Page 1

GPC1-10000-AF™

Gas Pressure Controller

Operation and Maintenance Manual

NSN 6685-01-529-6990 RN

(1 of 3)

© 2007 DH Instruments, a Fluke Company

Page 2

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

This equipment described in this manual is designed and manufactured for the intended purpose of

generating high pressure gas. Certain precautions need to be followed during installation and operation of this

device. Reading and understanding this material is essential to the safe and correct operation of the unit.

Pressurized equipment is potentially dangerous. The equipment described in this manual generates and

controls very high gas pressures. It should not be operated by anyone who has not become thoroughly familiar

with this manual. Additional training in general and pressure specific safety procedures will help assure

protection from harm or damage to personnel or property. Responsibility for the proper and safe operation of

this instrument rests with the user.

High pressure liquids and gases are potentially hazardous. Energy stored in these liquids and gases

can be released unexpectedly and with extreme force. High pressure systems should be assembled and

operated only by personnel who have been instructed in proper safety practices.

This instrument is not to be operated in any other manner than that specified by the manufacturer.

© 2005 DH Instruments, a Fluke Company All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments, a

Fluke Company 4765 East Beautiful Lane Phoenix AZ 85044-5318 USA.

DH Instruments makes sincere efforts to ensure accuracy and quality of its published materials; however, no warranty, expressed

or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or indirect damages resulting from the

use of the information in this manual or products described in it. Mention of any product or brand does not constitute an

endorsement by DH Instruments of that product or brand. This manual was originally composed in English and was subsequently

translated into other languages. The fidelity of the translation cannot be guaranteed. In case of conflict between the English version

and other language versions, the English version predominates.

DH Instruments, DH, DHI, DH500, GPC1, OPG1, PG7000, PG7202, RPM4 and HPMS are trademarks, registered and otherwise,

of DH Instruments, a Fluke Company.

Swagelok is a registered trademark of Swagelok Company.

Teflon is a registered trademark of 3M Corporation.

Krytox is a registered trademark of the Dupont de Nemours Company.

Document No. 550135b-01

070628

Printed in the USA

© 2007 DH Instruments, a Fluke Company

Page 3

TABLE OF CONTENTS

T

AABBLLEE OOFF

T

C

OONNTTEENNTTS

C

S

TABLE OF CONTENTS ...............................................................I

TABLES.................................................................................III

FIGURES................................................................................III

ABOUT THIS MANUAL...............................................................I

1. INTRODUCTION ................................................................. 3

1.1 PRODUCT OVERVIEW ...........................................................................................................................3

1.2 SPECIFICATIONS ...................................................................................................................................4

1.3 INSTRUMENT LAYOUT ..........................................................................................................................5

1.3.1 FRONT PANEL..............................................................................................................................................5

1.3.2 OVERALL DIMENSIONS...............................................................................................................................5

1.3.3 SYSTEM SCHEMATIC ..................................................................................................................................6

2. INSTALLATION .................................................................. 7

2.1 UNPACKING AND INSPECTION ............................................................................................................7

2.1.1 REMOVING FROM PACKAGING..................................................................................................................7

2.1.2 INSPECTING CONTENTS.............................................................................................................................7

2.2 PGC-10000-AF SYSTEM.........................................................................................................................8

2.3 SITE REQUIREMENTS............................................................................................................................9

2.4 INITIAL SETUP......................................................................................................................................10

2.4.1 SET UP GPC1..............................................................................................................................................10

2.4.2 CONNECT PNEUMATIC POWER (DRIVE AIR) .........................................................................................10

2.4.3 CONNECT HIGH PRESSURE GAS SUPPLY (GB-152-AF).......................................................................11

2.4.4 MAKE TEST PRESSURE INTERCONNECTIONS......................................................................................12

2.4.4.1 CONNECT THE SYSTEM REFERENCE PRESSURE MEASURING DEVICE (RPM4/HPMS

2.4.4.2 CONNECTING TO A DEVICE UNDER TEST..........................................................................................12

2.4.4.3 CLEANLINESS CONSIDERATIONS WHEN CONNECTING DUTS....................................................13

2.5 POWER UP AND VERIFICATION.........................................................................................................15

2.5.1 APPLY THE HIGH PRESSURE SUPPLY...................................................................................................15

2.5.2 ADJUST THE INLET PRESSURE...............................................................................................................15

2.5.3 APPLY PDVV DRIVE PRESSURE..............................................................................................................16

2.5.4 CHECK OPERATION OF COMPONENTS..................................................................................................16

2.5.5 PRECAUTIONS TO TAKE BEFORE WORKING WITH HIGH PRESSURE GAS / SAFETY

2.6 STORAGE AND SHIPPING...................................................................................................................18

A70M/A20M-AF).......................................................................................................................................12

CONSIDERATIONS.....................................................................................................................................17

Page I © 2007 DH Instruments, a Fluke Company

Page 4

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

3. OPERATION..................................................................... 19

3.1 OPERATING PRINCIPLE......................................................................................................................19

3.2 OPERATIONAL FUNCTIONS................................................................................................................21

3.2.1 SETTING INLET SUPPLY PRESSURE, TEST INLET SET REGULATOR ADJUSTMENT.......................21

3.2.2 ROUGH PRESSURE GENERATION/CONTROL, INLET AND OUTLET VALVE OPERATION................21

3.2.3 FINE PRESSURE ADJUSTMENT, PDVV (+) AND (-) VALVE OPERATION .............................................22

3.2.4 CONNECTING A DEVICE UNDER TEST....................................................................................................23

3.2.5 PURGING LIQUIDS FROM THE DUT/SYSTEM UNDER TEST .......................................................23

3.3 TYPICAL OPERATING SEQUENCE FOR A COMPLETE CALIBRATION OR TEST..........................24

4. MAINTENANCE AND ADJUSTMENTS .................................. 25

4.1 OVERVIEW............................................................................................................................................25

4.2 PURGING THE SUMP (DRAIN).............................................................................................................26

4.3 C L E A NI N G / R E P L AC I N G P D V V DR I V E A IR F I L T E R E L E M E N T ................................................ 26

4.4 ILLUSTRATED PARTS BREAKDOWN.................................................................................................27

5. TROUBLESHOOTING ........................................................ 31

6. APPENDICES................................................................... 33

6.1 GPC1 TERMS, LABELS, AND SYMBOLS (GLOSSARY)....................................................................33

6.2 WARRANTY STATEMENT....................................................................................................................34

© 2007 DH Instruments, a Fluke Company Page II

Page 5

TABLES & FIGURES

T

AABBLLEES

T

Table 1. GPC1-10000-AF Parts List............................................................................................................7

Table 2. Pneumatic power (drive air) requirements...................................................................................10

Table 3. GPC1 Main Assembly Illustrated Parts Breakdown (see Figure 13)...........................................27

Table 4. GPC1 Internal Assembly Illustrated Parts Breakdown (see Figure 14).......................................28

Table 5. GPC1 troubleshooting checklist...................................................................................................31

Table 6. DHI Authorized Service Providers ...............................................................................................34

F

IIGGUURREES

F

Figure 1. Front panel view ........................................................................................................................... 5

Figure 2. Front and side views with dimensions..........................................................................................5

Figure 3. System schematic.........................................................................................................................6

Figure 4. Typical PGC-10000-AF system installation..................................................................................8

Figure 5. Connecting GPC1-10000-AF to RPM4/HPMS A70M/A20M-AF ................................................12

Figure 6. Adapting TEST port to connect a device under test...................................................................13

Figure 7. Clean TEST1 port, sump and drain port.....................................................................................14

Figure 8. System schematic.......................................................................................................................20

Figure 9. Front panel view ......................................................................................................................... 21

Figure 10. PDVV plunger position indicator...............................................................................................22

Figure 11. Drain port location.....................................................................................................................26

Figure 12. PDVV drive air filter ..................................................................................................................27

Figure 13. GPC1 Main Assembly Illustrated Parts Breakdown.................................................................28

Figure 14. GPC1 Internal Assembly Illustrated Parts Breakdown.............................................................30

S

S

Page III © 2007 DH Instruments, a Fluke Company

Page 6

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page IV

Page 7

ABOUT THIS MANUAL

A

BBOOUUTT

A

T

T

HHIISS

M

AANNUUAALL

M

This manual provides the user with the information necessary to operate a GPC1-10000-AF Gas

Pressure Controller. It also includes a great deal of additional information provided to help you optimize

GPC1 use and take full advantage of its many features and functions.

FOR THOSE OF YOU WHO “DON’T READ MANUALS”, GO DIRECTLY TO SECTION 2.4 TO SET UP YOUR GPC1.

THEN GO TO SECTIONS 2.5.5 and 3.3. THIS WILL GET YOU RUNNING QUICKLY WITH MINIMAL RISK OF CAUSING

DAMAGE TO YOURSELF OR YOUR GPC1. THEN… WHEN YOU HAVE QUESTIONS OR START TO WONDER ABOUT

ALL THE GREAT FEATURES YOU MIGHT BE MISSING, GET INTO THE MANUAL!

GPC1-1000-AF is usually delivered as part of an PGC-10000-AF system which also includes an

RPM4/HPMS A70M/A20M-AF reference pressure monitor and and a GB-152-AF gas booster. The

RPM4/HPMS and the GB-152 have their own Operation and Maintenance Manuals.

Manual Conventions

(Caution) is used throughout the manual to identify user warnings and cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and additional

explanations.

Page I © 2007 DH Instruments, a Fluke Company

Page 8

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page II

Page 9

1. INTRODUCTION

.

11.

1.1 PRODUCT OVERVIEW

The GPC1-10000-AF Gas Pressure Controller is a stand alone, pressure setting and adjusting

component intended to be used as the means of pressure control in pneumatic calibration and test

systems. GPC1-10000-AF covers the range from atmosphere to 10 000 psi (70 MPa).

GPC1 combines the versatility, speed and reliability of direct operator control with the convenience and

effort-free operation of automation. It is the standard pressure control component in a PGC-10000-AF

Pneumatic Gauge Calibrator as well as in a PG7202 piston gauge system.

The GPC1-10000-AF is typically delivered as part of a PGC-10000-AF Pneumatic Gauge Calibrator. The

PGC-10000-AF system includes a GB-152-AF gas booster and an RPM4/HPMS A70M/A20M that have

their own Operation and Maintenance Manuals.

I

NNTTRROODDUUCCTTIIOON

I

N

Page 3 © 2007 DH Instruments, a Fluke Company

Page 10

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

1.2 SPECIFICATIONS

Electrical Power Requirements:

Pneumatic Power Requirements:

High Pressure Supply:

Operating Temperature Range:

Weight:

Dimensions:

Pressure Range:

Operating Medium:

Pneumatic Power Connection:

Test Connections:

Pneumatically Actuated Variable

Volume (PDVV) Displacement:

None

Clean, dry, low flow, compressed gas. Max flow 200 sccm

(<0.01 scfm):

Working P

- 750 psi (5 MPa): 45 psi (300 kPa)

- 7 500 psi (50 MPa): 87 psi (600 kPa)

- 10 000 psi (70 MPa) 100 psi (700 kPa)

Not to exceed 10 000 psi (10 MPa)

10 to 35 °C

24 kg (53 lb)

21.5 cm H x 30 cm W x 53.5 cm D (8.5 in. x 11.8 in. x 21.1 in.)

0 to 10 000 psi (70 MPa)

Any non-corrosive gas

1/4 in. NPT F

(3) DH500 F test connections ((1) left, rear side and (2) on top)

DH500™ is a gland and collar type fitting for ¼ in.

(6 mm) coned and left hand threaded tube. DH500 is equivalent to AE

F250C, HIP HF4, etc.

2 cc (0.12 in

Drive Air P

3

)

PGC-10000-AF SYSTEM

© 2007 DH Instruments, a Fluke Company Page 4

Temperature:

Relative Humidity:

Operating: 18 to 28 °C

Storage: -20 to 70 °C

Operating: 15 to 70%RH (non-condensing)

Storage: 10 to 90%RH (non-condensing)

Page 11

1. INTRODUCTION

1.3 INSTRUMENT LAYOUT

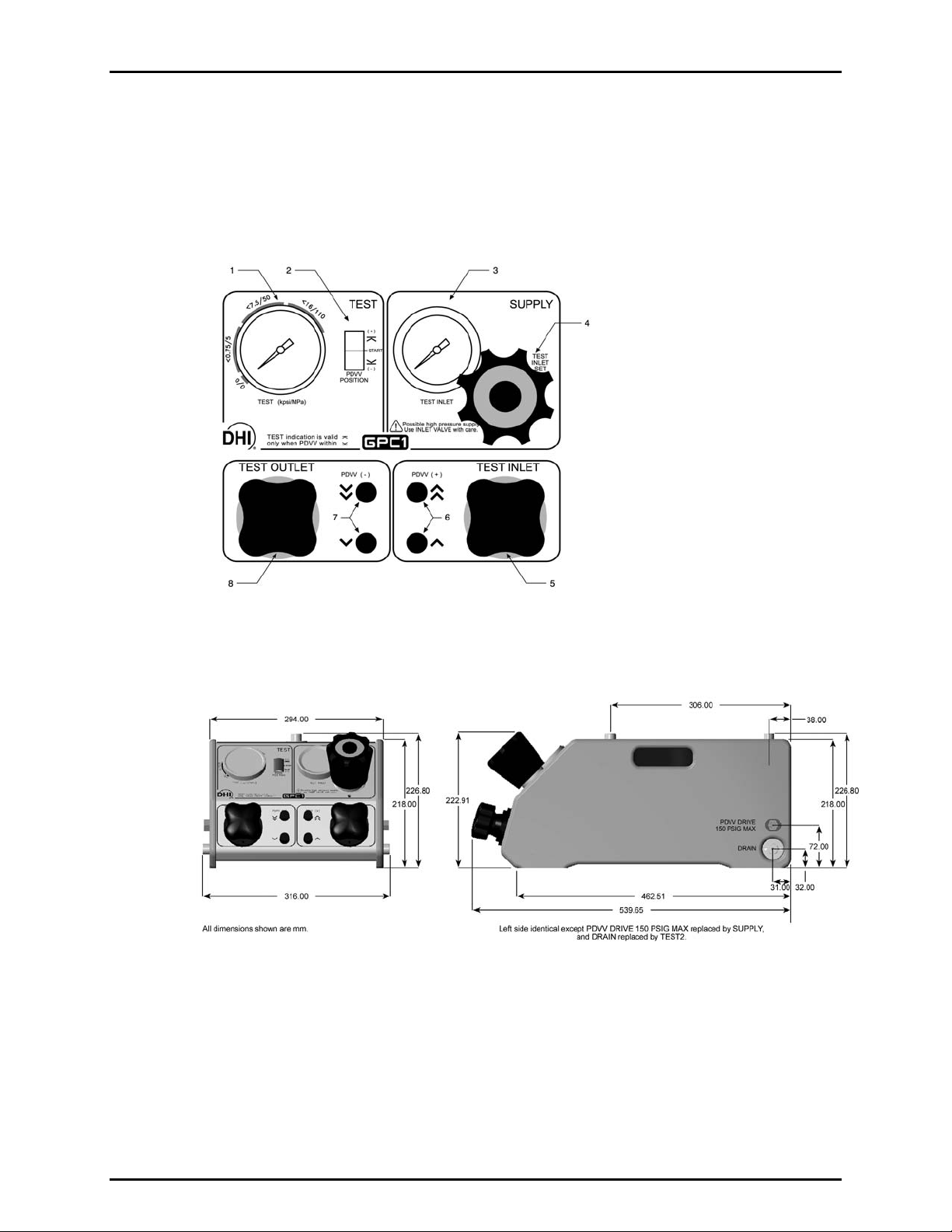

1.3.1 FRONT PANEL

The front panel provides all of the controls and indications needed to set and adjust pressure.

1. PDVV drive air/test gas pressure

gauge

2. PDVV plunger position indicator

3. Test inlet pressure gauge

4. Test inlet pressure regulator

5. Test inlet valve knob

6. PDVV increase fast and

slow buttons

7. PDVV decrease fast and slow

buttons

8. Test outlet valve knob

Figure 1. Front panel view

1.3.2 OVERALL DIMENSIONS

Figure 2. Front and side views with dimensions

Page 5 © 2007 DH Instruments, a Fluke Company

Page 12

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

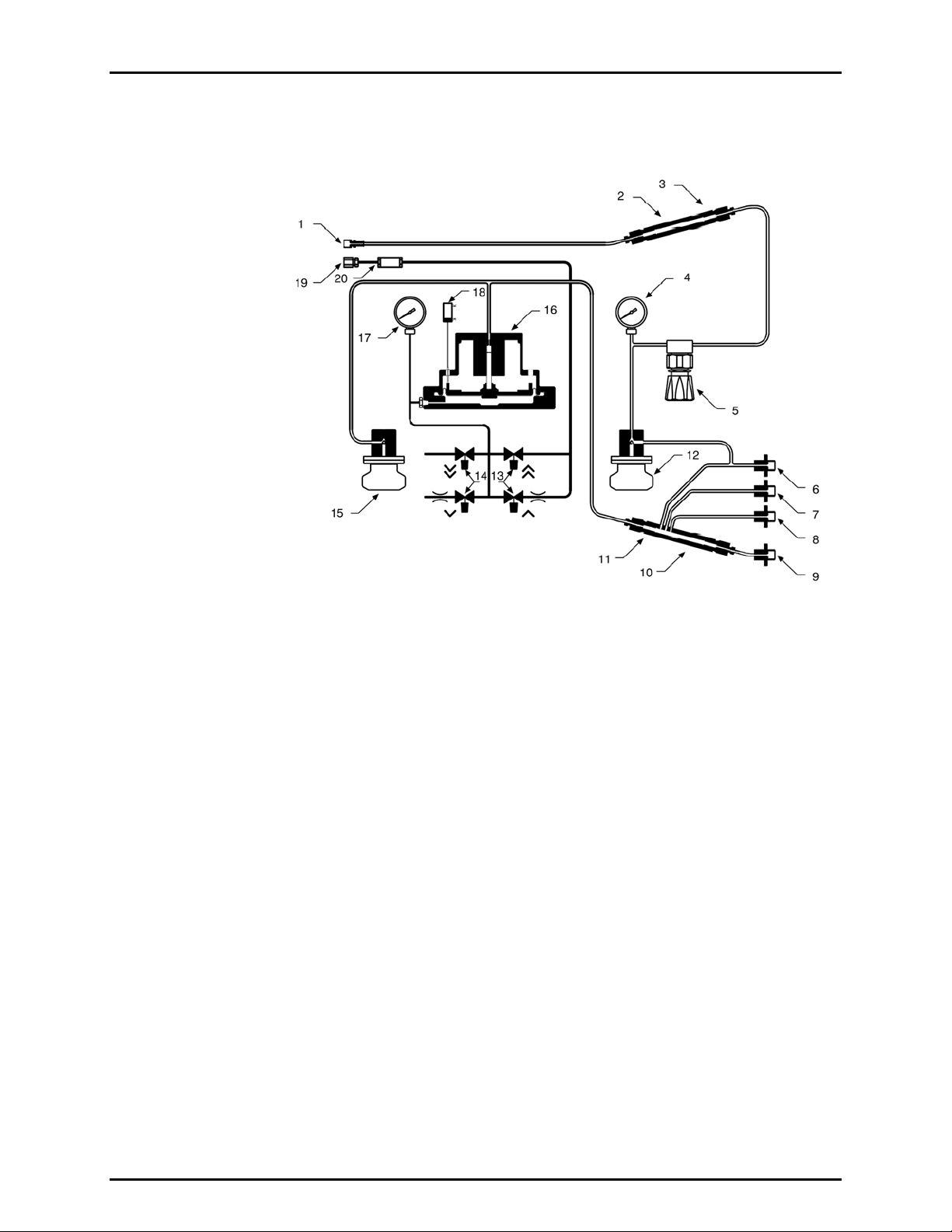

1.3.3 SYSTEM SCHEMATIC

1. High pressure gas SUPPLY connection

(left lateral)

2. Supply accumulator

3. Supply filter (not shown)

4. TEST INLET gauge

5. TEST INLET SET regulator

6. TEST1 port (rear top)

7. TEST2 port (left lateral)

8. TEST3 port (front top)

9. DRAIN port (right lateral)

10. Test liquid collection sump

Figure 3. System schematic

11. Sump filter (not shown)

12. TEST INLET valve

13. Fast and slow PDVV increase valves

14. Fast and slow PDVV decrease valves

15. TEST OUTLET valve

16. Pneumatically driven variable volume

(PDVV)

17. PDVV drive pressure gauge

18. PDVV plunger position indicator

19. PDVV DRIVE air connection (right lateral)

20. DRIVE air filter

© 2007 DH Instruments, a Fluke Company Page 6

Page 13

2. INSTALLATION

.

22.

I

NNSSTTAALLLLAATTIIOON

I

N

2.1 UNPACKING AND INSPECTION

2.1.1 REMOVING FROM PACKAGING

GPC1 is delivered, along with its standard accessories, in a corrugated container with

corrugated and polyurethane inserts to hold it in place.

Remove GPC1 and its accessories from the shipping container and remove each item from

its protective plastic bag.

Retain the specialized packing and shipping materials in case the GPC1 needs to be

shipped.

2.1.2 INSPECTING CONTENTS

Check that all items are present and have NO visible signs of damage.

Verify the items received against the parts list in Table 1.

Table 1. GPC1-10000-AF Parts List

DESCRIPTION PART #

GPC1-10000-AF instrument 402190

ACCESSORIES:

1 Mat, Top Surface Protection 123481

1 ea.

INTERCONNECTIONS KIT: 402165

2 ea. Nipple, 2.75 in. (70 mm), DH500 100207

1 ea. Nipple, 6 in. (152.4 mm), DH500 100208

1 ea. Nipple, 12 in. (30.5 mm), DH500 100209

1 ea. Elbow, 12 in. (30.5 mm), DH500 123136

1 ea. Adaptor, DH500 F x 1/8 in. NPT M 102819

1 ea. Adaptor, DH500 F x 1/4 in. NPT F 102820

1 ea Adaptor, DH500 F x 1/4 in. NPT M 102889

1 ea Adaptor, DH500 F x AN4 M 102888

3 ea. Plug, DH500 100285

3 ea. Collar, DH500 101201

PGC-10000-AF Documentation Disk including:

• RPM4/HPMS A70M/A20M-AF Operation and

Maintenance Manual, p/n 550136

• GPC1-10000-AF Operation and

Maintenance Manual, p/n 550135

• GB-152-AF Operation and Maintenance

Manual, p/n 550137

1 Wrench, Open End, 5/8 in. 103044

(Shipped with

RPM4/HPMS accessories

in transport case)

402189

Page 7 © 2007 DH Instruments, a Fluke Company

Page 14

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

2.2 PGC-10000-AF SYSTEM

GPC1-10000-AF is usually delivered as the pressure generation and control component of a PGC-10000AF Pneumatic Gauge Calibration System (see Figure 4). The PGC-10000-AF system includes:

• RPM4/HPMS A70M/A20M-AF: Reference pressure monitor and high pressure mounting system used

as the pressure measuring reference of the calibration system.

• GPC1-10000-AF: Gas pressure controller used to set and adjust high pressure gas in the calibration

system.

• GB-152-AF: Gas booster package used to supply gas pressure up to 10 000 psi (70 MPa) to the

GPC1-10000-AF pressure controller.

Each of the three components of the PGC-10000-AF system has its own Operation and Maintenance

Manual and individual setup and start up instructions. Figure 4 shows the typical setup configuration of

the complete PGC-10000-AF system.

RPM4/HPMS A70M/A20M Reference Pressure Monitor

RPM4/HPMS A70M/A20M Reference Pressure Monitor

GPC1-10000-AF

GPC1-10000-AF

Gas Pressure Control ler

Gas Pressure Control ler

CAUTION

CAUTION

Drive air

Drive air

connection

connection

Remote ENTER

Remote ENTER

Footswitch

Footswitch

GB152-AF

GB152-AF

Drive Air Control Kit

Drive Air Control Kit

GB152-AF

GB152-AF

Gas Booster

Gas Booster

Figure 4. Typical PGC-10000-AF system installation

High pressure

High pressure

instrument gas

instrument gas

connection

connection

© 2007 DH Instruments, a Fluke Company Page 8

Page 15

2. INSTALLATION

2.3 SITE REQUIREMENTS

The GPC1-10000-AF is typically delivered as part of a PGC-10000-AF Pneumatic Gauge Calibrator (see

Section 2.2). The PGC-10000-AF system also includes a GB-152-AF gas booster and an RPM4/HPMS

A70M/A20M that have their own Operation and Maintenance Manuals.

When selecting and preparing a site to setup a GPC1 system, the following should be considered:

• Bench stability: GPC1 weighs about 24 kg (53 lb). The RPM4/HPMS A70M/A20M-AF weighs

about 12 kg (26 lbs). Consider the combined weight of all components, including possible items to be

tested, when selecting a bench.

• Footprint: The PGC-10000-AF system requires a minimum bench space approximately 33 in. (84

cm) wide and 24 in. (60 cm) deep.

• Location of other components: Plan the space required and a convenient layout for the complete

system in which GPC1 is the pressure control component.

• If the GPC1 is to be used with an RPM4/HPMS, the GPC1 accessories include the hardware

necessary for setting up in a standard configuration (see Sections 2.2, 2.4.3, 2.4.4). The

RPM4/HPMS is normally placed to the left of the GPC1 and connected to the TEST2 port.

• DRAIN port: Provide access to the DRAIN port on the right, rear side of the GPC1. This port needs

to be accessed regularly to purge contaminants from GPC1.

• High pressure supply: Plan the connection from the high pressure gas supply to GPC1. If the high

pressure is being supplied by a GB-152-AF gas booster (included in GPC-10000-AF Pneumatic

Gauge Calibrator), interconnecting hardware to connect the booster output to the GPC1 SUPPLY

port is included with the booster (see the GB-152-AF Operation and Maintenance Manual).

• Drive air supply: Plan the PDVV drive air supply. The maximum drive air supply required is 100 psi

(700 kPa) but may be lower depending on the maximum test pressure to be adjusted (see Section

2.4.2, Table 2). The drive air PDVV DRIVE AIR port is on the right, rear side of GPC1. The

connection is 1/4 in. NPT female. This is usually supplied from an N2 or Air “K” bottle.

• Sy

stem interconnections: Plan the interconnections between GPC1 and any other components in

system. Minimizing the volume and maximizing the mass of all interconnecting elements will

the

reduce pressure generation and stabilization time (see Section 2.2).

ALWAYS use external tubing and fittings rated for pressures equal to or greater than the maximum

pressure which GPC1 will be used to control.

DH500 F fittings are delivered with disposable, orange, plastic dummy plugs installed. These are NOT

intended to hold high pressure. They should be removed and replaced with appropriate fittings or stainless

steel plugs before high pressure operation. Each dummy plug carries a DH500 collar. Remove and retain the

collar for use in connecting to the fitting.

Page 9 © 2007 DH Instruments, a Fluke Company

Page 16

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

2.4 INITIAL SETUP

Before setting up GPC1, see Section 2.3 for general information on site requirements.

To prepare a GPC1 for check out and operation:

Set up GPC1 (see Section 2.4.1).

Connect drive air (see Section 2.4.2).

Connect the high pressure supply (GB-152-AF) (see Section 2.4.3).

Make test pressure interconnections, including connecting the reference pressure measuring device

(RPM4/HPMS A70M/A20M-AF) (see Section 2.4.4).

2.4.1 SET UP GPC1

To set up GPC1 proceed as follows:

Place GPC1 on the site table in the proper orientation with the front panel controls

conveniently accessible.

Install the mat delivered with the GPC1 accessories on the top, front surface of the

GPC1.

2.4.2 CONNECT PNEUMATIC POWER (DRIVE AIR)

GPC1 requires pneumatic power to drive its pneumatically driven variable volume (PDVV).

The drive air requirements are summarized in Table 2. Since the flow requirements are very

low and cleanliness of the gas is important, the supply is usually regulated Nitrogen or

instrument grade air from a “K” bottle.

Connect the pneumatic pressure source to the 1/4 in. NPT F

connection

DRIVE on the right side of GPC1 housing. Use Teflon™ tape or another thread sealant to

minimize leakage.

GPC1 must be supplied with NON-LUBRICATED drive air. The internal components are

permanently lubricated. The oil in lubricated air can contaminate the small diameter tubing inside

GPC1 and lead to erratic behavior requiring difficult and costly cleaning.

Table 2. Pneumatic power (drive air) requirements

INTERNAL

COMPONENT

PDVV For 750 psi (5 MPa):

Supply 45 psi (300 kPa)

For 7 500 psi (50 MPa):

Supply 87 psi (600 kPa)

For 10 000 psi (70 MPa):

Supply 100 psi (700 kPa)

DRIVE AIR

PRESSURE NEEDED

MINIMUM

FLOW

< 0.01 scfm (200 sccm)

* This is very low flow.

LUBRICATION

REQUIRED

No Yes

labeled

CLEANLINESS

CRITICAL

PDVV

© 2007 DH Instruments, a Fluke Company Page 10

Page 17

2. INSTALLATION

2.4.3 CONNECT HIGH PRESSURE GAS SUPPLY (GB-152-AF)

GPC1 requires a high pressure gas supply of 10 000 psi (70 MPa) or lower. If the GPC1 is

part of a PGC-10000-AF Pneumatic Gauge Calibrator, the high gas pressure supply is

provided by a GB-152-AF gas booster. Hardware to connect the booster output to the GPC1

SUPPLY port is supplied with the booster. See the GB-152-AF Operation and Maintenance

Manual for instructions on making the connection using the GB-152-AF interconnections kit.

The high pressure gas supply is connected to the GPC1 SUPPLY port. The SUPPLY port is

a DH500 female (DH500 is equivalent to AE F250C, HIP HF4, etc.).

Do not connect pressure greater than 10 000 psi (70 MPa) to the GPC1 SUPPLY port.

Highly pressurized gas can be extremely hazardous. Before applying pressure to GPC1

and/or the system connected to it, be sure that all pressure vessels and connections are rated

for the pressure levels that will be applied and that all connections have been properly tightened

(see Section 2.5.5). Ensure that the GPC1 TEST INLET SET regulator is fully backed off and its

INLET valve is closed (see Section 2.5.1).

DH500 F fittings are delivered with disposable, orange, plastic dummy plugs installed.

These are NOT intended to hold high pressure. They should be removed and replaced with

appropriate fittings or stainless steel plugs before high pressure operation. Each dummy plug

carries a DH500 collar. Remove and retain the collar for use in connecting to the fitting.

Page 11 © 2007 DH Instruments, a Fluke Company

Page 18

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

2.4.4 MAKE TEST PRESSURE INTERCONNECTIONS

2.4.4.1 CONNECT THE SYSTEM REFERENCE PRESSURE MEASURING DEVICE (RPM4/HPMS A70M/A20M-AF)

GPC1-10000-AF is delivered with an interconnections kit (see Section 2.1.2,

Table 1). This kit includes a 12 in. (305 mm) DH500 elbow intended to connect

GPC1 to an RPM4/HPMS A70M/A20M-AF reference pressure monitor which is

included

in the PGC-10000-AF

the recommended layout. The setup assumes that one of the TEST ports on the

top of GPC1 or an open leg of the interconnecting tee will be used to connect to

the device or system under test.

Pneumatic Gauge Calibrator. See Figure 5 for

1.

RPM4/HPMS TEST port

2. 12 in. DH500 elbow (in GPC1 interconnections kit) 6.

3.

GPC1 TEST2 port

4. GCP1-10000-AF

Figure 5. Connecting GPC1-10000-AF to RPM4/HPMS A70M/A20M-AF

5.

GPC1 TEST1 port

GPC1 TEST3 port

7. RPM4 A70M/A20M-AF

2.4.4.2 CONNECTING TO A DEVICE UNDER TEST

In a PGC-10000-AF system, the device under test (DUT) is intended to be

connected to one of the TEST connections on the top surface of the GPC1. See

Section 2.4.4.3 concerning cleanliness considerations before connecting a DUT.

The TEST connections on the top of the GPC1 are DH500 F (DH500 is a gland

and collar type fitting for 1/4 in. (6 mm) coned and left hand threaded tube.

DH500 is equivalent to AE F250C, HIP HF4, etc.).

© 2007 DH Instruments, a Fluke Company Page 12

Page 19

2. INSTALLATION

The PGC-10000-AF fittings accessory kit includes adaptors to convert the DH500 F

TEST connection to other commonly used fittings. The adaptors are made by

combining a DH500 F adaptor with a 2.75 in., 6 in. or 12 in. DH500 nipple. The

nipple/adaptor assembly is then

installed on the DUT. Finally, the

nipple/adaptor/DUT assembly is

installed on the GPC1’s DH500 F TEST

connection. Note that the gland nut on

the DH500 nipple assembly can be

Connection to DUT

Connection to DUT

Adaptor, DH500 F to

Adaptor, DH500 F to

1/4 in. M, 1/4 in. F,

1/4 in. M, 1/4 in. F,

1/8 in. M, AN4 M

1/8 in. M, AN4 M

or other

or other

tightened into the DH500 F connection

without rotating the nipple or DUT.

Adaptors included in the GPC1

accessory kit are:

• 1/4 in. NPT F

DH500 nipple with

DH500 nipple with

glands and collars

glands and collars

installed

installed

• 1/4 in. NPT M

GPC1 TEST port

GPC1 TEST port

• 1/8 in. NPT M

• 37 degree flare M (AN4 M)

Figure 6. Adapting TEST port to connect a

device under test

Highly pressurized gas can be extremely hazardous. Before applying pressure

to GPC1 and/or the system connected to it, be sure that all pressure vessels and

connections are rated for the pressure levels that will be applied and that all

connections have been properly tightened (see Section 2.5.5).

2.4.4.3 CLEANLINESS CONSIDERATIONS WHEN CONNECTING DUTS

Special design features are included in GPC1 to avoid excessive contamination

of GPC1 if liquids should return from a DUT to which it is connected.

For this purpose, GPC1 is equipped with an inclined manifold that serves as a

liquid sump (see Figure 77). A DRAIN port is provided at the low point so that

the sump can be easily purged. The TEST ports all go directly through

so that any liquids returning from the system under test will collect there rather

than being carried throughout GPC1. The top, rear TEST1 port is supplied

directly from the

SUPPLY port so that it is always filled with clean gas from the

supply. Even if liquids are present in the sump, they will not enter the TEST1

port as gas that may have been exposed to liquids never flows into the port from

GPC1

(see Figure 77).

the sump

Below are recommendations for use of the three (3) GPC1 TEST

If there is no risk of return of

liquids from the devices that will be connected to

ports.

GPC1, it is not necessary to discriminate TEST port usage.

• TEST1 port (top, rear): This port is supplied directly with clean gas from the

SUPPLY port and should be reserved for connecting devices that are known

to be liquid free and must be protected from any risk of liquid contamination.

If no such devices will be connected to GPC1, then this port may be used as

any TEST port would.

• TEST2 port (left lateral): Normally, the system reference pressure

measurement device is connected here. In a PGC-10000-AF Pneumatic

Gauge Calibrator, this is an RPM4/HPMS A70M/A20M-AF.

Page 13 © 2007 DH Instruments, a Fluke Company

Page 20

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

• TEST3 port (top, front): This port is connected to the lowest point on the GPC1

sump and should be used for connecting test devices that may contain liquids.

By design, the TEST1 port is always filled directly with clean gas from the

SUPPLY port and exhausted away from the port. Do not break the TEST1 port

connection under pressure. If unclean gas is present in GPC1, flowing out the TEST1

port will contaminate the port.

1. High pressure gas SUPPLY connection 5. TEST3 port (top, front)

2. TEST INLET SET regulator 6. DRAIN port

3. TEST1 port (top, rear) 7. TEST INLET valve

4. TEST2 port (left lateral) 8. TEST OUTLET valve

Figure 7. Clean TEST1 port, sump and drain port

© 2007 DH Instruments, a Fluke Company Page 14

Page 21

2. INSTALLATION

2.5 POWER UP AND VERIFICATION

2.5.1 APPLY THE HIGH PRESSURE SUPPLY

This section assumes that the GPC1 system has already been set up, including pressure

interconnection (see Section 2.4.1).

Highly pressurized gas can be extremely hazardous. Before applying pressure to GPC1

and/or the system connected to it, be sure that all pressure vessels and connections are rated

for the pressure levels that will be applied and that all connections have been properly tightened

(see Section 2.5.5). Ensure that the GPC1 TEST INLET SET regulator is fully backed off and the

INLET valve is closed (see Section 2.4, 2.5.1).

Do not connect pressure greater than 10 000 psi (70 MPa) to the GPC1 SUPPLY port.

Proceed as follows (numerical references refer to Section 3.1, Figure 88):

Fully back off the TEST INLET SET regulator (5).

Close the TEST INLET valve (12).

Open the TEST OUTLET valve (15).

Apply the high pressure supply to the SUPPLY port (1).

2.5.2 ADJUST THE INLET PRESSURE

This section assumes that the GPC1 system has already been set up, including

pressure interconnection (see Section 2.4.1).

Be sure the INLET valve is CLOSED before adjusting the TEST INLET SET regulator.

If the INLET valve is open, the supply pressure will be admitted to GPC1 components and

TEST ports.

Turn the TEST INLET SET regulator clockwise while observing the TEST INLET gauge.

Set the pressure as indicated by the TEST INLET gauge to the desired maximum

test pressure. The pressure set by the TEST INLET SET regulator is applied to the inlet of

the INLET valve.

Page 15 © 2007 DH Instruments, a Fluke Company

Page 22

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

2.5.3 APPLY PDVV DRIVE PRESSURE

This section assumes that the GPC1 system has already been set up, including pressure

interconnections (see Section 2.4.1).

Apply drive pressure to the PDVV DRIVE port. See Table 2 to determine the necessary

PDVV drive pressure value.

2.5.4 CHECK OPERATION OF COMPONENTS

Highly pressurized gas can be extremely hazardous. Before applying pressure to the GPC1

and/or the system connected to it, be sure that all pressure vessels and connections are rated

for the pressure levels that will be applied and that all connections have been properly tightened

(see Section 2.4, 2.5.5).

When the GPC1 INLET valve is opened, the SUPPLY pressure may be applied to the test

system rapidly. Before operating the INLET valve, ALWAYS adjust the TEST INLET SET regulator

pressure low enough so that the SUPPLY pressure does not exceed the maximum pressure rating

of the devices or system to which GPC1 is connected (see Sections 2.5.2 and 3.2.1).

Proceed as follows:

If an RPM4 A70M/A20M-AF is not already connected, connect a high pressure indicating

device to one of GPC1’s TEST ports (see Section 3.2.4). Plug all other TEST ports using

DH500 plugs.

There are three TEST ports: One on the left, rear side and two on the top (see Section

2.4.4.2).

Fully close the OUTLET valve.

Slowly open the INLET valve.

The pressure indicated by the reference and/or device under test should begin to

increase. If the pressure does not increase, possible explanations are:

• The TEST INLET SET regulator has not been properly adjusted (see Section 2.4.2).

• There is no high pressure supply (see Section 2.4.3).

• There is a large leak in the system to which GPC1 is connected or in GPC1 itself.

Keep the INLET valve open until the desired gas pressure is set.

Fully close the INLET valve.

© 2007 DH Instruments, a Fluke Company Page 16

Page 23

2. INSTALLATION

Leak Check: The pressure indicated by the high pressure device connected to the

TEST port should stabilize and hold. If it does not, there is a leak in the system to which

GPC1 is connected or in GPC1 itself.

The time required for pressure to stabilize after the pressure has been changed is directly

proportional to the volume connected to GPC1, to the magnitude of the pressure change and to

the mechanical stability of the volume's connections and vessels. It may take up to 10 minutes to

stabilize pressure well enough to perform a valid leak test. To reduce stabilization time, go beyond

the pressure set point and return. If in doubt as to the validity of a leak test, consider running

the leak test overnight to observe the change in pressure over a very long time period. If the GPC1

is part of a PGC-10000-AF Pneumatic Gauge Calibrator, the RPM4/HPMS A70M/A20M-AF leak

test function can be used (see the RPM4/HPMS Operation and Maintenance Manual).

When leak checking is complete, slowly open the OUTLET valve to reduce pressure and

vent to atmosphere.

2.5.5 PRECAUTIONS TO TAKE BEFORE WORKING WITH HIGH

PRESSURE GAS / SAFETY CONSIDERATIONS

Highly pressurized gas can be extremely hazardous if proper procedures are not followed or

incorrect hardware is used. Before using GPC1 to set and adjust pressure, consider

the following:

• Double check that all connections, vessels and DUTs connected to GPC1 are rated for

the pressure to be set and that all fittings are properly tightened.

• Opening the INLET valve opens to the high pressure gas supply. To avoid accidental

overpressure of the any item connected to the GPC1, BEFORE opening the

INLET valve, ALWAYS adjust the TEST INLET SET regulator so that the supply to the

INLET valve is lower than the maximum pressure that is intended to be set with the

GPC1 (see Section 2.4.2).

• At high pressure, the

and push button PDVV valves increase pressure much more

quickly than at low pressure. Observe pressure evolution carefully when operating these

valves (see Section 3.2.3).

Drain/purge the GPC1 sump regularly to remove any contaminants that may

•

have

entered the system from the supply gas or devices connected to GPC1 (see Section 4.2).

• Put the PDVV plunger in the START position when starting a calibration or test sequence

(see Section 3.2.3).

• Systems and DUTs connected to GPC1 should be emptied of liquids before they are

pressurized (see Section 3.2.5, 4.2).

Page 17 © 2007 DH Instruments, a Fluke Company

Page 24

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

2.6 STORAGE AND SHIPPING

When leaving GPC1 at rest but still setup for operation:

Fully close the INLET valve.

Release gas pressure by fully opening the OUTLET valve.

Open the DRAIN port.

Release the high pressure supply and fully back off the TEST INLET SET regulator.

To prepare GPC1 for long term storage or shipping:

Disconnect all pneumatic pressure connections and plug the DH500 connections using DH500 plugs

or orange dummy plugs held by gland nuts. Plug the 1/4 in. NPT port with a plastic plug.

When shipping GPC1, use the original shipping materials, if possible. If it is necessary to use alternate

materials, use caution and ensure that: a) the front panel controls and indicators are protected; and, b) the

tubing and components exposed through GPC1’s open bottom are protected. GPC1 must ride on its four (4)

feet - NOT on its internal components.

© 2007 DH Instruments, a Fluke Company Page 18

Page 25

3. OPERATION

.

33.

O

PPEERRAATTIIOON

O

N

3.1 OPERATING PRINCIPLE

Numerical references in this section refer to Section 3.1, Figure 88.

GPC1 is a self-contained system designed to set and adjust gas pressure in static pressure test and

calibration systems. GPC1-10000-AF operates to 10 000 psi (70 MPa). GPC1 combines the capability to

execute large pressure changes very quickly with very fine pressure adjustment.

GPC1 uses two different techniques to set and adjust pressure. These are rough pressure control using

the TEST INLET and TEST OUTLET valves (12, 15) and fine pressure control using the PDVV (+) and (-)

valves (13, 14).

The first means of setting and adjusting pressure uses the external gas pressure supply (1) with the

TEST INLET SET regulator (5), TEST INLET valve (12) and TEST OUTLET valve (15). This combination

is used for filling the system under test, making large pressure changes and for rough pressure control.

The valves are Belleville spring loaded, half-turn needle valves. Their operation is highly progressive

over a half-turn with mechanical stops at each end so they cannot be over tightened. The regulator is self

venting and its output is indicated by the TEST INLET gauge (4). The valve is turned clockwise (CW) to

close and counter-clockwise (CCW) to open. A WHITE dot on the handle body indicates the valve’s

current open/close position. The TEST INLET SET regulator (5) and TEST INLET gauge (4) are used to

set the supply pressure to the TEST INLET valve (12). Opening the INLET valve (12) allows the supply

pressure to enter GPC1 and reach the TEST ports (6,7,8). Opening the OUTLET valve (15) exhausts

gas, reducing pressure in the system.

The second means of generating and adjusting pressure is the Pneumatically Driven Variable Volume

(PDVV) (16) combined with the PDVV (+) and (-) valves (13, 14). This combination is used for smaller

pressure changes and fine pressure control. The PDVV is a pneumatically actuated variable volume. A

piston or plunger in a cylinder is exposed to the high pressure gas to be adjusted.

The other end of the plunger is connected to a dome loaded pneumatic actuator. Changing the

pneumatic pressure on the dome loaded actuator causes the plunger to move, increasing or decreasing

the high gas pressure. A spring returns the plunger to its minimum stroke position when there is no

pressure on the dome or on the plunger. A mechanical system tracks movement of the plunger and an

indicator (18) displays the plunger position on the front panel. The PDVV (+) and (-) valves (13, 14) are

momentary, poppet valves that open when pressed. The (+) valves (13) admit drive air pressure to the

PDVV actuator causing the PDVV piston to move forward, compressing the high pressure gas and

increasing the pressure. Th e (-) valves (14) have the opposite effect, causing pressure to decrease when

they are operated.

Page 19 © 2007 DH Instruments, a Fluke Company

Page 26

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

1. High pressure gas SUPPLY connection

(left lateral)

2. Supply accumulator

3. Supply filter (not shown)

4. TEST INLET gauge

5. TEST INLET SET regulator

6. TEST1 port (rear top)

7. TEST2 port (left lateral)

8. TEST3 port (front top)

9. DRAIN port (right lateral)

10. Test liquid collection sump

Figure 8. System schematic

11. Sump filter (not shown)

12. TEST INLET valve

13. Fast and slow PDVV increase (plus) valves

14. Fast and slow PDVV decrease (minus) valves

15. TEST OUTLET valve

16. Pneumatically driven variable volume (PDVV)

17. PDVV drive pressure gauge

18. PDVV plunger position indicator

19. PDVV DRIVE air connection (right lateral)

20. DRIVE air filter

© 2007 DH Instruments, a Fluke Company Page 20

Page 27

3. OPERATION

3.2 OPERATIONAL FUNCTIONS

All GPC1 operational functions are accessed from the instrument front panel. Sections 3.2.1 to 3.2.5

detail the various functions.

1. PDVV drive air/test gas pressure

gauge

2. PDVV piston position indicator

3. Test inlet pressure gauge

4. Test inlet pressure regulator

5. Test inlet valve knob

6. PDVV increase fast and slow

buttons

7. PDVV decrease fast and slow

buttons

8. Test outlet valve knob

Figure 9. Front panel view

3.2.1 SETTING INLET SUPPLY PRESSURE, TEST INLET SET REGULATOR ADJUSTMENT

Numerical references in this section refer to Section 3.2, Figure 99. For information on the

GPC1 operating principle, see Section 3.1.

Setting inlet supply pressure is generally done at the beginning of a test or calibration based

on the maximum pressure of the calibration. To avoid accidental overpressure, it is good

practice to set the inlet pressure just below the maximum pressure desired. The PDVV can

then be used for the final pressure adjustment at the maximum pressure (see Section 3.2.3).

With the INLET valve (5) closed, use the INLET SET regulator (4) and

the INLET gauge (3)

indication to set the maximum desired test pressure.

The TEST INLET SET regulator sets the pressure to the TEST INLET valve. When the TEST

INLET valve is opened, this pressure can be generated rapidly in the system connected

to GPC1. Use caution in setting the TEST INLET regulator pressure and always check the setting

and adjust if necessary before using the TEST INLET valve (see Section 2.4.2).

3.2.2 ROUGH PRESSURE GENERATION/CONTROL, INLET

AND OUTLET VALVE OPERATION

Numerical references in this section refer to Section 3.2, Figure 99. For information on the

GPC1 operating principle, see Section 3.1.

The INLET and OUTLET valves (5, 8) are used to execute large pressure changes in the test

system and for rough pressure control. The INLET valve is used to increase pressure and the

Page 21 © 2007 DH Instruments, a Fluke Company

Page 28

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

OUTLET valve decreases pressure and vents the system to atmosphere, setting zero gauge

pressure. If finer pressure control is needed, use the PDVV valves (see Section 3.2.3).

To increase pressure in the GPC1 system, open the INLET valve (5) slowly. Use the

progressive nature of the valve to control the rate of pressure increase. Close the valve when the

desired pressure has been reached. When a gas booster is used to supply high pressure, the

booster may not be able to keep up with the flow rate needed to set the desired pressure. In this

case, with the INLET valve open, wait for the booster to reach the desired pressure.

To decrease pressure in the GPC1 system, open OUTLET valve (8) slowly. Open the valve

fully to vent the system to atmosphere (set zero gauge).

The TEST INLET valve connects the pressure supply to the test system. When the TEST

INLET valve is opened, high pressure can be generated rapidly in the system connected to GPC1.

Use caution when opening the TEST INLET valve and always check the TEST INLET pressure gauge

to know the supply pressure before doing so (see Section 2.4.2).

3.2.3 FINE PRESSURE ADJUSTMENT, PDVV (+) AND (-)

VALVE OPERATION

Numerical references in this section refer to Section 3.2, Figure 99 except where

specified otherwise. For information on the GPC1 operating principle, see Section 3.1.

Use the valves labeled

plunger to back off and pressure to decrease. Use the valves labeled

and to release gas from the PDVV actuator, causing the PDVV

are to admit gas

to the PDVV actuator, causing the PDVV plunger to move forward and pressure to increase.

The

and valves are for high speed PDVV operation. The and valves are for slow speed

PDVV operation.

The PDVV (+) and (-) valves (6, 7) are utilized to make small pressure changes and for fine

pressure control. Brief momentary action on the

and valves is used to bump or jog

pressure in very small amounts around a pressure point.

If the PDVV plunger reaches end of stroke during a calibration or test, use the INLET valve and/or

OUTLET valve (5, 8) to increase or decrease the pressure, as needed (see Section 3.2.2).

The actual rate of pressure change caused by the PDVV (+) and (-) valves is dependent on the

test volume that is connected to GPC1 and the current pressure value. Increasing the test

volume lowers the pressure rate of change and pressure step size. Increasing the volume

increases the rate and the pressure step size. The maximum pressure that can be generated by

the PDVV (+) valves is dependent on the PDVV drive air supply (see Section 2.4.2, Table 2).

position of the PDVV plunger is indicated

The

by the PDVV POSITION indicator (2).

The

RED index (Figure 10, Ref 4) on the

START

indicator tracks the movement of the PDVV

plunger. Minimum and maximum end of

stroke positions (Figure 10, Refs 3 and 1) as

well as a recommended start position

(Figure 10, Ref 2) are indicated. The full

stroke displacement of the GPC1 PDVV

plunger from maximum to minimum end of

stroke is 2 cc (0.12 in.

3

).

1. Maximum End of Stroke

2. Recommended Start Position

3. Minimum End of Stroke

4. Current Position (red/white line)

Figure 10. PDVV plunger position indicator

PDVV

POSITION

© 2007 DH Instruments, a Fluke Company Page 22

Page 29

3. OPERATION

The current drive air pressure on the PDVV actuator and approximate corresponding gas test

pressure are indicated by the PDVV DRIVE/TEST gauge (1). The gas test pressure

indication is highly approximate and only valid when the PDVV plunger is NOT at an end of

stroke position.

For the PDVV (+) and (-) valves (6, 7) to have an effect, the PDVV plunger must have stroke

available. If the PDVV is at its end of stroke position (Figure 10, Refs 1 and 3), the plunger

cannot move to change pressure. The recommended PDVV START position (Figure 10, Ref

2) puts the plunger at the middle of its stroke so 50 % of PDVV displacement is available in

either direction. The PDVV plunger can be positioned without affecting test pressure using

and valves when the OUTLET valve (8) is open (pressure vented). The plunger is

the

returned to minimum end of stroke position by a spring. The PDVV plunger is usually set to

the desired position at the start of a calibration or test.

The PDVV (+) valves generate pressure indefinitely when opened. Particularly when

operating at very high pressure, use caution when operating these valves so that they do not

generate more pressure than is desired.

3.2.4 CONNECTING A DEVICE UNDER TEST

The device to be tested or calibrated should be connected either to a TEST port configured on

the interconnections external to GPC1 or to one of GPC1’s top TEST ports (see Section 2.4.4.2).

The test connection is a DH500 F (DH500 is a gland and collar type fitting for 1/4 in. (6 mm)

coned and left hand threaded tube. DH500 is equivalent to AE F250C, HIP HF4, etc.).

The DH500 test connection can be converted to 1/8 in. NPT M, 1/4 in. NPT F, 1/4 in. NPTM

or AN4 M using the 2.75 in. (70 mm) tube and DH500 F X 1/8 in. NPT M or DH500 F x 1/4 in.

NPT F adaptor supplied with GPC1 accessories. Install the tube into the adaptor. Then

install that adaptor/tube assembly onto the DH500 F TEST port (see Section 2.4.4.2).

GPC1 covers a very wide range of pressure up to 10 000 psi (70 MPa). It is the user’s

responsibility to ensure that fittings and devices connected to GPC1 are rated for the pressures

at which they will be used.

By design, TEST1 port is always filled directly with clean gas from the SUPPLY port and

exhausted away from the port. Do not break the TEST1 port connection under pressure as, if

unclean gas is present in GPC1, this could cause it to flow to the TEST1 port.

3.2.5 PURGING LIQUIDS FROM THE DUT/SYSTEM UNDER TEST

For information on the GPC1 operating principle, see Section 3.1.

GPC1 includes a sump to collect liquids that may return from the device or system under test to

which it is connected. However, the amount of liquid that the sump can collect without liquids

entering other GPC1 internal circuitry is limited. Excessive fluids in GPC1 and test connections

can cause erratic pressure control and introduce unexpected uncertainty in measurements.

DUTs and the system under test should be cleaned of liquids to the extent reasonably possible

before being connected to GPC1. Also, see Section 2.4.4.3 for information about the appropriate

GPC1 TEST port connection to use.

Page 23 © 2007 DH Instruments, a Fluke Company

Page 30

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

The procedure to purge the GPC1 sump and/or a DUT connected to GPC1 is:

Use GPC1 to pressurize the system, including the DUT, to approximately 500 psi (3.5 MPa)

(or maximum pressure of the DUT if less than 500 psi).

Open DRAIN port. Use the 5/8 in. open end wrench supplied in the GPC1 accessories to slowly

and then more fully open the DRAIN port allowing gas to exhaust as quickly as is safe and practical.

Observe whether the gas coming out of the DRAIN port contains liquid or liquid vapor.

Repeat steps through until there is no evidence of liquid in the gas escaping from the

DRAIN port.

3.3 TYPICAL OPERATING SEQUENCE FOR A COMPLETE CALIBRATION OR TEST

GPC1 is most often used to set and adjust pressure to a reference measuring device and a DUT when

performing a test or calibration. If the GPC1 is part of a PGC-10000-AF Pneumatic Gauge Calibrator, the

reference measurement device is an RPM4/HPMS A70M/A20M. The typical operational sequence is as

follows:

Connect the DUT to the appropriate GPC1 TEST port or to a test port on the external system to

which GPC1 is connected (see Sections 3.2.4, 2.4.4.2).

Set the TEST INLET SET regulator (see Section 3.2.1)

Position the PDVV plunger (see Section 3.2.3).

Purge the DUT (if necessary) (see Section 3.2 5).

Take the starting zero reading on the DUT: With the OUTLET valve open, and the INLET valve

closed, the pressure in the test system is zero gauge.

Set ascending test pressures: Carefully open the INLET valve and control the gas input to set the

pressure in the test system just under the desired test point (see Section 3.2.2). Pause a moment.

Then use the PDVV (+)and/or (-) valves to adjust the pressure to the exact test pressure desired or, if

the reference is a piston gauge, to float the piston gauge piston (see Section 3.2.3). Repeat this

process for all of the ascending increments. If the increments are small enough for the PDVV

displacement to generate the pressure, only the PDVV (+) valves may be needed to reach the next

pressure. If the PDVV runs out of stroke, use the INLET valve to generate pressure and reposition

the PDVV plunger.

Set descending test pressures: Very carefully open the OUTLET valve and control the gas

exhaust to set pressure in the test system just over the desired test point (see Section 3.2.2). Then

use the PDVV (+) and/or (-) valves to adjust the pressure to the exact test pressure desired or, if the

reference is a piston gauge, to float the piston gauge piston (see Section 3.2.3). Repeat this process

for all of the descending increments. If the increments are small enough for the PDVV displacement

to generate the pressure, only the PDVV (-) valves may be needed to generate the next pressure. If

the PDVV runs out of stroke, use the OUTLET valve to reduce pressure.

Vent the system and disconnect the DUT: Open the OUTLET valve fully and check that the DUT

reads near zero. Disconnect the DUT.

© 2007 DH Instruments, a Fluke Company Page 24

Page 31

4. MAINTENANCE AND ADJUSTMENTS

.

44.

M

AAIINNTTEENNAANNCCEE AANNDD

M

A

DDJJUUSSTTMMEENNTTS

A

S

4.1 OVERVIEW

GPC1 was designed for maintenance free operation. The PDVV is permanently lubricated. No

maintenance is required other than:

• Purge the sump very regularly (see Section 4.2).

• Clean/replace the PDVV driv

contaminated and restrict the free flow of pressure. It should then be cleaned or replaced

(see Section 4.3).

Maintenance and repair services for GPC1 are offered by DHI Authorized Service Providers (see Section

6.2, Table 6).

GPC1 is a sophisticated pressure setting and adjusting instrument with advanced features and

functions. Before assuming that unexpected behavior is caused by a system defect or breakdown, use this

manual and other training and troubleshooting facilities to become thoroughly familiar with GPC1 operation.

For rapid troubleshooting assistance in specific situations, see Section 0.

e air filter element when needed: The drive air filter may become

GPC1 is covered by a limited 1 year warranty (see Section 6.2). Unauthorized service or repair during the

warranty period is undertaken at the owner's risk and may cause damage that is NOT covered under product

warranty and/or may void the product warranty.

Page 25 © 2007 DH Instruments, a Fluke Company

Page 32

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

4.2 PURGING THE SUMP (DRAIN)

The GPC1 sump (see Section 2.4.4.3, Figure 7) is designed to collect liquids that may be returned from

the pressure supply or system/device under test so that they do not contaminate the rest of the system.

The sump has a limited volume so it should be drained regularly as part of normal operation. The purge

process below should also be used when a DUT is connected that is known to contain liquids (see

Section 3.2.5). The procedure to purge the GPC1 sump and/or a DUT connected to GPC1 is:

Use the GPC1 to pressurize the system, including the DUT, to approximately 500 psi (3.5 MPa) (do

not exceed the pressure rating of the system or the DUT connected to GPC1).

Open the DRAIN port (see Figure 111). Use the 5/8 in. open end wrench supplied in the GPC1

accessories to slowly and then more fully open the DRAIN port allowing gas to exhaust as quickly as

is safe and practical.

Observe whether the gas coming out of the DRAIN port contains liquid or liquid vapor.

Repeat steps through until there is no evidence of liquid in the gas that vents through the DRAIN

port.

Figure 11. Drain port location

4.3 CLEANING/REPLACING PDVV DRIVE AIR FILTER ELEMENT

There is a filter on the PDVV DRIVE port. If the drive air supplied is excessively dirty, this filter may

become excessively dirty and restrict air flow to the PDVV actuator (see Section 3.1, Figure 88).

The drive air filter is a filter body with a

be removed from GPC1.

To remove and reinstall the drive air filter, proceed as follows (numerical references in this section

refer to Figure 122):

Place GPC1 on the bench, so that its front panel is up with its open bottom is facing you.

Disconnect the downstream filter connection fitting (2) and move the 1/4 in. PFA flexible tubing (1)

away from the filter body (3). Then disconnect the upstream filter connection (4) and remove the filter

body (3).

To reinstall the filter, make the upstream filter connection (4). Then make the downstream filter

connection (2). Use caution to ensure that the filter body (3) is oriented in the correct direction

(the arrow on the filter body should be pointing in the direction of flow in from the PDVV DRIVE port).

sintered element. To clean or replace the filter the filter body must

© 2007 DH Instruments, a Fluke Company Page 26

Page 33

4. MAINTENANCE AND ADJUSTMENTS

Connect recommended drive pressure (see Section 2.4.2, Table 2) to the PDVV DRIVE port.

Check the new connections for leaks using a liquid leak detector. Correct leaks, if present.

The filter may be replaced completely, cleaned by back flushing or disassembled and the filter

element cleaned or replaced.

To disassemble the filter body, open the body by unscrewing the filter body cap CCW.

Once the filter body cap is removed, the sintered filter element can be removed.

1. 1/4 in. (6 mm) PFA tube

2. PDVV DRIVE filter downstream connection

3. Filter body

4. PDVV DRIVE filter upstream connection

Figure 12. PDVV drive air filter

4.4 ILLUSTRATED PARTS BREAKDOWN

Table 3. GPC1 Main Assembly Illustrated Parts Breakdown (see Figure 13)

# REQUIRED DESCRIPTION PART NO.

1 Left panel wall 123980

1 Right panel wall 123981

1 Front panel 123476

1 Manual valve, outlet 400902-05

1 Manual valve, inlet 400902-01

4 Pushbuttons PT-2615-.125-BLK

1 Pressure gauge, 160 psi 25-1009AW02B-XUC-WN160PSI

1 Pressure gauge, 20000 psi KQUK-1/4MPMO

1 High pressure regulator 26-1061-44

5 DH500 gland 60-2HM4

5 Plug, DH500 60-7HM4-316

4 DH500/HF2 bulkhead 124139

1 Bulkhead fitting 4BCF4-316

1 Sight window 122877

8 Screw, M4 x 10 .40C100KCSS

8 Lockwasher .40NLOCS

8 Nut .40CNFHS

Page 27 © 2007 DH Instruments, a Fluke Company

Page 34

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

Figure 13. GPC1 Main Assembly Illustrated Parts Breakdown

Table 4. GPC1 Internal Assembly Illustrated Parts Breakdown (see Figure 14)

# REQUIRED DESCRIPTION PART NO.

1 Upstream flow controller SD63BDL

1 Adaptor 4CN4-BR

2 Adaptor B-100-1-4

2 Adaptor MPAH-4012

1 Downstream flow controller SD63BUL

1 PDVV assembly 400864

1 Tee, DH200 20-23LF4

1 Inlet manifold 124136-01

1 Drain manifold 124136-02

2 Seat, filter assembly 402186

2 Seat, manifold 124138

4 Nut, manifold 124137

11 Gland, 2HM2 60-2HM2

11 Collar, 2H2 60-2H2

8 DH500 gland 60-2HM4

8 DH500 collar 60-2H4-316

7 DH200 gland 20-2LM4

6 DH200 collar 20-2L4

2 Valve nut 122039

2 Vavle seat 123001

1 O-ring 2-010-N674-70

© 2007 DH Instruments, a Fluke Company Page 28

Page 35

4. MAINTENANCE AND ADJUSTMENTS

# REQUIRED DESCRIPTION PART NO.

1 Sintered element 1000-.375-.125-5

1 Bulkhead fitting tubeweld 124148

1 Tubeweld, 143 mm 124149

1 Tubeweld, 152 mm 123418-02

1 Tubeweld, 260 mm 123418-03

1 Tubeweld, tee TEST1 124144

1 Nipple, 16.651 inch 30-HM2-16.651

1 Nipple, 9.289 inch 30-HM2-9.289

1 Tubeweld, tee, PDVV 124145

1 Pilot tube, 450 mm 304-F1-0625X010S

1 Pilot tube, 290 mm 304-F1-0625X010S

1 Pilot tube, 260 mm 304-F1-0625X010S

1 Port connector SS-401-PC

1 Filter B-4F-2

1 Tube, PFA 0317-037

2 Tubing, polyurethane 3814-7-BK-RL

1 Valve manifold assembly 401641

2 Adaptor, barbed MH-1012-V

1 Tube, PFA 0317-037

1 Adaptor, O-seal B-100-1-OR

1 Adaptor, O-seal B-200-1-0S

1 Adaptor, gauge 2CF4-BR

9 O-ring 2-022-V884-75

Page 29 © 2007 DH Instruments, a Fluke Company

Page 36

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

Figure 14. GPC1 Internal Assembly Illustrated Parts Breakdown

© 2007 DH Instruments, a Fluke Company Page 30

Page 37

5. TROUBLESHOOTING

.

55.

T

RROOUUBBLLEESSHHOOOOTTIINNG

T

G

GPC1 is a sophisticated pressuring setting and adjusting instrument with advanced features and functions.

Before assuming that unexpected behavior is caused by a system defect or breakdown, the operator should

use this manual and other training facilities to become thoroughly familiar with GPC1 operation. This

troubleshooting guide is intended as an aid in identifying the cause of unexpected GPC1 behavior and

determining whether the behavior is due to normal operation or an internal or external problem.

Identify the symptom or unexpected behavior you are observing from the SYMPTOMS listed in Table 3.

A PROBABLE CAUSE is provided and a SOLUTION is proposed including references to manual

sections that provide information that may be of assistance.

Table 5. GPC1 troubleshooting checklist

SYMPTOM PROBABLE CAUSE SOLUTION

Test pressure continuously increases

even with all valves closed.

Test pressure continuously decreases

even with all valves closed.

Test pressure takes too long to

stabilize or will never stabilize.

Test pressure takes too long to

stabilize or will never stabilize.

Test pressure takes too long to

stabilize or will never stabilize.

PDVV will not increase pressure.

PDVV will not decrease pressure. PDVV is at minimum end of stroke

Opening INLET valve does not

increase pressure.

Leak in INLET valve or leak in PDVV

(+) valve(s).

Leak in OUTLET valve, leak in PDVV

(-) valve(s), leak in test system

connected to GPC1 or internal leak in

GPC1 high pressure gas system.

You are observing normal evolution

of pressure in an uncontrolled static

volume.

Leak in GPC1 or test system

connected to GPC1.

GPC1 and/or test system tubing is

contaminated with liquids that are

“plugging” tubes.

PDVV is at maximum end of stroke

position, PDVV drive air supply

pressure is not high enough, or

PDVV drive air supply is plugged.

position.

TEST INLET SET regulator is set too

low and/or external pressure supply

to low.

Isolate leak to INLET valve or PDVV (+)

valve(s) by checking whether pressure

continues to increase when PDVV is at

maximum end of stoke. Replace or repair

valve(s) if qualified to do so. 3.1, 3.2.2, 3.2.3.

Identify and correct leak in test system if

present. Disconnect from test system and

plug GPC1 TEST ports to test GPC1 alone.

Isolate leak to OUTLET valve or PDVV (-)

valve(s) by checking if pressure continues to

decrease when PDVV is in minimum end of

stroke position. Replace or repair valve(s) if

qualified to do so. 3.1, 3.2.2, 3.2.3

Reduce resolution of pressure reading to

appropriate level. Reduce test volume.

Increase stability of test tubing and vessels.

Wait longer for stability. Overshoot test point

and return to reduce stabilization time.

See troubleshooting tips “Test pressure

continuously increases…” and “Test pressure

continuously decreases…” above.

Thoroughly purge complete system.

3.2.5, 4.2

Verify PDVV piston position and readjust if

necessary. Use INLET valve to increase

pressure. Increase PDVV drive air supply

pressure. Clean filter. 3.2.3, 2.4.2, 4.3

Verify PDVV piston position and readjust if

necessary. Use OUTLET valve to decrease

pressure. 3.2.3, 3.2.2

Check value of supply pressure on TEST

INLET gauge. Adjust INLET regulator,

increase supply pressure if necessary. 3.2.1,

2.4.3

Page 31 © 2007 DH Instruments, a Fluke Company

Page 38

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page 32

Page 39

6. APPENDICES

.

66.

A

PPPPEENNDDIICCEES

A

S

6.1 GPC1 TERMS, LABELS, AND SYMBOLS (GLOSSARY)

, Fast ( ) and slow ( ), PDVV (-) valves. Used to decrease pressure and for fine

, Fast ( ) and slow ( ), PDVV (+) valves. Used to increase pressure and for fine

collar

CCW

CW

DH500

DUT

gland

PDVV (Pneumatically

Driven Variable Volume)

PDVV (+) valves

PDVV (-) valves

pressure adjustment.

pressure adjustment.

The DH500 fitting element that is threaded onto the tube and provides a surface for the

gland to push against.

Counter-clockwise

Clockwise

High pressure, gland and collar type fitting for 1/4 in. (6 mm) coned and left hand

threaded, stainless steel tubes. DH500 is equivalent to AE F250C, HIP HF4, etc.

Device or System Under Test. The device that is connected to GPC1 to be tested or

calibrated.

The “jam nut” in a DH500 fitting that pushes the collar on the tube into the seat.

A pneumatically actuated plunger in a cylinder used to increase and decrease the

volume of the high pressure gas test system and provide fine adjustment of the

test pressure.

Momentary, push button actuated, poppet valves that admit drive air drive pressure to

the PDVV actuator causing the PDVV plunger to move forward, compressing the high

pressure gas and increasing the test pressure. Used to increase pressure and for fine

pressure adjustment.

Momentary, push button actuated, poppet valves that release air drive pressure from the

PDVV actuator causing the PDVV plunger to move back, decompressing the high

pressure gas and decreasing the test pressure. Used to decrease pressure and for fine

pressure adjustment.

PDVV DRIVE gauge

TEST INLET gauge

TEST INLET valve

TEST INLET SET

regulator

TEST OUTLET valve

Test pressure

Page 33 © 2007 DH Instruments, a Fluke Company

Analog gauge that indicates the PDVV actuator air pressure and the approximate

corresponding gas test pressure.

Analog gauge that indicates the pressure set by the TEST INLET SET regulator and

applied to the TEST INLET valve.

Progressive, half-turn, needle valve used to admit high pressure gas into the test

system. Used for rough pressure adjustment.

Self venting regulator used to regulate the external high pressure gas supply.

Sets maximum TEST INLET valve pressure.

Progressive, half-turn, needle valve used to return exhaust gas from the test system.

Used to release pressure and for rough pressure adjustment.

The high gas pressure in GPC1 PDVV, at its TEST connections and in the system to

which GPC1 is connected.

Page 40

GPC1-10000-AF™ OPERATION AND MAINTENANCE MANUAL

6.2 WARRANTY STATEMENT

Except to the extent limited or otherwise provided herein, DH Instruments (DHI) warrants for one year

from purchase, each new product sold by it or one of its authorized distributors, only against defects in

workmanship and/or materials under normal service and use. Products which have been changed or

altered in any manner from their original design, or which are improperly or defectively installed, serviced

or used are not covered by this warranty.

DHI and any of its authorized service providers’ obligations with respect to this warranty are limited to the

repair or replacement of defective products after their inspection and verification of such defects. All

products to be considered for repair or replacement are to be returned to DHI, or its authorized service

provider, freight prepaid, after receiving authorization from DHI or its authorized service provider. The

buyer assumes all liability vis-à-vis third parties in respect to its acts or omissions involving use of the

products. In no event shall DHI be liable to purchaser or any party for any unforeseeable or indirect

damage, it being expressly stated that, for the purpose of this warranty, such indirect damage includes,

but is not limited to, loss of production, profits, revenue, or goodwill, even if DHI has been advised of the

possibility thereof, and regardless of whether such products are used individually or as components in

other products.

Items returned to DHI under warranty claim but determined to not have a defect covered under warranty

or to not have a defect at all are subject to an evaluation charge as well as applicable repair and/or

calibration costs.

The provisions of this warranty and limitation may not be modified in any respect except in writing signed

by a duly authorized officer of DHI.

The above warranty and the obligations and liability of DHI and its authorized service providers exclude

any other warranties or liabilities of any kind.

Table 6. DHI Authorized Service Providers

DH INSTRUMENTS, A FLUKE COMPANY

AUTHORIZED SERVICE PROVIDERS

COMPANY

DH Instruments, a Fluke

Company

Minerva Meettechniek B.V. Chrysantstraat 1

Ohte Giken, Inc.

Technology Center

4765 East Beautiful Lane

Phoenix AZ 85044-5318

USA

3812 WX Amersfoort

the NETHERLANDS

258-1, Nakadai

Kasumigaura-machi,

Niihari-Gun,

Ibaraki 300-0133

ADDRESS

TELEPHONE,

FAX & EMAIL

Tel 602.431.9100

Fax 602.431.9559

cal.repair@dhinstruments.com

Tel (+31) 33.46.22.000

Fax (+31) 33.46.22.218

info@minervaipm.com

Tel 81/29.840.9111

Fax 81/29.840.9100

tech@ohtegiken.co.jp

NORMAL SUPPORT

REGION

Worldwide

European Union

Japan/Asia

© 2007 DH Instruments, a Fluke Company Page 34

Loading...

Loading...