Page 1

Victoreen®

960SF-220, 960SF-221

960SF-230, & 960SF-231

March 2005

Manual No. 960SF-200-1 Rev. 2

©2004, 2005 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies

Scaler Module

Users Manual

Page 2

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

www.flukebiomedical.com/rms

Page 3

Table of Contents

Section 1: Introduction................................................................................................ 1-1

1.1 General Description ..................................................................................... 1-1

1.2 Application ................................................................................................... 1-1

1.3 Components ................................................................................................ 1-1

1.4 Specifications............................................................................................... 1-2

1.5 Receiving Inspection and Storage ............................................................... 1-3

1.6 Installation.................................................................................................... 1-3

1.7 Procedures, Warnings, and Cautions .......................................................... 1-3

Section 2: Theory of Operation................................................................................... 2-1

2.1 Theory of Operation..................................................................................... 2-1

2.2 Detector Input Circuitry ................................................................................ 2-1

2.3 Discriminator................................................................................................ 2-1

2.4 Counters ...................................................................................................... 2-1

2.5 Address Decoding Circuits........................................................................... 2-2

2.6 Bus Transceivers ......................................................................................... 2-2

2.7 Lamp Drivers ............................................................................................... 2-2

2.8 Relay Drivers ............................................................................................... 2-2

2.9 CHECK SOURCE and ACK/FAIL Switches................................................. 2-4

2.10 Analog Inputs............................................................................................... 2-4

2.11 Analog Output.............................................................................................. 2-4

2.12 High Voltage Power Supply ......................................................................... 2-4

2.13 High Voltage Shut Down.............................................................................. 2-5

2.14 Anti-Jam Printed Circuit Board..................................................................... 2-5

Section 3: Maintenance, Calibration and Troubleshooting...................................... 3-1

3.1 Maintenance ................................................................................................ 3-1

3.2 Calibration.................................................................................................... 3-1

3.3 Troubleshooting ........................................................................................... 3-1

Appendix A: Connector Designations ...........................................................................A-1

A.1 Connector Designations............................................................................... A-1

Appendix B: Applicable Drawings and Bill of Materials ............................................... B-1

B.1 Applicable Drawings ....................................................................................B-1

B.2 Bill of Materials ............................................................................................B-1

i

Page 4

(Blank Page)

Page 5

Introduction

General Information

1

Section 1

Introduction

1.1 General Description

The 960SF Scaler Module accumulates pulses from a remote radiation detector. The pulses are available

upon request from the associated controller. The discriminator permits adjustment of the scaler output to

eliminate the effects of extraneous input pulses or to select an input signal representing a single isotope.

The high voltage supply for energizing the remote detector is controlled by signals from the controller. The

controller can also select a digital signal representative of anyone of up to four separate analog input

signals.

An analog output signal representing the radiation level is provided. The scaler also provides up to six

digital output signals in response to the appropriate commands from the controller module. Figure 2-1 is a

block diagram of the scaler.

The module also provides an upper and lower discriminator adjustment for the input pulses. There are

four indicator lamps. They are controlled by the associated controller and are labeled ALARM, WARN,

ACK/FAIL, and CHECK SOURCE. The last two ACK/FAIL and CHECK SOURCE are lamp/pushbuttons

that communicate back to the controller.

A HIGH VOLTAGE adjustment provides the operator control over the remote detector high voltage

supply. A TEST INPUT jack and a TEST/NORM switch allows selection of a simulated detector input

signal for module testing.

1.2 Application

The scaler module is used in VICTOREEN 960 series digital radiation monitoring systems. The scaler is

compatible with both the 960MB and the 961MB motherboard bus structure.

1.3 Components

The scaler module contains the following basic components:

• Counter (18 bits)

• Relay drivers (6)

• Lamp drivers (6)

• Analog input (4)

• Switch inputs (C/S, ACK)

• Analog output (4-20 mA)

Options: 0-10 mV, 0-50 mV,

0-1 V, 0-5 V, and 0-10 V

• Signal select switch (TEST/NORM)

• Anti-jam board (960AJ)

• Automatic HV shutdown circuit

• Adjustable High Voltage

1-1

Page 6

Victoreen 960SF-220,221,230,231

Operators Manual

• Test Input

1.4 Specifications

General specifications for the scaler are listed below. The Scaler Module is rated for nuclear safetyrelated applications and any repairs made to the nuclear rated module will void the safety-related rating.

The module (Series 960SF-200) must be returned to the factory for authorized, qualified (ANSI 45.2.6,

1978,Skill Level II) service.

Dimensions (W x H) 7.5 x 11.5 in (29.2 x 19.1 cm)

Weight 1 lb 7 oz (0.64 kg)

Operating Temperature 32°F to 122°F (0°C to 50°C)

Relative Humidity 0 to 95% non-condensing

Power +5 V @ 600 mA, +15 V @ 350 mA, -15 V @ 100 mA

Address Lines A0, A1, & A2

Control and Timing R/W, SHORT 02, & DS

Data Bus 8-bit bi-directional D0 through D7

Analog Inputs Four analog inputs 0 to +10 V

Analog Outputs Standard 4 to 20 mA (500 Ω maximum load)

Relay Drivers Six 24 VDC relay drivers used to drive 961RE-200-10 or 961RE-210-10

Relay Modules

Lamp Drivers Four lamp drivers for ALARM, WARN FAIL, CHECK SOURCE (C/S)

Switch Inputs Two switch inputs for CHECK SOURCE (C/S) and ACKNOWLEDGE

(ACK)

High Voltage Power Supply Adjustable 400 to 1800 VDC @ 1 mA maximum for detector HV Model

960SF-231, adjustable -400 VDC to -1800 VDC @ 1 mA

Discriminator Two selectable thresholds (upper and lower discriminator)

Test/Normal Switch Switch selectable between test signal and detector input

Pulse Out (J7) Buffered signal output to be used by the analyzer

Anti-jam On board circuit to detect jam condition causing a bit to be set at a

register

HV Shutdown High voltage shutdown circuit enables automatic shutdown of high

voltage by the controller. LED in front panel also lights up

HV Test Point Accuracy Front panel test point available to measure HV value at ratio of 300:1 +/2%

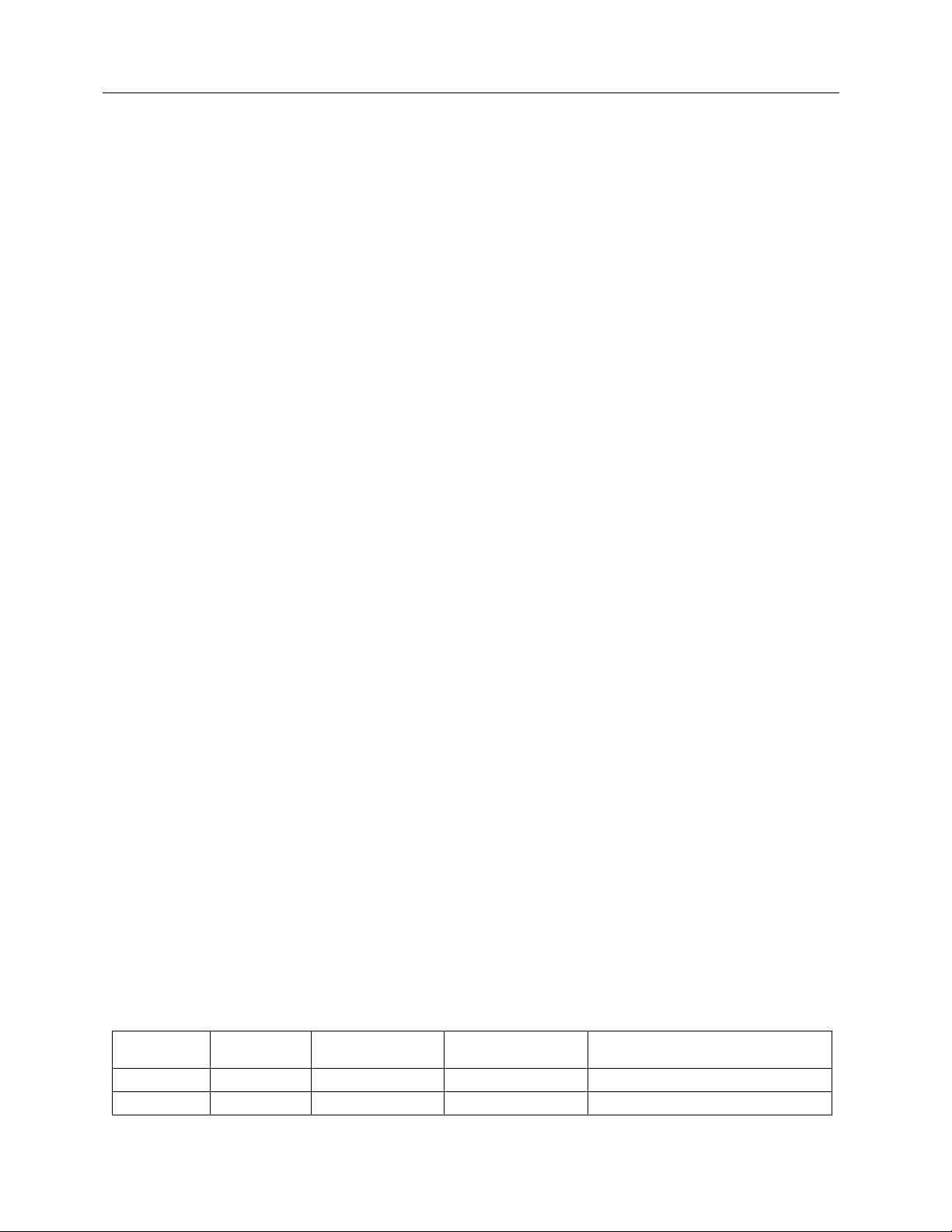

Table 1-1. Model Descriptions

Model No. High Voltage Analog Inputs (4) Analog Output (1)

960SF-220 Positive Yes Yes Yes

960SF-221 Positive No Yes Yes

1-2

24 V Solid State Relay Outputs

(6)

Page 7

Introduction

Specifications

960SF-230 Negative Yes Yes Yes

960SF-231 Negative No Yes Yes

1.5 Receiving Inspection and Storage

Receiving Inspection

Upon receipt of the unit:

1. Inspect the carton(s) and contents for damage. If damage is evident, file a claim with the carrier and

notify Fluke Biomedical, Radiation Management Services at 440.248.9300.

2. Remove the contents from the packing material.

3. Verify that all items listed on the packing list have been received and are in good condition.

1

NOTE

If any of the listed Items are missing or damaged,

notify Fluke Biomedical.

Storage

Storage of Victoreen instruments must comply with Level B storage requirements as outlined in ANSI

N45.2.2 (1972) Section 6.1.2 (.2). The storage area shall comply with ANSI N45.2.2 (1972) Section 6.2

Storage Area, Paragraphs 6.2.1 through 6.2.5. Housekeeping shall conform to ANSI N45.2.3 (1972).

Level B components shall be stored within a fire resistant, tear resistant, weather tight enclosure, in a

well-ventilated building or equivalent.

Storage of Victoreen instruments must comply with the following:

1. Inspection and examination of items in storage must be in accordance with ANSI N45.2.2 (1972)

Section 6.4.1.

2. Requirements for proper storage must be documented and written procedures or instructions must

be established.

3. In the event of fire, post-fire evaluation must be in accordance with ANSI N45.2.2 (1972), Section

6.4.3.

4. Removal of items from storage must be in accordance with ANSI N45.2.2 (1972), Sections 6.5 and

6.6.

1.6 Installation

The 960SF Scaler Module is supplied as part of a Radiation Monitoring System (RMS) or as a

replacement part for an existing RMS. When the module is shipped as part of a system, it is installed as

part of the RMS at the factory.

When a module is shipped as a replacement part, verify that jumper addresses and PROMs are in the

same configuration as the module that is being replaced.

1.7 Procedures, Warnings, and Cautions

The equipment described in this manual is intended to be used for the detection and measurement of

ionizing radiation. It should be used only by persons who have been trained in the proper interpretation of

its readings and the appropriate safety procedures to be followed in the presence of radiation.

1-3

Page 8

Victoreen 960SF-220,221,230,231

Operators Manual

Although the equipment described in this manual is designed and manufactured in compliance with all

applicable safety standards, certain hazards are inherent in the use of electronic and radiometric

equipment.

WARNINGS and CAUTIONS are presented throughout this document to alert the user to potentially

hazardous situations. A WARNING is a precautionary message preceding an operation that has the

potential to cause personal injury or death. A CAUTION is a precautionary message preceding an

operation that has the potential to cause permanent damage to the equipment and/or loss of data.

Failure to comply with WARNINGS and CAUTIONS is at the user's own risk and is sufficient cause to

terminate the warranty agreement between Fluke Biomedical and the customer.

Adequate warnings are included in this manual and on the product itself to cover hazards that may be

encountered in normal use and servicing of this equipment. No other procedures are warranted by Fluke

Biomedical. It shall be the owner’s or user's responsibility to see to it that the procedures described here

are meticulously followed, and especially that WARNINGS and CAUTIONS are heeded. Failure on the

part of the owner or user in any way to follow the prescribed procedures shall absolve Fluke Biomedical

and its agents from any resulting liability.

Indicated battery and other operational tests must be performed prior to each use to assure that the

instrument is functioning properly. If applicable, failure to conduct periodic performance tests in

accordance with ANSI N323-1978 (R1983) Radiation Protection Instrumentation Test and Calibration,

paragraphs 4.6 and 5.4, and to keep records thereof in accordance with paragraph 4.5 of the same

standard, could result in erroneous readings or potential danger. ANSI N323-1978 becomes, by this

reference, a part of this operating procedure.

1-4

Page 9

Theory of Operation

Theory of Operation

2

Section 2

Theory of Operation

2.1 Theory of Operation

During the following discussion, refer to block diagram, Figure 2-1, and the schematic diagrams in

Appendix B.

2.2 Detector Input Circuitry

Connector J5 is the detector signal input. Input impedance is 50 ohms to match the signal cable and the

detector's output impedance. The input signal is a pulse train that could be positive or negative depending

upon the detector used. Z5 is a unity gain differential amplifier with single ended output whose output is

fed into signal multiplexer Z6. Z6 selects detector input or test input, depending on the setting of the test

switch. The signal is then fed into the discriminator.

2.3 Discriminator

The function of the discriminator is to provide clock pulses to the counter, for those pulses which peak

between the LOW DISC and HIGH DISC threshold levels. The LOW DISC threshold is adjusted with

potentiometer R3 and measured at TP2. The HIGH DISC threshold is adjusted with potentiometer R2 and

is measured at TP1. When the signal level goes above LOW DISC threshold, Z7 pin 6 will go low. The

first half of flip-flop Z19 clocks and then latch. When the signal goes below LOW DISC threshold, Z7 pin 6

return to a high state. This will provide a clock pulse into the second half flip-flop of Z19. Z19 pin 8 will

goes low and CLOCK is active (high). The clock is fed to the counter circuit.

If the signal level goes above the HIGH DISC threshold, Z7 pin 1 will go low. This will reset the first flipflop. When the signal goes below the LOW DISC threshold, the second flip-flop is clocked keeping Z19

pin 8 high. Therefore Z22 pin 8 is low inactive and this pulse is not counted.

2.4 Counters

The CLOCK pulse from Z22 is inverted by inverting Schmidt trigger Z21. Z21 provides a negative going

clock pulse for Z24. Z24, Z25, and Z26 are 16-bit dual module counters. Bits 1 through 8 are from Z24.

Z25 contains bits 9 through 16 and Z26 pins 3 and 4 are bits 17 and 18 respectively. Bit 18 is a stop bit

that causes the CLOCK to stay low and is also provided to register 3 to indicate overrange. The output of

the counters are input to registers 0, 1, and 3 and are available to the bus upon READ 0, READ 1, or

READ 3 control signals. Register 0, 1, and 3 are read only registers.

2-1

Page 10

Victoreen 960SF-220,221,230,231

Operators Manual

2.5 Address Decoding Circuits

Device selection is set by a jumping option on SW1 or SW2. Input signals for decoding are DS, 02, R/W,

A0, A 1, and A2. These input signals are inverted through Z36 and Z37 and fed into Z27 and Z28 that are

decoders. Z27 decodes for READ ONLY registers and Z28 decodes for WRITE ONLY registers. The

decoding scheme is shown in Table 2-1.

Table 2-1. Address Decoding

A2 A1 A0 R/W DS Function Enable Signal

0 0 0 1 1

0 0 1 1 1

0 1 0 1 1 A/D UPPER BITS READ 2

0 1 1 1 1 SCALER STATUS READ 3

1 0 0 1 1 A/D LOWER 4 BITS READ 4

0 0 0 0 1 RELAYS WRITE 0

0 0 1 0 1 SCALER CONTORL WRITE 1

0 1 0 0 1 LAMPS WRITE 2

0 1 1 0 1 D/A CONVERTER WRITE 3

1 0 0 0 1 MPU RESET WRITE 4

x x x 0 1 - WRITE

x x x 1 1 - READ

COUNTER HIGH

BYTE

COUNTER LOW

BYTE

READ 0

READ 1

2.6 Bus Transceivers

Z31 and Z30 are data bus transceivers transferring data from the scaler to the external data bus when

READ is active (high) and from the external data bus to the scale when WRITE is active (low).

2.7 Lamp Drivers

Z32 is a WRITE only register used for lamps. It clocks the data in when WRITE 2 is active (low). Z23 is a

Darlington array driving the front panel ALARM, WARN, and FAIL lamps. The FAIL lamp is handled

through watchdog timer Z38 that is set for 5 seconds. If the fail light is not written to every 5 seconds or

sooner, it will go off to indicate failure and also provide a pulse to watchdog pin 72 on J1.

2.8 Relay Drivers

Z29 is a WRITE only register used for relays. It clocks data in when WRITE 0 is active (low). Z18 is a

Darlington array capable of switching +24 VDC at up to 150 mA with all outputs

simultaneously.

energized

2-2

Page 11

Theory of Operation

Relay Drivers

2

Figure 2-1. Scaler Module Functional Block Diagram

2-3

Page 12

Victoreen 960SF-220,221,230,231

Operators Manual

2.9 CHECK SOURCE and ACK/FAIL Switches

CHECK SOURCE is a front panel momentary switch which, when pressed, causes the check source in

the detector to move in front of the detector. The ACK/FAIL switch is a momentary switch used to

acknowledge an alarm or warn condition. When the microprocessor flags an out-of-limits operating

condition, the operator can press the ACK/FAIL pushbutton to acknowledge the alarm. Since the out-of-limits conditions which can be acknowledged by the microprocessor are firmware dependent, refer to the

operation section of the system manual to find out the additional alarms, other than WARN and ALARM,

that the ACK/FAIL pushbutton is used to acknowledge.

There are four indicator lights, controlled by the associated controller labeled ALARM, WARN, ACK/FAIL,

and CHECK SOURCE. The ACK/FAIL and CHECK SOURCE indicators are also pushbuttons and

provide a way to communicate with the controller. A HIGH VOLTAGE adjustment provides operator

control over the remote detector high voltage supply from the module. A TEST INPUT jack and an

associated TEST/NORM switch permits selection of a simulated detector signal for testing the module.

Normally the C/S Flip-Flop-flop is reset and the CHECK SET signal is low. When an operator pushes

SW4, he sets the C/S flip-flop and the CHECK SET signal becomes high (active) to cause the C/S

reading. FAIL SET will become active (high) if SW3 is pushed because the FAIL Flip-Flop is set.

2.10 Analog Inputs

This description applies only for the 960SF-220-10 Scaler and the 960SF-230-10 Scaler. There are four

0-10 V analog inputs that are converted to digital. These four analog signals are multiplexed by Z17 and

the signal to be converted is picked by decoding D0 and D1. CH2 (SIGNAL 2) is an optional high voltage

monitor-using jumper W15. Z8 is a 12-bit converter. Z9 and Z10 are READ ONLY registers. Digital data is

clocked into Z9 and Z10 upon end of conversion. They are read when READ 2 and READ 4 are active

(low) respectively.

2.11 Analog Output

Z11 is an 8-bit D/A converter and latches input data when WRITE 3 is active (high). R126 is ZERO

ADJUST and R127 is GAIN ADJUST. R126 sets the low limit and R127 sets the upper limit of the output.

DAC output goes into the input of Z2. Z2, Z3, and associated circuitry comprise the 4-20 mA analog

output. Feedback divider R23 and R24 insure load independent output to a maximum load impedance of

500 Ω.

2.12 High Voltage Power Supply

The scaler provides an adjustable high voltage power supply of 400 to 1800 V at 1 mA. R8 is the HIGH

VOLTAGE ADJUST driving Z4 that drives Q7. Q7drives the oscillator circuitry Q6, Q4 and T1 that

generates high voltage pulses rectified by bridge CR5, CR6, CR8, and CR9. This high voltage is divided

by a ratio of 300:1, then buffered by voltage follower Z39 that is fed back to the input of Z4 as feedback

for regulation. TP3 is the test point used to measure the scaled down voltage value. There is also an

ERROR input originated by an americium regulator (separate optional external module) that is fed into the

high voltage circuit at Z4 pin 3 to regulate high voltage when system gain needs to be changed. 960SF230 and 960SF-231 are configured for negative high voltage output.

2-4

Page 13

Theory of Operation

High Voltage Shut Down

2

2.13 High Voltage Shut Down

The microprocessor can generate, under overrange or jam conditions, a command to shut the high

voltage down. When the SHUT DOWN signal goes high, Q3 turns on, Q5 turns on and Z4 pin 2 will be

forced into about 4.5 V potential.

This will cause Z4 pin 6 to become positive, Q7 to turn off and high voltage to turn off. Model 960SF-231

provides negative high voltage and does not utilize transistor Q3, a jumper is provided from the base to

the collector of the Q3 position on the circuit board.

2.14 Anti-Jam Printed Circuit Board

The anti-jam condition is detected when a pulse pile up condition exists. Discriminator output is fed into a

comparator after integration.

Integration is determined by R7*C2 with a one millisecond time constant. Z2 is the comparator and

compares the integrated voltage to the threshold set by R6. When the duty cycle exceeds a preset value,

the output of Z2 pin 1 will go high. This will trigger Z1 to go into a latch up condition that will cause Z1 pin

4 to stay high. This condition will turn Q2 and Q3 on which will cause the following to occur:

1. The jam bit will go high to indicate a "jam" condition.

2. Fuse F1 will blow causing the input of F1 permanently to stay low, which keeps the jam bit high

(active).

There is a start-up delay of ½ second to allow the high voltage to stabilize upon power up of the monitor.

The associated controller module also has access to this to allow the controller to reset the anti-jam

circuit. This delay is caused by the time constant of R13*C4. When the scaler is used with a scintillation

detector, jumper W1 is connected between pins B and C. If a GM detector is in use, W1 is jumpered

between pins A and B on the module.

2-5

Page 14

Victoreen 960SF-220,221,230,231

Operators Manual

(Blank page)

Page 15

Maintenance, Calibration and Troubleshooting

Maintenance

Section 3

Maintenance, Calibration and Troubleshooting

3.1 Maintenance

No periodic maintenance is required for the module.

3

If a maintenance question arises and cannot be

resolved by using this manual, please contact the

Fluke Biomedical at 440.248.9300 for assistance.

NOTE

3.2 Calibration

The 960SF-220, 960SF-221, 960SF-230 and 960SF-231 modules do not require any calibration.

3.3 Troubleshooting

Extreme care must be used when troubleshooting a

system that has power applied. All standard

troubleshooting precautions apply.

Once a problem has been located, remove all

power before continuing with the repair.

Personnel performing the following procedure must

be familiar with the operation of the monitoring

system and the location of each piece of equipment

used in the system.

If a problem develops, verify that the voltages at connection point inputs and outputs are present and that

all wiring is secure. Refer to Appendix B for drawings.

WARNING

WARNING

CAUTION

3-1

Page 16

Victoreen 960SF-220,221,230,231

Operators Manual

The 960SF-220, 960SF-221, 960SF-230, and 960SF-231 Scaler Modules must be returned to the factory

for service if troubleshooting of the module is necessary.

NOTE

If a problem cannot be resolved by using the

drawings In Appendix B while applying the

troubleshooting Instructions found in this manual,

please contact Cardinal

Health for assistance.

3-2

Page 17

Appendix

Connector Designations

Appendix A

Connector Designations

A.1 Connector Designations

Pin Description Pin Description Pin Description Pin Description

1 GND 21 MICRO

RESTART

2 GND 22 BIT RATE 42 DS01E0 62 A7

3 GND 23 R/W 43 GND 63 A8

4 GND 24 02 44 GND 64 A9

5 +5V 25 IRQ 45 D0 65 A10

6 +5V 26 SHORT 02 46 D1 66 A11

7 +5V 27 DS 0000 47 D2 67 A12

8 +5V 28 DS 0020 48 D3 68 A13

9 +15V 29 DS 0040 49 D4 69 A14

10 +15V 30 DS 0060 50 D5 70 A15

11 GND 31 DS 0080 51 D6 71 EXMEM

12 GND 32 DS 00A0 52 D7 72 WATCH DOG

13 -15 33 DS 00C0 53 GND 73 PULSE OUT #1

14 -15 34 DS 00E0 54 GND 74 PULSE OUT #2

15 5 V BAT 35 DS 0100 55 A0 75 PULSE OUT #3

16 5 V BAT 36 DS 0120 56 A1 76 ERROR OUT

17 MEMORY

37 DS 0140 57 A2 77 GND

PROTECT

18 POWER FAIL 38 DS 0160 58 A3 78 GND

19 RESET 39 DS 0180 59 A4 79 GND

20 BNKG 40 DS 01A0 60 A5 80 GND

41 DSI0CO 61 A6

A

A-1

Page 18

Victoreen 960SF-220,221,230,231

Operators Manual

J2 Pin Designation

* Pin Description * Pin Description

A Analog Out + a SIG- (2)

B GND b SIG+ (1)

C Not Used c GND

D Not Used d Not Used

E Not Used e SIG+(2)

F Not Used f GND

H Not Used h GND

J Not Used i GND

K Not Used k Not Used

L GND m Not Used

M Not Used n Not Used

N Not Used D Not Used

P GND r K3 (ALARM)

R SIG- (3) s Relay Common

S

T GND u K4 (CHECK SOURCE)

U SIG+ (4) Y K1 (FAIL)

V SIG+ (3) w K6 (BEACON)

W GND x K2 (WARN)

X SIG- (1)

Y SIG- (4)

Z GND

Counter Enable (Not

Used)

t K5 (HORN)

J3 Pin Designation

Pin Description Pin Description

1 GND 14 FAIL/ACK SW

2 GND 15 C/S SW N.O.

3 - 16 C/S SW N.C.

4 - 17 -

5 - 18 TEST/NORMAL SW (TP)

6 - 19 +15 VDC

7 Warn Light 20 +15 VDC

8 C/S Light 21 SIG IN (TEST) (TP)

9 Scare Light 22 SHUT DOWN LED

10 Scare Light 23 +5 VDC

11 Alarm Light 24 +5 VDC

12 Scare Light 25 HV Test Point

13 Fail Light 26 -

N.O. - Normally Open Contacts

N.C. - Normally Closed Contacts

A-2

Page 19

Connector Designations

960SF Jumpers (Including 960AJ)

Designation Position Purpose Factory Setting

W2 N 4-20 mA OFFSET 960SF-220/221/230/231

W3 N 4-20 mA OFFSET 960SF-220/221/230/231

W5 A-B For – HV 960SF -230/231

B-C For + HV 960SF-220/221

W6 A-B For + HV 960SF-220/221

B-C For – HV 960SF-230/231

W7 N 4-20 mA 960SF-220/221/230/231

W8 N

OUT To digitize Flow 2 960SF-220/221/230/231

W10 A-B D1 enable sig. on PRAM 960SF-220/221/230/231

B-C +5 V to enable RAM -

W11 A-B +5 V to enable RAM -

B-C D0 enable signal 960SF-220/221/230/231

W9 A-B

B-C

J5 Conductor B

Conductor A

W12 A-B

B-C

W13 - Not Used

W14 - Not Used

To digitize 300:1 HV on

Flow input 2

Positive input signal from

detector. (GM)

Negative input signal from

detectors (Scintillation)

Positive input from

detectors (GM)

Negative input from

detectors (Scintillators)

Presence for Flow input or

analog output.

Indicates no Flow input or

analog output.

-

As required

As required

As required

As required

960SF-220/230

960SF-221/231

960AJ Jumpers

Designation Position Purpose Factory Setting

W1 A-B

W1 B-C

W2 N Disables Anti-Jam Factory test

W2 OUT Enables Anti-Jam Normal

W3 N Protects Fuse Factory test

W3 OUT

Use with 857/897 GM

detectors

Use with 843 Scintillation

detectors

Will allow fuse to blow if

Anti-Jam occurs

As required

As required

Normal

Appendix

A

A-3

Page 20

Victoreen 960SF-220,221,230,231

Operators Manual

(Blank page)

Page 21

Applicable Drawings and Bill of Materials

Applicable Drawings and Bill of Materials

B.1 Applicable Drawings

Drawing Number Description

960SF-220-10 Scaler Module Main Assembly

960SF-221-10 Scaler Module Main Assembly

960SF-230-10 Scaler Module Main Assembly

960SF-231-10 Scaler Module Main Assembly

960SF-220-13 Scaler Module Schematic Positive HV

960AJ-200-10 Anti-Jam Module Main Assembly

Appendix

B

Appendix B

960AJ-200-13 Anti-Jam Module Schematic

960SF-230-13 Scaler Module Schematic Negative HV

960SF-200-15 Scaler Switch/Indicator Circuit Board Assembly

960SF-200-18 Scaler Switch/Indicator Schematic

B.2 Applicable Bill of Materials

Drawing Number Description

960SF-220-10 Scaler Module Main Assembly

960SF-221-10 Scaler Module Main Assembly

960SF-230-10 Scaler Module Main Assembly

960SF-231-10 Scaler Module Main Assembly

960AJ-200-10 Anti-Jam Module Main Assembly

960SF-200-15 Scaler Switch/Indicator Circuit Board Assembly

B-1

Page 22

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

www.flukebiomedical.com/rms

Loading...

Loading...