Page 1

FPG8601™/VLPC™

Operation and Maintenance Manual

© 2007 DH Instruments, a Fluke Company

Page 2

FPG8601™/VLPC™ OPERATION AND MAINTENANCE MANUAL

High pressure liquids and gases are potentially hazardous. Energy stored in these liquids and gases

can be released unexpectedly and with extreme force. High pressure systems should be assembled and

operated only by personnel who have been instructed in proper safety practices.

© 2007 DH Instruments, a Fluke Company All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments, a

Fluke Company 4765 East Beautiful Lane Phoenix Arizona 85044-5318 USA.

DH Instruments makes sincere efforts to ensure the accuracy and quality of its’ published materials; however, no warranty,

expressed or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or indirect damages

resulting from the use of the information in this manual or products described in it. Mention of any product or brand does not

constitute an endorsement by DH Instruments of that product or brand. This manual was originally composed in English and was

subsequently translated into other languages. The fidelity of the translation cannot be guaranteed. In case of conflict between the

English version and other language versions, the English version predominates.

DH Instruments, DH, DHI, PG7000 and CalTool are trademarks, registered and otherwise, of DH Instruments, a Fluke Company.

Swagelok is a registered trademark of the Swagelok Company

Krytox is a trademark of the Dupont de Nemours Company

Document No. 550122e

060105

Printed in the USA

© 2007 DH Instruments, a Fluke Company

Page 3

TABLES AND FIGURES

T

AABBLLEE OOFF

T

C

OONNTTEENNTTS

C

S

TABLE OF CONTENTS .............................................................III

TABLES................................................................................VII

FIGURES..............................................................................VIII

ABOUT THIS MANUAL.............................................................XI

1. INTRODUCTION

1.1 OVERVIEW..............................................................................................................................................1

1.2 REQUIREMENTS.....................................................................................................................................2

1.3 SPECIFICATIONS....................................................................................................................................2

1.3.1 GENERAL SPECIFICATIONS.......................................................................................................................2

1.3.1.1 FPG8601 GENERAL SPECIFICATIONS...................................................................................................2

1.3.1.2 AMBIENT AND INSTRUMENT CONDITION MEASUREMENTS..............................................................3

1.3.1.3 PISTON-CYLINDER...................................................................................................................................3

1.3.1.4 PRESSURE MEASUREMENT...................................................................................................................3

1.3.2 VLPC GENERAL SPECIFICATIONS............................................................................................................4

1.4 FPG PLATFORM FRONT AND REAR PANELS AND VLPC FRONT AND REAR PANELS.................5

1.4.1 TERMINAL FRONT AND REAR PANELS....................................................................................................5

1.4.1.1 FPG TERMINAL FRONT PANEL...............................................................................................................5

1.4.1.2 FPG TERMINAL REAR PANEL .................................................................................................................6

1.4.2 FPG PLATFORM FRONT VIEW ...................................................................................................................7

1.4.3 FPG PLATFORM BACK VIEW .....................................................................................................................8

1.4.3.1 VLPC REAR PANEL ASSEMBLY..............................................................................................................9

................................................................. 1

2. FPG THEORY OF OPERATION ........................................... 11

2.1 OVERVIEW............................................................................................................................................ 11

2.2 PISTON-CYLINDER...............................................................................................................................11

2.3 LOAD CELL...........................................................................................................................................13

2.4 LUBRICATION PRESSURE..................................................................................................................14

2.5 VACUUM REFERENCE PRESSURE....................................................................................................14

2.6 SIMPLIFIED FORMULA FOR CALCULATING DIFFERENTIAL PRESSURE......................................15

2.6.1 REFERENCE LEVEL...................................................................................................................................16

2.7 CORRECTIONS.....................................................................................................................................16

2.7.1 δN1...............................................................................................................................................................16

2.7.2 δN2...............................................................................................................................................................16

2.7.3 δN3...............................................................................................................................................................17

2.8 COMPLETE DIFFERENTIAL PRESSURE EQUATION ........................................................................ 18

3. VLPC THEORY OF OPERATION.......................................... 19

3.1 OVERVIEW............................................................................................................................................ 19

3.2 SUPPLY AND REGULATION................................................................................................................20

3.3 FLOW CONTROL..................................................................................................................................20

3.4 RANGE RESTRICTIONS.......................................................................................................................21

3.5 CONTROL..............................................................................................................................................21

3.6 READY/NOT READY.............................................................................................................................22

Page III © 2007 DH Instruments, a Fluke Company

Page 4

FPG8601™/VLPC™ OPERATION AND MAINTENANCE MANUAL

4. GETTING STARTED .......................................................... 23

4.1 OVERVIEW............................................................................................................................................ 23

4.2 INSTALLING FPG TOOLS ....................................................................................................................23

4.3 SETTING UP FPG TOOLS ....................................................................................................................24

4.4 BASIC FPG HARDWARE SETUP.........................................................................................................25

4.5 SETTING UP THE PISTON-CYLINDER................................................................................................26

4.6 CONNECTING THE FPG MANIFOLD AND VALVES...........................................................................26

4.7 SETTING UP THE FPG FOR OPERATION...........................................................................................28

4.8 SETTING UP THE VLPC .......................................................................................................................29

4.9 INTRODUCING GAS TO THE FPG.......................................................................................................29

4.10 CONNECTING A DUT............................................................................................................................30

4.10.1 GAUGE MODE.............................................................................................................................................30

4.10.2 ABSOLUTE MODE......................................................................................................................................30

4.10.3 ABSOLUTE DIFFERENTIAL MODE...........................................................................................................31

4.11 CONNECTING THE DUT MANIFOLD...................................................................................................32

4.11.1 SETTING UP THE TURBO PUMP ..............................................................................................................33

4.11.2 CONNECTING THE ION GAUGE ...............................................................................................................33

4.12 CHANGING LUBRICATION GAS..........................................................................................................34

4.12.1 PURGING THE LUBRICATING VOLUME WITH A NEW GAS ................................................34

4.12.2 PURGING THE TEST PORT.......................................................................................................................35

5. SYSTEM OPERATION........................................................ 37

5.1 OVERVIEW............................................................................................................................................ 37

5.2 ZEROING THE FPG...............................................................................................................................37

5.2.1 ZERO CONDITION ......................................................................................................................................37

5.2.2 STABILITY TEST.........................................................................................................................................38

5.2.3 STORE ZERO DATA...................................................................................................................................38

5.3 INTERNAL CALIBRATION....................................................................................................................38

5.3.1 DETERMINING CALIBRATION MASS VALUE..........................................................................................38

5.3.2 ACTIVATING NEW CALIBRATION ............................................................................................................39

5.4 SETTING A MEASUREMENT MODE....................................................................................................41

5.5 USING A DUT WITH FPG TOOLS.........................................................................................................41

5.6 ZEROING THE DUT MANIFOLD...........................................................................................................42

5.7 CHANGING PRESSURE WITH THE VLPC...........................................................................................42

5.7.1 SETTING 0 PRESSURE..............................................................................................................................43

5.8 LOGGING DATA WITH THE FPG.........................................................................................................43

5.9 SHUTTING DOWN THE FPG ................................................................................................................44

6. FPG TOOLS ..................................................................... 45

6.1 OVERVIEW............................................................................................................................................ 45

6.2 MAIN MENU...........................................................................................................................................46

6.3 MAIN DISPLAY ......................................................................................................................................46

6.3.1 STATUS BAR ..............................................................................................................................................47

6.3.2 RUN DISPLAY.............................................................................................................................................47

6.3.3 TARE DISPLAY...........................................................................................................................................49

6.3.4 PLOT DISPLAY ...........................................................................................................................................50

6.3.4.1 CUSTOM PLOTS .....................................................................................................................................50

6.3.4.2 STRIP CHARTS .......................................................................................................................................51

6.3.5 LOGGED DATA...........................................................................................................................................52

6.3.6 VLPC CONTROL.........................................................................................................................................54

6.3.7 RUN DIAGNOSTICS....................................................................................................................................56

6.3.8 DUT MANIFOLD..........................................................................................................................................59

6.4 TOOLBARS ...........................................................................................................................................60

6.4.1 WINDOW DISPLAY TOOLBAR ..................................................................................................................60

6.4.2 FUNCTIONS TOOLBAR..............................................................................................................................61

6.4.3 VALVE CONTROL.......................................................................................................................................64

© 2007 DH Instruments, a Fluke Company Page IV

Page 5

TABLES AND FIGURES

6.5 [RUN] .....................................................................................................................................................65

6.5.1 RUN MODE INITIALIZATION......................................................................................................................65

6.5.2 [RUN MONITOR] .........................................................................................................................................66

6.5.3 [RUN W/POINT LOG]..................................................................................................................................66

6.5.4 [RUN TEST SEQUENCE]............................................................................................................................66

6.6 [CONFIG]...............................................................................................................................................68

6.6.1 [SETTINGS].................................................................................................................................................68

6.6.2 [SYSTEM SETUP] .......................................................................................................................................69

6.6.2.1 <SETUP> .................................................................................................................................................69

6.6.2.2 <OPTIONS> .............................................................................................................................................70

6.6.2.3 <DATA FILE> ...........................................................................................................................................72

6.6.3 [FPG CALIBRATION SETUP].....................................................................................................................73

6.6.4 [INTERNAL LIMITS]....................................................................................................................................75

6.6.4.1 <SETUP> .................................................................................................................................................75

6.6.4.2 <PRESSURE> .........................................................................................................................................76

6.6.4.3 <TEMPERATURE> ..................................................................................................................................77

6.6.4.4 <HUMIDITY>............................................................................................................................................78

6.6.4.5 <MASS> ...................................................................................................................................................79

6.6.4.6 <PURGE> ................................................................................................................................................80

6.6.4.7 <VLPC>.................................................................................................................................................... 81

6.6.5 [DUT SELECTION]......................................................................................................................................83

6.7 TEST SEQUENCE EDITOR...................................................................................................................84

6.7.1 TOOLBAR....................................................................................................................................................84

6.7.2 <POINTS> TABLE.......................................................................................................................................85

6.7.3 [POINTS] TAB .............................................................................................................................................87

6.7.4 <SEQUENCE> TAB.....................................................................................................................................88

6.7.5 <CONTROL> TAB.......................................................................................................................................89

6.7.6 <CYCLE> TAB.............................................................................................................................................90

6.8 DUT DEFINITION EDITOR ....................................................................................................................91

6.8.1 TOOLBAR....................................................................................................................................................91

6.8.2 DUT DEFINITION SELECTOR....................................................................................................................92

6.8.2.1 [HEADER] TAB ........................................................................................................................................93

6.8.2.2 [CORRECTION] TAB ...............................................................................................................................94

6.8.2.3 [RANGE] TAB...........................................................................................................................................95

6.8.2.4 [TOLERANCE] TAB .................................................................................................................................96

6.8.2.5 [READ] TAB .............................................................................................................................................97

6.8.2.6 REMOTE COMMAND EDITOR ...............................................................................................................99

6.9 [UNITS] ................................................................................................................................................102

6.9.1 [USER DEFINED UNITS] ..........................................................................................................................102

6.9.2 [ABSOLUTE MODE], [GAUGE MODE]....................................................................................................103

6.9.2.1 [GAUGE MODE].....................................................................................................................................103

6.9.2.2 [ABSOLUTE MODE] ..............................................................................................................................104

6.10 [CHANGE USER LEVEL]....................................................................................................................104

6.11 [TOOLS]...............................................................................................................................................105

6.11.1 [REMOTE COMMUNICATIONS]...............................................................................................................105

6.12 INTERNATIONAL ISSUES ..................................................................................................................105

7. PISTON-CYLINDER MAINTENANCE ...................................107

7.1 OVERVIEW..........................................................................................................................................107

7.2 REMOVING THE PISTON-CYLINDER FROM THE MOUNTING POST .............................................109

7.3 REMOVING THE PISTON FROM THE CYLINDER.............................................................................111

7.4 CLEANING THE PISTON AND CYLINDER ........................................................................................112

7.5 PUTTING THE PISTON INTO THE CYLINDER...................................................................................113

7.6 INS T A L L IN G T H E P I S TO N - C Y L I ND E R I N T HE M O U N TI N G P O S T ............................................114

7.7 RESTORING PISTON-CYLINDER LUBRICATION AND MOBILITY..................................................115

7.7.1 OVERVIEW................................................................................................................................................115

7.7.2 PISTON CENTERING AND LUBRICATING METHODS ..........................................................................115

7.8 DETERMINING EFFECTIVE AREA..................................................................................................... 117

7.8.1 SETTING UP THE SYSTEM......................................................................................................................117

7.8.2 GENERATING A PRESSURE...................................................................................................................118

7.8.3 ADJUSTING THE NEEDLE VALVE..........................................................................................................118

7.8.4 TAKING DATA (FOR EACH PRESSURE)................................................................................................119

7.8.5 CALCULATING THE EFFECTIVE AREA .................................................................................................119

Page V © 2007 DH Instruments, a Fluke Company

Page 6

FPG8601™/VLPC™ OPERATION AND MAINTENANCE MANUAL

8. GENERAL MAINTENANCE ................................................121

8.1 OVERVIEW..........................................................................................................................................121

8.2 REFILLING THE BUBBLER ON THE FPG.........................................................................................121

8.3 ZEROING THE VACUUM SENSOR....................................................................................................122

8.3.1 SET – UP....................................................................................................................................................123

8.3.2 WARM-UP..................................................................................................................................................123

8.3.3 TEST THE ZERO OF THE VACUUM SENSOR........................................................................................123

8.4 CALIBRATING THE INTERNAL CALIBRATION MASS.....................................................................125

8.4.1 INITIAL PREPARATIONS .........................................................................................................................125

8.4.2 REMOVE THE LOAD CELL COVER ........................................................................................................125

8.4.3 REMOVE THE CALIBRATION MASS AND DRIVE..................................................................................126

8.4.4 DETERMINE THE TRUE MASS VALUE OF THE INTERNAL CALIBRATION MASS............................126

8.4.5 PUT THE MASS BACK INTO THE DRIVE ASSEMBLY ..........................................................................127

8.4.6 REATTACH THE LOAD CELL COVER....................................................................................................127

8.4.7 FINAL STEPS............................................................................................................................................127

8.5 MOUNTING POST PRT CALIBRATION..............................................................................................128

8.5.1 REMOVE THE PRTS.................................................................................................................................128

8.5.2 CREATE THE PRT CABLE ADAPTER ....................................................................................................128

8.5.3 DETERMINE THE RO VALUE ..................................................................................................................129

8.5.4 ENTER THE RO VALUE INTO THE FPG TERMINAL..............................................................................129

8.5.5 REATTACH THE PRTS TO THE FPG ......................................................................................................130

8.6 PREPARING FOR STORAGE / SHIPMENT........................................................................................130

8.6.1 FPG8601....................................................................................................................................................130

8.6.2 VLPC..........................................................................................................................................................130

8.6.3 3-DUT MANIFOLD.....................................................................................................................................131

9. DATA FILES ...................................................................133

9.1 OVERVIEW..........................................................................................................................................133

9.2 POINT LOG DATA FILE (*.DAT).........................................................................................................133

9.2.1 NAMING AND STORING DATA FILES ....................................................................................................133

9.2.2 FILE FORMAT ...........................................................................................................................................133

9.3 INTERNAL CALIBRATION LOG FILE................................................................................................133

9.4 SYSTEM ZERO LOG FILE ..................................................................................................................134

9.5 ERROR LOG FILE...............................................................................................................................134

10. TROUBLESHOOTING .......................................................135

10.1 OVERVIEW ..........................................................................................................................................135

11. APPENDIX ......................................................................137

11.1 INTERNAL VALVES............................................................................................................................137

11.2 UNIT CONVERSIONS..........................................................................................................................139

11.3 FPG8601 PRESSURE CALCULATIONS ............................................................................................140

11.3.1 COMPENSATED PRESSURES ................................................................................................................140

11.3.2 DIFFERENTIAL PRESSURES ..................................................................................................................140

11.3.3 CORRECTI ON TE RMS..............................................................................................................................140

11.3.4 THERMAL TRANSPIRATION CORRECTION..........................................................................................141

11.3.5 SAMPLE CALCULATIONS.......................................................................................................................144

11.3.5.1 GAUGE PRESSURE..............................................................................................................................144

11.3.5.2 ABSOLUTE PRESSURE .......................................................................................................................145

11.3.5.3 ABSOLUTE DIFFERENTIAL PRESSURE.............................................................................................146

11.3.5.4 INTERNAL CALIBRATION (KCAL)........................................................................................................147

11.4 DECLARATION OF CONFORMITY..................................................................................................... 147

11.5 GROUNDING / ELECTRICAL SCHEMATICS.....................................................................................147

11.5.1 SYSTEM LEVEL GROUNDING.................................................................................................................148

11.5.2 FPG GROUN D DIAGRAM.........................................................................................................................149

11.5.3 VLPC POWER DIAGRAM.........................................................................................................................150

12. WARRANTY STATEMENT .................................................151

13. GLOSSARY

© 2007 DH Instruments, a Fluke Company Page VI

.....................................................................153

Page 7

TABLES AND FIGURES

T

AABBLLEES

T

Table 1. Nominal VLPC

Table 2. Nominal VLPC Ranges, 15 kPa Unit ........................................................................................... 21

Table 3. Equipment for Basic FPG Hardware Setup ................................................................................ 25

Table 4. Internal Calibration Results Options ............................................................................................40

Table 5. <Run Display> Labels.................................................................................................................. 48

Table 6. <Tare Display> Labels ................................................................................................................. 49

Table 7. <Custom Plot Properties> Tab Fields .......................................................................................... 51

Table 8. <Logged Points> Labels .............................................................................................................. 53

Table 9. <VLPC Interface> Options ........................................................................................................... 55

Table 10. <Diagnostics Display> Options.................................................................................................. 56

Table 11. <DUT Manifold> Color Scheme ................................................................................................. 59

Table 12. <DUT Manifold> Display ............................................................................................................ 60

Table 13. Window Display Toolbar Options............................................................................................... 61

Table 14. Functions Toolbar Option........................................................................................................... 61

Table 15. System Settings ......................................................................................................................... 68

Table 16. <System Setup><Setup> Options .............................................................................................69

Table 17. <System Setup><Options> Options .......................................................................................... 71

Table 18. <Options>, <Data File> Tab Fields............................................................................................ 72

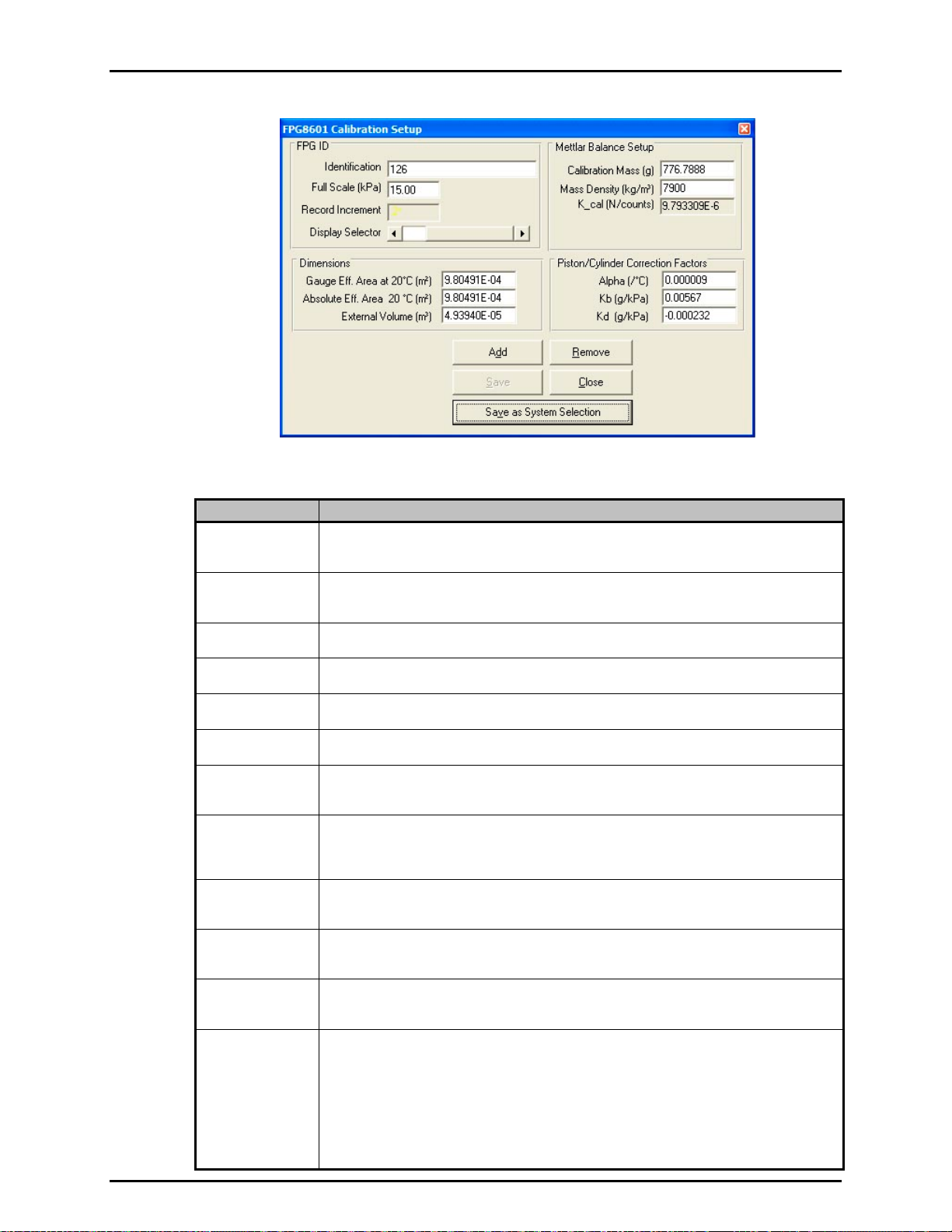

Table 19. <FPG8601 Calibration Setup> Options ..................................................................................... 74

Table 20. <Internal Limits> <Setup> Options ............................................................................................75

Table 21. <Internal Limits> <Pressure> Options .......................................................................................77

Table 22. <Internal Limits> <Temperature> Options ................................................................................. 78

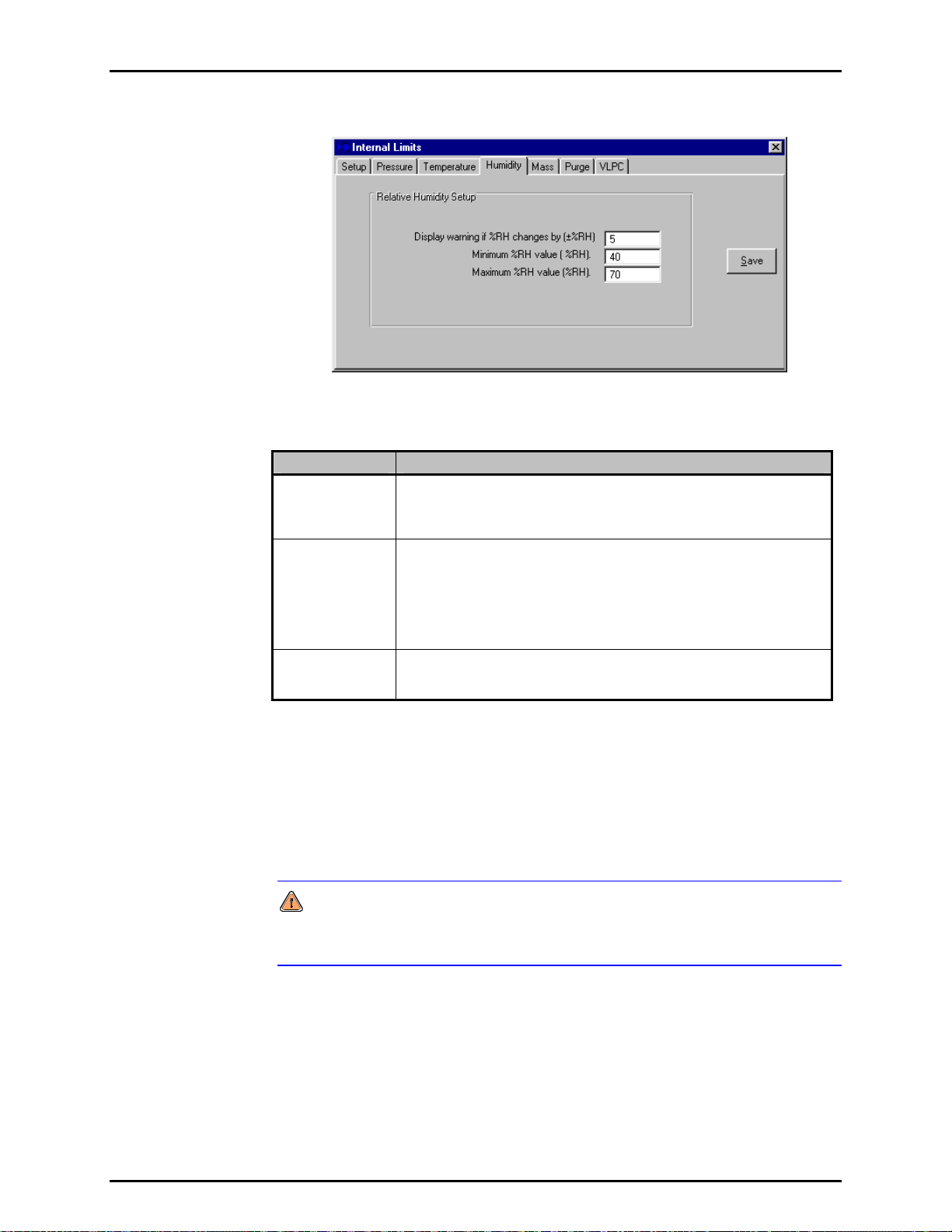

Table 23. <Internal Limits> <Humidity> Options........................................................................................ 79

Table 24. <Internal Limits> <Mass> Options ............................................................................................. 80

Table 25. <Internal Limits> <Purge> Options ............................................................................................ 81

Table 26. <Internal Limits> <VLPC> Options ............................................................................................ 82

Table 27. <DUT Selection & I/O Setup> Options....................................................................................... 83

Table 28. Test Sequence Editor, <Toolbar> Options ................................................................................ 84

Table 29. Test Sequence Editor, <Points> Options................................................................................... 86

Table 30. Test Sequence Editor, <Points> Tab Fields .............................................................................. 87

Table 31. Test Sequence Editor, <Sequence> Tab Fields ........................................................................ 88

Table 32. Test Sequence Editor, <Control> Tab Fields............................................................................. 89

Table 33. Test Sequence Editor, <Cycle> Tab Fields ............................................................................... 90

Table 34. DUT Definition Editor, <Toolbar> Features ............................................................................... 91

Table 35. DUT Definition Editor, [Header] Tab Fields ............................................................................... 93

Table 36. DUT Definition Editor, [Correction] Tab Fields........................................................................... 94

Table 37. DUT Definition Editor, [Range] Tab Fields................................................................................. 95

Table 38. DUT Definition Editor, [Tolerance] Tab Fields ........................................................................... 97

Table 39. DUT Definition Editor, [Read] Tab Fields................................................................................... 98

Table 40. Piston-Cylinder Maintenance Equipment................................................................................. 107

Table 41. Effective Area Calculation Variables........................................................................................ 119

Table 42. Sample Effective Area Spread Sheet ...................................................................................... 120

Table 43. Bubbler Maintenance Equipment............................................................................................. 121

Table 44. Vacuum Reference Zeroing Equipment List ............................................................................ 122

Table 45. Vacuum Reference Zeroing Equipment List ............................................................................ 125

Table 46. Effective Area Calculation Variables........................................................................................ 127

Table 47. PRT Calibration Cable Connections ........................................................................................ 128

Table 48. Effective Area Calculation Variables........................................................................................ 129

S

Ranges ................................................................................................................ 19

Page VII © 2007 DH Instruments, a Fluke Company

Page 8

FPG8601™/VLPC™ OPERATION AND MAINTENANCE MANUAL

Table 49. Troubleshooting Tips ............................................................................................................... 135

Table 50. Internal Valve Descriptions ...................................................................................................... 138

Table 51. Unit Conversion Factors .......................................................................................................... 139

Table 52. FPG Defined Pressure Calculation Variables.......................................................................... 142

Table 53. DHI Authorized Service Providers ...........................................................................................151

F

IIGGUURREES

F

Figure 1. FPG8601 Terminal Front Panel.................................................................................................... 5

Figure 2. FPG8601 Terminal Rear Panel

Figure 3. FPG Platform Front View

Figure 4. FPG Platform Back

Figure 5. VLPC Rear Panel.......................................................................................................................... 9

Figure 6. Piston-cylinder Lubric

Figure 7. Internal Calibrat

Figure 8. FPG Forc

Figure 9. Gauge Mode VLPC Block Diagram

Figure 10. Absolute Mode VLPC Bloc

Figure 11. VLPC Ready Criterion

Figure 12. FPG8601 Syst

Figure 13. FPG8601 Mani

Figure 14. Internal Calibration Res

Figure 15. FPG Tools

Figure 16. <Status

Figure 17. <Run Display>

Figure 18. <Tare Display

Figure 19. <Plot Data>

Figure 20. <Custom Plot Properties>

Figure 21. <Logged Point

Figure 22. <VLPC Interfac

Figure 23. <Select VLPC

Figure 24. <Diagnos

Figure 25. Window Dis

Figure 26. Window Dis

Figure 27. Manual Valve Control Tool

Figure 28. <Settings

Figure 29. <System Setup><

Figure 30. <System Setup><

Figure 31. <System Setup>

Figure 32. <FPG8601 Calibration Setup>

Figure 33. <Internal Limits>

Figure 34. <Internal Limits>

Figure 35. <Internal Limits>

Figure 36. <Internal Limits>

Figure 37. <Internal Limits>

Figure 38. <Internal Limits>

Figure 39. <Internal Limits>

Figure 40. <DUT Selec

Figure 41. Test Sequence Editor, <Tool

Figure 42. Test Sequence Editor, <Test Points> Tabl

Figure 43. Test Sequence Editor, <Points> Tab

Figure 44. Test Definition Editor, <

S

.................................................................................................... 6

.............................................................................................................. 7

View .............................................................................................................. 8

ating Flow ................................................................................................. 12

ion Mass Alignment........................................................................................... 13

es................................................................................................................................. 17

............................................................................................ 20

k Diagram....................................................................................... 20

.............................................................................................................. 22

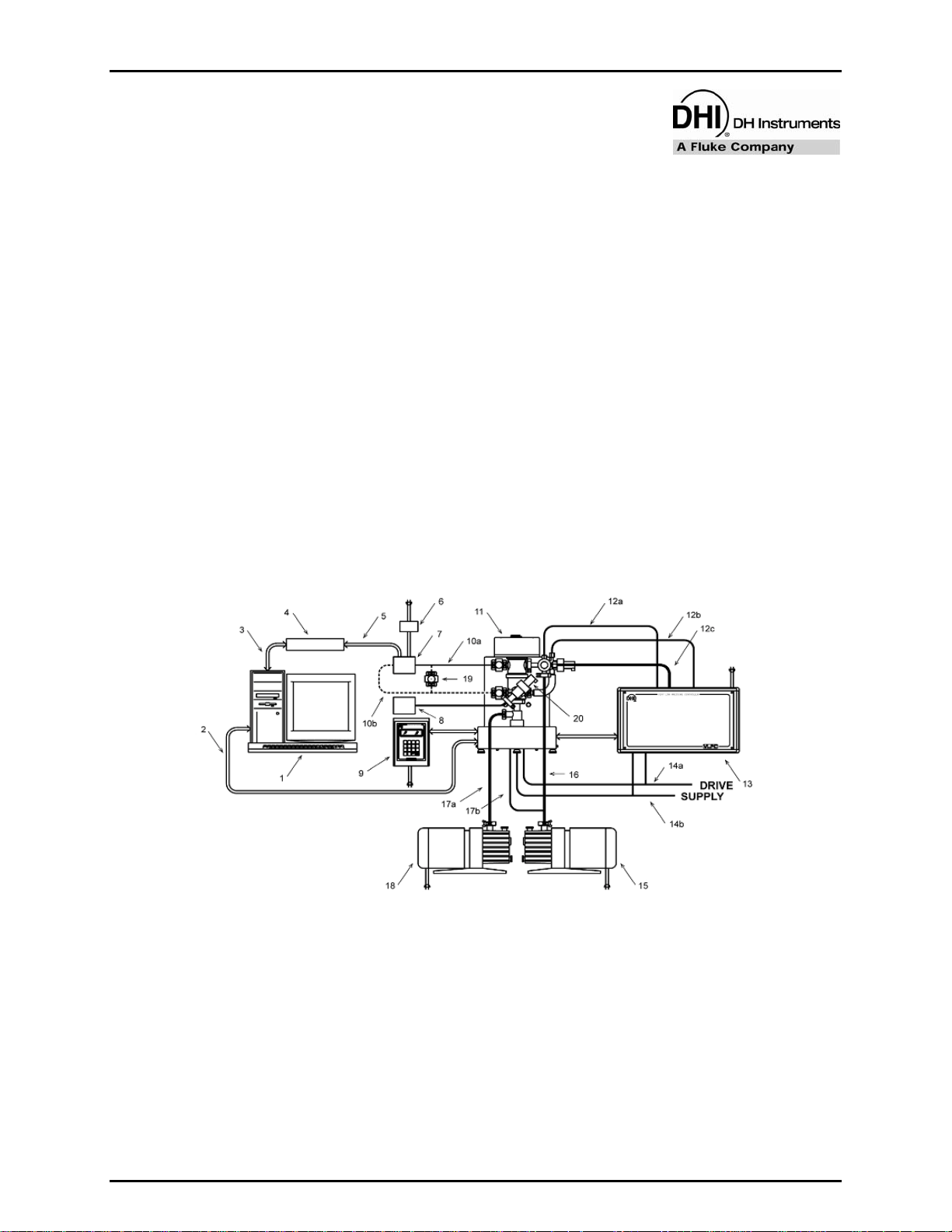

em Schematic.................................................................................................... 23

fold Connection................................................................................................. 27

ults Window......................................................................................... 39

(Factory Mode) ....................................................................................................... 46

Bar> ............................................................................................................................. 47

.......................................................................................................................... 47

>.......................................................................................................................... 49

............................................................................................................................... 50

......................................................................................................... 51

s> Display.......................................................................................................... 52

e> ..................................................................................................................... 55

Range>.............................................................................................................. 55

tics Display> .............................................................................................................. 56

play Toolbar ........................................................................................................... 59

play Toolbar ........................................................................................................... 60

bar .................................................................................................. 65

>................................................................................................................................. 68

Setup> Tab .................................................................................................. 69

Interface> ..................................................................................................... 71

, <Data File> Tab ...........................................................................................72

.................................................................................................. 74

<Setup>......................................................................................................... 75

<Pressure>.................................................................................................... 76

<Temperature> .............................................................................................78

<Humidity> .................................................................................................... 79

<Mass> ......................................................................................................... 80

<Purge> ........................................................................................................ 81

<VLPC>......................................................................................................... 82

tion & I/O Setup>................................................................................................... 83

bar>............................................................................................. 84

e............................................................................. 85

........................................................................................ 87

Control> Tab ....................................................................................... 89

© 2007 DH Instruments, a Fluke Company Page VIII

Page 9

TABLES AND FIGURES

Figure 45. Test Definition Editor, <Cycle> Tab .......................................................................................... 90

Figure 46. DUT Definition Editor, <

Figure 47. <DUT Selec

tion> Tool .............................................................................................................. 93

Figure 48. DUT Definition Editor, [Header Tab

Figure 49. DUT Definition Editor, [Correc

Figure 50. DUT Definition Editor, [Range] Tab

Figure 51. DUT Definition Editor, [Tolerance] Tab

Figure 52. DUT Definition Editor, [Read]

Figure 53. <Insert Speci

al Character> Panel............................................................................................. 99

Figure 54. <Initialization Commands

Figure 55. <Read Com

mands Editor> Panel........................................................................................... 101

Figure 56. <RS232 Settings> Panel

Figure 57. <User Defined Unit Setup>

Figure 58. <Remote Communications

Figure 59. FPG8601 Piston Assembly in

Figure 60. Removing the Mounting Post

Figure 61. Removing the Pis

Figure 62. Alignment of the FPG pis

Figure 63. FPG8601 and PG7000 Cross

Figure 64. FPG8601 Bubbling System

Figure 65. Calibration Mas

s Drive Assembly ........................................................................................... 126

Figure 66. PRT Calibration Cable Adaptor

Figure 67. FPG Internal V

alve Configuration........................................................................................... 137

Toolbar>.............................................................................................. 91

.......................................................................................... 93

tion] Tab .................................................................................... 94

.......................................................................................... 95

..................................................................................... 96

Tab ............................................................................................ 97

Editor> Panel................................................................................. 100

........................................................................................................ 101

..................................................................................................... 102

> ................................................................................................... 105

Mounting Post......................................................................... 108

.................................................................................................. 110

ton............................................................................................................... 110

ton in the cylinder ........................................................................... 113

Float Setup ............................................................................. 117

.................................................................................................... 122

.............................................................................................. 128

Page IX © 2007 DH Instruments, a Fluke Company

Page 10

FPG8601™/VLPC™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page X

Page 11

ABOUT THIS MANUAL

A

BBOOUUTT

A

This manual provides the user with the information necessary to operate the FPG8601 system. It also

includes a great deal of additional information provided to help you optimize system use and take full

advantage of its many features and functions.

Realize that the numbers on the PC software screen captures and the VLPC range information are for

example purposes only. In some cases the information required to setup the FPG is installed with FPG

Tools. In other cases, the values must be entered into the FPG calibration setup (see Section 6.6.3).

Before u

All first time FPG users should read Section 2 for a comprehensive description of general operating

prin

10 to troubleshoot unexpected system behavior b

Certain words and expressions have specific meaning as they pertain to the FPG System. The Glossary

(see Section 13) is useful as a quick reference for exact definition of specific words and expressions as

they are used

sing the manual, take a moment to familiarize yourself with the Table of Contents structure.

ciples. Section 8 provides maintenance and calibration information. Use the inform

FOR THOSE OF YOU WHO “DON’T READ MANUALS”, GO DIRECTLY TO SECTION 4 TO SET UP YOUR

FPG SYSTEM. THEN GO TO SECTIONS 5 and 6. THIS WILL GET YOU RUNNING QUICKLY WITH

MINIMAL RISK OF CAUSING DAMAGE TO YOURSELF OR YOUR FPG. THEN… WHEN YOU HAVE

QUESTIONS OR START TO WONDER ABOUT ALL THE GREAT FEATURES YOU MIGHT BE MISSING, GET

INTO THE MANUAL!

T

T

in this manual.

HHIISS

M

AANNUUAAL

M

L

ased on the symptoms of that behavior.

ation in Section

Manual Conventions

(CAUTION) is used in throughout the manual to identify user warnings and cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and additional

explanations.

[ ] indicates direct function keys or menu options (e.g., [Run]).

< > indicates FPG Tools screen displays (e.g., <FPG Pressure>).

Page XI © 2007 DH Instruments, a Fluke Company

Page 12

FPG8601™/VLPC™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page XII

Page 13

1. INTRODUCTION

.

11.

I

NNTTRROODDUUCCTTIIOON

I

N

1.1 OVERVIEW

The FPG8601 (Force-Balanced Piston Gauge), VLPC (Very Low Pressure Controller) and FPG Tools

(PC Based Software) are used in conjunction to act as a high precision pressure measurement and data

acquisition system. Operator interaction with the FPG/VLPC and its extensive capabilities is accomplished

through the PC based software from a computer via a standard RS232 port. FPG Tools also provides

features to define a test sequence, read DUT’s with a standard RS232 or IEEE-488 output, and log data

to a data file.

FPG pressure is defined by using a high precision load cell to measure the force exerted on the effective

area of a piston-cylinder (see Section 2). Instead of rotating the piston like othe

provides sensitivity between the piston and cylinder by maintaining a constant flow through the annular

gap. This flow generates a centering force that prevents the piston from touching the cylinder during

normal operation. Noise normally associated with rotation is therefore not present.

FPG platforms are designed to maximize metrological performance and ease of operation in both gauge

and absolute modes. Many features are included to enhance the fundamental precision and stability of

pressure measurements as well as simplifying use and reducing the operator influence on the

measurements.

r piston gauges, the FPG

The VLPC generates low pressure in gauge and absolute modes (0 to 15 kPa). It is used to set and

stabilize pressure as read by the FPG so that the VLPC/FPG combination can be used to set user

specified target pressure values. The general operating principle of the VLPC is to generate a stable flow

through one of a number of restrictions depending on the range of pressure to be controlled (see Section

3.4). The pressure drop across the restriction is the controlled

FPG is used to dynamically readjust the flow to obtain the desired target pressure.

FPG Tools is the complete interface to both the FPG and the VLPC. An interface to all functional aspects

of both instruments is provided by the software. FPG Tools uses three basic modes of operation to

remotely interact with the FPG and VLPC: [Run Mode], [Run w/Point Logging], and [Run Test Sequence]

(see Section 6.5). These modes respectively allow simple monitoring of pressure, monitoring of pressure

with user dep

A DUT can be used in any run mode for real-time error determination and/or data acquisition.

endant steps and data acquisition, and monitoring with defined test steps and data acquisition.

differential pressure. Feedback from the

Page 1 © 2007 DH Instruments, a Fluke Company

Page 14

FPG8601™/VLPC™ OPERATION AND MAINTENANCE MANUAL

1.2 REQUIREMENTS

FPG Tools is a PC based application designed for 32 bit versions of Windows. The PC requirements

stated below are necessary to maintain the minimum acceptable performance between the software and

related hardware components.

• Windows XP, 98, NT service pack 4 or greater

• 500 MHz Pentium Processor or compatible

• 32 Mb of Ram

• 12 Mb free hard drive space

1.3 SPECIFICATIONS

1.3.1 GENERAL SPECIFICATIONS

1.3.1.1 FPG8601 GENERAL SPECIFICATIONS

Power Requirements: 85 to 264 VAC, 50 to 60 Hz, 60 VA consumption

Operating Temperature:

Weight: Instrument platform

FPG Platform 31.2 kg (61 lb)

FPG Terminal 1.4 kg (3 lb)

Dimensions:

FPG Platform 53.4 cm H x 35.8 cm W x 35.5 cm D

FPG Terminal 12 cm H x 15 cm W x 20 cm D

Microprocessors:

Instrument Platform Motorola 68302

FPG Terminal Hitachi 64180

Communication Ports:

RS232

IEEE-488.2 Not used

Maximum Pressure Ranges: 0 – 15 kPa Gauge and Absolute

Operating Media: Gas: air or Nitrogen (N

Pressure Supplies: Lubrication port: 700 - 850 kPa (100 - 120 psi), supply

Drive In Supply: 600 to 1000 kPa (90 to 150 psi) air

Maximum Overpressure Limit: +20 kPa to –10 kPa (+3 to – 1.5 psi)

Pressure Connections:

Lubrication Supply Port

Upper Test Port

Lower Test Port

Drive In Port

Vacuum Port

CE Conformance: Not available

Driver Port (Ext Valve): Not used

15 to 35 °C

(21 in. H x 14.1 in. W x 14 in. D)

(4.7 in. H x 5.9 in. W x 7.9 in. D)

COM1: Host computer

COM2: VLPC

COM3: Not Used

)

2

must remain constant ± 1 % to meet control specifications

1/8 in. NPT

KF16

KF16

1/8 in. NPT

1/8 in. NPT

© 2007 DH Instruments, a Fluke Company Page 2

Page 15

1. INTRODUCTION

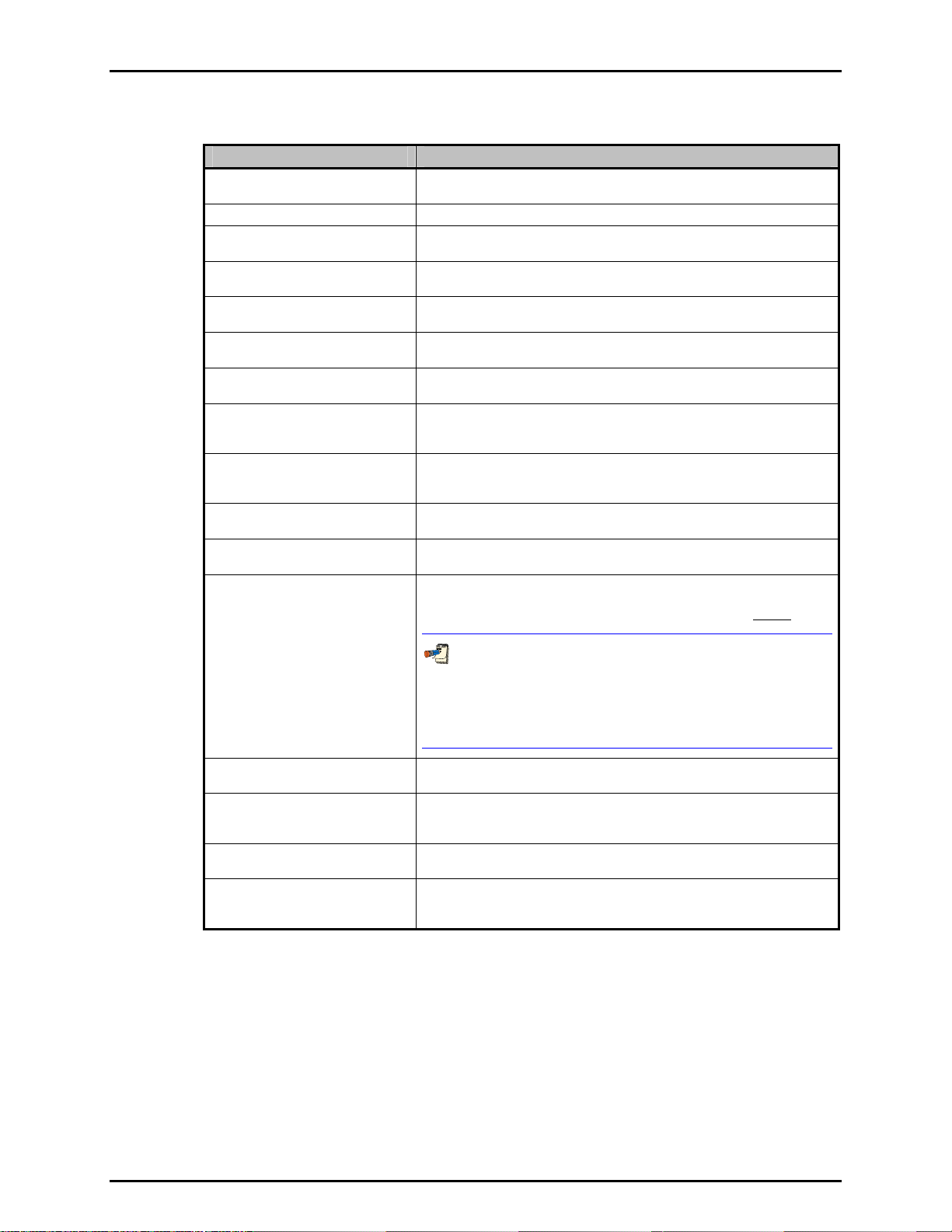

1.3.1.2 AMBIENT AND INSTRUMENT CONDITION MEASUREMENTS

Temperature:

Range

Resolution

Accuracy

Relative Humidity:

Range

Resolution

Accuracy

Vacuum:

Range

Resolution

Accuracy

Ambient and Lubrication

Pressure Sensor:

Range

Resolution

Accuracy

Lubrication Pressure

[°C] [°C]

0 to 40 0 to 40

0.1 0.01

± 0.2 ± 0.1

5 to 95 %RH

1 %RH

± 10 %RH

13 Pa

1 mPa

± 20 mPa

200 kPa

1 Pa

± 0.1 kPa

1.3.1.3 PISTON-CYLINDER

Cylinder Material: Tungsten carbide

Piston Material: Tungsten carbide

Nominal Diameter: 35 mm

Nominal Area:

Mounting System: Non-rotative piston

980.5164 mm

Piston-Cylinder

2

1.3.1.4 PRESSURE MEASUREMENT

Resolution1: 10 mPa

Precision Reproducability

Uncertainty

Standard Measurement:

1. Resolution: The smallest variation in input detectable in output.

2. Reproducibility: Combined reproducibility of force measurement and long term stability of

piston-cylinder effective area.

3. Standard Measurement Uncertainty: All sources of uncertainty under typical operating

conditions are identified, quantified and combined following ISO/TAG4/WG3. The result is then

rounded upwards to provide conservative global figures for the typical user in typical conditions

of the maximum deviation from the true value of the pressure determined by the FPG8601 and

the pressure actually present at the test point.

2

:

± 20 mPa

3

:

Absolute: ± (25 mPa + 0.003 % of reading)

Gauge and absolute differential: ± (20 mPa + 0.003 %

of reading)

Page 3 © 2007 DH Instruments, a Fluke Company

Page 16

FPG8601™/VLPC™ OPERATION AND MAINTENANCE MANUAL

1.3.2 VLPC GENERAL SPECIFICATIONS

Power Requirements: 85 to 264 VAC, 47 to 60 Hz, 70 VA max. consumption

Operating Temperature Range: 15 to 35 °C

Storage Temperature Range: - 20 to 70 °C

Weight: 41.6 kg (91.5 lb)

Dimensions: 30.5 cm H x 53.4 cm W x 50.5 cm D

Microprocessor: Motorola 68302, 16 MHz

Communication Ports:

RS232

IEEE-488.2

Control Specifications:

Operating Medium: Gas: air or Nitrogen (N

Pressure Supplies: SUPPLY port: 700 - 850 kPa (100 - 120 psi), supply must remain

Drive Air Supply: 600 to 1000 kPa (90 to 150 psi) air

Pressure Connections: Test (Lo) 1/4 VCO

(12 in. H x 21 in. W x 19.9 in. D)

COM1: FPG

COM2:: Not Used

Not used

± 0.02 Pa + 30 ppm of range selected

constant ± 1 % to meet control specifications

Test (Hi) 1/4 VCO

ATM 1/4 VCO

Vacuum 3/8 VCO

Supply 1/8 NPT F

Drive 1/8 NPT F

)

2

© 2007 DH Instruments, a Fluke Company Page 4

Page 17

1. INTRODUCTION

1.4 FPG PLATFORM FRONT AND REAR PANELS AND VLPC FRONT AND REAR PANELS

1.4.1 TERMINAL FRONT AND REAR PANELS

1.4.1.1 FPG TERMINAL FRONT PANEL

The front panel assembly provides a 2 x 20 vacuum fluorescent display and a 4 x 4

membrane keypad for local user interface.

1. Display

2. Multi-Function Keypad

Figure 1. FPG8601 Terminal Front Panel

Page 5 © 2007 DH Instruments, a Fluke Company

Page 18

FPG8601™/VLPC™ OPERATION AND MAINTENANCE MANUAL

1.4.1.2 FPG TERMINAL REAR PANEL

The rear panel assembly provides the communications connection to the FPG

platform and the power connection module.

1. Power Switch

2. Fuse

3. Power Receptacle

4. Connector for Cable to

FPG (25 pin

5. Cooling Fan

Figure 2. FPG8601 Terminal Rear Panel

© 2007 DH Instruments, a Fluke Company Page 6

Page 19

1. INTRODUCTION

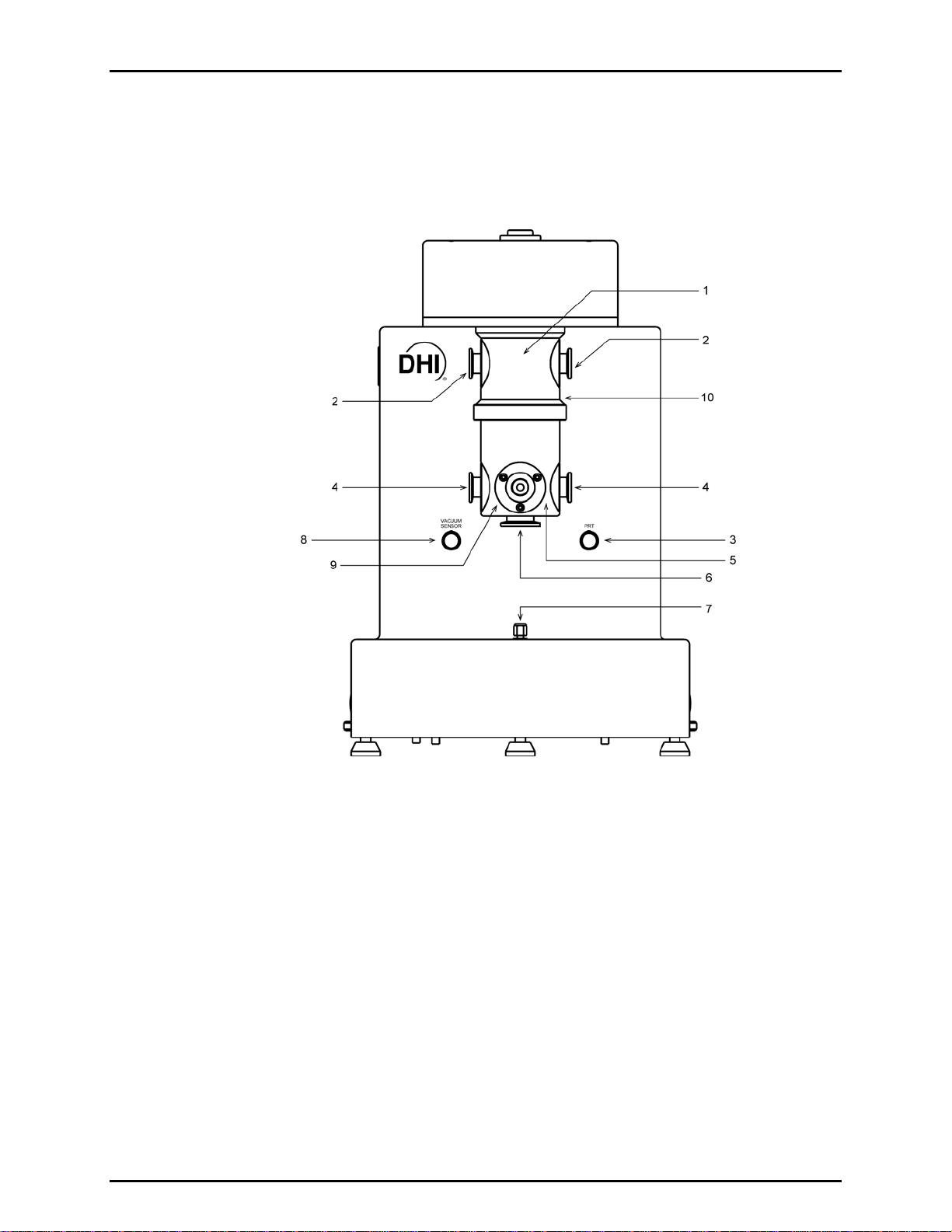

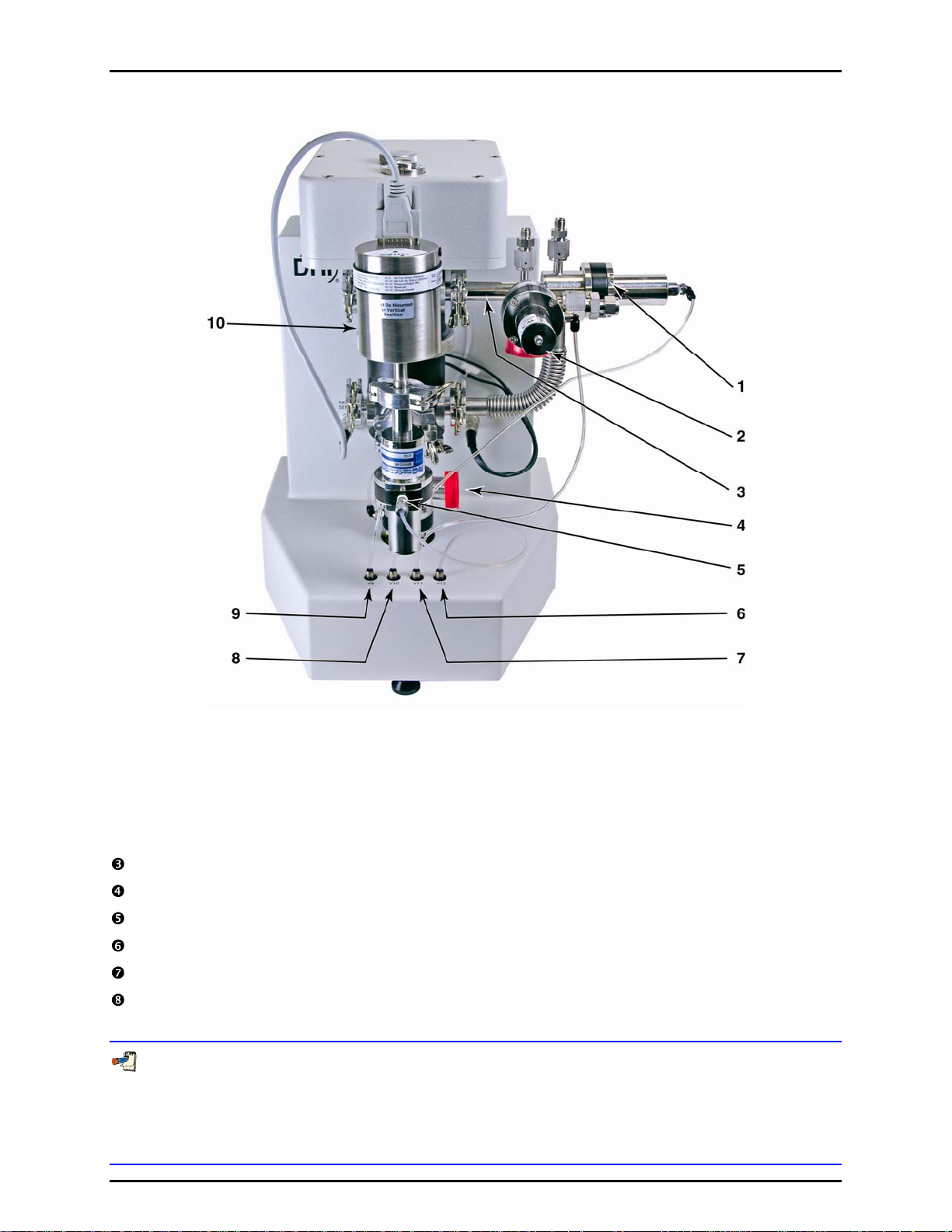

1.4.2 FPG PLATFORM FRONT VIEW

The front of the FPG provides the connections to the VLPC, DUT and vacuum sensor. It also

provides the electrical connection to the mounting post PRTs and vacuum sensor reading.

1. Upper Mounting Post

2. TEST+ (KF-16)

3. Mounting Post PRT Connector

4. TEST- (KF-16)

5. Lower Mounting Post

Figure 3. FPG Platform Front View

Page 7 © 2007 DH Instruments, a Fluke Company

6. Vacuum Reference Port (KF-25)

7. Mounting Post Reference

8. Vacuum Sensor Connector

9. Vacuum Sensor Port

10. Reference Level

Page 20

FPG8601™/VLPC™ OPERATION AND MAINTENANCE MANUAL

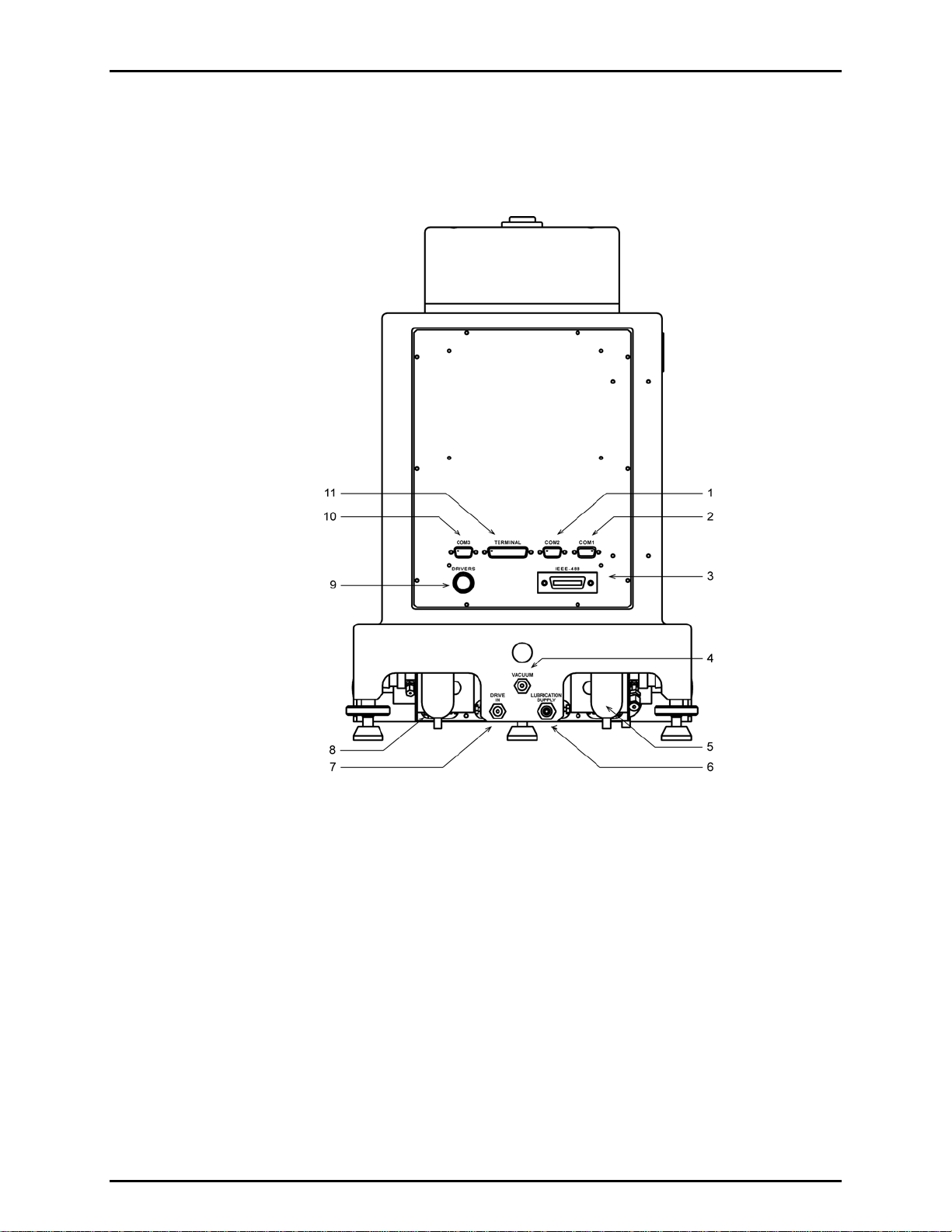

1.4.3 FPG PLATFORM BACK VIEW

The FPG platform rear panels provide the connection to the FPG Terminal, remote

communication connections and supply pressure connection ports.

1. COM2 (RS232) – VLPC

2. COM1 (RS232) – Remote Host

Communication

3. IEEE-488 – Not Used

4. Absolute Mode – Lubrication

Pressure Vacuum

5. Bubbler

Figure 4. FPG Platform Back View

© 2007 DH Instruments, a Fluke Company Page 8

6. Lubrication Supply

7. Drive In

8. Coalescing Filter

9. Drivers Option Connector Not Used

10. COM3 (RS232) – Not Used

11. FPG Terminal Port

Page 21

1. INTRODUCTION

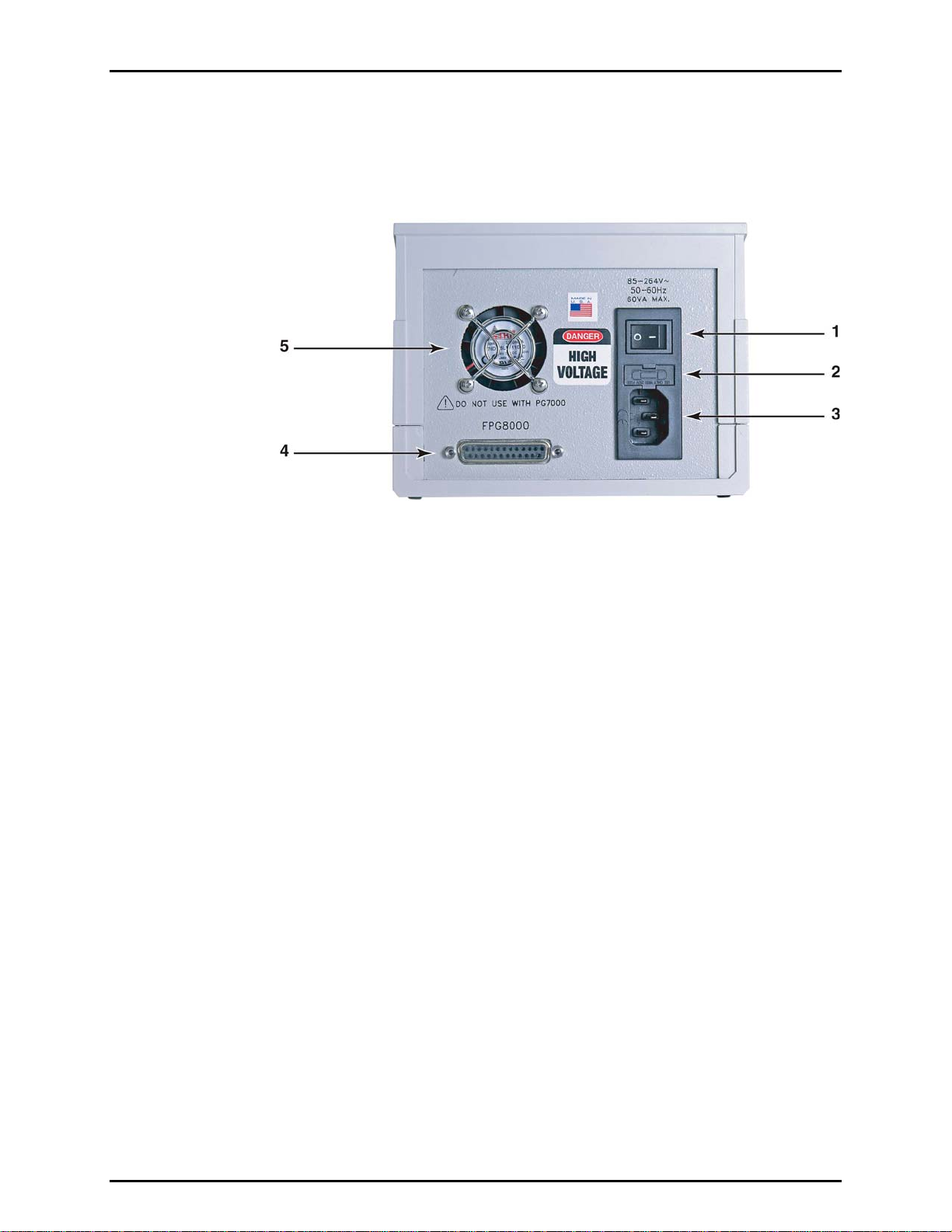

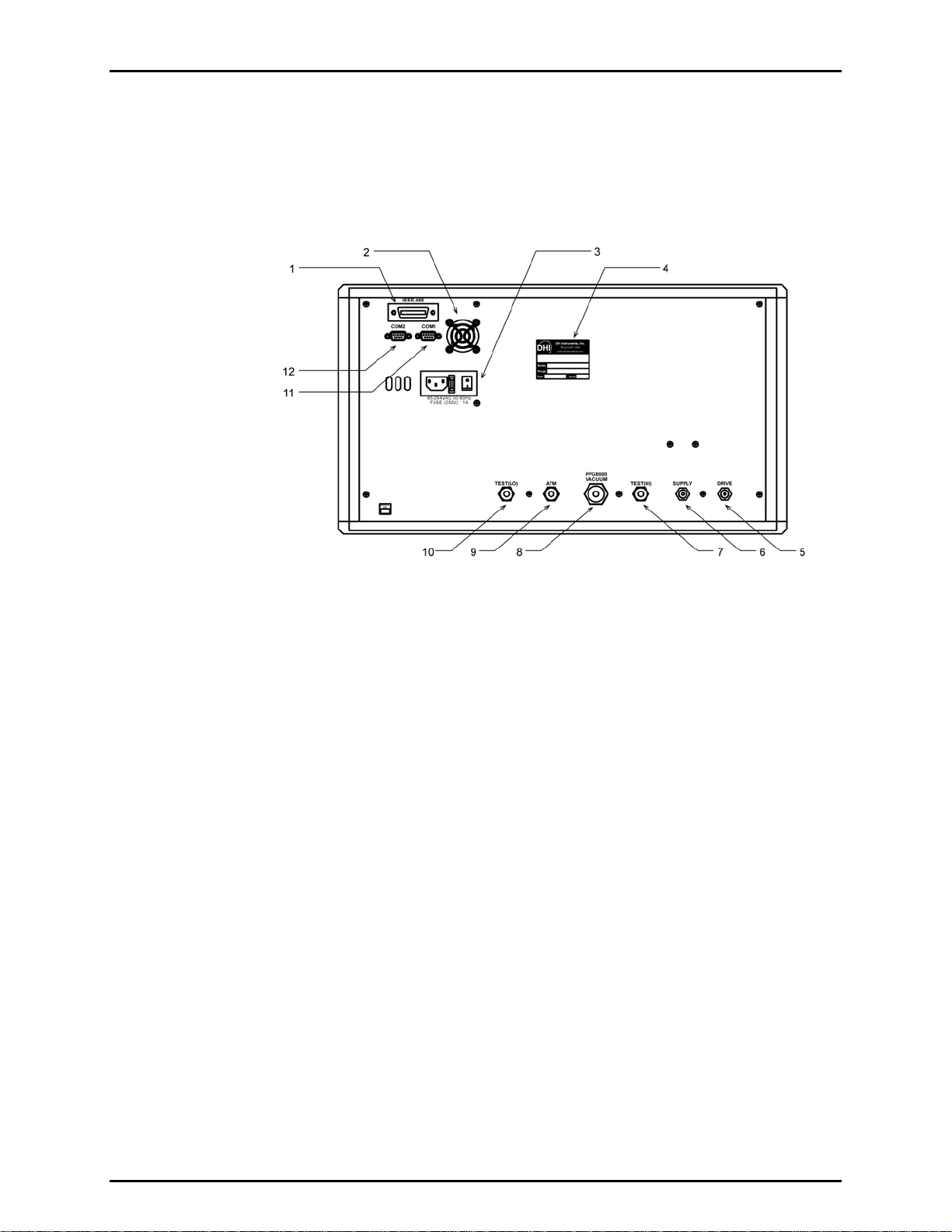

1.4.3.1 VLPC REAR PANEL ASSEM BLY

The rear panel assembly provides pressure connections, communications

interfaces, the power ON/OFF module and product labeling. Pressure fittings are

internally secured to prevent loosening when making and breaking connections.

1. IEEE-488 Connector – Not Available

2. Fan

3. Power Switch

4. Label, Product

5. Pressure Connection – Drive

6. Pressure Connection – Supply

Figure 5. VLPC Rear Panel

7. Pressure Connection – Test (Hi)

8. Pressure Connection – FPG

Vacuum

9. Pass Through – ATM Ref

10. Pressure Connection – Test (Lo)

11. COM1 (RS232) – To FPG

12. COM2 (RS232) – Not Used

Page 9 © 2007 DH Instruments, a Fluke Company

Page 22

FPG8601™/VLPC™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page 10

Page 23

2. FPG THEORY OF OPERATION

.

22.

G

FFPPG

T

HHEEOORRYY OOFF

T

O

PPEERRAATTIIOON

O

N

2.1 OVERVIEW

The FPG measures low gauge and absolute pressure by using a load cell to measure the force on the

effective area of a 35 mm piston. A measurement mode specific lubricating pressure is applied to the

annular gap of the piston-cylinder to provide a centering force on the piston. Compensation for the

effects of the lubrication pressure on the load cell and piston are determined during the

manufacturing process. The output of the load cell combined with the force components associated with

the lubrication pressure determines the total force on the piston. This force divided by the temperature

corrected effective area of the piston determines the differential pressure of the FPG.

In gauge mode, the FPG differential pressure is equivalent to the gauge pressure of the system since the

lower port of the FPG is exposed to atmosphere. In absolute mode, the lower port of the FPG is

connected to vacuum. Because of the lubricating flow, a perfect vacuum can never be achieved;

therefore a high precision low range vacuum reference sensor is used to measure the residual

vacuum pressure. This pressure is applied to the FPG differential pressure to obtain the final system

absolute pressure. Absolute differential operation of the FPG is the same as absolute mode operation

without the use of the vacuum reference sensor.

To support automatic zeroing and calibration of the FPG the mounting post assembly contains several

pneumatic valves that are automatically controlled by FPG Tools. Many internal sensors are also present

to verify that the FPG is operating in the required conditions and to make pressure buoyancy corrections.

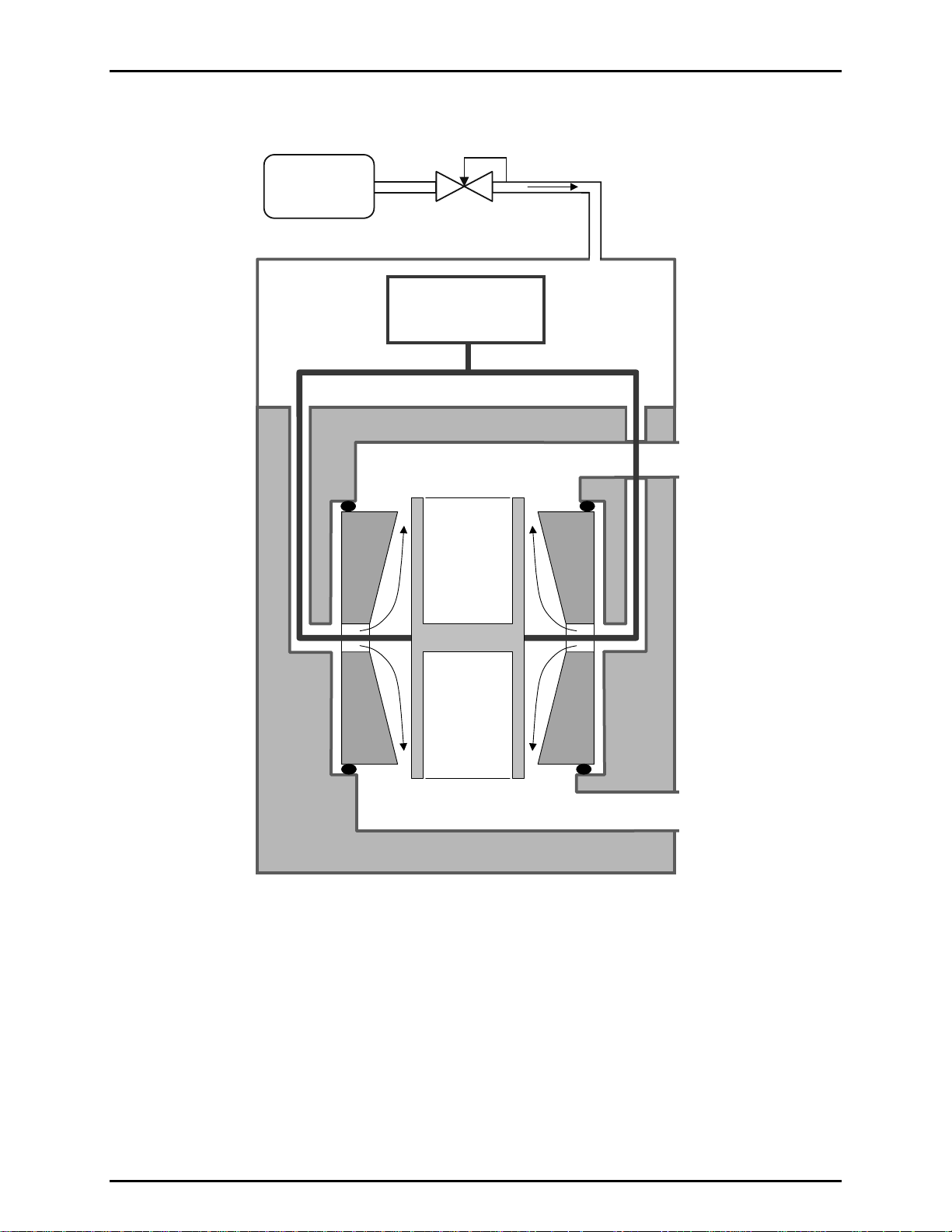

2.2 PISTON-CYLINDER

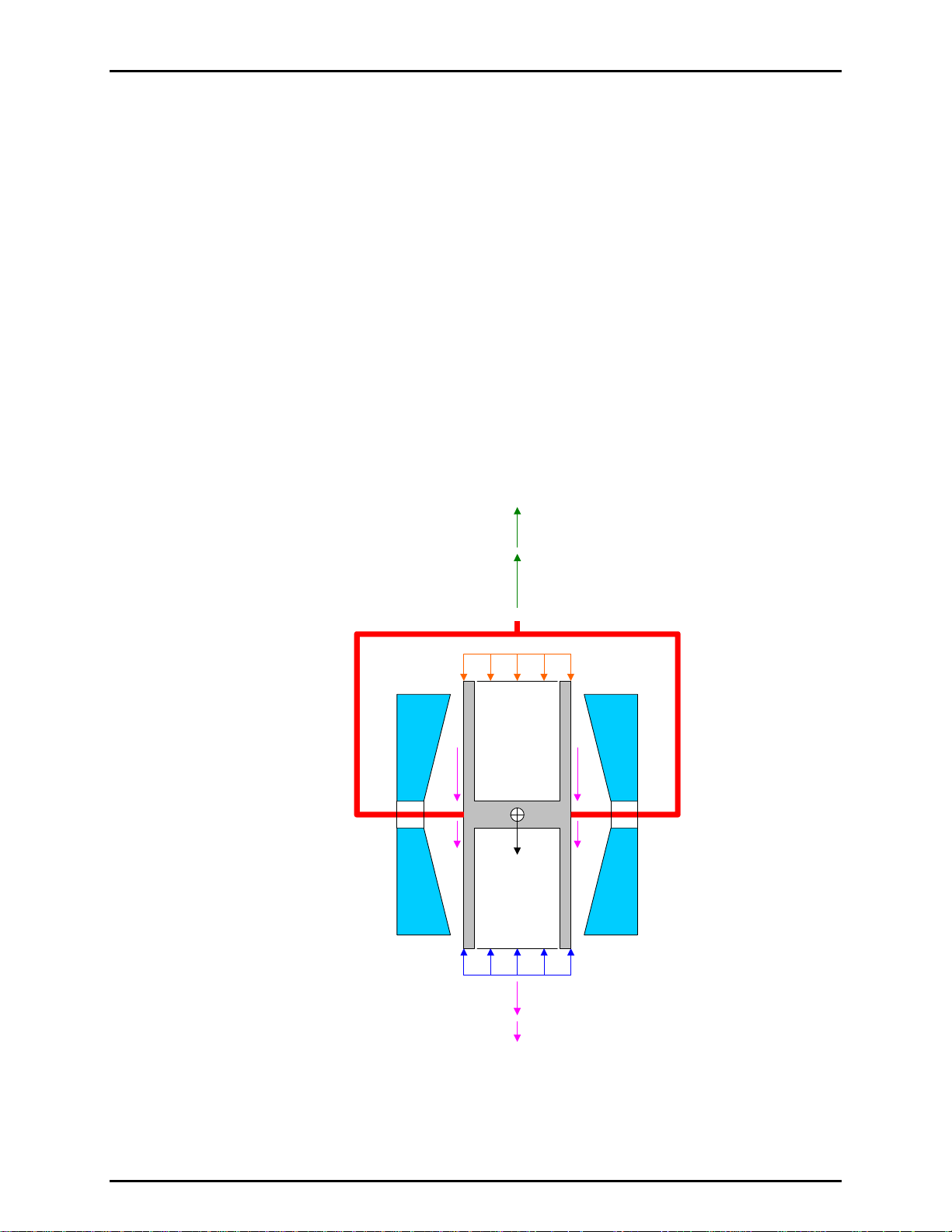

The FPG uses a 35 mm diameter, tungsten carbide piston-cylinder designed with a pressure to mass

conversion coefficient of 10 kPa/kg. The cylinder has a conical shape on its interior surface to generate a

centering force on the piston when a lubrication pressure is applied in the annular gap through the center

of the cylinder (see Figure 6). The non-rotating piston is conne

freedom mechanical assembly located at its center of gravity. This allows the piston to center itself in the

cylinder under the influence of the lubricating pressure. As a result, the piston is perfectly mobile, making

no contact with the cylinder.

cted to the load cell by a multi degree of

Page 11 © 2007 DH Instruments, a Fluke Company

Page 24

FPG8601™/VLPC™ OPERATION AND MAINTENANCE MANUAL

LUBRICATING

SUPPLY

REG

FLOW

MASS

COMPARATOR

P

hi

P

lub

P

ref

Figure 6. Piston-cylinder Lubricating Flow

The piston-cylinder resides in the mounting post that provides upper and lower measurement chambers

equipped with high pressure (P

) and low pressure (P

hi

) connections at the two extremities of the

ref

piston-cylinder. The high pressure port is the measurement port of the FPG. The low pressure port is

considered the reference port of the system. When the port is exposed to atmosphere, the FPG will read

gauge pressure. If the port is exposed to vacuum, the FPG will measure absolute differential pressure.

The measured value of the low pressure port must be applied to the FPG differential pressure to get an

absolute pressure.

© 2007 DH Instruments, a Fluke Company Page 12

Page 25

2. FPG THEORY OF OPERATION

2.3 LOAD CELL

The load cell has a measurement capacity equivalent to 2 300 g with a resolution of 1 mg. A force

equivalent to 1 500 g is used for the measuring range. The rest of the measurement capacity is used to

compensate for the mass of the piston and its carriage assembly.

During the manufacturing process, the load cell is calibrated and linearized within the required specifications.

Load cell accuracy is maintained by the ability to frequently zero null force error, and by making slope

corrections using an internal calibration mass. The FPG is specifically designed to allow the internal

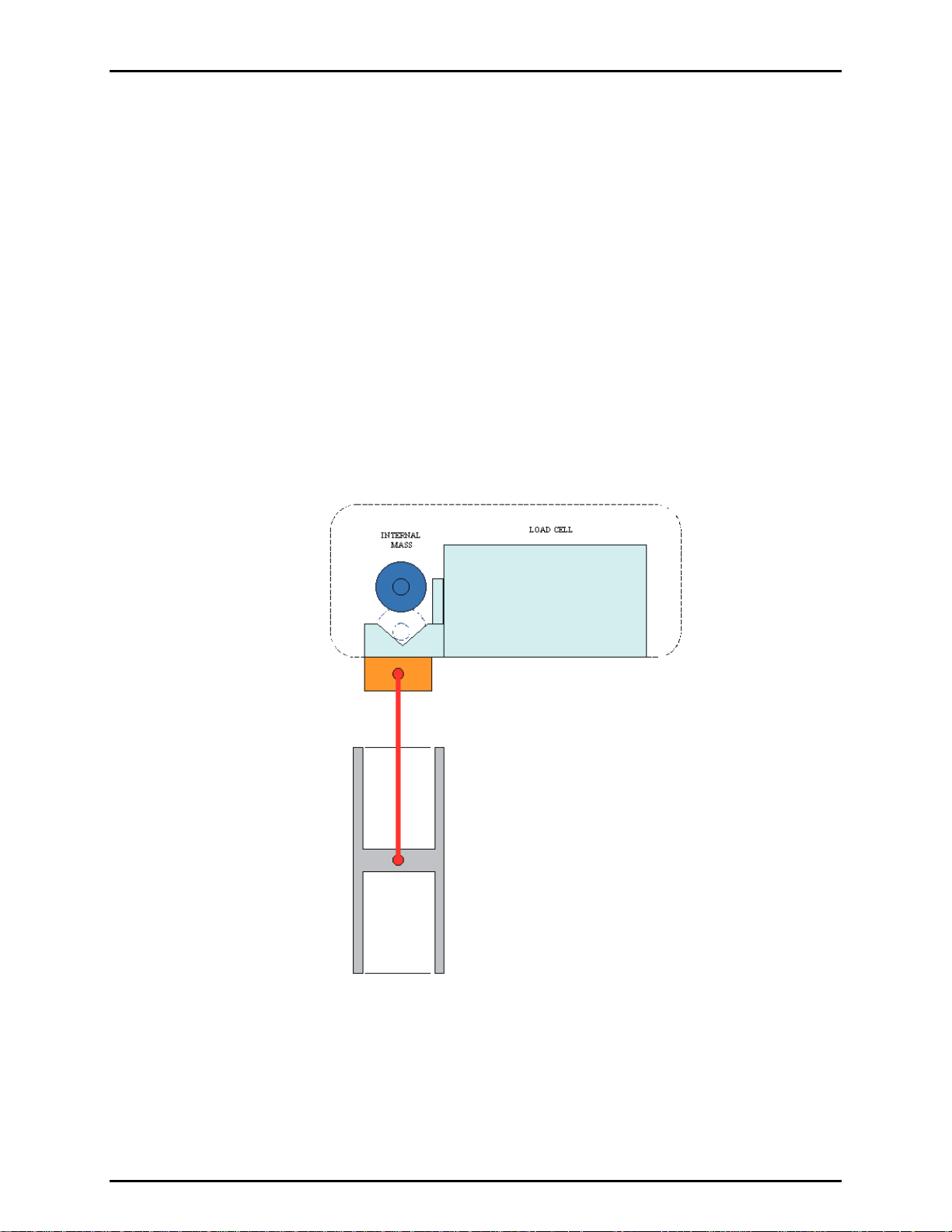

calibration mass to be measured in perfect alignment with the piston and cylinder (see Figure 7).

The ma

true mass value. When the mass is lowered in the operating conditions of the FPG, a correction factor is

determined to cause the buoyancy corrected output of the load cell to be equivalent to this true mass

value. Sensors internal to the FPG measure pressure, temperature and humidity around the load cell to

make the buoyancy correction. Since zeroing and running the internal calibration are integral parts of the

FPG, pneumatic valves are included with the FPG to allow the system to automatically set the necessary

conditions to perform each task.

ss value of the internal calibration mass is accurately determined and stored in FPG Tools as a

Figure 7. Internal Calibration Mass Alignment

The FPG configuration subjects the load cell to the lubricating pressure which significantly differs from

typical atmospheric conditions. The optimum environmental conditions of the balance are specified by

the manufacturer as temperature between 10 and 30 °C with relative humidity of 40 to 70 %. Typical

laboratory conditions yield the necessary temperature range. The humidity is, however, controlled to

approximately 50 % by a bubbling system internal to the FPG. FPG Tools will display a warning message

if these conditions change beyond these limits. Low humidity values cause electrostatic effects on the

load cell which have adverse influence on the zero stability of the load cell.

Page 13 © 2007 DH Instruments, a Fluke Company

Page 26

FPG8601™/VLPC™ OPERATION AND MAINTENANCE MANUAL

2.4 LUBRICATION PRESSURE

Two different values of lubricating pressure are used depending on whether the FPG is working in gauge

or absolute measurement modes. These two pressures are supplied by two independent regulators

which can be connected by valves depending on the measurement mode. In gauge measurement mode,

the nominal lubricating pressure value is 140 kPa absolute which is about 40 kPa gauge. In absolute

measurement mode, the nominal lubricating pressure is 40 kPa absolute. The absolute mode lubricating

pressure reduces the lubricating flow which allows the reference vacuum or back pressure to be less than

a Pascal with most standard vacuum pumps. Higher power vacuum pumps can be used to greatly

reduce this pressure.

The lubrication pressure affects buoyancy forces on the load cell and the piston-cylinder as well as

creating a change in the dragging force on the piston-cylinder. The buoyancy effect is characterized

during the manufacturing process by varying the lubrication pressure and recording the change in load

cell output relative to the change in lubrication pressure. The drag effect is determined by maintaining a

constant lubrication pressure and changing the reference (see Section 2.7). Each time the FPG is

zeroed, the

the lubrication pressure and reference pressure since the last zero. A high quality pressure regulator built

into the FPG prevents this pressure from changing significantly when proper system pressure is applied.

As a result, the influence of the lubrication pressure on the FPG is maintained at a minimum.

The FPG is intended to be used in ambient conditions which means that the gas present in the upper and lower

measurement chambers is ambient air. It is therefore desirable to use air as the lubricating medium.

This avoids gas mixtures in the measurement chamber. However, FPG Tools supports N

Prior to changing gases, the system must be thoroughly purged. This includes the lubricating volume and

the test and reference ports of the FPG. Lack of knowledge of the constitution of the test gas complicates

the calculation of density needed to make fluid head corrections.

se effects are also set to zero. Therefore, changes in these forces are only due to changes in

as a lubrication gas.

2

2.5 VACUUM REFERENCE PRESSURE

The FPG8601 inherently measures differential pressure. When the lower mounting post is exposed to

atmosphere, the FPG measures gauge pressure. If the lower mounting post is exposed to a vacuum, the

FPG measures absolute differential pressure. To measure absolute pressure, the residual vacuum

pressure in the lower mounting post must be added to the FPG differential pressure. As a result, a high

accuracy low range sensor is included with the FPG to define absolute pressure.

Depending on the vacuum pumps used, the residual vacuum pressure will be less than 1 Pa. At this

pressure, span error in the vacuum sensor does not significantly impact the overall uncertainty of

the FPG. A 0.5 % span error at 1 Pa results in a .005 Pa error. However, zero offset in the sensor is

directly transferred to the zero offset of the FPG. Therefore, the zero of the sensor should be checked

frequently (see Section 8.3). A pneumatic valve is provided to isolate the vacuum reference sensor when

the FPG is n

change from vacuum to atmosphere. FPG Tools automatically isolates the sensor depending on the

current mode of operation.

ot under vacuum. This helps to reduce zero drift by avoiding the shock associated with a

© 2007 DH Instruments, a Fluke Company Page 14

Page 27

2. FPG THEORY OF OPERATION

2.6 SIMPLIFIED FORMULA FOR CALCULATING DIFFERENTIAL PRESSURE

The calculation of differential pressure is made following the basic formula:

ΔP = F/A

eff.

(θ)

VARIABLE DEFINITION

ΔP

F Force measured by the load cell in counts (1 count = 1 mg).

A

(θ)

eff.

Differential pressure between the upper and lower chambers in Pa.

Effective area of the piston-cylinder at the operating temperature, θ.

The value is expressed in m

2

.

The force, F, measured by the load cell when it displays a number of counts, N, can be calculated using a

calibration coefficient, K

, following:

cal

F = K

cal.

. N

VARIABLE DEFINITION

K

Calibration coefficient of the load cell. This value contains any

cal.

N Number of counts output by the load cell representing the force

necessary slope correction for the load cell determined by the

internal calibration (see Section 5.3). The air density and local

gravit

y present at the time the calibration was performed are also

quantified by this value. The calibration factor is expressed in

Newtons/ Count (1 count = 1 mg).

measured. One count represents the force corresponding to a

mass of 1 mg loaded on the load cell under the calibration

conditions.

The effective area of the piston-cylinder at temperature θ, can be expressed using its value at 20 °C and

the linear thermal expansivity of the piston and the cylinder materials following:

A

(θ) = A

eff.

(20°C) . [ 1+ ( αp + αc ) . ( θ - 20 ) ]

eff.

VARIABLE DEFINITION

αp

αc

Linear thermal expansivity of the piston in K

Linear thermal expansivity of the cylinder in K

-1

.

-1

.

The piston and the cylinder are made of tungsten carbide therefore the thermal expansion coefficients are

the same; α

+ αc = 9 . 10-6 K-1. FPG Tools provides a single entry value for this combined effect in the

p

FPG calibration setup (see Section 6.6.3).

The sim

plified formula for the calculation of the differential pressure can therefore be expressed as:

ΔP = K

cal.

. N / A

(20°C) . [ 1+ ( αp + αc ) . ( θ - 20 ) ]

eff.

Page 15 © 2007 DH Instruments, a Fluke Company

Page 28

FPG8601™/VLPC™ OPERATION AND MAINTENANCE MANUAL

In gauge measurement mode, the differential pressure is defined as being the difference between the

pressure in the upper chamber at the reference level of the mounting post and the pressure at the

corresponding level in the ambient air.

In absolute measurement mode, the differential pressure is defined as being the difference between the

pressure in the upper chamber at the reference level of the mounting post and the reference vacuum in

the lower chamber measured by the capacitance diaphragm gauge.

The reference pressure is defined as the pressure surrounding the piston when the load cell is in a zero

condition with the upper and lower chambers in by-pass condition. Therefore, the reference pressure is

atmospheric pressure in gauge mode and vacuum in absolute mode.

2.6.1 REFERENCE LEVEL

The reference level of the mounting post is defined as the height at which a variation of

density in the upper chamber will not affect the differential pressure measurement.

This position depends on the internal geometry of the piston in the upper chamber, in this

case, the piston is hollow. The position of the reference level of the FPG is 25 mm above the

center of the piston. This is approximately the bottom of the upper mounting post (see Figure 3).

2.7 CORRECTIONS

The simplified formula of differential pressure is valid only in the special case where the conditions of the

gas surrounding the load cell and the piston do not change from the time the mobile assembly (made up

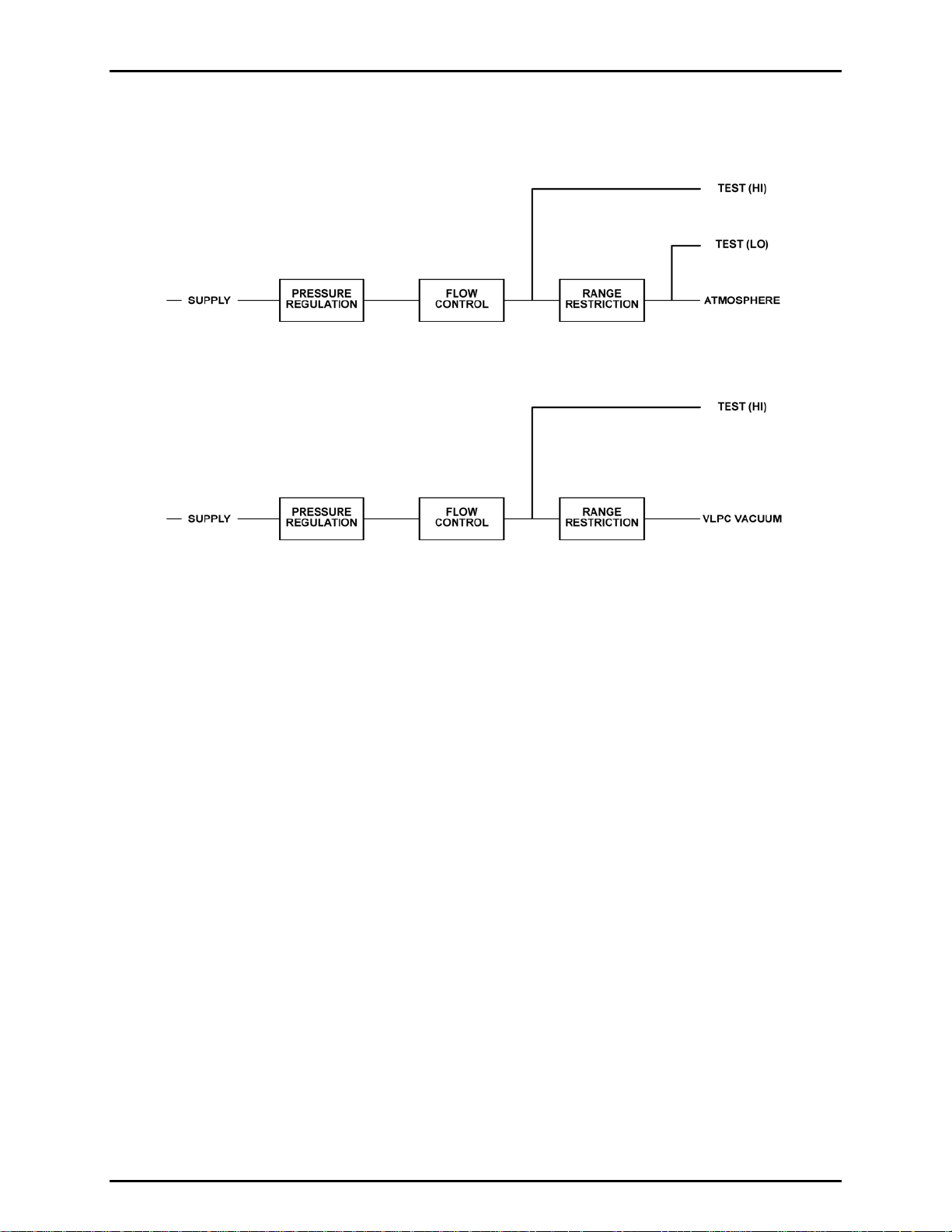

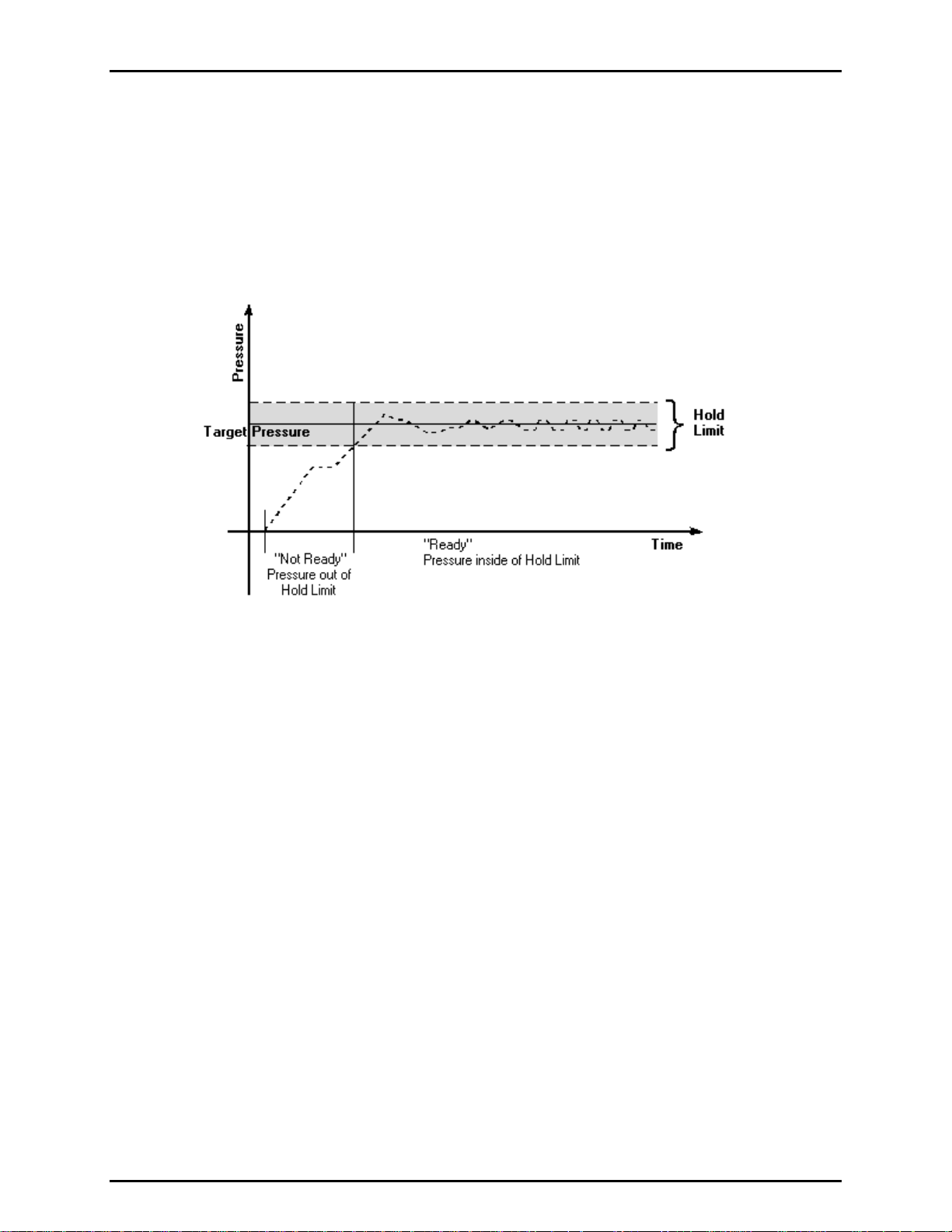

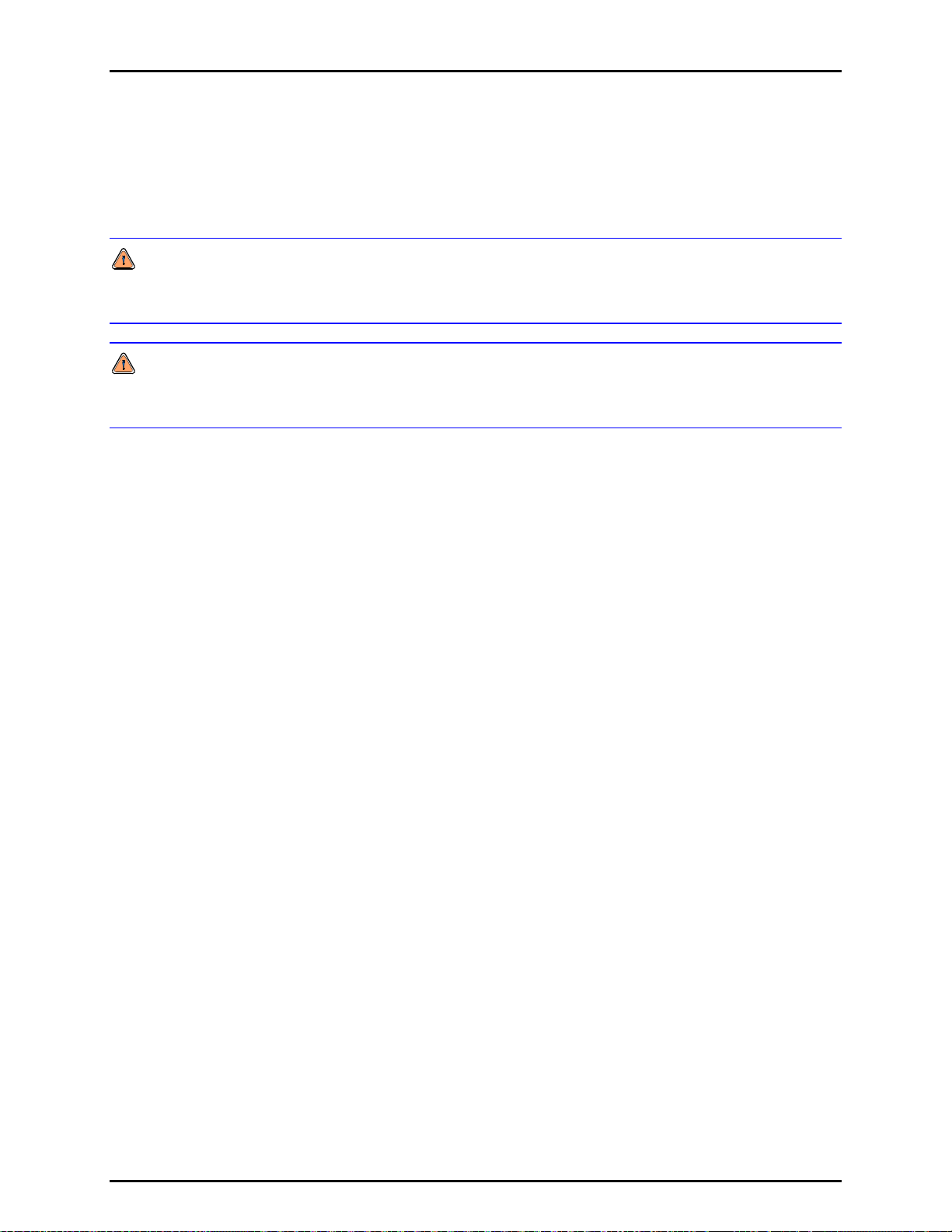

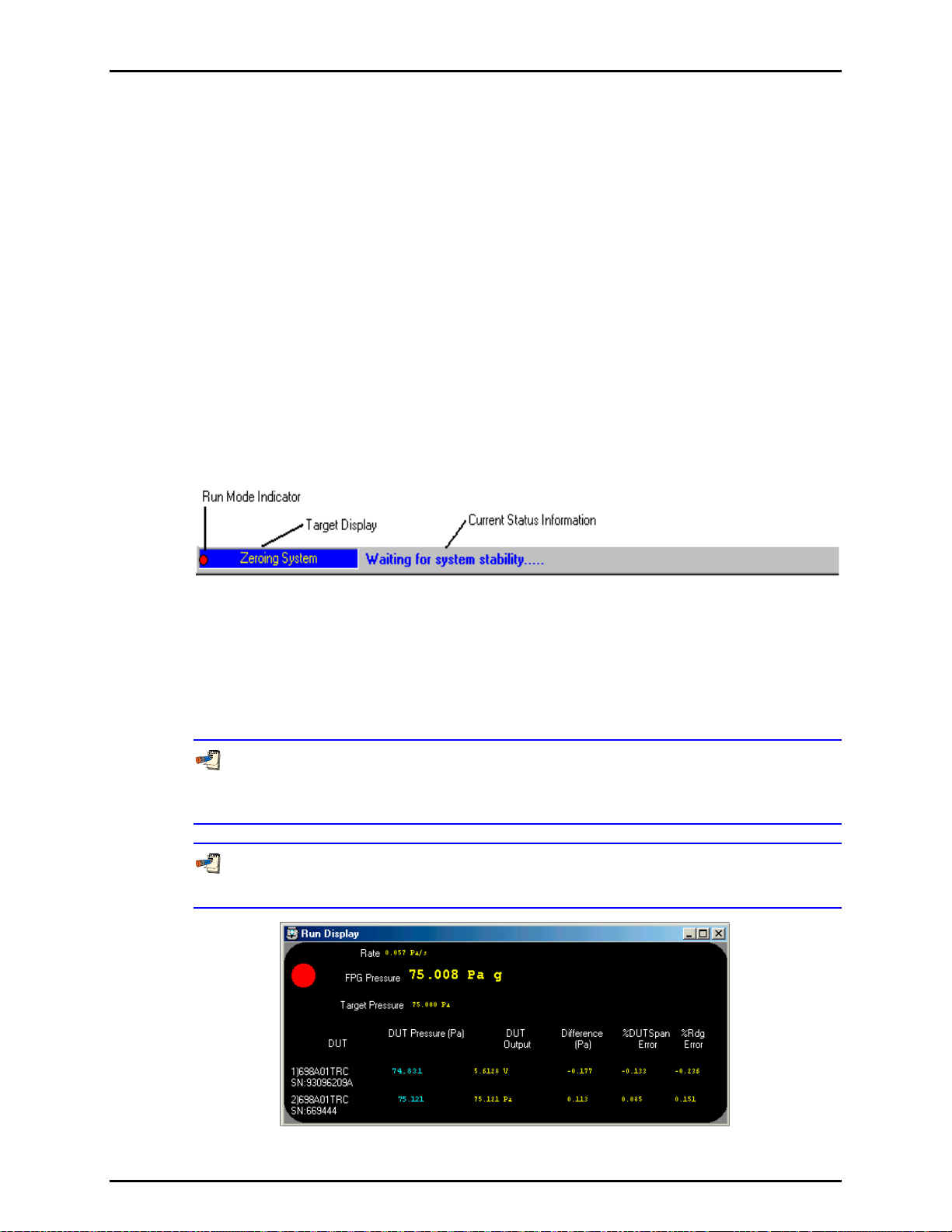

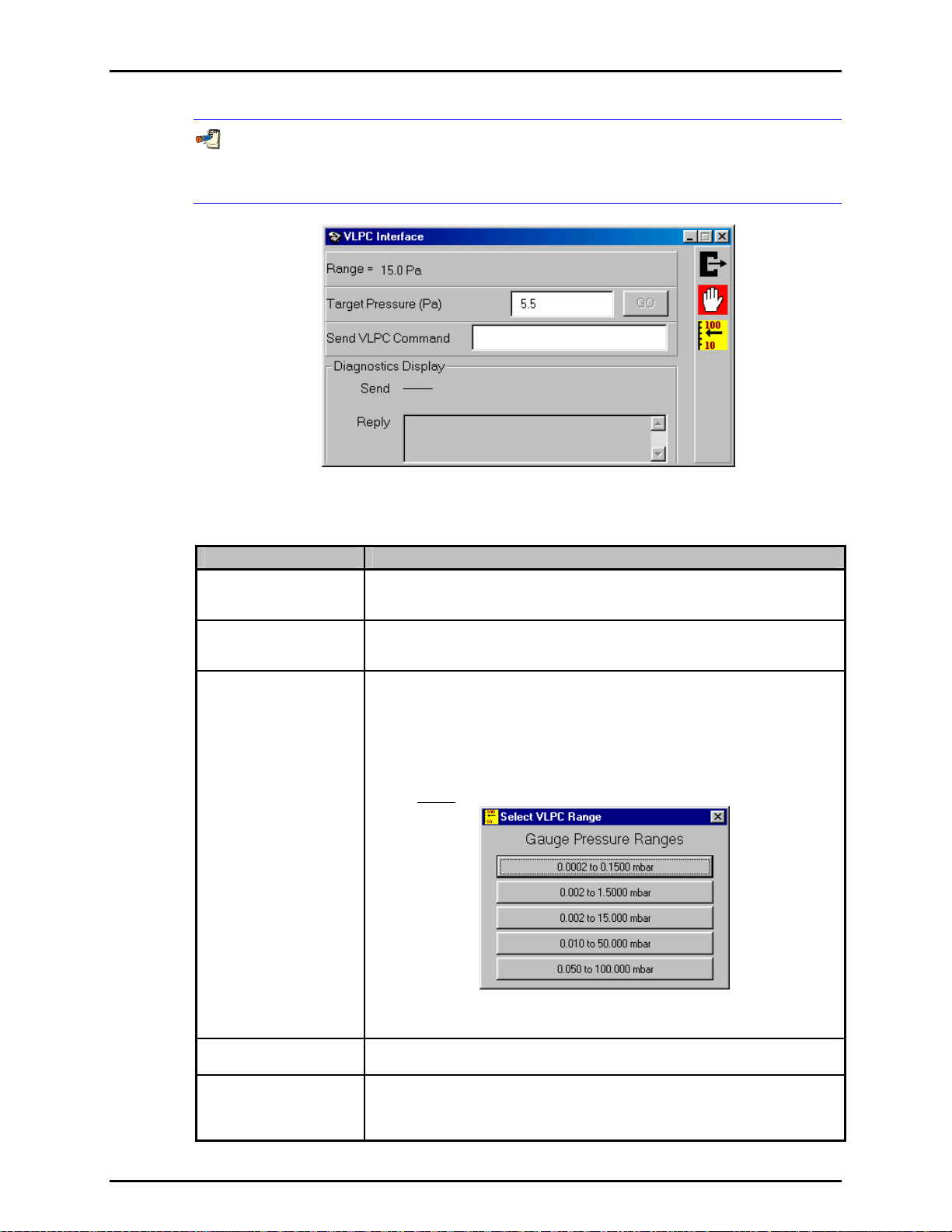

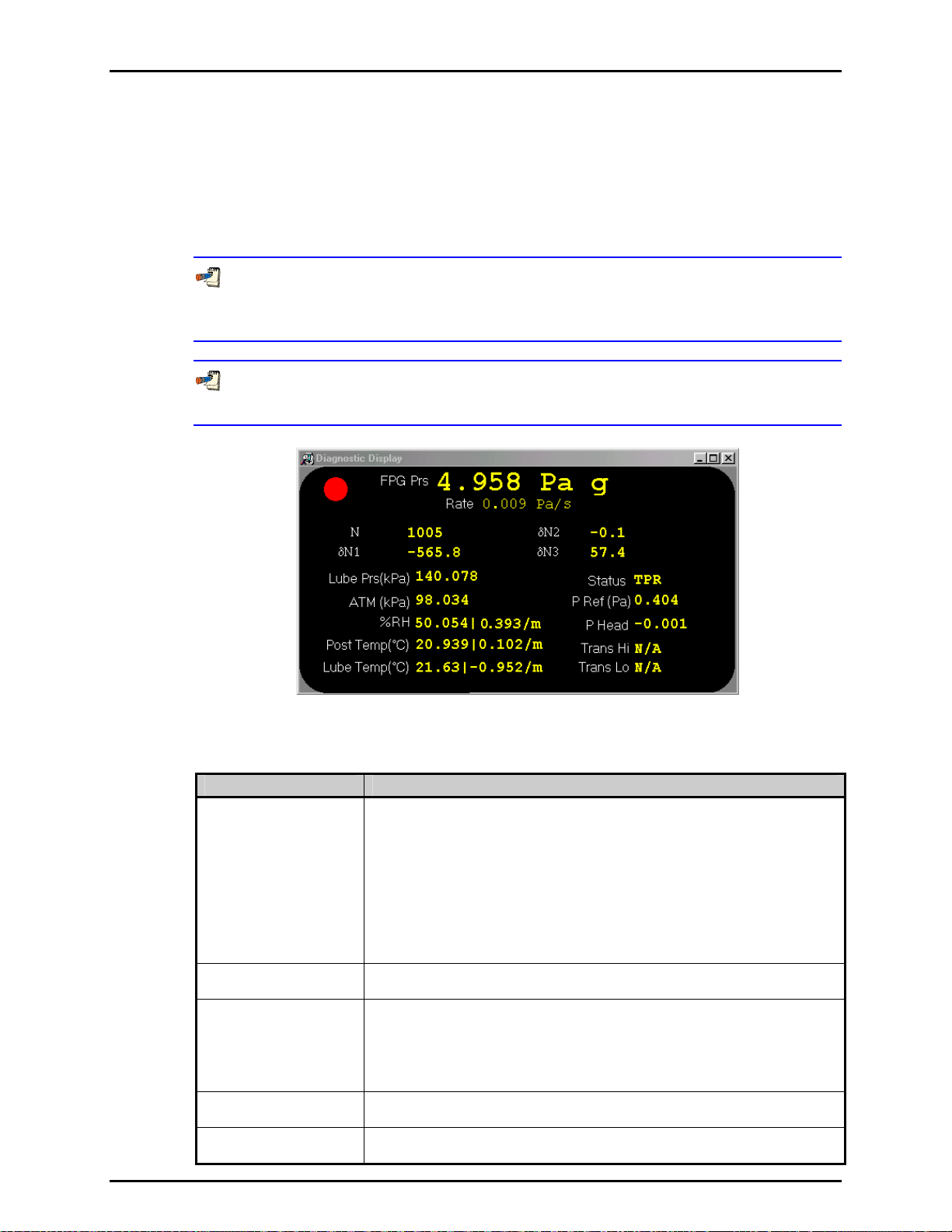

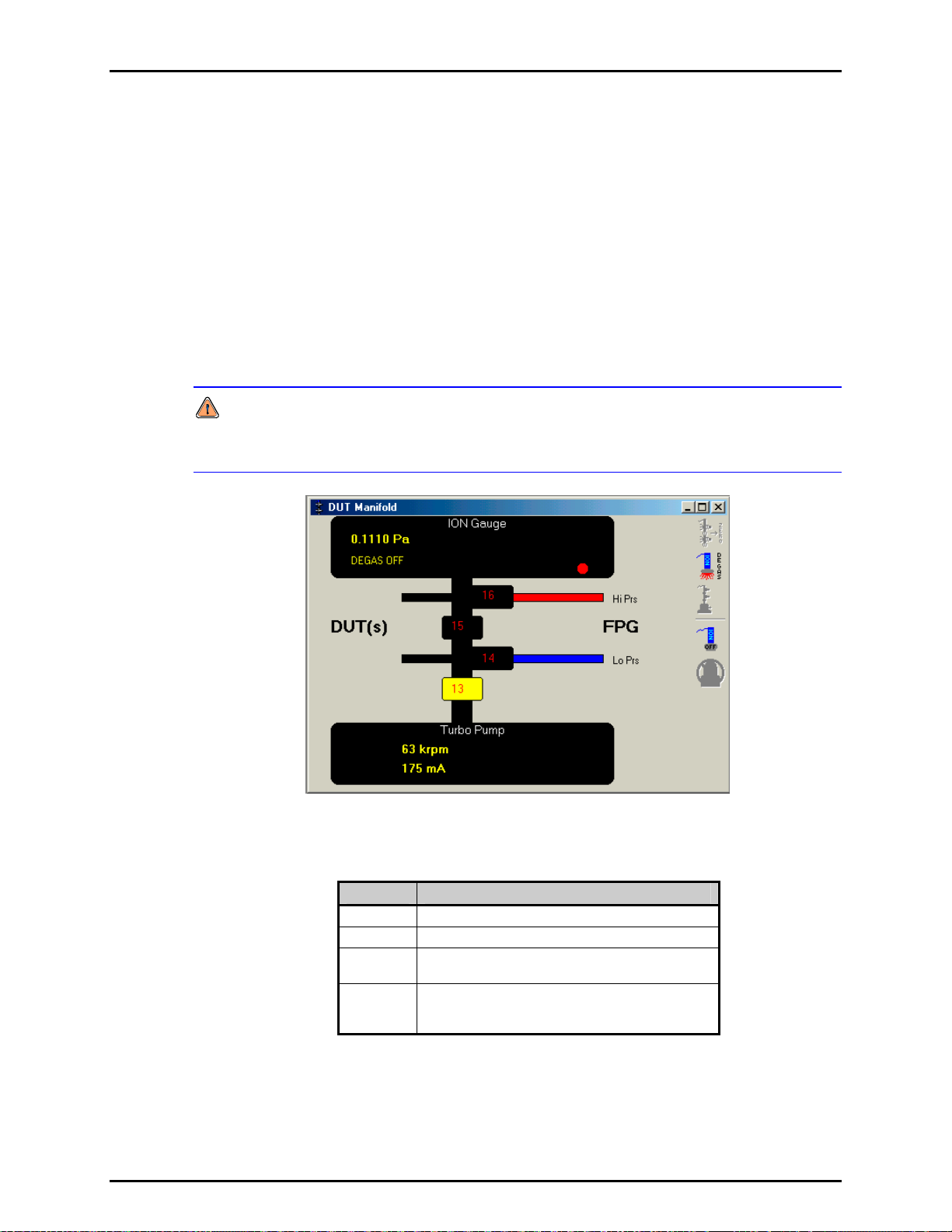

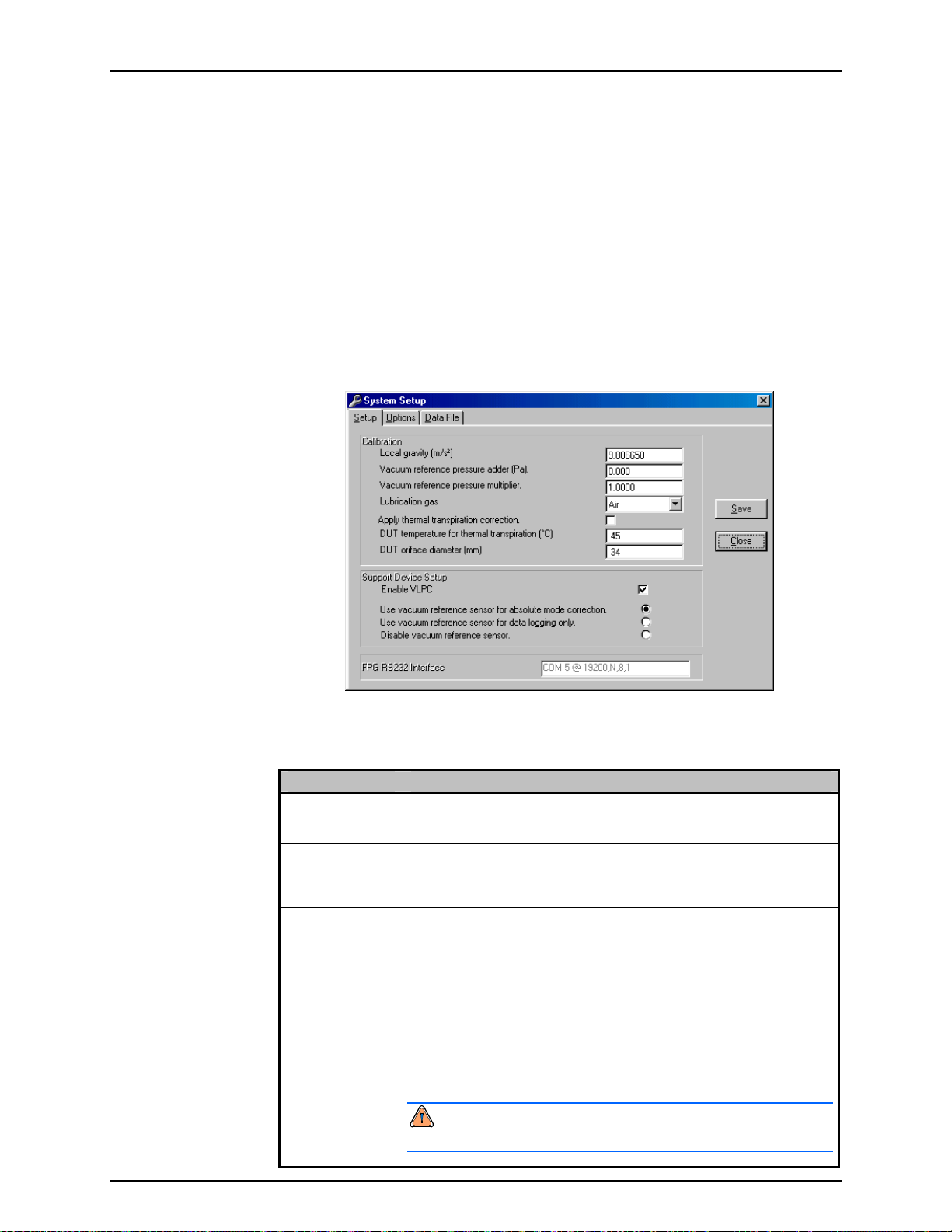

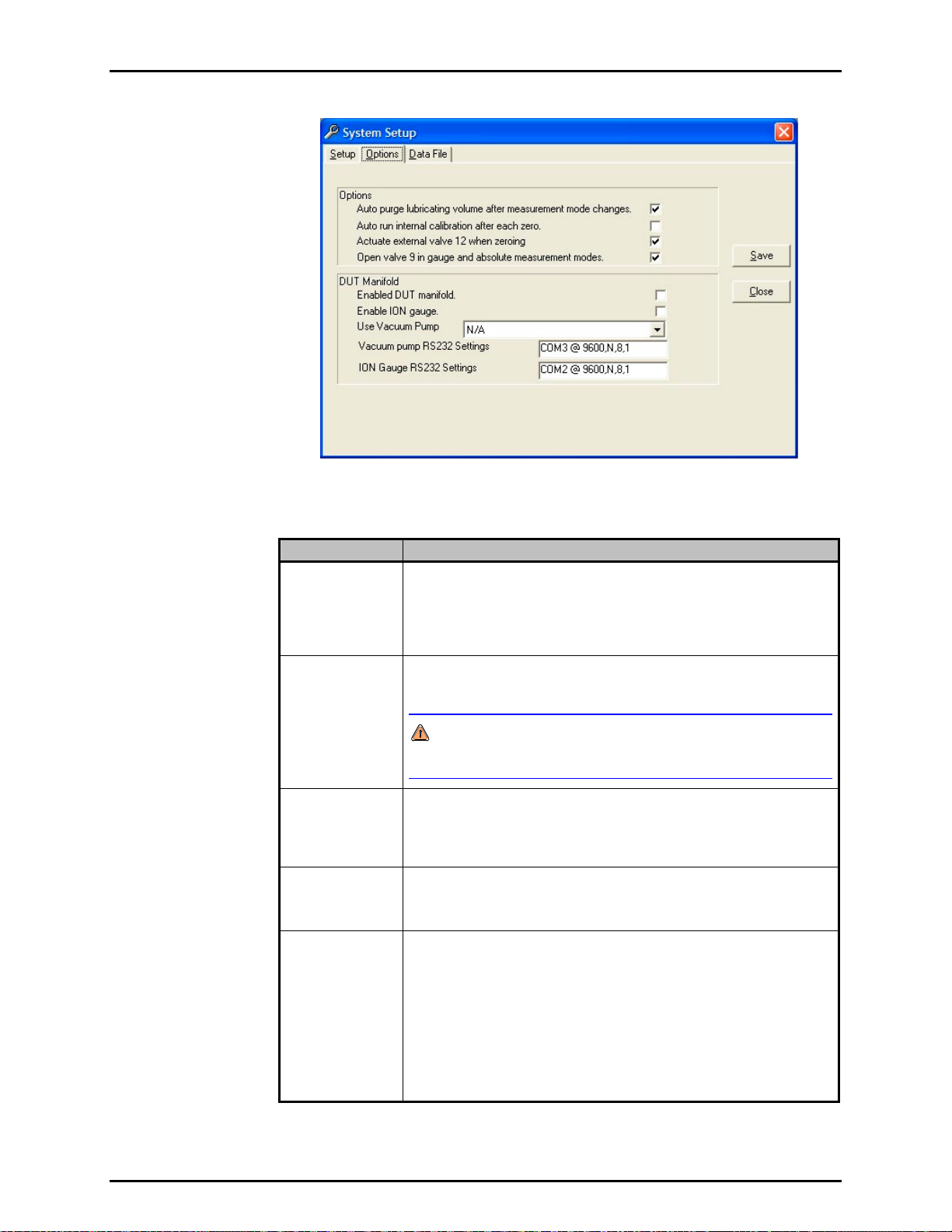

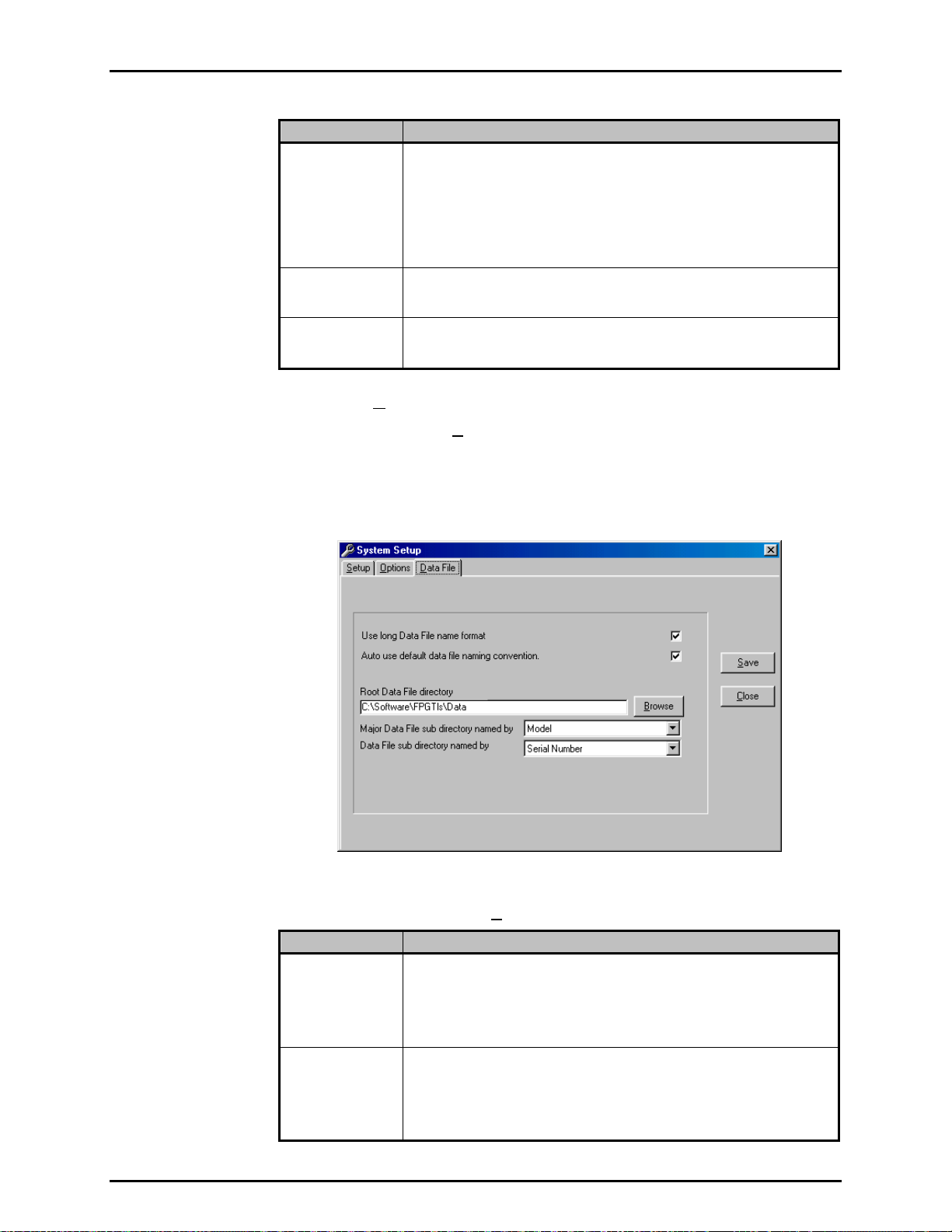

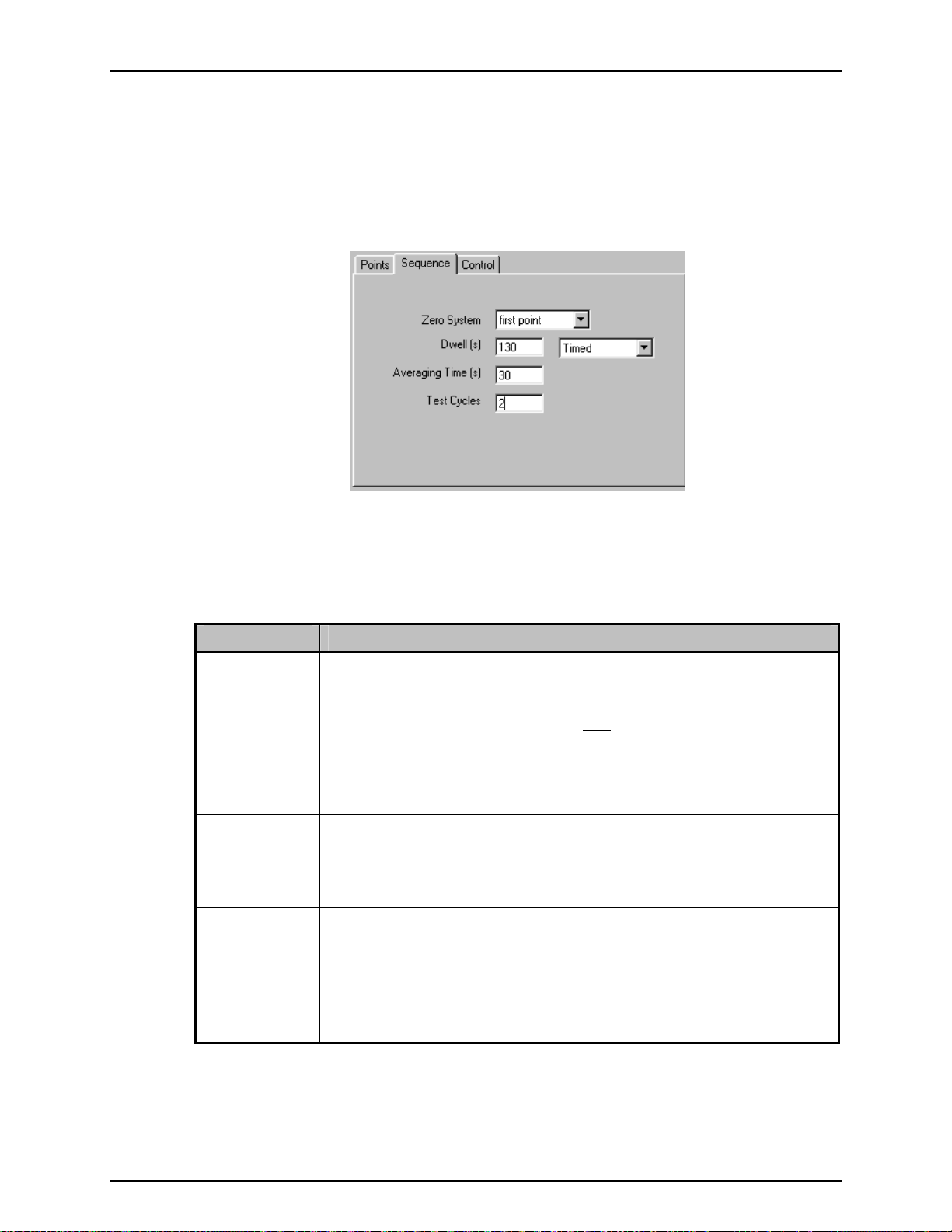

of the piston and its carriage) is zeroed and the time the differential pressure measurement is made.