Page 1

Victoreen®

943-25, 943-25A, 943-25B, 943-25T,

943-25TA, 943-25TB, 943-26, 943-26A,

943-26B, 943-26TT, 943-26TA, 943-26TB

Beta Detectors

March 2005

Manual No. 943-25-1 Rev. 2

©2004, 2005 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies

Users Manual

Page 2

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

120 Andrews Road

Hicksville, New York 11801

516.870.0100

www.flukebiomedical.com/rms

Page 3

Table of Contents

Section 1: Introduction................................................................................................ 1-1

1.1 General Description ..................................................................................... 1-1

1.2 Application ................................................................................................... 1-1

1.3 Specifications............................................................................................... 1-1

1.4 Functional Description ................................................................................. 1-2

1.5 Receiving Inspection.................................................................................... 1-3

1.6 Storage ........................................................................................................ 1-3

1.6.1 Control of Items in Storage..................................................................... 1-3

1.6.2 In Case of Fire........................................................................................ 1-3

1.6.3 Removal from Storage............................................................................ 1-3

1.7 Procedures, Warnings, and Cautions .......................................................... 1-3

Section 2: Operation.................................................................................................... 2-1

2.1 Installation.................................................................................................... 2-1

2.2 Detector Operation ...................................................................................... 2-1

2.3 Detector Replacement Parts........................................................................ 2-2

Section 3: Theory of Operation................................................................................... 3-1

3.1 Scintillator and Photomultiplier Tube ........................................................... 3-1

3.2 Preamplifier.................................................................................................. 3-1

Section 4: Maintenance, Calibration, and Troubleshooting..................................... 4-1

4.1 Maintenance ................................................................................................ 4-1

4.1.1 Detector Disassembly............................................................................. 4-1

4.1.2 Detector Assembly ................................................................................. 4-1

4.2 Calibration.................................................................................................... 4-2

4.3 Calibration Where Calibration Date is Available .......................................... 4-2

4.4 Calibration Where Detector is a Replacement Part ..................................... 4-3

4.5 Troubleshooting ........................................................................................... 4-3

4.6 Safety Related Detectors ............................................................................. 4-4

4.7 Commercial Detectors ................................................................................. 4-4

4.7.1 Preliminary ............................................................................................. 4-4

4.7.2 Dynode Test Measurement .................................................................... 4-5

4.7.3 Preamplifier Checkout ............................................................................ 4-5

4.8 Replacement Parts ...................................................................................... 4-6

Appendix A: Applicable Drawings..................................................................................A-1

A.1 Applicable Drawings ....................................................................................A-1

i

Page 4

(Blank page)

Page 5

Introduction

General Description

1

Section 1

Introduction

1.1 General Description

The 943 series beta detectors are designed to be sensitive to a beta radiation source.

Although the 943 series beta detectors are functionally identical, the detectors differ in the material used

for the housing; the material used for the end window, and in the response ratio achieved through the

scintillation disc area variations (refer to Section 1.2, Specifications).

Two end window materials are used for the 943 series beta detectors. The mylar end window is used for

replacement of existing beta detectors with similar windows. The beta detectors with titanium end

windows offer greater durability and ease of decontamination.

The beta detector has preamplifier circuitry located in the interior of the overall protective housing. The

preamplifier provides pulse conditioning and cable driving capabilities to match the input characteristics of

the Victoreen instruments used to monitor detector output. The detector is supplied with an eight (8) foot

coaxial cable that normally terminates in a junction box located within a sampling system.

1.2 Application

The detector can be used with Victoreen ratemeters or Scaler Module 960SF. Ratemeters are used with

beta detectors in small single channel analog monitoring systems while scaler modules and detectors are

primarily used in multiple channel digital monitoring systems.

1.3 Specifications

Detector

Dimensions 9 x 2.5 in (22.9 x 6.4 cm)

Weight 3 lbs (1.4 kg), approximately

Housing Stainless Steel 943-25, 943-25A, 943-25B, 943-25T, 943-25TA, 943-

25TB

Carbon Steel 943-26, 943-26A, 943-26B, 943-26T, 943-26TA, 943-

26TB

Power +2000 VDC @ 500 uA, +15 VDC @ 50 mA, -15 VDC @ 50 mA

Connector MS 3106E 2427B

Operating Temperature 32° to 122°F (0° to 50°C)

Storage Temperature 32° to 104°F (0° to 40°C)

Relative Humidity 0 to 95% non-condensing

1-1

Page 6

Victoreen 943-25, 943-26

Operators Manual

Response Ratio: 1:1 943-25, 943-26, 943-25T, 943-26T

10:1 943-25A, 943-26A, 943-25TA, 943-26TA

100:1 943-25B, 943-26B, 943-25TB, 943-26TB

End Window Material Mylar 943-25, 943-25A, 943-25B, 943-26, 943-26A, 943-26B

Titanium 943-25T, 943-25TA, 943-25TB, 943-26T, 943-26TA, 943-26TB

Preamplifier

Maximum Pressure 30 psi

(Face Exposure)

Rise Time < 60 ns

Input Impedance > 50 kilohms

Output Coupling AC

Voltage Gain 6 V/V

Configuration Voltage sensitive

Output Polarity Negative

Output Impedance 50 ohms

Maximum Cable Length 1500 ft

Maximum Pulse Amplitude @ -6 V

Maximum Cable Length

Dead Time Approximately 10 us @ 8 ft cable length

Maximum Count Rate 10

The beta detectors have been assembled with parts selected for the reliability required in a nuclear

application. Any unauthorized repairs made to the detectors utilized in nuclear applications will void the

safety-related rating. Safety-related detectors must be returned to Fluke Biomedical, Radiation

Management for authorized, qualified (ANSI 45.2.6, Skill Level II) service.

7

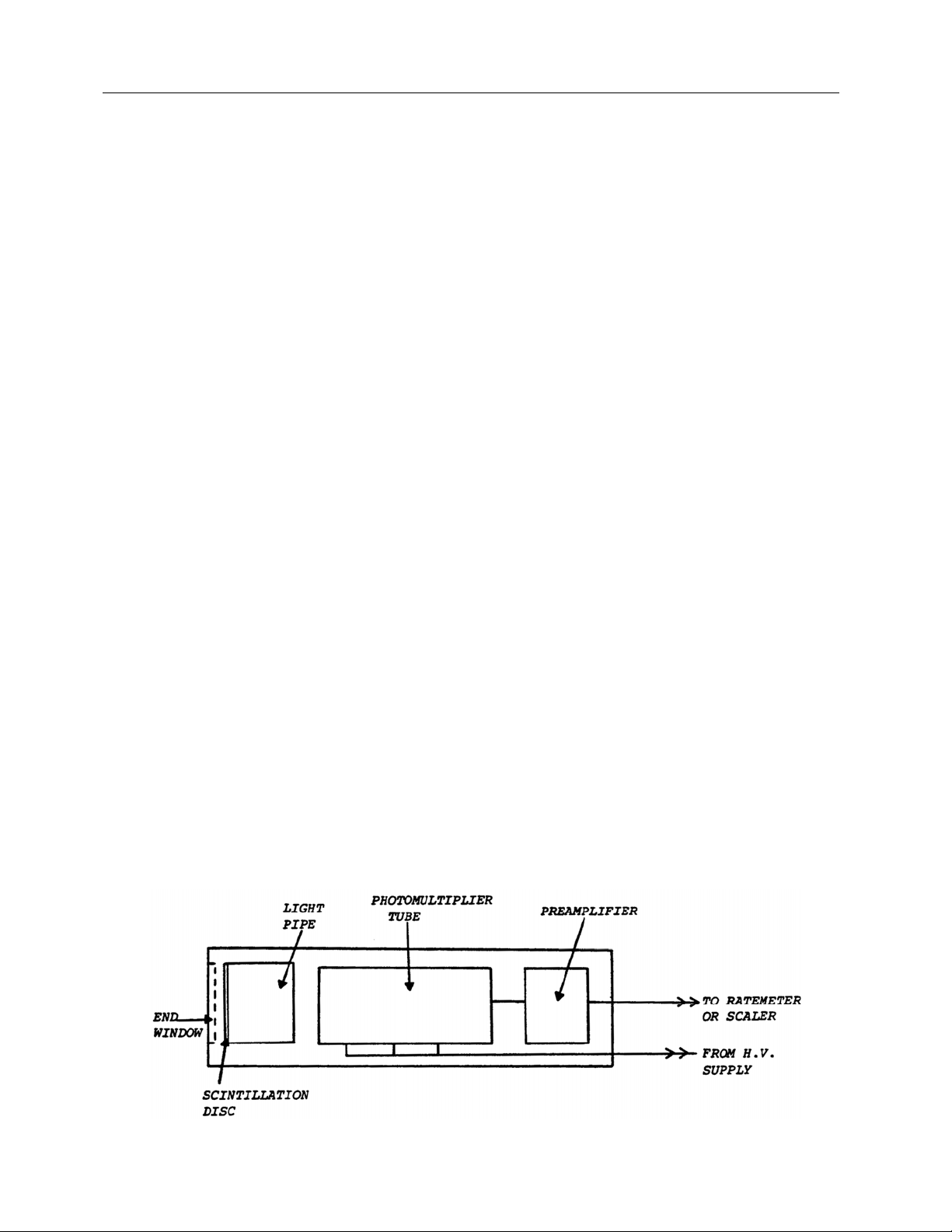

1.4 Functional Description

The Victoreen beta scintillation detector is shown in block diagram form in Figure 1-1. The detector

consists of a scintillation disc, a photomultiplier tube, a preamplifier assembly, and various interconnecting

cables connecting the detector, readout, and the detector power supply that is located at the ratemeter or

scaler module.

Figure 1-1. Block Diagram, 943 Series Beta Detector

1-2

Page 7

Introduction

Functional Description

Beta particles that have enough energy to penetrate the end window and impinge upon the disc will

produce light pulses, proportional to the energy deposited in the disc. The disc is thin so that gamma rays

will not have a high incidence of interaction with the disc. This yields a high rejection of gamma rays while

still possessing good sensitivity to beta particles.

A photomultiplier tube, optically coupled to the scintillator disc, detects visible light emitted from the disc

and converts this light to pulses of electrical energy whose voltage is proportional to the energy deposited

by the beta particle. The electrical pulse is sent to a preamplifier in the detector housing.

The preamplifier circuit amplifies the pulses received from the photomultiplier tube/crystal assembly,

providing a fixed gain of six (6). The current drive output of the preamplifier circuit will drive a 50-ohm

transmission line up to 1500 feet without degradation of the signal.

Should a very high intensity beta source be detected, the photomultiplier tube may become saturated.

That is, visible light from successive photon collisions within the scintillation disc may occur so often that

they are essentially continuous. This would have the effect of holding the output voltage of the

preamplifier at a relatively constant output voltage. Since the readout is designed to count pulses that

represent individual beta particle collisions, a high intensity beta signal could be interpreted as a low or no

radiation condition. An anti-jam circuit must be provided in the ratemeter or scaler to which the detector is

connected to prevent misinterpretation of the existing radiation field.

1

1.5 Receiving Inspection

The single channel analyzer board can be supplied independently or as a component of a UDR. Once the

SCA board has been received, unpack it from the shipping carton and inspect for damage.

1.6 Storage

Storage of Victoreen instruments shall comply with level B storage requirements as outlined in ANSI

N45.2.2 (1972) Section 6.1.2(.2). The storage area shall comply with ANSI N45.2.2 (1972) Section 6.2

Storage Area,

Level B components shall be stored within a fire resistant, tear resistant, weather tight, well-ventilated

building or equivalent enclosure.

Storage of Victoreen instruments must comply with the following considerations.

1.6.1 Control of Items in Storage

Inspection and examination of items in storage shall be in accordance with ANSI N45.2.2 (1972) Section

6.4.1. Requirements for proper storage shall be documented, and written procedures or instructions shall

be established.

1.6.2 In Case of Fire

Post-fire evaluation shall be in accordance with ANSI N45.2.2 (1972) Section 6.4.3.

Paragraphs 6.2.1 through 6.2.5. Housekeeping shall conform to ANSI N45.2.3 (1972).

1.6.3 Removal from Storage

Removal of items from storage shall be in accordance with ANSI N45.2.2 (1972) Sections 6.5 and 6.6.

1-3

Page 8

Victoreen 943-25, 943-26

Operators Manual

1.7 Procedures, Warnings, and Cautions

The equipment described in this manual is intended to be used for the detection and measurement of

ionizing radiation. It should be used only by persons who have been trained in the proper interpretation of

its readings and the appropriate safety procedures to be followed in the presence of radiation.

Although the equipment described in this manual is designed and manufactured in compliance with all

applicable safety standards, certain hazards are inherent in the use of electronic and radiometric

equipment.

WARNINGS and CAUTIONS are presented throughout this document to alert the user to potentially

hazardous situations. A WARNING is a precautionary message preceding an operation that has the

potential to cause personal injury or death. A CAUTION is a precautionary message preceding an

operation that has the potential to cause permanent damage to the equipment and/or loss of data.

Failure to comply with WARNINGS and CAUTIONS is at the user’s own risk and is sufficient cause to

terminate the warranty agreement between Fluke Biomedical and the customer.

Adequate warnings are included in this manual and on the product itself to cover hazards that may be

encountered in normal use and servicing of this equipment. No other procedures are warranted by Fluke

Biomedical. It shall be the owner’s or user’s responsibility to see to it that the procedures described here

are meticulously followed, and especially that WARNINGS and CAUTIONS are heeded. Failure on the

part of the owner or user in any way to follow the prescribed procedures shall absolve Fluke Biomedical

and its agents from any resulting liability.

Indicated battery and other operational tests must be performed prior to each use to assure that the

instrument is functioning properly. If applicable, failure to conduct periodic performance tests in

accordance with ANSI N323-1978 (R1983) Radiation Protection Instrumentation Test and Calibration,

paragraphs 4.6 and 5.4, and to keep records thereof in accordance with paragraph 4.5 of the same

standard, could result in erroneous readings or potential danger. ANSI N323-1978 becomes, by this

reference, a part of this operating procedure.

1-4

Page 9

2.1 Installation

Operation

Installation

2

Section 2

Operation

Do not apply voltage to the detector if the

mylar/titanium cover is not on the disc. Even slight

pinholes In the cover could admit enough light to

seriously damage the detector. Failure to observe

this precaution may destroy instrument calibration,

or may even cause destruction of the instrument

itself.

Install the detector into the sampler housing (refer to the sampler manual for specific mounting details).

Before connecting the detector to its readout, be sure channel power is turned off, and the high voltage

potentiometer is at the lowest setting.

On digital systems, the power should be turned off

before the detector cabling is connected to avoid a

surge that might destroy electronic components.

This is good practice with all systems, digital and

analog.

Connect the appropriate cables between the detector and the readout.

Do NOT exceed 2000 V to the detector under any

circumstances.

Operation of the detector during initial turn-on is dependent on whether the detector is supplied as part of

a radiation-monitoring channel or as a replacement part.

CAUTION

CAUTION

CAUTION

2.2 Detector Operation

Turn on channel power at the readout and slowly increase the high voltage to the value indicated on the

factory calibration sheet. This does not have to be an exact value because that value will be determined

during the calibration process. A two to four hour warm-up is recommended prior to commencing

calibration.

2-1

Page 10

Victoreen 943-25, 943-26

Operators Manual

2.3 Detector Operation - Replacement Parts

Turn on channel power at the readout and slowly increase the high voltage until a count rate of

approximately 100 cpm is achieved. This count rate assumes that the detector is in the open air and that

the discriminator threshold is set at 0.2 VDC in the readout. If the detector is placed within a lead shield,

the high voltage should be increased until a count rate of approximately 20 cpm is achieved. A two to four

hour warm-up is recommended prior to commencing calibration.

2-2

Page 11

Theory of Operation

Scintillator and Photomultiplier Tube

Section 3

3

Theory of Operation

3.1 Scintillator and Photomultiplier Tube

When beta particles enter the scintillation disc, pulses of light are emitted. The light pulses striking the

photocathode of the photomultiplier tube excite the electrons in the cathode to a high-energy state

causing them to escape from the surface of the cathode. The freed electrons are attracted by a voltage

potential to the first dynode of the photomultiplier tube. This starts a cascading effect where a charge is

passed from dynode to dynode, increasing in size at each stage until a shower of electrons is passed on

to the preamplifier.

3.2 Preamplifier

The schematic diagram for the preamplifier is located in Appendix A. The preamplifier provides

amplification of the output from the photomultiplier tube and cable driving capabilities. Negative pulses

derived from the photomultiplier tube are applied to the input of the preamplifier. Operational amplifier Z1

is configured as a non-inverting amplifier with a gain of approximately six (ratio of R6 + R7/R6). The

amplified pulses are coupled to transistors Q1 and Q2.

Resistor R11 allows impedance matching of the preamplifier to the 50-ohm transmission line connected to

the readout. The non-inverting input of Z1 (pin 3) is biased at +10 VDC potential. This enables the

operational amplifier, in conjunction with transistor Q1 and Q2, to drive 1500 feet of cable and produce a

6 V pulse at the readout

.

3-1

Page 12

Victoreen 943-25, 943-26

Operators Manual

(Blank page)

Page 13

Maintenance, Calibration, and Troubleshooting

Maintenance

Section 4

Maintenance, Calibration, and Troubleshooting

4.1 Maintenance

There is no periodic maintenance required for the detector. The following assembly/disassembly

procedure is to be used if the detector requires repair. Refer to Section 4.5, Troubleshooting, for the

troubleshooting procedure.

4.1.1 Detector Disassembly

Refer to the assembly drawings in Appendix A.

1. Remove the four screws from the base of the detector (connector end).

2. Take the assembly out using a pair of needle nose pliers, ensuring that it does not rotate during

removal.

The photomultiplier tube may separate from the

socket and remain within the detector sleeve. If this

occurs, pliers may be applied to the keyed plastic

base extrusion of the tube and carefully pulled from

within the detector sleeve with moderate vertical

force.

3. The photomultiplier tube can be completely removed from its socket by disconnecting the tube

shield wire.

NOTE

4

4.1.2 Detector Assembly

Refer to the assembly drawings in Appendix A.

1. Make sure the photomultiplier tube face (glass) is free of dust, fingerprints, etc. The tube can be

cleaned with methyl alcohol.

2. Lubricate the o-ring, located at the detector base, with a light consistency grease using P/N MSJ-

3306.

3. Connect the photomultiplier tube shield wire.

Rotating the assembly when fully installed inside

the detector sleeve will damage the interface

coupling. Align the base plate screw holes with the

sleeve holes prior to full Insertion of the assembly

into the sleeve.

4. Place the detector assembly inside the detector sleeve and press the baseplate into the sleeve,

aligning the four screw holes.

CAUTION

4-1

Page 14

Victoreen 943-25, 943-26

Operators Manual

5. Replace the four screws at the connector end of the detector.

4.2 Calibration

The beta scintillation detector is calibrated by adjusting the high voltage supply to the photomultiplier tube

(adjusting detector sensitivity to the photons that impinge on the scintillation disc).

This family of beta scintillation detectors essentially provides a linear output for all levels of beta radiation

until the disc starts to saturate. Setting the beta scintillation detector for the proper output count rate at

any point in its operating range assures an accurate measurement of any other point.

The beta scintillation detector is factory calibrated. It is usually shipped as part of a monitoring system and

the ratemeter or scaler module power supply is adjusted for an accurate reading over the entire operating

range.

After initial installation, at regular intervals after installation, if the detector is replaced, or if the power

supply output voltage changes, calibration should be repeated.

4.3 Calibration Where Calibration Data is Available

Calibration of the beta scintillation detector requires a standard button source of known beta activity for

which a known count rate is recorded in a standard geometry. The standard geometry (test fixture, P/N

844-36) is used to position the detector and button source with respect to each other (Figure 4-1). The

detector should be connected to the readout with all the cable that will be in place during normal

operation since the high voltage setting is slightly cable dependent. At the readout, set the discriminator

level to the level indicated on the data sheet (normally 0.2 VDC).

1. Insert the detector into the cavity provided in the standard geometry.

9O

2. Place the

3. The expected count rate for the button source should be determined. It is recorded on the

calibration data sheet. Correction must be made for decay. (The half-life of the source is 29.12

years.)

4. Adjust the high voltage power supply to the detector so that the net count rate corresponds to the

expected count rate calculated in Step 3.

Sr button source, blank side up (P/N 844-36-14), on the slide in the standard geometry.

NOTE

The net count rate is the indicated count rate minus

the background count rate.

5. The count rate will increase and decrease in conjunction with power supply voltage. If the high

voltage reaches 2000 VDC without achieving the necessary count rate, suspect a defect in the

detector, wiring, or readout device.

4-2

Page 15

Maintenance, Calibration, and Troubleshooting

Calibration Where Detector Is a Replacement Part

4.4 Calibration Where Detector Is a Replacement Part

Calibration of a replacement detector unit depends on the uniformity of response of the detector. The

replacement detector should have the same size scintillation disc as the original detector in the system.

The detector should be connected to the readout with all the cable that will be in place during normal

operation since the high voltage setting is slightly cable dependent. At the readout, set the discriminator

level to the level indicated on the data sheet (normally 0.2 VDC).

1. Insert the detector into the cavity provided in the standard geometry.

9O

2. Place the

(Figure 4-1).

3. The expected count rate for the button source should be determined. It is recorded on the

calibration data sheet. Correction must be made for decay. (The half-life of the source is 29.12

years.)

4. Adjust the high voltage power supply to the detector so that the net count rate corresponds to the

expected count rate calculated in Step 3.

5. The count rate will increase and decrease in conjunction with power supply voltage. If the high

voltage reaches 2000 VDC without achieving the necessary count rate, suspect a defect in the

detector, wiring, or readout device.

6. If more than one button source is available, measure all the button sources. The lowest activity

source should be used first. Record the high voltage values that reproduce the original count rates.

Average the high voltages to determine the best value for all the button sources.

Sr button source, blank side up (P/N 844-36-14), on the slide in the standard geometry

NOTE

The net count rate is the indicated count rate minus

the background count rate.

4

4.5 Troubleshooting

Troubleshooting is indicated for the detector when the measured output of the check source or some

other beta source shows a marked change in the count rate observed at the readout while high voltage

has remained constant.

Figure 4-1. Standard Geometry Drawer Inverted to Show Recess for Beta Disk Sources

4-3

Page 16

Victoreen 943-25, 943-26

Operators Manual

4.6 Safety Related Detectors

If the fault is isolated to the detector, repair can be performed by a technician rated to Skill level II as

described in Section 1.3, Specifications.

Any fault that cannot be isolated to the detector must be in the wiring to the readout or in the readout

itself. Consult the appropriate standard manual for the readout purchased so that the troubleshooting

procedure for that readout can be used. Defective wiring is replaced using the schematic diagram and

Table 4-1 as a guide.

Table 4-1. Cable Connector Pin Out

Pin Function

A High Voltage

B High Voltage Shield

E +15 VDC Supply

G

F -15 VDC

C Signal (Negative Pulses)

D Signal Ground

Power (± 15 V) Ground

4.7 Commercial Detectors

If the fault has been isolated to the detector, the following procedure can be used to identify the faulty

component. The schematic diagram in Appendix A can be used as a guide. Recommended test

equipment is listed in Table 4-2.

4.7.1 Preliminary

1. Turn off channel power at the readout.

2. Disassemble the detector according to Section 4.1.1, Detector Disassembly.

3. Remove and inspect the photomultiplier tube for visible signs of damage (cracks, excessive

rattling).

Do not replace the photomultiplier tube until

troubleshooting has been completed and power is

disconnected.

CAUTION

4-4

Page 17

Maintenance, Calibration, and Troubleshooting

Commercial Detectors

Table 4-2. Recommended Test Equipment

Feature Specification

Pulse Generator (Square Wave)

Pulse

Rise Time

Pulse Width 1.0 microsecond (variable)

Output Impedance 50 ohms

Maximum Repetition Rate 2 MHz

Digital Voltmeter

Ranges

Accuracy

Input Impedance

Oscilloscope (Dual Trace)

Bandwidth 10 MHz @ 10 mV/div

Fastest Sweep Time < 10 Microseconds/div

Electrostatic Voltmeter

Range 0 to 2000 VDC

Precision

Input Impedance 10

Counter/Scaler

Maximum Count Rate 105 cps

Minimum Pulse Width for Counting 40 ns

Preset Counting Time 0.1,1.0, and 10 minutes

± 0.1 to 5 V variable (into a 50 ohm load)

≤ 30 ns

± 0 to 100 mV up to ± 0 to 1000 V (20%

overrange)

± 0.1% of input +1 digit

≥ 10 megohms

± 1%

12

ohms

4

4.7.2 Dynode Test Measurement

Preamplifier input is easily damaged. Ground pin 3

of Z1 before applying power and measuring

photomultiplier tube anode or dynode voltage.

1. Using an electrostatic voltmeter, measure the total DC resistance of the dynode string. The value

should be 9.67 megohms ± 15%. If no reading is obtained, check dynode resistor interstage

connections.

2. Connect the cable to the readout.

3. Turn on channel power and apply 900 V to the detector. Measure the anode resistor voltage (R13)

using an electrostatic voltmeter. The value should be 900 V.

4. Remove channel power.

CAUTION

4.7.3 Preamplifier Checkout

High voltage must be removed for this test.

1. Remove the grounding jumper from pin 3 of Z1.

2. Connect an oscilloscope to the input circuitry of the readout (50 ohms terminated).

4-5

Page 18

Victoreen 943-25, 943-26

Operators Manual

3. Turn on channel power.

4. Using a pulse generator, inject negative pulses of -0.50 V amplitude, one microsecond pulse

duration, at a frequency of 1 kHz to the node of R13 and C6 (+) and gnd (-).

5. Output pulses should be -1.6 V ± 20% amplitude. If pulses are not present, check Z1 and

associated circuitry.

If the preamplifier and dynode tests are positive, the detector malfunction is probably in the

photomultiplier tube. Remove all power, replace the photomultiplier tube and reassemble the detector

according to the procedure in Section 4.1.2.

4.8 Replacement Parts

Drawing Number Description

943-25 Beta Scintillation Detector, Mylar End Window,

943-26 1:1 Response Ratio

943-25A Beta Scintillation Detector, Mylar End Window,

943-26A 10:1 Response Ratio

943-25B Beta Scintillation Detector, Mylar End Window,

943-26B 100:1 Response Ratio

943-25T Beta Scintillation Detector, Titanium End Window,

943-26T 1:1 Response Ratio

943-25TA Beta Scintillation Detector, Titanium End Window,

943-26TB 10:1 Response Ratio

943-25TB Beta Scintillation Detector, Titanium End Window,

943-26TB 100:1 Response Ratio

NOTE

Refer to the individual assembly drawings for a

breakdown of individual components.

4-6

Page 19

Applicable Drawings

Applicable Drawings

A.1 Applicable Drawings

Detectors 943-25, 94-25T, 943-25A, 943-25B, 943-25TA, 943-25TB

Drawing Number

943-25-5 Beta Scintillation Detector Assembly

943-25T-5 Beta Scintillation Detector Assembly

843-25-10 Preamplifier Circuit Board Assembly

843-25-3 Detector Schematic

Description

Appendix

A

Appendix A

Detectors 943-26, 943-26T, 943-26A, 943-26B, 943-26TA, 943-26TB

Drawing Number Description

943-26-5 Beta Scintillation Detector Assembly

943-26T-5 Beta Scintillation Detector Assembly

A-1

Page 20

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

120 Andrews Road

Hicksville, New York 11801

516.870.0100

www.flukebiomedical.com/rms

Loading...

Loading...