Page 1

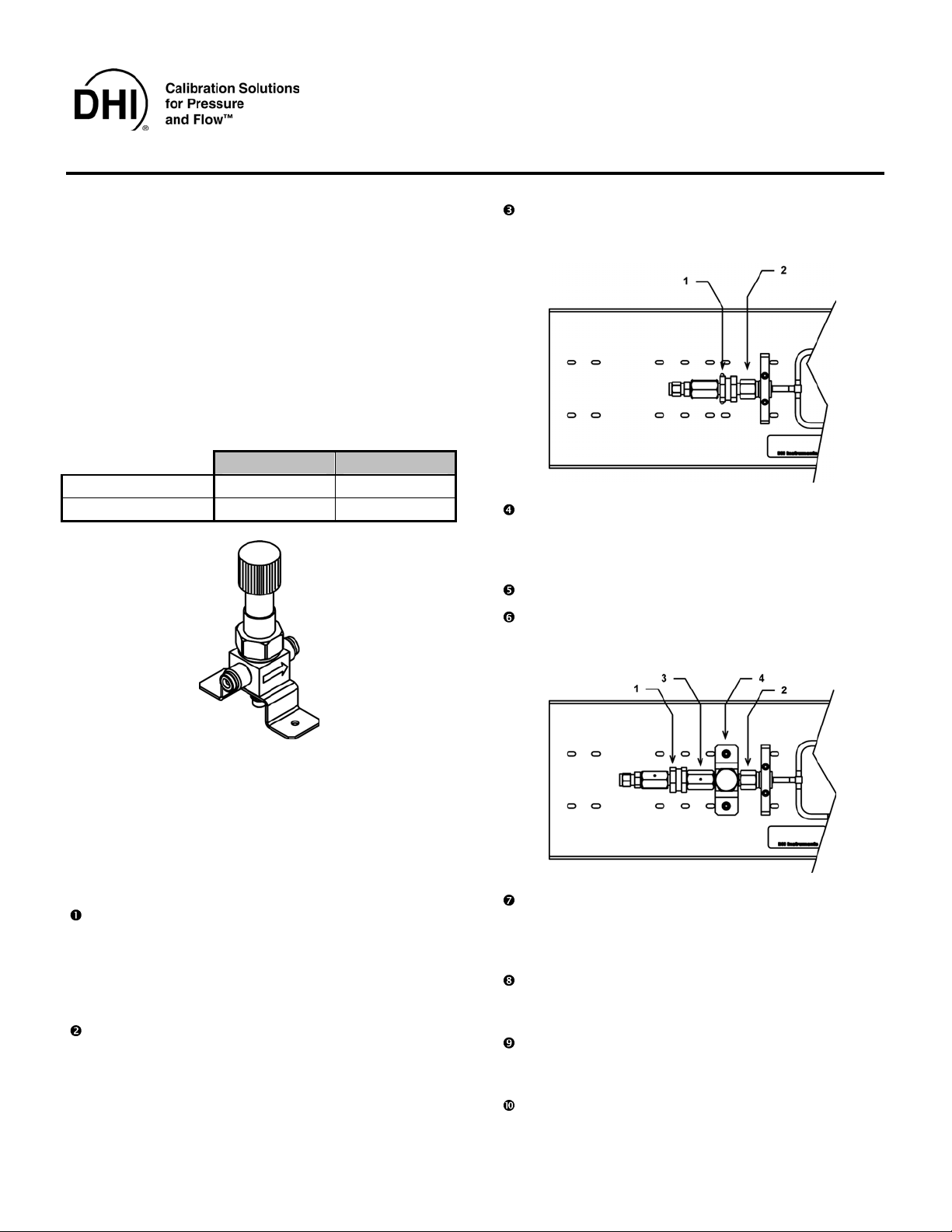

The 1/4 in. molstic-S™ is delivered with integrated

shut-off/metering valves. These valves provide a

measure of flow control for use when calibrating

devices that do not have their own flow control means.

However their primary use on the molstic-S is to

provide a means of positive flow shut-off to allow for

system leak testing. The 1/4 in. low-flow and 1/4 in.

mid-flow metering valve kits provide higher precision

flow control capability.

Recommendations for 1/4 in.

Low- and Mid-Flow Metering

Valve Kits for molstic-S™

P/Ns 401885 and 401666

Instruction Sheet

Place a new 1/4 in. VCR gasket (P/N 102183)

securely against the sealing surface inside the female

VCR swivel nut (2) of the molstic-S inlet.

Use the 1/4 in. metering valve kits with the following

molbloc-S

Low-Flow, P/N 401885

Mid-Flow, P/N 401666

®

ranges and molboxes™:

Table 1 Metering Valve Use with molbloc-S

MOLBOX1-A700K MOLBOX1-A350K

5E1-S 5E1-S

1E2-S, 2E2-S 1E2-S, 2E2-S

INSTALLATION OF 1/4 IN. METERING

VALVE ONTO MOLSTIC-S PLATFORMS

WITHOUT REGULATORS

Place the metering valve and bracket assembly (4)

onto the molstic-S platform and align the VCR

connection. Assure that the flow direction of the

valve matches the direction of flow of the molstic-S.

Tighten the female nut (2) finger-tight.

Hold male body stationary with a backup wrench.

Tighten the female nut (2) 1/8 turn past finger-tight.

Use the following procedure to install the metering

valve kit onto the molstic-S platform that does not have

the integrated regulator:

Attach the valve bracket to the base of the valve

using the two included #10-32 socket head cap

screws, the two #10 flat washers and the two #10

lock washers. The long side of the bracket should

be perpendicular to the direction of flow through

the valve.

Using a pair of properly sized wrenches, break the

connection between the downstream end of the

filter element (1) and the female VCR

®

swivel nut (2)

on the inlet of the molstic-S. Do not disassemble

the parts on the inlet side of the filter element (1).

Discard the VCR gasket, which is for one-time use.

Thread the included double female VCR union

(non-swivel type), (3), onto the inlet fitting of the

metering valve. Leave it approximately one full

revolution from the fully stopped position.

Place a new 1/4 in. VCR gasket (P/N 102183)

securely against the sealing surface inside the

double female VCR union (non-swivel type) (3).

Install the filter (1) and upstream plumbing into the

female VCR union (3). Tighten the female nut

finger-tight.

Hold male body stationary with a backup wrench.

Tighten the female nut 1/8 turn past finger-tight.

Page 2

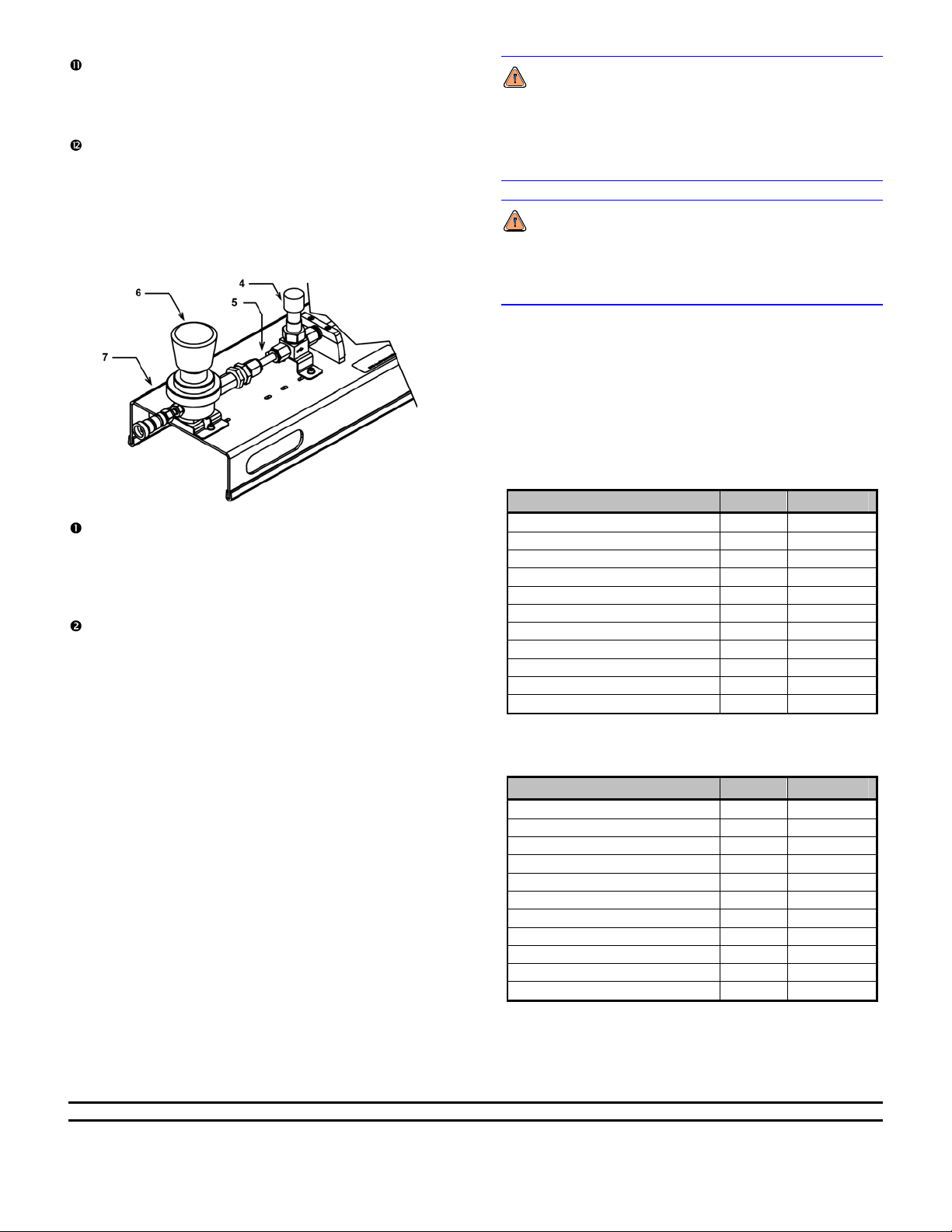

Place the flat side of the 60 mm nut plate under

the molstic-S platform (see figure below). Align it

with the holes in the platform and the valve bracket.

Hold it in place.

Thread the socket head cap screws through the

valve bracket and tighten securely into the nut plate.

Do not adjust the supply pressure to the 1/4 in.

metering valve in excess of the maximum operating

pressure of the molbox: 600 kPaa (87 psia) for

molbox1-A700K; 250 kPaa (36 psia) for molbox1A350K.

INSTALLATION OF 1/4 IN. METERING

VALVE ONTO MOLSTIC-S PLATFORMS

WITH REGULATORS

Use double female swivel union (5) in place of the

non-swivel union (3) when installing the metering

valve kit (4) onto a molstic-S that has the

integrated regulator. Use a new 1/4 in. VCR

gasket (P/N 102183) on each end of the union.

Re-secure the regulator (6) to the molstic-S

platform (7) with the socket head cap screws and

nut plate.

MOLSTIC-S OPERATION WITH 1/4 IN.

LOW-FLOW AND MID-FLOW METERING

VALVE

The flow shut-off/metering valve that is integral to the

molstic-S should be opened fully when using the 1/4 in.

low-flow and 1/4 in. mid-flow metering valves to adjust

flow to the molbloc-S. The metering valves supplied

with this kit may limit the maximum obtainable flow rate

of some of the molbloc-S elements that can be mounted

on the 1/4 in. molstic-S (see Table 1). In these cases the

shut-off/metering valve that is integral to the molstic-S

should be used, (and the metering valve removed).

In order to make extremely fine flow rate adjustments

the metering valve can be used in combination with

small adjustments in the supply pressure.

Do not attempt to completely close off flow

using the 1/4 in. low-flow or mid-flow metering

valve. They are not designed to be used as shut

off valves. Damage to the valve seat can occur.

PARTS INCLUDED WITH 1/4 IN.

LOW-FLOW AND MID-FLOW METERING

VALVE KITS

The following parts are included in the shipment:

P/N 401885

Low-Flow Metering Valve Kit

DESCRIPTION QTY PART NO.

Metering valve, low flow 1 102570

Bracket, valve 1 123612

Union, 4VCR F x 4VCR F 1 102181

Gasket, 4VCR 2 102183

Nut plate, 60 mm 1 123621

Washer, flat, M4 2 100918-Z

Screw, SHC, M4 X 12 2 101016-Z

Washer, split lock, #10 2 103021-Z

Screw, SHC, 10-32 X 3/8 2 103277-Z

Washer, flat, #10 2 103278-Z

Union, swivel, 4VCR F x 4VCR F 1 102144

P/N 401666

Mid-Flow Metering Valve Kit

DESCRIPTION QTY PART NO.

Metering valve, mid flow 1 102571

Bracket, valve 1 123612

Union, 4VCR F x 4VCR F 1 102181

Gasket, 4VCR 2 102183

Nut plate, 60 mm 1 123621

Washer, flat, M4 2 100918-Z

Screw, SHC, M4 X 12 2 101016-Z

Washer, split lock, #10 2 103021-Z

Screw, SHC, 10-32 X 3/8 2 103277-Z

Washer, flat, #10 2 103278-Z

Union, swivel, 4VCR F x 4VCR F 1 102144

molbloc, molbloc-S, molbox, molstic and molstic-s are trademarks, registered and otherwise, of DH Instruments, Inc.

Document 560055a 030108

DH Instruments, Inc.

4765 East Beautiful Lane

Phoenix AZ 85044-5318

USA

VCR is a registered trademark of the Swagelok Company.

Viton is a registered trademarks of DuPont deNemours Company.

Tel 602.431.9100

Fax 602.431.9559

dhi@dhinstruments.com

www.dhinstruments.com

Loading...

Loading...