Page 1

5500A

®

Multi-Product Calibrator

Operator Manual

December 1994, Rev.11, 7/06

© 1994 - 2006 Fluke Corporation. All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY & LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under

normal use and service. The warranty period is one year and begins on the date of shipment.

Parts, product repairs and services are warranted for 90 days. This warranty extends only to the

original buyer or end-user customer of a Fluke authorized reseller, and does not apply to fuses,

disposable batteries or to any product which, in Fluke's opinion, has been misused, altered,

neglected or damaged by accident or abnormal conditions of operation or handling. Fluke

warrants that software will operate substantially in accordance with its functional specifications

for 90 days and that it has been properly recorded on non-defective media. Fluke does not

warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user

customers only but have no authority to extend a greater or different warranty on behalf of

Fluke. Warranty support is available if product is purchased through a Fluke authorized sales

outlet or Buyer has paid the applicable international price. Fluke reserves the right to invoice

Buyer for importation costs of repair/replacement parts when product purchased in one country

is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of

charge repair, or replacement of a defective product which is returned to a Fluke authorized

service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center or send the

product, with a description of the difficulty, postage and insurance prepaid (FOB Destination), to

the nearest Fluke authorized service center. Fluke assumes no risk for damage in transit.

Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB

Destination). If Fluke determines that the failure was caused by misuse, alteration, accident or

abnormal condition of operation or handling, Fluke will provide an estimate of repair costs and

obtain authorization before commencing the work. Following repair, the product will be returned

to the Buyer transportation prepaid and the Buyer will be billed for the repair and return

transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL

OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER

ARISING FROM BREACH OF WARRANTY OR BASED ON CONTRACT, TORT, RELIANCE

OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or

exclusion or limitation of incidental or consequential damages, the limitations and exclusions of

this warranty may not apply to every buyer. If any provision of this Warranty is held invalid or

unenforceable by a court of competent jurisdiction, such holding will not affect the validity or

enforceability of any other provision.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

5/94

Page 3

LIMITE DE GARANTIE ET LIMITE DE RESPONSABILITE

La société Fluke garantit l'absence de vices des matériaux et à la fabrication de ce produit dans

des conditions normales d'utilisation et d'entretien. La période de garantie est de un an et prend

effet à la date d'expédition. Les pièces, les réparations de produit et les services sont garantis

pour un période de 90 jours. Cette garantie ne s'applique qu'à l'acheteur d'origine ou à l'utilisateur

final s'il est client d'un distributeur agréé par Fluke, et ne s'applique pas aux fusibles, aux

batteries/piles interchangeables ni à aucun produit qui, de l'avis de Fluke, a été malmené, modifié,

négligé ou endommagé par accident ou soumis à des conditions anormales d'utilisation et de

manipulation. Fluke garantit que le logiciel fonctionnera en grande partie conformément à ses

spécifications fonctionnelles pour une période de 90 jours et qu'il a été correctement enregistré sur

des supports non défectueux. Fluke ne garantit pas que le logiciel ne contient pas d'erreurs ou

qu'il fonctionne sans interruption.

Les distributeurs agréés par Fluke appliqueront cette garantie à des produits vendus à leurs

clients neufs et qui n'ont pas servi mais ne sont pas autorisés à appliquer une garantie plus

étendue ou différente au nom de Fluke. Le support de garantie est offert si le produit a été acquis

par l'intermédiaire d'un point de vente agréé par Fluke ou bien si l'acheteur a payé le prix

international applicable. Fluke se réserve le droit de facturer à l'acheteur les frais d'importation des

pièces de réparation ou de remplacement si le produit acheté dans un pays a été expédié dans un

autre pays pour y être réparé.

L'obligation de garantie de Fluke est limitée, au choix de Fluke, au remboursement du prix d'achat,

ou à la réparation/remplacement gratuit d'un produit défectueux retourné dans le délai de garantie

à un centre de service agréé par Fluke.

Pour avoir recours au service de la garantie, mettez-vous en rapport avec le centre de service

Fluke le plus proche ou envoyez le produit, accompagné d'une description du problème, port et

assurance payés (franco lieu de destination), au centre de service agréé par Fluke le plus proche.

Fluke dégage toute responsabilité en cas de dégradations survenues au cours du transport. Après

la réparation sous garantie, le produit sera retourné à l'acheteur, frais de port payés d'avance

(franco lieu de destination). Si Fluke estime que le problème a été causé par un traitement abusif,

une modification, un accident ou des conditions de fonctionnement ou de manipulation anormales,

Fluke fournira un devis des frais de réparation et ne commencera la réparation qu'après en avoir

reçu l'autorisation. Après la réparation, le produit sera retourné à l'acheteur, frais de port payés

d'avance, et les frais de réparation et de transport lui seront facturés.

LA PRESENTE GARANTIE EST EXCLUSIVE ET TIENT LIEU DE TOUTES AUTRES

GARANTIES, EXPLICITES OU IMPLICITES, Y COMPRIS, MAIS NON EXCLUSIVEMENT,

TOUTE GARANTIE IMPLICITE QUANT A L'APTITUDE DU PRODUIT A ETRE COMMERCIALISE

OU A ETRE APPLIQUE A UNE FIN OU A UN USAGE DETERMINE. FLUKE NE POURRA ETRE

TENU RESPONSABLE D'AUCUN DOMMAGE PARTICULIER, INDIRECT, ACCIDENTEL OU

CONSECUTIF, NI D'AUCUNS DEGATS OU PERTES DE DONNEES, QUE CE SOIT A LA SUITE

D'UNE INFRACTION AUX OBLIGATIONS DE GARANTIE, SUR UNE BASE CONTRACTUELLE,

EXTRA- CONTRACTUELLE OU AUTRE.

Etant donné que certains pays ou états n'admettent pas les limitations d'une condition de garantie

implicite, ou l'exclusion ou la limitation de dégâts accidentels ou consécutifs, les limitations et les

exclusions de cette garantie pourraient ne pas s'appliquer à chaque acheteur. Si une disposition

quelconque de cette garantie est jugée non valide ou inapplicable par un tribunal compétent, une

telle décision n'affectera en rien la validité ou le caractère exécutoire de toute autre disposition.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 B.D. Eindhoven

USA Pays-Bas

Page 4

BEFRISTETE GARANTIEBESTIMMUNGEN & HAFTUNGSBESCHRÄNKUNG

Für jedes Produkt, das Fluke herstellt, leistet Fluke eine Garantie für einwandfreie Materialqualitßt und fehlerfreie

Ausführung unter normalen Betriebs- und Wartungsbedingungen. Der Garantiezeitraum gilt für ein Jahr und beginnt

mit dem Lieferdatum. Die Garantiebestimmungen für Ersatzteile, Instandsetzungs- und Wartungsarbeiten gelten für

einen Zeitraum von 90 Tagen. Diese Garantie wird ausschließlich dem Ersterwerber bzw. dem Endverbraucher, der

das betreffende Produkt von einer von Fluke autorisierten Weiterverkaufsstelle erworben hat, geleistet und erstreckt

sich nicht auf Sicherungen, Einwegbatterien oder irgendwelche andere Produkte, die nach dem Ermessen von

Fluke unsachgemäß verwendet, verändert, vernachlässigt, durch Unfälle beschädigt oder abnormalen

Betriebsbedingungen oder einer unsachgemäßen Handhabung ausgesetzt wurden. Fluke garantiert für einen

Zeitraum von 90 Tagen, daß die Software im wesentlichen in Übereinstimmung mit den einschlägigen

Funktionsbeschreibungen funktioniert und daß diese Software auf fehlerfreien Datenträgern gespeichert wurde.

Fluke übernimmt jedoch keine Garantie dafür, daß die Software fehlerfrei ist und störungsfrei arbeitet.

Von Fluke autorisierte Weiterverkaufsstellen werden diese Garantie ausschließlich für neue und nichtbenutzte, an

Endverbraucher verkaufte Produkte leisten, sind jedoch nicht dazu berechtigt, diese Garantie im Namen von Fluke

zu verlängern, auszudehnen oder in irgendeiner anderen Weise abzuändern. Der Erwerber hat das Recht aus der

Garantie abgeleitete Unterstützungsleistungen in Anspruch zu nehmen, wenn er das Produkt bei einer von Fluke

autorisierten Vertriebsstelle gekauft oder den jeweils geltenden internationalen Preis gezahlt hat. Fluke behält sich

das Recht vor, dem Erwerber Einfuhrgebühren für Ersatzteile in Rechnung zu stellen, wenn dieser das Produkt in

einem anderen Land zur Reparatur anbietet, als das Land, in dem er das Produkt ursprünglich erworben hat.

Flukes Garantieverpflichtung beschränkt sich darauf, daß Fluke nach eigenem Ermessen den Kaufpreis ersetzt oder

aber das defekte Produkt unentgeltlich repariert oder austauscht, wenn dieses Produkt innerhalb der Garantiefrist

einem von Fluke autorisierten Servicezentrum zur Reparatur übergeben wird.

Um die Garantieleistung in Anspruch zu nehmen, wenden Sie sich bitte an das nächstgelegene und von Fluke

autorisierte Servicezentrum oder senden Sie das Produkt mit einer Beschreibung des Problems und unter

Vorauszahlung von Fracht- und Versicherungskosten (FOB Bestimmungsort) an das nächstgelegene und von Fluke

autorisierte Servicezentrum. Fluke übernimmt keinerlei Haftung für eventuelle Transportschäden. Im Anschluß an

die Reparatur wird das Produkt unter Vorauszahlung von Frachtkosten (FOB Bestimmungsort) an den Erwerber

zurückgesandt. Wenn Fluke jedoch feststellt, daß der Defekt auf unsachgemäße Handhabung, Veränderungen am

Gerät, einen Unfall oder auf anormale Betriebsbedingungen oder unsachgemäße Handhabung zurückzuführen ist,

wird Fluke dem Erwerber einen Voranschlag der Reparaturkosten zukommen lassen und erst die Zustimmung des

Erwerbers einholen, bevor die Arbeiten in Angriff genommen werden. Nach der Reparatur wird das Produkt unter

Vorauszahlung der Frachtkosten an den Erwerber zurückgeschickt und werden dem Erwerber die Reparaturkosten

und die Versandkosten (FOB Versandort) in Rechnung gestellt.

DIE VORSTEHENDEN GARANTIEBESTIMMUNGEN SIND DAS EINZIGE UND ALLEINIGE RECHT AUF

SCHADENERSATZ DES ERWERBERS UND GELTEN AUSSCHLIESSLICH UND AN STELLE VON ALLEN

ANDEREN VERTRAGLICHEN ODER GESETZLICHEN GEWÄHRLEISTUNGSPFLICHTEN, EINSCHLIESSLICH JEDOCH NICHT DARAUF BESCHRÄNKT - DER GESETZLICHEN GEWÄHRLEISTUNG DER

MARKTFÄHIGKEIT, DER GEBRAUCHSEIGNUNG UND DER ZWECKDIENLICHKEIT FÜR EINEN BESTIMMTEN

EINSATZ. FLUKE ÜBERNIMMT KEINE HAFTUNG FÜR SPEZIELLE, UNMITTELBARE, MITTELBARE, BEGLEITODER FOLGESCHÄDEN ODER ABER VERLUSTE, EINSCHLIESSLICH DES VERLUSTS VON DATEN,

UNABHÄNGIG DAVON, OB SIE AUF VERLETZUNG DER GEWÄHRLEISTUNGSPFLICHT, RECHTMÄSSIGE,

UNRECHTMÄSSIGE ODER ANDERE HANDLUNGEN ZURÜCKZUFÜHREN SIND.

Angesichts der Tatsache, daß in einigen Ländern die Begrenzung einer gesetzlichen Gewährleistung sowie der

Ausschluß oder die Begrenzung von Begleit- oder Folgeschäden nicht zulässig ist, könnte es sein, daß die

obengenannten Einschränkungen und Ausschlüsse nicht für jeden Erwerber gelten. Sollte irgendeine Klausel dieser

Garantiebestimmungen von einem zuständigen Gericht für unwirksam oder nicht durchsetzbar befunden werden, so

bleiben die Wirksamkeit oder Erzwingbarkeit irgendeiner anderen Klausel dieser Garantiebestimmungen von einem

solchen Spruch unberührt.

Fluke Corporation Fluke Europe B.V.

Postfach 9090 Postfach 1186

Everett, WA 98206-9090 5602 B.D. Eindhoven

USA Niederlande

Page 5

GARANTÍA LIMITADA Y LIMITACIÓN DE RESPONSABILIDAD

Se garantiza que cada uno de los productos de Fluke no tiene defectos de material y mano de

obra si es objeto de una utilización y un mantenimiento normales. El período de garantía es de

un año y comienza a partir de la fecha de envío. Las piezas, reparaciones y mantenimiento del

producto están garantizados durante 90 días. Esta garantía se concede exclusivamente al

comprador original o al cliente usuario final de un revendedor autorizado por Fluke, y no es de

aplicación a fusibles, baterías o pilas desechables o cualquier otro producto que, en opinión de

Fluke, haya sido objeto de una mala utilización, alteración, negligencia o daños por accidente o

manejo o manipulación anómalos. Fluke garantiza que el software operará sustancialmente de

acuerdo con sus especificaciones funcionales durante 90 días y que ha sido grabado

correctamente en medios no defectuosos. Fluke no garantiza que el software carezca de

errores ni opere sin interrupción.

Los revendedores autorizados por Fluke concederán esta garantía a productos nuevos y sin

utilizar suministrados a clientes usuarios finales exclusivamente, pero no tienen autoridad para

conceder una garantía diferente o mayor por cuenta de Fluke. Puede utilizar el servicio de

garantía si el producto ha si do comprado en una oficina de ventas Fluke autorizada o si el

Comprador ha pagado el importe de aplicación internacional. Fluke se reserva el derecho de

facturar al Comprador los costes de importación debidos a la reparación o sustitución de piezas

cuando el producto comprado en un país es enviado para su reparación a otro país.

La obligación de Fluke en concepto de garantía se limita, a criterio de Fluke, al reembolso del

importe de la compra, a la reparación gratis, o a la sustitución de un producto defectuoso que

sea devuelto a un centro de servicio Fluke autorizado dentro del período de garantía.

Para obtener servicio en garantía, póngase en contacto con el Servicio Oficial Fluke autorizado

más próximo o envíe el producto, con una descripción del problema surgido, a portes y seguros

pagados por anticipado (FOB en Destino), al Servicio Oficial Fluke autorizado más próximo.

Fluke no asume ningún riesgo por los daños en tránsito. Tras la reparación en concepto de

garantía, el producto será devuelto al Comprador, previo pago del transporte (FOB en Destino).

Si Fluke decide que la avería ha sido causada por una mala utilización, alteración, accidente o

manejo o manipulación anormales, Fluke hará una estimación de los costes de reparación y

solicitará autorización antes de comenzar el trabajo. Tras la reparación, el producto será

devuelto al Comprador, previo pago del transporte, y se facturarán al Comprador los gastos en

concepto de reparación y de transporte para su devolución (FOB en el Punto de envío).

ESTA GARANTÍA SE CONCEDE A TÍTULO ÚNICO Y EXCLUSIVO DEL COMPRADOR Y

SUSTITUYE A TODAS LAS DEMÁS GARANTÍAS, EXPRESAS O IMPLÍCITAS, INCLUYENDO,

PERO SIN LIMITARSE A, NINGUNA GARANTÍA IMPLÍCITA DE COMERCIABILIDAD O

IDONEIDAD PARA UN FIN O UN USO DETERMINADOS. FLUKE NO SE

RESPONSABILIZARÁ DE PÉRDIDAS O DAÑOS ESPECIALES, INDIRECTOS, IMPREVISTOS

O CONTINGENTES, INCLUIDA LA PÉRDIDA DE DATOS, YA SEAN PRODUCTO DE

VIOLACIÓN DE LA GARANTÍA O YA SEA EN RELACIÓN CON UN CONTRATO, POR

RESPONSABILIDAD CIVIL EXTRACONTRACTUAL, CONFIANZA O EN CUALQUIER OTRA

FORMA.

Dado que algunos países o estados no permiten la limitación del plazo de una garantía

implícita, ni la exclusión o limitación de daños imprevistos o contingentes, las limitaciones y

exclusiones de esta garantía pueden no ser de aplicación a todos los compradores. Si alguna

disposición de esta Garantía es considerada nula o no aplicable por un tribunal de justicia

competente, dicha consideración no afectará a la validez o aplicación de las demás

disposiciones.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 B.D. Eindhoven

ESTADOS UNIDOS Holanda

Page 6

W CAUTION

This is an IEC safety Class 1 product. Before using, the ground wire in the

line cord or rear panel binding post must be connected to an earth ground

for safety.

Interference Information

This equipment generates and uses radio frequency energy and if not installed and used in

strict accordance with the manufacturer’s instructions, may cause interference to radio and

television reception. It has been type tested and found to comply with the limits for a Class B

computing device in accordance with the specifications of Part 15 of FCC Rules, which are

designed to provide reasonable protection against such interference in a residential installation.

Operation is subject to the following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference received, including interference that may cause

undesired operation.

There is no guarantee that interference will not occur in a particular installation. If this equipment

does cause interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one of more of

the following measures:

• Reorient the receiving antenna

• Relocate the equipment with respect to the receiver

• Move the equipment away from the receiver

• Plug the equipment into a different outlet so that the computer and receiver are on different

branch circuits

If necessary, the user should consult the dealer or an experienced radio/television technician for

additional suggestions. The user may find the following booklet prepared by the Federal

Communications Commission helpful: How to Identify and Resolve Radio-TV Interference

Problems. This booklet is available from the U.S. Government Printing Office, Washington, D.C.

20402. Stock No. 004-000-00345-4.

Declaration of the Manufacturer or Importer

We hereby certify that the Fluke Model 5500A is in compliance with BMPT Vfg 243/1991 and is

RFI suppressed. The normal operation of some equipment (e.g. signal generators) may be

subject to specific restrictions. Please observe the notices in the users manual. The marketing

and sales of the equipment was reported to the Central Office for Telecommunication Permits

(BZT). The right to retest this equipment to verify compliance with the regulation was given to

the BZT.

Bescheinigung des Herstellers/Importeurs

Hiermit wird bescheinigt, daβ die Fluke Model 5500A in Übereinstimmung mit den

Bestimmungen der BMPT-AmtsblVfg 243/1991 funk-entstört sind. Der vorschriftsmäßige

Betrieb mancher Geräte (z.B. Meßsender) kann allerdings gewissen Einschränkungen

unterliegen. Beachten Sie deshalb die Hinweise in der Bedienungsanleitung. Dem Bundesamt

für Zulassungen in der Telecommunikation wurde das Inverkehrbringen dieses Gerätes

angezeigt und die Berechtigung zur Überprüfung der Serie auf Einhaltung der Bestimmungen

eingeräumt.

Fluke Corporation

Page 7

SAFETY TERMS IN THIS MANUAL

This instrument has been designed and tested in accordance with IEC publication

1010-1 (1992-1), Safety Requirements for Electrical Measuring, Control and Laboratory

Equipment, and ANSI/ISA-582.01-1994, and CAN/CSA-C22.2 No. 1010.1-92. This User

Manual contains information, warning, and cautions that must be followed to ensure safe

operation and to maintain the instrument in a safe condition. Use of this equipment in a

manner not specified herein may impair the protection provided by the equipment.

This instrument is designed for IEC 1010-1 Installation Category II use. It is not designed

for connection to circuits rated over 4800 VA.

WARNING statements identify conditions or practices that could result in personal injury

or loss of life.

CAUTION statements identify conditions or practices that could result in damage to

equipment.

SYMBOLS MARKED ON EQUIPMENT

WARNING

references).

Risk of electric shock. Refer to the manual (see the Index for

GROUND Ground terminal to chassis (earth).

Attention Refer to the manual (see the Index for references). This

symbol indicates that information about usage of a feature is contained in

the manual. This symbol appears on the rear panel ground post and by

the fuse compartment.

AC POWER SOURCE

The instrument is intended to operate from an ac power source that will not apply more

than 264V ac rms between the supply conductors or between either supply conductor

and ground. A protective ground connection by way of the grounding conductor in the

power cord is required for safe operation.

USE THE PROPER FUSE

To avoid fire hazard, for fuse replacement use only the specified unit: 110 or 120 V

operation, 2.5 ampere/250 volt time delay; 220 or 240 V operation, 1.25 ampere/250 volt

time delay.

GROUNDING THE INSTRUMENT

The instrument utilizes controlled overvoltage techniques that require the instrument to

be grounded whenever normal mode or common mode ac voltages or transient voltages

may occur. The enclosure must be grounded through the grounding conductor of the

power cord, or through the rear panel ground binding post.

Page 8

USE THE PROPER POWER CORD

Use only the power cord and connector appropriate for the voltage and plug

configuration in your country.

Use only a power cord that is in good condition.

Refer power cord and connector changes to qualified service personnel.

DO NOT OPERATE IN EXPLOSIVE ATMOSPHERES

To avoid explosion, do not operate the instrument in an atmosphere of explosive gas.

DO NOT REMOVE COVER DURING OPERATION

To avoid personal injury or death, do not remove the instrument cover without first

removing the power source connected to the rear panel. Do not operate the instrument

without the cover properly installed. Normal calibration is accomplished with the cover

closed. Access procedures and the warnings for such procedures are contained both in

this manual and in the Service Manual. Service procedures are for qualified service

personnel only.

DO NOT ATTEMPT TO OPERATE IF PROTECTION MAY BE IMPAIRED

If the instrument appears damaged or operates abnormally, protection may be impaired.

Do not attempt to operate the instrument under these conditions. Refer all questions of

proper instrument operation to qualified service personnel.

Page 9

Table of Contents

Chapter Contents Page

1 Introduction and Specifications......................................................... 1-1

1-1.

Introduction........................................................................................... 1-3

1-2. How to Contact Fluke........................................................................... 1-4

1-3. Operation Overview.............................................................................. 1-4

1-4. Local Operation................................................................................ 1-4

1-5. Remote Operation (RS-232)............................................................. 1-4

1-6. Remote Operation (IEEE-488) ......................................................... 1-5

1-7. Where To Go from Here....................................................................... 1-6

1-8. Instruction Manuals .............................................................................. 1-6

1-9. 5500A Operator Manual................................................................... 1-6

1-10. 5500A Operator Reference Guide .................................................... 1-7

1-11. 5500A Remote Programming Reference Guide............................... 1-7

1-12. 5500A Service Manual ..................................................................... 1-7

1-13. 5725A Amplifier................................................................................... 1-7

1-14. Specifications........................................................................................ 1-9

1-15. General Specifications.......................................................................... 1-10

1-16. DC Voltage Specifications ............................................................... 1-11

1-17. DC Current Specifications................................................................ 1-12

1-18. Resistance Specifications ................................................................. 1-13

1-19. AC Voltage (Sine Wave) Specifications .......................................... 1-14

1-20. AC Current (Sine Wave) Specifications........................................... 1-17

1-21. Capacitance Specifications............................................................... 1-19

1-22. Temperature Calibration (Thermocouple) Specifications ................ 1-20

1-23. Temperature Calibration (RTD) Specifications................................ 1-21

1-24. DC Power Specification Summary................................................... 1-22

1-25. AC Power (45 Hz to 65 Hz) Specification Summary, PF=1 ............ 1-22

1-26. Power and Dual Output Limit Specifications................................... 1-23

1-27. Phase Specifications ......................................................................... 1-24

1-28. Calculating Power Uncertainty......................................................... 1-25

i

Page 10

5500A

Operator Manual

1-29. Additional Specifications...................................................................... 1-26

1-30. Frequency Specifications.................................................................. 1-26

1-31. Harmonics (2nd to 50th) Specifications.............................................. 1-26

1-32. AC Voltage (Sine Wave) Extended Bandwidth Specifications........ 1-27

1-33. AC Voltage (Non-Sine Wave) Specifications .................................. 1-28

1-34. AC Voltage, DC Offset Specifications............................................. 1-29

1-35. AC Voltage, Square Wave Characteristics....................................... 1-29

1-36. AC Voltage, Triangle Wave Characteristics (typical)...................... 1-29

1-37. AC Current (Sine Wave) Extended Bandwidth Specifications ........ 1-29

1-38. AC Current (Non-Sinewave) Specifications .................................... 1-30

1-39. AC Current (Non-Sinewave) Specifications (cont).......................... 1-31

1-40. AC Current, Square Wave Characteristics (typical)......................... 1-31

1-41. AC Current, Triangle Wave Characteristics (typical) ...................... 1-31

2 Preparing for Operation...................................................................... 2-1

2-1. Introduction........................................................................................... 2-3

2-2. Unpacking and Inspection .................................................................... 2-3

2-3. Replacing The Fuse .............................................................................. 2-3

2-4. Selecting Line Voltage.......................................................................... 2-4

2-5. Connecting To Line Power ................................................................... 2-4

2-6. Service Information .............................................................................. 2-6

2-7. Placement and Rack Mounting ............................................................. 2-7

2-8. Cooling Considerations......................................................................... 2-7

2-9. Connecting the 5725A Amplifier ......................................................... 2-7

3 Features ............................................................................................... 3-1

3-1. Introduction........................................................................................... 3-3

3-2. Front Panel Features ............................................................................. 3-3

3-3. Rear Panel Features .............................................................................. 3-3

3-4. Softkey Menu Trees.............................................................................. 3-3

4 Front Panel Operation......................................................................... 4-1

4-1. Introduction........................................................................................... 4-3

4-2. Turning on the Calibrator ..................................................................... 4-3

4-3. Warming up the Calibrator ................................................................... 4-4

4-4. Using the Softkeys................................................................................ 4-4

4-5. Using the Setup Menu........................................................................... 4-4

4-6. Using the Instrument Setup Menu.................................................... 4-5

4-7. Selecting an External Amplifier ....................................................... 4-5

4-8. Utility Functions Menu .................................................................... 4-6

4-9. Using the Format EEPROM Menu .............................................. 4-6

4-10. Resetting the Calibrator ........................................................................ 4-7

4-11. Zeroing the Calibrator........................................................................... 4-7

4-12. Using the Operate and Standby Modes................................................. 4-8

4-13. Connecting the Calibrator to a UUT..................................................... 4-9

4-14. Recommended Cable and Connector Types..................................... 4-9

4-15. When to Use EARTH....................................................................... 4-10

4-16. Four-Wire versus Two-Wire Connections ....................................... 4-10

4-17. Cable Connection Instructions ......................................................... 4-11

ii

Page 11

4-18. Rms Versus Peak-to-Peak Waveforms ................................................. 4-16

4-19. Auto Range Versus Locked Range....................................................... 4-17

4-20. Setting the Output................................................................................. 4-17

4-21. Setting DC Voltage Output .............................................................. 4-18

4-22. Setting AC Voltage Output .............................................................. 4-19

4-23. Setting DC Current Output............................................................... 4-21

4-24. Setting AC Current Output............................................................... 4-22

4-25. Setting DC Power Output................................................................. 4-24

4-26. Setting AC Power Output................................................................. 4-25

4-27. Setting a Dual DC Voltage Output................................................... 4-28

4-28. Setting a Dual AC Voltage Output................................................... 4-30

4-29. Setting Resistance Output................................................................. 4-32

4-30. Setting Capacitance Output .............................................................. 4-33

4-31. Setting Temperature Simulation (Thermocouple)............................ 4-35

4-32. Setting Temperature Simulation (RTD) ........................................... 4-37

4-33. Measuring Thermocouple Temperatures.......................................... 4-39

4-34. Waveform Types................................................................................... 4-40

4-35. Sinewave .......................................................................................... 4-41

4-36. Trianglewave .................................................................................... 4-41

4-37. Squarewave ...................................................................................... 4-41

4-38. Truncated Sinewave ......................................................................... 4-42

4-39. Setting Harmonics................................................................................. 4-42

4-40. Adjusting the Phase .............................................................................. 4-43

4-41. Entering a Phase Angle .................................................................... 4-44

4-42. Entering a Power Factor ................................................................... 4-45

4-43. Entering a DC Offset ............................................................................ 4-46

4-44. Using the 5725A Amplifier .................................................................. 4-47

4-45. 5725A Amplifier Output .................................................................. 4-48

4-46. Editing and Error Output Settings ........................................................ 4-49

4-47. Editing the Output Setting................................................................ 4-49

4-48. Displaying the Output Error ............................................................. 4-50

4-49. Using Multiply and Divide............................................................... 4-50

4-50. Setting Output Limits............................................................................ 4-50

4-51. Setting Voltage and Current Limits.................................................. 4-51

4-52. Sample Applications ............................................................................. 4-52

4-53. Calibrating an 80 Series Handheld Multimeter ................................ 4-52

4-54. Cables .......................................................................................... 4-52

4-55. EARTH Connection..................................................................... 4-52

4-56. Testing the Meter ......................................................................... 4-53

4-57. Calibrating the Meter ................................................................... 4-57

4-58. Testing a Model 41 Power Harmonics Analyzer.............................. 4-58

4-59. Testing Watts, VA, VAR Performance........................................ 4-58

4-60. Testing Harmonics Volts Performance ........................................ 4-60

4-61. Testing Harmonics Amps Performance ....................................... 4-61

4-62. Calibrating a Fluke 51 Thermometer................................................ 4-61

4-63. Testing the Thermometer ............................................................. 4-62

4-64. Calibrating the Thermometer ....................................................... 4-63

5 Remote Operation ............................................................................... 5-1

5-1. Introduction........................................................................................... 5-4

iii

Page 12

5500A

Operator Manual

5-2. Setting up the IEEE-488 Port for Remote Control ............................... 5-4

5-3. IEEE-488 Port Setup Procedure ....................................................... 5-7

5-4. Testing the IEEE-488 Port................................................................ 5-8

5-5. Setting up the RS-232 Host Port for Remote Control........................... 5-10

5-6. RS-232 Host Port Setup Procedure .................................................. 5-10

5-7. Testing the RS-232 Host Port........................................................... 5-12

5-8. Testing RS-232 Host Port Operation using a Terminal ............... 5-12

5-9. Testing RS-232 Host Port Operation using Visual Basic ............ 5-14

5-10. Setting up the RS-232 UUT Port for Remote Control.......................... 5-15

5-11. RS-232 UUT Port Setup Procedure.................................................. 5-15

5-12. Testing the RS-232 UUT Port via RS-232 Host Port....................... 5-17

5-13. Testing RS-232 UUT Port Operation via a Terminal .................. 5-17

5-14. Testing RS-232 UUT Port Operation using Visual Basic............ 5-18

5-15. Testing the RS-232 UUT Port via IEEE-488 Port............................ 5-19

5-16. Changing between Remote and Local Operation ................................. 5-21

5-17. Local State........................................................................................ 5-21

5-18. Local with Lockout State.................................................................. 5-21

5-19. Remote State..................................................................................... 5-21

5-20. Remote with Lockout State .............................................................. 5-21

5-21. RS-232 Interface Overview .................................................................. 5-22

5-22. IEEE-488 Interface Overview............................................................... 5-23

5-23. Using Commands.................................................................................. 5-25

5-24. Types of Commands......................................................................... 5-25

5-25. Device-Dependent Commands..................................................... 5-25

5-26. Common Commands.................................................................... 5-26

5-27. Query Commands......................................................................... 5-26

5-28. Interface Messages (IEEE-488) ................................................... 5-26

5-29. Compound Commands................................................................. 5-28

5-30. Coupled Commands..................................................................... 5-28

5-31. Overlapped Commands................................................................ 5-29

5-32. Sequential Commands.................................................................. 5-29

5-33. Commands that Require the Calibration Switch to be Enabled ... 5-29

5-34. Commands for RS-232 Only........................................................ 5-29

5-35. Commands for IEEE-488 Only.................................................... 5-30

5-36. Command Syntax ............................................................................. 5-31

5-37. Parameter Syntax Rules ............................................................... 5-31

5-38. Extra Space or Tab Characters..................................................... 5-32

5-39. Terminators .................................................................................. 5-33

5-40. Incoming Character Processing.................................................... 5-33

5-41. Response Message Syntax ........................................................... 5-34

5-42. Checking 5500A Status ........................................................................ 5-35

5-43. Serial Poll Status Byte (STB) ........................................................... 5-35

5-44. Service Request (SRQ) Line ........................................................ 5-37

5-45. Service Request Enable Register (SRE)....................................... 5-37

5-46. Programming the STB and SRE .................................................. 5-38

5-47. Event Status Register (ESR)............................................................. 5-38

5-48. Event Status Enable (ESE) Register ............................................ 5-38

5-49. Bit Assignments for the ESR and ESE......................................... 5-38

5-50. Programming the ESR and ESE................................................... 5-39

5-51. Instrument Status Register (ISR)...................................................... 5-40

5-52. Instrument Status Change Registers............................................. 5-40

iv

Page 13

5-53. Instrument Status Change Enable Registers................................. 5-40

5-54. Bit Assignments for the ISR, ISCR, and ISCE ............................ 5-40

5-55. Programming the ISR, ISCR, and ISCE ...................................... 5-42

5-56. Output Queue ................................................................................... 5-42

5-57. Error Queue ...................................................................................... 5-43

5-58. Remote Program Examples................................................................... 5-43

5-59. Guidelines for Programming the Calibrator ..................................... 5-43

5-60. Writing an SRQ and Error Handler .................................................. 5-44

5-61. Verifying a Meter on the IEEE-488 Bus .......................................... 5-45

5-62. Verifying a Meter on the RS-232 UUT Serial Port .......................... 5-45

5-63. Using *OPC?, *OPC, and *WAI ..................................................... 5-45

5-64. Taking a Thermocouple Measurement............................................. 5-46

5-65. Using the RS-232 UUT Port to Control an instrument .................... 5-46

5-66. Input Buffer Operation ..................................................................... 5-47

6 Remote Commands............................................................................. 6-1

6-1. Introduction........................................................................................... 6-3

6-2. Command Summary by Function......................................................... 6-3

6-3. Summary of Commands and Queries ................................................... 6-8

7 Maintenance......................................................................................... 7-1

7-1. Introduction........................................................................................... 7-3

7-2. Replacing the Line Fuse ....................................................................... 7-3

7-3. Cleaning the Air Filter .......................................................................... 7-4

7-4. General Cleaning .................................................................................. 7-6

7-5. Performing a Calibration Check ........................................................... 7-6

7-6. Performance Tests ............................................................................ 7-7

7-7. DC Voltage Amplitude Accuracy (NORMAL) ........................... 7-7

7-8. DC Voltage Amplitude Accuracy (AUX).................................... 7-8

7-9. DC Current Amplitude Accuracy................................................. 7-9

7-10. Resistance Accuracy .................................................................... 7-10

7-11. Resistance DC Offset Measurement............................................. 7-11

7-12. AC Voltage Amplitude Accuracy (NORMAL) ........................... 7-12

7-13. AC Voltage Amplitude Accuracy (AUX).................................... 7-13

7-14. AC Current Amplitude Accuracy................................................. 7-14

7-15. Capacitance Accuracy.................................................................. 7-16

7-16. Thermocouple Measurement Accuracy ....................................... 7-17

7-17. Thermocouple Sourcing Accuracy............................................... 7-17

7-18. Thermocouple Measuring Accuracy ............................................ 7-17

7-19. DC Power Amplitude Accuracy (NORMAL).............................. 7-18

7-20. DC Power Amplitude Accuracy (AUX) ...................................... 7-18

7-21. AC Power Amplitude Accuracy (High Voltage) ......................... 7-19

7-22. AC Power Amplitude Accuracy (High Current).......................... 7-19

7-23. AC Power Amplitude Accuracy (High Power)............................ 7-20

7-24. Phase and Frequency Accuracy ................................................... 7-21

7-25. AC Voltage Amplitude Accuracy, Squarewave (NORMAL)...... 7-22

7-26. AC Voltage Amplitude Accuracy, Squarewave (AUX) .............. 7-23

7-27. AC Voltage Harmonic Amplitude Accuracy (NORMAL) .......... 7-24

7-28. AC Voltage Harmonic Amplitude Accuracy (AUX) ................... 7-25

7-29. DC Voltage Offset Accuracy ....................................................... 7-25

v

Page 14

5500A

Operator Manual

7-30. AC Voltage Accuracy with a DC Offset...................................... 7-26

7-31. Non-Operator Fuse Replacement.......................................................... 7-26

8 Oscilloscope Calibration Options...................................................... 8-1

5500A-SC600 Option ........................................................................... 8-3

8-1. Introduction........................................................................................... 8-5

8-2. SC600 Option Specifications................................................................ 8-5

8-3. Volt Specifications ........................................................................... 8-6

8-4. Edge Specifications .......................................................................... 8-7

8-5. Leveled Sine Wave Specifications ................................................... 8-8

8-6. Time Marker Specifications ............................................................. 8-9

8-7. Wave Generator Specifications ........................................................ 8-9

8-8. Pulse Generator Specifications......................................................... 8-10

8-9. Trigger Signal Specifications (Pulse Function)................................ 8-11

8-10. Trigger Signal Specifications (Time Marker Function) ................... 8-11

8-11. Trigger Signal Specifications (Edge Function) ................................ 8-11

8-12. Trigger Signal Specifications (Square Wave Voltage Function) ..... 8-11

8-13. Trigger Signal Specifications ........................................................... 8-11

8-14. Oscilloscope Input Resistance Measurement Specifications............ 8-12

8-15. Oscilloscope Input Capacitance Measurement Specifications ......... 8-12

8-16. Overload Measurement Specifications............................................. 8-12

8-17. Oscilloscope Connections..................................................................... 8-13

8-18. Starting the SC600 Option.................................................................... 8-13

8-19. The Output Signal ............................................................................ 8-14

8-20. Adjusting the Output Signal ............................................................. 8-14

8-21. Keying in a Value ........................................................................ 8-14

8-22. Adjusting Values with the Rotary Knob ...................................... 8-15

8-23. Using X and D .................................................................. 8-15

8-24. Resetting the SC600 Option ............................................................. 8-15

8-25. Calibrating the Voltage Amplitude on an Oscilloscope........................ 8-16

8-26. The VOLT Function......................................................................... 8-16

8-27. The V/DIV Menu ............................................................................. 8-17

8-28. Shortcuts for Setting the Voltage Amplitude ............................... 8-17

8-29. Oscilloscope Amplitude Calibration Procedure ............................... 8-18

8-30. Calibrating the Pulse and Frequency Response on an Oscilloscope..... 8-19

8-31. The Edge Function ........................................................................... 8-19

8-32. Oscilloscope Pulse Response Calibration Procedure ....................... 8-20

8-33. Pulse Response Calibration Using a Tunnel Diode Pulser............... 8-21

8-34. The Leveled Sine Wave Function .................................................... 8-21

8-35. Shortcuts for Setting the Frequency and Voltage............................. 8-22

8-36. The MORE OPTIONS Menu ........................................................... 8-23

8-37. Sweeping Through a Frequency Range............................................ 8-24

8-38. Oscilloscope Frequency Response Calibration Procedure ............... 8-24

8-39. Calibrating the Time Base of an Oscilloscope...................................... 8-26

8-40. The Time Marker Function .............................................................. 8-26

8-41. Time Base Marker Calibration Procedure for an Oscilloscope ........ 8-27

8-42. Testing the Trigger................................................................................ 8-28

8-43. Testing Video Triggers......................................................................... 8-30

8-44. Verifying Pulse Capture........................................................................ 8-31

vi

Page 15

8-45. Measuring Input Resistance and Capacitance....................................... 8-32

8-46. Input Impedance Measurement ........................................................ 8-32

8-47. Input Capacitance Measurement ...................................................... 8-33

8-48. Testing Overload Protection................................................................. 8-33

8-49. Remote Commands and Queries........................................................... 8-34

8-50. General Commands .......................................................................... 8-35

8-51. Edge Function Commands ............................................................... 8-38

8-52. Marker Function Commands............................................................ 8-38

8-53. Video Function Commands.............................................................. 8-38

8-54. Overload Function Commands......................................................... 8-39

8-55. Impedance/Capacitance Function Commands.................................. 8-40

8-56. Verification Tables ............................................................................... 8-41

8-57. DC Voltage Verification................................................................... 8-41

8-58. AC Voltage Amplitude Verification................................................. 8-42

8-59. AC Voltage Frequency Verification................................................. 8-42

8-60. Wave Generator Amplitude Verification: 1 MΩ Output

Impedance......................................................................................... 8-43

8-61. Wave Generator Amplitude Verification: 50Ω Output Impedance.. 8-44

8-62. Leveled Sinewave Verification: Amplitude ..................................... 8-45

8-63. Leveled Sinewave Verification: Frequency ..................................... 8-45

8-64. Leveled Sinewave Verification: Harmonics..................................... 8-46

8-65. Leveled Sinewave Verification: Flatness ......................................... 8-47

8-66. Edge Verification: Amplitude .......................................................... 8-53

8-67. Edge Verification: Frequency........................................................... 8-53

8-68. Edge Verification: Duty Cycle ......................................................... 8-53

8-69. Edge Verification: Rise Time........................................................... 8-54

8-70. Tunnel Diode Pulser Verification..................................................... 8-54

8-71. Marker Generator Verification ......................................................... 8-55

8-72. Pulse Generator Verification: Period................................................ 8-55

8-73. Pulse Generator Verification: Pulse Width ...................................... 8-55

8-74. Input Impedance Verification: Resistance........................................ 8-56

8-75. Input Impedance Verification: Capacitance ..................................... 8-56

5500A-SC300 Option ........................................................................... 8-57

8-76. Introduction........................................................................................... 8-59

8-77. Oscilloscope Calibration Option Specifications................................... 8-60

8-78. Volt Function Specifications ............................................................ 8-60

8-79. Edge Function Specifications ........................................................... 8-61

8-80. Leveled Sine Wave Function Specifications.................................... 8-62

8-81. Time Marker Function Specifications .............................................. 8-63

8-82. Wave Generator Specifications ........................................................ 8-63

8-83. Trigger Signal Specifications for the Time Marker Function .......... 8-64

8-84. Trigger Signal Specifications for the Edge Function ....................... 8-64

8-85. Oscilloscope Connections..................................................................... 8-65

8-86. Starting the Oscilloscope Calibration Option ....................................... 8-66

8-87. The Output Signal ............................................................................ 8-66

8-88. Adjusting the Output Signal ............................................................. 8-67

8-89. Keying in a Value ........................................................................ 8-67

8-90. Adjusting Values with the Rotary Knob ...................................... 8-67

8-91. Using X and D .................................................................. 8-68

vii

Page 16

5500A

Operator Manual

8-92. Resetting the Oscilloscope Option ................................................... 8-68

8-93. Calibrating the Voltage Amplitude on an Oscilloscope........................ 8-69

8-94. The Volt Function ............................................................................ 8-69

8-95. The V/DIV Menu ............................................................................. 8-70

8-96. Shortcuts for Setting the Voltage Amplitude ............................... 8-70

8-97. Amplitude Calibration Procedure for an Oscilloscope..................... 8-71

8-98. Calibrating the Pulse and Frequency Response on an Oscilloscope..... 8-72

8-99. The Edge Function ........................................................................... 8-72

8-100. Pulse Response Calibration Procedure for an Oscilloscope ............. 8-73

8-101. The Leveled Sine Wave Function .................................................... 8-74

8-102. Shortcuts for Setting the Frequency and Voltage............................. 8-74

8-103. The MORE OPTIONS Menu ........................................................... 8-75

8-104. Sweeping through a Frequency Range ............................................. 8-77

8-105. Frequency Response Calibration Procedure for an Oscilloscope..... 8-78

8-106. Calibrating the Time Base of an Oscilloscope...................................... 8-80

8-107. The Time Marker Function .............................................................. 8-80

8-108. Time Base Marker Calibration Procedure for an Oscilloscope ........ 8-81

8-109. Testing the Trigger................................................................................ 8-82

8-110. Summary of Commands and Queries ................................................... 8-83

8-111. Verification Tables ............................................................................... 8-86

8-112. Voltage Function Verification: AC Voltage into a 1 MΩ Load....... 8-86

8-113. Voltage Function Verification: AC Voltage into a 50 Ω Load ........ 8-87

8-114. Voltage Function Verification: DC Voltage into a 50 Ω Load ........ 8-88

8-115. Voltage Function Verification: DC Voltage into a 1 MΩ Load....... 8-89

8-116. Edge Function Verification .............................................................. 8-90

8-117. Wave Generator Function Verification: 1 MΩ Load ....................... 8-90

8-118. Wave Generator Function Verification: 50 Ω Load......................... 8-91

8-119. Leveled Sinewave Function Verification: Amplitude ...................... 8-91

8-120. Leveled Sinewave Function Verification: Flatness .......................... 8-92

8-121. Leveled Sinewave Function Verification: Frequency ...................... 8-95

8-122. Marker Generator Function Verification.......................................... 8-96

9 Accessories ......................................................................................... 9-1

9-1. Introduction........................................................................................... 9-3

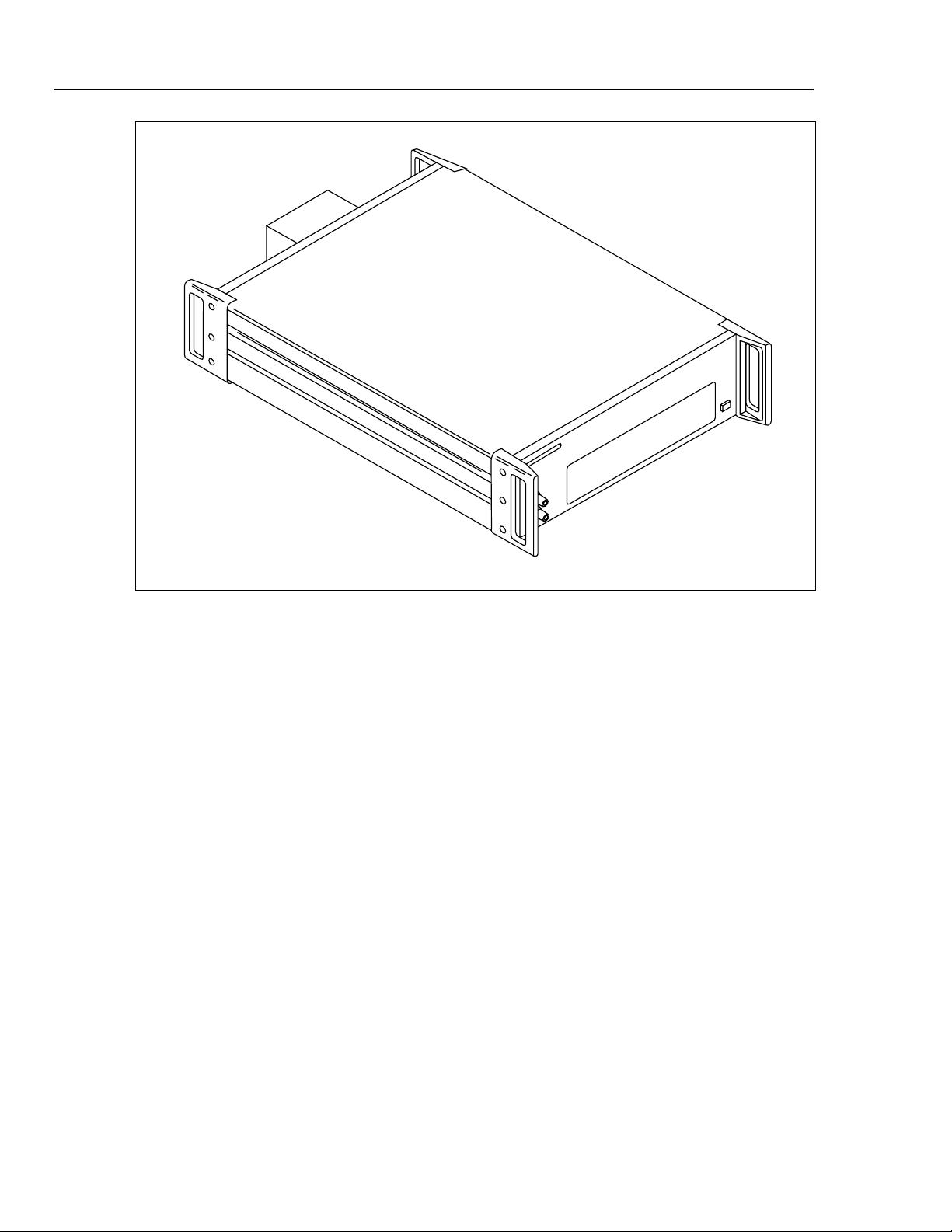

9-2. Rack Mount Kit .................................................................................... 9-4

9-3. IEEE-488 Interface Cables ................................................................... 9-4

9-4. RS-232 Null-Modem Cables ................................................................ 9-4

9-5. RS-232 Modem Cables......................................................................... 9-4

9-6. 5500A/LEADS ..................................................................................... 9-4

9-7. 5725A Amplifier Accessory ................................................................. 9-4

Index

viii

Page 17

List of Tables

Table Page

2-1. Standard Equipment ............................................................................................... 2-3

2-2. Line Power Cord Types Available from Fluke ...................................................... 2-6

3-1. Front Panel Features............................................................................................... 3-4

3-2. Rear Panel Features................................................................................................ 3-10

3-3. Factory Default Settings for the SETUP Menus .................................................... 3-22

4-1. Factory Defaults for SETUP .................................................................................. 4-7

4-2. UUT Connections................................................................................................... 4-11

4-3. Keys That Exit Error Mode.................................................................................... 4-49

4-4. Watts Performance, Text Screen............................................................................ 4-59

4-5. Harmonics Performance for Volts, Harmonics Screen .......................................... 4-60

4-6. Harmonics Performance for AMPS, Harmonics screen......................................... 4-61

4-7. Thermocouple Performance ................................................................................... 4-63

5-2. RS-232 Interface Wiring ........................................................................................ 5-22

5-3. RS-232 Emulation of IEEE-488 Messages ............................................................ 5-24

5-4. Interface Messages that the 5500A Accepts........................................................... 5-28

5-5. Interface Messages that the 5500A Sends.............................................................. 5-29

5-6. Commands for RS-232 Only.................................................................................. 5-31

5-7. Commands for IEEE-488 Only.............................................................................. 5-31

5-8. Units Accepted in Parameters and Used in Responses .......................................... 5-32

5-9. Terminator Characters............................................................................................ 5-34

5-10. Response Data Types ............................................................................................. 5-35

5-11. Status Register Summary ....................................................................................... 5-36

6-1. Command Summary by Function .......................................................................... 6-3

7-1. Replacement Fuses................................................................................................. 7-3

7-2. Required Equipment for Checking Calibration...................................................... 7-6

7-3. Non-Operator Fuse Replacement Locations .......................................................... 7-26

9-1. Options and Accessories ........................................................................................ 9-3

ix

Page 18

5500A

Operator Manual

x

Page 19

List of Figures

Figure Page

1-1. 5500A Multi-Product Calibrator ............................................................................ 1-3

1-2. RS-232 Remote Connections ................................................................................. 1-5

1-3. 5725A Amplifier .................................................................................................... 1-8

2-1. Accessing the Fuse and Selecting Line Voltage .................................................... 2-5

2-2. Line Power Cord Types Available from Fluke ...................................................... 2-6

3-1. Front Panel View.................................................................................................... 3-4

3-2. Rear Panel View..................................................................................................... 3-10

3-3. SETUP Softkey Menu Tree ................................................................................... 3-12

3-4. SETUP Softkey Menu Displays............................................................................. 3-13

3-5. MEAS TC Softkey Menu Tree............................................................................... 3-22

3-6. MEAS TC Softkey Menu Displays........................................................................ 3-23

4-1. UUT Connection: Resistance (Four-Wire Compensation)..................................... 4-12

4-2. UUT Connection: Resistance (Two-Wire Compensation)..................................... 4-12

4-3. UUT Connection: Resistance (Compensation Off)................................................ 4-13

4-4. UUT Connection: Capacitance (Four-Wire Compensation) .................................. 4-13

4-5. UUT Connection: Capacitance (Two-Wire Compensation) .................................. 4-14

4-6. UUT Connection: Capacitance (Compensation Off) ............................................. 4-14

4-7. UUT Connection: DC Voltage/AC Voltage........................................................... 4-15

4-9. UUT Connection: Temperature (RTD) .................................................................. 4-15

4-10. UUT Connection: Temperature (Thermocouple)................................................... 4-16

4-11. Sinewave ................................................................................................................ 4-41

4-12. Trianglewave.......................................................................................................... 4-41

4-13. Squarewave and Duty Cycle .................................................................................. 4-42

4-14. Truncated Sinewave ............................................................................................... 4-42

4-15. Cable Connections for Testing an 80 Series General Functions ............................ 4-53

4-16. Cable Connections for Testing an 80 Series Current Function .............................. 4-55

4-17. Cable Connections for Testing an 80 Series High Amps Function........................ 4-57

4-18. Cable Connections for Testing a 40 Series Watts Function ................................... 4-59

4-19. Cable Connections for Testing a 50 Series Thermometer...................................... 4-62

5-1. Typical IEEE-488 Remote Control Connections ................................................... 5-5

5-2. Typical RS-232 Remote Control Connections....................................................... 5-6

5-3. Typical IEEE-488 Port Connections ...................................................................... 5-8

5-4. Typical PC COM Port Connections ....................................................................... 5-12

xi

Page 20

5500A

Operator Manual

5-5. Typical RS-232 UUT Port via RS-232 Host Port Connections ............................. 5-17

5-6. Typical RS-232 UUT Port via IEEE-488 Port Connections .................................. 5-19

5-7. IEEE-488 Remote Message Coding....................................................................... 5-25

5-8. Status Register Overview ....................................................................................... 5-37

5-9. Status Byte and SRE Bit Definitions...................................................................... 5-38

5-11. Bit Assignments for the ISR, ISCEs and ISCRs .................................................... 5-42

7-1. Accessing the Fuse................................................................................................. 7-4

7-2. Accessing the Air Filter.......................................................................................... 7-5

xii

Page 21

Chapter 1

Introduction and Specifications

Contents Page

1-1.

Introduction........................................................................................... 1-3

How to Contact Fluke........................................................................... 1-4

1-2.

1-3. Operation Overview.............................................................................. 1-4

1-4. Local Operation................................................................................ 1-4

1-5. Remote Operation (RS-232)............................................................. 1-4

1-6. Remote Operation (IEEE-488) ......................................................... 1-5

1-7. Where To Go from Here....................................................................... 1-6

1-8. Instruction Manuals .............................................................................. 1-6

1-9. 5500A Operator Manual................................................................... 1-6

1-10. 5500A Operator Reference Guide .................................................... 1-7

1-11. 5500A Remote Programming Reference Guide............................... 1-7

1-12. 5500A Service Manual ..................................................................... 1-7

1-13. 5725A Amplifier................................................................................... 1-7

1-14. Specifications........................................................................................ 1-9

1-15. General Specifications .......................................................................... 1-10

1-16. DC Voltage Specifications ............................................................... 1-11

1-17. DC Current Specifications................................................................ 1-12

1-18. Resistance Specifications ................................................................. 1-13

1-19. AC Voltage (Sine Wave) Specifications .......................................... 1-14

1-20. AC Current (Sine Wave) Specifications........................................... 1-17

1-21. Capacitance Specifications............................................................... 1-19

1-22. Temperature Calibration (Thermocouple) Specifications ................ 1-20

1-23. Temperature Calibration (RTD) Specifications................................ 1-21

1-24. DC Power Specification Summary................................................... 1-22

1-25. AC Power (45 Hz to 65 Hz) Specification Summary, PF=1 ............ 1-22

1-26. Power and Dual Output Limit Specifications................................... 1-23

1-27. Phase Specifications ......................................................................... 1-24

1-28. Calculating Power Uncertainty......................................................... 1-25

1-29. Additional Specifications...................................................................... 1-26

1-30. Frequency Specifications.................................................................. 1-26

1-31. Harmonics (2nd to 50th) Specifications.............................................. 1-26

1-32. AC Voltage (Sine Wave) Extended Bandwidth Specifications........ 1-27

1-33. AC Voltage (Non-Sine Wave) Specifications .................................. 1-28

1-34. AC Voltage, DC Offset Specifications............................................. 1-29

1-35. AC Voltage, Square Wave Characteristics....................................... 1-29

1-1

Page 22

5500A

Operator Manual

1-36. AC Voltage, Triangle Wave Characteristics (typical)...................... 1-29

1-37. AC Current (Sine Wave) Extended Bandwidth Specifications ........ 1-29

1-38. AC Current (Non-Sinewave) Specifications .................................... 1-30

1-39. AC Current (Non-Sinewave) Specifications (cont).......................... 1-31

1-40. AC Current, Square Wave Characteristics (typical)......................... 1-31

1-41. AC Current, Triangle Wave Characteristics (typical) ...................... 1-31

1-2

Page 23

Introduction and Specifications

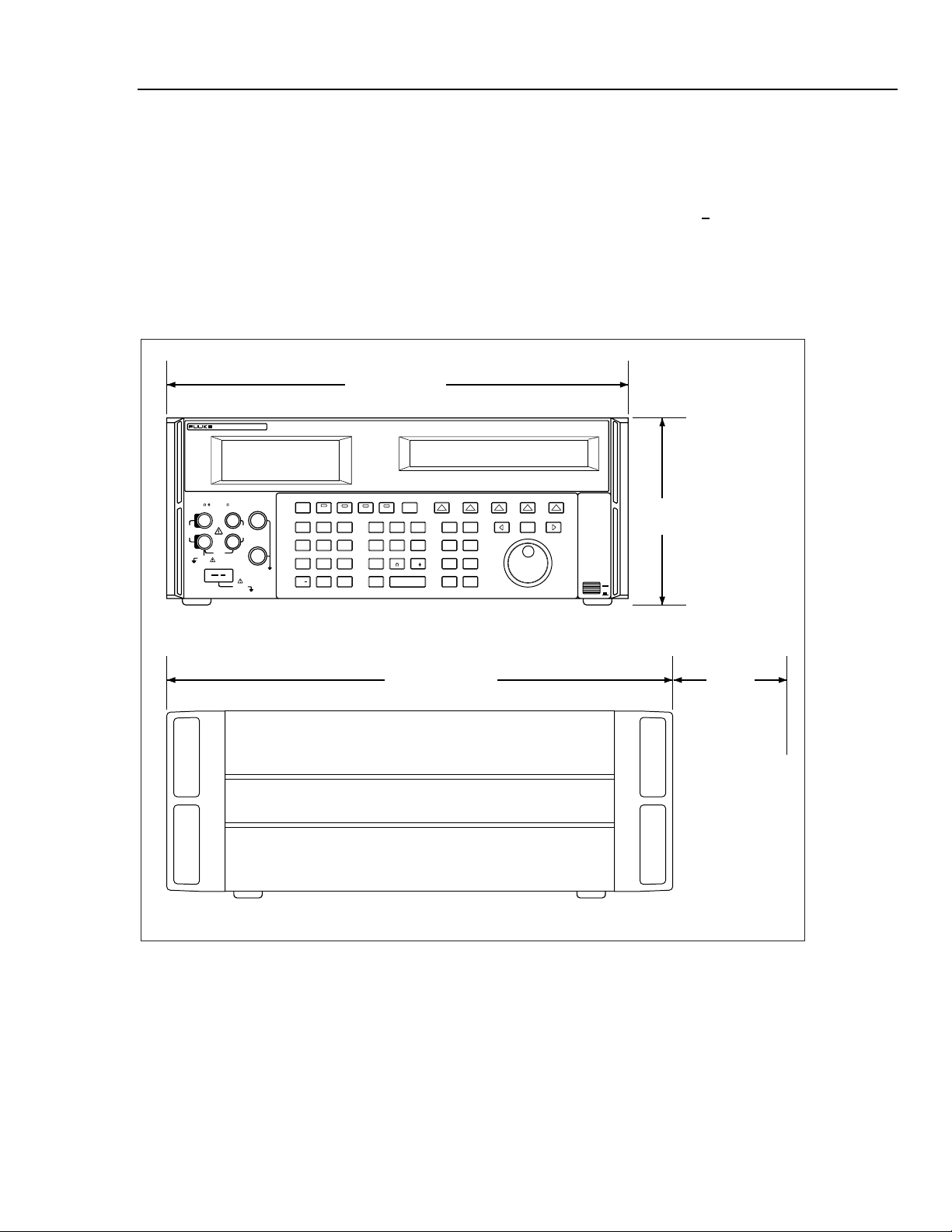

Introduction 1

1-1. Introduction

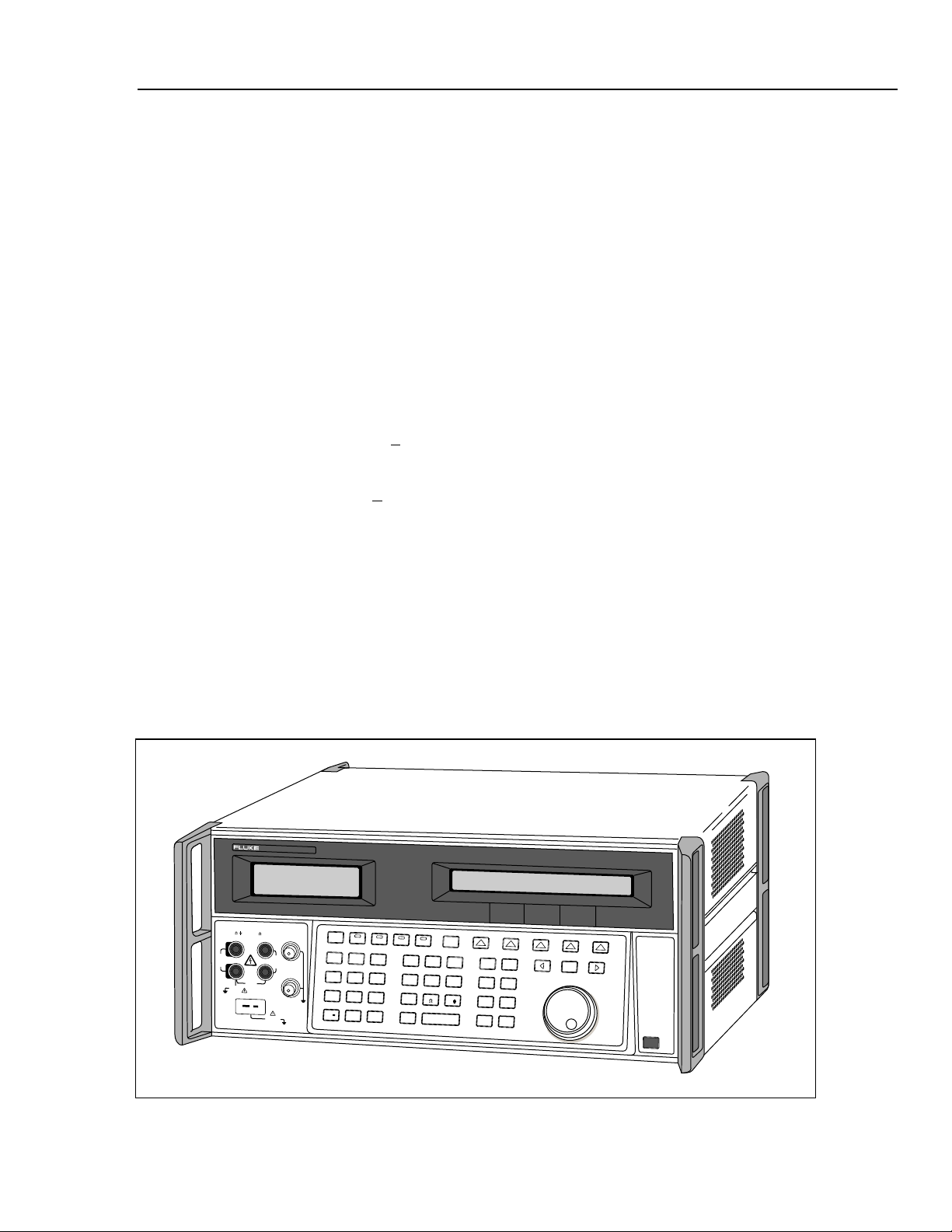

The Fluke Model 5500A Multi-Product Calibrator (Figure 1-1) is a precise instrument

that calibrates a wide variety of electrical measuring instruments. With the 5500A

Calibrator, you can calibrate precision multimeters that measure ac or dc voltage, ac or dc

current, ac or dc power, resistance, capacitance, and temperature. With the Oscilloscope

Calibration option, you can use the 5500A Calibrator to calibrate analog and digital

oscilloscopes. Specifications are provided in this chapter (specifications for the

Oscilloscope Calibration option are provided in Chapter 8).

XW Warning

If the 5500A Calibrator is operated in any way not specified by

this manual or other documentation provided by Fluke, the

protection provided by the Calibrator may be impaired.

The 5500A Calibrator is a fully programmable precision source of the following:

• DC voltage from 0 V to +

1020 V.

• AC voltage from 1 mV to 1020 V, with output from 10 Hz to 500 kHz.

• AC current from 0.01 µA to 11.0 A, with output from 10 Hz to 10 kHz.

• DC current from 0 to +

11.0 A.

• Resistance values from a short circuit to 330 MΩ.

• Capacitance values from 330 pF to 1100 µF.

• Simulated output for three types of Resistance Temperature Detectors (RTDs).

• Simulated output for nine types of thermocouples.

Features of the 5500A Calibrator include the following:

• Automatic meter error calculation.

• X and D keys that change the output value to pre-determined cardinal values

for various functions.

• Programmable entry limits that prevent invalid amounts from being entered.

5500A

CALIBRATOR

NORMAL AUX

V, ,

RTD

1000V

RMS

MAX

20V PK

MAX

TC

HI

LO

1V PK

MAX

A, -SENSE,

AUX V

SCOPE

60V PK

MAX

STBY

OPR

EARTH

SCOPE

20V

RMS

MAX

TRIG

OUT

20V PK

MAX

7

8

9

4

5

6

1

2

3

+

/

0

•

PREV

BOOST

MENU

µ

d

B

mse

c

m

V

n

W

k

A

p

M

SHIFT

ENTER

SETUP

Hz

¡F

¡C

F

RESET

NEW

CE

REF

MEAS

TRIG

TC

OUT

MULT

DIV

x

÷

EDIT

FIELD

POWER

F1-01.eps

Figure 1-1. 5500A Multi-Product Calibrator

1-3

Page 24

5500A

Operator Manual

1-2. How to Contact Fluke

• Simultaneous output of voltage and current, up to 11 kW.

• Simultaneous output of two voltages.

• Extended bandwidth mode outputs multiple waveforms down to 0.01 Hz, and sine

waves to 2 MHz.

• Variable phase signal output.

• Standard IEEE-488 (GPIB) interface, complying with ANSI/IEEE Standards

488.1-1987 and 488.2-1987.

• EIA Standard RS-232-C serial data interface for printing, displaying, or transferring

internally stored calibration constants, and for remote control of the 5500A.

• Pass-through RS-232-C serial data interface for communicating with the Unit Under

Test (UUT).

• Extensive automatic internal self testing and diagnostics of analog and digital

functions.

To contact Fluke, call one of the following telephone numbers:

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Fluke's Web site at www.fluke.com

To register your product, visit register.fluke.com

.

.

1-3. Operation Overview

The 5500A Calibrator may be operated at the front panel in the local mode, or remotely

using RS-232 or IEEE-488 ports. For remote operations, several software options are

available to integrate 5500A operation into a wide variety of calibration requirements.

1-4. Local Operation

Typical local operations include front panel connections to the Unit Under Test (UUT),

and then manual keystroke entries at the front panel to place the calibrator in the desired

output mode. The front panel layout facilitates hand movements from left to right, and

multiply and divide keys make it easy to step up or down at the press of a single key. You

can also review 5500A Calibrator specifications at the push of a button [available, July,

1995]. The backlit liquid crystal display is easy to read from many different viewing

angles and lighting conditions, and the large, easy-to-read keys are color-coded and

provide tactile feedback when they are pressed.

1-4

1-5. Remote Operation (RS-232)

There are two rear-panel serial data RS-232 ports: SERIAL 1 FROM HOST, and

SERIAL 2 TO UUT (Figure 1-2). Each port is dedicated to serial data communications

for operating and controlling the 5500A during calibration procedures. For complete

information on remote operations, see Chapter 5.

Page 25

Introduction and Specifications

Operation Overview 1

The SERIAL 1 FROM HOST serial data port connects a host terminal or personal

computer to the 5500A. You have several choices for sending commands to the 5500A:

you can enter commands from a terminal (for example, using the Terminal accessory

from Windows using a PC), you can write your own programs using BASIC, or you can

run optional Windows-based software such as 5500/CAL or MET/CAL. The 5500/CAL

software includes more than 200 example procedures covering a wide range of test tools