Page 1

5520A

®

Multi-Product Calibrator

Service Manual

PN 802303

April 1999 Rev. 1, 12/02

© 1999, 2002 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their r espective comp ani es

Page 2

LIMITED WARRANTY & LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke’s opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

Page 3

Safety Information

This Calibrator complies with IEC publication 1010-1 (1992-1), Safety Requirements for

Electrical Measuring, Control and Laboratory Equipment, and ANSI/ISA-S82.01-1994,

and CAN/CSA-C22.2 No. 1010.1-92. This manual contains information, warnings, and

cautions that must be followed to ensure safe operation and to maintain the Calibrator in

a safe condition. Use of this Calibrator in a manner not specified herein may impair the

protection provided by the Calibrator.

This Calibrator is designed for IEC 1010-1 Installation Category II use. It is not designed

for connection to circuits rated over 4800 VA.

Warning statements identify conditions or practices that could result in personal injury or

loss of life.

Caution statements identify conditions or practices that could result in damage to

equipment.

SYMBOLS MARKED ON THE CALIBRATOR

WARNING Risk of electric shock. Refer to the manual (see the Index for

references).

GROUND Ground terminal to chassis (earth).

Attention Refer to the manual (see the Index for references). This

symbol indicates that information about usage of a feature is contained in

the manual.

AC POWER SOURCE

The Calibrator is intended to operate from an ac power source that will not apply more

than 264V ac rms between the supply conductors or between either supply conductor

and ground. A protective ground connection by way of the grounding conductor in the

power cord is required for safe operation.

USE THE PROPER FUSE

To avoid fire hazard, use only the specified replacement fuse:

• For 100 V or 120 V operation, use a 5A/250V time delay fuse (Fluke PN 109215).

• For 220 V or 240 V operation, use a 2.5A/250V time delay fuse (Fluke PN 851931).

GROUNDING THE CALIBRATOR

The Calibrator uses controlled overvoltage techniques that require the Calibrator to be

grounded whenever normal mode or common mode ac voltages or transient voltages

may occur. The enclosure must be grounded through the grounding conductor of the

power cord, or through the rear panel CHASSIS GROUND binding post.

Page 4

USE THE PROPER POWER CORD

Use only the power cord and connector appropriate for the voltage and plug

configuration in your country.

Use only a power cord that is in good condition.

Refer power cord and connector changes to qualified service personnel.

DO NOT OPERATE IN EXPLOSIVE ATMOSPHERES

To avoid explosion, do not operate the Calibrator in an atmosphere of explosive gas.

CHECK INSULATION RATINGS

Verify that the voltage applied to the unit under test does not exceed the insulation rating

of the UUT and the interconnecting cables.

DO NOT REMOVE COVER DURING OPERATION

To avoid personal injury or death, do not remove the Calibrator cover without first

removing the power source connected to the rear panel. Do not operate the Calibrator

without the cover properly installed. Normal calibration is accomplished with the cover

closed. Access procedures and the warnings for such procedures are contained in the

Service Manual. Service procedures are for qualified service personnel only.

DO NOT ATTEMPT TO OPERATE IF PROTECTION MAY BE IMPAIRED

If the Calibrator appears damaged or operates abnormally, protection may be impaired. Do

not attempt to operate the Calibrator under these conditions. Refer all questions of proper

Calibrator operation to qualified service personnel.

Page 5

Table of Contents

Chapter Title Page

1 Introduction and Specifications........................................................ 1-1

1-1. Introduction........................................................................................... 1-3

1-2. Operation Overview.............................................................................. 1-4

1-3. Local Operation................................................................................ 1-4

1-4. Remote Operation (RS-232)............................................................. 1-4

1-5. Remote Operation (IEEE-488)......................................................... 1-4

1-6. Service Information.............................................................................. 1-5

1-7. How to Contact Fluke........................................................................... 1-5

1-8. Specifications........................................................................................ 1-6

1-9. General Specifications...................................................................... 1-7

1-10. DC Voltage Specifications............................................................... 1-8

1-11. DC Current Specifications................................................................ 1-9

1-12. Resistance Specifications................................................................. 1-11

1-13. AC Voltage (Sinewave) Specifications............................................ 1-12

1-14. AC Current (Sinewave) Specifications............................................. 1-14

1-15. Capacitance Specifications............................................................... 1-16

1-16. Temperature Calibration (Thermocouple) Specifications................ 1-17

1-17. Temperature Calibration (RTD) Specifications................................ 1-18

1-18. DC Power Specification Summary................................................... 1-19

1-19. AC Power (45 Hz to 65 Hz) Specification Summary, PF=1............ 1-19

1-20. Power and Dual Output Limit Specifications................................... 1-20

1-21. Phase Specifications......................................................................... 1-21

1-22. Calculating Power Uncertainty......................................................... 1-22

1-23. Additional Specifications...................................................................... 1-23

1-24. Frequency Specifications.................................................................. 1-23

1-25. Harmonics (2nd to 50th) Specifications........................................... 1-24

1-26. AC Voltage (Sinewave) Extended Bandwidth Specifications.......... 1-25

1-27. AC Voltage (Non-Sinewave) Specifications.................................... 1-26

1-28. AC Voltage, DC Offset Specifications............................................. 1-27

1-29. AC Voltage, Squarewave Characteristics......................................... 1-28

1-30. AC Voltage, Trianglewave Characteristics (typical)........................ 1-28

1-31. AC Current (Sinewave) Extended Bandwidth Specifications.......... 1-28

1-32. AC Current (Non-Sinewave) Specifications .................................... 1-29

1-33. AC Current, Squarewave Characteristics (typical)........................... 1-31

1-34. AC Current, Trianglewave Characteristics (typical)........................ 1-31

i

Page 6

5520A

Service Manual

2 Theory of Operation........................................................................... 2-1

2-1. Introduction........................................................................................... 2-3

2-2. Encoder Assembly (A2)........................................................................ 2-4

2-3. Synthesized Impedance Assembly (A5)............................................... 2-4

2-4. DDS Assembly (A6)............................................................................. 2-5

2-5. Current Assembly (A7)......................................................................... 2-6

2-6. Voltage Assembly (A8)........................................................................ 2-7

2-7. Main CPU Assembly (A9).................................................................... 2-8

2-8. Power Supplies ..................................................................................... 2-8

2-9. Outguard Supplies............................................................................ 2-8

2-10. Inguard Supplies............................................................................... 2-8

3 Calibration and Verification............................................................... 3-1

3-1. Introduction........................................................................................... 3-3

3-2. Equipment Required for Calibration and Verification.......................... 3-3

3-3. Calibration ............................................................................................ 3-5

3-4. Starting Calibration .......................................................................... 3-5

3-5. DC Volts Calibration (NORMAL Output)....................................... 3-6

3-6. DC Volts Calibration (30 Vdc and Above)...................................... 3-7

3-7. AC Volts Calibration (NORMAL Output)....................................... 3-8

3-8. Thermocouple Function Calibration................................................. 3-10

3-9. DC Current Calibration .................................................................... 3-11

3-10. AC Current Calibration .................................................................... 3-14

3-11. DC Volts Calibration (AUX Output)................................................ 3-20

3-12. AC Volts Calibration (AUX Output)................................................ 3-20

3-13. Resistance Calibration...................................................................... 3-21

3-14. Capacitance Calibration.................................................................... 3-24

3-15. Calibration Remote Commands............................................................ 3-27

3-16. Generating a Calibration Report........................................................... 3-33

3-17. Performance Verification Tests............................................................ 3-34

3-18. Zeroing the Calibrator...................................................................... 3-34

3-19. Verifying DC Volts (NORMAL Output)......................................... 3-35

3-20. Verifying DC Volts (AUX Output).................................................. 3-36

3-21. Verifying DC Current....................................................................... 3-36

3-22. Verifying Resistance ........................................................................ 3-38

3-23. Verifying AC Voltage (NORMAL Output)..................................... 3-40

3-24. Verifying AC Voltage (AUX Output).............................................. 3-42

3-25. Verifying AC Current....................................................................... 3-43

3-26. Verifying Capacitance...................................................................... 3-46

3-27. 200 µF to 110 mF Capacitance Verification .................................... 3-47

3-28. Capacitance Measurement................................................................ 3-47

3-29. Measurement Uncertainty................................................................. 3-51

3-30. Verifying Thermocouple Simulation (Sourcing).............................. 3-52

3-31. Verifying Thermocouple Measurement............................................ 3-52

3-32. Verifying Phase Accuracy, Volts and AUX Volts........................... 3-53

3-33. Verifying Phase Accuracy, Volts and Current................................. 3-54

3-34. Verifying Frequency Accuracy........................................................ 3-55

4 Maintenance........................................................................................ 4-1

4-1. Introduction........................................................................................... 4-3

4-2. Access Procedures................................................................................ 4-3

4-3. Removing Analog Modules.............................................................. 4-3

4-4. Removing the Main CPU (A9)......................................................... 4-3

ii

Page 7

Contents

4-5. Removing Rear Panel Assemblies.................................................... 4-4

4-6. Removing the Filter PCA (A12)....................................................... 4-4

4-7. Removing the Encoder (A2) and Display PCAs .............................. 4-4

4-8. Removing the Keyboard and Accessing the Output Block.............. 4-4

4-9. Diagnostic Testing................................................................................ 4-7

4-10. Running Diagnostics ........................................................................ 4-7

4-11. Testing the Front Panel..................................................................... 4-7

4-12. Complete List of Error Messages ......................................................... 4-8

5 List of Replaceable Parts................................................................... 5-1

5-1. Introduction........................................................................................... 5-3

5-2. How to Obtain Parts.............................................................................. 5-3

6 Oscilloscope Calibration Options..................................................... 6-1

SC600 Option...................................................................................... 6-3

6-1. Introduction........................................................................................... 6-5

6-2. Maintenance.......................................................................................... 6-5

6-3. SC600 Specifications............................................................................ 6-6

6-4. Volt Specifications........................................................................... 6-6

6-5. Edge Specifications.......................................................................... 6-7

6-6. Leveled Sine Wave Specifications................................................... 6-8

6-7. Time Marker Specifications............................................................. 6-9

6-8. Wave Generator Specifications........................................................ 6-9

6-9. Pulse Generator Specifications......................................................... 6-10

6-10. Trigger Signal Specifications (Pulse Function)................................ 6-10

6-11. Trigger Signal Specifications (Time Marker Function) ................... 6-10

6-12. Trigger Signal Specifications (Edge Function)................................ 6-11

6-13. Trigger Signal Specifications (Square Wave Voltage Function) ..... 6-11

6-14. Trigger Signal Specifications ........................................................... 6-11

6-15. Oscilloscope Input Resistance Measurement Specifications............ 6-11

6-16. Oscilloscope Input Capacitance Measurement Specifications......... 6-11

6-17. Overload Measurement Specifications............................................. 6-12

6-18. Theory of Operation.............................................................................. 6-12

6-19. Voltage Mode................................................................................... 6-12

6-20. Edge Mode........................................................................................ 6-12

6-21. Leveled Sine Wave Mode ................................................................ 6-12

6-22. Time Marker Mode........................................................................... 6-13

6-23. Wave Generator Mode ..................................................................... 6-13

6-24. Input Impedance Mode (Resistance)................................................ 6-13

6-25. Input Impedance Mode (Capacitance).............................................. 6-13

6-26. Overload Mode................................................................................. 6-13

6-27. Equipment Required for Calibration and Verification.......................... 6-15

6-28. SC600 Calibration Setup ...................................................................... 6-17

6-29. Calibration and Verification of Square Wave Voltage Functions ........ 6-18

6-30. Overview of HP3458A Operation.................................................... 6-18

6-31. Setup for SC600 Voltage Square Wave Measurements................... 6-18

6-32. Setup for SC600 Edge and Wave Gen Square Wave Measurements 6-20

6-33. DC Voltage Calibration.................................................................... 6-21

6-34. AC Voltage Calibration.................................................................... 6-21

6-35. Wave Generator Calibration............................................................. 6-22

6-36. Edge Amplitude Calibration............................................................. 6-22

6-37. Leveled Sine Wave Amplitude Calibration...................................... 6-23

(continued)

iii

Page 8

5520A

Service Manual

6-38. Leveled Sine Wave Flatness Calibration.......................................... 6-24

6-39. Low Frequency Calibration.......................................................... 6-24

6-40. High Frequency Calibration......................................................... 6-25

6-41. Pulse Width Calibration ................................................................... 6-25

6-42. MeasZ Calibration............................................................................ 6-26

6-43. Verification........................................................................................... 6-28

6-44. DC Voltage Verification................................................................... 6-29

6-45. Verification at 1 MΩ.................................................................... 6-29

6-46. Verification at 50 Ω..................................................................... 6-29

6-47. AC Voltage Amplitude Verification................................................. 6-31

6-48. Verification at 1 MΩ.................................................................... 6-31

6-49. Verification at 50 Ω..................................................................... 6-33

6-50. AC Voltage Frequency Verification................................................. 6-34

6-51. Edge Amplitude Verification............................................................ 6-35

6-52. Edge Frequency Verification............................................................ 6-35

6-53. Edge Duty Cycle Verification.......................................................... 6-36

6-54. Edge Rise Time Verification............................................................ 6-36

6-55. Edge Abberation Verification........................................................... 6-38

6-56. Tunnel Diode Pulser Drive Amplitude Verification......................... 6-39

6-57. Leveled Sine Wave Amplitude Verification .................................... 6-39

6-58. Leveled Sine Wave Frequency Verification..................................... 6-41

6-59. Leveled Sine Wave Harmonics Verification.................................... 6-42

6-60. Leveled Sine Wave Flatness Verification ........................................ 6-44

6-61. Equipment Setup for Low Frequency Flatness............................ 6-44

6-62. Equipment Setup for High Frequency Flatness............................ 6-44

6-63. Low Frequency Verification........................................................ 6-46

6-64. High Frequency Verification........................................................ 6-46

6-65. Time Marker Verification................................................................. 6-48

6-66. Wave Generator Verification............................................................ 6-49

6-67. Verification at 1 MΩ.................................................................... 6-50

6-68. Verification at 50 Ω..................................................................... 6-50

6-69. Pulse Width Verification.................................................................. 6-53

6-70. Pulse Period Verification.................................................................. 6-54

6-71. MeasZ Resistance Verification......................................................... 6-54

6-72. MeasZ Capacitance Verification...................................................... 6-55

6-73. Overload Function Verification........................................................ 6-56

6-74. SC600 Hardware Adjustments.............................................................. 6-57

6-75. Equipment Required......................................................................... 6-57

6-76. Adjusting the Leveled Sine Wave Function..................................... 6-57

6-77. Equipment Setup.......................................................................... 6-57

6-78. Adjusting the Leveled Sine Wave VCO Balance......................... 6-58

6-79. Adjusting the Leveled Sine Wave Harmonics............................. 6-58

6-80. Adjusting the Aberrations for the Edge Function............................. 6-59

6-81. Equipment Setup.......................................................................... 6-60

6-82. Adjusting the Edge Aberrations................................................... 6-60

SC300 Option...................................................................................... 6-63

6-83. Introduction........................................................................................... 6-65

6-84. Maintenance.......................................................................................... 6-65

6-85. SC300 Specifications............................................................................ 6-66

6-86. Voltage Function Specifications....................................................... 6-66

6-87. Edge Function Specifications........................................................... 6-67

6-88. Leveled Sine Wave Function Specifications.................................... 6-68

6-89. Time Marker Function Specifications.............................................. 6-69

iv

Page 9

Contents

6-90. Wave Generator Specifications........................................................ 6-69

6-91. Trigger Signal Specifications for the Time Marker Function .......... 6-70

6-92. Trigger Signal Specifications for the Edge Function....................... 6-70

6-93. Theory of Operation.............................................................................. 6-71

6-94. Voltage Mode................................................................................... 6-71

6-95. Edge Mode........................................................................................ 6-71

6-96. Leveled Sine Wave Mode ................................................................ 6-71

6-97. Time Marker Mode........................................................................... 6-72

6-98. Wave Generator Mode ..................................................................... 6-72

6-99. Equipment Required for Calibration and Verification.......................... 6-74

6-100. SC300 Calibration Setup ...................................................................... 6-76

6-101. Calibration and Verification of Square Wave Functions...................... 6-77

6-102. Overview of HP3458A Operation.................................................... 6-77

6-103. Setup for Square Wave Measurements............................................. 6-77

6-104. DC Voltage Calibration.................................................................... 6-78

6-105. AC Square Wave Voltage Calibration.............................................. 6-79

6-106. Edge Amplitude Calibration............................................................. 6-80

6-107. Leveled Sine Wave Amplitude Calibration...................................... 6-80

6-108. Leveled Sine Wave Flatness Calibration.......................................... 6-81

6-109. Low Frequency Calibration.......................................................... 6-82

6-110. High Frequency Calibration......................................................... 6-82

6-111. Verification........................................................................................... 6-83

6-112. DC Voltage Verification................................................................... 6-83

6-113. Verification at 1 MΩ.................................................................... 6-83

6-114. Verification at 50 Ω ..................................................................... 6-83

6-115. AC Voltage Amplitude Verification................................................. 6-86

6-116. Verification at 1 MΩ.................................................................... 6-86

6-117. Verification at 50 Ω ..................................................................... 6-88

6-118. AC Voltage Frequency Verification................................................. 6-89

6-119. Edge Amplitude Verification............................................................ 6-90

6-120. Edge Frequency Verification............................................................ 6-91

6-121. Edge Duty Cycle Verification.......................................................... 6-92

6-122. Edge Rise Time Verification............................................................ 6-92

6-123. Edge Abberation Verification........................................................... 6-94

6-124. Leveled Sine Wave Amplitude Verification .................................... 6-95

6-125. Leveled Sine Wave Frequency Verification..................................... 6-96

6-126. Leveled Sine Wave Harmonics Verification.................................... 6-97

6-127. Leveled Sine Wave Flatness Verification ........................................ 6-99

6-128. Equipment Setup for Low Frequency Flatness............................ 6-99

6-129. Equipment Setup for High Frequency Flatness............................ 6-99

6-130. Low Frequency Verification........................................................ 6-101

6-131. High Frequency Verification........................................................ 6-101

6-132. Time Marker Verification................................................................. 6-103

6-133. Wave Generator Verification............................................................ 6-104

6-134. Verification at 1 MΩ.................................................................... 6-105

6-135. Verification at 50 Ω ..................................................................... 6-105

6-136. SC300 Hardware Adjustments.............................................................. 6-107

6-137. Equipment Required......................................................................... 6-107

6-138. Adjusting the Leveled Sine Wave Function..................................... 6-108

6-139. Equipment Setup.......................................................................... 6-108

6-140. Adjusting the Leveled Sine Wave Harmonics............................. 6-108

6-141. Adjusting the Aberrations for the Edge Function............................. 6-109

6-142. Equipment Setup.......................................................................... 6-109

6-143. Adjusting the Edge Aberrations................................................... 6-109

(continued)

Index

v

Page 10

5520A

Service Manual

vi

Page 11

List of Tables

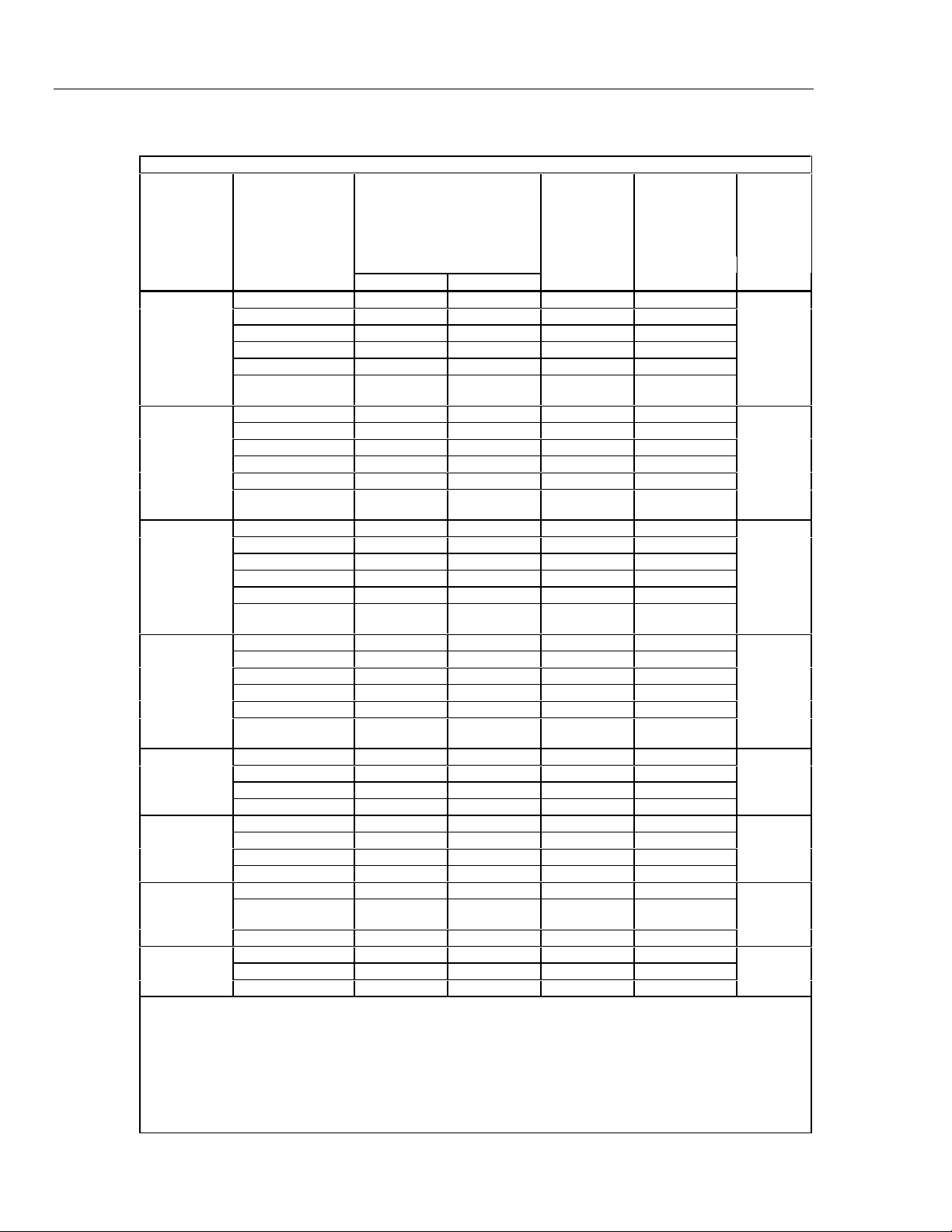

Table Title Page

3-1. Consolidated List of Required Equipment for Calibration and Verification.......... 3-3

3-2. Test Equipment Required for Calibrating DC Volts.............................................. 3-6

3-3. Calibration Steps for DC Volts.............................................................................. 3-7

3-4. Test Equipment Required for Calibrating AC Volts.............................................. 3-8

3-5. Calibration Steps for AC Volts.............................................................................. 3-9

3-6. Test Equipment Required for Calibrating the Thermocouple Function................. 3-10

3-7. Calibra tio n Steps for Th erm ocoupl e Measu rement................................................ 3-10

3-8. Test Equipment Required for Calibrating DC Current........................................... 3-12

3-9. Calibration Steps for DC Current........................................................................... 3-13

3-10. Test Equipment Required for Calibrating AC Current........................................... 3-15

3-11. Calibration Steps for AC Current........................................................................... 3-16

3-12. Calibration Steps for AUX DC Volts..................................................................... 3-20

3-13. Calibration Steps for AUX Output AC Volts......................................................... 3-20

3-14. Test Equipment Required for Calibrating Resistance............................................ 3-21

3-15. Calibration Steps for Resistance ............................................................................ 3-22

3-16. Test Equipment Required for Calibrating Capacitance.......................................... 3-24

3-17. Calibration Steps for Capacitance.......................................................................... 3-25

3-18. Jumping to a Specific Calibration Step.................................................................. 3-27

3-19. Verification Tests for DC Voltage (NORMAL Output)........................................ 3-35

3-20. Verification Tests for DC Voltage (AUX Output)................................................. 3-36

3-21. Shunt Values for DC Current Calibration and Verification................................... 3-36

3-22. Verification Tests for DC Current (AUX Output)................................................. 3-37

3-23. Verification Tests for Resistance ........................................................................... 3-38

3-24. Verification Tests for AC Voltage (NORMAL Output)........................................ 3-40

3-25. Verification Tests for AC Voltage (AUX Output)................................................. 3-42

3-26. Shunt Values for AC Current Verification............................................................. 3-43

3-27. Verification Tests for AC Current.......................................................................... 3-44

3-28. Verification Tests for Capacitance......................................................................... 3-46

3-29. Test Equipment Required for High-value Capacitance Measurement................... 3-48

3-30. Verification Tests for Thermocouple Simulation................................................... 3-52

3-31. Verification Tests for Thermocouple Measurement............................................... 3-52

3-32. Verification Tests for Phase Accuracy, V and V................................................... 3-53

3-33. Verification Tests for Phase Accuracy, V and I..................................................... 3-54

3-34. Verification Tests for Frequency............................................................................ 3-55

4-1. Error Message Format............................................................................................ 4-8

vii

Page 12

5520A

Service Manual

5-1. Chassis Assembly................................................................................................... 5-4

5-2. Front Panel Assembly............................................................................................ 5-7

5-3. Rear Panel Assembly ............................................................................................. 5-11

6-1. Volt Specifications................................................................................................. 6-6

6-2. Edge Specifications................................................................................................ 6-7

6-3. Leveled Sine Wave Specifications......................................................................... 6-8

6-4. Time Marker Specifications................................................................................... 6-9

6-5. Wave Generator Specifications.............................................................................. 6-9

6-6. Pulse Generator Specifications............................................................................... 6-10

6-7. Trigger Signal Specifications (Pulse Function)...................................................... 6-10

6-8. Trigger Signal Specifications (Time Marker Function)......................................... 6-10

6-9. Trigger Signal Specifications (Edge Function)...................................................... 6-11

6-10. Trigger Signal Specifications (Square Wave Voltage Function)........................... 6-11

6-11. TV Trigger Signal Specifications........................................................................... 6-11

6-12. Oscilloscope Input Resistance Measurement Specifications ................................. 6-11

6-13. Oscilloscope Input Capacitance Measurement Specifications............................... 6-11

6-14. Overload Measurement Specifications................................................................... 6-12

6-15. SC600 Calibration and Verification Equipment .................................................... 6-15

6-16. Voltage HP3458A Settings .................................................................................... 6-19

6-17. Edge and Wave Generator HP3458A Settings....................................................... 6-20

6-18. Verification Methods for SC600 Functions ........................................................... 6-28

6-19. DC Voltage Verification at 1 MΩ.......................................................................... 6-30

6-20. DC Voltage Verification at 50 Ω ........................................................................... 6-31

6-21. AC Voltage Verification at 1 MΩ.......................................................................... 6-32

6-22. AC Voltage Verification at 50 Ω ........................................................................... 6-33

6-23. AC Voltage Frequency Verification....................................................................... 6-34

6-24. Edge Amplification Verification............................................................................ 6-35

6-25. Edge Frequency Verification ................................................................................. 6-36

6-26. Edge Rise Time Verification.................................................................................. 6-38

6-27. Edge Aberrations.................................................................................................... 6-39

6-28. Tunnel Diode Pulser Amplitude Verification ........................................................ 6-39

6-29. Leveled Sine Wave Amplitude Verification.......................................................... 6-40

6-30. Leveled Sine Wave Frequency Verification .......................................................... 6-41

6-31. Leveled Sine Wave Harmonics Verification.......................................................... 6-43

6-32. Low Frequency Flatness Verification at 5.5 V....................................................... 6-46

6-33. High Frequency Flatness Verification at 5.5 V...................................................... 6-47

6-34. Time Marker Verification ...................................................................................... 6-48

6-35. Wave Generator Verification at 1 MΩ................................................................... 6-51

6-36. Wave Generator Verification at 50 Ω.................................................................... 6-52

6-37. Pulse Width Verification........................................................................................ 6-53

6-38. Pulse Period Verification ....................................................................................... 6-54

6-39. MeasZ Resistance Verification .............................................................................. 6-55

6-40. MeasZ Capacitance Verification............................................................................ 6-56

6-41. SC300 Calibration and Verification Equipment .................................................... 6-74

6-42. AC Square Wave Voltage and Edge Settings for the HP3458A............................ 6-77

6-43. DC Voltage Verification at 1 MΩ.......................................................................... 6-84

6-44. DC Voltage Verification at 50 Ω ........................................................................... 6-85

6-45. AC Voltage Verification at 1 MΩ.......................................................................... 6-87

6-46. AC Voltage Verification at 50 Ω ........................................................................... 6-88

6-47. AC Voltage Frequency Verification....................................................................... 6-90

6-48. Edge Amplification Verification............................................................................ 6-91

6-49. Edge Frequency Verification ................................................................................. 6-91

6-50. Edge Rise Time Verification.................................................................................. 6-94

6-51. Edge Aberrations.................................................................................................... 6-95

6-52. Leveled Sine Wave Amplitude Verification.......................................................... 6-96

viii

Page 13

Contents

6-53. Leveled Sine Wave Frequency Verification .......................................................... 6-97

6-54. Leveled Sine Wave Harmonics Verification.......................................................... 6-98

6-55. Low Frequency Flatness Verification at 5.5 V....................................................... 6-101

6-56. High Frequency Flatness Verification at 5.5 V...................................................... 6-102

6-57. Time Marker Specifications................................................................................... 6-103

6-58. Wave Generator Verification at 1 MΩ................................................................... 6-106

6-59. Wave Generator Verification at 50 Ω.................................................................... 6-107

(continued)

ix

Page 14

5520A

Service Manual

x

Page 15

List of Figures

Figure Title Page

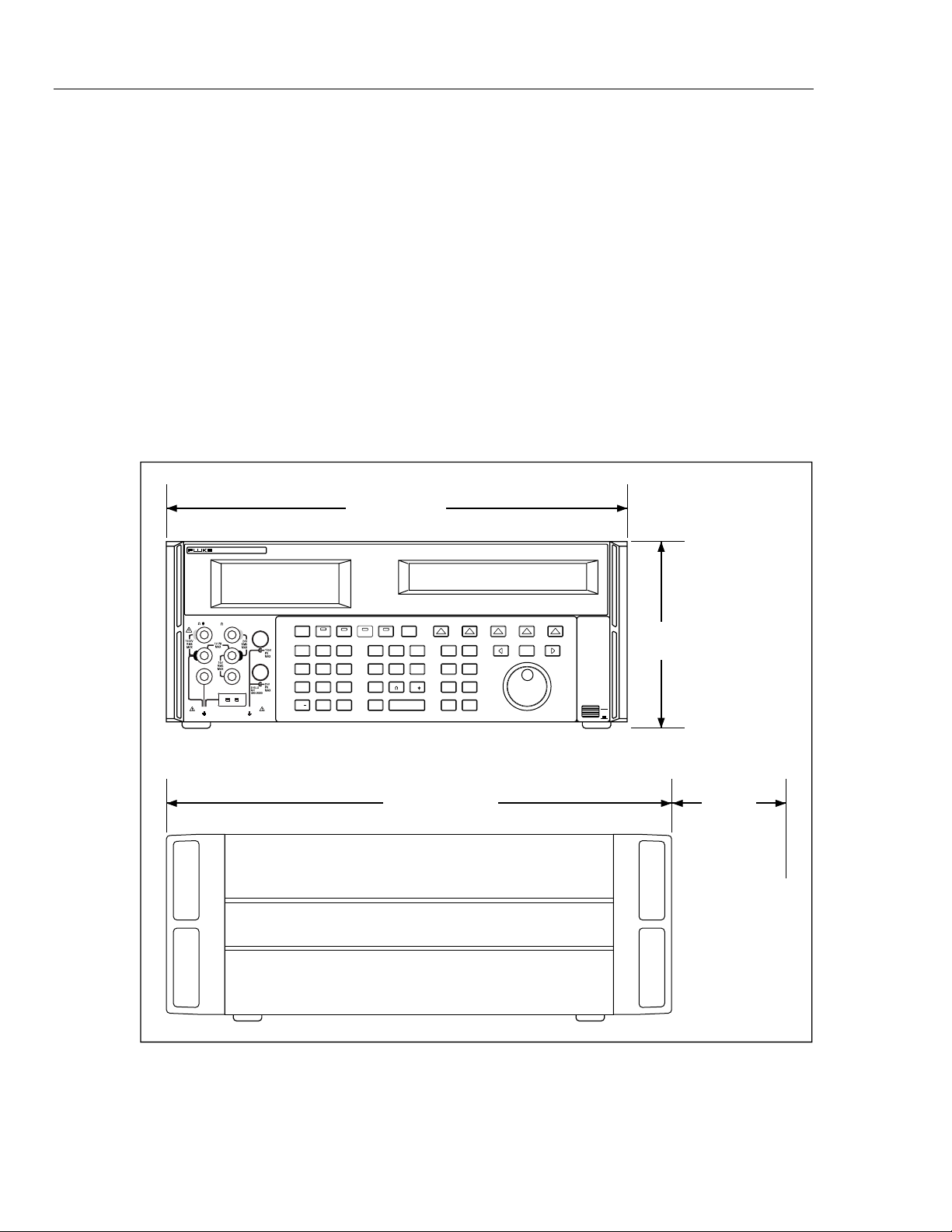

1-1. 5520A Multi-Product Calibrator............................................................................ 1-3

1-2. RS-232 Remote Connections................................................................................. 1-5

1-3. 5520A Calibrator Dimensional Outline ................................................................. 1-6

1-4. Allowable Duration of Current > 11 A.................................................................. 1-10

2-1. 5520A Internal Layout........................................................................................... 2-3

2-2. Synthesized Resistance Function........................................................................... 2-4

2-3. Synthesized Capacitance Function......................................................................... 2-5

2-4. Current Function (AUX Out Ranges) .................................................................... 2-6

2-5. Voltage Function.................................................................................................... 2-7

3-1. Connections for Calibrating DC Volts up to 30 V................................................. 3-7

3-2. Connections for Calibrating DC Volts 30 V and Above........................................ 3-8

3-3. Connections for Calibrating AC Volts................................................................... 3-9

3-4. Connections for Calibrating Thermocouple Sourcing............................................ 3-11

3-5. Connections for Calibrating Thermocouple Measuring......................................... 3-11

3-6. Connections for Calibrating DC Current................................................................ 3-13

3-7. Connections for Calibrating AC Current with a Fluke A40 Shunt ........................ 3-14

3-8. Connections for Calibrating AC Current with a Fluke A40A Shunt...................... 3-17

3-9. Sample MET/CAL Program................................................................................... 3-18

3-10. Four-Wire Resistance Connection.......................................................................... 3-23

3-11. Scaling the DMM to a Fluke 742A........................................................................ 3-23

3-12. Two-Wire Resistance Connection.......................................................................... 3-24

3-13. Scaling the DMM to a Guildline 9334................................................................... 3-24

3-14. Connections for Calibrating Capacitance............................................................... 3-26

3-15. Normal Volts and AUX Volts Phase Verification................................................. 3-26

3-16. Volts and Current Phase Verification..................................................................... 3-27

3-17. Connections for Verifying AC Current with a Metal Film Resistor

(3.2999 mA and Below)......................................................................................... 3-43

3-18. High Value Capacitance Measurement Set-up....................................................... 3-49

3-19. Example Visual Basic Program.............................................................................. 3-50

4-1. Exploded View of Rear Panel Assemblies............................................................. 4-5

4-2. Exploded View of Front Panel Assemblies............................................................ 4-6

5-1. Chassis Assembly................................................................................................... 5-5

5-2. Front Panel Assembly ............................................................................................ 5-9

5-3. Rear Panel Assembly ............................................................................................. 5-13

5-4. Wiring Diagram...................................................................................................... 5-14

xi

Page 16

5520A

Service Manual

6-1. SC600 Block Diagram ........................................................................................... 6-14

6-2. Equipment Setup for SC600 Voltage Square Wave Measurements ...................... 6-19

6-3. Equipment Setup for SC600 Edge and Wave Gen Square Wave Measurements.. 6-20

6-4. Connecting the Calibrator Mainframe to the 5790A AC Measurement Standard . 6-24

6-5. MeasZ Function Calibration Setup ........................................................................ 6-27

6-6. AC Voltage Frequency Verification Setup ............................................................ 6-34

6-7. Edge Rise Time Verification Setup........................................................................ 6-37

6-8. Edge Rise Time...................................................................................................... 6-38

6-9. Leveled Sine Wave Harmonics Verification Setup................................................ 6-42

6-10. Connecting the Calibrator Mainframe to the 5790A AC Measurement Standard . 6-44

6-11. Connecting the HP 437B Power Meter to the HP 8482A or 8481D Power Sensor 6-45

6-12. Connecting the Calibrator Mainframe to the HP Power Meter and Power Sensor 6-45

6-13. Wave Generator Verification Setup....................................................................... 6-49

6-14. Overload Function Verification Setup ................................................................... 6-56

6-15. Adjusting the Leveled Sine Wave Balance............................................................ 6-58

6-16. Adjusting the Leveled Sine Wave Harmonics ....................................................... 6-59

6-17. Adjusting Short-Term Edge................................................................................... 6-61

6-18. SC300 Block Diagram........................................................................................... 6-73

6-19. Equipment Setup for SC300 Square Wave Measurements.................................... 6-78

6-20. Connecting the Calibrator Mainframe to the 5790A AC Measurement Standard . 6-81

6-21. Frequency Verification Setup................................................................................. 6-89

6-22. Edge Rise Time Verification Setup........................................................................ 6-93

6-23. Edge Rise Time...................................................................................................... 6-94

6-24. Leveled Sine Wave Harmonics Verification Setup................................................ 6-97

6-25. Connecting the Calibrator Mainframe to the 5790A AC Measurement Standard . 6-99

6-26. Connecting the HP 437B Power Meter to the HP 8482A or 8481D Power Sensor 6-100

6-27. Connecting the Calibrator Mainframe to the HP Power Meter and Power Sensor 6-100

6-28. Wave Generator Verification Setup....................................................................... 6-105

6-29. Adjusting the Leveled Sine Wave Harmonics ....................................................... 6-109

6-30. Adjusting Short-Term Edge................................................................................... 6-110

xii

Page 17

Chapter 1

Introduction and Specifications

Title Page

1-1. Introduction........................................................................................... 1-3

1-2. Operation Overview.............................................................................. 1-4

1-3. Local Operation................................................................................ 1-4

1-4. Remote Operation (RS-232)............................................................. 1-4

1-5. Remote Operation (IEEE-488)......................................................... 1-4

1-6. Service Information.............................................................................. 1-5

1-7. How to Contact Fluke........................................................................... 1-5

1-8. Specifications........................................................................................ 1-6

1-9. General Specifications...................................................................... 1-7

1-10. DC Voltage Specifications............................................................... 1-8

1-11. DC Current Specifications................................................................ 1-9

1-12. Resistance Specifications................................................................. 1-11

1-13. AC Voltage (Sine Wave) Specifications.......................................... 1-12

1-14. AC Current (Sine Wave) Specifications........................................... 1-14

1-15. Capacitance Specifications............................................................... 1-16

1-16. Temperature Calibration (Thermocouple) Specifications................ 1-17

1-17. Temperature Calibration (RTD) Specifications................................ 1-18

1-18. DC Power Specification Summary................................................... 1-19

1-19. AC Power (45 Hz to 65 Hz) Specification Summary, PF=1............ 1-19

1-20. Power and Dual Output Limit Specifications................................... 1-20

1-21. Phase Specifications......................................................................... 1-21

1-22. Calculating Power Uncertainty......................................................... 1-22

1-23. Additional Specifications...................................................................... 1-23

1-24. Frequency Specifications.................................................................. 1-23

1-25. Harmonics (2nd to 50th) Specifications........................................... 1-24

1-26. AC Voltage (Sine Wave) Extended Bandwidth Specifications........ 1-25

1-27. AC Voltage (Non-Sine Wave) Specifications.................................. 1-26

1-28. AC Voltage, DC Offset Specifications............................................. 1-27

1-29. AC Voltage, Square Wave Characteristics....................................... 1-28

1-30. AC Voltage, Triangle Wave Characteristics (typical)...................... 1-28

1-31. AC Current (Sine Wave) Extended Bandwidth Specifications........ 1-28

1-32. AC Current (Non-Sine Wave) Specifications .................................. 1-29

1-33. AC Current, Square Wave Characteristics (typical)......................... 1-31

1-34. AC Current, Triangle Wave Characteristics (typic al )...................... 1-31

1-1

Page 18

5520A

Service Manual

1-2

Page 19

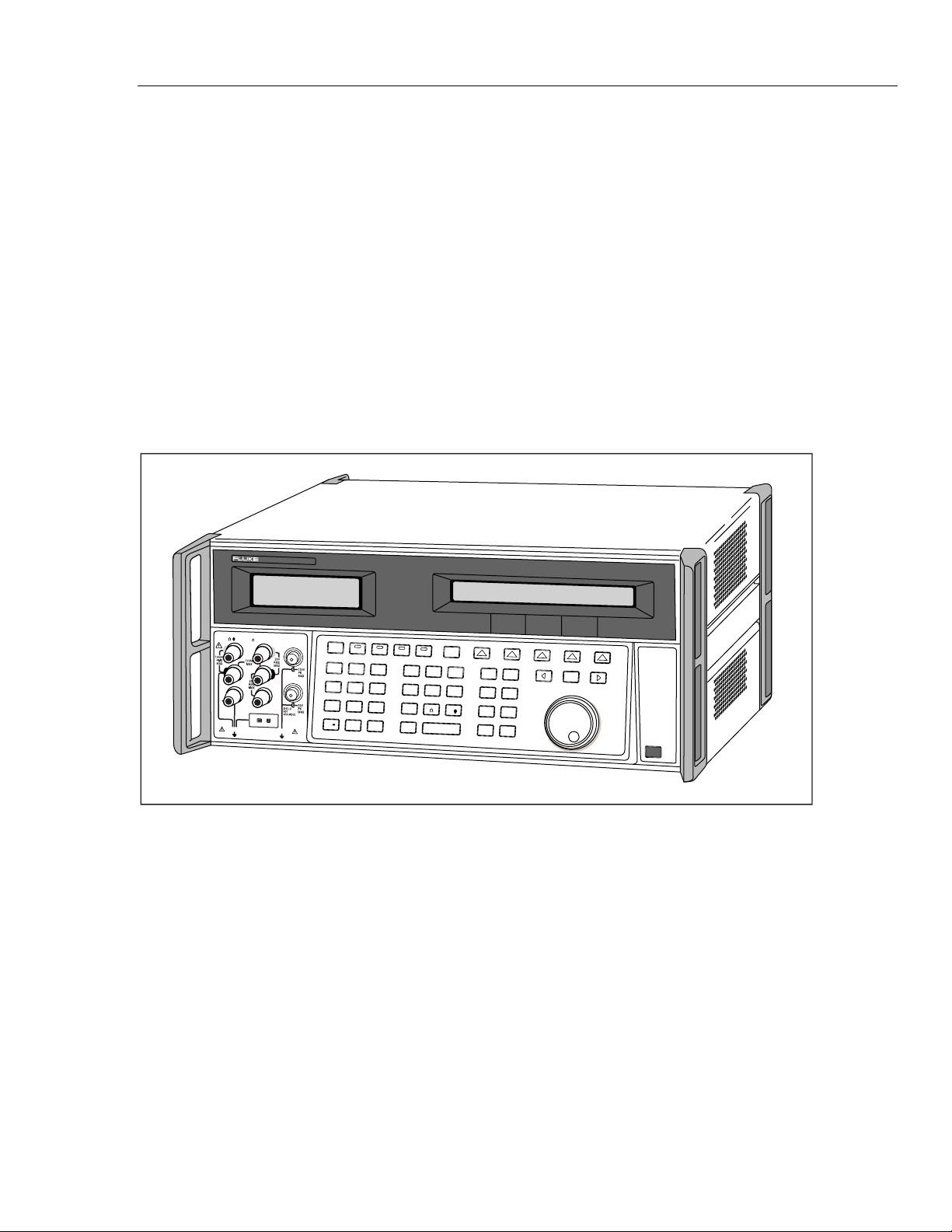

1-1. Introduction

The Fluke Model 5520A Multi-Product Calibrator (Figure 1-1) is a precise instrument

that calibrates a wide variety of electrical measuring instruments. With the 5520A

Calibrator, you can calibrate precision multimeters that measure ac or dc voltage, ac or dc

current, ac or dc power, resistance, capacitance, and temperature. The 5520A can display

pressure measurements when used with a Fluke 700 Series Pressure Module. With the

SC600 and SC300 Oscilloscope Calibration options, you can use the 5520A Calibrator to

calibrate analog and digital oscilloscopes. Specifications are provided in this chapter

(specifications for the oscilloscope calibration options are provided in Chapter 6).

If the 5520A Calibrator is operated in any way not specified by

this manual or other documentation provided by Fluke, the

protection provided by the Calibrator may be impaired.

XWWarning

Introduction and Specifications

Introduction

1

NORMAL AUX

V, , ,

RTD

A, -SENSE,

HI

LO

GUARD

20V PK MAX

5520A

TC

AUX V

20A

20V PK MAX

CALIBRATOR

SCOPE

OUT

TRIG

p

SHIFT

µ

n

M

SCOPE

m

k

PREV

MENU

dBm sec

VHz

W

¡F

A

¡C

F

ENTER

SETUP

RESET

NEW

CE

REF

MEAS

MORE

TC

MODES

MULT

DIV

x

÷

EDIT

FIELD

OPRSTBY EARTH

789

456

123

+

/

0•

EXGRD

Figure 1-1. 5520A Multi-Product Calibrator

POWER

yg030f.eps

1-3

Page 20

5520A

Service Manual

1-2. Operation Overview

1-3. Local Operation

1-4. Remote Operation (RS-232)

The 5520A Calibrator may be operated at the front panel in the local mode, or remotely

using RS-232 or IEEE-488 ports. For remote operations, several software options are

available to integrate 5520A operation into a wide variety of calibration requirements.

Typical local operations include front panel connections to the Unit Under Test (UUT),

and then manual keystroke entries at the front panel to place the calibrator in the desired

output mode. The front panel layout facilitates hand movements from left to right, and

multiply and divide keys make it easy to step up or down at the press of a single key. You

can also review 5520A Calibrator specifications at the push of two keys.

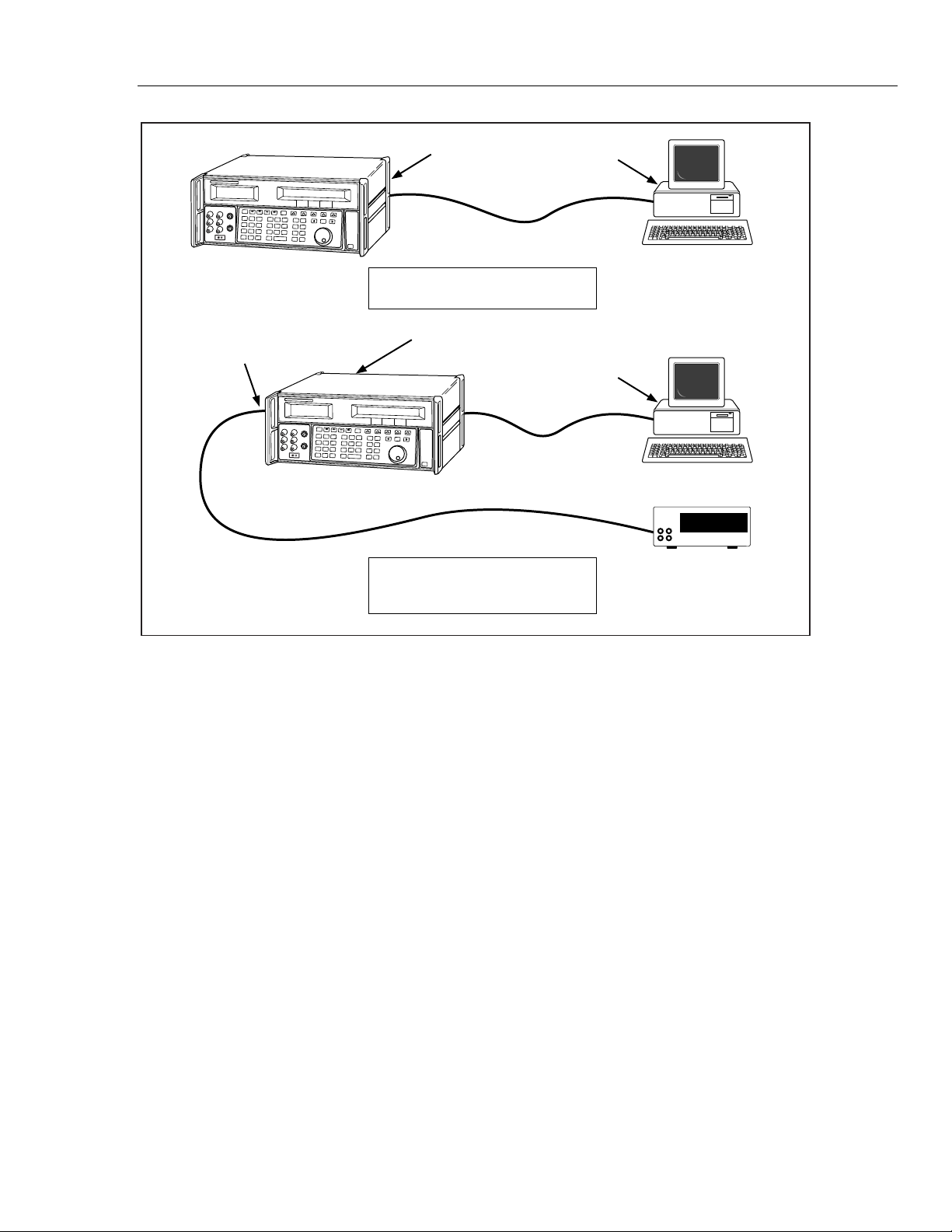

There are two rear-panel serial data RS-232 ports: SERIAL 1 FROM HOST, and

SERIAL 2 TO UUT (Figure 1-2). Each port is dedicated to serial data communications

for operating and controlling the 5520A during calibration procedures. For complete

information on remote operation, see Chapter 5 of the 5520A Operators Manual.

The SERIAL 1 FROM HOST serial data port connects a host terminal or personal

computer to the 5520A. You have several choices for sending commands to the 5520A:

you can enter commands from a terminal (or a PC running a terminal program), you can

write your own programs using BASIC, or you can run optional Windows-based software

such as 5500/CAL or MET/CAL. The 5500/CAL software includes more than 200

example procedures covering a wide range of test tools the 5520A can calibrate.

The SERIAL 2 TO UUT serial data port connects a UUT to a PC or terminal via the

5520A (see Figure 1-3). This “pass-through” configuration eliminates the requirement for

two COM ports at the PC or terminal. A set of four commands control the operation of

the SERIAL 2 TO UUT serial port. See Chapter 6 of the 5520A Operators Manual for a

discussion of the UUT_* commands. The SERIAL 2 TO UUT port is also used to

connect to the Fluke 700 series pressure modules.

1-5. Remote Operation (IEEE-488)

The 5520A rear panel IEEE-488 port is a fully programmable parallel interface bus

meeting standard IEEE-488.1 and supplemental standard IEEE-488.2. Under the remote

control of an instrument controller, the 5520A Calibrator operates exclusively as a

“talker/listener.” You can write your own programs using the IEEE-488 command set or

run the optional Windows-based MET/CAL software. (See the 5520A Operators Manual

for a discussion of the general commands available for IEEE-488 operation, and

Chapter 3 of this manual for remote commands used for 5520A calibration.)

1-4

Page 21

Introduction and Specifications

Service Information

1

5520A

SERIAL 2

TO UUT port

SERIAL 1 FROM HOST port

RS-232 Remote Operation using the

SERIAL 1 FROM HOST port

SERIAL 1 FROM HOST port

5520A

RS-232 Remote Operation using the

SERIAL 1 FROM HOST and

SERIAL 2 TO UUT ports

COM port

PC or Terminal

COM port

PC or Terminal

Unit Under Test

Figure 1-2. RS-232 Remote Connections

1-6. Service Information

In case of difficulty within the 1-year Warranty period, return the Calibrator to a Fluke

Service Center for Warranty repair. For out of Warranty repair, contact a Fluke Service

Center for a cost estimate.

This service manual provides instructions for verification of performance, calibration,

and maintenance. If you choose to repair a malfunction, information in this manual can

help you to determine which module (printed circuit assembly) has a fault.

1-7. How to Contact Fluke

To contact Fluke, call one of the following telephone numbers:

• 1-888-99FLUKE (1-888-993-5853) in U.S.A.

• 1-800-36-FLUKE (1-800-363-5853) in Canada

• +31-402-678-200 in Europe

• +81-3-3434-0181 Japan

• +65-738-5655 Singapore

• +1-425-446-5500 from other countries

Or, visit Fluke’s Web site at www.fluke.com.

nn031f.eps

1-5

Page 22

5520A

Service Manual

1-8. Specifications

The following tables list the 5520A specifications. All specifications are valid after

allowing a warm-up period of 30 minutes, or twice the time the 5520A has been turned

off. (For example, if the 5520A has been turned off for 5 minutes, the warm-up period is

10 minutes.)

All specifications apply for the temperature and time period indicated. For temperatures

outside of t

±5 °C (t

cal

is the ambient temperature when the 5520A was calibrated), the

cal

temperature coefficient as stated in the General Specifications must be applied.

The specifications also assume the Calibrator is zeroed every seven days or whenever the

ambient temperature changes more than 5 °C. The tightest ohms specifications are

maintained with a zero cal every 12 hours within ±1 °C of use.

Also see additional specifications later in this chapter for information on extended

specifications for ac voltage and current. The dimensional outline for the 5520A

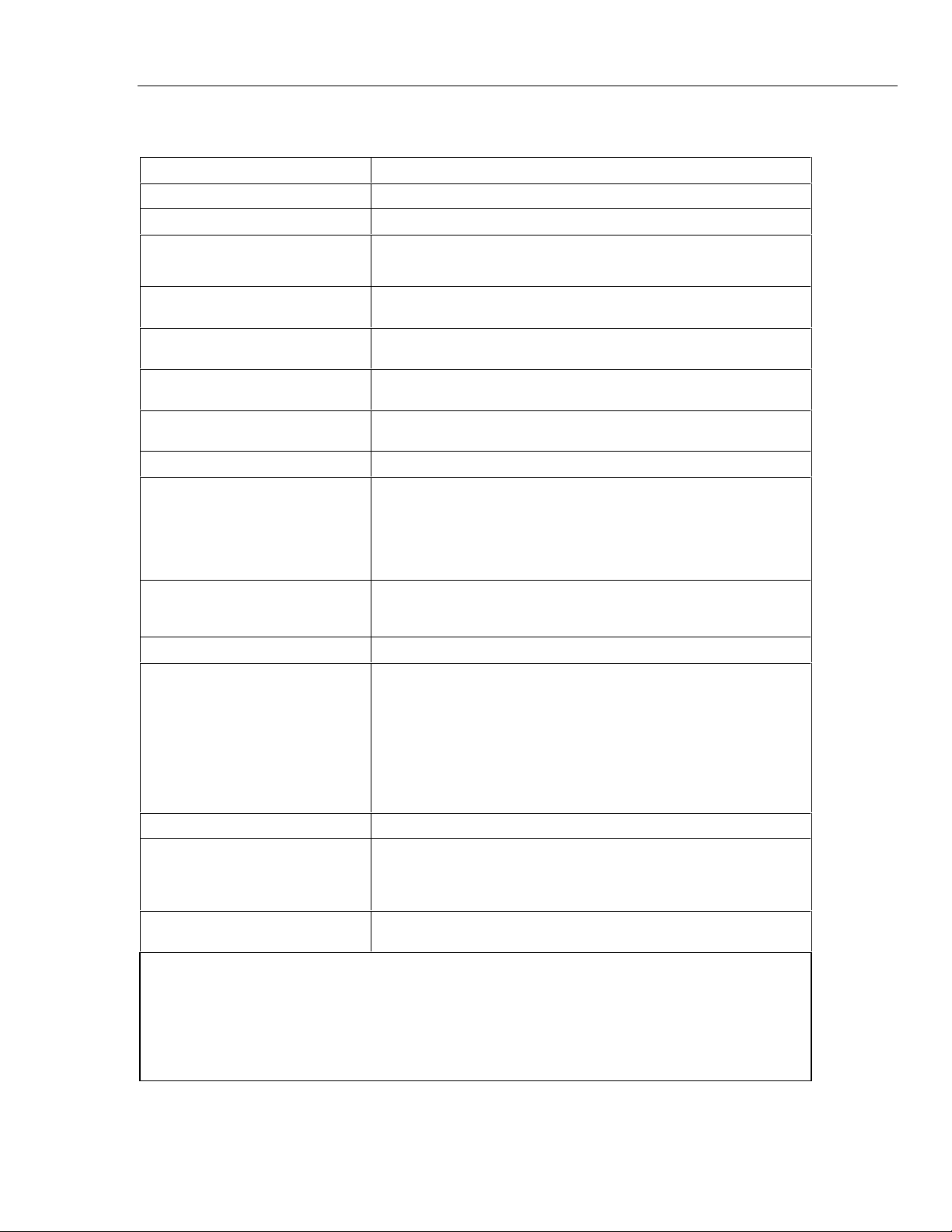

Calibrator is shown in Figure 1-3.

43.2 cm (17 in)

5520A CALIBRATOR

NORMAL AUX

V, , ,

RTD

A, -SENSE,

HI

LO

GUARD

20V PK MAX

SCOPE

AUX V

OUT

STBY

OPR EARTH EXGRD SCOPE MENU

789

TRIG

456

20A

20V PK MAX

TC

123

+

0•

/

µ

m

n

k

p

M

SHIFT

PREV

dBm sec

VHz

W

¡F

¡CA

F

ENTER

SETUP

NEW

REF

MEAS

TC

MULTxDIV

RESET

MORE

MODES

EDIT

FIELD

CE

÷

POWER

(7 in)

I

O

17.8 cm

47.0 cm (18.5 in) 6.4 cm

(2.5 in)

For Cable

Access

1-6

nn032f.eps

Figure 1-3. 5520A Calibrator Dimensional Outline

Page 23

Introduction and Specifications

1-9. General Specifications

Warmup Time Twice the time since last warmed up, to a maximum of 30 minutes.

Settling Time Less than 5 seconds for all functions and ranges except as noted.

Standard Interfaces IEEE-488 (GPIB), RS-232, 5725A Amplifier

Temperature Performance • Operating: 0 °C to 50 °C

• Calibration (tcal): 15 °C to 35 °C

• Storage: -20 °C to 70 °C [3]

Temperature Coefficient Temperature Coefficient for temperatures outsi de tc al +5 °C is 0.1X/°C of

the 90-day specification (or 1-year, as applicable) per ° C.

Relative Humidity [1] • Operating: <80% to 30 °C, <70% to 40 °C, <40% to 50 °C

• Storage: <95%, non-condensing

Altitude • Operating: 3,050 m (10,000 ft) maximum

Safety Complies with IEC 1010-1 (1992-1); ANSI/ISA-S 82.01-1994;

Analog Low Isolation 20 V

EMC Designed to comply with FCC Rules Part 15; VFG 243/1991. If used in

Line Power [2] • Line Voltage (selectable): 100 V, 120 V, 220 V, 240 V

Power Consumption 5500A Calib rat o r, 300 VA; 5725A Ampl i fi er, 750 VA

Dimensions 5500A Calibrator:

Weight (without options) 5500A Calibrator, 22 kg (49 lb); 5725A Amplifier 32 kg (70 pounds)

Absolute Uncertainty Definition The 5500A specifications include stability, temperature coefficient, lineari ty,

Specification Confidence

Interval

• Non-operating: 12,200 m (40,000 ft) maximum

CAN/CSA-C22.2 No. 1010.1-92

areas with Electromagnetic fields of 1 to 3 V/m, resistance outputs have a

floor adder of 0.508 •. Performance not specified above 3 V/m. This

instrument may be susceptible to electro-stat ic disc harge (ES D) f rom direct

contact to the binding posts. Good static aware practices should be

followed when handling this and other pieces of electronic equipment.

• Line Frequency: 47 Hz to 63 Hz

• Line Voltage Variation: ±10% about line voltage setting

• Height: 17.8 cm (7 inches), standard rack increment, plus 1.5 cm (0.6

inch) for feet on bottom of unit;

• Width: 43.2 cm (17 inches), standard rack width

• Depth: 47.3 cm (18.6 inches) overall 5725A Amplifier:

• Height, 13.3 cm (5.25 inches), standard rack increment, plus 1.5 cm (0.6

inch) for feet on bottom of unit;

• Width, 43.2 cm (17 inches), standard rack width

• Depth, 63.0 cm (24.8 inches) overall.

line and load regulation, and the traceability of the external standards used

for calibration. You do not need to add anything to determine the total

specification of the 5520A for the temperature range indicated.

99%

Specifications

1

[1] After long periods of storage at high humidity, a drying out period (with the power on) of at least one week may be

required.

[2] For optimal performance at full dual outputs (e.g. 1000 V, 20A) choose a line voltage sett i ng that is ± 7.5% from

nominal.

[3] The DC Current ranges 0 to 1.09999 A and 1.1 A to 2.99999 A are sensitive to storage temperatures above 50 °C.

If the 5520A is stored above 50 °C for greater than 30 minutes, these ranges must be re-calibrated. Otherwi se, the

90 day and 1 year uncertainties of these ranges double.

1-7

Page 24

5520A

Service Manual

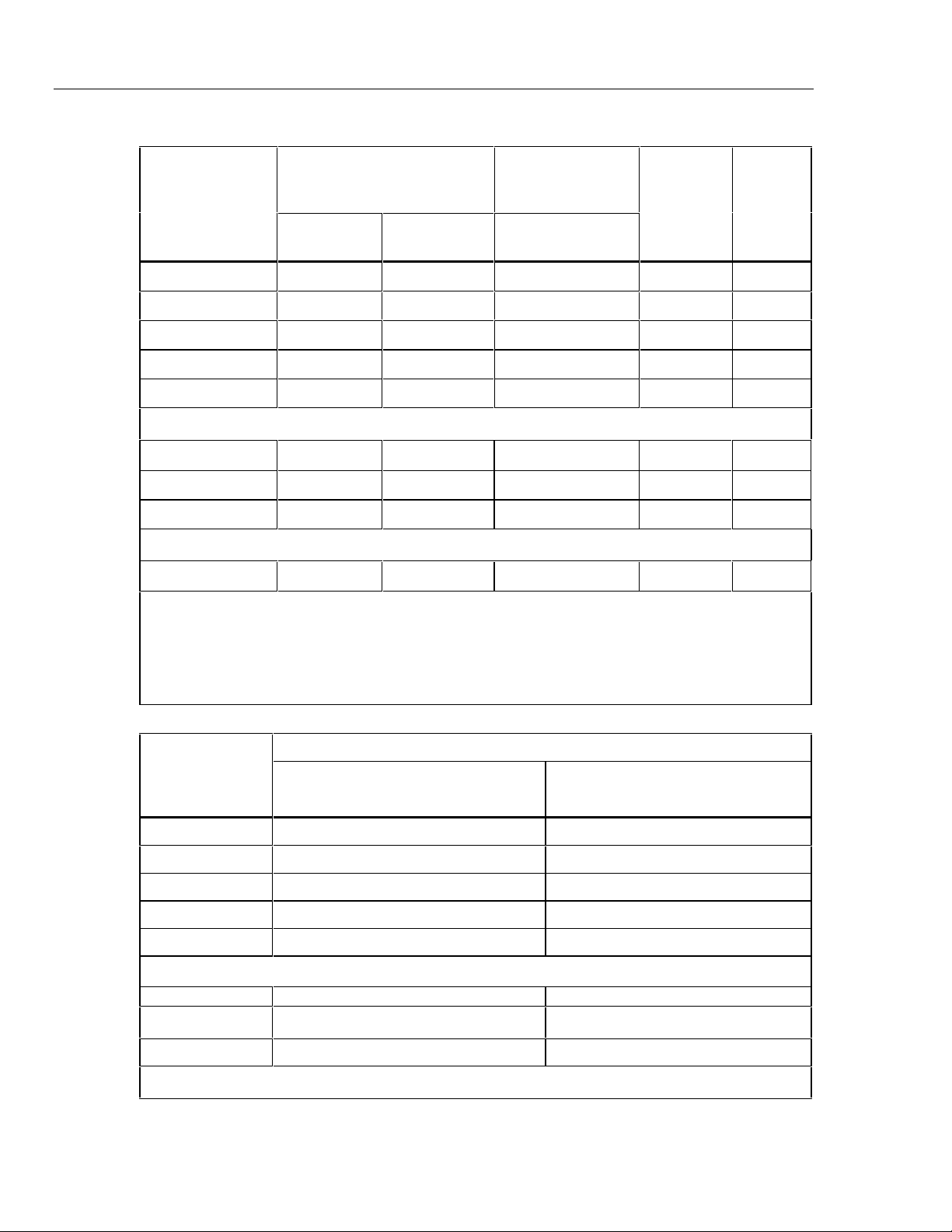

1-10. DC Volt age Specifi cati ons

Absolute Uncertainty, tcal

± 5 °C

± (ppm of output + µV)

Range 90 days 1 year

0 to 329.9999 mV 15 + 1 20 + 13 + 1 0.1 50 Ω

0 to 3.299999 V 9 + 2 11 + 22 + 1.5 1 10 mA

0 to 32.99999 V 10 + 20 12 + 20 2 + 15 10 10 mA

30 V to 329.9999 V 15 + 150 18 + 150 2 .5 + 100 100 5 mA

100 V to 1000.000 V 15 + 1500 18 + 1500 3 + 300 1000 5 mA

Auxiliary Output (dual output mode only) [2]

0 to 329.999 mV 300 + 350 400 + 350 30 + 100 1 5 mA

0.33V to 3.29999V 300 + 350 400 + 350 30 + 100 10 5 mA

3.3 V to 7 V 300 + 350 400 + 350 30 + 100 100 5 mA

TC Simulate and Measure in Linear 10 µV/°C and 1 mV/°C modes [3]

0 to 329.999 mV 40 + 3 50 + 35 + 2 0.1 10 Ω

[1] Remote sensing is not provided. Output resistance is < 5 mΩ for outputs ≥ 0.33 V. The AUX output

has an output resistance of < 1Ω. TC simulation has an output impedance of 10 Ω ± 1 Ω.

Stability

24 hours, ± 1 °C

± (ppm output + µV)

Resolution

µV[1]

Max

Burden

[2] Two channels of dc voltage output are provided.

[3] TC simulating and measuring are not specified for operation in electromagnetic fields above 0.4 V/m.

Noise

Range

0 to 329.9999 mV 0 + 1 µV6 µV

0 to 3.299999 V 0 + 10 µV 60 µV

0 to 32.99999 V 0 + 100 µV 600 µV

30 to 329.9999 V 10 + 1 mV 20 mV

100 to 1000.000 V 10 + 5 mV 20 mV

0 to 329.999 mV 0 + 5 µV 20 µV

0.33 V to

3.29.999 V

3.3 V to 7 V 0 + 100 µV 1000 µV

[1] Two channels of dc voltage output are provided.

Bandwidth 0.1 Hz to

10 Hz p-p

± (ppm output + floor)

Auxiliary Output (dual output mode only) [1]

0 + 20 µV 200 µV

Bandwidth 10 Hz to 10 kHz

rms

1-8

Page 25

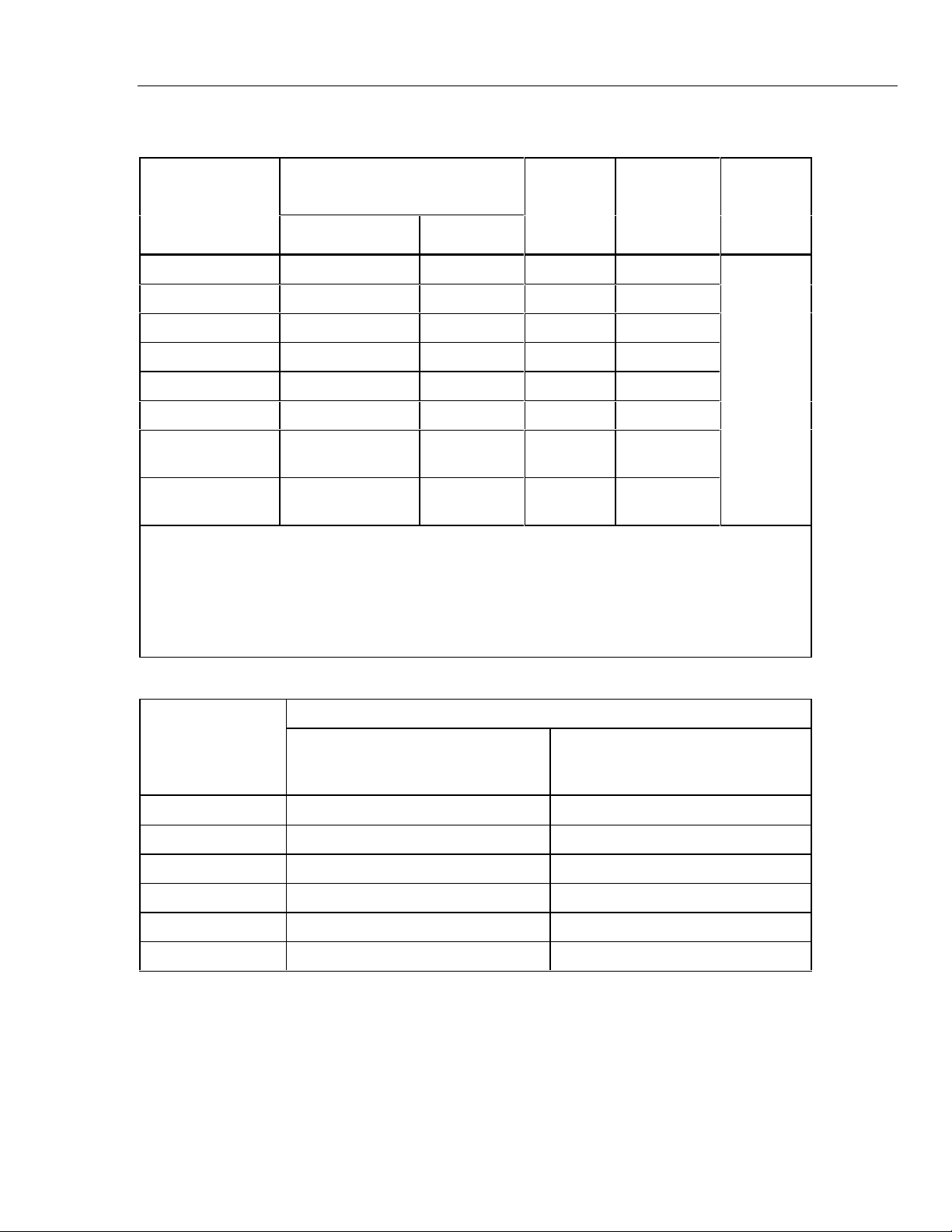

1-11. DC Current Specifi cations

Introduction and Specifications

Specifications

1

Absolute Uncertainty,

tcal ± 5 °C

± (ppm of output + µA)

Range

0 to 329.999 mA 120 + 0.02 150 + 0.02 1 nA 10

0 to 3.29999 mA 80 + 0.05 100 + 0.05 0.01 mA 10

0 to 32.9999 mA 80 + 0.25 100 + 0.25 0.1 mA 7

0 to 329.999 mA 80 + 2.5 100 + 2.5 1 mA 7 400

0 to 1.09999 A 160 + 40 200 + 40 10 mA 6

1.1 to 2.99999 A 300 + 40 380 + 40 10 mA 6

0 to 10.9999 A

(20 A Range) 380 + 500 500 + 500 100 mA 4

11 to 20.5 A [1] 800 + 750 [2] 1000 + 750

[1] Duty Cycle: Currents < 11 A may be provided continuously. For currents >11 A, see Figure 1-4. The current may be

provided 60-T-I minutes any 60 minute period where T is the temperature in °C (room temperature is about 23 °C)

and I is the output current in amperes. For example, 17 A, at 23 °C could be provided for 60-17-23 = 20 minutes

each hour.

90 days 1 year

[2]

Resolution

100 mA 4

Max

Compliance

Voltage

V

Max

Inductive

Load

mH

[2] Floor specification is 1500 µA within 30 seconds of selecting operate. For operating times > 30 seconds, the floor

specification is 750 µA.

Noise

Bandwidth

10 Hz to 10 kHz

rms

Range

Bandwidth

0.1 Hz to 10 Hz

p-p

0 to 329.999 µA 2 nA 20 nA

0 to 3.29999 mA 20 nA 200 nA

0 to 32.9999 mA 200 nA 2.0 µA

0 to 329.999 mA 2000 nA 20 µA

0 to 2.99999 A 20 µA1 mA

0 to 20.5 A 200 µA 10 mA

1-9

Page 26

5520A

Service Manual

DC Current Specifications (cont)

50

45

40

35

10 °C

30

25

Minutes per Hour

20

15

10

5

0

11 12 13 14 15 16 17 18 19 20

40 °C

30 °C

Current (Amps)

20 °C

Ambient

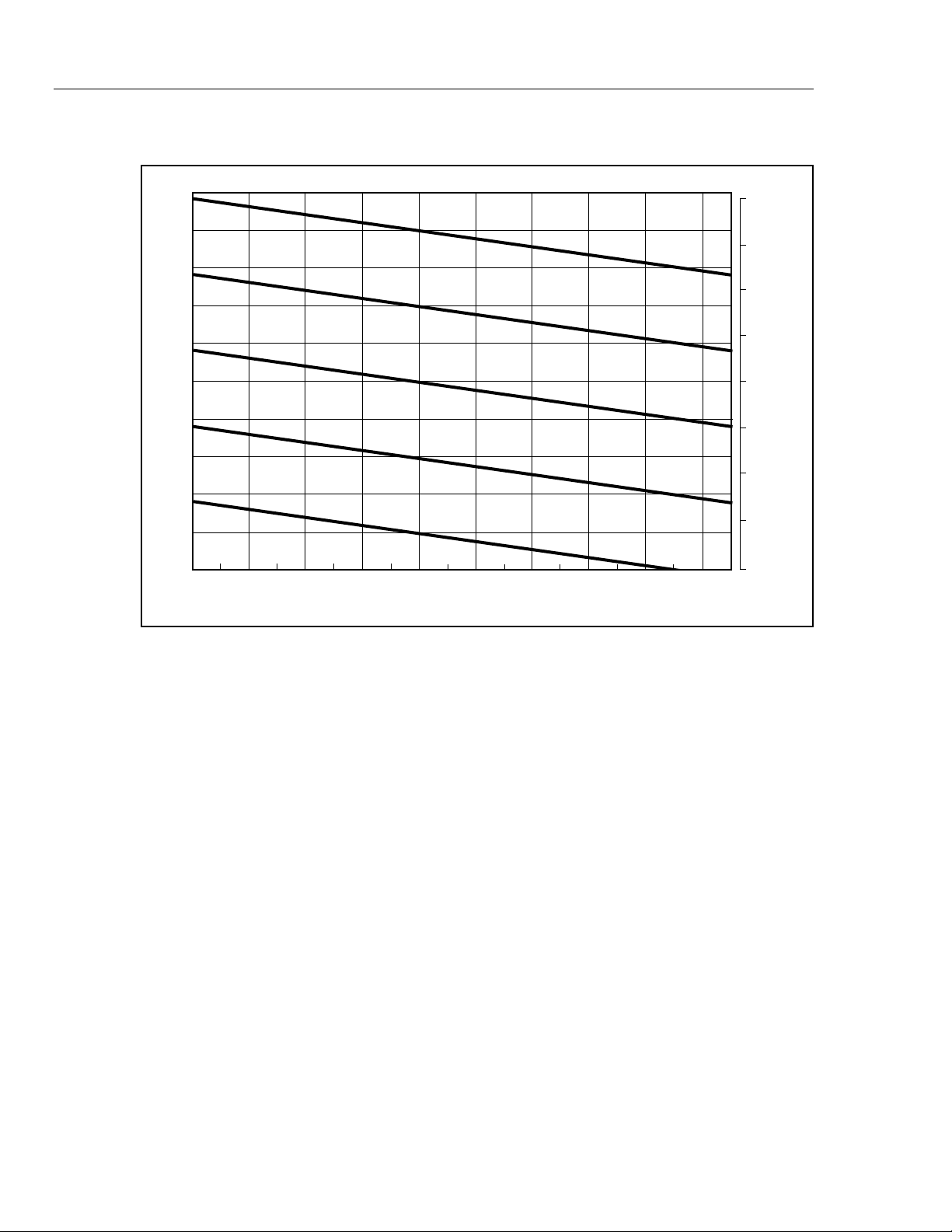

Figure 1-4. Allowable Duration of Current > 11 A

0 °C

80%

70%

60%

50%

40%

Duty Cycle (%)

30%

20%

10%

0%

nn326f.eps

1-10

Page 27

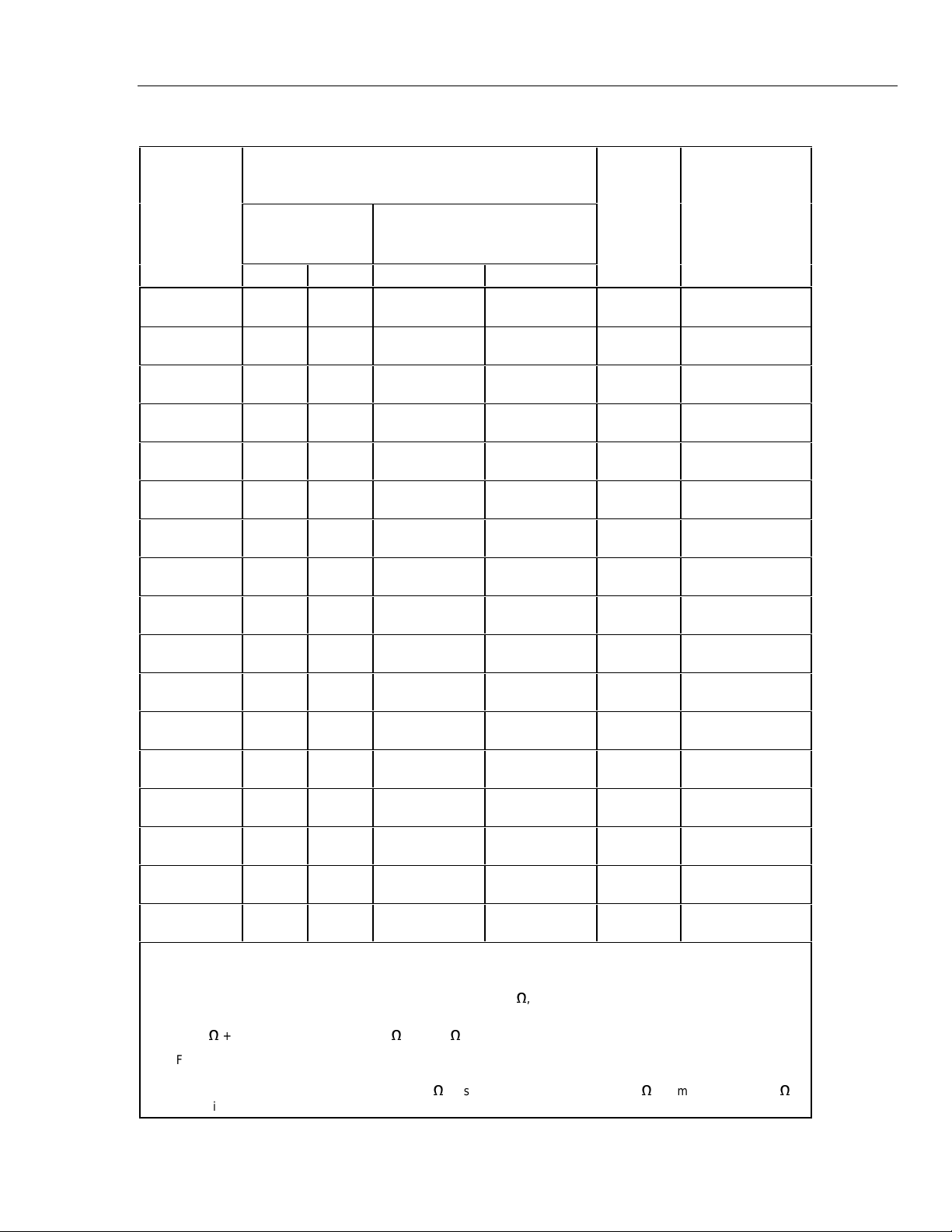

1-12. Resistance Specifications

Introduction and Specifications

Specifications

1

Range

[1]

0 to

10.9999 Ω

11 Ω to

32.9999 Ω

33 Ω to

109.9999 Ω

110 Ω to

329.9999 Ω

330 Ω to

1.099999 kΩ

1.1 kΩ to

3.299999 kΩ

3.3 kΩ to

10.99999 kΩ

11 kΩ to

32.99999 kΩ

33 kΩ to

109.9999 kΩ

110 kΩ to

329.9999 kΩ

330 kΩ to

1.099999 MΩ

1.1 MΩ to

3.299999 MΩ

3.3 MΩ to

10.99999 MΩ

11 MΩ to

32.99999 MΩ

33 MΩ to

109.9999 MΩ

110 MΩ to

329.9999 MΩ

330 MΩ to

1100 MΩ

[1] Continuously variable from 0 Ω to 1.1 G Ω.

[2] Applies for a 4-WIRE compensation only. For 2-WIRE and 2-WIRE COMP, add 5 µV per Amp of stimulus current

to the floor specification. For example, in 2-WIRE mode, at 1 ke, the floor specification within 12 hours of an ohms

zero cal for a measurement current of 1 mA is:

0.002 e + 5 µV/1 ma = (0.002 + 0.005) e = 0.007

[3] For currents lower than shown, the floor adder increases by:

Floor (new) = Floor (old) XImin/Iactual.

For example, a 50 µA stimulus measuring 100 e, has a floor specification of: 0.0014 e X 1 mA/50 µA = 0.028 e,

assuming an ohms zero cal within 12 hours.

ppm of output

90 days 1 year 12 hrs ± 1 °C 7 days ± 5 °C

110 130 50 250 10 250 nA to 1.8 µA

200 250 2500 2500 10 25 nA to 500 nA

400 500 3000 3000 100 25 nA to 180 nA

2500 3000 100000 100000 1000 2.5 nA to 50 nA

12000 15000 500000 500000 10000 1 nA to 13 nA

Absolute Uncertainty, tcal ± 5 °C

± (ppm of output + floor) [2]

Floor

Time & temp since ohms zero

cal

35 40 0.001 0. 01 0.0001 1 mA to 125 mA

25 30 0.0015 0.015 0.0001 1 mA to 125 mA

22 28 0.0014 0.015 0.0001 1 mA to 70 mA

22 28 0.002 0.02 0.0001 1 mA to 40 mA

22 28 0.002 0.02 0.001 1 mA to 18 mA

22 28 0.02 0.2 0.001 100 µA to 5 mA

22 28 0.02 0.1 0.01 100 µA to 1.8 mA

22 28 0.2 1 0.01 10 µA to 0.5 mA

22 28 0.2 1 0. 1 10 µA to 0.18 mA

25 32 2 10 0.1 1 µA to 0.05 mA

25 32 2 10 1 1 µA to 0.018 mA

40 60 30 150 1 250 nA to 5 µA

e

Resolution Allowable

Ω Current [3]

1-11

Page 28

5520A

Service Manual

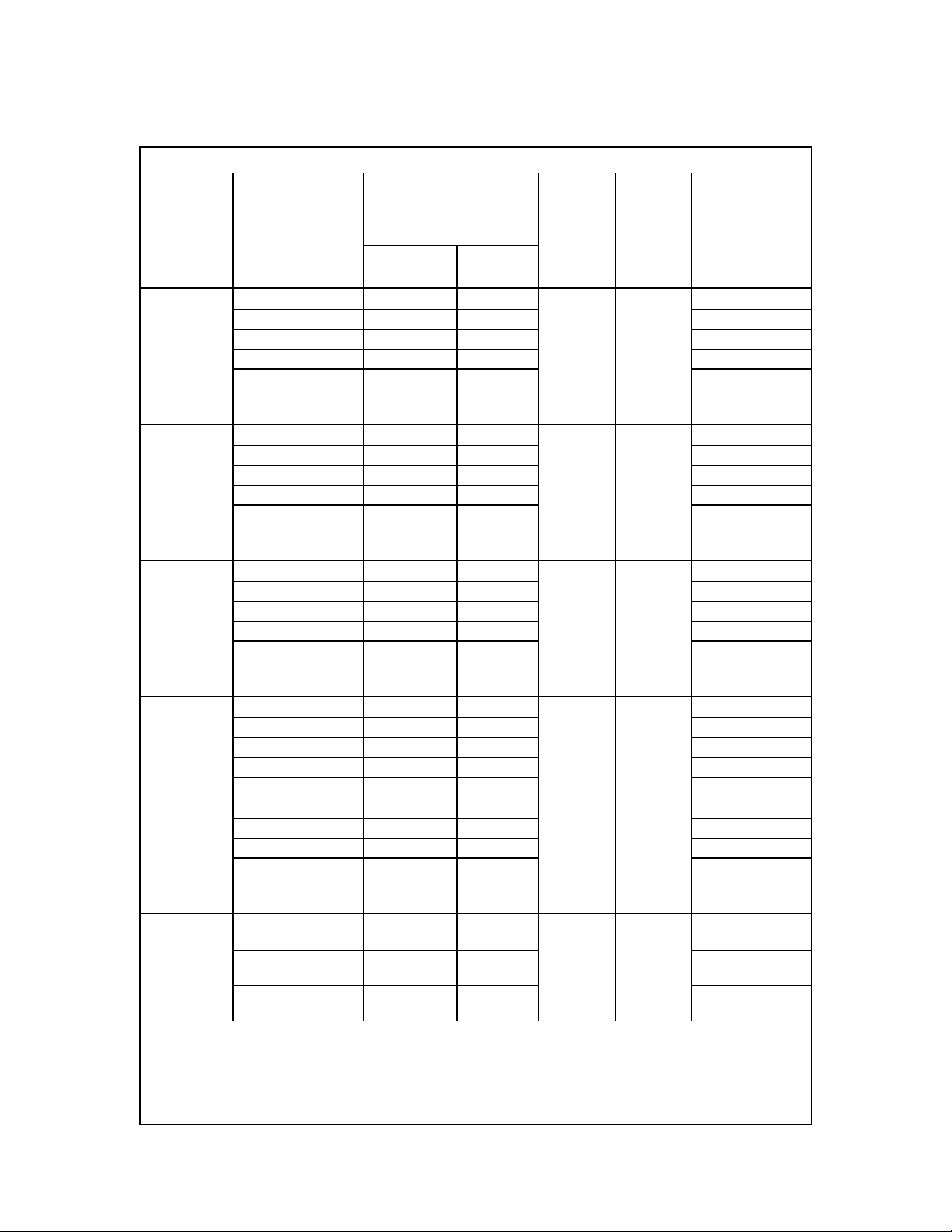

1-13. AC Voltage (Sine Wave) Specifications

NORMAL (Normal Output)

Absolute Uncertainty,

Range Frequency

1.0 mV to 10 Hz to 45 Hz 600 + 6 800 + 61 µV 50 Ω

32.999 mV 45 Hz to 10 kHz 120 + 6 150 + 6 0.035 + 90 µV

10 kHz to 20 kHz 160 + 6 200 + 6 0.06 + 90 µV

20 kHz to 50 kHz 800 + 6 1000 + 6 0.15 + 90 µV

50 kHz to 100 kHz 3000 + 12 3500 + 12 0.25 + 90 µV

100 kHz to

500 kHz

33 mV to 10 Hz to 45 Hz 250 + 8 300 + 81 µV 50 Ω

329.999 mV 45 Hz to 10 kHz 140 + 8 145 + 8 0.035 + 90 µV

10 kHz to 20 kHz 150 + 8 160 + 8 0.06 + 90 µV

20 kHz to 50 kHz 300 + 8 350 + 8 0.15 + 90 µV

50 kHz to 100 kHz 600 + 32 800 + 32 0.20 + 90 µV

100 kHz to

500 kHz

0.33 V to 10 Hz to 45 Hz 250 + 50 300 + 50 10 µV 10 mA

3.29999 V 45 Hz to 10 kHz 140 + 60 150 + 60 0.035 + 200 µV

10 kHz to 20 kHz 160 + 60 190 + 60 0.06 + 200 µV

20 kHz to 50 kHz 250 + 50 300 + 50 0.15 + 200 µV

50 kHz to 100 kHz 550 + 125 700 + 125 0.20 + 200 µV

100 kHz to

500 kHz

3.3 V to 10 Hz to 45 Hz 250 + 650 300 + 650 100 µV 10 mA

32.9999 V 45 Hz to 10 kHz 125 + 600 150 + 600 0.035 + 2 mV

10 kHz to 20 kHz 220 + 600 240 + 600 0.08 + 2 mV

20 kHz to 50 kHz 300 + 600 350 + 600 0.2 + 2 mV

50 kHz to 100 kHz 750 + 1600 900 + 1600 0.5 + 2 mV

33 V to 45 Hz to 1 kHz 150 + 2000 190 + 2000 1 mV 5 mA,

329.999 V 1 kHz to 10 kHz 160 + 6000 200 + 6000 except 0.05 + 10 mV

10 kHz to 20 kHz 220 + 6000 250 + 6000 20 mA for 0.6 + 10 mV

20 kHz to 50 kHz 240 + 6000 300 + 6000 45 Hz to 0.8 + 10 mV

50 kHz to 100 kHz 1600 +

330 V to

1020 V

[1] Max Distortion for 100 kHz to 200 kHz. For 200 kHz to 500 kHz, the maximum distortion is 0.9% of

output + floor as shown.

Note

• Remote sensing is not provided. Output resistance is < 5 mΩ for outputs ≥0.33 V. The AUX output

resistance is < 1Ω. The maximum load capacitance is 500 pF, subject to the maximum burden current

limits.

45 Hz to 1 kHz 250 + 10000 300 +

1 kHz to 5 kHz 200 + 10000

5 kHz to 10 kHz 250 + 10000 300 +

6000 + 50 8000 + 50 0.3 + 90 µV [1]

1600 + 70 2000 + 70 0.20 + 90 µV [1]

2000 + 600 2400 + 600 0.20 + 200 µV [1]

50000

tcal ± 5 °C

± (ppm of output + µV)

90 days 1 year

2000 +

50000

10000

250 +

10000

10000

Resolution

10 mV 2 mA,

Max

Burden

65 Hz 1.0 + 10 mV

except

6 mA for

45 Hz to

65 Hz 0.07 + 30 mV

Max Distortion

and Noise

10 Hz to 5 MHz

Bandwidth

± (% output +

floor)

0.15 + 90 µV

0.15 + 90 µV

0.15 + 200 µV

0.15 + 2 mV

0.15 + 10 mV

0.15 + 30 mV

0.07 + 30 mV

1-12

Page 29

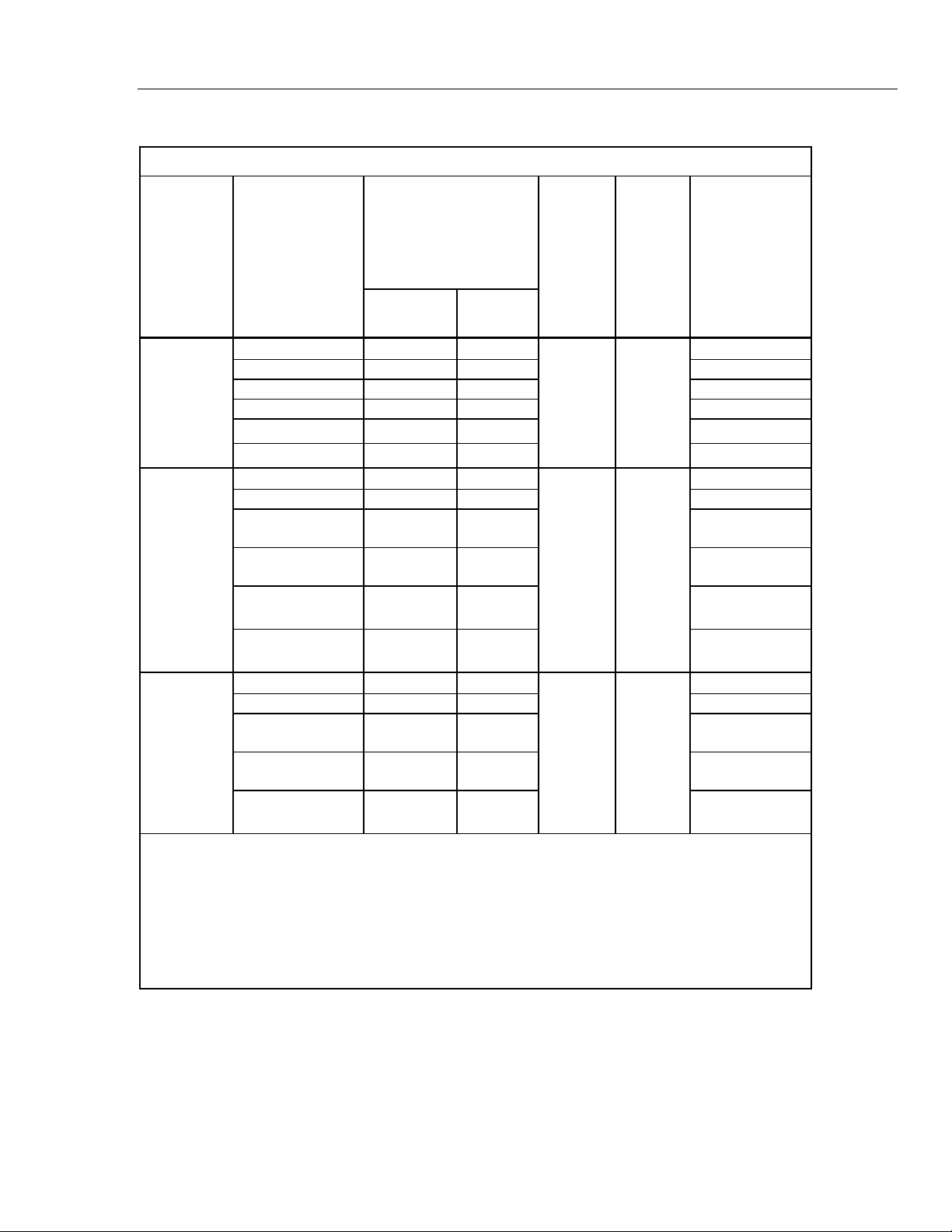

AC Voltage (Sine Wave) Specifications (cont)

AUX (Auxiliary Output) [dual output mode only] [1]

Introduction and Specifications

Specifications

1

Absolute Uncertainty,

Range Frequency

10 mV to 10 Hz to 20 Hz 0.15 + 370 0.2 + 370 1 µV5 mA

329.999 mV 20 Hz to 45 Hz 0.08 + 370 0.1 + 370 0.06 + 200 µV

45 Hz to 1 kHz 0.08 + 370 0.1 + 370 0.08 + 200 µV

1 kHz to 5 kHz 0.15 + 450 0.2 + 450 0.3 + 200 µV

5 kHz to 10 kHz 0.3 + 450 0.4 + 450 0.6 + 200 µV

10 Hz to 30 kHz 4.0 + 900 5.0 + 900 1 + 200 µV

0.33 V to 10 Hz to 20 Hz 0.15 + 450 0.2 + 450 10 µV5 mA

3.29999 V 20 Hz to 45 Hz 0.08 + 450 0.1 + 450 0.06 + 200 µV

45 Hz to 1 kHz 0.07 + 450 0.09 +

1 kHz to 5 kHz 0.15 + 1400 0.2 +

5 kHz to 10 kHz 0.3 + 1400 0.4 +

10 kHz to 30 kHz 4.0 + 2800 5.0 +

3.3 V to 5 V 10 Hz to 20 Hz 0.15 + 450 0.2 + 450 100 µV5 mA

20 Hz to 45 Hz 0.08 + 450 0.1 + 450 0.06 + 200 µV

45 Hz to 1 kHz 0.07 + 450 0.09 +

1 kHz to 5 kHz 0.15 + 1400 0.2 +

5 kHz to 10 kHz 0.3 +1400 0.4 +

tcal ± 5 °C

± (% of output + µV)

90 days 1 year

450

1400

1400

2800

450

1400

1400

Resolution

Max

Burden

Max Distortion

and Noise

10 Hz to

100 kHz

Bandwidth

± (% output +

floor)

0.2 + 200 µV

0.2 + 200 µV

0.08 + 200 µV

0.3 + 200 µV

0.6 + 200 µV

1 + 200 µV

0.2 + 200 µV

0.08 + 200 µV

0.3 + 200 µV

0.6 + 200 µV

[1] There are two channels of voltage output. The maximum frequency of the dual output is 30 kHz.

Note

• Remote sensing is not provided. Output resistance is < 5 mΩ for outputs ≥0.33 V. The AUX output

resistance is < 1Ω. The maximum load capacitance is 500 pF, subject to the maximum burden

current

limits.

1-13

Page 30

5520A

y

Service Manual

1-14. AC Current (Sine Wave) Specifications

LCOMP off

Max

Distortion &

Range Frequency

29.00 µA to 10 Hz to 20 Hz 0.16 + 0.1 0.2 + 0.1 0.05 0.15 + 0.5 µA 200

329.99 µA 20 Hz to 45 Hz 0.12 + 0.1 0.15 + 0.1 0.05 0.1 + 0.5 µA

45 Hz to 1 kHz 0.1 + 0.1 0.125 + 0.1 0.05 0.05 + 0.5 µA

1 kHz to 5 kHz 0.25 + 0.15 0.3 + 0.15 1.5 0.5 + 0.5 µA

5 kHz to 10 kHz 0.6 + 0.2 0.8 + 0.2 1.5 1.0 + 0.5 µA

10 kHz to 30

kHz

0.33 mA to 10 Hz to 20 Hz 0.16 + 0.15 0.2 + 0.15 0.05 0.15 + 1.5 µA 200

3.2999 mA 20 Hz to 45 Hz 0.1 + 0.15 0.125 + 0.15 0.05 0.06 + 1.5 µA

45 Hz to 1 kHz 0.08 + 0.15 0.1+ 0.15 0.05 0.02 + 1.5 µA

1 kHz to 5 kHz 0.16 + 0.2 0.2 + 0.2 1.5 0.5 + 1.5 µA