Page 1

®

77 Series III

Multimeter

Service Manual

PN 800604

November 1998 Rev.1, 11/99

© 1998,1999 Fluke Corporation. All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

Page 2

Table of Contents

Chapter Title Page

1 Introduction and Specifications................................. 1-1

1-1. Introduction ................................................................. 1-3

1-2. Organization of the Service Manual ........................... 1-3

1-3. Conventions ................................................................ 1-4

1-4. Specifications .............................................................. 1-4

2 Theory of Operation.................................................... 2-1

2-1. Introduction ................................................................. 2-3

2-2. Functional Block Description ..................................... 2-3

2-3. Detailed Description ................................................... 2-3

2-4. Voltage Signal Conditioning .................................. 2-3

2-5. Current Conditioning .............................................. 2-4

2-6. Ohms ....................................................................... 2-4

2-7. Additional Circuitry ................................................ 2-4

2-8. AC Converter ..................................................... 2-5

2-9. Active Filter ....................................................... 2-5

2-10. Rotary Switch ..................................................... 2-5

2-11. A/D Conversion .................................................. 2-5

3 Maintenance ................................................................ 3-1

3-1. Introduction ................................................................. 3-3

3-2. PCA Access and General Maintenance ...................... 3-3

3-3. Display Access ............................................................ 3-4

3-4. Cleaning ...................................................................... 3-4

3-5. Performance Test ........................................................ 3-7

3-6. Initial Procedure ..................................................... 3-7

3-7. DC Voltage Test ..................................................... 3-7

3-8. AC Voltage Test ......................................................... 3-8

3-9. Resistance Test ....................................................... 3-8

i

Page 3

77 Series III

Service Manual

3-10. Diode Test .............................................................. 3-9

3-11. DC mA Test ............................................................ 3-10

3-12. DC Amps Test ........................................................ 3-11

3-13. Calibration .............................................................. 3-11

3-14. Troubleshooting .......................................................... 3-11

3-15. Supplemental Troubleshooting Procedures ............ 3-13

3-16. Checking the Crystal Oscillator ......................... 3-13

3-17. Checking The Reference Voltage ...................... 3-13

3-18. Checking Display Drive Voltage ....................... 3-13

3-19. Checking Beeper Drive Signal ........................... 3-13

3-20. Tracing the VDC Signal Path ............................. 3-13

4 List of Replaceable Parts............................................ 4-1

4-1. Introduction ................................................................. 4-3

4-2. How to Obtain Parts .................................................... 4-3

4-3. Newer Instruments ...................................................... 4-3

4-4. Service Centers ........................................................... 4-3

4-5. Manual Status Information ......................................... 4-4

4-6. Parts Lists .................................................................... 4-4

5 Schematic Diagrams................................................... 5-1

ii

Page 4

List of Tables

Table Title Page

1-1. Specifications ..................................................................... 1-5

2-1. S1 Function Codes.............................................................. 2-6

3-1. Recommended Test Equipment.......................................... 3-3

3-2. DC Voltage Test................................................................. 3-8

3-3. AC Voltage Test................................................................. 3-8

3-4. Resistance Test................................................................... 3-10

3-5. DC mA Test........................................................................ 3-11

3-6. DC Amps Test.................................................................... 3-11

4-1. Final Assembly................................................................... 4-5

4-2. A1 Main PCA..................................................................... 4-7

5-1. Abbreviations ..................................................................... 5-3

iii

Page 5

77 Series III

Service Manual

iv

Page 6

List of Figures

Figure Title Page

2-1. Overview ............................................................................ 2-3

2-2. AC and A/D Converter....................................................... 2-7

3-1. Assembly Details................................................................ 3-6

3-2. Troubleshooting Tree......................................................... 3-12

4-2. A1 Main PCA..................................................................... 4-9

5-1. A1 Main PCA..................................................................... 5-4

v

Page 7

77 Series III

Service Manual

vi

Page 8

OPERATOR SAFETY

INFORMATION

This instrument has been designed and tested in accordance with IEC

Publication 348, Safety Requirements for Electronic Measuring Apparatus. This

manual contains information and warnings which have to be followed by the

user to ensure safe operation and to retain the instrument in safe condition.

Warning statements identify conditions or practices that could result in

personal injury or loss of life.

Caution statements identify conditions or practices that could result in damage

to the equipment or other property.

•

Never use the meter if the meter or test leads look damaged.

•

Always turn off power to the circuit before cutting, unsoldering, or breaking

the circuit. Small amounts of current can be dangerous.

•

Never measure resistance in a circuit when power is applied to the circuit.

•

Never touch the probes to a voltage source when the test leads are

plugged into the 10A or 300 mA input jack.

•

Never apply more than 1000V dc or ac rms (sine) between any input jack

and earth ground.

•

Always be careful when working with voltages above 60V dc or 30V ac

rms. Such voltages pose a shock hazard.

•

Always keep your fingers behind the finger guards on the probe when

making measurements.

•

Always use a high voltage probe to measure voltage if the peak voltage

might exceed 1000V.

SAFETY-1

Page 9

Symbols Marked on Equipment

DANGER — High Voltage

Attention — refer to the manual. This symbol indicates that

information about the usage of a feature is contained in the

l.

manua

I Fuse information

Use the Proper Fuse

To avoid fire hazard, use only the fuse identical in type, voltage

rating, and current rating as specified on the case bottom fuse rating

label.

Do Not Remove Cover

Always operate the meter with case top and bottom properly

assembled.

Access procedures and the warnings for such procedures are

contained in this Service Manual Service procedures are for qualified

service personnel only.

Do Not Attempt to Operate if Protection May be

Impaired

If the meter appears damaged or operates abnormally, protection may

be impaired. Do not attempt to operate it. When is doubt, have the

instrument serviced.

SAFETY-2

Page 10

Chapter 1

Introduction and

Specifications

Contents Page

1-1. Introduction.................................................................. 1-3

1-2. Organization of the Service Manual............................ 1-3

1-3. Conventions ................................................................. 1-4

1-4. Specifications............................................................... 1-4

1-1

Page 11

77 Series III

Service Manual

1-2

Page 12

Introduction and Specifications

Introduction

1-1. Introduction

This manual presents service information for the Fluke 77 Series III

Multimeter. The manual includes a theory of operation, general maintenance

procedures, performance tests, calibration procedures, troubleshooting

information, a list of replaceable parts, and schematic diagrams.

A meter under warranty will be promptly repaired or replaced (at Fluke’s

option) and returned at no charge. See the registration card for warranty terms.

To locate an authorized service center, visit us on the World Wide Web:

www.fluke.com or call using any of the phone numbers listed below:

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-678-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

1-2. Organization of the Service Manual

The following descriptions briefly describe each chapter in the manual.

1

Chapter 1 Introduction and Specifications

This chapter describes use of the Service Manual and application of special

terminology (conventions) to describe the meter’s circuitry. A complete set of

specifications appears at the end of this chapter.

Chapter 2 Theory of Operation

This chapter first categorizes instrument circuitry into functional blocks, with

a description of each block’s role in overall operation. A detailed circuit

description is then given for each block. These descriptions explore operation

to the component level and fully support troubleshooting and repair

procedures defined in Section 3.

Chapter 3 Maintenance

Provides complete maintenance information, from general maintenance and

cleaning instructions to detailed troubleshooting and repair procedures to the

component level. Troubleshooting and repair procedures rely heavily on both

the Theory of Operation presented in Chapter 2 and the Schematic Diagrams

shown in Section 5.

Chapter 4 List of Replaceable Parts

Includes parts lists for all standard assemblies. Information on how and where

to order parts is also provided.

Chapter 5 Schematic Diagrams

Includes schematic for the A1 Main PCA.

1-3

Page 13

77 Series III

Service Manual

1-3. Conventions

Through the manual, certain notational conventions are used. A summary of

these conventions follow:

• Instrument Reference

The Fluke 77 Series III Multimeter is also referred to throughout this

manual as “the meter”.

• Printed Circuit Assembly

The term “pca” is used to represent a printed wiring board and its

attached parts.

• Circuit Nodes

Individual pins or connections on a component are specified by a dash

(-) following the component reference designator. For example, pin 19

of U30 would be U30-19.

• User Notation

Generally, push buttons, function positions, input terminals, and

display notation are presented in this manual as they are seen on the

meter.

Special terms (mnemonics) used in text descriptions of meter circuitry

correspond to terms used on the schematic diagrams in Chapter 5.

1-4. Specifications

Specifications for the meters are presented in Table 1-1.

1-4

Page 14

Introduction and Specifications

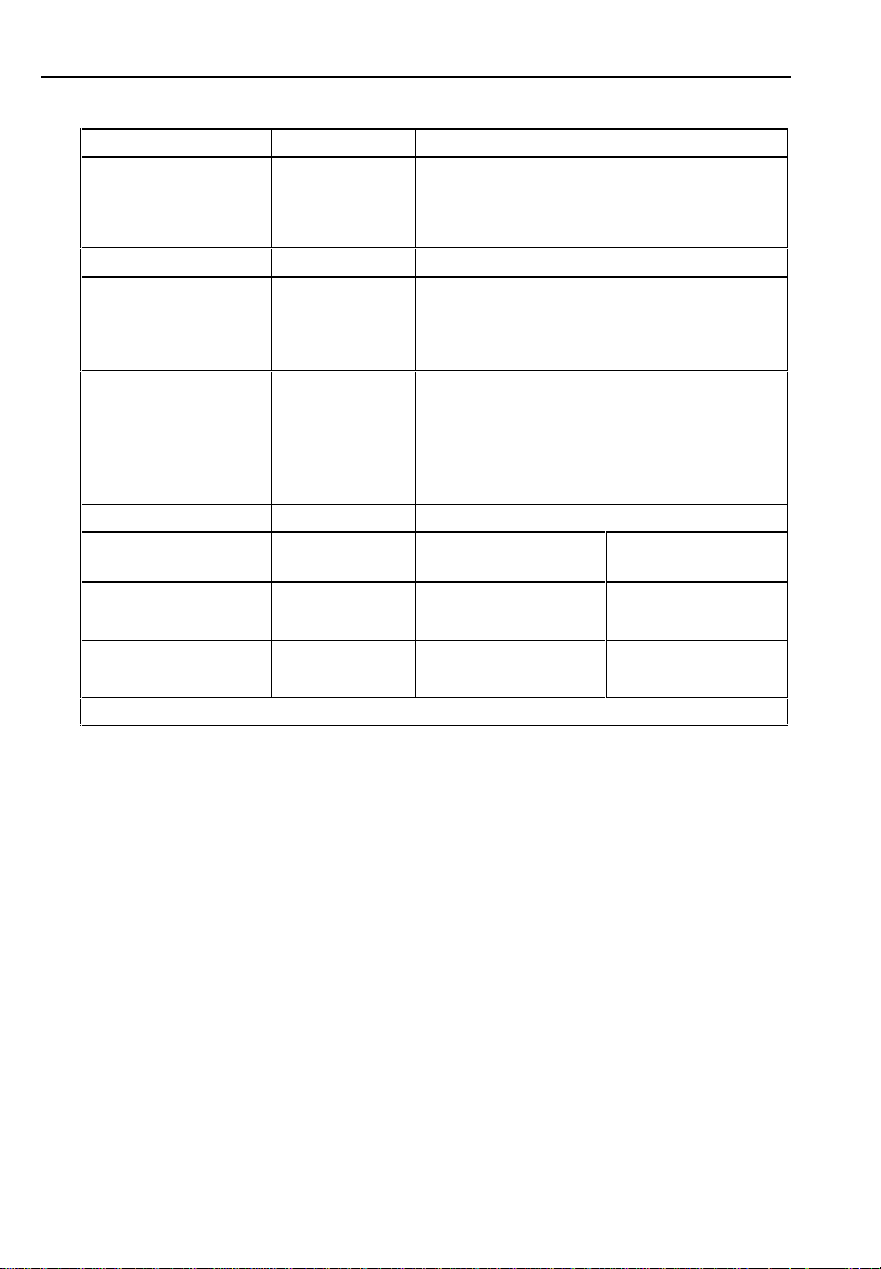

Table 1-1. Specifications

Specifications

1

Maximum Voltage Between any

Terminal and Earth Ground

Display Digital: 3,200 counts, updates 2.5/sec

Response Time of Digital Display V ac < 2 s

Operating Temperature 0°C to 50°C

Storage Temperature -40°C to 60°C

Temperature Coefficient 0.1 x (specified accuracy)/°C

Electromagnetic Compatibility In

RF field of 3 V/m on all functions.

Relative Humidity

except 32 MΩ range

32 MΩ range only

Altitude Operating: 2000 meters

Battery Type 9 V NEDA 1604 or 6F22 or 006P,

Battery Life 2000 hrs typical with alkaline

Continuity Beeper 4096 Hz

Shock, Vibration per MIL-T-PRF 28800F Class III, Sinusoidal,

Size (H x W x L) 3.7 cm x 8.9 - 7.8 cm x 19 cm

Weight 365 g (12.9 oz)

Safety 600 V CAT III and 1000 V CAT II per

EMC Regulations EN 61326-1 1997.

Certifications/Listings

Rated voltage

Analog: 31 segments, updates 25/sec

V dc < 1 s

Ω < 1s to 320 kΩ, < 2s to 3.2 MΩ,

< 10 s to 32 MΩ

(<18°C or >28°C)

Total accuracy = Specified accuracy

+ 0.1% of range.

0% to 90% (0°C to 35°C)

0% to 70% (35°C to 50°C)

0% to 80% (0°C to 35°C)

0% to 70% (35°C to 50°C)

Storage: 12,000 meters

or NEDA 1604A or 6LR61

1600 hrs typical with carbon zinc

Non Operating

(1.5 in x 3.5 - 3.1 in x 7.49 in)

ANSI/ISA S82.01-1994, EN 61010-1: 1993,

CSA C22.2 No 1010.1-92, UL 3111-1.

1-5

Page 15

77 Series III

Service Manual

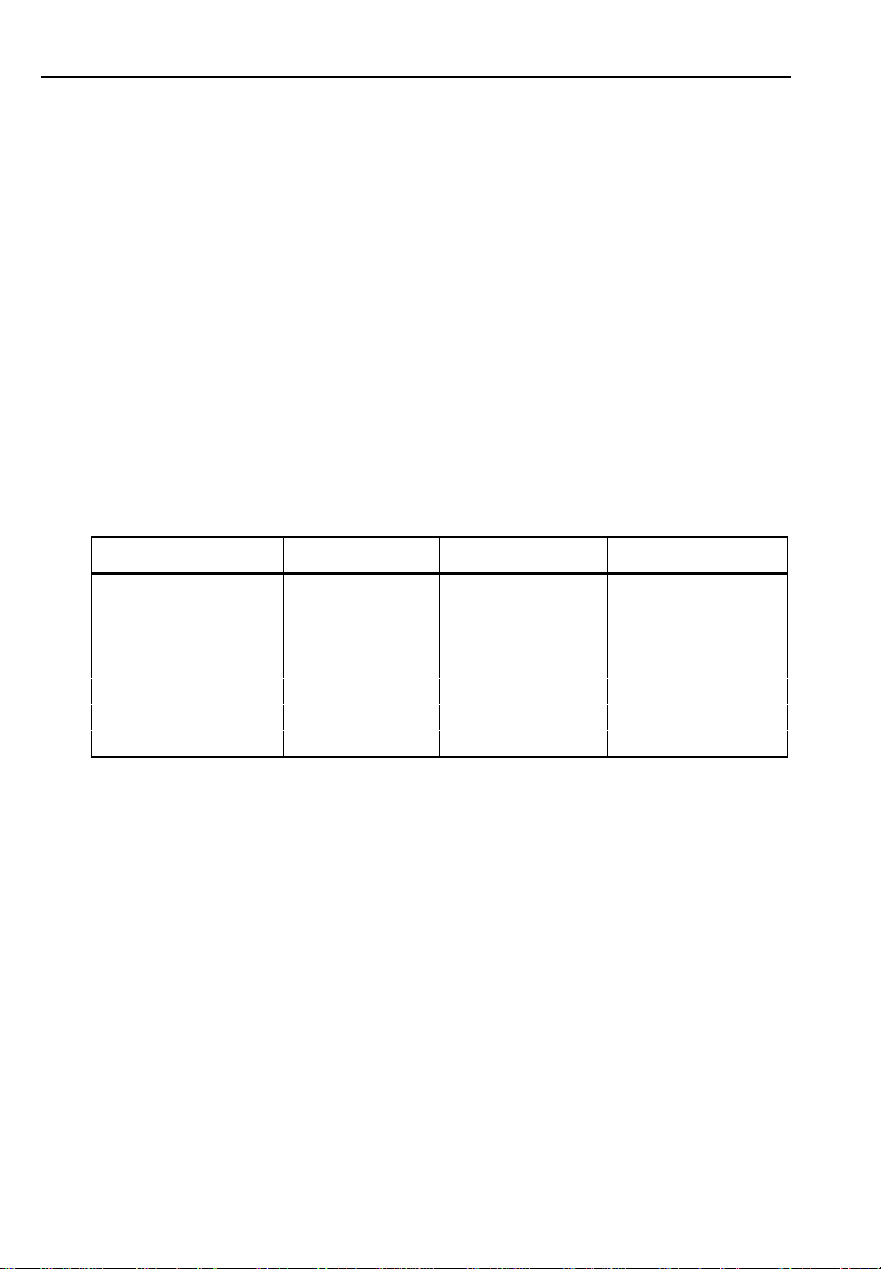

Table 1-1. Specifications (cont)

Function Range Accuracy

L

L

m

K (45 to 500 Hz,

3.2 V range. Other

ranges 45 to 1

kHz)

e

G R 2.0 V ±(1% typical)

Function Range Accuracy Burden Voltage

? (45 Hz to 1 kHz)

A

* 10 A continuous, 20 A for 30 seconds maximum.

3.200 V

32.00 V

320.0 V

1000 V

320.0 mV ±(0.3%+1)

3.200 V

32.00 V

320.0 V

1000 V

320.0 Ω

3200 Ω

32.00 kΩ

320.0 kΩ

3.200 MΩ

32.00 MΩ

32.00 mA,

320.0 mA

10.00 A *

32.00 mA,

320.0 mA

10.00 A *

±(2.5%+2)

±(2.5%+2)

±(1.5%+2)

±(1.5%+2)

±(0.3%+1)

±(0.3%+1)

±(0.3%+1)

±(0.4%+1)

±(2%+2)

±(2%+2)

±(2%+2)

±(2%+2)

±(0.5%+3)

±(0.5%+1)

±(0.5%+1)

±(0.5%+1)

±(0.5%+1)

±(2.0%+1)

(typical)

6 mV/mA

50 mV/A

6 mV/mA

50 mV/A

1-6

Page 16

Introduction and Specifications

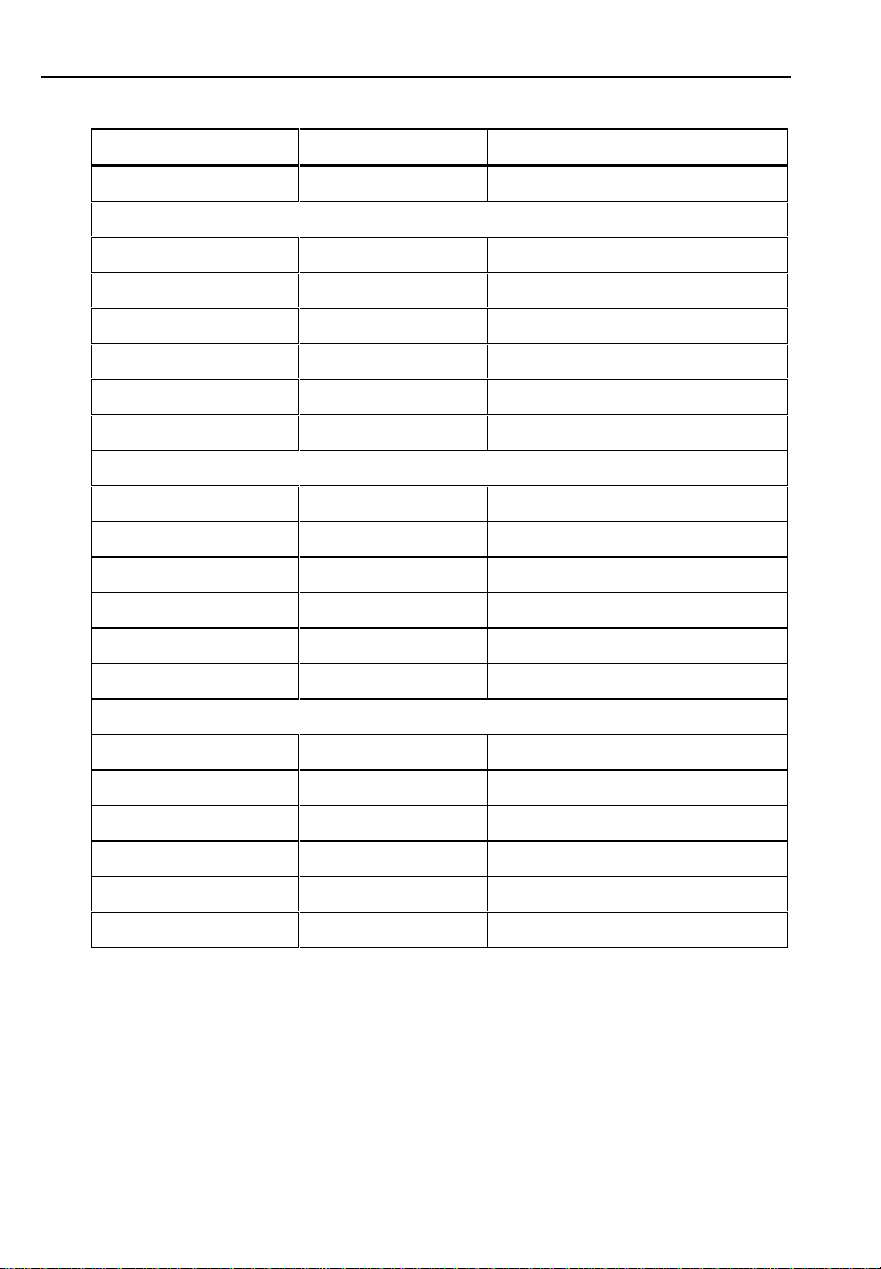

Overload protection for all functions and ranges: Rated voltage.

Function Input Impedance (Nominal)

L, mL, K

L,

L

m

K

e

G R

e

G R

G

>10 MΩ, <50 pF

Common Mode Rejection

Ratio (1 kΩ Unbalanced)

>120 dB at dc, 50 Hz, or 60 Hz >60 dB at 50 Hz or 60 Hz

>60 dB dc to 60 Hz

Open Circuit Test Voltage Full Scale Voltage

<3.1 V dc

<2.8 V dc (typical)

Open Circuit Test Voltage Full Scale Voltage

<3.1 V dc 2.0 V dc

Short Circuit Current (typical)

300 µA

400 µA

V

F

0.0 V

0.6 V

1.2 V

2.0 V

Normal Mode Rejection

To 3.2 MΩ 32 MΩ

<440 mV dc

<420 mV dc

(typical)

Current (typical)

0.4 mA

0.3 mA

0.2 mA

0.1 mA

Specifications

<1.4 V dc

<1.3 V dc

(typical)

1

1-7

Page 17

77 Series III

Service Manual

1-8

Page 18

Chapter 2

Theory of Operation

Contents Page

2-1. Introduction.................................................................. 2-3

2-2. Functional Block Description...................................... 2-3

2-3. Detailed Description.................................................... 2-3

2-4. Voltage Signal Conditioning................................... 2-3

2-5. Current Conditioning............................................... 2-4

2-6. Ohms........................................................................ 2-4

2-7. Additional Circuitry................................................. 2-4

2-8. AC Converter ...................................................... 2-4

2-9. Active Filter ........................................................ 2-5

2-10. Rotary Switch...................................................... 2-5

2-11. A/D Conversion................................................... 2-5

2-1

Page 19

77 Series III

Service Manual

2-2

Page 20

Theory of Operation

Introduction

2-1. Introduction

This chapter contains a brief overview of the 77 Series III Multimeter,

followed by a more detailed explanation of operation.

2-2. Functional Block Description

The heart of the instrument consists of a two-chip CMOS system: U1, a

primarily analog IC, and U2, a calculator-style microcomputer (see Figure 2-

1).

ACV

DCV

S1

DCmV

300 mV

OHMS

ACmV

To Bar

Graph

LCD

To Digital

Display

J1

OFF

Input

Signal

Conditioning

2

Range and

Function

Control

U2 Microcomputer

A/D Samples

aaa01f.eps

Y1

32.768

kHz

V

REF

A/D

Counter

U1 Analog Chip

Figure 2-1. Overview

2-3. Detailed Description

The following paragraphs describe the 77 Series III Multimeter in more detail.

While reading this description, refer to the schematic diagram in Chapter 5.

2-4. Voltage Signal Condi t ioning

Input divider Z1 and dc blocking capacitor C1 make up an input voltage signal

conditioning circuit.

2-3

Page 21

77 Series III

Service Manual

The pins of Z1 are used as follows:

Z1-PIN NUMBER FUNCTION

1 input

3 3.2V range tap

4 32V range tap

5 320V range tap

6 1000V dc/750V ac range tap

Overvoltage protection is provided by R1, RV1, RV2, RV3, and RT1.

RT1 is a thermistor that normally has about 1 kΩ of resistance, but increases

to very high impedance as it heats up with an overload voltage. R1 provides

current limiting for the input until RT1 heats up. In an overload condition,

RV1, RV2, and RV3 clamp the voltage at the switch to approximately 2000V.

2-5. Current Conditioning

Current input conditioning is provided by R6, R7, R5 and R13. R6 and R7

develop input voltage from the applied current. R5 and R13 act as a voltage

divider for the 300-mA range. F1 protects the mA circuitry; F3 protects the

10A circuitry.

2-6. Ohms

When the ohms function is selected, the meter compares the unknown

resistance at J1 with the reference resistors in Z1.

Input protection for the ohms ranges consists of Q1, Q2, Q3, R1, R2, R3, R4,

and RT1. Q1 and Q2 serve as back-to-back zener diodes which limit the input

to between 7 and 9V. Also, R2 R3, and R4 limit current, and Q3 clamps pin

29 of U1 to approximately 2.5V.

2-7. Additional Circuitry

In addition to the above circuitry, the following circuitry is also used in the

Series II meters: AC Converter, Active Filter, Rotary Switch, and A/D

Conversion.

2-8. AC Converter

The ratio of R17 and R18 determines ac voltage and current accuracy (see

Figure 2-2, AC and A/D Converter), and C11 is the averaging capacitor for

the half-wave ac converter portion of U1.

2-4

Page 22

Theory of Operation

Detailed Description

2-9. Active Filter

An active filter that includes R9, R10, C5, and C6 is located in U1.

Conditioned input signals are passed through the active filter in route to the

a/d converter section of U1. (See Figure 2-2, AC and A/D Converter.)

The clock frequency for the digital portion of the circuit is a function of

32.768-kHz crystal Y1. Y1, C12, C15, and amplifiers in U1 make up the

oscillator circuit.

2-10. Rotary Switch

Rotary switch S1 FRONT selects and routes the input signals. Function codes

for switch S1 REAR are shown in Table 2-1. Range switch S2 signals the

microcomputer U2 for the manual ranging and automatic Touch Hold

function.

CR1 acts as protection for U1 if the battery is installed backwards. C2 is part

of the power-on reset for microcomputer U2.

2-11. A/D Conversion

Analog-to-digital (a/d) conversion is accomplished within U1 using a

modified dualslope a/d converter circuit. (See Figure 2-2, AC and A/D

Converter.)

2

Since the a/d conversion process is essentially a dual slope method, two

voltages are required to complete a measurement cycle. One is the unknown

input and the other is the reference voltage.

2-5

Page 23

77 Series III

Service Manual

Conditioned input signals are routed to the a/d converter in U1, where they are

integrated. The reference voltage developed by reference supply VR1, R15,

R16, and R8 is routed to the a/d converter in U1, where it is used for the

integrate reference (de-integrate) portions of the measurement cycle.

C7 stores offsets of the buffer, integrator, and comparator amplifiers of the a/d

converter. The gain of the buffer is determined by the resistors of Z1 between

pins 8, 9, and 10. C8 is the integrator capacitor.

A series of 10 minor cycle conversions occurs without taking time for an

autozero phase between the conversions. These minor cycle conversions, or

samples, occur at a rate of 25 per second, and are used to provide the fast

response bar-graph display and fast autoranging.

New samples are taken every 40 ms. Ten samples are summed to produce a

full- resolution digital display, with full scale greater than 3200 counts. A 50ms autozero phase occurs following every 10 sample sequence.

Table 2-1. S1 Function Codes

Function B0 B1 B2

ACV 1 1 1

DCV 0 1 1

300 mV 0 0 0

Ohms 0 0 1

10 0

ACA 1 1 0

DCA 0 1 0

2-6

Page 24

COMPARATOR

DIGITAL

+

SECTION

Theory of Operation

Detailed Description

U1

2

INTEGRATOR

DE-INT

REF REF

ACTIVE FILTER BUFFER

AC CONVERTER

46 47

R10

16 17 28 26 39 40 27 44 45

C7

C8

R9

C11 C5 C6

Z1 Z1

10 9 8

R17

+

R19

+

R18

C9

+

+

INT

FILTER

AC

+

AC

+

AC

FILTER

AC

AC

INPUT

Figure 2-2. AC and A/D Converter

aaa03f.eps

2-7

Page 25

77 Series III

Service Manual

2-8

Page 26

Chapter 3

Maintenance

Contents Page

3-1. Introduction..................................................................... 3-3

3-2. PCA Access and General Maintenance.......................... 3-3

3-3. Display Access................................................................ 3-4

3-4. Cleaning.......................................................................... 3-4

3-5. Performance Test............................................................ 3-7

3-6. Initial Procedure ......................................................... 3-7

3-7. DC Voltage Test......................................................... 3-7

3-8. AC Voltage Test ............................................................. 3-8

3-9. Resistance Test........................................................... 3-8

3-10. Diode Test .................................................................. 3-9

3-11. DC mA Test................................................................ 3-10

3-12. DC Amps Test............................................................ 3-11

3-13. Calibration.................................................................. 3-11

3-14. Troubleshooting.............................................................. 3-11

3-15. Supplemental Troubleshooting Procedures................ 3-13

3-16. Checking the Crystal Oscillator............................. 3-13

3-17. Checking The Reference Voltage .......................... 3-13

3-18. Checking Display Drive Voltage........................... 3-13

3-19. Checking Beeper Drive Signal............................... 3-13

3-20. Tracing the VDC Signal Path................................. 3-13

3-1

Page 27

77 Series III

Service Manual

3-2

Page 28

Maintenance

Introduction

Warning

These service instructions are for use by qualified

personnel only. To avoid electric shock, do not

perform any servicing other than that contained in

the operator’s manual unless you are qualified to do

so.

3-1. Introduction

This chapter contains maintenance information for the performance testing,

calibration, general maintenance, and troubleshooting of the 77 Series III

Multimeter. For operator maintenance, refer to the Instruction Sheet.

The performance tests are recommended as a preventive maintenance tool to

verify proper instrument operation. A one year calibration cycle is

recommended to maintain the specifications given in the Users Manual. Test

equipment required for the performance tests and calibration is listed in Table

3-1. If the recommended equipment is not available, instruments with

equivalent specifications may be used.

Table 3-1. Recommended Test Equipment

3

Instrument Type Recommended Model

Multi-Product Calibrator Fluke 5500A

3-2. PCA Access and General Maintenance

Warning

To avoid electrical shock, remove the test leads

before opening the case, and close the case before

operating the meter. To prevent fire, instal l fuses

with the rating shown on the back of t he met er.

Caution

To avoid contaminating the pca with oil from the

fingers, handle it by the edges or wear gloves. PCA

contamination may not cause immediate instrument

failure in controlled environments. Failures typically

show up when contaminated units are operated in

humid areas.

Use the following procedure for removing the pca (printed circuit assembly)

from its case:

3-3

Page 29

77 Series III

Service Manual

1. Set the function switch to OFF, and disconnect test leads if they are

installed.

2. Remove the four Phillips screws from the bottom cover.

3. Turn the meter face up, grasp the top cover, and pull the top cover

from the meter.

4. Remove the 11A fuse to access the screw that holds the pca to the

case bottom.

5. The pca may now be removed from the bottom cover.

3-3. Display Access

Do not handle the conductive edges of the LCD

interconnects. If contaminated, clean with alcohol.

Refer to Figure 3-1.

1. Remove the four Phillips screws from the back side of the pca.

2. Remove the LCD mounting bracket.

Caution

3. Insert a small screwdriver under the edges of the display holding

bracket, and gently pry the bracket loose from the snaps.

4. Turn the bracket upside down to remove the LCD.

5. Before installing a new LCD, make sure that all connector contact

points are clean.

3-4. Cleaning

Caution

To avoid damaging the meter, do not use aromatic

hydrocarbons or chlorinated solvents for cleaning.

These solutions will react with the plastics used in

instruments.

Do not allow the LCD to get wet. Remove the display

assembly before washing the pca and do not install

until the pca is completely dry.

Do not use detergent of any kind for cleaning the

pca.

Do not remove lubricants from the swit ch w hen

cleaning the pca.

3-4

Page 30

Maintenance

Cleaning

Clean the instrument case with a mild detergent and water.

The pca may be washed with isopropyl alcohol or deionized water and a soft

brush. Remove the display assembly and fuses before washing, and avoid

washing the switch if possible. Dry the pca with clean dry air at low pressure,

then bake it at 50°C for 24 hours.

3

3-5

Page 31

77 Series III

Service Manual

Knob Assembly

Shock Absorber

Detent Spring

Key Pad

Screw, 4-24

F1

F2

Decal Window

Case Top

LCD Window

Mask Bracket

LCD

Elastomeric Connector

Internal Cover

Shaft Adapter

AC Shield

Main PCA

Screw, 4-14

3-6

Battery

Annunciator

Contact

Bottom Shield

Case Bottom Assembly

Screw, 5-14

Probe Holder

Tilt Stand

FLUKE-77-3

aaa12c.eps

Figure 3-1. Assembly Details

Page 32

Maintenance

Performance Test

3-5. Performance Test

Performance tests are recommended for incoming inspection, periodic

maintenance, and for verifying the specifications in the Instruction Sheet. If

the instrument fails any part of the test, calibration and/or repair is indicated.

In the performance tests, the Fluke 77 Series III is referred to as the unit under

test (UUT).

3-6. Initial Procedure

1. Allow the UUT to stabilize to room temperature 23°C ± 5°C (73°F ±

9°F).

2. Check the fuses and battery, and replace them if necessary.

Warning

To prevent fire, install fuses in accordance with the

rating shown on the back of the meter.

Warning

To avoid false readings, which could l ead t o

possible electric shock or personal injury, replace

the battery as soon as the battery indicator (N)

appears.

3

3-7. DC Voltage Test

Warning

Connect the ground/common/low side of the DC

calibrator to COM on the UUT.

1. Set the UUT function switch to VDC, and connect the DC Voltage

Calibrator output to the z and COM input terminals of the

UUT.

2. Referring to Table 3-2, set the DC Voltage Calibrator for the output

indicated in steps 1 through 4 only. Verify that the UUT display

reading is within the limits shown.

3. Set the DC Voltage Calibrator for an output of +300 mV, and switch

the UUT to the 300 mV function. Verify that the UUT display reading

is within the limits shown in Table 3-2 (step 5).

3-7

Page 33

77 Series III

Service Manual

Step DC Input Voltage Display Reading

1 +2.7V 2.691 to 2.709V DC

2 +27V 26.91 to 27.09V DC

3 +270V 269.1 to 270.9V DC

4 +1000V 995 to 1005V DC

5* +300 mV 299.0 to 301.0V DC

*300 mV function only

3-8. AC Voltage Test

Connect the ground/common/low side of the AC

calibrator to COM on the UUT.

1. Set the UUT function switch to VAC, and connect the AC Voltage

Calibrator to the z and COM input terminals.

2. Set the AC Voltage Calibrator for the output given in Table 3-3,

verify that the UUT display reading is within the limits shown.

Table 3-2. DC Voltage Test

Warning

Note

When the input is open in the VAC function, it is normal for

the meter to read some counts on the display. This is due to

ac pickup in the ac amplifier when the ac amplifier when the

ac amplifier is unterminated.

Table 3-3. AC Voltage Test

Input

Step Voltage Frequency Display Reading

1 2.7V 100 Hz 2.644 to 2.756V AC

2 2.7V 500 Hz 2.644 to 2.756V AC

3 1000V 100 Hz 978 to 1022V AC

4 1000V 1000 Hz 978 to 1022V AC

3-9. Resistance Test

1. Select the ohms function on the UUT.

2. Connect the Ohms Calibrator or Decade Resistor to the z and

COM input terminals of the UUT.

3-8

Page 34

Maintenance

AC Voltage Test

Referring to Table 3-4, set the Ohms Calibrator or Decade Resistor to the

resistance value indicated in steps 1 through 6. Verify that the display reading

is within the limits shown.

3-10. Diode Test

1. Set the UUT to the Diode Test function.

Note

Ω

On Fluke 5100 series calibrators, activate the 50

override. On Fluke 5500A calibrators, lock voltage to the 33V

range.

2. Apply an input from the DC Voltage Calibrator of +.090V dc to the

z and COM input terminals of the UUT, and verify that the

beeper is on.

3. Increase the DC Voltage Calibrator output to +.110V dc, and verify

that the beeper is off.

divider

3

3-9

Page 35

77 Series III

Service Manual

Decades of 1:

Decades of 1.9:

Table 3-4. Resistance Test

Step Input Resistance Display Reading

1 short 0.0 to 0.3Ω

2 100Ω 99.2 to 100.8Ω (plus 0 reading)

31kΩ 994 to 1006 Ω

4 10 kΩ 9.94 to 10.06 kΩ

5 100 kΩ 99.4 to 100.6 kΩ

61 MΩ .994 to 1.006 MΩ

7 10 MΩ 9.79 to 10.21 MΩ

2 190Ω 188.7 to 191.3Ω (plus 0 reading)

3 1.9 kΩ 1889 to 1911 Ω

4 19 kΩ 18.89 to 19.11 kΩ

5 190 kΩ 188.9 to 191.1 kΩ

Decades of 2.7:

3-11. DC mA Test

1. Set the output of the DC Current Calibrator to zero, and connect it to

the 300mA and COM input terminals of the UUT.

2. Set the DC Current Calibrator to the output shown in Table 3-5, and

verify that the UUT display reading is within the limits shown.

3-10

6 1.9 MΩ 1.889 to 1.9111 MΩ

7 19 MΩ 18.61 to 19.39 MΩ

2 270Ω 268.3 to 271.7Ω (plus 0 reading)

3 2.7 kΩ 2685 to 2715Ω

4 27 kΩ 26.85 to 27.15 kΩ

5 270 kΩ 268.5 to 271.5 kΩ

6 2.7 MΩ 2.685 to 2.715 MΩ

7 27 MΩ 26.45 to 27.55 MΩ

Page 36

Maintenance

Troubleshooting

Table 3-5. DC mA Test

Step Input Current Display Reading

1 +27 mA 26.57 to 27.43 DC

2 +200 mA 196.8 TO 203.2 DC

3-12. DC Amps Test

1. Set the DC Current Calibrator to standby and connect it to the 10A

and COM input terminals of the UUT.

2. Apply currents as indicated in Table 3-6, and verify that the display

reading is within the limits shown.

Table 3-6. DC Amps Test

Step Input Current Display Reading

1 +10A 9.83 to 10.17 DC

3-13. Calibration

1. Set the DC Voltage Calibrator to zero, and set the UUT to the VDC

function.

3

2. Remove the case top cover as previously described.

3. Connect the DC Voltage Calibrator to the zand COM input

terminals of the UUT.

4. Set the DC Voltage Calibrator for an output of +3.000V dc, and adjust

R8 for a display reading of +3.000V dc ± .001V.

3-14. Troubleshooting

A troubleshooting tree for the meter is given in Figure 3-2. Faults are listed in

the order of probability. This tree gives a systematic approach to isolation of

problems to a component or component area. Complete the procedures in the

order listed in this table; all measurements are made with respect to common.

Also, supplemental troubleshooting procedures are presented in the following

paragraphs.

When troubleshooting the meter, use the precautions listed on the static

awareness sheet to prevent damage from static discharge.

3-11

Page 37

77 Series III

Service Manual

1.

2.

3.

4.

Turn meter on

Does meter power up?

Meter powers up, but

does not come out of

self-test.

Meter comes up with

missing segments.

Switch meter to V and

apply 3V dc. Does

meter display 3 VDC?

ON

YES

YES

NO

YES

NO

ON

YES

Check:

a. Power supplies

TP1 = 3.1V dc +/-0.1V

TP3 = 1.5V dc

U1 pin 48 = 6V dc (Battery voltage - TPIV)

(If any of these voltages are high, low, or missing,

replacement of U1 is usually necessary)

b. For loose pins on U1, U2

c. Battery voltage

d. S1 for bad contacts

e. VR1 for 1.2V dc

f. Shield for short to Q3

g. For solder debris/shortd

Check:

a. For loose pins on U1, U2

b. For shorted C5, 6, 7, or 8

c. Contacts of S1

d. For shorted pins on U1, U2

e. Y1 Frequency @ 32.768 kHz

Check:

a. LCD for cracks

b. For contaminated display interconnects or display

contact areas

c. For loose pins on U2

d. For cracks in U2 package

e. Junction of R11 and R12 for 1.6V dc.

Probable cause:

a. RV1 or RV2 or RV3 shorted

b. S1 Contacts bad

c. Z1 open or out of tolerance

d. U1 bad

e. U1 loose/shorted pins

Does meter autorange

5.

correctly?

6.

Switch meter to V.

Apply 3V @ 500 Hz.

Does meter display

3 VAC?

7.

Switch meter to .

Apply 100 ohms. Does

meter display 100 ?

8.

Switch meter to A.

Apply 300 mA dc. Does

meter display 300 DC?

9.

Switch meter to .

Does beeper sound

when leads are

shorted?

ON

YES

YES

NO

NO

YES

NO

YES

NO

Probable cause:

a. U1 bad

b. S1 bad

Probable cause:

a. U1 bad (also check for loose or shorted pins)

b. S1 bad

c. C9, C11 shorted

Probable cause:

a. S1 bad

b. Q1, Q2 shorted

c. Loose pins on U1, U2

d. U1 bad

Probable cause:

a. F1, F2 open

b. S1 bad

c. R7 open

d. Open land patterns in current path

Check:

a. Connector contact points

b. For correct signal at contact points. Should be 4.1 kHz

waveform. (If above checks are good, LS1

replacement is necessary.)

Figure 3-2. Troubleshooting Tree

aaa02f.eps

3-12

Page 38

Maintenance

Troubleshooting

3-15. Supplemental Troubleshooting Procedures

3-16. Checking the Crystal Oscillator

Connect an oscilloscope or counter to pin 54 U1 or to the junction of C12 and

the Y1 crystal. Check for a 32.768-kHz sine wave approximately 600 mV p-p

in amplitude. Note that U2 and the display will not work if the clock circuit is

not working.

Probable related failures include: U1, Y1, or C12.

3-17. Checking The Reference Voltage

Check for a reference voltage of 1.00V dc (adjustable by R8) at pin 14 of U1

or at the junction of R15 and R16.

Probable related failures include: R8, R14, R15, R16, VR1, or CR2.

3-18. Checking Display Drive Voltage

Check that VM (V middle) is 1.6V dc ±.1V at pin 28 U2 or at the junction of

R11 and R12.

Probable related failures include: R11 or R12.

3-19. Checking Beeper Drive Signal

Put the unit in the Diode Test Mode and short the input leads. Using an

oscilloscope, measure the signal at pin 3 of U1. The signal should be a 4V p-p

symmetrical square wave at about 4.1 kHz.

3

A probable related failure is: U1

3-20. Tracing the VDC Signal Path

Use the following procedure to trace the VDC signal path:

1. Set the UUT to the VDC function and apply 2V dc to the input.

2. Using a DVM, measure the input at J1 for 2V dc.

3. Measure pin 1 of Z1 input divider for 2V dc. Probable related failures

include: R1, S1, RV1, or RV2.

Note

Measurements in steps 4,5, and 6 may be affected by loading.

4. Measure Z1 pin 3 for 200 mV dc. Probable related failures are: Z1,

U1.

5. Measure for 200 mV dc at the active filter input (AFI, pin 26 of U1 or

R9). A probable failures is: U1

6. Measure for 200 mV at the active filter output (AFO, pin 27 of U1 or

R9). Probable related failures are: R9, C5, or C6.

3-13

Page 39

77 Series III

Service Manual

3-14

Page 40

static awareness

A Message From

Fluke Corporation

Some semiconductors and custom IC's can be

damaged by electrostatic discharge during

handling. This notice explains how you can

minimize the chances of destroying such devices

by:

1. Knowing that there is a problem.

2. Leaning the guidelines for handling them.

3. Using the procedures, packaging, and

bench techniques that are recommended.

The following practices should be followed to minimize damage to S.S. (static sensitive) devices.

3. DISCHARGE PERSONAL STATIC BEFORE

HANDLING DEVICES. USE A HIGH RESIS-

1. MINIMIZE HANDLING

TANCE GROUNDING WRIST STRAP.

2. KEEP PARTS IN ORIGINAL CONTAINERS

UNTIL READY FOR USE.

Static Awareness -1

4. HANDLE S.S. DEVICES BY THE BODY.

Page 41

5. USE STATIC SHIELDING CONTAINERS FOR

HANDLING AND TRANSPORT.

6. DO NOT SLIDE S.S. DEVICES OVER

ANY SURFACE.

8. WHEN REMOVING PLUG-IN ASSEMBLIES

HANDLE ONLY BY NON-CONDUCTIVE

EDGES AND NEVER TOUCH OPEN EDGE

CONNECTOR EXCEPT AT STATIC-FREE

WORK STATION. PLACING SHORTING

STRIPS ON EDGE CONNECTOR HELPS

PROTECT INSTALLED S.S. DEVICES.

9. HANDLE S.S. DEVICES ONLY AT A

STATIC-FREE WORK STATION.

10. ONLY ANTI-STATIC TYPE SOLDER SUCKERS SHOULD BE USED.

11. ONLY GROUNDED-TIP SOLDERING

IRONS SHOULD BE USED.

7. AVOID PLASTIC,VINYL AND STYROFOAM

IN WORK AREA.

PORTIONS REPRINTED

WITH PERMISSION FROM TEKTRONIX INC.

AND GERNER DYNAMICS, POMONA DIV.

Dow Chemical

Static Awareness-2

Page 42

Chapter 4

List of Replaceable Parts

Contents Page

4-1. Introduction..................................................................... 4-3

4-2. How to Obtain Parts........................................................ 4-3

4-3. Newer Instruments.......................................................... 4-3

4-4. Service Centers ............................................................... 4-3

4-5. Manual Status Information ............................................. 4-4

4-6. Parts Lists........................................................................ 4-4

4-1

Page 43

77 Series III

Service Manual

4-2

Page 44

List of Replaceable Parts

Introduction

4-1. Introduction

This section contains an illustrated list of replaceable parts for 77 Series III

Multimeter.

4-2. How to Obtain Parts

Electrical components may be ordered directly from the Fluke Corporation

and its authorized representatives by using the part number under the heading

FLUKE PN. In the U.S., order directly from the Fluke Parts Dept. by calling

1-800-526-4731. Parts price information is available from the Fluke

Corporation or its representatives. Prices are also available in a Fluke

Replacement Parts Catalog which is available on request.

In the event that the part ordered has been replaced by a new or improved part,

the replacement will be accompanied by an explanatory note and installation

instructions, if necessary.

To ensure prompt delivery of the correct part, include the following

information when you place an order:

• Part number and revision level of the pca containing the part.

• Reference designator

• Fluke stock number

• Description (as given under the DESCRIPTION heading)

• Quantity

• Instrument Model, Serial Number, and Firmware Numbers

4

4-3. Newer Instruments

Changes and improvements made to the instrument are identified by

incrementing the revision letter marked on the affected pca. These changes are

documented on a manual supplement which, when applicable, is included with

the manual.

4-4. Service Centers

To locate an authorized service center, call Fluke using any of the phone

numbers listed below, or visit us on the World Wide Web: www.fluke.com

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-678-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

4-3

Page 45

77 Series III

Service Manual

4-5. Manual Status Information

The following Manual Status Information table defines the assembly revision

levels that are documented in the manual. Revision levels are printed on the

component side of each pca.

Manual Status Information

Assembly Revision Level

A1 Main PCA c

4-6. Parts Lists

The following tables list the replaceable parts for the 77 Series III Multimeter.

Parts are listed by assembly; alphabetized by reference designator. Each

assembly is accompanied by an illustration showing the location of each part

and its reference designator. The parts lists give the following information:

• Reference designator

• An indication if the part is subject to damage by static discharge

• Description

• Fluke stock number

• Total quantity

• Any special notes (i.e., factory-selected part)

4-4

Caution

A * symbol indicates a device that may be damaged

by static discharge.

Note

This instrument may contain a Nickel-Cadmium battery. Do

not mix with the solid waste stream. Spent batteries should be

disposed of by a qualified recycler or hazardous materials

handler. Contact your authorized Fluke service center for

recycling information.

Warning

This instrument contains a fusible resistor (pn

740662). To ensure safety, use exact replacement

only.

Page 46

List of Replaceable Parts

Parts Lists

Table 4-1. Final Assembly

Ref Des Description Fluke PN Qty Notes

A1 MAIN PCA NA 1

BT1 BATTERY,9V,0-15MA 696534 1

DS1 LCD,3.75 DIGIT,BAR GRAPH,MULTIPLED 602927 1

F1W FUSE,.406x1.375,0.440A,1000V,FAST 943121 1

F2W FUSE,.406X1.5, 11A, 1000V, FAST 803293 1

H1 SCREW,PH,P,THD FORM,STL,4-24,.250 519116 1

H2 SCREW,PH,P,AM THD FORM,STL,4-14,375 448456 5

H7 SCREW,PH,P,AM THD FORM,STL,5-14,.759 832246 4

LS1 AF TRANSD,PIEZO,20MM,600MW,6KHZ 642991 1

MP4 HOLDER,PROBE 648748 1

MP5 STAND,TILT 648961 1

MP6 LABEL,WINDOW 844337 1

MP9 SHIELD,AC 648755 1

MP10 SPRING,DETENT 822643 4

MP11 KNOB,SWITCH 648706 1

MP12 ADAPTER,SHAFT 649175

MP14 CASE BOTTOM ASSEMBLY 659786 1

MP16 SHOCK ABSORBER 428441 1

MP17 CASE TOP PAD XFR 648763 1

MP18 WINDOW, LCD 648714 1

MP19 COVER,INTERNAL 648722 1

MP20 MASK,BRACKET,77-3 WITH LOGO 648771 1

MP21 CONN,ELASTOMERIC,LCD TO PWB,1.900 L 650264 2

MP23 SHIELD,BOTTOM 648839 1

MP32 TEST LEADS TL75 1

MP40 CONTACT,ANNUNCIATOR 642983 1

S2 KEYPAD 648847 1

TM1 77/75/23/21 SERIES III INSTRUCTION

SHEET

TM2 77 SERIES III SERVICE MANUAL 800604 1

686571 1

4

W To ensure safety, use exact replacement only.

4-5

Page 47

77 Series III

Service Manual

F2

F1

MP11

MP16

MP10

S2

H1

MP6

MP17

MP18

MP20

DS1

MP21

MP19

MP12

MP9

A1

H2

4-6

BT1

MP40

LS1

MP23

MP14

H7

MP4

MP5

FLUKE-77-3

aaa05c.eps

Figure 4-1. Final Assembly

Page 48

List of Replaceable Parts

Parts Lists

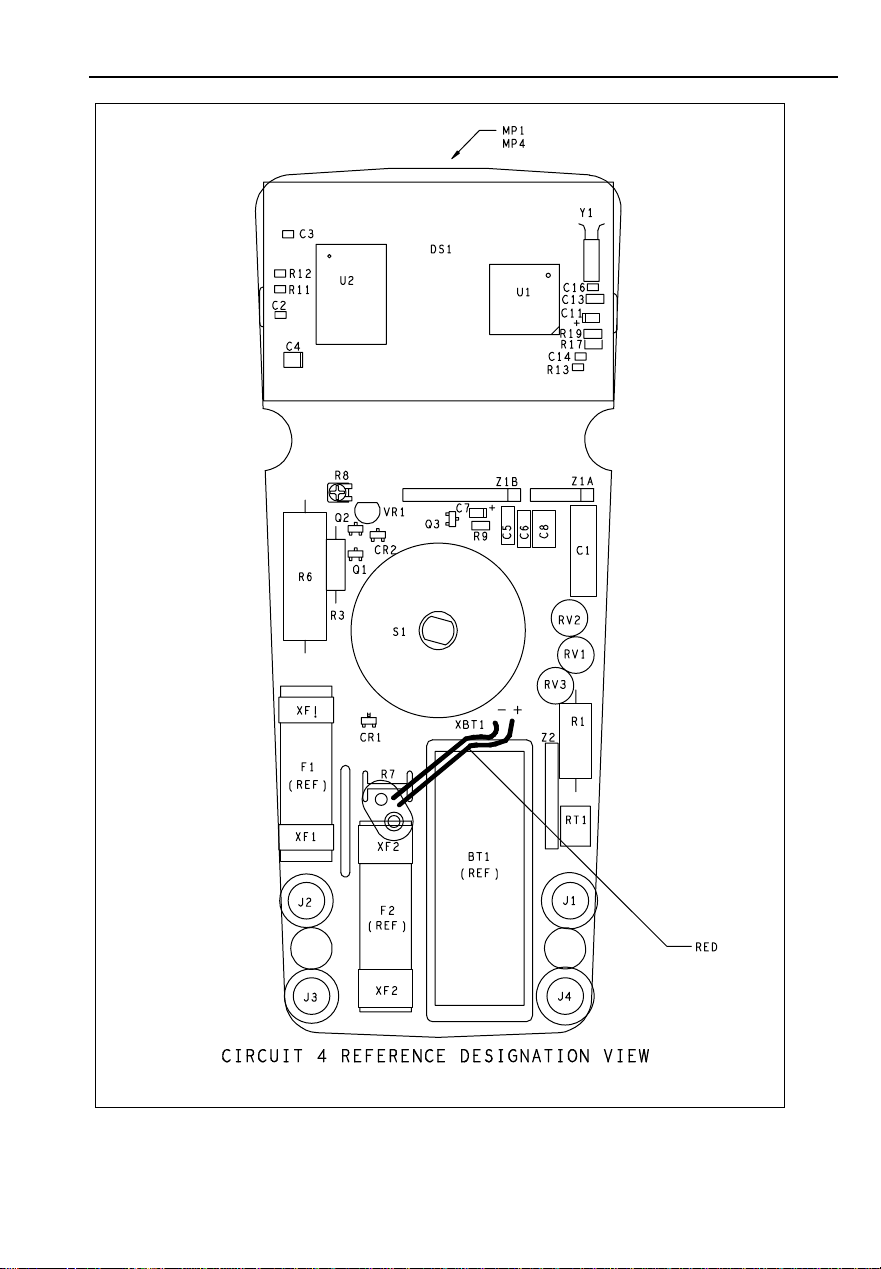

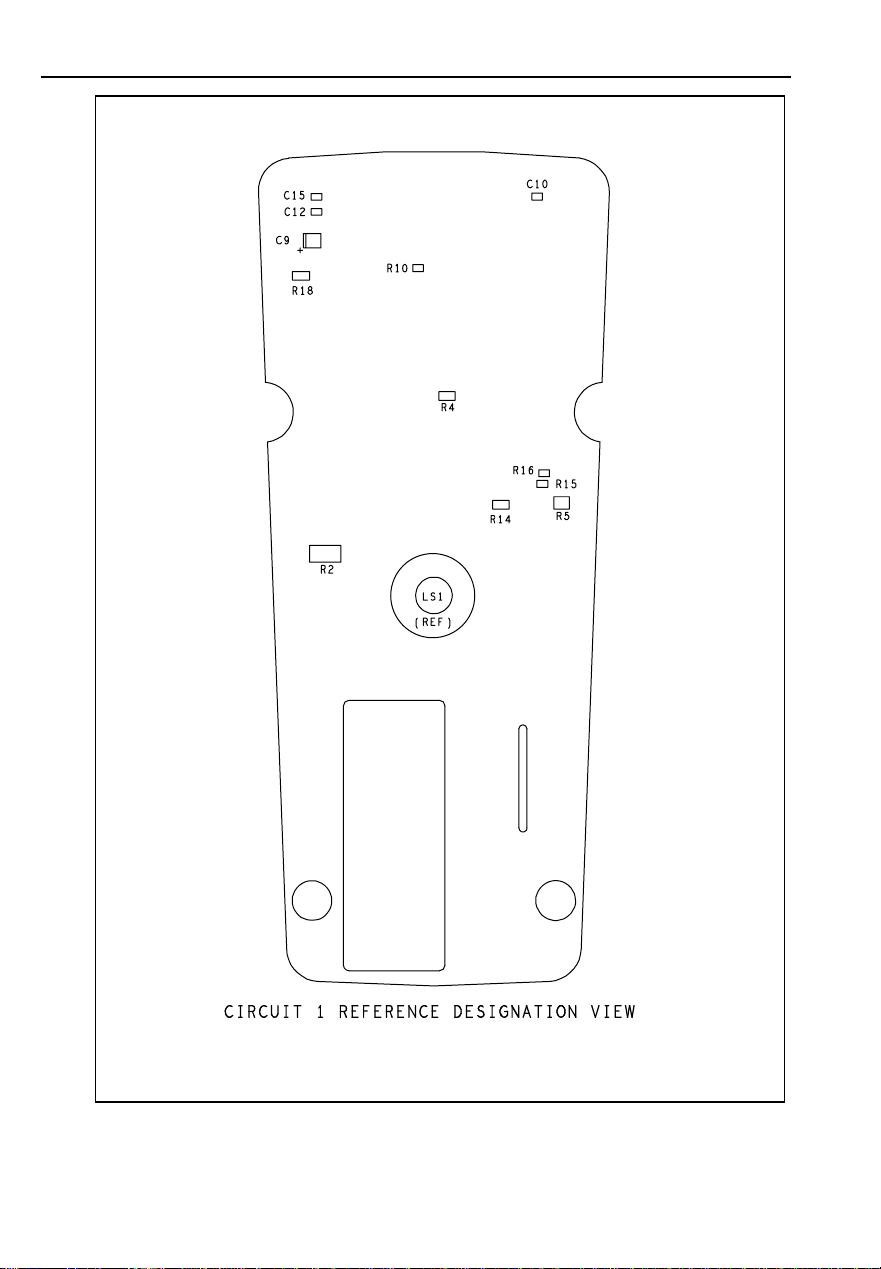

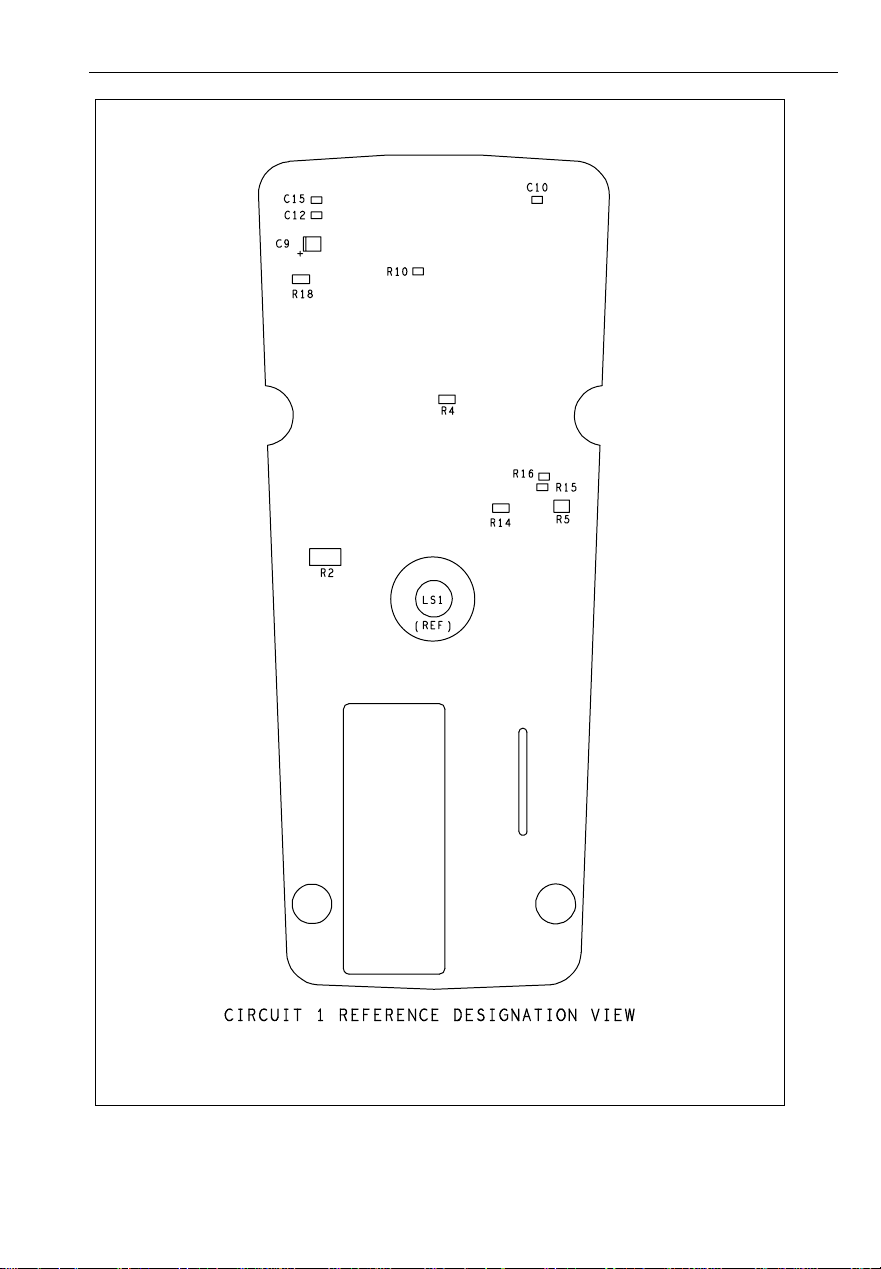

Table 4-2. A1 Main PCA

Ref Des Description PN Qty. Notes

C1 CAP,POLYES,0.0UF, ±10%,1000V 822361 1

C2,C3 CAP,CER,0.1UF, ±10%,25v,X7R 942529 2

C4 CAP,TA,2.2UF, ±20%,20V 854760 1

C5,C6 CAP,POLYCA,0.027UF, ±10%,63V 720979 2

C7 CAP,TA,0.47UF, ±20%,25V 876180 1

C8 CAP,POLYPR,0.033UF, ±10%,63V 721050 1

C9 CAP,TA,10UF, ±20%,10V,3528 603032 1

C10 CAP,CER,0.1UF, ±10%,25V,XR7 942529 1

C11 CAP,TA,2.2UF, ±20%,6V,3216 930248 1

C12 CAP,CER,47PF, ±5%,50V,C0G 494633 1

C13 CAP,CER,0.22UF,+80%,-20%,50V,Y5V 740597 1

C14,C15 CAP,CER,33PF, ±5%,50V,C0G 603172 1

C16 CAP,CER,47PF, ±5%,50V,COG 494633 1

CR1,CR2 * DIODE,SI,75V,250MA,SOT-23 830489 2

J1-4 RECEPTACLE,INPUT 658580 4

Q1,Q3 * XSTR,SI,NPN,25V,.3W,SEL,SOT-23 821637 2

Q2 * XSTR,SI,NPN,60V,350MW,SOT-23 742676 1

R1 RES,WW,3.5K, ±5%,5W,20PPM 107695 1

R2 RES,CERM,1K, ±5%,1W,200PPM 601176 1

R3 RES,CERM,1M, ±5%,1W 655175 1

R4 RES,CF,100K, ±1%,0.25W,100PPM 769802 1

R5 RES,MF,402K, ±0.25%,0.25W,50PPM 602664 1

R6 RES,WW,4.99, ±1%,5W 642923 1

R7 RES,WW,.005, ±1%,.5W 740415 1

R8 RES,VAR,CERM,100K, ±25% 912493 1

R9,R19 RES,CERM,1M, ±1%,0.125W,100PPM 836387 2

R10 RES,CERM,1.5M, ±1%,.1W,400PPM, 602703 1

R11,12 RES,MF,10K, ±1%,0.1W,100PPM 928791 2

R13 RES,MF,44.8K, ±0.25%,0.1W,50PPM 602679 1

R14 RES,CF,61.9K, ±1%,0.125W,100PPM 821330 1

R15 RES,MF,56.2K, ±1%,0.1W,100PPM 602687 1

R16 RES,MF,205K, ±1%,0.1W,100PPM 602935 1

R17 RES,CERM,20.5K, ±0.5%,100PPM 107711 1

R18 RES,CERM,9.2K, ±0.5%,100PPM 107745 1

RT1 THERMISTOR,POS,1.1K, ±+-20%,25 C 602995 1

RV1-,RV3 VARISTOR,910, ±+-10%,1.0MA 876193 3

S1 SWITCH,ROTARY 642918 1

U1 * IC CHIP 791269 1

U2 * IC, CMOS SM5A 603669 1

VR1 * IC, 1.23V,150 PPM T.C.,BANDGAP 634451 1

XBT1 BATTERY CONNECTOR 825976 1

XF1 CONTACT, FUSE 659524 2

4

4-7

Page 49

77 Series III

Service Manual

Ref Des Description PN Qty. Notes

XF2 CONTACT, FUSE 707190 2

Y1 CRYSTAL,32.768KHZ, ±+-1%,3 X 8MM 643031 1

Z1 * RNET,CERM,SIP,FLUKE 77 HI V DIV. 946202 1

Z2 * RNET,CERM,SIP, HI V PROTECT 103454 1

Table 4-2. A1 Main PCA (cont)

4-8

Page 50

List of Replaceable Parts

Parts Lists

4

Figure 4-2. A1 Main PCA

FLUKE 77-3-4001

aaa06f.eps

4-9

Page 51

77 Series III

Service Manual

4-10

FLUKE 77-3-4001

aaa07f.eps

Figure 4-2. A1 Main PCA (cont.)

Page 52

Chapter 5

Schematic Diagrams

5-1

Page 53

77 Series III

Service Manual

5-2

Page 54

Schematic Diagrams

Table 5-1. Abbreviations

Abbreviation Definition

ACA AC Converter Feedback

ACHI AC Converter High

ACL All Clear, Reset

ACLO AC Converter Low

AFI Active Filter Input

AFO Active Filter Output

AM0 Amp[s Input

AM1 Amps Divide by 10

AZ Auto Zero Point

BPR Beeper Driver

BT Battery

CLK Clock Output

COM Common

DCS DC Sense

EC Reference Voltage

FA0 Active Filter Amp Output

FA(-) Active Filter Amp Feedback

INT Integrator Oputput

K0 Buffer x 1 Output

K1 Buffer Divide by 3 Output

LS Loud Speaker

LO Low

OHS Ohms Sense

RNG Range

RRS Reference Resistor Sense

RT Thermistor

VSS Negative Supply Voltage

BDD Positive Supply Voltage

VM Volts Middle

WW Wirewound

XTL Crystal Oscillator Inputs

Z Impedance

5

5-3

Page 55

77 Series III

Service Manual

5-4

FLUKE 77-3-4001

aaa06f.eps

Figure 5-1. A1 Main PCA

Page 56

Schematic Diagrams

5

Figure. A1 Main PCA (cont)

FLUKE 77-3-4001

aaa07f.eps

5-5

Page 57

77 Series III

Service Manual

VOLTS/

COMMON

OHMS

MA

10A

Z2 1.0M

RT1

1.1K

J1

J2

J3

J4

LAST

USED

BT1

C15

CR2

DS1

F2

J4

LS1

Q3

RT1

RV3

S3

U2

VR1

Y1

Z2

20%

6MM 4MM

1000V

44/100A FAST

6MM

11A FAST

6MM

1000V

REFERENCE DESIGNATON

NOT USED

R2R19

TP2TP3

9

OHMS,DT,CONT

RV3

910V

R6

4.99

5W

WW

1.5MM

R2

1.0K

5%

402K

0.25W

S1

11 10

C1

0.01

2MM

1000V

M

S1

12

OHMS,VDC,MVDC

OHMS,DT

CONT,MVDC

S1

32

R5

0.25%

MF1000V

Q2

MMBT3904

VDD

R14

61.9K

CR2

BAS16

VR1

1.23V

2.7V

CAL

12

Z1

7

Q1

SEL

SEL

CW

C14

33PF

5%

Z1

10M

1.1M

101K

10K

1.0K

R4 100K

1%

R3 1.0M

5%

7

S1

VAC,VDC

8

Q3

R15

56.2K

0.1W

R16

205K

0.1W

R8

100K

25%

3

4

5

6

1W

2MM

R1

5%

3.5K

2MM

5W

WW

RV2

910V

1MM

RV1

910V

F1

F2

R7

.005

1%

0.5W

WW

1342

COM

19

20

10

21

11

30

31

32

33

34

35

36

37

18

12

29

42

24

22

0.25%

15

R1 3 44.8K

25

0.1W

MF

GUARD

GUARD

OHS

GUARD

GUARD

GUARD

V0

GUARD

V1

GUARD

V2

V3

V4

RRS

DCS

AM0

AMI

COM

LO

GUARD

13

MV

300MA

GUARD

GUARD

41

43

5-6

FLUKE 77-3-1001

aaa09f.eps

Figure 5-1. A1 Main PCA (cont)

Page 58

Y1

32.768KHZ

C12

47PF

5%

54 55 32488

XTAL1

XTAL2

C15

33PF

5%

TEST

LS1

BT1

9V

BPR

S1

96

CR1

BAS16

-VSS

+VDD

S1 S1

B0

465

Schematic Diagrams

5

TP1

VDD

6

6

S1

B1

C16

12

47PF

5%

4567

B3

B2

C13

0.22

20%

ON

MOHMS

3V,300K

30V,30K

300V,3K

1000V,300

MA,10A

AC

CONVERTER

AC*

AC*

ACA

C11

2.2

6V

U1

AP75

ANALOG

LOW

HIGH

AC

ACLO

PROCESSOR

OHMS

VOLTAGE

SOURCE

ACTIVE

FILTER INTEGRATOR

FILTER*

FA(-)

AFI

1.50M

0.1W

C5

R9 1.00M

.027

PC

63V

R10

FAO

C6

PC

63V

.027

INT

INT

AFO

OHMS

DT,OHMSV

ACAC

ACHI

1716 26 4645443928 2740 47

1.00MR19

0.5%

R17

20.5K

R18

9.20K

0.5%

C9

10

10V

OHMS

DE-INT

DE-INT

BUFFER

X1

K1

Z1

10

K0

9

225K

FUNCTION

CODE

X0.3

AZ

C7

0.47

25V

110K

8

NDAV

TO

DIGITAL

SECTION

INT

C8

.033

PP

63V

49

D3

50

D2

51

D1

52

D0

56

CLK

57

58

C0

59

C1

60

C2

1

C3

14

EC

COMPARATOR

RANGE

Figure 5-1. A1 Main PCA (cont)

FLUKE 77-3-1001

aaa10f.eps

5-7

Page 59

77 Series III

Service Manual

C2

0.1

25V

C4

2.2

20V

C3

0.1

25V

VDD

C10

0.1

25V

26

22

79

20

23

24

25

CK2

19

3

4

18

5

6

7

8

9

10

11

12

13

14

15

16

17

RESET

DDC

INTA

F

T

P00

P01

P02

P03

P10

P11

P12

P13

P20

P21

P22

P23

OSCIN

OSCOUT

S3S2S1

S0

30

S7S6S5S8S4

S9

S11

S12

31

34

33

S10

363735

60

5857385949

2

80

T1

VM

T2

VDD

VDD

VCC

U2

SMN3

S13

S14

S18

S17

S16

S15

S19

S20

S22

S21

5051535254555627632829

S23

S24

S27

S26

S25

S28

S29

S31

S30

39

43424445464847646566686769

S32

S33

S34

S35

S36

S37

78

H0

77

H1

GND

S39

S38

S40

S41

GND

71

72

747332

70

TP3

R12

10.0K

0.1W 0.1W

1

S2

2

R11

10.0K

2

HOLD

S3

1

3547681091112131514

BG1

BG5

BG3

S1 POSITIONS PROCEDING CLOCKWISE

FUNCTION

CODE*

FUNCTION B0 B1 B2

1 OFF - - 2 AC VOLTS 1 1 1

3 DC VOLTS 0 1 1

4 300 MVDC 0 0 0

5 OHMS 0 0 1

6 DIODE TEST/CONTINUITY 1 0 0

7 AC CURRENT 1 1 0

8 DC CURRENT 0 1 0

*1=VDD

0=COMMON

Figure 5-1. A1 Main PCA (cont)

BG7

BG9

BG11

BG13

BG15

BG17

2425272829303435333238

26

22

171618

BG19

BG21

BG31

BG25

BG23

BG29

BG27

M DESIGNATES MYLAR/POLYESTER FILM CAPACITOR

CER DESIGNATES CERAMIC CAPACITOR

TA DESIGNATES TANTALUM CAPACITOR

PP DESIGNATES POLYPROPYLENE CAPACITOR

PC DESIGNATES POLYCARBONATE CAPACITOR

WW DESIGNATES WIRE WOUND RESISTOR

MG DESIGNATES METAL GLAZE RESISTOR

MF DESIGNATES METAL FILM RESISTOR

CERM DESIGNATES CERMET FILM RESISTOR

4A

4C

MAN

AUTO

LCD-PANTHER

3D

DS1

3A

3E

2E

2A

2D

3B

3736402192139

202331

K

M

1E

1A

1D

AC

2B

+/-

4142

BT

HV

DC

H0H1

HOLD

FLUKE 77-3-1001

aaa11f.eps

5-8

Loading...

Loading...