Page 1

Electronics in your building

don’t like power problems

Lightning strikes,

power loss/generator testing,

utility problems

By Ron Auvil

In my role as a senior project technician I spend a lot of time

in buildings diagnosing problems. My responsibilities involve

electronic controls on HVAC equipment. I also try to help the

customer by diagnosing common problems with other

equipment, which might include telephone systems, elevators,

security equipment, and life safety systems.

Admittedly, while working on

problems with these various

systems I can be a little slow

to note a common denominator. But over a period of time

I have noticed something that

repeats itself over and over

again—problems due to power!

Approximately 25 to 35 percent

of the service calls I get are

related somehow to a power

issue of one type or another.

Application Note

Prevalence of electronics

It does not take a genius to

recognize that almost every major

subsystem in today’s commercial buildings has some type of

solid-state electronics package

installed. Virtually every HVAC

unit purchased today has an

electronics board in the control

panel. Ditto for security, fire,

and life-safety systems. Digital

telephone and computer network

systems are the same. Regardless of system type, the common

element is the electronics.

Another factor in this electronics equation is that there are

“old” electronics and “new” electronics. Some electronic systems

in today’s building equipment

were installed 20 or more years

ago, and are even more susceptible to problems.

All of the electronic systems

mentioned above can have

problems due to power. Many

electronics and device manufacturers will claim an amount

of tolerance to power problems.

Many will say that a fault due

to power “should not” happen.

Unfortunately the nice tech

support folks on the other end

of the telephone are not stuck

on an elevator or listening to

the fire alarms going off after a

thunderstorm.

Typical power scenarios

Anyone working in a field utilizing electronics in a building

should be able to easily recognize the scenarios that affect the

power to the electronics. These

scenarios typically are very

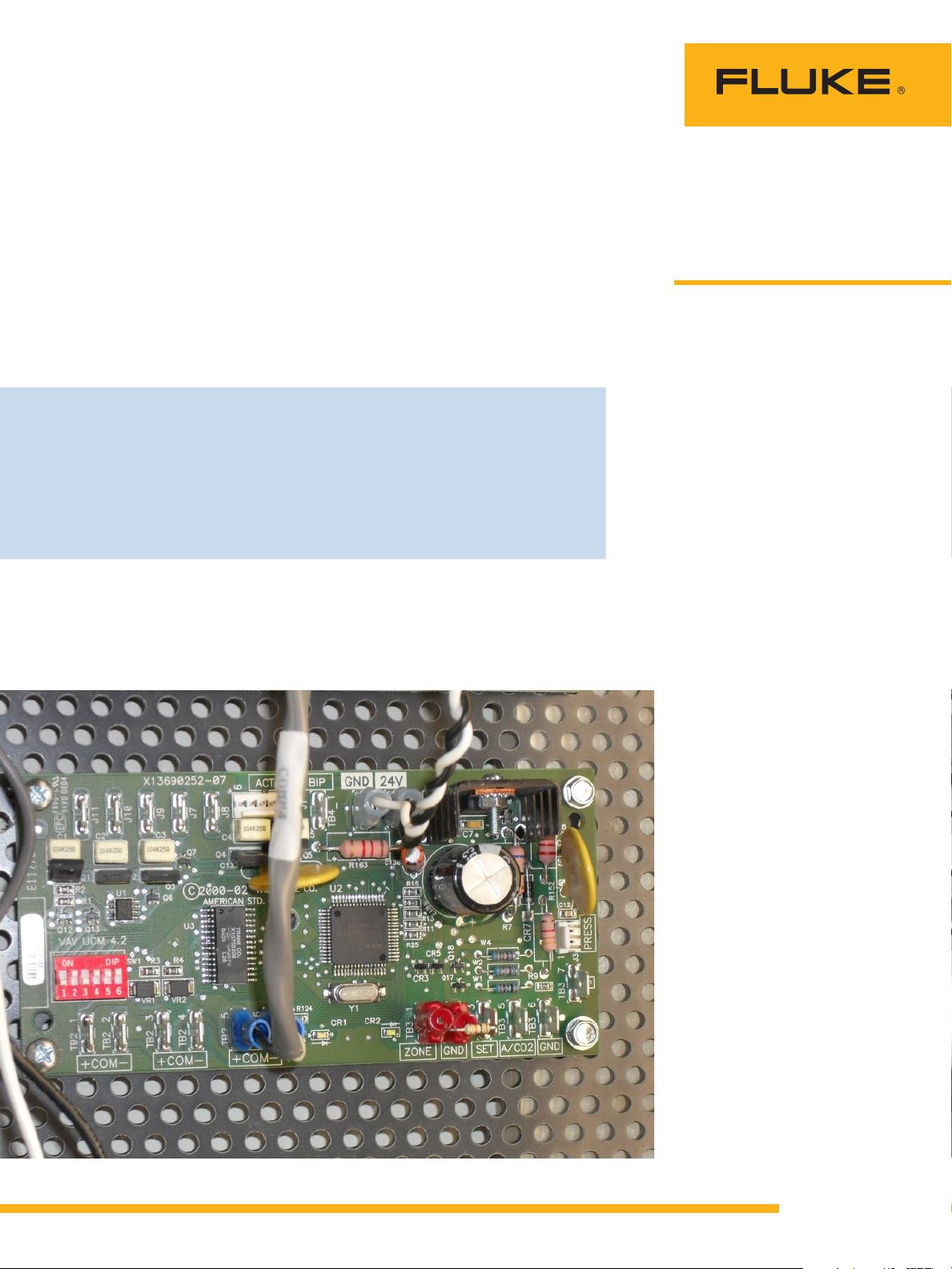

A communications card can be easily damaged by incoming power problems. Burn marks

on the electronics and a burning smell are indicators.

From the Fluke Digital Library @ www.fluke.com/library

repetitive in the building and in

some cases occur frequently.

Page 2

Lightning strike

One of the most common scenarios is a lightning strike. The

prevalence of this problem will

depend greatly on your location

and climate. I happen to live in

the southeastern United States,

which is famous for summer

thunderstorms in the afternoon.

My personal rule of thumb is

that after a thunderstorm moves

through I will get at least one

or two calls from a building that

are lightning-related. Sometimes

I can even watch weather radar

and know exactly which of my

buildings will be calling me.

Lightning can cause a whole

host of problems. Keep in mind

that a lot of the electronics,

especially HVAC equipment, are

located on the roof or outside

the building. This makes it even

more susceptible to lightning. If

lightning is the culprit, its effects

can be catastrophic. In many

cases the electronics are wiped

out, with visible burn marks and

a burned smell.

Moving the electronics, as

well as better lightning protection and grounding, can help.

If a computer program is

running on an electronic chip

in the device (EEPROM or Flash

ROM) it may be wiped clean by

the lightning strike and start

up “stupid”—not operate at all. I

have a building with old 1990s

electronics that have to be

reprogrammed after every major

thunderstorm. It is not uncommon, after a power problem, that

1 to 5 percent of the devices on

a building automation system

network do not communicate or

function properly.

Recently I received a call that

the fireman’s panel in a building was not functioning. This

building has suffered from many

power problems in the recent

past, usually one every two

weeks or so. The electronic controller in the panel had faulted

out and had to be replaced.

Obviously this was a critical

system. The electronic controller

was replaced and started up. It

worked for a few seconds and

then rebooted every 10 seconds.

An iFlex™ flexible cur rent probe is wrapped around the motor leads

at a variable speed drive so the c urrent can be measured with the

Fluke 381 Clamp Meter. This shows whether or not a variable speed

drive has been damaged by a lightning strike.

The incoming power was turning

on and off every 10 seconds.

I could hear a clicking noise

and traced it to an uninterrupt

ible power supply (UPS) in the

ceiling. The continuous power

problems had damaged the UPS

and caused it to cycle on and off.

If left as-is, the life safety panel

would not function properly

and the new controller would

be damaged. We had to replace

the damaged UPS as well. The

fireman’s panel then functioned

properly.

Power loss/generator

testing

Another problem is power loss.

There can be many causes of a

power loss, including utility prob

lems, maintenance lapses, device

surges, and others. Depending

on the condition that caused it,

an electronic device may not

recover properly after the power

is restored.

When a power loss occurs, the

backup generator will start after

a short time delay. I happen to

work in hospitals a lot, and by

code the backup generators have

to start within 10 seconds after

utility power loss. Also by code

the backup generators are tested

-

You can check the controller power supply voltage with a Flu ke 773

Milliamp Process Clamp Meter. Power problems can affec t the power

supply and cause the controller to ma lfunction or fail.

once per month. Important building electronic devices are on this

backup power circuit. Depending on the causes, there may be

power surges as well as voltage

and current problems as the

2 Fluke Corporation Electronics in your building don’t like power problems

Page 3

generators start. This may cause

electronic circuit problems. It is

not uncommon that one percent

of electronic devices have some

kind of problem after the generator test is performed.

If a system is critical a small

UPS is installed at the electronic

device power supply. In this way

the device does not really ever

see a power failure. Another

advantage of some UPS systems

is that they may also provide

some surge protection.

Summary

As we have seen, power problems have a bad effect on

electronic devices. To detect a

power problem, a technician will

first check out the power supply

to a device to make sure it is

functioning properly.

If left uncorrected, these

power problems will cause electronic devices to fail, which will

in turn cause critical building

systems to operate improperly.

Another time-tested technique

is to just reboot the device, usually by removing power until it is

completely off, then turning the

power on again.

Utility problems

A large number of problems with

electronic devices are due to the

power utility. These problems

can be more systemic, ongoing,

and difficult to solve. They are

also unique in that some utilities will not readily acknowledge

power problems. In the event

of continuous, repetitive power

problems with no apparent cause

such as lightning, suspect utility

problems.

In my experience, one of the

main indicators is the location

of the utility power feed. Some

of the utilities feed power to a

building from a substation that is

distant and has other large customers on it. A problem with one

or more customers on the same

power feed will show itself in

building power problems. Often

the different facilities will have

the same power problems and

symptoms.

If you suspect utility problems, the best solution may be

to install power quality measuring equipment at the building to

show what the problem is and

when it occurred. This is often

enough to go back to the utility and ask for an adjustment, or

even a reimbursement in some

cases.

3 Fluke Corporation Electronics in your building don’t like power problems

A technician checks the voltages at a centrifugal ch iller electronic

control panel. Tens of thousands of dollars in damage can occur due

to incoming power problems.

Fluke. The Most Trusted Tools

in the World.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2014 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 1/2014 6001599A_EN

Modification of this document is not permitted

without written permission from Fluke Corporation.

Loading...

Loading...