Page 1

Nuclear Associates

76-907 and 76-908

AAPM MRI Phantoms

March 2005

Manual No. 38616 Rev. 3

©2003, 2005 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies

Users Manual

Page 2

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

www.flukebiomedical.com/rms

Page 3

Table of Contents

Section 1: General Information................................................................................... 1-1

1.1 Introduction .................................................................................................. 1-1

1.2 Phantom Description.................................................................................... 1-1

1.2.1 3D Resolution and Slice (3DRAS) Phantom (Model 76-908) ................. 1-2

1.2.2 Uniformity and Linearity (UAL) Phantom (76-907).................................. 1-4

Section 2: Operations .................................................................................................. 2-1

2.1 Phantom Preparation................................................................................... 2-1

2.1.1 Signal Producing Solution ...................................................................... 2-1

2.1.2 Filling the Phantom................................................................................. 2-1

2.2 Preparation for Scanning ............................................................................. 2-2

2.2.1 Positioning the Phantom......................................................................... 2-2

2.2.2 Scanning Parameters............................................................................. 2-2

2.3 Tests with 3D Resolution and Slice (3DRAS) Phantom............................... 2-2

2.3.1 Resonance Frequency ........................................................................... 2-2

2.3.2 Signal-To-Noise Ratio ............................................................................ 2-3

2.3.3 High-Contrast Spatial Resolution ........................................................... 2-3

2.3.4 Slice Thickness ...................................................................................... 2-4

2.3.5 Slice Position and Separation................................................................. 2-4

2.3.6 Example Images..................................................................................... 2-5

2.4 Tests with Uniformity and Linearity (UAL) Phantom .................................. 2-10

2.4.1 Image Uniformity .................................................................................. 2-10

2.4.2 Spatial Linearity (Distortion) ................................................................. 2-10

2.4.3 Image Artifacts ..................................................................................... 2-11

2.4.4 Action Criteria....................................................................................... 2-12

2.4.5 Example Images................................................................................... 2-12

i

Page 4

(Blank page)

Page 5

General Information

Introduction

Section 1

General Information

1.1 Introduction

This user's manual describes a set of MRI phantoms that were manufactured based on the AAPM

recommendations and their use in measuring the MRI system performance. These phantoms were

designed to measure them conveniently and quickly. The AAPM recommended image parameters

described in this document are:

• Image uniformity

• Resonance frequency

• Slice position/separation

• Spatial linearity

• Phase related image artifacts

• Signal-to-noise

• Slice thickness

• Spatial resolution

This set of parameters is measured for monitoring the sensitivity and geometric characteristics of MR

imaging clinical systems as specified in the AAPM document.

1

Two phantoms were designed to meet the AAPM specifications. This manual describes a set of test

procedures associated with the phantoms that can be used to evaluate the performance of clinical

magnetic resonance imaging systems. These procedures and tests, which are described in the AAPM

document, can be used to establish absolute performance standards as well as routine quality assurance

programs.

The manual does not include procedures to measure any T1, T2, or proton density, because at the

present time there are no commonly accepted standard methods for determining T1, T2, and proton

density from image data and because the assessment of these parameters is not currently a part of

clinical practice.

1.2 Phantom Description

AAPM specifications provide a framework of requirements for MRI phantoms and their use, but it defines

neither how phantoms should be constructed nor how inserts are to be organized. The AAPM MR

Phantoms take into consideration a number of factors that maximize convenience and time efficiency for

the user. The phantoms were designed to provide maximum amount of information in a reproducible

manner with the shortest data acquisition time.

The set consists of two phantoms: a three dimensional resolution and slice (3DRAS) phantom and an

uniformity and linearity (UAL) phantom

1-1

Page 6

Nuclear Associates 76-908 & 76-907

Operators Manual

1.2.1 3D Resolution and Slice (3DRAS) Phantom (Model 76-908)

The 3DRAS phantom has outer dimensions of 6" x 6" x 5" (Figure 1-1). Six resolution inserts and slice

thickness 4 ramp sets were placed inside of the rectangular box to allow image acquisition in any one of

the three directions (sagital, coronal, and transaxial) without repositioning the phantom.

Outer Shape 6" X 6" X 5" Cubical Box

Figure 1-1. 3DRAS Phantom

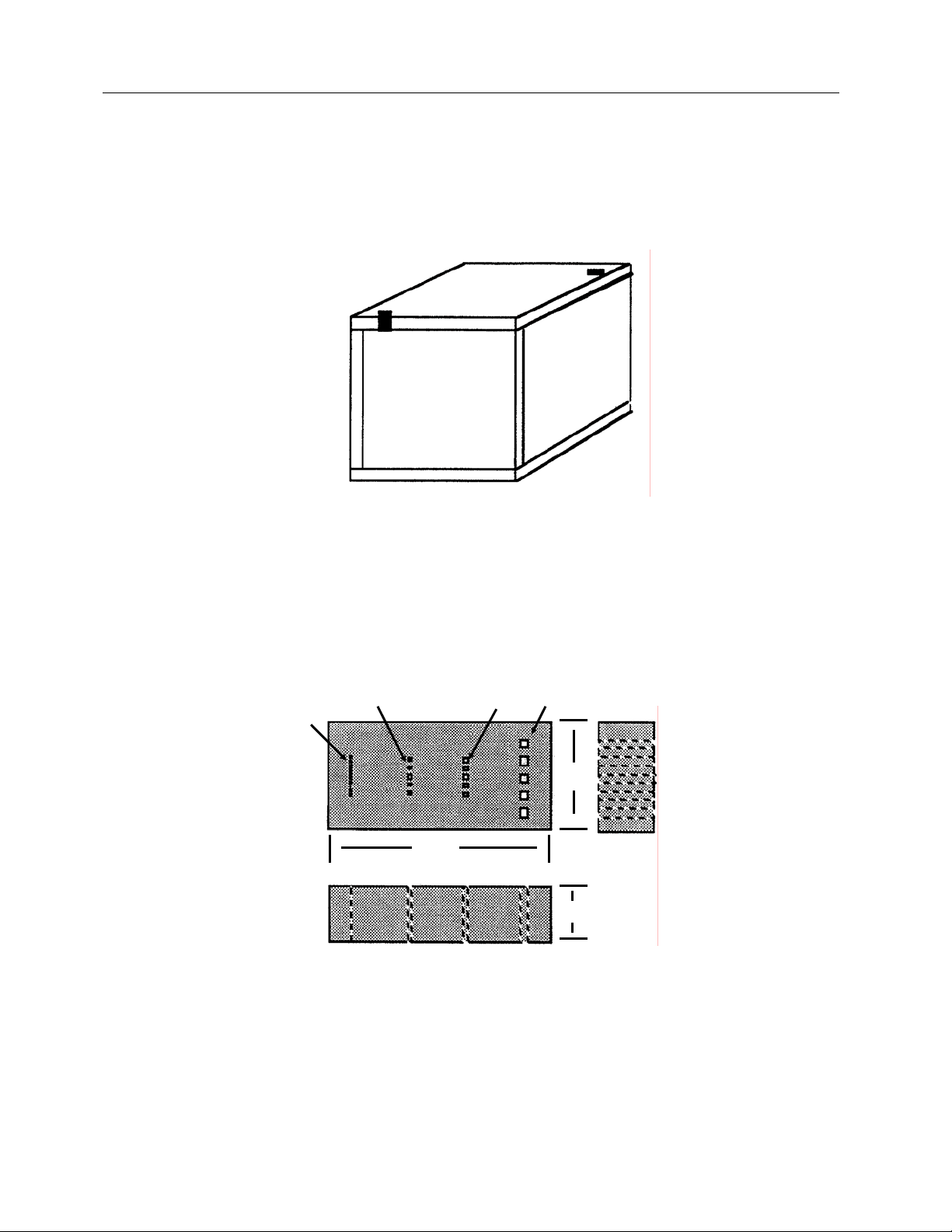

The resolution section (Figure 1-2) has square holes of 0.5 mm, 0.75 mm, 1.0 mm and 2.0 mm side

dimensions. The spacing between the holes is equal to their side dimensions. The holes are precisely

parallel to each other and are ¾” long. Square holes are used rather than drilled cylindrical holes because

square holes can be manufactured more precisely than cylindrical holes.

Resolution Block Detail - 2 Required

A set of two resolution sections are positioned perpendicular to each other (Figure 1-3) in three imaging

planes (sagital, coronal, and transaxial). Two sections are used per imaging plane since the spatial

resolution of MR images can be asymmetric between the encoding and frequency (read-out) direction.

0.5 x 0.5 mm

0.75 x 0.75 mm

Figure 1-2. Resolution Block Detail

1.0 x 1.0 mm 2.0 x 2.0 mm

1”

2 ¼ “

”

Not to scale

1-2

Page 7

General Information

p

Phantom Description

#1

1

#4

1 mm Gap

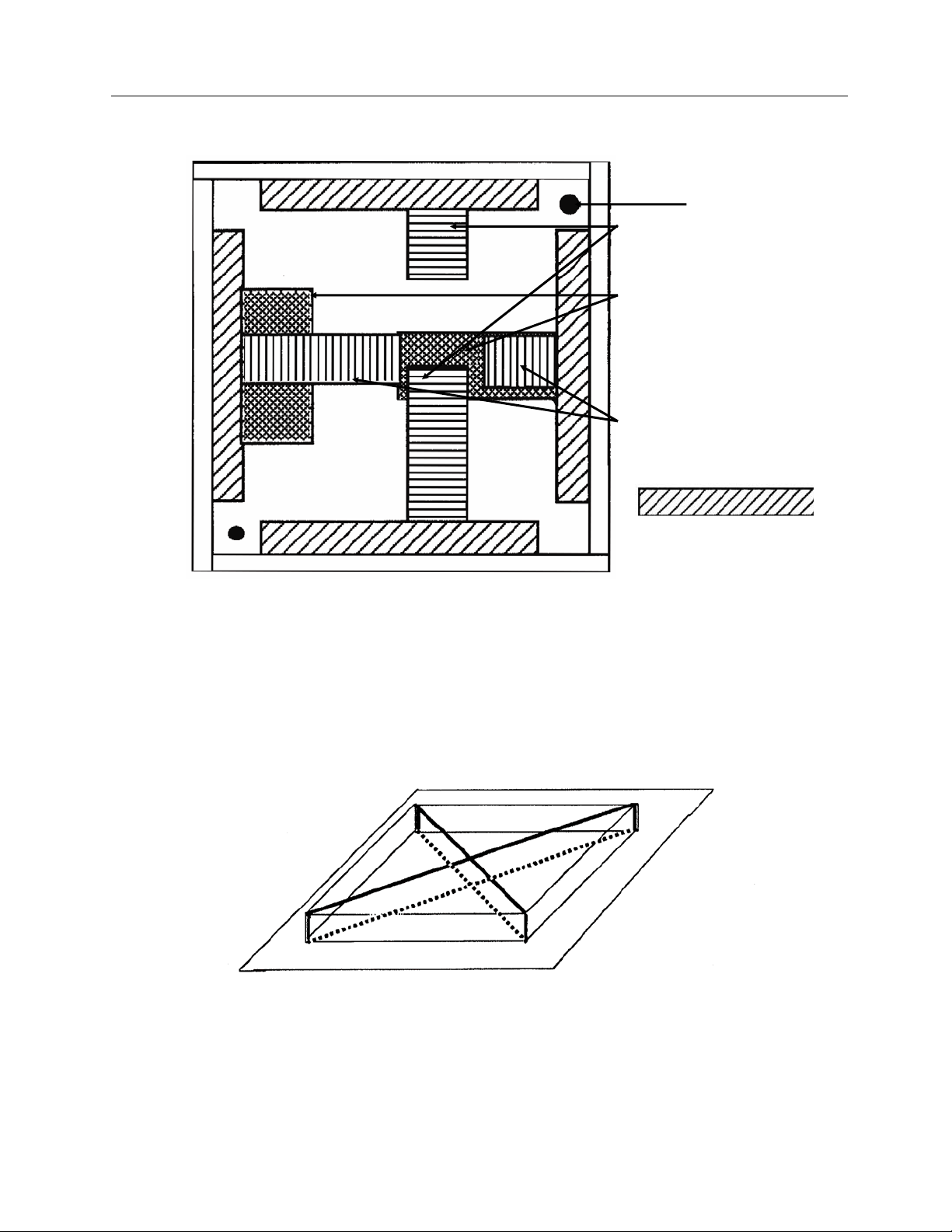

Box Dimension of the Box 6: x 6:

Walls are Made with ¼” Material

2 mm Gap

1 mm Ga

#3

Filling Hole ( ¼”)

Resolution Block

Resolution Blocks

#2

2 mm Gap

Resolution Blocks

w/Vertical Holes

Slice Thickness

Block Groups (4)

Figure 1-3. Resolution Sections in Three Imaging Planes

The slice-thickness phantom consists of two crossed thin ramps (Figure 1-4).

Figure 1-4. Slice Thickness Phantom

Triangular blocks make 4" x 4" square with diagonal gaps of 1 or 2 mm. Four triangular blocks are glued

with 1 mm or 2 mm gap.

1-3

Page 8

Nuclear Associates 76-908 & 76-907

Operators Manual

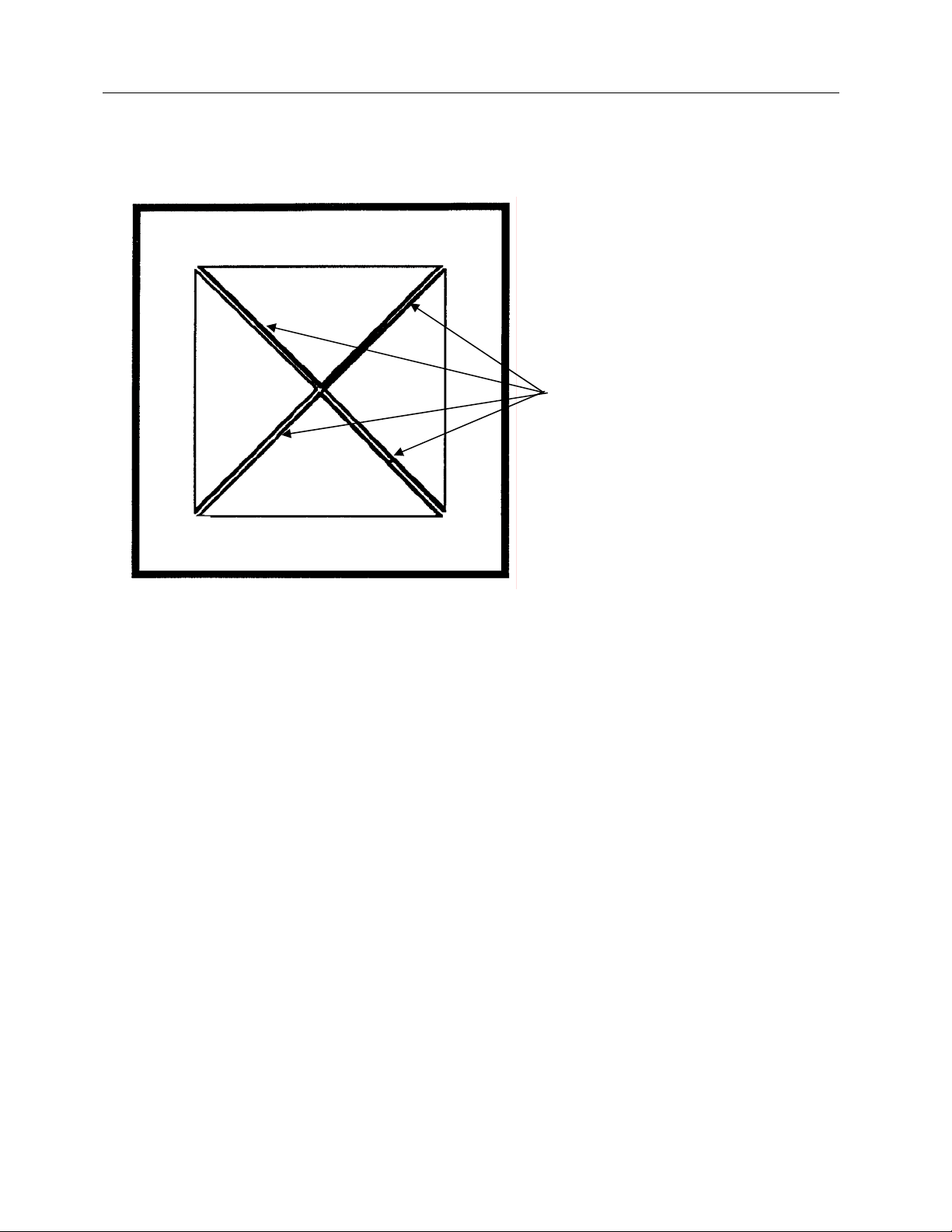

A ramp-crossing angle of 90° yields an angle of 45° between the ramp and the imaging slice plane. Each

slice thickness section consists of four triangular blocks arranged to form (signal producing) hot ramps

filling the gaps of 1 mm or 2 mm (Figure 1-5).

Slice Thickness Measurement Gaps

Gaps are 1 mm or 2 mm Throughout

Figure 1-5. Slice Thickness Sections

The ramps of the 1 mm gaps (forming diagonal lines) are glued at the opposite side inner wall of the

3DRAS phantom. Two sets of ramp sections are included in the phantom in order to allow the slice

thickness measurements in all three dimensions.

In a single multi-slice scan, the user can obtain images for signal-to-noise ratio, resolution in two

directions, slice thickness, and slice-to-slice gap.

1.2.2 Uniformity and Linearity (UAL) Phantom (76-907)

The UAL phantom has outer dimensions of 13" x 13" x 4" (Figure 1-6) with a small bubble (Figure 1-7)

filled with a solution attached on the surface of the phantom. A rectangular shape was adopted for ease

of reproducible positioning. Two parts of the phantom, flood and grid, are incorporated into one.

1-4

Page 9

General Information

Phantom Description

MR Phantom for Spatial Linearity, Signal-To-Noise, and Image Artifact

1

Glue

13”

Glue

13”

Figure 1-6. UAL Phantom

Glue

Linearity Grid, Light Cover

Glue,

Glue

MRI Phantom for Spatial Linearity, Signal-To-Noise, and Image Artifact

Glue

Glue

Glue

13”

Glue

4”

Figure 1- 7. UAL Phantom with Side View

Glue

Glue

1”

Flood Section

Two Grids Stacked

Glue

3/16” Wall

¼” Wall

Not to Scale

Not To Scale

1-5

Page 10

Nuclear Associates 76-908 & 76-907

Operators Manual

The flood phantom has a uniform solution, the image of which can be used to measure the uniformity in

signal intensity in the images. The grid section consists of grids that can be used to assess geometric

linearity.

A small pancake shaped container holding producing solution is attached on the diagonal surface of the

phantom. It is used to detect phase errors.

1-6

Page 11

Operation

Phantom Preparation

2

Section 2

Operation

2.1 Phantom Preparation

The phantoms can be shipped filled with solutions or solutions can be shipped separately. Each user can

also prepare a solution.

2.1.1 Signal Producing Solution

At each operating field strength, AAPM recommends that the chosen NMR material should exhibit the

following characteristics:

100 msec < T1 < 1200 msec

400 msec > T2 > 50 msec

proton density = H

One of the following solutions is suggested as a signal producing solution. It should be noted that

relaxation times are both temperature and field strength dependent. The relaxation rates (inverse of

relaxation times) are approximately linear with ion concentration.

O density

2

Agent Concentration T1 T2

CuS0

4

NiC

12

Propanediol 0-100% 2134-217 msec 485-72 msec

MnC

12

1-2SmM 860-40 msec 625-38 msec

1-25mM 806-59 msec 763-66 msec

0.1-1mM 982-132 msec --

2.1.2 Filling the Phantom

Degassed water should be used to make MR solution. Water can be degassed by boiling and cooling.

The following amount of water should be prepared:

Cubical Phantom: 4,000 cc/4 liters

Flood Phantom: 12,000 cc/12 liters

Once the solution has been prepared, it is recommended that several drops of wetting agent be added to

reduce surface tension and that some hydrochloric acid be added as a fungicide. As the solution is

poured into the phantom one should watch for air bubbles, especially any trapped in the resolution

section. It is recommended that the phantom be placed in a vacuum chamber for several hours to remove

the trapped bubbles.

2-1

Page 12

Nuclear Associates 76-908 & 76-907

Operators Manual

2.2 Preparation for Scanning

2.2.1 Positioning the Phantom

The 3DRAS phantom can be placed in a head coil or a body coil. The center of the phantom should

coincide approximately with the center of the RF coil. The UAL phantom can be used only with a body

coil.

2.2.2 Scanning Parameters

For all measurements, scan conditions should be carefully recorded. Scan conditions records should

include:

• Any image processing which may have been used

• Field-of-view or zoom factor

• Image matrix size

• Imaging coil

• Number of signal (excitation) acquisitions

• Phantom and phantom material

• Pulse sequence name or code and software version number

• RF power settings

• Scan timing parameters (TE, TI, TR)

• Slice excitation order

• Slice number and thickness

• Tuning parameters

2.3 Tests with 3D Resolution and Slice (3DRAS) Phantom

2.3.1 Resonance Frequency

Resonance frequency is defined as that RF frequency (f) which matches the static B-field (Bo) according

to the Larmor equation. For protons, the Larmor frequency is 42.58 MHz/Tesla, e.g., for a 1.5 Tesla

system, the resonance frequency should be 63.87 MHz.

Prior to the performance of any imaging protocol, the resonance frequency must be checked first.

Changes in the resonance frequency reflect changes in the static magnetic field (B-field). Changes in the

B-field may be due to superconductor "run down" (typically on the order of 1 ppm/day, e.g., about 60

Hz/day at 1.5 Tesla), changes in current density due to thermal or mechanical effects, shim-coil changes,

or effects due to external ferromagnetic materials.

The effects of off-resonance operation relate primarily to a reduction in image signal-to-noise. Secondary

effects are reflected in image linearity due to the summation of the image gradients with the inconsistent

static B-field value.

It is recommended that a resonance frequency check be performed prior to any measurements and each

time a different phantom is used.

The phantom is positioned in the center of the magnet (with all gradient fields turned off) and the RF

frequency is adjusted by controlling the RF synthesizer center frequency to achieve maximum signal.

Some resistive systems may also allow adjustment of the magnet current in order to alter the magnetic

field strength so as to achieve resonance. Most vendors will provide a specific user protocol for

2-2

Page 13

Operation

Tests with 3D Resolution and Slice (3DRAS) Phantom

resonance frequency adjustment and some may be completely automated. Resonance frequency should

be recorded daily for trend analysis.

Values of resonance frequency should generally not deviate by more than 50 ppm between successive

daily measurements.

2

2.3.2 Signal-To-Noise Ratio

The signal is defined as the mean pixel value within the region-of-interest minus any pixel offset. Noise is

defined as the random variations in pixel intensity. Images with obvious artifacts are not suitable for

signal-to-noise ratio (SNR) determinations.

Factors contributing to variations in signal-to-noise include:

(I) General system calibration (resonance frequency, flip angles)

(2) Slice thickness

(3) Coil tuning

(4) RF shielding

(5) Coil loading

(6) Image processing

(7) Scan parameters (TR, TE)

(8) T-1 and T-2 solution values

When using large volume fluid-filled phantoms, it should be recognized that thermal and mechanically

induced motions can introduce artifacts. The unloaded coil allows the evaluation of system noise that is

the parameter of interest. In a clinical scan, it is recognized that the patient is the dominant source of

noise. In order to approximate the clinical situation, the coil must be electrically loaded by using an

appropriate filler material.

The signal is measured using a ROI that contains at least 100 pixels or 10% of the area of the signal

producing material, whichever is greater. The ROI should be positioned in the center of the image and

should not include any obvious artifacts. The signal is the mean value of the pixel intensity in the ROI

minus any offset. (An indication of the existence of an image intensity offset may be gained from an

examination of intensity values from ROl's taken over non-signal producing portions of a phantom.

Specific offset values should be obtained from the system manufacturer). The noise is the standard

deviation derived from the same ROI. The signal-to-noise ratio is then calculated.

2.3.3 High-Contrast Spatial Resolution

High contrast spatial resolution is a measure of the capacity of an imaging system to show separation of

objects when there is no significant noise contribution. High contrast spatial resolution for MRI systems is

typically limited by pixel size (field-of-view divided by the sampling in x or y). Traditionally, resolution has

been quantified by the point spread function (PSF), line spread function (LSF), or modulation transfer

function (MTF); however, these methods are not practical for routine measurements. Therefore, a visual

evaluation of test objects is used.

Factors contributing to high-contrast resolution include:

• Field-of-view (determined by gradient strength, acquisition matrix, sampling period), and image

reconstruction and display method.

• The image will be evaluated visually. Image analysis consists of viewing the image to determine the

smallest resolvable hole array (magnification may be used if desired). For an array to be resolved, all

holes and spaces must be displayed as separate and distinct then viewed with the narrowest window

width. The window level should be adjusted for optimum visualization.

2-3

Page 14

Nuclear Associates 76-908 & 76-907

Operators Manual

• The high contrast resolution should remain constant for repeated measurements under the same

scan conditions and should be equal to the pixel size. For example, for a 25.6 cm field of view with a

256 x 256 acquisitions matrix, the resolution should be 1 mm.

2.3.4 Slice Thickness

Slice thickness is defined as the full width at half maximum (FWHM) of a slice profile. The full width at

tenth maximum (FWTM) is an additional descriptor of the slice profile. The slice profile is defined as the

response of the magnetic resonance imaging system to a point source as it moves through the plane of

the reconstruction at that point.

Factors Affecting Slice Thickness include the following:

(1) Gradient field non-uniformity

(2) RF field non-uniformity

(3) Non-uniform static magnetic field,

(4) Non-coplanar slice selection pulses between excitation and readout gradient

(5) TR/T1 ratio

(6) RF pulse shape and stimulated echoes

Any typical multi-slice acquisition may be used provided TR is greater than 3T1 of the filler material and

the highest pixel resolution is used. Slice thickness should be measured both centrally and peripherally

within an image and at both central (magnet isocenter) and offset slice locations.

High signal ramps (HSR) at 90 degrees to each other are used for slice thickness measurement. The

ramps have 1 mm gaps on one side and 2 mm gaps on the opposite side

Slice thickness (FWHM, FWTM):

In the resultant image, the signal level is read out across the ramp on a pixel-by-pixel basis along a lineof-interest oriented orthogonally to the ramp width dimension. As noted previously, to assure adequate

S/N, it may be necessary to either use multiple excitations or several line profiles. The FWHM or FWTM

parameters should be determined for each of the dual ramps. The FWHM from imaging opposed high

signal ramps oriented at a 45 degree angle with respect to the image plane is equal to the square root of

the product of a and b where a and b are the FWHM of the intensity profile of ramps I and 2.

Assuring adequate measurement accuracy, the measured value of slice thickness should generally agree

with the indicated slice thickness within the 1 mm for slice thicknesses greater than 5 mm.

2.3.5 Slice Position and Separation

Slice position is the absolute location of the midpoint of the FWHM of the slice profile. Slice separation is

the distance between any two-slice positions. Slice locations are indicated by external positioning devices

or by the selected inter-slice spacing.

Factors Affecting Slice Position/Separation

(1) Misalignment of positioning devices

(2) Gradient field non-uniformity

(3) B-1 non-uniformity

(4) Non-coplanar slice selection pulses

(5) Static magnetic field

The midpoint of the FWHM of the slice profile in the image of interest is determined. The distance from

the profile midpoint to a landmark that remains stationary from slice-to-slice (parallel to the slice selection

2-4

Page 15

Operation

Tests with 3D Resolution and Slice (3DRAS) Phantom

direction) is measured and related to the slice position. For a 45° ramp, the distance from a centered

reference pin to the slice profile midpoint will be equal to the point of the ramps located at the isocenter.

All measurements should be made along the line made up of the magnet isocenter and the centers of the

imaging planes.

Comparison of external position marker should generally agree with the actual slice position within +2

mm. Slice separation disagreement should typically be less than 20% of the total slice separation or

whichever is greater.

2

2.3.6 Example Images

Figures 2-1 through 2-12 represent examples of images obtained using the phantom in a 1.5 T MR

system.

Figure 2-1 is an axial image with imaging parameters of TR=60 msec, TE=22 msec and slice thickness of

3 mm. This axial image from a body coil shows resolution holes of 2 mm, 1 mm, and 0.75 mm well

resolved. There are two sets of holes shown in vertical and horizontal directions. The resolution image

can be viewed in a zoom mode. Thin vertical lines from the resolution pin within two black blocks are

placed in other orientations and have no meaning in axial orientation.

Figure 2-1.

On the right and left-hand sides of the phantom image two sets of horizontal short lines are shown. They

represent the slice thickness image of hot ramps sandwiched between two cold ramps. The thinner set is

from the 1 mm ramp and the thicker set comes from the 2 mm ramp. A set of two crossed ramps are used

as shown in Figure 1-4.

It should also be noted that the gap between the slice thickness lines on the left side of the figure is larger

than that on the right, indicating that the phantoms were not placed properly in the MRI system. In a

proper setting the gaps should be identical on both sides.

2-5

Page 16

Nuclear Associates 76-908 & 76-907

Operators Manual

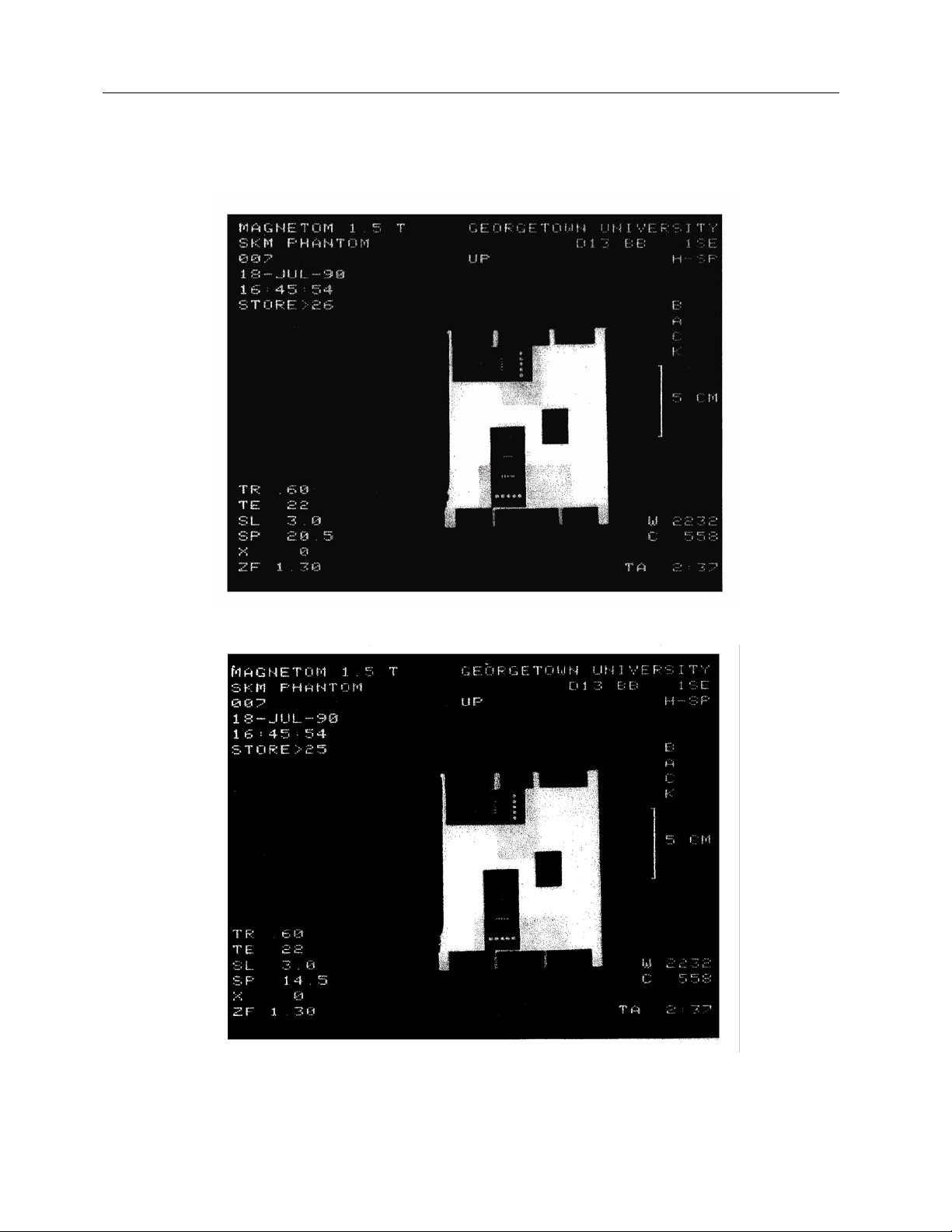

Figures 2-2 and 2-3 represent two adjacent sagital views of the phantom. The resolution holes are well

resolved in vertical and horizontal direction and the two slices are 6 mm apart (SP = 14.5 and 20.5). The

slice thickness images of short vertical lines on top and bottom of the phantom image again are from the

crossed hot ramps of 2 mm (top) and 1 mm (bottom).

Figure 2-2.

Figure 2-3.

2-6

Page 17

Operation

Tests with 3D Resolution and Slice (3DRAS) Phantom

Figures 2-4 and 2-5 show two adjacent coronal views of the phantom. The slice thickness lines of 1 mm

ramps on the right and bottom of the images are too faint to be seen.

Figure 2-4.

Figure 2-5

2

2-7

Page 18

Nuclear Associates 76-908 & 76-907

Operators Manual

Figure 2-6 shows a resolution hole image against a background less opaque than in previous images,

indicating that the position of the resolution block is such that it is partially covered by the slice. For

resolution measure, it is advised to use a slice that covers the central portion of the slice hole section.

Figure 2-6

2-8

Page 19

Operation

Tests with 3D Resolution and Slice (3DRAS) Phantom

Figures 2-7 and 2-8 show an example of the slice thickness measurement analysis. A signal intensity

profile is drawn vertically through a set of slice thickness ramp Images. The profile is the slice thickness

profile. One can also obtain the slice thickness by measuring full width half maximum of the profile. Figure

2-8 represents the same data using a larger zoom factor.

Figure 2-7.

Figure 2-8

2

2-9

Page 20

Nuclear Associates 76-908 & 76-907

Operators Manual

2.4 Tests With Uniformity and Linearity (UAL) Phantom

2.4.1 Image Uniformity

Image uniformity refers to the ability of the MR imaging system to produce a constant signal response

throughout the scanned volume when the object being imaged has homogeneous MR characteristics.

Factors Affecting Image Uniformity include:

(1) Static-field inhomogeneities

(2) RF field non-uniformity

(3) Eddy currents

(4) Gradient pulse calibration

(5) Image processing

Any typical multi-slice acquisition may be used provided the signal-to-noise ratio is sufficiently large so

that it does not affect the uniformity measurement. Adequate signal-to-noise may be insured by either

increasing the number of acquisitions (NEX) or by applying a low-pass smoothing filter. In practice, it has

been found that a signal-to-noise ratio of 80:1 or greater will yield good results.

For pixels within a centered geometric area that encloses approximately 75% of the phantom area, the

maximum (S max) and minimum (S min) values are determined. Care should be taken to not include

edge artifacts in the ROI.

A range (R) and mid-range value S are calculated as follows:

R = (S max- S min) /2

S = (S max+ S min) / 2

The relationship for calculating integral uniformity (U) is:

U = (1 – (R/S)) x 100%

Perfect integral uniformity using this relationship is when U = 100%

In some cases (e.g., low-field imaging) signal-to-noise may be a limiting factor in the measurement of

image uniformity. To help minimize the effect of noise on the measurement the image may be convolved

with a 9-point low-pass filter.

For a 20 cm field-of-view or less, the uniformity should be typically 80% or better. It should be realized

that for larger fields-of-view, the uniformity may diminish. Image uniformity in the above context is not

defined for surface coils.

SNR results are only applicable to the specific system, phantom and scan conditions. It is important to reemphasize that the signal and noise measurements are dependent on essentially all scan parameters

and test conditions. SNR should be normalized to voxel size for comparison.

2.4.2 Spatial Linearity (Distortion)

Spatial linearity describes the degree of geometrical distortion present in images produced by any

imaging system. Geometrical distortion can refer to either displacement of displayed points within an

image relative to their known location, or improper scaling of the distance between points anywhere within

the image.

The primary factors that introduce geometrical distortion in MR imaging are:

(1) Inhomogeneity of the main magnetic field

2-10

Page 21

Operation

Tests with Uniformity and Linearity (UAL) Phantom

(2) Non-linear magnetic field gradients

Variability is best observed over the largest field-of-view. The phantom should occupy at least 60% of the

largest field-of-view. Figure 1-1 provides an illustration of a pattern that is used to evaluate spatial

linearity.

Consideration should be given to determining the spatial linearity for a typical multi-slice acquisition with

the largest available image matrix to maximize spatial resolution. Since NMR imaging is inherently a

volumetric imaging technique, the evaluation should be performed for each orthogonal plane to define the

useful imaging volume. Spatial linearity is not expected to depend significantly on image timing

parameters such as TE, TR, and the number of signal acquisitions.

Percent distortion = (true dimension -observed dimension) / true) x 100%

Distortion measurement may be performed between any two points within the field-of-view, provided that

pixel-resolution is not a significant source of error. It is recommended that the true dimension be greater

than 10 pixels. Spatial linearity measurements performed directly on the image-processing unit will

provide information only about the MR imaging system. Measurements can also be performed upon

filmed images and will provide combined performance information about the MR imager, as well as the

video and filming systems.

Percent distortions in the linearity are generally acceptable if they are less than 5%.

2

2.4.3 Image Artifacts

Phase related errors are defined in terms of inappropriate (either increased or decreased) image signal at

specified spatial locations. Generally, these artifacts are characterized by increased signal intensity in

areas that are known to contain no signal producing material. Commonly called "ghosts," the application

of phase-encoding gradients for imaging and errors in both RF transmit and receive quadrature phase,

result in unique ghost artifacts. A "DC-offset" error is defined here as high-intensity or low-intensity pixels

at the center of the image matrix due to improper scaling of low-frequency components (typically DC) in

the Fourier transformation of the NMR time domain signal.

(1) Phase encoding gradient instability

(2) Quadrature phase maladjustment in the synthesis of slice selective RF pulses (transmit error)

(3) Improper quadrature phase decoding on receive

Any typical multi-slice sequence may be used. Separate scans must be made to assess both transmit and

receive errors if a phantom similar to the phantom in Figure 1-5 is used. More complex volume phantoms

may be designed which both transmit and receive errors and may be assessed with a single scan

sequence. The scan for assessing receive quadrature errors is made with the phantom placed at the

magnet isocenter with the central slice of the multi-slice sequence passing through the phantom. The

same scan may be used to assess both DC-offset and phase encoding errors. The scan for assessing

transmit quadrature errors is made with the phantom placed at a convenient offset slice position (typically

either + or - S cm from the isocenter slice) with the center slice passing through the magnet isocenter and

an offset slice passing through the phantom.

Phase Encoding Errors: Phase-encoding ghosts will appear as multiple images (possibly smeared into a

column) originating at the true object position but displaced along the phase-encoding axis of the image

(perpendicular to the frequency encoding direction). The presence of these characteristic ghost images

will generally identify the two axes; however, the orientations should be verified by the manufacturer or

the operator’s manual. Regions-of-interests values are taken from both the true image and the brightest

ghost image. The magnitude of the error (E) is quantified by expressing the ghost ROI value (G) as a

percent of the true ROI (T):

E = ((T-G)/T) x 100%

2-11

Page 22

Nuclear Associates 76-908 & 76-907

Operators Manual

DC-Offset Errors

DC-offset errors typically appear as a single bright pixel (sometimes as a dark pixel if overflow or

processing has occurred) at the center of the image matrix. The existence of this error is assessed

visually.

Receive Quadrature Errors

Receive quadrature ghosts will be evaluated using the central slice of the multi-slice sequence acquired

with the phantom at the isocenter. Receive ghosts will appear upside down and reversed from the true

signal producing objects (object in the upper left-hand corner will appear as a ghost in the lower righthand corner). Regions-of-interest values are taken from both the true image and the ghost image. The

receive Quadrature Error (E) is quantified by expressing the ghost ROI value (G) as a percent of the true

ROI (T).

E = ((T-G/T) x 100%

Transmit Quadrature Errors

Transmit quadrature ghosts are evaluated using images acquired in the multi-slice mode in which the

phantom is placed at a location offset from the isocenter. A transmit ghost appears in the slice located in

the opposite offset direction at a distance equal to the distance at which the true object is located from the

isocenter (mirror image from the isocenter). The ghost and true object image will be located at the same

relative positions in their respective images. For example, a true object located in the upper left comer at

a distance of +5 cm from the isocenter will produce a transmit quadrature ghost in the upper left comer of

the image at -5 cm ROl's taken over the true object and the ghost are used to determine the percent error

(E).

E = ((T-G)/T) x 100%

2.4.4 Action Criteria

Phase related errors should typically be less than 5% of the true signal value. DC-offset errors should not

be present in images from a properly functioning system.

2.4.5 Example Images

Figure 2-9 is an image of the linearity section of the phantom demonstrating the non-linearity that exists in

the magnetic field especially on the outer edge of the field of view. Three black squares are markers for

phantom orientations.

2-12

Page 23

Operation

Tests with Uniformity and Linearity (UAL) Phantom

Figure 2-9

2

2-13

Page 24

Nuclear Associates 76-908 & 76-907

Operators Manual

Figure 2-10 is a flood image showing the uniformity of signal intensity. Field non-uniformity is also shown

on the outer edges.

Figure 2-10

Figure 2-11 shows a horizontal intensity profile with a narrow window setting. Such information can be

used as baseline data.

Figure 2-11

2-14

Page 25

Operation

Tests with Uniformity and Linearity (UAL) Phantom

Figure 2-12 is an image of the signal bubble for quadrature error. If there were any quadrature phase

error, another ghost circle would be visible in the lower right-hand corner of the image. Quadrature error

has become less common in most of the recent MRI systems.

Figure 2-12

2

2-15

Page 26

Fluke Corporation

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

www.flukebiomedical.com/rms

Loading...

Loading...