Page 1

9133

Infrared Thermometer Calibrator

User’s Guide

Rev. 180601

Page 2

Copyright © 2002 All Rights Reserved

Hart Scientific, Inc.

799 E. Utah Valley Drive

American Fork, Utah 84003-9775

Telephone: (801) 763-1600 • Fax: (801) 763-1010

Internet: http://www.hartscientific.com

E-mail: support@hartscientific.com

Rev. 180601

Page 3

Table of Contents

1 Before You Start . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Symbols Used. . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety Information. . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Customer Service Information . . . . . . . . . . . . . . . . . 3

2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Specifications and Environment Conditions . . . . . . . . 7

3.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Environmental Conditions . . . . . . . . . . . . . . . . . . . . 8

3.3 Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . 11

5 Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.3 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.4 Setting the Temperature . . . . . . . . . . . . . . . . . . . . 14

6 Parts and Controls . . . . . . . . . . . . . . . . . . . . . 15

6.1 Back Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7 General Operation . . . . . . . . . . . . . . . . . . . . . 19

7.1 Changing Display Units . . . . . . . . . . . . . . . . . . . . 19

7.2 Switching to 230 V Operation . . . . . . . . . . . . . . . . . 19

7.3 Ice Buildup/Purge . . . . . . . . . . . . . . . . . . . . . . . 19

8 Controller Operation . . . . . . . . . . . . . . . . . . . . 21

8.1 Target Temperature . . . . . . . . . . . . . . . . . . . . . . 21

8.2 Temperature Set-point . . . . . . . . . . . . . . . . . . . . . 21

8.2.1 Programmable Set-points . . . . . . . . . . . . . . . . . . . . . . . . 21

8.2.2 Set-point Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.3 Temperature Scale Units. . . . . . . . . . . . . . . . . . . . 24

8.4 Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

i

Page 4

8.4.1 Scan Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.4.2 Scan Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.5 Set-point Resistance. . . . . . . . . . . . . . . . . . . . . . 25

8.6 Temperature Scale Units. . . . . . . . . . . . . . . . . . . . 25

8.7 Secondary Menu. . . . . . . . . . . . . . . . . . . . . . . . 25

8.8 Heater Power . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.9 Proportional Band . . . . . . . . . . . . . . . . . . . . . . . 26

8.10 Controller Configuration . . . . . . . . . . . . . . . . . . . . 27

8.11 Operating Parameters . . . . . . . . . . . . . . . . . . . . . 28

8.12 Serial Interface Parameters . . . . . . . . . . . . . . . . . . 28

8.12.1 BAUD Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.12.2 Sample Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.12.3 Duplex Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.12.4 Linefeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.13 Calibration Parameters. . . . . . . . . . . . . . . . . . . . . 30

8.13.1 R0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.13.2 ALPHA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.13.3 DELTA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.13.4 BETA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9 Digital Communication Interface . . . . . . . . . . . . . 33

9.1 Serial Communications . . . . . . . . . . . . . . . . . . . . 33

9.1.1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.1.2 Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.1.2.1 BAUD Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.1.2.2 Sample Period . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.1.2.3 Duplex Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.1.2.4 Linefeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.1.3 Serial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.2 Interface Commands. . . . . . . . . . . . . . . . . . . . . . 35

10 Calibration Procedure . . . . . . . . . . . . . . . . . . . 39

10.1 Calibration Points . . . . . . . . . . . . . . . . . . . . . . . 39

10.2 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . 39

10.2.1 Compute DELTA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

10.2.2 Compute R0 and ALPHA . . . . . . . . . . . . . . . . . . . . . . . . 40

10.2.3 Compute BETA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.2.4 Accuracy and Repeatability . . . . . . . . . . . . . . . . . . . . . . . 41

11 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 43

12 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 45

12.1 Troubleshooting Problems, Possible Causes, and Solutions . 45

12.2 Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

ii

Page 5

12.2.1 EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12.2.2 Low Voltage Directive (Safety) . . . . . . . . . . . . . . . . . . . . . . 47

12.3 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . 48

iii

Page 6

Figures and Tables

Table1 International Electrical Symbols . . . . . . . . . . . . . . . . . . . 1

Figure 1 Temperature Gradient Between Probe and IR Target

Surface at Ambient of 30°C . . . . . . . . . . . . . . . . . . . . . 8

Figure 2 Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 3 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 4 Controller Operation Flow Chart . . . . . . . . . . . . . . . . . . 22

Figure 5 Serial Cable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 2 Controller Communications Commands . . . . . . . . . . . . . . 36

Table 2 Controller Communications Commands continued . . . . . . . . . 37

Figure 6 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

iv

Page 7

1 Before You Start

1.1 Symbols Used

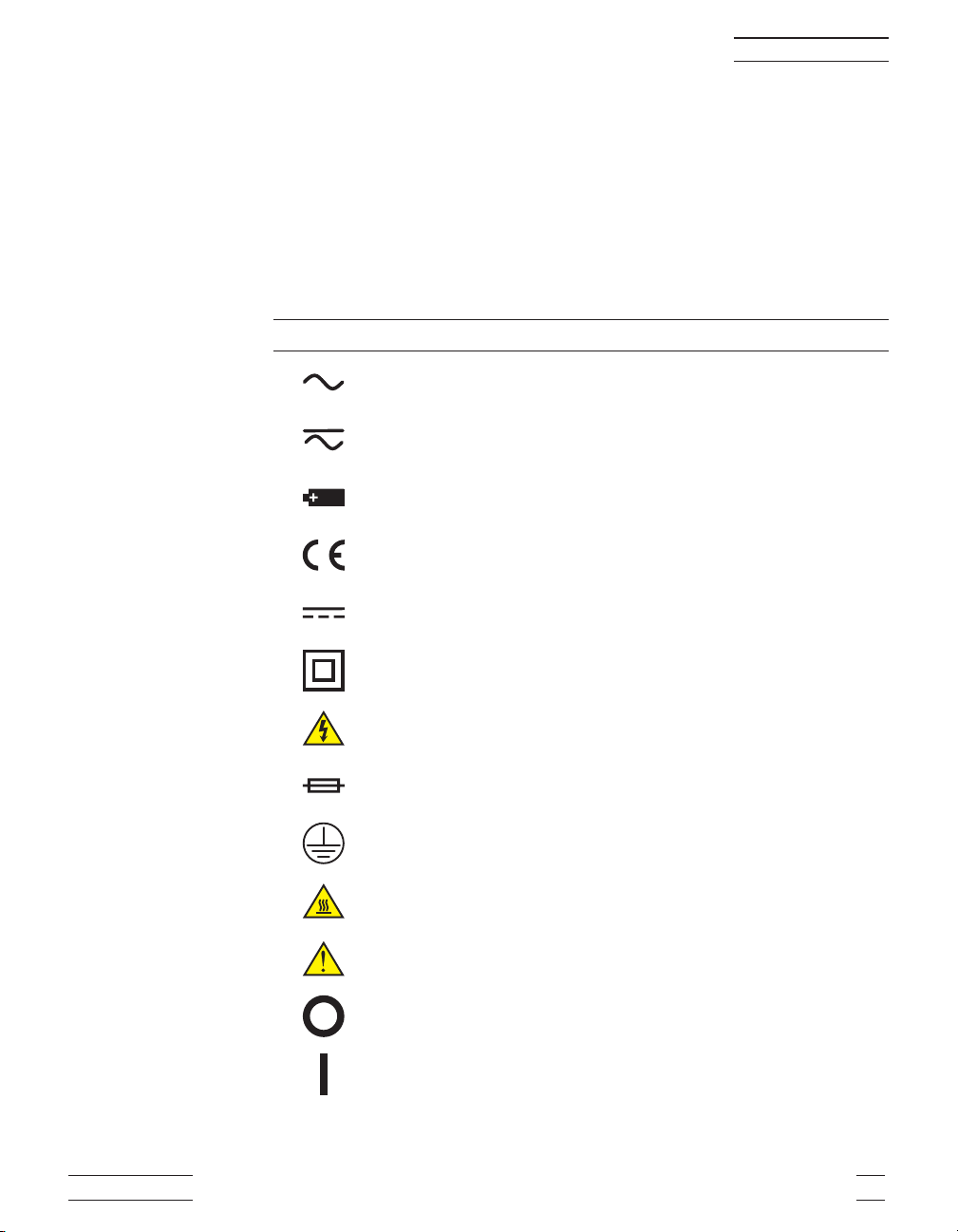

Table 1 lists the International Electrical Symbols. Some or all of these

symbols may be used on the instrument or in this manual.

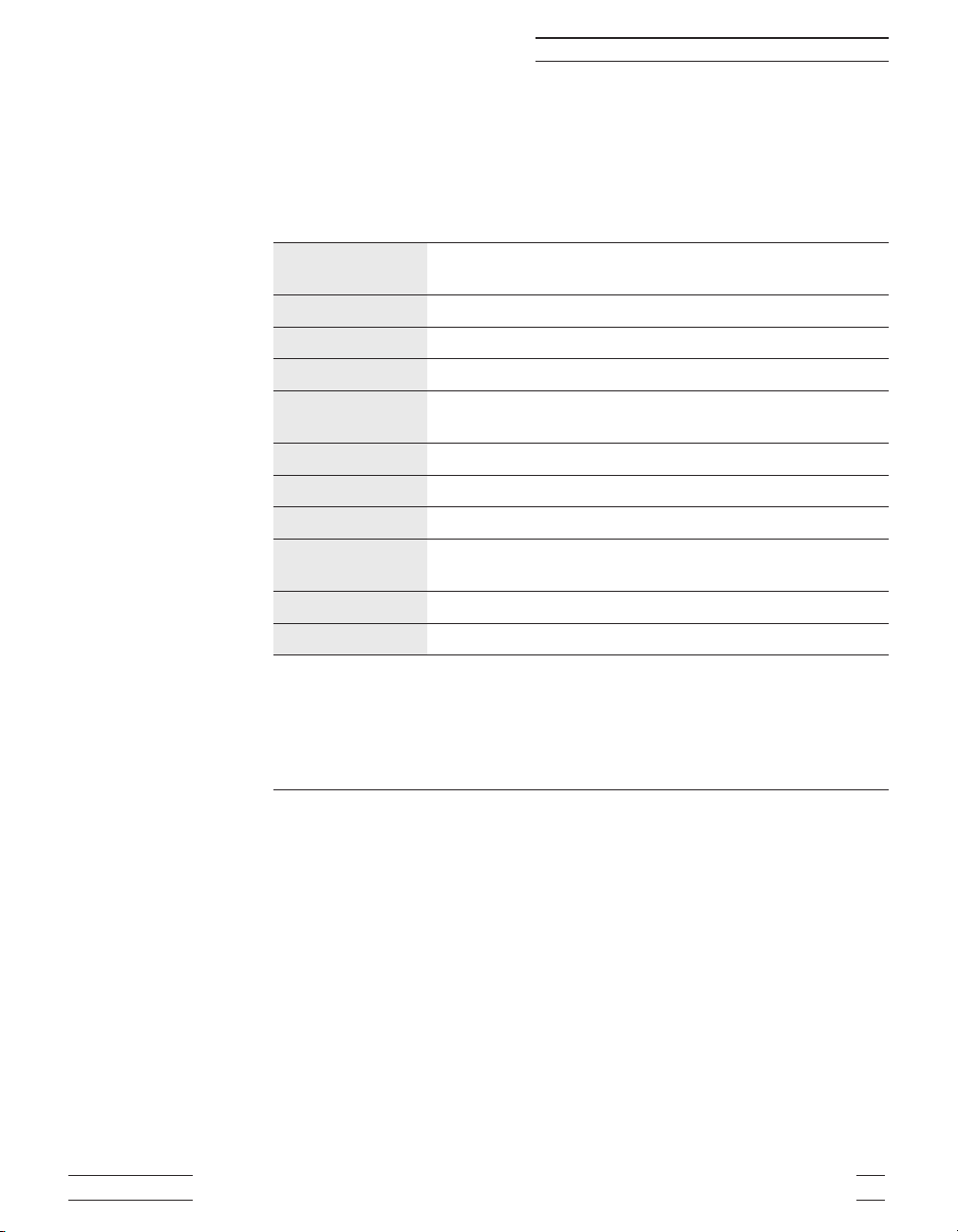

Table1 International Electrical Symbols

Symbol Description

AC

AC-DC

Battery

Complies with European Union directives

1 Before You Start

DC

Double Insulated

Electric Shock

Fuse

PE Ground

Hot Surface

Read the User’s Manual

Off

On

Hart Scientific Manual Rev. 180601 1

Page 8

1 Before You Start

Symbol Description

Canadian Standards Association

CAT II

OVERVOLTAGE (Installation) CATEGORY II, Pollution Degree

2 per IEC1010-1 revers to the level of Impulse Withstand Volt

age protection provided. Equipment of OVERVOLTAGE CATE

GORY II is energy-consuming equipment to be supplied from

the fixed installation. Examples include household, office, and

laboratory appliances.

1.2 Safety Information

Use this instrument only as specified in this manual. Otherwise, the pro

tection provided by the instrument may be impaired. Refer to the safety

information in Warnings and Cautions.

The following definitions apply to the terms “Warning” and “Caution”.

•

“Warning” identifies conditions and actions that may pose hazards to

the user.

•

“Caution” identifies conditions and actions that may damage the instrument being used.

Warnings

To avoid possible electric shock or personal injury, follow these guidelines.

BURN HAZARD – DO NOT touch the IR target surface of the unit.

The temperature of the IR target surface is the same as the actual

temperature shown on the display. If the unit is set at 150°C and the

display reads 150°C, the target surface is at 150°C.

Temperatures above 70°C (158°F) are considered hazardous. Use ex

treme care when working with these temperatures. Observe all warn

ings and cautions given in this manual.

The sheet metal of the instrument may exhibit extreme temperatures

for areas close to the IR target surface.

-

-

-

-

-

DO NOT turn off the unit at temperatures higher than 100°C. This

could create a hazardous situation. Select a set-point less than 100°C

and allow the unit to cool before turning it off.

DO NOT operate this unit without a properly grounded, properly polar

ized power cord.

DO NOT connect this unit to a non-grounded, non-polarized outlet.

2 Manual Rev. 180601 9133

-

Page 9

1 Before You Start

HIGH VOLTAGE is used in the operation of this equipment. SEVERE

INJURY OR DEATH may result if personnel fail to observe safety pre

cautions. Before working inside the equipment, turn the power off and

disconnect the power cord.

Always replace the fuse with one of the same rating, voltage, and type.

Allow at least six inches of space between the instrument and nearby

objects. DO NOT place instrument under a flammable structure.

DO NOT use this unit for any application other than calibration work.

DO NOT use this unit in environments other than those listed in the

user’s guide.

DO NOT operate near flammable materials.

-

Use of this instrument at HIGH TEMPERATURES for extended peri

ods of time requires caution.

Completely unattended high temperature operation is not recom

mended for safety reasons.

Before initial use, after transport, and anytime the instrument has not

been energized for more than 10 days, the calibrator must be energized for a dry-out period of 1 to 2 hours before it can be assumed to

meet all of the safety requirements of the IEC1010-1.

This instrument is intended for indoor operation only.

Follow all safety guidelines listed in the user’s manual.

Calibration Equipment should only be used by Trained Personnel.

-

-

Cautions

To avoid possible damage to the instrument, follow these guidelines.

Use the target cover at temperatures below 5°C. If ice forms on the tar

get, the IR probe will not indicate the correct temperature.

DO NOT use fluids to clean out the target surface.

DO NOT change the values of the calibration constants from the fac

tory set values. The correct setting of these parameters is important to

the safety and proper operation of the calibrator.

DO use a ground fault interrupt device.

-

-

1.3 Customer Service Information

Hart Scientific can be contacted by writing to:

Hart Scientific, Inc.

799 E. Utah Valley Drive

Hart Scientific Manual Rev. 180601 3

Page 10

1 Before You Start

American Fork, UT 84003-9775

Or by calling or faxing:

Telephone: (801) 763-1600

Fax: (801) 763-1010

Our World Wide Web site is: http://www.hartscientific.com

E-mail: support@hartscientific.com

When calling Hart Scientific Customer Service, please have the following

information available:

•

Model Number

•

Serial Number

•

Voltage

4 Manual Rev. 180601 9133

Page 11

2 Introduction

The Hart Scientific Model 9133 Mid-Range Field IR Calibrator may be

used as a portable instrument or bench top temperature calibrator for cal

ibrating point IR thermometers. The Model 9133 is small enough to use

in the field, and accurate enough to use in the lab. Calibrations may be

done over a range of -30°C to150°C (-22°F to 302°F). Temperature dis

play and setability resolution of the 9133 is 0.1 degrees.

The instrument features:

•

Rapid heating and cooling

•

RS-232 interface capability

Built in programmable features include:

•

Temperature scan rate control

•

Eight set-point memory

•

Adjustable readout in °C or °F

The temperature is accurately controlled by Hart’s digital controller. The

controller uses a precision platinum RTD as a sensor and controls the

well temperature with a FET driven thermal electric device.

2 Introduction

-

-

For improved uncertainties, a 0.125" diameter external reference thermometer may be used in the calibration probe hole at the top of the instrument. When using an external reference thermometer, the instrument

accuracy, stability, and ambient temperature effects on the surface can

be minimized.

The LED front panel continuously shows the current temperature. The

temperature may be easily set with the control buttons to any desired

temperature within the specified range. The instrument’s multiple fault

protection devices insure user and instrument safety and protection.

The Model 9133 calibrator was designed for portability, low cost, and

ease of operation. Through proper use, the instrument will provide con

tinued accurate calibration of temperature sensors and devices. The

user should be familiar with the safety guidelines and operating proce

-

dures of the calibrator as described in this user guide.

Hart Scientific Manual Rev. 180601 5

-

Page 12

3 Specifications and Environment Conditions

3 Specifications and Environment

Conditions

3.1 Specifications

Temperature

†

Range

Accuracy

Stability ±0.1°C (±0.18°F)

Target Size 2.25" (57 mm)

Target Emissivity 0.95

Resolution 0.1

Heating Time 15 minutes (25°C to 150°C)

Cooling Time 15 minutes (25°C to -20°C)

Power 115 VAC (±10%), 3 A, or 230 VAC (±10%), 1.6 A, switch-

Size 6" H x 11.25" W x 10.5" H (152 x 286 x 267 mm)

Weight 10 lb. (4.6 kg)

†

When using a purge, the high and low range are reduced. This amount de-

pends on the flow and temperature of the purge.

‡

Temperature difference between the IR target surface and the reference probe

are calculated as shown in the graph in Figure 1 on page 8. Note: As the tem

perature of the IR target surface increases, the temperature difference de

creases.

‡

–30°C to 150°C (-22°F to 302°F)

±0.4°C (±0.72°F) [using 1/8" PRT]

able, 50/60 Hz

-

-

Hart Scientific Manual Rev. 180601 7

Page 13

3 Specifications and Environment Conditions

0

C

0.15

0.1

0.05

0

-0.05

delta T °

-0.1

-0.15

-0.2

-30 -10 10 30 50 70 90 110 130 15

Figure 1 Temperature Gradient Between Probe and IR Target Surface at Ambient of 30°C

Reference Probe °C

3.2 Environmental Conditions

Although the instrument has been designed for optimum durability and

trouble-free operation, it must be handled with care. The instrument

should not be operated in an excessively dusty or dirty environment.

Maintenance and cleaning recommendations can be found in the Maintenance section of this manual.

The instrument operates safely under the following conditions:

•

temperature range: 5–50°C (41–122°F)

•

ambient relative humidity: 15–60%

•

pressure: 75kPa–106kPa

•

mains voltage within ±10% of nominal

•

vibrations in the calibration environment should be minimized

•

altitudes less than 2,000 meters

3.3 Warranty

Hart Scientific, Inc. (Hart) warrants this product to be free from defects in

material and workmanship under normal use and service for a period as

stated in our current product catalog from the date of shipment. This war

ranty extends only to the original purchaser and shall not apply to any

-

8 Manual Rev. 180601 9133

Page 14

3 Specifications and Environment Conditions

product which, in Hart’s sole opinion, has been subject to misuse, alter

-

ation, abuse or abnormal conditions of operation or handling.

Software is warranted to operate in accordance with its programmed in

structions on appropriate Hart products. It is not warranted to be error

free.

Hart’s obligation under this warranty is limited to repair or replacement of

a product which is returned to Hart within the warranty period and is de

termined, upon examination by Hart, to be defective. If Hart determines

that the defect or malfunction has been caused by misuse, alteration,

abuse or abnormal conditions or operation or handling, Hart will repair

the product and bill the purchaser for the reasonable cost of repair.

To exercise this warranty, the purchaser must forward the product after

calling or writing Hart for authorization. Hart assumes NO risk for in-tran

sit damage.

For service or assistance, please contact the manufacturer.

Hart Scientific, Inc.

799 East Utah Valley Drive

American Fork, UT 84003-9775

Phone: (801) 763-1600 – Fax: (801) 763-1010

E-mail: support@hartscientific.com

THE FOREGOING WARRANTY IS PURCHASER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OR MERCHANTABILITY, OR FITNESS FOR

ANY PARTICULAR PURPOSE OR USE. HART SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES OR LOSS WHETHER IN CONTRACT, TORT, OR OTHER

-

WISE.

-

Hart Scientific Manual Rev. 180601 9

Page 15

4 Safety Guidelines

•

Operate the instrument in room temperatures between 5–50°C

(41–122° F). Allow sufficient air circulation by leaving at least 6 inches

of space between the instrument and nearby objects.

•

The instrument is a precision instrument. Although is has been de

signed for optimum durability and trouble free operation, it must be

handled with care. The convenient fold-up handle allows one hand

carrying. The instrument should not be operated in excessively wet,

oily, dusty, or dirty environments. It is important to keep the calibration

probe well and the IR target surface clean and clear of any foreign

matter. Do not operate near flammable materials.

•

DO NOT use fluids to clean out the calibration probe well or on the IR

target surface.

•

The instrument can generate extreme temperatures. Precautions

must be taken to prevent personal injury or damage to objects.

•

Use only a grounded AC mains supply of the appropriate voltage to

power the instrument. Refer to Section 3.1, Specifications for power

details.

•

Before initial use, after transport, and anytime the instrument has not

been energized for a “dry-out” period of 1-2 hours before it can be assumed to meet all of the safety requirements of the IEC 1010-1.

•

The instrument is equipped with operator accessible system fuses. If

a fuse blows, it may be due to a power surge or failure of a component.

Replace the fuse once. If the fuse blows a second time, it is likely

caused by failure of a component part. If this occurs, contact Hart Sci

entific Customer Service. Always replace the fuse with one of the

same rating, voltage, and type. Never replace the fuse with one of a

higher current rating.

•

If a main supply power fluctuation occurs, immediately turn off the in

strument. Wait until the power has stabilized before re-energizing the

instrument.

4 Safety Guidelines

-

-

-

Hart Scientific Manual Rev. 180601 11

Page 16

5 Quick Start

5.1 Unpacking

Unpack the calibrator carefully and inspect it for any damage that may

have occurred during shipment. If there is shipping damage, notify the

carrier immediately.

Verify that the following components are present:

•

9133 Calibrator

•

Power Cord

•

User Guide

•

Serial Cable

•

Target Cover

•

9930 Software

5.2 Set Up

Place the calibrator on a flat surface with at least 6 inches of free space

around the instrument. The prop may be swung down to raise the front

of the instrument from a horizontal position. Plug the power cord into a

grounded mains outlet. Observe that the nominal voltage corresponds to

that indicated on the back of the calibrator.

5 Quick Start

Turn on the power to the calibrator by toggling the power switch on. The

fan should begin quietly blowing air through the instrument and the con

troller display should illuminate after 3 seconds. After a brief self-test the

controller should begin normal operation. If the unit fails to operate

please check the power connection.

The thermal electric devices will start operating to bring the temperature

of the calibrator to the set-point temperature and the display will begin to

show the actual target temperature.

Caution:

forms on the target, the IR probe will not indicate the correct tempera

ture.

Use the target cover at temperatures below 5°C. If ice

-

5.3 Power

Plug the instrument power cord into a mains outlet of the proper voltage,

frequency, and current capability. Refer to Section 3.1, Specifications for

Hart Scientific Manual Rev. 180601 13

-

Page 17

5 Quick Start

power details. Turn the instrument on using the rear panel “POWER”

switch. The instrument turns on and begins to heat to the previously pro

grammed temperature set-point. The front panel LED display indicates

the actual instrument temperature.

5.4 Setting the Temperature

Section 8.2 explains in detail how to set the temperature set-point on the

calibrator using the front panel keys. The procedure is summarized here.

1. Press the “SET” button twice to access the set-point value.

2. Press the “UP” or “DOWN” button to change the set-point value.

3. Press the “SET” button to program in the new set-point.

4. Press the “EXIT” button to return to the temperature display.

When the set-point temperature is changed the controller switches the

heater on or off to raise or lower the temperature. The displayed temperature gradually changes until it reaches the set-point temperature. The

target may require 5 to 10 minutes to reach the set-point depending on

the span. Another 5 to 10 minutes is required to stabilize within ±0.1°C

of the set-point. Ultimate stability may take 15 to 20 minutes more of stabilization time.

-

14 Manual Rev. 180601 9133

Page 18

6 Parts and Controls

6.1 Back Panel

6 Parts and Controls

The back panel (Figure 2) consists of the power inlet, power switch, se

-

rial port, and fan.

115 VAC 50/60 Hz 3A

230 VAC 50/60 Hz 1.6A

~

Figure 2 Back Panel

RS-232

115V -3AT 250V

230V -1.6AT 250V

Power Inlet – At the rear of the calibrator is the removable power cord in

let that plugs into an IEC grounded socket.

Power Switch – The power switch is located on the power entry module

(PEM). The PEM also houses the fuses. The PEM allows the unit to be

field switchable for 115 VAC (±10%) or 230 VAC ±10%) operation. (See

Section 7.2, Switching to 230 V Operation.)

Serial Port – A DB-9 male connector is present for interfacing the cali

-

brator to a computer or terminal with serial RS-232 communications.

Fan – The fan inside the calibrator varies in speed. As the target temper

ature increases the fan speed decreases. Slots are provided for airflow.

The area around the calibrator must be kept clear to allow adequate ven

tilation. The airflow is directed out the two sides.

Hart Scientific Manual Rev. 180601 15

-

-

Page 19

6 Parts and Controls

6.2 Front Panel

The front panel (Figure 3) consists of the controller display, controller

key-pad, and target assembly.

SET UPDOWN EXIT

9133

Infrared Calibrator

Figure 3 Front Panel

Controller Display – The digital display displays set and actual tempera-

tures and various calibrator functions, settings, and constants. The display shows temperatures in units according to the selected scale °C or

°F.

Controller Keypad – The four button keypad allows easy setting of the

set-point temperature. The control buttons (SET, DOWN, UP, and EXIT)

are used to set the calibrator temperature set-point, access and set other

operating parameters, and access and set calibration parameters.

Setting the control temperature is done directly in degrees of the current

scale. The control temperature can be set to one-tenth of a degree Cel

sius or Fahrenheit.

The functions of the buttons are as follows:

SET – Used to display the next parameter in a menu and to set parame

ters to the displayed value.

DOWN – Used to decrement the displayed value of parameters.

UP – Used to increment the displayed value.

EXIT – Used to exit from a menu. When the EXIT button is pressed any

changes made to the displayed value are ignored.

16 Manual Rev. 180601 9133

-

-

Page 20

6 Parts and Controls

Target Assembly – The target assembly is 2.25” (57 mm) in diameter

and has an emissive of 0.95.

Hart Scientific Manual Rev. 180601 17

Page 21

7 General Operation

7.1 Changing Display Units

The Model 9133 can display temperature in Celsius or Fahrenheit. The

temperature units are shipped from the factory set to Celsius. There are

two ways to change to Fahrenheit or back to Celsius as described below.

1. Press the “SET” and “UP” buttons simultaneously. The units are

changed.

Or

1. Press the “SET” button three times from the temperature display

to show Un =C

2. Press the “UP” or “DOWN” button to change units.

7.2 Switching to 230 V Operation

The Model 9133 is switchable from 115 VAC to 230 VAC 50/60 Hz. To

change from 115 VAC to 230 VAC follow the steps below.

7 General Operation

1. Unplug the instrument.

2. With a small straight slot screwdriver remove the fuse holder lo-

cated on the rear panel.

3. Replace the two 3 A 250 V fuses with two 1.6 AT 250 V fuses.

4. Replace the fuse holder with the “~” in the display window.

Note: If “~” is not displayed in the window, the unit will not heat or cool.

7.3 Ice Buildup/Purge

To prevent ice buildup on the target at temperatures below 5°C, use the

target cover and/or a dry gas purge. When taking measurements using

the target cover, place the target cover in place and set the set-point tem

perature to the desired temperature, remove the target cover, take a

sample, and replace the cover. When ice forms on the target, change the

unit set-point higher than 5°C to melt the excess ice. When the ice melts

pat the excess water off with a clean dry cloth. Do not wipe the front

plate. If a clean dry cloth is not available, change the set-point to 100°C

or higher, to evaporate the excess water.

Hart Scientific Manual Rev. 180601 19

-

Page 22

7 General Operation

When using a dry gas purge, the instrument will not reach minimum tem

perature. An example of a gas purge is dry nitrogen connected through a

1/8” inner diameter tube to the purge fitting located at the front bottom of

the target. The nitrogen gas is controlled to fill the chamber in front of the

target at a rate that will not allow airflow to affect the target. Note: If the

gas contains any moisture, ice will form on the target.

-

20 Manual Rev. 180601 9133

Page 23

8 Controller Operation

8 Controller Operation

This section discusses in detail how to operate the instrument tempera

ture controller using the front control panel. By using the front panel

key-switches and LED display, the user may monitor the target tempera

ture, adjust the set-point temperature in degrees C or F, monitor the out

put power, adjust the controller proportional band, and program the

operating parameters, program parameters, serial interface configuration,

and the controller calibration parameters. Operation of the functions and

parameters is shown in the flowchart in Figure 4 on page 22. This chart

may be copied for reference.

In the following discussion a button with the word “SET”, “UP”, “DOWN”,

or “EXIT” inside indicates the panel button while the dotted box indicates

the display reading. Explanation of the button or display reading is to the

right of each button or display value.

8.1 Target Temperature

The digital LED display on the front panel allows direct viewing of the actual temperature. This temperature value is what is normally shown on

the display. The units C or F, of the temperature value are displayed at

the right. For example,

100.0 C

The temperature display function may be accessed from any other function by pressing the “EXIT” button.

Target temperature in degrees Celsius

-

-

-

8.2 Temperature Set-point

The temperature set-point can be set to any value within the range and

resolution as given in the specifications.

Setting the temperature involves selecting one of the eight set-points in

memory and then adjusting the set-point value.

8.2.1 Programmable Set-points

The controller stores eight (8) set-point temperatures in memory. The

set-points can be quickly recalled to conveniently set the instrument to a

previously programmed temperature set-point.

To set the temperature, first select the set-point memory. This function is

accessed from the temperature display function by pressing the “SET”

Hart Scientific Manual Rev. 180601 21

Page 24

8 Controller Operation

Display

Temperature

SET

Select Setpoint

Adjust Setpoint

Units °C/°F

Scan On/Off

Scan Rate

EXIT

(2 Seconds)

(2 Seconds)

Operating

Parameters

Menu

SET

HL

Adj.HL

+

SET

DOWN

Displays Set-Point Resistance

+

SET

UP

Tog gl es ° C / ° F

Automatically returns to display

Secondary Functions

+

SET

EXIT

Display Power

Set Proportional Band

Configuration Menu

SET

EXITEXIT

UP

DOWN DOWN

Serial

Interface

Menu

SET

BAUD

Rate

Adjust

BAUD Rate

EXIT

EXIT

Cal

Cal

Menu

Menu

SET

SET

X5

X5

DO NOT CHANGE THESEVALUES. SEE MANUAL

DO NOT CHANGE THESEVALUES. SEE MANUAL

R0

R0

Adj. R0

Adj. R0

ALPHA

ALPHA

Adj. ALPHA

Adj. ALPHA

DELTA

DELTA

UP

DO NOT CHANGE THESEVALUES. SEE MANUAL

DO NOT CHANGE THESEVALUES. SEE MANUAL

Ad j. D ELTA

Ad j. D ELTA

BETA

BETA

Adjust

Adjust

BETA

BETA

Sample

Menu Legend:

Press “SET” to step through the menu and

to store the parameter value.

Press “EXIT” briefly to skip a parameter

without storing the parameter value.

Hold “EXIT”( 2 seconds) to exit the menu

and display the temperature

≈

Period

Adj. Sample

Period

Duplex

Mode

Adj. Duplex

Mode

Linefeed

Adjust

Linefeed

Figure 4 Controller Operation Flow Chart

22 Manual Rev. 180601 9133

Page 25

8 Controller Operation

button. The number of the set-point memory currently being used is

shown at the left on the display followed by the current set-point value.

100.0 C

S

Access set-point memory

1 100.

To change the set-point memory to another preset value press the “UP”

or “DOWN” button.

4 150

Press the “SET” button to display the new selection and access the

set-point value.

S

Accept selected set-point memory

8.2.2 Set-point Value

The set-point value may be adjusted after selecting the set-point memory

and pressing the “SET” button. The set-point value is displayed with the

units, C or F, at the left.

4 120.

Well temperature in degrees Celsius

Set-point memory 1, 100°C currently used

New set-point memory 4, 150°C

Set-point value 4, 120.0°C

If the set-point value does not need to be changed, press the “EXIT” but

ton to resume displaying the instrument temperature. Press the “UP” or

the “DOWN” button to adjust the set-point value.

U

When the desired set-point value is reached press the “SET” button to

accept the new value. If the “EXIT” button is pressed, any changes made

to the set-point are ignored.

S

Hart Scientific Manual Rev. 180601 23

Increment display

125.0

Accept new set-point value

New set-point value

-

Page 26

8 Controller Operation

8.3 Temperature Scale Units

The temperature scale units of the controller can be set by the user to

degrees Celsius (°C) or Fahrenheit (°F). The units are used in displaying

the well temperature, set-point, and proportional band.

Press the “SET” button after adjusting the set-point value to change dis

play units

Un= C

Press the “UP” or “DOWN” button to change the units.

U

Change units

Un = F

Press the “SET” button to accept the new selection and resume display

ing the display temperature.

8.4 Scan

The scan rate can be set and enabled so that when the set-point is

changed the instrument heats or cools at a specified rate, in degrees C

per minute only, until it reaches the new set-point. With the scan disabled

the instrument heats or cools at the maximum possible rate.

8.4.1 Scan Control

The scan is controlled with the scan on/off function that appears in the

main menu after the temperature scale units.

-

Scale units currently selected

New units selected

-

Sc=OFF

Press the “UP” or “DOWN” button to toggle the scan on or off.

Sc=On

Press the “SET” button to accept the present setting and to continue.

S

24 Manual Rev. 180601 9133

Accept scan setting

Scan function off

Scan function on

Page 27

8.4.2 Scan Rate

The next function in the main menu is the scan rate. The scan rate can

be set from .1 to 99.9°C/min. The maximum scan rate however is actually

limited by the natural heating or cooling rate of the instrument.

The scan rate function appears in the main menu after the scan control

function. The scan rate units are in degrees Celsius per minute.

8 Controller Operation

Sr=10.0

Press the “UP” or “DOWN” button to change the scan rate.

Sr=2.0

Press the “SET” button to accept the new scan rate and continue.

S

Accept scan rate

Scan rate in C/min

New scan rate

8.5 Set-point Resistance

To display the Set-point Resistance, press the “SET” and “DOWN” buttons simultaneously when the temperature is displayed. When the “SET”

and “DOWN” buttons are released the temperature is again displayed.

This value is used to calibrate the unit and is not adjustable.

8.6 Temperature Scale Units

To toggle between °C and °F, press the “SET” and “UP” keys simulta

neously when the temperature is displayed.

8.7 Secondary Menu

-

Functions used less often are accessed within the secondary menu.

Press and hold the “SET” and EXIT buttons to access the secondary

menu. The first function in the secondary menu is the heater power dis

play. (See Figure 4 on page 22.)

8.8 Heater Power

The temperature controller controls the temperature of the well by puls

ing the heater on and off. The total power being applied to the heater is

determined by the duty cycle or the ratio of heater on time to the pulse

cycle time. By knowing the amount of heating the user can tell if the in

strument is heating “UP” to the set-point, cooling “DOWN”, or controlling

at a constant temperature. Monitoring the percent heater power lets the

Hart Scientific Manual Rev. 180601 25

-

-

-

Page 28

8 Controller Operation

user know the stability of the well temperature. With good control stability

the percent heating power should not fluctuate more than ±1% within one

minute.

The heater power display is accessed in the secondary menu. Press and

hold the “SET” and “EXIT: buttons. The heater power is displayed as a

percentage of full power.

100.0 C

S+E

SEC

12.0P

To exit out of the secondary menu press and hold the “EXIT” button. To

continue on to the proportional band setting function, press the “SET”

button.

Target temperature

Access heater power in percent

Flashes for secondary menu and then displays

the heater power

Heater power in percent

8.9 Proportional Band

In a proportional controller such as this, the heater output power is proportional to the target temperature over a limited range of temperatures

around the set-point. This range of temperature is called proportional

band. At the bottom of the proportional band, the heater output is 100%.

At the top of the proportional band, the heater output is 0. Thus as the

temperature rises the heater power is reduced. In this way the tempera

ture is maintained at a fairly constant level.

The temperature stability of the instrument depends on the width of the

proportional band. If the band is too wide, the target temperature devi

ates excessively from the set-point due to varying external conditions.

This deviation is caused by the power output changing very little with

temperature and the controller not responding well to changing condi

tions or noise in the system. If the proportional band is too narrow the

temperature may swing back and forth because the controller overreacts

to temperature variations. For best stability control, the proportional band

must be set for the optimum width by the user in any given application.

-

-

-

The optimum proportional band width is set at the factory to about

25.0°C. The user may alter the proportional band width to optimize the

control characteristics for a particular application. However, we recom

mend the proportional band be changed only by knowledgeable person

nel.

26 Manual Rev. 180601 9133

-

-

Page 29

8 Controller Operation

The proportional band width is easily adjusted from the front panel. The

width may be set to discrete values in degrees C or F depending on the

selected units. The proportional band adjustment can be accessed within

the secondary menu. Press the “SET” and “EXIT” buttons to enter the

secondary menu and show the heater power. Then press the “SET” but

ton to access the proportional band.

-

S+E

SEC

12.0P

S

Prob

4.1

To change the proportional band setting press the “UP” or “DOWN” buttons.

U

10.

To store the new setting press the “SET” button. Press the “EXIT” button

to continue without storing the new value.

Access heater power in secondary menu

Flashes for secondary menu and then displays

the heater power

Heater power in percent

Access proportional band

Flashes for proportional band and then displays

the proportional band setting

Proportional band setting

Increment display

New proportional band setting

S

Accept the new proportional band setting

8.10 Controller Configuration

The controller has a number of configuration, operation, and calibration

parameters that are programmable via the front panel. These are ac

cessed from the secondary menu after the proportional band by pressing

the “SET” button. There are three sets of configuration parameters – op

erating parameters, serial interface parameters, and calibration parame

ters. The menus are selected by using the “UP” and “DOWN” buttons and

then pressing the “SET” button.

Hart Scientific Manual Rev. 180601 27

-

-

-

Page 30

8 Controller Operation

8.11 Operating Parameters

The operating parameters menu contains the High Limit parameter. The

operating parameter menu is indicated by,

PAr

The High Limit parameter adjusts the upper set-point temperature limit.

The factory default and maximum are set to 160°C. For safety, a user can

adjust the High Limit parameter down so the maximum temperature

set-point is restricted. Press the “SET” button to enable adjustment of the

High Limit parameter.

HL

H=126

To change to High Limit setting, use the “UP” or “DOWN” button.

H=90

Press the “SET” button to save this setting.

Operating parameters menu

Flashes and then displays the setting

Current HL setting

New High Limit setting

8.12 Serial Interface Parameters

The serial interface parameters menu contains parameters, which determine the operation of the serial interface. The parameters in the menu

are – BAUD rate, sample period, duplex mode, and linefeed. The serial

RS-232 interface parameters menu is indicated by,

SEriAL

Press the “UP” button from the operations Parameters Menu to access

the Serial menu. Press “SET” to enter the menu.

Serial RS-232 interface parameters menu

8.12.1 BAUD Rate

The BAUD rate is the first parameter in the menu. The BAUD rate setting

determines the serial communications transmission rate. The BAUD rate

of the serial communications may be programmed to 300, 600, 1200,

2400, 4800, or 9600. The default setting is 2400 baud.

bAUd

28 Manual Rev. 180601 9133

Flashes and then displays the setting

Page 31

8 Controller Operation

2400 b

Use the “UP” or “DOWN” buttons to change the baud rate setting.

4800 b

Press the “SET” button to store the new setting as the baud rate or press

the “EXIT” button to skip to the next parameter without storing the new

setting.

8.12.2 Sample Period

The sample period is the next parameter in the serial interface parame

ters menu. The sample period is the time period in seconds between

temperature measurements transmitted from the serial interface. If the

sample rate is set to 5, the instrument transmits the current measure

ment over the serial interface approximately every five seconds. The au

tomatic sampling is disabled with a sample period of 0.

SPEr

SP= 1

Use the “UP” or “DOWN” buttons to adjust the setting.

Current BAUD rate

New BAUD rate

-

-

-

Flashes and then displays the setting

Current sample period (seconds)

SP=60

Press the “SET” button to store the new setting as the sample period or

press the “EXIT” button to skip to the next parameter without storing the

new setting.

New sample period

8.12.3 Duplex Mode

The next parameter is the duplex mode. The duplex mode may be set to

full duplex or half duplex. With full duplex any commands received by the

instrument via the serial interface are immediately echoed or transmitted

back to the device of origin. With half duplex the commands are executed

but not echoed.

duPL

d=FULL

Use the “UP” or “DOWN” buttons to adjust the setting.

Hart Scientific Manual Rev. 180601 29

Flashes and then displays the setting

Current duplex mode

Page 32

8 Controller Operation

d=HALF

Press the “SET” button to store the new setting as the duplex mode or

press the “EXIT” button to skip to the next parameter without storing the

new setting.

8.12.4 Linefeed

The final parameter in the serial interface menu is the linefeed mode.

This parameter enables (on) or disables (off) transmission of a linefeed

character (LF, ASCII 10) after transmission of any carriage-return.

LF

LF=On

Use the “UP” or “DOWN” buttons to adjust the setting.

LF=OFF

Press the “SET” button to store the new setting as the linefeed or press

the “EXIT” button to skip to the next parameter without storing the new

setting.

New duplex mode setting

Flashes and then displays the setting

Current linefeed setting

New linefeed setting

8.13 Calibration Parameters

The probe parameters menu contains the parameters, R0, ALPHA,

DELTA, and BETA, which characterize the resistance-temperature rela

tionship of the platinum control probe. These values are set at the factory

and must not be altered. The correct values are important to the accu

racy and proper and safe operation of the instrument. Access to these

parameters is available to the user so that in the event that the controller

memory fails the user may restore these values to the factory settings.

The user should have a list of these constants on the Report of Calibra

tion that ships with the instrument.

Caution: DO NOT change the value of the instrument cali

bration constants from the factory set values. The correct setting of

these parameters is important to the safety and proper operation of

the unit.

The calibration parameters menu is indicated by,

30 Manual Rev. 180601 9133

-

-

-

-

Page 33

8 Controller Operation

CAL

Press the “SET” button five times to enter the menu. The name of the pa

rameter flashes on the display and then the value is displayed. The value

of the parameter may be changed using the “UP” and “DOWN” buttons.

After the desired value is reached press the “SET” button to set the pa

rameter to the new value. Pressing the “EXIT” button causes the parame

ter to be skipped ignoring any changes that may have been made.

8.13.1 R0

This probe parameter refers to the resistance of the control probe at 0°C.

The value of this parameter is set at the factory for best instrument accu

racy.

8.13.2 ALPHA

This probe parameter refers to the average sensitivity of the probe between 0 and 100°C. The value of this parameter is set at the factory for

best instrument accuracy.

8.13.3 DELTA

This probe parameter refers to the curvature of the resistance-temperature relationship or the sensor. The value of this parameter is set at the

factory for best instrument accuracy.

calibration parameters menu

-

-

-

-

8.13.4 BETA

This probe parameter characterizes the low temperatures. The value of

this parameter is set at the factory for best instrument accuracy.

Hart Scientific Manual Rev. 180601 31

Page 34

9 Digital Communication Interface

9NC

9 Digital Communication Interface

The Model 9133 calibrator is capable of communicating with and being

controlled by other equipment through the digital interface. With a digital

interface the instrument may be connected to a computer or other equip

ment. This allows the user to set the instrument temperature, monitor the

temperature, and access any of the other controller functions, all using

remote communications equipment. Communications commands are

summarized in Table 1 on page x.

9.1 Serial Communications

The RS-232 serial interface allows serial digital communications over

fairly long distances (15.24 meters). With the serial interface the user

may access any of the functions, parameters and settings discussed in

Section 8, Controller Operation with the exception of the BAUD rate set

ting. The serial interface operates with eight data bits, one stop bit, and

no parity.

9.1.1 Wiring

The serial communications

cable attaches to the instrument through the DB-9 connector at the back of the

instrument. Figure 5 shows

the pin-out of this connector

and suggested cable wiring.

To eliminate noise, the serial

cable should be shielded with

low resistance between the

connector (DB-9) and the

shield.

RS-232Cable Wiring for

IBM PC and Compatibles

Instrument

Connector

(DB 9-Pin)

1NC

2RxD

3TxD

4NC

5GND

6NC

7RTS

8CTS

9NC

-

Computer (DTE)

Connector

(DB 9-Pin)

1 DCD

2RxD

3TxD

4DTR

5GND

6DSR

7RTS

8CTS

9NC

-

9.1.2 Setup

Before operation, the serial

interface of the instrument

must be set up by program

ming the BAUD rate and

other configuration parame

ters. These parameters are

programmed within the serial

Instrument

Connector

(DB 9-Pin)

1NC

-

2RxD

3TxD

4NC

5GND

-

6NC

7RTS

8CTS

Computer (DTE)

Connector

(DB 25-Pin)

2TxD

3RxD

4RTS

5CTS

6DSR

7GND

8 DCD

20 DTR

Figure 5 Serial Cable Wiring

Hart Scientific Manual Rev. 180601 33

Page 35

9 Digital Communication Interface

interface menu. The serial interface parameters menu is outlined in Sec

tion 8.12.

To enter the serial parameter programming mode first, press the “EXIT”

button while pressing the “SET” button and release to enter the second

ary menu. Press the “SET” button repeatedly until the display reads

“ProbE”. This is the menu selection. Press the “UP” button repeatedly

until the serial interface menu is indicated with “SErIAL”. Finally press the

“SET” button to enter the serial parameter menu. The serial interface pa

rameter menu contains the BAUD rate, the sample rate, the duplex

mode, and the linefeed parameter.

9.1.2.1 BAUD Rate

The BAUD rate is the first parameter in the menu. The display prompts

with the BAUD rate parameter by showing “BAUd”. Press the “SET” but

ton to choose to set the BAUD rate. The current BAUD rate value is dis

played. The BAUD rate of the instrument may be programmed to 300,

600, 1200, or 2400 BAUD. The BAUD rate is pre-programmed to 2400

BAUD. Use “UP” or “DOWN” to change the BAUD rate value. Press the

“SET” button to set the BAUD to the new value or the “EXIT” button to

abort the operation and skip to the next parameter in the menu.

9.1.2.2 Sample Period

The sample period is the next parameter in the menu and prompted with

“SAMPLE”. The sample period is the time period, in seconds, between

temperature measurements transmitted from the serial interface. If the

sample rate is set to 5, the instrument transmits the current measurement over the serial interface approximately every five seconds. The au

tomatic sampling is disabled with a sample period of 0. Press the “SET”

button to choose to set the sample period. Adjust the period with the “UP”

or “DOWN” button and then use the “SET” to set the sample rate to the

displayed value.

-

-

-

-

-

-

9.1.2.3 Duplex Mode

The next parameter is the duplex mode indicated with “dUPL”. The du

plex mode may be set to half duplex (“HALF”) or full duplex (“FULL”). With

full duplex any commands received by the instrument via the serial inter

face are immediately echoed or transmitted back to the device of origin.

With half duplex the commands are executed but not echoed. The default

setting is full duplex. The mode may be changed using “UP” or “DOWN”

and pressing “SET”.

34 Manual Rev. 180601 9133

-

Page 36

9.1.2.4 Linefeed

The final parameter in the serial interface menu is the linefeed mode.

This parameter enables (“On”) or disables (“OFF”) transmission of a line

feed character (LF, ASCII 10) after transmission of any carriage-return.

The default setting is with linefeed on. The mode may be changed using

“UP” or “DOWN” and pressing “SET”.

9.1.3 Serial Operation

Once the cable has been attached and the interface set up properly the

controller immediately begins transmitting temperature readings at the

programmed rate. The set-point and other commands may be sent to the

instrument via the serial interface to set the instrument and view or pro

gram the various parameters. The interface commands are discussed in

Section 9.3, Interface Commands.

9.2 Interface Commands

The various commands for accessing the instrument controller functions

via the digital interfaces are listed in Table 4. These commands are used

with both the RS-232 serial interface and the IEEE-488 GPIB interface. In

either case the commands are terminated with a carriage-return character. The interface makes no distinction between upper and lower case letters, hence either may be used. Commands may be abbreviated to the

minimum number of letters, which determines a unique command. A

command may be used to either set a parameter or display a parameter

depending on whether or not a value is sent with the command following

a “=” character. For example, an “s”<cr> returns the current set-point and

an “s=50.00”<cr> sets the set-point to 50.00 degrees.

9 Digital Communication Interface

-

-

In the following list of commands, characters or date within brackets, “[“

and “]”, are optional. A slash, “/”, denotes alternate characters or data.

Numeric data, denoted by “n”, may be entered in decimal or exponential

notation. Characters are shown in lower case although upper case may

be used. Spaces may be added within command strings and are simply

ignored. Backspace (BS, ASCII 8) may be used to erase the previous

character. A terminating CR is implied with all commands.

Hart Scientific Manual Rev. 180601 35

Page 37

9 Digital Communication Interface

Table 2 Controller Communications Commands

Command Description

Command

Format

Command

Example Returned

Returned

Example

Acceptable

Values

Display Temperature

Read current set-point s[etpoint] s set: 999.9 {C or F} set: 100.00 C

Set current set-point to n s[etpoint]=n s=200.0 Instrument Range

Read temperature t[emperature] t t: 999.9 {C or F} t: 55.6 C

Read temperature units u[nits] u u: x u: C

Set temperature units: u[nits]=c/f

Set temperature units to Celsius

Set temperature units to

Fahrenheit

Read scan mode sc[an] sc scan: {ON or OFF} scan:ON

Set scan mode sc[an]=on/off sc=on ON or OFF

Read scan rate sr[ate] sr srat: 99.9 {C or F}/min srat:12.4C/min

Set scan rate sr[ate]=n sr=1.1 .1 to 99.9

u[nits]=c u=c

u[nits]=f u=f

C or F

Secondary Menu

Read proportional band setting pr[opband] pr pb: 999.9 pb: 15.9

Set proportional band to

Read heater power

(duty cycle)

n

pr[opband]=n pr=8.83 Depends on

po[wer] po po: 999.9 po: 1.0

Configuration

Configuration Menu

Operating Parameters Menu

Read high limit hl hl hl:999 hl:126

Set high limit hl=n hl=90 50–160

Serial Interface Menu

Read serial sample setting sa[mple] sa sa: 9 sa: 1

n

Set serial sampling setting to

seconds

Set serial duplex mode: du[plex]=f[ull]/h[alf]

Set serial duplex mode to full

Set serial duplex mode to half

Set serial linefeed mode: lf[eed]=on/of[f]

Set serial linefeed mode to on

Set serial linefeed mode to off

Calibration Menu

Read R0 calibration parameter r[0] r r0: 999.999 r0: 100.578

Set R0 calibration parameter to

Read ALPHA calibration parameter al[pha] al al: 9.9999999 al: 0.0038573

Set ALPHA calibration parameter to

Read DELTA calibration parameter de[lta] de de:9.99999 de: 1.507

Set DELTA calibration parameter de[lta]=n de=1.3742 0–3.0

Read BETA calibration parameter be[ta] be be:9.999 be:0.342

Set BETA calibration parameter be[ta]=n be=0.342 –100.0 to 100.0

sa[mple]=n sa=0 0 to 999

du[plex]=f[ull] du=f

du[plex]=h[alf] du=h

lf[eed]=on lf=on

lf[eed]=of[f] lf=of

n

r[0]=n r=100.324 90 to 110

n

al[pha]=n al=0.0038433 .002 to .005

FULL or HALF

ON or OFF

36 Manual Rev. 180601 9133

Page 38

Controller Communications Commands continued

9 Digital Communication Interface

Command

Command Description

Functions not on menu

Read firmware version number *ver[sion] *ver ver.9999,9.99 ver.9133,1.00

Read structure of all commands h[elp] h list of commands

Read all operating parameters all all list of parameters

Legend:

Note:

Format

[] Optional Command data

{} Returns either information

n Numeric data supplied by user

9 Numeric data returned to user

x Character data returned to user

When DUPLEX is set to FULL and a command is sent to READ, the command is returned followed by a carriage return

and linefeed. Then the value is returned as indicated in the RETURNED column.

Command

Example Returned

Returned

Example

Acceptable

Values

Hart Scientific Manual Rev. 180601 37

Page 39

10 Calibration Procedure

Sometimes the user may want to calibrate the instrument to improve the

temperature set-point accuracy. Calibration is done by adjusting the con

troller probe calibration constants R0, ALPHA, DELTA, and BETA so that

the temperature of the calibrator as measured with a standard thermom

eter agrees more closely with the set-point. The thermometer used must

be able to measure the well temperature with higher accuracy than the

desired accuracy of the calibrator. By using a good thermometer and fol

lowing this procedure the instrument can be calibrated to an accuracy of

better than 0.5°C up to 150°C.

10.1 Calibration Points

10 Calibration Procedure

-

-

-

In calibrating the instrument, R0, ALPHA, DELTA, and BETA, are ad

justed to minimize the set-point error at each of three different tempera

tures. Any three appropriately separated temperatures may be used for

the calibration. Improved results can be obtained for shorter ranges when

using temperatures that are just within the most useful operating range of

the instrument. The farther apart the calibration temperatures, the larger

the calibrated range. However, the calibration error will also be greater

over that range. If, for instance, –20°C to 100°C is chosen as the calibration range, the calibrator may achieve an accuracy of ±0.3°C over that

range (–20 to 100°C). Choosing a range of 50°C to 90°C may allow the

calibrator to have a better accuracy of maybe ±0.2°C over the narrower

range but, outside that range, the accuracy may be only ±1.5°C.

10.2 Calibration Procedure

1. Choose four set-points to use in the calibration of the R0, AL

PHA, DELTA, and BETA parameters. These set-points are gener

ally –25°C, 0°C, 60°C, and 125°C but other set-points may be

used if desired or necessary.

2. Set the instrument to the low set-point. When the instrument

reaches the set-point and the display is stable, wait 15 minutes

or so and then take a reading. Sample the set-point resistance

by holding down the “SET” key and pressing the “DOWN” key.

Write these values down as T

and R1respectively.

1

-

-

-

-

3. Repeat step 2 for the other three set-points recording them as

T

, R1, T2, R2, T3, R3, T4and R4respectively.

1

Hart Scientific Manual Rev. 180601 39

Page 40

10 Calibration Procedure

10.2.1 Compute DELTA

4. Using the recorded data, calculate new values for R0, ALPHA,

DELTA, and BETA parameters using the equations given below.

AT T

=−

43

BT T

=−

32

TTTT

C

4433

=

100

TTTT

3322

D

=

100

ER R

=−

43

FR R

=−

32

delta

T

R

AF BE

=

DE CF

- Measured temperature using the reference thermometer

1-3

- Value of R from the 9133 display (Press SET and DOWN at the

1-3

1

−

100 100

1

−

100 100

−

−

−

−

1

−

100

1

−

100

same time)

Where

T

and R1are the measured temperature and resistance at –25°C

1

T

and R2are the measured temperature and resistance at 0°C

2

T

and R3are the measured temperature and resistance at 60°C

3

T

and R4are the measured temperature and resistance at 125°C

4

10.2.2 Compute R0 and ALPHA

TT

=+

a T delta

12

=+

a T delta

34

Ra Ra

rzero

alpha

41 2 3

=

=

Ra Ra

22

100

TT

44

100

−

aa

−

13

RR

−

24

−

41 2 3

40 Manual Rev. 180601 9133

1

−

100

1

−

100

Page 41

delta is the new value of DELTA computed above.

10.2.3 Compute BETA

T

1

x

=

y

=

beta

Where T1and R1are the measured temperature and resistance at

–25.00°C and alpha, rzero, and delta are the new values of ALPHA, R0,

and DELTA calculated above.

Program the new values for R0 (rzero), ALPHA (alpha), DELTA (delta),

and BETA (beta) into the instrument with the following steps.

1. Reference Section 8.13 to display R0.

1

−

100

T

1

100

=+−−

()()

1

alpha x y

()()()

10 Calibration Procedure

R

1

3

T

xy

delta

1

2

3

y

r

0

alpha x y

()()

3

()

2. Press the “SET” button then use the “UP” or “DOWN” buttons un-

til the correct numerical setting is displayed. Press the “SET” button to accept the new value.

3. Repeat step 2 for ALPHA, DELTA, and BETA.

10.2.4 Accuracy and Repeatability

Check the accuracy of the instrument at various points over the cali

brated range. If the instrument does not pass specification at all

set-points, repeat the Calibration Procedure.

-

Hart Scientific Manual Rev. 180601 41

Page 42

11 Maintenance

•

The instrument has been designed with the utmost care. Ease of op

eration and simplicity of maintenance have been a central theme in

the product development. Therefore, with proper care the instrument

should require very little maintenance.Avoid operating the instrument

in an oily, wet, dirty, or dusty environment.

•

Ice will build up on the target surface over a period of time if the unit is

operated at sub-zero temperatures, allowing water to pool in the well

at temperatures above 0.0°C. The user needs to drain the water build

up after every use. To drain the water build up, set the instrument to a

temperature above 100°C for a period of one hour causing the water

to evaporate.Wipe any remaining water witha dry nonabrasive cloth.

•

If the outside of the instrument becomes soiled, it may be wiped clean

with a damp cloth and mild detergent. DO NOT use harsh chemicals

on the surface, which may damage the paint or target.

•

It is important to keep the well and target surface of the instrument

clean and clear of any foreign matter.

•

The instrument should be handled with care. Avoid knocking or dropping the instrument.

•

If a hazardous material is split on or inside the equipment, the user is

responsible for taking the appropriate decontamination steps as outlined by the national safety council with respect to the material.

•

If the mainssupply cord becomesdamaged, replace itwith a cordwith

the appropriate gauge wire for the current of the unit. If there are any

questions, call Hart ScientificCustomer Service for more information.

•

Before using any cleaning or decontamination method except those

recommended by Hart, users should check with Hart Scientific Cus

tomer Service to be sure that the proposed method does not damage

the equipment.

•

If the instrument is usedin a manner not in accordance with the equip

ment design, the operation of the unit may be impaired or safety haz

ards may arise.

11 Maintenance

-

-

-

-

Hart Scientific Manual Rev. 180601 43

Page 43

12 Troubleshooting

12 Troubleshooting

This section contains information on troubleshooting, CE Comments, and

a wiring diagram.

12.1 Troubleshooting Problems, Possible Causes,

and Solutions

In the event that the instrument appears to function abnormally, this sec

tion may help to find and solve the problem. Several possible problem

conditions are described along with likely causes and solutions. If a prob

lem arises, please read this section carefully and attempt to understand

and solve the problem. If the problem cannot otherwise be solved, con

tact Hart Scientific Customer Service for assistance (1-801-763-1600).

Be sure to have the model number and serial number of your instrument

available.

Problem Possible Causes and Solutions

Incorrect temperature reading

Blank display after

mains power ap

plied

Incorrect R0, ALPHA, DELTA, and BETA parameters.

Find the value for R0, ALPHA, DELTA, and BETA on the

Report of Calibration that was shipped with the instrument.

Reprogram the parameters into the instrument (see Section 8.13, Calibration Parameters). Allow the instrument to

stabilize and verify the accuracy of the temperature reading.

Controller locked up. The controller may have locked up

due to a power surge or other aberration. Initialize the sys

tem by performing the Factory Reset Sequence.

Factory Reset Sequence. Hold the SET and EXIT buttons

down at the same time while powering up the instrument.

The instrument displays shows ‘-init-‘, the model number,

and the firmware version. Each of the controller parameters

and calibration constants must be reprogrammed. The val

ues can be found on the Report of Test that was shipped

with the instrument.

Blown fuse. A fuse may have blown due to a power surge

-

or failure of a component. Replace the fuse once. If the

fuse blows a second time, it is likely caused b the failure of

a component. Always replace the fuse with one of the

same rating, voltage, and type. Never replace the fuse with

one of a higher current rating.

-

-

-

-

Hart Scientific Manual Rev. 180601 45

Page 44

12 Troubleshooting

Problem Possible Causes and Solutions

The Instrument

heats or cools too

quickly or too

slowly

The display shows

any of the follow

ing: err 1 , err

2 , err 3 , err 4

, err 5, Err 6,

or Err 7

Temperature cannot be set above a

certain point

Ice buildup

Incorrect scan and scan rate settings. The scan and

scan rate settings may be set to unwanted values. Check

the Scan and Scan Rate settings. The scan may be off (if

the unit seems to be responding too quickly). The scan

may be on with the Scan Rate set low (if unit seems to be

responding too slowly).

Controller problem. The error messages signify the fol

-

lowing problems with the controller.

Err 1 - a RAM error

Err 2 - a NVRAM error

Err 3 - a Structure error

Err 4 - an ADC setup error

Err 5 - an ADC ready error

Err 6 – a defective control sensor

Err 7 – a heater error

Initialize the system by performing the Factory Reset Se

quence describe above.

Incorrect High Limit parameter. The High Limit parameter may be set below 150°C. Check this value as described

in Section 8.11, Operating Parameters.

At temperatures below 5°C, use the target cover and/or

a gas purge. When taking measurements using the target

cover, place the target cover in place and set the set-point

to the desired temperature, remove the target cover, take a

sample, and replace the cover. When ice forms on the target, change the set-point higher than 5°C to melt the excess ice. When the ice melts pat the excess water off with

a clean dry cloth. Do not wipe the front plate. If a clean

dry cloth is not available, change the set-point to 100°C or

higher, to evaporate the excess water.

-

-

Use a dry gas purge. When using a dry gas purge, the in

strument will not reach minimum temperature. An example

of a dry gas purge is dry nitrogen connected through a 1/8”

inner diameter tube to the purge fitting located at the front

bottom of the target. The nitrogen gas is controlled to fill

the chamber in front of the target at a rate that will not allow

airflow to affect the target. Note: If the gas contains any

moisture, ice will form on the target.

46 Manual Rev. 180601 9133

-

Page 45

Problem Possible Causes and Solutions

The IR probe does

not read what the

IR heat source in

dicates

Emissivity is not the same as the IR probe and target.

Adjust the IR gun or use a look up table from the IR probe

-

manufacturer.

Ice is on the target. Heat the unit above 5°C and remove

the water.

Ambient light may change the reading of the IR probe.

Get closer to the target. A channeling tube may remove

some external environmental factors.

The laser indicator (red dot) is not the actual surface

center of the IR probe (field of measurement. Check the

proper use of the instrument in the IR probe manual. The

field of measurement changes with distance.

There is a difference between the display temperature

and the IR heat source target (temperature gradient).

The closer to ambient the target is, the lower the error will

be. See Figure 1, Temperature Gradient Between Reference Probe and target Surface.

IR probe is reading incorrectly (optic problems) or may

be within its given specifications (1-10°C). Check the

heat source with a known good IR probe.

12 Troubleshooting

IR heat source is out of calibration. Use an external reference.

12.2 Comments

12.2.1 EMC Directive

Hart Scientifics’ equipment has been tested to meet the European Elec

tromagnetic Compatibility Directive (EMC Directive, 89/336/EEC). The

Declaration of Conformity for your instrument lists the specific standards

to which the unit was tested.

12.2.2 Low Voltage Directive (Safety)

In order to comply with the European Low Voltage Directive (73/23/EEC),

Hart Scientific equipment has been designed to meet the IEC 1010-1

(EN 61010-1) and the IEC 1010-2-010 (EN 61010-2-010) standards.

Hart Scientific Manual Rev. 180601 47

-

Page 46

12 Troubleshooting

12.3 Wiring Diagram

D

C

B

1

2

A

A

REV

h 84003

Uta

,

Utah Valley Drive

t

(801) 763-1600

799 Eas

American Fork

SHEET

-2W??

1

B033

WG NO

D

9133 Wiring

64841

CAGECODE

C

TITLE

SIZE

SCALE

2/26/2001

SDM

2

3

4

D

B

A

3

4

Figure 6 Wiring Diagram

48 Manual Rev. 180601 9133

Loading...

Loading...