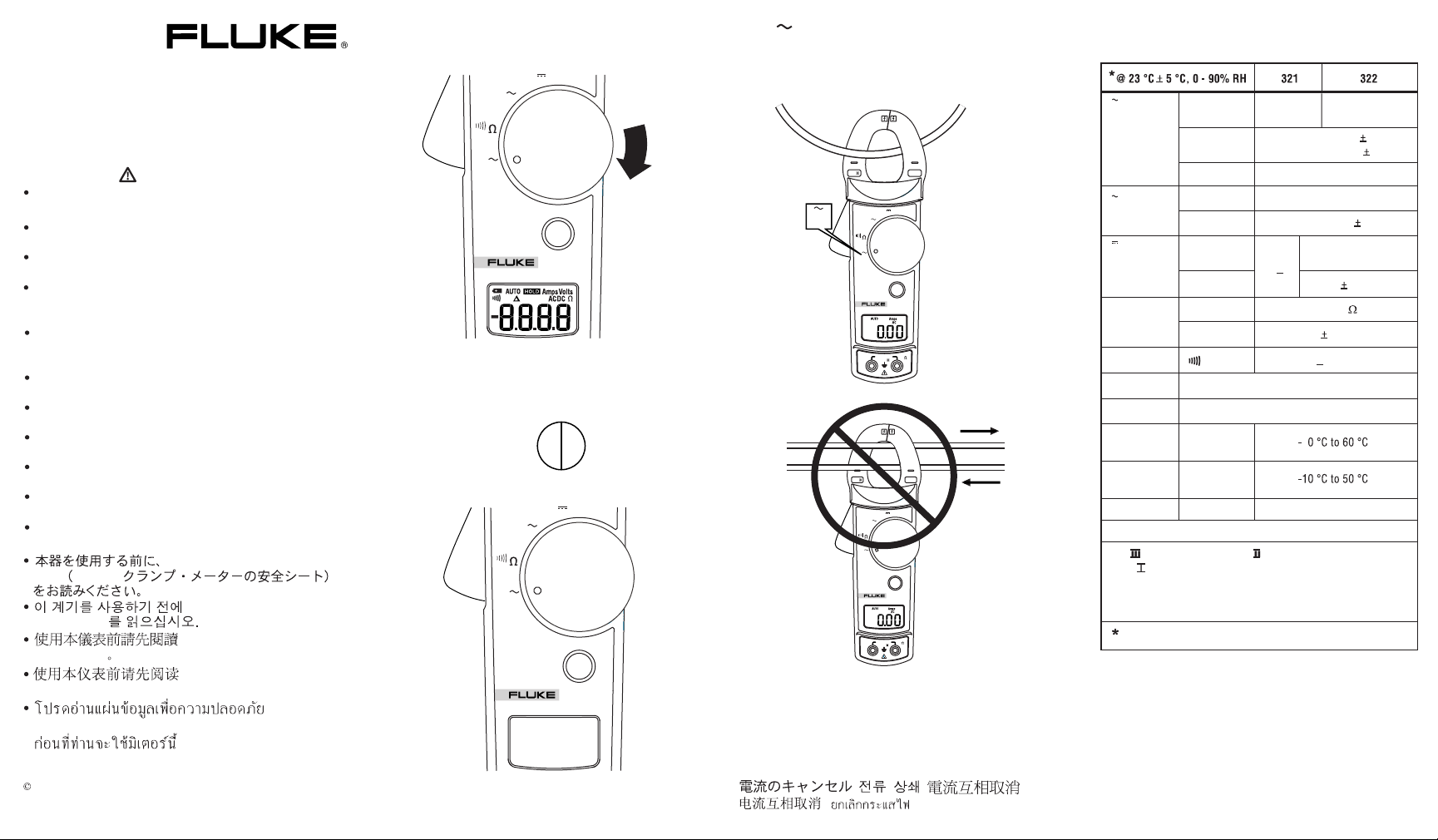

321 and 322

Clamp Meter

Instr

uction Card

Read the 321, 322 Clamp Meter Safety Sheet

before using this meter.

Lisez la fiche de sécurité 321, 322 Clamp Meter

Safety Sheet avant d'utiliser cet appareil.

Prima di usare questo strumento, leggere il

documento 321, 322 Clamp Meter Safety Sheet.

Vor der Verwendung des Meßgeräts die

Sicherheitsinformationen zum 321, 322, Clamp

Meter lesen

Lea la hoja de instrucciones de seguridad "321, 322

Clamp Meter Safety Sheet" antes de utilizar este

medidor.

Leia "321, 322 Clamp Meter Safety Sheet" antesde

usar este medidor.

Lees het 321, 322 Clamp Meter Safety Sheet

voordat u deze meter gebruikt

Les 321, 322 Clamp Meter Safety Sheet før

måleinstrumentet tas i bruk.

Man skal læse "321, 322 Clamp Meter Safety Sheet"

inden man tager instrumentet i brug.

Lue 321, 322 Clamp Meter Safety Sheet ennen

tämän laitteen käyttöä.

Läs säkerhetsdatabladet "321, 322 Clamp Meter

Safety Sheet" innan du använder detta instrument.

Sheet

321, 322

Safety Sheet

Safety Sheet

Safety Sheet

321, 322 Clamp Meter Safety Sheet

PN 1615194 February 2002

2001, 2002 Fluke Corporation, All rights reserved. Printed in Taiwan.

www.fluke.com

Warning

321, 322 Clamp Meter Safety

321, 322 Clamp Meter

321, 322 Clamp Meter

321, 322 Clamp Meter

On/Off

V

V

MET

A

P

OFF

HOLD

AM

L

322

C

Automatic Off

30 Min

V

A

OFF

HOLD

AM

L

C

A

Specifications

Fluke 321 0 - 400.0 A

ER

V

ER

MET

P

322

Fluke 322 0 - 40.00 A, 40.0 - 400.0 A

CAT

A

COM

CAT

600V

400A

V

ER

V

MET

A

P

OFF

HOLD

AM

L

322

C

600V MAX

V

CAT

600V

400A

V

ER

V

MET

A

P

OFF

HOLD

AM

L

322

C

600V MAX

V

COM

CAT

Currents Cancel

Les courants s'annulent, Le correnti si cancellano,

A

V

V

Ω

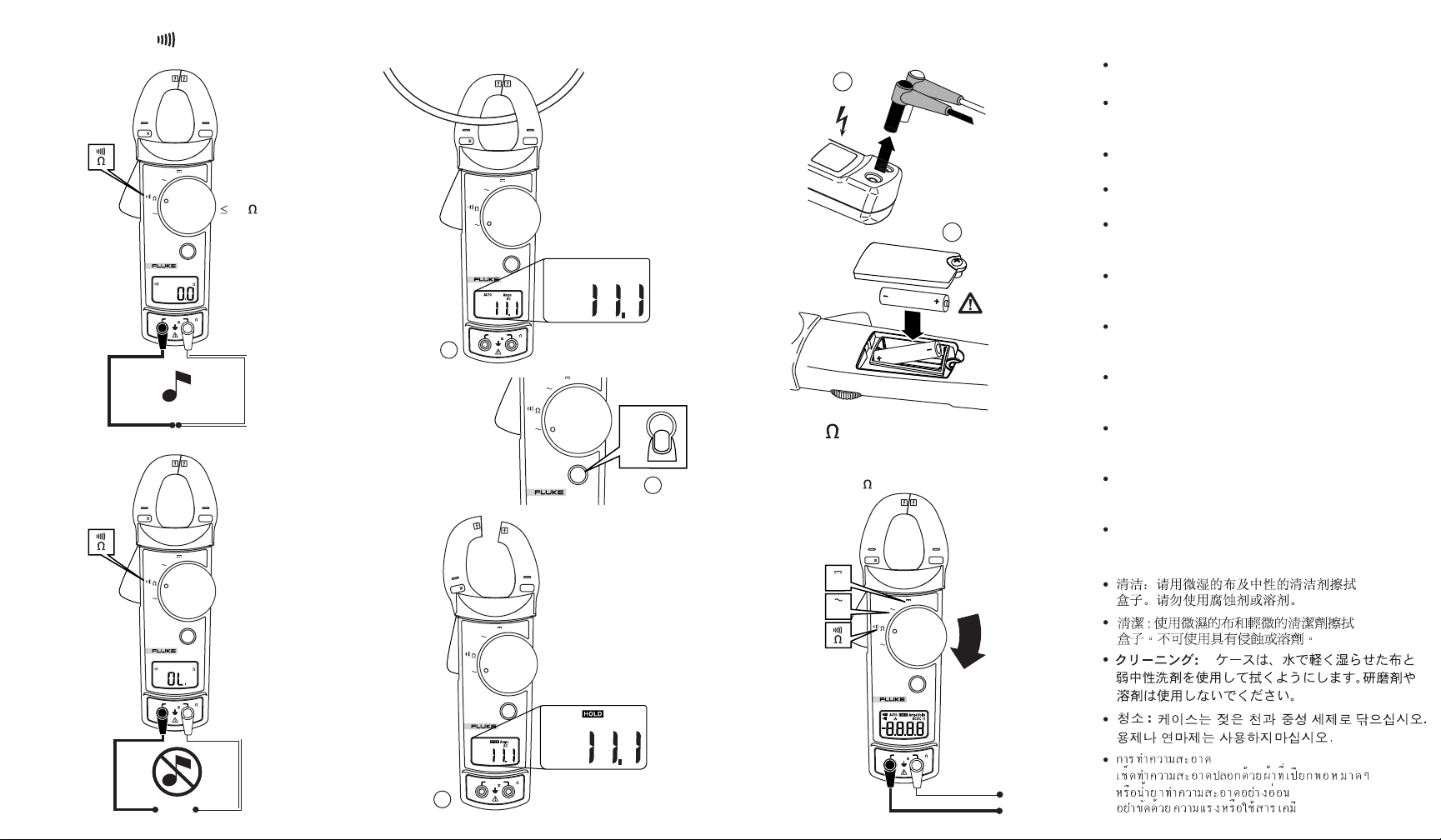

Continuity

Jaw Opening

IP Rating

Storage

Temperature

Range

Accuracy

AC Response

Range

Accuracy

Range

Accuracy

Range

Accuracy

0 - 400.0 A

50 - 60 Hz 1.8% 5 counts

60 Hz - 400 Hz 3.0% 5 counts

50 - 400 Hz 1.2% 5 counts

1 inch or 26 mm

0 - 40.00 A

40.0 - 400.0 A

Avg

0 - 400.0, 400 - 600 V

0 - 400.0,

400 - 600 V

1% 5 counts

0 - 400.0

1.0% 5 counts

<

30 Ω

40

3

Operating

Temperature

Altitude

2000 m

EMC - EN61326

CAT III 600V, pollution degree II:

CAT III equipment is designed to protect against transients in

equipment in fixed - equipment installations, such as distribution

panels, feeders and short branch circuits, and lighting systems

in large buildings.

< 18 C, > 28 C add 0.1 x (specified accuracy)/ C.

Ströme abbrechen, Se cancelan las corrientes,

Cancelamento de correntes, Stromen compenseren

elkaar, Strømutjevning, Strømstyrkeannullering

Strømstyrker udbalancerer, Virta pois, Avbryt ström

,

,

,,

Continuity

Hold Battery Replacement

Cleaning

Wipe the case with a damp cloth and mild

1

detergent. Do not use abrasives or solvents.

Nettoyage : essuyer l'étui à l'aide d'un chiffon humide

CAT

600V

400A

CAT

600V

400A

et d'un détergent non-abrasif. Ne pas utiliser

d'abrasifs ou de solvents.

Pulizia : pulire l'involucro con un panno umido e un

V

A

V

OFF

HOLD

CLAMP METER

30

322

A

V

OFF

HOLD

CLAMP METER

V

2

AmpsAuto

322

AC

AAA

600V MAX

V

COM

CAT

600V MAX

V

COM

CAT

1

V

V

detergente neutro. Non usare né abrasivi né solventi.

Limpieza: Limpie la caja con un paño húmedo y un

detergente suave. No utilice abrasivos ni solventes.

Reinigung: Das Gehäuse mit einem feuchten

Lappen und mildem Reinigungsmittel abwischen.

Keine Scheuer- oder Lösungsmittel verwenden.

Limpeza: Para limpar a parte externa, use um pano

úmido com detergente neutro. Não use produtos

abrasivos nem solventes.

Reinigen: Veeg de behuizing af met een vochtige

doek en niet-agressief detergens. Gebruik geen

schuurmiddelen of oplosmiddelen.

Rengjøring: Tørk av huset med en fuktig klut og

mildt vaskemiddel. Bruk ikke skuremidler eller

løsemidler.

A

OFF

HOLD

322

CAT

600V

400A

CLAMP METER

HOLD

V,

0 - 600 V dc 322

0 - 600 V ac

2

0 - 400.0

Rengøring: Tør instrumenthuset af udenpå med en

fugtig klud og mildt sæbevand. Der må ikke benyttes

skure- og opløsningsmidler.

Puhdistaminen: Pyyhi kotelo kostealla kankaalla ja

miedolla pesuaineella. Älä käytä hankausaineita tai

liuottimia.

Rengöring: Torka av kåpan med en fuktad trasa och

ett milt rengöringsmedel. Använd inte nötande

rengöringsmedel eller lösningsmedel.

V

OFF

HOLD

CLAMP METER

600V MAX

600V

400A

V

322

V

CAT

V

V

600V

V

OFF

HOLD

CLAMP METER

600V MAX

400A

V

Amps

322

V

CAT

AC

A

OFF

HOLD

322

CLAMP METER

600V MAX

V

COM

CAT

CAT

A

COM

CAT

V

V

A

COM

3

(German)

W

Bitte zuerst lesen: Sicherheitshinweise

Vor Betrieb und Wartung des Meßgeräts bitte di e folge nde n

Sicherheitshinweise sorgfältig lesen:

• Wenn möglich, nicht allein arbeiten, damit Hilfestellung

gewährleistet werden kann.

• Das Meßgerät nicht bei Spannungen über 600 V oder

Frequenzen über 400 Hz Grundfrequenz be nutz e n, um

Geräteschäden zu vermeiden.

• Keine Strommessungen vornehme n, sol a nge Tes tl ei t unge n a n

den Eingangsbuchsen angeschlossen sind.

• Bei sichtbaren oder vermuteten Beschädigungen das

Meßgerät oder die Testleitunge n nic ht benutz e n.

• In der Nähe von Stromleitern und Sammelschie ne n ä ußer s te

Vorsicht walten lassen, da Berührungen elektrische Schläge

verursachen können.

• Vor dem Gebrauch die Anleitungskart e durchlesen und alle

Sicherheitshinweise befolgen.

• Das Meßgerät nur wie in der Anleitungskar te besc hrieben

benutzen, da sonst die Schutzvorr ic ht unge n des Gerä t s

beeinträchtigt werden können.

• Bei Gleichspannungen über 60 V und Wechsels pa nnunge n

über 30 V Vorsicht walten lassen, da derarti ge Spannunge n

eine Stromschlaggefahr darstellen.

Symbole

Die Anwendung im Bereich GEFÄHRLICHER

STROMFÜHRENDER Leiter sowie das Trennen von

,

solchen Leitern ist zulässig.

W

M

Gefahrenrisiko. Wichtige Informationen. Anleitungskarte

einsehen

Geräteschutz durch doppelte oder verstärkte Isolation

T

Batterielage

Entspricht CSA C22.2 Nr. 1010. 2.032-96

P

J

F

B

;

N10140

t

Dieses Fluke-Produkt ist für 2 Jahre ab Kaufdatum frei von Material- und

Fertigungsdefekten. Diese Garantie erstreckt sich nicht auf Sicherungen,

Einwegbatterien oder Schäden durch Unfälle, Fahrlässigkeit, Mißbrauch,

Änderungen oder abnor male Betriebsbedingu ng en bzw. unsachgemäße

Bedienung. Die Verkaufsstellen sind nicht dazu berechtigt, diese Garantie im

Namen von Fluke zu erweitern. Um die Garantieleistung in Anspruch zu

nehmen, wenden Sie sich an das nächstgelegene Fluke-Service-Center, um

Informationen zur Rücksendeautorisierung zu erhalten, und senden Sie das

Produkt anschließend mit einer Beschreibung des Problems an dieses

Service-Center.

DIESE GARANTIE IST IHR EINZIGER RECHTSANSPRUCH. KEINE

ANDEREN GARANTIEN, WIE DIE DER ZWECKDIENLICHKEIT FÜR EINEN

BESTIMMTEN EINSATZ, WERDEN AUSDRÜCKLICH ERTEILT ODER

IMPLIZIERT. FLUKE ÜBERNIMMT KEINE HAFTUNG FÜR AUS

IRGENDWELCHEN GRÜNDEN ODER RECHTSTHEORIEN

ABGELEITETEN SPEZIELLEN, MITTELBAREN, BEGLEIT- ODER

FOLGESCHÄDEN BEZIEHUNGSWEISE VERLUSTE.

Da in einigen Ländern der Ausschluß oder die Begrenzung von Begleit- oder

Folgeschäden nicht zulässig ist, kann es sein, daß die obengenannten

Haftungsbegrenzung für Sie nicht zutrifft.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Übereinstimmung mit der Richtlinien der Europäischen

Union.

Erde

Gleichstrommessung

Wechselstrommessung

Entspricht den relevanten australischen Standards

Entspricht UL 3111-1 und UL 3111-2-032

Geprüft und lizenziert durch TÜV Product Services

Beschränkte Garantie & Haftungsbeschränkung

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

Niederlande

Bitte besuchen Sie www.fluke-warranty.com, um das

Produkt zu registrieren

11/99

321, 322

Clamp Meter

Safety Sheet

(English)

W

Read First: Safety Information

To ensure safe operation and service of the meter, follow

these instructions:

• Avoid working alone so assistance can be rendered.

• Never use the meter on a circuit with voltages higher than

600 V or a frequency higher than 400 Hz fundamental. The

meter may be damaged.

• Never measure current while the test leads are inserted into

the input jacks.

• Do not use the meter or test leads if they look damag ed .

• Use extreme caution when working around bare conduc t ors

or bus bars. Contact with the conductor could result in

electric shock.

• Read the instruction card before use and follow all safety

instructions.

• Use the meter only as specified in the instruction card;

otherwise, the meter’s safety features may not protect you.

• Use caution when working with voltages above 60 V dc or

30 V ac. Such voltages pose a shock hazard.

Symbols

Application around and removal from HAZARDOUS LIVE

,

conductors permitted.

W

M

F

B

;

N10140

t

Risk of danger. Important information. See instruction card

Equipment protected by double or reinforced insulation

T

Battery

Conforms to CSA C22.2 No 1010. 2.032-96

Conforms to EU directives

P

Earth

J

DC measurement

AC measurement

Conforms to relevant Australian standards

Conforms to UL 3111-1 and UL 3111-2-032

Inspected and licensed by TÜV Product Services

®

Limited Warranty and Limitation of Liability

This Fluke product will be free from defects in material and

workmanship for 2 years from the date of purchase. This warranty does

not cover fuses, disposable batteries, or damage from accident, neglect,

misuse, alteration, contamination, or abnormal conditions of operation

or handling. Resellers are not authorized to extend any other warranty

on Fluke’s behalf. To obtain service during the warranty period, contact

your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that Service Center

with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER

WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR PURPOSE,

ARE EXPRESSED OR IMPLIED. FLUKE IS NOT LIABLE FOR ANY

SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES

OR LOSSES, ARISING FROM ANY CAU SE OR THEORY. Since some

states or countries do not allow the exclusion or limitation of an implied

warranty or of incidental or consequential damages, this limitation of

liability may not apply to you.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

To register your product, visit www.fluke-warranty.com

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

ClampMeters

Calibration Information

Introduction

WWarning

To avoid electric shock or injury, do not perform the performance tests or

calibration procedures unless you are qualified to do so.

The information provided in this manual is for the use of qualified personnel

only.

The 32X Calibration Information provides the information necessary to verify the performance and adjust

the calibration of the Fluke 321 and 322 ClampMeters, hereafter known as the Meter(s).

®

32X

The following information is included in this document:

• Safety Information and International Electrical Symbols

• Specifications

• Replacing the Batteries

• Cleaning

• Performance Tests

• Calibration Adjustment

• User-Replaceable Parts and Accessories

• Warranty Statement

See the 321,322 Instruction Card for complete operating instructions.

Contact Information

To contact Fluke, call:

1-888-99-FLUKE (1-888-993-5853) in USA

1-800-36-FLUKE (1-800-363-5853) in Canada

+31 402-675-200 in Europe

+81-3-3434-0181 Japan

+65-738-5655 Singapore

+1-425-446-5500 in other countries

For additional information about Fluke, its products, and services, visit Fluke’s web site at:

www.fluke.com

To register this product, go to register.fluke.com

PN 1631636 October 2001 Rev.1, 12/03

© 2001-2003 Fluke Corporation. All rights reserved. Printed in U.S.A.

1

32x

Calibration Information

Safety Information

WWarnings and Precautions

To avoid possible electric shock or personal injury, and to avoid possible damage to the Meter

or the equipment under test, adhere to the following practices:

Avoid working alone so assistance can be rendered.

•

Never use the Meter on a circuit with voltages higher than 600 V or a frequency

•

higher than 400 Hz fundamental. The meter may be damaged.

Do not use the Meter or test leads if they look damaged.

•

Use extreme caution when working around bare conductors or bus bars. Contact

•

with the conductor could result in electric shock.

Read the instruction card and safety sheet before use and follow all safety instructions.

•

Use the Meter only as specified in the instruction card; otherwise, the Meter’s safety

•

features may be impaired.

Use caution when working with voltages above 60 V dc or 30 V ac. Such voltages

•

pose a shock hazard.

Before using the Meter, inspect the case. Do not use the Meter if it is damaged. Look for

•

cracks or missing plastic. Pay particular attention to the insulation around the connectors.

Verify the Meter’s operation by measuring a known voltage. Do not use the Meter if it

•

operates abnormally. Protection may be impaired. When in doubt, have the Meter serviced.

Do not apply more than the rated current or voltage, as marked on the Meter.

•

Use the proper terminals, function, and range for your measurements.

•

Do not operate the Meter with the case (or part of the case) removed.

•

When servicing the Meter, use only specified replacement parts.

•

International Electrical Symbols

The following international symbols appear in this document and on the Meter.

N10140

Risk of electric shock

Risk of danger. Important Information. See manual.

Equipment protected by double or reinforced Insulation

Battery

Conforms to CSA C22.2 No 1010. 2.032-96

Conforms to EU directives

Earth

DC measurement

AC measurement

Conforms to relevant Australian standards

Conforms to UL 3111-1 and UL 3111-2-032

Inspected and licensed by TÜV Product Services

2

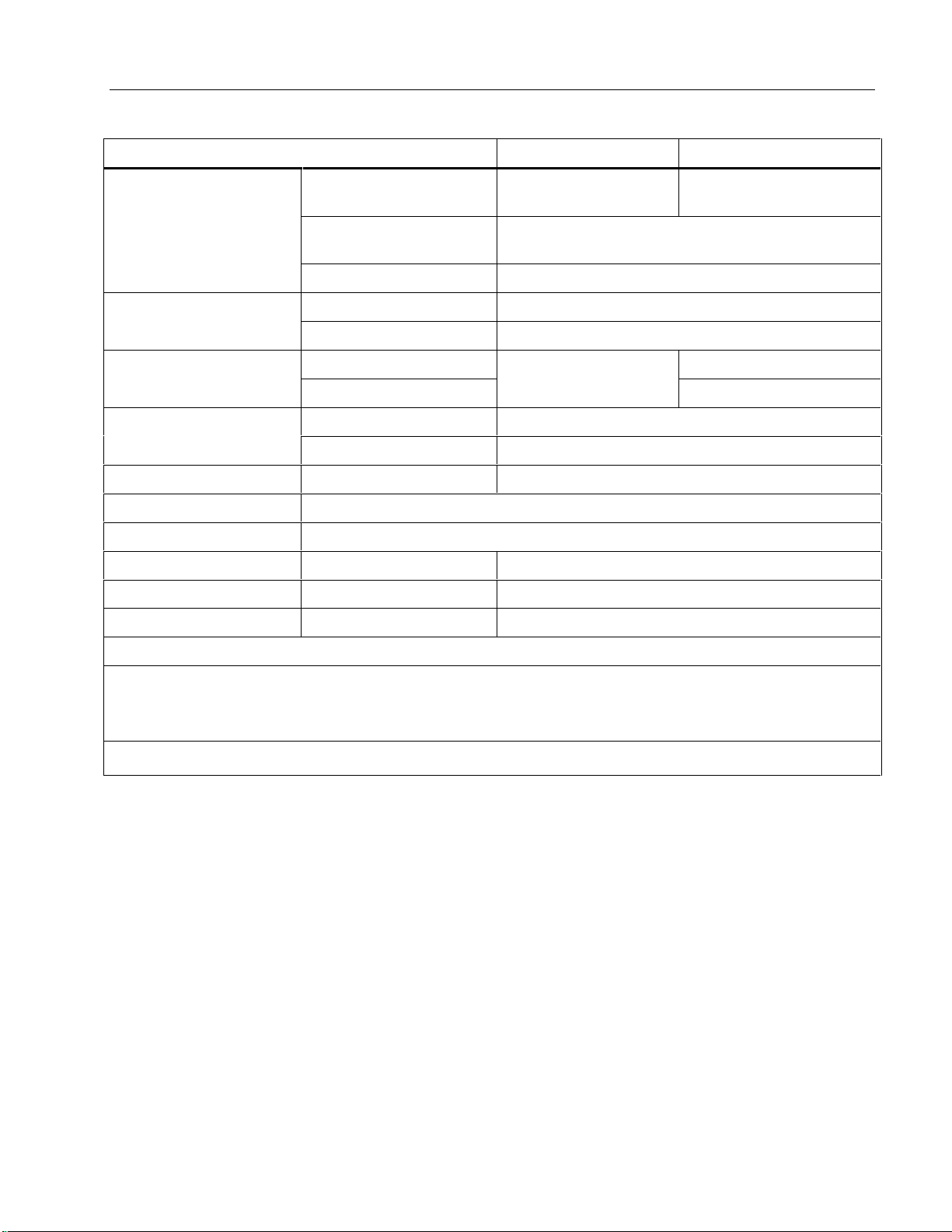

Specifications

*@ 23 °C ± 5 °C, 0 - 90% RH 321 322

ClampMeters

Specifications

?

(50/60 Hz)

Continuity R ≤ 30 Ω

Jaw Opening 1 inch (26 mm)

IP Rating 40

Storage Temperature -40 °C to 60 °C

Operating Temperature -10 °C to 50 °C

Altitude 2000 m

Range 0 - 400.0 A 0 - 40.0 A

40 .0 - 400.0 A

Accuracy 50 Hz - 60 Hz 1.8 % ± 5 counts

60 Hz - 400 Hz 3.0 % ± 5 counts

AC Response Avg

Range 0 - 400.0 V, 400 - 600 VK

Accuracy 50 Hz - 400 Hz 1.2 % ± 5 counts

Range 0 - 400.0 V, 400 - 600 VL

Accuracy

Range 0 - 400.0 Ωe

Accuracy 1.0 % ± 5 counts

_

1 % ± 5 counts

EMC- EN61326

CAT III 600 V, pollution degree II:

CAT III equipment is designed to protect against transients in equipment in fixed-equipment installations, such as

distribution panels, feeders and short branch circuits, and lighting syst ems in large buildings.

* < 18 °C, > 28 °C add 0.1 x (specified accuracy)/ °C

3

32x

Calibration Information

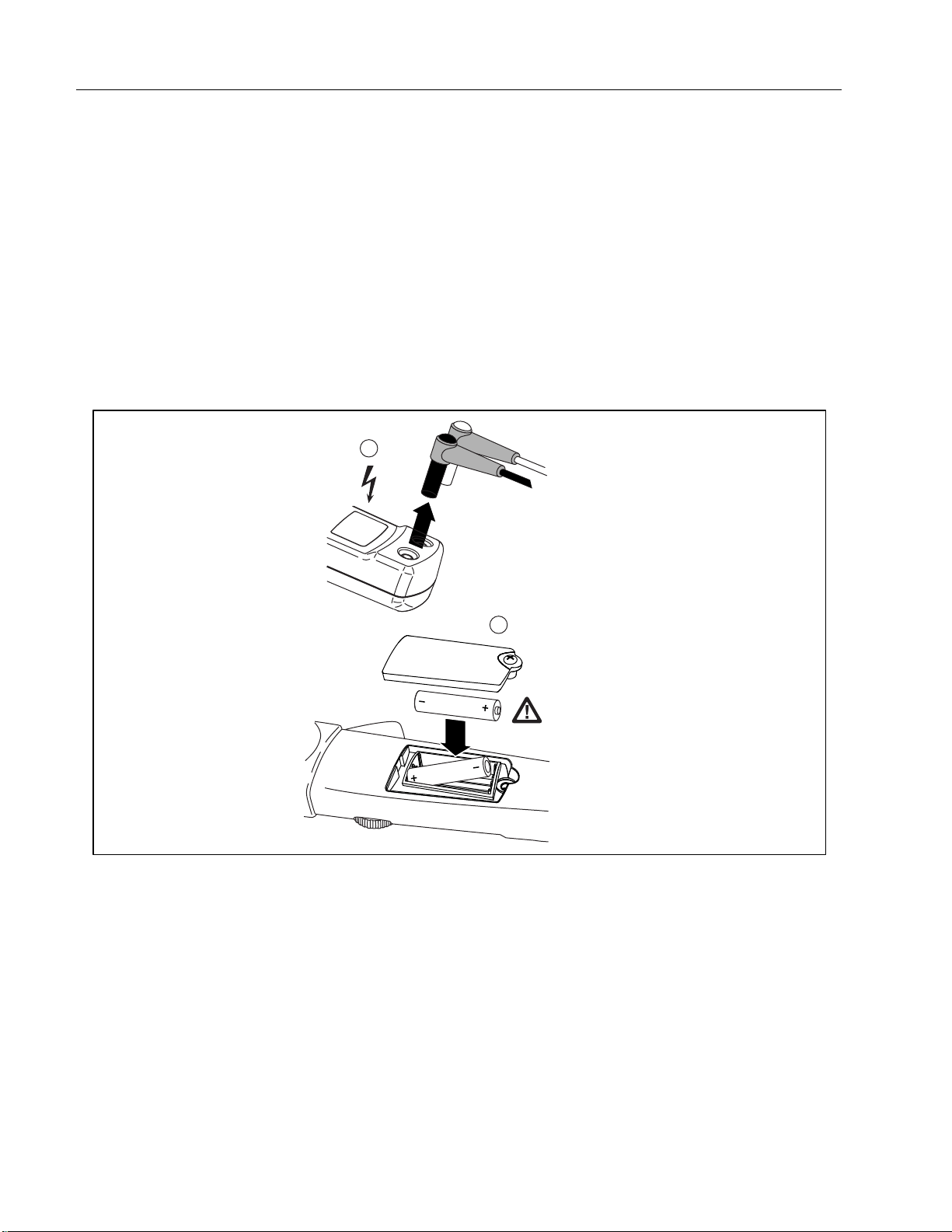

Replacing the Batteries

To avoid false readings, that could lead to possible electric shock or personal

injury, replace the batteries as soon as the low battery indicator (

Disconnect the test leads before replacing the batteries.

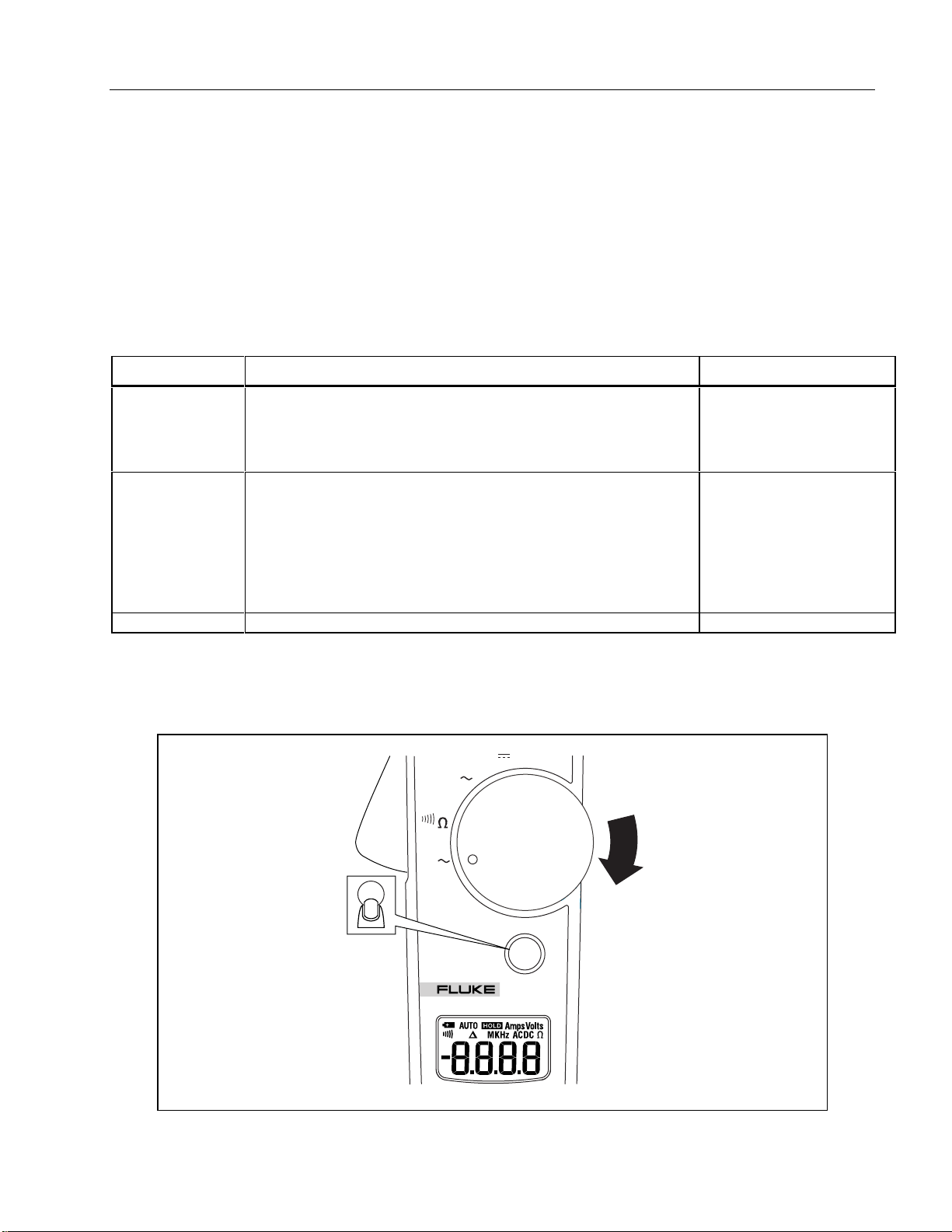

To replace the batteries (refer to Figure 1):

WWarning

b ) appears.

1. Turn the rotary switch to

OFF and remove the test leads from the terminals.

2. Loosen the battery compartment door screw, and remove the door from the case bottom.

3. Remove the batteries.

4. Replace the batteries with 2 new AAA batteries.

5. Reattach the battery compartment door to the case bottom and tighten the screw.

1

2

AAA

Figure 1. Replacing the Batteries

Cleaning

W Warning

To avoid electrical shock, remove any input signals before cleaning.

Caution

To avoid damaging the Meter, do not use aromatic hydrocarbons or chlorinated

solvents for cleaning. These solutions will react with the plastics used in the

instruments.

Clean the instrument case with a damp cloth and mild detergent.

4

ade02.eps

ClampMeters

Performance Tests

Performance Tests

WWarning

To avoid electric shock, do not perform the performance test procedures unless

the Meter is fully assembled.

The following performance tests verify the complete operation of the Meter and check the accuracy of

each meter function against the Meter’s specifications. If the Meter fails any part of the test, calibration

adjustment and/or repair is indicated.

In the performance tests, the Meter is referred to as the unit under test (UUT).

Table 1. Required Equipment

Equipment Minimum Specifications Recommended Model

AC Calibrator

50-Turn Current

Coil

DC Voltage: 0 to ±1020 V

AC Voltage: 1 mV to 1020 V, 10 Hz to 500 kHz, Sine

AC Current: 29 µA to 20.5 A, 10 Hz to 30 kHz, Sine

Ohms: 0 to 1100 MΩ

Uncertainty due to Clampmeter/ Coil Interaction: ± (0.25% of effective

output + 0.5A), for toroidal-wound current clamps, such as the Fluke

80I and 80I-1000.

± (0.50% of effective output + 0.5A), for current clamps like the Fluke

80i-kw, 80i-400, 80i-410, 80i-500, 80i-1010, Fluke 31, Fluke 33, or

equivalent.

Fluke 5520A

Fluke 5500A/Coil

Mirror

Testing the Display

Test the display by turning the Meter on while holding down the HOLD button. Check all segments for

clarity and contrast. Refer to Figure 2.

V

V

On/Off

A

OFF

HOLD

322

CLAMP METER

Figure 2. Testing the Display

ade01f.eps

5

32x

Calibration Information

Hold Button Test

To test the HOLD button, turn the Meter on and push the hold button. Each button push will cause the

Meter to beep.

Preparing for the Performance Test

WWarning

To avoid possible electric shock or personal injury:

Do not perform the following procedures unless qualified to do so. Some

•

procedures involve the use of high voltages.

Before handling the test connections and in between tests, make sure the

•

calibrator is in standby mode (STBY).

To prepare for the performance test:

1. Make sure that you have the required equipment, see Table 1.

2. Warm up the calibrator as required by its specifications.

3. Allow the temperature of the UUT to stabilize at room temperature ( 23 °C ± 5 °C [73 °F ± 9 °F] ).

6

ClampMeters

Performance Tests

Performance Test Procedure

To test each of the Meter’s functions and operating ranges, do the following:

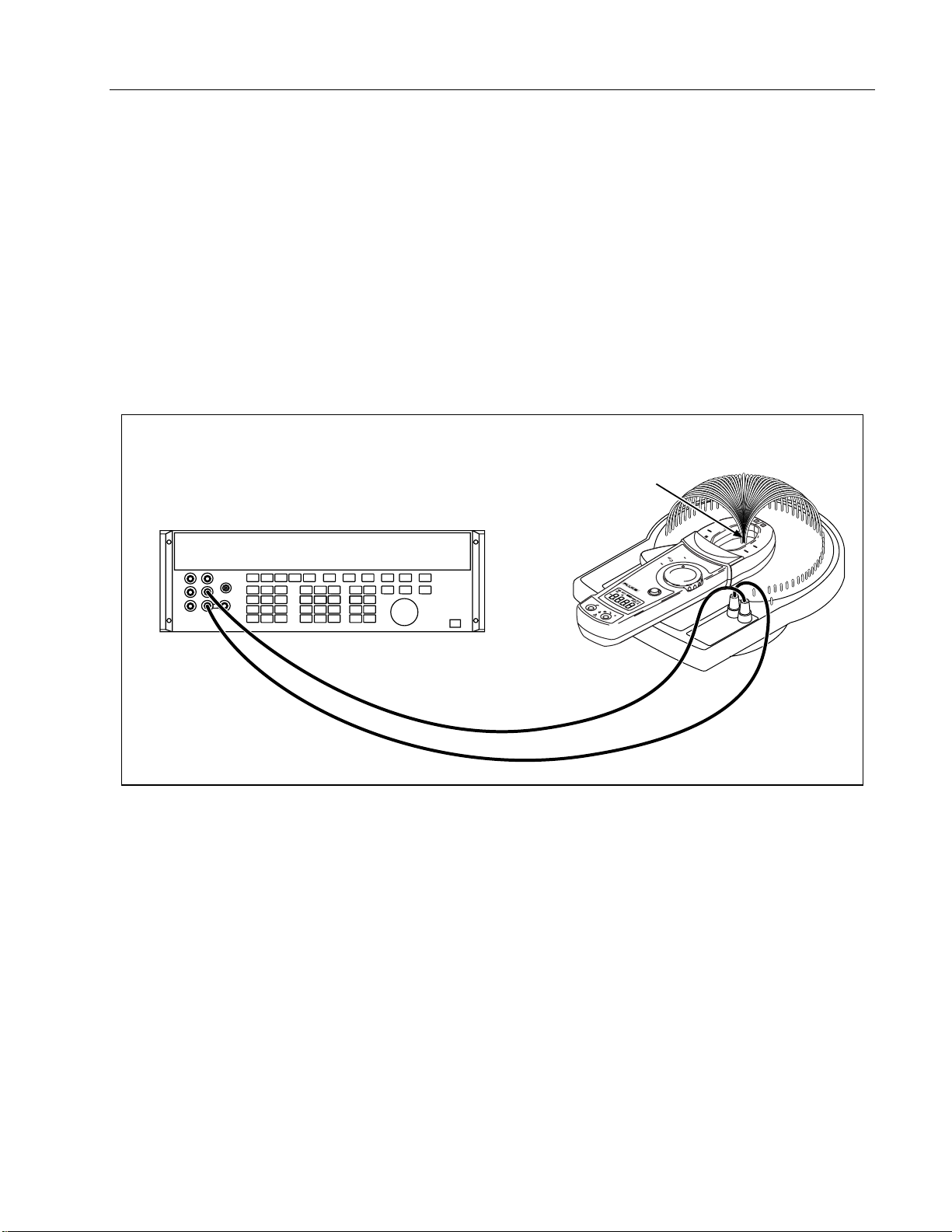

1. Connect the source to the Meter’s VΩ and COM input jacks.

2. Referring to Table 2 for the 321 and Table 3 for the 322, put the Meter in the desired function and

range for each test.

3. Apply the indicated output from the 5520A Calibrator.

4. When using the amp function on the 5520A, make sure LCOMP on the 5520A is ON.

5. The reading on the Meter display should be within the low and high limits shown in the table.

6. Repeat steps 1-4 for each function and range in Table 2 or Table 3.

If the Meter fails to perform within the low-high range indicated for each test in Table 2 or Table 3, the

Meter needs to be calibrated and adjusted, or requires some repair.

50-Turn Current Coil

Conductor

5520A Calibrator

Figure 3. 32x Amps/Hz Verification Setup

CAT

600V

V

A

OFF

HOLD

CLAMP METER

COM

322

600V MAX

CAT

V

400A

ade07f.eps

7

32x

Calibration Information

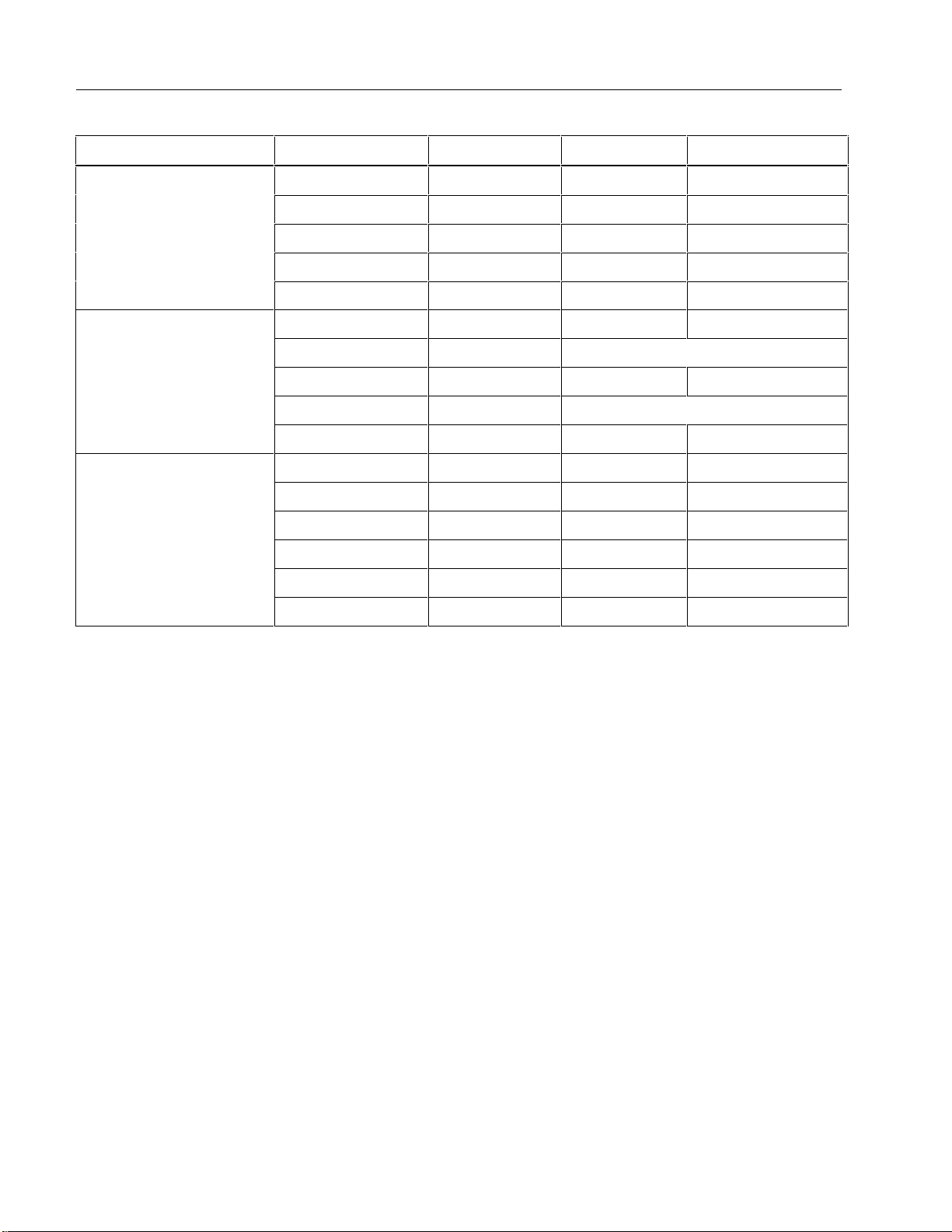

Table 2. Performance Tests 321

Functional Test 5520 output Nominal Low Limit High Limit

AC Amps

Ohms

AC Volts

0.7 A @ 50 Hz 35 A @ 50 Hz 33.8 36.2

0.7 A @ 400 Hz 35 A @ 400 Hz 33.4 36.6

6 A @ 60 Hz 300 A @ 60 Hz 294.1 305.9

7 A @ 50 Hz 350 A @ 50 Hz 343.2 356.8

7 A @ 400 Hz 350 A @ 400 Hz 339.0 361.0

30 Ohm 30 Ohms 29.2 30.8

Beeper must be on

50 Ohm 50 Ohms 49.0 51.0

Beeper must be off

350 Ohm 350 Ohms 346.0 354.0

35 V @ 50 Hz 35 V @ 50 Hz 34.0 36.0

350 V @ 60 Hz 350 V @ 60 Hz 345.3 354.7

600 V @ 60 Hz 600 V @ 60 Hz 592.3 607.7

35 V @ 400 Hz 35 V @ 400 Hz 34.0 36.0

350 V @ 400 Hz 350 V @ 400 Hz 345.3 354.7

600 V @ 400 Hz 600 V @ 400 Hz 592.3 607.7

8

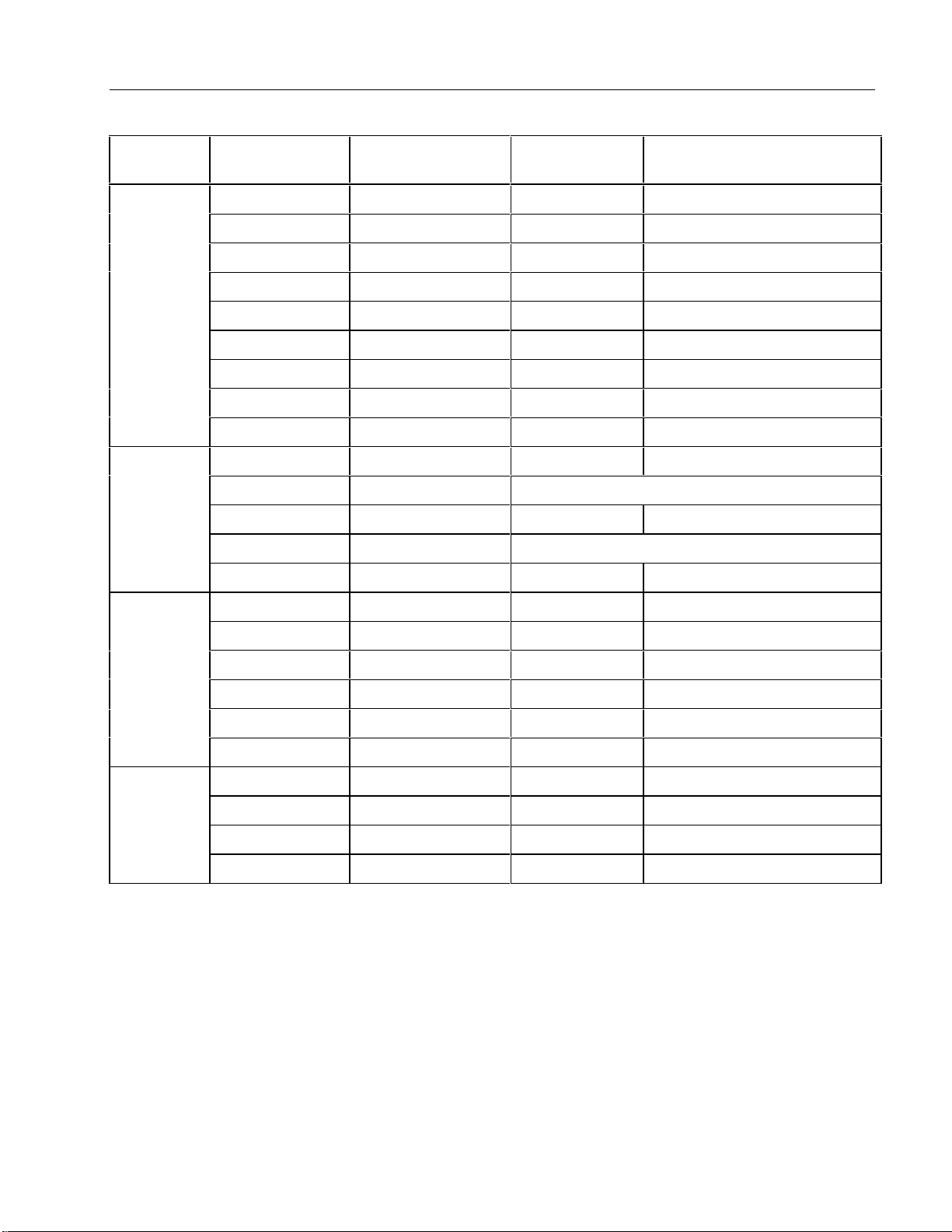

Table 3. Performance Tests 322

Functional

Test 5520A Output Nominal Low Limit High Limit

ClampMeters

Performance Tests

AC Amps

Ohms

AC Volts

0.6 A @ 60 Hz 30 A @ 60 Hz 28.9 31.1

0.07 A @ 50 Hz 3.5 A @ 50 Hz 2.9 4.1

0.7 A @ 50 Hz 35 A @ 50 Hz 33.4 36.6

0.07 A @ 400 Hz 3.5 A @ 400 Hz 2.9 4.1

0.7 A @ 400 Hz 35 A @ 400 Hz 33.4 36.6

1 A @ 50 Hz 50 A @ 50 Hz 48.6 51.4

7 A @ 50 Hz 350 A @ 50 Hz 343.2 356.8

7 A @ 400 Hz 350 A @ 400 Hz 339.0 361.0

1 A @ 400 Hz 50 A @ 400 Hz 48.0 52.0

30 Ohm 30 Ohms 29.2 30.8

Beeper must be on

50 Ohm 50 Ohms 49.0 51.0

Beeper must be off

350 Ohm 350 Ohms 346.0 354.0

35 V @ 50 Hz 35 V @ 50 Hz 34.0 36.0

350 V @ 60 Hz 350 V @ 60 Hz 345.3 354.7

DC Volts

600 V @ 60 Hz 600 V @ 60 Hz 592.3 607.7

35 V @ 400 Hz 35 V @ 400 Hz 34.0 36.0

350 V @ 400 Hz 350 V @ 400 Hz 345.3 354.7

600 V @ 400 Hz 600 V @ 400 Hz 592.3 607.7

-350 V -350V -355.8 -344.2

35 V 35V 33.9 36.1

350 V 350V 344.2 355.8

600 V 600V 590.5 609.5

9

32x

Calibration Information

321 Calibration Adjustment

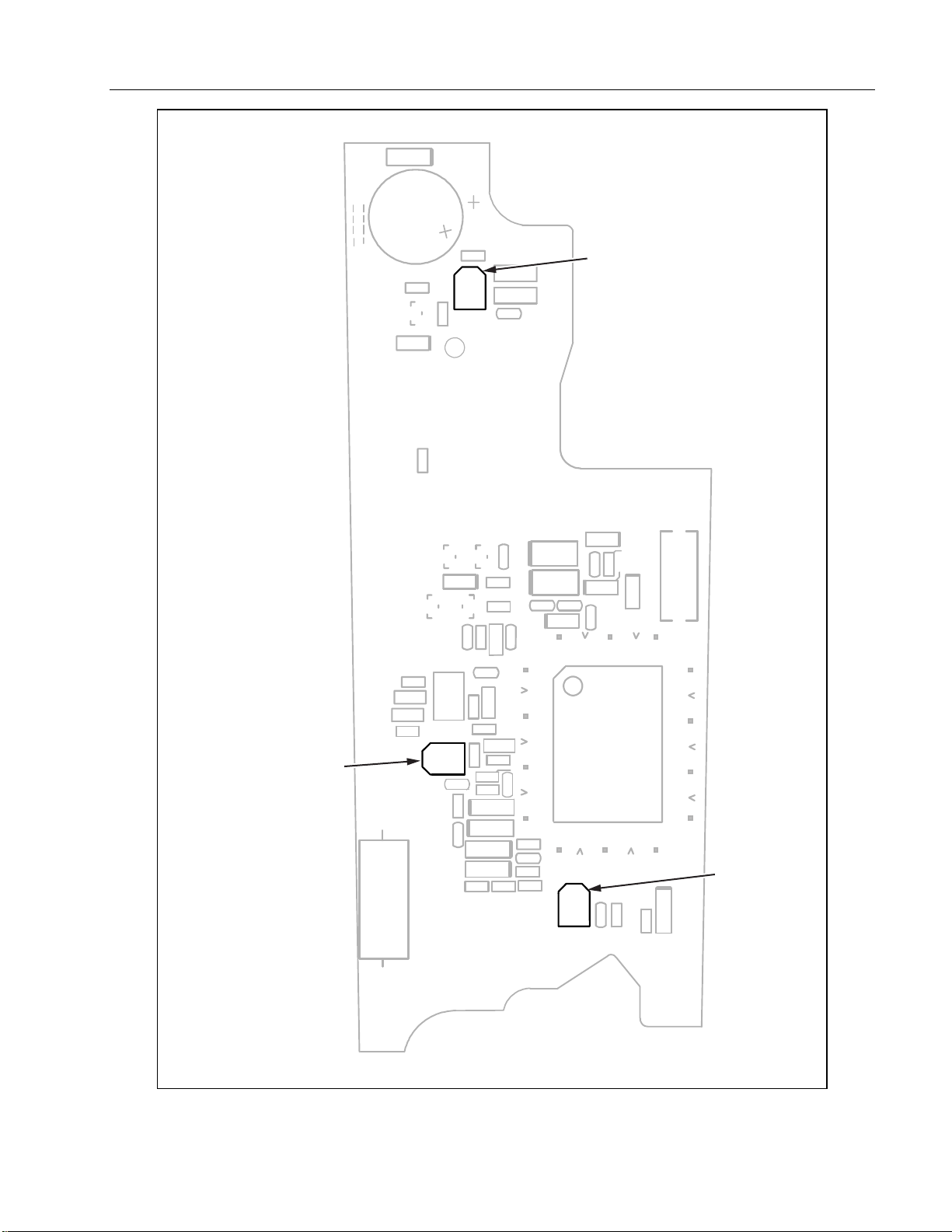

Use the following steps to adjust the calibration of the 321 (refer to Figure 4):

1. Remove the screws on the bottom of the Meter.

2. Lift off the top case.

3. Apply 600.0 V 50 Hz from the 5520A.

4. Adjust VR1 until display reads within 1.0 V.

5. Apply 4 A 50 Hz from the 5520A to the 50-turn coil. The 50-turn coil will make the meter read 200.0

A 50 Hz .

6. Adjust VR2 until the display reads within 0.5 A. A mirror will need to be used because the calibration

point cannot be seen from the top side of the meter.

7. Replace the top case.

8. Replace the case screws.

9. Verify the calibration by going through the performance test procedures.

10

VR3

ClampMeters

Performance Tests

VR2

Figure 4. Calibration Adjustment Points (321)

VR1

ade05f.eps

11

32x

Calibration Information

322 Calibration Adjustment

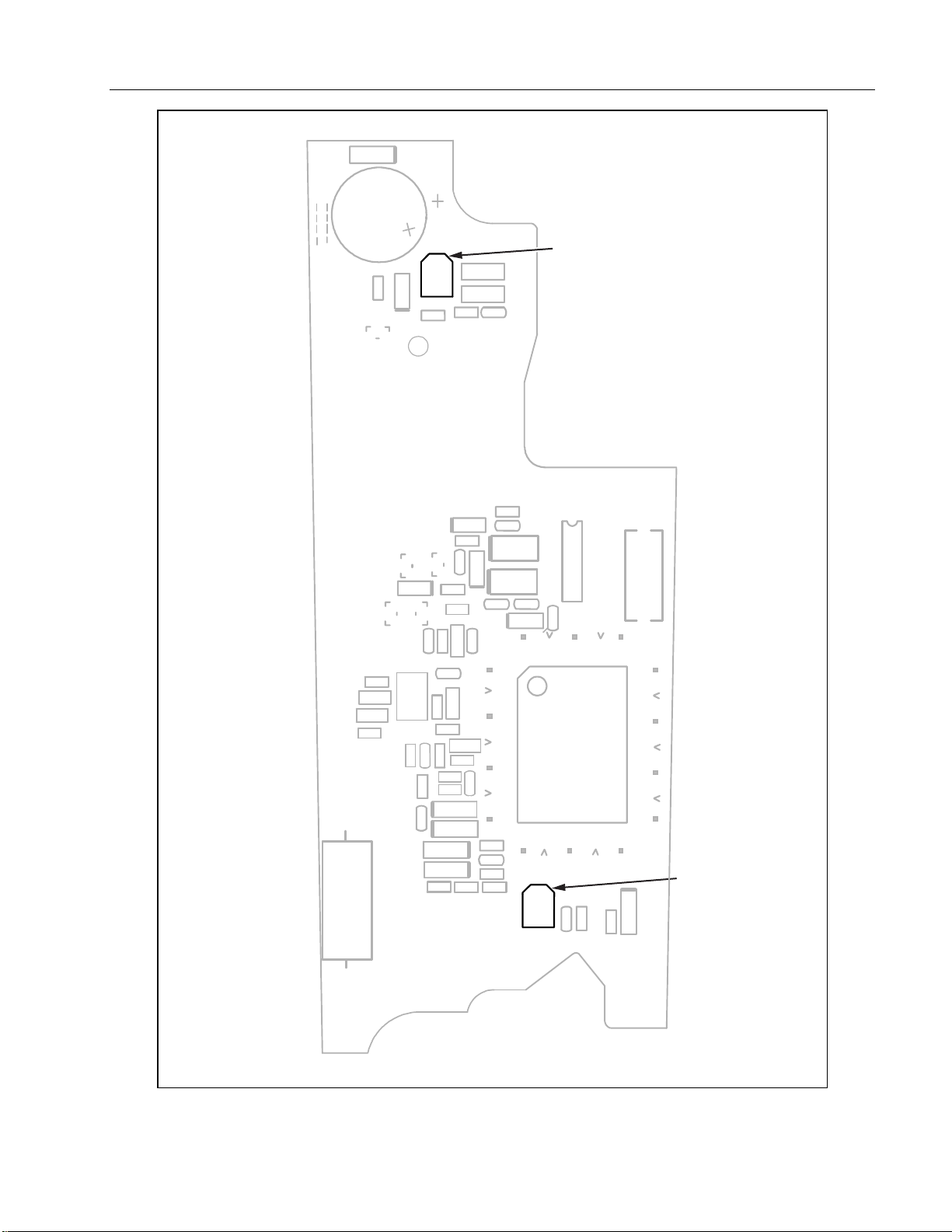

Use the following steps to adjust the calibration of the meter (refer to Figure 5):

1. Turn the meter to DC V.

2. Remove the screws on the bottom of the Meter.

3. Lift off the top case.

4. Apply 300.0 V DC from the 5520A to the Meter..

5. Adjust VR1 until the UUT (Unit Under Test) display reads within 0.1 V.

6. Change the meter to the V AC function.

7. Apply 300 V @ 60 Hz.

8. Adjust VR2 until the UUT display reads within 0.1. V.

9. Change to the A AC function.

10. Apply 6 A 60 Hz to the 50-turn coil. The 50-turn coil will cause the Meter read this as 300.0 A 60Hz.

11. Adjust VR3 until this difference between steps 8 and 11 is within 0.1 A. A mirror will need to be used

because the calibration point cannot be seen from the top side of the meter.

12. Replace top case.

13. Verify the calibration by going through the Performance Test procedures.

12

VR2

ClampMeters

Performance Tests

Figure 5. Calibration Adjustment Points 322

VR1

ade06f.eps

13

32x

Calibration Information

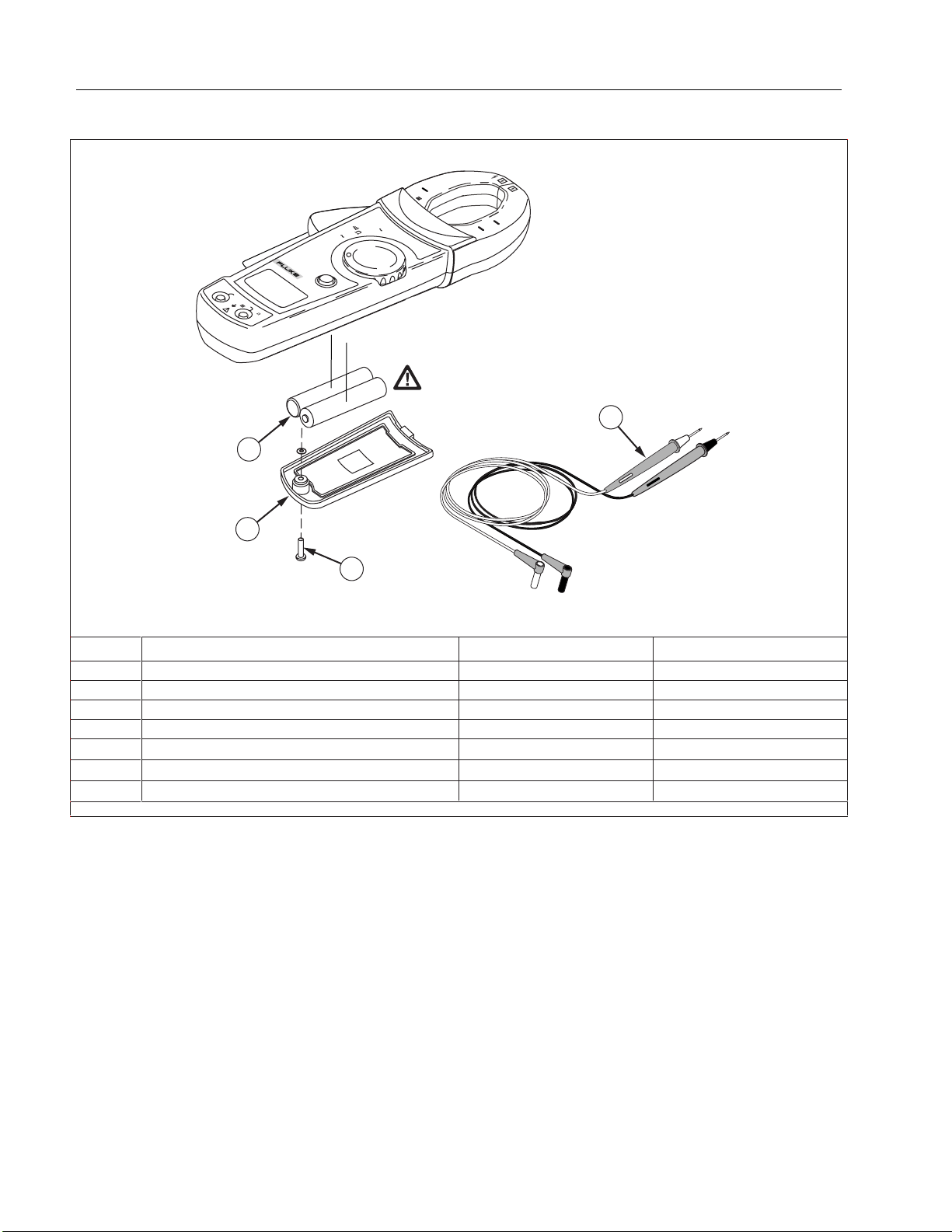

User-Replaceable Parts and Accessories

CAT

600V

V

A

OFF

HOLD

CLAMP METER

COM

600V MAX

CAT

322

V

1

400A

4

2

3

Item # Description Part No Qty

A

B

C

D

Not Shown

Not Shown

Not Shown

** Fluke accessories are available from your authorized Fluke dis t ribut or.

Battery,1.5V,0-150MA, AA Alkaline 376756 2

Battery Door 1630734 1

Battery Door Screw 1611694 1

TL75 Test Lead Set** 855705 1

321, 322 Safety Sheet

321, 322 Instruction Card

Calibration Information (this document)

1615215 1

1615194 1

1631636 1

Figure 6. User-Replaceable Parts and Accessories

ade08f.eps

14

ClampMeters

User-Replaceable Parts and Accessories

LIMITED WARRANTY AND LI M ITATION OF LIABILITY

This Fluke product is warranted to be free from defects in mat eri al and workmanship under normal use and servic e. The warranty period

is 2 years and begins on the date of shipment. Parts, product repairs, and services are warrant ed f or 90 days. This warranty extends only

to the original buyer or end-user customer of a Fluke authorized reseller, and does not apply to fuses, di sposable batteries, or to any

product which, in Fluke’s opinion, has been misused, altered, neglec ted, contaminated, or damaged by ac cident or abnormal conditions

of operation or handling. Fluke warrants that s of tware will operate substantially in accordance wit h its functional specificat ions for 90 days

and that it has been properly recorded on non-defect i v e media. Fluke does not warrant that software will be error f ree or operate without

interruption.

Fluke authorized resellers shall extend this warranty on new and unus ed products to end-user customers only but have no authority to

extend a greater or different warranty on behal f of Fluke. Warranty support i s available only if product is purchased through a Fluke

authorized sales outlet or Buyer has paid the applicable international price. Fluke reserves t he ri ght to invoice Buyer for im portation costs

of repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price, free of c harge repai r, or replacement of a

defective product whic h i s returned to a Fluke authorized serv i c e center within the warranty period.

To obtain warranty service, contact your nearest Fluke aut hori zed service center to obtai n ret urn authorization information, then send the

product to that service center, with a descripti on of the difficulty, postage and insurance prepaid (FOB Destinat i on). Fluke assumes no

risk for damage in transit. Following warranty repair, the product will be returned to Buyer, trans port at i on prepaid (FOB Destination). If

Fluke determines that fai l ure was caused by neglect, misuse, contamination, al teration, accident, or abnormal condition of operation or

handling, including overvoltage failures caused by use outside the product’s specified rating, or normal wear and tear of mechani cal

components, Fluke will provide an estimate of repair costs and obtain authorization bef ore commencing the work. Following repair, the

product will be returned to the Buyer transport at i on prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDI NG B UT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHA NT ABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR

LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limit ation of the term of an implied warrant y, or exclusion or limit ation of incidental or

consequential damages, the l i mitations and exclusi ons of this warranty may not apply to every buyer. If any provision of this Warranty i s

held invalid or unenforceable by a court or other decis ion-maker of competent jurisdiction, s uc h holding will not affect the validity or

enforceability of any other provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

To register this product, go to www.register.fluke.com

15

32x

Calibration Information

16

Models 110, 111 & 112

Bedienungshandbuch

True RMS Multimeters

®

November 2000 (German), Rev 1, 7/01

© 2000-2001 Fluke Corporation. All rights reserved. Printed in USA.

Begrenzte Gewährleistung und Haftungsbeschränkung

Fluke gewährleistet, daß jedes Fluke-Produkt unter normalem Gebrauch und Service frei von Material- und Fertigungsdefekten ist. Die Garantiedauer beträgt

3 Jahre ab Versanddatum. Ersatzteile, Produktreparaturen und Servicearbeiten haben eine Garantie von 90 Tagen. Diese Garantie wird ausschließlich dem

Ersterwerber bzw. dem Endverbraucher, der das betreffende Produkt von einer von Fluke autorisierten Verkaufsstelle erworben hat, geleistet und erstreckt sich

nicht auf Sicherungen, Einwegbatterien oder irgendwelche anderen Produkte, die nach dem Ermessen von Fluke unsachgemäß verwendet, verän de rt,

vernachlässigt, verunreinigt, durch Unfälle beschädigt oder abnormalen Betriebsbedingungen oder einer unsachgemäßen Handhabung ausgesetzt wurden.

Fluke garantiert für einen Zeitraum von 90 Tagen, daß die Software im wesentlichen in Übereinstimmung mit den einschlägigen Funktionsbeschreibungen

funktioniert und daß diese Software auf fehlerfreien Datenträgern gespeichert wurde. Fluke übernimmt jedoch keine Garantie dafür, daß die Software fehlerfrei

ist und störungsfrei arbeitet.

Von Fluke autorisierte Verkaufsstellen werden diese Garantie ausschließlich für neue und nicht benutzte, an Endverbraucher verkaufte Produkte leisten. Die

Verkaufsstellen sind jedoch nicht dazu berechtigt, diese Garantie im Namen von Fluke zu verlängern, auszudehnen oder in irgendeiner ander en W eis e

abzuändern. Der Erwerber hat nur dann das Recht, aus der Garantie abgeleitete Unterstützungsleistungen in Anspruch zu nehmen, wenn er das Produkt bei

einer von Fluke autorisierten Vertriebsstelle gekauft oder den jeweils geltenden internationalen Preis gezahlt hat. Fluke behält sich das Recht vor, dem Erwerber

Einfuhrgebühren für Reparatur/Ersatzteile in Rechnung zu stellen, wenn dieser das Produkt in einem anderen Land zur Reparatur anbietet, als dem Land, in

dem er das Produkt ursprünglich erworben hat.

Flukes Garantieverpflichtung beschränkt sich darauf, daß Fluke nach eigenem Ermessen den Kaufpreis ersetzt oder aber das defekte Produkt unentgeltlich

repariert oder austauscht, wenn dieses Produkt innerhalb der Garantiefrist einem von Fluke autorisierten Servicezentrum zur Reparatur üb erg eb en wi rd .

Um die Garantieleistung in Anspruch zu nehmen, wenden Sie sich bitte an das nächstgelegene von Fluke autorisierte Servicezentrum, um Rücknahmeinformationen zu erhalten, und senden Sie dann das Produkt mit einer Beschreibung des Problems und unter Vorauszahlung von Fracht- und Versicherungskosten

(FOB Bestimmungsort) an das nächstgelegene von Fluke autorisierte Servicezentrum. Fluke übernimmt keine Haftung für Transportschäden. Im Anschluß an

die Reparatur wird das Produkt unter Vorauszahlung der Frachtkosten (FOB Bestimmungsort) an den Käufer zurückgesandt. Wenn Fluke feststellt, daß der

Defekt auf Vernachlässigung, unsachgemäße Handhabung, Verunreinigung, Veränderungen am Gerät, einen Unfall oder auf anormale Betriebsbedingungen,

einschließlich durch außerhalb der für das Produkt spezifizierten Belastbarkeit verursachter Überspannungsfehler oder normaler Abnutzung mechanischer

Komponenten, zurückzuführen ist, wird Fluke dem Erwerber einen Voranschlag der Reparaturkosten zukommen lassen und erst die Zustimmung des Erwerbers

einholen, bevor die Arbeiten in Angriff genommen werden. Nach der Reparatur wird das Produkt unter Vorauszahlung der Frachtkosten an den Käufer

zurückgesendet, und es werden dem Käufer die Reparaturkosten und die Versandkosten (FOB Versandort) in Rechnung gestellt.

DIE VORSTEHENDEN GARANTIEBESTIMMUNGEN STELLEN DEN EINZIGEN UND ALLEINIGEN RECHTSANSPRUCH AUF SCHADENERSATZ DES

ERWERBERS DAR UND GELTEN AUSSCHLIESSLICH UND AN STELLE VON ALLEN ANDEREN VERTRAGLICHEN ODER GESETZLICHEN

GEWÄHRLEISTUNGSPFLICHTEN, EINSCHLIESSLICH - JEDOCH NICHT DARAUF BESCHRÄNKT - DER GESETZLICHEN GEWÄHRLEISTUNG DER

MARKTFÄHIGKEIT UND DER ZWECKDIENLICHKEIT FÜR EINEN BESTIMMTEN EINSATZ. FLUKE HAFTET NICHT FÜR SPEZIELLE, UNMITTELBARE,

MITTELBARE, BEGLEIT- ODER FOLGESCHÄDEN ODER VERLUSTE, EINSCHLIESSLICH VERLUST VON DATEN, UNABHÄNGIG VON DER URSACHE

ODER THEORIE.

Angesichts der Tatsache, daß in einigen Ländern die Begrenzung einer gesetzlichen Gewährleistung sowie der Ausschluß oder die Begrenzung von Begleitoder Folgeschäden nicht zulässig ist, kann es sein, daß die obengenannten Einschränkungen und Ausschlüsse nicht für jeden Erwerber gelten. Sollte eine

Klausel dieser Garantiebestimmungen von einem zuständigen Gericht oder einer anderen Entscheidungsinstanz für unwirksam oder nicht durchs etzbar

befunden werden, so bleiben die Wirksamkeit oder Durchsetzbarkeit anderer Klauseln dieser Garantiebestimmungen von einem solchen Spruch unberührt.

Fluke Corporation

P. O. Box 9090

Everett, WA 98206-9090

USA

Fluke Europe B.V.

P. O. Box 1186

5602 BD Eindhoven

Niederlande

11/99

Inhaltsverzeichnis

Vor Gebrauch des Meßgeräts lesen: Warnungen und Sicherheitshinweise.......................... ii

Kontaktaufnahme mit Fluke................................................................................................... 1

Warnungen und Vorsichtshinweise ....................................................................................... 1

Unsichere Spannung............................................................................................................. 1

Prüfleiteralarm....................................................................................................................... 1

Batteriesparmodus (Ruhemodus).......................................................................................... 2

Anschlüsse............................................................................................................................ 2

Drehschalterpositionen ......................................................................................................... 2

Anzeige................................................................................................................................. 3

MIN-MAX-AVG-Aufzeichnungsmodus................................................................................... 4

Anzeigehaltemodus (H OLD) ................................................................................................. 4

Hintergrundbeleuchtung (nur Modell 112) ............................................................................. 4

Manuelle und automatische Bereichswahl ............................................................................ 5

Einschaltoptionen.................................................................................................................. 5

Grundlegende Meßfunkt ionen............................................................................................... 6

Messen von Wechselspannung und Gleichspannung...................................................... 6

Messen von Widerstand ................................................................................................... 7

Messen von Kapazität...................................................................................................... 7

Kontinuitätsprüfungen ...................................................................................................... 7

Prüfen von Dioden ........................................................................................................... 8

Messen von Wechselstromstärke und Gleichstromstärke (Modelle 111 und 112)............ 8

Messen von Frequenz...................................................................................................... 9

Verwendung der Balkenanzeige............................................................................................ 9

Reinigung.............................................................................................................................. 9

Prüfen der Sicherung (Modelle 111 und 112)........................................................................ 10

Ersetzen der Batterie und Sicherung..................................................................................... 10

Spezifikationen...................................................................................................................... 11

Überschrift Seite

i

Models 110, 111 & 112

Bedienungs-Handbuch

W

Zur Vermeidung von Stromschlag oder Verletzungen folgende Richtlinien einhalten:

• Das Meßgerät ausschließlich wie in diesem Handbuch beschrieben einsetzen, da sonst die im Meßgerät integrierten

Schutzeinrichtungen beeinträchtigt werden könnten.

• Das Meßgerät nicht benutzen, wenn das Meßgerät oder die Prüfleitungen äußerliche Beschädigungen aufweisen oder wenn

das Meßgerät nicht einwandfrei funktioniert.

• Immer die richtigen Anschlüsse, die richtige Drehschalterposition und den richtigen Bereich für die jeweils anstehende

Messung auswählen.

• Die Funktion des Meßgeräts durch Messen einer bekannten Spannung überprüfen. Das Meßgerät im Zweifelsfall warten

lassen.

• Zwischen den Anschlüssen bzw. zwischen den Anschlüssen und Erde nie eine Spannung anlegen, die die am Meßgerät

angegebene Nennspannung überschreitet.

• Bei Spannungen über 30 V Wechselspannung rms, 42 V Wechselspannung Spitze oder 60 V Gleichspannung besondere

Vorsicht walten lassen. Bei solchen Spannungen besteht Stromschlaggefahr.

• Zur Vermeidung falscher Ablesungen, die zu Stromschlag oder Verletzungen führen können, die Batterie ersetzen, sobald

die Anzeige für schwache Batterie (N) eingeblendet wird.

• Vor dem Prüfen von Widerstand, Kontinuität, Dioden oder Kapazität den Strom des Stromkreises abschalten und alle

Hochspannungskondensatoren entladen.

• Das Meßgerät nicht in Umgebungen mit explosiven Gasen oder Dampf betreiben.

• Bei der Verwendung von Prüfleitern oder Prüfspitzen müssen die Finger hinter dem Fingerschutz bleiben.

• Vor dem Öffnen des Meßgerätgehäuses oder der Batteriefachabdeckung die Prüfleitungen abnehmen.

Vor Gebrauch des Meßgeräts lesen: Warnungen und Sicherheitshinweise

Symbole

B Wechselstrom (AC - Alternating Current) I Sicherung

F Gleichstrom (DC - Direct Current) P Übereinstimmung mit den Richtlinien der Europäischen Union.

D Wechselstrom oder Gleichstrom Canadian Standards Association

J Erde, Masse

W Wichtige Informationen, siehe Handbuch.

Batterie (Batterie schwach, wenn eingeblendet).

N

Geprüft und lizenziert durch TÜV Product Services

T

t

950 Z Listed

;

N10140

ii

Schutzisoliert

Underwriters Laboratories, Inc.

Stimmt mit den relevanten Australischen Normen überein.

Models 110, 111 & 112

True RMS Multimeters

g

Die Fluke True RMS Multimeter (Modell 110, Modell 111 und

Modell 112) sind batteriebetriebene Effektivwert-Multimeter

(hiernach “Meßgerät” genannt) mit 6000-Zählwerk und

Balkenanzeige. Dieses Handbuch gilt für alle drei Modelle. Alle

Abbildungen zeigen das Modell 112.

Das Meßgerät dient für folgende Messungen oder Prüfungen:

• Wechsel-/Gleichspannung und Wechsel-/Gleichstromstärke

• Widerstand

• Kontinuität

• Dioden

• Spannungs- und Stromfrequenz

• Kapazität

Diese Meßgeräte erfüllen CAT III IEC 61010-1-95-Standards. Der

Sicherheitsstandard IEC 61010-1-95 definiert vier Überspannungskategorien (CAT I bis IV) basierend auf der durch

Störimpulse verursachten Gefahr. CAT III-Meßgeräte sind so

konzipiert, daß sie auf Verteilerebene gegen impulsförm i ge

Störsignale in festinstallierten Geräten schützen.

Kontaktaufnahme mit Fluke

Fluke-Rufnummern:

(+1) 1 888 993 5853 - USA und Kanada

(+31) 402-678-200 - Europa

(+81) 3 3434 0181 - Japan

(+65) 738 5655 - Singapur

(+1) 425 446 5500 - weltweit

Fluke-Website: www.fluke.com.

Registrierung des Meßgerätes: www.fluke-warranty.com.

“Warnungen” und “Vorsichtshinweise”

Eine “WWarnung” identifiziert gefährliche Bedingungen und

Aktivitäten, die Körperverletzungen oder Tod verursachen können.

“Vorsicht” identifiziert Bedingungen und Aktionen, die das

Meßgerät oder die zu prüfende Ausrüstung beschädigen können.

Unsichere Spannung

Dieser Alarm signalisiert das Vorhandensein einer pot enti ell

gefährlichen Spannung. Das Symbol

Meßgerät eine Spannung ≥ 30 V oder eine Überspannung (OL)

feststellt.

Prüfleiteralarm

Das Messen mit einem Prüfleiter an einem falschen

Anschluß kann das Meßgerät beschädigen oder

Körperverletzungen verursachen.

LEAd

richtigen Anschlüssen angeschlossen si nd, kurz angez ei gt, wenn

der Drehschalter in eine beliebige A-Position oder von

A-Position in eine andere Position geschaltet wird.

Y wird angezeigt, wenn das

W

Warnung

wird als Erinnerung zum Prüfen, ob die Prüfleiter an den

einer

1

Models 110, 111 & 112

Bedienungshandbuch

Batteriesparmodus (“Ruhemodus”)

Das Meßgerät wechselt automatisch in den “Ruhemodus” und

löscht die Anzeige, wenn das Gerät eingeschaltet ist und

20 Minuten lang nicht gebraucht wird. Um den Ruhemodus zu

deaktivieren, die Taste Hz beim Einschalten des Meßgeräts

gedrückt halten. Der Ruhemodus ist im MIN-MAX-AVG-Modus

immer deaktiviert.

Anschlüsse

10 A

FUSED

COMAV

3

aej01f.eps

1

2

Nr. Beschreibung

Eingang für Wechselstrom- und Gleichstrommessungen

1

bis 10 A bzw. 20 A Überlast für bis zu 30 Sekunden und

für Frequenz des Stroms.

Gemeinsame Rückleitung für alle Messungen.

2

Eingang für Spannungs-, Kontinuitäts-, Widerstands-,

3

Kapazitäts- und Spannungsfrequenzmessungen sowie

Diodenprüfung.

Drehschalterpositionen

Schalterposition Meßfunktion

K

Hz (Taste)

L

Hz (Taste)

R

e

G

E

(Modelle 111 und 112)

?

Hz (Taste)

(Modelle 111 und 112)

A

Hz (Taste)

Hinweise: Wechselspannung und Wechselstromstärke wechselstrom-

gekoppelt, Effektivwert, bis 500 Hz.

Wechselspannung von 300 mV bis 600 V.

Frequenz von 5 Hz bis 50 kHz.

Gleichspannung von 1 mV bis 600 V.

Frequenz von 5 Hz bis 50 kHz.

Piepser aktiviert bei < 20 Ω, deaktiviert bei

> 250 Ω.

Widerstand von 0,1 Ω bis 40 MΩ.

Diodenprüfung. Zeigt OL oberhalb von

2,4 V an.

Farad von 1 nF bis 9999 µF.

Wechselstrom von 3 A bis 10 A.

(20 A Überlast für 30 Sekunden maximal.)

>10,00-Anzeige blinkt.

>20 A, OL wird angezeigt.

Frequenz von 50 Hz bis 5 kHz.

Gleichstrom von 0,001 A bis 10 A.

(20 A Überlast für 30 Sekunden maximal.)

>10,00-Anzeige blinkt.

>20 A, OL wird angezeigt.

Frequenz von 50 Hz bis 5 kHz.

2

True RMS Multimeters

Anzeige

Anzeige

5

4

3

2

1

13

Nr. Symbol Bedeutung

1

2

3

4

5

6

7

12

s

R

O

Y

K

M

X W V

nµF

mVA

Mk

e

kHz

6

11

14

Meßgerät ist auf Kontinuitätsfunktion

eingestellt.

Diodenprüfung.

Negative Meßwerte.

Unsichere Spannung. Spannung

≥ 30 V oder Spannungsüberlastbedingung (OL).

Anzeigehaltemodus (HOLD) ist

aktiviert. Anzeige friert aktuellen

Meßwert ein.

Im MIN-MAX-AVG-Modus ist MINMAX-AVG-Aufzeichnung pausiert.

MIN MAX AVG ist akti vie r t.

Höchst-, Niedrigst- oder

Durchschnittsmeßwert

Meßeinheiten.

Nr. Symbol Bedeutung

8

DC AC

9

N

7

8

7

9

10

15

aej02f.eps

10

610000 mV

11

(Balkenanzeige)

12 Auto Range

Manual Range

13

±

14

0L

15

LEAd

diSC

EEPr

EEPr

Err

CAL

Err

Wird angezeigt, während der Kondensator

entladen wird. Nur in der Funktion Kapazität.

Daten vom EEPROM können nicht gelesen

werden. Den Betriebsschalter aus-, dann wieder

einschalten. Wird die Nachricht weiter angezeigt,

das Meßgerät reparieren lassen.

Ungültige EEPROM-Daten. Das Meßgerät

reparieren lassen.

Ungültige Kalibrierdaten. Das Meßgerät

kalibrieren.

Gleichstrom (DC), Wechselstrom (AC).

Batterie unverzüglich ersetzen.

Alle möglichen Segmente des

Bereichanzeigers.

Analoganzeige.

Automatische Bereichswahl: das

Meßgerät wählt den Bereich mit

der besten Auflösung aus.

Manuelle Bereichswahl: Der

Bediener wählt den Bereich aus.

Balkenanzeigepolarität.

Der Eingang überschreitet den

ausgewählten Bereich.

W

Prüfleiteralarm.

Wird kurz angezeigt, wenn der

Drehschalter in eine beliebige

A-Position oder von einer

A-Position in eine andere Position

geschaltet wird.

Fehlermeldungen

3

Models 110, 111 & 112

Bedienungshandbuch

MIN-MAX-AVG-Aufzeichnungsmodus

Im MIN-MAX-AVG-Aufzeichnungsmodus werden die niedrigsten

und die höchsten Eingangswerte aufgezeichnet und der laufende

Durchschnitt aller Meßwerte berechnet. Wenn ein neuer Höchstoder Niedrigstwert gemessen wird, piepst das Meßgerät.

Am Meßgerät die gewünschte Funktion und den gewünschten

Bereich einstellen.

⇒ MIN MAX drücken, um den MIN-MAX-AVG-Modus zu

aktivieren.

M

Aktivierung des MIN-MAX-AVG-Modus gemessene Meßwert

wird angezeigt.

⇒ Die Taste MIN MAX drücken, um der Reihe nach den

Niedrigstwert (MIN), den Durchschnittswert (AVG) und den

aktuellen Wert anzuzeigen.

⇒ Um die MIN-MA X -AV G -Aufz eic hnung zu pausieren, ohne

aufgezeichnete Werte zu löschen, HOLD drücken.

wird angezeigt.

⇒ Um die MIN-MA X -AV G -Aufz eic hnung zu reaktivieren, HOLD

noch einmal drücken.

⇒ Um den Modus zu beenden und gespeicherte Werte zu

löschen, MIN MAX mindestens 1 Sekunde lang drücken oder

den Drehschalter drehen.

und MAX werden angezeigt, und der höchste seit

K

Anzeigehaltemodus (HOLD)

W

Warnung

Zur Vermeidung von Stromschlag bei aktiviertem

Anzeigehaltemodus (HOLD) beachten, daß sich die

Anzeige nicht verändert, wenn eine andere Spannung

angelegt wird.

Im Anzeigehaltemodus HOLD friert das Meßgerät die Anzeige ein.

⇒ HOLD drücken, um den Anzeigehaltemodus zu aktivieren.

K

(

wird angezeigt.)

⇒ Um zu beenden und zu Normalbetrieb zurückzukehren,

HOLD drücken oder den Drehschalter in eine andere Position

drehen.

Hintergrundbeleuchtung (nur Modell 112)

T

drücken, um die Hintergrundbeleuchtung ein- bzw.

auszuschalten. Die Hintergrundbeleuchtung wird nach 2 Minuten

automatisch ausgeschaltet.

Um die automatische 2-Minuten-Hintergrundbeleuchtungsabschaltung zu deaktivieren, die Taste T beim Einschalten des

Meßgeräts gedrückt halten.

4

True RMS Multimeters

Manuelle und automatische Bereichswahl

Manuelle und automatische Bereichswahl

Das Meßgerät verfügt über manuelle und automatische

Bereichswahl.

⇒ Im Modus “Automatische Bereichswahl” wählt das Meßgerät

den Bereich mit der besten Auflösung aus.

⇒ Im Modus “Manuelle Bereichswahl”, der den automatischen

Modus übersteuert, wählt der Bediener den Bereich aus.

Unmittelbar nach dem Einschalten befindet sich das Meßgerät im

automatischen Modus und zeigt Auto Range an.

1. Um die manuelle Bereichswahl zu aktivieren, die Taste

RANGE drücken. Manual Range wird angezeigt.

2. Im Modus “Manuelle Bereichswahl” RANGE drücken, um den

Bereich zu erhöhen. Nach dem höchsten Bereich zeigt das

Meßgerät wieder den niedrigsten Bereich an.

Hinweis

Der Bereich kann im MIN-MAX-AVG- und

Anzeigehaltemodus HOLD nicht manuell verändert werden.

Wenn

RANGE

Anzeigehaltemodus HOLD gedrückt wird, piepst das

Meßgerät, um eine ungültige Bedienung zu signalisieren,

und der Bereich bleibt unverändert.

3. Um die manuelle Bereichswahl zu beenden, RANGE

mindestens 1 Sekunde lang drücken oder den Drehschalter

drehen.

Das Meßgerät kehrt zu automatischer Bereichswahl zurück

und Auto Range wird angezeigt.

im MIN-MAX-AVG- oder

Einschaltoptionen

Um eine Einschaltoption zu aktivieren, die entsprechende Taste

beim Einschalten des Meßgeräts mindestens 1 Sekunde gedrückt

halten.

Einschaltoptionen werden deaktiviert, wenn das Meßgerät

ausgeschaltet wird.

Taste Einschaltoptionen

HOLD

MIN MAX

Hz

S

Schaltet alle Anzeigesegmente ein.

HOLD loslassen, um fortzufahren; die

Softwareversionsnummer wird kurz angezeigt, und

das Meßgerät kehrt zu Normalbetrieb zurück.

Deaktiviert Piepser.

Deaktiviert die automatische Ausschaltfunktion

(“Ruhemodus”).

Deaktiviert die automatische 2-MinutenHintergrundabschaltung. (Nur Modell 112.)

5

Models 110, 111 & 112

Bedienungshandbuch

Grundlegende Meßfunktionen

Die Abbildungen auf den folgenden Seiten zeigen, wie

grundlegende Meßfunktionen durchgeführt werden.

Beim Anklemmen der Prüfleitungen an den Stromkreis oder das

Gerät den gemeinsamen Prüfleiter (COM) vor der spannungs-

führenden Leitung anschließen. Beim Abklemmen der

Prüfleitungen die spannungsführende Prüfleitung vor der

gemeinsamen Prüfleitung abtrennen.

W

Warnung

Zur Vermeidung von Stromschlägen, Verletzungen oder

Schäden am Meßgerät vor Widerstands-, Kontinuitäts-,

Dioden- oder Kapazitätsprüfungen sicherstellen, daß

die Netzstromverbindung abgetrennt ist und alle

Hochspannungskondensatoren entladen sind.

Hinweis

Beim Ablesen von Wechselspannung oder -stromstärke

(zum korrekten Messen verzerrter Signalformen durch den

integrierten RMS-Wandler) steigt die Meßwerteinschwingzeit am unteren Ende der Wechselspannungs- und

Wechselstromstärkebereiche auf mehrere Sekunden.

Das Meßgerät ist nicht zur Verwendung mit

Stromklemmenzubehör ausgelegt.

Messen von Wechselspannung und Gleichspannung

V Wechselspannung

V

V Gleichspannung

V

aej03f.eps

6

True RMS Multimeters

Grundlegende Meßfunktionen

Messen von Widerstand

Messen von Kapazität

aej04f.eps

Kontinuitätsprüfungen

Hinweis

Die Kontinuitätsfunktion ist die beste Methode zum

schnellen, bequemen Prüfen von offenen Schaltungen und

Kurzschlüssen. Für maximale Genauigkeit beim Messen

(e)

von Widerstand die Widerstandsfunktion

des Meßgeräts

verwenden.

aej06f.eps

aej05f.eps

7

Models 110, 111 & 112

Bedienungshandbuch

Prüfen von Dioden

Gute Diode Gute Diode

Vorwärts-Bias

Schlechte Diode

Offen

Einzelpiepton

Rückwärts-Bias

Schlechte Diode

und

kurzgeschlossen

aej07f.eps

Messen von Wechselstromstärke und Gleichstromstärke

(Modelle 111 und 112)

W

Warnung

Zur Vermeidung von Verletzungen und Beschädigung

des Meßgeräts folgende Vorschriften einhalten:

• Unter keinen Umständen eine Schaltkreismessung

vornehmen, wenn das Ruhepotential zur Masse

> 600 V beträgt.

• Vor Gebrauch die Sicherung des Meßgeräts prüfen.

(Siehe “Prüfen der Sicherung”.)

• Die richtigen Anschlüsse, die richtige

Drehschalterposition und den richtigen Bereich für

die jeweils anstehende Messung auswählen.

• Die Sonden nie parallel zu einer Schaltung oder

Komponente plazieren, wenn die Prüfleitungen in die

Strombuchsen eingesteckt sind.

Die Stromversorgung abtrennen (OFF), den Stromkreis

unterbrechen, das Meßgerät in Serie einfügen und die

Stromversorgung wieder einschalten.

A

A

aej08f.eps

8

True RMS Multimeters

Verwendung der Balkenanzeige

Messen von Frequenz

W

Achtung

Zur Vermeidung von Stromschlag das Balkendiagramm

für Frequenzen > 500 Hz nicht beachten. Beträgt die

Frequenz des gemessenen Signals > 500 Hz, zeigt das

Balkendiagramm keine relevanten Werte an.

Das Meßgerät mißt die Frequenz eines Signals, indem es zählt,

wie oft pro Sekunde das Signal einen Trigger (Auslösepegel)

überschreitet. Der Auslösepegel ist 0 V, 0 A für alle Bereiche.

Wechsel-/Gleichspannungsfrequenz Wechselstromfrequenz

Hz

V

Hz

V

Hz

Hz

A

A

Hz

aej09f.eps

⇒ Hz drück en, um die Frequenzm eßfunktion ein- bzw.

auszuschalten.

⇒ In der Frequenzfunktion zeigen die Balkenanzeige und der

Bereichanzeiger die vorhandene Wechsel-/Gleichspannung

bzw. Wechsel-/Gleichstromstärke an.

⇒ Für genauere Meßwerte mit Hilfe der manuellen

Bereichswahl immer niedrigere Bereiche auswählen.

Verwendung der Balkenanzeige

Die Balkenanzeige gleicht der Nadel eines analogen Meßgeräts.

Die Balkenanzeige hat auf der rechten Seite einen Überlastanzei-

) und auf der linken Seite einen Polaritätsanzeiger (±).

ger (

Da die Balkenanzeige ungefähr vierzigmal pro Sekunde

aktualisiert wird, zehnmal schnell er als die Di git al anzei ge, i st sie

für Spitzen- und Nulljustierungen nützlich.

Die Balkenanzeige ist beim Messen von Kapazität deaktiviert. In

der Frequenzfunktion zeigen die Balkenanzeige und der

Bereichanzeiger die unterlegte Spannung bzw. Stromstärke an.

Die Anzahl der leuchtenden Segmente repräsentiert, falls nicht in

einem 10-A-Bereich, den gemessenen Wert im Verhältnis zum

Vollausschlag des ausgewählten Bereichs.

Beispiel: Im 60-V-Bereich (siehe unten) repräsentieren die

Haupteinteilungen auf der Skala 0, 30 und 60 V. Ein Eingang von

Hz

−30 V aktiviert das Minuszeichen und die Segmente bis zur Mitte

der Skala.

aej11f.eps

Reinigung

Das Gehäuse mit einem feuchten Lappen und mildem Reinigungsmittel abwischen. Keine Schleifmittel oder Lösungsmittel

verwenden. Schmutz und/oder Feuchtigkeit an den Anschlüsse n

kann die Meßwerte beeinträchtigen.

9

Models 110, 111 & 112

Bedienungshandbuch

Prüfen der Sicherung (Modelle 111 und 112)

W

Warnung

Zur Vermeidung von Stromschlag oder Verletzungen

vor dem Ersetzen der Sicherungen die Prüfleitungen

und alle Eingangssignale entfernen.

Die Sicherung wie unten abgebildet prüfen.

<.5

Ω

OK

OK

Ersetzen der Batterie und Sicherung

W

Warnung

Zur Vermeidung von Stromschlag, Verletzungen oder

Beschädigung des Meßgeräts folgende Vorschriften

einhalten:

• Vor dem Öffnen des Gehäuses oder der

Batteriefachabdeckung die Prüfleitungen abnehmen.

• AUSSCHLIE SSLICH Sicherungen verwend en, die die

spezifizierten Nennwerte erfüllen (Stromstärke,

Unterbrechung, Spannung, Auslö segeschwindigkeit).

• Zur Vermeidung falscher Meßwerte die Batterie

ersetzen, sobald die Ladeanzeige (

wird.

B ) eingeblendet

Entfernen der Batteriefachabdeckung:

1. Schraube von der Batteriefachabdeckung lösen.

2. Die Fingervertiefung verwenden, um die Abdeckung leicht

anzuheben.

3. Die Abdeckung gegen die untere Kante des Meßgeräts

schieben, um die Verriegelung zu lösen.

4. Die Abdeckung senkrecht anheben, um sie vom Gehäuse zu

trennen.

Die Batterie paßt in die in die Batteriefachabdeckung in t egrierte

Halterung. Die Batteriefachabdeckung wieder gerade auf das

Gehäuse aufsetzen, so daß sie einrastet. Die Batterie nicht di rekt

in das Gehäuse installieren.

Sicherung Batterie

aej12f.eps

aej13f.eps

Sicherung F1 (Modelle 111 und 112) 11 A, 1000 V, FLINKE

SICHERUNG. Nennwert Mindest-Abschaltst rom 17000 A.

Ausschließlich Fluke-Ersatzteilnummer 803293 verwenden.

Batterie, 9 V Alkalibatteri e, NEDA 1604A / IEC 6LR61

10

True RMS Multimeters

Spezifikationen

Spezifikationen

Genauigkeit ist spezifiziert für die Dauer von einem Jahr ab Kalibrierung, bei Betriebstemperaturen von 18 °C bis 28 °C mit relativer Feuchtigkeit

von 0 % bis 95 %. Die Genauigkeitsspezifikationen werden wie folgt angegeben:

Höchste Spannung zwischen beliebigem Anschluß und Masse: 600 V

Überspannungsschutz 6 kV Spitze gemäß IEC 61010.1-95

W

Sicherung für A-Eingang: 11 A, 1000 V, flinke Sicherung

Anzeige: Digital: 6000 Zählimpulse, 4 Aktualisierungen/Sekunde

Temperatur:

Temperaturkoeffizient 0,1 X (spezifizierte Genauigkeit) / °C

Elektromagnetische Verträglichkeit: Leistung ≥ 3 V/m ist nicht spezifiziert .

Relative Feuchtigkeit: Nichtkondensierend < 10 °C

Batterielebensdauer: Alkalibatterie: 300 Stunden, typisch, ohne Hintergrundbeleuchtung

Größe mit Halterung (H x B x L): 4,6 cm x 9,6 cm x 16,0 cm

Gewicht: 350 g

Sicherheitsnormen:

Zertifizierung: UL (3111),

Balkenanzeige: 33 Segmente, 40 Aktualisierungen/Sekunde

Frequenz: 9999 Zählimpulse

Kapazität: 9999 Zählimpulse

−10 °C bis +50 °C

Betrieb:

Lagerung:

für <18 °C oder >28 °C

0 % bis 95 % bei 10 °C bis 30 °C

0 % bis 75 % bei 30 °C bis 40 °C

0 % bis 45 % bei 40 °C bis 50 °C

ANSI/ISA S82.01-1988, CSA C22.2 Nr. 231 und IEC 61010-1-95 Überspannungskategorie III

(CAT III), 600 V.

−30 °C bis +60 °C

P

CSA, TÜV,

,

;

(N10140)

± ( [ % des Meßwerts ] + [ Zählimpulse ] )

11

Models 110, 111 & 112

Bedienungshandbuch

Genauig k eit ± ( [ % des Meßwerts ] + [ Zählimp ulse ] )

Funktion Bereich Auflösung Modell 110 Modell 111 Model l 1 1 2

Volt Wechselspannung

Effektivwert

(50 Hz bis 500 Hz)

Volt Gleichspannung 6000 mV

Kontinuität 600 Ω 1 Ω Piepser garantiert ein bei < 20 Ω; Piepser garantiert aus bei

Ohm 600,0 Ω

Diodenprüfung 2,200 V 0,001 V 0,9 % + 2

Kapazität

Ampere Wechselstrom –

Effektivwert

(50 Hz bis 500 Hz)

(Modelle 111 und 112)

4

5

1,2

-

6000 mV

6,000 V

60,00 V

600,0 V

6,000 V

60,00 V

600,0 V

6,000 kΩ

60,00 kΩ

600,0 kΩ

6,000 MΩ

40,00 MΩ

1000 nF

10,00 µF

100,0 µF

3

3

1 mV

0,001 V

0,01 V

0,1 V

1 mV

0,001 V

0,01 V

0,1 V

0,1 Ω

0,001 kΩ

0,01 kΩ

0,1 kΩ

0,001 MΩ

0,01 MΩ

1 nF

0,01 µF

0,1 µF

1,0 % + 3 1,0 % + 3 1,0 % + 3

0,7 % + 2 0,7 % + 2 0,7 % + 2

> 250 Ω; erkennt offene Schaltkreise und Kurzschlüsse von

250 µs und länger.

0,9 % + 2

0,9 % + 1

0,9 % + 1

0,9 % + 1

0,9 % + 1

1,5 % + 3

1,9 % + 2

1,9 % + 2

1,9 % + 2

10000 µF1 µF 100 µF - 1000 µF: 1,9 % + 2

>1000 µF: 10 % + 90 typisch

10,00 A kontinuierlich

oder 20 A Überlast für

maximal 30 Sekunden

0,01 A Nicht zutreffend 1,5 % + 3 1,5 % + 3

0,9 % + 2

0,9 % + 1

0,9 % + 1

0,9 % + 1

0,9 % + 1

1,5 % + 3

1,9 % + 2

1,9 % + 2

1,9 % + 2

0,9 % + 2

0,9 % + 1

0,9 % + 1

0,9 % + 1

0,9 % + 1

1,5 % + 3

1,9 % + 2

1,9 % + 2

1,9 % + 2

12

True RMS Multimeters

Genauig k eit ± ( [ % des Meßwerts ] + [ Zählimp ulse ] )

Funktion Bereich Auflösung Modell 110 Modell 111 Modell 112

Ampere Gleichstrom

(Modelle 111 und 112)

Hz6 (V- oder A-Eingang ) 99,99 Hz

MIN-MAX-AVGGenauigkeit und Ansprechzeit

1. Alle Wechselspannungsbereiche sind von 5 % bis 100 % des Bereichs spezifiziert.

2. Spitzenfaktor von ≤ 3 bei Vollausschlag bis zu 300 V, linear abnehmend bis Spitzenfaktor ≤ 1,5 bei 600 V.

3. Der 6000-mV-Bereich kann nur mit manuelle r Be reic hsw a hl aktivi e rt wer de n.

4. Für Schichtkondensatoren.

5. Spitzenfaktor ≤ 3. Die Wechselstromstärke ist unterhalb von 3 A nic ht spezifiziert.

6. Für Volt ist Hz von 5 Hz bis 50 kHz spezifiziert, für Ampere von 50 Hz bis 5 kHz.

6,000 A

10,00 A kontinuierlich oder 20 A

Überlast für maximal 30 Sekunden

999,9 Hz

9,999 kHz

50,00 kHz

Die Genauigkeit entspricht der spezifizierten Genauigkeit der Meßfunktion ± 12 Stellen für Änderungen >275 ms

Dauer (± 40 Stellen in Wechselstrom). Typische Ansprechzeit: 100 ms bis 80 % des Signals, ausgenommen V

Wechselspannung und Ampere Wechs elstrom.

0,001 A

0,01 A Nicht zutreffend 1,0 % + 3 1,0 % + 3

0,01 Hz

0,1 Hz

0,001 kHz

0,01 kHz

0,1 % + 2 0,1 % + 2 0,1 % + 2

Spezifikationen

Funktion

Volt

Wechselspannung

Volt

Gleichspannung

Ohm

Diodenprüfung

Eingangsimpedanz

(nominell) Gleichtaktunterdrückungsverhältni s Gegentaktunterdrückung

> 5 MΩ < 100 pF > 60 dB bei Gleichstrom, 50 Hz oder 60 Hz

> 10 MΩ < 100 pF > 100 dB bei Gleichstrom, 50 Hz oder 60 Hz > 50 dB bei 50 Hz oder 60 Hz

Spannung bei Vollausschlag

Leerlaufprüfspannung Bis 6 MΩ 40 MΩ Kurzschlußstrom

< 1,5 V Gleichspannung < 600 mV Gleichspannung < 1,5 V DC < 500 µA

2,4 V bis 3,0 V

Gleichspannung

2,400 V Gleichspannung 1,2 mA typisch

13

Models 110, 111 & 112

Bedienungshandbuch

14

Models 110, 111 & 112

Multimeters

Calibration Information

Introduction

The Fluke Model 110, Model 111, and Model 112 True RMS Multimeters (hereafter "the Meter") are

battery-powered, with a 6000-count display and a bar graph.

This calibration information applies to all three models. All figures show the Model 112.

The Meter measures or tests the following:

• AC and DC voltage

• Resistance

• Continuity

• Diodes

• Frequency

• Capacitance

• AC and DC current (Model 111 and Model 112)

®

"Warning" and "Caution" Statements

A "WWarning" statement identifies hazardous conditions and actions that could cause bodily harm or

death.

A "Caution" statement identifies conditions and actions that could damage the Meter or the equipment

under test.

Unsafe Voltage Symbol

To alert you to the presence of a potentially hazardous voltage, the Y symbol is displayed when the Meter

detects a voltage ≥ 30 V or a voltage overload (OL) condition.

Test Lead Alert

WWarning

Personal injury or damage to the Meter can occur if you attempt to make a

measurement with a lead in an incorrect terminal.

To remind you to check that the test leads are in the correct terminals, LEAd is displayed briefly when you

move the rotary switch to or from

These Meters meet CAT III IEC 61010-1-95 standards. The IEC 61010-1-95 safety standard defines four

overvoltage categories (CAT I to IV) based on the magnitude of danger from transient impulses. CAT III

meters are designed to protect against transients in fixed-equipment installations at the distribution level.

any A position.

PN 1608592 March 2001 Rev.1, 9/03

©2001-2003 Fluke Corporation. All rights reserved. Printed in U.S.A.

1

Models 110, 111 & 112

Calibration Information

WWarning

To avoid electric shock or injury, do not perform the performance tests or

calibration procedures unless you are qualified to do so.

The information provided in this manual is for the use of qualified personnel

only.

This document provides the information necessary to calibrate and verify the performance of the Fluke

Model 110, 111, and 112 Multimeters.

The following information is included:

• Safety Information and international symbols (Page 3)

• Specifications (Pages 4 - 5)

• Testing the fuse (Page 6)

• Replacing the battery and fuse (Pages 7 - 8)

• Replacing the LCD (Pages 9 - 10)

• Performance tests (Pages 10 - 12)

• Calibrating the Meter (Pages 13 - 14)

• Display messages (Page 14)

• Cleaning the Meter (Page 15)

• User-replaceable parts (Page 16)

See the Models 110, 111 & 112 Users Manual for operating instructions.

Warranty and Service Information

The Meter has a three year limited warranty, which is printed in the Users Manual.

To contact Fluke, call:

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Fluke’s Web site at www.fluke.com.

2

Safety Information

Safety Information

WWarnings and Precautions

To avoid possible electric shock or personal injury, follow these guidelines:

• Use the Meter only as specified in this manual or the protection provided by the Meter might

be impaired.

• Do not use the Meter or test leads if they appear damaged, or if the Meter is not operating

properly.

• Always use proper terminals, switch position, and range for measurements.

• Verify the Meter’s operation by measuring a known voltage. If in doubt, have the Meter

serviced.

• Do not apply more than the rated voltage, as marked on the Meter, between terminals or

between any terminal and earth ground.

• Use caution with voltages above 30 V ac rms, 42 V ac peak, or 60 V dc. These voltages pose a

shock hazard.

• To avoid false readings that can lead to electric shock and injury, replace the battery as soon

as the low battery indicator (

• Disconnect circuit power and discharge all high-voltage capacitors before testing resistance,

continuity, diodes, or capacitance.

N) appears.

• Do not use the Meter around explosive gas or vapor.

• When using test leads or probes, keep your fingers behind the finger guards.

• Remove test leads from the Meter before opening the battery door or the Meter case.

International Symbols

The following international symbols appear in this document and on the Meter.

AC (Alternating Current)

DC (Direct Current)

AC or DC

Fuse Double insulated

Important Information. Refer to the

manual.

Battery (Low battery when shown on the

display)

Inspected and licensed by TÜV Product Services

LISTED

950 Z

N10140

Earth ground

Conforms to European Union directives

Canadian Standards Association

Underwriters Laboratories, Inc.

Conforms to relevant Australian standards

3

Models 110, 111 & 112

Calibration Information

Specifications

Accuracy is specified for 1 year after calibration, at operating temperatures of 18 °C to 28 °C (64 °F to 82 °F), with

relative humidity at 0 % to 95 %.

The accuracy specifications take the form of: ± ( [ % of Reading ] + [ Counts ] )

Maximum voltage between any

terminal and earth ground:

Surge Protection: 6 kV peak per IEC 61010-1-95

W Fuse for A input: 11 A, 1000 V FAST Fuse

600 V

Display: Digital:

Bar Graph:

Frequency:

Capacitance:

Temperature: Operating:

Storage:

6,000 counts, updates 4/sec

33 segments, updates 40/sec

9,999 counts

9,999 counts

−10 °C to +50 °C

−30 °C to +60 °C

Temperature Coefficient: 0.1 x (specified accuracy)/ °C for <18 °C or > 28 °C

Electromagnetic Compatibility: Performance ≥ 3 V/m is not specified.

Relative Humidity: Noncondensing < 10 °C

0 % to 95 % @ 10 °C to 30 °C

0 % to 75 % @ 30 °C to 40 °C

0 % to 45 % @ 40 °C to 50 °C

Battery Life: Alkaline: 300 hours typical, without backlight

Size, with Holster (H x W x L): 4.6 cm x 9.6 cm x 16.0 cm

Weight: 350 g

Safety Compliance: ANSI/ISA-S82.01-1994, CSA C22.2 No 1010.1-92 and IEC 61010-1-95

Overvoltage Category III (CAT III), 600 V

Certifications: UL (3111), P, CSA, TÜV,

; (N10140)

Accuracy ± ( [ % of Reading ] + [ Counts ] )

Function Range Resolution Model 110 Model 111 Model 112

AC Volts

(50 Hz to 500 Hz)

1,2

- True RMS

6000 mV

6.000 V

60.00 V

600.0 V

DC Volts 6000 mV

6.000 V

60.00 V

600.0 V

3

1 mV

0.001 V

0.01 V

1.0 % + 3 1.0 % + 3 1.0 % + 3

0.1 V

3

1 mV

0.001 V

0.7 % + 2 0.7 % + 2 0.7 % + 2

0.01 V

0.1 V

Continuity 600 Ω 1 Ω Beeper guaranteed on < 20 Ω, guaranteed off > 250 Ω;

detects opens or shorts of 250 µs or longer.

Ohms 600.0 Ω

6.000 kΩ

60.00 kΩ

600.0 kΩ

6.000 MΩ

40.00 MΩ

0.1 Ω

0.001 kΩ

0.01 kΩ

0.1 kΩ

0.001 MΩ

0.01 MΩ

0.9 % + 2

0.9 % + 1

0.9 % + 1

0.9 % + 1

0.9 % + 1

1.5 % + 3

0.9 % + 2

0.9 % + 1

0.9 % + 1

0.9 % + 1

0.9 % + 1

1.5 % + 3

0.9 % + 2

0.9 % + 1

0.9 % + 1

0.9 % + 1

0.9 % + 1

1.5 % + 3

1. AC voltage ranges are specified from 5% of range to 100% of range.

2. Crest factor of ≤ 3 at full scale up to 300 V, decreasing linearly to crest factor ≤ 1.5 at 600 V.

3. The 6000 mV range can only be entered in Manual Range mode. Use the 6000 mVDC range with accessories.

4

Specifications

Specifications (continued)

Accuracy ± ( [ % of Reading ] + [ Counts ] )

Function Range Resolution Model 110 Model 111 Model 112

Diode test 2.200 V 0.001 V 0.9 % + 2

Capacitance

AC Amps5 - True RMS

(50 Hz to 500 Hz)

(Models 111 and 112)

DC Amps

(Models 111 and 112)

Hz6 (V or A input ) 99.99 Hz

MIN MAX AVG

Accuracy and

Response Time

4. For film capacitors.

5. Crest factor of ≤ 3. AC current is not specified below 3A.

6. Hz is specified from 5 Hz to 50 kHz in volts, from 50 Hz to 5 kHz in amps.

Function

Volts AC

Volts DC > 10 MΩ < 100 pF > 100 dB at DC, 50 Hz or 60 Hz > 50 dB at 50 Hz or

Ohms

Diode test

4

Input Impedance

> 5 MΩ < 100 pF > 60 dB at DC, 50 Hz or 60 Hz

Open Circuit Test

1000 nF

10.00 µF

100.0 µF

10000 µF

10.00 A

continuous or

20 A overload

for 30 seconds

maximum

6.000 A

10.00 A

continuous or

20 A overload

for 30 seconds

maximum

999.9 Hz

9.999 kHz

50.00 kHz

Accuracy is the specified accuracy of the measurement function ± 12 digits for changes >200

ms in duration (± 40 digits in AC). Typical response time: 100 ms to 80 % of signal, except V

AC and A AC.

(Nominal) Common Mode Rejection Ratio

Voltage

< 1.5 V DC < 600 mV DC < 1.5V DC < 500 µA

2.4 to 3.0 V DC 2.400 V DC 1.2 mA typical

1 nF

0.01 µF

0.1 µF

1 µF

0.01 A N/A 1.5 % + 3 1.5 % + 3

0.001 A

0.01 A

0.01 Hz

0.1 Hz

0.001 kHz

0.01 kHz

To 6 MΩ 40 MΩ Short Circuit Current

1.9 % + 2

1.9 % + 2

1.9 % + 2

100 µF - 1000 µF: 1.9% + 2

> 1000 µF: 10% + 90 typical

N/A 1.0 % + 3 1.0 % + 3

0.1 % + 2 0.1 % + 2 0.1 % + 2

Full Scale Voltage

1.9 % + 2

1.9 % + 2

1.9 % + 2

1.9 % + 2

1.9 % + 2

1.9 % + 2

Normal Mode

Rejection

60 Hz

5

Models 110, 111 & 112

Calibration Information

Testing the Fuse (Models 111 and 112)

WWarning

To avoid electrical shock or injury, remove the test leads and any input signals

before replacing the fuse.

Test the fuse as shown below.

Ω

<.5

Figure 1. Testing the Fuse

OK

OK

aej12f.wmf

6

Replacing the Battery and Fuse

Replacing the Battery and Fuse

WWarning

To avoid electric shock, injury, or damage to the Meter:

• Remove test leads from the Meter before opening the case or battery door.

• Use ONLY a fuse with the amperage, interrupt, voltage, and speed ratings

specified.

• Replace the battery as soon as the low battery indicator ( N ) appears to

avoid false readings.

To replace the battery

1. Turn the rotary switch to OFF and remove the test leads from the terminals.

2. Lift the tilt stand to access the battery door.

3. Remove the screw from the battery door.

4. Use the finger recess to lift the battery door slightly.

5. Pull the door toward the bottom of the Meter to release the latch.

6. Lift the battery door straight up to separate it from the case. You can now remove and replace the

battery.

The battery fits inside the battery door, which is then inserted straight into the case until it clicks into

place. Do not attempt to install the battery directly into the case.

Figure 2. Replacing the Battery

aej14f.wmf

7

Models 110, 111 & 112

Calibration Information

To replace the fuse (Models 111 and 112)

1. Turn the rotary switch to OFF and remove the test leads from the terminals.

2. Remove the Meter from the protective yellow holster.

3. Remove the battery and battery door.

4. Remove the two screws holding the case together.

5. Remove the bottom case and set it aside.

6. Remove and replace the fuse.

7. Reassemble the case and reinstall the battery, battery door, screws, and holster.

Figure 3. Replacing the Fuse

8

aej15f.wmf