Page 1

9190A

Ultra-Cool Drywell

January 2013

© 2013 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Operators Manual

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

To register your product online, visit register.fluke.com

Page 3

Table of Contents

Chapter Title Page

1 Product Overview and Specifications ............................................... 1-1

Product Overview .............................................................................................. 1-3

Safety Information ............................................................................................. 1-4

Manual Set ......................................................................................................... 1-5

Contact Fluke Calibration .................................................................................. 1-5

Calibration and Repair Information ................................................................... 1-6

Specifications ..................................................................................................... 1-6

Base Unit Specifications ................................................................................ 1-6

-P Specifications ............................................................................................ 1-7

2 Operation ............................................................................................. 2-1

Introduction ........................................................................................................ 2-3

Calibrator Features ............................................................................................. 2-3

Display and Control Panel ............................................................................. 2-4

-P Option Panel (Input Panel) ........................................................................ 2-5

Power and Remote Interface Panel ................................................................ 2-6

Startup and Main Screen ............................................................................... 2-6

Calibrator Setup ................................................................................................. 2-8

Unpack and Inspect ....................................................................................... 2-8

Placement ...................................................................................................... 2-8

Connect to Mains Power ............................................................................... 2-9

Turn On the Product ...................................................................................... 2-9

Change Language .......................................................................................... 2-9

Set Display Contrast ...................................................................................... 2-9

Toggle Key Beep On or Off .......................................................................... 2-10

Security and Password ................................................................................... 2-10

Menus and Menu Navigation ............................................................................. 2-11

Temperature Setup Menu (TEMP SETUP) ................................................... 2-11

Temperature Setup .................................................................................... 2-12

Cutout ........................................................................................................ 2-13

Cooler Status ............................................................................................. 2-14

Program Menu (PROG MENU) .................................................................... 2-14

Program Setup ........................................................................................... 2-15

Ramp/Soak ................................................................................................ 2-15

i

Page 4

9190A

Operators Manual

Test Result (-P Only) ................................................................................ 2-16

System Menu (SYSTEM MENU) ................................................................. 2-17

Display Setup ............................................................................................ 2-17

Communications Setup ............................................................................. 2-18

Date/Time Setup (-P Only) ....................................................................... 2-18

Calibration Setup Menu ................................................................................. 2-19

Calibration Points Setup ............................................................................ 2-19

Control Setup ............................................................................................ 2-20

Reference Input Calibration (-P Only) ...................................................... 2-21

TC Input Calibration (-P Only) ................................................................. 2-21

mA Input Calibration (-P Only) ................................................................ 2-22

System Information ................................................................................... 2-22

Input Setup Menu (INPUT SETUP) .............................................................. 2-23

Select Unit Input Menu (-P Only) ............................................................. 2-23

RTD Setup ................................................................................................. 2-24

TC Setup ................................................................................................... 2-25

mA Setup ................................................................................................... 2-25

Test UUT Calculation ............................................................................... 2-26

REF Input Menu ........................................................................................ 2-26

Reference Probe Setup .............................................................................. 2-27

Test Calculation Menu .............................................................................. 2-28

Probe Preparation ............................................................................................... 2-29

Clamp-On Ferrites ......................................................................................... 2-29

Reference PRT Connection Preparation ........................................................ 2-29

4-Wire Reference Probe Wiring Instructions ............................................ 2-29

2-Wire Reference Probe Wiring Instructions ............................................ 2-29

Reference Probe Input Setup ..................................................................... 2-31

PRT/RTD Connection Preparation ................................................................ 2-32

Operation ........................................................................................................... 2-33

Insert Installation and Removal Procedure .................................................... 2-33

Probe Insertion and Removal Procedure ....................................................... 2-35

Set Temperature ............................................................................................. 2-36

Set the Temperature SETPOINT Manually .............................................. 2-36

Set the Temperature with a Preset SETPOINT ......................................... 2-36

Change a Preset SETPOINT ..................................................................... 2-37

Cancel or Stop Temperature Change ............................................................. 2-37

Set a Soft Cutout ............................................................................................ 2-37

Reset an Over-Temperature Cutout ............................................................... 2-38

Programs (Automated Tests) ......................................................................... 2-38

Run a Program........................................................................................... 2-38

Stop a Program .......................................................................................... 2-38

3 Remote Operation ............................................................................... 3-1

Introduction ........................................................................................................ 3-3

Remote Operation Setup .................................................................................... 3-3

RS-232 Remote Serial Interface .................................................................... 3-4

Wiring ....................................................................................................... 3-4

Communication Setup ............................................................................... 3-5

USB Remote Interface ................................................................................... 3-6

Wiring ....................................................................................................... 3-6

Communication Setup ............................................................................... 3-6

Remote Operation Commands ........................................................................... 3-7

Overview of Command Structures ................................................................ 3-7

Commands by Function or Group ................................................................. 3-7

Alphabetical List of Serial Commands .......................................................... 3-13

ii

Page 5

Contents (continued)

4 Calibration ............................................................................................ 4-1

Introduction ........................................................................................................ 4-3

Temperature Source Calibration ........................................................................ 4-3

Fundamentals ................................................................................................. 4-4

Terminology .................................................................................................. 4-5

Calibration Equipment ................................................................................... 4-6

Temperature Source Specifications ............................................................... 4-6

Environmental Conditions ............................................................................. 4-6

Temperature Source Calibration Procedure................................................... 4-6

UUT and Equipment Setup ....................................................................... 4-6

As Found Data Collection ......................................................................... 4-8

Uniformity Alignment 1st Iteration ........................................................... 4-9

Uniformity Alignment 2nd Iteration ......................................................... 4-10

Uniformity Alignment 3rd Iteration .......................................................... 4-10

Accuracy Alignment ................................................................................. 4-12

As Left Accuracy ...................................................................................... 4-13

As Left Uniformity .................................................................................... 4-13

As Left Stability ........................................................................................ 4-14

Guard Bands .............................................................................................. 4-14

9190A Input Panel Calibration .......................................................................... 4-15

Fundamentals ................................................................................................. 4-15

Terminology .................................................................................................. 4-15

Calibration Equipment ................................................................................... 4-16

Environmental Conditions ............................................................................. 4-17

Input Panel Calibration Procedure ................................................................. 4-17

Input Panel Calibration/Tests .................................................................... 4-17

Readout Specifications .............................................................................. 4-17

Reference Accuracy Test .......................................................................... 4-17

UUT PRT 4-Wire Test .............................................................................. 4-18

UUT PRT 3-Wire Test .............................................................................. 4-19

Reference Accuracy Alignment ................................................................ 4-20

UUT Thermocouple Calibration ............................................................... 4-21

Thermocouple Accuracy Test ................................................................... 4-21

Thermocouple Reference Junction Accuracy Test .................................... 4-22

Thermocouple Reference Junction and Accuracy Alignment ................... 4-22

Thermocouple Accuracy Alignment ......................................................... 4-23

4-20 mA Input Calibration ........................................................................ 4-23

4-20 mA Accuracy Test ............................................................................ 4-23

24 V Source Test ....................................................................................... 4-24

4-20 mA Accuracy Alignment .................................................................. 4-24

5 Maintenance and Troubleshooting .................................................... 5-1

Introduction ........................................................................................................ 5-3

Maintenance ....................................................................................................... 5-3

Clean the Product .......................................................................................... 5-3

Moisture Removal ......................................................................................... 5-3

Clean the Insert .............................................................................................. 5-3

Change the Fuses ........................................................................................... 5-3

User-Replaceable Parts and Accessories ........................................................... 5-5

Troubleshooting ................................................................................................. 5-5

iii

Page 6

9190A

Operators Manual

iv

Page 7

List of Tables

Table Title Page

1-1. Symbols .................................................................................................................. 1-4

2-1. Controller Controls and Indicators ......................................................................... 2-3

2-2. Display and Control Panel...................................................................................... 2-4

2-3. -P Option Panel (Input Panel) ................................................................................ 2-5

2-4. Power and Remote Interface Panel ........................................................................ 2-6

2-5. Main Screen ........................................................................................................... 2-7

2-6. Parts and Accessories ............................................................................................. 2-8

2-7. Security Levels ....................................................................................................... 2-10

2-8. Menu Navigation .................................................................................................... 2-11

2-9. Temperature Setup Menu ....................................................................................... 2-12

2-10. Cutout Menu ........................................................................................................... 2-13

2-11. Cooler Status Menu ................................................................................................ 2-14

2-12. Program Setup Menu .............................................................................................. 2-15

2-13. Ramp/Soak Setup Menu ......................................................................................... 2-15

2-14. Test Result Menu ................................................................................................... 2-16

2-15. Display Setup Menu ............................................................................................... 2-17

2-16. Communication Setup Menu .................................................................................. 2-18

2-17. Date and Time Setup Menu .................................................................................... 2-18

2-18. Calibration Setup Menu ......................................................................................... 2-19

2-19. Control Setup Menu ............................................................................................... 2-20

2-20. Reference Input Calibration Menu ......................................................................... 2-21

2-21. TC Input Calibration Menu .................................................................................... 2-21

2-22. mA Input Calibration Menu ................................................................................... 2-22

2-23. System Information Menu ...................................................................................... 2-22

2-24. Select Unit Input Menu .......................................................................................... 2-23

2-25. RTD Setup Menu ................................................................................................... 2-24

2-26. TC Setup Menu ...................................................................................................... 2-25

2-27. mA Setup Menu ..................................................................................................... 2-25

2-28. Test UUT Calculation Menu .................................................................................. 2-26

2-29. Reference Probe Setup Menu ................................................................................. 2-27

2-30. Test Calculation Menu ........................................................................................... 2-28

3-1. Power and Remote Interface Panel ........................................................................ 3-3

3-2. Communication Setup Menu .................................................................................. 3-5

3-3. Communication Setup Menu .................................................................................. 3-6

3-4. Commands by Function or Group .......................................................................... 3-8

v

Page 8

9190A

Operators Manual

3-5. PROG:SEQ:PAR Parameters ................................................................................. 3-19

4-1. Calibration Terminolgy .......................................................................................... 4-5

4-2. Calibration Equipment ........................................................................................... 4-6

4-3. As Found Accuracy Results ................................................................................... 4-8

4-4. As Found Uniformity Results ................................................................................ 4-9

4-5. As Found Stability Specifications .......................................................................... 4-9

4-6. Accuracy Calibration Parameter Serial Commands ............................................... 4-12

4-7. As Left Accuracy Specifications ............................................................................ 4-13

4-8. As Left Uniformity Results .................................................................................... 4-13

4-9. As Left Stability Specifications .............................................................................. 4-14

4-10. Calibration Terminology ........................................................................................ 4-15

4-11. External Reference Calibration Equipment Specifications .................................... 4-16

4-12. Standard Resistor Specificatons ............................................................................. 4-16

4-13. Reference Probe and UUT PRT Input Process ...................................................... 4-17

4-14. Thermocouple Input Testing Process ..................................................................... 4-21

4-15. 4-20 mA Input Calibration Steps ........................................................................... 4-23

5-1. User-Replaceable Parts and Accessories ................................................................ 5-5

5-2. Troublehooting Chart ............................................................................................. 5-6

vi

Page 9

List of Figures

Figure Title Page

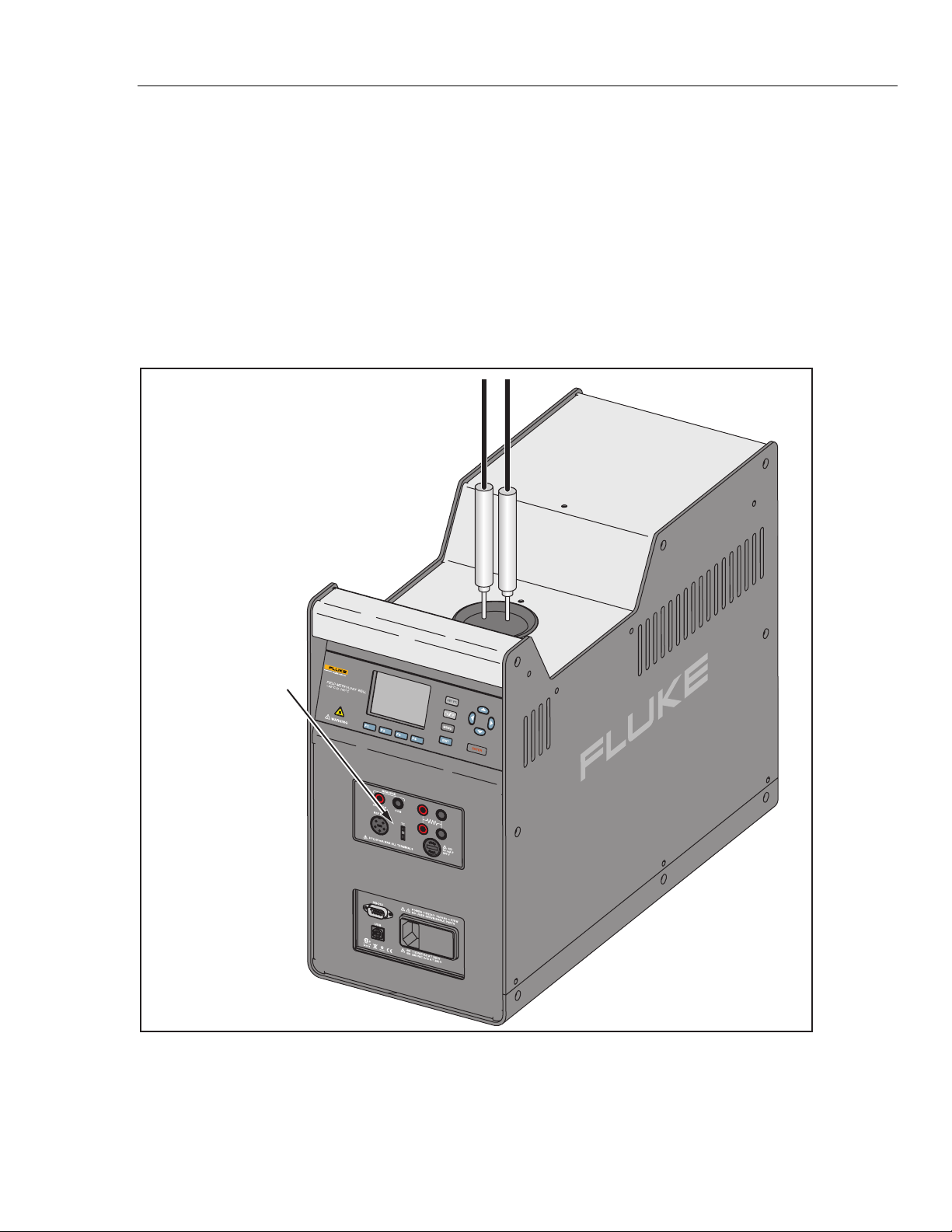

1-1. 9190A Ultra-Cool Drywell (-P Option Shown) ..................................................... 1-3

2-2. Program Menu ........................................................................................................ 2-14

2-4. Input Menu ............................................................................................................. 2-23

2-5. Clamp-On Ferrite Installation ................................................................................ 2-29

2-7. PRT/RTD Probe Setup ........................................................................................... 2-32

2-8. Insert Installation and Removal .............................................................................. 2-34

2-10. Set Temperature SETPOINT ................................................................................. 2-36

2-12. Edit SETPOINT Preset .......................................................................................... 2-37

2-13. Soft Cutout ............................................................................................................. 2-38

4-1. Change the Product Fuses ...................................................................................... 4-4

4-2. Calibration Procedure ............................................................................................. 4-5

4-3. Test Sleeve Orientation .......................................................................................... 4-8

vii

Page 10

9190A

Operators Manual

viii 1-1

Page 11

Chapter 1

Product Overview and Specifications

Title Page

Product Overview ................................................................................................ 1-3

Safety Information ............................................................................................... 1-4

Manual Set ........................................................................................................... 1-5

Contact Fluke Calibration .................................................................................... 1-5

Calibration and Repair Information ..................................................................... 1-6

Specifications ....................................................................................................... 1-6

Base Unit Specifications .................................................................................. 1-6

-P Specifications .............................................................................................. 1-7

Page 12

9190A

Operators Manual

1-2

Page 13

Product Overview and Specifications

Product Overview 1

Product Overview

The Fluke Calibration 9190A Ultra-Cool Drywell (the Product or Calibrator) is a benchtop temperature calibrator that can calibrate precision temperature instruments from

−95 °C to 140 °C (see Figure 1-1).

The Calibrator has two models: the 9190A and the 9190A-P. The 9190A-P is a “Process”

version of the 9190A that combines the heat source with a built-in thermometer input

panel. The Input Panel includes an input for an external reference/control thermometer

that makes it possible to perform a transmitter loop calibration, comparison calibration, or

a simple check of a temperature sensor. In addition, the Input Panel can read resistance

and current from a probe. For probes that require power to operate, the 4-20 mA input has

a loop-power function that can source up to 24 volts of power.

-P Option Panel

(Input Panel)

9190A

Figure 1-1. 9190A Ultra-Cool Drywell (-P Option Shown)

gzs053.eps

1-3

Page 14

9190A

Operators Manual

Safety Information

A Warning identifies conditions and procedures that are dangerous to the user. A

Caution identifies conditions and procedures that can cause damage to the Product or the

equipment under test.

See Table 1-1 for a list of symbols used in this manual and on the Calibrator.

Table 1-1. Symbols

Symbol Description Symbol Description

Conforms to European Union

directives

Risk of Danger. Important

information. See manual.

Conforms to relevant North

American Safety Standards.

Conforms to relevant Australian

EMC requirements

Earth ground Hazardous voltage

This product complies with the WEEE Directive (2002/96/EC) marking requirements.

The affixed label indicates that you must not discard this electrical/electronic product

in domestic household waste. Product Category: With reference to the equipment

types in the WEEE Directive Annex I, this product is classed as category 9 "Monitoring

and Control Instrumentation” product. Do not dispose of this product as unsorted

municipal waste. Go to Fluke’s website for recycling information.

Warning

To prevent possible electrical shock, fire, or personal injury:

• Read all safety Information before you use the Product.

• Use the Product only as specified, or the protection

supplied by the Product can be compromised.

• Use this Product indoors only.

• Do not use the Product around explosive gas, vapor, or in

damp or wet environments.

1-4

• Do not use and disable the Product if it is damaged.

• Use only the mains power cord and connector approved for

the voltage and plug configuration in your country and rated

for the Product.

• Replace the mains power cord if the insulation is damaged

or if the insulation shows signs of wear.

• Make sure the ground conductor in the mains power cord is

connected to a protective earth ground. Disruption of the

protective earth could put voltage on the chassis that could

cause death.

• Do not put the Product where access to the mains power

cord is blocked.

• Use caution when you install and remove probes and

inserts from the Product. They can be hot.

Page 15

Product Overview and Specifications

Manual Set 1

• Do not touch voltages > 30 V ac rms, 42 V ac peak, or

60 V dc.

• Do not apply more than the rated voltage, between the

terminals or between each terminal and earth ground.

• Do not touch the well access surface of the instrument.

• Do not turn off the product at block temperatures higher

than 100 °C. Select a SETPOINT less than 100 °C and let the

instrument to cool before turning it off.

• Use the correct terminals, function, and range for

measurements.

• Do not use test leads if they are damaged. Examine the test

leads for damaged insulation, exposed metal, or if the wear

indicator shows. Check test lead continuity.

• Do not touch the probes to a voltage source when the test

leads are connected to the current terminals.

• Keep fingers behind the finger guards on the probes.

• Do not exceed the Measurement Category (CAT) rating of

the lowest rated individual component of a Product, probe,

or accessory.

Manual Set

The Calibrator includes an Operators Manual and a Getting Started Manual. Both

manuals are online at

This 9190A Operators Manual contains feature information, operation instructions, and

basic user maintenance and troubleshooting information.

The 9190A Getting Started Manual is translated and contains basic information to

quickly set up and use the Calibrator.

The 9190A Product CD contains the Operators Manual, the Getting Started Manual, and

the 9190A Remote Operation interface drivers.

www.flukecal.com and on a CD in the Accessory Kit.

Contact Fluke Calibration

To contact Fluke Calibration, call one of the following telephone numbers:

• Technical Support USA: 1-877-355-3225

• Calibration/Repair USA: 1-877-355-3225

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31-40-2675-200

• Japan: +81-3-6714-3114

• Singapore: +65-6799-5566

• China: +86-400-810-3435

• Brazil: +55-11-3759-7600

• Anywhere in the world: +1-425-446-6110

To see product information and download the latest manual supplements, visit Fluke

Calibration’s website at

To register your product, visit http://flukecal.com/register-product.

www.flukecal.com.

1-5

Page 16

9190A

Operators Manual

Calibration and Repair Information

Specifications

Base Unit Specifications

Temperature Range at 23 °C ................................ –95 °C to 140 °C (–139 °F to 284 °F)

Display Accuracy .................................................. ±0.2 °C Full Range

Accuracy with External Reference

Stability .................................................................. ±0.015 °C Full Range

Axial Uniformity at 40 mm (1.6 in) ....................... ±0.05 °C Full Range

Radial Gradient ..................................................... ±0.01 °C Full Range

Loading Effect

(with a 6.35 mm reference

probe and three 6.35 mm probes) ...................... ±0.006 °C Full Range

(versus display with

6.35 mm probes)................................................. ±0.25 °C at –95 °C

±0.10 °C at 140 °C

Operating Conditions ........................................... 0 °C to 35 °C, 0 % to 90 %

Environmental conditions for all

specifications except temperature range ........... 13 °C to 33 °C

Immersion (Well) Depth ........................................ 160 mm (6.3 in)

Well Diameter ........................................................ 30 mm (1.18 in)

Heating Time

Cooling Time

23 °C to –95 °C: 90 min

140 °C to 23 °C: 60 min

Stabilization Time

Resolution ............................................................. 0.01 °

Display ................................................................... LCD, °C or °F user selectable

Size (H x W x D) ..................................................... 480 mm x 205 mm x 380 mm (18.8 in x 8.0 in x 14.9 in)

Weight .................................................................... 16 kg (35 lb)

Power Requirements ............................................ 100 V to 115 V (±10 %) 50/60 Hz, 575 W

200 V to 230 V (±10 %) 50/60 Hz, 575 W

System Fuse Ratings............................................ 115 V: 6.3 A T 250 V

230 V: 3.15 A T 250 V

4–20 mA Fuse (-P model only) ............................. 50 mA F 250 V

Computer Interface ............................................... RS-232, USB Serial, and 9930 Interface-it Temperature Calibration

Safety ..................................................................... IEC 61010-1, Installation Category II, Pollution degree 2

To schedule and send the Calibrator to Fluke for calibration or repair:

1. Contact the Fluke Calibration Service Center in your area to schedule the calibration

or repair (see “Contact Fluke Calibration” on page 1-5).

2. Pack and secure the Calibrator in a shipment box with a minimum of 2 inches of

packing around the Calibrator to prevent damage.

3. Send the Calibrator to the Service Center.

[3]

................. ±0.05 °C Full Range

RH (non-condensing) < 2000 m altitude

[1]

..................................................... –95 °C to 140 °C: 40 min

[1]

..................................................... 23 °C to –90 °C: 80 min

[2]

............................................. 15 min

Software included

1-6

Electromagnetic Environment ............................. IEC 61326-1: Basic

Refrigerants

R32 (Difluoromethane) ....................................... < 20 g, ASHRAE Safety Group A2L

R704 (Helium) ..................................................... < 20 g, ASHRAE Safety Group A1

Page 17

Product Overview and Specifications

Specifications 1

-P Specifications

Built-in Reference Thermometer Readout

Accuracy (4-Wire Reference Probe)

±0.013 °C at –25 °C

±0.015 °C at 0 °C

±0.020 °C at 50 °C

±0.025 °C at 140 °C

Reference Resistance Range............................... 0 Ω to 400 Ω

Reference Resistance Accuracy

42 Ω to 400 Ω: ±60 ppm of reading

Reference Characterizations ............................... ITS-90, CVD, IEC-751, Resistance

Reference Measurement Capability .................... 4 wire

Reference Probe Connection .............................. 6-Pin Din with INFO-CON Technology

Built-in RTD Thermometer Readout Accuracy .. NI-120: ±0.015 °C at 0 °C

PT-100 (385): ±0.02 °C at 0 °C

PT-100 (3926): ±0.02 °C at 0 °C

PT-100 (JIS): ±0.02 °C at 0 °C

RTD Resistance Range......................................... 0 Ω to 400 Ω

Resistance Accuracy

[4]

....................................... 0 Ω to 25 Ω: ±0.002 Ω

25 Ω to 400 Ω: ±80 ppm of reading

RTD Characterizations ......................................... PT-100 (385),(JIS),(3926), NI-120, Resistance

RTD Measurement Capability .............................. 2-wire, 3-wire, and 4-wire RTD with Jumpers only

RTD Connection .................................................... 4-terminal input

Built-in TC Thermometer Readout Accuracy

Type K: ±0.75 °C at 140 °C

Type T: ±0.60 °C at 140 °C

Type E: ±0.60 °C at 140 °C

Type R: ±1.60 °C at 140 °C

Type S: ±1.60 °C at 140 °C

Type M: ±0.65 °C at 140 °C

Type L: ±0.65 °C at 140 °C

Type U: ±0.70 °C at 140 °C

Type N: ±0.75 °C at 140 °C

Type C: ±1.00 °C at 140 °C

TC Millivolt Range ................................................. –10 mV to 75 mV

Voltage Accuracy .................................................. 0.025 % of reading +0.01 mV

Internal Cold Junction

Compensation Accuracy ...................................... ±0.35 °C (ambient of 13 °C to 33 °C)

TC Connection ...................................................... Miniature Connectors (ASTM E1684)

Built-in mA Readout Accuracy ............................ 0.02 % of reading + 0.002 mA

mA Range .............................................................. Cal 4-22 mA, Spec 4-24 mA

mA Connection ..................................................... 2 terminal input

Loop Power Function ........................................... 24 VDC loop power

Built-in Electronics Temperature Coefficient

(0 °C to 13 °C, 33 °C to 50 °C) ............................... ±0.005 % of range per °C

Notes:

[1] – For ambient temperature of 23 °C.

[2] – Time from when the SETPOINT is reached to when the unit is with in Stability specification.

[3] – The temperature range may be limited by the reference probe connected to the readout. The built-in Reference Accuracy does not

include the sensor probe accuracy. It does not include the probe uncertainty or probe characterization errors.

[4] – Measurement accuracy specifications apply within the operating range and assume 4 wires for PRTs. With 3-wire RTDs add 0.05 Ω

to the measurement accuracy plus the maximum possible difference between the resistances of the lead wires.

[5] – The thermocouple input readout is sensitive to EM fields in the frequency range of 500 MHz to 700 MHz.

[3]

................ ±0.010 °C at –95 °C

[4]

..................... 0 Ω to 42 Ω: ±0.0025 Ω

[5]

. Type J: ±0.70 °C at 140 °C

1-7

Page 18

9190A

Operators Manual

1-8

Page 19

Chapter 2

Operation

Title Page

Introduction .......................................................................................................... 2-3

Calibrator Features ............................................................................................... 2-3

Display and Control Panel ............................................................................... 2-4

-P Option Panel (Input Panel) .......................................................................... 2-5

Power and Remote Interface Panel .................................................................. 2-6

Startup and Main Screen ................................................................................. 2-6

Calibrator Setup ................................................................................................... 2-8

Unpack and Inspect ......................................................................................... 2-8

Placement ........................................................................................................ 2-8

Connect to Mains Power ................................................................................. 2-9

Turn On the Product ........................................................................................ 2-9

Change Language ............................................................................................ 2-9

Set Display Contrast ........................................................................................ 2-9

Toggle Key Beep On or Off ............................................................................ 2-10

Security and Password ..................................................................................... 2-10

Menus and Menu Navigation ............................................................................... 2-11

Temperature Setup Menu (TEMP SETUP) ..................................................... 2-11

Temperature Setup ...................................................................................... 2-12

Cutout .......................................................................................................... 2-13

Cooler Status ............................................................................................... 2-14

Program Menu (PROG MENU) ...................................................................... 2-14

Program Setup ............................................................................................. 2-15

Ramp/Soak .................................................................................................. 2-15

Test Result (-P Only) .................................................................................. 2-16

System Menu (SYSTEM MENU) ................................................................... 2-17

Display Setup .............................................................................................. 2-17

Communications Setup ............................................................................... 2-18

Date/Time Setup (-P Only) ......................................................................... 2-18

Calibration Setup Menu ................................................................................... 2-19

Calibration Points Setup .............................................................................. 2-19

Control Setup .............................................................................................. 2-20

Reference Input Calibration (-P Only) ........................................................ 2-21

TC Input Calibration (-P Only) ................................................................... 2-21

mA Input Calibration (-P Only) .................................................................. 2-22

System Information ..................................................................................... 2-22

Input Setup Menu (INPUT SETUP) ................................................................ 2-23

Select Unit Input Menu (-P Only) ............................................................... 2-23

RTD Setup ................................................................................................... 2-24

2-1

Page 20

9190A

Operators Manual

TC Setup ..................................................................................................... 2-25

mA Setup ..................................................................................................... 2-25

Test UUT Calculation ................................................................................. 2-26

REF Input Menu .......................................................................................... 2-26

Reference Probe Setup ................................................................................ 2-27

Test Calculation Menu ................................................................................ 2-28

Probe Preparation ................................................................................................. 2-29

Clamp-On Ferrites ........................................................................................... 2-29

Reference PRT Connection Preparation .......................................................... 2-29

4-Wire Reference Probe Wiring Instructions .............................................. 2-29

2-Wire Reference Probe Wiring Instructions .............................................. 2-29

Reference Probe Input Setup ....................................................................... 2-31

PRT/RTD Connection Preparation .................................................................. 2-32

Operation ............................................................................................................. 2-33

Insert Installation and Removal Procedure ...................................................... 2-33

Probe Insertion and Removal Procedure ......................................................... 2-35

Set Temperature ............................................................................................... 2-36

Set the Temperature SETPOINT Manually ................................................ 2-36

Set the Temperature with a Preset SETPOINT ........................................... 2-36

Change a Preset SETPOINT ....................................................................... 2-37

Cancel or Stop Temperature Change ............................................................... 2-37

Set a Soft Cutout .............................................................................................. 2-37

Reset an Over-Temperature Cutout ................................................................. 2-38

Programs (Automated Tests) ........................................................................... 2-38

Run a Program............................................................................................. 2-38

Stop a Program ............................................................................................ 2-38

2-2

Page 21

Operation

Introduction 2

Introduction

This chapter supplies instructions on how to set up and operate the Calibrator. The

control panels and features of the Calibrator are described first, followed by setup, menus,

and operation.

Calibrator Features

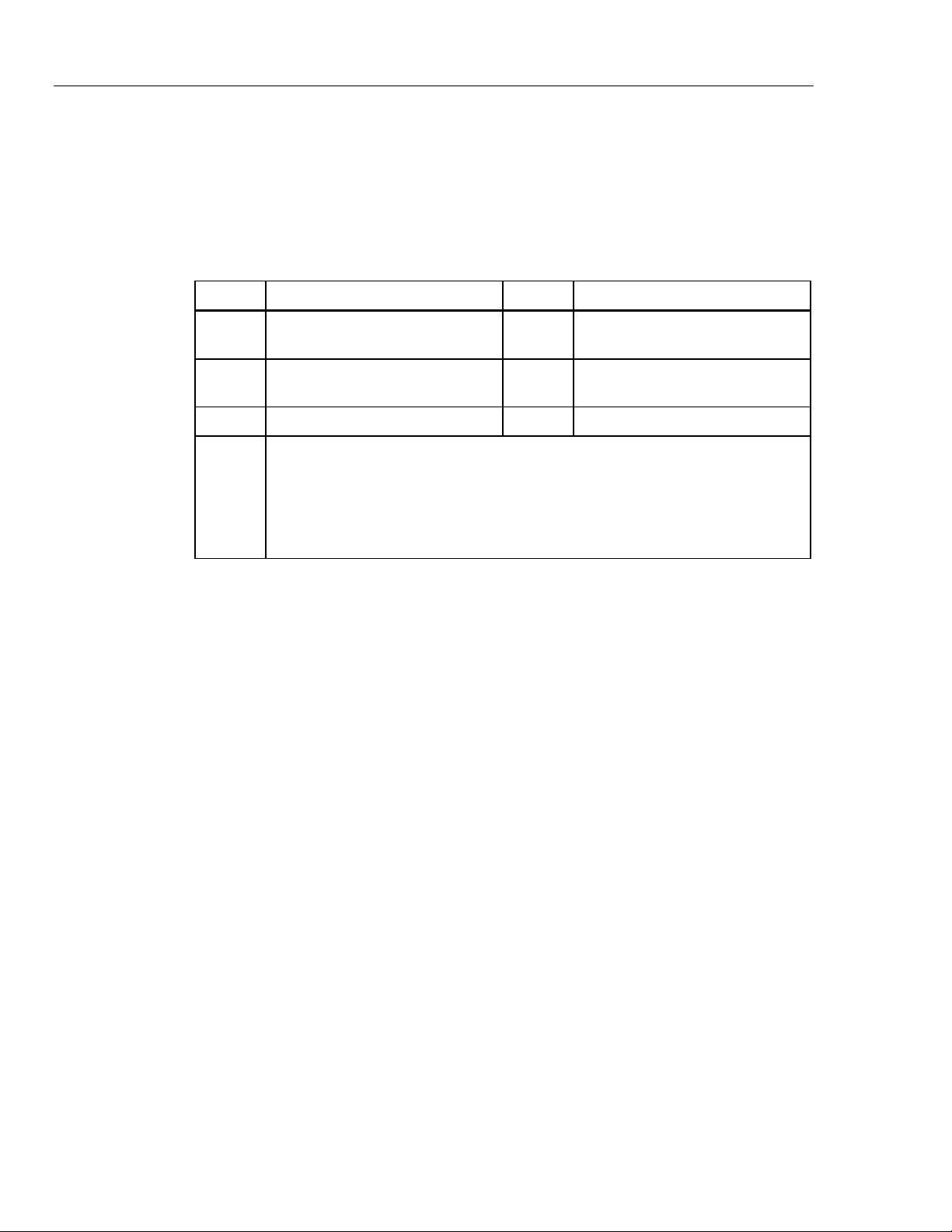

Table 2-1 identifies and describes the panels on the front of the Calibrator.

Table 2-1. The 9190A Front Panel

9190A Model

9190A

1

3

9190A

9190A-P Model

1

2

3

gzs046.eps

Item Name Function

Display and Control Panel

Control panel and display. See “Display and Control Panel” on

page 2-4.

Input panel used to connect to external sensors and probes.

-P Option Panel (Input Panel)

Panel is only available on the “-P” model. See “-P Option Panel”

on page 2-5.

Power and Remote Interface

Panel

Power module and Remote Interface Panel. See “Power and

Remote Interface Panel” on page 2-6.

gzs001.eps

2-3

Page 22

9190A

Operators Manual

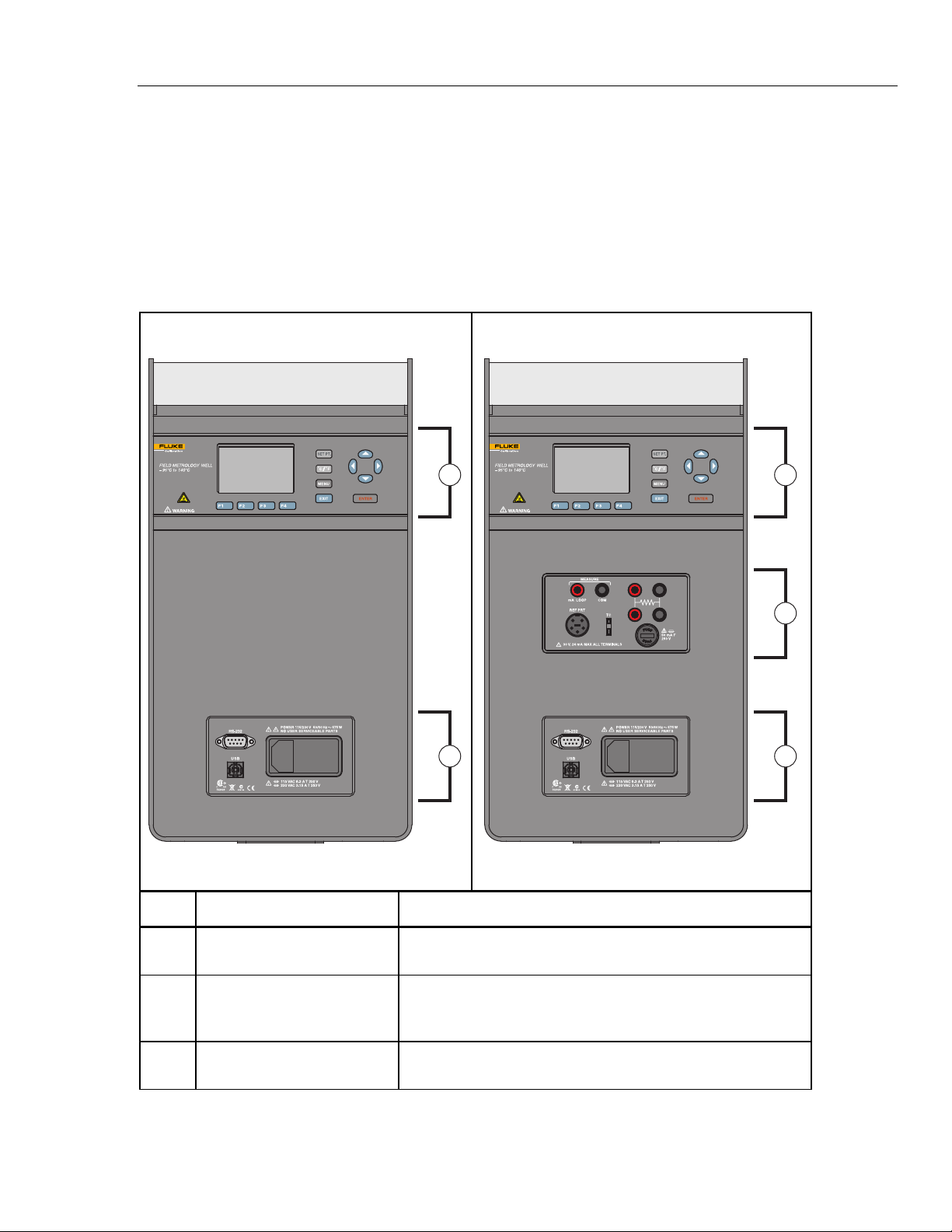

Display and Control Panel

Table 2-2 shows and describes the function of each button on the Control Panel.

Table 2-2. Display and Control Panel

4 5

1

9190A

9

8

Item Name Function

Shows block temperature, measurements, status information, operating

Display

Arrow Keys

▲▼◄►

Enter Key

SET Point Key

parameters, and softkey functions. The contrast of the display is adjustable.

To adjust the contrast, push ▲ to increase contrast or ▼ to decrease

contrast while the Main screen is shown.

Navigates through menu selections, increases or decreases numbers, and

scrolls menus up or down.

Selects menus and sets new values.

Set a SETPOINT temperature to heat or cool to.

2

3

67

gzs002.eps

2-4

°C/°F Key

Menu Key

Exit Key

Softkeys

Block Temperature

Indicator

Switches the displayed temperature units between °C and °F. Key is

enabled only when the Main screen is shown.

Note

This key is disabled in some regions of the world.

Opens the Main menu. See “Menus and Menu Navigation” on page 2-10 for

information on each menu and the settings found in the menus.

Cancels all changes and navigates back to the previous menu.

Navigates the menus on the display. The functions of the softkeys are

shown on the display above the buttons.

Visual safety indicator that illuminates when the block temperature is unsafe

and extinguishes when the block temperature is safe. If the block

temperature is unsafe and the Calibrator is turned off or the mains power

cord is disconnected, the indicator flashes until the block temperature cools

to a safe temperature. Do not transport or remove Inserts until the indicator

is off.

Warning

For safe operation and maintenance of the product, do not

remove Inserts when the Block Temperature indicator is

illuminated.

Page 23

Operation

Calibrator Features 2

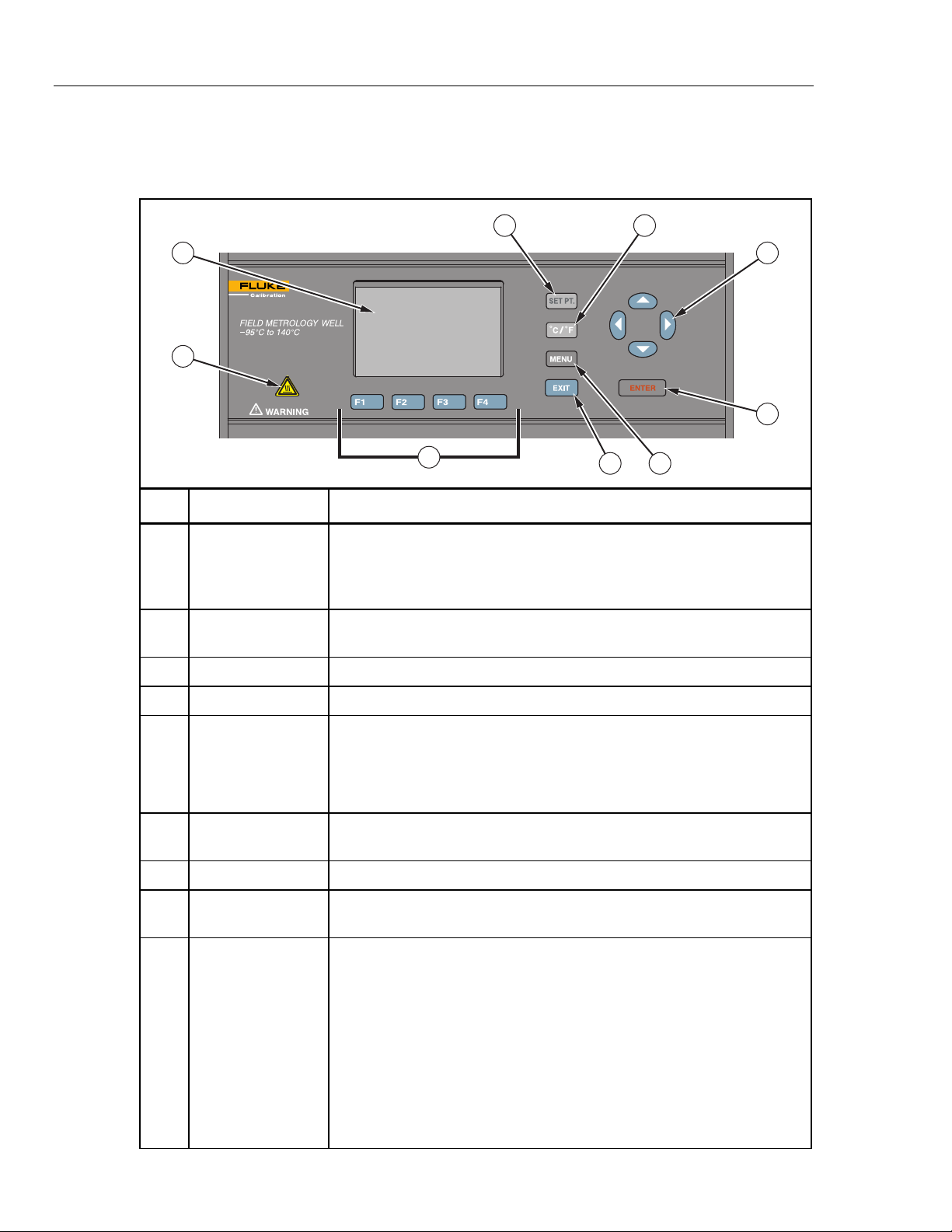

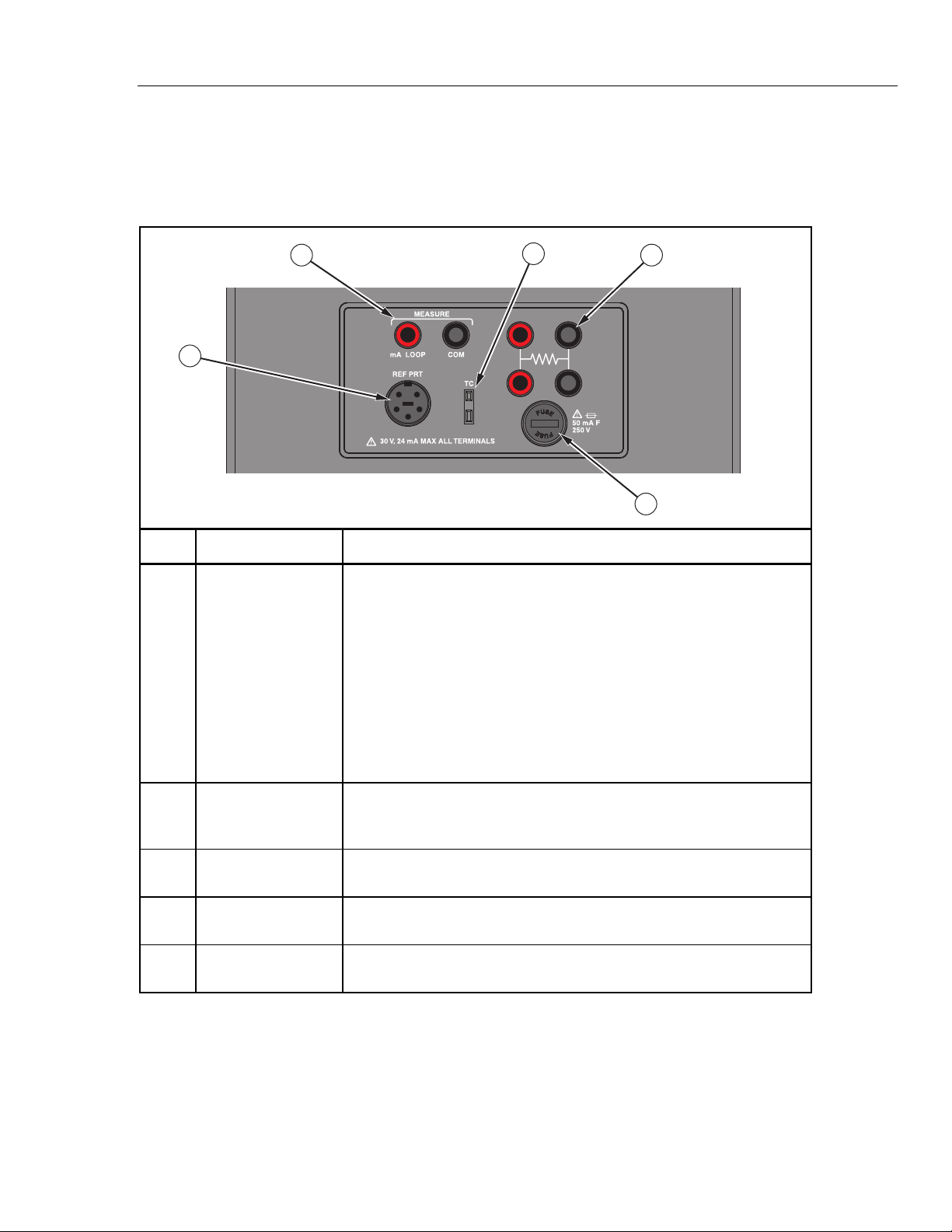

-P Option Panel (Input Panel)

Table 2-3 shows and describes the connectors and ports on the -P Option Panel. The

optional process version -P Option Panel is also referred to as the Input Panel.

Table 2-3. -P Option Panel (Input Panel)

2

1

Item Name Function

Connect a Reference PRT probe to the Calibrator for use with the

reference thermometer function. The Reference Thermometer Input

accepts 4-wire or 2-wire traditional 6-pin DIN Smart Connectors (see

“Reference PRT Connection Preparation” on page 2-29).

Reference

Thermometer Input

(REF PRT)

The Reference Thermometer Input can store calculated probe calibration

coefficients. Coefficient values can be manually keyed into the readout or

a characterization curve can be selected through the user interface.

4

3

5

gzs003.eps

4-20 mA Connectors

4-Wire PRT/RTD

Connector

Thermocouple (TC)

Connector

Fuse

Note

A Platinum Resistance Thermometer (PRT) is the only type of

probe that is supported by the Reference Thermometer Input.

Connect a 4-20 mA transmitter to the Calibrator. The 4-20 mA

Connectors can supply a low voltage (24 V) to power a transmitter. See

“mA Setup” on page 2-25.

Connect a 4-wire, 3-wire, or 2-wire PRT/RTDs to be tested to the input.

See “PRT/RTD Connection Preparation” on page 2-30.

Connect a thermocouple to be tested that is fitted with a subminiature

thermocouple (TC) connector.

Fuse for the 4-20 mA circuit. See Chapter 4 for fuse replacement

instructions.

2-5

Page 24

9190A

Operators Manual

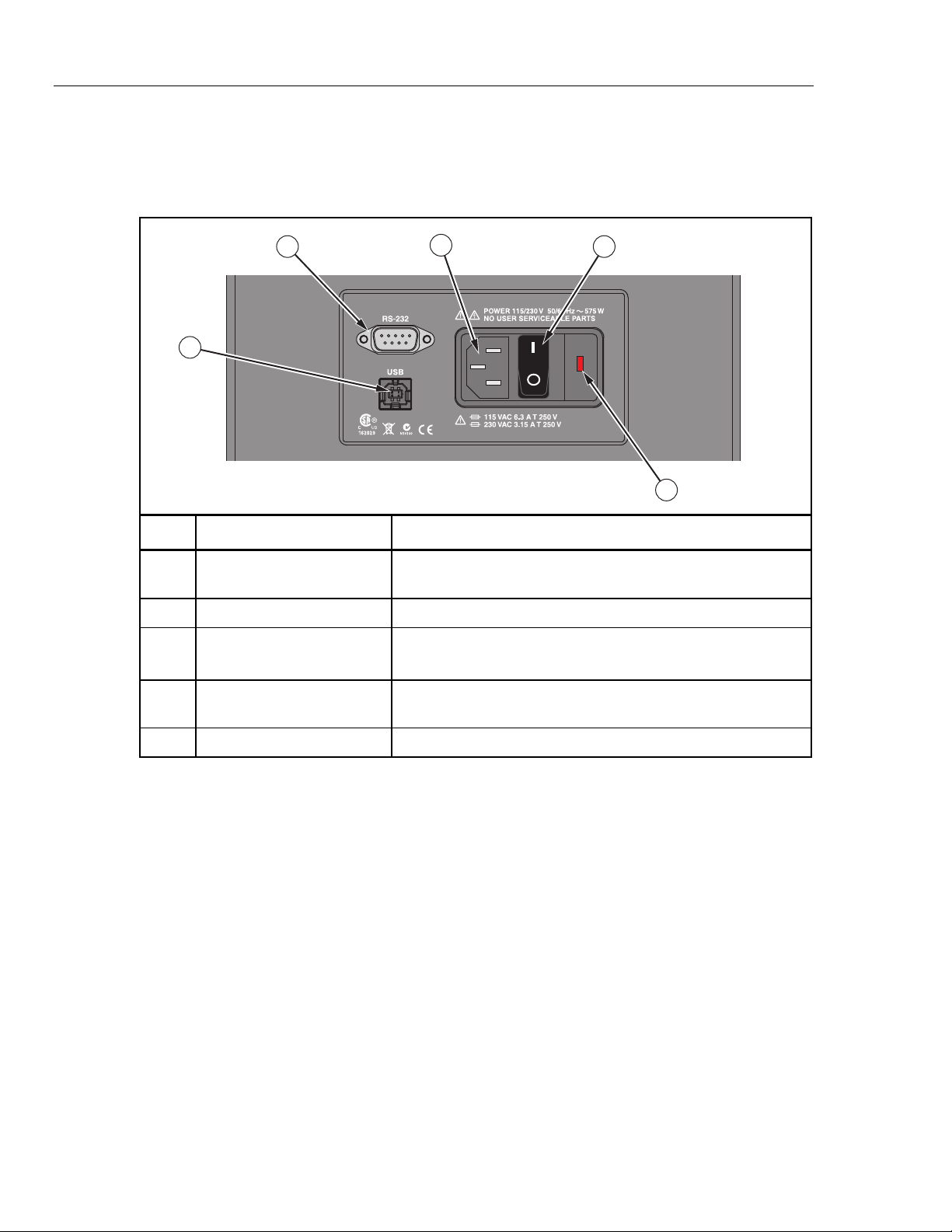

Power and Remote Interface Panel

Table 2-4 shows and describes the connectors and ports on the Power and Remote

Interface Panel.

Table 2-4. Power and Remote Interface Panel

3

4

Item Name Function

Mains Power Cord

Receptacle

Power Switch Turn on (I) and turn off (O) the Calibrator.

9-pin Subminiature

Serial Connector (RS-232)

1

Receptacle for the mains power cord. Use an AC mains supply

appropriate for the voltage range and region of use.

Transmits measurements and remotely controls the operation of

the instrument. See Chapter 3, “Remote Operation”.

2

5

gzs004.eps

USB Serial Connector

Fuse Product fuse. See Chapter 4 for fuse replacement instructions.

Transmits measurements and remotely controls the operation of

the instrument. See Chapter 3, “Remote Operation”.

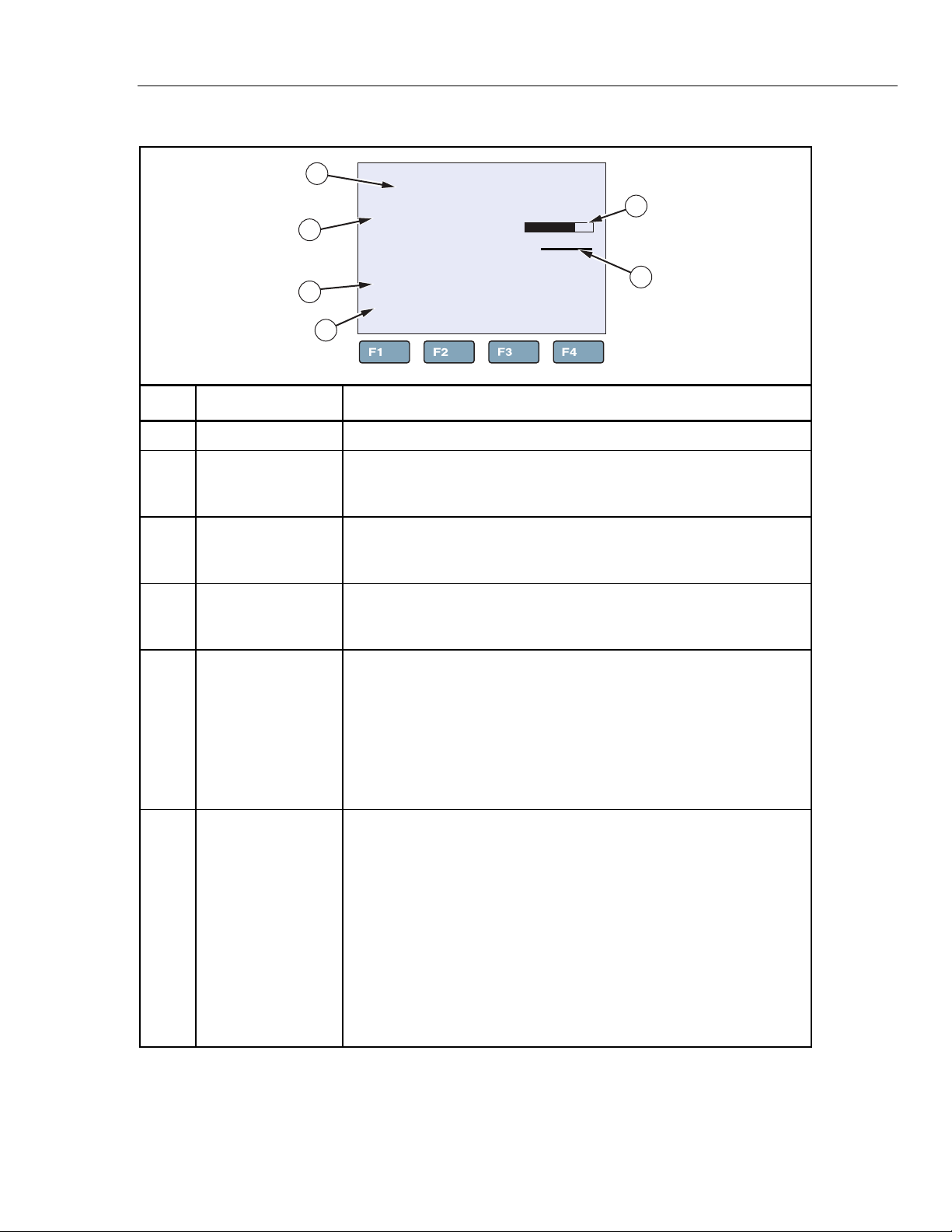

Startup and Main Screen

When the Calibrator turns on, the system initializes, does a self-check, then shows a

startup screen that shows the model number and firmware version information. If the selfcheck finds an error, the error is shown on the Startup screen. Contact Fluke Calibration

if an error shows on the Startup screen.

After the start-up initialization is complete, the Startup screen disappears and the Main

screen shows on the display. Table 2-4 shows and describes the indicators on the Main

screen.

2-6

Page 25

Operation

Calibrator Features 2

Table 2-5. Main Screen

1

-80.01 °C

2

SETPT: -80.00°C

COOL: 67%

5

3

REF : -79.964 °C

6

TC-T : -79.81 °C

4

Item Name Function

Block Temperature Temperature of the internal temperature block.

SETPOINT

Temperature

Reference

Temperature

UUT Output

Heating/Cooling

Status

[-P Only]

[-P Only]

Target SETPOINT temperature. A set temperature value is referred to as

a “SETPOINT”. The Calibrator uses the SETPOINT value to know what

temperature to heat or cool to.

Shows the most recent reference measurement when a Reference PRT

probe is connected and set up. See “Reference PRT Connection

Preparation” on page 2-29.

Shows the most recent UUT output measurement of a probe that is

connected and setup. The value shown depends on the output type

selected in the Input Setup Menu (see page 2-23).

Shows the mode the calibrator is in. The modes are: OFF, COOL, HEAT,

and CUTOUT. The bar under the mode corresponds to the percent

heating or cooling. The bar is blank at 0 % when HEATING or COOLING

is off or not necessary. The bar is completely dark at 100 % HEATING or

COOLING. CUTOUT is a feature that shuts off power to the heat source if

the well temperature exceeds the set limit value. CUTOUT shows when a

limit has been exceeded. For more information on CUTOUT, see “Cutout”

on page 2-13.

gzs005.eps

Stability Status

Indicator

Visually shows if the block temperature is stable and within the Stability

Limits.

When temperature of the internal temperature block is not within the

Stability Limits, the indicator shows a wavy line (

temperature is within the Stability Limits, the indicator shows as a flat line

(

---) which indicates that a measurement can be made. See “Stability

Limits” on page 2-12.

). When the

Note

To prevent inaccurate measurements, do not make

measurements until the Stability Indicator shows as a flat

line

(---).

2-7

Page 26

9190A

Operators Manual

Calibrator Setup

Unpack and Inspect

9190-INSX Insert (X=A, B, C, D, E, or F) 1

2-meter (6-foot) Mains Power Cord 1

USB Cable 1

Getting Started Manual 1

Product CD that contains manuals and remote interface driver files 1

9930 Interface-it Calibration Software and Users Guide 1

Unpack the instrument carefully and examine it for any damage that could have occurred

during shipment. If there is shipping damage, notify the Fluke Calibration and the carrier

immediately. Table 2-6 lists the equipment and the accessories that comes with the

Calibrator. Verify that all the equipment and accessories in Table 2-6 are in the box.

Table 2-6. Parts and Accessories

Name Quantity

Report of Calibration and Calibration Label 1

Well Insulator Cap 1

Insert Removal Tool 1

Clamp-on Ferrites (-P model only) 4

6-pin DIN Connector (-P model only) 1

Test Lead Kit (-P model only) 1

Placement

Put the Calibrator on a clean, flat surface. Make sure the Calibrator is 150 mm (6 inches)

away from all objects. For best results, choose a location to set up the Product where

room temperature changes are minimum.

Warning

To prevent possible fire or personal injury:

• Do not operate Product in orientations other than upright. A

fire hazard can be made if the Product is put on its side.

• Do not remove Inserts when the Product shows

temperatures more than 50 °C.

• Do not operate near flammable materials.

2-8

• Do not touch the well access surface of the Product.

• Do not turn off the Product when the temperature is above

100 °C. Set a SETPOINT temperature below 100 °C and let

the Product cool.

Page 27

Operation

Calibrator Setup 2

Caution

For safe operation and maintenance of the Product:

• Energize the Product for a 2-hour dry-out period before use, if the

Product was:

o In transport

o In a humid or semi-humid storage environment

o Not energized for more than 10 days

If the product is wet or has been in a wet environment, take

necessary measures to remove moisture prior to applying

power.

• Always operate this Product on a flat, level, stable surface.

• Do not store the Product at temperatures above 50 °C. The

Product has a refrigeration system and contains gasses

under pressure.

• Do not turn the Product upside down. The inserts will fall

out.

• To prevent damage to the cooling system, do not tilt the

Product on its side or upside down while the Product is

operating.

Connect to Mains Power

Use the 2-meter (6-foot) mains power cord to connect the Product to a 120 V ac or 230 V

ac outlet rated for at least 15 amps.

Turn On the Product

1. Push the “I” side of the power switch on the front panel of the Calibrator.

2. Monitor the Startup screen for errors while the product turns on. If an error shows,

contact Fluke Calibration.

Change Language

To change the display language:

1. Push .

2. Push .

3. Push .

4. Push .

5. Push or to highlight a language.

6. Push to set language.

If the incorrect language is set by accident, push softkeys and at

the same time to temporarily switch back to the English language.

Set Display Contrast

With the Main screen shown in the display, push to increase or push to decrease

display contrast.

Note

2-9

Page 28

9190A

Operators Manual

Toggle Key Beep On or Off

Security and Password

Security Level Definition

With the Main screen shown in the display, push and at the same time to

enable or disable key beep.

The Calibrator has two user-level access security levels (Low and High) to protect from

undesired changes to the settings (see Table 2-7). The Calibrator comes from the factory

with the security level set to High and a default password of “1234”.

If the password is not available, the information can still be viewed. To view the

information without the password, push twice or push when prompted for the

password. The information is then shown on the screen, but cannot be changed.

Note

The Calibrator does not have a password reset function. If the password is

lost, contact Fluke Calibration for password reset assistance.

Table 2-7. Security Levels

Low

High

Protects the specific metrological information and calibration information settings.

Protects all operating parameters. It is intended to minimize user choices, for example

to perform repeated identical calibrations under consistent conditions.

To change the password:

1. Push .

2. Push .

3. Push .

4. Enter the current 4-digit password to open the password screen (the default factory

password is

1234).

5. Push and to highlight a digit then push to increase the digit or push to

decrease the digit.

6. Push to save the password.

To change the security level:

1. Push .

2. Push .

3. Push .

2-10

4. Enter the current 4-digit password to open the password screen (the default factory

password is

5. Push and to highlight

1234).

HIGH or LOW.

6. Push to save the selection.

Page 29

Operation

Menus and Menu Navigation 2

Menus and Menu Navigation

The Main menu () contains four submenus that supply access to all features, tools,

and functions. The four submenus are: Temperature Setup, Program Setup, System, and

Input Setup.

Table 2-8 shows and describes the buttons used to navigate the submenus.

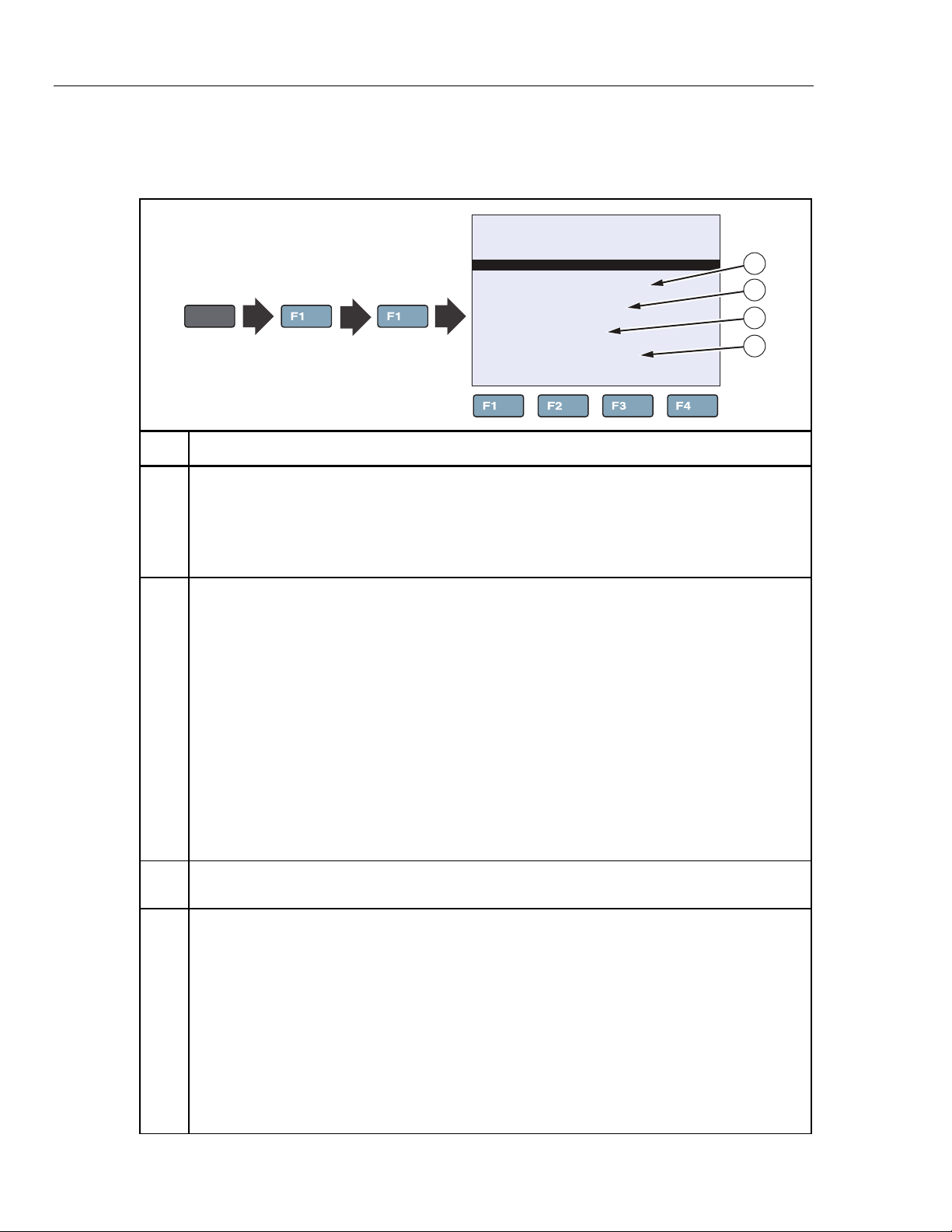

Table 2-8. Menu Navigation

Button Navigation Function

Function softkeys to open submenus.

Scroll menus, increases or decreases values, and highlights selections.

Saves changes and navigates to the next menu.

Cancels all changes and navigates back to the Main menu.

Temperature Setup Menu (TEMP SETUP)

The Temperature Setup menu contains Field Metrology Well functions related to

temperature setup. The TEMP SETUP menu has three submenus: SETUP, CUTOUT,

and STATUS.

66.03°C

TEMERATURE SETUP MENU

SETUP CUTOUT STATUS

Figure 2-1. Temperature Setup Menu

gzs006.eps

2-11

Page 30

9190A

Operators Manual

Temperature Setup

Item Function

Table 2-9 shows and describes the menu selections on the Temperature Setup menu.

Table 2-9. Temperature Setup Menu

66.03°C

TEMPERATURE SETUP

SCAN RATE: 180.00 °C/m

STABLE LIMIT: 0.04 °C

STABLE ALARM: ON

CONTROL SENSOR: INTERNAL

MENU

TEMP

SETUP SETUP

SCAN RATE sets the rate at which the Calibrator heats or cools in degrees per minute (°C/min or

°F/min). The Scan Rate can be set from 0.1 °C/min to 500 °C/min (0.2 °F/min to 900 °F/min).

Note

The actual Scan Rate is limited to the natural rate the Product heats and cools. This

is less than the maximum Scan Rate setting.

1

2

3

4

gzs007.eps

STABLE LIMIT sets the temperature stability parameter the Calibrator uses to determine when

the temperature is stable enough to make a measurement.

When the temperature is within the range of the Stable Limit, the Calibrator shows a flat bar (---)

on the Main screen (Stability Status Indicator) and audibly sounds the Stable Alarm if it is set to

ON (see item ). The Stable Alarm sounds once per SETPOINT.

Example: A specific calibration process requires the instrument to operate within ±0.1°C. “0.1” is

entered into the Stability Limit parameter. When the block temperature is within ±0.1°C, the

Stability Status indicator on the Main screen changes to a flat line (---) and the Stable Alarm

sounds once.

Note

The 9190A and 9190A-P should not be expected to operate better than the stability

specification found in the Specifications section of this manual. Thus, the minimum setting of

the Stability Limit should not be less than the stability specification. See the “Base Unit

Specifications” in Chapter 1.

STABLE ALARM turns on or turns off the audible Stable Alarm that sounds when the block

temperature is within the Stable Limit. See item .

[-P Only]

CONTROL SENSOR

sets the Calibrator to use the internal sensor or an external sensor to

control the block temperature. The Control Sensor setting has two options: Internal and Reference.

Note

Use of an external sensor such as a PRT can result in improved temperature accuracy

Internal tells the Calibrator to use the internal sensor for temperature control. In return, it relies on

its own calibration for accuracy.

Reference tells the Calibrator to use a PRT that is connected to the Reference Probe input

(REF PRT) for temperature control. In this mode, the temperature of the reference PRT is

measured and shown on the Main screen, and the block temperature is automatically adjusted so

that the temperature of the Reference PRT aligns with the SETPOINT.

.

2-12

Page 31

Operation

Menus and Menu Navigation 2

Cutout

Table 2-10 shows and describes the menu selections on the Cutout menu.

Table 2-10. Cutout Menu

66.03°C

CUTOUT

SOFT CUTOUT: 150 °C

HARD CUTOUT: 160 °C

MENU

TEMP

SETUP CUTOUT

Item Function

SOFT CUTOUT and HARD CUTOUT are limit parameters that shut off power to the heat source

if the well temperature exceeds the set limit value.

The Soft Cutout is a safety barrier to protect probes from temperatures more than their specified

temperature limits.

The Hard Cutout protects the Calibrator from irreparable internal damage. See “Set Soft Cutout”

on page 2-37.

1

gzs008.eps

The Soft Cutout is user configurable and should be set within 5 °C to 10 °C above the

temperature limit of the instrument being calibrated. The Hard Cutout is not user

configurable and is set by the factory to approximately 160 °C.

If the cutout is activated because of an excessive well temperature, the Calibrator enters a

“Cutout mode” where power to the heat source is shut off to immediately cool the Calibrator and

Note

instrument. When in Cutout mode, the instrument displays “

indicator. The instrument stays in Cutout mode until the temperature is below the cutout

SETPOINT and the cutout is reset. See “Reset an Over-Temperature Cutout” on page 2-38.

CUTOUT” above the Stability Status

2-13

Page 32

9190A

Operators Manual

Cooler Status

Table 2-11 shows and describes the menu selections on the Cooler Status menu.

Note

The information on the Cooler Status menu is not editable. Fluke

Calibration Service Center personnel use this information to help

troubleshoot the system if a malfunction occurs.

Table 2-11. Cooler Status Menu

66.03°C

COOLER STATUS

TEMPERATURE: 27.99 °C

SELF TEST: OK

HEAT BALANCE: 0.000

MENU

TEMP

SETUP STATUS

1

2

3

gzs009.eps

Item Function

TEMPERATURE shows the temperature of the condenser.

SELF TEST shows the Stirling Cooler self-test result.

HEAT BALANCE shows the power difference between the top and bottom heaters.

Program Menu (PROG MENU)

The Program menu supplies access to the automated and manual program selections (see

Figure 2-2). A Program is a test that can be configured and run to calibrate an instrument.

66.03°C

PROGRAM MENU

RUN

PROG

RAMP/

SOAK

TEST

RESULT

Figure 2-2. Program Menu

gzs010.eps

2-14

Page 33

Operation

Menus and Menu Navigation 2

Program Setup

Table 2-12 shows and describes the menu selections on the Program Setup menu.

Table 2-12. Program Setup Menu

66.03°C

PROGRAM SETUP

TEST STATUS: OFF

RECORD DATA: NO

TEST ID: 0

MENU

PROG

MENU

RUN

PROG

Item Function

TEST STATUS starts (ON) or stops (OFF) a Program.

RECORD DATA

TEST ID

numeric entry up to 16 characters in length.

[-P Only]

[-P Only]

turns on (YES) or turns off (NO) the data record function of the Program.

is a unique identification of the Program. The identification can be an alpha-

1

2

3

gzs011.eps

Ramp/Soak

Table 2-13 shows and describes the menu selections on the Ramp/Soak Setup menu.

Table 2-13. Ramp/Soak Setup Menu

66.03°C

RAMP/SOAK SETUP

NO. SETPOINTS: 8

SOAK TIME: 15 MIN

NO. CYCLES: 1

DIRECTION:

PASS TOLERENCE: 1.80 °C

MENU

PROG

MENU

RAMP/

SOAK

SET

POINTS

6

Item Function

NO. SETPOINTS is the number of SETPOINTS for a Program. Eight SETPOINTs can be set for

the program. Set the maximum number of SETPOINTS necessary.

SOAK TIME is the duration (in minutes) that each of the programmed SETPOINTS temperature is

maintained. The time starts when the temperature settles to within the specified stability. The

Stability Limit is set in the Temperature Setup menu (see page 2-12).

1

2

3

4

5

gzs013.eps

NO. CYCLES is the number of times that the Program is repeated.

2-15

Page 34

9190A

Operators Manual

Item Function

Test Result (-P Only)

Table 2-13. Ramp/Soak Setup Menu (cont.)

DIRECTION controls whether the SETPOINTS are sequenced in one direction “→” (ascending

from 1 to 8) or in both directions “ ” (ascending from 1 to 8 and then descending from 8 to 1)

before the sequence is repeated. If the both directions option is selected, the Program sequences

from the first SETPOINT to the last and then reverses direction sequencing from the last to the

first.

PASS TOLERANCE

[-P Only]

is the allowable tolerance condition for the test and is used to highlight

test points that have large errors.

SETPOINTS MENU opens a menu to set each of the SETPOINTS for the Program. Only the

number of SETPOINTS defined by NO. SETPOINTS will be displayed.

Table 2-14 shows and describes the menu selections on the Test Result menu. This menu

is available on the -P Model only.

Table 2-14. Test Result Menu

66.03°C

TEST RESULT MENU

PRINT

TEST

ERASE

TEST

2 3

gzs012.eps

MENU

PROG

MENU

TEST

RESULT

VIEW

TEST

1

Item Function

VIEW TEST

PRINT TEST

printed. The data is transmitted from the RS-232 or USB port in ASCII format. Terminal emulator

[-P Only]

opens a menu where test results can be viewed.

[-P Only]

opens a menu to select a programs results and transmit them to a PC to be

or other software can be used to receive the data and save it to a text file on a computer.

ERASE TESTS

[-P Only]

opens a menu to erase test results.

2-16

Page 35

Operation

Menus and Menu Navigation 2

System Menu (SYSTEM MENU)

The System menu lets the user set up the display settings, communications protocol,

date/time settings (-P model only), password settings, calibrations settings, and view

system information (see Figure 2-3).

66.03°C

SYSTEM MENU

SYSTEM

SETUP

PASS

WORD CALIB

SYSTEM

INFO

gzs014.eps

Figure 2-3. System Menu

Display Setup

Table 2-15 shows and describes the menu selections on the Display Setup menu.

Table 2-15. Display Setup Menu

66.03°C

DISPLY

SETUP

DISPLAY SETUP

LANGUAGE: ENGLISH

DECIMAL: PERIOD

KEY AUDIO: ON

MENU

SYSTEM

MENU

SYSTEM

SETUP

Item Function

1

2

3

gzs015.eps

LANGUAGE sets the display language. See “Change Language” on page 2-9.

DECIMAL set the decimal separator to be a period (.) or a comma (,).

KEY AUDIO turns on (ON) or turns off (OFF) the key-beep sound. See “Toggle Key Beep On or

Off” on page 2-10.

With the Main screen shown in the display, push and at the same time to

Note

quickly toggle key beep on or off.

2-17

Page 36

9190A

Operators Manual

Communications Setup

Table 2-16 shows and describes the menu selections on the Communication Setup menu.

Table 2-16. Communication Setup Menu

66.03°C

COMMUNICATION SETUP

BAUD RATE: 9600

LINEFEED: ON

MENU

SYSTEM

MENU

SYSTEM

SETUP

COMM

SETUP

tem Function

BAUD RATE is the serial communication transmission rate or baud rate. BAUD can be set to

1200, 2400, 4800, 9600, 19200, or 38400 baud.

LINEFEED turns on or turns off transmission of a line feed character (LF, ASCII 10) after

transmission of a carriage-return.

Date/Time Setup (-P Only)

Table 2-17 shows and describes the menu selections on the Date and Time Setup menu.

Table 2-17. Date and Time Setup Menu

1

2

gzs016.eps

2-18

66.03°C

DATE/TIME SETUP

TIME: 12:00:00

DATE: 2000-01-01

REPORT DATES: DD/MM/YYYY

MENU

SYSTEM

MENU

SYSTEM

SETUP

DATE

TIME

Item Function

TIME

DATE

REPORT DATE

[-P Only]

sets the internal time of the instrument. The Product uses a 24-hour clock.

[-P Only]

sets the date for the date and time stamp function.

[-P Only]

sets the date format used in the reports.

1

2

3

gzs017.eps

Page 37

Operation

Menus and Menu Navigation 2

Calibration Setup Menu

The Calibration Setup menu supplies access to all calibration parameters for the

Calibrator. Calibration parameters are set at the factory when the instrument is calibrated.

Access to these parameters is protected by a password to prevent unauthorized changes

that could make the Calibrator inoperable. These parameters require periodic adjustments

by trained, knowledgeable personnel to maintain the accuracy of the instrument. For

Calibration instructions, see Chapter 4.

Caution

Do not change the values of the control parameters from the

factory set values. Calibration parameters must be correct for

the instrument to function properly.

Calibration Points Setup

Table 2-18 shows and describes the menu selections on the Calibration Points Setup

menu.

Table 2-18. Calibration Setup Menu

1

MENU

SYSTEM

MENU CALIB

CAL

POINTS

66.03°C

CALIBRATION POINTS

TEMP 1: -0.218

TEMP 2: -0.172

TEMP 3: -0.201

GRAD TEMP: -0.004°C

GRAD 1: -0.029

GRAD 2: -0.013

GRAD 3: 0.062

CAL DATE: 2012-05-01

2

3

4

5

6

7

8

gzs019.eps

Item Function

TEMP 1 sets the offset in °C for the heat source accuracy at the 1st calibration point.

TEMP 2 sets the offset in °C for the heat source accuracy at the 2

nd

calibration point.

TEMP 3 sets the offset in °C for the heat source accuracy at the 3rd calibration point.

GRAD TEMP is a view only parameter that shows the gradient temperature. Fluke Calibration

Service Center personnel use this to help troubleshoot the system if a malfunction occurs.

GRAD 1 sets the offset for the top zone heater control for the axial gradient calibration at the 1

calibration point.

GRAD 2 sets the offset for the top zone heater control for the axial gradient calibration at the 2

calibration point.

GRAD 3 sets the offset for the top zone heater control for the axial gradient calibration at the 3

calibration point.

st

nd

rd

CAL DATE is the calibration date for the Calibrator.

2-19

Page 38

9190A