Page 1

HART® Transmitter

Calibration

Application Note

Introduction

In today’s process plants, most

new field instruments are smart

digital instruments. Smart

implies a microprocessor-based

instrument with extra functionality and digital compensation,

supporting multiple sensor types

or multiple variables. These

instruments generally offer

better accuracy, long-term stability, and reliability than conventional analog instruments.

The most common class of

smart instruments incorporates the HART protocol, with

more than five million HART

instruments in use in 100,000

plants worldwide. HART, an

acronym for Highway Addressable Remote Transducer, is an

industry standard that defines

the communications protocol

between smart field devices and

a control system that employs

traditional 4-20 mA wiring.

Two capabilities are required

to properly service HART instruments: precision analog source

and measure capability and

digital communication capability. Until recently, this required

two separate tools, a calibrator

and a communicator. Today, the

capabilities of those two tools

are available in a single HART

Documenting Process Calibrator that can help you quickly

and effectively service HART

instruments.

From the Fluke Digital Library @ www.fluke.com/library

Page 2

HART calibration

Sensor

Sensor Trim LRV/URV Adjust Output Trim

PV PVAO 4-20 mA

Input

Section

Conversion

Section

Output

Section

Analog

Input

(digital

input)

(digital

4-20 mA)

Analog

mA Output

is required!

A common misconception is

that the accuracy and stability

of HART instruments eliminate

the need for calibration. Another

misconception is that calibration can be accomplished by reranging field instruments using

only a HART communicator. Still

another misconception is that

the control system can remotely

calibrate smart instruments.

These are not true. All instruments drift. Re-ranging with

just a communicator is not calibration. A precision calibrator

or standard is required. Regular

performance verification with a

calibrator traceable to national

standards is necessary due to:

1. Shifts in performance of

electronic instruments over

time, due to exposure of the

electronics and the primary

sensing element to temperature, humidity, pollutants,

vibration, and other field

environmental factors.

2. Regulations governing occupational safety, consumer

safety, and environmental

protection.

3. Quality programs such as ISO

9000 standards for all instruments that impact product

quality.

4. Commercial requirements

such as weights, measures,

and custody transfer.

Regular calibration is also

prudent since performance

checks will often uncover

problems not directly caused

by the instrumentation, such as

solidified or congealed pressure

lines, installation of an incorrect thermocouple type, or other

errors and faults.

A calibration procedure consists of a verification (As Found)

test, adjustment to within

acceptable tolerance if necessary, and a final verification (As

Left) test if an adjustment has

been made. Data from the calibration are collected and used

to complete a report of calibration, documenting instrument

performance over time.

All instruments, even HART

instruments, must be calibrated on a regular, preventive

maintenance schedule. The

calibration interval should be

set short enough to insure that

an instrument never drifts out

of tolerance, yet long enough

to avoid unnecessary calibrations. Alternatively, the interval

may be determined by critical

process requirements, e.g., calibration before each batch.

How are HART

instruments properly

calibrated?

To calibrate a HART instrument

consistent with its application, it

is very helpful to understand the

functional structure of a typical

HART transmitter.

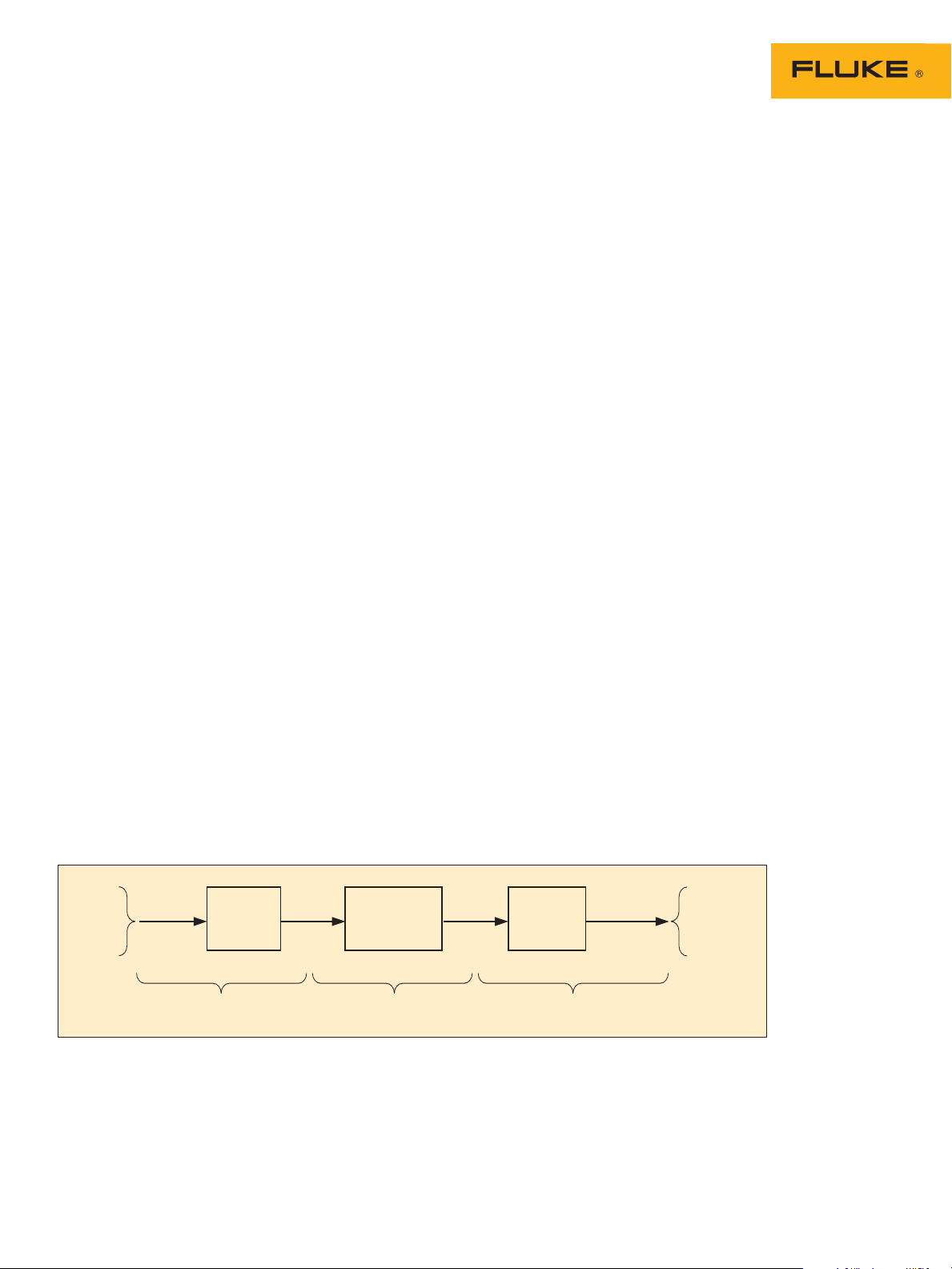

HART instruments consist

of three distinct sections (see

Figure 1). Proper HART calibration may involve either or both

sensor trim and output trim.

Adjusting range values (LRV

and URV) without a calibrator

is not calibration. Performing

an output trim while ignoring

the input section is not proper

calibration. Adjusting range

values with a calibrator may be

a practical calibration alternative for instruments operated in

4-20 mA analog mode, provided

that the PV and PVAO are not

used for process control.

Figure 1.

2 Fluke Corporation Abridged HART Transmitter Calibration

Page 3

Model Number

PV

(Primary Variable)

PVAO

(Digital representation

of the Primary Variable

Analog Output)

Analog Measure Value

Analog Source Value

Tag ID

PV LRV

(Primary Variable

Lower Range Value)

PV URV

(Primary Variable

Upper Range Value)

Figure 2.

New tool speeds

calibration

Today, instrument maintenance

is moving out of the shop and

into the field. This reduces

process interruptions and

avoids the time and expense

of returning instruments to the

shop. Portable communicators

and calibrators are often used

3 Fluke Corporation Abridged HART Transmitter Calibration

together to complete field calibrations. However, the desire to

carry less equipment and to perform maintenance in the field

has created a need for a new

class of calibration tool.

The new 754 Documenting

Process Calibrator from Fluke

is a powerful yet easy-to-use

tool for field calibration of HART

instrumentation. Pressing a

single key enters the HART

mode and displays the essential

HART information in the Active

Device Screen, shown in Figure

2. Additional HART functionality is accessed with only a few

more keystrokes, per the menu

tree in Figure 3.

Page 4

Process

Setup

•

View process

variables

•

View variable

map

•

Re-map process

variables

(Dual sensor

temperature

devices)

Basic

Detailed

(coriolis)

Sensor

Device

Identification

•

T a g

•

PV units

•

LRV, URV

•

Damping

•

Transfer function

• Config Sensor

• Config Output

• Software Version

• Final assembly number

• LRV, URV

• Damping

• Transfer function

• Keypad input

• Adjust URV, LRV to

applied values

Sensor 1

Sensor serial number

•

•

Sensor lower and

upper limits

•

Sensor minimum span

Temperature

devices only:

•

Change Sensor Type

•

Change Sensor

Connections

Sensor 2

• Change Sensor Type

• Change Sensor

Connections

(Dual sensor

temperature devices)

Loop test

Service

Abort

Figure 3.

Pressure

zero trim

Output trim

Sensor trim

No communicator is

required!

The 754 requires no external box or communicator for

everyday HART calibration

and maintenance. It supports

many popular models of HART

transmitters, with more devicespecific command support than

any other HART field calibrator.

HART

Output

• Manufacturer

• Model

HART

Information

• Device HART ID

• Software revision

• Hardware revision

• Number of preambles

• Interrogate HART devices to

determine type, manufacturer, model, tag-ID, PV, and

PVAO

• Perform automated HART

sensor trim and output trim

for selected devices

• Adjust ranging, damping, and

other basic process–configuration settings

• Dual Sensor Config

(Dual sensor

temperature devices)

• Write protect

• Alarm state

• HART poll address

• HART burst mode

• HART burst command

• Read and write HART tag and

message fields to re-label

smart transmitters

• Clone additional transmitters

with basic HART configura-

tion data

4 Fluke Corporation Abridged HART Transmitter Calibration

Page 5

CLEAR

(ZERO)

Example 1

Calibration of a

Rosemount 3051 HART

Pressure Transmitter

Basic connections

This example assumes that

the transmitter is isolated from

the process and is not electrically connected to a loop power

supply. Make basic connections

to the 3051 per the diagram in

Figure 4. A separate 250 ohm

resistor is not necessary because

the 754 incorporates a resistor

in series with the loop supply

through its mA jacks. The 3051

in this example is configured for

mbar units.

2. Press the key again and

you are prompted to select

the 754 configuration (Figure

6). Selecting MEAS mA,

SOURCE mbar will configure

the calibrator to measure

the analog mA output and

the pressure being applied

simultaneously to the transmitter input and the pressure

module. (Selecting MEAS PV,

SOURCE mbar will configure the 754 to evaluate the

digital PV output from the

transmitter.) Press to

select.

Figure 6.

output, select Instru-

ment.) Notice that the

calibration template is automatically completed with the

exception of Tolerance. Fill in

the appropriate test tolerance

and press Done.

4. Press the Manual Test

softkey to begin calibration.

Apply the input pressures

as instructed in the SOURCE

screen. Press the Accept

Point softkey when the correct pressure is applied for

each point. When the test is

complete, the error summary

table is displayed (Figure

7). Test errors exceeding

the tolerance are highlighted. When done viewing

the table, press the Done

softkey. Press Done again

to accept, or to change

the tag, serial number or ID

fields.

Figure 4.

Procedure

1. Power on the Fluke 754

Calibrator. Press the red

key followed by the Loop

Power softkey and the 754

will display the basic HART

information for the 3051

(Figure 5).

Figure 5.

3. Vent the pressure line and

press

to zero the pressure module. Press the As

Found softkey, and then

press to select Instru-

ment for a linear transmitter

calibration. (If the 3051 is

configured for square root

Figure 7.

5 Fluke Corporation Abridged HART Transmitter Calibration

Page 6

5. If the As Found test failed

CLEAR

(ZERO)

(i.e., there were highlighted

errors in the error summary table), adjustment is

necessary. Press the Adjust

softkey. Select Sensor Trim

and press . (Do not select

Pressure Zero Trim. It is the

same as trimming the lower

sensor point at zero, which is

useful for pressure transmitters that do not offer Sensor

Trim.) The 754 screen should

look like Figure 8.

Figure 8.

6. Select Perform user trim –

both and press . Zero

the pressure module (vented

to atmosphere) by pressing

. Press the Continue softkey and you are prompted

for the Lower Trim value. For

best results, apply the LRV

pressure and press Fetch

to load the value being

measured by the pressure

module. Press Trim. Then

press Continue to move to

the Upper Trim. As before,

apply the URV pressure,

press Fetch, and press Trim.

If the 3051 is used with the

digital PV output, skip to step

8 and perform the As Left

test. If the 4-20 mA analog

output is used in the process,

continue on to step 7.

7. Select Output Trim and

press . The value of the

primary variable (PVAO) is in

the upper right corner of the

display. This is normally a

4 mA signal. The mA value,

as constantly measured

by the Fluke 754, is in the

center of the display. Press

the Fetch softkey to load the

measured mA value. Press

Send to send the value to

the 3051 to trim the output

section for the 4 mA value.

Press Continue for the

20 mA trim and repeat this

step.

8. After completing Output Trim,

press the Done softkey and

proceed with the As Left

verification test. Press the

As Left softkey. Press Done

and then press Manual

Test. Apply the requested

pressures and press Accept

Point when the readings

are stable. On completion

an error summary table is

displayed. If none of the

errors are highlighted (Figure

9), the 3051 passes the

calibration test. If errors are

highlighted, the test has

failed and further adjustment

is required. Return to step 5

for adjustment of the 3051.

Figure 9.

DOCUMENTING PROCESS CALBRATOR

754

Figure 10.

Example 2

Calibration of a

Rosemount 3144 HART

Temperature Transmitter

Basic connections

This example assumes that

the transmitter is isolated from

the process and is not electrically connected to a loop power

supply. Make basic connections

to the 3144 per the diagram in

Figure 10. A separate

250 ohm resistor is not necessary because the 754

incorporates a resistor in series

with the loop supply through

its mA jacks. The 3144 in this

example is configured for a type

K thermocouple sensor with a

span of 0 °C to 300 °C.

TC

TC

+

–

2

3

1

4

–

5

+

T

3144

Transmitter

6 Fluke Corporation Abridged HART Transmitter Calibration

Page 7

Procedure

1. Power on the Fluke 754

Calibrator. Press the red

key followed by the Loop

Power softkey. Press to

bypass the warning screens

and the 754 will display the

basic HART information for

the 3144 (Figure 11).

Figure 11.

4. Press the Auto Test softkey to begin calibration.

Once the test is complete,

an error summary table is

displayed (Figure 13). Test

errors exceeding the tolerance are highlighted. When

done viewing the table,

press the Done softkey. Press

Done again to accept, or

to change the tag, serial

number or ID fields.

7. Select Output Trim and

press . The value of the

primary variable (PVAO) is

in the upper right corner of

the display. (Figure 5). This

is normally a 4 mA signal.

The mA value, as constantly

measured by the Fluke 754,

is in the center of the display. Press the Fetch softkey

to load the measured mA

value. Press Send to send

the value to the 3144 to trim

the output section for the

4 mA value. Press Continue

for the 20 mA trim and

repeat this step.

2. Press the key again and

you are prompted to select

the 754 configuration (Figure

12). Selecting MEAS mA,

SOURCE T/C typ K configures

the calibrator to measure

the analog mA output of the

transmitter and source the

correct temperature stimulus

at the 3144 input. (Selecting

MEAS PV, SOURCE T/C typ

K will configure the 754 to

evaluate the digital PV output

from the transmitter.) Press

to select.

Figure 12.

3. Press the As Found softkey,

and then press to select

Instrument for a linear

transmitter calibration. Notice

that the calibration template

is automatically completed

with the exception of the

Tolerance. Fill in the appropriate test tolerance and

press the Done softkey.

Figure 13.

5. If the As Found test failed

(i.e., there were highlighted

errors in the error summary table), adjustment is

necessary. Press the Adjust

softkey. Select Sensor Trim

and press . Select Perform user trim – both and

press . The 754 screen

should look like Figure 14.

6. For best results, press LRV to

apply the LRV for the Lower

Trim value. Press Trim and

then Continue to move to

the Upper Trim. Press URV,

press Trim, and then press

Done. If the 3144 is used

with the digital PV output,

skip to step 8 and perform

the As Left test. If the analog

4-20 mA output is used in

the process, continue on to

step 7.

Figure 14.

Figure 15.

8. After completing Output Trim,

press the Done softkey and

proceed with the As Left

verification test. Press the As

Left softkey. Press Done and

then press Auto Test. On

completion, an error summary table is displayed. If

errors are highlighted, the

test has failed and further

adjustment is required.

Return to step 5 for adjustment of the 3144.

Figure 16.

7 Fluke Corporation Abridged HART Transmitter Calibration

Page 8

Note on Uploading Results to Your PC

If you are using a 743/744 or 753/754, you may choose an

instrumentation management software package from this list:

Fluke DPC/TRACK2

AMS from Emerson Process

Management, (formerly

Fisher-Rosemount).

All trademarks are the property of their respective holders.

™

PRM (Plant Resource

Manager) from Yokogawa

Electric Corporation.

Ordering information

FLUKE-753 Documenting Process Calibrator

FLUKE-754 Documenting Process Calibrator-HART

Standard accessories include: Three sets of stackable test leads, three

sets of TP220 Test Probes with three sets of “extended tooth” alligator

clips, two sets AC280 Hook Clips, BP7240 Li-ion Battery Pack, BC7240

Battery Charger, C799 Field Soft Case, USB communication cable,

getting started guide, instruction manual on CD-ROM, NIST traceable

certificate of calibration, DPC/TRACK2 sample software that enables

upload and printing of calibration records, three-year warranty. Model

Fluke-754 includes HART communication cable.

FLUKE-750SW DPC/TRACK2 Software

Included with DPC/TRACK software: Software media, instruction

manual, USB cable.

FLUKE-700 Pxx Pressure Modules

Included with each Fluke Pressure Module: BP-ISO Adapter(s)

(except with P29 - P31), Instruction Sheet, NIST traceable calibration

report and data, one-year warranty.

Accessories

Fluke-700PMP Pressure Pump; 100 psi/7 bar

Fluke-700LTP-1 Low Pressure Test Pump

Fluke-700PTP-1 Pneumatic Test Pump; 600 psi/40 bar

Fluke-700HTP-2 Hydraulic Test Pump; 10,000 psi/700 bar

Fluke-700HTH-1 Hydraulic Test Hose

Fluke-700PRV-1 Pressure Relief Valve Kit for HTP

Fluke-700-IV Current Shunt (for mA/mA applications)

Fluke-700PCK Pressure Calibration Kit

Fluke-700TC1 TC Mini-Plug Kit, 9 types

Fluke-700TC2 TC Mini-Plug Kit, JKTERS

Fluke-700TLK Process Test lead kit

754HCC Smart Instrument Communication Cable

BC7240 Battery Charger

BP7240 Li-on Battery Pack

C700 Hard Carrying Case

C781 Soft Carrying Case

C799 Field Soft Case

8 Fluke Corporation Abridged HART Transmitter Calibration

E

G

M

A

N

E

N

A

T

M

S

Y

Y

T

S

I

L

A

U

Q

ISO 9001

C

E

R

T

I

F

I

T

E

M

1

0

0

9

O

E

S

I

D

T

T

E

O

E

M

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2012 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 2/2012 4156648A A-EN-N

Modification of this document is not permitted

without written permission from Fluke Corporation.

®

Loading...

Loading...