Page 1

525B

Temperature/Pressure Calibrator

July 2012

© 2012 Fluke Corporation, All rights reserved.

All product names are trademarks of their respective companies.

Users Manual

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal

use and service. The warranty period is one year and begins on the date of shipment. Parts, product

repairs, and services are warranted for 90 days. This warranty extends only to the original buyer or

end-user customer of a Fluke authorized reseller, and does not apply to fuses, disposable batteries,

or to any product which, in Fluke's opinion, has been misused, altered, neglected, contaminated, or

damaged by accident or abnormal conditions of operation or handling. Fluke warrants that software

will operate substantially in accordance with its functional specifications for 90 days and that it has

been properly recorded on non-defective media. Fluke does not warrant that software will be error

free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user

customers only but have no authority to extend a greater or different warranty on behalf of Fluke.

Warranty support is available only if product is purchased through a Fluke authorized sales outlet or

Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for

importation costs of repair/replacement parts when product purchased in one country is submitted for

repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge

repair, or replacement of a defective product which is returned to a Fluke authorized service center

within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the

difficulty, postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in

transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB

Destination). If Fluke determines that failure was caused by neglect, misuse, contamination,

alteration, accident, or abnormal condition of operation or handling, including overvoltage failures

caused by use outside the product’s specified rating, or normal wear and tear of mechanical

components, Fluke will provide an estimate of repair costs and obtain authorization before

commencing the work. Following repair, the product will be returned to the Buyer transportation

prepaid and the Buyer will be billed for the repair and return transportation charges (FOB Shipping

Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY

CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion

or limitation of incidental or consequential damages, the limitations and exclusions of this warranty

may not apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a

court or other decision-maker of competent jurisdiction, such holding will not affect the validity or

enforceability of any other provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

To register your product online, visit register.fluke.com

Page 3

Table of Contents

Chapter Title Page

1 Getting Started ................................................................................... 1-1

Introduction ...................................................................................................... 1-1

Contacting Fluke .............................................................................................. 1-1

Standard Equipment ......................................................................................... 1-2

Options and Accessories .................................................................................. 1-2

Safety Information ........................................................................................... 1-2

Getting Acquainted with the Calibrator ........................................................... 1-5

Input and Output Terminals ...................................................................... 1-5

Using the Keys .......................................................................................... 1-6

Display Error Messages ............................................................................ 1-10

Rear Panel View ........................................................................................ 1-11

2 Using Output Mode ........................................................................... 2-1

Using Output Mode ......................................................................................... 2-1

Simulating Thermocouple Temperature .................................................... 2-2

Simulating Temperature Using Resistance Temperature

Detectors (RTDs) ...................................................................................... 2-3

Simulating Custom RTD Coefficients ...................................................... 2-4

Default RTD Coefficients ......................................................................... 2-5

Entering Custom Standard Platinum Resistance Thermometer (SPRT)

Coefficients ............................................................................................... 2-6

Output DC Voltage.................................................................................... 2-7

Output Resistance ...................................................................................... 2-8

Output Current ................................................................................................. 2-9

3 Using Input Mode .............................................................................. 3-1

Using Input Mode ............................................................................................ 3-1

Measuring Resistance ................................................................................ 3-1

Measuring Temperature Using Thermocouples ........................................ 3-2

i

Page 4

525B

Users Manual

Thermocouple Zero Calibration ........................................................... 3-4

Measuring Temperature Using Resistance Temperature

Detectors (RTDs) ...................................................................................... 3-5

Entering and Using Custom RTDs ........................................................... 3-7

Default RTD Coefficients ......................................................................... 3-8

Entering Custom SPRT Coefficients ........................................................ 3-9

Measuring Pressure ................................................................................... 3-10

4 Remote Operation ............................................................................. 4-1

Introduction ..................................................................................................... 4-1

Setting up the RS-232 Port for Remote Control .............................................. 4-2

RS-232 Port Setup Procedure ................................................................... 4-2

Testing the RS-232 Port ....................................................................... 4-2

RS-232 Interface Overview ............................................................................. 4-5

Setting up the IEEE-488 Port for Remote Control .......................................... 4-5

IEEE-488 Port Setup Procedure ............................................................... 4-7

Testing the IEEE-488 Port ........................................................................ 4-7

Changing Between Remote and Local Operation ........................................... 4-8

Local State ................................................................................................ 4-8

Local with Lockout State .......................................................................... 4-8

Remote State ............................................................................................. 4-8

Remote with Lockout State ....................................................................... 4-9

IEEE-488 Interface Overview ......................................................................... 4-10

Using Commands ............................................................................................ 4-13

Types of Commands ................................................................................. 4-13

Device-Dependent Commands ............................................................. 4-13

Common Commands ............................................................................ 4-13

Query Commands ................................................................................. 4-14

Interface Messages (IEEE-488) ............................................................ 4-14

Compound Commands ......................................................................... 4-16

Overlapped Commands ........................................................................ 4-16

Sequential Commands .......................................................................... 4-17

Commands for RS-232 Only ................................................................ 4-17

Commands for IEEE-488 Only ............................................................ 4-17

Command Syntax ...................................................................................... 4-18

Parameter Syntax Rules ........................................................................ 4-18

Extra Space or Tab Characters ............................................................. 4-19

Terminators .......................................................................................... 4-19

Incoming Character Processing ............................................................ 4-20

Response Message Syntax .................................................................... 4-20

Checking 525B Status ..................................................................................... 4-21

Serial Poll Status Byte (STB) ................................................................... 4-23

Service Request (SRQ) Line ................................................................ 4-23

Service Request Enable Register (SRE) ............................................... 4-24

ii

Page 5

Contents (continued)

Programming the STB and SRE ........................................................... 4-24

Event Status Register (ESR) ................................................................. 4-24

Event Status Enable (ESE) Register ..................................................... 4-24

Bit Assignments for the ESR and ESE ................................................. 4-25

Programming the ESR and ESE ........................................................... 4-26

Output Queue ............................................................................................ 4-26

Error Queue ............................................................................................... 4-26

Input Buffer Operation .............................................................................. 4-26

5 Remote Commands ........................................................................... 5-1

Introduction ...................................................................................................... 5-1

Command Summary by Function .................................................................... 5-1

Common Commands ................................................................................. 5-1

External Connection Commands ............................................................... 5-2

Output Commands .................................................................................... 5-3

Measurement Commands .......................................................................... 5-3

RS-232 Port Commands ............................................................................ 5-3

Status Commands ...................................................................................... 5-4

Error Code Listing ........................................................................................... 5-4

Remote Command Listing ............................................................................... 5-5

6 Maintaining the Calibrator ................................................................ 6-1

Maintenance ..................................................................................................... 6-1

Cleaning the Calibrator ............................................................................. 6-1

Replacing a Line Fuse ............................................................................... 6-1

Changing Line Voltage ............................................................................. 6-2

Performance Tests ........................................................................................... 6-4

Required Equipment List .......................................................................... 6-4

Testing DC Voltage ................................................................................... 6-5

Testing DC Current ................................................................................... 6-6

Testing Thermocouple Output .................................................................. 6-7

Testing CJC (Cold Junction Compensation) ......................................... 6-8

Testing Thermocouple Input ................................................................. 6-9

Testing Ohms Output ................................................................................ 6-10

Testing Ohms Input ................................................................................... 6-11

Testing Pressure Modules ......................................................................... 6-13

Service Center Calibration or Repair ............................................................... 6-14

Replacement Parts ........................................................................................... 6-15

Accessories ...................................................................................................... 6-17

7 Specifications .................................................................................... 7-1

General Specifications ..................................................................................... 7-1

Electrical Specifications .................................................................................. 7-2

DC Voltage Specifications, Output ........................................................... 7-2

iii

Page 6

525B

Users Manual

DC Current Specifications, Output ........................................................... 7-2

Resistance Specifications, Output ............................................................. 7-3

Resistance Specifications, Input ............................................................... 7-3

Thermocouple Specification, Output and Input ........................................ 7-4

RTD and Thermistor Specification, Output .............................................. 7-5

RTD and Thermistor Specification, Input ................................................ 7-6

Pressure Measurement ..................................................................................... 7-8

iv

Page 7

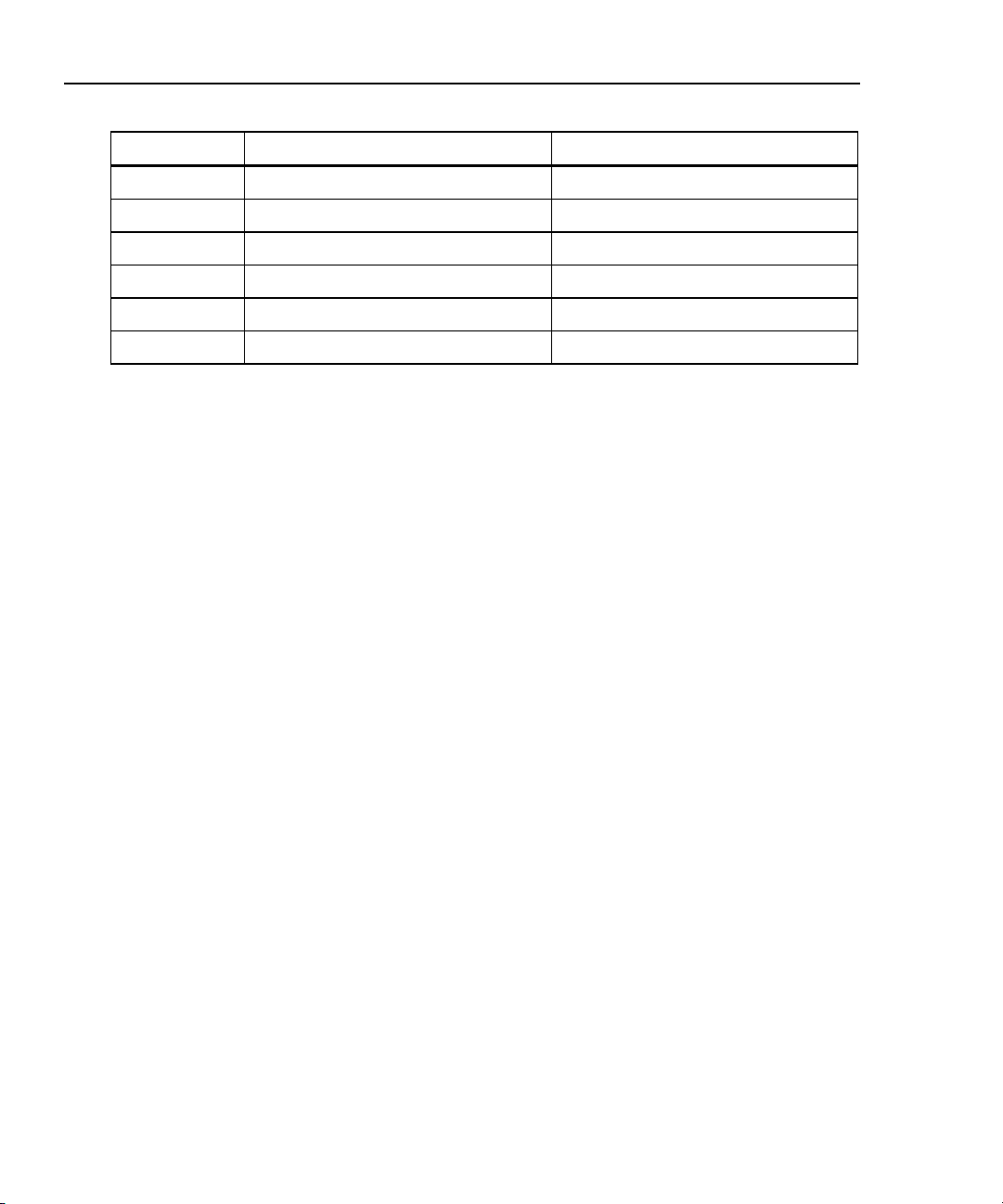

List of Tables

Table Title Page

1-1. Summary of Input and Output Functions......................................................... 1-2

1-2. Symbols Used on the Calibrator ...................................................................... 1-4

1-3. Pushbutton Usage Functions ............................................................................ 1-7

1-4. Function Keys .................................................................................................. 1-8

1-5. Display Error Messages ................................................................................... 1-10

2-1. Default RTD Coefficients ................................................................................ 2-5

2-2. Other Commonly Used RTDs .......................................................................... 2-5

3-1. Default RTD Coefficients ................................................................................ 3-8

3-2. Other Commonly Used RTDs .......................................................................... 3-8

4-1. RS-232 Interface Wiring .................................................................................. 4-5

4-2. Operating State Transitions ............................................................................. 4-9

4-3. RS-232 Emulation of IEEE-488 Messages ...................................................... 4-10

4-4. IEEE-488 Remote Message Coding ................................................................ 4-11

4-5. IEEE-488 Interface Messages (Received) ....................................................... 4-15

4-6. IEEE-488 Interface Messages (Sent) ............................................................... 4-16

4-7. Commands for RS-232 Only ........................................................................... 4-17

4-8. Units Accepted in Parameters and Used in Responses .................................... 4-18

4-9. Terminator Characters ..................................................................................... 4-19

4-10. Response Data Types ....................................................................................... 4-21

4-11. Status Register Summary ................................................................................. 4-21

6-1. Replacement Fuses .......................................................................................... 6-2

6-2. Required Equipment ........................................................................................ 6-4

6-3. Measuring DC Voltage .................................................................................... 6-5

6-4. Measuring DC Current..................................................................................... 6-6

6-5. TC Temperatures ............................................................................................. 6-7

6-6. Ohms Output Ranges ....................................................................................... 6-10

6-6. Ohms Ratio Table ............................................................................................ 6-12

6-8. Replacement Parts ........................................................................................... 6-16

6-9. Fluke 700 SeriesPressure Modules .................................................................. 6-17

6-10. Fluke 525A-P Series Pressure Modules ........................................................... 6-18

v

Page 8

525B

Users Manual

vi

Page 9

List of Figures

Figure Title Page

1-1. Input and Output Terminals and Connectors ................................................... 1-5

1-2. Pushbuttons ...................................................................................................... 1-6

1-3. Calibrator Function Keys ................................................................................. 1-8

1-4. Rear Panel View .............................................................................................. 1-11

2-1. Connection to Simulate Thermocouple Temperature ...................................... 2-2

2-2. Connection to Simulate a RTD Temperature ................................................... 2-3

2-3. Connection for Setting DC Voltage Output ..................................................... 2-7

2-4. Connection for Setting Resistance Output ....................................................... 2-8

2-5. Connection for Setting Current Output ............................................................ 2-9

3-1. Measuring Resistance Using a 4-Wire to 2-Wire Connection ......................... 3-2

3-2. Measuring Temperature with a Thermocouple ................................................ 3-3

3-3. Measuring RTD Output from an Instrument ................................................... 3-5

3-4. Measuring Temperature using an RTD Probe ................................................. 3-6

3-5. Connection for Measuring Pressure ................................................................. 3-10

4-1. Testing the RS-232 Port ................................................................................... 4-2

4-2. Typical RS-232 Remote Control Connections ................................................ 4-4

4-3. Typical IEEE-488 Remote Control Connections ............................................. 4-6

4-4. Testing the IEEE-488 Port ............................................................................... 4-7

4-5. Status Register Overview................................................................................. 4-22

4-6. Serial Poll Status Byte (STB) and Service Request Enable (SRE) .................. 4-23

6-1. Accessing the Fuse .......................................................................................... 6-3

6-2. Measuring DC Current..................................................................................... 6-6

6-3. Testing TC Output ........................................................................................... 6-7

6-4. Connections for CJC Calibration ..................................................................... 6-8

6-5. Connections for Measuring TC Input .............................................................. 6-9

6-6. Connection for Measuring Resistance Output ................................................. 6-10

6-7. 8508A/01 Connection Diagram ....................................................................... 6-11

6-8. Connection for Measuring Ohms ..................................................................... 6-13

6-9. Exploded View of the 525B ............................................................................. 6-15

vii

Page 10

525B

Users Manual

viii

Page 11

Introduction

Your Fluke 525B Temperature/Pressure Calibrator (referred to as the Calibrator) is

an instrument designed to meet the demands of your process tools calibration

workload.

In addition to the functions in Table 1-1, the Calibrator has the following features

and functions.

• Two line backlit LCD display

• 5-way binding posts

• IEEE 488.2 parallel interface

• RS-232 serial interface

Contacting Fluke

To order accessories or get the location of the nearest Fluke distributor or Service

Center, call:

Chapter 1

Getting Started

• USA: 1-888-99-FLUKE (1-888-993-5853)

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31-402-678-200

• Japan: +81-3-3434-0181

• Singapore: +65-738-5655

• Anywhere in the world: +1-425-446-5500

Or, visit Fluke’s Web site at www.fluke.com.

To register your product, visit register.fluke.com.

1-1

Page 12

525B

Users Manual

Table 1-1. Summary of Input and Output Functions

Function Input Output

dc V None 0 V to 100 V

dc mA None 0 to 100 mA

Resistance 0 to 4000 Ω (4-wire) 5 to 4000 Ω (2-wire)

Thermocouple Yes Yes

RTD Yes Yes

Pressure Yes No

Standard Equipment

The items listed below are included with your Calibrator. If the Calibrator is

damaged or something is missing, contact the place of purchase immediately. To

order replacement parts or spares, see the replacement parts list in Chapter 6.

• 525B Getting Started Guide, Part No. 3064079

• 525B CD-ROM (contains the 525B Users Manual and 525B Getting Started

Guide), Part No. 3064087

• Power Cord (120 V cord, Part No.1618621 or 240 V cord, Part No. 769422)

• Thermocouple Shorting Jumper, Part No. 610747

Options and Accessories

For more information about these accessories and their prices, contact your Fluke

representative.

• 5520A – 525A Leads kit

• Y525 Rack Mount kit

• Fluke 700 and 525A-P series pressure modules

• MET/CAL with 525B Function Select Code (FSC)

• MET/CAL 525B calibration procedure

Safety Information

This Calibrator complies with IEC 61010, ANSI/ISA-S82.01-1994, CAN/CSAC22.2 No. 1010.1-92. Use the Calibrator only as specified in this manual,

otherwise the protection provided by the Calibrator may be impaired.

CAT II equipment is designed to protect against transients from energy-consuming

equipment supplied from the fixed installation, such as TVs, PCs, portable tools,

and other household appliances.

1-2

Page 13

Getting Started

Safety Information

A Warning statement identifies hazardous conditions and actions that could cause

bodily harm or death.

A Caution statement identifies conditions and actions that could damage the

Calibrator or the equipment under test.

International symbols used on the Calibrator and in this manual are explained in

Table 1-2.

Warning

To avoid possible electric shock or personal injury, follow these guidelines:

• Use the Calibrator only as specified in this manual, or the protection provided by

the Calibrator might be impaired.

• Inspect the Calibrator before using it. Do not use the Calibrator if it appears

damaged. Look for cracks or missing plastic. Pay particular attention to the

insulation around the connectors.

• Have the Calibrator serviced only by qualified service personnel.

• Do not apply more than the rated voltage between the terminals, as marked on

the Calibrator, or between any terminal and earth ground.

• Always use the power cord and connector appropriate for the voltage and outlet

of the country or location in which you are working.

1

• Never operate the Calibrator with the cover removed or the case open.

• Never remove the cover or open the case of the Calibrator without first removing

the power source.

• Use caution when working with voltages above 30 V ac rms, 42 V ac peak, or 60

V dc. These voltages pose a shock hazard.

• Use only the replacement fuse(s) specified in this manual.

• Use the proper terminals, function, and range for your measurements.

• Do not operate the Calibrator around explosive gas, vapor, or dust.

• When servicing the Calibrator, use only specified replacement parts.

1-3

Page 14

525B

Users Manual

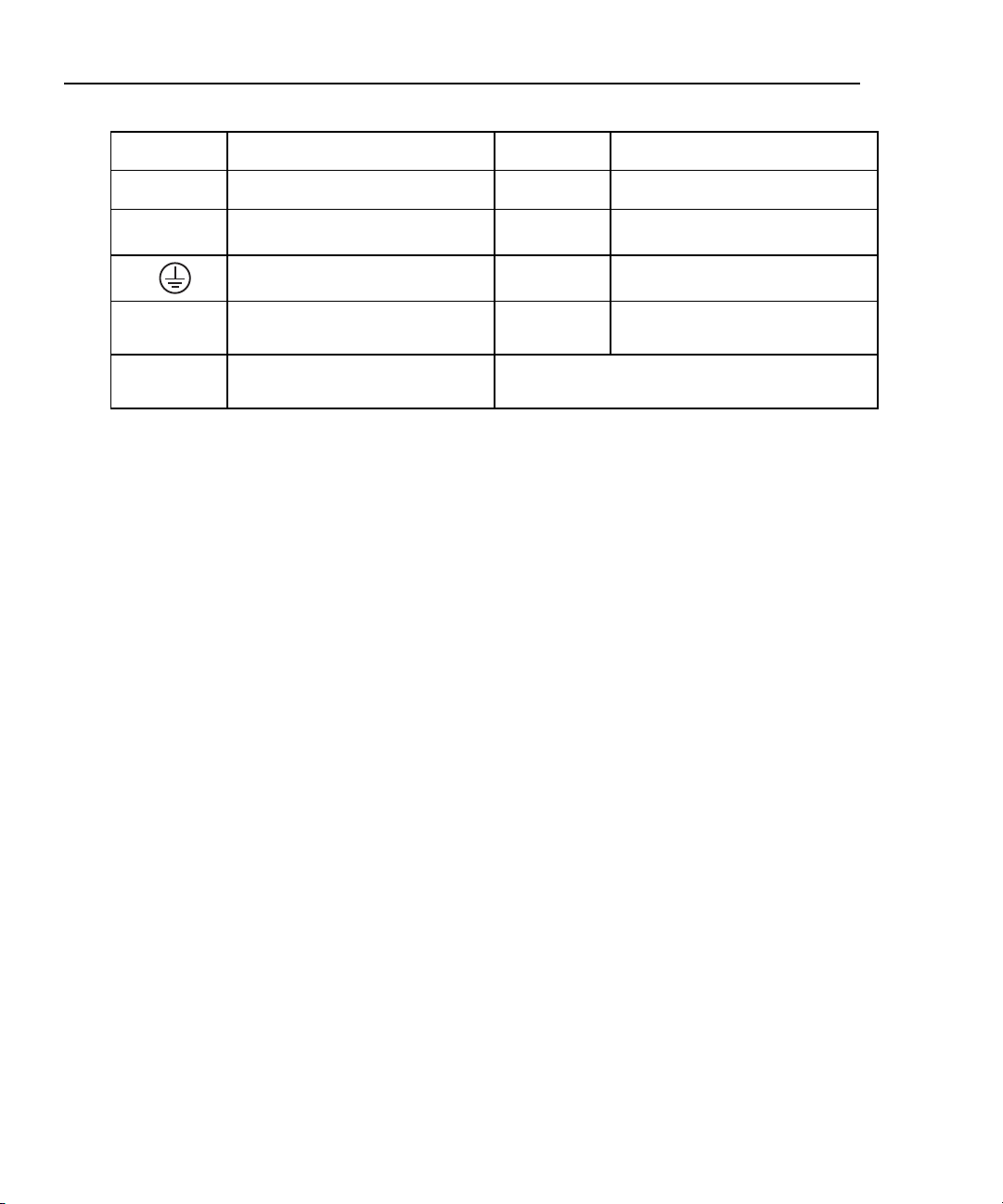

Table 1-2. Symbols Used on the Calibrator

AC (Alternating Current)

DC (Direct Current)

Pressure

Chassis protective ground

Important Information. See

manual.

Hazardous voltage. Risk of

electric shock

Earth ground

Resistance

Conforms to European Union

directives

Canadian Standards Association,

NRTL

International ON/OFF symbol.

1-4

Page 15

Getting Started

Getting Acquainted with the Calibrator

Getting Acquainted with the Calibrator

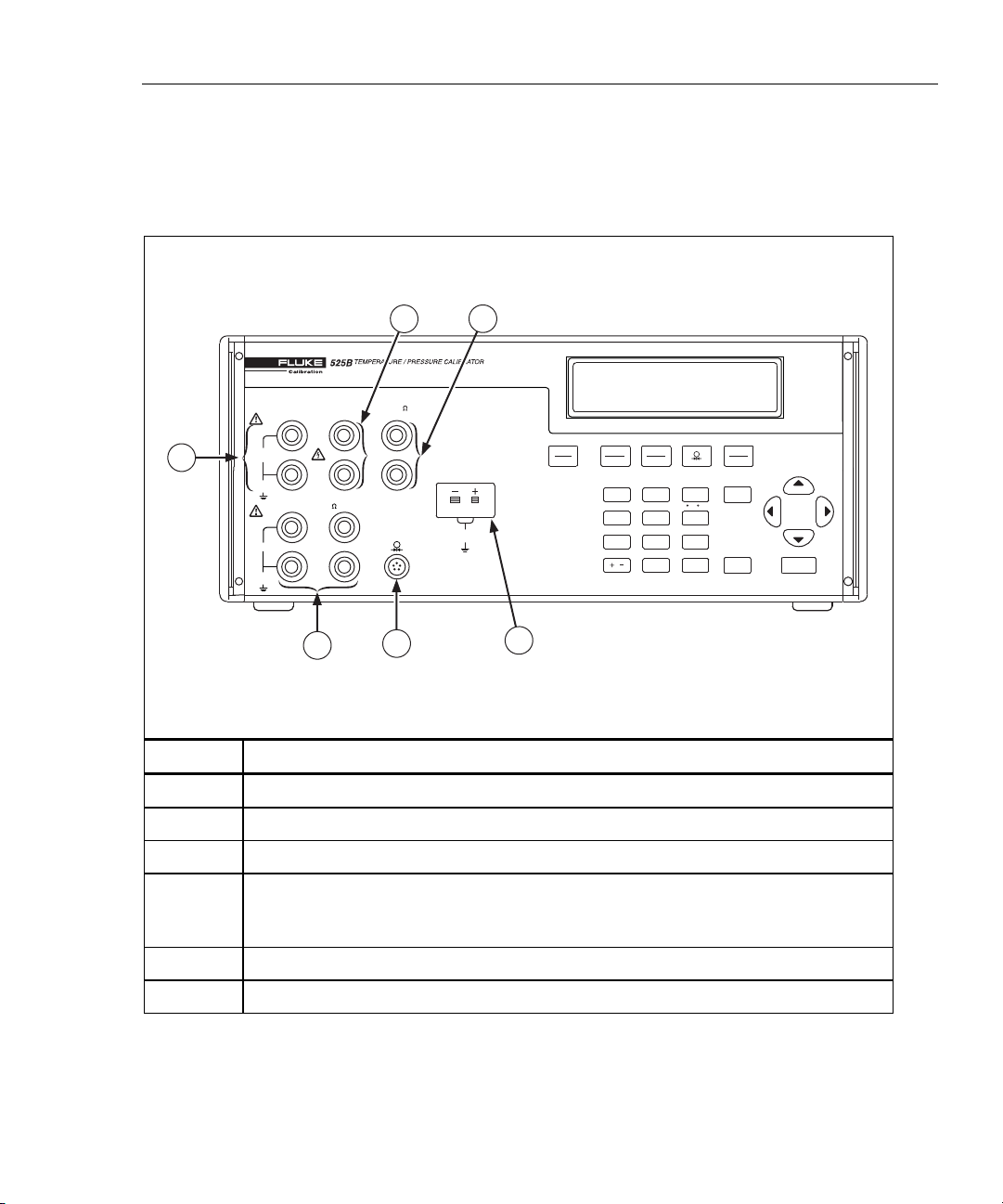

Input and Output Terminals

Figure 1-1 shows the Calibrator input and output terminals and explains their use.

1

2

VOLTS

100mA MAX

OUTPUT

1

100V MAX

20V PK

MAX

INPUT

20V PK

MAX

HI

LO

4W RTD

HI

LO

6

mA

RTD

HI

LO

SENSE

5

TC

INPUT/OUTPUT

20V PK

MAX

3

ZERO

9

C / F

6

AUTOSET

3

•

TYPE

UNITS

SHIFT

ENTER

CE

STBY

OPR

VOLTS

TC

mA

RTD

OUTPUT

INPUT

8

7

CJC SETUP

5

4

SET RECALL

2

1

LOCAL EXP

RNG LOCK

/

0

4

fcn08f.eps

No Description

Terminals used to output DC Volts.

Terminals used to output DC current.

Terminals used to simulate RTDs and resistance.

Terminal for thermocouple input and simulation. The terminal accepts a miniature

polarized thermocouple plug with flat, in-line blades spaced 7.9 mm (0.312 in) center

to center.

Pressure module input.

Input terminals used to measure 4-wire RTD and resistance.

Figure 1-1. Input and Output Terminals and Connectors

1-5

Page 16

525B

Users Manual

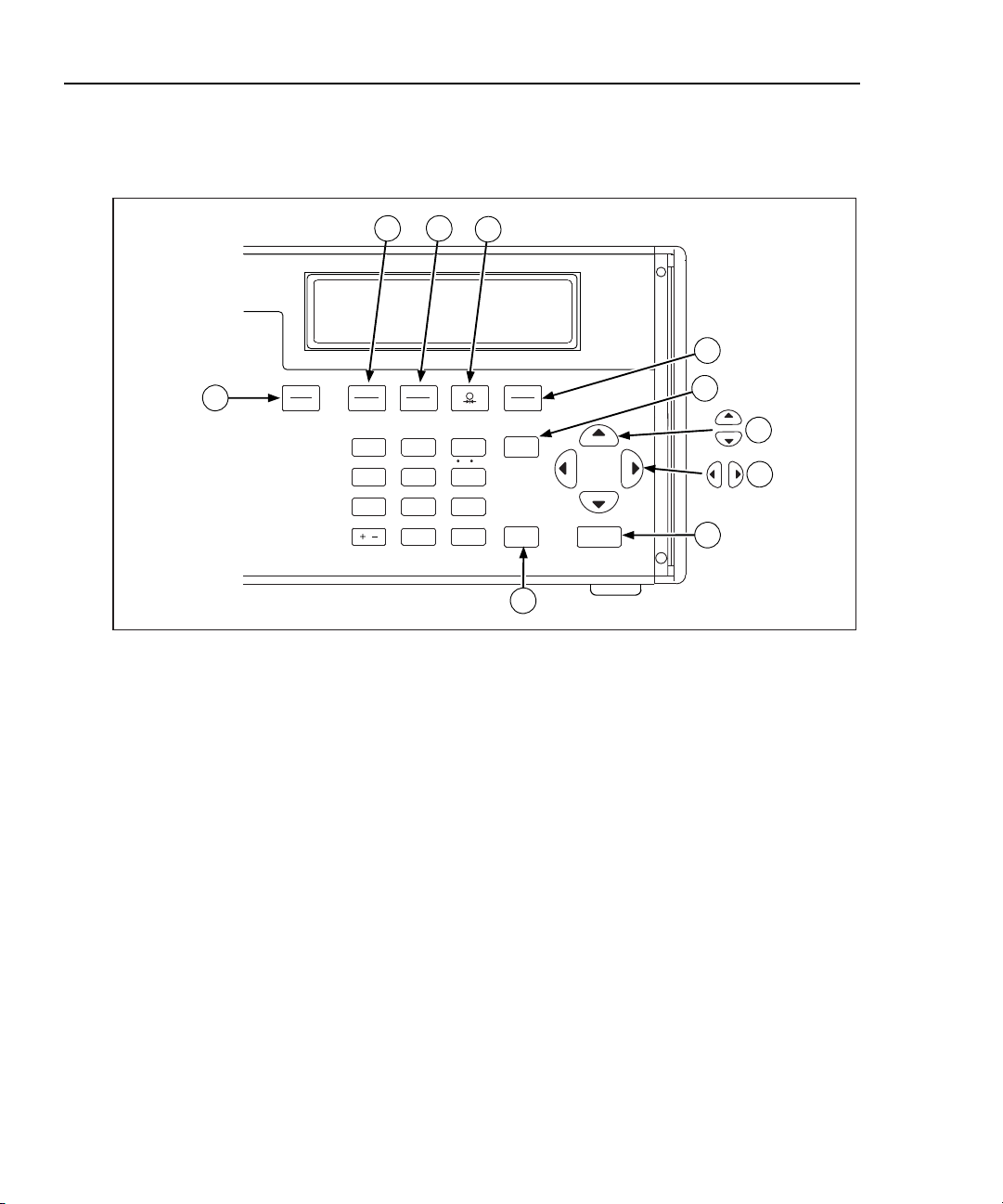

Using the Keys

Figure 1-2 shows the Calibrator pushbuttons and Table 1-3 explains their use.

Other function keys are shown in Figure 1-3 and described in Table 1-4.

32

4

5

6

7

8

9

ZERO

C / F

TYPE

UNITS

SHIFT

9

6

3

ENTER

•

CE

1

STBY

OPR

VOLTS

OUTPUT

RNG LOCK

TC

mA

RTD

INPUT

8

7

CJCSETUP

5

4

SET RECALL

2

1

LOCAL EX P

/

0

AUTOSET

10

fcn09f.eps

Figure 1-2. Pushbuttons

1-6

Page 17

Getting Started

Getting Acquainted with the Calibrator

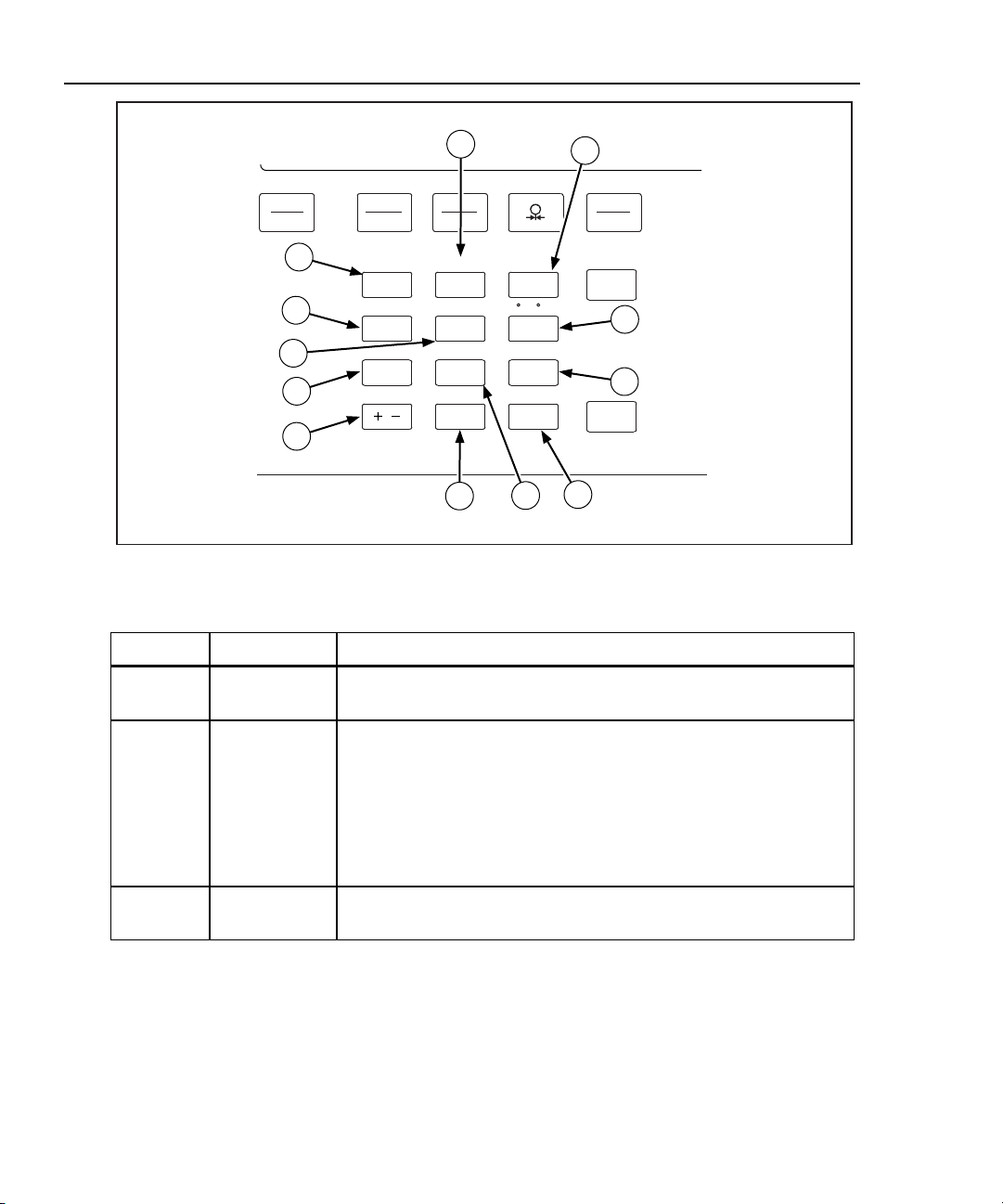

Table 1-3. Pushbutton Usage

No Name Description

1

Cycles the Calibrator through Standby and Operate

modes.

Toggles between DC voltage and DC current modes.

Toggles between the current thermocouple and current

RTD.

Selects the pressure measurement mode.

Selects a thermocouple or RTD type. For pressure

measurement, this is used to select the pressure

conversion units.

Selects the alternate function above the numeric keys.

• Increases or decreases the output level.

• Also used to adjust LCD contrast and brightness and

to select options on the Interface and Address

menus.

Selects a different digit to change.

CE (Clear Entry) clears a partially completed keypad entry

from the display. The display reverts to the last known

good entry.

Loads a newly entered output value into the Calibrator.

The new value is an entry from the numeric keypad. Also

used when entering custom RTD coefficients and when

you adjust the display or contrast.

1-7

Page 18

525B

Users Manual

STBY

OPR

6

VOLTS

mA

5

OUTPUT

7

4

4

3

SET RECALL

1

2

RNG LOCK

/

TC

RTD

INPUT

ZERO

8

CJCSETUP

C / F

5

AUTOSET

2

LOCAL EXP

0

7

TYPE

UNITS

9

6

3

•

SHIFT

8

9

ENTER

1

10

12

11

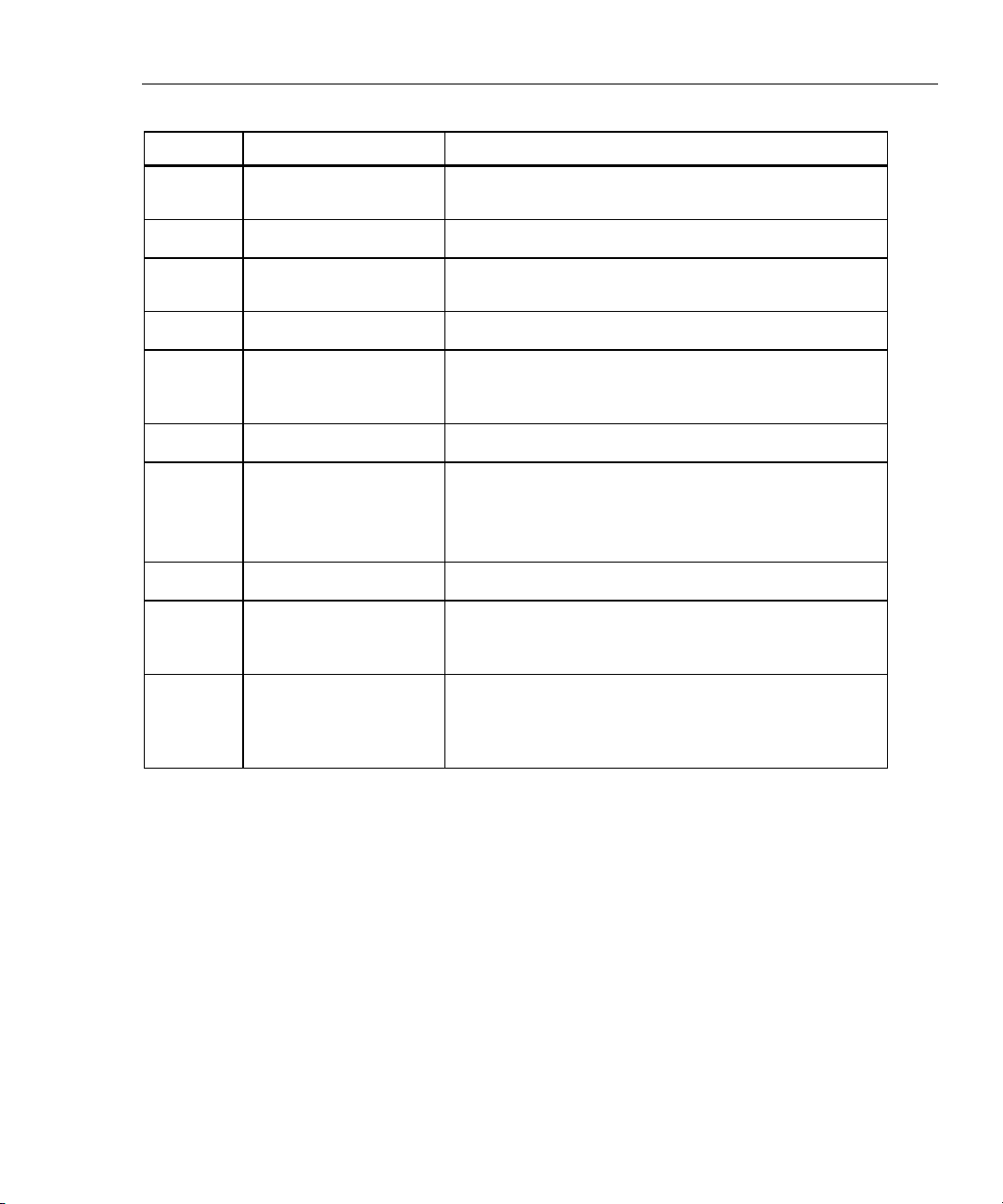

Figure 1-3. Calibrator Function Keys

Table 1-4. Function Keys

No Name Description

RNG LOCK

SET

Activates/deactivates the autorange feature of the Calibrator in

Voltage source modes.

Used to program a setpoint step for any output mode.

Key in the desired output and press . SETPOINT # appears

on the display. Select a setpoint number from 1 to 9. The output you

entered can now be recalled or used in the AUTOSET key

described later in this manual.

Each TC type, each RTD/OHMS type, mA, and Volts each have 9

programmable setpoints.

CJC

Toggles between the internal and external cold junction reference

locations.

fcn11f.eps

1-8

Page 19

Getting Started

Getting Acquainted with the Calibrator

Table 1-4. Function Keys (cont)

No Name Description

SETUP

OUTPUT

INPUT

ZERO

°C/°F

AUTOSET

Press to advance through the LCD Backlight, Interface, and

Address menus.

• Use and to adjust LCD backlight when the LCD menu is

displayed.

• Use and to toggle between Serial and GPIB interface when

the Interface menu is displayed.

• Use and to scroll from Address:1 to Address 30 when the

address menu is displayed.

Selects Output mode.

Selects Input mode.

Zeros the pressure module reading when in Pressure Measurement

mode.

Zeros the thermocouple TC mV/°C offset when in TC Measurement

mode.

Toggles between Centigrade and Fahrenheit when you are using

the TC or RTD functions.

AUTOSET runs through the setpoints you entered using the SET

function. Press . AUTO SET POINT? appears on the

display.

Enter a number between 1 and 9 that corresponds to the number of

setpoints being used. DWELL TIME 5-500? appears on the display.

Dwell time is the number of seconds between each setpoint. The

output cycles through each setpoint and then reverses the order.

For example, if 5 is entered for the number of setpoints, the

Calibrator cycles through setpoints 1, 2, 3, 4, 5 and then reverses to

setpoints 4, 3, 2, and 1.

1

Caution

Setpoints of 30 V or greater will not go to standby

when you use this feature.

EXP

Enters an exponent when you define a custom RTD.

1-9

Page 20

525B

Users Manual

No Name Description

Display Error Messages

Table 1-5 lists informative messages that may appear on the front panel display.

An explanation of each message is also provided.

RECALL

LOCAL

Table 1-4. Function Keys (cont)

Used to recall a programmed set point.

Press . RECALL SPT # appears on the display. Enter the

number of the output setpoint that you want to use. The output will

then be programmed to the setpoint you entered.

Used to regain local control of the Calibrator. If you set the

Calibrator to a remote state using the remote commands, all the

front panel keys are locked out except the Local key. When you

press the Local key, the front panel is unlocked.

Note

This function does not work when you set the Calibrator using the

Remote with Lockout command. In Remote with Lockout mode,

ALL keys are locked out and the Local key will not unlock the

front panel

.

Table 1-5. Display Error Messages

Message Explanation

OVER RANGE May be displayed in all output modes if you enter a value from the

front panel keypad that exceeds the output range of the function.

OVER LOAD May be displayed in V and mA output modes when the current is

exceeded for volts and the resistance is exceeded for mA.

OL Displayed in Input modes when the measured value exceeds the

upper limit of the range.

This error may also display in Output mode when the range is

locked and an automatically recalled set point exceeds the locked

range. For example, set point 1 (SP1) is set to 1V, SP2 is set to 2V,

and SP3 is set to 100V, the range is locked to 10V range and the

Calibrator is set up to automatically output the first 3 setpoints.

When the Calibrator reaches SP3, the display reads OL, and the

output is set to 0 for the duration of that setpoint.

-OL Displayed in Input modes when the measured value exceeds the

lower limit of the range.

INITIALIZATION FAILURE Displayed when the Calibrator fails to power up properly.

1-10

Page 21

Getting Started

Getting Acquainted with the Calibrator

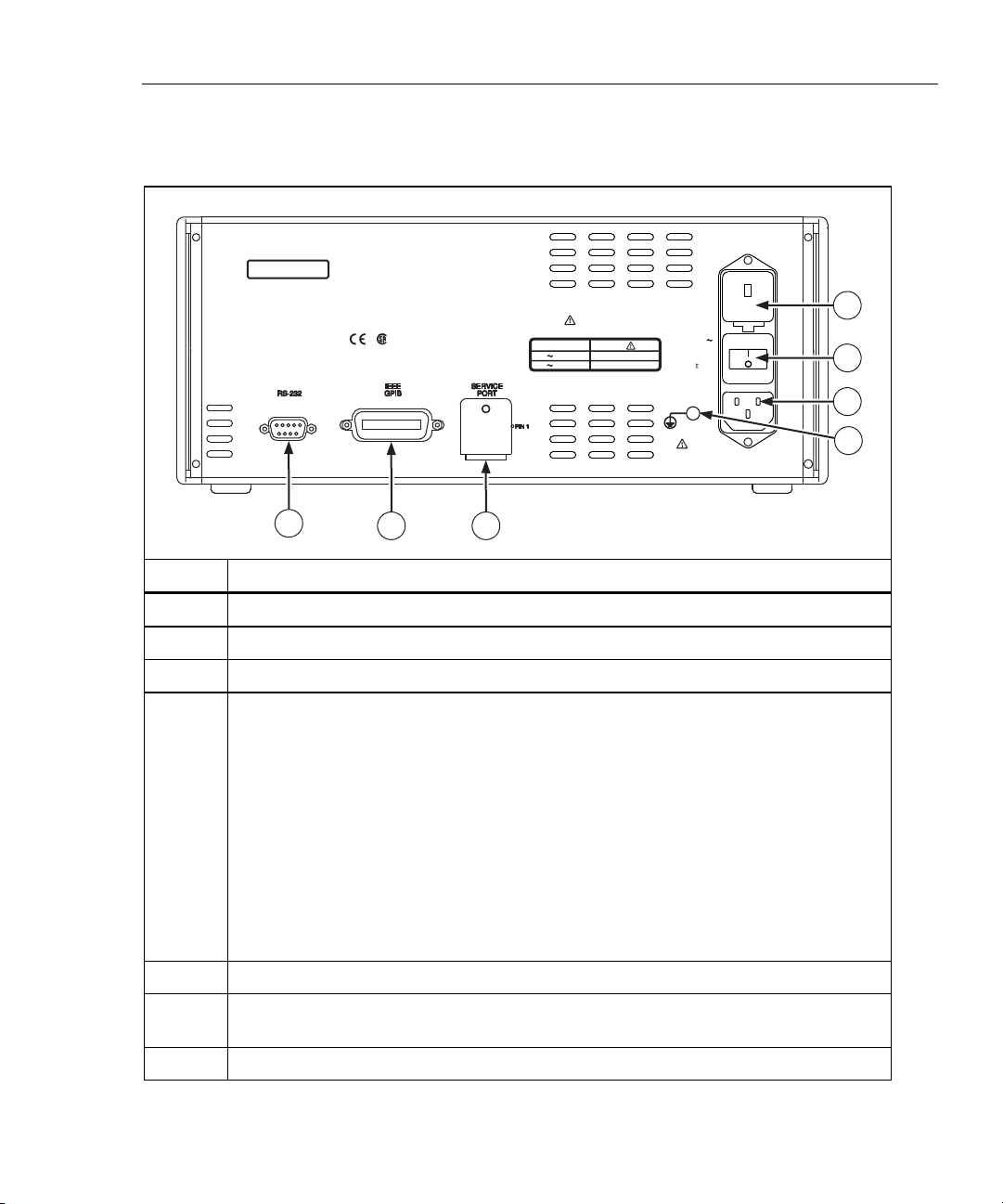

Rear Panel View

Figure 1-4 shows the features on the rear panel of the Calibrator and explains their

use.

NO INTERNAL USER SERVICEABLE PARTS

REFER SERVICE TO QUALIFIED

SERVICE PERSONNEL

FLUKE CORPORATION

MADE IN USA

PATENTS PENDING

www.fluke.com

C US

WARNING: FOR FIRE PROTECTION

REPLACE ONLY

WITH A 250V FUSE

OF INDICATED RATING?

MAINS SUPPLY

:

198V - 264V

5x20mm0.25A 250V

5x20mm0.125A 250V

120V: 90V - 132V

240V

FUSE

47Hz - 63Hz

15VA MAX

300V

CAT

CHASSIS

GROUND

1

2

3

1

WARNING: TO AVOID ELECTRIC SHOCK

GROUNDING CONNECTOR IN POWER CORD

MUST BE CONNECTED

7

56

4

fcn10f.eps

No Description

Power line fuse compartment. Contains fuses and line voltage selector.

The power switch turns the power on and off.

A grounded three-prong AC connector that accepts the line power cord.

The Chassis Ground terminal is internally connected to the ground prong of the AC

connector.

Warning

To avoid shock hazard, connect the factory supplied threeconductor power cord to a properly grounded power outlet. Do not

use a two-conductor adapter or extension cord; this will break the

protective ground connection.

Use the rear panel CHASSIS GROUND terminal as a connection

point for a protective grounding wire if there is any question about

the effectiveness of instrument earth grounding through the line

power cord ground wire.

Service port used to download new firmware to the Calibrator.

The IEEE-488 connector is a standard parallel interface for operating the 525B in

remote control as a talker/listener on the IEEE-488 bus.

The RS-232 connector is used for serial remote control of the 525B.

Figure 1-4. Rear Panel View

1-11

Page 22

525B

Users Manual

1-12

Page 23

Using Output Mode

In Output mode, the Calibrator generates calibrated signals for testing and

calibrating process instruments. In Output mode, the Calibrator:

• supplies voltage, current, and resistance

• simulates the output of RTD and TC temperature sensors

The

OVER RANGE message displays if you enter an invalid output

using the keypad. If you enter an out-of-range value, the Calibrator

reverts to the last known good value. You do not need to press .

When adjusting an output using the keys, the Calibrator will

not display or let you enter an out-of-range value.

Chapter 2

Using Output Mode

Note

Note

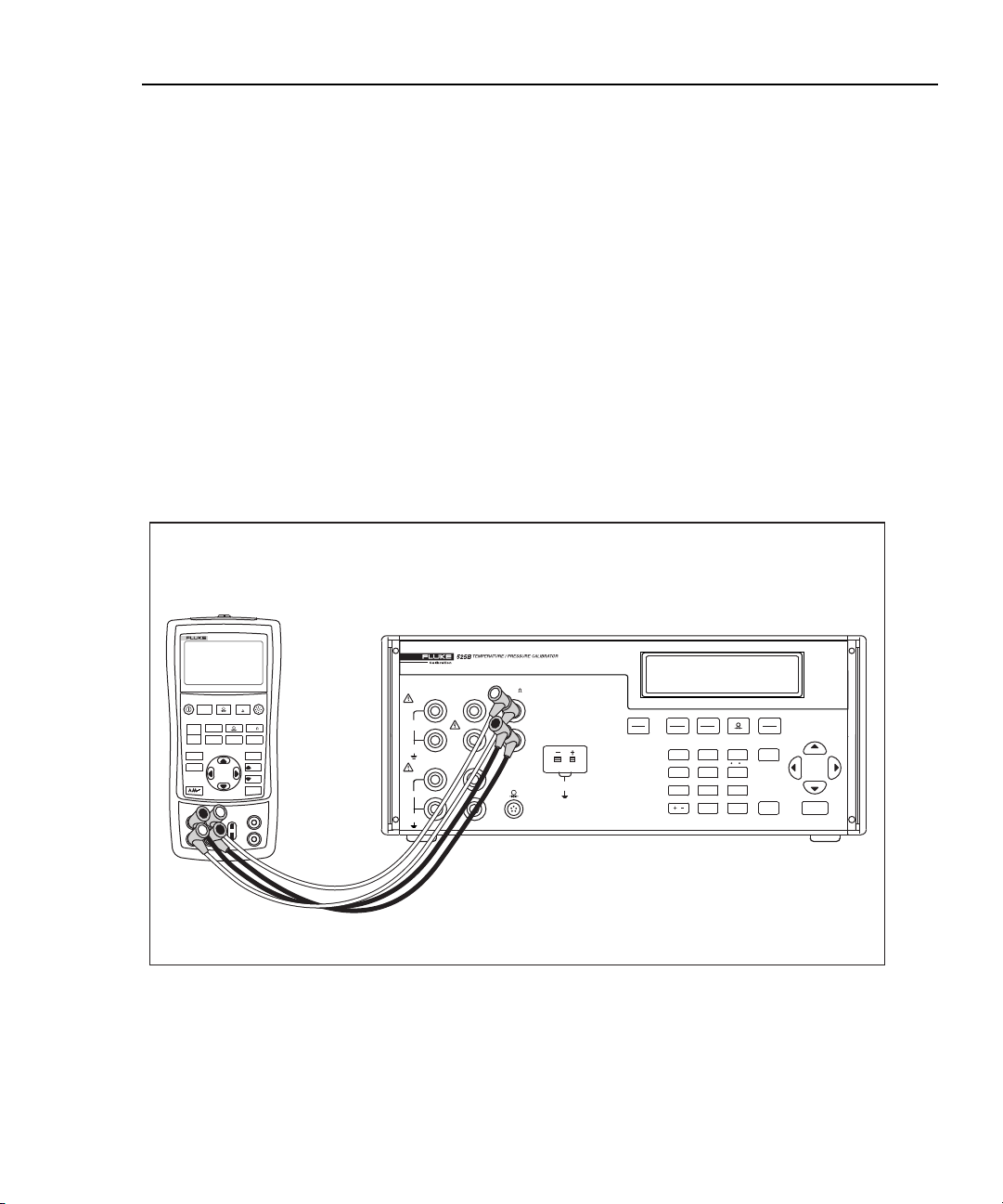

The figures is this chapter show how to connect to a Fluke 725

Multifunction Process Calibrator. For other instruments, refer to the

users manual for connection instructions.

2-1

Page 24

525B

Users Manual

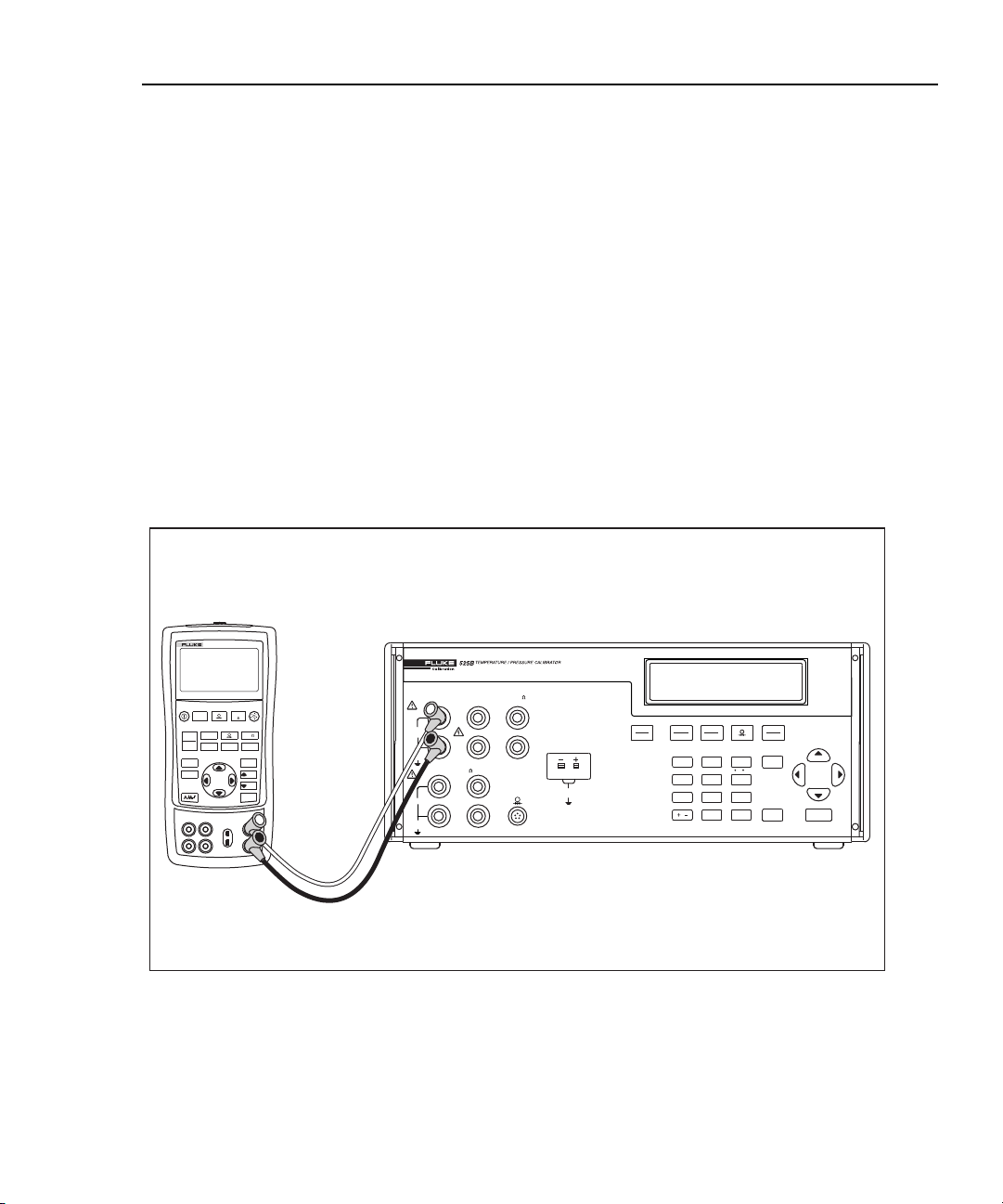

Simulating Thermocouple Temperature

Connect the Calibrator TC input/output to the unit under test (UUT) with

thermocouple wire and the appropriate thermocouple mini-connector. Supported

TC types are listed in Chapter 7. Figure 2-1 shows this connection.

To simulate temperature using a thermocouple (TC):

1. Attach the thermocouple extension wire as shown in Figure 2-1. One pin is

wider than the other. Do not try to force a miniplug in the wrong polarization.

2. Press until TC is selected.

3. If necessary, press for TC OUT mode.

4. Press to select the desired thermocouple type.

5. Use the numeric keypad to enter the desired output value and press . You

can also adjust the output value by pressing . Press to select a

different digit to modify.

HI

LO

HI

LO

mA

100mA MAX

SENSE

RTD

HI

LO

TC

INPUT/OUTPUT

TC

20V PK

MAX

STBY

OPR

VOLTS

mA

OUTPUT

INPUT

7

4

SET RECALL

1

LOCAL EXP

RNG LOCK

/

TC

RTD

8

CJC SETUP

5

2

0

TYPE

UNITS

ZERO

C / F

AUTOSET

SHIFT

9

6

3

ENTER

•

OUTPUT

100V MAX

20V PK

MAX

INPUT

20V PK

MAX

VOLTS

4W RTD

Figure 2-1. Connection to Simulate Thermocouple Temperature

CE

fcn07f.eps

2-2

Page 25

Using Output Mode

Using Output Mode

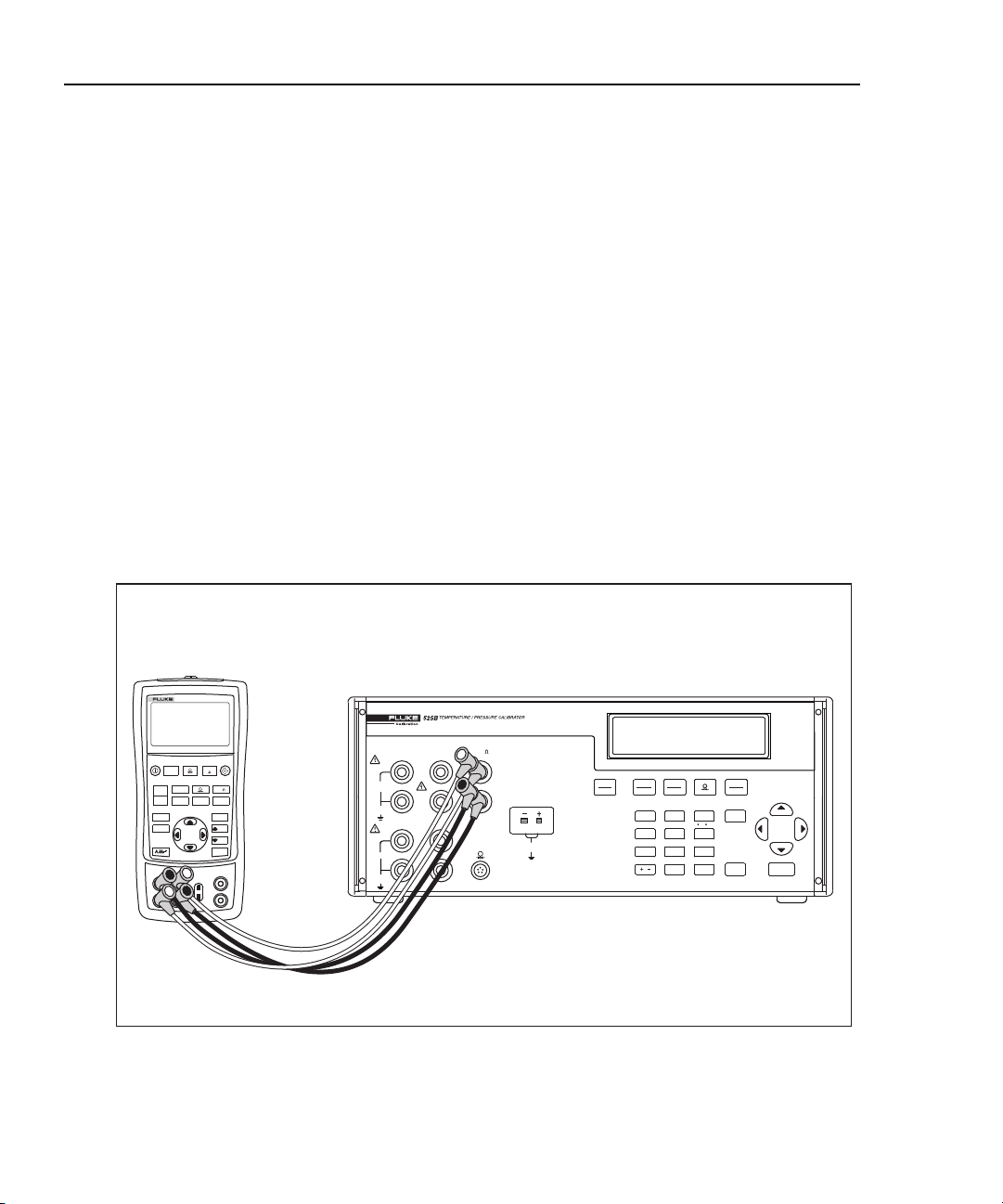

Simulating Temperature Using Resistance Temperature Detectors (RTDs)

RTDs have a characteristic resistance at specific temperatures. The simulated

output, then, is a resistance value based on the selected temperature and type of

RTD being simulated.

To simulate temperature using a resistance temperature detector:

1. Connect the Calibrator to the unit under test (UUT) as shown in Figure 2-2.

2. Press until RTD is selected.

3. If necessary, press for RTD OUT mode.

4. Press to select the desired RTD type.

5. Use the numeric keypad to enter the desired output value and press . You

can also adjust the output value by pressing . Press to select a

different digit to modify.

6. Press to activate output.

2

725

MULTIFUNCTION CALIBRATOR

RTD

mA

100mA MAX

HI

HI

LO

LO

HI

SENSE

LO

TC

INPUT/OUTPUT

20V PK

MAX

STBY

OPR

VOLTS

TC

mA

RTD

OUTPUT

INPUT

7

CJC SETUP

4

SET RECALL

1

LOCAL EXP

RNG LOCK

/

8

5

2

0

TYPE

UNITS

ZERO

C / F

AUTOSET

SHIFT

9

6

3

ENTER

•

CE

fcn01f.eps

SOURCE

STORE

SETUP

RECALL

MEAS

V mA

LOOP

V mA

TC RTD

ZERO

Hz

C °F

°

100%

25%

25%

0%

OUTPUT

100V MAX

20V PK

MAX

INPUT

20V PK

MAX

VOLTS

4W RTD

Figure 2-2. Connection to Simulate a RTD Temperature

2-3

Page 26

525B

Users Manual

Simulating Custom RTD Coefficients

The USR_DEF RTD type allows the Calibrator to simulate a custom curve-fit

RTD.

To enter the coefficients for a custom RTD:

1. Press to select RTD mode.

2. Press until you get the

3. Press to enter custom RTD information.

USR_DEF display.

RTD CUSTOM (1-5) appears on

the Calibrator display. You can store up to five custom RTD definitions on the

Calibrator.

4. Press a number key to specify the RTD you want to define (1-5). You can

press to step through definitions without changing the values.

5. When the

SET/RECALL display appears, press to define a custom RTD

coefficient.

6. Enter the

7. Enter the

8. Enter the nominal resistance (R

MIN TEMP and press .

MAX TEMP and press .

) and press .

0

9. Enter the temperature coefficients and press . Press to enter a

positive or negative exponent for the coefficient.

To use a custom RTD:

1. Press to enter RTD mode.

2. Press until you get the

3. Press to use custom RTD information.

USR_DEF display.

RTD CUSTOM (1-5) appears on the

Calibrator display. You can store up to five custom RTD definitions on the

Calibrator.

2-4

4. Press a number key to select the RTD you want to use (1-5).

5. When the

SET/RECALL display appears, press to recall and use the

selected RTD.

Page 27

Using Output Mode

Using Output Mode

Default RTD Coefficients

The USR_DEF function of the calibrator uses the Calendar-Van Dusen equation

for outputting and measuring custom RTDs. The C coefficient is only used for the

subrange –260 to 0 degrees Celsius. Only the A and B coefficients are needed for

the subrange 0 to 630 degrees. The R0 is the resistance of the probe at 0 degrees

Celsius. All of the USR_DEF will be set to PT385 as shown in Table 2-1.

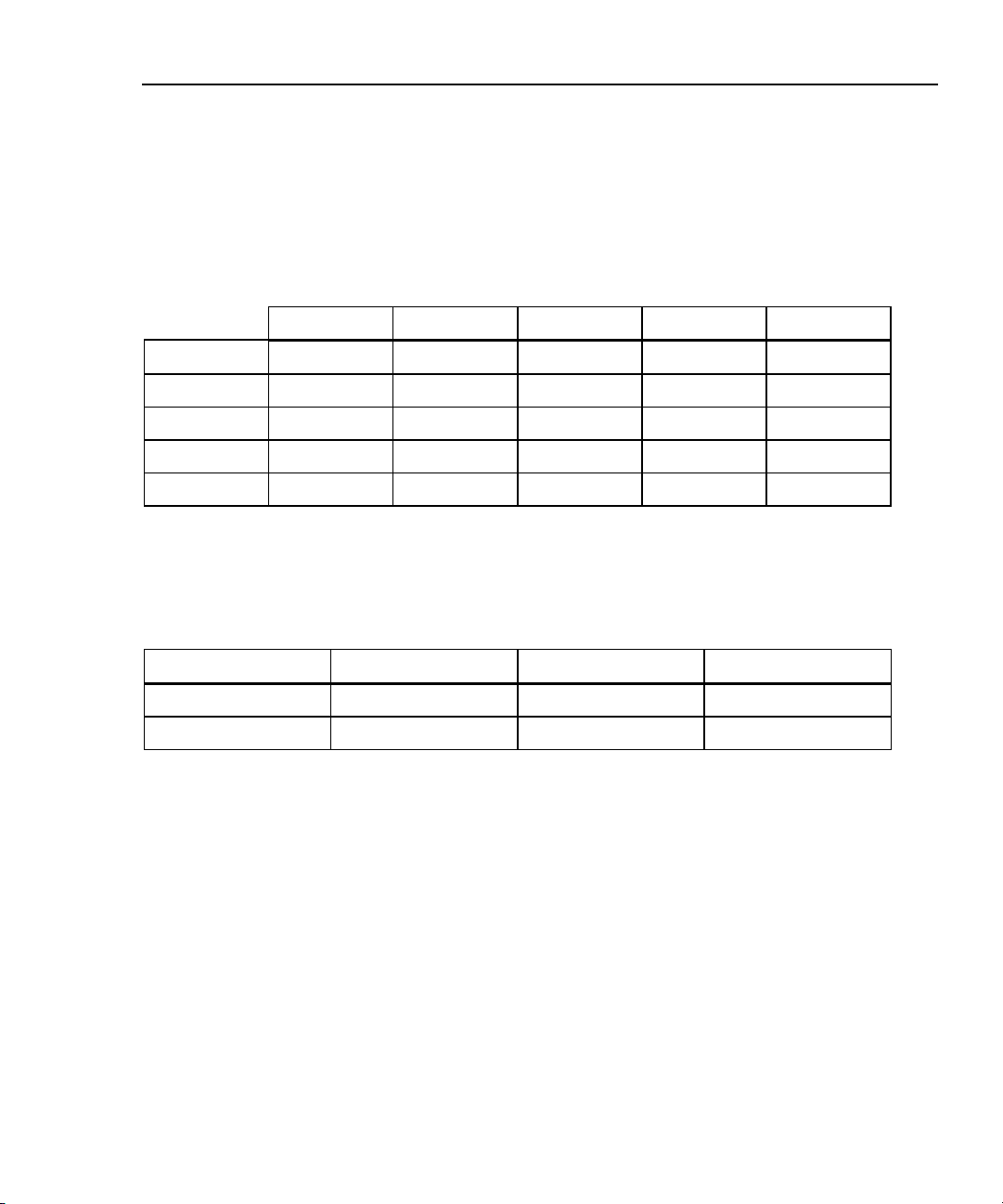

Table 2-1. Default RTD Coefficients

Sub range R0 Coefficient A Coefficient B Coefficient C

USR_DEF1 0 to 630 100 3.908X10-3 -5.775e-7

USR_DEF2 -260 to 0 100 3.908X10-3 -5.775e-7 -4.183e-12

USR_DEF3 0 to 630 100 3.908X10-3 -5.775e-7

USR_DEF4 -260 to 0 100 3.908X10-3 -5.775e-7 -4.183e-12

USR_DEF5 0 to 630 100 3.908X10-3 -5.775e-7

If other types of RTDs are required, Table 2-2 shows the coefficients for types

PT391 and PT392. The C coefficient is only used for temperatures below 0

degrees Celsius.

2

Table 2-2. Other Commonly Used RTDs

RTD Type Coefficient A Coefficient B Coefficient C

PT392 3.9848X10-3 -5.87X10-7 -4X10-12

PT391 3.9692X10-3 -5.8495X10-7 -4.2325X10-12

The SPRT function of the calibrator uses ITS-90 standard coefficients for

measuring a SPRT. Since the five coefficients are deviations all of them will be set

to 0.

The coefficients A- and B- represent the A4 and B4 coefficient, obtained when the

SPRT is calibrated at the triple points of argon, mercury and water. This covers the

83.8058K to 273.16K subrange. Coefficients A, B and C can represent different

coefficients based on which subranges of the SPRT has been calibrated. For

example, if the 273.15K to 933.473K subrange was used, A, B and C would

represent A7, B7 and C7 whereas if the 273.15K to 692.67K subrange was used, A

and B would represent A8 and B8 and C=0.

2-5

Page 28

525B

Users Manual

Entering Custom Standard Platinum Resistance Thermometer (SPRT) Coefficients

To enter coefficients for a custom SPRT:

1. Press to enter RTD mode.

2. Press until you get the

3. Enter the

4. Enter the

MIN TEMP and press .

MAX TEMP and press .

5. Enter the nominal resistance (R

RTD SPRT display and press .

) and press .

0

6. Enter the temperature coefficients and press . Press to enter a

positive or negative exponent for the coefficient.

2-6

Page 29

Using Output Mode

Using Output Mode

Output DC Voltage

The Calibrator is a fully programmable precision source of DC voltage from 0 V

to 100 V. The Calibrator can only output positive (+) values.

To output DC voltage:

1. Connect the Calibrator to the UUT as shown in Figure 2-3.

2. Press for V out display.

3. Use the numeric keypad to enter the desired output value and press . You

can also adjust the output value by pressing . Press to select a

different digit to modify.

4. Press to activate output.

Note

For safety purposes, the Calibrator resets to standby when output is

set to 30 V or greater.

2

725

MULTIFUNCTION CALIBRATOR

RTD

mA

100mA MAX

HI

HI

LO

LO

HI

SENSE

LO

TC

INPUT/OUTPUT

20V PK

MAX

STBY

OPR

VOLTS

TC

mA

RTD

OUTPUT

INPUT

7

CJC SETUP

4

SET RECALL

1

LOCAL EXP

RNG LOCK

/

8

5

2

0

TYPE

UNITS

ZERO

C / F

AUTOSET

SHIFT

9

6

3

ENTER

•

CE

fcn02f.eps

MEAS

SOURCE

STORE

SETUP

RECALL

V mA

LOOP

V mA

TC RTD

ZERO

Hz

C °F

°

100%

25%

25%

0%

OUTPUT

100V MAX

20V PK

MAX

INPUT

20V PK

MAX

VOLTS

4W RTD

Figure 2-3. Connection for Setting DC Voltage Output

2-7

Page 30

525B

Users Manual

Output Resistance

To output resistance:

1. Connect the Calibrator to the UUT as shown in Figure 2-4.

2. Press until RTD mode is selected.

3. If necessary, press for RTD OUT mode.

4. Press to select the appropriate ohms output range (400 or 4000 ohms).

5. Use the numeric keypad to enter the desired output value and press . You

6. Press to activate output.

can also adjust the output value by pressing . Press to select a

different digit to modify.

Note

If the input current is excessive, the Calibrator will beep, display the

message

OVER LOAD, and enter Standby mode. You will need to

check the input current and change it accordingly. Resistance

specifications are listed in Chapter 7.

2-8

MEAS

SOURCE

STORE

SETUP

RECALL

725

V mA

LOOP

V mA

TC RTD

MULTIFUNCTION CALIBRATOR

ZERO

VOLTS

OUTPUT

Hz

C °F

°

100%

25%

25%

0%

100V MAX

20V PK

MAX

INPUT

20V PK

MAX

4W RTD

RTD

mA

100mA MAX

HI

HI

LO

LO

HI

SENSE

LO

TC

INPUT/OUTPUT

20V PK

MAX

STBY

OPR

VOLTS

mA

RTD

OUTPUT

INPUT

7

CJC SETUP

4

SET RECALL

1

LOCAL EXP

RNG LOCK

/

TC

8

5

2

0

TYPE

UNITS

ZERO

C / F

AUTOSET

SHIFT

9

6

3

ENTER

•

CE

fcn01f.eps

Figure 2-4. Connection for Setting Resistance Output

Page 31

Using Output Mode

Output Current

Output Current

The Calibrator is a fully programmable precision source of DC current from 0 mA

to 100 mA. The Calibrator can only output positive (+) values.

To output current:

1. Connect the Calibrator to the UUT as shown in Figure 2-5.

2. If necessary, press to select mA.

3. Use the numeric keypad to enter the desired output value and press . You

can also adjust the output value by pressing . Press to select a

different digit to edit.

4. Press activate output.

Note

If

OVER LOAD appears on the display you may not have a

completed circuit loop. When the circuit is complete, the message

will disappear.

2

725

MULTIFUNCTION CALIBRATOR

RTD

mA

100mA MAX

HI

HI

LO

LO

HI

SENSE

LO

TC

INPUT/OUTPUT

20V PK

MAX

STBY

OPR

VOLTS

TC

mA

RTD

OUTPUT

INPUT

7

CJC SETUP

4

SET RECALL

1

LOCAL EXP

RNG LOCK

/

8

5

2

0

ZERO

C / F

AUTOSET

TYPE

UNITS

SHIFT

9

6

3

ENTER

•

CE

fcn03f.eps

MEAS

SOURCE

STORE

SETUP

RECALL

V mA

LOOP

V mA

TC RTD

ZERO

Hz

C °F

°

100%

25%

25%

0%

OUTPUT

100V MAX

20V PK

MAX

INPUT

20V PK

MAX

VOLTS

4W RTD

Figure 2-5. Connection for Setting Current Output

2-9

Page 32

525B

Users Manual

2-10

Page 33

Using Input Mode

In Input mode, the Calibrator measures resistance, and temperature from RTD and

thermocouple sensors and displays pressure measurements from Fluke 700 and

525A-P series pressure modules.

The figures in this chapter show how to connect to a Fluke 725

Multifunction Process Calibrator. For other instruments, refer to

their users manual for connection instructions.

Measuring Resistance

The Calibrator will only measure resistance using a 4-wire system. The Input

terminals supply a fixed DC current and the Sense terminals measure the voltage.

When you connect to a 4-wire calibrator, connect the Input to the output terminals

and the Sense to the sense terminals for proper measurement.

Chapter 3

Using Input Mode

Note

To measure resistance using a 4-wire to 2-wire connection:

1. Connect the Calibrator to the instrument you want to test as shown in

Figure 3-1.

2. If necessary, press to select RTD mode.

3. Press to select an ohms range (400 or 4000 ohms).

4. If necessary, press for RTD IN mode.

3-1

Page 34

525B

Users Manual

725

MULTIFUNCTION CALIBRATOR

RTD

mA

100mA MAX

HI

HI

LO

LO

HI

SENSE

LO

TC

INPUT/OUTPUT

20V PK

MAX

MEAS

SOURCE

STORE

SETUP

RECALL

V mA

LOOP

V mA

TC RTD

ZERO

Hz

C °F

°

100%

25%

25%

0%

OUTPUT

100V MAX

20V PK

MAX

INPUT

20V PK

MAX

VOLTS

4W RTD

Figure 3-1. Measuring Resistance Using a 4-Wire to 2-Wire Connection

Measuring Temperature Using Thermocouples

The Calibrator supports numerous standard thermocouples. See Chapter 7 for

supported thermocouple specifications.

You can use the key to toggle the cold junction reference location (CJC)

between the internal and external cold junction reference locations. External cold

junction reference is 0 °C or 32 °F. This is used primarily when you want to use an

external cold junction for conducting temperature measurements. The

message appears on the display when the Calibrator is in external CJC mode.

STBY

OPR

VOLTS

TC

mA

RTD

OUTPUT

INPUT

7

CJC SETUP

4

SET RECALL

1

LOCAL EXP

RNG LOCK

/

TYPE

UNITS

ZERO

C / F

AUTOSET

SHIFT

9

6

3

ENTER

•

CE

fcn04f.eps

8

5

2

0

XCJC status

3-2

Page 35

Using Input Mode

Using Input Mode

To measure temperature using a thermocouple:

1. Attach the thermocouple leads to the TC input/output connector as shown in

Figure 3-2. One pin is wider than the other. Do not attempt to force the plug in

the wrong polarization.

Note

If the Calibrator and the TC plug are at different temperatures, wait

three minutes or more for the connector temperature to stabilize

after you plug the miniplug into the connector.

2. Press to select TC mode.

3. If necessary, press to place the Calibrator in TC IN mode.

4. Press to select the desired TC type. You can toggle between ºC and ºF

temperature units by pressing .

3

RTD

mA

100mA MAX

HI

HI

LO

LO

HI

SENSE

LO

TC

INPUT/OUTPUT

TC

20V PK

MAX

STBY

OPR

VOLTS

TC

mA

RTD

OUTPUT

INPUT

8

7

CJC SETUP

5

4

SET RECALL

2

1

LOCAL EXP

RNG LOCK

/

0

ZERO

9

C / F

6

AUTOSET

3

•

OUTPUT

100V MAX

20V PK

MAX

INPUT

20V PK

MAX

VOLTS

4W RTD

Figure 3-2. Measuring Temperature with a Thermocouple

TYPE

UNITS

SHIFT

ENTER

CE

fcn07f.eps

3-3

Page 36

525B

Users Manual

Thermocouple Zero Calibration

To obtain the optimum measurement accuracy, you must perform a zero

calibration when operating the Calibrator outside of the ambient temperature range

of 18 ºC to 28 ºC. The zero calibration must be performed with the Calibrator

thermally stable at the ambient temperature of operation.

To perform a thermocouple zero calibration:

1. Insert the supplied Thermocouple Shorting Jumper in the TC input/output

connector. One pin is wider than the other.

2. Allow time for the connection to become thermally stable.

3. Press to select TC mode.

4. If necessary, press to put the Calibrator in TC IN mode.

5. Press to select mV/ºC.

6. If the display does not read 0.000 mV, press to zero the Calibrator.

Offset values within the range of

measurement.

Note

±

1.000 mV can be zeroed out of the

3-4

Page 37

Using Input Mode

Using Input Mode

Measuring Temperature Using Resistance Temperature Detectors (RTDs)

You must use a 4-wire connection to achieve the Calibrator accuracy

specifications.

To measure the RTD output from an instrument:

1. Connect the Calibrator to the instrument you want to measure as shown in

Figure 3-3.

2. Press to select RTD mode.

3. If necessary, press to put the Calibrator in RTD IN mode.

4. Press to select the desired RTD type.

You can toggle between ºC and ºF temperature units by pressing

.

725

MULTIFUNCTION CALIBRATOR

3

RTD

mA

100mA MAX

HI

HI

LO

LO

HI

SENSE

LO

TC

INPUT/OUTPUT

20V PK

MAX

STBY

OPR

VOLTS

TC

mA

RTD

OUTPUT

INPUT

7

CJC SETUP

4

SET RECALL

1

LOCAL EXP

RNG LOCK

/

8

5

2

0

TYPE

UNITS

ZERO

C / F

AUTOSET

SHIFT

9

6

3

ENTER

•

CE

fcn06f.eps

MEAS

SOURCE

STORE

SETUP

RECALL

V mA

LOOP

V mA

TC RTD

ZERO

Hz

C °F

°

100%

25%

25%

0%

OUTPUT

100V MAX

20V PK

MAX

INPUT

20V PK

MAX

VOLTS

4W RTD

Figure 3-3. Measuring RTD Output from an Instrument

To measure temperatures using an RTD probe:

1. Connect an RTD probe to the Calibrator as shown in Figure 3-4.

2. Press to select the RTD mode.

3. If necessary, press to put the Calibrator in RTD IN mode.

3-5

Page 38

525B

Users Manual

4. Press to select the desired RTD type.

You can toggle between ºC and ºF temperature units by pressing

.

OUTPUT

100V MAX

20V PK

MAX

INPUT

20V PK

MAX

VOLTS

HI

LO

4W RTD

HI

LO

mA

100mA MAX

HI

LO

SENSE

RTD

TC

INPUT/OUTPUT

20V PK

MAX

STBY

OPR

VOLTS

TC

mA

RTD

OUTPUT

INPUT

8

7

CJC SETUP

5

4

SET RECALL

2

1

LOCAL EXP

RNG LOCK

/

0

ZERO

C / F

AUTOSET

Figure 3-4. Measuring Temperature using an RTD Probe

TYPE

UNITS

SHIFT

9

6

3

ENTER

•

CE

fcn05f.wmf

3-6

Page 39

Using Input Mode

Using Input Mode

Entering and Using Custom RTDs

The USR_DEF RTD type allows the Calibrator to simulate a custom curve-fit

RTD.

To enter the coefficients for custom RTDs:

1. Press to select RTD mode.

3

2. Press until you get the

3. Press to enter custom RTD information.

USR_DEF display.

RTD CUSTOM (1-5) appears on

the Calibrator display. You can store up to five custom RTD definitions on the

Calibrator.

4. Press a number key to specify the RTD you want to define (1-5).

5. When the

SET/RECALL display appears, press to define a custom RTD

coefficient.

6. Enter the

7. Enter the

8. Enter the nominal resistance (R

MIN TEMP and press .

MAX TEMP and press .

) and press .

0

9. Enter the temperature coefficients and press . Press to enter a

positive or negative exponent for the coefficient.

To use a custom RTD:

1. Press to enter RTD mode.

2. Press until you get the

3. Press to use custom RTD information.

USR_DEF display.

RTD CUSTOM (1-5) appears on the

Calibrator display. You can store up to five custom RTD definitions on the

Calibrator.

4. Press a number key to select the RTD you want to use (1-5).

5. When the

SET/RECALL display appears, press to recall and use the

selected custom RTD.

3-7

Page 40

525B

Users Manual

Default RTD Coefficients

The USR_DEF function of the calibrator uses the Calendar-Van Dusen equation

for outputting and measuring custom RTDs. The C coefficient is only used for the

subrange –260 to 0 degrees Celsius. Only the A and B coefficients are needed for

the subrange 0 to 630 degrees. The R0 is the resistance of the probe at 0 degrees

Celsius. All of the USR_DEF will be set to PT385 as shown in Table 3-1.

Table 3-1. Default RTD Coefficients

Sub range R0 Coefficient A Coefficient B Coefficient C

USR_DEF1 0 to 630 100 3.908X10-3 -5.775e-7

USR_DEF2 -260 to 0 100 3.908X10-3 -5.775e-7 -4.183e-12

USR_DEF3 0 to 630 100 3.908X10-3 -5.775e-7

USR_DEF4 -260 to 0 100 3.908X10-3 -5.775e-7 -4.183e-12

USR_DEF5 0 to 630 100 3.908X10-3 -5.775e-7

If other types of RTD are required, Table 3-2 shows the coefficients for PT391 and

PT392. Again, C is only used for temperatures below 0 degrees Celsius.

Table 3-2. Other Commonly Used RTDs

RTD Type Coefficient A Coefficient B Coefficient C

PT392 3.9848X10-3 -5.87X10-7 -4X10-12

PT391 3.9692X10-3 -5.8495X10-7 -4.2325X10-12

The SPRT function of the calibrator uses ITS-90 standard coefficients for

measuring a SPRT. Since the five coefficients are deviations all of them will be set

to 0.

The coefficients A- and B- represent the A4 and B4 coefficient, obtained when the

SPRT is calibrated at the triple points of argon, mercury, and water. This covers

the 83.8058K to 273.16K subrange. Coefficients A, B, and C can represent

different coefficients based on which subranges of the SPRT has been calibrated.

For example, if the 273.15K to 933.473K subrange was used, A, B, and C would

represent A7, B7, and C7 whereas if the 273.15K to 692.67K subrange was used,

A and B would represent A8 and B8 and C=0.

3-8

Page 41

Using Input Mode

Using Input Mode

Entering Custom SPRT Coefficients

To enter coefficients for a custom SPRT:

1. Press to enter RTD mode.

2. If necessary, press for RTD IN mode.

3

3. Press until you get the

4. Enter the

5. Enter the

6. Enter the nominal resistance (R

7. Enter the temperature coefficients and press . Press to enter a

positive or negative exponent for the coefficient.

MIN TEMP and press .

MAX TEMP and press .

RTD IN SPRT display and press .

) and press .

0

3-9

Page 42

525B

Users Manual

Measuring Pressure

Many ranges and types of pressure modules are available from Fluke. See

“Accessories” in Chapter 6 of this manual for a complete list of supported pressure

modules. Before you use a pressure module, read its instruction sheet. Pressure

modules vary in use, media, and accuracy.

To measure pressure, attach the appropriate pressure module for the process

pressure to be tested as shown in Figure 3-5.

To measure pressure:

1. Connect a pressure module to the Calibrator as shown in Figure 3-5.

2. Press . The Calibrator automatically senses which pressure module is

3. If appropriate, zero the pressure module as described in the module’s

4. Pressurize the module with a pressure source to the desired level.

attached and sets its range accordingly.

instruction sheet. Modules vary in zeroing procedures depending on the

module type, but all require you to press .

You can press to change pressure display units to psi, inH20 4ºC,

inH20 20ºC, cmH20 4ºC, cmH20 20º C, bar, mbar, kPa, inHg 0ºC, mmHg 0ºC,

kg/cm2.

3-10

MAX TORQUE, SEE MANUAL

700PD6

L H

PRESSURE MODULE

RANGE

-15/+100 PSIG

-1/+7 bar

BURST PRESSURE 300 PSIG

Figure 3-5. Connection for Measuring Pressure

OUTPUT

100V MAX

20V PK

MAX

INPUT

20V PK

MAX

VOLTS

HI

LO

4W RTD

HI

LO

mA

100mA MAX

HI

LO

SENSE

RTD

TC

INPUT/OUTPUT

20V PK

MAX

fcn21f.eps

Page 43

Introduction

This chapter describes methods for operating the Calibrator by remote control.

Remote control can be interactive, with the user controlling each step from a

terminal, or under the control of a computer program running the Calibrator in an

automated system. The Calibrator rear panel has two ports for remote operations:

• RS-232 serial port

• IEEE-488 parallel port (General Purpose Interface Bus or GPIB port)

RS-232 The serial port connects the PC and Calibrator. You can write your own

computer programs using the command set, or operate the PC as a terminal and

enter individual commands, or you can purchase optional Fluke MET/CAL

software for RS-232 system operations. Typical RS-232 remote configurations are

shown in Figure 4-2.

Chapter 4

Remote Operation

IEEE-488 The IEEE-488 parallel port is usually used in larger control and

calibration systems. An IEEE-488 system has the ability to serve multiple

Calibrators and multiple UUTs. Also, parallel system throughput is faster than

serial system throughput. The controller in an IEEE-488 system is typically a

Windows

488 ports. You can write your own computer programs for system operation using

the command set, or you can purchase optional Fluke calibration software

MET/CAL. Typical IEEE-488 configurations are shown in Figure 4-3. The

configuration showing the PC with two IEEE-488 ports is used with MET/CAL,

which prefers UUTs on a separate IEEE-488 port. You can also “piggy-back” the

connectors on a single IEEE-488 port.

After configuring the IEEE-488 or RS-232 port for remote operation, you are

ready to begin using the command set. The operation of the command set is

described under “Using Commands” in this chapter. A summary of remote

commands is in Chapter 5, “Remote Commands.”

4-1

®

compatible personal computer (PC) equipped with one or more IEEE-

Page 44

525B

Users Manual

Setting up the RS-232 Port for Remote Control

The Calibrator is fully programmable over an RS-232 link with a PC. You can

enter individual commands from a terminal, write your own programs using, for

example, a Windows

®

Windows

-based Fluke software such as MET/CAL.

The RS-232 cable length for the port should not exceed 15 meters (50 feet),

although longer cable lengths are permitted if the load capacitance measured at a

connection point (including signal terminator) does not exceed 2500 pF.

RS-232 Port Setup Procedure

Serial parameters are fixed with the values shown below:

• 9600 baud

• 8 data bits

• 1 stop bit

• no parity

• Xon/Xoff

• EOL (end-of-line) character CR (Carriage Return)

®

-based language such as Visual Basic, or run optional

Testing the RS-232 Port

Use the following procedure to test the Calibrator RS-232 Port connected to a PC

COM port. A typical connection is shown in Figure 4-1. Note the use of a null

modem cable for connection.

Controller

4-2

Null Modem Cable

COM Port

Figure 4-1. Testing the RS-232 Port

525B Calibrator

UUT

SERIAL

Port

fcn14f.eps

Page 45

Remote Operation

Setting up the RS-232 Port for Remote Control

4

Complete the following procedure to test RS-232 port operation using the

Windows

To test port operation:

1. Select Start->Programs->Accessories->Hyperterminal->Hyper Terminal.

2. Enter 525B for Name:, and select OK.

3. Select PC serial port which 525B is connected to (from drop-down list), for

4. Select the following setting and then select OK:

5. Select File->Properties->Settings->ASCII Setup.

6. Select the following settings and then select OK:

®

HyperTerminal application (or equivalent).

Connect using: and select OK

Bits per second: 9600

Data bits: 8

Parity: None

Stop bits: 1

Flow control: Xon / Xoff

Echo typed characters locally

Append line feeds to incoming line ends

7. Select OK.

8. Enter *IDN? and press Enter.

9. Verify that that the returned string is Fluke,525B,0,<firmware revision>.

4-3

Page 46

525B

Users Manual

RS-232

Port

COM Port

Controller

System for a UUT without a remote port.

COM PortCOM Port

SERIAL

FROM HOST

Port

525B Calibrator

UUT

SERIAL

FROM HOST

Port

4-4

UUT

525B Calibrator

Controller

System for a UUT with an RS-232 port (via PC).

Figure 4-2. Typical RS-232 Remote Control Connections

fcn15f.eps

Page 47

Remote Operation

RS-232 Interface Overview

RS-232 Interface Overview

The Calibrator RS-232 port is designed in accordance with EIA (Electronic

Industries Association) standard RS-232-C. RS-232 is a serial binary data

interchange operating at 9600 baud and distances up to 50 feet. The Calibrator rear

panel serial port is configured as DTE (Data Terminal Equipment). For detailed

information, see the EIA standard RS-232-C.

A summary of RS-232 terms, interface lines and mnemonics are shown in

Table 4-1.

Table 4-1. RS-232 Interface Wiring

Mnemonic Description

DB-9 Type DB connector, 9 pins

DTE Data Terminal Equipment

GND Ground

RX Receive Line

TX Transmit Line

4

Setting up the IEEE-488 Port for Remote Control

The Calibrator is fully programmable for use on the IEEE Standard 488 interface

bus. The IEEE-488 interface is also designed in compliance with supplemental

standard IEEE-488.2, which describes additional IEEE-488 features. Devices

connected to the IEEE-488 bus are designated as talkers, listeners, talker/listeners,

or controllers. Under remote control of an instrument, the Calibrator operates as a

talker/listener. Figure 4-3 shows typical IEEE-488 remote control connections.

A PC equipped with an IEEE-488 interface controls the Calibrator. Compatible

software for IEEE-488 operation, MET/CAL, may be purchased from Fluke.

When using the IEEE-488 remote control interface, there are two restrictions:

1. Number of Devices A maximum of 15 devices can be connected in a single

IEEE-488 bus system. For example, one instrument controller, one Calibrator,

and thirteen units under test (UUTs).

2. Cable Length The total length of IEEE-488 cables used in one IEEE-488

system is 2 meters times the number of devices in the system, or 20 meters,

whichever is less. For example, if 8 devices are connected, the maximum cable

length is 2 x 8 = 16 meters. If 15 devices are connected, the maximum cable

length is 20 meters.

4-5

Page 48

525B

Users Manual

UUT

IEEE-488 Port

Controller

System for a UUT without a remote port.

Controller

IEEE-488 Port

525B Calibrator

UUT

525B Calibrator

4-6

RS-232

Port

System for a UUT with an IEEE-488 remote port.

COM Port

UUT

Controller

System for a UUT with an RS-232 remote port.

Figure 4-3. Typical IEEE-488 Remote Control Connections

525B Calibrator

fcn13f.eps

Page 49

Remote Operation

Setting up the IEEE-488 Port for Remote Control

IEEE-488 Port Setup Procedure

Complete the following procedure to set up the Calibrator for remote operations

using the IEEE-488 remote control port. The purpose is to select GPIB as the

interface and to select the GPIB address for the interface. See Figure 4-4 for

typical connections.

To set up the IEEE-488 port:

1. Turn the Calibrator power on and wait until the initialization procedure

completes. You may operate the Calibrator during warm-up, but specifications

are not guaranteed until warm-up is complete.

2. Press SETUP ( + ).

3. Press until Remote Interface: is displayed.

4. Press the or key to select GPIB, if not already selected.

5. Press until Address: is displayed.

6. Press the or key to select the desired address. The factory default is 4.

7. Press to exit the Setup menu.

4

Testing the IEEE-488 Port

Port

Controller

Figure 4-4. Testing the IEEE-488 Port

It is beyond the scope of this manual to describe how to test the 525B IEEE-488

interface in general because Windows is not provided by default with an

application to exercise a device attached to an IEEE-488 interface card. However

if MET/CAL has been purchased, the following steps may be performed to verify

that the 525B IEEE-488 interface is functioning properly.

IEEE-488 Cable

IEEE-488 PortIEEE-488

525B Calibrator

UUT

fcn16f.eps

xx

4-7

Page 50

525B

Users Manual

To test the IEE-488 port:

1. Open the MET/CAL Editor application.

2. Select File->New or press Ctrl+N.

3. Enter IEEE [@4]*IDN?[I$]. If you did not select address 4 in step 6 above,

substitute the address you entered for the 4.

4. Select Edit->Name Procedure or press Ctrl+I and enter Test 525B GPIB.

5. Select Compile->Next Error or press F9.

6. Select Test Run->Restart or press F2.

7. Check the S-Reg check box.

8. Select Run.

9. Verify that the S-Reg (MEM2) window displays Fluke,525B,0,<firmware

rev.>.

10. Select Quit.

11. Select File->Save or press Ctrl+S to save the procedure.

12. Exit the MET/CAL Editor.

Changing Between Remote and Local Operation

In addition to Local mode (front panel operation) and remote, the Calibrator can be

placed in a local lockout condition at any time by command of the controller.

Combined, the local, remote, and lockout conditions yield four possible operating

states described as follows.

Local State

The Calibrator responds to local and remote commands. This is normal front panel

operation. All remote commands are allowed to execute.

Local with Lockout State

Local with lockout is identical to local, except the Calibrator will go into the

remote with lockout state instead of the remote state when it receives a remote

command. You can only enter the Local with Lockout State by sending the IEEE488 GTL (Go to Local) message when the 525B is in remote with lockout.

Remote State

When the Calibrator is placed in remote, either via RS-232 REMOTE command,

or via IEEE-488 asserting the REN line, it enters the remote state. The top line of

the display changes to: REM.

4-8

Page 51

Remote Operation

Changing Between Remote and Local Operation

Front panel operation is disabled except for the LOCAL (0 key). Pressing 0, using

RS-232 to send the command LOCAL, or IEEE-488 to send the GTL (Go To

Local) message returns the Calibrator to the local state.

Remote with Lockout State

When the Calibrator is placed in lockout, either via RS-232 LOCKOUT command,

or via the IEEE-488 message LLO, the 525B front panel controls are totally locked

out. The top line of the display changes to: REM.

To return the Calibrator to the local with lockout state, send the RS-232 LOCAL

command or the IEEE-488 GTL (Go To Local) message.

Table 4-2 summarizes the possible Operating state transitions. (For more

information on IEEE-488 GPIB messages, see “IEEE-488 Overview.”

Table 4-2. Operating State Transitions

4

From To

Local

Remote

Local with Lockout

Remote with Lockout

Front

Panel

Remote MLA (REN True) REMOTE