Page 1

LinkIQ™

Cable+Network Tester

Users Manual

February 2021 (English)

© 2021 Fluke Corporation. All rights reserved.

Specifications are subject to change without notice.

Find Quality Products Online at: sales@GlobalTestSupply.com

All product names are trademarks of their respective companies.

www.GlobalTestSupply.com

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of repair/

replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any

other provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/9 9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Table of Contents

Title Page

Introduction ............................................................................................... 1

Automatic Test Discovery ......................................................................... 1

Contact Fluke ............................................................................................ 2

Safety Information ..................................................................................... 2

Product Familiarization.............................................................................. 2

Parts ................................................................................................... 3

Controls and Connections .................................................................. 4

Hang Strap ......................................................................................... 5

Display................................................................................................ 6

Main Menu ................................................................................................ 7

Menu Controls .................................................................................... 7

Settings Menu..................................................................................... 8

Tools Menu......................................................................................... 11

Tests ......................................................................................................... 12

Cable Test .......................................................................................... 12

Do a Cable Test ........................................................................... 13

Wire Map Screens........................................................................ 17

Test Limit Failure.......................................................................... 20

Switch Test ......................................................................................... 21

Do a Switch Test .......................................................................... 21

Network Test Results ................................................................... 23

PoE Test Results ......................................................................... 25

Save a Test Result.................................................................................... 28

Results Menu ............................................................................................ 28

Delete Test Results................................................................................... 29

Upload Results to LinkWare PC................................................................ 30

Tests with MS-IE-Adapter Set................................................................... 30

Maintenance.............................................................................................. 31

Clean the Product............................................................................... 31

Battery ................................................................................................ 31

Product Specifications............................................................................... 32

i

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

LinkIQ

Users Manual

ii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

Introduction

The Fluke Networks LinkIQ Cable+Network Tester (the Product or Tester) is a unique handheld

test instrument for use in many applications to test twisted pair cables, network connectivity, and

Power over Ethernet (PoE). These applications include system integration, cable installation, and

network and security system maintenance. The Product provides an automatic test discovery

suite that recognizes a connected device and automatically selects the appropriate type of test

for the device. See Automatic Test Discovery. The Product can be set manually to do a cable or

switch test.

The Product shows images on a high-visibility, industrial-quality LCD touch screen. The Product

saves data to internal memory which can be transferred to a PC through a direct USB connection

to the PC.

The Product includes LinkWare PC desktop software. LinkWare PC software is a highperformance, professional software suite for quality analysis and reporting.

The Product is compatible with the MicroScanner PoE Remote Identifer and the

IntelliTone Pro Toner, Tracer, and Probe.

Automatic Test Discovery

The Product is set up in Auto Test mode by default. The automatic test discovery feature

recognizes a connected device and automatically selects the appropriate type of test compatible

with the device.

Automatic test discovery selects a:

• Cable test if the Product detects a Remote ID. See Cable Test.

• Switch test if the Product detects a network device. See Switch Test.

• Switch test with Power over Ethernet (PoE) if the Product detects a Power Sourcing

Equipment (PSE) device. See Switch Test.

1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

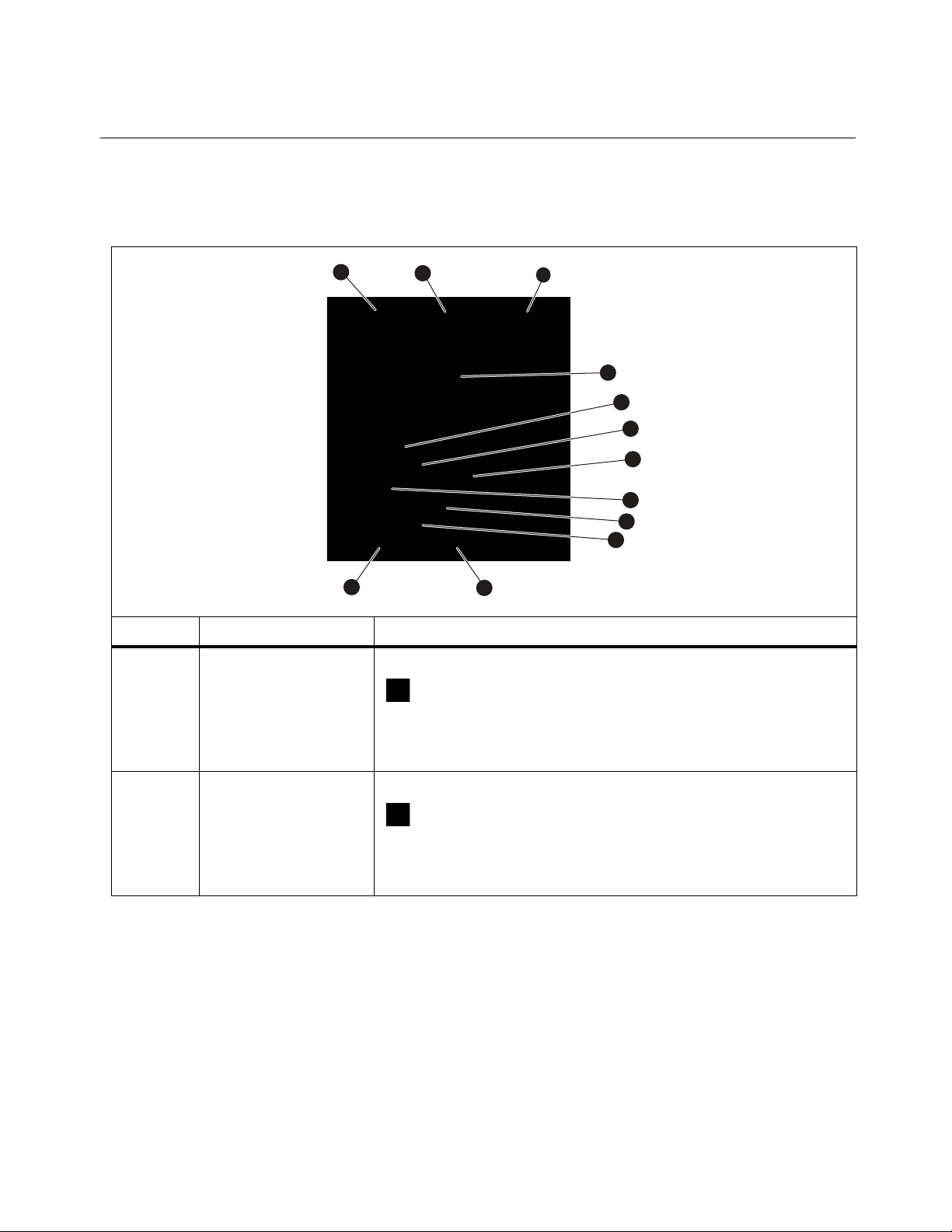

Parts

8

7

6

5

4

3

2

1

Ta bl e 1 shows the parts of the Product.

Cable+Network Tester

Product Familiarization

Table 1. Part s

Item Description Item Description

D

[1] Not available in all kits.

[2] The Product can work with Remote ID 2 to Remote ID 7 (available separately as REMOTE-ID KIT or included

with LIQ-KIT)

Product

Battery charger

Universal power adapter kit

Hang strap

E

F

[1]

G

H

#1 Office locator (Remote ID 1)

Office locator holder

USB C to USB A cable

CAT6A Copper patch cable

[2]

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

LinkIQ

Users Manual

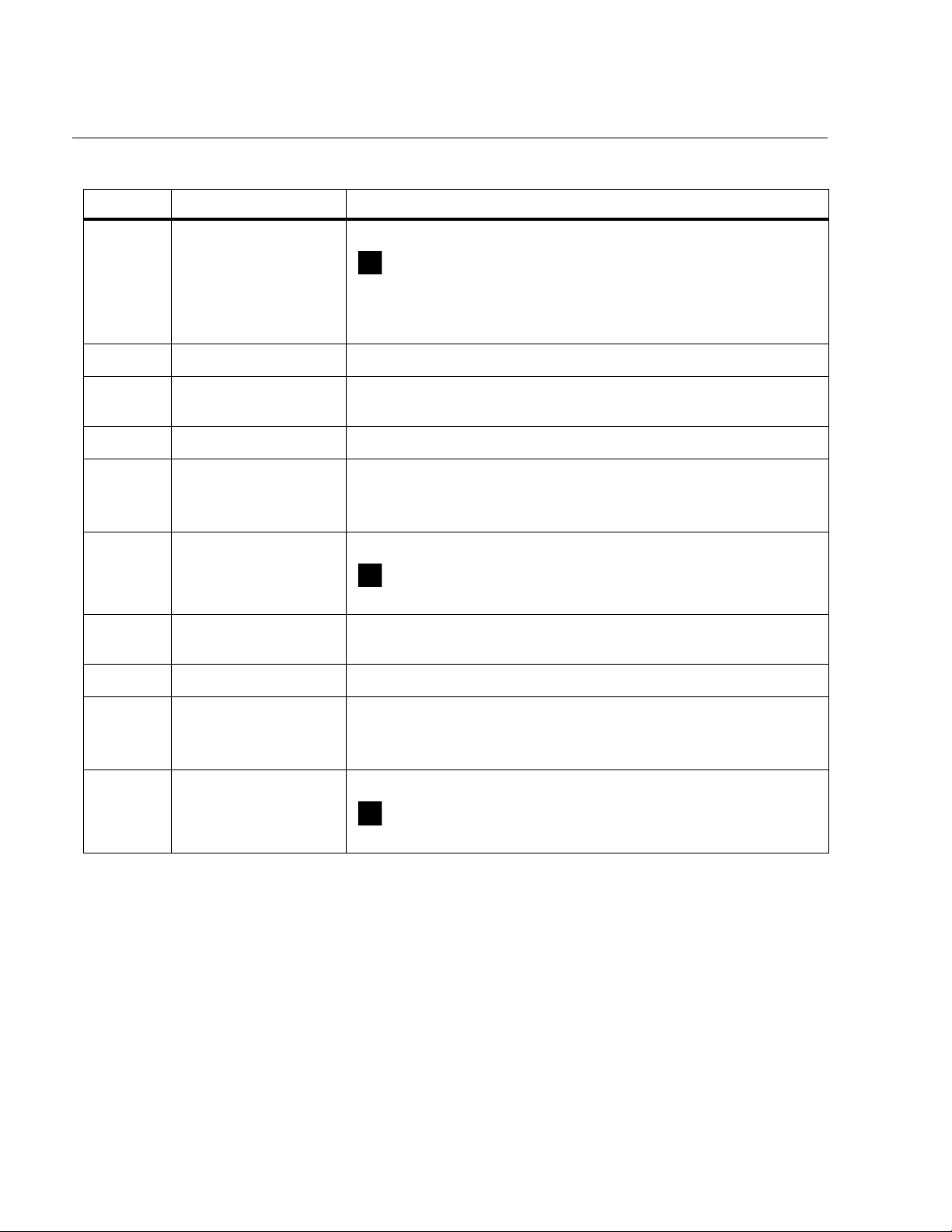

Controls and Connections

Ta bl e 2 shows the controls and connections of the Product.

Table 2. Controls and Connections

2

1

2

3

4

5

Item Description Item Description

RJ45 jack

Hang strap attachment slots

USB C input terminal used to charge the battery or upload results to LinkWare PC.

The Product cannot do a test while the battery charges or while results upload to

LinkWare PC.

D

E

LCD touch screen (display)

Power button.

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

Hang Strap

1 2 3

Figure 1 shows how to attach the hang strap.

Figure 1. Hang Strap Attachment

Cable+Network Tester

Product Familiarization

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

LinkIQ

3

4

5

6

02/15/2021 09:24 AM

1

2

7

Users Manual

Display

Ta bl e 3 shows the items on the display.

Table 3. Display

Item Description Item Description

D

Time

Date

Battery status

Main menu toolbar See Main Menu.

E

F

G

Results and information screen

Information/Command button. The function changes

based on the screen. Tap AUTO TEST to do a test

and automatically select the appropriate type of test

for the device. See Automatic Test Discovery.

Manual test selection button. Tap to select to do a

cable or switch test.

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Main Menu

Ta bl e 4 lists the submenus available in the Main Menu.

Table 4. Main Menu

Submenu Function

Cable+Network Tester

Main Menu

Home

Results Tap to view or manage results. See Results Menu.

Tools

Settings

If necessary, tap to return to the Home screen. Use the Home

screen to start a test or upload results to LinkWare PC.

Tap to access additional tools. The tools cannot be used while in

a test. See Tools M e nu.

Tap to set user preferences and view information about the

Product. See Settings Menu.

Menu Controls

To use the menus to change and view settings:

1. Tap an icon on the main menu to open a submenu. See Ta bl e 4 .

The foreground of the selected icon changes to white.

2. Tap a menu control to set and change options. See Table 5.

Some menus contain a scroll bar on the right side to indicate there are additional options. The

scroll bar is not a control. To view additional options, touch the display and slide the screen

up or down. The scroll bar indicates the location in the menu.

3. To close a submenu and return to the Home screen, tap .

Ta bl e 5 is a list of the menu controls.

Table 5. Menu Controls

Item Control Function

Slider bar

Selection indicator

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Adjusts a value. Touch and slide the bar to the left to

decrease the value or to the right to increase the value.

Indicates which of two options is selected.

Option selected.

7

Page 11

LinkIQ

Users Manual

Item Control Function

Selection indicator

Table 5. Menu Controls (cont.)

To select an item from a list, tap an option. The indicator

Y/+

shows the selected option. In the Results menu more

than one item may be selected at a time. See Results

Menu.

Option menu button

Numerical value

adjuster buttons

Back arrow

Exit button

OK button OK

Cancel button CANCEL Do not do an action and return to the previous screen.

U

I/L

J/K

G

n

Tap to open an option menu to adjust a setting.

Decreases a numerical value.

Increases a numerical value.

Return to the previous screen and, if necessary, save

changes.

Return to the previous screen without saving changes.

Save changes or do an action. Then, return to the

previous screen.

Settings Menu

Ta bl e 6 is a list of the options available in the Settings menu. The Product uses the last saved

settings when the Product is turned off and back on.

Table 6. Settings Menu

Option Menu Option Description

Wire map Settings

On

Shield Test

Off

Uses the continuity of the shield on the cable to

determine if a test passes. Default setting.

Even if a shield is connected to a cable, the continuity of

the shield is not used to determine if a test passes.

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

Table 6. Settings Menu (cont.)

Option Menu Option Description

Cable+Network Tester

Main Menu

On

Allow

Crossover

Pinout <options>

Cable Settings

Test L i mit

Off

10BASE-T

100BASE-TX

1000BASE-T

2.5GBASE-T

5GBASE-T

The wire map of either a straight through cable or a

crossover cable is used to determine if a test passes.

The wire map of a straight through cable is used to

determine if a test passes. A wire map of a crossover

cable fails. Default setting.

Select to set the pinout configuration to use to do a test.

T568A is the default setting.

Verify if a cable with continuity on at least the 1,2 and 3,6

pairs can support 10BASE-T (10) data rate throughput.

Default setting.

Verify if a cable with continuity on at least the 1,2 and 3,6

pairs can support 100BASE-TX (100) data rate

throughput.

Verify if a 4-pair cable with continuity on all 4 pairs can

support 1000BASE-T (1G) data rate throughput.

Verify if a 4-pair cable with continuity on all 4 pairs can

support 2.5GBASE-T (2.5G) data rate throughput.

Verify if a 4-pair cable with continuity on all 4 pairs can

support 5GBASE-T (5G) data rate throughput.

10GBASE-T

NVP 50-99

Verify if a 4-pair cable with continuity on all 4 pairs can

support 10GBASE-T (10G) data rate throughput.

Set the Nominal Velocity of Propagation (NVP) value

based on the cable. The default NVP value is 68.

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

LinkIQ

Users Manual

Table 6. Settings Menu (cont.)

Option Menu Option Description

General Settings

Auto Increment

PoE Test

CDP/LLDP

Timeout

Auto Shutoff

Sound

On

Off Use to manually increment the Test ID.

On

Off

<options>

--

On

Off

On

Off

Automatically increments the Test ID by one number or

letter for the next test.

Enable PoE detection. Use to do a PoE test after you do

a network switch test.

Disable PoE detection. Use to decrease the time to do a

switch test.

Tap to select the time in seconds to wait for a CDP/LLDP

response before the Product retries network discovery.

The default is 30 sec.

Use the slider bar at the right of the image to adjust the

brightness of the image.

The Product turns off after 15 minutes of no use. While

the Product charges, Auto Shutoff is disabled.

The Product remains on until the battery needs to be

charged again.

The Product emits an audible sound at the completion of

a test.

The Product does not emit an audible sound at the

completion of a test.

Numbers -- Set or view the decimal point indicator.

Units -- Set or view the units to use in measurements.

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

Table 6. Settings Menu (cont.)

Option Menu Option Description

Cable+Network Tester

Main Menu

Date/Time <options>

About --

Factory Reset --

Tap to select options to set the date, time, date format,

and time format.

Tap to view the serial number, MAC address, and

version information of the Product.

Tap to delete all test results and reset the Product to the

factory default settings.

Tools Menu

Ta bl e 7 is a list of the options available in the Tools Menu.

Table 7. Tools Menu

Options Menu Option Description

The Product emits a digital tone that an

Tone Generator

Blink Port Light --

IntelliTone

Analog Tone 1

Analog Tone 2

Analog Tone 3

IntelliTone probe can use to locate and isolate

cables behind walls, at patch panels, or in bundles.

The Product emits an analog signal that a standard

analog probe can use to identify cables in bundles.

Tap to blink a port light on a hub or switch to verify

connectivity and cable routes.

11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

LinkIQ

Users Manual

Tests

Read the warnings below before you do a test.

XW Warning

To prevent possible electrical shock, fire, personal injury, or damage to the

Product:

• To activate the input protection circuitry of the Product, turn on the Product before

you connect a cable to the Product.

• During a test, do not connect a cable to the Product.

• During a test, do not disconnect a cable from the Product.

• The tester is not intended to be connected to active telephone inputs, systems, or

equipment, including ISDN devices. Exposure to the voltages applied by these

interfaces may damage the tester and create a potential shock hazard.

• Use caution when working in potentially hazardous locations such as an elevated

location on a ladder or roof top, especially if work is occurring in proximity to a

lightning storm. Also use caution if external communication cables are run at

length in parallel to electrical power installation cables. These types of

installations can expose communication cables to coupled electrical transients

that could be accessible on exposed conductive parts of the equipment during

operation. While in general these transients are not expected to be an electric

shock hazard, startle reaction from these transients could lead to a secondary

hazard such as loss of balance and lead to a fall or other injury. To reduce risk of

exposure, limit contact to accessible conductive parts of I/O terminals during

operation.

Cable Test

In a twisted pair cable test, the Product performs a series of radio frequency (RF) tests to

determine the transmission parameters of the cable. The parameters are compared to the test

limits specified by IEEE 802.3 for Ethernet. Unlike transmission testers that pass bits across the

cable, the Product evaluates the physical qualities of the cable.

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

• Transmission parameters used to qualify the cable:

◦ Insertion loss

◦ Return loss

◦ NEXT loss

◦ Delay skew

◦ Length

◦ Wire map

• Cable qualification to IEEE 802.3 standards:

◦ 10BASE-T

◦ 100BASE-TX

◦ 1000BASE-T

◦ 2.5GBASE-T

◦ 5GBASE-T

◦ 10GBASE-T

Cable+Network Tester

Te st s

• Measures length up to 304.8 m (1000 feet)

• Uses wire maps to show:

◦ Opens

◦ Shorts

◦ Split pairs

◦ Miswires

• Delay skew between pairs

Do a Cable Test

Cable tests pass or fail based on the settings selected for the test. To pass a test:

• The Product must detect a Remote ID.

• The wire map must match the selected wire map settings.

• The cable under test must meet or exceed the selected test limit.

To do a cable test:

1. Turn on the Product.

2. If necessary, adjust the settings. See Settings Menu.

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

LinkIQ

02/15/2021 09:56 AM

02/15/2021 09:56 AM

Users Manual

3. Connect one end of the CAT6A copper patch cable or other approved cable into the RJ45

jack on the Product. See Figure 2.

Figure 2. Cable Test Set Up

4. Connect the other end of the patch cable into an RJ45 jack or into an adapter that is

connected to the near end of the cable under test. Then, connect the Remote ID into an RJ45

jack or adapter that is connected to the far end of the cable under test.

Or,

Connect the Remote ID into an RJ45 jack or into an adapter that is connected to the near end

of the cable under test. Then, connect the other end of the patch cable into an RJ45 jack or

into an adapter that is connected to the far end of the cable under test.

5. Tap AUTO TEST to do a test.

The results show on the display. See Tabl e 8 .

6. To save the results. See Save a Test Result.

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

Ta bl e 8 shows the results of a cable test.

2/15/2021 2:20 PM2/15/2021 2:20 PM

1

Wire Map

1

1

2

3

4

5

6

8

10

9

7

Table 8. Cable Test Results Screen

Cable+Network Tester

Te st s

Item Description Function

The background is green if the test passed.

Result label

The background is red if the test failed.

The background is blue if the screen is for information only.

Cable length Shows the length of the shortest pair in the cable.

Pairs button

Tap to open the PAIRS screen. If a cable end length is found,

the lengths of the cable pairs show.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

15

Page 19

LinkIQ

Users Manual

Table 8. Cable Test Results Screen (cont.)

Item Description Function

Shows the Remote ID number used in the test and information

about the test.

Remote ID The Product detects the Remote ID and the

wire map test passes.

Remote ID The Product detects the Remote ID, but the

D

E

F

G

H

Remote ID label

Wire and shield

identifiers (far end)

Wire map results Shows the results of the wire map. See Wire Map Screens.

Wire and shield

identifiers (near

end)

Cable performance

results

wire map test fails.

No Remote ID There is a short on the cable under test,

so the Product cannot detect the Remote ID. The wire map

test fails.

No Remote ID The test did not detect the Remote ID

because a Remote ID is not connected.

See Wire Map Screens.

Numbers: Indicates which wire from the near end maps to

which wire on the far end.

SH: Indicates the shield on the far end of a cable.

A red box around a wire number indicates that the wire did not

pass based on the settings selected for the test.

A red box around SH indicates that the continuity of the shield

test did not pass.

When a wire map passes, the results show:

• The cable performance capability.

• Whether the cable performance test passes (green) or

fails (red) based on the test limit selected for the test. If a

wire map fails, the segments show gray because the

Product cannot determine the cable performance

capability.

16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

Table 8. Cable Test Results Screen (cont.)

Item Description Function

Cable+Network Tester

Te st s

I

J

Fail explanation

label

SAVE AS...

When a test fails, the label shows the reason why the test

fails.

When there is memory available to save the result, tap SAVE

AS... to save the result. See Save a Test Result.

Wire Map Screens

Ta bl e 9 shows a wire map of a cable test that failed for multiple reasons.

Table 9. Multiple Failures

1

2

3

4

5

1

6

7

Item Description

Pairs 1,2 are the shortest pair of the cable and open at 43.1 m.

The Product detected the Remote ID, and the wire map failed. The wires are not

wired correctly based on the settings selected for the test.

Wire Map

17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

LinkIQ

Users Manual

Table 9. Multiple Failures (cont.)

Item Description

The wire map shows how the cable is wired. The wire map passes or fails based

on the settings selected for the test. For this test, the settings are set to test:

D

E

F

G

Figure 3 shows a wire map of a cable test that fails because wires 4, 5, 7, and 8 are open. The

wires are not connected on the far end and the test limit is set to ≥1000BASE-T (1G) to verify a

4-pair cable. With a test limit set to 10BASE-T or 100BASE-TX, the wire map of the cable test

passes. The length of the wires on the wire map indicates the distance to the open.

• A straight through cable (Allow Crossover can be On or Off to test a straight

through cable.)

• The continuity of the shield on the cable (Shield > On)

• The test limit is set to ≥1000BASE-T (1G) to verify a 4-pair cable.

Pairs 1,2 fail because they are open.

Pairs 7,8 fail because they are a reverse pair.

The continuity of the shield fails because the continuity of the shield cannot be

verified.

Because the wire map failed, the Product cannot test the performance capability

of the cable.

Figure 3. Open Pairs

1

Wire Map

18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

Cable+Network Tester

Te st s

Figure 4 shows a wire map that fails because wires 1 and 2 are shorted together. The length of

the wire on the wire map indicates the distance to the short. With wires shorted together, the

Product cannot detect the Remote ID. Repair the short and do the test again to verify the wire

map of the other pairs.

Figure 4. Wires Shorted Together

Wire Map

Figure 5 shows a wire map of a cable test that fails because pairs 3,6 and 7,8 are split pairs.

Figure 5. Split Pairs

1

Split pair

19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

LinkIQ

1

NEXT

1

3

2

Users Manual

Test Limit Failure

Ta bl e 1 0 shows a cable test that fails because of near end cross talk (NEXT).

Table 10. NEXT Failure

Item Description

The Product detected the Remote ID, and the wire map passed.

The wire map passes because:

• The wires are all connected correctly on both the near and far ends for a

straight through cable. Allow Crossover can be On or Off to test a straight

through cable.

• The continuity of the shield is not included as part of the test (Shield > Off).

The cable can support 10BASE-T (10), 100BASE-TX (100), and 1000BASE-T (1G)

data rate throughputs. The cable cannot support 2.5BASE-T (2.5G) data rate

throughput. The test fails because the test limit is set to verify the cable can

support a 2.5BASE-T (2.5G) data rate throughput.

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

Cable+Network Tester

Te st s

Switch Test

In a network connectivity test, the Product performs a series of queries to determine and report

information about a switch or device. The Product determines information about the device and

reports advertised data rates with full-duplex or half-duplex. See Switch Test.

In a Power over Ethernet (PoE) test, the Product reports the power class that the device can

negotiate if the device is Power Sourcing Equipment (PSE) compliant with the IEEE 802.3

standard. Additionally, the Product places a load on the PSE to determine if the PSE can support

the load of the negotiated power level at the Powered Device (PD).

The PSE is a device, such as a switch, that can provide PoE. The PD is a device that can receive

PoE from a PSE.

With PoE Test enabled, the Product automatically does a PoE test after the completion of a

network switch test

Do a Switch Test

To do a switch test:

1. Turn on the Product.

2. If necessary, adjust the settings. See Settings Menu.

3. Connect one end of the CAT6A copper patch cable or other approved cable into the RJ45

jack on the Product. See Figure 6.

21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

LinkIQ

1234 5 6

1234 5 6

02/15/2021 09:56 AM 02/15/2021 09:56 AM

Users Manual

Figure 6. Switch Test Set Up

4. Connect the other end of the patch cable into an RJ45 jack in an outlet connected to a switch.

5. Tap AUTO TEST to do a test.

The results show on the display. See Network Test Results and PoE Test Results.

6. To save the results. See Save a Test Result.

22

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

Network Test Results

3

6

4

1

2

5

Ta bl e 11 is a list of the results of a network switch test.

Table 11. Network Test Results

Cable+Network Tester

Te st s

Item Description Function

Port

NAME

VLAN

When the Product receives an LLDP or CDP packet from a

device, the port number of the switch on the device shows.

When the Product receives an LLDP or CDP packet from a

device, the name of the device shows.

When the Product receives an LLDP or CDP packet from a

device, the VLAN the device is assigned to shows.

Shows the advertised speeds of the device. Speeds in black

D

Advertised

Speeds

indicate the switch advertises that speed.

Speeds in gray indicate the switch does not advertise that

speed.

23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

LinkIQ

Users Manual

Table 11. Network Test Results (cont.)

Item Description Function

E

F

Full Duplex

Half Duplex

A check mark (

communication simultaneously at the advertised speed.

A dash (—) indicates the device does not have full-duplex

capability at the advertised speed.

A check mark (

communication but not simultaneously at the advertised

speed.

A dash (—) indicates the device does not have half-duplex

capability at the advertised speed.

A blank space indicates that half-duplex capability is not

available at the advertised speed.

Y) indicates the device can send and receive

Y) indicates the device can send and receive

24

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

PoE Test Results

Ta bl e 1 2 shows the results of a PoE test.

Table 12. PoE Test Results

Cable+Network Tester

Te st s

1

12

2

11

3

4

5

6

7

8

9

10

Item Description Function

Tap to view single signature power results.

: Indicates the switch can negotiate single signature

Single

power.

The tab is gray if the switch cannot negotiate single signature

power.

Tap to view Dual A signature power results.

: Indicates the switch can negotiate dual signature power

Dual A

on pairs 1,2 and 3,6.

The tab is gray if the switch cannot negotiate dual signature

power.

25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

LinkIQ

Users Manual

Table 12. PoE Test Results (cont.)

Item Description Function

Tap to view Dual B signature power results.

: Indicates the switch can negotiate dual signature power

Dual B

on pairs 4,5 and 7,8.

The tab is gray if the switch cannot negotiate dual signature

power.

D

E

F

G

H

I

J

K

Powered pairs Shows which pairs have power.

HW: Class

Watts at PD The loaded power in watts provided by the PSE at the PD.

Volt minimum

Volts under load

SW Negotiated

Class:

Watts at PD The loaded power in watts provided by the PSE at the PD.

Volt minimum

The hardware negotiated power class (Class 0 to Class 8) of

the PSE device.

The minimum required volts the device needs to meet under

load per the IEEE 802.3 standard based on the HW

negotiated power class (

Measured voltage under load at reported power draw.

: Indicates the voltage meets the requirements for the

HW negotiated power class (

The software negotiated power class (Class 1 to Class 8) of

the device.

The minimum required volts the device needs to meet under

load per the IEEE 802.3 standard based on the SW

negotiated power class (

Measured voltage under load at reported power draw.

E).

E).

I).

L

26

Find Quality Products Online at: sales@GlobalTestSupply.com

Volts under load

: Indicates the voltage meets the requirements for the

SW negotiated power class (

I).

www.GlobalTestSupply.com

Page 30

Cable+Network Tester

Te st s

Figure 7 shows an example of test results of a single signature PoE device that passes.

Figure 7. PoE Test Pass Example

HW Class: 6

51.0 W at PD

55.0 V Under Load, 42.5 V Minimum

SW Negotiated Class: 8

71.3 W at PD

54.2 V Under Load, 41.1 V Minimum

The hardware class section passes because:

• The device identifies as a HW Class 6 capable of 51.0 W at PD.

• The Product applies a load to the device to validate if the available power from the PSE at the

PD meets the standard of the negotiated class (in this example, a Class 6 device).

• The device delivers 55.0 V under the load which is ≥42.5 V, the minimum amount required for

a device to meet the Class 6 standard.

The software class section passes because:

• The device identifies as a SW Negotiated Class 8 capable of 71.3 W at PD.

• The Product applies a load to the device to validate the available power from the PSE at the

PD meets the standard of the negotiated class (in this example, a Class 8 device).

• The device delivers 54.2 V under the load which is ≥41.1 V, the minimum amount required for

a device to meet the Class 8 standard.

PoE devices fail a test if:

• The device identifies as capable of a negotiated hardware class greater than the power the

device can deliver under the load required to meet the standard for the stated class.

• The device identifies as capable of a negotiated software class greater than the power the

device can deliver under the load required to meet the standard for the stated class.

• The switch under test cannot deliver power to the device because the maximum power which

the switch can deliver is already in use.

27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

LinkIQ

Users Manual

Save a Test Result

To save a test:

1. On a test result screen, tap SAVE AS....

2. If necessary, use the onscreen keyboard to enter the Test ID, Project Name, and Operator

Name.

3. Tap OK.

Results Menu

Ta bl e 1 3 is a list of the symbols in the Results menu.

Table 13. Results Menu

02/15/2021 09:24 AM

1

2

3

4

5

Item Description Function

Project selection box

Tap to select a project. You can select more than one

project.

8

7

6

Number of results Shows the number of results selected to view.

28

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

Table 13. Results Menu (cont.)

Item Description Function

Shows the remainder of available results that can be

Available results

saved in memory. The Product can save a maximum of

1000 results.

Cable+Network Tester

Delete Test Results

D

E

F

G

H

Test information

MANAGE RESULTS

Result symbol

Upload symbol

Sort button

Shows the Test ID, Project Name, and the date and

time of the test.

Tap to select which results to delete. See Delete Test

Results.

The result passed.

The result failed.

The result is for information only.

The result is uploaded to LinkWare PC.

The result is not uploaded to LinkWare PC.

Tap to select how to sort the results: Oldest,

Newest, Test ID (A-Z), Test ID (Z-A).

Delete Test Results

To delete a test result:

1. Tap Results > MANAGE RESULTS.

2. Tap the box to the left of each result to delete.

3. Tap DELETE.

4. Tap OK.

To delete all of the test results:

1. Tap Results > MANAGE RESULTS > SELECT ALL.

2. Tap DELETE.

3. Tap OK.

29

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

LinkIQ

Users Manual

Upload Results to LinkWare PC

To upload results to LinkWare PC:

1. If necessary, tap on Home.

2. Connect the USB-C end of the USB cable into the USB port on the Product. See Figure 8.

3. Connect the USB-A end of the USB cable into a USB port on a PC.

4. On a PC, use LinkWare PC to upload results.

Figure 8. Product to PC Connection

30

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

Cable+Network Tester

Maintenance

Maintenance

XW Warning

To prevent possible electrical shock, fire, or personal injury:

• Do not open the case. You cannot repair or replace parts in the case.

• Use only specified replacement parts.

• Have an approved technician repair the Product.

Clean the Product

Clean the case and display with a soft cloth dampened with water and a mild soap solution. Do

not use solvents, isopropyl alcohol, or abrasive cleansers.

To clean the ports, use a pressurized can of air or a dry nitrogen-ion gun, if available, to blow the

particulates from the ports.

Battery

Note

The Product only operates on battery power. You cannot do a test while the battery

charges.

XW Warning

To prevent possible electrical shock, fire, personal injury, or damage to the

Product:

• Use only Fluke Networks approved power adapters to charge the battery.

• Batteries contain hazardous chemicals that can cause burns or explode. If

exposure to chemicals occurs, clean with water and get medical aid.

• Do not disassemble the battery.

• Do not put battery cells and battery packs near heat or fire. Do not put in sunlight.

• Do not disassemble or crush battery cells and battery packs.

• Do not short the battery terminals together.

• Use only the external mains power supply included with the Product.

31

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

LinkIQ

Users Manual

• Disconnect the battery charger and move the Product or battery to a cool, nonflammable location if the rechargeable battery becomes hot (>50 °C) during the

charge period.

• Replace the rechargeable battery after 5 years of moderate use or 2 years of heavy

use. Moderate use is defined as recharged twice a week. Heavy use is defined as

discharged to cutoff and recharged daily.

• To replace the battery, send the product to an authorized Fluke Networks Service

Center.

To get the best performance from the lithium-ion battery:

• Do not charge the Product for more than 24 hours as a reduced battery life may result.

• Charge the Product for at least 1.5 hours every 6 months for maximum battery life. Without

use, the battery will self-discharge in approximately 6 months.

Figure 9 shows how to charge the battery.

Figure 9. Charge the Battery

Product Specifications

For complete Product Specifications go to our website.

32

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...