Page 1

Get more

done

Now includes the

NEW Fluke 922

Airflow Meter

HVAC/Indoor

Air Quality

Reference Guide

Volume 2, 2007

• Glossary

• Helpful tips

• Application notes

Page 2

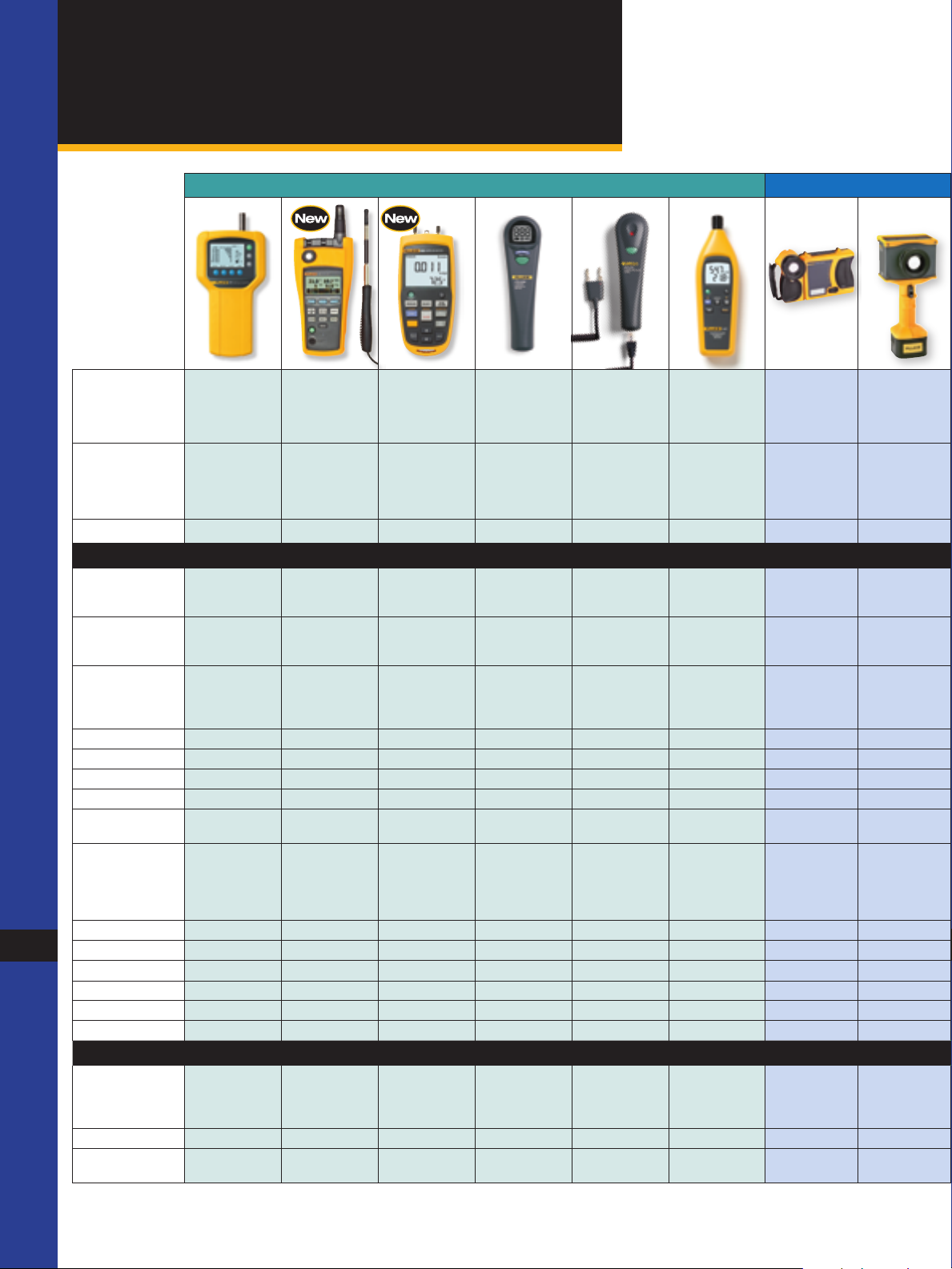

HVAC/Indoor Air Quality

Selection Guide

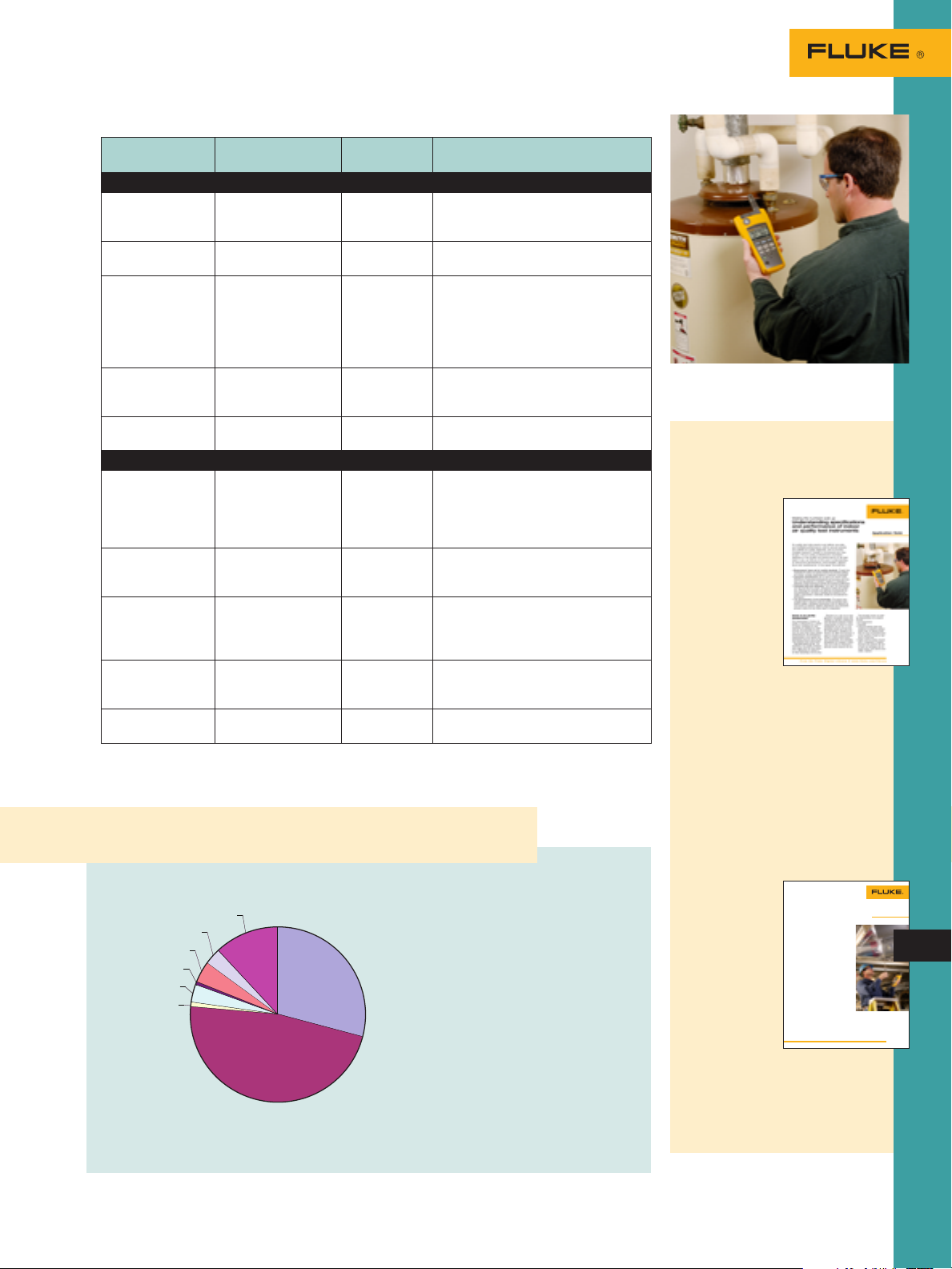

Air Composition Thermal Imaging IR Temperature TC Temperature Pressure HVAC Electrical Tools

Model 983

Particle

Counter

975

AirMeter

922

™

Airflow

Meter

CO-220

CO Detector

CO-210

CO Probe

(1)

Temperature

971

Humidity

TiR Series

Thermal

Imagers*

IR-InSight

Infrared

Imagers*

Meter

Description Measu re six

Page Number 4 6 8 9 9 10 11 12 14 15 18

Measurement s

Part icle size 0.3, 0.5, 1.0,

Temperature +40 °C

Air velocity 50 fpm to

CO

2

CO 500 ppm 0 to 999 ppm 0 to 1000 ppm

Optical resolution 12:1 10:1

Relative humidity 20 % to 90 % 10 % to 90 % 5 % to 95 %

Vacuum 76 cm Hg

particle sizes

simultaneously

2.0, 5.0,

10.0 µm

(104 ºF)

Measu re

temperat ure,

humidity, CO2, CO,

Velocity with one

tool

+50 °C

(122 °F)

3000 f pm,

0.25 m/sec to

15 m/sec

5000 ppm

Combines air

pressure, velocity

and flow into one

rugged, easy-to-

use meter

+50 °C

(122 °F)

250 fpm to

16,000 fpm,

1 m/sec to

80 m/sec

Quickly test

CO levels

Conveniently

measu re CO

with t his

DMM accessory

Measure humidity

faster, calculate

wet bulb and

dew point

temperatures

+60 ºC

(140 ºF)

Provides fast and

easy precision

temperat ure

measu rements

+600 °C

(1112 °F)

Low contrast

thermal

application

imager

+100 °C

(212 °F)

Pressure ± 4000 Pascals

Voltage ac/dc 600 V ac 600 V 600 V, 600 mV 1000 V

2

Current ac/dc 600 A/200 µA 600 µA 400 mA

Resistance

Frequency 50 kHz 100 k Hz

Capacitance 1000 µF 9999 µF 999 µF

Conductance

Data storage

Data logging 5000 readings 99 readings

Min/Max/Avg Yes/Yes/Yes Yes/Yes /Yes No/Yes/No Yes/Yes/Yes Yes/Yes/No No/Yes /No Yes/Yes/Yes Yes/Yes/No Yes/Yes/Yes Yes/Yes/No

Display Hold/

Auto (Touch) Hold

(1) Accessory for use with a digital multimeter with dc millivolt inputs.

(discrete),

25,000 readings

(continuous)

± 16 in H2O

± 400 mm H2O

± 40 mbar

± 0.6 PSI

99 readings 99 readings 500 readings

Yes/No Yes/ No Yes/No Yes/No Yes/No Yes/No Yes/ No No/No

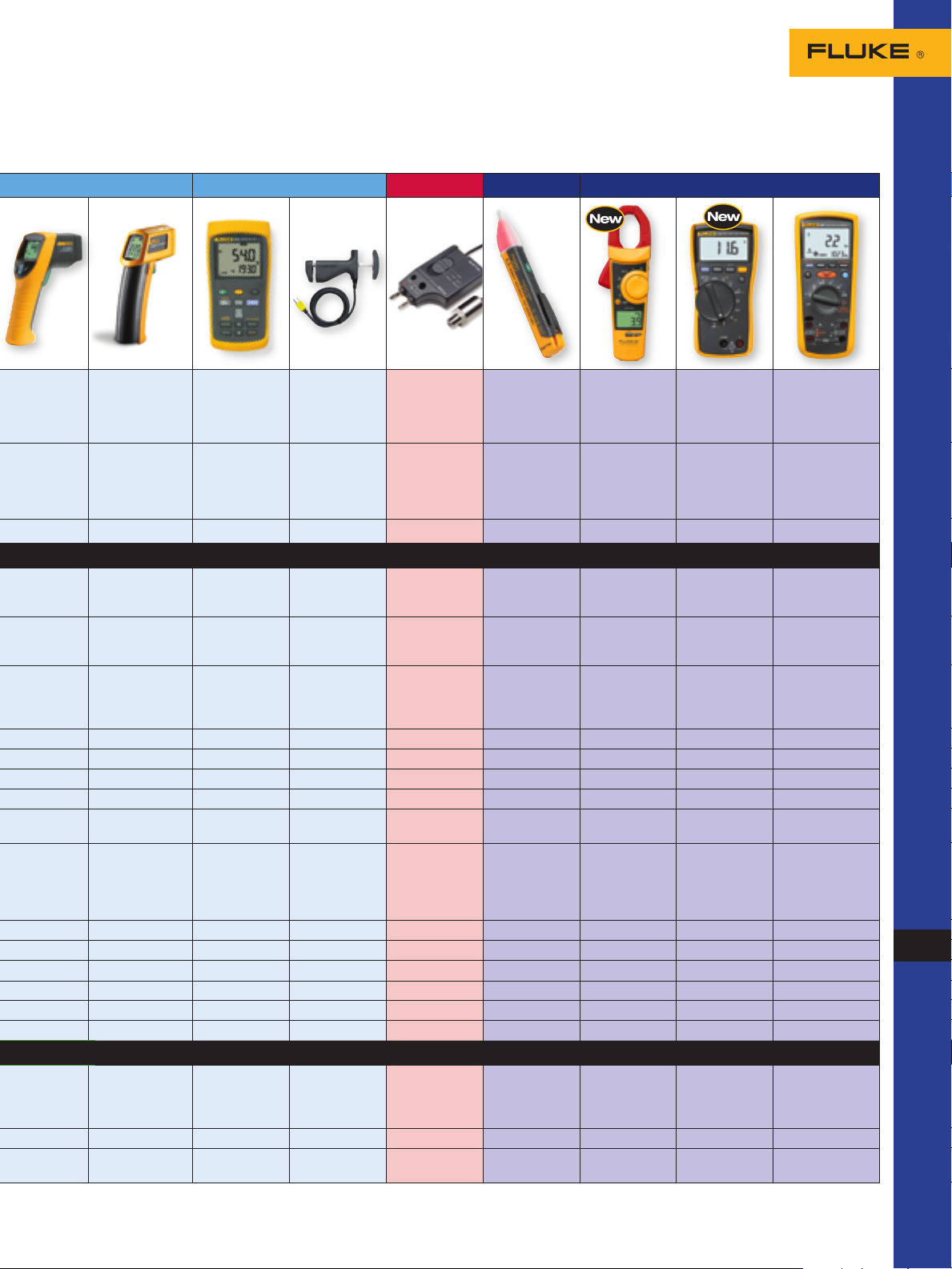

Page 3

561

HVACPro

IR Thermo-

meter

Contact and

non-contact

temperat ure in

one

62

Mini IR Ther-

mometer

Best accuracy in

its class, perfect

introduction to IR

thermometers

54

TC Ther-

mometer

Dual-temperature

for ∆T across

fur naces and

coils

80PK-8

TC Clamp

DMM accessory

captures liquid

and suction line

temperat ures

18 19 20 21 22 23

PV350 Pres-

(1)

sure/Vac

DMM accessory

captures liquid

and suction line

pressure values

(1)

1AC II

VoltAlert

Voltage

Detector

Non-contact

voltage w ith

audio alarm

902

True-rms

HVAC Clamp

Meter

Desig ned for

HVAC, with

temperat ure, dc

microamps and

capacitance

116

HVAC

Multimeter

Basic DMM

built for

HVAC

technicians

1587

Insulation

Multimeter

Insulation tester

and tr ue-rms

digital

multimeter

in one

+550 °C

(1022 ºF)

+500 ºC

(932 ºF)

+1767 ºC

(3212 ºF)

J, K, T, E, N, R, S

+149 °C

(300 ºF)

(406.7 in H20)

3447 kPa

(499.9 psi)

+400 °C

(752 °F)

K

9999 W 40 MW 50 MW

+400 °C

(752 ºF)

K

+537 °C

(998 º F)

K

3

*Multiple models available to suit your specific needs. See www.fluke.com for more information.

Page 4

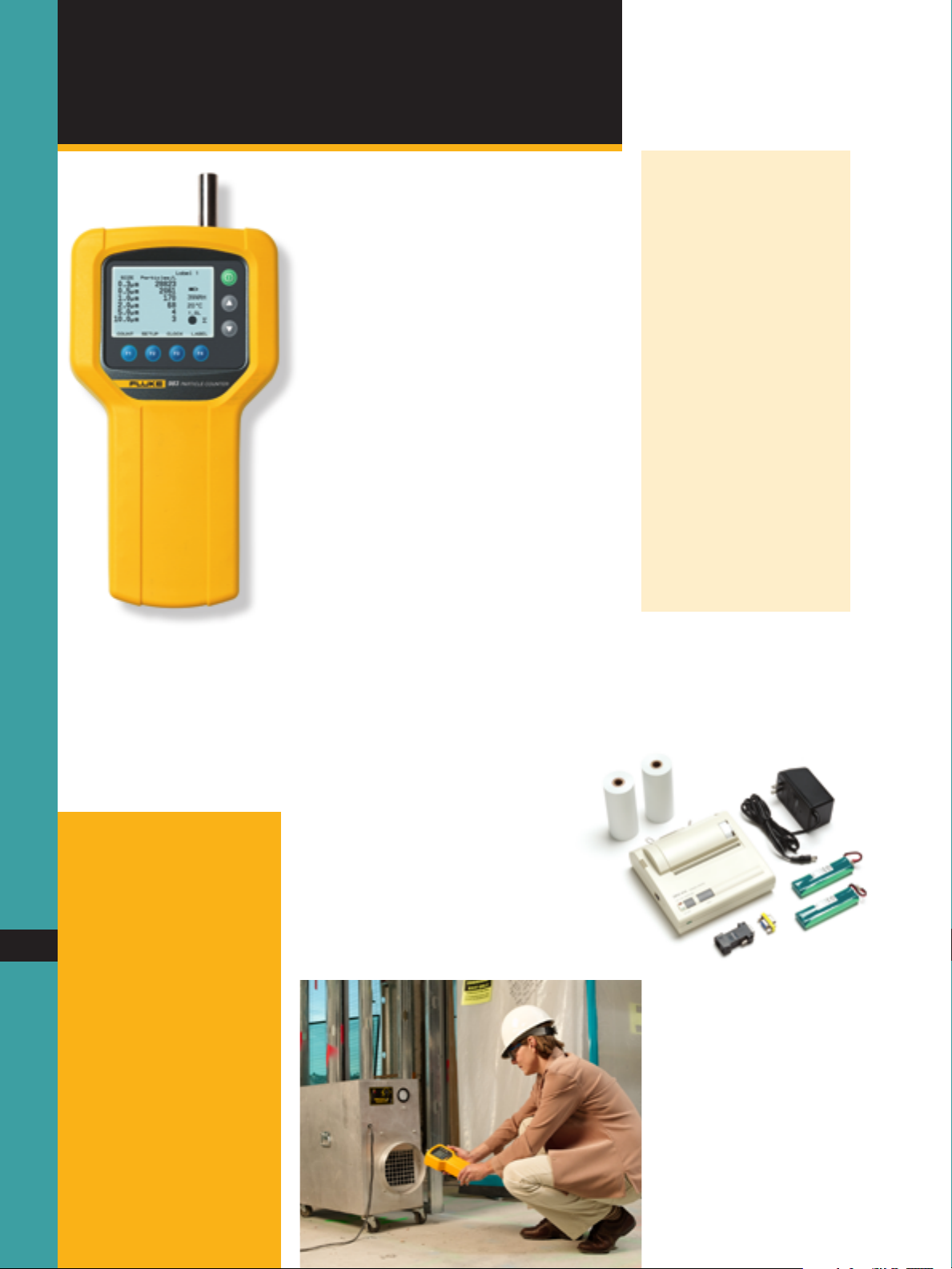

Air Composition

Particle Counter

Fluke 983 Particle Counter

Troubleshoot and maintain

indoor air quality.

The new Fluke 983 Particle Counter, the preferred choice for HVAC and IAQ professionals,

measures temperature and relative humidity as

well as particle size. With expanded data

logging and six-channel particle size display,

the Fluke 983 allows users to run more tests

quickly, with less time spent cycling through

screens to obtain data. The Fluke 983 is lightweight and easy to use in any position, with a

comfortable hand strap and rugged holster.

Use it to:

Monitor HVAC filter efficiency

•

Assess duct cleanliness per NADCA ACR

•

2006 Particle Profiling procedure

Verify compliance to cleanroom standards

•

Locate particle sources and report back on

•

post-remediation conditions

The Fluke 983 Particle Counter offers:

Selectable sample time, count data, and

•

programmable delay

User-defined sample size (cubic feet or liters)

•

and temperature measurements (°C or °F)

Data displayed in totalize or concentration

•

modes

Logged samples include date, time, particle

•

counts, sample volume, temperature, and

relative humidity

Quick Tips

Particle counts

Particle counts vary according

to a number of factors such

as location, time of year, and

occupants. When taking particle counts, always establish

an outside baseline reading to

compare indoor particle levels

against. Ideally, indoor particle

levels will be less then outdoor

levels.

Filter bypass

When testing for filter bypass,

take particle counts before

and after sealing the edges of

the filter with duct tape. This

will provide an indication of

how much particulate matter is

bypassing the filter due to poor

fitment or compromised sealing

surfaces.

Fluke TP120 Thermal Printer

Kit includes:

Thermal printer

•

(2) rolls paper

•

Battery pack

•

Serial adapter

•

Ordering information

Fluke-983 Particle

Counter

Includes: Certificate of

Calibration (NIST), Windows-

4

compatible software download

utility, DB9 to RS-232 adapter

and cable, Isokinetic probe, zero

count filter, high purity tubing,

1

/8 in. hose barb adapter,

power supply, hard molded

plastic case, and users manual

Page 5

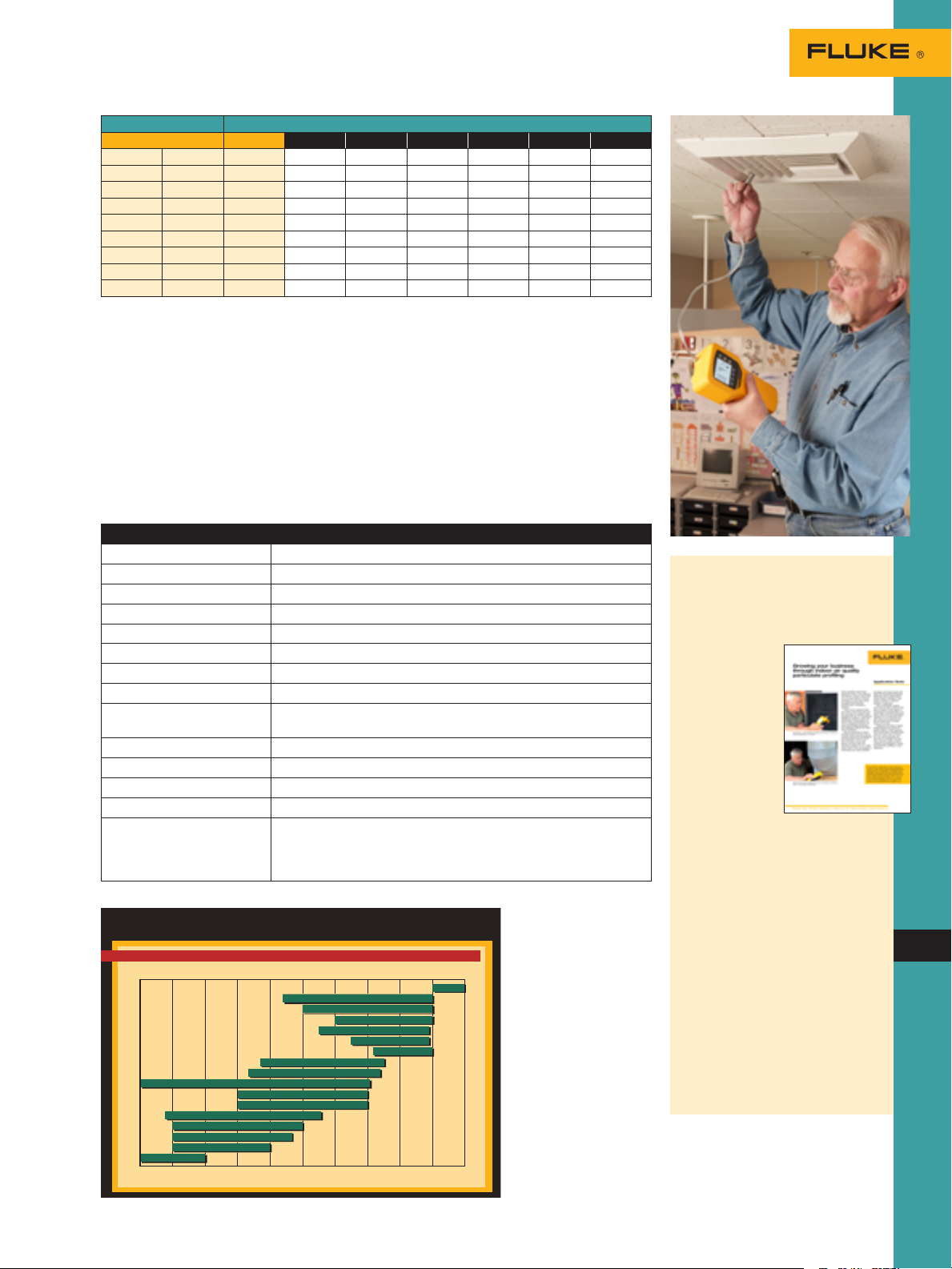

Class Number of Particles per Cubic Meter by Micrometer Size

.OTE-ICRONX-ETERS≈ X)NCHES)NCHES

!NGSTROMUNIT

-ETERS-ICROMETERS-ICRONS

0ARTICLE#HAR T

0ARTICLE3IZE

-ICROMETERS-ICRONS

2ELATIVESIZEOFCOMMONMATERIALS

!NGSTROM5NITS

(EAVY$UST

&LY!SH

3ETTLING$UST

#EMENT$UST

-OLD3PORES

0OLLEN

(UMAN(AIR

#OOKING/IL3MOKE'REASE

"ACTERIA

3USPENDED!TMOSPHERIC$UST

(OME$UST

!NIMAL$ANDER

3MOG

4OBACCO3MOKE

3OOT

#ARBON"LACK0HOTOCOPIER

6IRUSES

Federal Std 209E ISO 14644 0.1 µm 0.2 µm 0.3 µm 0.5 µm 1 µm 5 µm

ISO 1 10 2

ISO 2 100 24 10 4

1 M1.5 ISO 3 1,000 237 102 35 8

10 M2.5 ISO 4 10,000 2,370 1,020 352 83

100 M3.5 ISO 5 100,000 23,700 10,200 3,520 832 29

1,000 M4.5 ISO 6 1,000,000 237,000 102,000 35,200 8,320 293

10,000 M5.5 ISO 7 352,000 83,200 2,930

100,000 M6.5 ISO 8 3,520,000 832,000 29,300

ISO 9 35,200,000 8,320,000 293,000

Summary of cleanroom classification standards

Cleanroom particle concentrations

The above table presents airborne

particle limits for cleanroom applications per Federal Std 209E and ISO

14644 standards. The number of

particles per cubic meter represent the

maximum concentration limits for particles equal to and larger than the size

tested for. For example, an ISO class

5 cleanroom certified at 0.3 microns

should have no more than 10,200

particles 0.3 microns and larger. There

are other requirements regarding

sample volumes, locations and procedures that must be adhered to. Refer to

the applicable cleanroom standard for

more information.

Summary specifications

Feature Description

6 size channels 0.3, 0.5, 1.0, 2.0, 5.0, 10.0 µm

Flow rate 0.1 cfm (2.83 L/min) controlled by internal pump

Count modes Concentration, totalize, audio

Counting efficiency 50 % @ 0.3 µm; 100 % for particles > 0.45 µm (per JIS B9921:1997)

Zero count 1 count /5 minute (JIS B9921:1997)

Coincidence loss 5 % at 2,000,000 particles per ft

Relative humidity ± 7 %, 20 % to 90 % non-condensing

Temperature ± 3 °C, 10 °C to 40 °C (50 °F to 104 °F)

Data storage 5000 sample records (rotating buffer) of date, time, counts, relative

Alarms Counts, low battery, sensor fail

Delay time 0 to 24 hours

Sample inlet Isokinetic probe

Interface RS-232 and RS-485 via RJ-45

Environmental Operating: 10 °C to 40 °C (50 °F to 104 °F), 20 % to 90 % relative

humidity, temperat ure, sample volumes, alarms, and label

humidity, non-condensing

Storage: -10 °C to 50 °C (14 °F to 122 °F), up to 90 % relative humidity,

non-condensing

Growing your business

through indoor air quality

particulate profiling

You’ve probably heard mold referred to

as the “new asbestos”

for HVAC/R.

Concern about

mold and its health

effects is driving consumers to

have their indoor

air quality (IAQ)

situation assessed

and, if necessary,

repaired.

If you’re the

contractor they

call, keep in mind

that mold isn’t the

only issue to consider when assessing the IAQ of a commercial building

or residence. Many different kinds of

particulates in a work or living environment can cause Sick Building Syndrome

and aggravate allergy and respiratory

conditions. Read a detailed application

note on www.fluke.com/iaq

Common airborne particles and their sizes.

For more product information and detailed specifications, go to www.fluke.com

5

Page 6

Air Composition

Fluke 975V

Ordering information

Fluke-975 AirMeter

Fluke-975V AirMeter

with Velocity

Includes: AA alkaline batteries

(3), users manual (with safety

information), calibration cap,

hard carrying case, FlukeView™

6

Forms software, power

adapter, international power

plugs and air velocity probe

(Fluke 975V only)

AirMeter

™

New! Fluke 975 AirMeter™

Five powerful tools in one!

The new Fluke 975 AirMeter test tool raises

indoor air monitoring to the next level by

combining five powerful tools in one rugged

and easy-to-use handheld tool by measuring

temperature, humidity, velocity, CO2 and CO.

The Fluke 975 AirMeter test tool makes indoor

air quality testing easier and faster.

Use it to:

Optimize HVAC system operation and

•

manage energy costs

Respond to comfort-related occupant calls

•

Verify the operation of building HVAC control

•

systems

Monitor air flow and velocity (975V only)

•

Test for dangerous carbon monoxide leaks

•

Monitor and data log conditions, then

•

download for further analysis

Features include:

Simultaneously measures, logs, and displays

•

temperature, humidity, CO2, and CO on a

bright, backlit LCD display

One-touch air flow and velocity with

•

available probe (975V only)

Wet bulb and dew point temperature

•

% of outside air calculation

•

CO2 and CO field calibration feature

•

Self-test function at startup

•

Auto-backlight

•

Automatically compensates for barometric

•

pressure changes

Min/Max/Average on all measured and

•

calculated readings

Multi-language user interface

•

Metric or standard units

•

Audible and visual threshold alarms

•

Extensive discrete or continuous data

•

logging capacity, downloadable to PC

via USB interface

Keypad lock for security

•

Included FlukeView Forms® software

•

Using the velocity probe to check velocity

within a duct.

Quick Tips

Frequent Calibration is Key

Frequent calibration of gas

sensors is key to maintaining

the accuracy and performance

of the device. Both CO2 and

CO sensors can exhibit tendencies to drift over time due to

environmental factors such as

temperature, humidity, and

pressure.

Fluke recommends monthly

calibration of the CO sensor,

and an annual calibration for

CO2 for optimum performance.

Optional accessories

Fluke-975CK AirMeter

Calibration Kit

Includes: Zeroing and span gas,

tubing, regulator, hard carrying

case

Fluke-975VP AirMeter

Velocity Probe

Fluke-975CK Calibration Kit

Page 7

Summary specifications

Odor (3%)

Too Dry (4%)

Too Humid (1%)

Noisy (3%)

Drafty (1%)

Too Hot (29%)

Too Cold (47%)

Smell (12%)

Adapted from: Federspiel, C.C. 1998. Statistical Analysis of Unsolicited Thermal

Sensation Complaints in Commercial Buildings. ASHRAE Transactions 104(1): 4, 8.

Application Note

Measuring air velocity with

the Fluke 975 AirMeter:

Using the velocity probe

Fro m t h e F lu k e D ig i ta l L i br ar y @ w ww .f l uk e .c o m/ l ib ra r y

Air velocity is a key parameter in evaluating airflow system performance. As part of basic testing, adjusting

and balancing of HVAC air distribution systems, most

HVAC technicians now use an anemometer to measure air velocity at grilles-registers-diffusers, within a

duct, or in open spaces.

Anemometers are typically very accurate tools,

especially at low velocities, but they must compensate

for air temperature, absolute pressure, and ambient

absolute pressure. The Fluke 975 AirMeter tool has an

accessory velocity probe that uses a thermal anemometer to measure air velocity. A temperature sensor in

the probe tip compensates for air temperature, a sensor in the meter reads absolute pressure, and ambient

absolute pressure is determined upon meter initialization. For users who prefer to calculate their own compensation factors, the meter will also display air velocity

or volume at standard conditions.

This application note describes how to take accurate

air volume measurements within a duct, air measurements at grilles-registers-diffusers, and other locations.

Air volumes within a duct

The ultimate goal of any duct

system is to move the required

air volume, while keeping all

other factors within acceptable

limits, and to deliver it in quantities and patterns that serve the

intended purpose: heating, cooling, ventilating, exhausting, mixing, humidifying, dehumidifying,

or otherwise conditioning the air

within a space. Velocity within

a duct is determined not only

by application, but also by how

the duct is designed. Key design

factors include: The level of

available static pressure that can

be overcome by the fan due to

friction losses and pressure drops

of devices within the air stream;

the cost of duct work; the space

available for duct work; and

acceptable noise levels.

To determine the air volume

delivered to all downstream terminal devices, technicians use a

duct traverse. Duct traverses can

determine air volume in any duct

by multiplying average velocity

readings by the inside area of

the duct. Traverses in main ducts

measure total system air volume,

which is critical to HVAC system

performance, efficiency, and even

life expectancy. The difference

in air volumes between the main

supply duct traverse and the

main return duct traverse results

in outdoor air volume. A traverse

in run-outs is the most accurate

way to determine the air volume

delivered by the terminal device

(grille-register-diffuser). A traverse in exhaust ducts reveals

exhaust air volume.

Measuring air velocity in a duct.

Feature Range Display

resolution

Measured specifications

Temperature -5 °F to 122 °F

(-20 °C to 50 °C)

Relative humidity 10 % to 90 % RH

0.1 °F

(0.1 °C)

1 % ± 2 % RH

non-condensing

Air velocity 50 fpm to 3000 f pm

0.25 m/sec to

1 fpm

0.001 m/sec

15 m/sec

CO

2

0 to 5000 ppm 1 ppm Warm up t ime 1 min (5 minutes for full

CO 0 to 500 ppm 1 ppm ± 5 % or ± 3 ppm, whichever is greater,

Calculated specifications

Dew point

temperat ure

Wet bulb

temperat ure

Volume flow rate

(in a duct)

% outside air

-44 °C to 50 °C

0.1 °C (0.1 °F) ± 1 °C when temp: -20 °C to 50 °C

(-47 °F to 122 °F)

-16 °C to 50 °C

0.1 °C (0.1 °F) ± 1.2 °C when RH: 20 % to 90 %

(3 °F to 122 °F)

0.01 M3/min

(1 cfm)

0 to 100 % 0.1 % N/A

(based on

temperat ure)

% outside air

0 to 100 % 0.1 % N/A

(based on CO2)

Accu racy

± 0.9 °C/± 1.62 °F from 40 °C to 50 °C

± 0.5 °C/± 1.00 °F from 5 °C to 40 °C

± 1.1 °C/± 1.98 °F from -20 °C to 5 °C

(10 % RH to 90 % RH )

± 4 % or 4 fpm*

± 4 % or 0.02 m/sec* whichever is

greater

*Accuracy specification only valid for

velocity readi ngs above 50 fpm or

0.25 m/sec.

specification)

2.75 % + 75 ppm

@ 20 °C and 50 % R H

RH: 40 % to 90 %

± 2 °C when temp: -20 °C to 50 °C

RH: 20 % to 4 0 %

± 4 °C when RH: 10 % to 20 %

temp: -20 °C to 50 °C

± 2.1 °C when RH: 10 % to 20 %

N/A

The volume flow calculation will be a

simple average of the data points times

the duct area

Technician using the 975 AirMeter to

check for carbon monoxide leaks.

Making the numbers add up:

Understanding specifications

and performance of indoor air

quality test instruments

Air quality test

instruments must

deliver accurate

and verifiable performance, both to

ensure precise and

reliable air quality

diagnosis, and to

provide credible

answers if results

or procedures are

challenged. The

air quality professional’s reputation

depends on the quality and performance of the test tools in use, as well

as on their understanding of instrument

specifications, technologies, applications

and maintenance.

Read more about indoor air parameters, the technology to measure them,

and the importance of calibration to

optimize performance and promote

safety. Read a detailed application note

on www.fluke.com/iaq

Did You Know?

Common occupant complaints

For more product information and detailed specifications, go to www.fluke.com

Just the facts:

77 % of occupant

•

complaints are due to

thermal conditions

Technicians will take

•

from 1.5 to 2 hours to

respond to and diagnose those complaints

Fluke 975 helps technicians diagnose conditions

quickly and with fewer

tools. Do more. Carry less.

Measuring air velocity with the

Fluke 975 Airmeter using the

velocity probes

Air velocity is a key

parameter in evaluating airflow system performance.

As part of basic

testing, adjusting

and balancing of

HVAC air distribution systems, technicians measure air

velocity at grilles/

registers/diffusers

within a duct or in

open space.

Read more about effectively measuring airflow and other IAQ and HVAC

issues on www.fluke.com/iaq

7

Page 8

Ordering information

Fluke-922 Airflow Meter

Includes: Two rubber hoses,

four AA batteries 1.5 V alkaline,

users manual and soft carrying

case

8

Fluke-922/Kit

Includes: Fluke 922 Airflow

Meter, 12 inch Pitot tube, two

rubber hoses, TPak magnetic

strip, TPak strap, 9 inches, TPak

latch tab, four AA batteries 1.5

V alkaline, users manual, hard

carrying case

Optional accessories

PT12 12” Pitot Tube

Fluke-TPAK ToolPak™

Air Composition

Airflow Meter

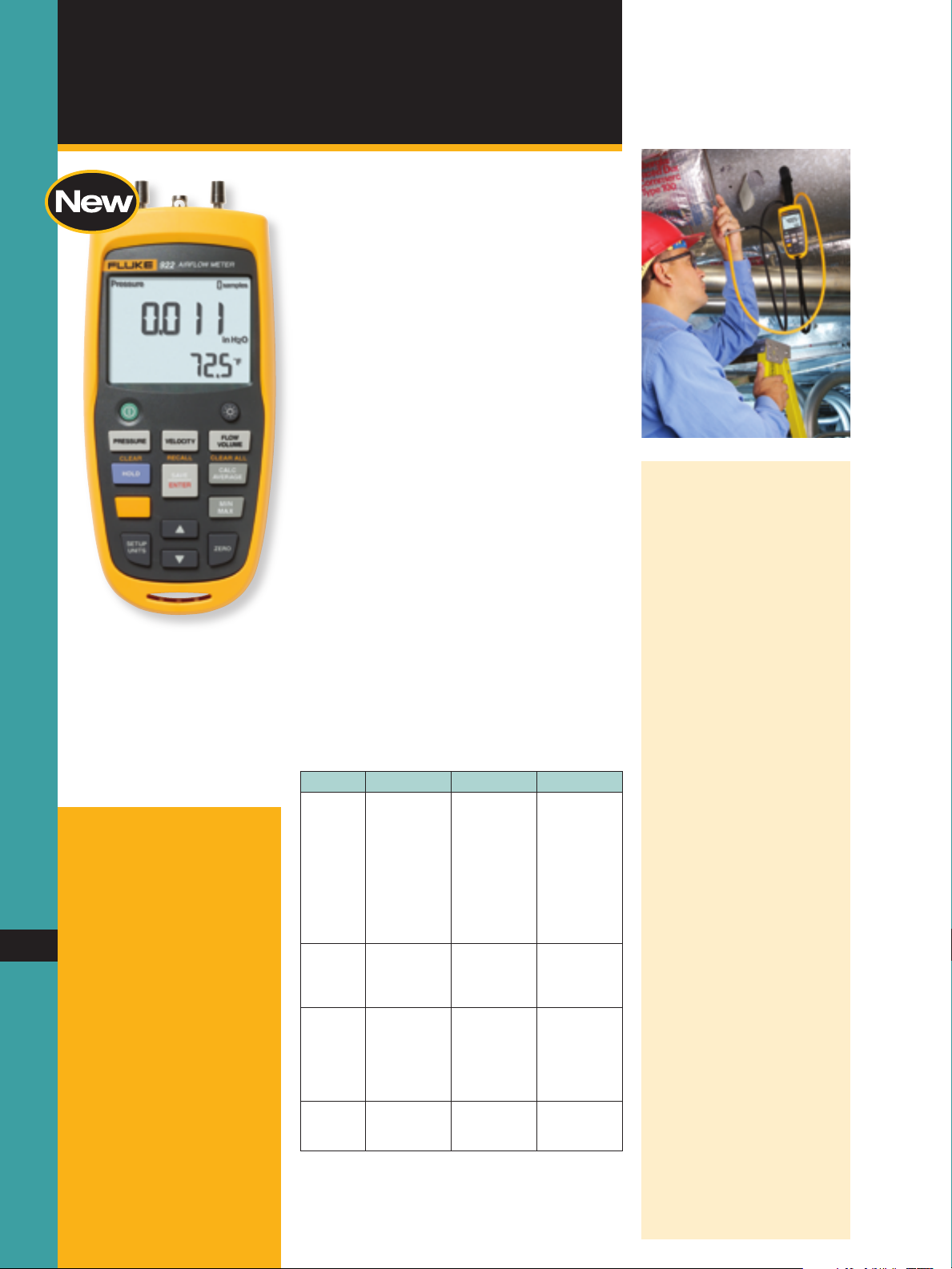

New! Fluke 922 Airflow Meter

Today’s HVAC technicians want a simple

solution for diagnosing ventilation issues. The

Fluke 922 makes airflow measurements easy

by combining pressure, air flow, and velocity

into a single, rugged meter.

Use the Fluke 922 to:

Ensure proper air flow balance

•

Monitor pressure to extend HVAC

•

component life

Promote good indoor air quality

•

Maintain a comfortable environment

•

Features include:

Powerful meter provides differential and

•

static pressure, air velocity and flow

readings

Rugged case and holster for real-world use

•

Easy to use without sacrificing performance

•

User-defined duct shape and size for maxi-

•

mum utility

Convenient colored hoses helps users prop-

•

erly diagnose pressure readings

Bright, backlit display for less than ideal

•

environments

Min/Max/Average/Hold functions for easy

•

data analysis

Auto power off saves battery life

•

Operating specifications

Feature Range Resolution Accuracy

Air

Pressure

Air

Velocity

Air Flow

(Volume)

Temperature

± 4000

Pasca ls

± 16 in H2O

± 400 mm

H2O

± 40 mbar

± 0.6 PSI

250 to

16,000 fpm

1 to 80 m/s

0 to

99,999 cfm

0 to

99,999 m3/hr

0 to

99,999 l /s

0 °C to 50 °C

32 °F to 122

°F

1 Pasca l

0.001 in H2O

0.1 mm H2O

0.01 mbar

0.0001 PSI

1 fpm

0.001 m/s

1 cfm

1 m3/hr

1 l/s

± 1 % + 2 °C

± 1 % + 4 °F

± 1 % + 1

Pasca l

± 1 % + 0.01

in H2O

± 1 % + 0.1

mm H2O

± 1 % + 0.01

mbar

± 1 % +

0.0001 PSI

± 2.5 % of

reading at

2000 fpm

(10.00 m/s)

Accuracy is a

function of

velocity and

duct si ze

0.1 °C

0.1 °F

Quick Tips

How HVAC airflow impacts

operating costs

Dirty coils, fans, and filters

will increase static pressure

by reducing airflow, causing HVAC equipment to work

harder to meet occupant loads

and increasing energy costs.

With HVAC energy costs often

comprising over 50 % of

the total energy bill, tighter

monitoring and control of

HVAC airflow can have a direct

impact on the bottom line.

In a study1 on coil clean-

•

ing and energy savings in

a New York City high rise,

pressure monitoring and

visual inspection led to

restoration of the coils and

components. The restoration resulted in a 14 %

decrease in pressure drop

across the coils, a 25 %

increase in the coil’s thermal efficiency, and energy

savings of up to $40,000 in

the first year.

EPA studies2 show that a 15

•

cfm airflow differential can

impact annual HVAC energy

costs by up to 8 % depending upon the HVAC system

and variations in climate.

1

Baker, Robert G.; Montgomery,

Ross D. “Coil Cleaning and its

Resultant Energy Savings and

Maintenance Enhancements.”

Indoor Air Quality Conference

Proceedings, 2006:22-27.

2

“Energy Cost and IAQ Perfor-

mance of Ventilation Systems

and Controls, Project Report #4.”

United States Environmental

Protection

Agency, January 2000:10.

Page 9

Air Composition

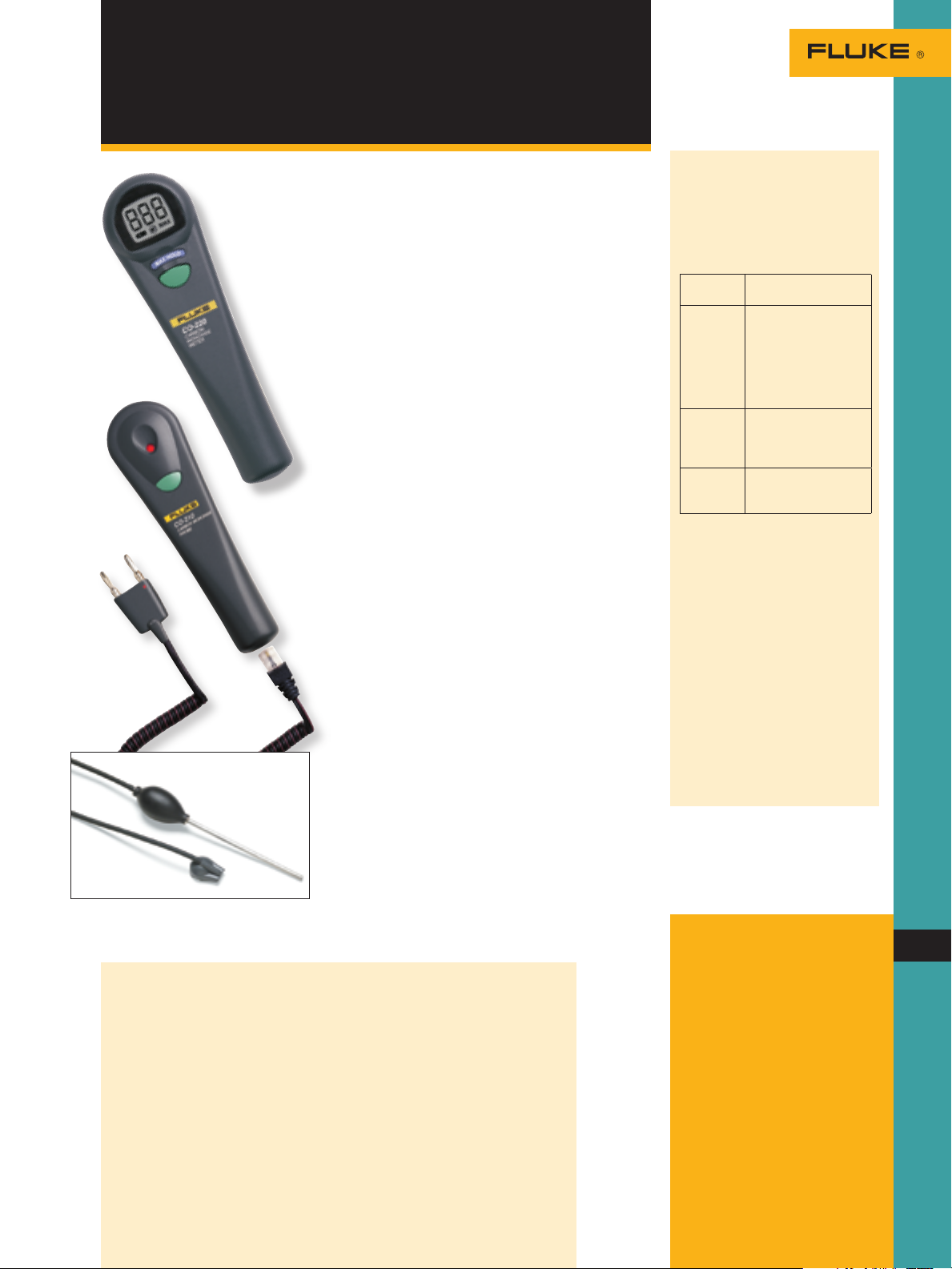

CO Detector and Probe

Fluke CO-220 Carbon

Monoxide Meter

Standalone CO meter that does not require

•

a digital multimeter

Large backlit LCD displays CO levels from

•

0 to 999 ppm, with a resolution of 1 ppm and

accuracy of ± 5 %

Beeper triggers with increasing frequency

•

as CO levels rise

MAX hold function stores and displays the

•

maximum CO level

Automatic sensor zeroing and self-test upon

•

startup

Fluke CO-210 Carbon

Monoxide Probe

Used as an accessory to a digital multimeter

•

with dc millivolt inputs

Displays CO level readings from 0 to

•

1000 ppm, with a resolution of 1 ppm and

accuracy of ± 5 %

Also used as a standalone device with an

•

LED indicator and beeper that triggers with

increasing frequency as CO levels rise

Fluke CO-205 Aspirator Kit

The CO-205 flue gas sampling accessory kit

contains all the components necessary to

provide a clean sample for the Fluke family of

gas measuring devices.

The CO-205 accessory kit includes:

Stainless steel sampling tube

•

Industrial-grade hand operated aspirator

•

to draw flue sample

Easily replaceable particulate filter

•

Specially designed nose cap for connection

•

to the Fluke CO-210/220

What is carbon

monoxide (CO)?

Carbon monoxide (CO) is a colorless, odorless, poisonous gas

with potentially serious health

consequences given adequate

exposure.

CO levels Exposure

70 to

100 ppm

150 to

300 ppm

400 and

higher

ppm

Treatment options

Get victim to fresh air

immediately.

If you can’t get victim out of the

building open all windows and

doors.

Take victim to a hospital

emergency room for a carbon

monoxide blood test.

symptoms

Flu or food

poisoning like:

Mild headaches

Sore eyes

Runny nose

Mild nausea

Shortness of breath

Dizziness

Headaches

Drowsiness

Vomiting

Unconsciousness

Brain damage

Death

How many people are unintentionally poisoned by CO?

Every year, over 200 people in the

United States die from CO produced

by fuel-burning appliances (furnaces, ranges, water heaters, room

heaters). Others die from CO produced while burning charcoal inside

a home, garage, vehicle or tent. Still

others die from CO produced by cars

left running in attached garages.

Several thousand people go to hospital emergency rooms for treatment

for CO poisoning.

For more product information and detailed specifications, go to www.fluke.com

What is the permissible

exposure to CO?

The current Occupational Safety

and Health Administration (OSHA)

permissible exposure limit (PEL) for

carbon monoxide is 50 ppm over an

8-hour time period.

Ordering information

Fluke-CO-220 Carbon

Monoxide Meter

Includes: Soft carrying case,

battery and instruction sheet

Fluke-CO-210 Carbon

Monoxide Probe

Includes: Soft carrying case,

battery and instruction sheet

Fluke-CO-205

Aspirator Kit

Includes: Instruction sheet

9

Page 10

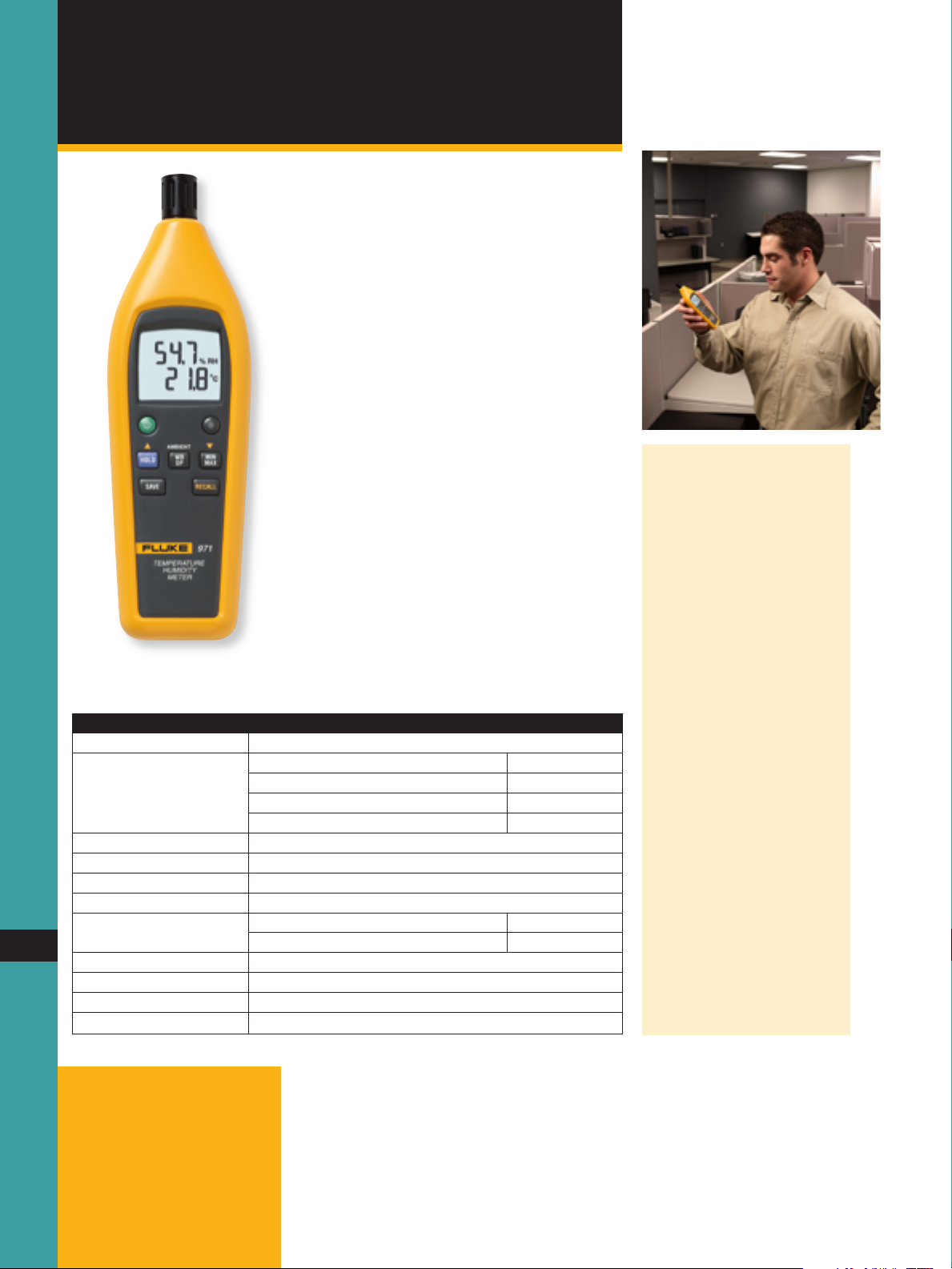

Air Composition

Temperature Humidity Meter

Fluke 971 Temperature

Humidity Meter

The rugged new answer to

humidity and temperature in

your building.

Quickly take accurate humidity and temperature readings. Temperature and humidity are

two important factors in maintaining optimal

comfort levels and good indoor air quality.

The Fluke 971 is rugged, lightweight, and easy

to hold.

Use it to:

Monitor indoor comfort conditions and

•

respond to “hot/cold” calls from occupants

Matching HVAC system capacity to the load

•

Promote good indoor air quality

•

Key features:

Fast-settling humidity sensor

•

Instant wet bulb and dewpoint temperature

•

calculations

Bright backlit display

•

Rugged holster and protective twist-open

•

sensor cover

Convenient Min/Max feature and data

•

storage capacity

Summary specifications

Feature

Temperature range -20 °C to 60 °C ( -4 °F to 140 °F)

Temperature accuracy 0 °C to 45 °C ± 0.5 °C

-20 °C to 0 °C and 45 °C to 60 °C ± 1.0 °C

32 °F to 113 °F ± 1.0 °F

-4 °F to 32 °F and 113 °F to 140 °F ± 2.0 °F

Resolution 0.1 °C / 0.1 °F

Temperature update rate 500 ms

Temperature sensor type NTC

Relative humidity range 5 % to 95 % R.H.

Relative humidity accuracy 10 % to 90 % R.H. @ 23 °C (73.4 °F) ± 2.5 % R.H.

10

Resolution 0.1 % R.H.

Response time ( humidity) For 90 % of total range—60 sec. with 1 m/s air movement

Humidity sensor Electronic capacitance polymer fi lm sensor

Data storage 99 points

<10 %, > 90 % R.H. @ 23 °C (73.4 °F) ± 5.0 % R.H.

Quick Tips

Duct temperatures

Use the Fluke 971 and an infrared thermometer to monitor duct

temperatures at the register.

Easily calculate dewpoint with

the Fluke 971, then compare it

to register temperatures to see

if they fall below the dewpoint.

Use an infrared thermometer

in this application as a general

indicator only. Many factors

come into play when taking IR

measurments, such as emissivity and spot-to-distance ratio.

Lower temperatures can lead to

condensation forming on ductwork. If uninsulated, moisture

can fall onto ceiling materials

and cause potential mold issues

and water damage.

Did you know?

Studies indicate that productivity

can increase anywhere from

0.5 % to 5 % given a comfortable

work environment. Use the Fluke

971 to monitor and maintain

comfortable conditions for your

customers—and demonstrate the

effectiveness of your repairs.

Ordering information

Fluke-971 Temperature

Humidity Meter

Includes: Users manual, and

4 AAA alkaline batteries

Page 11

Thermal Imaging

Thermal Imager

Fluke TiR Series Flexcam

Thermal Imagers

The expert’s choice

for building diagnostics.

High resolution, industry leading

sensitivity and large, five-inch

color display make these imagers

perfect for building diagnostics.

IR Fusion technology integrates

thermal and visual images. A

180° articulating lens plus onefinger SmartFocus deliver great

images when access is poor.

Built-in auto-capture, alarm,

and analysis functions help you

locate intermittent problems

(TiR2 and TiR4 only). Powerful

analysis and reporting software

is included with the TiR cameras.

IR-Fusion™

Technology

Infrared and

visible light

images fused

together on

one display.

IR-Fusion™ Technology

captures a visible

light image in addition to

the infrared image and

takes the mystery out

of IR image analysis. It

helps to better identify

and report suspect components and enable the

repair to be done right

the first time.

Use it for:

Moisture detection:

Accurately detect moisture

behind interior walls, in

ceilings, and under carpets.

Mold remediation: Control

mold by revealing undetected

sources of moisture.

Roofing: Detect watersaturated insulation in flat-roof

systems to locate damaged

portions of roofing structure.

Energy audits: Perform

residential and commercial

energy audits by scanning for

heat loss, moisture invasion

and HVAC problems.

Ordering information

Fluke-TiR2-20 IR FLEXCAM BD Thermal Imager

Fluke-TiR2/FT-20 IR

FLEXCAM BD Thermal

Imager with IR-Fusion

Fluke-TiR3-20 IR FLEXCAM BD Thermal Imager

Fluke-TiR3/FT-20 IR

FLEXCAM BD Thermal

Imager with IR-Fusion

Fluke-TiR4-20 IR FLEXCAM BD Thermal Imager

with IR-Fusion

Includes: Heavy duty carrying

case, 2 rechargeable battery

packs, battery charger, ac

adapter (for R2 and R4 models

only), video cable, 512 MB compact flash card, compact flash

card adaptor and USB cable,

PCMCIA compact flash card

reader, neck strap, SmartView™

reporting and analysis, software

on CD and user manual on CD

11

For more product information and detailed specifications, go to www.fluke.com

Page 12

Thermal Imaging

Infrared Imager

Fluke IR InSight® Thermal Imagers

The perfect camera for quick,

accurate building surveys.

Combine outstanding image quality and

thermal sensitivity. InSight infrared imagers

are optimized for low contrast thermal applications encountered in building applications and

easily show problems other infrared cameras

cannot. These easy-to-use cameras include

SmartView™ software to prepare professional

infrared survey reports.

Key features:

160 x 120 focal plane array

•

High resolution, ultra high-quality images

•

Industry-leading thermal sensitivity

•

(≤ 0.07 °C NETD)

Simple, robust one-button operation

•

3.5 inch, 30 bit color, high resolution

•

high-contrast display

SmartView™ professional report

•

writing software

Ordering information

Fluke-INSXT-20

IR InSight, 20MM, XST

Fluke-INSXS-20

IR InSight, 20MM, XS

12

12

Includes: Heavy-duty carrying

case, 2 rechargeable battery

packs, battery charger, video

cable, serial/USB download

adapter kit/cable, neck strap,

SmartView reporting and

analysis software on CD and

users manual on CD

SmartView™ Software

For the XS and XST InSight®

Thermal Imagers.

Fluke SmartView™ software is included with

each Fluke InSight Thermal Imager. This powerful software provides all the tools you need

to organize your infrared images.

Easily generate customized, professional

•

reports

Images transferred as PGM format and saved

•

as JPEG or BMP (Microsoft® Word compatible)

View images in 10 color palette

•

Parameter controls: Emissivity and

•

background temperature

For detailed specifications, see

www.fluke.com/buildingresources.

Navigate, analyze and

enhance IR images

For detailed product specifications visit: w ww.fluke.com/thermography

Page 13

Summary specifications for TiR and Insight thermal imagers

Feature TiR4-FT TiR4 TiR3-FT TiR3 TiR2-FT TiR2 Insight

XST

High-resolution, low noise VOx detector for

high-quality images

Temperature range for building diagnostic

applications

High thermal sensitiv ity for viewing even the

smallest temperature differences

180° art iculating flexible lens to view images in

every situation

Choice of three interchangeable lenses to cover

every application

Large 5 in. high-contrast color LCD for a clear

picture independent of lighting conditions

Fully radiometric for detailed temperature

analysis and tracking

Smar tFocus for best image quality and accurate

temperat ure measurements

Windows CE based menu structure for ease

of use

Personalized instrument set-up for multiple

user profiles

Compact Flash memory cards store more

than 1000 IR images plus fu lly radiometric

temperat ure data

Smar tView reporting and analysis software

included

AutoCapture for making intermittent problems

visible

On-board analysis functions

User defined text annotations for simplified

reporting

Built-in visible light (digital) camera

IR-Fusion blending thermal and visible light

images to easily pinpoint suspect components

IR/ Visible Alarm function

Laser pointer for easy targeting

Flash and torch l ight for high quality images in

dark env ironments

Imaging performance: thermal

Field of v iew (FOV)* 23° hori zontal x 17° vertical

Spatial resolution (IFOV)* 1.30 mrad 2.60 mrad

Minimum focus distance* 0.15 m

Thermal sensitivity (NETD) ≤ 0.05 °C at 30 °C ≤ 0.07 °C at 30 °C

Detector data acquisition/image frequency 60 Hz 30 Hz

Focus Smar tFocus; one finger continuous focus ring focus

IR digital zoom 2x, 4x, 8x 2x

Detector type Vanadiu m Oxide (VOx) Uncooled Microbolometer

Detector size 320 x 240 Focal Plane Array 160 x 120

Spectral band 8 µm to 14 µm

Digital image enhancement Automatic full-time enhanced

Temperature measurement

Calibrated temperature range -20 °C to 100 °C ( -4 °F to 212 °F) 0 °C to 100 °C

Accuracy ± 2 °C or 2 % (whichever is greater)

Measu rement modes TiR2/TiR4: Centerpoint, center box (area min/max, average) , moveable spots/boxes, user defined

Emissivity correction 0.1 to 1.0 (0.01 increments)

≤ 0.05 °C ≤ 0.07 °C

• • • • • •

• • • • • •

• • • • • •

• • • • • •

• • • • • •

•

• • • • • •

• • • • • •

• • • • • • • •

• • • •

• • • •

• • • •

• • •

• • •

• • •

• • •

• • •

field/text annotations, isotherms, automatic hot and cold point detection, visible color alarm

above and below

TiR3: Centerpoint, center box (area min/max, average)

320 x 240 160 x 120

-20 °C to +100 °C 0 °C to +100 °C

center

point

• • • • •

300 300

Insight

XS

imager

only

13

For more product information and detailed specifications, go to www.fluke.com

Page 14

IR Temperature

IR Thermometer

Fluke 561 HVACPro

Multipurpose thermometer for

heating, ventilation, air conditioning and refrigeration inspections

Combine the temperature measurement functions professionals need most for inspecting

heating, ventilation, air conditioning and

refrigeration systems. The Fluke 561 HVACPro

provides both non-contact, and contact temperature measurements replacing several other

test tools. It is fast, efficient and easy to use,

saving you valuable time, and effort.

Ordering information

14

Fluke-561 HVACPro

Includes: Type-K thermocouple

Velcro pipe probe, Durable

hard case, 2 AA batteries,

user’s manual with step-bystep application instructions

(available in English, Spanish,

French, Italian, German, Portuguese, and Simplified Chinese)

and two-year warranty

Use it to:

Measure hot, moving, electrically energized

•

and hard-to-reach objects instantly

Check motors, insulation, breakers, radiant

•

heating, pipes, corroded connections and

wires plus scan ducts in the ceiling from the

floor without a ladder

Handy Velcro® pipe probe included for super-

•

heat and sub-cooling contact measurements

Or, plug in your own industry-standard

•

type-K thermocouple probes and get the

most out of your tool investments

Key features:

Compatible with all standard mini-connector

•

type-K thermocouples

Velcro pipe probe for superheat, sub-cooling

•

or other contact and ambient measurements

Single-point laser sighting, 12:1 distance-to-

•

spot ratio

Temperature range optimized for HVAC/R

•

applications

Easy emissivity adjustment for measuring

•

pipes and ducts more accurately

Lightweight, only 340 grams (12 ounces)

•

and portable

Easy to use

•

Efficient—no need to shut down equipment

•

when making IR measurements

MIN, MAX and DIF temperature readings help

•

you quickly identify problems

Scan large areas or small objects quickly and

•

efficiently

HVAC/R measurement guide included to

•

maximize your productivity

Indoor air quality: Can your

schools pass the test?

Increases in temperature are often

the first sign of trouble for mechanical equipment, electrical circuits and

building systems

such as heating,

ventilation and

air conditioning

(HVAC). Read

about how to

take basic, quick

temperature

checks using

infrared thermometers at

www.fluke.

com/iaq

Page 15

IR Temperature

Mini IR Thermometer

Fluke 62 Mini Infrared

Thermometer

Measuring temperature in

hard-to-reach, hot, rotating

or dangerous situations.

The Fluke 62 Mini Non-contact Thermometer is the perfect introduction to infrared

(IR) thermometers. With the best accuracy in

its class, the Fluke 62 Mini offers quick and

reliable surface temperature readings. This

compact and portable tool enables professionals to diagnose heating and ventilation

problems and monitor the temperature of

electrical motors and electrical panels without

contact. Rugged enough for industrial environments with its protective rubber “boot”, the

62 Mini also comes with a handy nylon

holster, keeping quick temperature checks at

your fingertips.

Key features:

Single point offset laser sighting, 10:1

•

distance-to-spot ratio

Best accuracy in its class: +1 % of reading

•

Holds temperature readings for seven

•

seconds

Dual displays shows current and MAX

•

measurements simultaneously

Backlit display for poorly lit areas

•

Comfortable ergonomic handle with

•

protective rubber boot for added durability

Fitted carrying case

•

Robust, award winning design

•

Wide temperature range from

•

-30 ºC to 500 ºC (–20 ºF to 932 ºF)

The Fluke 62 Mini Infrared

Thermometer

Inspections: Ambient air, diffuser,

window, and wall-surface temperature;

blower component temperatures; subcooling; electrical

inspection. Read a

detailed application note on www.

fluke.com/iaq

For more product information and detailed specifications, go to www.fluke.com

15

Ordering information

Fluke-62 Mini Infrared

Thermometer

Includes: Storage pouch and

instruction sheet

Page 16

Fluke 975

AirMeter

See page 6

for details

Fluke 983

Particle

Counter

See page 4

for details

Fluke test tools to help

you get the job done

Fluke 971

Temperature

Humidity

Meter

See page 10

for details

Fluke 922

Airflow

Meter

16

See page 9

for details

Fluke 116

Digital HVAC

Multimeter

0

0

0

12

4

See page 22

for details

For more product information and detailed specifications,

go to ww w.fluke.com

Page 17

Fluke 561

HVACPro

See page 14

for details

Fluke 902

True-rms

HVAC Clamp

Meter

See page 20

for details

Fluke IR

InSight

XS/XST

Thermal

Imagers

Legend

Air Comfort

Filtration

Ventilation

Electrical

Motors, Pumps, Drives

Furnace

Buiding Structure

See page 12

for details

Fluke TiR

Series IR

Flexcam

Thermal

Imagers

17

See page 11

for details

Fluke

C0-220

Carbon

Monoxide

Meter

See page 8

for details

Page 18

Gas heat

Heated air

Cold air

Primary

voltage

Flue gas

Inducer fan

Control

module

Carbon

monoxide

Use a carbon monoxide

meter to check for CO leaks

around the heat exchanger,

flue and other points

within a building.

Control voltage

Use a voltage detector or

DMM to test for energized

24 V ac contacts. Use an

infrared (IR) thermometer to

check for loose connections

or overloaded circuits.

Belts and

bearings

Use an infrared

thermometer to

check belts for

alignment and

bearings for

excessive

friction.

Air temperature difference

Check the temperature difference across the heat exchanger

with a digital thermometer, with the burner working. Expect

a 40-75 °F temperature difference (TD). If the TD is low, then

the fan is running too fast. If the TD is high, then the fan is

running too slow or there is restricted air flow.

Flame rod µA test

Verify proper operation of the flame

rectification circuit with a clamp meter or

digital multimeter in the µA mode. Compare

measured value against flame control module

specifications. Typical values vary widely and

can be as low as 0.16 to 18.0 µA or more.

If the µA reading is below specification,

the flame rod may need to be

repositioned, cleaned, or replaced.

T1

T2

T1-T2

SETUP

ENTER

CANCEL

MIN

MAX

HOLD˚C˚FK

52

THERMOMETER

F

TYPE

K

T2

HOLD

T1

56

1

H

V

A

C

P

r

o

I

R

T

H

E

R

M

O

M

E

T

E

R

Fluke 54-II

Fluke 80PK-8

TC Temperature

TC Thermometer

Fluke 54 Thermometer

Laboratory accuracy.

Wherever you go.

The Fluke 54 Series II contact thermometer

offers fast response and laboratory accuracy

(0.05 % + 0.3 °C) in a rugged, handheld

test tool.

Key features:

• Relative time clock on MIN, MAX, and AVG

provides a time reference for major events

• Electronic offset function allows compen-

sation of thermocouple errors to maximize

overall accuracy

• Readout in ºC, ºF, or Kelvin (K)

• Splash and dust resistant case protected by

impact absorbing holster

• User-friendly front panel is easy to set up

and operate

• Sleep mode increases battery life; typical

1000-hour battery life

• Battery door allows easy battery replacement

without breaking the calibration seal

• Large backlit dual display shows any

combination of T1, T2, T1-T2, plus MIN,

MAX, or AVG

• Recall function allows logged data to be

easily reviewed on the meter display

• IR communication port allows data to be

exported to optional FlukeView® Forms

Temperature PC software for further analysis

and graphing

• Data Logging up to 500 points of data with

user adjustable recording interval

80PK-8 Pipe Clamp

Temperature Probe

Type-K thermocouple

•

for fast temperature and

superheat measurements

of pipe surfaces

Durable ribbon sensor

•

Measurement range: -29 °C

•

to 149 °C (-20 °F to 300 °F)

for pipe diameters from

6.4 mm to 34.9 mm

(.25 in to 1.375 in)

One-year warranty

•

Accessory for use with DMM

•

with dc millivolt input and

80AK DMM adapter

18

Ordering information

Fluke-54 II Dual Input

Digital Thermometer

Includes: Impact absorbing

holster and two 80PK-1 beaded

probe thermocouples

Fluke-80PK-8 Pipe Clamp

Temperature Probe

Page 19

Pressure

Bubble Point Used to determine

subcooling

Constant

temperature lines

BTU’s/Lb-Enthalpy

Evaporator

Compressor

Condenser

Metering

Device

Pressure-Enthalpy (PH) diagram for refrigerant blends

Dew Point - Used to

determine superheat

Psia

Condenser

Compressor

Evaporator

Liquid psig

refrigerant bubble point

Metering

device

Liquid receiver

Vapor psig

refrigerant dew point

HVAC Pressure Module

For use with:

Fluke 116

Fluke PV350 Pressure

Vacuum Module

Key features:

Compatible with all Fluke and most

•

popular DMMs

Digital pressure and vacuum measurements

•

in a single module

Transducer sealed in 316 stainless steel

•

compatible with a variety of liquids and

gases

Measures vacuum to 76 cm Hg

•

Displays results in English (psig or Hg) or

•

metric (kPa or cm Hg) units

Measures pressure to 3447 kPa (500 psig)

•

Refrigeration cycle

Quick Tips

Measuring superheat

and subcooling

To measure superheat:

1) Measure suction pressure

with a pressure module

and your digital multimeter

(DMM). Convert pressure

to temperature using your

PT chart.

2) Measure the pipe temperature

at the outlet of the evaporator

with a pipe clamp and your

temperature meter.

3) Subtract the difference

in temperatures to obtain

superheat.

To measure subcooling:

1) Measure liquid line pressure

(or discharge pressure if there

is no liquid line access valve)

with a pressure module and

your DMM. Convert the pressure to temperature using your

PT chart.

2) Measure the pipe temperature

at the outlet of the condenser

with a pipe clamp and your

temperature meter.

3) Subtract the difference

in temperatures to obtain

subcooling.

For more product information and detailed specifications, go to www.fluke.com

19

Superheat temperature measurement points.

Ordering information

Fluke-PV350 Pressure

Vacuum Module

Page 20

HVAC Electrical Tools

Voltage Detectors

Fluke 1AC-II/1LAC-II VoltAlert™

Easy-To-Use Voltage Detector.

The next generation VoltAlert™ ac non-contact

voltage testers from Fluke are easy to use—just

touch the tip to a terminal strip, outlet, or

supply cord. When the tip glows red and the

unit beeps, you know there is voltage present.

Electricians, maintenance, service, safety personnel and homeowners can quickly test for

energized circuits in the workplace or at home.

Two models to choose from:

1AC-II: detects voltage from

•

90 V ac to 1000 V ac

1LAC-II: detects voltage from

•

20 V ac to 90 V ac

Key features:

Fits in a shirt pocket for convenience

•

All outer surfaces are non-conductive

•

for safety

Detects voltage without metallic contact

•

Quickly locates the hot, neutral and

•

ground terminals in any receptacle

Certified up to CAT IV 1000 V

•

Verifying lockout/tagout

electrically safe status

For non-electricians working in

electrical environments

Lockout/Tagout

procedures specify

the steps electricians must follow

to remove power

from an electrical

circuit or panel,

and to lock out

and tag the panel

or circuit, so that

no one can

re-energize it

while work is in

progress. Read a

detailed application note on

www.fluke.com /iaq

20

Ordering information

Fluke-1AC-II

Voltage Detector

Fluke-1LAC-II

Voltage Detector

Page 21

HVAC Electrical Tools

True-rms Clamp Meter

New Fluke 902 True-rms

HVAC Clamp Meter

Clamp designed just for HVAC

professionals.

Heating, ventilation, air conditioning (HVAC)

technicians require a service tool that can

consistently keep up with their demands. The

Fluke 902 expands the existing line of quality

Fluke clamp meters by delivering the features necessary to diagnose and repair HVAC

systems. Combined with true-rms technology

and a CAT III 600 V rating, the Fluke 902 helps

technicians do their jobs safely and accurately.

Use it to:

Capture flue gas temperatures

•

Conduct flame rod testing

•

Measure start and run motor capacitors

•

Key features:

Capacitance

•

DC current to 200 uA

•

Contact temperature (Type-K thermocouple)

•

True-rms

•

Min/Max

•

Hold

•

Summary specifications

Feature Range Accuracy

Voltage dc 0 to 600.0 V 1 % ± 5 counts

Voltage ac (true-rms) 0 to 600.0 V 1 % ± 5 counts (50/60 Hz)

Current ac (true-rms) 0 to 600.0 A 2.0 % ± 5 counts (50/60 Hz)

Current dc 0 to 200.0 µA 1.0 % ± 5 counts

Resistance

Continuity

Temperature*

(Type-K thermocouple)

Capacitance 1 µF to 1000 µF 1.9 % ± 2 counts

Warranty Three-years

0 to 9999 W

<= 30 W

-10 °C to 400 °C

(-14 °F to 752 °F)

-40 °C to -10 °C

(-40 °F to -14 °F)

1.5 % ± 5 counts

± 1.0 % + 0.8 °C

(± 1.0 % + 1.5 °F) typical

± 5.0 % + 1.5 °C

(± 5.0 % + 3.3 °F) typical

Why true-rms matters

for HVAC technicians

Non-linear loads need a true-rms

test tool for accurate readings

For today’s

HVAC

technician,

troubleshooting

electrical problems is becoming

more difficult

without the use

of true-rms test

tools. This is

due in part to

the prol iferation

of new solid

state adjustable speed

motor dr ives and heating controls

containing power semiconductors or

rectifiers. These loads are referred

to as “non-linear.” Non-linear loads

draw current in short pulses rather

than the smooth sine wave drawn

by a linear load such as an induction

motor. The c urrent wave shape can

have a drastic effect on a test tool

reading. Read a detailed application

note on www.fluke.com/iaq

21

Ordering information

Fluke-902 HVAC

Clamp Meter

Includes: AA alkaline batteries (2), users manual (w/safety

information), soft carrying

case, TL75 Test Leads (1 pair),

and 80BK Integrated DMM

Temperature Probe (1)

For more product information and detailed specifications, go to www.fluke.com

Page 22

HVAC Electrical Tools

(A)

Current

(Ω)

Resistance

(V)

Voltage

V = A x Ω

Where: V = Volts

A = Current in Amps

Ω = Resistance in Ohms

Ohm’s Law explains the

relationship between voltage,

current and resistance.

Put your finger over the value

you want to find. Multiply

the remaining values if sideby-side; divide if one is over the

other. But it really is much

easier just to use your DMM.

Temperature DMM

Fluke 116 HVAC Multimeter

with Thermometer

Measures temperature

and microamperes

The Fluke 116 was specifically designed for the

HVAC professional. It has everything needed

in an HVAC meter including temperature and

microamp measurements to quickly troubleshoot problems with HVAC equipment and

flame sensors. Use the Fluke 116 to test motor

start and run capacitors up to 10,000 microfarads. Rely on the Fluke 116 to make your

everyday measurements—up to 600 volts ac or

dc, 40 MW, diode test and exceptionally fast

continuity.

Key features:

Built in thermometer

•

Microamps to test flame sensors

•

LoZ: helps prevent false readings due to

•

ghost voltage

Resistance, continuity, frequency and

•

capacitance

Min/Max/Average

•

Compact ergonomic design

•

Compatible with optional magnetic hanger

•

(ToolPak™)

CAT III 600 V safety rated

•

IP52 rating for dust and water protection

•

Quick Tips

Understanding

Ohm’s Law

22

Ordering information

Fluke-116 HVAC Multimeter with Temperature

and Microamps

Includes: TL75 Test Leads, 80BK

Integrated Temperature Probe,

holster, User’s manual and 9 V

battery (installed).

Func tion Range and resolution

mV dc true rms 600.0 mV 2.0 % + 3

V dc 6.000 V, 60.00 V, 600.0 V 2.0 % + 3

mV ac true rms 600.0 mV 1.0 % + 3

V ac true rms 6.000 V, 60.00 V, 600.0 V 1.0 % + 3

Resistance

Capacitance 1000 nF, 10.00 µF, 100.0 µF, 9999 µ F

Lo-Z Capacitance 1 nF to 500 µF 10 % + 2 typical

Temperature (Type K) -40 °C to 400 °C ( -40 °F to 752 °F) 1 % + 10 (1 % + 18)

AC µA true rms

(45 Hz to 500 Hz)

DC µA 600.0 µA 1.0 % + 2

Frequency 99.99 Hz, 999.9 Hz, 9.999 Hz, 50.00 kHz 0.1 % + 2

600.0 W, 6.000 kW, 60.00 kW,

600.0 k W, 6.000 MW, 40.00 MW

100 µF to 1000 µF, > 1000 µF

600.0 µ A 1.5 % + 3 (2.5 % + 3 > 500 Hz)

Best accuracy

± ([% of reading] + [counts])

0.9 % + 1

1.9 % + 2

Page 23

HVAC Electrical Tools

Insulation Multimeters

Fluke 1587 Insulation Multimeters

Two powerful tools in one.

The Fluke 1577 and 1587 Insulation Multimeters combine a digital insulation tester with a

full-featured, true-rms digital multimeter in a

single compact, handheld unit, which provides

maximum versatility for both troubleshooting and preventative maintenance. Like other

tools you have come to expect from Fluke, the

1577 and 1587 are rugged, reliable, and easy

to use. Whether you work on motors, generators, cables, or switch-gear, the Fluke 1577

and 1587 Insulation Multimeters are ideally

suited to help you with your tasks.

Key features:

Insulation test (1587: 0.01 MW to 2 GW)

•

(1577: 0.1 MW to 600 MW)

Insulation test voltages (1587: 50 V, 100 V,

•

250 V, 500 V, 1000 V), (1577: 500 V, 1000 V)

for many applications

Live circuit detection prevents insulation

•

test if voltage > 30 V is detected for added

user protection

Auto-discharge of capacitive voltage for

•

added user protection

Filter for motor drive measurements

•

(1587 only)

AC/DC voltage, dc millivolts, ac/dc

•

milliamps, resistance (W ) and continuity

Capacitance, diode test, temperature,

•

Min/Max, frequency (Hz) (1587 only)

Auto power off to save battery power

•

Large display with backlight and large digits

•

Accepts optional Fluke TPAK™ magnetic

•

hanging system to free your hands for other

work

Rugged, utility hard case allows you to bring

•

everything you need for the job

Three-year warranty

•

Insulation resistance testing

Insulation resistance testers can be

used to determine the integrity of

windings or cables in motors, transformers, switchgear, and electrical

installations.

The most important reason for

testing insulation is to insure

public and

personal safety.

The second

most important

reason for insulation testing is

to protect and

prolong the life

of electr ical

systems and motors. Read more

about the importance of insulation

testing and the tools and techniques

to use in the application note on

www.fluke.com /electrical

For more product information and detailed specifications, go to www.fluke.com

23

Ordering information

Fluke-1577 Insulation

Multimeter

Fluke-1587 Insulation

Multimeter

Includes: Remote probe, test

leads, alligator clips, type-K

thermocouple (1587 only), hard

case, and user documentation.

Page 24

Accessories

Test Leads and Probes Test Lead and Probe in One

TL71 Premium DMM Test Lead Set

Flexible silicone insulated leads are heat and

•

cold resistant

Distinctive comfort grip probes

•

Recommended for µV

•

measurements

CAT III 1000 V, 10 A,

•

CAT IV 600 V, 10 A

Use with 16, 179, 87V DMM and

•

336 Clamp Meter

TL81A Deluxe Electronic Test Lead Set

22 piece set with quadfold pouch

•

Includes mini alligator clips, hooks and

•

pincers for virtually every electronic need

Slide-on lc probe tip adapter and test

•

lead couplers

Both modular test leads and lead-probe

•

combinations

CAT II 300 V

•

Use with 179 and 87V DMM

•

TL910 Electronic Test Probes

with replacement tips

Small profile provides

•

accessibility

Comes with five sets

•

of replaceable tips

Replacement tips: TP912

•

CAT III 1000 V, 3 A

•

TL76 2 mm/4 mm Test Lead Set

2 mm threaded probes with removable 4 mm

•

banana-style spring contacts

Flexible 1.5 m silicone leads

•

CAT III 1000 V, CAT IV 600 V, 10 A

•

Use with 16, 179, 87V DMM and

•

336 Clamp Meter

Sets and Kits

TL220 Industrial Test Lead Set

Starter kit for industrial applications

•

TP220 has round, stainless steel tip

•

Includes one pair: AC220, TP220 and

•

TL222

CAT III 1000 V, CAT IV 600 V, 10 A

•

Use with 16, 179, 87V DMM and

•

336 Clamp Meter

24

Push-On Clips

AC72 Alligator Clips

Slide-on style for test probes

•

Jaws open to 8 mm

•

For use with TL71 and TL75

•

test lead and probe sets

CAT III 1000 V, 10 A,

•

CAT IV 600 V, 10 A

High-Voltage Probes

80K-40 High Voltage Probes

Allows a digital multimeter to measure

•

up to 40,000 volts peak

1000:1 division ratio output when

•

connected to 10 MW multimeter

Ground clip included

•

Intended for low energy applica-

•

tions that are referenced to ground

Page 25

Accessories

AC Current Clamp Adapters

i400s AC current clamp for oscilloscopes

and power quality analyzers

Pair a current clamp with your scope

•

or power quality meter to

measure up to 400 A ac

Only current

•

clamp available

with a CAT IV

600 V/CAT II

1000 V safety

rating makes

them ideal companions for modern

CAT IV rated meters

Specially designed to offer maximum utility

•

in a compact shape

Take accurate current readings without

•

breaking the circuit

Soft non-slippery overmold handle

•

Can be used with DMMs with optional

•

PM9081/001 BNC/Banana adapter

PM9081

Dual

•

Banana

Plug

4 mm male

to female

BNC Adapter

The set consists of two adapters

•

Temperature Accessories

80AK DMM Adapter

Adapts type-K

•

thermocouple

mini-connector

to dual banana

plug inputs

Compatible with

•

all Fluke DMMs with

temperature

measurement functions

80BK Integrated DMM

Temperature Probe

Compatible with all Fluke

•

Modular Clips ( for use with test leads)

AC220 SureGrip™

Alligator Clips

Insulated, nickel plated jaws

•

grip objects up to 3/8 in.

Blunt tip grabs round

•

screw heads

CAT III 1000 V,

•

CAT IV 600 V, 10 A

AC285 SureGrip™

Alligator Clips

Multi-purpose tooth pattern

•

grips anything from fine gauge

wire to a 3/4 in. nut

Nickel-plated steel jaws

•

CAT III 1000 V,

•

CAT IV 600 V, 10 A

DMMs with temperature

measurement functions

Type-K thermocou-

•

ple with standard

banana jack

Measurement

•

range:

-40 °C to 260 °C

(-40 °F to 500 °F)

80PK-11 Type-K Velcro™

Temperature Probe

Designed for hands

•

free measurement

of HVAC temperature measuring

applications

Use multiple and

•

leave in place for

route-based

routine maintenance

Use with any temperature

•

measuring instrument

designed to accept type-K

thermocouples

Holster

C10 Meter Holster

Snap on yellow

•

holster absorbs

shocks and

protects meter

from rough

handling

Fits Fluke 10

•

Series DMMs

Soft Cases

C12A Meter Case

Zippered carrying case

•

with inside pockets and

belt loop

For 110, 111,

•

112, 12 and

16 DMMs

C90 Meter Case

Zippered carrying case

•

with inside

pocket and

belt loop

Holds mid-

•

sized DMMs

and process meters

C25 Meter Case

Zippered carrying case

•

with padding

and inside

pocket

Holds large

•

DMMs and

process meters

C125 Meter Case

Zippered carry-

•

ing case with

detachable

external pouch

25

For more product information and detailed specifications, go to www.fluke.com

Page 26

A detailed list of heating,

air conditioning, and HVAC terms

Glossary

26

Absolute humidity: The mass of water vapor per

unit volume of air.

Absolute pressure: Pressure above a perfect

vacuum. Absolute pressure is the sum of gage

pressure plus atmospheric pressure.

Air exchange rate: Used in two ways: 1. the

number of times the outdoor air replaces the

volume of air in a building per unit time, typically

expressed as air changes per hour; 2. the number

of times that the ventilation system replaces the

air within a room or area within the building.

Air flow: The movement of air from one location

to another, commonly measured in cubic feet per

minute (CFM).

Air velocity: The distance traveled per unit of time,

commonly measured in feet per minute (FPM).

Air handling unit (AHU): Refers to equipment that

includes a blower or fan, heating and/or cooling

coils, and related equipment such as controls,

condensate drain pans, and air filters. Does not

include ductwork, registers or grilles, or boilers

and chillers.

Allergen: A substance capable of causing an aller-

gic reaction because of an individual’s sensitivity

to that substance.

Ambient air: Unconditioned atmospheric air.

Atmospheric pressure: Standard atmosphere is

the pressure equivalent of 14.696 psi or 29.921 in.

Hg at sea level. Measured with a barometer, it is

an indication of the “weight” of the air.

Boiler: A pressure vessel that safely and efficiently

transfers heat to water.

BTU: British Thermal Unit. A measure of the heat

given off when fuel is combusted. One BTU is

equal to the heat necessary to raise one pound of

water 1 °F.

Building envelope: Elements of the building,

including all external building materials, windows, and walls, that enclose the internal space.

Building-related illness (BRI): Diagnosable

illness whose symptoms can be identified and

whose cause can be directly attributed to airborne

building pollutants (e.g., Legionnaire’s disease,

hypersensitivity pneumonitis).

Capacity: The output of a heating or cooling system

for a given amount of space. For heating, this is

usually expressed in BTU’s. For cooling, it is usually expressed in tons.

Carbon dioxide: (CO2), a clear, odorless gas found

in nature (around 380 ppm), most commonly

associated with respired air. The gas is largely

considered non-poisonous, but can result in suffocation in sufficient quantities.

Carbon monoxide: A clear, odorless gas made

when carbon or other fuel is burned during the

combustion process. The gas is poisonous, with

exposure resulting in symptoms such as headaches, nausea, or even death.

Ceiling plenum: Space below the flooring and

above the suspended ceiling that accommodates

the mechanical and electrical equipment and that

is used as part of the air distribution system. The

space is kept under negative pressure.

Central air handling unit (Central AHU): This is

the same as an Air Handling Unit, but serves more

than one area.

Chiller: Hydronic air conditioning system which

cools water, which cools air.

Compressor: Mechanical device that compresses

refrigerant or other fluid.

Condensate: Liquid formed when a vapor has

cooled below its dewpoint.

Condenser: Heat exchanger that removes heat from

high-pressure refrigerant vapor.

Conditioned air: Air that has been heated, cooled,

humidified, or dehumidified to maintain an interior space within the “comfort zone.” (Sometimes

referred to as “tempered” air.)

Constant air volume systems: Air handling

system that provides a constant air flow while

varying the temperature to meet heating, and

cooling needs.

Cooling coil: Typically copper or aluminum

tubing arranged to transfer the heat from air

to a refrigerant.

Dampers: Controls that vary airflow through an

air outlet, inlet, or duct. A damper position may

be immovable, manually adjustable or part of an

automated control system.

Demand controlled ventilation: Any system used

to vary air intake rates based upon the loads

placed upon the system, given a predefined space.

Dewpoint temperature (dp): Temperature below

which moisture in the air begins to condense.

Differential pressure: The difference in static

pressure measured between two locations.

Diffusers: Components of the ventilation system

that distribute and diffuse air to promote air circulation in the occupied space. Diffusers supply air,

and grilles return air.

Draft: Air movement resulting in a local cooling

effect on the body. The intensity of the draft is

dependent upon a variety of factors which include

air velocity, temperature, occupant activity, and

occupant clothing.

Drain trap: A dip in the drain pipe of sinks, toilets,

floor drains, etc., which is designed to stay filled

with water, thereby preventing sewer gases from

escaping into the room.

Page 27

Dry bulb temperature: Measurement of sensible

heat.

Economizer: A mechanical device that makes

system adjustments in response to changing

conditions in order to maximize energy efficiency.

An economizer typically contains a thermostat

control that opens the dampers when outside air

temperatures are lower than indoors, providing

“free cooling”. Many economizers will incorporate

humidity sensors to ensure outside air is both cool

and dry enough to allow indoors, unconditioned.

Emissivity: The efficiency with which the surface

material of a certain object emits energy. Emissivity is an important consideration in using infrared

to measure temperatures on reflective surfaces.

Enthalpy: (h) Total heat contained in a substance,

which is the sum of sensible heat and latent heat.

Evaporator coil: Cools and dehumidifies the air

by converting liquid refrigerant into a gas, which

absorbs the heat from the air.

Exfiltration: The controlled or uncontrolled move-

ment of air out of a building, through cracks, and

other openings.

Exhaust air: Air that is removed from a space, and

not recirculated into the system.

Exhaust ventilation: Mechanical removal of air

from a portion of a building (e.g., piece of equipment, room, or general area).

Fan coil: A component of a heat pump system, used

to provide additional heat when the heat pump

does not provide adequate heating.

Filter efficiency: The ratio of particles trapped by

filter media compared to the total number of particles found in the air upstream of the filter.

Filter, HEPA: High-efficiency particulate arrestance

(HEPA) filter that is at least 99.97 percent efficient

in removing particulate matter with a diameter of

0.3 micrometers or greater.

Flame rod: Combustion safety control that conducts

electricity through a flame for flame detection.

Forced-air heating system: Uses air to carry heat.

Fungi: Any of a group of parasitic lower plants that

lack chlorophyll, including molds and mildews.

Green buildings: The building industry is increas-

ingly focused on making its buildings “greener,”

which includes using healthier, less polluting and

more resource-efficient practices. Indoor environmental quality (IEQ) refers to the quality of

the air and environment inside buildings, based

on pollutant concentrations and conditions that

can affect the health, comfort and performance of

occupants—including temperature, relative humid

ity, light, sound, and other factors. Good IEQ is an

essential component of any building, especially a

green building.

Heat exchanger: Material that transfers heat from

one substance to another without allowing the

substances to mix.

Heat pump: Mechanical compression refrigeration

system that contains devices and controls that

reverse the flow of refrigerant. Reversing the flow

of refrigerant switches the relative position of the

evaporator and condenser.

Heat: Form of energy identified by temperature

difference or a change of state.

HEPA: High efficiency particulate arrestance (filters).

Hydronic heating system: Heating system that

uses water, steam, or other fluid to carry heat from

the point of generation to the point of use.

Indoor air pollutant: Particles and dust, fibers,

mists, bioaerosols, and gases or vapors.

Infiltration air: Air that flows into a building when

outer doors are open or when air leaks in through

cracks around doors, windows, or other openings.

Laminar air flow: Streamlined airflow in which

the entire mass of air within a designated space

moves with uniform velocity in one direction

along parallel flow lines with minimal mixing.

Latent heat: Heat identified by a change of state

and no temperature change.

Load: The amount of heat imposed on a refriger-

ant system, or the required rate of heat removal

in order to maintain a constant temperature in a

building. Typically expressed as a unit of heat per

unit of time (i.e. BTU/hr).

Makeup air: Air that is used to replace air that

is lost to exhaust.

Mixed air: A combination of return air and

outside air, prior to conditioning and being

supplied to the building.

Negative pressure: Condition that exists when

less air is supplied to a space than is exhausted

from the space, so the air pressure within that

space is less than that in surrounding areas.

Under this condition, if an opening exists, air will

flow from surrounding areas into the negatively

pressurized space.

Organic compounds: Chemicals that contain

carbon. Volatile organic compounds vaporize at

room temperature and pressure. They are found in

many indoor sources, including common household products, and building materials.

Outdoor air supply: Air brought into a building

from the outdoors (often through the ventilation