Page 1

Hart Scientific

http://www.rongqe.cn/

3125

Detachable Hot Plate

Users’ Manual

Rev. 622101

Page 2

Limited Warranty & Limitation of Liability

Each product from Fluke's Hart Scientific Division ("Hart") is warranted to be free from defects in mate

rial and workmanship under normal use and service. The warranty period is one year for the Surface Cal

ibrator. The warranty period begins on the date of the shipment. Parts, product repairs, and services are

warranted for 90 days. The warranty extends only to the original buyer or end-user customer of a Hart

authorized reseller, and does not apply to fuses, disposable batteries or to any other product which, in

Hart's opinion, has been misused, altered, neglected, or damaged by accident or abnormal conditions of

operation or handling. Hart warrants that software will operate substantially in accordance with its func

tional specifications for 90 days and that it has been properly recorded on non-defective media. Hart does

not warrant that software will be error free or operate without interruption. Hart does not warrant calibra

tions on the Surface Calibrator.

Hart authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Hart. Warranty support is

available if product is purchased through a Hart authorized sales outlet or Buyer has paid the applicable

international price. Hart reserves the right to invoice Buyer for importation costs of repairs/replacement

parts when product purchased in one country is submitted for repair in another country.

Hart's warranty obligation is limited, at Hart's option, to refund of the purchase price, free of charge re

pair, or replacement of a defective product which is returned to a Hart authorized service center within

the warranty period.

To obtain warranty service, contact your nearest Hart authorized service center or send the product, with

a description of the difficulty, postage, and insurance prepaid (FOB Destination), to the nearest Hart authorized service center. Hart assumes no risk for damage in transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Hart determines that the

failure was caused by misuse, alteration, accident or abnormal condition or operation or handling, Hart

will provide an estimate or repair costs and obtain authorization before commencing the work. Following

repair, the product will be returned to the Buyer transportation prepaid and the Buyer will be billed for

the repair and return transportation charges (FOB Shipping Point).

-

-

-

-

-

Rev. 622101

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IM

PLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

HART SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL. OR CONSE

QUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER ARISING FROM

BREACH OF WARRANTY OR BASED ON CONTRACT, TORT, RELIANCE OR ANY OTHER

THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court of com

petent jurisdiction, such holding will not affect the validity or enforceability of any other provision.

Fluke Corporation, Hart Scientific Division

799 E. Utah Valley Drive • American Fork, UT 84003-9775 • USA

Phone: +1.801.763.1600 • Telefax: +1.801.763.1010

E-mail: support@hartscientific.com

www.hartscientific.com

Subject to change without notice. • Copyright © 2006 • Printed in USA

-

-

-

Page 3

Table of Contents

1 Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.2 Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Authorized Service Centers. . . . . . . . . . . . . . . . . . . . . . 4

2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Specifications and Environmental Conditions . . . . . . . . . . 9

3.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . 9

4 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Troubleshooting Problems, Possible Causes, and Solutions . . . . 11

4.2 Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.1 EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.2 Low Voltage Directive (Safety) . . . . . . . . . . . . . . . . . . . . . . . . . 12

i

Page 4

Page 5

1 Before You Start

1.1 Symbols Used

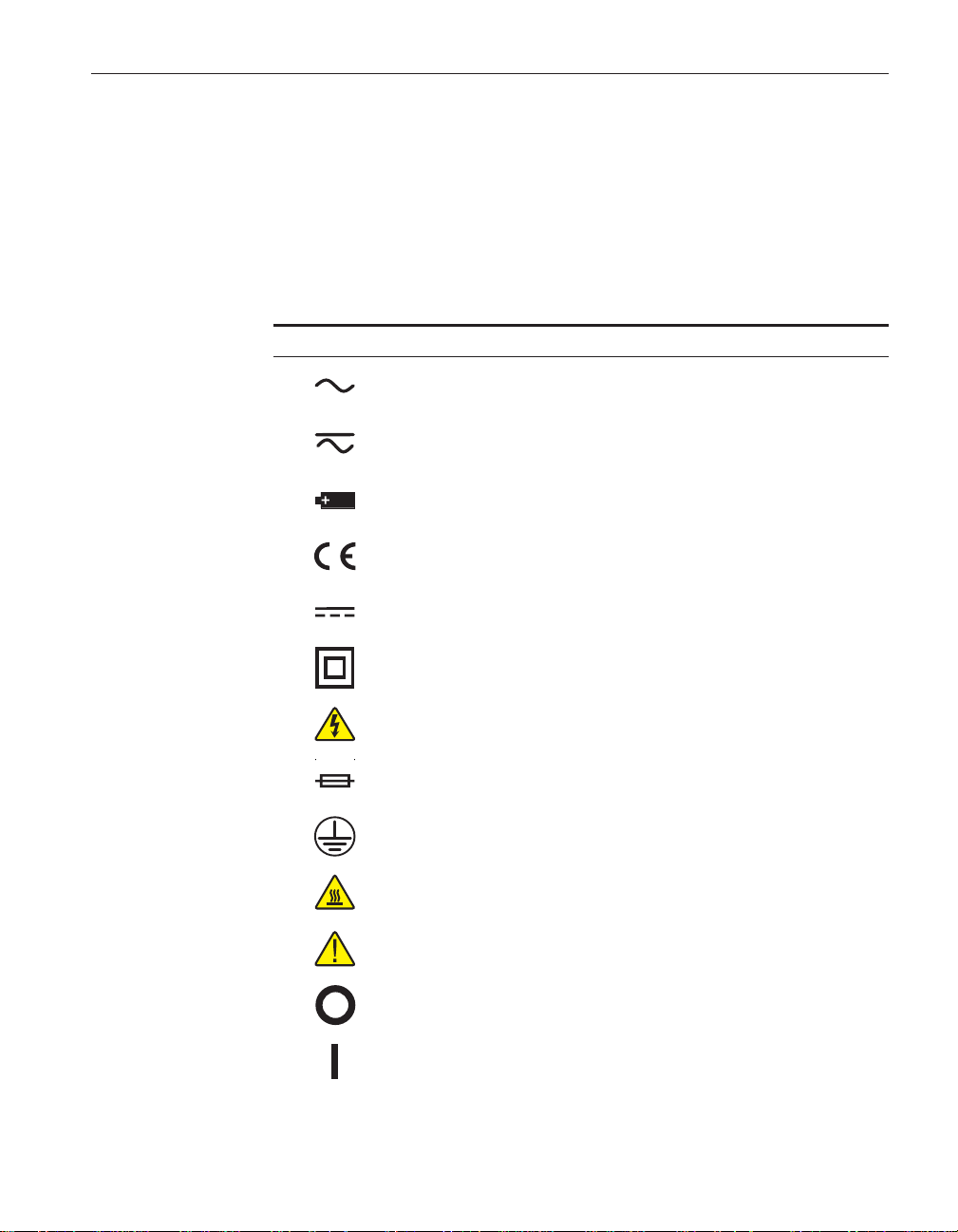

Table 1 lists the International Electrical Symbols. Some or all of these symbols

may be used on the instrument or in this manual.

Table 1 International Electrical Symbols

Symbol Description

AC (Alternating Current)

AC-DC

Battery

CE Complies with European Union Directives

1 Before You Start

Symbols Used

DC

Double Insulated

Electric Shock

Fuse

PE Ground

Hot Surface (Burn Hazard)

Read the User’s Manual (Important Information)

Off

On

1

Page 6

3125 Detachable Hotplate

User’s Guide

Symbol Description

Canadian Standards Association

OVERVOLTAGE (Installation) CATEGORY II, Pollution Degree 2 per IEC1010-1 re

fers to the level of Impulse Withstand Voltage protection provided. Equipment of

OVERVOLTAGE CATEGORY II is energy-consuming equipment to be supplied from

the fixed installation. Examples include household, office, and laboratory appliances.

C-TIC Australian EMC Mark

The European Waste Electrical and Electronic Equipment (WEEE) Directive

(2002/96/EC) mark.

1.2 Safety Information

Use this instrument only as specified in this manual. Otherwise, the protection

provided by the instrument may be impaired.

The following definitions apply to the terms “Warning” and “Caution”.

• “Warning” identifies conditions and actions that may pose hazards to the

user.

• “Caution” identifies conditions and actions that may damage the instrument being used.

1.2.1

Warnings

To avoid personal injury, follow these guidelines.

•

BURN HAZARD – DO NOT touch the plate or surrounding areas of the

unit.The temperature of the plate surface is the same as the actual temper

ature shown on the display. If the unit is set at 400°C and the display

reads 400°C, the target surface is 400°C.The top sheet metal of the instru

ment may exhibit extreme temperatures. DO NOT turn off the unit at

temperatures higher than 100°C. This could create a hazardous situation.

Select a set-point less than 100°C and allow the unit to cool before turn

ing it off.

•

DO NOT operate this unit without a properly grounded, properly polar

ized power cord.

•

DO NOT connect this unit to any other instrument or outlet other than the

2200 controller.

•

DO NOT connect the 2200 to a non-grounded, non-polarized outlet.

•

The 2200 Controller and the 3125 Detachable Hot Plate are a matched

set. DO NOT mix and match sets.

•

HIGH VOLTAGE is used in the operation of this equipment. SEVERE

INJURY OR DEATH may result if personnel fail to observe safety pre

-

-

-

-

-

-

2

Page 7

1 Before You Start

Safety Information

cautions. Before working inside the equipment, turn the power off and

disconnect the power cord.

Always replace the fuse with one of the same rating, voltage, and type.

•

This instrument is intended for indoor use only.

•

Overhead clearance is required. DO NOT place this instrument under a

•

cabinet or other structure.

DO NOT use this unit for any application other than calibration work.

•

DO NOT use this unit in environments other than those listed in the

•

user’s guide.

DO NOT operate near flammable materials.

•

Use of this instrument at HIGH TEMPERATURES for extended periods

•

of time requires caution.

Completely unattended high temperature operation is not recommended

•

for safety reasons.

• If this equipment is used in a manner not specified by the manufacturer,

the protection provided by the equipment may be impaired.

• Before initial use, or after transport, or after storage in humid or semi-hu-

mid environments, or anytime the instrument has not been energized for

more than 10 days, the instrument needs to be energized for a "dry-out"

period of 2 hours before it can be assumed to meet all of the safety requirements of the IEC 1010-1. If the product is wet or has been in a wet

environment, take necessary measures to remove moisture prior to applying power such as storage in a low humidity temperature chamber

operating at 50°C for 4 hours or more.

• The instrument generates extreme temperatures. Precautions must be

taken to prevent personal injury or damage to objects. Sensors may be ex

tremely hot when removed from the instrument. Cautiously handle sen

sors to prevent personal injury. Carefully place sensors on a heat resistant

surface or rack until they are at room temperature. Allow the surface to

cool before transporting the instrument.

•

Use only a grounded AC mains supply of the appropriate voltage to

power the instrument. Refer to Section 3.1, Specifications for power de

-

tails.

•

The instrument is equipped with operator accessible system fuses. If a

fuse blows, it may be due to a power surge or failure of a component. Re

place the fuse once. If the fuse blows a second time, it is likely caused by

failure of a component part. If this occurs, contact an Authorized Hart

Scientific Service Center (see Section 1.3). Always replace the fuse with

one of the same rating, voltage, and type. Never replace the fuse with one

of a higher current rating.

•

Follow all safety guidelines listed in the user’s manual.

•

Calibration Equipment should only be used by Trained Personnel.

-

-

3

Page 8

3125 Detachable Hotplate

User’s Guide

1.2.2

Cautions

DO NOT plug the unit into 230V if the heater switches and fuse holder

•

read 115V. This action will cause the fuses to blow and may damage the

instrument.

Components and heater lifetime can be shortened by continuous high

•

temperature operation.

DO NOT change the values of the calibration constants from the factory

•

set values. The correct setting of these parameters is important to the

safety and proper operation of the calibrator.

DO use a ground fault interrupt device.

•

Operate the instrument in room temperatures between 5 and 50°C.

•

(41–122° F). Allow sufficient air circulation by leaving at least 6 inches

of space between the instrument and nearby objects.

Never introduce any foreign material onto the surface plate. Fluids, etc.

•

can leak into the instrument causing damage.

• The instrument is a precision instrument. Although is has been designed

for optimum durability and trouble free operation, it must be handled with

care. Always carry the unit in an upright position. The instrument should

not be operated in excessively wet, oily, dusty, or dirty environments. Do

not operate near flammable materials.

• If a main supply power fluctuation occurs, immediately turn off the instrument. Wait until the power has stabilized before re-energizing the instrument.

1.3 Authorized Service Centers

Please contact one of the following authorized Service Centers to coordinate

service on your Hart product:

Fluke Corporation, Hart Scientific Division

799 E. Utah Valley Drive

American Fork, UT 84003-9775

USA

Phone: +1.801.763.1600

Telefax: +1.801.763.1010

E-mail: support@hartscientific.com

Fluke Nederland B.V.

Customer Support Services

Science Park Eindhoven 5108

5692 EC Son

4

Page 9

NETHERLANDS

Phone: +31-402-675300

Telefax: +31-402-675321

E-mail: ServiceDesk@fluke.nl

Fluke Int'l Corporation

Service Center - Instrimpex

Room 2301 Sciteck Tower

22 Jianguomenwai Dajie

Chao Yang District

Beijing 100004, PRC

CHINA

Phone: +86-10-6-512-3436

Telefax: +86-10-6-512-3437

E-mail: xingye.han@fluke.com.cn

1 Before You Start

Authorized Service Centers

Fluke South East Asia Pte Ltd.

Fluke ASEAN Regional Office

Service Center

60 Alexandra Terrace #03-16

The Comtech (Lobby D)

118502

SINGAPORE

Phone: +65 6799-5588

Telefax: +65 6799-5588

E-mail: antng@singa.fluke.com

When contacting these Service Centers for support, please have the following

information available:

•

Model Number

•

Serial Number

•

Voltage

•

Complete description of the problem

5

Page 10

Page 11

2 Introduction

2 Introduction

Hart Scientific’s Model 3125 Detachable Hot Plate is controlled by Hart Scien

tific’s 2200 controller and uses a precision platinum RTD as a sensor with a

heater to control the temperature. The 3125 and 2200 are a matched set.

The controller display shows the temperature and also the set-point tempera

ture. The temperature may be set to any temperature within the range of 35°C

to 400°C in 0.01°C or °F increments by using the buttons on the control panel.

The controller’s multiple fault protection devices insure user and instrument

safety and protection.

The Detachable Hot Plate (see Figure 1) consists of a controlled plate made of

aluminum. A heater is attached to the bottom with an RTD temperature sensor

used to control it. The housing consists of a top cover and a base, which serve

as a clamp and strain relief point for the wiring. The Reference Well is avail

able for use with a 3/16-inch diameter probe, which may be used to check the

plate temperature. This well is used to calibrate the system.

1150/2300 W

10 A

115/230 V

50/60 Hz

115V

1

HEATER

3

PROBE

2

4

RS-232

-

115/230 VAC 50/60 Hz

2200 Controller Back Panel

3125 Hot Plate Assembly

Figure 1 Controller and Hotplate Assembly

7

Page 12

Page 13

3 Specifications and Environmental

Conditions

3.1 Specifications

Temperature Range 35°C to 400°C (95°F to 752°F)

Display Accuracy ±0.5°C to 200°C

Stability ±0.2°C to 300°C

Resolution 0.01°

Uniformity ±0.3°C at 100°C

Heating Time

Cooling Time

Stabilization Time 8 minutes

Controller Model 2200 Microprocessor based with RS-232 serial port

Readout °C or °F switchable

Sensor

Heater 325 Watt, solid state controlled

Surface Plate 6061 aluminum; top surface machine finished to 0.000032" (0.0008 mm), 3.8" (96

Power 115 VAC (±10%), 2.8 A or 230 VAC (±10%), 1.4 A, specify, 50/60 Hz, 325 W

Weight 7 lb. (3.2 kg) with 2200 Controller

NIST-Traceable

Calibration

Safety OVERVOLTAGE (Installation) CATEGORY II, Pollution Degree 2 per IEC1010-1

±1.0°C to 400°C

±0.3°C to 400°C

±0.6°C at 200°C

±0.9°C at 300°C

±1.4°C at 400°C

°

C to 400°C: 22 minutes

25

°

C to 100°C: 65 minutes

400

Ω

RTD, 100

mm) diameter accessible

Data at 50°C, 120°C, 190°C, 260°C, 330°C, and 400°C

3.2 Environmental Conditions

Although the instrument has been designed for optimum durability and trou

ble-free operation, it must be handled with care. The instrument should not be

operated in an excessively dusty or dirty environment. The instrument operates

safely under the following conditions:

•

temperature range: 5-40°C (41-104°F)

-

9

Page 14

ambient relative humidity: maximum 80% for temperature <31°C, de

•

creasing linearly to 50% at 40°C

pressure: 75kPa-106kPa

•

mains voltage within ±10% of nominal

•

vibrations in the calibration environment should be minimized

•

altitude does not effect the performance or safety of the unit

•

-

10

Page 15

4 Troubleshooting

4 Troubleshooting

4.1 Troubleshooting Problems, Possible Causes,

and Solutions

In the event that the instrument appears to function abnormally, this section

may help to find and solve the problem. Several possible problem conditions

are described along with likely causes and solutions. If a problem arises, please

read this section carefully and attempt to understand and solve the problem. If

the problem cannot otherwise be solved, contact an Authorized Service Center

(see Section 1.3). Be sure to have the model number, serial number, and voltage

of your instrument available.

Problem Possible Causes and Solutions

Incorrect temperature

reading

Incorrect R0, ALPHA, and DELTA parameters. Find the values for R0, AL

PHA, and DELTA on the Report of Calibration that was shipped with the instru

ment (or from subsequent calibrations of the instrument). Reprogram the

parameters into the 2200 memory (see the 2200 User’s Guide). Allow the instrument to stabilize and verify the accuracy of the temperature reading.

Controller locked up. The controller may have locked up due to a power

surge or other aberration. Initialize the system by performing the Factory Reset

Sequence.

-

-

Blank display after

mains power applied

The Instrument heats or

cools too quickly or too

slowly

Factory Reset Sequence. Hold the SET and EXIT buttons down at the same

time while powering up the instrument. After the instrument displays

release the buttons. The display shows

displays the firmware version. After performing the master reset sequence, all

of the configuration parameters are reset to their default values. Reprogram the

R0, ALPHA, and DELTA parameters into the Model 9132 memory (see Section

, Calibration Parameters) and any other applicable configuration parameters.

Allow the instrument to stabilize and verify the accuracy of the temperature

reading.

Blown fuse. A fuse may have blown due to a power surge or failure of a com

ponent. Replace the fuse once. If the fuse blows a second time, it is likely

caused by the failure of a component. Always replace the fuse with one of the

same rating, voltage, and type. Never replace the fuse with one of a higher cur

rent rating.

Incorrect scan and scan rate settings. The scan and scan rate settings may

be set to unwanted values. Check the Scan and Scan Rate settings. The scan

may be off (if the unit seems to be responding too quickly). The scan may be

on with the Scan Rate set low (if unit seems to be responding too slowly).

-init-

, then displays

9132

-init-

,

, and then

-

-

11

Page 16

3125 Detachable Hotplate

User’s Guide

Problem Possible Causes and Solutions

The display shows any

of the following:

err 2,err 3,err

4

,

Err 5,Err 6

Err 7

Temperature cannot be

set above a certain point

4.2 Comments

4.2.1 EMC Directive

Hart Scientifics’ equipment has been tested to meet the European Electromagnetic Compatibility Directive (EMC Directive, 89/336/EEC). The Declaration

of Conformity for your instrument lists the specific standards to which the unit

was tested.

err 1

,or

Controller problem. The error messages signify the following problems with

,

the controller.

Err 1

- a RAM error

Err 2

- a NVRAM error

Err 3

- a Structure error

Err 4

- an ADC setup error

Err 5

- an ADC ready error

Err 6

– a defective control sensor

Err 7

– a heater error

Initialize the system by performing the Factory Reset Sequence describe

above.

Incorrect High Limit parameter. The High Limit parameter may be set below

400°C. Check this value as described in the 2200 User’s Guide.

12

4.2.2 Low Voltage Directive (Safety)

In order to comply with the European Low Voltage Directive (73/23/EEC),

Hart Scientific equipment has been designed to meet the IEC 1010-1 (EN

61010-1) and the IEC 1010-2-010 (EN 61010-2-010) standards.

Loading...

Loading...