Page 1

2635A-PRINT 120

2635A-PRINT 230

Serial 80 Column Dot-Matrix Printers

Instruction Sheet

®

Introduction

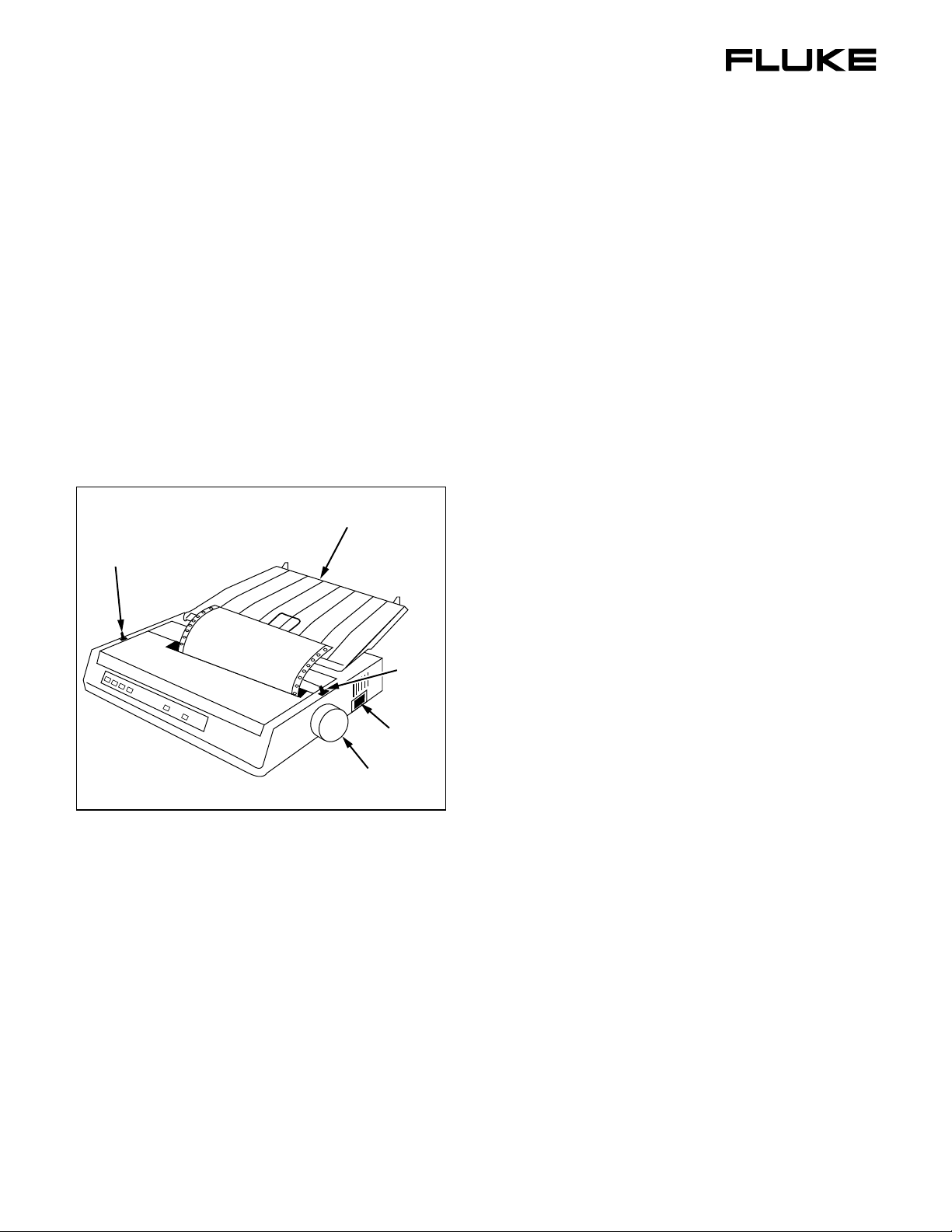

The 2635A-PRINT 120 and 2635A-PRINT 230 Serial

Printers (hereafter referred to as “the Printer”) are 80Column Dot-Matrix Serial Printers that can be

connected directly to the Fluke Hydra Series (2635A,

2625A, and 2620A models hereafter referred to as

“the Hydra”) to provide printed hard-copy output

without the need for a computer or software. The

Printer is shown in Figure 1.

Paper Separator

Bail Arm

Lever

Paper

Lever

Power

Switch

Installation

XWWarning

To avoid possible electric shock or

personal injury:

• Verify that the line voltage marked

on the back of the printer matches

the local mains supply before

connection.

• Check that the voltage listed on

the rating plate, located on the

back of the printer, matches the

local mains supply voltage before

applying power.

Some Printer parts have been removed for shipping.

Reassemble its detached parts, as follows (see

Figure 1 and the Quick Setup Guide for details):

1. Install the platen knob on the shaft on the rightside of the Printer, lining up the slot in the knob

with the pin on the shaft.

2. Remove shipping tape from the Printer, and open

the top cover.

Platen Knob

Figure 1. 2635A-PRINT Printer

egv001.eps

Shipping Contents

The Printer comes with the following items:

• Instructions for Printer setup and use (this sheet)

• Quick Start Guide

• Platen knob

• Ribbon cartridge

• Paper separator

• CD-ROM with User’s Guide and print drivers

• Fluke RS42 serial printer cable

PN 2558806 February 2006 ©2006 Fluke Corporation. All rights reserved. Printed in U.S.A. 1

3. The print head is held to one side by a plastic

shipping retainer. Remove the retainer. Save the

retainer in case the Printer ever needs to be

shipped.

4. Center the print head by gently pushing it to the

center of the platen area.

5. Attach the ribbon cartridge to the print head by

setting the front-end in place and carefully

snapping the ribbon down between the print head

and platen.

6. Attach the paper separator by slipping the hooks

on its front into the two slots on the top of the

Printer.

Page 2

2635A-PRINT 120, 2635A-PRINT 230

Instruction Sheet

Loading Printer Paper

XWWarning

If the printer has been recently used,

the print head may still be hot.

To allow continuous printing of Hydra scan data,

Continuous Forms-type paper is recommended.

Load continuous forms paper as follows (see

Figure 1):

1. Set the paper lever (located on the right-side) to

its forward position to select “Continuous

Forms”.

2. Move the bail arm lever (located on the left-side)

forward to release bail arm pressure from the

platen.

3. With the top-cover open, thread the continuous

forms paper either in from the back, under the

paper separator and down behind the platen, or up

through the slot on the bottom of the Printer.

4. Raise the paper in front of the platen to a level

above the Printer top.

5. If the paper has sprocket holes on the sides, adjust

the spacing of the sprockets on the platen to fit the

paper properly. For more details, see the User’s

Guide on the included CD-ROM.

6. With the paper in the correct position on the

platen and sprockets, move the bail arm lever

back to press the bail arm against the paper.

7. Close the top cover, making sure to thread the

paper up through the slot.

8. Using the platen knob, adjust the paper to the

right starting position with the top edge of the

paper above the bail arm.

Connecting the Printer

The Printer connects directly to the Hydra’s RS-232C

connector on the Hydra rear panel, using the supplied

RS42 serial printer cable.

To simplify system setup, Printer default settings

correspond to Hydra series instruments. No

adjustments to these settings are necessary.

To set up the Printer:

1. Connect the larger 25-pin connector end of the

RS42 serial printer cable to the serial interface

connector on the Printer.

2. Connect the 9-pin connector end of the RS42

serial cable to the RS-232C serial connector on

the rear panel of the Hydra.

3. Connect power cord to the rear of the Printer, and

plug it into an appropriate power outlet.

4. Turn the Printer power on.

To set up the Hydra:

1. Check that the Hydra is set to 9600 Baud and No

Parity (refer to the proper Hydra Users Manual

for instructions). Use the

[COMM]

buttons on the Hydra front panel to

SHIFT and LIST

check and set if needed.

2. Set the Hydra for Autoprint mode. See the

instructions below for the appropriate model:

• 2635A Data Bucket

1. Press the

SHIFT and FILES [MODE]

buttons.

2. Select PRINT (or BOTH) Destination

using up or down arrow keys.

3. Press

ENTER.

9. Press the

SELECT button on the front of the

Printer to put it on-line. The light next to the

SELECT button indicates the printer is online.

2

4. Select ALL for the Mode.

5. Press the

ENTER key again.

• 2625A Data Logger

1. Press the

SHIFT and PRINT [MODE]

buttons.

2. Select PRINT (or BOTH) Destination

using up or down arrow keys.

3. Press

ENTER.

4. Select ALL for the Mode.

5. Press the

6. Check that the

ENTER key again.

PRN annunciator on the

display is on.

Page 3

Serial 80 Column Dot-Matrix Printers

Operation

7. Press the PRINT button on the Hydra if

necessary to turn

PRN on.

• 2620A Data Acquisition Unit

1. Check that the

PRN annunciator on the

display is on.

2. Press the

necessary to turn

PRINT button on the Hydra if

PRN on.

Operation

Before starting Scan on the Hydra, ensure that the

Printer is set up and paper is loaded. Also check that

the Hydra is set to Autoprint mode as described

above. Press the

Printer if necessary to put it on-line.

Press the

SCAN button on the Hydra to start scanning.

The Printer should print each scan as it occurs. Press

SCAN again to stop scanning.

The Printer has been set to operate in its

default factory setting as an accessory to the

Hydra. Please refer to the manufacturer’s

instructions and supplied software for

operating the Printer in other applications.

Refer to the included CD-ROM for other

applications.

SELECT button on the front of the

Note

Paper

Type Feed Weight Width

Cut Sheets Top only

Continuous,

Single Part

Continuous,

Multipart

• 4 sheets

(orig.+3),

Carbonless

• Up to 0.11"

(0.28 mm)

Rear/

Bottom

Rear/

Bottom

16 to 21 lb.

US Bond

(60 to 81 g/m²)

14 to 20 lb.

US Bond

(53 to 75 g/m²)

14 to 20 lb.

US Bond

(53 to 75 g/m²)

3 in to 9.5 in

(76 to 241 mm)

3 in to 9.9 in

(76 to 251 mm)

3 in to 9.9 in

(76 to 251 mm)

Reliability

Ribbon Life 3 million characters (avg.)

Print head Life 200 million characters average in

10 cpi utility mode

Mean Time

Between

20,000 hours at 25 % duty cycle

and 35 % page density

Failures

(MTBF)

Specifications

General

Print Method Impact dot matrix

Print head

Emulations

(co-resident)

Print Speed,

characters per

second (cps)

Buffer size 128 Kb

9 pins, 0.0118 in (0.30 mm)

diameter, with thermal protection

IBM 2480

Epson ESC/P2

Okidata MICROLINE Standard

Super Speed

Draft (SSD)

High Speed

Draft (HSD)

Utility (UTL) 250 cps

Near Letter

Quality (NLQ)

375 cps

(12 cpi only)

333 cps

62.5 cps

Physical

Height 3.15 in (80 mm)

Width 14.65 in (372 mm)

Depth 10.83 in (275 mm)

Weight 9.9 lb (4.5 Kg)

Electrical

Voltage 120 V, +6 %, -15 %

(2635A-PRINT 120 model)

230 V, +15 %, -14 %

(2635A-PRINT 230 model)

Frequency 50 or 60 Hz, ±2 %

3

Page 4

2635A-PRINT 120, 2635A-PRINT 230

Instruction Sheet

Environmental

Temperature

Operating

Storage

Humidity

Operating

Storage

Noise level

Normal:

Quiet Mode:

41 to 104 °F (5 to 40 °C)

-40 to 158 °F (-40 to +70 °C)

20 to 80 % RH

5 to 95 % RH

Less than 54 dBA

Less than 51 dBA

Interfaces

Serial Models RS-232C Serial

USB 1.1

Contacting Fluke

To locate an authorized service center, visit us on the

World Wide Web at www.fluke.com

using any of the following numbers:

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

LIMITED WARRANTY AND LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and

workmanship for 90 days from the date of purchase. This warranty

does not cover fuses, disposable batteries, or damage from

accident, neglect, misuse, alteration, contamination, or abnormal

conditions of operation or handling. Resellers are not authorized to

extend any other warranty on Fluke’s behalf. To obtain service

during the warranty period, contact your nearest Fluke authorized

service center to obtain return authorization information,

then send the product to that Service Center with a description of

the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES,

SUCH AS FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSED

OR IMPLIED. FLUKE IS NOT LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, ARISING

FROM ANY CAUSE OR THEORY.

Since some states or countries do not allow the exclusion or

limitation of an implied warranty or of incidental or consequential

damages, this limitation of liability may not apply to you.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

or call Fluke

4

Loading...

Loading...