Page 1

3130

Portable Pressure Calibrator

PN 4222409

February 2013

© 2013 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Users Manual

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

To register your product online, visit register.fluke.com

Page 3

Table of Contents

Title Page

Introduction ........................................................................................................ 1

How to Contact Fluke Calibration ..................................................................... 2

Safety Information ............................................................................................. 2

Standard Equipment ........................................................................................... 3

Features .............................................................................................................. 4

Buttons ........................................................................................................... 4

Display ........................................................................................................... 5

Calibrator Interface ........................................................................................ 6

Typical Connections ...................................................................................... 7

Power Options .................................................................................................... 9

Product Startup .................................................................................................. 9

Product Menus ................................................................................................... 9

Top-Level Menu ............................................................................................ 11

Main Menu .................................................................................................... 11

Display Configuration Menu ......................................................................... 12

Zero Function ..................................................................................................... 13

Internal Sensor and Pressure Module (non-absolute) .................................... 13

Absolute Pressure .......................................................................................... 13

Other Menu Controlled Functions ..................................................................... 14

Contrast Main Menu ...................................................................................... 14

Lock or Unlock the Display Configuration ................................................... 14

Save and Recall Menu Setups ....................................................................... 15

Automatic Shutdown ..................................................................................... 15

Activate and Deactivate a Display ................................................................. 16

Damping ........................................................................................................ 16

HART Resistor .............................................................................................. 16

Pump Limits .................................................................................................. 16

Initial Setup and Basic Pressure Generation ...................................................... 17

Pressure Measurement ....................................................................................... 17

Media Compatibility ...................................................................................... 18

External Modules ........................................................................................... 18

Measure and Source Current (4… 20 mA) .................................................... 18

Measure Voltage ............................................................................................ 20

Pressure Switch Test ...................................................................................... 21

Calibrate Transmitters ................................................................................... 23

Use the mA Measurement Function .......................................................... 23

i

Page 4

3130

Users Manual

Calibrate a Pressure-to-Current Transmitter ............................................. 24

Calibrate a Pressure-to-Voltage Transmitter ............................................. 25

%-Error Function ...................................................................................... 26

Storage Capability .............................................................................................. 29

Remote Operation .............................................................................................. 29

Set Up the RS-232 Port for Remote Control ................................................. 30

Change from Remote to Local Operation ...................................................... 31

Command Use ............................................................................................... 31

Character Processing ..................................................................................... 32

Response Data Types .................................................................................... 32

Calibrator Status ............................................................................................ 33

Error Queue ............................................................................................... 33

Input Buffer ............................................................................................... 33

Remote Commands and Error Codes ............................................................ 33

Enter Commands ........................................................................................... 36

Common Commands ................................................................................. 36

Calibrator Commands ............................................................................... 37

Maintenance ....................................................................................................... 43

User-Replaceable Parts and Accessories ........................................................... 43

Specifications ..................................................................................................... 44

Electrical Specification .................................................................................. 44

Pressure ......................................................................................................... 44

Accuracy ........................................................................................................ 44

Loop Power ................................................................................................... 44

Mechanical Specification .............................................................................. 44

Environmental ............................................................................................... 44

Standards and Agency Approval ................................................................... 45

Power ............................................................................................................. 45

ii

Page 5

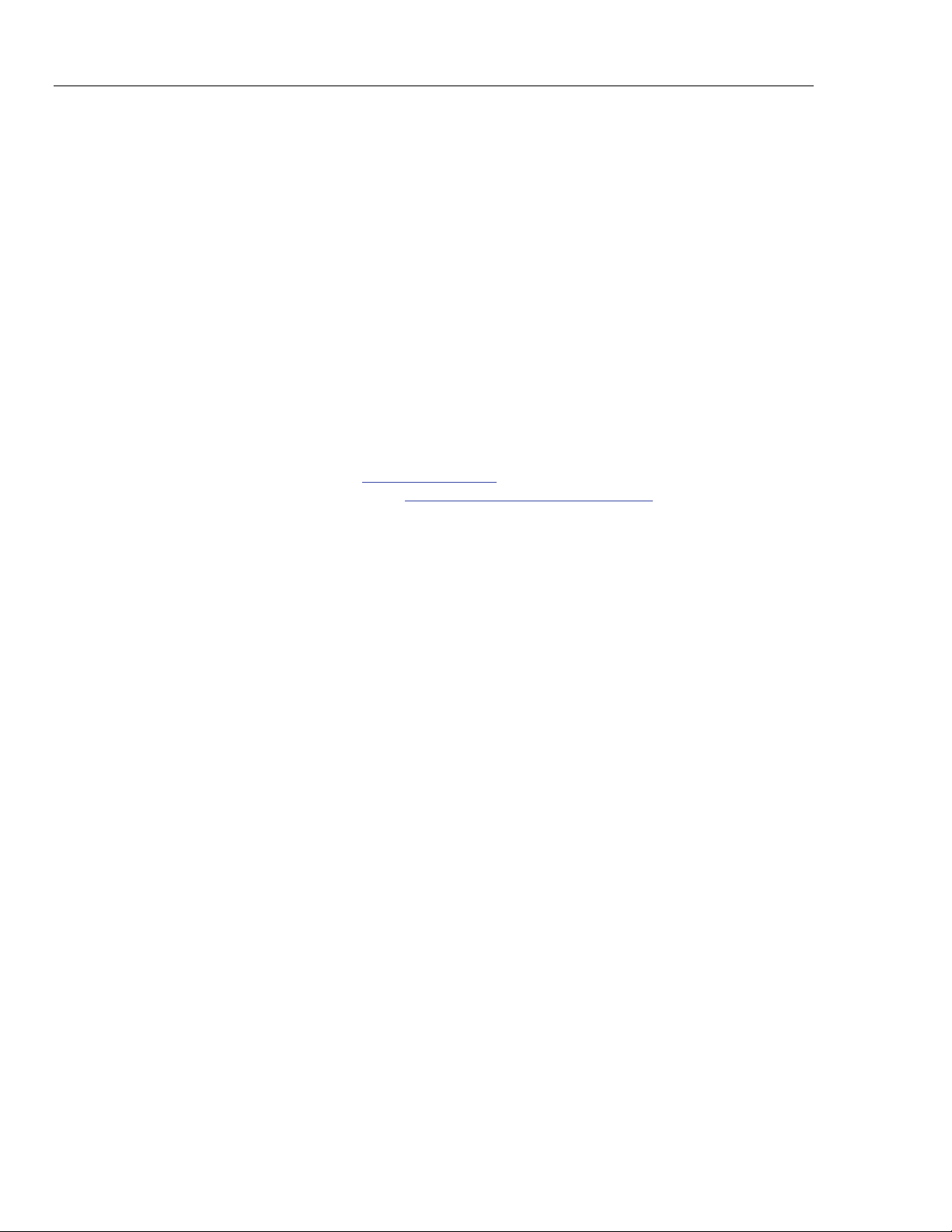

List of Tables

Table Title Page

1. Symbols .................................................................................................................. 3

2. Mode Concurrency ................................................................................................. 13

3. Common Commands .............................................................................................. 33

4. Product Commands ................................................................................................ 34

5. Parameter Units ...................................................................................................... 35

6. Error Codes ............................................................................................................ 36

7. Replaceable Parts ................................................................................................... 43

iii

Page 6

3130

Users Manual

iv

Page 7

List of Figures

Figure Title Page

1. Buttons ................................................................................................................... 4

2. Display ................................................................................................................... 5

3. Controls .................................................................................................................. 6

4. External Pressure Supply ....................................................................................... 7

5. Pressure Supply with Internal Pump ...................................................................... 8

6. Pressure Measurement ........................................................................................... 8

7. Menu Map .............................................................................................................. 10

8. Top-Level Menu ..................................................................................................... 11

9. Main Menu ............................................................................................................. 12

10. Display Configuration Menu .................................................................................. 12

11. Absolute Pressure ................................................................................................... 13

12. Contrast Menu ........................................................................................................ 14

13. Display Configuration Menu .................................................................................. 14

14. Setups Menu ........................................................................................................... 15

15. Auto Shutdown Menu ............................................................................................ 15

16. Active Display Menu ............................................................................................. 16

17. Pressure Module ..................................................................................................... 18

18. Measure and Sourcing Current ............................................................................... 19

19. Measure Voltage .................................................................................................... 20

20. Switch Test Connections ........................................................................................ 21

21. Switch Test Screen ................................................................................................. 21

22. Switch Test Screen (Open) ..................................................................................... 22

23. Opened Switch Reading ......................................................................................... 22

24. Switch Test and Deadband Results ........................................................................ 23

25. Passive and Active Screens .................................................................................... 23

26. Calibrate a Pressure-to-Current Transmitter .......................................................... 24

27. Calibrate a Pressure-to-Voltage Transmitter .......................................................... 25

28. Connections with a Pressure Transmitter with % Error Function .......................... 26

29. Port Setting Screen ................................................................................................. 27

30. Loop Power Screen ................................................................................................ 27

31. Set Unit Screen ....................................................................................................... 27

32. Setting the Upper Limit .......................................................................................... 28

33. % ERROR Screen .................................................................................................. 28

34. Saved Upper and Lower Limits ............................................................................. 28

35. Remote Operation .................................................................................................. 29

v

Page 8

3130

Users Manual

vi

Page 9

Introduction

The Fluke 3130 (the Product) is a portable pressure calibrator that can use two methods

to source pressure:

• An internal, electronic pump that has a range of -12 psi to 300 psi (-0.8 bar to 20 bar)

• An external connection that lets you use externally-sourced, clean, dry air to regulate

pressures to a maximum of 300 psi

Product features include:

• A built-in needle valve for metering in pressure

• Variable volume for small pressure changes

• An internal pressure sensor

• Measurement of 0 V dc to 30 V dc and 0 mA to 24 mA from a unit under test (UUT).

• Sourcing current of 0 mA to 24 mA to a UUT also available

• A 24 V dc loop power supply that uses dedicated front panel jacks. For voltage

transmitters, a dedicated 24 V dc loop power supply is available in volts measure

mode. mA loop power is supplied from the left-most jacks.

• An internal, high-capacity NiMH battery

• A universal power supply (90 V ac to 250 V ac) that can charge the battery pack

while it powers the Product

• Pressure measurement with the internal pressure sensor or with a Fluke 700 Series

external pressure module

• The Product can show pressure units in these different values:

• psi

• mH2O20°C

• MPa

• kPa

• inHg 0°C

• mmHg 0°C

• kg/cm

• mmH

2

O 4°C

2

• inH

• inH

2

2

• cmH

• cmH

• bar

• mbar

O 4°C

O 60°C

O 4°C

2

O 20°C

2

1

Page 10

3130

Users Manual

How to Contact Fluke Calibration

To contact Fluke Calibration, call one of the subsequent telephone numbers:

• Technical Support USA: 1-877-355-3225

• Calibration/Repair USA: 1-877-355-3225

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31-40-2675-200

• Japan: +81-3-6714-3114

• Singapore: +65-6799-5566

• China: +86-400-810-3435

• Brazil: +55-11-3759-7600

• Anywhere in the world: +1-425-446-6110

To see product information and download the latest manual supplements, visit Fluke

Calibration’s website at www.flukecal.com.

To register your product, visit http://flukecal.com/register-product.

Safety Information

A Warning identifies conditions and procedures that are dangerous to the user. A

Caution identifies conditions and procedures that can cause damage to the Product or the

equipment under test.

To prevent possible electrical shock, fire, or personal injury:

• Read all safety Information before you use the Product.

• Use the Product only as specified, or the protection

supplied by the Product can be compromised.

• Do not use the Product around explosive gas, vapor, or in

damp or wet environments.

• Do not use and disable the Product if it is damaged.

• Only assemble and operate high-pressure systems if you

know the correct safety procedures. High-pressure liquids

and gases are hazardous and the energy from them can be

released without warning.

For safe operation and maintenance of the Product:

• Use only Fluke approved power adapters to charge the

battery. See the “User-Replaceable Parts and Accessories”

section.

Warnings

2

Page 11

Portable Pressure Calibrator

Standard Equipment

Symbols used on the Product and in this manual are in Table 1.

Table 1. Symbols

Symbol Meaning Symbol Meaning

Risk of danger. Important

information. See manual.

Pressure Battery

Hazardous voltage. Risk of electrical

shock.

Standard Equipment

Items included with the Product are in the list below. If the Product is damaged or

something is missing, immediately contact Fluke Calibration. See the “How to Contact

Fluke Calibration” section.

Conforms to European Union

directives.

This product complies with the

WEEE Directive (2002/96/EC)

marking requirements. The

affixed label indicates that you

must not discard this

electrical/electronic product in

domestic household waste.

Product Category: With

reference to the equipment types

in the WEEE Directive Annex I,

this product is classed as

category 9 "Monitoring and

Control Instrumentation” product.

Do not dispose of this product as

unsorted municipal waste. Go to

Fluke’s website for recycling

information.

• Printed 3130 Safety Information

• 3130 Manual CD-ROM with multilingual users manuals

• Six 1/8 inch NPT quick connectors for calibration hoses

• Two 3 foot sections of 1/8 inch O.D. hose

• One 1/8 inch NPT female on 1/4 inch NPT female fitting

• One 1/8 inch NPT female on 1/4 inch BSP female fitting

• Thread seal tape

• Test cables (two red, two black)

• Universal power supply

• Traceable calibration certificate

3

Page 12

3130

Users Manual

Features

Product features and user interface information is in the subsequent sections.

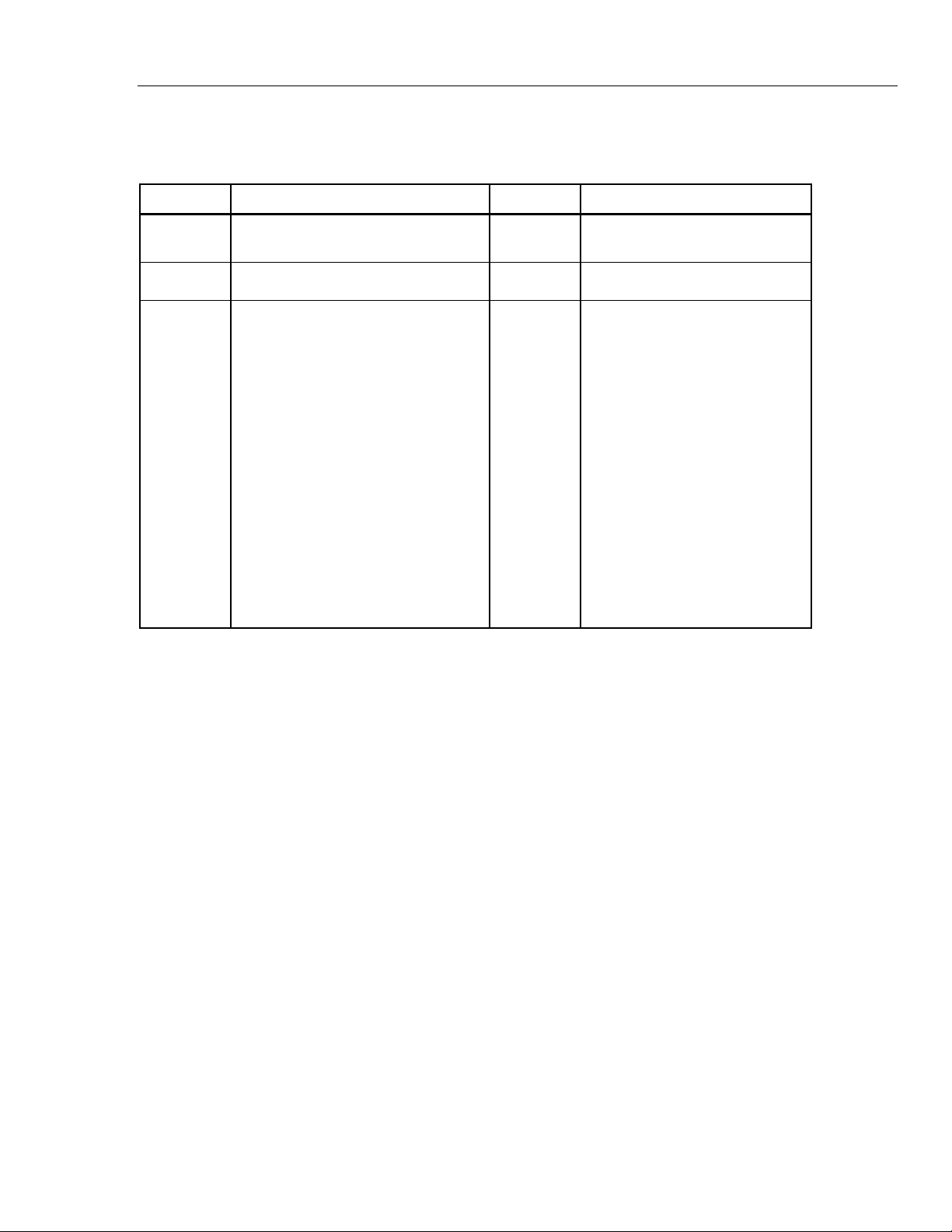

Buttons

The Product buttons are on the left-side of the Product face and are shown in Figure 1.

F1 F2 F3

HOME

ZERO PUMP

Button Description

hbb005.eps

Push to turn on the Product.

, ,

Push to zero pressure measurements.

Push to start the electric pump.

, , ,

Softkeys to configure the Product and move through the Product menus. The button

function changes in relation to the navigation menu.

Push to control mA source/sim and to set pump and % error limits.

Push to go to the Product main screen.

Figure 1. Buttons

4

Page 13

Portable Pressure Calibrator

Features

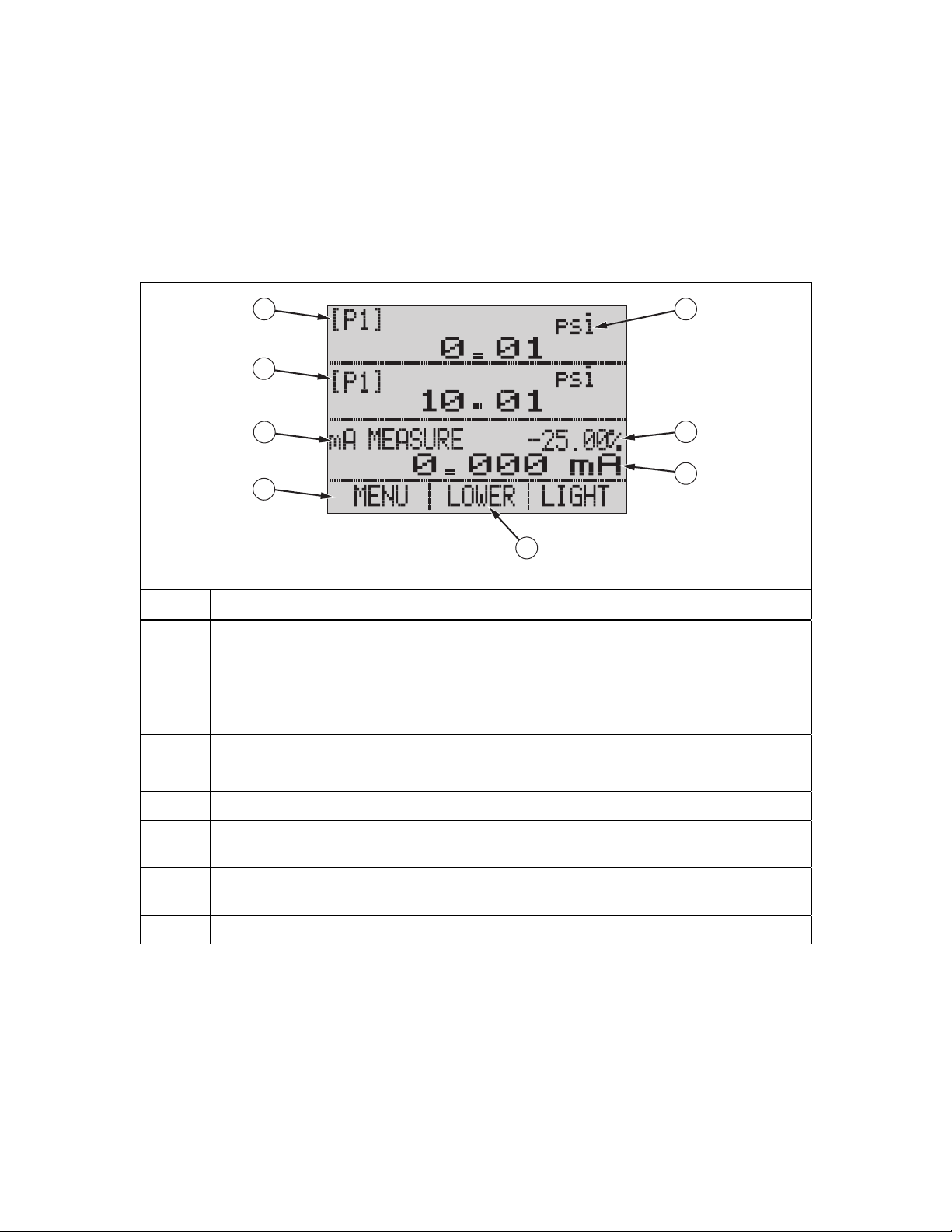

Display

The display can be made up of a maximum of three process measurement sections plus the

menu bar which is always at the bottom of the display. The sections of the display are

referred to by the Product and in this manual as UPPER, MIDDLE, LOWER, and menu bar.

Push the softkeys that correspond to items shown on the menu bar to move through the

Product menus. The arrow keys change values for some menu steps. See “Product Menus”.

The Display sections are shown in Figure 2.

3

4

5

1

2

Item Description

Menu Bar- Access the Product menus and parameters from the menu bar. See the “Product

Menus” section.

Active Display- On the main menu, the middle of the menu bar shows the active display. In

this image, the LOWER display is active. This section of the menu bar can also say UPPER

and MIDDLE. This depends on which section is active.

6

7

8

hbb008.eps

UPPER display section

MIDDLE display section

LOWER display section

Pressure Units- Pressure units are shown in this section of the display. Select from 14

pressure units.

Span Indicator- Percentage of the 4 mA to 20 mA span when the mA or mA loop functions

that are used show in this section of the display.

Primary Parameter- Shows the current measured parameter.

Figure 2. Display

5

Page 14

3130

Users Manual

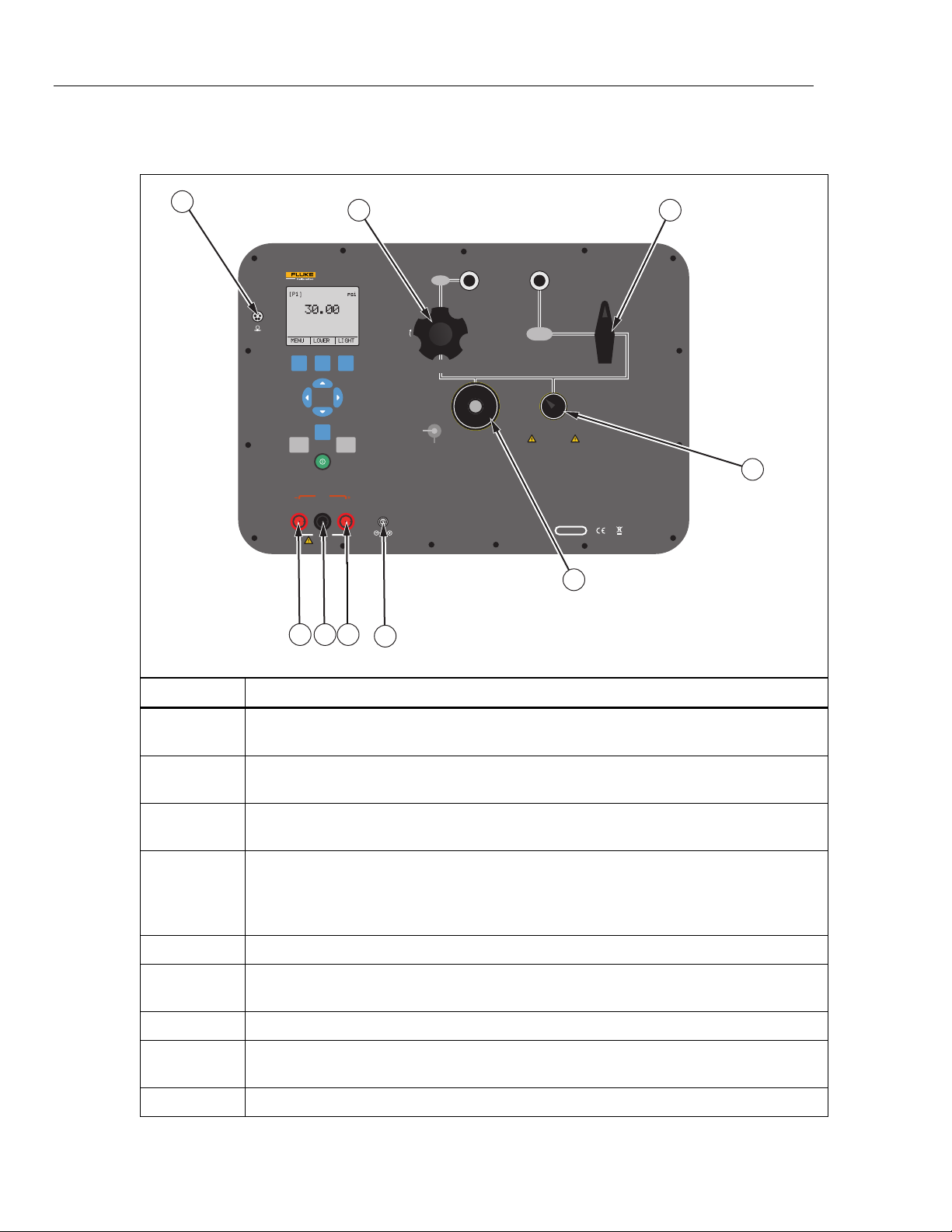

Calibrator Interface

The pressure controls are shown in Figure 3.

9

PORTABLE PRESSURE CALIBRATOR

EXTERNAL

PRESSURE MODULE

3130

F1 F2 F3

HOME

ZERO PUMP

CLOSE VALVE BEFORE

OPERATING PUMP

FILTER

SUPPLY

METERING VALVE

VENT

VENT

FINE

ADJUSTMENT

FINE

ADJUSTMENT

AIR SUPPLY

330 PSI MAX

(2.3 MPa)

OUTPUT

-12 PSI TO 300 PSI

(-8 kPa TO 2 MPa)

PRESSURE

SENSOR

PRESSURE

VACUUM

PUMP

CAUTION

VENT LINE BEFORE MAKING SELECTION

CLOSED

ISOLATION

VALVE

21

3

LOOP

V mA

SWITCH TEST

COM

24 V DC

CHARGE

30 V MAX

16 V DC

5.6 A

SERIAL NO.

FLUKE CORPORATION

EVERETT, WA USA

www.flukecal.com

4

6

78

5

hbb006.eps

Item Description

Supply metering valve. Use the supply metering valve to regulate the incoming air supply.

See the “Typical Connections” section for more.

Isolation valve. This valve isolates the right-most port and pressure sensor from the

Vent/Fine adjust, pump, and Supply Metering Valve.

Pump Pressure/Vacuum. In the + position, the pump operates from 0 psi to 300 psi. In

the - position, the pump runs in vacuum mode, which is 0 psi to -12 psi.

Fine adjust/vent. Use the small silver knob of this valve to bleed off the pressure in a

controlled manner. If left open, it will vent all pressure off safely. The outer-most knob

(black) is a vernier control that varies the volume which finely reduces or increases the

pressure.

Power Adapter input.

24 V power for voltage transmitters. This jack only powered when in Voltage Measure

mode.

Common Jack.

Input Jacks. Use the input jacks for volts and milliamp functions. See the “Measure and

Source Current (4… 20 mA)” and “Measure Voltage” sections. Also used for switch test.

External pressure module connection. See the “External Modules” section.

Figure 3. Controls

6

Page 15

Portable Pressure Calibrator

Features

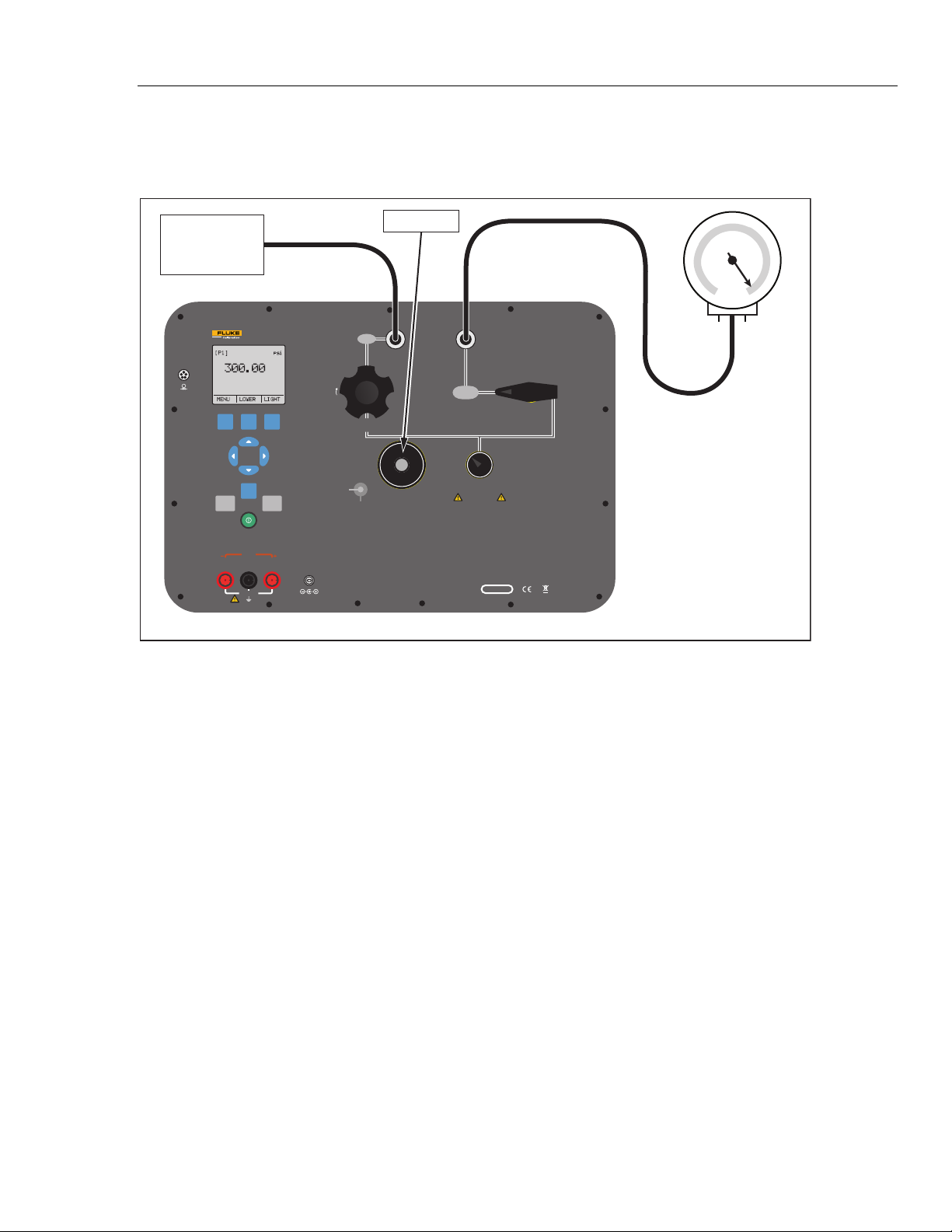

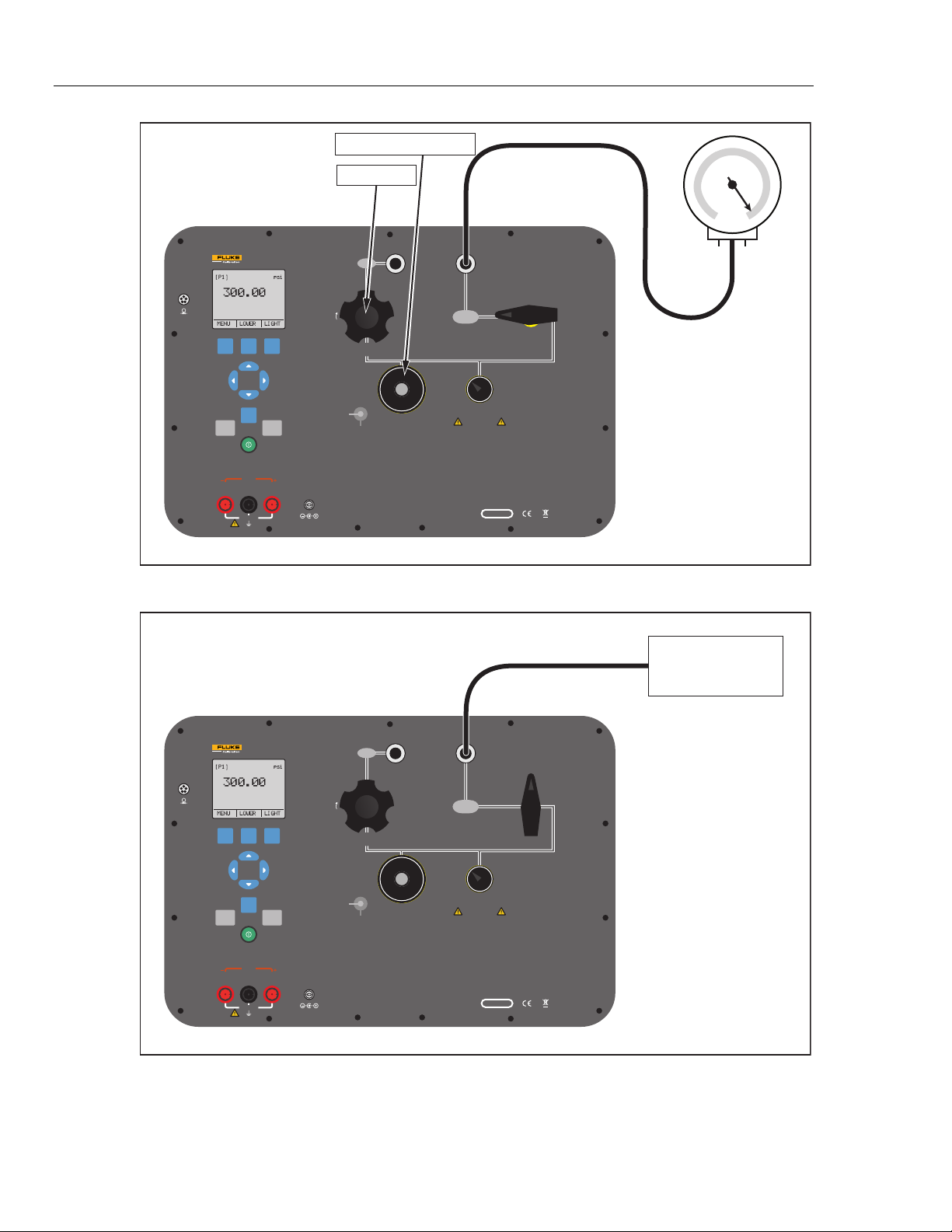

Typical Connections

Typical connections of the pressure controls, connection port, and electrical inputs are

shown in Figures 4, 5, and 6.

Fully Closed

0 psi to 300 psi

Air Supply

PORTABLE PRESSURE CALIBRATOR

EXTERNAL

PRESSURE MODULE

3130

CLOSE VALVE BEFORE

OPERATING PUMP

FILTER

AIR SUPPLY

330 PSI MAX

(2.3 MPa)

PRESSURE

SENSOR

OUTPUT

-12 PSI TO 300 PSI

(-8 kPa TO 2 MPa)

CLOSED

F1 F2 F3

HOME

ZERO PUMP

LOOP

V mA

SWITCH TEST

COM

30 V MAX

24 V DC

CHARGE

16 V DC

SUPPLY

METERING VALVE

PRESSURE

VENT

VENT

ADJUSTMENT

5.6 A

FINE

ADJUSTMENT

FINE

CAUTION

VENT LINE BEFORE MAKING SELECTION

PUMP

VACUUM

SERIAL NO.

ISOLATION

VALVE

FLUKE CORPORATION

EVERETT, WA USA

www.flukecal.com

hbb002.eps

Figure 4. External Pressure Supply

7

Page 16

3130

Users Manual

EXTERNAL

PRESSURE MODULE

PORTABLE PRESSURE CALIBRATOR

3130

Closed Silver Vent Knob

Fully Closed

FILTER

CLOSE VALVE BEFORE

OPERATING PUMP

AIR SUPPLY

330 PSI MAX

(2.3 MPa)

PRESSURE

SENSOR

OUTPUT

-12 PSI TO 300 PSI

(-8 kPa TO 2 MPa)

CLOSED

EXTERNAL

PRESSURE MODULE

F1 F2 F3

HOME

ZERO PUMP

LOOP

V mA

SWITCH TEST

COM

30 V MAX

3130

24 V DC

PORTABLE PRESSURE CALIBRATOR

CLOSE VALVE BEFORE

OPERATING PUMP

CHARGE

16 V DC

SUPPLY

METERING VALVE

PRESSURE

VENT

VENT

ADJUSTMENT

5.6 A

FINE

ADJUSTMENT

FINE

CAUTION

VENT LINE BEFORE MAKING SELECTION

PUMP

VACUUM

SERIAL NO.

ISOLATION

VALVE

FLUKE CORPORATION

EVERETT, WA USA

www.flukecal.com

Figure 5. Pressure Supply with Internal Pump

FILTER

AIR SUPPLY

330 PSI MAX

(2.3 MPa)

PRESSURE

SENSOR

OUTPUT

-12 PSI TO 300 PSI

(-8 kPa TO 2 MPa)

CLOSED

-12 psi to 300 psi

Pressure Source

hbb003.eps

8

F1 F2 F3

HOME

ZERO PUMP

LOOP

V mA

SWITCH TEST

COM

30 V MAX

24 V DC

CHARGE

16 V DC

SUPPLY

METERING VALVE

PRESSURE

VENT

VENT

ADJUSTMENT

5.6 A

FINE

ADJUSTMENT

FINE

CAUTION

VENT LINE BEFORE MAKING SELECTION

PUMP

VACUUM

SERIAL NO.

ISOLATION

VALVE

FLUKE CORPORATION

EVERETT, WA USA

www.flukecal.com

hbb004.eps

Figure 6. Pressure Measurement

Page 17

Portable Pressure Calibrator

Power Options

Power Options

The Product can be powered with the internal, high-capacity NiMH battery and/or the

universal power supply (90 V ac to 250 V ac) that charges the battery pack. The universal

power supply can power the Product at the same time it charges the battery pack. A fullydischarged battery can take a maximum of 14 hours to recharge. When the Product is first

received, plug it into the universal power supply for that period to ensure the Product is

fully charged.

Product Startup

When you turn on the Product, it goes through a short self-test. The display shows the

current firmware version, auto-shutdown status, and the range of the internal pressure

sensor. The Product also shows the warning “ FOR USE WITH DRY GAS ONLY”.

A minimum 5-minute warm-up is necessary to get the rated accuracy of the Product. If

there are large changes in ambient temperature, a longer warm-up is necessary.

Pressure ranges must be zeroed each time the Product is started. See the “Zero Function”

section for instructions to zero the pressure sensor displays.

Product Menus

The menu bar at the bottom of the display is controlled with the softkeys or arrow keys,

this depends on which menu is in use. Use the menu bar to navigate the Product menus.

The menus are explained in the subsequent sections. A menu map is shown in Figure 7.

9

Page 18

3130

Users Manual

Active

Display

Active

Display

10

Figure 7. Menu Map

hbb001.eps

Page 19

Portable Pressure Calibrator

Product Menus

Top-Level Menu

The top-level menu is shown in Figure 8. It has three levels.

Figure 8. Top-Level Menu

hbb009.eps

• MENU- Push the MENU softkey to get to the main menu. See the “Main Menu”

section.

• [Active Display]- The active display is shown in the middle field on the top-level

and main menu. In Figure 8 the active display is the LOWER display. This menu

item lets you assign the ZERO key to one of the three display sections. Push the

softkey that corresponds to the display named on the menu bar to change the active

display. If the chosen display is a pressure range, then the ZERO key becomes active.

• LIGHT- The Product has a backlight for low-light situations. To turn on or turn off

the backlight, push the LIGHT softkey on the main menu. The backlight cannot be

controlled by the serial interface.

Main Menu

To go to the main menu, push the MENU softkey from the top-level menu. From the

main menu, the submenus can be accessed. The main menus are:

• Config- Display Configuration menu

• % Error Main Menu

• MinMax Menu

• Contrast Main Menu

• Lock Config Menu

• Setups Main Menu

• Save/Recall Menu

• Auto Off Main Menu

• Setups Main Menu

• Display Main Menu

• Damp Main Menu

• HART Main Menu

• Pump Limit Main Menu

Some of these menus are broken up into more submenus.

11

Page 20

3130

Users Manual

The main menu is shown in Figure 7 and has three levels.

• CONFIG (Configuration) - Push to access the config menu. Push again to go

to the Display Configuration menu. This will let you change the parameters for each

display section. See the Parameter Selection portion of the Figure 7.

• [Active Display] - See the “Top-Level Menu” section.

• MORE- Push to access the % Error Main Menu.

Display Configuration Menu

Use the display configuration menu to set the parameters of the active display. Push the

SELECT softkey to move through this menu. See Figure 13.

Figure 10. Display Configuration Menu

Figure 9. Main Menu

hbb010.eps

hbb011.eps

The first parameter is Mode. Since voltage, current, and switch test modes all use the

same jacks, two of these functions cannot be used at the same time. What can be selected

depends on what is already selected in another display.

Push the NEXT softkey to change the second parameter. Pressure can be read in 14

different engineering units. Only Pressure mode has a second parameter.

These modes are available with a single display:

• P[1] = Pressure internal sensor

• [EXT] = Pressure with external pressure module

• P[1] ST = Switch Test with internal sensor

• [EXT] ST = Switch Test with external pressure module

Note

mA functions are only available on the lower section of the display.

• mA Measure = Milliamps measure.

• mA Source = Milliamps source.

• SIM-2W = Milliamps simulate using an external supply from the UUT.

• VOLTS = Voltage Measure.

• mA MEAS/24v

12

Table 2 shows which functions are available concurrently.

An X in a column indicates that the mode in the active display is not available for

selection if the mode in that row is in use in a different display.

Use the MORE option on the main menu to access other menu functions.

Page 21

Portable Pressure Calibrator

Zero Function

Table 2. Mode Concurrency

Active Display

P[1] [EXT] P[1]ST [EXT]ST mA

P[1] x x x x x x x

[EXT] x x x x x x x

P[1]ST x x

Other

Displays

[EXT]ST x x

mA x x x

mA

MEAS/24V

Volts x x x

x x x

Zero Function

When is pushed, the Product zeros its active display if a pressure mode is selected,

and the pressure is within the zero limit. The zero limits are within 10 % of the full-scale

range of the selected sensor. If the display shows “OL,” the zero function will not

operate. is only used for pressure.

Internal Sensor and Pressure Module (non-absolute)

When a sensor or pressure module is selected on the active display and is pushed, the

Product subtracts the current reading from the output. The zero limits are within 10 % of

the full-scale range of the selected sensor. If the display shows “OL,” the zero function

will not operate.

mA

MEAS/24V

Volts

Absolute Pressure

When an absolute pressure range is selected on the active display and is pushed, the

Product prompts you to enter the barometric reference pressure. Record the barometric

reference pressure with the arrow buttons. While you do this procedure, make sure the

sensor port is open (vented) to the atmosphere. See Figure 11.

Figure 11. Absolute Pressure

hbb012.eps

13

Page 22

3130

Users Manual

Other Menu Controlled Functions

There are many submenus below the main menu. These can be accessed through the

MORE option of the main menu. A submenu contains three options. The first option is

unique to the function. The second and third options are always the same. The NEXT

option leads to the subsequent menu. The DONE option goes home. For the last menu,

the NEXT option goes home. See Figure 7 for the menu structure.

In this manual, if a submenu has subsequent menus below it, it is referred to as

{function} main menu. As an example, the display contrast submenu will be called the

Contrast main menu.

Contrast Main Menu

To set the contrast, go through the menu list until CONTRAST is shown. Push the

CONTRAST softkey to access the Contrast Adjustment menu.

Push the up arrow or down arrow softkey to change the display to the necessary contrast

level. When completed, push the CONTRAST DONE softkey to go home. See

Figure 12.

Figure 12. Contrast Menu

Lock or Unlock the Display Configuration

To lock or unlock the display configuration settings, go through the menu list until

LOCK CFG is shown. Push the LOCK CFG or UNLOCK CFG softkeys from the

Configuration Lock menu. See Figure 13.

Figure 13. Display Configuration Menu

When the LOCK CFG option is used, the menu goes home and the CONFIG option on

the main menu shows that it is locked. All menus are now locked except for Min Max,

Contrast Adjustment, and Configuration Lock. When the UNLOCK CFG option is used,

the configuration is unlocked and the menu goes to the next sub menu.

hbb013.eps

hbb014.eps

14

Page 23

Portable Pressure Calibrator

Other Menu Controlled Functions

Save and Recall Menu Setups

The current Product setup is saved for recall at the next power up. Five different setups

can be saved for later use. To access these setups, go through the menu list until SETUPS

is shown. Push the SETUPS softkey from the Setups Main menu. Push the RECALL

softkey to recall a setup or the SAVE softkey to save a setup. Push the DONE softkey to

do nothing and go to the home menu.

If SAVE or RECALL is selected, push the arrow keys to select the setup location. Then

push the SAVE softkey to store the current setup into the selected location. You can also

push the RECALL softkey to recall the setup stored in the selected location. The display

menu will go to home. See Figure 14.

Automatic Shutdown

The Product can be set to turn off after a preprogrammed time interval, 0 minutes to 30

minutes. To set the automatic shutdown, go through the menu list until AUTO OFF is

shown. Select the AUTO OFF option on the Auto Shutdown main menu

Push the arrow softkeys to choose the number of minutes the Product functions. Or push

the down arrow softkey until OFF is shown to disable the automatic shutdown. When

you have made the selection, push the AUTO OFF DONE softkey to set the selection.

The Product menu will go to the home menu. The auto shutdown timer is reset when a

button is pushed. See Figure 15.

Figure 14. Setups Menu

Figure 15. Auto Shutdown Menu

hbb015.eps

hbb016.eps

15

Page 24

3130

Users Manual

Activate and Deactivate a Display

Use the DISPLAY menu to select which display to use. The ON/OFF option turns the

selected display on or off. The selected display and current on/off state are shown in the

lower display. See Figure 16.

To choose which displays are active:

1. Go through the menu list until DISPLAY is shown.

2. Push the DISPLAY softkey to access the Display Activation menu.

3. Push the UPPER, MIDDLE, or LOWER softkey to make your selection.

4. Push the ON/OFF softkey to the change the display state.

5. Push the DONE softkey to save the changes and go to the home screen.

When a display is deactivated, its configuration is saved. When the display is activated,

its configuration is verified against the configurations of the other currently-active

displays. If the configurations are in conflict, the recalled-display configuration is

changed to prevent the conflict. If all three displays are deactivated, the lower display

will turn on automatically.

Damping

Damping can be turned ON or OFF with the DAMP menu selection. Go through the

menu list until DAMP is shown. Select ON or OFF. When damping is ON, the Product

shows a running average indication of ten measurements. The Product makes

approximately three readings per second.

HART Resistor

An internal 250 HART resistor can be enabled when the Product is used in the mA

Measure-24V mode. This lets a HART communicator be connected across the mA

terminals and makes it unnecessary to add an external resistor.

When the HART resistor is on, the maximum load-driving capacity is

750

Go through the menu list until HART is shown. Use the arrow softkeys to select ON or

OFF.

Pump Limits

To prevent overpressure of sensitive devices the maximum pressure (pump limit) can be

set. Go through the menu list until PUMP is shown. When in this mode, use SELECT

and the arrow buttons to change the pump limit. Push the DONE SET softkey to save the

selection and go to the main menu. This limit can be set to 10 % above full scale.

Figure 16. Active Display Menu

hbb017.eps

Note

.

16

Page 25

Portable Pressure Calibrator

Initial Setup and Basic Pressure Generation

Initial Setup and Basic Pressure Generation

The Product has a special low-volume calibration hose for faster pressure generation and

quick pressure stabilization. "Quick-fit" hose connectors and different adapters are

included. It is recommended that this hose is used to get the best results. After the fittings

are installed and the Product is connected to the UUT (unit under test), the Product is

ready for use.

To configure the Product for the appropriate application:

1. Set the pressure/vacuum selection knob to the necessary function (+ for pressure

and - for vacuum).

2. Close the vent knob.

3. Close the supply metering valve.

4. Push and hold and see the pressure rise (or vacuum generation) until you reach

the necessary pressure.

5. Release when the necessary pressure is reached.

Note

The motor speed starts slow while the pressure is low <15 psi (1 bar) for

better control at low pressures.

6. The fine pressure adjustment lets you set the correct pressure.

7. To decrease or bleed off all pressure, slowly turn the vent knob counter clockwise to

the open position. When the valve is slowly opened, there is a slow decrease of

pressure. Open the valve more to vent the pressure.

Pressure Measurement

To measure pressure:

1. Connect the Product with the correct adapter.

2. Select the pressure parameter for the display used.

3. The Product has an internal sensor and optional external sensors are available. Select

a sensor that is correct for the pressure range and accuracy.

To prevent injury, only assemble and operate high-pressure

systems if you know the correct safety procedures. Highpressure liquids and gases are hazardous and the energy from

them can be released without warning.

For a better understanding with respect to overpressure and burst pressure, follow the

specifications and these operation instructions. See the “Specifications” section. The

Product display will show "OL" when an inappropriate pressure is applied. When "OL"

is shown on a pressure display, immediately decrease the pressure to prevent damage or

possible physical injury. "OL" is shown if the pressure exceeds the nominal range by

110 %. Push to zero the pressure sensor after it is vented to atmospheric pressure.

Warning

17

Page 26

3130

Users Manual

Media Compatibility

The Product is only to be used with clean, dry gases.

External Modules

The Product has a digital interface to support the Fluke 700P series of pressure modules.

These modules are available for different ranges that include gauge, vacuum, differential,

and absolute pressure. The modules work in conjunction with the Product. Connect them

to the interface and select [EXT] (external sensor). Since the interface between the

Product and the module is digital, the accuracy and display resolution depends on the

module. See Figure 17.

Valve

Pressure

Module

EXTERNAL

PRESSURE MODULE

PORTABLE PRESSURE CALIBRATOR

3130

F1 F2 F3

HOME

ZERO PUMP

CLOSE VALVE BEFORE

OPERATING PUMP

FILTER

SUPPLY

METERING VALVE

VENT

VENT

FINE

ADJUSTMENT

FINE

ADJUSTMENT

AIR SUPPLY

330 PSI MAX

(2.3 MPa)

OUTPUT

-12 PSI TO 300 PSI

(-8 kPa TO 2 MPa)

PRESSURE

SENSOR

PRESSURE

VACUUM

PUMP

CAUTION

VENT LINE BEFORE MAKING SELECTION

CLOSED

ISOLATION

VALVE

Figure 17. Pressure Module

Measure and Source Current (4… 20 mA)

To measure and source current:

1. To measure current, use the input terminals on the front of the Product. Select the mA

function on the lower display. Current is measured in mA and a percentage of the

measuring range. The measuring range on the Product is set to 0 % at 4 mA and

100 % at 20 mA. See Figure 18 for connections.

Example:

If the current measured is shown as 75 %, then the value is 16 mA.

Note

The display shows "OL" when the measured current exceeds the nominal

range of current measurement (24 mA).

V mA

SWITCH TEST

30 V MAX

LOOP

COM

24 V DC

CHARGE

16 V DC

5.6 A

SERIAL NO.

FLUKE CORPORATION

EVERETT, WA USA

www.flukecal.com

hbb007.eps

18

Page 27

Portable Pressure Calibrator

Pressure Measurement

2. The same connections are used for the current source. Select mA-Source or mA

Sim-2W from the configuration display.

3. This selection can only be made in the lower display. Also, in source mode, the

Product generates 0... 24 mA that uses its own internal 24 V supply, whereas in

simulation mode the Product acts as a 2-wire transmitter and an external 24 V supply

is necessary.

4. Push the arrow key to start the output mode and then use the arrow keys to adjust the

mA output. The function keys can also be used to control the output in 25 % steps (4,

8, 12, 16, 20 mA) or 0 % (4 mA) and 100 % (20 mA). See Figure 18.

5. While in the mA output mode, if the loop is broken or the resistance burden is

exceeded, the Product will flash "OL".

ZERO PUMP

LOOP

V mA

SWITCH TEST

COM

24 V DC

30 V MAX

4...20 mA

UUT

ZERO PUMP

LOOP

V mA

SWITCH TEST

COM

30 V MAX

ZERO PUMP

LOOP

V mA

SWITCH TEST

COM

30 V MAX

ZERO PUMP

LOOP

V mA

SWITCH TEST

COM

30 V MAX

24 V DC

24 V DC

24 V DC

–

4...20 mA

4...20 mA

UUT

DC 24 V

4...20 mA

UUT

Powe r

+

Supply

+

–

UUT

Figure 18. Measure and Sourcing Current

hbb018.eps

19

Page 28

3130

Users Manual

Measure Voltage

To measure voltage, use the connections on the front of the Product. Select the VOLTS

function on one of the displays. The Product can measure to a maximum of 30 V dc. See

Figure 19.

The display shows "OL" when the measured voltage is larger than the

nominal range of voltage measurement (30 V).

HOME

ZERO PUMP

LOOP

V mA

SWITCH TEST

COM

30 V MAX

Note

24 V DC

30 V dc Maximum

Test Item

Figure 19. Measure Voltage

hbb019.eps

20

Page 29

Portable Pressure Calibrator

Pressure Measurement

Pressure Switch Test

To do a pressure switch test:

1. Set the upper display to [P1] ST, all other displays are switched off.

Note

The pressure switch test can be done with these functions: [P1] ST or EXT

ST.

2. Connect the Product to the pressure switch with the switch terminals. The polarity of

the terminals is not important. See Figure 20.

Fully Closed

PORTABLE PRESSURE CALIBRATOR

EXTERNAL

PRESSURE MODULE

3130

F1 F2 F3

HOME

ZERO PUMP

CLOSE VALVE BEFORE

OPERATING PUMP

METERING VALVE

VENT

FINE

ADJUSTMENT

FILTER

SUPPLY

VENT

FINE

ADJUSTMENT

AIR SUPPLY

330 PSI MAX

(2.3 MPa)

OUTPUT

-12 PSI TO 300 PSI

(-8 kPa TO 2 MPa)

PRESSURE

SENSOR

PRESSURE

VACUUM

PUMP

CAUTION

VENT LINE BEFORE MAKING SELECTION

CLOSED

ISOLATION

VALVE

Use low volume

hose if possible

LOOP

V mA

SWITCH TEST

COM

24 V DC

30 V MAX

CHARGE

16 V DC

5.6 A

SERIAL NO.

FLUKE CORPORATION

EVERETT, WA USA

www.flukecal.com

Figure 20. Switch Test Connections

3. Connect the Output of the Product to the pressure switch.

4. Open the vent button on the pump and zero the Product.

5. Close the vent after you reset the Product.

The top of the display shows "CLOSE". See Figure 22.

Pressure

Switch

hbb020.eps

Figure 21. Switch Test Screen

hbb021.eps

21

Page 30

3130

Users Manual

6. Apply pressure with the pump slowly until the switch opens.

Note

In the switch test mode, the display-update rate is increased to help capture

changes to pressure inputs. Even with this enhanced sample rate, the UUT

should be charged slowly with pressure to ensure accurate readings.

7. After the switch is open, "OPEN" will be shown. Bleed the pump slowly until the

pressure switch closes. See Figure 22.

Figure 22. Switch Test Screen (Open)

hbb022.eps

8. The top display now shows "SW OPENED AT" and gives you the pressure at which

the switch opened. See Figure 23.

Figure 23. Opened Switch Reading

hbb023.eps

22

Page 31

Portable Pressure Calibrator

Pressure Measurement

9. Select the "NEXT" option to show the pressure at which the switch closed and the

deadband. See Figure 24.

Figure 24. Switch Test and Deadband Results

hbb024.eps

10. Select the "NEW TEST" option to clear the data and do another test.

11. Select the "DONE" option to complete the test and go to the standard pressure

setting.

Example:

[P1] ST will return to [P1].

This example uses a normally closed switch. The basic procedure is effectively the

same for a normally open switch. The display reads "OPEN" instead of "CLOSE".

Calibrate Transmitters

Use the mA Measurement Function

The mA function lets you read the 4... 20 mA output from the UUT. This can be done in

two ways:

1. Passively – the UUT generates 4... 20 mA directly. This can be read on the Product.

2. Actively – the Product supplies a loop power of 24 V dc to the UUT to power the

device while it reads the 4... 20 mA signal. See Figure 25.

Passive Active

Figure 25. Passive and Active Screens

hbb025.eps

23

Page 32

3130

+

–

Users Manual

Calibrate a Pressure-to-Current Transmitter

To calibrate a pressure-to-current transmitter (P/I):

1. Connect the Product pump to the transmitter.

2. Apply pressure from the pump.

3. Measure the current output of the transmitter.

4. Make sure that the read value is correct. If it is not correct, the transmitter must be

adjusted. See Figure 26.

EXTERNAL

PRESSURE MODULE

3130

F1 F2 F3

HOME

ZERO PUMP

LOOP

V mA

SWITCH TEST

COM

30 V MAX

PORTABLE PRESSURE CALIBRATOR

24 V DC

Fully Closed

CLOSE VALVE BEFORE

OPERATING PUMP

CHARGE

16 V DC

5.6 A

FILTER

SUPPLY

METERING VALVE

VENT

VENT

FINE

ADJUSTMENT

Close silver vent knob

FINE

ADJUSTMENT

AIR SUPPLY

330 PSI MAX

(2.3 MPa)

-12 PSI TO 300 PSI

PRESSURE

SENSOR

PRESSURE

PUMP

CAUTION

VENT LINE BEFORE MAKING SELECTION

OUTPUT

(-8 kPa TO 2 MPa)

VACUUM

SERIAL NO.

CLOSED

ISOLATION

VALVE

FLUKE CORPORATION

EVERETT, WA USA

www.flukecal.com

Figure 26. Calibrate a Pressure-to-Current Transmitter

Use low volume

hose if possible

hbb026.eps

24

Page 33

Portable Pressure Calibrator

Pressure Measurement

Calibrate a Pressure-to-Voltage Transmitter

To calibrate a pressure-to-voltage transmitter (P/V):

1. Connect the Product pump to the transmitter.

2. Apply pressure from the pump.

3. Connect the 24 V to the transmitter.

4. Measure the voltage output of the transmitter.

5. Make sure that the read value is correct. If it is not correct, the transmitter must be

adjusted. See Figure 27 for connections.

PORTABLE PRESSURE CALIBRATOR

EXTERNAL

PRESSURE MODULE

3130

F1 F2 F3

HOME

ZERO PUMP

LOOP

V mA

SWITCH TEST

COM

30 V MAX

24 V DC

CLOSE VALVE BEFORE

OPERATING PUMP

CHARGE

16 V DC

5.6 A

METERING VALVE

VENT

ADJUSTMENT

FILTER

SUPPLY

VENT

FINE

FINE

ADJUSTMENT

AIR SUPPLY

330 PSI MAX

(2.3 MPa)

OUTPUT

-12 PSI TO 300 PSI

(-8 kPa TO 2 MPa)

PRESSURE

SENSOR

PRESSURE

VACUUM

PUMP

CAUTION

VENT LINE BEFORE MAKING SELECTION

SERIAL NO.

CLOSED

ISOLATION

VALVE

FLUKE CORPORATION

EVERETT, WA USA

www.flukecal.com

Pressure

Transmitter

+24 V Power

Common

Signal Output

hbb035.eps

Figure 27. Calibrate a Pressure-to-Voltage Transmitter

25

Page 34

3130

+

–

Users Manual

%-Error Function

The Product has a special function which can calculate the error in the pressure value

from the mA value as a percentage of the 4 ... 20 mA loop span. The %-Error mode uses

all three screens and has a special menu structure. It shows pressure, mA and %-Error

simultaneously. See Figure 28.

EXTERNAL

PRESSURE MODULE

Close silver vent knob

FINE

ADJUSTMENT

AIR SUPPLY

330 PSI MAX

(2.3 MPa)

-12 PSI TO 300 PSI

PRESSURE

SENSOR

PRESSURE

PUMP

CAUTION

VENT LINE BEFORE MAKING SELECTION

OUTPUT

(-8 kPa TO 2 MPa)

VACUUM

SERIAL NO.

CLOSED

ISOLATION

VALVE

FLUKE CORPORATION

EVERETT, WA USA

www.flukecal.com

Use low volume

hose if possible

3130

F1 F2 F3

HOME

ZERO PUMP

LOOP

V mA

SWITCH TEST

COM

30 V MAX

PORTABLE PRESSURE CALIBRATOR

24 V DC

Fully Closed

CLOSE VALVE BEFORE

OPERATING PUMP

CHARGE

16 V DC

5.6 A

FILTER

SUPPLY

METERING VALVE

VENT

VENT

FINE

ADJUSTMENT

Figure 28. Connections with a Pressure Transmitter with % Error Function

Example:

hbb027.eps

If a pressure transmitter under test has a full-scale range of 2 bar and gives a 4 ... 20 mA

output signal, you can program in a 0 ... 2 bar pressure span into the Product. The Product

will then calculate and show the deviation or %-Error value from the 4 ... 20 mA output.

This makes manual calculations unnecessary.

To use the "%-ERROR" function:

1. Once the Product is turned on, push to start the "MORE" menu option. Then Push

to start the "%-ERROR" option.

2. Push to select the "CONFIG" option.

26

Page 35

Portable Pressure Calibrator

Pressure Measurement

3. The first option is the port setting. Use the "SELECT" option to scroll through the

choice of ports (pressure connections). When this is done, select the "NEXT" option.

See Figure 29.

Figure 29. Port Setting Screen

hbb028.eps

4. "LOOP POWER" can be toggled on or off. Select "NEXT" when done. See

Figure 30.

Figure 30. Loop Power Screen

hbb029.eps

5. Use "SELECT" to scroll through the "UNIT" options, and select "NEXT" to move

on. See Figure 31.

Figure 31. Set Unit Screen

hbb030.eps

27

Page 36

3130

Users Manual

6. Use the arrow keys to set the upper limit of the measurement range. Select DONE

SET when finished. See Figure 32.

Figure 32. Setting the Upper Limit

hbb031.eps

7. Use the arrow keys to set lower limit of the measurement range, and select DONE

SET when finished. The "%-ERROR" mode will be ready to use. See Figure 33.

Figure 33. % ERROR Screen

hbb032.eps

The lower and upper limit of the measuring range is saved in non-volatile memory

until they are changed by the user for the internal sensors and the external pressure

modules. See Figure 34.

28

Figure 34. Saved Upper and Lower Limits

hbb033.eps

Page 37

Portable Pressure Calibrator

Storage Capability

Storage Capability

The Product has a min/max feature to capture the minimum and maximum values of a

shown parameter.

The min/max function can be accessed by going through the menu options until the

MINMAX menu choice is shown. Push the MINMAX softkey to see the min/max values

that are stored in the min/max registers. These readings are live so that the new min/max

values are recorded while in this mode.

To reset the min/max registers, push the CLEAR softkey. These registers are also cleared

at power-up or when the configuration is changed.

Remote Operation

The Product can be remotely controlled with a PC terminal, or by a computer program

that runs the Product in an automated system. An RS-232 serial port connection is used

for remote operation.

Note

To use the remote control option, a custom RS-232 cable must be

purchased. See the “How to Contact Fluke Calibration” section.

With this connection, you can write programs on the PC. Use Windows languages like

Visual Basic to operate the Product, or use a Windows terminal like Hyper Terminal, for

single commands. A typical RS-232 remote configuration is shown in Figure 35.

PORTABLE PRESSURE CALIBRATOR

EXTERNAL

PRESSURE MODULE

3130

F1 F2 F3

HOME

ZERO PUMP

LOOP

V mA

SWITCH TEST

COM

30 V MAX

24 V DC

CLOSE VALVE BEFORE

OPERATING PUMP

CHARGE

16 V DC

5.6 A

VENT

FILTER

SUPPLY

METERING VALVE

VENT

FINE

ADJUSTMENT

FINE

ADJUSTMENT

AIR SUPPLY

330 PSI MAX

(2.3 MPa)

OUTPUT

-12 PSI TO 300 PSI

(-8 kPa TO 2 MPa)

PRESSURE

SENSOR

PRESSURE

VACUUM

PUMP

CAUTION

VENT LINE BEFORE MAKING SELECTION

SERIAL NO.

CLOSED

ISOLATION

VALVE

FLUKE CORPORATION

EVERETT, WA USA

www.flukecal.com

COM Port

Figure 35. Remote Operation

hbb034.eps

29

Page 38

3130

Users Manual

Set Up the RS-232 Port for Remote Control

Note

The RS-232 connection cable must be less than 15 m unless the load

capacitance measured at connection points is less than 2500 pF.

Serial parameter values:

1. 9600 baud

2. 8 data bits

3. 1 stop bit

4. no parity

5. Xon/Xoff

6. EOL (End of Line) character or CR (Carriage Return) or both

An RS-232 cable is used for RS-232 communications from the Product to a

computer. If the computer only has USB ports, a USB to RS-232 converter will be

necessary. To connect the Product to a computer, attach the LEMO connector end

of the cable to the pressure module port on the right side of the Product. Then

connect the DB-9 connector to the RS-232 port on the computer. The Product

must be off before you make the connection.

To set up remote operation of the Product with Windows Hyper Terminal, connect the

Product to a COM port on the PC. See Figure 35.

Do the subsequent procedure:

1. Start Hyper Terminal (located on your computer in Accessories/Communications of

the Windows Start menu).

2. Select New Connection.

3. For Name enter “Fluke 3130”.

4. Select the serial port that the Product is connected to.

5. Enter the above information for port settings.

6. Select ASCII setup from File/Properties/Settings and mark these choices:

1. Echo typed characters locally

2. Wrap lines that exceed terminal width

7. Select Ok.

8. To see if the port functions, enter *IDN?. This command shows information on the

Product.

30

Page 39

Portable Pressure Calibrator

Remote Operation

Change from Remote to Local Operation

The Product uses three modes of operation:

• Local

• Remote

• Remote with Lockout

Local mode is the default mode. Commands can be entered with the buttons on the

Product or with a computer. In Remote mode, the buttons are disabled and commands can

only be entered with a computer. Select [GO TO LOCAL] from the menu on the

Product display to restore button operation. In Remote with Lockout mode, the buttons

cannot be used.

To switch modes:

1. To start Remote mode, enter the serial command “REMOTE” at the computer

terminal.

2. To start Remote with Lockout mode, enter “REMOTE LOCKOUT” in either order.

3. To go back to Local Operation mode, enter “LOCAL” at the terminal. This

command also turns off LOCKOUT if it is on. For more information on commands,

see the “Remote Commands” section.

Command Use

The Product can be controlled by commands and queries. All commands can be entered

with upper or lower case. See the Remote Commands section for all available commands.

The commands are divided into these categories:

Calibrator Commands

Only the Product uses these commands.

For example:

VAL?

This command requests the values shown on the Product display.

Common Commands

Standard commands used by most devices. These commands always start with an

“*”.

For example:

*IDN?

This command tells the Product to show its identification.

Query Commands

Commands that request information and always end with a “?”.

For example:

FUNC?

This command shows the current modes of the Product displays.

31

Page 40

3130

Users Manual

Compound Commands

Commands that have more than one command on one line.

For example:

PRES_UNIT LOWER, PSI;PRES_UNIT?

This command sets the pressure unit to PSI on the lower display and queries the

Product to verify. In this case, it will show the pressure units of all three displays:

BAR,BAR,PSI

Character Processing

The data entered into the Product is processed as follows:

• ASCII characters are discarded if their decimal equivalent is less than 32 (space),

except 10 (LF) and 13 (CR):

• Data is taken as 7-bit ASCII.

• The most significant data bit is ignored.

• Upper or lower case is acceptable.

Response Data Types

The data shown by the Product can be divided into these types:

Integer

For most computers and controllers they are decimal numbers ranging from -32768

to 32768.

For example:

FAULT?

Could show 110

Refer to the Error Codes table (Table 8) for more information on error codes.

Floating

Floating numbers can have a maximum of 15 significant figures and exponents.

For example:

VAL?

Shows 5.830000E01,PSI,0.000000E00,PSI,0.000000E+00,A

Character Response Data (CRD)

Data shown as keywords.

For example:

PRES_UNIT?

Shows BAR,BAR,PSI

32

Indefinite ASCII (IAD)

Any ASCII characters followed by a terminator. For example:

*IDN?

Shows Fluke, 3130, 1234567, 1.00 (1234567 is the serial number)

Page 41

Portable Pressure Calibrator

Remote Operation

Calibrator Status

Error Queue

If an error occurs from invalid input or buffer overflow, its error code is sent to the error

queue. The error code can be read from the queue with the command FAULT?. The error

queue holds 15 error codes. When it is empty, FAULT? shows 0. The error queue is

cleared when power is reset or when the clear command *CLS is entered.

Input Buffer

The calibrator stores all received data in the input buffer. The buffer holds 250 characters

and they are processed on a first in, first out basis.

Remote Commands and Error Codes

This section shows and describes all of the remote commands that are accepted by the

Product.

Table 3. Common Commands

Command Description

*CLS (Clear status.) Clears the error queue.

*IDN? Identification query. Shows the manufacturer,

model number, and firmware revision level of the

Product.

*RST Resets the Product to the power up state.

33

Page 42

3130

Users Manual

Table 4. Product Commands

Command Description

DAMP Turns on or off Damp

DAMP? Show if DAMP is on/off

DISPLAY Turns on or off the displays specified in the command

DISPLAY? Shows which displays are on/off

ERROR_LOOP Turns on or off loop power in percent error mode

ERROR_LOOP? Shows the current state of loop power in error mode

ERROR_MODE Turns on or off percent error mode

ERROR_MODE? Shows if percent error mode is on or off

ERROR_PORT Set the pressure port for percent error mode

ERROR_PORT? Shows the pressure port for percent error mode

FAULT? Shows the most recent error code

FUNC Sets the display mode as specified in the command

FUNC? Shows the current mode of the upper, middle, and lower display

HART_ON Turns on the HART resistor

HART_OFF Turns off the HART resistor

HART? Shows the current state of the HART resistor.

HI_ERR Sets the 100 % of span limit for percent error mode

HI_ERR? Shows the 100 % of span limit for percent error mode

IO_STATE Set the Product mA state

IO_STATE? Shows the Product mA state

LOCAL Shows user to manual operation of the Product

LOCKOUT Locks out the keypad of the Product in remote operation

LO_ERR Sets the 0 % of span limit for percent error mode

LO_ERR Shows the 0 % of span limit for percent error mode

MOTOR_ON Turns on the motor

MOTOR_OFF Turns off the motor

MOTOR? Shows the current state of the HART resistor

34

OUT Set the Product to output the requested current

OUT? Shows the value of the current being simulated

Page 43

Portable Pressure Calibrator

Remote Operation

Table 4. Product Commands (cont.)

Command Description

PRES_UNIT Set the pressure unit for the indicated display

PRES_UNIT? Shows the pressure from the indicated display

PUMP_LIMIT Sets the approximate value at which the pump will turn off

PUMP_LIMIT? Shows the approximate value at which the pump will turn off

REMOTE Puts the Product in remote mode

SIM Set the Product to simulate the requested current

SIM? Shows the value of the current being simulated

ST_CLOSE? Shows pressure value at which the switch closed

ST_DEAD? Shows pressure value of the deadband of the switch

ST_OPEN? Shows pressure value at which the switch opened

ST_START Starts a switch test

VAL? Shows the measured values

ZERO_MEAS Zeros the pressure module

ZERO_MEAS? Shows the zero offset of the pressure module

Table 5. Parameter Units

Units Meaning

DCI Current function

DCV Voltage measure function

EXT External pressure measurement function

LOWER Designates Lower display

MA Milliamps of current

MEASURE Measure state

MEAS_LOOP Measure with loop power state

MIDDLE Designates Middle display

PCT_ERR Percent Error

PERCENT Percent

P1 P1 pressure measurement function

ST_P1 Switch test mode with P1

ST_EXT Switch test mode with external module

SOURCE Source state

SIM Simulate state

UPPER Designates Upper display

V Voltage

35

Page 44

3130

Users Manual

Table 6. Error Codes

Error Number Error Description

100 A non-numeric entry was received where it should be a numeric entry

101 Too many digits entered

102 Invalid units or parameter value received

103 Entry is above the upper limit of the allowable range

104 Entry is below the lower limit of the allowable range

105 A required command parameter was missing

106 An invalid command parameter was received

107 Pressure not selected

108 Invalid sensor type

109 Pressure module not connected

110 An unknown command was received

111 Bad Parameter received

112 The serial input buffer overflowed

113 Too many entries in the command line

114 The serial output buffer overflowed

Enter Commands

Commands for the Product can be entered in upper or lower case. There is a minimum of

one space necessary between the command and parameter. All other spaces are optional.

Most of the commands for the Product are sequential. Any overlapped commands will be

shown as such. This section describes each of the commands and their general use, which

will include any parameters that can be entered with the command as well as what the

output of the command is.

Common Commands

*CLS

Clears the error queue. Also ends all pending operations. When you write programs, use

this command before each procedure to prevent buffer overflow.

*IDN?

Shows the manufacturer, model number, and firmware revision of the Product.

For example:

*IDN?

Shows Fluke, 3130 0, 1.00

36

Page 45

Portable Pressure Calibrator

Remote Operation

Calibrator Commands

DAMP

Turns on or off the dampening function.

For example:

If you send DAMP ON, this will turn the dampening function on.

DAMP?

Shows the current state of the dampening function.

For example:

If you send DAMP?, this will show ON if the dampening function is on.

DISPLAY

Turns on or off the indicated display.

For example:

If you send DISPLAY LOWER, ON, this will turn on the lower display.

DISPLAY?

Shows the current state of the each of the displays.

For example:

If you send DISPLAY?, it will show ON, ON, ON if the all the displays are on.

FAULT?

Shows the error code number of an error that has occurred. The command can be entered

if the previous command did not do what it was meant to do.

For example, if a value for current output is entered that is larger than the supported

range (0-24 mA), FAULT? shows:

103 which is the code number for an entry over range.

Refer to Table 6 for more information about error code numbers.

ERROR _LOOP

Turns on or off loop power in percent error mode.

For example:

To set loop power on, send ERROR_LOOP ON.

37

Page 46

3130

Users Manual

ERROR _LOOP?

Shows the current state of loop power in percent error mode.

For example:

If you send ERROR_LOOP?, it will show ON if loop power is on in error mode.

ERROR_ MODE

Turns on or off percent error mode.

For example:

To turn on percent error mode, send ERROR_MODE ON.

ERROR _ MODE?

Shows the current state of percent error mode.

For example:

If you send ERROR_MODE?, it will show ON if the Product is in percent error mode.

ERROR_ PORT

Sets the pressure port for percent error.

For example:

To set the pressure port for percent error to [P1] send ERROR_ PORT P1.

ERROR _ PORT?

Shows the current pressure port for percent error mode.

For example:

If you send ERROR _PORT?, it will show P1 if the pressure port in percent error is [P1].

FUNC

Sets the display indicated in argument 1 to the function indicated in argument 2.

For example:

To set the lower display to pressure mode, send FUNC LOWER,[P1].

FUNC?

38

Shows the current mode of all displays. For example if the Product is set to [P2] ST on

the upper display, [P1] on the middle, and [P1] on the lower, FUNC? shows:

ST_P2,P1,[P1]

Page 47

Portable Pressure Calibrator

Remote Operation

HART_ON

Turns on the Hart resistor.

HART_OFF

Turns off the Hart resistor.

HART?

Shows the state of the Hart resistor.

For example:

If the Hart resistor was on, HART? shows ON.

HI_ERR

Sets the 100 % point for the percent error mode calculation in the current engineering

units.

For example:

To set the 100 % point to 100 psi, send HI_ERR 100.

HI_ERR?

Shows the 100 % point for the percent error mode calculation.

For example:

If the 100 % point is set to 100 psi, HI_ERR? shows 1.000000E+02, PSI .

IO_STATE

Sets the input/output/simulate state of the mA function of the Product. This does not put

the Product into mA if it is not in it already.

For example:

If the Product is in mA simulate modem sending IO_STATE MEASURE would put it

into measure mode.

IO_STATE?

Shows the input/output/simulate state of the mA function of the Product.

For example:

If the Product was in mA simulate mode, IO_STATE? shows SIM.

39

Page 48

3130

Users Manual

LOCAL

Returns the Product to local operation if it was in remote mode. The command also clears

LOCKOUT if the Product was in lockout mode.

LOCKOUT

Sending this command sets the lockout state, when the unit is in REMOTE or goes to

remote, it stops use of the keypad completely. The lockout state can only be cleared by

sending the LOCAL command.

LO_ERR

Sets the 0 % point for the percent error mode calculation in the current engineering units.

For example:

To set the 0 % point to 20 psi, send LO_ERR 20.

LO_ERR?

Shows the 0 % point for the percent error mode calculation.

For example:

If the 0 % point is set to 20 psi, LO_ERR? shows 2.000000E+01, PSI .

MOTOR_ON

Turns on the motor.

MOTOR_OFF

Turns off the motor.

MOTOR?

Shows the state of the motor.

For example:

If the motor was on, MOTOR? shows ON.

40

Page 49

Portable Pressure Calibrator

Remote Operation

OUT

This command also switches the Product into mA output mode. A number and a unit

must be entered after the command.

For example:

OUT 5 MA sets the current output at 5 mA.

OUT?

Shows the output of the Product.

Using the above example, OUT? shows: 5.000000E-03, A.

PRES_UNIT

Used to set the pressure unit for the indicated display.

For example:

To set the pressure unit to psi on the lower display, send PRES_UNIT LOWER, PSI.

PRES_UNIT?

Shows the pressure unit used when measuring pressure for each of the three displays.

PUMP_LIMIT

Sets the approximate pressure in psi at which the pump will turn off.

For example:

PUMP_LIMIT 50 sets the approximate value that the pump will shut off at to 50 psi.

PUMP_LIMIT?

Shows the pump limit. Using the above example, PUMP_LIMIT? Shows:

50.000

REMOTE

Puts the Product into remote mode. From the remote mode the user can still use the

keypad to get back to local mode unless the command LOCKOUT was entered before

REMOTE. Then the keypad is completely locked out, and the user has to send the

LOCAL command to go to local operation.

41

Page 50

3130

Users Manual

SIM

Sets the output for current simulation. This command also switches the Product into mA

simulation mode. A number and a unit must be entered after the command.

For example:

SIM 5 MA sets the current simulation at 5 mA

SIM?

Shows the output of the current simulation. With the example above, the output would be:

5.000000E-03, A

ST_START

Starts a switch test.

ST_CLOSE?

Shows the pressure that the switch closed at in the current pressure units.

ST_OPEN?

Shows the pressure that the switch opened at in the current pressure units.

ST_DEAD?

Shows deadband of the switch in the current pressure units.

VAL?