Page 1

Hart Scientific

9112A

Calibration Furnace

User’s Guide

Rev. 5B2901

Page 2

Fluke Corporation, Hart Scientific Division

799 E. Utah Valley Drive • American Fork, UT 84003-9775 • USA

Phone: +1.801.763.1600 • Telefax: +1.801.763.1010

E-mail: support@hartscientific.com

www.hartscientific.com

Subject to change without notice. • Copyright © 2005 • Printed in USA

Rev. 5B2901

Page 3

Table of Contents

1 Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.2 Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Authorized Service Centers. . . . . . . . . . . . . . . . . . . . . . 5

2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Specifications and Environmental Conditions . . . . . . . . . 11

3.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . 11

3.3 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Unpacking & Inspection . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 “Dry-out” Period . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5 Equilibration Block Assembly Installation . . . . . . . . . . . . . 14

4.6 Probe Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Parts and Controls . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Front View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.1 Temperature Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.2 Over Temperature Cutout . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.3 Power and Heater Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Heater Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.1 Equilibration Block Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.2 Temperature Control and Cutout Sensor . . . . . . . . . . . . . . . . . . . . 20

5.3 Back View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.1 The Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.2 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.3 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

i

Page 4

6.2 Operating the Furnace . . . . . . . . . . . . . . . . . . . . . . . . 23

7 Digital Communication Interface . . . . . . . . . . . . . . . . 25

8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9 Appendix A - Material Safety Data Sheets (MSDS) . . . . . . 29

ii

Page 5

Figures

Figure 1 Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 2 Sectional Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 3 Back View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 4 RS-232 Cable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . 25

iii

Page 6

1 Before You Start

1.1 Symbols Used

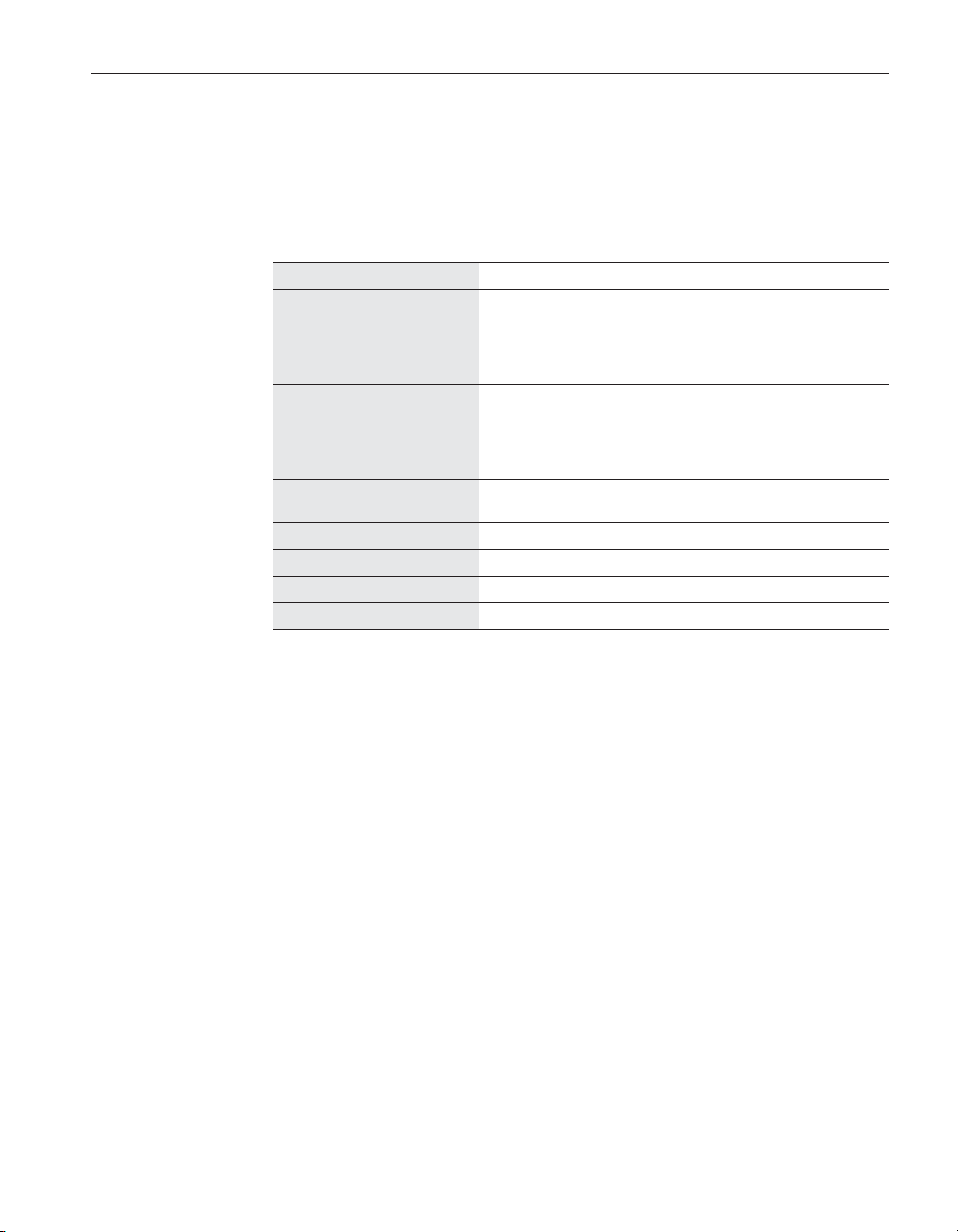

Table 1 lists the International Electrical Symbols. Some or all of these symbols

may be used on the instrument or in this manual.

Tabl e 1 International Electrical Symbols

Symbol Description

AC (Alternating Current)

AC-DC

Battery

CE Complies with European Union Directives

1 Before You Start

Symbols Used

DC

Double Insulated

Electric Shock

Fuse

PE Ground

Hot Surface (Burn Hazard)

Read the User’s Manual (Important Information)

Off

On

1

Page 7

9112A Calibration Furnace

User’s Guide

Symbol Description

Canadian Standards Association

OVERVOLTAGE (Installation) CATEGORY II, Pollution Degree 2 per IEC1010-1 re

fers to the level of Impulse Withstand Voltage protection provided. Equipment of

OVERVOLTAGE CATEGORY II is energy-consuming equipment to be supplied from

the fixed installation. Examples include household, office, and laboratory appliances.

C-TIC Australian EMC Mark

The European Waste Electrical and Electronic Equipment (WEEE) Directive

(2002/96/EC) mark.

1.2 Safety Information

Use this instrument only as specified in this manual. Otherwise, the protection

provided by the instrument may be impaired.

The following definitions apply to the terms “Warning” and “Caution”.

• “WARNING” identifies conditions and actions that may pose hazards to

the user.

• “CAUTION” identifies conditions and actions that may damage the instrument being used.

1.2.1

WARNINGS

To avoid personal injury, follow these guidelines.

-

DISCLAIMER: Hart Scientific manufactures instruments for the purpose

of temperature calibration. Instruments used for applications other than

calibration are used at the discretion and sole responsibility of the cus

tomer. Hart Scientific cannot accept any responsibility for the use of in

-

-

struments for any application other than temperature calibration.

GENERAL

Appropriate personal safety protection should be worn by the operator at all

times while using the furnace.

DO NOT use the instrument for any application other than calibration work.

The instrument was designed for temperature calibration. Any other use of the

unit may cause unknown hazards to the user.

DO NOT use the unit in environments other than those listed in the user’s

guide.

Completely unattended operation is not recommended.

2

Page 8

1 Before You Start

Safety Information

Follow all safety guidelines listed in the user’s manual.

Calibration Equipment should only be used by Trained Personnel.

If this equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired or safety hazards may

arise.

Inspect the instrument for damage before each use. DO NOT use the instrument

if it appears damaged or operates abnormally.

Before initial use, or after transport, or after storage in humid or semi-humid

environments, or anytime the instrument has not been energized for more than

10 days, the instrument needs to be energized for a “dry-out” period of 2 hours

before it can be assumed to meet all of the safety requirements of the IEC

1010-1. If the product is wet or has been in a wet environment, take necessary

measures to remove moisture prior to applying power such as storage in a low

humidity temperature chamber operating at 50°C for 4 hours or more.

The instrument is intended for indoor use only.

BURN HAZARD

High temperatures may be present in this equipment. Fires and severe burns

may result if personnel fail to observe safety precautions.

The furnace generates extreme temperatures. Precautions must be taken to prevent personal injury or damage to objects. Probes may be extremely hot when

removed from the furnace. Cautiously handle probes to prevent personal injury.

Carefully place probes on a heat resistant surface rack until they are at room

temperature.

DO NOT lift the back of this instrument with the equilibration block in place.

The equilibration block will fall out of the instrument.

DO NOT operate near flammable materials. Extreme temperatures could ignite

the flammable material.

Use of this instrument at HIGH TEMPERATURES for extended periods of

time requires caution.

DO NOT touch the well access cover of the instrument, it is extremely hot.

For compliance with IEC 1010-1, it is recommended that the cutout mode al

ways be set to the manual mode requiring user intervention to reset the

instrument.

Take extreme care in handling hot probes. The extreme temperatures generated

in a furnace of this type can cause serious personal injury. Do not touch them

on external surfaces of the furnace or set them on any other surfaces unable to

withstand those temperatures. A fire hazard exists. Do not touch the access tube

end plate or severe burns can result.

3

Page 9

9112A Calibration Furnace

User’s Guide

ELECTRICAL HAZARD

These guidelines must be followed to ensure that the safety mechanisms in this

instrument will operate properly. This instrument must be plugged into a 230

VAC (± 10%) 50/60 Hz only electric outlet. The power cord of the instrument

is equipped with a three-pronged grounding plug for your protection against

electrical shock hazards. It must be plugged directly into a properly grounded

three-prong receptacle. The receptacle must be installed in accordance with lo

cal codes and ordinances. or adapter plug. Additionally, the instrument has a

Permanent Earth Ground that must be connected during use. DO NOT use an

extension cord Consult a qualified electrician.

Always replace the power cord with an approved cord of the correct rating and

type. If you have questions, contact a Hart Scientific Authorized Service Center

(see Section 1.3).

The instrument is not equipped with easily accessible fuses. The fuses are lo

cated inside the control drawer. We do not recommend replacing the fuses with

out calling a Hart Scientific Authorized Service Center first.

High voltage is used in the operation of this equipment. Severe injury or death

may result if personnel fail to observe the safety precautions. Before working

inside the equipment, turn off the power and disconnect the power cord.

Always ensure that the equilibration block ground is connection prior to use of

the instrument.

-

-

-

1.2.2

Cautions

Always operate this instrument at room temperature between 41°F and 104°F

(5°C to 40°C). Allow sufficient air circulation by leaving at least 18 inches (45

cm) of clearance around the instrument. DO NOT place instrument in a corner

or block the back of the instrument. Extreme temperatures are emitted from the

back and front of the furnace. Allow sufficient space in front of the furnace to

work and to insert and remove the probes.

Read Section 4, Installation, before placing the instrument into service.

DO NOT use fluids to clean out the well. Fluids could leak into and damage the

instrument.

Never introduce any foreign material into the probe hole of the insert. Fluids,

etc. can leak into the instrument causing damage.

DO NOT change the values of the calibration constants from the factory set

values. The correct setting of these parameters is important to the safety and

proper operation of the unit.

Read and understand the controller operation prior to operating the instrument.

The controller manufacturer’s manual is included with the instrument.

DO NOT operate this instrument in an excessively wet, oily, dusty, or dirty

environment.

4

Page 10

1 Before You Start

Authorized Service Centers

The unit is a precision instrument. Although it has been designed for optimum

durability and trouble free operation, it must be handled with care.

Most probes have handle temperature limits. Be sure that the probe handle tem

perature limit is not exceeded in the air above the instrument.

The instrument and any thermometer probes used with it are sensitive instru

ments that can be easily damaged. Always handle these devices with care. Do

not allow them to be dropped, struck, stressed, or overheated.

When calibrating PRTs always follow correct calibration procedure and cali

brate from high temperatures to low temperatures with the appropriate triple

point of water checks. Never immerse a wet or cold PRT into a bath filled with

hot medium. Severe damage to the PRT may result as well as personal injury to

the calibration technician.

This furnace is not designed to be portable. Therefore, moving the furnace once

it has been installed should be kept to a minimum. To safely move the furnace,

two people are required. One person should lift the furnace at each end of the

furnace, place their hand under the control drawer, and lift simultaneously be

ing careful not to tip. Ensure that the furnace is de-energized and cooled to less

then 100°C. Remove the equilibration block prior to moving. The equilibration

block can damage the fused silica tube that is extremely fragile.

The control probe must be inserted properly in the instrument and plugged into

the socket at the back of the furnace. DO NOT operate the furnace without the

control probe properly inserted and attached. The furnace will not operate correctly without the control probe. Injury to operating personnel and permanent

damage to the furnace could occur.

Components and heater lifetimes can be shortened by continuous high temperature operation.

If a mains supply power fluctuation occurs, immediately turn off the furnace.

Power bumps from brown-outs and black-outs can damage the instrument. Wait

until the power has stabilized before re-energizing the furnace.

The probe and the block may expand at different rates. Allow for probe expan

sion inside the well as the block heats. Otherwise, the probe may become stuck

in the well.

Be aware that the equilibration block expands as the furnace heats. It will ex

tend beyond the front of the furnace at high temperatures anywhere from ¼ to

approximately ½ inch. This is normal and is due to thermal expansion.

Take care that all sensors used as references or being calibrated in the furnace

are capable of withstanding the desired temperature range to be used.

-

-

1.3 Authorized Service Centers

Please contact one of the following Authorized Service Centers to coordinate

service on your Hart product:

5

Page 11

9112A Calibration Furnace

User’s Guide

Hart Scientific, Inc.

Fluke Nederland B.V.

799 E. Utah Valley Drive

American Fork, UT 84003-9775

USA

Phone: +1.801.763.1600

Telefax: +1.801.763.1010

E-mail: support@hartscientific.com

Customer Support Services

Science Park Eindhoven 5108

5692 EC Son

NETHERLANDS

Phone: +31-402-675300

Telefax: +31-402-675321

E-mail: ServiceDesk@fluke.nl

Fluke Int'l Corporation

Service Center - Instrimpex

Room 2301 Sciteck Tower

22 Jianguomenwai Dajie

Chao Yang District

Beijing 100004, PRC

CHINA

Phone: +86-10-6-512-3436

Telefax: +86-10-6-512-3437

E-mail: xingye.han@fluke.com.cn

Fluke South East Asia Pte Ltd.

Fluke ASEAN Regional Office

Service Center

60 Alexandra Terrace #03-16

The Comtech (Lobby D)

118502

SINGAPORE

6

Page 12

1 Before You Start

Authorized Service Centers

Phone: +65 6799-5588

Telefax: +65 6799-5588

E-mail: antng@singa.fluke.com

When contacting these Service Centers for support, please have the following

information available:

Model Number

•

Serial Number

•

Voltage

•

Complete description of the problem

•

7

Page 13

2 Introduction

The 9112A Calibration Furnace was designed specifically for calibrating PRTs,

fiber optic sensors and thermocouples at higher temperature ranges up to

1100°C. The furnace utilizes an equilibration block capable of making compar

ison measurements on multiple probes. The standard equilibration block is

sized for ¼ inch probes, however, custom options are possible. Temperature

stability is better than ± 0.1°C throughout the range and the gradient between

wells at full insertion is less than 0.5°C (± 0.25°C).

The temperature control system utilizes a digital controller with a Type K ther

mocouple control sensor and RS-232 interface. The controller displays the set

temperature and the actual temperature simultaneously. The display shows tem

perature to the nearest degree in °C or °F (shipped in °C). The temperature is

set with convenient up and down buttons on the front panel.

Sensors being calibrated as well as the furnace itself are protected from exces

sive temperature with an over-temperature cutout. The cutout is easily adjusted

from the front panel. This device is relay operated and protects against the possibility of thermal runaway due to a shorted solid-state relay which controls the

heaters.

2 Introduction

-

-

-

-

9

Page 14

3 Specifications and Environmental Conditions

3 Specifications and Environmental

Conditions

3.1 Specifications

Operating Range 300°C to 1100°C

Stability 300°C ±0.05°C

500°C ±0.05°C

700°C ±0.1°C

1000°C ±0.1°C

1100°C ±0.1°C

Uniformity 300°C ±0.05°C

500°C ±0.08°C

700°C ±0.2°C

1000°C ±0.25°C

1100°C ±0.3°C

Stabilization Time Typically 2 hours midrange, slower at the low temperature end (4

hours), faster at the high temperature end

Heater Power 3700 Watts High

Power Requirements 230 VAC (±10%), 50/60 Hz, 20 A

Outside Dimensions 18” H x 14.25”W x 26”D (457mm x 362mm x 660mm)

Weight 72.5 lbs

Specifications

3.2 Environmental Conditions

Although the instrument has been designed for optimum durability and trouble-free operation, it must be handled with care. The instrument should not be

operated in an excessively dusty or dirty environment. Maintenance and clean

ing recommendations can be found in the Maintenance Section of this manual.

The instrument operates safely under the following conditions:

•

temperature range: 5 - 40°C (41 - 104°F)

•

ambient relative humidity: 15 - 50%

•

pressure: 75kPa - 106kPa

•

mains voltage within ± 10% of nominal

•

vibrations in the calibration environment should be minimized

•

altitude less than 2000 meters

•

indoor use only

3.3 Warranty

Fluke Corporation, Hart Scientific Division (Hart) warrants this product to be

free from defects in material and workmanship under normal use and service

-

11

Page 15

9112A Calibration Furnace

User’s Guide

for a period as stated in our current product catalog from the date of shipment.

This warranty extends only to the original purchaser and shall not apply to any

product which, in Hart’s sole opinion, has been subject to misuse, alteration,

abuse or abnormal conditions of operation or handling.

Software is warranted to operate in accordance with its programmed instruc

tions on appropriate Hart products. It is not warranted to be error free.

Hart’s obligation under this warranty is limited to repair or replacement of a

product which is returned to Hart within the warranty period and is determined,

upon examination by Hart, to be defective. If Hart determines that the defect or

malfunction has been caused by misuse, alteration, abuse or abnormal condi

tions or operation or handling, Hart will repair the product and bill the pur

chaser for the reasonable cost of repair.

To exercise this warranty, the purchaser must forward the product after calling

or writing Hart for authorization. Hart assumes NO risk for in-transit damage.

For service or assistance, please contact an Authorized Service Center (see Sec

tion 1.3).

THE FOREGOING WARRANTY IS PURCHASER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OR MERCHANTABILITY, OR FITNESS FOR ANY

PARTICULAR PURPOSE OR USE. HART SHALL NOT BE LIABLE FOR

ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR LOSS WHETHER IN CONTRACT, TORT, OR OTHERWISE.

-

-

-

-

12

Page 16

4 Installation

4.1 Unpacking & Inspection

The furnace has been carefully packed for safe shipment by traditional means.

Unpacking should be done carefully. Check carefully for all parts. If any dam

age has occurred, you should notify the shipper immediately and make the ap

propriate claim.

The equilibration block assembly has been packed separately in order to protect

the fused silica tube from breakage during shipment. The block assembly

should not be installed into the furnace until it has been placed in its final

location.

Verify that the following components are present:

Furnace

•

2 – Thermocouples

•

• Equilibration Block Assembly (2 pieces)

• Block Assembly Instruction Sheet

• Diskette

• Controller Manual

• User’s Guide

• Serial Cable

Unpacking & Inspection

4 Installation

-

-

4.2 Location

The furnace is intended to be installed into any typical calibration facility envi

ronment. The best results from the furnace are realized if the temperature fluc

tuations in the room are not excessive. A minimum of 18 inches free air space

around the furnace must be allowed. This air space allows exchange to occur

and safely remove heat from the furnace.

WARNING: This furnace is intended for high temperature use and conse

quently a fire danger exists. DO NOT mount the furnace on a flammable

surface and keep fire-extinguishing equipment near by.

Extremely humid environments may require startup on low heat after long peri

ods of disuse.

-

-

-

-

13

Page 17

9112A Calibration Furnace

User’s Guide

4.3 “Dry-out” Period

WARNING: Before initial use, after transport, and any time the instru

ment has not been energized for more than 10 days, the instrument needs

to be energized for a “dry-out” period of 1-2 hours before it can be as

sumed to meet all of the safety requirements of the IEC 1010-1. If the

product is wet or has been in a wet environment, take necessary measures

to remove moisture prior to applying power such as storage in a low hu

midity temperature chamber operating at 50°C for 4 hours or more.

4.4 Power

The furnace utilizes a grounded AC supply of 230 VAC (±10%), 20 amps, sin

gle phase, 50/60 HZ. An eight foot 2 conductor with ground, power cord is pro

vided. A separate ground connection is provided and required to permanently

connect the instrument to earth ground for added operator safety.

WARNING: Ensure accessability to the mains plug for disconnection

from supply source.

4.5 Equilibration Block Assembly Installation

After the furnace has been installed and the permanent earth ground appropriately attached, the equilibration block assembly may be inserted. Carefully insert the block assembly into the tube with its insulation packing per Figure 1.

Extreme care should be taken installing the Equilibration Block since it is very

heavy and the fused silica tube is very fragile. A 1/8 to ¼ inch air gap between

the front access plate and the front panel of the furnace is required in order to

prevent the front panel from getting too hot. Care must be taken to prevent dirt,

insulation, or anything else from getting between the block and the fused silica

tube or it might break during heat up due to thermal expansion differences. The

fit between the block and the tube is typically loose in order to accommodate

this expansion.

-

-

-

-

-

14

CAUTION: If the furnace must be moved for any reason, remove the

block assembly to prevent breakage of the fused silica tube.

4.6 Probe Installation

Install the temperature control and over temperature cutout probes from the as

shown in Figure 1 and Figure 3. Insert the probes carefully to the depth shown

in order to insure that the sensor is properly located in the equilibration block.

The control probe should be inserted through the guard cover first so that the

cover can be properly installed afterward. Position the rear guard block as

Page 18

4 Installation

Probe Installation

shown and then insert the insulation (ceramic fiber, see MSDS in the Appen

dix) being careful no to bend the probe sheath. The insulation should generally

block air movement in and out of the back of the fused silica tube. Install the

Guard Cover to prevent physical contact with parts that become dangerously

hot when in use. Be sure to connect the probes properly on the rear panel.

15

Page 19

5 Parts and Controls

5.1 Front View

5 Parts and Controls

Front View

Figure 1 Front View

5.1.1 Temperature Controller

The temperature controller is a full PID micro-processor based instrument as

indicated. The controller is set to cover the range of 0 to 1100°C and features

17

Page 20

9112A Calibration Furnace

User’s Guide

two LED type displays. The upper display normally indicates the actual tem

perature while the lower display indicates the set temperature. The displays are

also utilized in setup and alarm functions. Other indicators include the OP1 and

OP2 indicator lights. The OP1 indicator lights when the heater is on. The OP2

is not functional on the unit. The “R” indicator lights during programmed

ramping. The “M” indicator flashes if the sensor fails. If the sensor opens, the

heaters shut off.

The up and down Temperature Adjustment arrow keys are the only temperature

controls normally used. A quick single stroke increments or decrements the

temperature setting. Holding the buttons down causes a gradual acceleration of

the temperature setting. These same buttons are used to adjust other parameters

in conjunction with the “PAR” button.

Further information about the controller operation can be obtained from the

temperature controller installation and operation manual included with the

instrument.

5.1.2 Over Temperature Cutout

The over temperature cutout is located at the left side of the control panel. The

controls include a temperature limit adjustment control knob calibrated in Celsius and “limit exceeded” indicator light. The cutout is adjustable by the user

within the temperature range of the furnace with divisions shown every 25°C.

The indicator light turns on when the set limit is reached. The cutout can be set

to Manual Reset or Auto Reset. The button on front panel allows the user to reset the cutout. The unit leaves the factory with the unit set in the Manual Reset

Mode. In the Auto Reset Mode, the temperature resets when it has dropped

about 20 degrees.

The cutout is provided to allow the user to set the maximum furnace temperature to a point within the safe range of the sensor(s) being calibrated and to pro

tect the furnace from exceeding its own safe operating range. Limiting the top

end also helps extend the life of the heaters.

The cutout controls a relay which is wired in series with the heater circuit. The

cutout is provided as a safety backup in case the solid state relay driven by the

temperature controller fails (shorts) causing thermal runaway.

-

-

18

5.1.3 Power and Heater Switches

The power switch is located just left of the temperature controller. The top is

pressed inward to turn the unit on.

Note: The internal fans are wired ahead of the switch so they stay on until

the unit is cooled even though the main power may have been turned off.

This way the outer surfaces of the enclosure are not heated to dangerous

levels from stored heat.

Page 21

5.2 Heater Assembly

5 Parts and Controls

Heater Assembly

Front

Guide Tubes

The heater is a made of fiber ceramic insulating material with imbedded heat

ing. The heater is made up with two halves, each with a separate heating ele

-

-

ment. The heating elements are wired in parallel.

The heater is primarily a radiating device and is rated for a maximum furnace

operating temperature of 1100°C. Realize, however, that the higher the operat

ing temperature, the lower the lifetime of the heater. Limiting the number of

hours at the extreme high end of the temperature range to only the time re

-

quired for calibrations increases the longevity of your furnace heating element.

Quartz Tube

Isothermal Block

Back

Cutout Probe

Control Probe

-

Figure 2 Sectional Side View

5.2.1 Equilibration Block Assembly

The Equilibration Block Assembly consists of 1) the test well, 2) access tubes

and end plate, 3) the front and rear guard blocks, 4) insulation on each end and

5) the center block. The center block is intended to stabilize the temperature

fluctuations and to conduct heat between the test wells in order to equalize

them. The guard blocks shunt heat to the various probes to reduce heat loss out

the ends. The whole assembly is supported by a fused silica tube. All heated

materials are fused silica, ceramic fiber, or Inconel (alloy 600).

19

Page 22

9112A Calibration Furnace

User’s Guide

20

Figure 3 Back View

5.2.2 Temperature Control and Cutout Sensor

The temperature control sensor is a Type K Thermocouple as indicated. This

sensor is 3/16 inch in diameter and 12 inches long. Its location in the block is

important and can cause the gradient in the block to move back and forth. The

probe is normally inserted as shown in Figures 2 and 3.

The cutout sensor is the same as the control sensor, 12 inches long. This sensor

is inserted through a tube in the back of the block. Its location here helps pre

vent the heater elements from overheating thus prolonging their life.

-

Page 23

5 Parts and Controls

Back View

The sensor connectors are provided on the rear panel of the furnace for con

necting the control and cutout thermocouples. They are Type K miniature con

nectors and allow for ease of system assembly and sensor replacement.

5.3 Back View

See Figure 3.

5.3.1 The Power Cable

The furnace is provided with a 12 gauge two conductor with ground power ca

ble. The user must provide a connector to meet the needs of the installation. Be

sure to follow electrical codes. A separate permanent earth ground is provided

with this instrument. This is required to be installed correctly for safe operation

of the instrument.

5.3.2 Nomenclature

The nomenclature on the rear of the furnace provides information to the user in

case service is required. The nomenclature includes the manufacturer, manufacturer location, model number, and serial number specific to this unit. Refer to

the model number and serial number whenever service is required.

5.3.3 Fuses

Two 20 A F 250 V fuses are used to protect the system, one for each leg of the

230 VAC power. The fuses are located inside the control cabinet. If the furnace

fails to operate, check the fuses first.

Two 1 A F 250 V fuses are located inside the control cabinet for the controller.

-

-

-

21

Page 24

6 Operation

6.1 Overview

The Model 9112A is basically a temperature controlled furnace utilizing a full

PID micro-processor based temperature controller with a Type K thermocouple

temperature sensor. The temperature controller sends a time proportional signal

to the solid state relay which regulates the current to the heater. The heater

power can be switched to HIGH or LOW power positions. The object of the

temperature control is the equilibration block with test wells containing the ref

erence probe and the sensors to be calibrated inside. The block provides a ther

mal mass which tends to stabilize the temperature and reduce the gradients

between the test wells. The user settable “over-temperature cut-out” can open

the heater circuit with a relay if the safe temperature for the test probe or for

the furnace is exceeded. The enclosure is designed to limit the heat seen by the

various components of the furnace as well as the user. The control section is in

a separate cabinet below the furnace heat preventing damage or accuracy er

rors. The furnace part of the cabinet contains ventilation holes as well as two

fans controlled by the thermostat. This cooling capability prevents the surface

of the enclosure from getting dangerously hot. In the event that the fans should

fail, a second thermostat is installed in the cabinet which shuts down the furnace heaters if the cabinet exceeds a safe temperature.

6 Operation

Overview

-

-

-

6.2 Operating the Furnace

Operating the Model 9112A is straight forward once you have grasped all the

important principles.

When the unit is turned on, the cutout reset button must be pushed before the

unit will heat.

Temperature selection is accomplished by using the up and down arrow keys on

the front of the temperature controller. The lower display indicates the new

temperature setting while the upper display shows the actual temperature.

When scanning from one temperature to another, notice that the temperature

controller seems to be ahead of the equilibration block temperature. This differ

ence is because the temperature control sensor is near the outside of the block

and it takes some time for the heat to conduct into the center. Depend on an ex

ternal temperature monitor to establish when the equilibration block has

reached the desired temperature and achieved stability.

The actual temperature indication made by the temperature controller is not in

tended to be a calibration reference, but to merely provide a general indication

of the furnace temperature. NIST traceable standard thermometers are available

and should be used in making comparison measurements. For less stringent

measurements you may make a calibration of the controller and control probe

at particular temperature points and use that with reasonable accuracy for a

time.

-

-

-

23

Page 25

9112A Calibration Furnace

User’s Guide

CAUTION: Take care that all sensors used as references or being cali

brated in the furnace are capable of withstanding the desired temperature

range to be used.

WARNING: Take extreme care in handling hot probes. The ex

treme temperatures generated in a furnace of this type can cause serious

personal injury. Do not touch them on external surfaces of the furnace or

set them on any other surfaces unable to withstand those temperatures. A

fire hazard exists. Do not touch the access tube end plate or severe burns

can result.

Some kind of metal and/or ceramic fiber surface or container should be used to

set the hot probes on to prevent injury, damage, and fire.

For best results, all reference or sample probes should be inserted into the full

depth of the well. At this position the stability is the highest and the gradient

the lowest. Each user should satisfy themselves as to what the uncertainties are

in terms of stability and gradients between the test wells. Variations in equipment, probe size, configuration, etc affect these important factors. A solid

(unstirred) mass such as in a furnace is subject to heat losses from the probe

stem which varies from probe to probe and temperature to temperature. Typically, stabilities are less than ±0.1°C and can be as little as ±0.015°C at 500°C.

Similarly, gradients between the measuring cells can range from ±0.2°C to well

under ±0.1°C. For calibrations that must be less than full insertion into the test

well, make your own comparisons between the reference and test cell at that

depth to establish the uncertainties.

The furnace can be used throughout the temperature range of 300 to 1100°C.

Lower temperatures are sluggish however. High integrating values are required

to maintain controller stability (1200 sec) at the lower temperatures. Expect

some offset from the indicated temperature and the actual temperature. Stability

and gradients between test wells are similar at higher temperatures but time to

stability is much longer.

24

Page 26

7 Digital Communication Interface

7 Digital Communication Interface

To control the furnace through a computer, follow the instructions listed below.

The program supplied is a demo program and may be altered by you for your

specific needs.

First make the appropriate cable assembly for your computer system. The serial

communications cable attaches to the calibrator through the DB-9 connector at

the back of the instrument. Figure 4 shows the pin-out of this connector and

suggested cable wiring. To eliminate noise, the serial cable should be shielded

with low resistance between the connector (DB-9) and the shield.

Figure 4 RS-232 Cable Wiring

Connect the appropriate connectors to your computer and to the furnace. To

communicate with the furnace:

25

Page 27

9112A Calibration Furnace

User’s Guide

•

•

•

•

•

Tabl e 2. Command Parameters

Load GWBASIC

Load and then run the program TC847.BAS

Set the Baud Rate on the Controller of the 9112A to 9600

Set the address of your furnace to 10 or greater

Set the temperature or if needed the furnace parameters. A listing of the

parameters and their meaning are in the following table.

PV process value (temperature)

SL set-point

OP output power

XP proportional band

TI integration time

TD derivative time

CH Cycle time

To set a parameter, simply type in the parameter and the value. For example, to

set the control temperature to 800°C, type SL=800.

26

Page 28

8 Maintenance

8 Maintenance

The calibration instrument has been designed with the utmost care. Ease of op

eration and simplicity of maintenance have been a central theme in the product

development. Therefore, with proper care the instrument should require very

little maintenance. Avoid operating the instrument in an oily, wet, dirty, or

dusty environment.

If the outside of the instrument becomes soiled, it may be wiped clean

•

with a damp cloth and mild detergent. Do not use harsh chemicals on the

surface which may damage the paint.

Be sure that the well of the furnace is kept clean and clear of any foreign

•

matter. Do not use fluids to clean out the well.

If a hazardous material is spilt on or inside the equipment, the user is re

•

sponsible for taking the appropriate decontamination steps as outlined by

the national safety council with respect to the material.

• If the mains supply cord becomes damaged, replace it with a cord with

the appropriate gauge wire for the current of the instrument. If there are

any questions, call Hart Scientific Customer Service for more information.

• Before using any cleaning or decontamination method except those recommended by Hart, users should check with Hart Scientific Customer

Service to be sure that the proposed method will not damage the equipment.

• If the instrument is used in a manner not in accordance with the equip ment design, the operation of the furnace may be impaired or safety hazards may arise.

•

The over-temperature cut-out should be checked every 6 months to ensure

that it is working properly. Set the unit to 300°C and let it stabilize. Turn

the adjustable cutout knob down until the cutout is activated. Turn the

knob back up and push the reset button.

•

Periodically remove the equilibration block and use emery cloth to re

move the oxidation build up on the block.

-

-

-

27

Page 29

9 Appendix A - Material Safety Data Sheets (MSDS)

9 Appendix A - Material Safety Data Sheets

(MSDS)

29

Page 30

MATERIAL SAFETY DATA SHEET

Product Group:

g

-

-

4:30 p.m. EST)

(

COMPONENTS

MSDS No. M0001 Effective Date: 06/10/2003

1. CHEMICAL PRODUCT AND COMPANY IDENTIFICATION

REFRACTORY CERAMIC FIBER PRODUCT

Chemical Name:

Synonym(s):

Trade Names: FIBERFRAX® CERAMIC FIBER PRODUCTS

VITREOUS ALUMINOSILICATE FIBER

RCF, ceramic fiber, synthetic vitreous fiber (SVF), man-made vitreous fiber

(MMVF), man-made mineral fiber (MMMF)

FIBERS

FIBERFRAX® HIGH PURITY FIBERS

Chopped; H Bulk; Regular Bulk, Spun Bulk, Fiberfrax FPP Fiber.

FIBERFRAX® 6000 SERIES FIBERS

ZZZ, 6900-70A to 6900-99Z.

FIBERFRAX® 7000 SERIES FIBERS

FIBERFRAX® MILLED FIBERS

Ball Milled C/D.

FIBERFRAX® HIGH INDEX FIBERS

CW; MX-400-CW; HS-70; HS-70C.

FIBERFRAX® HSA™ FIBERS

FIBERFRAX® KAOLIN FIBERS

BLANKETS

Durablanket® AC; Durablanket® HP; Durablanket® HP-S; Durablanket® S;

Durablanket® Strip; Duraback®; Duraback® S; Tank Car Insulation; TCB; SMB;

QSB600; QSB800; FIBERMAT®; LO-CON™ BLANKET

: All bulk fibers from 6000-AAA to 6100-

: 7000-AA to 7100-ZZ.

: EF-119; HP Ball Milled A; HP Ball Milled B; HP

: W-657; W-707; W-758; HS-95C; MX-135-

: HSA-K; HSA-HP.

: K-Chopped; KMTX; MT; MTX; MT-T; MX-150.

,

INCLUDES:

: HP-ODB; Module Trim; MT-HP; HP-

PAPERS

FIBERFRAX® BINDERLESS PAPERS

Manufacturer/Supplier:Unifrax Corporation

CHEMTREC Assist:

JH; HSA-F without binder; HSA-J without binder.

2351 Whirlpool St.

ara Falls, NY 14305-2413

Nia

Product Stewardship Information Hotline

800-322-2293 (Monday -Friday 8:00 a.m.

1

For additional MSDSs, visit our web page, http: //www.unifrax.com, or call

Unifrax Customer Service at

CHEMTREC will provide assistance for chemical emergencies. Call

9300

: 972-AH; 972-FH; 972-JH; 882-FH; 882-

716) 278-3872

1-800-424-

2. COMPOSITION / INFORMATION ON INGREDIENTS

Refractories, Fibers, Aluminosilicate 142844-00-6 100

(See Section 8 "Exposure Controls / Personal Protection" for exposure guidelines)

CAS NUMBER % BY WEIGHT

3. HAZARDS IDENTIFICATION

EMERGENCY OVERVIEW

WARNING!

Page 31

POSSIBLE CANCER HAZARD BY INHALATION.

(See Section 11 for more information)

CHRONIC EFFECT

There has been no increased incidence of respiratory disease in studies examining occupationally exposed

workers. In animal studies, long-term laboratory exposure to doses hundreds of times higher than normal

occupational exposures has produced fibrosis, lung cancer, and mesothelioma in rats or hamsters. The fibers

used in those studies were specially sized to maximize rodent respirability.

OTHER POTENTIAL EFFECTS

TARGET ORGANS:

Respiratory Tract (nose & throat), Eyes, Skin

RESPIRATORY TRACT (nose & throat) IRRITATION:

If inhaled in sufficient quantity, may cause temporary, mild mechanical irritation to respiratory tract.

Symptoms may include scratchiness of the nose or throat, cough or chest discomfort.

EYE IRRITATION:

May cause temporary, mild mechanical irritation. Fibers may be abrasive; prolonged contact may cause

damage to the outer surface of the eye.

SKIN IRRITATION:

May cause temporary, mild mechanical irritation. Exposure may also result in inflammation, rash or itching.

GASTROINTESTINAL IRRITATION:

Unlikely route of exposure.

MEDICAL CONDITIONS AGGRAVATED BY EXPOSURE:

Pre-existing medical conditions, including dermatitis, asthma or chronic lung disease may be aggravated by

exposure; individuals who have a history of allergies may experience greater amounts of skin and

respiratory irritation.

HAZARD CLASSIFICATION

Although studies, involving occupationally exposed workers, have not identified any increased incidence of

respiratory disease, results from animal testing have been used as the basis for hazard classification. In each of

the following cases, the conclusions are qualitative only and do not rest upon any quantitative analysis suggesting

that the hazard actually may occur at current occupational exposure levels.

In October 2001, the

human carcinogen) remains the appropriate IARC classification for RCF.

The Seventh Annual Report on Carcinogens (1994), prepared by the

classified respirable RCF and glasswool as substances reasonably anticipated to be carcinogens.

The

American Conference of Governmental Industrial Hygienists (ACGIH)

Suspected Human Carcinogen.”

The

Commission of The European Communities (DG XI)

regarded as if it is carcinogenic to man.

The

State of California

International Agency for Research on Cancer (IARC)

has classified RCF as a substance that should be

, pursuant to Proposition 65, The Safe Drinking Water and Toxic Enforcement Act of

confirmed that Group 2b (possible

National Toxicology Program (NTP),

has classified RCF as “A2-

Page 32

1986, has listed "ceramic fibers (airborne fibers of respirable size)" as a chemical known to the State of California

NFPA Codes:

to cause cancer.

The

Canadian Environmental Protection Agency (CEPA)

carcinogenic" (Group 2).

The

Canadian Workplace Hazardous Materials Information System (WHMIS)

D2A – Materials Causing Other Toxic Effects

The

Hazardous Materials Identification System (HMIS)

Health 1* Flammability 0 Reactivity 0 Personal Protection Index: X (Employer Determined)

(* denotes potential for chronic effects)

has classified RCF as "probably

– RCF is classified as Class

–

4. FIRST AID MEASURES

FIRST AID PROCEDURES

RESPIRATORY TRACT (nose & throat) IRRITATION:

If respiratory tract irritation develops, move the person to a dust free location. Get medical attention if the irritation

continues. See Section 8 for additional measures to reduce or eliminate exposure.

EYE IRRITATION:

If eyes become irritated, flush immediately with large amounts of lukewarm water for at least 15 minutes. Eyelids

should be held away from the eyeball to ensure thorough rinsing. Do not rub eyes. Get medical attention if

irritation persists.

SKIN IRRITATION:

If skin becomes irritated, remove soiled clothing. Do not rub or scratch exposed skin. Wash area of contact

thoroughly with soap and water. Using a skin cream or lotion after washing may be helpful.

GASTROINTESTINAL IRRITATION:

If gastrointestinal tract irritation develops, move the person to a dust free environment.

NOTES TO PHYSICIANS:

Skin and respiratory effects are the result of temporary, mild mechanical irritation; fiber exposure does not result

in allergic manifestations.

NFPA Unusual Hazards:

Flammable Properties:

Flash Point:

Hazardous Decomposition Products:

Unusual Fire and Explosion Hazard:

Extinguishing Media:

5. FIRE FIGHTING MEASURES

Flammability: 0 Health: 1 Reactivity: 0 Special: 0

None

None

None

None

None

Use extinguishing media suitable for type of surrounding fire.

6. ACCIDENTAL RELEASE MEASURES

Page 33

SPILL PROCEDURES

Avoid creating airborne dust. Dust suppressing cleaning methods such as wet sweeping or vacuuming should be

used to clean the work area. If vacuuming, the vacuum must be equipped with a HEPA filter. Compressed air or

dry sweeping should not be used for cleaning.

7. HANDLING AND STORAGE

STORAGE

Store in original container in a dry area. Keep container closed when not in use.

HANDLING

Handle ceramic fiber carefully. Limit use of power tools unless in conjunction with local exhaust. Use hand tools

whenever possible. Frequently clean the work area with HEPA filtered vacuum or wet sweeping to minimize the

accumulation of debris. Do not use compressed air for clean

EMPTY CONTAINERS

Product packaging may contain residue. Do not reuse.

-up.

8. EXPOSURE CONTROLS/PERSONAL PROTECTION

EXPOSURE GUIDELINES

COMPONENTS OSHA PEL MANUFACTURER REG

Refractories, Fibers,

Aluminosilicate

There is no specific regulatory standard for RCF in the U.S. OSHA’s “Particulate Not Otherwise Regulated

*

(PNOR)” standard [29 CFR 1910.1000, Subpart Z, Air Contaminants] applies generally; Total Dust 15 mg/m

Respirable Fraction 5 mg/m

** The Refractory Ceramic Fibers Coalition (RCFC) has sponsored comprehensive toxicology and epidemiology

studies to identify potential RCF-related health effects [see Section 11 for more details], consulted experts familiar

with fiber and particle science, conducted a thorough review of the RCF-related scientific literature, and further

evaluated the data in a state-of-the-art quantitative risk assessment. Based on these efforts and in the absence of

an OSHA PEL, RCFC has adopted a recommended exposure guideline, as measured under NIOSH Method

7400 B. The manufacturers’ REG is intended to promote occupational health and safety through prudent

exposure control and reduction and it reflects relative technical and economic feasibility as determined by

extensive industrial hygiene monitoring efforts undertaken pursuant to an agreement with the U.S. Environmental

Protection Agency.

OTHER OCCUPATIONAL EXPOSURE LEVELS (OEL)

RCF-related occupational exposure limits vary internationally. Regulatory OEL examples include: Australia – 0.5

f/cc; Austria – 0.5 f/cc; Canada – 0.5 to 1.0 f/cc; Denmark – 1.0 f/cc; France – 0.6 f/cc; Germany – 0.5 f/cc;

Netherlands – 1.0 f/cc; New Zealand – 1.0 f/cc; Norway – 2.0 f/cc; Poland – 2.0 f/cc; Sweden – 1.0 f/cc; United

Kingdom – 2.0 f/cc. Non-regulatory OEL examples include: ACGIH TLV 0.2 f/cc; RCFC REG 0.5 f/cc. The

³.

None Established* 0.5 f/cc, 8-hr. TWA**

³

;

Page 34

objectives and criteria underlying each of these OEL decisions also vary. The evaluation of occupational exposure

limits and determining their relative applicability to the workplace is best performed, on a case-by-case basis, by a

qualified Industrial Hygienist.

ENGINEERING CONTROLS

Use engineering controls such as local exhaust ventilation, point of generation dust collection, down draft work

stations, emission controlling tool designs, and materials handling equipment designed to minimize airborne fiber

emissions.

PERSONAL PROTECTION EQUIPMENT

Respiratory Protection – RCF:

When engineering and/or administrative controls are insufficient to maintain workplace concentrations within the

0.5 f/cc REG, the use of appropriate respiratory protection, pursuant to the requirements of OSHA Standards 29

CFR 1910.134 and 29 CFR 1926.103, is recommended. The following information is provided as an example of

appropriate respiratory protection for aluminosilicate fibers. The evaluation of workplace hazards and the

identification of appropriate respiratory protection is best performed, on a case by case basis, by a qualified

Industrial Hygienist.

MANUFACTURER’S RESPIRATORY PROTECTION RECOMMENDATIONS

WHEN HANDLING RCF PRODUCTS

Respirable Airborne Fiber Concentration

(levels are 8-hr. time-weighted averages)

Not yet determined but expected to be below 5.0 f/cc

based on operation

Respirator Recommendation

Half-face, air purifying respirator equipped with a

NIOSH certified P100 particulate filter cartridge

†

"Reliably" less than 0.5 f/cc Optional

0.5 f/cc to 5.0 f/cc Half-face, air purifying respirator equipped with a

NIOSH certified P100 particulate filter cartridge

5.0 f/cc to 25 f/cc Full-facepiece, air purifying respirator equipped with a

NIOSH certified P100 particulate filter cartridge or

PAPR

Greater than 25 f/cc PAPR with tight-fitting full facepiece or a supplied air

respirator in continuous flow mode

When individual workers request respiratory protection

as a matter of personal comfort or choice where

exposures are "reliably" below 0.5 f/cc

†

The P100 recommendation is a conservative default choice; in some case, solid arguments can be made that

A NIOSH certified respirator, such as a disposable

particulate respirator, or respirators with filter cartridges

rated N95 or better

other respirator types (e.g., N95, R99, etc.) may be suitable for some tasks or work environments. The P100

recommendation is not designed to limit informed choices, provided that respiratory protection decisions comply

with 29 CFR 1910.134.

Other Information:

Concentrations based upon an eight-hour time weighted average (TWA) as determined by air samples

collected and analyzed pursuant to NIOSH method 7400 (B) for airborne fibers.

The manufacturer recommends the use of a full-facepiece air purifying respirator equipped with an

appropriate particulate filter cartridge during furnace tear-out events and the removal of used RCF to

Page 35

control exposures to airborne fiber and the potential presence of crystalline silica. If exposure levels are

(%)

pH

VAPOR DENSITY

% VOLATILE

known, the respiratory protection chart provided above may be applied.

Potential exposure to other airborne contaminants should be evaluated by a qualified Industrial Hygienist

for the selection of appropriate respiratory protection and air monitoring.

Skin Protection:

Wear gloves, head coverings and full body clothing as necessary to prevent skin irritation. Washable or

disposable clothing may be used. If possible, do not take unwashed clothing home. If soiled work clothing must be

taken home, employers should ensure employees are thoroughly trained on the best practices to minimize or

avoid non-work dust exposure (e.g., vacuum clothes before leaving the work area, wash work clothing separately,

rinse washer before washing other household clothes, etc.).

Eye Protection:

Wear safety glasses with side shields or other forms of eye protection in compliance with appropriate OSHA

standards to prevent eye irritation. The use of contact lenses is not recommended, unless used in conjunction

with appropriate eye protection. Do not touch eyes with soiled body parts or materials. If possible, have eyewashing facilities readily available where eye irritation can occur.

9. PHYSICAL AND CHEMICAL PROPERTIES

ODOR AND APPEARANCE

CHEMICAL FAMILY

BOILING POINT

WATER SOLUBILITY

MELTING POINT

SPECIFIC GRAVITY

VAPOR PRESSURE

: Not Applicable

MOLECULAR FORMULA

: Not Applicable

: 1760° C (3200° F)

(Air = 1): Not Applicable

: Not Applicable

: White, odorless, fibrous material

: Vitreous Aluminosilicate Fibers

:

: 2.50 – 2.75

: Not Applicable

: Not Applicable

Not Soluble in Water

10. STABILITY AND REACTIVITY

CHEMICAL STABILITY:

INCOMPATIBILITY:

CONDITIONS TO AVOID:

HAZARDOUS DECOMPOSITION

PRODUCTS:

HAZARDOUS POLYMERIZATION:

Stable under conditions of normal use.

Soluble in hydrofluoric acid, phosphoric acid, and concentrated

alkali.

None.

None.

Not Applicable.

11. TOXICOLOGICAL INFORMATION

HEALTH DATA SUMMARY

Epidemiological studies of RCF production workers have indicated no increased incidence of respiratory

disease nor other significant health effects. In animal studies, long-term, high-dose inhalation exposure

resulted in the development of respiratory disease in rats and hamsters.

EPIDEMIOLOGY

Page 36

The University of Cincinnati is conducting an ongoing epidemiologic investigation. The evidence obtained from

employees in U. S. RCF manufacturing facilities is as follows:

1) There is no evidence of any fibrotic lung disease (interstitial fibrosis) from evaluations of chest X-rays.

2) There is no evidence of an elevated incidence of lung disease among RCF manufacturing employees.

3) In early studies, an apparent statistical “trend” was observed, in the exposed population, between RCF

exposure duration and some measures of lung function. The observations were clinically insignificant. If these

observations were made on an individual employee, the results would be interpreted as being within the normal

(predicted) respiratory range. A more recent longitudinal study of employees with 5 or more pulmonary function

tests found that there was no effect on lung function associated with RCF production experience. Initial data (circa

1987) seemed to indicate an interactive effect between smoking and RCF exposure; more recent data, however,

found no interactive effect. Nevertheless, to promote good health, RCF employees are still actively encouraged

not to smoke.

4) Pleural plaques (thickening along the chest wall) have been observed in a small number of RCF employees.

Some studies appear to show a relationship between the occurence of pleural plaques on chest radiographs and

the following variables: (a) years since RCF production hire date; (b) duration of RCF production employment;

and (c) cumulative RCF exposure. The best evidence to date indicates that pleural plaques are a marker of

exposure only. Pleural plaques are not associated with pulmonary impairment. The pathogenesis of pleural

plaques remains incompletely understood; however, the mechanism appears to be an inflammatory response

caused by inhaled fibers.

TOXICOLOGY

A number of toxicological studies designed to identify any potential health effects from RCF exposure have been

completed. In one study, conducted by the Research and Consulting Company, (Geneva, Switzerland), rats and

hamsters were exposed to 30 mg/m³ (about 200 fibers/cc) of specially-prepared RCF for 6 hours/day, 5

days/week, for up to 24 months. In rats, a statistically significant increase in lung tumors was observed; two

mesotheliomas (cancer of the pleural lining between the chest wall and lung) were also identified. Hamsters did

not develop lung tumors; however, interstitial fibrosis and mesothelioma was found. Some, in the scientific

community, have concluded that the “maximum tolerated dose” was exceeded and that significant particle

contamination was a confounding issue; therefore, these study findings may not represent an accurate

assessment of the potential for RCF to produce adverse health effects.

In a related multi-dose study with a similar protocol, other rats were exposed to doses of 16 mg/m³, 9 mg/m³, 3

mg/m³ which corresponds to about 115, 75, and 25 fibers per cubic centimeter respectively. This study found no

statistically significant increase in lung cancer. Some cases of pleural and parenchymal fibrosis were seen in the

16 mg/m³ dose group. Some cases of mild fibrosis and one mesothelioma were observed in the 9 mg/m³ group.

No acute respiratory effects were seen in the rats in the 3 mg/m³ exposure group, which suggests that there may

be a dose/response threshold, below which irreversible respiratory impacts do not occur.

Other toxicological studies have been conducted which utilized non-physiological exposure methods such as

intrapleural, intraperitoneal and intratracheal implantation or injection. Some of these studies have found that RCF

is a potential carcinogen. Some experts, however, suggest that these tests have limited relevance because they

bypass many of the biological mechanisms that prevent fiber deposition or facilitate fiber clearance.

To obtain more epidemiology or toxicology information, please call the toll free telephone number for the Unifrax

Corporation Product Stewardship Program found in Section 16 - Other Information.

12. ECOLOGICAL INFORMATION

Page 37

No ecological concerns have been identified.

A

13. DISPOSAL CONSIDERATIONS

WASTE MANAGEMENT

To prevent waste materials from becoming airborne during waste storage, transportation and disposal, a covered

container or plastic bagging is recommended.

DISPOSAL

RCF, as manufactured, is not classified as a hazardous waste according to Federal regulations (40 CFR 261).

Any processing, use, alteration or chemical additions to the product, as purchased, may alter the disposal

requirements. Under Federal regulations, it is the waste generator's responsibility to properly characterize a waste

material, to determine if it is a "hazardous" waste. Check local, regional, state or provincial regulations to identify

all applicable disposal requirements.

14. TRANSPORT INFORMATION

U.S. DEPARTMENT OF TRANSPORTATION (DOT)

Hazard Class: Not Regulated United Nations (UN) Number: Not Applicable

Labels: Not Applicable North America (NA) Number: Not Applicable

Placards: Not Applicable Bill of Lading: Product Name

INTERNATIONAL

Canadian TDG Hazard Class & PIN: Not regulated

Not classified as dangerous goods under ADR (road), RID (train) or IMDG (ship).

15. REGULATORY INFORMATION

UNITED STATES REGULATIONS

EPA: Superfund Amendments and Reauthorization Act (SARA)

does not contain any substances reportable under Sections 302, 304, 313, (40 CFR

372). Sections 311 and 312 (40 CFR 370) apply (delayed hazard).

Toxic Substances Control Act (TSCA)

required, on the TSCA inventory. RCF has been assigned a CAS number; however,

it is a simple mixture and therefore not required to be listed on the TSCA inventory.

The components of RCF are listed on the inventory.

Comprehensive Environmental Response, Compensation and Liability Act

(

CERCLA)

diameter greater than one micron and thus is not considered a hazardous air

and the

Clean Air Act (CAA)

ll substances in this product are listed, as

-

- RCF contains fibers with an average

Title III - This product

Page 38

pollutant.

OSHA:

California

Other

States

INTERNATIONAL REGULATIONS

Comply with

1926.59 and the

1926.103.

: Ceramic fibers (airborne particles of respirable size)” is listed in

Safe Drinking Water and Toxic Enforcement Act of 1986

the State of California to cause cancer.

RCF products are not known to be regulated by states other than California;

:

however, state and local OSHA and EPA regulations may apply to these products. If

in doubt, contact your local regulatory agency.

Hazard Communication Standards

Respiratory Protection Standards

29 CFR 1910.1200 and 29 CFR

29 CFR 1910.134 and 29 CFR

Proposition 65, The

as a chemical known to

:

Canada

European

:

Union

Canadian Workplace Hazardous Materials Information System (WHMIS)

is classified as Class D2A – Materials Causing Other Toxic Effects

Canadian Environmental Protection Act (CEPA)

are listed, as required, on the Domestic Substance List (DSL)

European Directive 97/69/EC

“should be regarded as if it is carcinogenic to man.”

classified RCF as a Category 2 carcinogen; that is it

- All substances in this product

– RCF

16. OTHER INFORMATION

RCF DEVITRIFICATION

As produced, all RCF fibers are vitreous (glassy) materials which do not contain crystalline silica. Continued

exposure to elevated temperatures may cause these fibers to devitrify (become crystalline). The first crystalline

formation (mullite) begins to occur at approximately 985° C (1805° F). Crystalline silica (cristobalite) formation

may begin at temperatures of approximately 1200° C (2192° F). The occurrence and extent of crystalline phase

formation is dependent on the duration and temperature of exposure, fiber chemistry and/or the presence of

fluxing agents. The presence of crystalline phases can be confirmed only through laboratory analysis of the "hot

face" fiber.

IARC’s evaluation of crystalline silica states “Crystalline silica inhaled in the form of quartz or cristobalite from

occupational sources is carcinogenic to humans (Group 1)” and additionally notes “carcinogenicity in humans was

not detected in all industrial circumstances studied” (IARC Monograph Vol. 68, 1997). NTP lists all polymorphs of

crystalline silica amongst substances which may "reasonably be anticipated to be carcinogens".

IARC and NTP did not evaluate after-service RCF, which may contain various crystalline phases. However, an

analysis of after-service RCF samples obtained pursuant to an exposure monitoring agreement with the USEPA,

found that in the furnace conditions sampled, most did not contain detectable levels of crystalline silica. Other

relevant RCF studies found that (1) simulated after-service RCF showed little, or no, activity where exposure was

by inhalation or by intraperitoneal injection; and (2) after-service RCF was not cytotoxic to macrophage-like cells

²

at concentrations up to 320 g/cm

lower levels (circa 20 g/cm

- by comparison, pure quartz or cristobalite were significantly active at much

²

).

RCF AFTER

Respiratory protection should be provided in compliance with OSHA standards. During removal operations, a full

face respirator is recommended to reduce inhalation exposure along with eye and respiratory tract irritation. A

specific evaluation of workplace hazards and the identification of appropriate respiratory protection is best

performed, on a case by case basis, by a qualified industrial hygiene professional.

PRODUCT STEWARDSHIP PROGRAM

The Unifrax Corporation has established a program to provide customers with up-to-date information regarding

the proper use and handling of refractory ceramic fiber. In addition, Unifrax Corporation has also established a

program to monitor airborne fiber concentrations at customer facilities. If you would like more information about

-SERVICE REMOVAL

Page 39

this program, please call the Unifrax Corporation Product Stewardship Information Hotline at 1-800-322-2293.

CERCLA:

f/cc:

g

p

NIOSH:

RID:

A

A

On February 11, 2002, the Refractory Ceramic Fibers Coalition (RCFC) and the U.S. Occupational Safety and

Health Administration (OSHA) introduced a voluntary worker protection program entitled PSP 2002, a

comprehensive, multi-faceted risk management program designed to control and reduce workplace exposures to

refractory ceramic fiber (RCF). Unifrax Corporation, as a member of RCFC, is participating in this highly

acclaimed product stewardship program. For more information regarding PSP 2002, please call the Unifrax

Corporation's Product Stewardship Information Hotline at 1-800-322-2293 or refer to the RCFC web site:

http://www.rcfc.net

.

DEFINITIONS

ACGIH:

ADR:

CAA:

CAS:

DSL:

EPA:

EU:

HEPA:

HMIS:

IARC:

IATA:

IMDG:

m

/m³:

cf:

mm

NFPA:

OSHA:

29 CFR 1910.134 & 1926.103:

29 CFR 1910.1200 & 1926.59:

PEL:

PIN:

PNOC:

PNOR:

PSP:

RCFC:

RCRA:

REG:

REL:

SARA:

SARA Title III:

SARA Section 302:

SARA Section 304:

Section 311:

SAR

Section 312:

SAR

SARA Section 313:

STEL:

SVF:

TDG:

TLV:

American Conference of Governmental Industrial Hygienists

Carriage of Dangerous Goods by Road (International Regulation)

Clean Air Act

Chemical Abstracts Service

Comprehensive Environmental Response, Compensation and Liability Act

Domestic Substances List

Environmental Protection Agency

European Union

Fibers per cubic centimeter

High Efficiency Particulate Air

Hazardous Materials Identification System

International Agency for Research on Cancer

International Air Transport Association

International Maritime Dangerous Goods Code

Milligrams per cubic meter of air

Million particles per cubic meter

National Fire Protection Association

National Institute for Occupational Safety and Health

Occupational Safety and Health Administration

OSHA Respiratory Protection Standards

OSHA Hazard Communication Standards

Permissible Exposure Limit (OSHA)

Product Identification Number

Particulates Not Otherwise Classified

Particulates Not Otherwise Regulated

Product Stewardship Program

Refractory Ceramic Fibers Coalition

Resource Conservation and Recovery Act

Recommended Exposure Guideline (RCFC)

Recommended Exposure Limit (NIOSH)

Carriage of Dangerous Goods by Rail (International Regulations)

Superfund Amendments and Reauthorization Act

Emergency Planning and Community Right to Know Act

Extremely Hazardous Substances

Emergency Release

MSDS/List of Chemicals and Hazardous Inventory

Emergency and Hazardous Inventory

Toxic Chemicals and Release Reporting

Short Term Exposure Limit`

Synthetic Vitreous Fiber

Transportation of Dangerous Goods

Threshold Limit Value (ACGIH)

Page 40

TSCA:

TWA:

WHMIS:

Toxic Substances Control Act

Time Weighted Average

Workplace Hazardous Materials Information System (Canada)

Revision Summary:

MSDS Prepared By:

Section 1: Added new product name. Replaces 02/11/02 MSDS.

UNIFRAX RISK MANAGEMENT DEPARTMENT

DISCLAIMER

The information presented herein is presented in good faith and believed to be accurate as of the effective date of

this Material Safety Data Sheet. Employers may use this MSDS to supplement other information gathered by

them in their efforts to assure the health and safety of their employees and the proper use of the product. This

summary of the relevant data reflects professional judgment; employers should note that information perceived to

be less relevant has not been included in this MSDS. Therefore, given the summary nature of this document,

Unifrax Corporation does not extend any warranty (expressed or implied), assume any responsibility, or make any

representation regarding the completeness of this information or its suitability for the purposes envisioned by the

user.

Page 41

Thermal Ceramics

MATERIAL SAFETY DATA SHEET

MSDS No: 350 Date Prepared: 03/24/1992 Current Date: 7/26/2002

Last Revised: (03/20/2002)

1. PRODUCT AND COMPANY IDENTIFICATION

Product Group: ALKALINE EARTH SILICATE (AES) WOOL PRODUCT

Chemical Name: Calcium-Magnesium-Silicate Wool or Calcium-Magnesium-Zirconium-Silicate Wool

Synonyms: CMS, Synthetic Vitreous Fiber (SVF), Man-made Vitreous Fiber (MMVF), Man-made Mineral

Trade Names: Superwool™ (*) Bulks, Blankets, Mats and Modules (ALL GRADES)

Manufacturer/Supplier: Thermal Ceramics Inc.

* Superwool™ is a trademark of The Morgan Crucible Company plc

Fiber (MMMF)

P. O. Box 923; Dept. 300

Augusta, GA 30903-0923

For Product Stewardship and Emergency Information -

Hotline: 1-800-722-5681

Fax: 706-560-4054

For additional MSDSs and to confirm this is the most current MSDS for the

product, visit our web page [www.thermalceramics.com] or call our automated

FaxBack: 1-800-329-7444

2. COMPOSITION/INFORMATION ON INGREDIENTS

INGREDIENT &

CAS NUMBER

Calcium-Magnesium-Silicate Mixture

329211-92-9 5 mg/m

OR

Calcium-Magnesium-Zirconium-Silicate Mixture

308084-09-5 5 mg/m

(1)

May contain alumina and titania as minor constituents

(See Section 8 "Exposure Controls / Personal Protection" for exposure guidelines.)

(1)

% BY WEIGHT OSHA PEL ACGIH TLV

100 15 mg/m3 (total dust) 10 mg/m3 (inhalable dust)

(1)

100 15 mg/m3 (total dust) 10 mg/m3 (inhalable dust)

3

(respirable dust) 3 mg/m3 (respirable dust)

3

(respirable dust) 3 mg/m3 (respirable dust)

3. HAZARDS IDENTIFICATION

• May cause temporary, mild mechanical irritation to the eyes, skin, nose and/or throat.

• Pre-existing skin and respiratory conditions may be aggravated by exposure.

Page 1 Of 7

Page 42

MATERIAL SAFETY DATA SHEET

MSDS No: 350 Date Prepared: 03/24/1992 Current Date: 7/26/2002

Last Revised: (03/20/2002)

4. FIRST AID MEASURES

RESPIRATORY TRACT (nose and throat) IRRITATION

If respiratory tract irritation develops, move the person to a dust free location. See Section 8 for additional measures to

reduce or eliminate exposure.

EYE IRRITATION

If eyes become irritated, flush immediately with large amounts of lukewarm water for at least 15 minutes. Eyelids

should be held away from the eyeball to ensure thorough rinsing. Do not rub eyes.

SKIN IRRITATION

If skin becomes irritated, remove soiled clothing. Do not rub or scratch exposed skin. Wash area of contact

thoroughly with soap and water. Using a skin cream or lotion after washing may be helpful.

GASTROINTESTINAL IRRITATION

If gastrointestinal tract irritation develops, move the person to a dust free environment.

- If symptoms persist, seek medical attention. -

NOTE TO PHYSICIANS

Skin and respiratory effects are the result of temporary, mild mechanical irritation; fiber exposure does not result in

allergic manifestations.

5. FIRE FIGHTING MEASURES

NFPA Codes: Flammability: _ 0_ , Health: _1_ , Reactivity: _ 0_ , Special: _ 0_

NFPA Unusual Hazards: None

Flammable Properties: None

Flash Point: None

Hazardous Decomposition Products: None

Unusual Fire and Explosion Hazard: None

Extinguishing Media: Use extinguishing media suitable for type of surrounding fire.

6. ACCIDENTAL RELEASE MEASURES

SPILL PROCEDURES

Avoid creating airborne dust. Dust suppressing cleaning methods such as wet sweeping or vacuuming should be used

to clean the work area. If vacuuming, the vacuum should be equipped with a HEPA filter. Compressed air or dry

sweeping should not be used for cleaning.

7. HANDLING AND STORAGE

STORAGE

Store in original factory container in a dry area. Keep container closed when not in use.

HANDLING

Limit use of power tools unless in conjunction with local exhaust. Use hand tools whenever possible. Frequently clean

the work area with HEPA filtered vacuum or wet sweeping to minimize the accumulation of debris. Do not use

compressed air for clean-up.

EMPTY CONTAINERS

Do not reuse the container.

Page 2 Of 7

Page 43

MATERIAL SAFETY DATA SHEET

MSDS No: 350 Date Prepared: 03/24/1992 Current Date: 7/26/2002

Last Revised: (03/20/2002)

8. EXPOSURE CONTROLS/PERSONAL PROTECTION

MANUFACTURER'S RECOMMENDATION

It is prudent to reduce exposure to respirable dusts to the lowest attainable level through the use of engineering controls

such as ventilation and dust collection devices. Industrial hygiene standards and occupational exposure limits may vary

between countries, state and local jurisdictions. Contact your employer to determine which exposure levels apply to

your facility. If no regulatory dust or other standards apply, a qualified industrial hygienist can assist with a specific

workplace evaluation including recommendations for respiratory protection. In the absence of such guidance, the

manufacturer generally recommends the control of CMS wool exposures to 1 fiber/cc or less.

ENGINEERING CONTROLS