Accuracy Test (Resistance) (2640A)............ 6-24

6-22. RTD Temperature Accuracy Test (Resistance) (2645A)............ 6-25

6-23. RTD Temperature Accuracy Test (DIN/IEC 751 RTD) ............. 6-25

6-24. Digital Input/Output Tests ............................................................... 6-26

6-25. Digital I/O Output Test................................................................ 6-26

6-26. Digital Input Test......................................................................... 6-27

6-27. Totalizer Tests.................................................................................. 6-28

6-28. Totalizer Count Test.................................................................... 6-28

v

Page 12

2640A/2645A NetDAQ

Users Manual

6-29. Totalizer Sensitivity Test............................................................ 6-28

6-30. Master Alarm Output Test............................................................... 6-29

6-31. Trigger Input Test............................................................................ 6-30

6-32. Trigger Output Test......................................................................... 6-30

6-33. Calibration............................................................................................ 6-31

6-34. Adding Calibration to the Utilities Menu........................................ 6-32

6-35. Instrument Calibration Dialog Box................................................. 6-33

6-36. Calibration Steps Dialog Box.......................................................... 6-33

6-37. Variations in the Display ..................................................................... 6-34

6-38. Service.................................................................................................. 6-34

6-39. Replacement Parts................................................................................ 6-36

Appendices

A Specifications........................................................................................... A-1

B Noise, Shielding, and Crosstalk Considerations ...................................... B-1

C True-RMS Measurements........................................................................ C-1

D RTD Linearization.................................................................................... D-1

E Computed Channel Equations.................................................................. E-1

F Data File Format....................................................................................... F-1

G Dynamic Data Exchange (DDE).............................................................. G-1

H Ethernet Cabling....................................................................................... H-1

I Network Considerations........................................................................... I-1

J Error Messages & Exception Conditions................................................. J-1

K Fluke Service Centers............................................................................... K-1

Index

vi

Page 13

List of Tables

Table Title Page

1-1. Models, Options and Accessories................................................................... 1-14

2-1. Front Panel Key Descriptions ......................................................................... 2-17

2-2. Annunciator Display Descriptions.................................................................. 2-18

2-3. Instrument Default Parameters........................................................................ 2-21

2-4. Network Error Messages................................................................................. 2-58

2-5. Ethernet Indicators .......................................................................................... 2-60

2-6. Troubleshooting .............................................................................................. 2-61

3-1. NetDAQ Logger Default Instrument Configuration ....................................... 3-27

6-1. Self-Test Error Codes...................................................................................... 6-3

6-2. Recommended Test Equipment....................................................................... 6-7

6-3. Replacement Parts........................................................................................... 6-36

A-1. 2640A/2645A General Specifications............................................................. A-2

A-2. 2640A/2645A Environmental Specifications.................................................. A-4

A-3. 2640A/2645A DIGITAL I/O Specification..................................................... A-4

A-4. 2640A/2645A Trigger In (TI) Specification................................................... A-5

A-5. 2640A/2645A Trigger Out (TO) Specification............................................... A-6

A-6. 2640A/2645A Master Alarm (MA) Specification .......................................... A-6

A-7. 2640A/2645A Totalizer Specification ............................................................ A-7

A-8. 2640A/2645A Real-Time Clock and Calendar ............................................... A-7

A-9. 2640A DC Voltage Measurement General Specifications.............................. A-8

A-10. 2640A DC Voltage Range and Resolution Specifications.............................. A-8

A-11. 2640A DC Voltage Accuracy Specifications.................................................. A-9

A-12. 2640A AC Voltage General Specifications .................................................... A-9

A-13. 2640A AC Voltage Range and Resolution Specifications.............................. A-10

A-14. 2640A AC Voltage Accuracy Specifications.................................................. A-11

A-15. 2640A 4-Wire Resistance Temperature Coefficient....................................... A-12

A-16. 2640A 4-Wire Resistance Range and Resolution Specifications ................... A-12

A-17. 2640A 4-Wire Resistance Accuracy Specifications........................................ A-12

A-18. 2640A 4-Wire RTD Temperature Coefficient ................................................ A-13

A-19. 2640A 4-Wire RTD Specifications................................................................. A-13

A-20. 2640A Thermocouple General Specifications................................................ A-14

vii

Page 14

2640A/2645A NetDAQ

Users Manual

A-21. 2640A Thermocouple Specifications ............................................................. A-15

A-22. 2640A Frequency Accuracy Specifications.................................................... A-16

A-23. 2640A Frequency Sensitivity Specifications.................................................. A-16

A-24. 2645A DC Voltage Measurement General Specifications............................. A-17

A-25. 2645A DC Voltage Resolution and Repeatability Specifications.................. A-18

A-26. 2645A DC Voltage Accuracy Specifications ................................................. A-18

A-27. 2645A AC Voltage General Specifications.................................................... A-19

A-28. 2645A AC Voltage Range and Resolution Specifications ............................. A-20

A-29. 2645A AC Voltage Accuracy Specifications ................................................. A-20

A-30. 2645A 4-Wire Resistance Temperature Coefficient....................................... A-21

A-31. 2645A 4-Wire Resistance Range and Resolution Specifications................... A-21

A-32. 2645A 4-Wire Resistance Accuracy Specifications....................................... A-21

A-33. 2645A 4-Wire RTD Temperature Coefficient................................................ A-22

A-34. 2645A 4-Wire RTD Specifications................................................................. A-22

A-35. 2645A Thermocouple General Specifications................................................ A-23

A-36. 2645A Thermocouple Specifications ............................................................. A-23

A-37. 2645A Frequency Accuracy Specifications.................................................... A-25

A-38. 2645A Frequency Sensitivity Specifications.................................................. A-25

B-1. 2645A Crosstalk Specifications...................................................................... B-3

B-2. 2640A Crosstalk Specifications...................................................................... B-4

I-1. Newt Quick Check.......................................................................................... I-29

I-2. Additions to Host Computer Files made by Newt Installation....................... I-30

viii

Page 15

List of Figures

Figure Title Page

1-1. 2640A/2645A NetDAQ Networked Data Acquisition Units.......................... 1-3

1-2. 2640A/2645A Front Panel .............................................................................. 1-4

1-3. Typical Front Panel Display During Scanning and Monitoring ..................... 1-5

1-4. 2640A/2645A Rear Panel................................................................................ 1-6

2-1. Instrument Preparation.................................................................................... 2-4

2-2. Connecting the Instrument to a Power Source................................................ 2-6

2-3. Universal Input Module Connections ............................................................. 2-9

2-4. 2-Wire and 4-Wire Connections..................................................................... 2-10

2-5. DIGITAL I/O Connector................................................................................. 2-12

2-6. ALARM/TRIGGER I/O Connector................................................................ 2-14

2-7. External Trigger Wiring for a Group Instrument............................................ 2-16

2-8. Front Panel Controls........................................................................................ 2-17

2-9. Front Panel Indicators ..................................................................................... 2-18

2-10. Rear Panel Controls......................................................................................... 2-20

2-11. Rear Panel Indicators ...................................................................................... 2-20

2-12. Displaying a Monitor Channel ........................................................................ 2-22

2-13. Examples During Monitor............................................................................... 2-23

2-14. Displaying the Digital I/O Status .................................................................... 2-24

2-15. Examples for Digital I/O and Totalizer Status................................................ 2-25

2-16. Displaying the Totalizer Status ....................................................................... 2-26

2-17. Reviewing and Setting the Base Channel Number ......................................... 2-27

2-18. Examples for Reviewing and Setting the BCN............................................... 2-28

2-19. Reviewing and Setting the Line Frequency .................................................... 2-29

2-20. Examples for Reviewing and Setting the Line Frequency.............................. 2-30

2-21. Reviewing and Setting the Isolated Network Type to Isolated....................... 2-31

2-22. Examples for Reviewing and Setting the Network Type................................ 2-32

2-23. Reviewing and Setting the Network Type to General..................................... 2-33

2-24. Examples for Reviewing and Setting General Network Parameters............... 2-34

2-25. Reviewing and Setting the General Network Socket Port .............................. 2-36

2-26. Reviewing and Setting the General Network IP Address............................... 2-37

2-27. Reviewing and Setting the Subnet Mask and Default Gateway...................... 2-40

ix

Page 16

2640A/2645A NetDAQ

Users Manual

2-28. Viewing the Instrument Ethernet Address...................................................... 2-41

2-29. Examples for Viewing the Ethernet Address.................................................. 2-42

2-30. Preparing for Network Operation ................................................................... 2-44

2-31. Interconnection Using 10Base2 (Coaxial) Wiring.......................................... 2-46

2-32. Host Computer/Instrument Direct Connection............................................... 2-47

2-33. Interconnection Using 10BaseT (Twisted-Pair) Wiring................................. 2-49

3-1. NetDAQ Logger for Windows Main Window............................................... 3-4

3-2. Communications Configuration Dialog Box.................................................. 3-5

3-3. Instrument Configuration Dialog Box............................................................ 3-16

3-4. Channels Configuration Dialog Box............................................................... 3-18

3-5. Configuration Text File.................................................................................. 3-29

6-1. Replacing the Fuse.......................................................................................... 6-5

6-2. Performance Test Setup.................................................................................. 6-8

6-3. 2-Wire Connections to 5700A........................................................................ 6-8

6-4. 4-Wire Connections to the Universal Input Module (Resistor)...................... 6-20

6-5. 4-Wire Connections to the Universal Input Module (5700A)........................ 6-21

C-1. Comparison of Common Waveforms............................................................. C-3

D-1. 385 RTD ......................................................................................................... D-2

D-2. 375 RTD ......................................................................................................... D-3

D-3. 391 RTD ......................................................................................................... D-4

D-4. 392 RTD ......................................................................................................... D-6

H-1. 10BaseT Ethernet Cables................................................................................ H-2

x

Page 17

Chapter 1

Overview

Contents Page

1-1. Introduction.......................................................................................... 1-3

1-2. Instrument Features and Capabilities................................................... 1-4

1-3. Analog Channels.............................................................................. 1-7

1-4. Computed Channels......................................................................... 1-7

1-5. Channel Numbering......................................................................... 1-7

1-6. Mx+B Scaling.................................................................................. 1-7

1-7. Alarms.............................................................................................. 1-8

1-8. Channel Monitoring......................................................................... 1-8

1-9. Digital I/O........................................................................................ 1-8

1-10. Totalizer........................................................................................... 1-8

1-11. Trigger Input.................................................................................... 1-9

1-12. Trigger Output.................................................................................. 1-9

1-13. Master Alarm................................................................................... 1-10

1-14. Interval Trigger................................................................................ 1-10

1-15. External Trigger............................................................................... 1-10

1-16. Alarm Trigger .................................................................................. 1-10

1-17. NetDAQ Logger Features and Capabilities.......................................... 1-11

1-18. Operating a NetDAQ Data Acquisition System................................... 1-11

1-19. Isolated Networks ............................................................................ 1-12

1-20. General Networks ............................................................................ 1-12

1-21. Ethernet Port Selection .................................................................... 1-12

1-22. Asynchronous Instrument Operations.............................................. 1-12

1-23. Group Instrument Operations........................................................... 1-12

1-24. Scanning and Logging...................................................................... 1-13

1-25. RS-232 Interface.............................................................................. 1-13

1-26. Host Computer Requirements.............................................................. 1-14

1-27. Options and Accessories ...................................................................... 1-14

1-28. Instrument Connector Set................................................................. 1-15

1-29. Host Computer Ethernet Adapters................................................... 1-15

1-1

Page 18

2640A/2645A NetDAQ

Users Manual

1-2

Page 19

Overview

Introduction

Introduction 1-1.

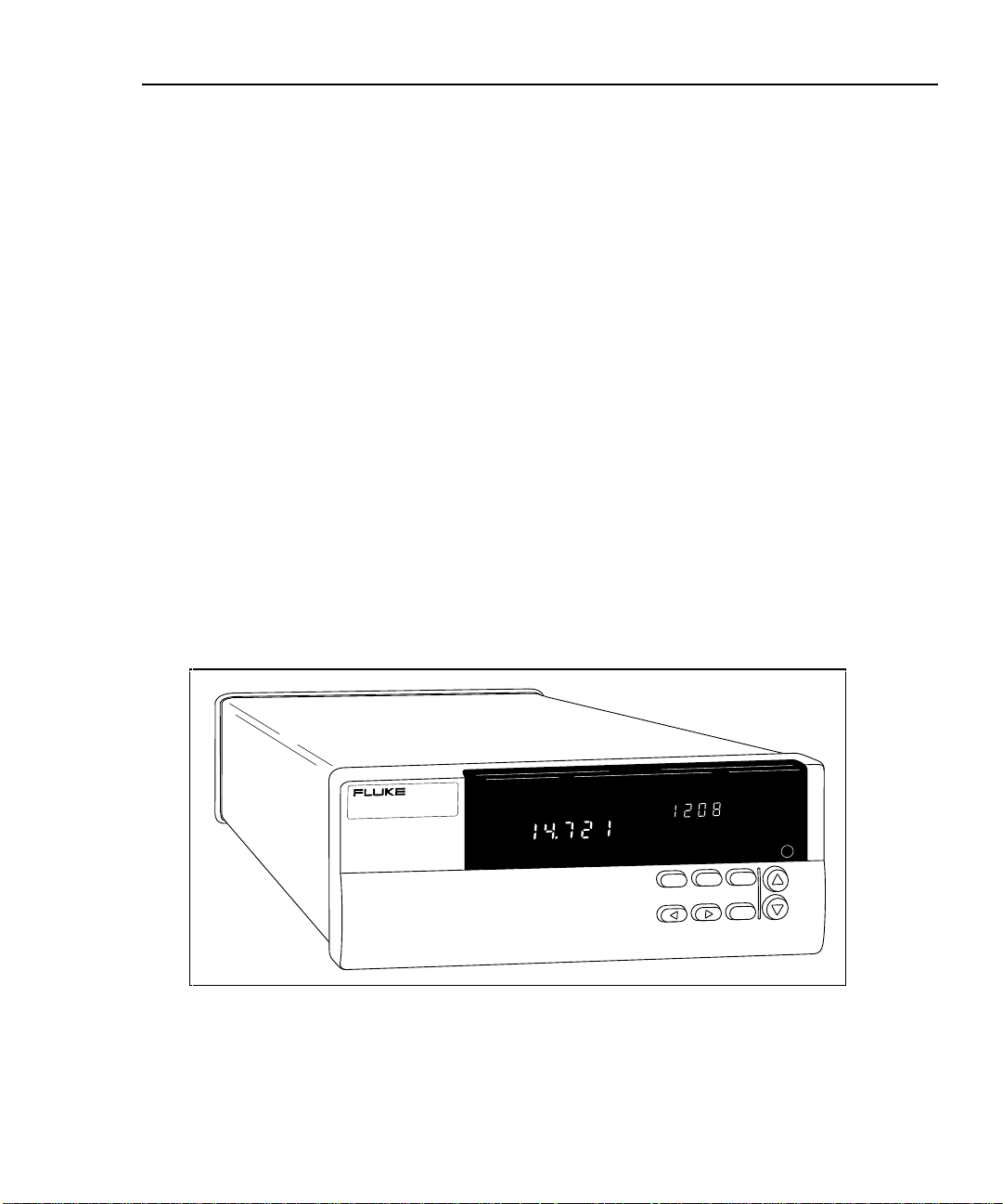

The 2640A and 2645A NetDAQ Networked Data Acquisition Units are

20-channel front ends that operate in conjunction with NetDAQ Logger for

Windows (hereafter known as NetDAQ Logger) to form a data acquisition

system.

The instruments measure dc volts, ac volts, Ohms, temperature, frequency, and dc

current. Temperature measurements use thermocouples or resistance-temperature

detectors (RTDs). To measure other parameters, use an appropriate transducer.

The instrument also includes ten computed channels for custom calculations

based on measured values.

The NetDAQ instruments scan the 20 analog channels in sequence and calculate

the values for the ten computed channels. Interval timers, alarm conditions, and/or

an external signal input can trigger scans. The NetDAQ Logger software

configures and controls up to 20 instruments via an Ethernet connection. The

software provides the means to view scan data and log it into files.

The 2640A and 2645A instruments (Figure 1-1) are identical in operation and

appearance, and vary only in emphasis. The 2640A emphasizes precision and

supports up to 100 measurements per second, with 5 ½ digits of resolution, .02%

accuracy, and 150-volt common mode voltage (300 volts on channels 1 and 11).

The 2645A emphasizes increased measurement speed supporting up to 1000

measurements per second, with 4 ½ digits of resolution, 0.04% accuracy, and 50volt common mode voltage. See Appendix A for instrument specifications.

1

NetDAQ

NETWORKED DATA ACQUISITION UNIT

REM SCAN

MON

V DC

COMM

CH

MON

DIO

ENTER

Figure 1-1. 2640A/2645A NetDAQ Networked Data Acquisition Units

CAL

ENABLE

1-3

Page 20

2640A/2645A NetDAQ

Users Manual

Instrument Features and Capabilities 1-2.

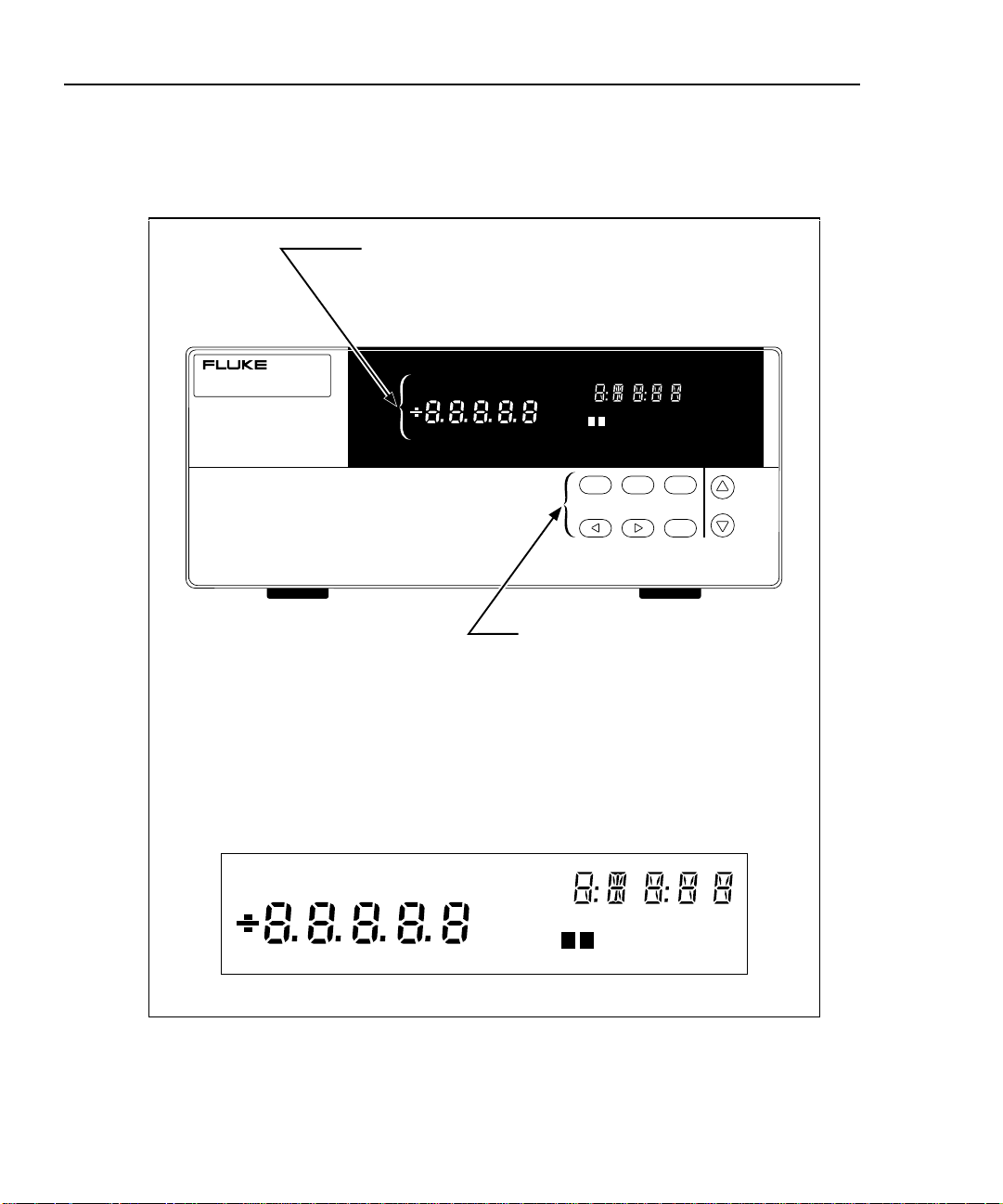

The following describes the front and rear panels of the instrument and its

capabilities (Figures 1-2 to 1-4).

Primary, Secondary, and

Annunciator Displays.

Indicators and annunciators for

operating mode, configuration,

display, and data measurements.

NetDAQ

NETWORKED DATA ACQUISITION UNIT

REVIEW

LAST

MAX

REM

MIN

AUTO

SCAN

MON

SET

Mx+B

FUNC

ALARM

°C °F RO

mV AC DC

x1Mk

F

PRN

OFF

HI

LIMIT

Hz

Ω

12

COMM

CAL

LO

DIO MON

EXTCHTR

ENTER

CAL

ENABLE

1-4

REVIEW

LAST

Function Keys.

User keys for configuring

operating parameters such as

Base Channel Number, and front

panel displays such as channel

monitoring, digital I/O status, and

totalizer count.

MAX

MIN

REM

AUTO

SCAN

MON

SET

Mx+B

ALARM

°C °F RO

FUNC

mV AC DC

Hz

x1Mk

Ω

Display Detail

Figure 1-2. 2640A/2645A Front Panel

F

LIMIT

12

HI

LO

OFF

CAL

PRN

EXTCHTR

Page 21

Overview

Instrument Features and Capabilities

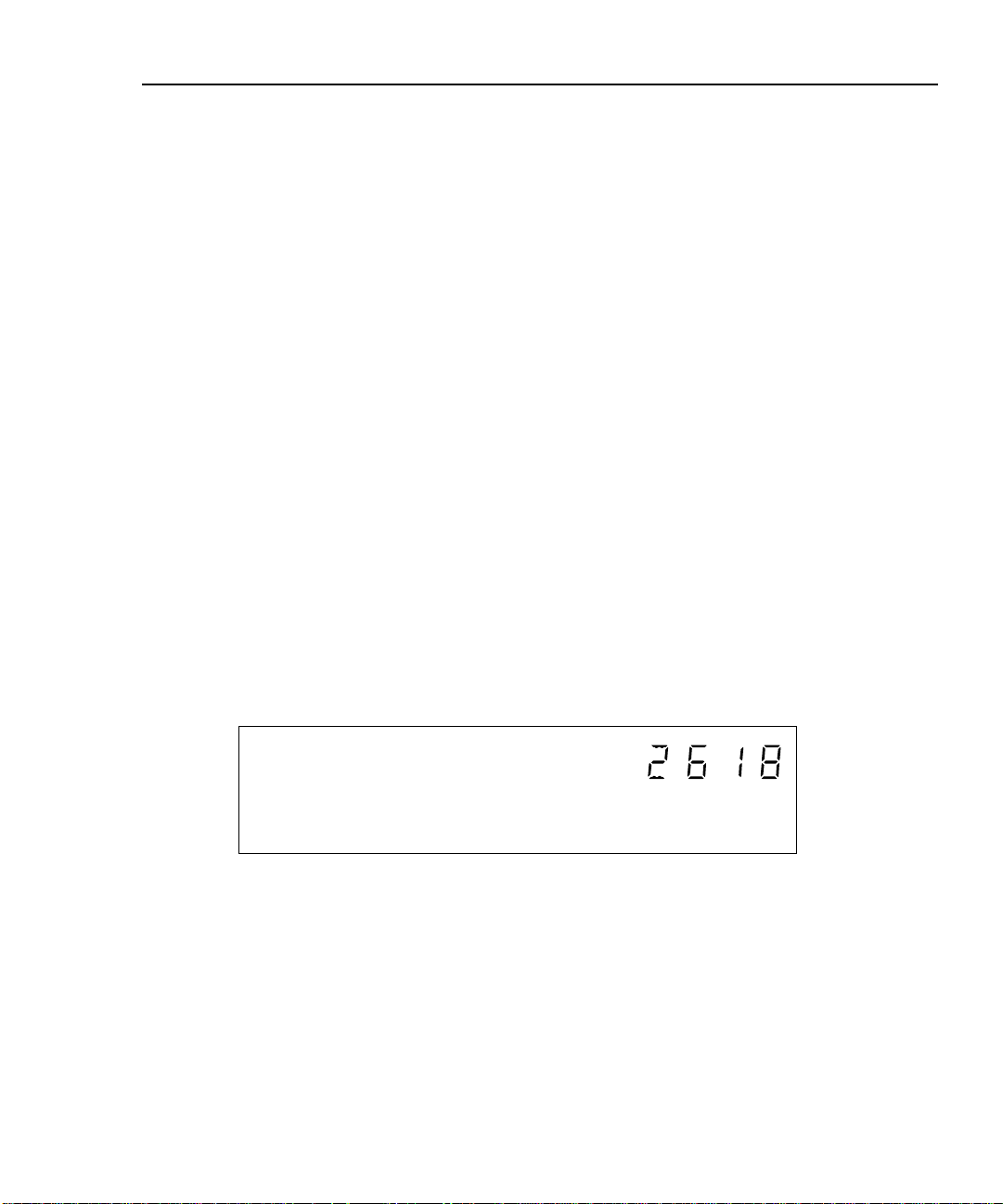

1

REM (Remote)

Annunciator.

Indicates the Host

Computer and the

Instrument are

communicating on the

network, i.e., the

instrument is being

operated remotely.

SCAN (Scanning)

Annunciator.

Indicates the

instrument is

scanning.

REM SCAN

MON

MON (Monitor)

Annunciator.

Indicates the

instrument is

monitoring a channel

(in this example,

analog channel 8).

You can monitor a

channel with or

without instrument

scanning.

mV DC

1208 (Global Channel

Number).

Indicates the channel

being monitored is

1208. This number

consists of the

instrument Base

Channel Number (12)

and the selected

channel (08).

CH

14.721 (Reading).

Indicates the reading

of the channel being

monitored has a value

of 14.721. This

display is limited to 4

1/2 digits of resolution.

Figure 1-3. Typical Front Panel Display During Scanning and Monitoring

m Annunciator.

Indicates the multiplier

for the reading is .001

(milli). The other

multipliers are k (kilo,

1000), and M (mega,

1,000,000).

V DC (Volts DC)

Annunciator.

Indicates that the

number shown in the

primary display

(14.721) is the

function volts dc.

CH (Channel)

Annunciator.

Indicates the number

shown in the

secondary display

(1208) is the Global

Channel Number.

1-5

Page 22

2640A/2645A NetDAQ

Users Manual

Ground Terminal.

Connects mainframe to ground.

Power Switch.

Applies power to the

instrument (ac or dc

operation).

AC Power Connector.

Connects to any line

source of 107 to 264 volts

ac (50/60 Hz).

107-264V

50/60 Hz

15VA

ON/ OFF

MATO TI 0 1 2 3 4 5 6 7

+30V

+

9-16V

DC PWR

ALARM/TRIGGER I/O

Universal Input Module.

Directly wires 20 analog inputs

(Channels 1 to 20) without need

for external signal conditioning.

Serial Port.

OVERVOLTAGE CATEGORY II PER IEC 1010-1

WARNING: TO AVOID ELECTRICAL SHOCK, DISCONNECT LINE CORD BEFORE REMOVING COVER

DIGITAL I/O

MEETS VFG 243 / 1991

MODEL: 2640A / 41A 2645A / 46A

SERIAL PORT

Ethernet 10BaseT

Connector.

A RJ-45 connector that

interfaces the instrument with

a 10BaseT Twisted-Pair

Ethernet network. The

instrument automatically

selects the active 10Base2 or

10BaseT connector.

RCV LK

XMT

NOT FOR CONNECTION TO

PUBLIC TELEPHONE SYSTEMS

ETHERNET

1-6

ALARM/TRIGGER I/O

Connector.

MA (Master Alarm)

output is logic low when

any channel is in alarm;

TO (Trigger Output)

output is logic low for

µ

nominal 125

s at the

start of any scan; TI

(Trigger Input) input

logic low triggers

scanning; DC PWR (dc

volts input) input is 9 to

16V dc to power the

instrument.

DIGITAL I/O

Connector.

Alarm outputs (logic

low for a channel in

Ground Terminal.

Use for 50-ohm

termination ground

lug.

alarm) and general

purpose I/O (terminals

0 to 7); totalizer input,

and GND.

Ethernet 10Base2

Connector.

A BNC-type connector that

interfaces the instrument

with a 10Base2 coax

network. The instrument

automatically selects the

active 10Base2 or 10BaseT

connector.

Figure 1-4. 2640A/2645A Rear Panel

Ethernet Indicators.

XMT (transmit) blinks

red for instrument

Ethernet transmissions;

RCV (receive) blinks

red for any Ethernet

activity on the network;

LK (link) lights amber

when the Ethernet

interface is active for

the Twisted-Pair

connection, and blinks

for a data collision for

the coaxial connection.

Page 23

Overview

Instrument Features and Capabilities

Analog Channels 1-3.

The analog channel (1 to 20) measurement connections are made via the

Universal Input Module. External signal conditioning for the analog inputs is not

necessary. The host computer configures all analog channels using NetDAQ

Logger.

Computed Channels 1-4.

In addition to the 20 analog channels, the instrument provides an additional 10

computed channels (21 to 30) by processing analog channels and other computed

channels. The following methods are used:

• The average of a group of channels,

• The difference between any two channels,

• The difference between a channel and the average of a group of channels,

• A mathematical equation.

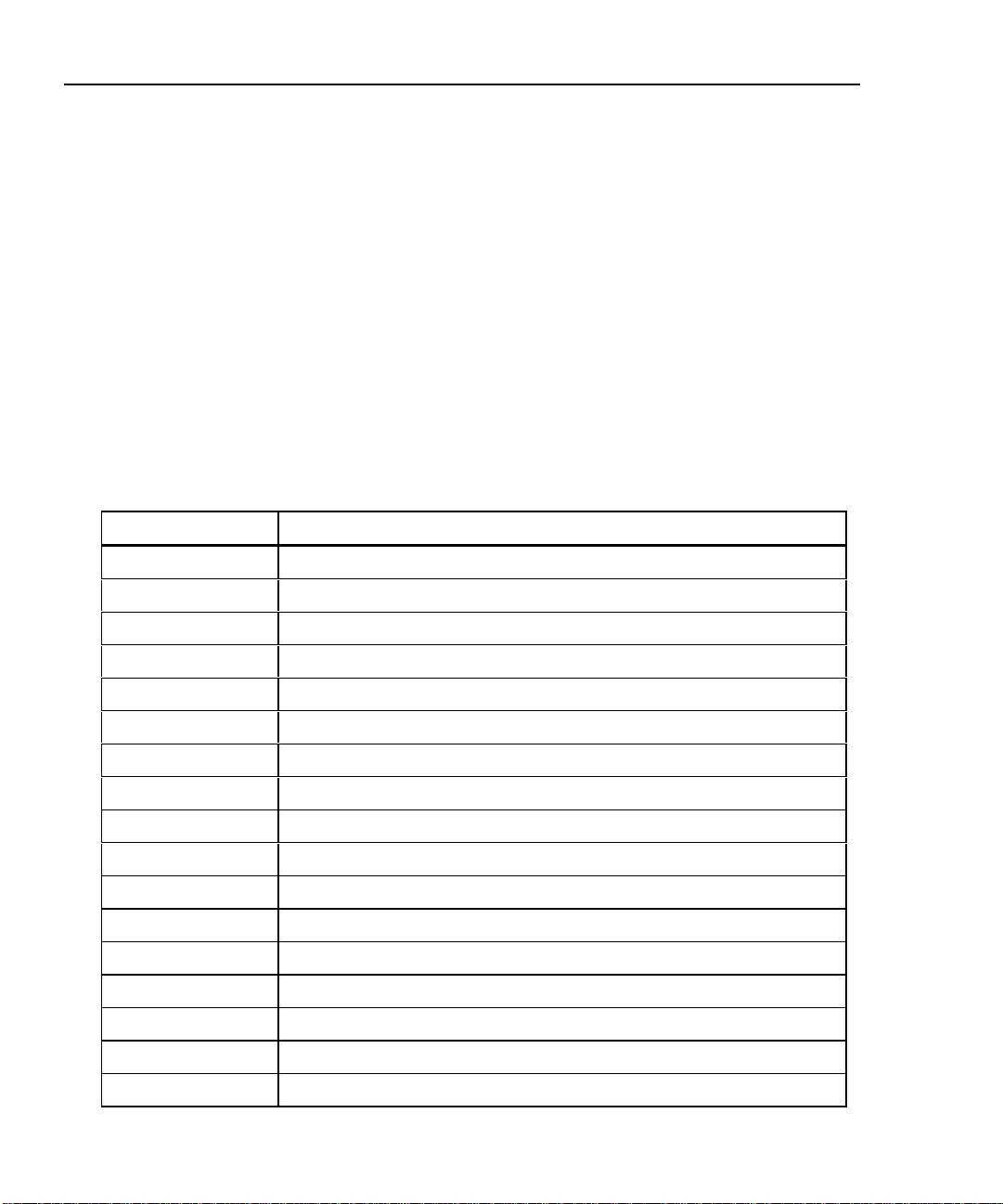

Channel Numbering 1-5.

Each instrument channel, measured or computed, is identified by Global Channel

Number (GCN). The first two digits of the GCN are the Base Channel Number

(01 to 99) that identifies the instrument. The last two digits are the channel

number. For example, GCN 2618 indicates instrument 26 and analog channel 18

(below). When the instrument is in the quiescent state, the channel number of the

GCN shows dashes, for example, 45-- for instrument 45.

1

SCAN

MON

Mx+B

ALARM

CH

Mx+B Scaling 1-6.

Mx+B scaling multiplies a measurement by a multiplier M and then offsets it by

an offset B. For example, Mx+B scaling of 100x+50 applied to a measured or

computed channel value of 1.15 results in a reading of 100(1.15)+50=165. A

common use of Mx+B scaling is to calibrate a sensor or transducer to provide for

display and recording in engineering units. The Mx+B annunciator lights when a

monitored channel has scaling applied.

1-7

Page 24

2640A/2645A NetDAQ

Users Manual

Alarms 1-7.

Two alarms, Alarm 1 and Alarm 2, can be applied to any configured channel. An

alarm condition occurs when a measurement falls below a low alarm value or

rises above a high alarm value. You can use alarms to trigger scanning (see

“Alarm Triggering”) and to set a Digital I/O line to a logic low (see “Digital I/O”

below). NetDAQ Logger displays and records alarm conditions.

If you apply Mx+B scaling as part of the channel configuration, the instrument

bases the alarms on the scaled values. When any configured channel is in alarm,

the ALARM annunciator is on dim, or bright if a channel in alarm is being used as

an Alarm Trigger. When a channel is in alarm, the rear-panel Master Alarm

output is asserted (logic low). NetDAQ Logger displays and records alarm

conditions.

Channel Monitoring 1-8.

Channel monitoring takes place at the front panel of the instrument. Use the front

panel MON key and arrow keys to select a channel for monitoring. NetDAQ

Logger also allows the selection of a channel to monitor during scanning. For an

example of a front panel display of the instrument during monitoring, see Figure

1-3. The channel monitoring display updates once per second (nominal).

Digital I/O 1-9.

Eight general-purpose open-collector Transistor-Transistor Logic (TTL) digital

input/output (I/O) lines are available at the instrument rear-panel DIGITAL I/O

connector, terminals 7 through 0 (Figure 1-4). A logic low externally applied to an

I/O line is an input; a logic low internally set by the instrument is an output. An

output logic low condition takes precedence over an input logic high condition.

When the I/O lines are used as inputs, they signal an external condition that can

be correlated to the data measurements.

NetDAQ Logger displays and records the status of the Digital I/O as the decimal

equivalent of the eight binary bits. For example, 11111111 (DIO7 to DIO0) is

represented by decimal 255; 00001111 is represented by decimal 15.

The instrument can display the Digital I/O status in binary format at the front

panel with updates each second.

Totalizer 1-10.

The totalizer input counts contact closures or voltage transitions with a maximum

count of 4,294,967,295. The connections for the totalizer input line are at the

instrument rear panel DIGITAL I/O connector, terminals Σ and GND (Figure 1-

4). The instrument continuously detects the totalizer input on the rear panel

independently from instrument scanning and other activities. If the Totalizer

1-8

Page 25

Overview

Instrument Features and Capabilities

overflows (reaching the maximum count), the display briefly shows OL

(overload) and begins counting from zero again

A totalizer input from contact closures increments on the “open” portion of the

switch sequence close-open. To prevent switch contact “bounce” from triggering

false readings, select the Totalizer Debounce feature. A totalizer input from

voltage transitions increments during low-to-high voltage transitions with a

nominal threshold of +1.4 volts. The maximum voltage input is +30V dc, and the

minimum voltage input is -4.0V dc. The maximum totalizer rate is 5,000

transitions per second without debounce and 500 transitions per second with

debounce.

The instrument reports Totalizer status with scan data and can display it at the

front panel. You can clear the Totalizer count by cycling power to the instrument

or via NetDAQ Logger.

Trigger Input 1-11.

Trigger Input is an instrument connection used to trigger scans from an external

source. The connection uses the ALARM/TRIGGER I/O terminals TI and GND

(Figure 1-4). A contact closure or logic low between TI and GND triggers an

instrument scan if External Trigger is enabled. While the trigger input line is held

low, the instrument continues to scan at Interval 2.

1

When there is no trigger input, an internal pull-up resistor holds the input at logic

high (nominal +5.0V dc).

Trigger Output 1-12.

Trigger Output is an output line that, when enabled, goes to logic low for 125 µs

every time a scan begins. The connection uses the ALARM/TRIGGER I/O

terminals TO and GND (Figure 1-4). Use the Trigger Output to trigger other

instruments by their Trigger Input connection and to interface with external

equipment. An internal pull-up resistor holds the trigger output line at a logic high

(nominal +5.0V dc) when there is no trigger output.

1-9

Page 26

2640A/2645A NetDAQ

Users Manual

Master Alarm 1-13.

Master Alarm is an instrument output line that is logic low (nominal +0.8V dc)

for as long as any channel is in alarm while scanning is active. The connection

uses the ALARM/TRIGGER I/O terminals MA and GND (Figure 1-4). This TTL

output interfaces with external equipment such as warning lights, alarms,

automatic shutdowns, and paging systems. When the alarm condition ends or

scanning stops, an internal pull-up resistor sets the output at logic high (nominal

+5.0V dc).

Interval Trigger 1-14.

Interval Trigger triggers scanning at regular time intervals using Interval 1.

Interval 1 is in seconds, with a minimum of 0.000 (continuous scanning) and a

maximum of 86400.000 (one scan every 24 hours). The time resolution is to the

millisecond, for example, 12.345 seconds.

External Trigger 1-15.

External Trigger triggers scanning when an external logic low is applied to the

instrument TI (Trigger In) line. As long as the Trigger Input remains low, scans

are triggered at regular time intervals using Interval 2. Interval 2 is in seconds,

with a minimum of 0.000 (continuous scanning) and a maximum of 86400.000

(one scan every 24 hours). The time resolution is to the millisecond, for example,

12.345 seconds. When scanning starts, if the External Trigger is logic low,

scanning begins at the Interval 2 rate. If the External Trigger is logic high, no

scans are triggered until the trigger line is set to logic low.

You can combine External Trigger with Alarm Trigger and Interval Trigger. For

example, if the Interval Trigger is set for 60 seconds (Interval 1) and the External

Trigger is set for 10 seconds (Interval 2), scanning is at 60-second intervals except

when External Trigger is low, when scanning is at 10-second intervals.

If one or more external trigger events occur while a scan is in progress, one scan

triggers following the scan in progress.

Alarm Trigger 1-16.

Alarm Trigger triggers scanning when a channel designated as an alarm trigger

goes into alarm. As long as any such channel is in alarm, scans are triggered at

regular time intervals using Interval 2. Interval 2 is in seconds, with a minimum of

0.000 (continuous scanning) and a maximum of 86400.000 (one scan every 24

hours). The time resolution is to the millisecond, for example, 12.345 seconds.

The instrument performs background monitoring of channels designated as alarm

triggers to check for alarm conditions using Interval 3. (See “Configuring the

netdaq.ini File” in Chapter 3 of this manual.)

1-10

Page 27

Overview

NetDAQ Logger Features and Capabilities

You can combine Alarm Trigger with External Trigger and Interval Trigger. For

example, set the Interval Trigger for 60 seconds (Interval 1) and the Alarm

Trigger for 10 seconds (Interval 2). Scanning is at 60-second intervals except

when a channel designated as an alarm trigger is in alarm, when scanning is at 10second intervals.

NetDAQ Logger Features and Capabilities 1-17.

NetDAQ Logger is the operating software for NetDAQ instruments. It lets you

configure and operate your system through a Windows-based environment. The

package installs either a 32-bit version for Windows 95 and Windows NT, or a

16-bit version for Windows 3.1. Chapters 3 and 4 of this manual provide an

overview of operating NetDAQ Logger. Online help provides more details.

Some major features of NetDAQ Logger include:

• Multiple Instruments. NetDAQ Logger lets you configure and control up to

20 instruments either as Asynchronous instruments or a Group Instrument.

• Data File Recording. NetDAQ Logger logs scan data into a choice of several

file types for each instrument or instrument group.

• Online Help. Online help describes the controls and operations.

1

• Real-time Data Display. The Readings Table displays the latest scan data

from the currently selected instrument. Quick Plot graphs scan data from any

eight channels. The Spy utility gets current readings from any eight channels

whether or not scanning is active.

• Real-Time Trend Plotting. Trend Link for Fluke (optional) lets you view real-

time or historical trends in your collected data. It compares data from multiple

sources, performs simple Statistical Process Control (SPC) calculations on

selected data portions, annotates data, highlights curve limits, zooms in on

data of interest, compares batches, and exports to spreadsheets or other

applications.

• Dynamic Data Exchange (DDE). You can link data to other Windows-based

applications, such as spreadsheets, with Dynamic Data Exchange (DDE).

Operating a NetDAQ Data Acquisition System 1-18.

You can configure NetDAQ hardware and software to operate over either an

isolated or general network. An isolated network includes NetDAQ instruments

and host computers only. A general network may also include servers, routers,

gateways, or other network devices. Both types of networks interconnect using

Ethernet (i.e., using the IEEE 802.3 or ISO 8802-3 standards).

A unique 2-digit Base Channel Number (BCN) entered at the instrument front

panel identifies each NetDAQ instrument on the network. All subsequent

1-11

Page 28

2640A/2645A NetDAQ

Users Manual

operations refer to the instrument by BCN. NetDAQ Logger supports up to 20

instruments for operation. You cannot operate an instrument from more than one

host computer at a time.

Isolated Networks 1-19.

An isolated network consists of only NetDAQ instruments and host computers.

The advantages include simplified setup, faster network operation, and freedom

from general network problems. Data throughput specifications are guaranteed

only for isolated networks. When you install NetDAQ Logger for an isolated

network, it automatically handles instrument IP addressing. You must configure

your host computer networking software to use a host computer IP address of

198.178.246.1xx and subnet mask of 255.255.255.0. See “Setting Host Computer

Network Parameters” in Chapter 2 of this manual.

General Networks 1-20.

A general network consists of host computers, NetDAQ instruments, and servers,

routers, gateways, or other network devices. Refer connectivity issues to your

network administrator and review Appendix I “Network Considerations” for more

information. When you install the NetDAQ software for a general network, you

must enter the instrument IP addresses manually.

Ethernet Port Selection 1-21.

Each instrument has two network ports: 10Base2 coaxial and 10BaseT twisted

pair Ethernet. The instrument automatically monitors and selects the active

Ethernet port. You may change ports at any time and the instrument will detect

the change and automatically connect to the active port.

Asynchronous Instrument Operations 1-22.

Using NetDAQ Logger, you denote instruments as asynchronous or grouped. An

asynchronous (independent) instrument controls its own scanning operations,

including scan interval and method of triggering scans. NetDAQ Logger records

measurement data from each asynchronous instrument in an individual data file.

Group Instrument Operations 1-23.

Using NetDAQ Logger, you can group multiple instruments to act as one

instrument. NetDAQ Logger records data from all instruments in the group into a

single data file. You can group up to 20 instruments for up to 400 time-correlated

channels.

1-12

Page 29

Overview

Host Computer Requirements

Designate one instrument in the group as the Master and the others as Slaves. The

Master controls scanning operations, including the scan intervals and method of

scan triggering. You can create only one group instrument.

Scanning and Logging 1-24.

When a scan is triggered, the instrument scans the 20 analog channels and

calculates the 10 computed channels. It stores the resulting time-stamped data in a

scan record. Scans can be triggered from several sources:

• Interval Trigger, where an elapsed interval timer triggers a scan.

• External Trigger, where an external input (ground or logic low) applied to the

instrument TI (Trigger In) line triggers a scan.

• Alarm Trigger, where a channel going into alarm status a scan.

NetDAQ Logger obtains scan records from the instruments and logs the data into

files. Each scan record written in the data file consists of a timestamp, values from

all configured analog channels and computed channels, the alarm states, the

digital I/O line status, and the count of the totalizer.

RS-232 Interface 1-25.

1

The instruments include an RS-232 port for calibration and factory procedures;

the RS-232 port is not used for instrument control or scan data collection. The

NetDAQ Service Manual (PN 942615) describes calibration and factory

procedures that use the RS-232 port. See also “Calibration” in Chapter 6 of this

manual.

1-13

Page 30

2640A/2645A NetDAQ

Users Manual

Host Computer Requirements 1-26.

The host computer used for instrument operations must meet the following

minimum requirements:

• IBM PC with an Intel 386 microprocessor or greater, running Windows 95,

Windows NT, or Windows 3.1.

• Color VGA Monitor.

• A Hard disk drive with 2 MB of free disk space.

• A 1.44 Mbyte (3 1/2-inch) floppy disk drive.

Options and Accessories 1-27.

Table 1-1 summarizes the available Models, Options and Accessories, including

measurement transducers, software, connector sets, Ethernet adapters, cables, and

components.

Table 1-1. Models, Options and Accessories

Model Description

2640A NetDAQ Networked Data Acquisition Unit

2645A NetDAQ Networked Data Acquisition Unit

2640A-911 NetDAQ Logger for Windows

2640A-912 NetDAQ Logger with Trending

264XA-903 NetDAQ Developer’s Toolbox

2600A-904 Trend Link for Fluke

264XA-801 Ethernet Card (10Base2, 10BaseT)

264XA-802 Parallel-to-LAN Adapter (10Base2)

264XA-803 PCMCIA Adapter (10Base2, 10BaseT)

2640A-913 Newt Networking Software

2620A-100 Input Module Option

2620A-101 4-20 mA Current Shunt Strip

942615 NetDAQ

Y2641 19” Rackmount Kit Single/Dual

Y2642 Wall/Cabinet Mounting Plate

Y2643 4-meter Cable Kit

Y2644 NEMA 4X (IP65) Enclosure

Service Manual

1-14

Page 31

Overview

Options and Accessories

Instrument Connector Set 1-28.

The 2620A-100 is a complete set of input connectors: one Universal Input

Module, one ALARM/TRIGGER I/O connector, and one DIGITAL I/O

connector. A 2620A-100 Instrument Connector Set comes with each instrument.

You can wire additional connector sets to allow quick interfacing to multiple

wiring setups.

Host Computer Ethernet Adapters 1-29.

The 264XA-801, 264XA-802, and 264XA-803 are the recommended Ethernet

adapters. The 264XA-801 is a plug-in card, the 264XA-802 is an external parallelto-LAN adapter, and the 264XA-803 is a PCMCIA card.

1

1-15

Page 32

2640A/2645A NetDAQ

Users Manual

1-16

Page 33

Chapter 2

Preparing for Operation

Contents Page

2-1. Introduction.......................................................................................... 2-3

2-2. Instrument Preparation......................................................................... 2-3

2-3. Unpacking and Inspecting the Instrument........................................ 2-5

2-4. Positioning and Rack Mounting....................................................... 2-5

2-5. Connecting to a Power Source and Grounding................................ 2-5

2-6. AC Power..................................................................................... 2-6

2-7. DC Power..................................................................................... 2-7

2-8. Grounding and Common Mode Voltage...................................... 2-7

2-9. Universal Input Module Connections.............................................. 2-7

2-10. Shielded Wiring........................................................................... 2-11

2-11. Crosstalk Considerations............................................................. 2-11

2-12. Digital I/O Connections................................................................... 2-11

2-13. Digital I/O.................................................................................... 2-12

2-14. Totalizer....................................................................................... 2-12

2-15. Alarm/Trigger I/O Connections....................................................... 2-12

2-16. Trigger Input................................................................................ 2-13

2-17. Trigger Output............................................................................. 2-14

2-18. Master Alarm............................................................................... 2-14

2-19. External Trigger Wiring for a Group Instrument............................. 2-15

2-20. Controls and Indicators.................................................................... 2-15

2-21. Front Panel Controls.................................................................... 2-17

2-22. Front Panel Indicators.................................................................. 2-18

2-23. Rear Panel Controls..................................................................... 2-20

2-24. Rear Panel Indicators................................................................... 2-20

2-25. Front Panel Operating Procedures ................................................... 2-21

2-26. Power-On Options ....................................................................... 2-21

2-27. Displaying a Monitor Channel..................................................... 2-22

2-28. Displaying the Digital I/O Status................................................. 2-24

2-1

Page 34

2640A/2645A NetDAQ

Users Manual

2-29. Displaying the Totalizer Status................................................... 2-26

2-30. Reviewing and Setting the Base Channel Number ..................... 2-27

2-31. Reviewing and Setting the Line Frequency................................ 2-29

2-32. Reviewing and Setting the Network Type .................................. 2-31

2-33. Reviewing and Setting the General Network Socket Port .......... 2-36

2-34. Reviewing and Setting the General Network IP Address........... 2-37

2-35. Reviewing and Setting the Subnet Mask and Default Gateway.. 2-38

2-36. Viewing the Instrument Ethernet Address.................................. 2-41

2-37. Host Computer and Network Preparation............................................ 2-43

2-38. Installing Host Computer Ethernet Adapter.................................... 2-43

2-39. Instrument and Host Computer Interconnection.............................. 2-45