Page 1

5220A

®

Transconductance Amplifier

Instruction Manual

PN 491936

June 1979 Rev. 3, 6/97

© 1997 Fluke Corporation. All rights reserved. Printed in USA

All product names are trademarks of their r espective comp ani es.

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under

normal use and service. The warranty period is one year and begins on the date of shipment.

Parts, product repairs, and services are warranted for 90 days. This warranty extends only to the

original buyer or end-user customer of a Fluke authorized reseller, and does not apply to fuses,

disposable batteries, or to any product which, in Fluke’s opinion, has been misused, altered,

neglected, contaminated, or damaged by accident or abnormal conditions of operation or

handling. Fluke warrants that software will operate substantially in accordance with its functional

specifications for 90 days and that it has been properly recorded on non-defective media. Fluke

does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user

customers only but have no authority to extend a greater or different warranty on behalf of Fluke.

Warranty support is available only if product is purchased through a Fluke authorized sales outlet

or Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for

importation costs of repair/replacement parts when product purchased in one country is submitted

for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price, free of

charge repair, or replacement of a defective product which is returned to a Fluke authorized

service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the

difficulty, postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in

transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid

(FOB Destination). If Fluke determines that failure was caused by neglect, misuse, contamination,

alteration, accident, or abnormal condition of operation or handling, including overvoltage failures

caused by use outside the product’s specified rating, or normal wear and tear of mechanical

components, Fluke will provide an estimate of repair costs and obtain authorization before

commencing the work. Following repair, the product will be returned to the Buyer transportation

prepaid and the Buyer will be billed for the repair and return transportation charges (FOB

Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, ARISING FROM

ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or

exclusion or limitation of incidental or consequential damages, the limitations and exclusions of

this warranty may not apply to every buyer. If any provision of this Warranty is held invalid or

unenforceable by a court or other decision-maker of competent jurisdiction, such holding will not

affect the validity or enforceability of any other provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Page 3

Table of Contents

Section Title Page

1 Introduction and Specifications ........................................................ 1-1

1-1. Introduction.......................................................................................... 1-1

1-2. Specifications ....................................................................................... 1-2

2 Operating Instructions....................................................................... 2-1

2-1. Introduction.......................................................................................... 2-1

2-2. Shipping Information............................................................................ 2-1

2-3. Input Power .......................................................................................... 2-1

2-4. Fuse Replacement................................................................................. 2-2

2-5. AC Line Fuse................................................................................... 2-2

2-6. Power Supply Fuses......................................................................... 2-2

2-7. Rack Installation................................................................................... 2-2

2-8. Operating Features................................................................................ 2-2

2-9. Operating Notes.................................................................................... 2-5

2-10. AC Line Connection ........................................................................ 2-5

2-11. Transconductance Amplifier............................................................ 2-5

2-12. Input Voltage Requirements ............................................................ 2-5

2-13. Input Voltage Selection, Front/Rear ................................................ 2-6

2-14. Current Output, Front/Rear.............................................................. 2-6

2-15. Standby/Operate............................................................................... 2-6

2-16. Local/Remote................................................................................... 2-6

2-17. Status Indicators............................................................................... 2-6

2-18. Audible Output................................................................................. 2-7

2-19. Inductive Loads................................................................................ 2-7

2-20. Operation.............................................................................................. 2-9

3 Theory of Operation........................................................................... 3-1

3-1. Introduction.......................................................................................... 3-1

3-2. Overall Functional Description ............................................................ 3-1

3-3. General............................................................................................. 3-1

3-4. Analog Section................................................................................. 3-1

3-5. Digital Section.................................................................................. 3-4

3-6. Circuit Analysis.................................................................................... 3-4

3-7. Power Supply................................................................................... 3-4

i

Page 4

5220A

Instruction Manual

3-8. Preamplifier...................................................................................... 3-6

3-9. A6 Driver ......................................................................................... 3-7

3-10. A7 Output......................................................................................... 3-9

3-11. A8 Analog Control........................................................................... 3-10

3-12. A9 Front Panel................................................................................. 3-11

3-13. A10 Logic ........................................................................................ 3-11

3-14. Reset Logic.................................................................................. 3-11

3-15. Timing Logic............................................................................... 3-13

3-16. Standby/Operate Logic................................................................ 3-14

3-17. Local/Remote Logic .................................................................... 3-15

3-18. Front/Rear Input Logic................................................................ 3-15

3-19. Failure Status Logic..................................................................... 3-16

3-20. A11 MIS Bus Interface.................................................................... 3-16

4 Maintenance....................................................................................... 4-1

4-1. Introduction.......................................................................................... 4-1

4-2. Service Information.............................................................................. 4-2

4-3. General Maintenance............................................................................ 4-2

4-4. Cleaning........................................................................................... 4-2

4-5. Air Filter Maintenance..................................................................... 4-2

4-6. Access Information.......................................................................... 4-2

4-7. Internal Components/Assemblies................................................ 4-4

4-8. Front Panel Removal ................................................................... 4-4

4-9. A9 Front Panel PCB Removal..................................................... 4-4

4-10. A2 Transformer Assembly Removal........................................... 4-4

4-11. A6 Driver and A7 Output Assembly Removal............................ 4-5

4-12. A3 Cap Bus Removal .................................................................. 4-5

4-13. A12 Shunt Assembly Removal.................................................... 4-5

4-14. Fuse Replacement............................................................................ 4-6

4-15. Ac Line Fuse................................................................................ 4-6

4-16. Power Supply Fuses..................................................................... 4-6

4-17. Line Voltage Selection..................................................................... 4-6

4-18. Output Terminal Selection, Front/Rear............................................ 4-7

4-19. Service Tools.................................................................................... 4-8

4-20. Performance Test.................................................................................. 4-8

4-21. Initial Conditions.............................................................................. 4-8

4-22. Front Panel Tests.............................................................................. 4-9

4-23. Zero Output...................................................................................... 4-9

4-24. DC Accuracy and Line Regulation.................................................. 4-10

4-25. Harmonic Distortion......................................................................... 4-10

4-26. Frequency Response......................................................................... 4-11

4-27. Overcurrent Trip Test....................................................................... 4-11

4-28. Overvoltage Trip Test...................................................................... 4-12

4-29. Calibration Adjustments....................................................................... 4-12

4-30. Initial Conditions.............................................................................. 4-13

4-31. Input Offset Adjustment................................................................... 4-13

4-32. Driver Offset Adjustment................................................................. 4-13

4-33. Output Bias Adjustment................................................................... 4-14

4-34. DC Accuracy Adjustment................................................................ 4-14

4-35. Frequency Response......................................................................... 4-14

4-36. Overcurrent Adjustment................................................................... 4-15

4-37. Overvoltage Adjustment.................................................................. 4-15

4-38. Replacement of Selected Components................................................. 4-15

4-39. Resistors R11 and R12..................................................................... 4-16

ii

Page 5

Contents

4-40. Resistor R13..................................................................................... 4-17

4-41. Troubleshooting.................................................................................... 4-18

5 List of Replaceable Parts................................................................... 5-1

5-1. Introduction.......................................................................................... 5-1

5-2. How to Obtain Parts............................................................................. 5-1

5-3. Manual Status Information................................................................... 5-2

5-4. Newer Instruments................................................................................ 5-2

5-5. Service Centers..................................................................................... 5-2

6 Option and Accessory Information................................................... 6-1

6-1. Introduction.......................................................................................... 6-1

6-2. Accessories........................................................................................... 6-1

6-3. Rack Mounting Kit (M08-205-600)................................................. 6-1

6-4. Rack Slide Kit (M00-280-610) ........................................................ 6-3

6-5. Precision Y5020A Current Shunt..................................................... 6-3

7 Schematic Diagrams.......................................................................... 7-1

(continued)

iii

Page 6

5220A

Instruction Manual

iv

Page 7

List of Tables

Table Title Page

1-1. Accessories ............................................................................................................ 1-2

1-2. Specifications......................................................................................................... 1-2

2-1. Controls, Indicators, and Connectors..................................................................... 2-4

3-1. Effect of Reset Command on A10 Logic and A9 Front Panel............................... 3-13

4-1. Required Test Equipm ent...................................................................................... 4-1

4-2. DC Accuracy Test.................................................................................................. 4-10

4-3. Frequency Response Test ...................................................................................... 4-11

4-4. Replacement Resistors for R11 and R12............................................................... 4-17

4-5. Replacement Resistors for R13.............................................................................. 4-18

4-6. Mainframe and Digital Section Troubleshooting Guide........................................ 4-21

4-7. Analog Section Troubleshooting Guide................................................................. 4-25

5-1. 5220A Final Assembly .......................................................................................... 5-4

5-2. A1 Motherboard PCB Assembly........................................................................... 5-17

5-3. A2 Power Transformer Assembly ......................................................................... 5-18

5-4. A3 Capacitor Bus PCB Assembly......................................................................... 5-19

5-5. A4 Regulator PCB Assembly................................................................................ 5-21

5-6. A5 Preamplifier PCB Assembly............................................................................ 5-23

5-7. A6 Driver PCB Assembly...................................................................................... 5-26

5-8. A7 Output PCB Assembly..................................................................................... 5-28

5-9. A8 Analog Control PCB Assembly....................................................................... 5-31

5-10. A9 Front Panel PCB Assembly.............................................................................. 5-33

5-11. A10 Logic PCB Assembly..................................................................................... 5-34

5-12. A11 MIS Bus Interface PCB Assembly................................................................. 5-36

5-13. A12 Shunt Assembly............................................................................................. 5-38

5-14. A13 Output Termination PCB Assembly.............................................................. 5-40

5-15. A14 Extender PCB Assembly................................................................................ 5-41

v

Page 8

5220A

Instruction Manual

vi

Page 9

List of Figures

Figure Title Page

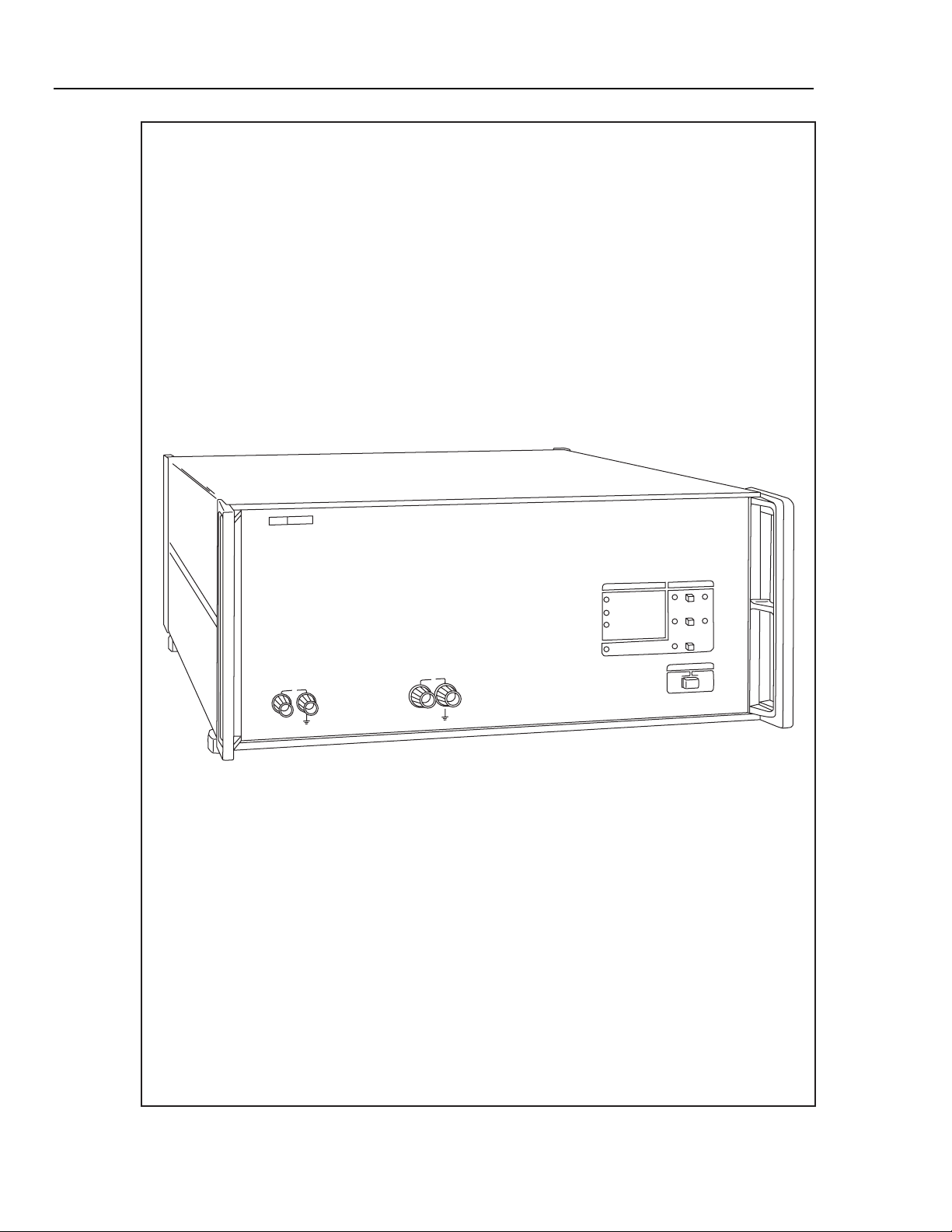

5220A Transconductance Amplifier...................................................................... x

1-1. Outline Drawings................................................................................................... 1-5

2-1. Controls, Indicators, and Connectors..................................................................... 2-3

2-2. Maximum Load Inductance vs Frequency............................................................. 2-8

2-3. Typical Transconductance Error for Inductive Loads........................................... 2-9

3-1. 5

3-2. Transconductance Amplifier Simplified Circuit Diagram..................................... 3-3

3-3. Power Supply Functional Block Diagram............................................................. 3-5

3-4. A5 Preamplifier Functional Block Diagram.......................................................... 3-6

3-5. A6 Driver Functional Block Diagram.................................................................... 3-8

3-6. A7 Output Functional Block Diagram................................................................... 3-9

3-7. A8 Analog Control Simplified Block Diagram ..................................................... 3-10

3-8. A10 Logic Simplified Block Diagram................................................................... 3-12

3-9. Timing Sequence ................................................................................................... 3-14

3-10. A11 MIS Bus Interface.......................................................................................... 3-18

4-1. Internal Component/Assembly Locations.............................................................. 4-3

4-2. Line Voltage Selec tion........................................................................................... 4-7

4-3. Test Point Location/Identification......................................................................... 4-19

4-4. Flowchart Summary of Mainframe and Digital Section Troubleshooting Guide.. 4-20

4-5. Flowchart Summary of Analog Section Troubleshooting Guide........................... 4-24

5-1. 5220A Final Assembly .......................................................................................... 5-8

5-2. A1 Motherboard PCB Assembly........................................................................... 5-17

5-3. A2 Power Transformer Assembly ......................................................................... 5-18

5-4. A3 Capacitor Bus PCB Assembly......................................................................... 5-20

5-5. A4 Regulator PCB Assembly................................................................................ 5-22

5-6. A5 Preamplifier PCB Assembly............................................................................ 5-25

5-7. A6 Driver PCB Assembly...................................................................................... 5-27

5-8. A7 Output PCB Assembly..................................................................................... 5-29

5-9. A8 Analog Control PCB Assembly....................................................................... 5-32

5-10. A9 Front Panel PCB Assembly.............................................................................. 5-33

5-11. A10 Logic PCB Assembly..................................................................................... 5-35

5-12. A11 MIS Bus PCB Assembly................................................................................ 5-37

5-13. A12 Shunt Assembly............................................................................................. 5-39

5-14. A13 Output Termination PCB............................................................................... 5-40

5-15. A14 Extender PCB Assembly................................................................................ 5-41

220A Functional Block Diagram......................................................................... 3-2

vii

Page 10

5220A

Instruction Manual

6-1. Rack Mounting Kit ................................................................................................ 6-2

6-2. Rack Slide Kit........................................................................................................ 6-4

7-1. Interconnect Diagram............................................................................................. 7-2

7-2. Chassis Wiring....................................................................................................... 7-4

7-3. Power Supply......................................................................................................... 7-6

7-4. A5 Preamplifier PCB Assembly............................................................................ 7-8

7-5. A6 Driver and A7 Output PCB Assemblies .......................................................... 7-10

7-6. A8 Analog Control PCB Assembly....................................................................... 7-12

7-7. A9 Front Panel PCB Assembly.............................................................................. 7-14

7-8. A10 Logic PCB Assembly..................................................................................... 7-16

7-9. A11 MIS Bus Interface PCB Assembly................................................................. 7-18

viii

Page 11

Contents

(continued)

ix

Page 12

5220A

Instruction Manual

5220A Transconductance Amplifier

x

ajs36f.eps

Page 13

Introduction and Specifications

1-1. Introduction

The Model 5220A is a transconductance amplifier designed to operate as either a stand

alone unit or an extension of the Fluke Model 5100 Series Calibrator. Functionally, the

instrument operates as a precision ac/dc current source for calibrating current shunts

and/or current meters. As the name (trans condu cta nce amp l if ier ) impli es, the output

current level is a function of an input control voltage. The input/output ratio is established

at 1:1 so that a voltage input in the range of -20 to +20 volts will produce a proportional

current output of -20 to +20 amperes. Input voltages may be either dc or ac levels,

depending on the output requirements. Bandwidth for ac operation is dc to 5 kHz.

Control of the 5220A can be handled locally using front panel controls or remotely by

way of the 5100 Series Calibrator. (The 5100 must be equipped with a Model Y5000

Interface.) Control mode selection is accomplished using two front-panel push button

switches, INPUT and LOCAL. The INPUT switch allows selection of either front or rear

control-voltage input connections. The LOCAL switch is used to recall the 5220A from

remote to local operation.

Section 1

A series of front panel indicators are used to visually display both the control and

operating status of the 5220A. Control indicators include OPER (operate), STDBY

(standby), FRONT input, REAR input, REMOTE, and LOCAL LOCKOUT. The

combination of lit LEDs indicates the present status of the control mode. Status indicators

include THERMAL CUT-OFF, OVER COMPLIANCE, and OVER CURRENT. When

any one of these indicators is lit, an overload condition has been detected causing the

5220A to switch to standby operation. All indicators are active regardless of the selected

control mode, local or remote.

Current output connections are provided on both the front and rear panels. However, only

one set of terminals is active. Selection of the desired set is accomplished internally and

is, therefore, not considered an operator fun ction. Neit her loc al nor re mot e opera tion is

affected by the selection of front or rear output.

Forced-air circulation is incorporated in the 5220A to ensure adequate cooling of the

current output stage. Air is pulled in through a rear-panel filter, passed over the output

stage heat sink, and exhausted through the unit’s side panels.

The 5220A is designed to operate from ac line voltages within the range of 90 V ac to

264 V ac, 50 to 60 Hz. One-of-eight specific voltages (100, 110, 115, 120, 200, 220, 230,

240 V ac +10 %) can be selected to ensure compatibility with the local line voltage. The

1-1

Page 14

5 2 20A

Instruction Manual

1-2. Specifications

selection switches are inside the 5220A. Refer to Section 4 of this manual for information

on how to properly set the line power switches.

Accessories available for use with the 5220A are listed and described in Table 1-1. The

rack mounting kits are designed for use with a standard 19-inch equipment rack. The

Model Y5020A is a precision current shunt recommen ded for use in calibr at ing the

5220A. Specify both model number and description when ordering accessories.

Table 1-1. Accessories

Model No. Description

M07-205-600 Rack Mounting Kit

M00-260-610 Rack Slide Kit, 18 in

M00-280-610 Rack Slide Kit, 24 in

Y5020 Precision Shunt

Specifications for the Model 5220A are given in Table 1-2.

Table. 1-2. Specifications

Calibration Cycle All specifications are valid for a 180-day period at an operating

temperature of 20 °C to 30 °C and a relative humidity of 70 % or

less.

Basic

Transconductance 1 Siemen (1 ampere per volt)

Output Range 0 A to 20 A dc or rms ac (28.3 A peak)

Compliance Voltage ≥±4 V dc or 3 V rms ac (4.25 V peak)

DC Accuracy ±(0.025 % of output +1 mA)

AC Accuracy ±(0.05 % of output + 1 mA) from 30 Hz to 1 kHz, and ±(0.05 % of

output + 1 mA) x f from 1 kHz to 5 kHz, where f = frequency in kHz.

Short Term DC Stability Output changes less than ±(0.005 % + 200 µA) in 10 minutes, with

constant line, load, and temperature.

Short Term AC Stability Output changes less than ±(0.01 % + 500 µA) in 10 minutes, with

constant line, load, and temperature.

Harmonic Distortion and Noise ±(0.05 % of output ±1 mA rms) over frequency range of 30 Hz to 1

kHz and measured with a noise bandwidth of 300 kHz, ±(0.05 % of

output + 1 mA) x f from 1 kHz to 5 kHz, where f = frequency in kHz.

Temperature Coefficient ±(0.0025 % of output + 100 µA) per degree C above 30 °C or

below 20 °C.

1-2

Transient Recovery Output will settle to within 0.01 % of final value within 2 seconds

following a programmed change in output current or frequency

(10 ms for 5220A alone).

Page 15

Introduction and Specifications

Table 1-2. Specifications (cont.)

Electromagnetic Compatibility This instrument is designed to operate in Standard Laboratory

environments where in electromagnetic environment is highly

controlled. If used in areas with RF fields >0.4 V/m there could be

errors in measurement.

DC Mode (including 5100 Series B)

Output Range ±1 to ±19.9999 A

Accuracy of Output ±(0.025 % of selected output + 1 mA)

Resolution ±0.1 mA

Temperature Coefficient ±(0.003 % of selected output + 100 µA) / °C, above 30 °C and

below 20 °C

Line Regulation Output changes less than 0.001 % for a ±10 % change in line

voltage.

Load Regulation Output changes less than ±(0.005 % + 0.3 mA) for a full load

changes of 4 V of compliance.

AC Mode (including 5100 Series B)

Specifications

1

Output Range 1 A rms to 19.9999 A rms

Accuracy of Output ±(0.07 % of selected output + 1 mA rms) from 50 Hz to 1 kHz,

and ±(0.07 % of selected output + 1 mA rms) x f from 1 kHz to 5

kHz, where f = fr equency in kHz.

Resolution ±0.1 mA rms

Temperature Coefficient ±(0.003 % of selected output + 100 µA rms) per °C, above 30 °C

and below 20 °C.

Short Term Stability Output changes less than ±(0.02 % + 500 µA rms) in 10 minutes,

with constant line, load, and temperature.

Harmonic Distortion and Noise ±(0.07 % of output + 1 mA rms) over frequency range of 30 Hz to

1 kHz a noise bandwidth of 300 kHz, ±(0.07 % of output + 1 mA)

x f from 1 kHz to 5 kHz, where f = frequency in Hz.

Line Regulation Output changes less than 0.005 % for ±10 % changes in line

voltage.

Load Regulation For frequencies less than 1 kHz:

±(0.005 % lout + 150 µA) per volt of output compliance voltage.

For frequencies greater than 1 kHz:

±(0.005 % lout + 150 µA) x f per volt of output compliance

voltage, where f = frequency in kHz.

1-3

Page 16

5 2 20A

Instruction Manual

General

Table 1-2. Specifications (cont.)

Load Capability Drives all resistive and capacitive loads consistent with current and

compliance voltage capability. For inductive loads greater than

1 µH and less than maximum inductive loads, output current is

limited to 16 A rms (22.6 A peak)

Maximum Isolation Voltage ±20 V dc or 20 V ac rms

Temperature Range Operating: 0 °C to 50 ° C

Storage: +20 °C to 56 °C

Relative Humidity 50 % to 50 °C, 75 % to 40 °C, 95 % to 25 °C

Altitude Operating: 0 ft to10,000 ft

Non-operating: 0 ft to 40,000 ft

Vibration 2 g maximum, 5 Hz to 55 Hz for 15 minutes

Shock 15 g maximum, half sinewave

Power Requirements 100, 110, 115, 120, 200, 220, 230, or 240 V ac ±10 %, switch-

selectable, 50 Hz to 60 Hz, 300 W

Weight 27 kg (50 lb)

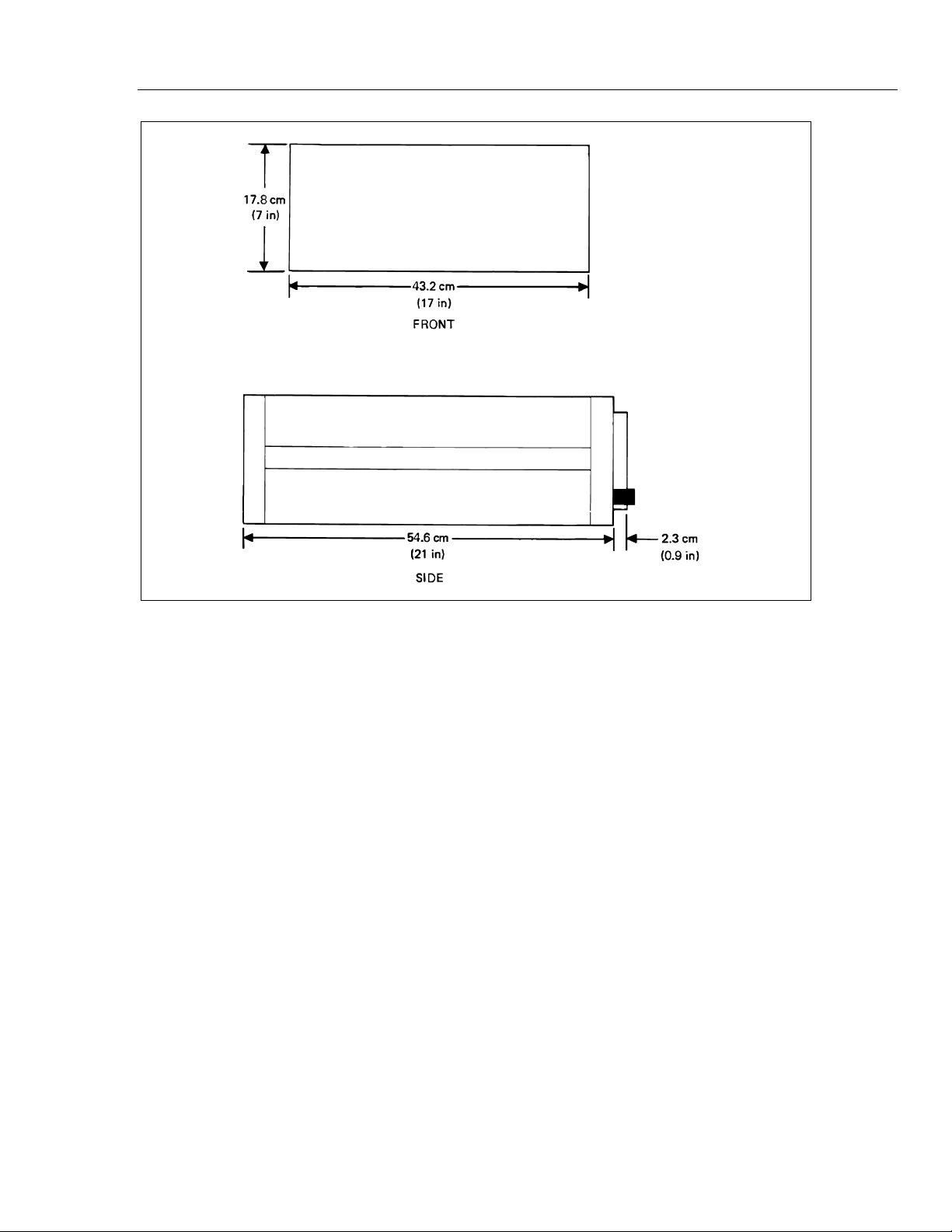

Dimensions 17.8 cm H x 43.2 cm W x 55.9 cm D (7 in H x 17 in W x 22 in D),

case only (See Figure 1-1).

Protection Safety Class 1 Relates solely to insulation or grounding properties as defined in

IEC 348.

1-4

Page 17

Introduction and Specifications

Specifications

1

Figure1-1. Outline Drawings

ajs01f.wmf

1-5

Page 18

5 2 20A

Instruction Manual

1-6

Page 19

2-1. Introduction

This section of the manual contains information concerning the installation and operation

of the Model 5220A transconductance Amplifier. It is recommended that the contents of

this section be read and understood before any attempt is made to operate the unit. Should

any difficulties arise during operation, contact your nearest John Fluke Sales

representative, or the John Fluke Mfg. Co., Inc., P.O. Box C9090, Everett, WA 98206;

telephone (206) 347-6100.

2-2. Shipping Information

The 5220A is packaged and shipped in a foam-packed container. Upon receipt of the

instrument, a thorough inspection should be made to reveal any possible shipping

damage. Special instructions for inspection and claims are included on the shipping

carton.

If reshipment of the instrument is necessary, the original container should be used. If the

original container is not available, a new container can be obtained from the John Fluke

Mfg. Co., Inc. Please reference the instrument’s model number when requesting a new

shipping container.

Section 2

Operating Instructions

2-3. Input Power

The 5220A can be operated from any one of the following 50 to 60 Hz (±1 %) line

voltages: 100, 110, 115, 120, 200, 220, 230, or 240 V ac (±10 %). A rear panel decal

specifies the voltage selected prior to shipment. If a change in voltage is required, refer to

Section 4 of this manual for the selection procedure.

2-1

Page 20

5 2 20A

Instruction Manual

2-4. Fuse Replacement

2-5. AC Line Fuse

2-6. Power Supply Fuses

2-7. Rack Installation

The ac line fuse is accessible by way of a rear-panel fuse holder located to the left of the

input power connector. If fuse replacement is required, disconnect the 5220A from line

power and remove the fuse cap and fuse (twist the fuse cap ccw using a screw driver).

Select and install a replacement fuse whose rating is compatible with the local line

voltage.

1. 100 to 120 V ac use fuse type MDA 3 A

2. 200 to 240 V ac use fuse type MDX 1.5 A

Each of the secondary windings on the power transformer is fused to protect the power

supplies from damage in the event of an overload. These fuses, six in al l, are inte rna l to

the 5220A and are not available to the operator. Details for replacement by qualified

personnel are given in Section 4 of this manual.

The 5220A is designed for either bench-top use or for installation in a standard 19-inch

equipment rack using the accessory Rack Mounting Kit (John Fluke P/N M08-205-600).

Chassis slides (John Fluke P/N M00-280-610) can also be installed to facilitate access to

the instrument when it is installed in an equipment rack. Information regarding the

installation of the rack-mounting accessories is included in Section 6.

2-8. Operating Features

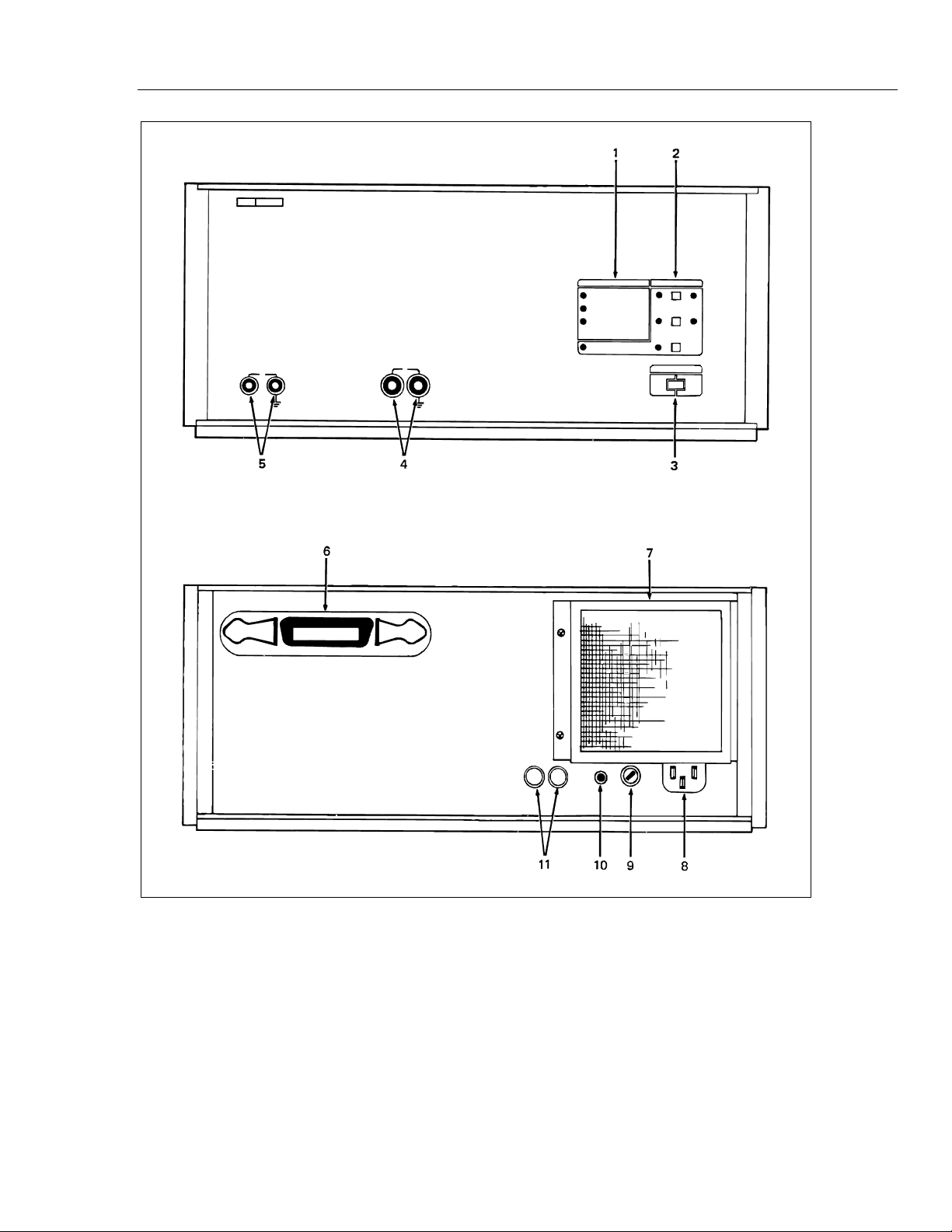

The function and location of all 5220A controls, indicators, and connectors are shown in

Figure 2-1 and described in Table 2-1.

2-2

Page 21

Operating Instructions

Operating Features

2

Figure 2-1. Controls, Indicators, and Connectors

ajs02f.wmf

2-3

Page 22

5 2 20A

Instruction Manual

Ref.

No Name Function

1 STATUS Indicators Three LEDs that light on an individual basis to indicate that the 5220A

Table 2-1. Controls, Indicators, and Connectors

has exceeded an operating limit. When the limit condition is detected the

5220A is switched to the standby mode. When the limit condition is

cleared the LED will remain lit until the 5220A is commanded to the

operate mode. The three status conditions are as follows:

THERMAL CUTOFF: Indicates that the output stage of the 5220A has

exceeded its maximum operating temperature.

OVERCOMPLIANCE: Indicates that the compliance voltage at the output

terminals has exceeded its limit.

OVERCURRENT: Indicates that the output current has been

programmed beyond its upper limit.

2 CONTROL Switches

and Indicators

3 POWER Switch A push-push switch used to switch instrument power on and off.

4 CURRENT OUTPUT

Terminals (Front)

A series of pushbutton switches and LEDs used to select and indicate

the 5220A operating mode. The function of each is as follows:

OPR/STDBY Switch: Allows alternate selection of the standby and

operate modes.

INPUT Switch: Allows alternate selection of the front and rear input

connectors.

REMOTE Switch: Allows recall of the local mode when remote is

enabled and the LOCAL LOCKOUT LED is not lit.

OPR/STBY LEDs: One of the two is lit to indicate the current operating

mode, operate or standby.

FRONT/REAR LEDs: One is lit to indicate the selected voltage input

connector, front or rear.

REMOTE LED: Lights to indicate that the remote mode has been

remotely selected. If the LED is not lit the local mode is enabled.

LOCAL LOCKOUT LED: Lights to indicate that the unit has been

remotely locked in the remote mode. In this event, the three front panel

CONTROL switches are disabled.

A pair of banana-jack terminals used to provide front-panel connection to

the output of he current source. The terminals are inactive when the rearpanel output terminals are selected.

2-4

5 VOLTAGE INGUT

Terminals (Front)

6 MIS* Bus Connector A 24-pin connector used as an I/O port for remote operation (Fluke MIS

7 Ventilation Filter Prevents dirt and debris from being drawn into the 5220A intake

A pair of banana-jack terminals that serve as control voltage input

connections in the local/front-input mode.

Bus) of the 5220A. When the 5220A is interfaced with a 5100 Series

Calibrator (by way of a Y5000 interface) the 5220A output can be

controlled from the 5100 front panel.

ventilation port.

Page 23

Operating Instructions

Operating Notes

Table 2-1. Controls, Indicators, and Connectors (cont.)

Ref.

No Name Function

8 Power Connector Provides the means of connecting the 5220A to ac line power by way of

a 3-wire power cord.

9 Fuse Holder Houses the ac line fuse and allows easy access for fuse replacement.

10 Ground Connector A binding post positioned to provide a convenient connection to chassis

ground.

2

11 Current Output

Terminals (Rear)

A pair of banana-jack terminals used as rear-panel current output

connections. The terminals are inactive when the front-panel CURRENT

OUTPUT terminals are selected.

2-9. Operating Notes

The following paragraphs describe the various conditions that should be considered

before operating the 5220A.

2-10. AC Line Connection

The rear-panel three-prong, U-ground connector permits the 5220A to be connected,

through a power cord to 50 or 60 Hz line power. The offset prong on this connector is

connected to the 5220A chassis and should be connected, via the power cord, to a highquality earth ground.

2-11. Transconductance Amplifier

A transconductance amplifier is a current source whose output current level is

proportional to an analog input voltage. Electrically, the output of the unit appears as a

constant current source with an output impedance that is much greater than the load

resistance. Similarly, its input impedance is much greater than that of the input voltage

source.

The input/output ratio of the 5220A is 1:1, and the output current range is +20 to –20 A.

Therefore, the range of the input control voltage is +20 to –20 V dc. The compliance

voltage of the 5220A is 3 V rms ac or +4 V dc.

2-12. Input Voltage Requirements

Input control voltage for the 5220A can be supplied by any low-impedance voltage

source with an output proportional to the desired output current. The source may be either

ac (30 Hz to 1 kHz) or dc, fixed or adjustable, depending upon the output requirements.

The control voltage source may be connected to either the front-panel VOLTAGE

INPUT terminals or the rear-panel voltage input terminals (Pins 5 (low) and 6 (high) of

the 24-pin connector), but not both simultaneously. Instrument damage will not result

from the simultaneous connection of two sources. However, interaction between the two

inputs can result in source loading, which in turn can cause inaccuracy in the expected

current output level.

If a rear-panel input is desirable, the use of the 5100 Series Calibrator and a Y5000

Interface is recommended. This combination allows the 5220A to be operated remotely

as an extension of the 5100. If the use of an alternate rear-input source is desirable, the

user is responsible for the proper interface. Details for custom interface requirements can

be derived from the theory of operation (Section 3) and the detailed schematics (Section

8).

2-5

Page 24

5 2 20A

Instruction Manual

2-13. Input Voltage Selection, Front/Rear

2-14. Current Output, Front/Rear

2-15. Standby/Operate

Selection of the front or rear terminals for control voltage input is manually accomplished

by pressing the INPUT push button switch on the front panel. Each depression alternately

selects front or rear as indicated by the lit FRONT/REAR LED indicator. This switch is

active in the local mode, and inactive in the remote mode.

The 5220A current output can be taken from either a front- or rear-panel set of five-way

binding post terminals, but not both simultaneously. An internal jumper configuration

allows qualified personnel to establish the desired output. A detailed output selection

procedure is given in Section 4, Maintenance.

When the 5220A is energized it can be placed into one-of-two operating modes; standby

or operate. The enabled mode is indicated by a lit front panel LED; OPR (operate) or

STDBY (standby). Standby is essentially a reset state, in which the output of the

transconductance amplifier is forced to zero regardless of the input control voltage level.

In the standby mode both the amplifier and the device connected to its output are

protected from accidental overloads. The operate mode is enabled when an output is

required. It causes the amplifier to respond to the control voltage input, and thereby

provides the appropriate current level output.

A front panel pushbutton switch (located between the OPR/STDBY LEDs) allows

manual selection of either mode when the LOCAL LOCKOUT LED is not lit. However,

the selection can be counteracted under certain conditions. For example, either mode may

be remotely selected, and the detection of an output overload will command the standby

mode. Similarly, when the unit is initially energized it is forced to standby.

2-16. Local/Remote

The 5220A can be operated manually using the front panel controls, or remotely by way

of the rear panel connector. When the unit is initially energized, it is forced to the local

control mode (REMOTE LED is not lit). The remote mode can only be selected by way

of a remote control source. When remote is enabled (REMOTE LED is lit) the local

mode can be recalled by a remote command or by pressing the LOCAL push-button

switch on the front panel. However, if the LOCAL LOCKOUT is lit (this is also a remote

command) the local mode can only be recalled by a remote command.

2-17. Status Indicators

A series of three front-panel STATUS LEDs provide a visual indication of overload

conditions that have been detected at the 5220A output. They are: THERMAL CUTOFF,

OVERCOMPLIANCE, and OVERCURRENT. When any one of these conditions is

detected the appropriate LED is lit and the unit is commanded to standby. The LED will

remain lit even after the overload condition has been relieved. To return the unit to the

operate mode the overload must be cleared and the operate mode must be commanded. If

operate is commanded while the overload is still present, the unit will remain in standby.

2-6

A thermal cutoff indication identifies overheating of the current output stage. If the

heating is excessive a cooling-down period may be required before the condition is

cleared.

The presence of an open-circuit or a high impedance load at the output terminals will

cause an overcompliance indication. In this case, an appropriate load will have to be

Page 25

connected to the output before the condition can be cleared. Overcompliance is detected

as an output voltage outside the range of +4 V dc or 3 V rms ac.

Output current in excess of 20 A will cause an overcurrent indication. To correct the

condition, the input control voltage must be reduced to an acceptable level.

2-18. Audible Output

When the 5220A is used to output high current at high frequencies (above 10 A and 1

kHz) it may emit an audible tone. The sound is normal and is characteristic of power

transistors that are operated at high current density. Several factors will cause the sound

to be more or less apparent. They include background noise, location of the 5220A

relative to the operator, and operator’s hearing ability.

2-19. Inductive Loads

The 5220A will drive an inductive load of up to 200 µH. However, reasonable care must

be exercised to ensure the desired results. One or more of the following considerations

may apply to a given application:

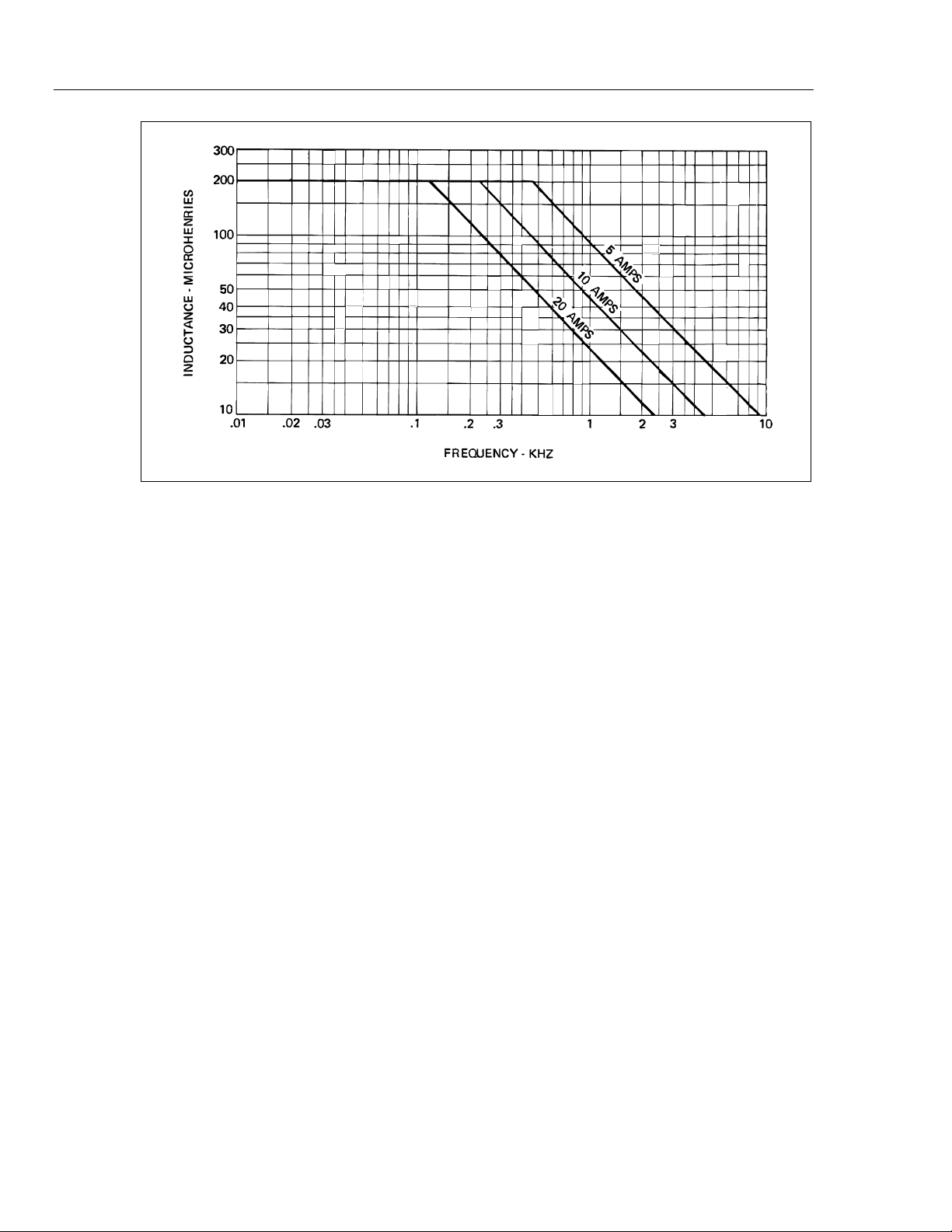

1. Compliance voltage (3.0 V maximum) places a restriction on the product of

inductance and operating frequency for a given output current. This is illustrated in

Figure 2-2 for maximum load inductance vs frequency at output currents of 5, 10,

and 20 A.

Operating Instructions

Operating Notes

2

2. A step change in output current into an inductive load can easily produce an

overcompliance condition. If the control voltage is being input at the front panel

terminals, the rate of change must be controlled to avoid an overcompliance trip. An

alternate approach is to set the 5220A to standby before making a change in the

control voltage, then select the operate mode. This allows the 5220A to internally

control the rate of change. If the control voltage is taken fr om a Fluke Mode l 5100

Series Calibrator, the calibrator will limit its output to an acceptable rate of change.

3. The leads used to connect a load to the 5220A can add appreciably to load

inductance. For example, a pair of 5-foot leads (10 feet of wire) made of 18 gauge

wire (AWG) will have a calculated inductance of 3.86 µH. This is enough to cause an

overcompliance trip if a step change in the input control voltage occurs.

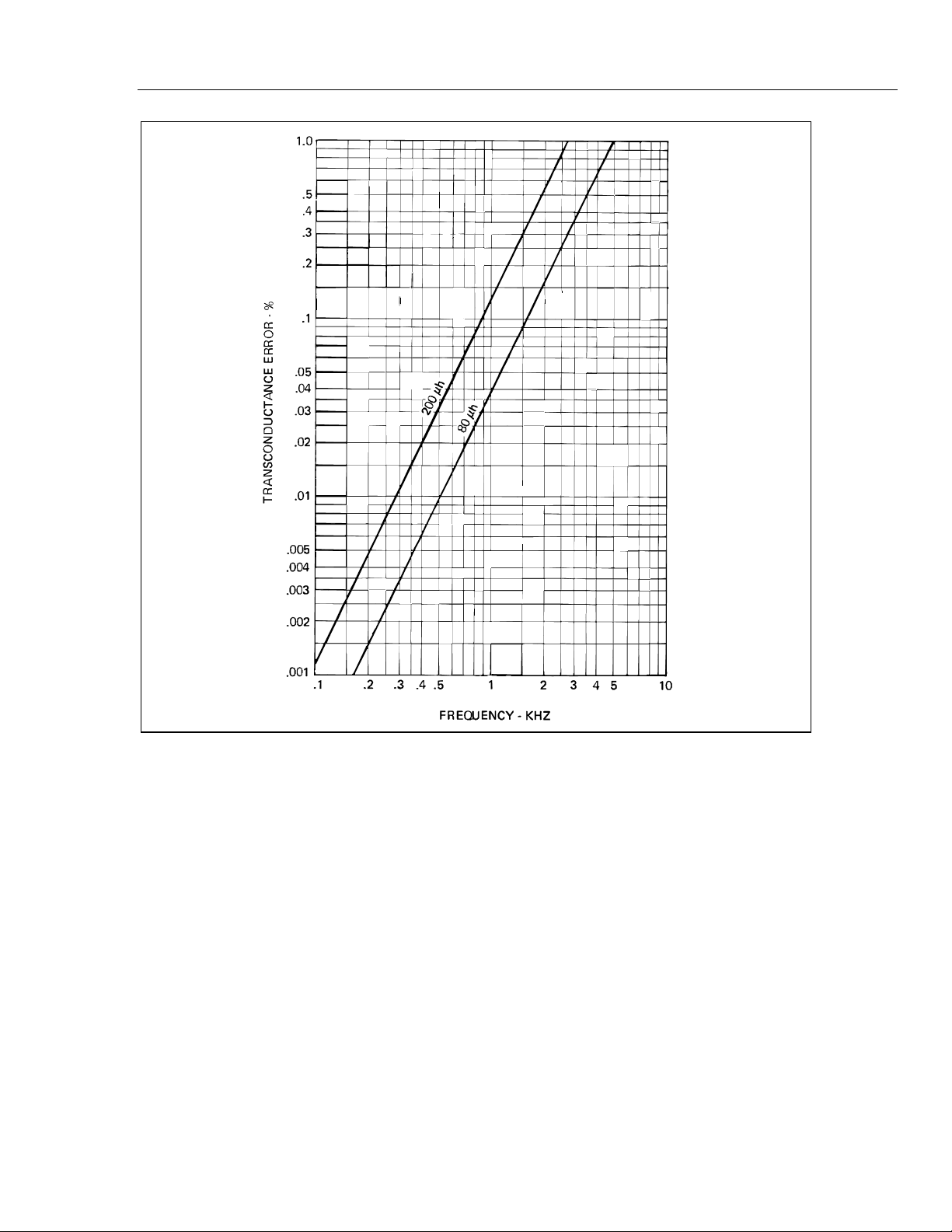

4. When driving an ac current through an inductive load the 5220A will exhibit

increased distortion and transconductance error. This is due to a reduction in loop

gain caused by the inductance. The graph in Figure 2-3 illustrates the typical

transconductance error, as a function of frequency, for two different inductive load

values.

2-7

Page 26

5 220A

Instruction Manual

Figure 2-2. Maximum Load Inductance vs Frequency

ajs03f.wmf

2-8

Page 27

Operating Instructions

Operation

2

Figure 2-3. Typical Transconductance Error for Inductive Loads

2-20. Operation

The following procedure is suggested for operating the 5220A. With reference to the

previous paragraphs proceed as follows:

1. Connect the 5220A to the 5100 Series Calibrator via the Y5000 Interface if remote

operation is desired. See the 5100B/Y5000 Instruction Manuals for details.

2. Connect the 5220A to line power.

3. Turn-on the 5220A by depressing the POWER switch to the ON position. Only the

STDBY and FRONT indicators should be lit.

4. Energize peripheral equipment as required.

5. If local operation is required, connect the control voltage source to the front-panel

VOLTAGE INPUT terminals.

6. Adjust the output of the control voltage source (remote or local) to approximately

1 V.

ajs04f.wmf

2-9

Page 28

5220A

Instruction Manual

7. Determine the active output terminals (front or rear) by connecting a short jumper

wire between the front-panel CURRENT OUTPUT terminals and then pressing the

OPR/STDBY switch. If the OVERCOMPLIANCE LED lights, the rear output

terminals are active. Otherwise, the OPR LED will light indicating that the front

CURRENT OUTPUT terminals are active.

8. Press the STDBY switch and then remove the short from the front output terminals.

9. Connect the intended load between the active output terminals.

10. Adjust the control voltage to the desired level.

11. Command the operate mode. If the OPR LED is lit, the predetermined current level is

flowing through the load.

12. Set the unit to standby before disconnecting the load or setting the POWER switch to

OFF.

2-10

Page 29

Theory of Operation

3-1. Introduction

This section of the manual contains an overall functional description followed by a

detailed circuit analysis of the 5220A. Both descriptions are supported by block

diagrams. Component level descriptions contained in the circuit analysis are referenced to

the detailed schematics in Section 8 of this manual.

3-2. Overall Functiona l Description

3-3. General

The 5220A is a transconductance amplifier. That is, a current source whose output

current is proportional to an analog input voltage. Electrically viewed at the output

terminals, the 5220A appears as a current source with an output impedance that is very

much greater than the load resistance. It s inp ut te rm ina ls exhib it a similar cha rac teri s ti c;

the input impedance is larger than that of the input voltage source.

Section 3

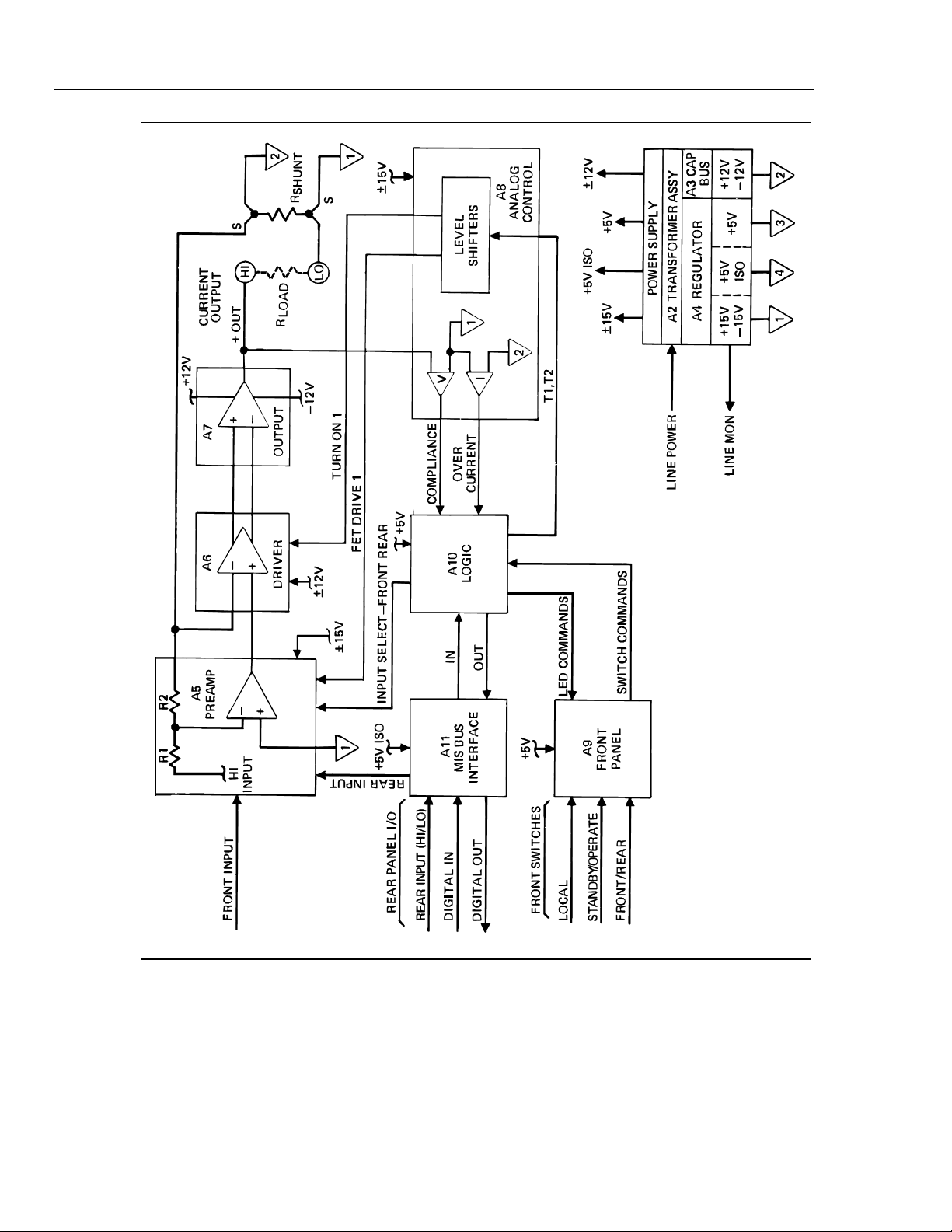

Functionally, the 5220A, as shown in Figure 3-1, can be divided into two sections, analog

and digital. The analog section consists of the power supplies, the transconductance

amplifier, and associated analog control circuitry. The digital section comprises the logic

necessary for overall control, and the interfaces necessary for front panel (local)

operation and remote operation by way of the Fluke MIS Bus.

3-4. Analog Section

The power supply used in the 5220A provides operating voltages for both the analog and

the digital section of the unit. It consists of three separate assemblies: the A2 Transformer

Assembly, the A3 Cap Bus, and the A4 Regulator. The Cap Bus and Regulator

Assemblies comprise the output po rtion of the supply, while the Transformer Assem bly

provides isolated ac power for the power supplies. Regulated supply voltages are a

function of the A4 Regulator. These include +5 V dc and +5 V dc Isolated for the digital

circuits and +15/-15 V dc for analog circuit operation. Unregulated voltages are a

function of the A3 Cap Bus. The Cap Bus is a high-current, +12/-12 V dc source for the

5220A current output.

3-1

Page 30

5 2 20A

Instruction Manual

3-2

Figure 3-1. 5220A Functional Block Diagram

ajs05f.wmf

Page 31

Theory of Operation

Overall Functional Description

The transconductance amplifier is a three-stage, closed-loop amplifier whose feedback

signal is proportional to the 5220A output (load) current. It consists of the A5 Preamp,

the A6 Driver, the A7 Output, and a precision four-terminal shunt. Input voltage to the

amplifier is presented, by way of front or rear input terminals, to the A5 Preamp. This

assembly includes relays for front/rear input selection, precision feedback resistors to

establish overall loop gain, and a high-gain amplifier equipped with on/off control for

power-on/off sequencing and failure control. The output of the A5 Preamp is input

directly to the A6 Driver where it is buffered and passed on as a differential input to the

high-current A7 Output stage. Output current from this stage is returned through the

output load and a precision current shunt to power supply common (COM 2) of the A3

Cap Bus (high-current supply). The voltage drop that occurs across the shunt is sent to

the A5 Preamp as a feedback signal, thus closing the loop.

Overall operation of the transconductance amplifier is illustrated in Figure 3-2. When an

input voltage, EIN, is applied to the amplifier an output current, IOUT, is produced. The

current passes through the series connec ted load and the prec is ion shunt, RS. Current

passing through the shunt produces a voltage (IR) drop, EOUT, whose polarity (with

respect to COM 1) is opposite that of the input voltage. This voltage is returned to the

amplifier as negative feedback through resistor R2. The values of R1, R2 and RS

established the 1:1 ratio of input voltage to output current. See equations in Figure 3-2.

The analog control circuit constantly monitors the voltage and current outputs of the

transconductance amplifier and provides overcompliance and overcurrent indications to

the digital section of the 5220A. When an overload condition occurs, the digital section

responds by sending shut-down signals to the amplifier by way of the analog control

logic. Control sequencing signals (T1, T2) for amplifier turn-on are also processed by the

analog control circuit.

3

Figure 3-2. Transconductance Amplifier Simplified Circuit Diagram

ajs07f.wmf

3-3

Page 32

5 2 20A

Instruction Manual

3-5. Digital Section

3-6. Circuit Analysis

The logic portion of the 5220A controls the sequencing of input relays (front/rear) and

other control signals that turn the transconductance amplifier on and off. It also provides

drive commands to light appropriate front panel status LEDs. Inputs to the logic are in the

form of local/remote control commands from the front panel switches or the remote MIS

Bus Interface, and overload signals from the analog control circuit.

Local or front panel control of the 5220A is accomplished through a series of front panel

pushbutton switches which provide direct inputs to the logic circuit. Control and/or status

responses to the commands are displayed on the front panel LEDs.

Remote control of the 5220A is enabled by the A11 MIS Bus Interface. The interface is

intended for use with a 5100 Series Calibrator equipped with a Y5000 Interface. Control

data (analog and digital) is received at the A11 MIS Bus Interface by way of a connector

on the rear panel of the 5220A. In the remote mode, this data is processed by the interface

and internally coupled with the analog and digital sections of the 5220A.

A detailed circuit description of the 5220A is given in the following paragraphs. The

description is keyed to the functional blocks defined in Figure 3-1. Each block is

described separately and is supported by both a block diagram and a detailed schematic

diagram (see Section 8 for schematics).

3-7. Power Supply

The power supply, as shown in Figure 3-3, consists of the three major assemblies: A2

Transformer, A3 Cap Bus, and A4 Regulator. Its function is to transform line power into

four sets of 5220A operating voltages. Each voltage set is isolated from the other, and

three of the four are regulated. The three regulated voltage sets are +15/-15 V dc,

+5 V dc, and +5 V ISO (isolated). The unregulated voltage set is +12/-12 V dc.

The A2 Transformer assembly consists of a series of three line-voltage selection

switches, a power transformer, and appropriate secondary output fuses. Line power to the

transformer passes through the fro nt pane l powe r switch (S4) and the line voltage

selection switches before reaching the two primary windings. The setting of the line

voltage switches (S1) connects the primary windings in either a parallel or a series

configuration. Parallel connection is required for 115 V ac operation and the series

connection is used for 230 V ac. Switches S2 and S3 allow selection of alternate primary

winding taps. They allow operation from 100, 110, 115 or 120 V ac line voltages in the

parallel configuration, or from 200, 220, 230 or 240 V ac in the series configuration. The

115 V ac ventilation fan is permanently connected to one of the primary windings, thus

ensuring proper operation in either voltage configuration. Fuse protection for the power

line is provided by an external fuse (F1) mounted on the rear panel. Supply overload

protection for the regulated supplies is provided by secondary-winding fuses F4, F5, F6,

and F7 located on the A2 Transformer Assembly.

The A3 Cap Bus is a high-current, unregulated, +12/-12 V dc power supply designed to

provide operating power to the output amplifier. It consists of two fuses, a full-wave

rectifier, two bleeder resistors, and a bank of filter capacitors. Operating voltage is

derived from a high-current center-tapped secondary winding of T1. It enters the A3 Cap

Bus through overload fuses F2 and F3, and is full-wave rectified by diodes CR1 through

CR4 to establish both positive and negative supply voltages. Filter capacitors, C1 through

C8, filter the supply outputs. Bleeder resistors, R2 and R3, discharge the filter capacitors

when line power is turned off.

3-4

Page 33

Theory of Operation

Circuit Analysis

The A4 Regulator is designed to convert the ac outputs from the three remaining

secondary windings of T1 into three sets of isolated and regulated voltages: +5 V dc,

+15/-15 V dc, and +5 V dc ISO (isolated). Each voltage is produced using conventional

regulating techniques. That is, it is rectified, filtered, regulated by a three-terminal

regulator, and filtered again before being output. A fifth voltage, Line Mon (monitor), is

also produced on the A4 Regulator. It is derived from the T1 windings used for the

+15/-15 V dc supply and is used to convey the line power status of the 5220A to the A10

Logic. The voltage is rectified by diodes CR8 and CR9, and clipped by zener VR1 before

being output.

3

Figure 3-3. Power Supply Functional Block Diagram

ajs08f.wmf

3-5

Page 34

5 2 20A

Instruction Manual

3-8. Preamplifier

The A5 Preamplifier, as shown in Figure 3-4, is a high-gain amplifier designed to accept

a front/rear panel input signal and provide an amplified output to the A6 Driver stage of

the transconductance amplifier. It consists of a high-gain differential amplifier with

feedback resistors, front/rear input select relays, and turn-on/off control circuitry.

In operation, the input voltage source (front or rear), as selected by the A10 Logic, is

connected through reed relay K1 (front) or K2 (rear) and input resistors R1, R3, and R13

to the inverting input of a differential transistor pair, Q2. The non-inverting input of Q2 is

connected to COM 1 through parallel resistors R9 and R14. The resistance value

approximates the value of R1 and R2 in parallel and, thereby balances the source

impedance at the amplifier inputs. Balance is required to minimize apparent input offset

voltage that may result from input currents. Diode CR3 and diode-connected transistor

Q3 are voltage clamps that prevent amplifier saturation on high input transients. The

collectors of Q2A and Q2B drive the emitters of a pair of grounded base amplifiers

formed by transistor array, U1. This holds the collectors of Q2 at a low and equal level to

maintain low and equal collector-to-base leakage currents (ICER) at Q2. The actual

collector voltage of Q2 is set by the temperature corrected divider formed by R4, R19,

and the diode connected transistor U1C. Voltage variations at the collectors of U1A and

U1B constitute the output of the differential amplifier, and are used as the input to opamp, U2. Diodes CR4 and CR5 clamp the inputs to prevent U2 saturation when transient

voltages appear. An ac feedback network, R15 and C7, fix the frequency response of the

preamplifier to satisfy the overall transconductance amplifier loop. Amplifier zero is

established by the selected values of collector resistors R11 and R12, and the setting of

the zero-adjust potentiometer, R6.

3-6

Figure 3-4. A5 Preamplifier Functional Block Diagram

ajs09f.wmf

The turn-on/off control FET (Q1) operates as FET switch to control the overall gain of

the A5 Preamplifier in both the standby and operate modes. Q1 responds to the FET

Drive 1 signal initiated (as T2) on the A10 Logic.

In the standby mode FET Drive 1 is near zero volts causing Q1 to turn on. FET Q1

completes the feedback loop between the output of U2 and the inverting input of Q2. This

in effect reduces the gain of the A5 Preamplifier to zero. As a result the output of the

transconductance amplifier is forced to zero amperes. Photo resistor U3 is used to control

Page 35

Theory of Operation

Circuit Analysis

the rate at which the input voltage is applied to the A5 Preamplifier when the 5220A is

switched from standby to operate. This is necessary to prevent a step output which, if

applied to an inductive load, would result in an overvoltage transient, forcing the 5220A

back to standby. In standby both input select relays, K1 and K2, are open, capacitors, C3

and C12, are discharged, and the photo resistor U3 is a very high impedance with the

LED drive removed. Thus, the A5 Preamplifier is effectively isolated from the input

voltage.

In the operate mode FET Drive 1 is stepped to –15 V dc causing FET Q1 to turn off.

With Q1 off, the A5 Preamplifier returns to its high gain state with feedback established

by resistors R1 and R2. If front input is selected, the Relay 1 drive signal is low and

capacitor C12 begins charging. The increasing voltage across C12 increased the LED

output from U3 which, in turn, decreases the impedance of the photo resistor. Since the

resistor is in parallel with the input contacts of the still open front input relay K1, it acts

as a variable input attenuator. In other words, the front input voltage is applied to the

input of the A5 Preamplifier at a controlled rate and not as a step input. At the same time,

a low Relay 1 drive signal is inverted by U4 causing C3 to charge through R24. When the

charge reaches the threshold of the second inverter (U4) relay K1 is energized by a set of

four parallel connected inverters. The charge time for C3 and C12 are designed to ensure

that K1 closes after photo resister U3 changes to a low impedance. When K1 closes, it

places a short across the resistor in U3 and selects the front panel input voltage to drive

the A5 Preamplifier. If the rear panel input signal is selected, a variable attenuator is not

necessary because the signal from the remote 5100A rises at a controlled rate when

switched from standby to operate.

3

3-9. A6 Driver

The A6 Diver, as shown in Figure 3-5, is a differential amplifier designed to accept its

input from the A5 Preamplifier and to provide a differential drive signal to the A7 Output

stage. The amplifier itself is of a discrete-component, complementary, push-pull design.

Its features include the following:

• Temperature compensated biasing for both itself and the A7 Output stage

• An amplifier-disable circuit for standby operation

• An output-leakage current sink for standby oper ation.

The input section of the driver amplifier consists of a differential transistor pair, Q2 and

Q3; a current regulator, Q4; and a common base driver, Q1, for the bias circuit.

Transistor Q3 of the input pair receives the drive input from the A5 Preamplifier. The

other input transistor, Q2, is driven by Shunt Sense 2, which provides negative feedback

from the output current shunt to reduce distortion in the A7 Output stage. Current

regulator Q4 regulates the emitter current of the differential pair, and provides isolation

from variations in the –12 V supply. Output from the differential pair is taken at the

collector of Q3 by way of a common-base driver, Q1.

The bias section of the driver amplifier consists of resistors, R13 through R17, current

regulator, CR1, and transistors, Q5 and Q107 (Q107 is physically located on the output

amplifier's heat sink). Resistors R13 through R17 and current regulator CR1 form a series

string that is driven by the output driver Q1 of the input amplifier. Regulator CR1 is at

the end of the string and connected to –12 V dc. This ensures a constant current of

approximately 5.2 mA through the string. Transistors Q5 and Q107 are connected across

resistors R14, R15 and R16, R17 as VBE multipliers to ensure that the voltage drop

across the resistor string changes at a rate which will compensate for VBE temperature

changes in the A6 Driver and A7 Output stages. Transistor Q5 senses ambient

temperature changes while Q107 senses temperature changes due to power dissipation in

the A7 output. The temperature compensated voltage drop developed across the resistor

3-7

Page 36

5 2 20A

Instruction Manual

string is used as a voltage source to set the quiescent bias for the remaining stages of the

complementary A7 Driver and A7 Output. Variable resistor R13 is used to set the initial

bias voltage.

Figure 3-5. A6 Driver Functional Block Diagram

ajs10f.wmf

The characteristics of the VBE multipliers used in the bias section are stated in terms of

Q5 in the following formulas:

VBE = [R14/R14 + R15] VCE

VCE = VBE [R14 + R15/R14]

The output section of the A6 Driver consists of transistors Q8, Q9, Q10, Q12, and

associated components. Transistors Q8 and Q9 are arranged as complementary emitter

followers that are both biased and driven by the bias section. This is followed by a

common collector stage using Q10 and Q12. Overcurrent protection is provided in the

stage by the 10 ohms resistors, R30 and R31, in the collector circuits. The differential

output at the emitters of Q10 and Q12 is used as the drive input to the A7 output stage.

In the standby mode of operation it is necessary to reduce the 5220A output to a zerovolt/zero-current condition. This is accomplished on the A6 Driver by two separate FET

circuits. FETs Q6 and Q7 comprise the voltage shut-down circuit, and FET Q11 is the

output current-sink. Both are enabled by a Turn-on 1 signal which is initiated (as T1) by

the A10 Logic when the 5220A is switched to standby. When Q6 and Q7 are enabled

(turned on) they remove the bias from the output stage of the A6 Driver, and thereby

disable the bias to the A7 Output stage. In this state the output is essentially floating and

is influenced only by leakage current that may be present in the output drivers. FET Q11

remedies the floating condition by effectively clamping the output to output commo n

(COM 2).

3-8

Page 37

3-10. A7 Output

The A7 Output is a discrete-component, complementary-output, high-current amplifier

which serves as the final output stage of the transconductance amplifier. See Figure 3-6.

It consists of a pair of driver transistors, Q101 and Q102; two parallel pair(s) of output

transistors, Q103, Q104 and Q105, Q106; a thermal sensing transistor, Q107; and a

thermal overload switch S101. The differential output from the A6 Driver is applied to

the bases of Q101 and Q102. These transistors are configured as emitter followers and

provide the high current drive required by the output transistors. Collector resistors, R114

and R115, for Q101 and Q102 provide current limit protection under transient or fault

conditions. Emitter resistors in the parallel output pairs prevent current hogging which

would otherwise occur due to unequal VBE characteristics.

Theory of Operation

Circuit Analysis

3

Figure 3-6. A7 Output Functional Block Diagram

All transistors in the A7 Output as well as the thermostatic switch, S101, are physically

mounted on a common heat sink. The temperature of the heat sink is sensed by Q107

(part of the A7 Driver’s bias network) and returned to the A7 Driver to provide bias

compensation for the change in VBE with output-transistor temperature. (See A7 Driver

description given earlier in this section of the manual.) Thermostatic switch S101 senses

the temperature of the heat sink and provides an open contact output when an overtemperature condition is detected. The open output is sent to the A10 Logic which reacts

by switching the 5220A to standby (over temperature may result from a loss or restriction

of cooling airflow).

ajs11f.wmf

3-9

Page 38

5 2 20A

Instruction Manual

3-11. A8 Analog Control

The A8 Analog Control Assembly, as shown in Figure 3-7, contains an overcompliance

detector, an overcurrent detector and two TTL-to-FET level shifters. The detection

circuits are used to switch the 5220A to standby when an overcurrent or overcompliance

condition occurs. The level shifters are driven by the A10 Logic to control the turn-on/off

sequencing of the transconductance amp li fier.

Figure 3-7. A8 Analog Control Simplified Block Diagram

ajs12f.wmf

The detection circuits are absolute value level detectors that provide a TTL output

indication of the transconductanc e amp lifie r’s opera ting status; i.e., output voltage status

and output current status. As long as both output voltage and current are within their

specified operating range, both detectors will output a low logic level as a normaloperation status indication. However, if either or both the specified compliance voltage

and/or the output current are exceeded, the appropriate detector will output a high logic

level. Upon receipt of a high logic level from either detector the A10 Logic switches the

5220A to standby.

Each of the detectors is basically the same. They consist of an absolute value amplifier

(full-wave rectifier), a level conditioner, a zener diode threshold detector, and a TTL

buffered output stage. The absolute value amplifier is essentially a pair of operational

amplifiers configured to provide an output voltage that is equal to the amplified positive

absolute value of the input signal. The input to the compliance detector is connected to

sense the voltage present at the output terminals (+OUT and COM 1). Similarly, the input

to the overcurrent detector is connected to sense the voltage drop across the current shunt

(COM 2 and COM 1). The result, in both cases, is a negative output level that is equal to

the absolute value of the input signal. This level is sent to a level conditioner where it is

filtered/integrated, inverted, and amplified. An adjustable gain control in the level

conditioner’s feedback loop provid es for accu ra te adjust ment of the trip level.

The output of the level conditioner feeds a series connected zener/resistor circuit with the

resistor connected to logic common (COM 3). When the output of the level conditioner

exceeds the zener voltage, the excess is dropped across the zener resistor. This voltage is

monitored by a series-connected-pair of inverters which respond to the voltage drop as if

3-10

Page 39

it were a logic level. That is, voltages from 0 to an approximate 2 V threshold are

considered a low logic level. A high logic level is approximately 2 to 4.5 V.

The TTL-to-FET level shifters are used to interface turn on/off commands TTL logic

levels, T1 and T2, from the A10 Logic with the standby/operate control FETs in the

transconductance amplifier. Both level shifters are identical in design. The input is

designed to respond to voltage levels from +0.01 to +5.0 V dc. Corresponding output

levels to drive the FET gates are 0 to –15 V dc.

3-12. A9 Front Panel

The A9 Front Panel Assembly contains the switches (with the exception of the power

switch) and LEDs that comprise the 5220A controls and indicators. The switches are used

to manually convey control information to the A10 Logic. This includes selection of the

local operating mode, standby/operate, and front/rear panel input. The LEDs display the

current operating status of the 5220A as determined by the A10 Logic. Status conditions

include: remote, local lockout (LLO), overcompliance, overcurrent, thermal cutout, front

panel input, rear panel input, standby, and operate.

Electrically, the LEDs (anode end) and the switches (arm) are connected to a common +5

V bus powered by the logic supply. A switch depression represents a +5 V output to the

A10 Logic. A series resistor connected to the anode end of each LED serves as a current

limiter when the LED is lit. A low logic level from the A10 Logic lights the appropriate

LEDs.

Theory of Operation

Circuit Analysis

3

3-13. A10 Logic

The A10 Logic, as shown in Figure 3-8, is designed to process and control the timing and

the input/output of all 5220A digital control data. Input data is received from the front

panel controls, the A11 MIS Bus Interface, and the analog protection circuits of the

transconductance amplifier. Output data provides timing and control signals to the

amplifier (including its relays) and the front panel indicator LEDs.

3-14. Reset Logic

The reset logic consists of dual multivibrator U11, RC network R7/C2, or gate U9-10,

and inverter U3-10. Its function is to command the reset of the A10 Logic, and thus the

5220A, to an initial state when any one of the following events occur:

1. The 5220A is initially energized.

2. The +15/-15 V dc power supply is interrupted.

3. Control is switched from remote to local.

When the 5220A is energized the +5 V dc power supply rapidly rises to its +5 V level to

supply operating voltage to the A10 Logic Assembly. The voltage rise is integrated by

RC network R7, C2. The slow rising voltage across C2 is used as a momentary low logic

level to issue a reset command to all sections of the A10 Logic. Some sections are reset

directly by the voltage across C2 while others are reset indirectly by the response of U1110 to the voltage across C2.

3-11

Page 40

5 2 20A

Instruction Manual

3-12

Figure 3-8. A10 Logic Simplified Block Diagram

ajs13f.wmf

Loss or interruption of the +15/-15 V dc supply output causes the Line Mon (monitor)

input from the power supply to go low. Normally, the line monitor input is a clipped fullwave rectified 60 Hz waveform which is generated on the A4 Regulator Assembly. The

negative-going edge is used as the trigger for monostable U11-7 which is timed to

provide an output pulse of approximately 0.1 second. Since the output is longer than the

time between triggers, it will remain active (Q low) as long as the Line Mon (moni tor )

Page 41

input is present. Under normal operating condition the reset command is high at U9-10

and low at U3-10.

When the 5220A is switched from remote to local operation the local/remote logic

triggers monostable U11-10 in the reset logic circuit. The result is a momentary positivegoing pulse at the Q output of U11-10. This in turn drives the complementary reset lines

of U9-10 and U3-10.

The overall result of a reset command, regardless of how it is initiated, is to set the output

commands of the A10 Logic to the states shown in Table 3-1. Essentially the unit is

commanded to standby operation with front panel inputs selected. Remote and Local

Lockout (LLO) commands are not affected by the reset command.

Table 3-1. Effect of Reset Command on A10 Logic and A9 Front Panel

Signal Name Logic State Front Panel LED Status

Interface Operate Status Low None

Operate LED High OPER LED off

Standby LED Low STDBY LED on

Theory of Operation

Circuit Analysis

3

T1, T2, and T4 Low None

Relay 1 High None

Relay 2 High None

Front Panel Input LED Low FRONT LED on

Rear Panel Input LED High FRONT LED OFF

Overcompliance LED High OVERCOMPLIANCE LED off

Overcurrent LED High OVERCURRENT LED off

Thermal Cutout LED High THERMAL CUTOFF LED off

Interface Overload Status Low None

3-15. Timing Logic

The timing logic controls the timing sequence used to switch the transconductance

amplifier between the standby and operate modes. It consists of a bi-directional shift

register U22, D-type flip-flops U17-1, and free running multivibrator U23. The

multivibrator runs at a frequency of 100 Hz (10 ms period) and serves as the clock for

both the flip-flop and the shift register. Flip-flop U17-1 responds to the Reset command

(reset input) and the standby/operate commands (D-input) to select the shift register’s