Page 1

MPG2-H™ and MPG2-H-HV™

Manual Pressure Generator/Controller

for Hydraulic Pressure

Operation and Maintenance Manual

© 2004-2008 DH Instruments, a Fluke Company

Page 2

High pressure liquids and gases are potentially hazardous. Energy stored in these liquids and gases

can be released unexpectedly and with extreme force. High pressure systems should be assembled and

operated only by personnel who have been instructed in proper safety practices.

© 2008 DH Instruments, a Fluke Company All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or

transmitted in any form or by any means, electronic or mechanical, for any purpose, without the express written

permission of DH Instruments, a Fluke Company, 4765 East Beautiful Lane Phoenix AZ 85044-5318 USA.

DH Instruments makes sincere efforts to ensure the accuracy and quality of its’ published materials; however,

no warranty, expressed or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct

or indirect damages resulting from the use of the information in this manual or products described in it. Mention of

any product or brand does not constitute an endorsement by DH Instruments of that product or brand. This manual

was originally composed in English and was subsequently translated into other languages. The fidelity of the

translation cannot be guaranteed. In case of conflict between the English version and other language versions, the

English version predominates.

DH Instruments, DH, DHI, E-DWT, GPC1, MPG2, MPG2-H, MPG2-H-HV, OPG1, PG7000, RPM4 are trademarks,

registered and otherwise, of DH Instruments, a Fluke Company.

Document No. 3340765

080515

Printed in the USA

© 2004-2008 DH Instruments, a Fluke Company

Page 3

TABLE OF CONTENTS

T

AABBLLEE OOFF

T

TABLE OF CONTENTS ...............................................................I

TABLES..................................................................................II

FIGURES.................................................................................II

ABOUT THIS MANUAL.............................................................III

1. INTRODUCTION ................................................................. 1

1.1 PRODUCT OVERVIEW ...........................................................................................................................1

1.2 SPECIFICATIONS ...................................................................................................................................1

1.3 LOCATION OF THE COMPONENTS......................................................................................................2

1.4 DIMENSIONAL SCHEMATICS................................................................................................................4

1.5 HYDRAULIC SCHEMATIC......................................................................................................................5

2. INSTALLATION .................................................................. 7

2.1 UNPACKING AND INSPECTION ............................................................................................................7

2.2 SITE REQUIREMENTS............................................................................................................................7

2.3 INITIAL SETUP........................................................................................................................................8

C

OONNTTEENNTTS

C

S

3. OPERATION....................................................................... 9

3.1 GENERAL OPERATING PRINCIPLES AND INFORMATION.................................................................9

3.1.1 OVERVIEW....................................................................................................................................................9

3.1.2 VALVES.........................................................................................................................................................9

3.1.3 PRIMING PUMP.............................................................................................................................................9

3.1.4 VARIABLE VOLUME (VV).............................................................................................................................9

3.1.5 RESERVOIR ................................................................................................................................................10

3.2 OPERATION..........................................................................................................................................10

3.2.1 FILLING AND PRIMING THE SYSTEM UNDER TEST, PRIMING PUMP..................................................10

3.2.2 GENERATING AND ADJUSTING PRESSURE, VARIABLE VOLUME AND FINE ADJUST VALVE........11

3.2.3 REFILLING OR EMPTYING THE VARIABLE VOLUME WITHOUT RELEASING TEST PRESSURE......12

4. MAINTENANCE AND ADJUSTMENTS .................................. 13

4.1 REPLACING LIQUID AND FLUSHING HYDRAULIC SYSTEM............................................................13

5. WARRANTY STATEMENT .................................................. 15

Page I © 2004-2008 DH Instruments, a Fluke Company

Page 4

MPG2-H OPERATION AND MAINTENANCE MANUAL

T

AABBLLEES

T

Table 1. MPG2-H and MPG2-H-HV Parts List.............................................................................................7

Table 2. DHI Authorized Service Providers ...............................................................................................16

F

IIGGUURREES

F

Figure 1. Front view .....................................................................................................................................2

Figure 2. Rear view......................................................................................................................................2

Figure 3. Top view........................................................................................................................................3

Figure 4. Front view dimensions..................................................................................................................4

Figure 5. Bottom and side view dimensions................................................................................................4

Figure 6. System schematic.........................................................................................................................5

S

S

© 2004-2008 DH Instruments, a Fluke Company Page II

Page 5

ABOUT THIS MANUAL

A

BBOOUUTT

A

This manual provides the user with the information necessary to operate an MPG2-H Manual Pressure

Generator/Controller for Hydraulic pressure. It also includes additional information provided to help you

optimize MPG2 use and take full advantage of its many features and functions.

For those of you who “don’t read manuals”, go directly to Section 2.3 to set up your MPG2. Then go to

Section 3.2. This will get you running quickly with minimal risk of causing damage to yourself or your MPG2.

Then… when you have questions or start to wonder about all the great features you might be missing, get into

the manual!

(CAUTION) is used throughout the manual to identify user warnings and cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and

additional explanations.

T

T

HHIISS

M

AANNUUAAL

M

L

Manual Conventions

Page III © 2004-2008 DH Instruments, a Fluke Company

Page 6

MPG2-H OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2004-2008 DH Instruments, a Fluke Company Page IV

Page 7

1. INTRODUCTION

.

11.

I

NNTTRROODDUUCCTTIIOON

I

N

1.1 PRODUCT OVERVIEW

The DHI Manual Pressure Generator/Controller for Hydraulic Pressure (MPG2-H) provides a compact

and easy to use system for manually generating, setting and finely adjusting pressures between

atmosphere and 200 MPa (30 000 psi) in closed volumes. MPG2 is a standard pressure generation and

control component for working with DHI PG7302 piston gauges or liquid operated RPM4 reference

pressure monitors. MGP2 and RPM4 are available as a single, integrated pressure calibration instrument

designated E-DWT

The MPG2-H-HV has a larger displacement variable volume (7 cc rather than 3 cc) and is intended for

applications with higher test volumes to reduce variable volume stroke needed to generate the desired

pressure. The maximum working pressure of MPG2-H-HV is 100 MPa (15 000 psi). The MPG2-H

requires less variable volume torque and adjusts pressure more precisely.

1.2 SPECIFICATIONS

MPG2-H MPG2-H-HV

Pressure range

Variable volume piston

Variable volume stroke

Priming pump displacement

Reservoir capacity

TEST1, TEST2 connections

Due to a policy of continuous product improvement all specifications are subject to change

without notice.

diameter

Variable volume

displacement

Operating fluid

Dimensions

Weight:

Atmosphere to 200 MPa (30 000 psi) Atmosphere to 100 MPa

7.9 mm 12 mm

6 cm 6 cm

7 cc (.43 in.3) 3 cc (0.18 in. 3)

3

3.7 cc (0.23 in.

300 cc (18 in.

DH 500 (DH500 is a gland and collar type fitting for ¼ in. (6 mm) coned and

left hand threaded tube. DH500 is equivalent to AE F250C, HIP HF4, etc.)

Any non-corrosive oil, water, water/alcohol. Inquire about other fluids

400 mm W x 136 mm H x 300 mm D (15.8 in. x 5.4 in. x 11.8 in.)

(see Section 1.4 )

10 kg (22 lbs.)

)

3

)

(15 000 psi)

Page 1 © 2004-2008 DH Instruments, a Fluke Company

Page 8

MPG2-H OPERATION AND MAINTENANCE MANUAL

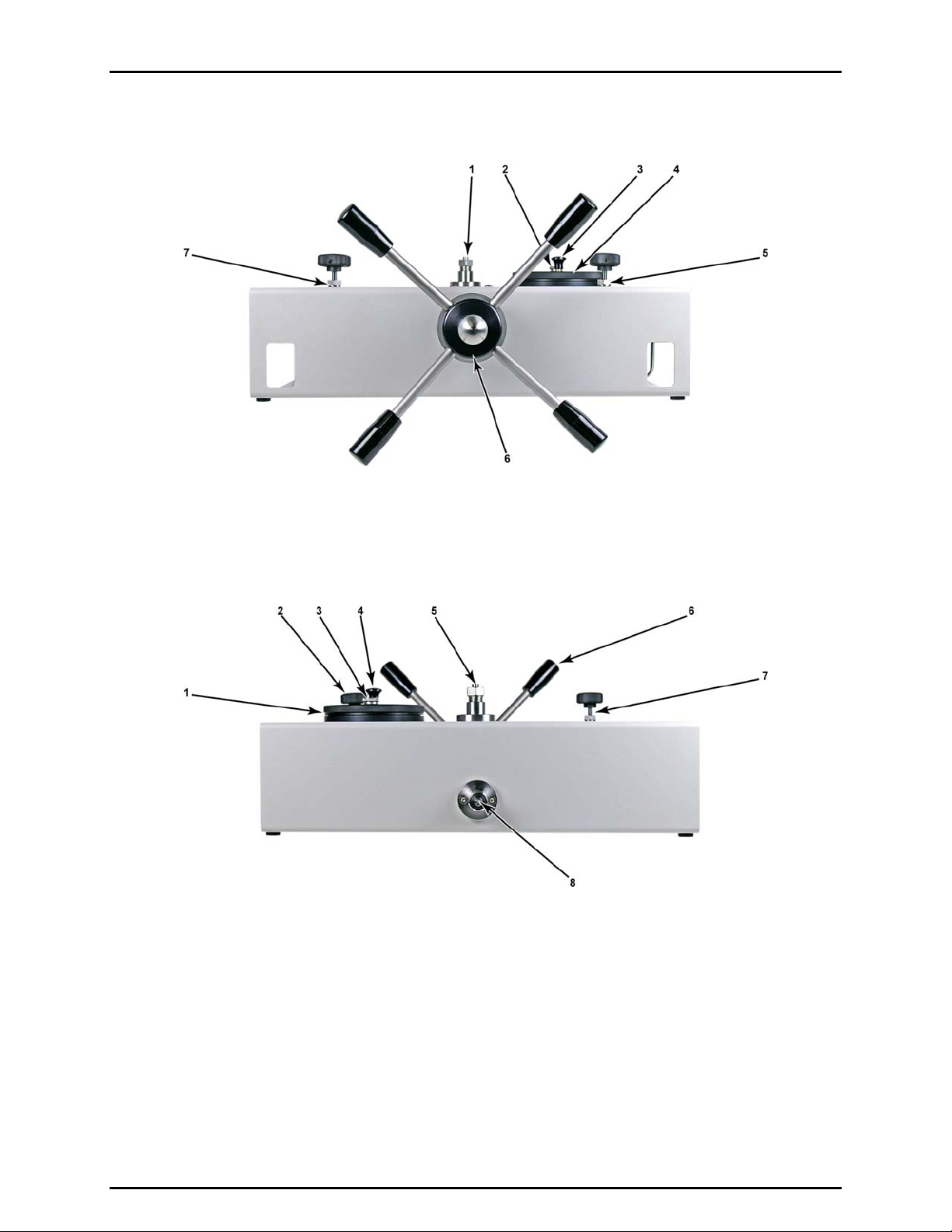

1.3 LOCATION OF THE COMPONENTS

1. TEST1 connection (DH500)

2. Reservoir cover vent valve

3. Priming pump

4. Reservoir cover

5. Reservoir shut off valve

6. Variable volume

7. Test shut off valve and

fine pressure adjustment

Figure 1. Front view

1. Reservoir

2. Test shut off valve

3. Reservoir vent valve

4. Priming pump

5. TEST1 connection

6. Variable volume

7. Reservoir shut off valve and

fine pressure adjustment

Figure 2. Rear view

© 2004-2008 DH Instruments, a Fluke Company Page 2

Page 9

1. INTRODUCTION

1. TEST1 connection

2. TEST2 connection

3. Reservoir cover vent valve

4. Priming pump

5. Reservoir cover

6. Test shut off valve and fine pressure

adjustment

7. Variable volume

8. Variable volume piston position indicator

9. Reservoir shut off valve

Figure 3. Top view

Page 3 © 2004-2008 DH Instruments, a Fluke Company

Page 10

MPG2-H OPERATION AND MAINTENANCE MANUAL

1.4 DIMENSIONAL SCHEMATICS

All dimensions are in millimeter [mm]

Figure 4. Front view dimensions

Figure 5. Bottom and side view dimensions

© 2004-2008 DH Instruments, a Fluke Company Page 4

Page 11

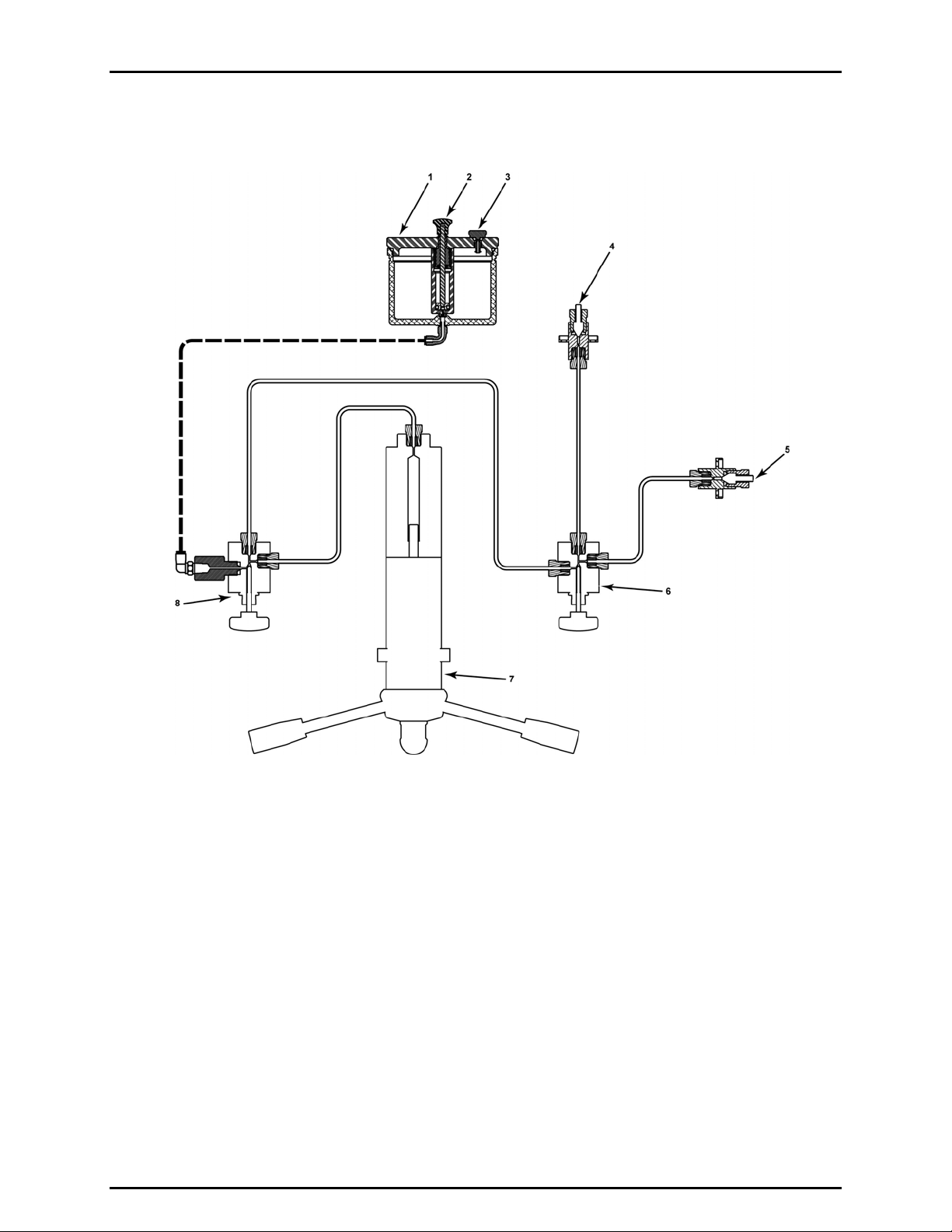

1.5 HYDRAULIC SCHEMATIC

1. INTRODUCTION

1. Reservoir cover

2. Priming pump

3. Reservoir cover vent valve

4. TEST1 connection

5. TEST2 connection

6. Test shut off valve and fine pressure adjustment

7. Variable volume

8. Reservoir shut off valve

Figure 6. System schematic

Page 5 © 2004-2008 DH Instruments, a Fluke Company

Page 12

MPG2-H OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2004-2008 DH Instruments, a Fluke Company Page 6

Page 13

2. INSTALLATION

.

22.

I

NNSSTTAALLLLAATTIIOON

I

N

2.1 UNPACKING AND INSPECTION

MPG2-H is delivered, along with its standard accessories, in a corrugated container held in place by

expandable foam.

The MPG2 is delivered with its valves closed and the variable volume (VV) fully screwed in. The

reservoir and the MPG2 plumbing are free of fluid.

Remove MPG2 and its accessories from the shipping container and remove each item from its protective bag.

Check that all items are present and have no visible signs of damage.

Table 1. MPG2-H and MPG2-H-HV Parts List

DESCRIPTION ITEM NO.

MPG2-H or MPG2-H-HV instrument

Accessories including:

4 ea. Variable volume handle 3329907

1 ea. Plug, DH500 3068470

1 Operation and Maintenance Manual 3340765

3323107 or 3341293

2.2 SITE REQUIREMENTS

• MPG2 should be installed on a stable surface. It may be necessary to anchor MPG2 using the

mounting holes in the bottom of the housing. This is to hold the housing firmly in place when turning

the variable volume, particularly at high pressures and to avoid applying the torque from variable

volume rotation to the tubing and fittings which may be connected to the MPG2. “C” clamps may also

be used, fitting in the openings on the lower front corners of the MPG2 housing.

• As the span of the variable volume handles is wider than the MPG2 housing, the MPG2 needs to be

mounted so that the handles hang over the edge of the mounting surface, for example over the front of a

work bench.

Page 7 © 2004-2008 DH Instruments, a Fluke Company

Page 14

MPG2-H OPERATION AND MAINTENANCE MANUAL

2.3 INITIAL SETUP

High pressure fluids are potentially hazardous. Energy stored in pressurized fluids can be released

unexpectedly and with extreme force. High pressure systems should be assembled and operated only by

personnel who have been instructed in proper safety practices.

To set up the MPG2 for operation, proceed as follows:

Set the MPG2 on a hard, flat surface. If desired, anchor the MPG2 to a stable working surface using

the mounting holes on the bottom of the MPG2 platform or the clamp openings on the front. The

mounting hole diameter is 6.4 mm (0.26 in.) suitable for M6 or 1/4 in. screws. If mounting to a wood

bench top, use of threaded inserts and machine screws is recommended.

Connect the TEST1 and/or TEST2 port to the system into which pressure is to be generated and

controlled. All MPG2 pressure connections are DH500 female (DH500 is a gland and collar type

fitting for 1/4 in. (6 mm) coned and left hand threaded tube. DH500 is equivalent to AE F250C, HIP

HF4, etc.). If a TEST port is not being used, plug it using the DH500 plug supplied in the MPG2

accessories.

ALWAYS use external tubing and fittings rated for pressures equal to or greater than the maximum

pressure which MPG2 will be used to generate.

DH500 F fittings are delivered with disposable, orange, plastic dummy plugs installed. These are NOT

intended to hold high pressure. They should be removed and replaced with appropriate fittings or stainless

steel plugs before high pressure operation. Each dummy plug carries a DH500 collar. Remove and retain the

collar for use in connecting to the mating tube.

Fill the fluid reservoir: Close the reservoir shutoff valve. Remove the reservoir cover by rotating it

CW. Pour the desired fluid into the reservoir. Do not overfill. MPG2 is tested with a low viscosity,

fluorinated liquid and should be free of significant fluid residue as delivered.

Prime and leak check pressurized system (see Section 3.2.1).

© 2004-2008 DH Instruments, a Fluke Company Page 8

Page 15

3. OPERATION

.

33.

O

PPEERRAATTIIOON

O

N

3.1 GENERAL OPERATING PRINCIPLES AND INFORMATION

3.1.1 OVERVIEW

See Section 1.5, Figure 6

MPG2-H is used to manually generate and adjust liquid pressure from atmosphere to

200 MPa (30 000 psi) (limited to 100 MPa (15 000 psi) with MPG2-H-HV) or using a priming

pump, two valves and a variable volume. Fittings for connecting to a device or system under

test are located on the top and middle rear of the instrument housing. A reservoir holds a

supply of fluid.

3.1.2 VALVES

The reservoir shutoff and test shutoff valves are manually operated needle valves.

The reservoir shut valve isolates the reservoir from the pressurized circuit. It is opened use

the priming pump, to fill the variable volume with fluid and to open the pressurized circuit to

atmosphere (vent).

The test shutoff valve isolates the TEST1 and TEST2 ports from the rest of the MPG2 circuit.

It can be used to isolate the variable volume and reservoir from the pressurized test system,

for example, if it becomes necessary to refill the variable volume with fluid when it reaches

end of stroke.

As test shutoff the valve needle displaces fluid when it is operated, it can also be used as a

very fine variable volume for very fine pressure adjustment.

3.1.3 PRIMING PUMP

The priming pump is a syringe style fluid injector, built into the reservoir cover. On its plunger

upstroke, it draws oil from the reservoir into its barrel. On the down stoke, the barrel tip seals

with the connection on the bottom of the reservoir and the plunger pushes oil into the rest of

MPG2 and out the test port.

The priming pump is used to fill the MPG2 and system to which it is connected with hydraulic

fluid and then generate a low, starting pressure.

3.1.4 VARIABLE VOLUME (VV)

The variable volume (VV) is a piston-cylinder type screw press. Rotating the variable volume

handles, moves the piston in or out decreasing or increasing the volume and therefore

increasing or decreasing pressure.

The VV is used to generate and adjust pressure in the system to which MPG2 is connected

when the reservoir shut valve is closed and test shut off valve is open. The torque necessary

to rotate the VV handle is proportional to the pressure in the variable volume.

Generally, the starting position of the VV when beginning to generate pressure from

atmosphere is with the piston fully retracted (handles rotated maximum CCW) so that the full

stroke of the VV is available to fill the test system and generate pressure.

Page 9 © 2004-2008 DH Instruments, a Fluke Company

Page 16

MPG2-H OPERATION AND MAINTENANCE MANUAL

During operation, if the VV runs out of stroke, the test shut off and reservoir shutoff valves

can be used in sequence to allow the variable volume to be refilled without releasing the

pressure on the TEST1 and TEST2 port (see Section 3.2.3).

The maximum operating pressure of the variable volume is 200 MPa (30 000 psi) with

MPG2-H and 100 MPa (15 000 psi) with MPG-H-HV and. Do not generate pressure greater than

the maximum operating pressure.

3.1.5 RESERVOIR

The reservoir is a 300 cc (18 in3) aluminum vessel mounted inside the MPG2 housing. It is

accessed for filling or cleaning by a screw on cover on the top surface of the MPG2 housing. The

reservoir is connected to the RESERVOIR ISOLATION valve by flexible tubing. The reservoir lid

can used to force fluid out of the reservoir into the system connected to the OPG1.

3.2 OPERATION

Operation of the MPG2 can be divided into three common tasks: filling and priming the system under test

(See Section 3.2.1); generating and adjusting pressure (see Section 3.2.2); filling or emptying the variable

volume while maintaining test system pressure (see Section 3.2.3).

3.2.1 FILLING AND PRIMING THE SYSTEM UNDER TEST,

PRIMING PUMP

It is important to remove air from the test system by filling and priming it before using the

variable volume to generate pressure. Failure to fill and prime will result in the need to use

multiple variable volume strokes to generate pressure.

The reservoir pump is designed to push oil through the MPG2 and out the TEST port into the

test system. It can also generate an initial pressure, saving variable volume stroke.

To fill and prime the test system, prior to generating pressure with the variable volume,

proceed as follows:

Leave an open purge point (for example a loose fitting) at the highest point possible in

the system that is connected to the MPG2.

Open the reservoir shut off valve and the test shut off valve to connect the reservoir to

the rest of the system.

Position the reservoir cover correctly by rotating it CW until the reservoir vent valve is at

the CLOSE position. Do not over tighten; do not turn CW beyond CLOSE position.

Be sure that the reservoir cover vent valve is open (loosened CCW).

Pull the reservoir handle pump up slowly to fill it with oil from the reservoir. Then push

the handle down firmly with moderate speed to seal the tip of the pump against the

reservoir seat and inject oil into the MPG2 and out the TEST port.

Repeat while observing the open purge point in the test system. When only oil and no

air comes out of the purge point, close and tighten the purge point.

If desired, repeat to set an initial pressure with the reservoir pump.

Be sure the variable volume is already filled and in the start position (Section 3.2.2,

and the reservoir shut off valve is open.

© 2004-2008 DH Instruments, a Fluke Company Page 10

- ),

Page 17

3. OPERATION

Press down on the pump handle but do not release your downward force when the pump

gets to end of stroke or becomes to difficult to push down. While maintaining the

downward force on the pump handle, close the reservoir shut off valve to capture the

priming pressure.

Do not attempt to generate greater than 700 kPa (100 psi) using the reservoir priming pump.

Once the system is filled and primed, use the variable volume to generate pressure to the

desired pressure set point (see Section 3.2.2).

When the reservoir cover vent valve is closed, the reservoir is not connected to atmosphere

so opening the reservoir shut off valve and the test shut off valve may not fully vent the system

connected to the MPG2. To be sure the system is fully vented to atmosphere, OPEN the reservoir

cover shut off valve and/or disconnect at the TEST port.

3.2.2 GENERATING AND ADJUSTING PRESSURE, VARIABLE

VOLUME AND FINE ADJUST VALVE

The variable volume can generate very high pressure very quickly. When using the variable

volume, use caution not to generate pressure more quickly than desired and not to exceed the

pressure rating of the MPG2 (see Section 1.2) or any component of the system to which it is

connected.

Before attempting to use the MGP2 to generate pressure, the system to which it is connected

should be as free of air as possible. See Section 3.2.1 to fill and prime the test system.

Once the system to which MPG2 is connected, filled and primed, to generate and adjust

pressure proceed as follows:

Open the reservoir shut off valve to connect the reservoir to the variable volume.

Close the TEST shut off valve to avoid ‘pulling’ oil out of the test system in step

.

Rotate the variable volume CCW until the piston position indicator is at the beginning of

its stroke (indicator white).

Close the reservoir shut off valve to shut off the reservoir from the variable volume.

Open the TEST shut off valve to connect the variable volume to the test system.

Rotate the variable volume CW to increase pressure to the desired set point. Using the

variable volume, it should be easy to adjust the set pressure within 700 kPa (100 psi) or

less of the desired pressure.

To adjust pressure more finely than is possible with the variable volume, use the fine

adjust valve (see Section 3.1.2).

If the variable volume runs out of stroke (piston position indicator red and variable volume

will not rotate CW further) before the desired set pressure is reached, the variable

volume can be isolated from the TEST port and refilled to continue generating pressure

(see Section 3.2.3).

To reduce pressure, rotate the variable volume CCW.

To vent the system to atmosphere, once the pressure is low enough to be safely be

dropped very rapidly, open the reservoir shut off valve (with the test shut off valve open).

Page 11 © 2004-2008 DH Instruments, a Fluke Company

Page 18

MPG2-H OPERATION AND MAINTENANCE MANUAL

Opening the reservoir shut off valve while the MPG2 is under pressure will very rapidly drop

the pressure. Generally, it is not recommended to drop the pressure applied to pressure

measuring devices very rapidly. To reduce pressure slowly, use the variable volume and only open

the reservoir shut off valve to open the system to atmosphere.

3.2.3 REFILLING OR EMPTYING THE VARIABLE VOLUME

WITHOUT RELEASING TEST PRESSURE

When working to high pressure with large test volumes or test volumes that are not fully

purged of air, the volume displaced by a single stroke of the variable volume may not be

sufficient to generate the maximum pressure desired. Conversely, when lowering pressure

the variable volume may run out of stroke before it is desirable to use the RESERVOIR

ISOLATION valve to release pressure rapidly. In these cases, the variable volume can be

backed off and refilled without releasing the pressure in the test system.

To refill or empty the variable volume without releasing test pressure, proceed as follows:

Close the test shut off valve. This isolates the system connected to the TEST port(s)

from the variable volume and the reservoir shut off valve. Note that after refilling the

variable volume, the test shut off valve will be opened again. At that time, the pressure

on both sides of the valve will not be perfectly equal so the pressure in the system

connected to the TEST port(s) will change. Consider this possibility before closing the

test shut off valve. For example, if using a piston gauge, put the piston gauge piston at

its bottom stop before closing the test shut off valve.

Open the reservoir shut off valve. This vents the pressure in the variable volume and

connects it to the reservoir.

Back out the variable volume (CCW) to fill it or screw it in (CW) to empty it, as desired.

Close the reservoir shut off valve. DO NOT OPEN THE TEST ISOLATION VALVE YET.

Operate the variable volume as needed to generate a pressure equal to the pressure in

the system connected to the TEST port(s). This is the pressure that was present on the

variable volume before the test shutoff valve was closed in

. The pressure may be

reasonably approximated by the feel (torque) on the variable volume.

Slowly open the TEST ISOLATION valve to equalize the pressure. Proceed to generate

and adjust pressure as desired (see Section 3.2.2).

© 2004-2008 DH Instruments, a Fluke Company Page 12

Page 19

4. MAINTENANCE AND ADJUSTMENTS

.

44.

M

AAIINNTTEENNAANNCCE

M

E

A

NNDD

A

MPG2 was designed for maintenance free operation. The only recommended regular maintenance is to

flush the hydraulic system and replace the operating liquid.

4.1 REPLACING LIQUID AND FLUSHING HYDRAULIC SYSTEM

Regular replacement of MPG2’s operating liquid and flushing of the hydraulic system is recommended.

To empty the reservoir, remove the reservoir cover and siphon the bulk of liquid out of the reservoir.

Remove the balance of liquid from the system by screwing the variable volume all the way in (CW) with

the TEST1 port plugged and the TEST2 port open. Then use the filling and priming procedure described

in Section 3.2.1 to expel the rest of the liquid from MPG2. Collect the used liquid as

TEST2 port.

Refill the reservoir with fresh liquid.

Refill the MPG2 volumes with liquid by plugging the TEST1 port and opening the TEST2 port. Then use

the reservoir pump to inject liquid into MPG2 until only liquid and no air comes out of the TEST 2 port.

Plug the TEST2 port, and with the reservoir shut off valve open, fully unscrew (CCW) the variable

volume.

A

DDJJUUSSTTMMEENNTTS

A

S

it comes out of the

When flushing the MPG2, repeat the procedure above until the liquid coming out of the TEST2 port is clean.

Page 13 © 2004-2008 DH Instruments, a Fluke Company

Page 20

MPG2-H OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2004-2008 DH Instruments, a Fluke Company Page 14

Page 21

5. WARRANTY STATEMENT

.

55.

Except to the extent limited or otherwise provided herein, DH Instruments, a Fluke Company (DHI)

warrants for one year from purchase, each new product sold by it or one of its authorized distributors,

only against defects in workmanship and/or materials under normal service and use. Products which

have been changed or altered in any manner from their original design, or which are improperly or

defectively installed, serviced or used are not covered by this warranty.

DHI and any of its Authorized Service Providers’ obligations with respect to this warranty are limited to

the repair or replacement of defective products after their inspection and verification of such defects. All

products to be considered for repair or replacement are to be returned to DHI, or its Authorized Service

Provider, freight prepaid, after receiving authorization from DHI or its Authorized Service Provider. The

buyer assumes all liability vis-à-vis third parties in respect of its acts or omissions involving use of the

products. In no event shall DHI be liable to purchaser for any unforeseeable or indirect damage, it being

expressly stated that, for the purpose of this warranty, such indirect damage includes, but is not limited to,

loss of production, profits, revenue, or goodwill, even if DHI has been advised of the possibility thereof,

and regardless of whether such products are used individually or as components in other products.

W

AARRRRAANNTTYY

W

S

TTAATTEEMMEENNT

S

T

Items returned to DHI under warranty claim but determined to not have a defect covered under warranty

or to not have a defect at all are subject to an evaluation and shipping charge as well as applicable repair

and/or calibration costs.

The provisions of this warranty and limitation may not be modified in any respect except in writing signed

by a duly authorized officer of DHI.

The above warranty and the obligations and liability of DHI and its authorized service providers exclude

any other warranties or liabilities of any kind.

Page 15 © 2004-2008 DH Instruments, a Fluke Company

Page 22

MPG2-H OPERATION AND MAINTENANCE MANUAL

Table 2. DHI Authorized Service Providers

DH INSTRUMENTS, A FLUKE COMPANY

WWW.DHINSTRUMENTS.COM

AUTHORIZED SERVICE PROVIDERS

COMPANY

DH Instruments, a Fluke

Company

Ohte Giken, Inc.

DHI Products Technical

Service Division

Minerva Meettechniek B.V.

4765 East Beautiful Lane

Phoenix AZ 85044-5318

USA

Technology Center

258-1 Nakadai Nihari-Gun

Ibaraki 300-0133

JAPAN

National Institute of Metrology

Heat Division

Pressure & Vacuum Lab

NO. 18, Bei San Huan Donglu

Beijing 100013

PR China

Chrysantstraat 1

3812 WX Amersfoort

the NETHERLANDS

ADDRESS

TELEPHONE

& FAX

Tel 602.431.9100

Fax 602.431.9559

Tel 0298-55-8778

Fax 0298-55-8700

Tel 010-64291994 ext 5

Tel 010-64218637 ext 5

Fax 010-64218703

Tel (+31) 33.46.22.000

Fax (+31) 33.46.22.218

EMAIL

cal.repair@dhinstruments.com

tohte@ohtegiken.co.jp

cxcen@mx.cei.go.cn

info@minervaipm.com

© 2004-2008 DH Instruments, a Fluke Company Page 16

Loading...

Loading...