Page 1

2620A/2625A

®

Hydra Series II Data Acquisition Unit

Hydra Series II Data Logger

Users Manual

PN 686675

November 1997

© 1997 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY & LIMITATI O N OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under

normal use and service. The warranty period is one year and begins on the date of shipment.

Parts, product repairs and services are warranted for 90 days. This warranty extends only to the

original buyer or end-user customer of a Fluke authorized reseller, and does not apply to fuses,

disposable batteries or to any product which, in Fluke’s opinion, has been misused, altered,

neglected or damaged by accident or abnormal conditions of operation or handling. Fluke

warrants that software will operate substantially in accordance with its functional specifications for

90 days and that it has been properly recorded on non-defective media. Fluke does not warrant

that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user

customers only but have no authority to extend a greater or different warranty on behalf of Fluke.

Warranty support is available if product is purchased through a Fluke authorized sales outlet or

Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for

importation costs of repair/replacement parts when product purchased in one country is submitted

for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price, free of

charge repair, or replacement of a defective product which is returned to a Fluke authorized

service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center or send the

product, with a description of the difficulty, postage and insurance prepaid (FOB Destination), to

the nearest Fluke authorized service center. Fluke assumes no risk for damage in transit.

Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB

Destination). If Fluke determines that the failure was caused by misuse, alteration, accident or

abnormal condition of operation or handling, Fluke will provide an estimate of repair costs and

obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return

transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER

ARISING FROM BREACH OF WARRANTY OR BASED ON CONTRACT, TORT, RELIANCE OR

ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or

exclusion or limitation of incidental or consequential damages, the limitations and exclusions of

this warranty may not apply to every buyer. If any provision of this Warranty is held invalid or

unenforceable by a court of competent jurisdiction, such holding will not affect the validity or

enforceability of any other provision.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

5/94

Page 3

Table of Contents

Chapter Title Page

1 Introduction........................................................................................ 1-1

The Hydra Series II Data Acquisition Unit....................................................... 1-3

The Hydra Series II Data Logger...................................................................... 1-3

Options and Accessories ................................................................................... 1-3

Applications Software................................................................................... 1-3

IEEE-488 Interface Assembly....................................................................... 1-3

Connector Set (2620A-100).......................................................................... 1-3

Accessories.................................................................................................... 1-5

Where to go From Here..................................................................................... 1-5

2 Overview............................................................................................. 2-1

Introduction....................................................................................................... 2-3

Setting Up the Instrument.................................................................................. 2-3

Unpacking and Inspecting the Instrument..................................................... 2-3

Adjusting the Handle .................................................................................... 2-3

Line Power.................................................................................................... 2-4

Front/Rear Panel Features............................................................................. 2-4

Input Channels .............................................................................................. 2-9

Operating Modes............................................................................................... 2-9

Turning the Instrument On................................................................................ 2-9

Front Panel Display........................................................................................... 2-10

Reading the Display .......................................................................................... 2-10

Left Display................................................................................................... 2-10

Right Display ................................................................................................ 2-10

Specific Annunciators................................................................................... 2-10

Front Panel Buttons........................................................................................... 2-11

Selecting a Channel....................................................................................... 2-11

Using the Buttons.......................................................................................... 2-11

Setting up a Channel.......................................................................................... 2-12

Setting Alarm Limits and Mx+B Scaling Values.............................................. 2-14

Alarm Limits................................................................................................. 2-14

Mx+B Scaling............................................................................................... 2-15

Setting the Scan Interval.................................................................................... 2-15

Using the Monitor Function.............................................................................. 2-16

i

Page 4

2620A/2625A

Users Manual

Using the Scan Function.................................................................................... 2-16

Reviewing Channel Data................................................................................... 2-16

Viewing the Totalizer Count............................................................................. 2-17

Using External DC Power................................................................................. 2-17

Using the Rack Mount Kit................................................................................. 2-18

3 Operating the Instrument from the Front Panel............................... 3-1

Introduction....................................................................................................... 3-3

Operating Modes............................................................................................... 3-3

Other Displayed Data........................................................................................ 3-4

What is the Present Configuration?................................................................... 3-4

If Power is Interrupted .................................................................................. 3-4

If the Configuration is Reset......................................................................... 3-4

Channel Configuration...................................................................................... 3-4

Selecting Channel, Function, and Range...................................................... 3-4

Setting Alarms............................................................................................... 3-9

Alarm Limits............................................................................................. 3-9

Alarm Indications ..................................................................................... 3-10

Resetting Alarm Conditions ..................................................................... 3-11

Using the Digital I/O Lines........................................................................... 3-11

Mx+B Scaling............................................................................................... 3-12

Instrument Configuration.................................................................................. 3-14

Entering and Changing Numeric Values....................................................... 3-14

Selecting Scan Interval.................................................................................. 3-15

Selecting the Measurement Rate................................................................... 3-15

Triggering...................................................................................................... 3-16

External Triggering....................................................................................... 3-16

Changing the Temperature Unit.................................................................... 3-16

Setting Date and Time of Day....................................................................... 3-17

Measurement Connections................................................................................ 3-17

DC Volts, AC Volts, Frequency, and Thermocouples.................................. 3-18

Resistance and RTD...................................................................................... 3-20

Totalizing........................................................................................................... 3-22

General.......................................................................................................... 3-22

Connections................................................................................................... 3-22

Review Array..................................................................................................... 3-22

List Button Functions........................................................................................ 3-23

Autoprint ........................................................................................................... 3-25

Memory Storage................................................................................................ 3-25

Front Panel Lock out Conditions....................................................................... 3-26

Front Panel Review Only Function............................................................... 3-26

Front Panel Monitor Only Function.............................................................. 3-26

Computer Interface-Initiated Lockouts......................................................... 3-27

REM Annunciator ............................................................................................. 3-27

Calibration......................................................................................................... 3-27

4 Using the Computer Interface ........................................................... 4-1

Introduction....................................................................................................... 4-3

Front Panel and Computer Interface Operations........................................... 4-3

Types of Computer Interface........................................................................ 4-3

Using the RS-232 Computer Interface .............................................................. 4-3

Setting Communication Parameters (RS-232).............................................. 4-4

Autoprint and Memory Storage (RS-232)..................................................... 4-5

ii

Page 5

Contents

Autoprint: Computer Interface Control.................................................... 4-5

Autoprint: Output Format......................................................................... 4-5

Memory Storage: Computer Interface Control......................................... 4-6

Memory Retrieval..................................................................................... 4-6

Memory Full Operation............................................................................ 4-7

Clearing Memory...................................................................................... 4-7

Cabling the Instrument to a Host or Printer (RS-232) .................................. 4-7

Installation Test............................................................................................. 4-8

RS-232 Information....................................................................................... 4-8

Character Echoing .................................................................................... 4-8

Character Deletion.................................................................................... 4-8

Device Clear Using Ctrl C........................................................................ 4-8

RS-232 Prompts........................................................................................ 4-9

Sample Program Using the RS-232 Computer Interface.............................. 4-9

Using the IEEE-488 Interface............................................................................ 4-9

IEEE-488 Operating Limitations .................................................................. 4-9

Installing the IEEE-488 Interface.................................................................. 4-9

Enabling the IEEE-488 Interface.................................................................. 4-12

Installation Test............................................................................................. 4-13

General Information (RS-232 and IEEE-488)................................................... 4-13

How the Instrument Processes Input............................................................. 4-13

Input Strings.............................................................................................. 4-14

Input Terminators ..................................................................................... 4-14

Typical Input Strings................................................................................ 4-14

Sending Numeric Values to the Instrument (RS-232 and IEEE-488) ...... 4-16

Sending Input Strings to the Instrument................................................... 4-16

How the Instrument Processes Output.......................................................... 4-16

Service Requests (IEEE-488 only) and Status Registers.............................. 4-17

Event Status and Event Status Enable Registers...................................... 4-19

Status Byte Register.................................................................................. 4-19

Reading the Status Byte Register ............................................................. 4-20

Service Request Enable Register.............................................................. 4-21

Instrument Event Register........................................................................ 4-21

Computer Interface Command Set.................................................................... 4-22

(continued)

5 Additional Considerations ................................................................ 5-1

Introduction....................................................................................................... 5-3

Measurement Rate............................................................................................. 5-3

Advanced Trigger Mechanisms......................................................................... 5-3

Front Panel Trigger Control.......................................................................... 5-3

Computer Interface Trigger Control............................................................. 5-3

Both External and Monitor Alarms Disabled (Type 0) ................................ 5-4

External Trigger Enabled (Type 1)............................................................... 5-4

Monitor Alarm Enabled (Type 2)................................................................. 5-6

Thermal Voltages.............................................................................................. 5-6

When Measuring Resistance or Temperature (RTD)........................................ 5-6

True RMS Measurements.................................................................................. 5-8

Effects of Internal Noise in AC Measurements............................................ 5-8

Waveform Comparison (True RMS vs Average Responding)..................... 5-8

Making Mixed Measurements........................................................................... 5-9

Using Shielded Wiring...................................................................................... 5-11

General Rule ................................................................................................. 5-11

Alternate Suggestions ................................................................................... 5-11

Non-Isolated Sensor Configuration.......................................................... 5-11

iii

Page 6

2620A/2625A

Users Manual

Isolated and Shielded Sensor Configuration ............................................ 5-11

In More Detail............................................................................................... 5-12

6 Maintenance....................................................................................... 6-1

Introduction....................................................................................................... 6-3

Cleaning............................................................................................................. 6-3

Line Fuse........................................................................................................... 6-3

Self-Test Diagnostics and Error Codes............................................................. 6-3

Performance Tests............................................................................................. 6-4

Accuracy Verification Test........................................................................... 6-7

Channel Integrity Test................................................................................... 6-7

Thermocouple Measurement Range Accuracy Test..................................... 6-9

4-Terminal Resistance Test........................................................................... 6-10

Thermocouple Temperature Accuracy Test.................................................. 6-11

Open Thermocouple Response Test ............................................................. 6-13

RTD Temperature Accuracy Test................................................................. 6-14

RTD Temperature Accuracy Test (Using Decade Resistance Source).... 6-14

RTD Temperature Accuracy Test (Using DIN/IEC 751)......................... 6-15

Digital Input/Output Verification Tests........................................................ 6-15

Digital Output Test................................................................................... 6-16

Digital Input Test...................................................................................... 6-16

Totalizer Test............................................................................................ 6-17

Totalizer Sensitivity Test.......................................................................... 6-18

Dedicated Alarm Output Test....................................................................... 6-19

External Trigger Input Test........................................................................... 6-21

Calibration......................................................................................................... 6-21

Variations in the Display................................................................................... 6-22

Service............................................................................................................... 6-22

Appendices

A Specifications.............................................................................................. A-1

B ASCII & IEEE-488 Bus Codes................................................................... B-1

C IEEE-488.2 Devise Documentation Requirements..................................... C-1

D Making Mixed Measurements.................................................................... D-1

E Binary Upload of Logged Data (LOG_BIN?) (2625A only)...................... E-1

F RS-232 Cabling........................................................................................... F-1

Index

iv

Page 7

List of Tables

Table Title Page

1-1. Hydra Features....................................................................................................... 1-4

1-2. Accessories............................................................................................................ 1-5

2-1. Display Annunciators ............................................................................................ 2-7

2-2. Front Panel Pushbuttons........................................................................................ 2-11

2-3. Review Array......................................................................................................... 2-17

3-1. Configuration Reset Settings................................................................................. 3-5

3-2. DC Voltage, AC Voltage....................................................................................... 3-6

3-3. Resistance.............................................................................................................. 3-7

3-4. Frequency............................................................................................................... 3-7

3-5. Thermocouple Temperature................................................................................... 3-8

3-6. RTD Temperature.................................................................................................. 3-9

3-7. Alarm Selection..................................................................................................... 3-10

3-8. Initial Alarm Assignments, Digital I/O Lines 4 Through 7................................... 3-12

3-9. Mx+B Selection..................................................................................................... 3-14

3-10. Scan Interval.......................................................................................................... 3-15

3-11. Measurement Rate Selection ................................................................................. 3-16

3-12. Trigger Type Selection .......................................................................................... 3-16

3-13. Date/Time Selection .............................................................................................. 3-17

3-14. Thermocouple Ranges ........................................................................................... 3-20

3-15. Review Array......................................................................................................... 3-23

3-16. List Button Operation ............................................................................................ 3-24

3-17. Autoprint/Memory Storage Selection.................................................................... 3-26

3-18. Clearing Memory Storage...................................................................................... 3-26

3-19. REM Annunciation................................................................................................ 3-27

4-1. RS-232 Setup......................................................................................................... 4-4

4-2. IEEE-488.1 Capabilities........................................................................................ 4-12

4-3. IEEE-488 Setup ..................................................................................................... 4-12

4-4. Status Byte Register............................................................................................... 4-19

4-5. Event Status Register............................................................................................. 4-20

4-6. Instrument Event Register (IER) ........................................................................... 4-22

4-7. Command and Query Summary............................................................................. 4-23

4-8. Command and Query Reference............................................................................ 4-26

5-1. Ohms Test Voltage................................................................................................ 5-8

6-1. Power-Up Error Codes........................................................................................... 6-5

6-2. Recommended Test Equipment............................................................................. 6-6

v

Page 8

2620A/2625A

Users Manual

6-3. Performance Tests (Voltage, Resistance, and Frequency).................................... 6-8

6-4. Performance Tests for Thermocouple Temperature Function (IPTS-68/ITS-90). 6-13

6-5. Performance Tests for RTD Temperature Function (Resistance) (DIN/IEC 751

Amendment 1) (IPTS-68) ...................................................................................... 6-14

6-6. Performance Tests for RTD Temperature Function (DIN/IEC 751 Amendment 1)

(IPTS-68)............................................................................................................... 6-15

6-7. Digital Input Values............................................................................................... 6-17

E-1. Floating Point Format............................................................................................ E-4

vi

Page 9

List of Figures

Figure Title Page

2-1. Adjusting Handle................................................................................................... 2-3

2-2. Front Panel............................................................................................................. 2-5

2-3. Left Display........................................................................................................... 2-6

2-4. Right Display......................................................................................................... 2-6

2-5. Annunciators.......................................................................................................... 2-6

2-6. Rear View.............................................................................................................. 2-8

3-1. Configuration Mode............................................................................................... 3-3

3-2. Input Module Connections .................................................................................... 3-19

3-3. 2-Terminal and 4-Terminal Connections............................................................... 3-21

3-4. Totalizing Connection ........................................................................................... 3-22

4-1. Data/Stop Bits........................................................................................................ 4-4

4-2. Sample Program..................................................................................................... 4-10

4-3. Typical Input Strings ............................................................................................. 4-15

4-4. Overview of Status Data Registers........................................................................ 4-18

5-1. External Trigger Timing........................................................................................ 5-5

5-2. 2T and 4T-Connections ......................................................................................... 5-7

5-3. Comparison of Common Waveforms.................................................................... 5-10

6-1. Replacing the Line Fuse ........................................................................................ 6-4

6-2. 4-Terminal Connections to 5700A ........................................................................ 6-12

6-3. 4-Terminal Connections to Decade Resistance Box ............................................. 6-13

6-4. Dedicated Alarms Output Test .............................................................................. 6-20

6-5. External Trigger Test............................................................................................. 6-21

E-1. ASCII String Decoding.......................................................................................... E-2

E-2. Floating Point Conversion..................................................................................... E-5

E-3. Example................................................................................................................. E-6

F-1. Summary of RS-232 Connections ......................................................................... F-3

F-2. Hydra (DB-9) to PC (DB-9) RS-232 Connection (Generic) ................................. F-4

F-3. Hydra (DB-9) to PC (DB-25) RS-232 Connection................................................ F-5

F-4. Hydra (DB-9) to Modem (DB-25) RS-232 Connection ........................................ F-6

F-5. Hydra (DB-9) to Printer (DB-25) RS-232 Connection.......................................... F-7

F-6. RS-232 DB9 and DB-25 Connectors..................................................................... F-8

vii

Page 10

Caution

THIS IS AN IEC SAFETY CLASS 1 PRODUCT. BEFORE USING, THE GROUND WIRE IN THE

LINE CORD OR THE REAR PANEL BINDING POST MUST BE CONNECTED FOR SAFETY.

Interference Information

This equipment generates and uses radio frequency energy and if not installed and used in strict

accordance with the manufacturer’s instructions, may cause interference to radio and television

reception. It has been type tested and found to comply with the limits for a Class B computing

device in accordance with the specifications of Part 15 of FCC Rules, which are designed to

provide reasonable protection against such interference in a residential installation.

Operation is subject to the following two conditions:

This device may not cause harmful interference.

•

This device must accept any interference received, including interference that may cause

•

undesired operation.

There is no guarantee that interference will not occur in a particular installation. If this equipment

does cause interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one of more of

the following measures:

Reorient the receiving antenna

•

Relocate the equipment with respect to the receiver

•

Move the equipment away from the receiver

•

Plug the equipment into a different outlet so that the computer and receiver are on different

•

branch circuits

If necessary, the user should consult the dealer or an experienced radio/television technician for

additional suggestions. The user may find the following booklet prepared by the Federal

Communications Commission helpful: How to Identify and Resolve Radio-TV Interference

Problems. This booklet is available from the U.S. Government Printing Office, Washington, D.C.

20402. Stock No. 004-000-00345-4.

Declaration of the Manufacturer or Importer

We hereby certify that the Fluke Model 2620A Data Acquisition Unit and 2625A Data Logger are in

compliance with BMPT Vfg 243/1991 and is RFI suppressed. The normal operation of some

equipment (e.g. signal generators) may be subject to specific restrictions. Please observe the

notices in the users manual. The marketing and sales of the equipment was reported to the

Central Office for Telecommunication Permits (BZT). The right to retest this equipment to verify

compliance with the regulation was given to the BZT.

Bescheinigung des Herstellers/Importeurs

Hiermit wird bescheinigt, daβ Fluke Model 2620A Data Acquisition Unit and 2625A Data Logger in

Übereinstimung mit den Bestimmungen der BMPT-AmtsblVfg 243/1991 funk-entstört ist. Der

vorschriftsmäßige Betrieb mancher Geräte (z.B. Meßsender) kann allerdings gewissen

Einschränkungen unterliegen. Beachten Sie deshalb die Hinweise in der Bedienungsanleitung.

Dem Bundesamt für Zulassungen in der Telekcommunikation wurde das Inverkehrbringen dieses

Gerätes angezeigt und die Berechtigung zur Überprüfung der Seire auf Einhaltung der

Bestimmungen eingeräumt.

Fluke Corporation

viii

Page 11

Safety Terms in this Manual

This instrument has been designed and tested in accordance with IEC publication 1010,

Safety Requirements for Electrical Measuring, control and Laboratory Equipment. This

Users Manual contains information, warnings, and cautions that must be followed to

ensure safe operation and to maintain the instrument in a safe condition. Use of this

equipment in a manner not specified herein may impair the protection provided by the

equipment.

The meter is designed for IEC 664, Installation Category II use. It is not designed for use

in circuits rated over 4800VA.

Warning statements identify conditions or practices that could result in personal injury

or loss of life.

Caution statements identify conditions or practices that could result in damage to

equipment.

Symbols Marked on Equipment

Danger - High voltage.

Ground (earth) terminal.

Protective ground (earth) terminal. Must be connected to safety earth

ground when the power cord is not used. See Chapter 2.

Attention - refer to the manual. This symbol indicates that information

about usage of a feature is contained in the manual. This symbol appears

in the following two places on the instrument rear panel:

1. Ground Binding Post (left of line power connector). Refer to "Using

External DC Power" in Chapter 2.

2. Alarm Outputs/Digital I/O Connectors. Refer to Appendix A,

Specifications.

Warning

To avoid electric shock:

• When the input module is installed, consider all channels

with connections as accessible terminals that may be

hazardous live.

• Disconnect the input module before touching or changing

external wiring.

• Remove inputs from live voltages before opening the i nput

module.

ix

Page 12

2620A/2625A

Users Manual

AC Power Source

DC Power Source

Use the Proper Fuse

Grounding the Instrument

The instrument is intended to operate from an ac power source that will not apply more

than 264V ac rms between the supply conductors or between either supply conductor and

ground. A protective ground connection by way of the grounding conductor in the power

cord is required for safe operation.

The instrument may also be operated from a 9 to 16V dc power source when either the

rear panel ground binding post or the power cord grounding conductor is properly

connected.

To avoid fire hazard, use only a fuse identical in type, voltage rating, and current rating

as specified on the rear panel fuse rating label.

The instrument utilizes controlled overvoltage techniques that require the instrument to

be grounded whenever normal mode or common mode ac voltages or transient voltages

may occur. The enclosure must be grounded through the grounding conductor of the

power cord, or if operated on battery with the power cord unplugged, through the rear

panel ground binding post.

Use the Proper Power Cord

Use only the power cord and connector appropriate for the voltage and plug

configuration in your country.

Use only a power cord that is in good condition.

Refer cord and connector changes to qualified service personnel.

Do Not Operate in Explosive Atmospheres

To avoid explosion, do not operate the instrument in an atmosphere of explosive gas.

Do Not Remove Cover

To avoid personal injury or death, do not remove the instrument cover. Do not operate

the instrument without the cover properly installed. Normal calibration is accomplished

with the cover closed, and there are no user-serviceable parts inside the instrument, so

there is no need for the operator to ever remove the cover. Access procedures and the

warnings for such procedures are contained in the Service Manual. Service procedures

are for qualified service personnel only.

Do Not Attempt to Operate if Prot ect ion may be Impaired

If the instrument appears damaged or operates abnormally, protection may be impaired.

Do not attempt to operate it. When in doubt, have the instrument serviced.

x

Page 13

Introduction

This section will have you operating Hydra in a matter of minutes. All basic operating

information is covered in this short Getting Started guide. Subsequent chapters of the

manual cover the instrument in more detail.

This manual contains information and warnings that must be followed to

ensure safe operation and retain the instrument in safe condition.

The Basics

Hydra has 21 input channels: channel 0 is on the front panel, and channels 1 through 20

are on the rear input module.

There are two ways Hydra takes measurements (these can be used separately or

together):

• A Scan function, which measures all channels at a specified scan interval.

• A Monitor function, which repeatedly measures any one channel.

The instrument has three different modes of operation:

• Active Mode - when the Scan and/or Monitor functions are on.

• Configuration Mode - when any of the setup parameters are being changed.

Getting Started

Note

• Inactive mode - when the instrument is powered up, and sitting idle (i.e., not in

Active Mode or Configuration Mode).

Turning On the Instrument

Press R ON. The entire display lights up as the instrument steps through a series of

self tests. (Refer to Chapter 6 if any error messages are displayed during this self-test

sequence.) When the self-tests are finished, the instrument resumes whatever mode it

was in the last time power went off.

Normally it will go to Inactive Mode, and sit idle with a channel number on the righthand display. You can change the displayed channel with G and D. Other annunciators

are lit dimly to provide a summary description of the selected channel’s setup.

The initial setup for all channels should be "off": as you scroll through the channels with

G or D, the "OFF" annunciator should be on dimly. If any of the channels are set up

otherwise, or if the instrument immediately starts taking measurements after the self-test

sequence, then it still contains the previous user’s setup. You can quickly get the

instrument back to the initial setup by performing a "Configuration Reset".

To perform a Configuration Reset, press R OFF. Then hold C in, while pressing

R ON; keep C pressed until the self-test sequence is finished and the instrument

beeps one time.

Setting Up a Channel

1. Press G, D to select a channel to modify. For this example, start with channel 0.

2. Press F to access the function setup menu.

The "SET" and "FUNC" annunciators come on, and the instrument goes into

Configuration Mode. The present function for this channel is also highlighted (for

xi

Page 14

2620A/2625A

Users Manual

this example, "OFF" is lit if you’re working with channel 0, and have already

performed the Configuration Reset).

3. Press G, D to cycle through the choices for measurement function. For now, select

"V AC", to set up the channel for AC voltage measurements.

4. Press E to confirm your choice. The instrument then offers a choice of

measurement ranges for this function, starting with "Auto" for autoranging.

5. Press G, D to cycle through the choices for range. Select the 300v range. (300v is

available only on channels 0, 1 and 11.)

6. Press E to confirm your choice.

This completes setting up channel 0 to measure AC voltage. The instrument returns to

Inactive Mode, and the new setup for channel 0 is shown dimly on the display.

The sequence for setting up a channel to measure DC Voltage, Frequency or Resistance

is very similar:

1. Press G, D to select a channel to set up.

2. Press F to access the function setup menu.

3. Press G, D to cycle through the choices for measurement function, then press

E.

4. Press G, D to cycle through the choices for range, then press E. This

completes the setup for the channel and the instrument returns to Inactive Mode.

When you set up a channel to measure resistance, the instrument also lets you choose 2Terminal or 4-Terminal measurements ("2T" or "4T") before returning to Inactive Mode.

Note that 4-Terminal measurements are supported only on channels 1 - 10.

The sequence for setting up a channel to measure temperature is similar:

1. Press G, D to select a channel to set up.

2. Press F to access the function setup menu.

3. Press G, D to select "°C" from the list of measurement functions, then press E.

(Chapter 3 of the manual explains how to change temperature measurement units.)

4. The instrument then offers a choice of 9 different thermocouple types, as well as

"Pt" for platinum RTD’s.

Press G, D to select a thermocouple type, then press E. This completes the setup

for the channel and the instrument returns to Inactive Mode.

When setting up a channel to measure RTD’s, the instrument also prompts for 2Terminal vs 4-Terminal measurements, and then allows you to specify a value for R0.

(Note that Channel 0 cannot be set up to measure thermocouples or 4-Terminal RTD’s.)

Subsequent sections of the manual explain how to set up alarm values and Mx+B linear

scaling for each channel.

Selecting the Scan Data Destination

The 2620A will always send the scan data to the RS-232 printer port, following each

scan. The 2625A can be configured to send the scan data to the RS-232 printer port, or to

the internal Memory Storage, or to both simultaneously. Begin this procedure by

selecting MODE (shift print). Select the scan data destination (“dESt” in the right

display) as “Print” (left display) to send the data to the RS-232 port, as “StoreE” to send

the data to Memory Storage, or as “both” for simultaneous storage and printing. Then

xii

Page 15

select the mode (“Mode” in right display) from “All” to output all scan data, “ALAr” to

output only alarm data, or “trAnS” to output data scanned only when the Hydra goes into

or out of alarm.

Once the destination and mode have been set, enable Memory Storage by pressing: print.

The “PRN” annunciator lights to indicate that Memory Storage is enabled.

No data will be saved unless the “PRN” annunciator is lit on the

on the Hydra from panel florescent display.

Memory contents can be sent to the RS-232 port for listing directly to a printer (refer to

Table 3-16 in Chapter 3) or through the computer interface.

Taking Measurements

Before taking any measurements, you might want to set up a few more channels... set up

three additional channels, as described below. (Remember, use G or D when in

inactive Mode to select a channel, and then press F.)

Channel Function

0 V AC, 300V range

1 V DC, 30V range

2 (leave set up as "OFF")

3 Resistance, 3 mΩ range

4 Thermocouple Temperature ("°C" or "°F")

5 .. 20 (leave set up as "OFF")

Warning

Getting Started

(continued)

Warning

Inputs may be connected to live voltages. To avoid electric

shock remove inputs from live voltages before openi ng t his

module.

You need to connect wires to these channels before taking measurements. Insert a pair of

test leads into the jacks on the front panel for channel 0. For channels on the rear Input

Module, proceed as follows:

1. Remove the input module from the rear panel.

2. Loosen the two large screws on top and open the module.

3. Connect wires to the pairs of terminals for channels 1 and 3. We’ve enclosed some

thermocouple wire for you to connect to channel 4; the thermocouple’s red lead must

be connected to the "low" input terminal, labeled "L". (Note that the enclosed

thermocouple is for demonstration purposes only. Measurements taken with it may

be off by 1 - 2 degrees.) Refer to Table 3-14 in Chapter 3 to identify the type of

thermocouple by positive lead color. This table also shows the appropriate usable

temperature range.

4. Thread the wires through the strain-relief pins and out the back of the module.

5. Close the cover, secure the screws, and insert the module back in the instrument.

The instrument is now ready to take measurements. Start with the Monitor function,

which takes repeated measurements on a channel.

Press G, D to select a channel to Monitor.

Press M to activate the monitor function.

xiii

Page 16

2620A/2625A

Users Manual

Note

You cannot activate the Monitor function if the selected channel is set up

as OFF; the instrument gives a long beep and ignores your request.

The "MON" annunciator comes on, and the instrument starts taking measurements on the

selected channel. If you haven’t connected the input leads to a signal, the instrument

simply displays a nominal noise reading; on channels set up to measure resistance, "OL"

is displayed for overload. (The instrument also displays "OL", or "otc" for open

thermocouple, when attempting to measure temperatures on channels to which no sensor

has been connected.)

Press G, D to scroll through other channels and take additional measurements. Note

that the instrument automatically skips over channels that are not set up (i.e., those

channels still set to "OFF").

Press M to deactivate the Monitor function when you’re through. ( M toggles the

Monitor function on and off.)

Next, press Q to activate the Scan function. The "Scan" annunciator comes on, and the

instrument begins taking measurements on all the channels you’ve set up.

When the scan completes, the instrument normally then counts down the time interval

remaining until the next scan is due. (the countdown appears on the right display.)

However, if you performed a Configuration Reset, then the scan interval has been set

back to 0:00:00. Under this condition, the instrument performs continuous scanning.

Subsequent sections of the manual explain how to change the scan interval.

Even with the scan function on, you can still use the Monitor function to watch a

channel:

Press M to activate the Monitor function.

Press G, D to change the monitor channel, as desired. (The instrument continues to

take scan measurements in the background.)

Press M to deactivate the Monitor function when you are through.

Similarly, press Q to deactivate the Scan function when you are through.

Viewing Minimum, Maxi mum, and Last Data Values

While taking scan measurements, the instrument also collects Minimum, Maximum and

Last values for each channel. These values are stored in the "Review Array." You can

examine the data in the Review array when the instrument is in Active Mode or Inactive

Mode. If you are in Active Mode, (i.e. the Scan and/or Monitor functions are on), the

instrument will continue to take measurements in the background while you examine the

Review data.

Press N to call up the Review array onto the display.

Use the four arrow buttons to examine different entries in the Review array. The arrow

buttons move around in the Review array, as illustrated below.

xiv

Page 17

Getting Started

(continued)

20

.

.

.

.

.

.

.

0

LAST MIN MAX

LAST MIN MAX

oo24f.eps

Press N or C to remove the Review data from the display when you’re through.

The remainder of this manual covers all aspects of using Hydra. Glance over the Table

of Contents; you’ll find that each section presents an additional layer of information. You

can use as little as (or as much as) you need for your Hydra application.

xv

Page 18

2620A/2625A

Users Manual

xvi

Page 19

Chapter 1

Introduction

Title Page

The Hydra Series II Data Acquisition Unit....................................................... 1-3

The Hydra Series II Data Logger...................................................................... 1-3

Options and Accessories ................................................................................... 1-3

Applications Software....................................................................................... 1-3

IEEE-488 Interface Assembly........................................................................... 1-3

Connector Set (2620A-100) .............................................................................. 1-3

Accessories........................................................................................................ 1-5

Where to go From Here..................................................................................... 1-5

1-1

Page 20

2620A, 2625A

Users Manual

1-2

Page 21

The Hydra Series II Data Acquisition Unit

Note

This manual contains information and warnings that must be followed to

ensure safe operation and retain the instrument in safe condition.

The Hydra Series II Data Acquisition Unit

The Hydra Series II Data Acquisition Unit (Model 2620A) is a multi-channel data

acquisition unit able to measure ac and dc voltages, temperature via thermocouples and

RTDs, resistance, and frequency. It features 21 measurement channels, 8 digital

input/output lines, a Totalizer input, and 4 alarm output lines. The Data Acquisition Unit

is easily carried by hand and can be ac or dc powered. The user can choose

communications with a host computer over an RS-232 (standard) or IEEE-488

(2620A/05) computer interface. Refer to Table 1-1 for a list of operating features.

The Hydra Serie s II Data Logger

The Hydra Series II Data Logger (Model 2625A) combines data logging memory with

the features of the Data Acquisition Unit. The RS-232 computer interface is standard

(IEEE-488 capability is not available.)

Introduction

1

Options and Accessories

Applications Software

The following software packages are available for the instrument:

• Hydra Starter (included with instrument)

Allows for communication from an IBM-compatible personal computer through the

RS-232 interface, emphasizing transfer of measurement and configuration settings to

and from the instrument.

• Hydra Logger Package (order separately)

Hydra Logger (model 2635A-901) is a Windows-based package that allows

complete set up and data collection and data conversion from up to 2 Hydra units.

Logger communicates over the RS-232 port on a personal computer and may be used

with telephone modems. Hydra Logger with Trending (model 2635A-902) includes a

comprehensive trending package that simulates a chart recorder. A brochure with

complete details is available.

IEEE-488 Interface Assembly

Model 2620A/05 includes an IEEE-488 Interface. Commands for the IEEE-488 interface

are virtually identical to those used with the RS-232 Interface

If your Hydra Series II Data Acquisition Unit does not have an IEEE-488 Interface, a

field-installable kit (2620A-05K) is available. The Hydra Series II Data Logger cannot

be equipped with an IEEE-488 Interface.

Connector Set (2620A-100)

The 2620A-100 is a complete set of input connectors (one Input Module and two Digital

I/O Connectors). These connectors allow for additional wiring setups so that a single

Hydra Series II Data Acquisition Unit or Data Logger can then be moved among

multiple installations.

1-3

Page 22

2620A, 2625A

Users Manual

Table 1-1. Hydra Features

• Channel Scanning

Can be continuous scanning, scanning at an interval time, single scans, or triggered (internal or

external) scans.

• Channel Monitoring

Make measurements on a single channel and view these measurements on the display.

• Channel Scanning and Monitoring

View measurements made for the monitor channel while scanning of all active channels continues.

• Multi-Function Display

Left (numeric) display shows measurement readings; also used when setting numeric parameters.

Right (alphanumeric) display used for numeric entries, channel number selection and display, status

information, and operator prompts.

• Front-Panel Operation

Almost all operations can be readily controlled with the buttons on the front panel.

• Measurement Input Function and Range

Volts dc (VDC), volts ac (VAC), frequency (Hz), and resistance (Ω) inputs can be specified in a fixed

measurement range. Autoranging, which allows the instrument to use the measurement range

providing the optimum resolution, can also be selected.

• Temperature Measurement

Thermocouple types J, K, E, T, N, R, S, and B, and Hoskins Engineering Co. type C are supported.

Also, DIN/IEC 751 Platinum RTDs are supported.

• Totalize Events on the Totalizing Input

• Alarm Limits and Digital Output Alarm Indication

• 4-Terminal Resistance Measurements (Channels 1 through 10 only)

• RS-232 Computer Interface Operation

• Measurement Rate Selection

• Nonvolatile Memory

Storage of minimum, maximum, and most recent measurements for all scanned channels.

Storage of Computer Interface setup, channel configurations, and calibration values.

Storage of measurement data: storage for 2047 scans of up to 21 channels, representing up to

42,987 readings (Hydra Data Logger only).

1-4

Page 23

Introduction

Where to go From Here

Accessories

Accessories available for the instrument are described in Table 1-2.

Table 1-2. Accessories

Model Description

80I-410

80i-1010 Clamp-On DC/AC Current Probes.

80J-10 Current Shunt.

2620A-05K Field-installable IEEE-488 Option kit (Hydra Data Acquisition Unit only).

2620A-901 Hydra Data Logger Applications Package.

C40 Soft carrying case. Provides padded protection for the instrument. Includes a pocket for

the manual and pouch for the line cord.

M00-200-634 Rackmount Kit. Provides standard 19-inch rack mounting for one instrument (right or left

side).

PM 8922 Switchable x1, x10 passive probe.

1

RS40 Shielded RS-232 terminal interface cable. Connects the instrument to any terminal or

printer with properly configured DTE connector (DB-25 socket), including an IBM PC(\R),

IBM PC/XT(\R) or IBM PS/2 (models 25, 30, 50, P60, 70, and 80).

RS41 Shielded RS-232 modem cable. Connects the instrument to a modem with properly

configured DB-25 male pin connector. Use an RS40 and an RS41 cable in series to

connect with an IBM PC/AT(\R).

RS42 Serial printer cable. Contact Fluke for list of compatible printers.

TL20 Industrial test lead set.

TL70 Test lead set.

Y8021 Shielded IEEE-488 one-meter cable, with plug and jack at each end.

Y8022 Shielded IEEE-488 two-meter cable, with plug and jack at each end.

Y8023 Shielded IEEE-488 four-meter cable, with plug and jack at each end.

Y9109 Binding post to BNC plug.

Fluke PN

268789

10Ω Precision Resistor, metal film, +/- 1%, 1/8 watt, 100 ppm. For use with 4 - 20 mA

signals.

Where to go From Here

You might want take a minute to familiarize yourself with this manual. Glance through

the table of contents at the front to see the overall layout of the manual and the major

parts of the instrument. If you have questions about specific topics, the Index at the end

of the manual will be useful. Or, just fan through the headers at the top of each page;

each header reveals the chapter number and the chief subject for that page.

The chapters are summarized in the following paragraphs:

1-5

Page 24

2620A, 2625A

Users Manual

Getting Started

Chapter 1 Introduction

Chapter 2 Overview

Chapter 3 Operating the Instr um ent from the Front Panel

Provides a quick introduction to instrument setup and operation.

Describes standard features, options, and accessories for the Fluke Hydra Series II Data

Acquisition Unit and Hydra Series II Data Logger. Also, this chapter discusses the

organization and intended uses of this manual.

Brings the instrument from its shipping container to operating status. This chapter

provides brief descriptions and a quick walk-through of instrument operation. Read this

chapter to gain a feel for instrument use. But please don’t avoid reading Chapter 3 (for

in-depth operation from the front panel) and Chapter 4 (for computer interface

operation); the instrument is far more powerful than suggested in Chapter 2.

Describes all capabilities available through front panel control. The features introduced

in Chapter 2 are described more fully, including descriptions for setting up and using

each type of measurement input (dc volts, thermocouple, etc.) and digital input

(Totalizer, etc.) or output (such as alarms). Other features of the Hydra Series II Data

Acquisition Unit and the Hydra Series II Data Logger are also more fully explained.

Chapter 4 Using the Computer Interface

Describes connecting the instrument to a terminal or host computer and operating the

instrument over the RS-232 Interface. For the Hydra Series II Data Acquisition Unit

only, use of the optional IEEE-488 Interface is also described here. This chapter is

detailed and requires a good knowledge of instrument operation via the front panel (see

Sections 2 and 3).

Chapter 5 Additional Considerations

Provides detailed operating information not provided elsewhere. This chapter also

describes instrument operation for the advanced user. This chapter is written with the

assumption that you have full knowledge of instrument operation from the front panel

(Chapter 3).

Chapter 6 Maintenance

Provides performance tests (suitable as acceptance testing procedures) and routine

maintenance information. Refer to this chapter for explanation of error codes

encountered during instrument operation. Also, this chapter provides parts ordering

information for such commonly used items as fuses, accessories, and publications.

Refer to the "Hydra Series II Service Manual" (P/N 688868) for complete service, repair,

and parts ordering information.

Appendices

A. Specifications

B. ASCII/IEEE-488 Bus Codes

C. IEEE-488.2 Device Documentation Requirements

D. Making Mixed Measurements Service Centers

E. Binary Upload of Logged Data (LOG_BIN?) (2625A only)

1-6

Index

Page 25

Chapter 2

Overview

Title Page

Introduction....................................................................................................... 2-3

Setting Up the Instrument.................................................................................. 2-3

Unpacking and Inspecting the Instrument..................................................... 2-3

Adjusting the Handle .................................................................................... 2-3

Line Power.................................................................................................... 2-4

Front/Rear Panel Features............................................................................. 2-4

Input Channels .............................................................................................. 2-9

Operating Modes............................................................................................... 2-9

Turning the Instrument On................................................................................ 2-9

Front Panel Display........................................................................................... 2-10

Reading the Display .......................................................................................... 2-10

Left Display................................................................................................... 2-10

Right Display ................................................................................................ 2-10

Specific Annunciators................................................................................... 2-10

Front Panel Buttons........................................................................................... 2-11

Selecting a Channel....................................................................................... 2-11

Using the Buttons.......................................................................................... 2-11

Setting up a Channel.......................................................................................... 2-12

Setting Alarm Limits and Mx+B Scaling Values.............................................. 2-14

Alarm Limits................................................................................................. 2-14

Mx+B Scaling............................................................................................... 2-15

Setting the Scan Interval.................................................................................... 2-15

Using the Monitor Function.............................................................................. 2-16

Using the Scan Function.................................................................................... 2-16

Reviewing Channel Data................................................................................... 2-16

Viewing the Totalizer Count............................................................................. 2-17

Using External DC Power................................................................................. 2-17

Using the Rack Mount Kit................................................................................. 2-18

2-1

Page 26

2620A, 2625A

Users Manual

2-2

Page 27

Introduction

Chapter 2 provides an overview of the major features of the instrument. Comprehensive

details on all instrument features are found in Chapter 3 (for front panel operation) and

Chapter 4 (for computer interface operation.)

Setting Up the Instrument

Unpacking and Inspecting the Instrument

The following items are included in the shipping container:

• This manual

• Hydra Series II Starter Software

• Hydra Series II Data Acquisition Unit (2620A) or Hydra Series II Data Logger

(2625A)

• Input Module

• Digital I/O and Alarms Connector

Overview

Introduction

2

• Test leads

• Line cord

Carefully remove the instrument from its shipping container and inspect it for possible

damage or missing items. If the instrument is damaged or something is missing, contact

the place of purchase immediately. Save the container and packing material in case you

have to return the instrument.

Rotate the rear feet 180 degrees so that their support pads extend slightly below the

bottom of the case.

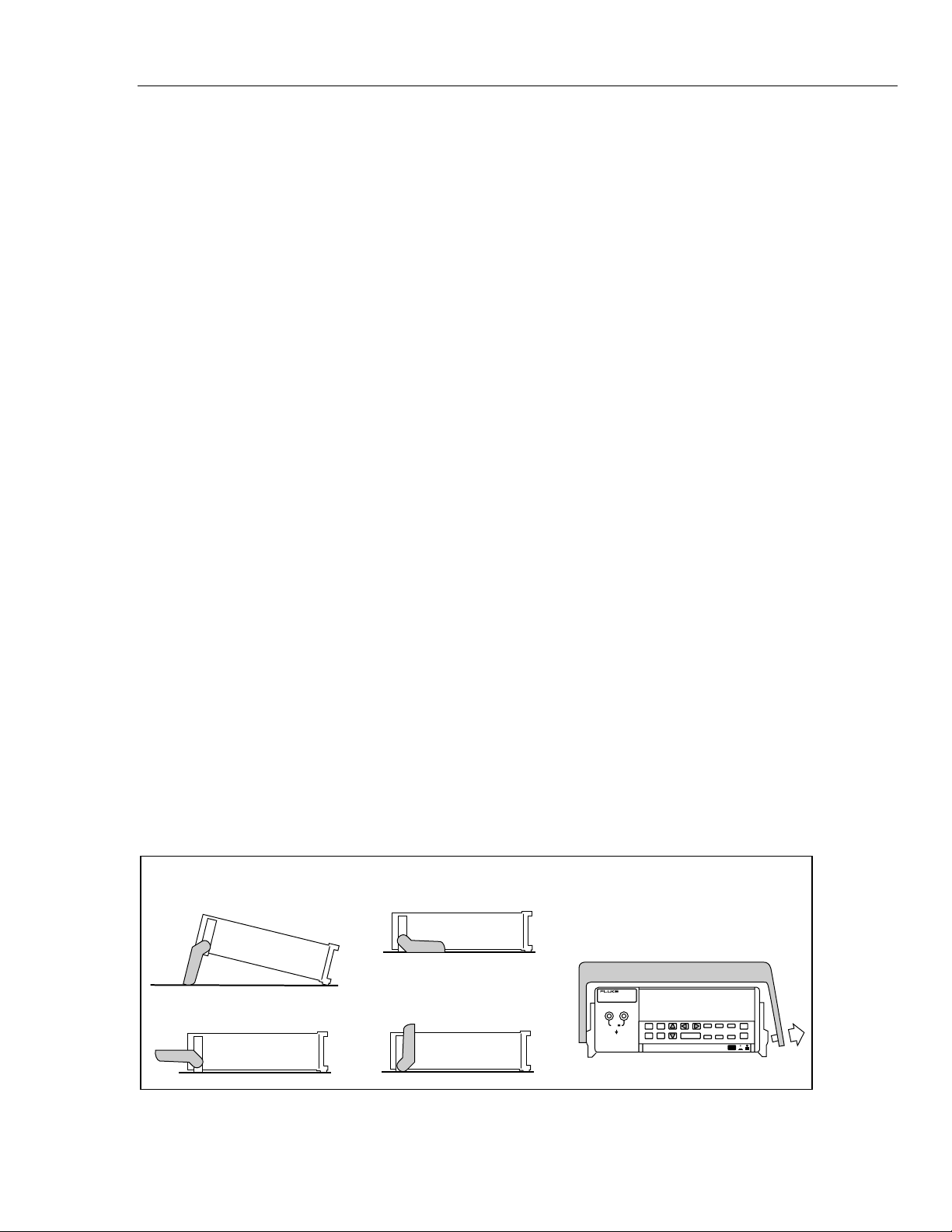

Adjusting the Handle

The handle can be positioned to four angles: one for carrying, two for viewing, and one

for handle removal. To change the angle, simultaneously pull both handle ends outward

to hard stops (about 1/4 inch on each side) and then rotate the handle to one of the four

stop positions shown in Figure 2-1. With the handle in the straight-up removal position

(4 in Figure 2-1), you can disengage and free one handle side at a time.

1. Viewing Position

2. Alternate Viewing Position

Pull One End Out and Towards You.

Then Pull the Other End Out.

3. Carrying Position

4. Removal Position

(to Remove, Pull Ends Out)

Figure 2-1. Adjusting Handle

V

COM

Ω

300V

MAX

oo01f.eps

2-3

Page 28

2620A, 2625A

Users Manual

Line Power

Front/Rear Panel Features

Warning

To avoid shock hazard, connect the instrument power cord to a

power receptacle with earth ground.

Plug the line cord into the connector on the rear of the instrument. The instrument

operates on any line voltage between 90 and 264V ac without adjustment, and at any

frequency between 45 and 440 Hz. However, the instrument is warranted to meet

published specifications only at 50/60 Hz.

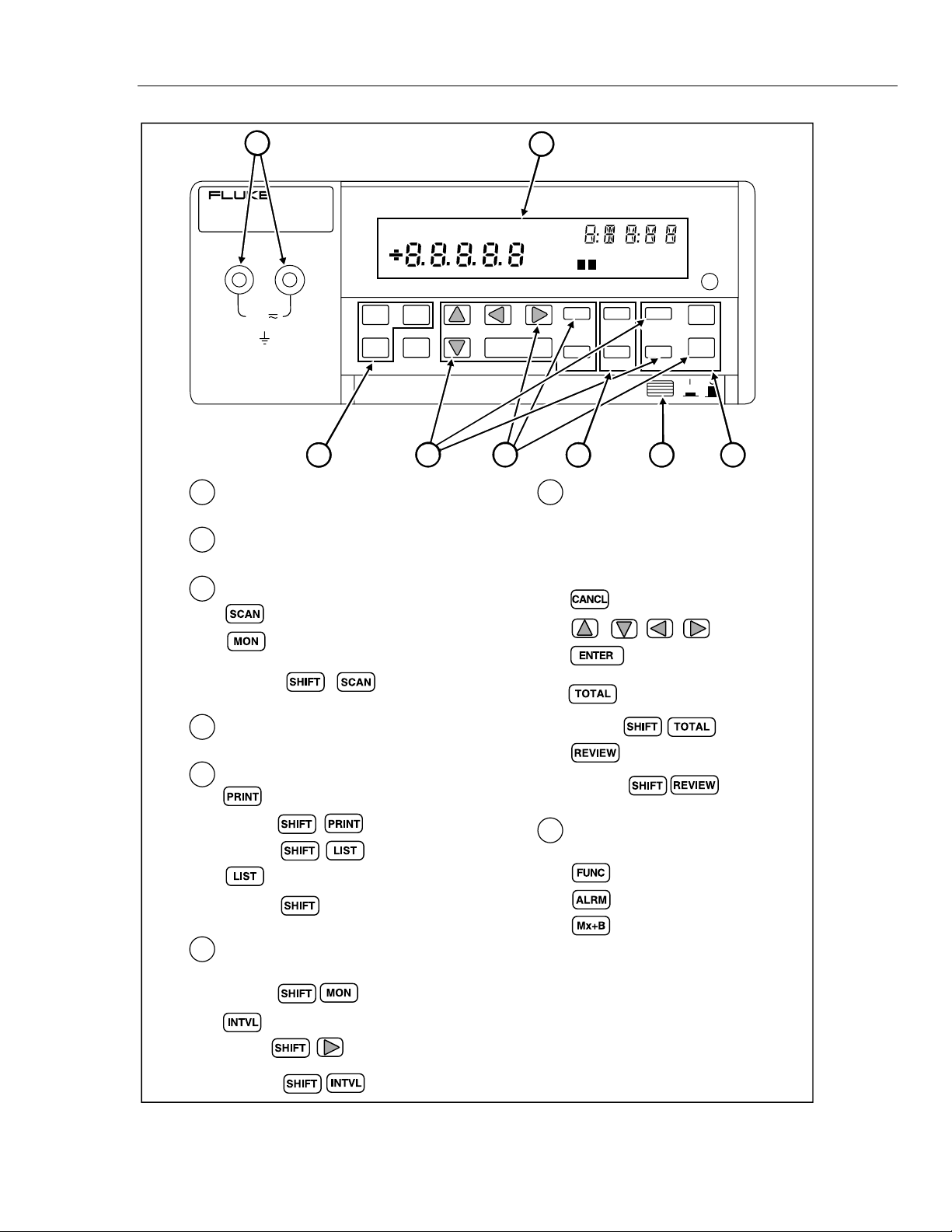

The Front Panel (shown in Figure 2-2) provides a two-terminal input for channel 0, a

multipurpose display, and a set of control buttons. The display includes the following

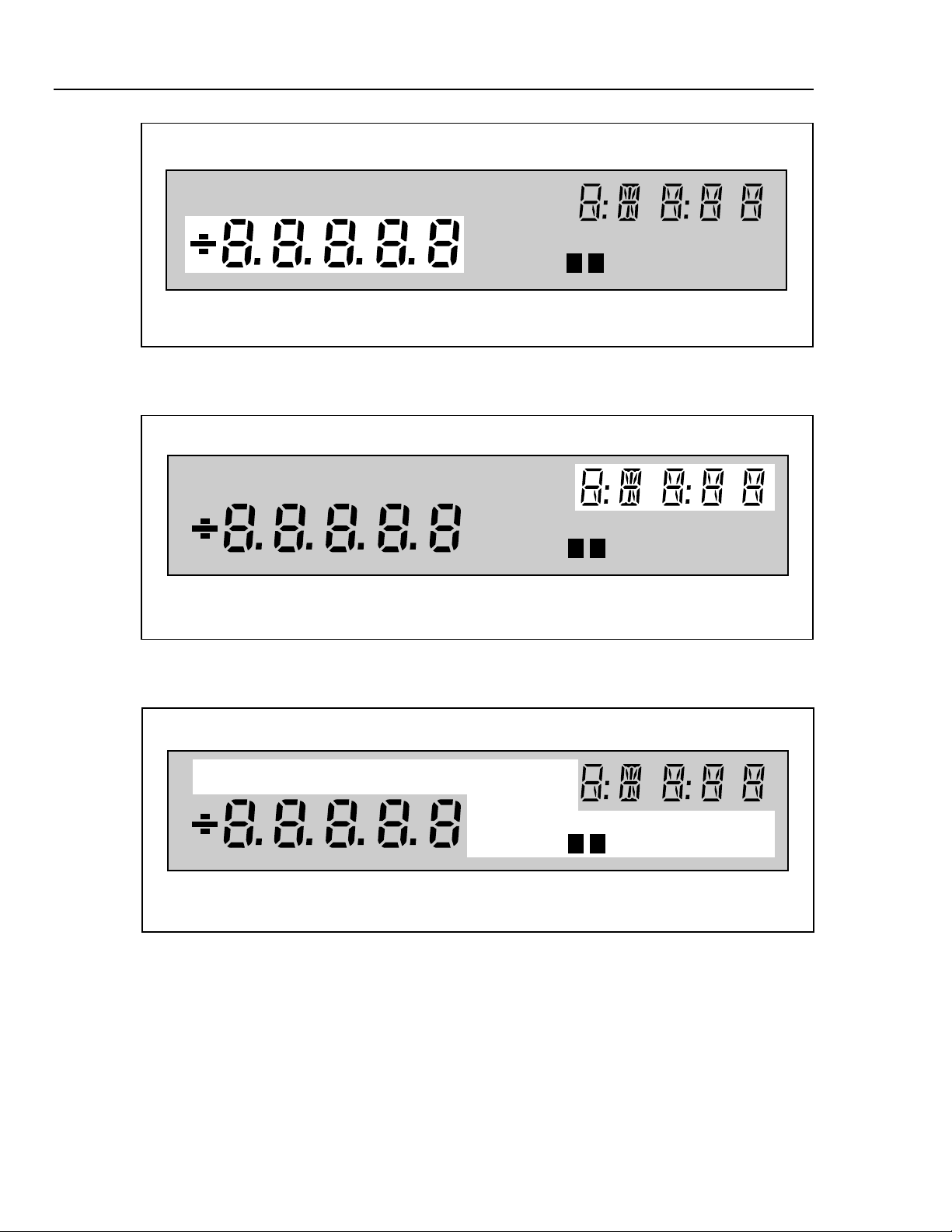

elements:

• A major numeric chapter (called the Left Display). See Figure 2-3.

• An auxiliary alphanumeric chapter (called the Right Display). See Figure 2-4.

• A set of Display Annunciators. See Figure 2-5 and Table 2-1.

The buttons control all instrument operations: channel configuration, instrument

configuration, measurement functions, and print/communications selections. The buttons

are introduced in this chapter, with a more detailed description following in Chapter 3.

The Rear Panel (shown in Figure 2-6) provides input and output connections: power

input, measurement input, digital input/output, Totalizer input, alarm output, and

computer interface connections. These connections are introduced in this chapter and

explained in greater detail in subsequent chapters of this manual. Inputs and outputs are

described with their related functions (Measuring DC Voltage, Totalizing, etc.) in

Chapter 3. RS-232 and IEEE-488 Computer Interface connections are detailed in

Chapter 4.

2-4

Page 29

Overview

Setting Up the Instrument

2

1

REVIEW

LAST

300V

MAX

V

Ω

FUNC ALRM

Mx+B

CANCL

COM

8 4

INPUT TERMINALS (Channel 0)

2

DISPLAY (See Figures 2-3, 2-4, and 2-5)

ACTIVE MODE BUTTONS

3

2

MAX

REM

MIN

AUTO

7

SCAN

MON

SET

Mx+B

ENTER

6

ALARM

°C °F RO

mV AC DC

LIMIT

Hz

x1Mk

Ω

12

INTVL

CLOCK CLEAR

RATE

SHIFT

LOCAL COMM ZERO

5

71

OTHER BUTTONS

PRN

OFF

HI

EXTCHTR

CAL

LO

PRINT REVIEW

MODE

LIST

POWER

TOTAL

CAL

ENABLE

SCAN

SINGLE

MON

TRIGS

3

F

FUNC

These buttons are used to both

configure and operate the

instrument:

SINGLE ( )

4

POWER BUTTON

PRINT/COMMUNICATIONS BUTTONS

5

MODE ( )

COMM ( )

LOCAL ( )

6

INSTRUMENT CONFIGURATION

BUTTONS

TRIGS ( )

RATE ( )

CLOCK ( )

Figure 2-2. Front Panel

,,,

ZERO ( )

CLEAR ( )

CHANNEL CONFIGURATION

8

BUTTONS

oo02f.eps

2-5

Page 30

2620A, 2625A

Users Manual

REVIEW

LAST

REVIEW

LAST

MAX

MIN

MAX

MIN

REM

AUTO

REM

AUTO

FUNC

SCAN

MON

SET

Mx+B

ALARM

°C °F RO

mV AC DC

x1Mk

Figure 2-3. Left Display

FUNC

SCAN

MON

SET

Mx+B

ALARM

°C °F RO

mV AC DC

x1Mk

Ω

Ω

Hz

Hz

F

LIMIT

12

F

LIMIT

12

HI

LO

HI

LO

OFF

CAL

OFF

CAL

CH

PRN

TR

EXT

PRN

EXTCHTR

oo03f.eps

REVIEW

LAST

MAX

MIN

REM

AUTO

Figure 2-4. Right Display

FUNC

SCAN

MON

SET

Mx+B

ALARM

°C °F RO

mV AC DC

Ω

x1Mk

Figure 2-5. Annunciators

Hz

F

LIMIT

12

HI

LO

OFF

CAL

oo04f.eps

PRN

EXTCHTR

oo05f.eps

2-6

Page 31

Overview

Setting Up the Instrument

Table 2-1. Display Annunciators

MON Indicates that the Monitor function is enabled.

SCAN Indicates that the Scan function is enabled. Scanning can be enabled as a single

scan (SINGLE K Q), with a scan interval, with an alarm-triggered scan, or as an

externally triggered scan.

CH Indicates that the channel number is displayed immediately above, in the right

display.

SET Lit when the instrument is in Configuration Mode.

Mx+B Lit while Mx+B scaling is being defined and when a measurement on the display

has been scaled with an M value other than 1 and/or a B value other than 0. Also

dimly lit when in the Inactive Mode to indicate that an M value other than 1 and/or a

B value other than 0 has been defined for this channel.

FUNC Lit when a measurement function is being defined for this channel.

ALARM Lit when alarm values are being defined for this channel or when an alarm limit has

been exceeded while measuring.

V Indicates that the measurement function is volts for this channel (used with the AC

or DC annunciator).

2

DC Indicates that the measurement function is dc voltage for this channel.

AC Indicates that the measurement function is ac voltage for this channel.

Ω Indicates that the measurement function is resistance for this channel.

Hz Indicates that the measurement function is frequency for this channel.

°C Indicates that the measurement function is temperature for this channel and that the

degree unit is Celsius.

°F Indicates that the measurement function is temperature for this channel and that the

degree unit is Fahrenheit.

m (milli) a multiplier for the displayed value, e.g., mV for millivolts. Also used when

defining alarm and Mx+B values.

x1 (times 1) a multiplier for the displayed value. Used when defining alarm and Mx+B

values.

k (kilo) a multiplier for the displayed value, e.g., kHz for kilohertz. Also used when

defining alarm and Mx+B values.

M (mega) a multiplier for the displayed value, e.g., MΩ for megohms. Also used when

defining alarm and Mx+B values.

R0 Lit when the ice point resistance is being defined for RTD measurements on the

displayed channel.

OFF Indicates there is no measurement function defined for the displayed channel; OFF

channels are skipped over when scanning. OFF is also used when defining an

alarm value to indicate that the alarm limit is to be ignored.

AUTO Indicates that autoranging is enabled for the displayed channel.

LIMIT Used with the S and T annunciators when you are setting an alarm limit value. Also

lit when displaying a measurement value (LAST, Monitor) which has exceeded an

alarm limit.

2-7

Page 32

2620A, 2625A

Users Manual

Table 2-1. Display Annunciators (cont)

"1" Lit when alarm limit 1 is being defined. Also lit when displaying a measurement

value (LAST, Monitor) which has exceeded alarm limit 1.

"2" Lit when alarm limit 2 is being defined. Also lit when displaying a measurement

value (LAST, Monitor) which has exceeded alarm limit 2.

HI, LO Identifies alarm limit sensing (high or low) during channel configuration. At other

times, identifies an alarm condition.

REVIEW Indicates that review data is being displayed (used in conjunction with the MIN,

MAX, and LAST annunciators).

MIN, MAX Indicates that the displayed value is the minimum (maximum) value measured on

this channel.

LAST Indicates that the displayed value is the most recent scan measurement taken on

this channel.

PRN Indicates that the autoprint function is enabled (to send readings to a printer) or the

memory storage function is on (to store readings in internal memory.) Internal

memory is available with Hydra Data Logger only.

F Bright when memory storage is full, dim when memory storage is nearly full. Hydra

Data Logger only.

EXT Indicates that external triggering (on the rear panel) is enabled.

TR Indicates that internal triggering (from the monitor alarm) is enabled. Also used with

EXT when external triggering is enabled.

REM Indicates that the instrument is under the remote control of one of the computer

interfaces.

CAL Indicates that the instrument’s internal calibration constants have been corrupted.

CAUTION

90-264V

50/60 Hz

15VA

ALARM OUTPUTS DIGITAL I/O

+–

0123TR

+–0123TR 01234567

9-16 V

DC PWR

FOR FIRE PROTECTION REPLACE WITH T 1/8A 250V (SLOW) FUSE

+30V

!

MEETS 0871 B

COMPLIES FCC-15B

Σ

GND

RS-232C

TX

DTR

2620 2625MODEL:

IEC 664 INSTALLATIONCATEGORY II

IEEE STD-488 PORT

RX

SH1, AH1, T5, L4, SR1, RL1, DC1, DT1, PP0, C0, E1

EXTERNAL BATTERY

WARNING: If voltages greater than 30V are to be measured, a safety ground must be attached

to the rear panel ground connector when the instrument is operated from battery power.

Figure 2-6. Rear View

oo06f.eps

2-8

Page 33

Input Channels

The instrument provides one input (channel 0) on the front panel and 20 inputs (channels

1 .. 20) through a connector on the rear panel. Channels 0, 1, and 11 can measure a

maximum of 300V; all other channels can measure a maximum of 150V.

The maximum input that can be applied between any terminal

of channels 2..10 and 12..20 is 150V dc or ac rms. The

maximum input that can be applied between any terminal of

channels 0, 1, and 11 and ground is 300V dc or ac rms. The

maximum common mode input that can be applied is 300V dc

or ac rms.

Operating Modes

The instrument provides three modes of operation:

• Active Mode

The instrument is in Active Mode whenever the Monitor and/or Scan functions are

enabled. Scans are activated by the interval timer, an external trigger, an alarm

trigger, or a single scan (SINGLE K Q) command. When in Active Mode, the

MON and/or SCAN annunciators are lighted.

Caution

Overview

Operating Modes

2

• Configuration Mode