Page 1

Note

This manual applies to SN 6560XXX and higher.

HYDRA

2620A Data Acquisition Unit

®

2625A Data Logger

2635A Data Bucket

Service Manual

PN 202231

February 1997

© 1997 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY & LIMITATI O N OF LIABILITY

Each Fluke product is warranted to be free fr om defects in material and workmanship

under normal use and service. The warranty period is one year and begins on the date

of shipment. Parts, product repairs and services are warranted for 90 days. This

warranty extends only to the original buyer or end- user customer of a Fluke authorized

reseller, and does not apply to fuses, disposable batt er ies or to any product which, in

Fluke’s opinion, has been misused, altered, neglected or damaged by accident or

abnormal conditions of operation or handling. Fluke warr ant s t hat software will operate

substantially in accordance with its functional specifications for 90 days and that it has

been properly recorded on non-defective media. Fluke does not war r ant that software

will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to

end-user customers only but have no authority t o extend a greater or different warr anty

on behalf of Fluke. Warranty support is available if product is purchased through a Fluke

authorized sales outlet or Buyer has paid the applicable international price. Fluke

reserves the right to invoice Buyer for im por tation costs of repair/replacement par t s

when product purchased in one country is submitted f or r epair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase pr ice,

free of charge repair, or replacem ent of a defective product which is returned to a Fluke

authorized service center within the warranty period.

To obtain warranty service, contact your near est Fluke authorized service center or

send the product, with a description of the dif ficulty, postage and insurance prepaid

(FOB Destination), to the nearest Fluke authorized service center. Fluke assumes no

risk for damage in transit. Following warr ant y r epair , the product will be returned to

Buyer, transportation prepaid (FO B Dest inat ion) . If Fluke determines that the failur e

was caused by misuse, alteration, accident or abnormal condition of operation or

handling, Fluke will provide an estimate of repair costs and obt ain aut horization before

commencing the work. Following repair, t he pr oduct will be returned to the Buyer

transportation prepaid and the Buyer will be billed for t he r epair and return transportation

charges (FOB Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU O F

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIM ITED

TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECI AL,

INDIRECT, INCIDENTAL OR CO NSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, W HETHER ARI SING FROM BREACH OF WARRANTY

OR BASED ON CONTRACT, TORT, RELI ANCE O R ANY OTHER THEORY.

Since some countries or states do not allow limitat ion of the term of an implied warranty,

or exclusion or limitation of incidental or consequential damages, the limitations and

exclusions of this warranty may not apply to every buyer . If any provision of this

Warranty is held invalid or unenforceable by a court of com petent jurisdiction, such

holding will not affect the validity or enfor ceabilit y of any other provision.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

5/94

Page 3

Caution

This is an IEC Safety Class 1 product. Before usi ng, the ground

wire in the line cord or the rear panel bi nding post must be

connected for safety.

Interference Information

This equipment generates and uses radio frequency energy and if not installed and used in strict

accordance with the manufacturer’s instructions, may cause interference to radio and television

reception. It has been type tested and found to comply with the limits for a Class B computing

device in accordance with the specifications of Part 15 of FCC Rules, which are designed to

provide reasonable protection against such interference in a residential installation.

Operation is subject to the following two conditions:

This device may not cause harmful interference.

•

This device must accept any interference received, including interference that may cause

•

undesired operation.

There is no guarantee that interference will not occur in a particular installation. If this equipment

does cause interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one of more of

the following measures:

Reorient the receiving antenna

•

Relocate the equipment with respect to the receiver

•

Move the equipment away from the receiver

•

Plug the equipment into a different outlet so that the computer and receiver are on different

•

branch circuits

If necessary, the user should consult the dealer or an experienced radio/television technician for

additional suggestions. The user may find the following booklet prepared by the Federal

Communications Commission helpful: How to Identify and Resolve Radio-TV Interference

Problems. This booklet is available from the U.S. Government Printing Office, Washington, D.C.

20402. Stock No. 004-000-00345-4.

Declaration of the Manufacturer or Importer

We hereby certify that the Fluke Models 2625A Data Logger, 2620A Data Acquisition Unit and

2635A Data Bucket are in compliance with BMPT Vfg 243/1991 and is RFI suppressed. The

normal operation of some equipment (e.g. signal generators) may be subject to specific

restrictions. Please observe the notices in the users manual. The marketing and sales of the

equipment was reported to the Central Office for Telecommunication Permits (BZT). The right to

retest this equipment to verify compliance with the regulation was given to the BZT.

Bescheinigung des Herstellers/Importeurs

Hiermit wird bescheinigt, daβ Fluke Models 2625A Data Logger, 2620A Data Acquisition Unit und

2635A Data Bucket in Übereinstimung mit den Bestimmungen der BMPT-AmtsblVfg 243/1991

funk-entstört ist. Der vorschriftsmäßige Betrieb mancher Geräte (z.B. Meßsender) kann allerdings

gewissen Einschränkungen unterliegen. Beachten Sie deshalb die Hinweise in der

Bedienungsanleitung. Dem Bundesamt für Zulassungen in der Telekcommunikation wurde das

Inverkehrbringen dieses Gerätes angezeigt und die Berechtigung zur Überprüfung der Seire auf

Einhaltung der Bestimmungen eingeräumt.

Fluke Corporation

Page 4

Page 5

Safety Summary

Safety Terms in this Manual

This instrument has been designed and tested in accordance with IEC Publication 1010,

Safety Requirements for Electronical Measuring, Control and Laboratory Equipment. This

Service Manual contains information, warnings, and cautions that must be followed to

ensure safe operation and to maintain the instrument in a safe condition. Use of this

equipment in a manner mot specified herein may impair the protection by the equipment.

This meter is designed for IEC 64, Installation Category II use. It is not designed for use in

circuits rated over 48000VA.

Warning statements identify conditions or practices that could result in personal injury or

loss of life.

Caution statements identify conditions or practices that could result in damage to the

equipment.

Symbols Marked on Equipment

Danger - High voltage

Ground (Earth) Terminal

Protective ground (earth) terminal. Must be connected to safety earth ground

when the power cord is not used. See Section 2.

Attention — refer to the manual. This symbol indicates that information

about the use of a feature is contained in the manua

the following places on the rear panel:

1. Ground Binding Post (left of line power connector). Refer to “Using

External DC Power” in Section 2.

2. Alarm Ouputs/Digital I/O Connectors. Refer to Appendix A, Specifications.

AC Power Source

The instrument is intended to operate from a ac power source that will not apply more

than 264V ac rms between the supply conductors or between either supply conductor and

ground. A protective ground connection by way of the grounding conductor in the power

cord is required for safe operation.

DC Power Source

The instrument may also be operated from a 9 to 16V dc power source when either the

rear panel ground binding post or the power cord grounding conductor is properly

connected.

l. This symbol appears in

Page 6

Use the Proper Fuse

To avoid fire hazard, use only a fuse identical in type, voltage rating, and current rating

as specified on the rear panel fuse rating label.

Grounding the Standard

The instrument utilized controlled overvoltage techniques that require the instrument to

be grounded whenever normal mode or common mode ac voltage or transient voltages

may occur. The enclosure must be grounded through the grounding conductor of the

power cord, or if operated on battery with the power cord unplugged, through the rear

panel ground binding post.

Use the Proper Power Cord

Use only the power cord and connector appropriate for the voltage and plug

configuration in your country.

Use only a power cord that is in good condition.

Refer cord and connector changes to qualified service personnel.

Do Not Operate in Explosive Atmospheres

To avoid explosion, do not operate the instrument in an atmosphere of explosive gas.

Do Not Remove Cover

To avoid personal injury or death, do not remove the instrument cover. Do not operate

the instrument without the cover properly installed. Normal calibration is accomplished

with the cover closed, and there are no user-serviceable parts inside the instrument, so

there is no need for the operator to ever remove the cover. Access procedures and the

warnings for such procedures are contained in the Service Manual. Service procedures

are for qualified service personnel only.

Do Not Attempt to Operate if Protection May be Impaired

If the instrument appears damaged or operates abnormally, protection may be impaired.

Do not attempt to operate it. When is doubt, have the instrument serviced.

Page 7

Table of Contents

Chapter Title Page

1 Introduction and Specifications........................................................ 1-1

1-1. Introduction ......................................................................................... 1-3

1-2. Options and Accessories ..................................................................... 1-3

1-3. Operating Instructions ......................................................................... 1-3

1-4. Organization of the Service Manual ................................................... 1-4

1-5. Conventions ......................................................................................... 1-5

1-6. Specifications ...................................................................................... 1-7

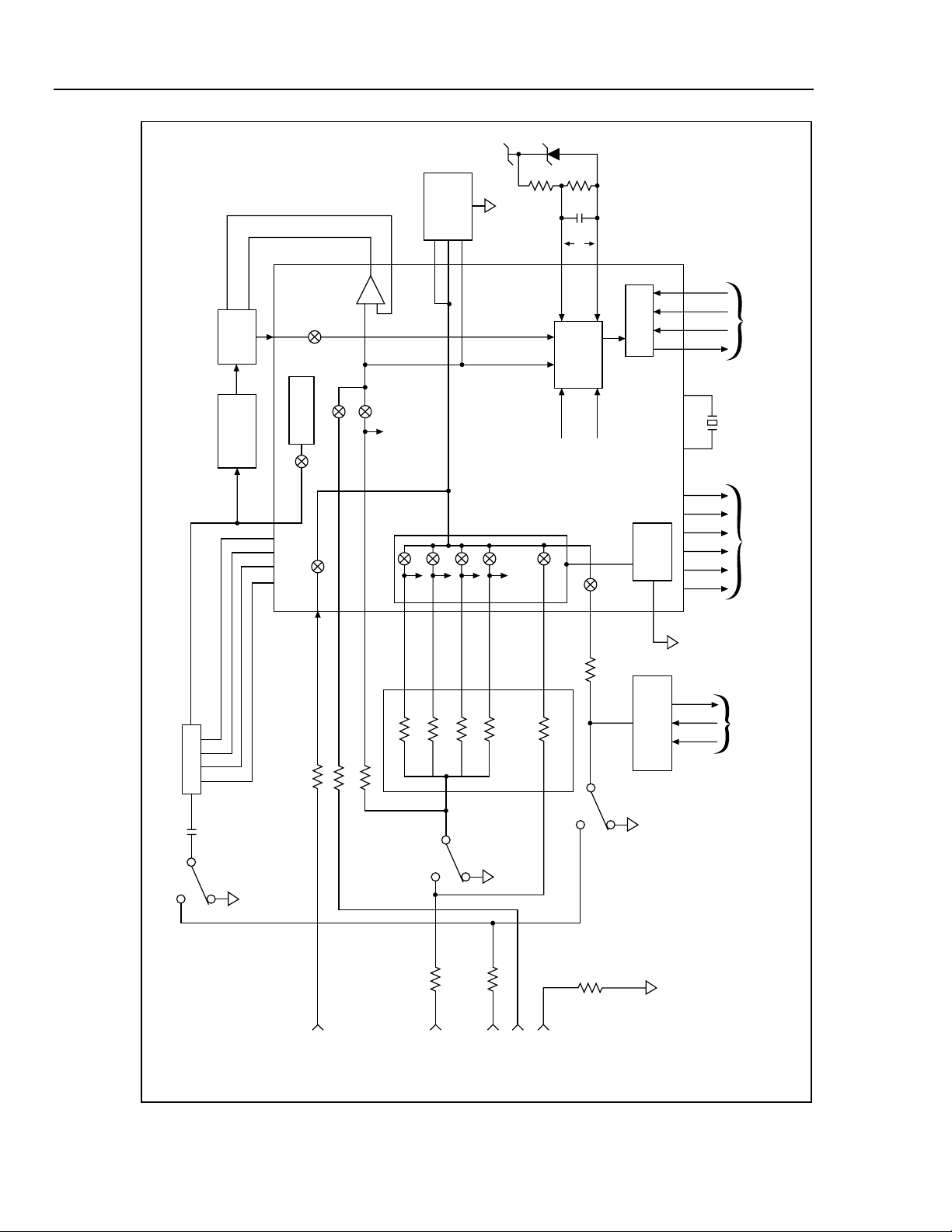

2 Theory of Operation (2620A/2625A).................................................. 2-1

2-1. Introduction ........................................................................................ 2-3

2-2. Functional Block Description .............................................................. 2-3

2-3. Main PCA Circuitry ........................................................................ 2-3

2-4. Power Supply .............................................................................. 2-3

2-5. Digital Kernel ............................................................................. 2-3

2-6. Serial Communication (Guard Crossing) ................................... 2-6

2-7. Digital Inputs and Outputs .......................................................... 2-6

2-8. A/D Converter PCA ........................................................................ 2-6

2-9. Analog Measurement Processor ................................................. 2-6

2-10. Input Protection Circuitry ........................................................... 2-6

2-11. Input Signal Conditioning .......................................................... 2-6

2-12. Analog-to-Digital (A/D) Converter ............................................ 2-6

2-13. Inguard Microcontroller Circuitry .............................................. 2-6

2-14. Channel Selection Circuitry ....................................................... 2-7

2-15. Open Thermocouple Check Circuitry ......................................... 2-7

2-16. Input Connector Assembly ............................................................. 2-7

2-17. 20 Channel Terminals ................................................................. 2-7

2-18. Reference Junction Temperature ................................................ 2-7

2-19. Display PCA ................................................................................... 2-7

2-20. Memory PCA (2625A Only) ........................................................... 2-7

2-21. IEEE-488 Option (-05) ................................................................... 2-7

2-22. Detailed Circuit Description ............................................................... 2-8

2-23. Main PCA ....................................................................................... 2-8

2-24. Power Supply Circuit Description .............................................. 2-8

i

Page 8

HYDRA

Service Manual

2-32. Digital Kernel ............................................................................. 2-10

2-43. Digital I/O ................................................................................... 2-14

2-44. Digital Input Threshold .............................................................. 2-15

2-45. Digital Input Buffers ................................................................... 2-15

2-46. Digital and Alarm Output Drivers .............................................. 2-15

2-47. Totalizer Input ............................................................................ 2-16

2-48. External Trigger Input Circuits .................................................. 2-16

2-49. A/D Converter PCA ........................................................................ 2-16

2-50. Analog Measurement Processor ................................................. 2-17

2-51. Input Protection .......................................................................... 2-17

2-52. Input Signal Conditioning .......................................................... 2-20

2-58. Passive and Active Filters .......................................................... 2-25

2-59. A/D Converter ............................................................................ 2-26

2-60. Inguard Microcontroller Circuitry .............................................. 2-27

2-61. Channel Selection Circuitry ....................................................... 2-27

2-62. Open Thermocouple Check ........................................................ 2-28

2-63. Input Connector PCA ...................................................................... 2-28

2-64. Display PCA ................................................................................... 2-29

2-65. Main PCA Connector ................................................................. 2-29

2-66. Front Panel Switches .................................................................. 2-29

2-67. Display ........................................................................................ 2-30

2-68. Beeper Drive Circuit ................................................................... 2-30

2-69. Watchdog Timer and Reset Circuit ............................................ 2-30

2-70. Display Controller ...................................................................... 2-31

2-71. Memory PCA (2625A Only) ........................................................... 2-33

2-72. Main PCA Connector ................................................................. 2-33

2-73. Address Decoding ....................................................................... 2-33

2-74. Page Register .............................................................................. 2-34

2-75. Byte Counter ............................................................................... 2-34

2-76. Nonvolatile Memory ................................................................... 2-34

2-77. IEEE-488 Interface (Option -05) .................................................... 2-34

2A Theory of Operation (2635A)............................................................. 2A-1

2A-1. Introduction.......................................................................................... 2A-3

2A-2. Functional Block Description............................................................... 2A-3

2A-3. Main PCA Circuitry......................................................................... 2A-3

2A-4. Power Supply............................................................................... 2A-3

2A-5. Digital Kernel.............................................................................. 2A-3

2A-6. Serial Communication (Guard Crossing).................................... 2A-6

2A-7. Digital Inputs and Outputs........................................................... 2A-6

2A-8. A/D Converter PCA......................................................................... 2A-6

2A-9. Analog Measurement Processor.................................................. 2A-6

2A-10. Input Protection Circuitry............................................................ 2A-6

2A-11. Input Signal Conditioning ........................................................... 2A-6

2A-12. Analog-to-Digital (A/D) Converter............................................. 2A-6

2A-13. Inguard Microcontroller Circuitry............................................... 2A-6

2A-14. Channel Selection Circuitry ........................................................ 2A-7

2A-15. Open Thermocouple Check Circuitry.......................................... 2A-7

2A-16. Input Connector Assembly .............................................................. 2A-7

2A-17. 20 Channel Terminals.................................................................. 2A-7

2A-18. Reference Junction Temperature................................................. 2A-7

2A-19. Display PCA .................................................................................... 2A-7

2A-20. Memory Card Interface PCA........................................................... 2A-7

2A-21. Detailed Circuit Description ................................................................ 2A-7

ii

Page 9

Contents

2A-22. Main PCA ........................................................................................ 2A-7

2A-23. Power Supply Circuit Description............................................... 2A-8

2A-31. Digital Kernel.............................................................................. 2A-10

2A-42. Digital I/O.................................................................................... 2A-18

2A-43. Digital Input Threshold ............................................................... 2A-19

2A-44. Digital Input Buffers.................................................................... 2A-19

2A-45. Digital and Alarm Output Drivers............................................... 2A-19

2A-46. Totalizer Input ............................................................................. 2A-19

2A-47. External Trigger Input Circuits ................................................... 2A-20

2A-48. A/D Converter PCA......................................................................... 2A-20

2A-49. Analog Measurement Processor.................................................. 2A-20

2A-50. Input Protection ........................................................................... 2A-23

2A-51. Input Signal Conditioning ........................................................... 2A-24

2A-57. Passive and Active Filters ........................................................... 2A-29

2A-58. A/D Converter ............................................................................. 2A-29

2A-59. Inguard Microcontroller Circuitry............................................... 2A-31

2A-60. Channel Selection Circuitry ........................................................ 2A-31

2A-61. Open Thermocouple Check......................................................... 2A-31

2A-62. Input Connector PCA....................................................................... 2A-32

2A-63. Display PCA .................................................................................... 2A-32

2A-64. Main PCA Connector .................................................................. 2A-32

2A-65. Front Panel Switches................................................................... 2A-33

2A-66. Display......................................................................................... 2A-33

2A-67. Beeper Drive Circuit.................................................................... 2A-33

2A-68. Watchdog Timer and Reset Circuit............................................. 2A-34

2A-69. Display Controller ....................................................................... 2A-34

2A-70. Memory Card Interface PCA........................................................... 2A-37

2A-71. Main PCA Connector .................................................................. 2A-37

2A-72. Microprocessor Interface............................................................. 2A-37

2A-73. Memory Card Controller............................................................. 2A-37

2A-74. PCMCIA Memory Card Connector............................................. 2A-39

(continued)

3 General Maintenance......................................................................... 3-1

3-1. Introduction ........................................................................................ 3-3

3-2. Warranty Repairs and Shipping .......................................................... 3-3

3-3. General Maintenance ........................................................................... 3-3

3-4. Required Equipment ....................................................................... 3-3

3-5. Power Requirements ....................................................................... 3-3

3-6. Static Safe Handling ....................................................................... 3-3

3-7. Servicing Surface-Mount Assemblies ............................................ 3-4

3-8. Cleaning ............................................................................................... 3-4

3-9. Line Fuse Replacement ....................................................................... 3-5

3-10. Disassembly Procedures ...................................................................... 3-5

3-11. Remove the Instrument Case .......................................................... 3-6

3-12. Remove Handle and Mounting Brackets ........................................ 3-6

3-13. Remove the Front Panel Assembly ................................................. 3-6

3-14. Remove the Display PCA ............................................................... 3-6

3-15. Remove the IEEE-488 Option (2620A Only) ................................. 3-11

3-16. Remove the Memory PCA (2625A Only) ...................................... 3-11

3-17. Remove the Memory Card I/F PCA (2635A Only) ........................ 3-11

3-18. Remove the Main PCA ................................................................... 3-12

3-19. Remove the A/D Converter PCA .................................................... 3-12

3-20. Disconnect Miscellaneous Chassis Components ............................ 3-13

3-21. Assembly Procedures .......................................................................... 3-13

iii

Page 10

HYDRA

Service Manual

3-22. Install Miscellaneous Chassis Components .................................... 3-13

3-23. Install the A/D Converter PCA ....................................................... 3-13

3-24. Install the Main PCA ...................................................................... 3-14

3-25. Install the IEEE-488 Option (2620A Only) .................................... 3-14

3-26. Install the Memory PCA (2625A Only) .......................................... 3-14

3-27. Install the Memory Card I/F PCA (2635A Only) ........................... 3-15

3-28. Assemble the Front Panel Assembly .............................................. 3-15

3-29. Install the Front Panel Assembly .................................................... 3-15

3-30. Install the Handle and Mounting Brackets ..................................... 3-15

3-31. Install the Instrument Case ............................................................. 3-15

4 Performance Testing and Calibration............................................... 4-1

4-1. Introduction ........................................................................................ 4-3

4-2. Required Equipment ............................................................................ 4-3

4-3. Performance Tests ............................................................................... 4-4

4-4. Accuracy Verification Test ............................................................. 4-4

4-5. Channel Integrity Test ..................................................................... 4-4

4-6. Thermocouple Measurement Range Accuracy Test ....................... 4-6

4-7 4-Terminal Resistance Test. ............................................................ 4-7

4-8. Thermocouple Temperature Accuracy Test ................................... 4-8

4-9. Open Thermocouple Response Test ............................................... 4-11

4-10. RTD Temperature Accuracy Test ................................................... 4-11

4-11. RTD Temperature Accuracy Test (Using Decade Resistance

Source) ........................................................................................ 4-11

4-12. RTD Temperature Accuracy Test (Using DIN/IEC 751) ........... 4-12

4-13. Digital Input/Output Verification Tests .......................................... 4-13

4-14. Digital Output Test ..................................................................... 4-13

4-15. Digital Input Test ........................................................................ 4-14

4-16. Totalizer Test .............................................................................. 4-14

4-17. Totalizer Sensitivity Test ............................................................ 4-15

4-18. Dedicated Alarm Output Test ......................................................... 4-16

4-19. External Trigger Input Test ............................................................. 4-18

4-20. Calibration ........................................................................................... 4-18

4-21. Using Hydra Starter Calibration Software ...................................... 4-20

4-22. Setup Procedure Using Starter .................................................... 4-20

4-23. Calibration Procedure Using Starter ........................................... 4-21

4-24. Using a Terminal ............................................................................. 4-22

4-25. Setup Procedure Using a Terminal ............................................. 4-22

4-26. Calibration Procedure Using a Terminal .................................... 4-22

4-28. Reference Junction Calibration ....................................................... 4-24

4-29. Concluding Calibration ................................................................... 4-25

4-30. Updating 2635A Data Bucket Embedded Instrument Firmware ........ 4-27

4-31. Using the PC Compatible Firmware Loader Software ................... 4-28

4-32. Setup Procedure for Firmware Download .................................. 4-29

4-33. Default Instrument Firmware Download Procedure .................. 4-29

4-34. Using LD2635 Firmware Loader Directly ................................. 4-30

5 Diagnostic Testing and Troubleshooting (2620A/2625A)................ 5-1

5-1. Introduction ........................................................................................ 5-3

5-2. Servicing Surface-Mount Assemblies ................................................. 5-3

5-3. Error Codes .......................................................................................... 5-4

5-4. General Troubleshooting Procedures .................................................. 5-6

5-5. Power Supply Troubleshooting ........................................................... 5-8

5-6. Raw DC Supply .............................................................................. 5-8

iv

Page 11

Contents

5-7. Power Fail Detection ....................................................................... 5-8

5-8. 5-Volt Switching Supply.................................................................. 5-8

5-9. Inverter ............................................................................................ 5-9

5-10. Analog Troubleshooting ...................................................................... 5-12

5-11. DC Volts Troubleshooting .............................................................. 5-17

5-12. AC Volts Troubleshooting .............................................................. 5-17

5-13. Ohms Troubleshooting .................................................................... 5-18

5-14. Digital Kernel Troubleshooting .......................................................... 5-19

5-15. Digital and Alarm Output Troubleshooting ........................................ 5-21

5-16. Digital Input Troubleshooting ............................................................. 5-21

5-17. Totalizer Troubleshooting ................................................................... 5-21

5-18. Display Assembly Troubleshooting .................................................... 5-23

5-19. Variations in the Display ..................................................................... 5-25

5-20. Calibration Failures ............................................................................. 5-26

5-21. Introduction ..................................................................................... 5-26

5-22. Calibration-Related Components .................................................... 5-26

5-23. Retrieving Calibration Constants .................................................... 5-28

5-24. Replacing the EEPROM (A1U1) .................................................... 5-28

5-25. IEEE-488 Interface PCA (A5) Troubleshooting ................................. 5-29

5-26. Memory PCA (A6) Troubleshooting .................................................. 5-29

5-27. Power-Up Problems ........................................................................ 5-29

5-28. Failure to Detect Memory PCA .................................................. 5-29

5-29. Failure to Store Data ................................................................... 5-29

(continued)

5A Diagnostic Testing and Troubleshooting (2635A)........................... 5A-1

5A-1. Introduction.......................................................................................... 5A-3

5A-2. Servicing Surface-Mount Assemblies.................................................. 5A-3

5A-3. Error Codes........................................................................................... 5A-4

5A-4. General Troubleshooting Procedures................................................... 5A-6

5A-5. Power Supply Troubleshooting............................................................ 5A-8

5A-6. Raw DC Supply ............................................................................... 5A-8

5A-7. Power Fail Detection........................................................................ 5A-8

5A-8. 5A-Volt Switching Supply............................................................... 5A-8

5A-9. Inverter............................................................................................. 5A-9

5A-10. Analog Troubleshooting....................................................................... 5A-11

5A-11. DC Volts Troubleshooting............................................................... 5A-16

5A-12. AC Volts Troubleshooting............................................................... 5A-17

5A-13. Ohms Troubleshooting..................................................................... 5A-17

5A-14. Digital Kernel Troubleshooting ........................................................... 5A-18

5A-15. Digital and Alarm Output Troubleshooting......................................... 5A-21

5A-16. Digital Input Troubleshooting.............................................................. 5A-21

5A-17. Totalizer Troubleshooting.................................................................... 5A-23

5A-18. Display Assembly Troubleshooting..................................................... 5A-23

5A-19. Variations in the Display...................................................................... 5A-26

5A-20. Calibration Failures.............................................................................. 5A-27

5A-21. Introduction...................................................................................... 5A-27

5A-22. Calibration-Related Components..................................................... 5A-27

5A-23. Retrieving Calibration Constants..................................................... 5A-29

5A-24. Replacing the Flash Memory (A1U14 and A1U16)........................ 5A-29

5A-25. Memory Card I/F PCA (A6) Troubleshooting..................................... 5A-30

5A-26. Power-Up Problems......................................................................... 5A-30

5A-27. Failure to Detect Memory Card I/F PCA.................................... 5A-30

5A-28. Failure to Detect Insertion of Memory Card............................... 5A-31

5A-29. Failure to Power Card / Illuminate the Busy Led........................ 5A-31

v

Page 12

HYDRA

Service Manual

5A-30. Failure to Illuminate the Battery Led .......................................... 5A-31

5A-31. Failure to Write to Memory Card................................................ 5A-32

5A-32. Write/Read Memory Card Test (Destructive)............................. 5A-32

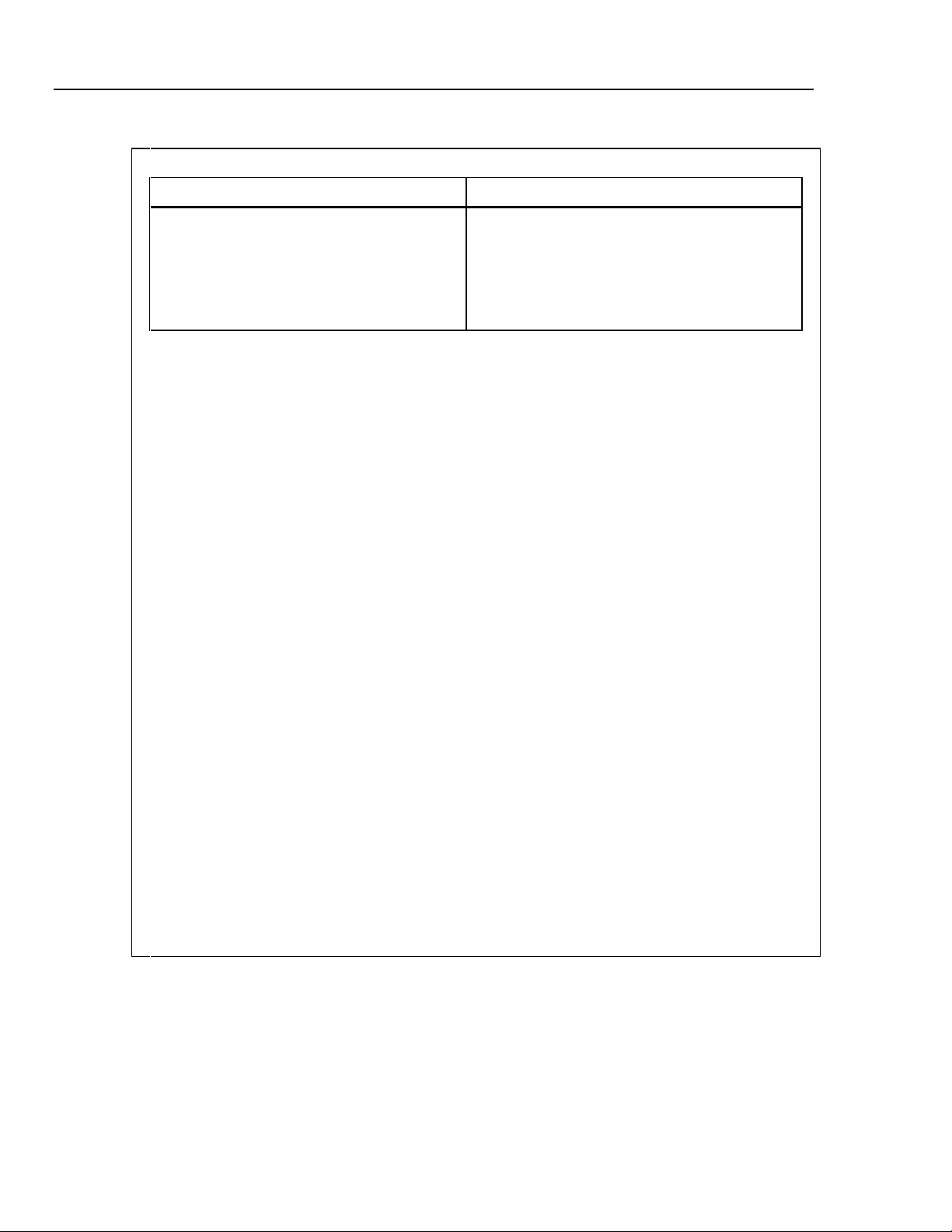

6 List of Replaceable Parts .................................................................. 6-1

6-1. Introduction ........................................................................................ 6-3

6-2. How to Obtain Parts ............................................................................ 6-3

6-3. Manual Status Information .................................................................. 6-3

6-4. Newer Instruments .............................................................................. 6-4

6-5. Service Centers .................................................................................... 6-4

7 IEEE-488 Option -05........................................................................... 7-1

7-1. Introduction ........................................................................................ 7-3

7-2. Theory of Operation ............................................................................ 7-3

7-3. Functional Block Description ......................................................... 7-3

7-4. IEEE-488 PCA Detailed Circuit Description (2620A Only) .............. 7-3

7-5. Main PCA Connector ...................................................................... 7-4

7-6. IEEE-488 Controller ....................................................................... 7-4

7-7. IEEE-488 Transceivers/Connector ................................................. 7-5

7-8. General Maintenance ........................................................................... 7-5

7-9. Removing the IEEE-488 Option ..................................................... 7-5

7-10. Installing the IEEE-488 Option ...................................................... 7-7

7-11. Performance Testing ........................................................................... 7-7

7-12. Troubleshooting .................................................................................. 7-8

7-13. Power-Up Problems ........................................................................ 7-8

7-14. Communication Problems ............................................................... 7-8

7-15. Failure to Select IEEE-488 Option ............................................. 7-8

7-16. Failure to Handshake on IEEE-488 Bus ..................................... 7-8

7-17. Failure to Enter Remote .............................................................. 7-8

7-18. Failure to Receive Multiple Character Commands .................... 7-9

7-19. Failure to Transmit Query Responses ........................................ 7-9

7-20. Failure to Generate an End or Identify (EOI) ............................. 7-9

7-21. Failure to Generate a Service Request (SRQ) ............................ 7-9

7-22. List of Replaceable Parts ..................................................................... 7-9

7-23. Schematic Diagram ............................................................................. 7-9

8 Schematic Diagrams.......................................................................... 8-1

9 Hydra Starter Calibration Software................................................... 9-1

Introduction....................................................................................................... 9-3

vi

Page 13

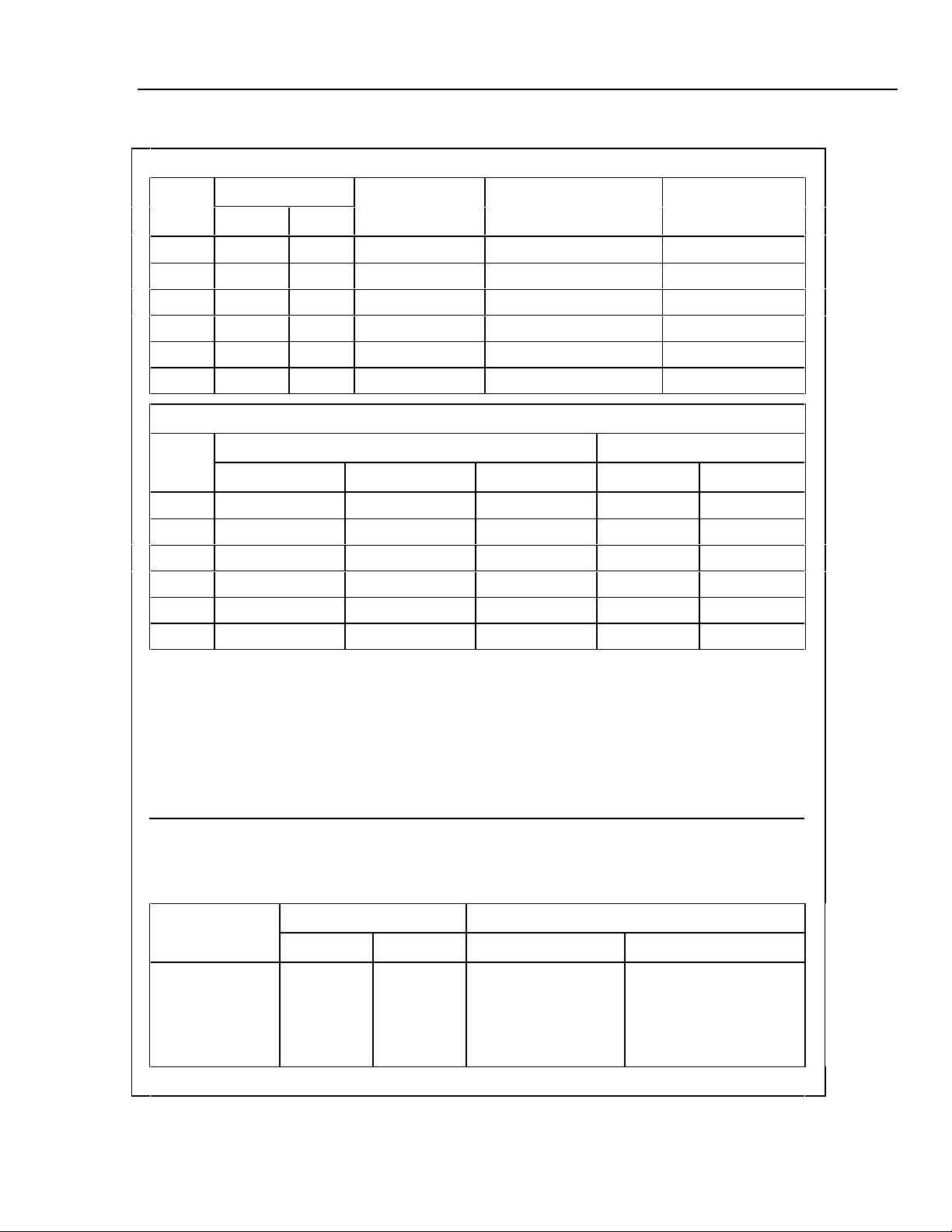

List of Tables

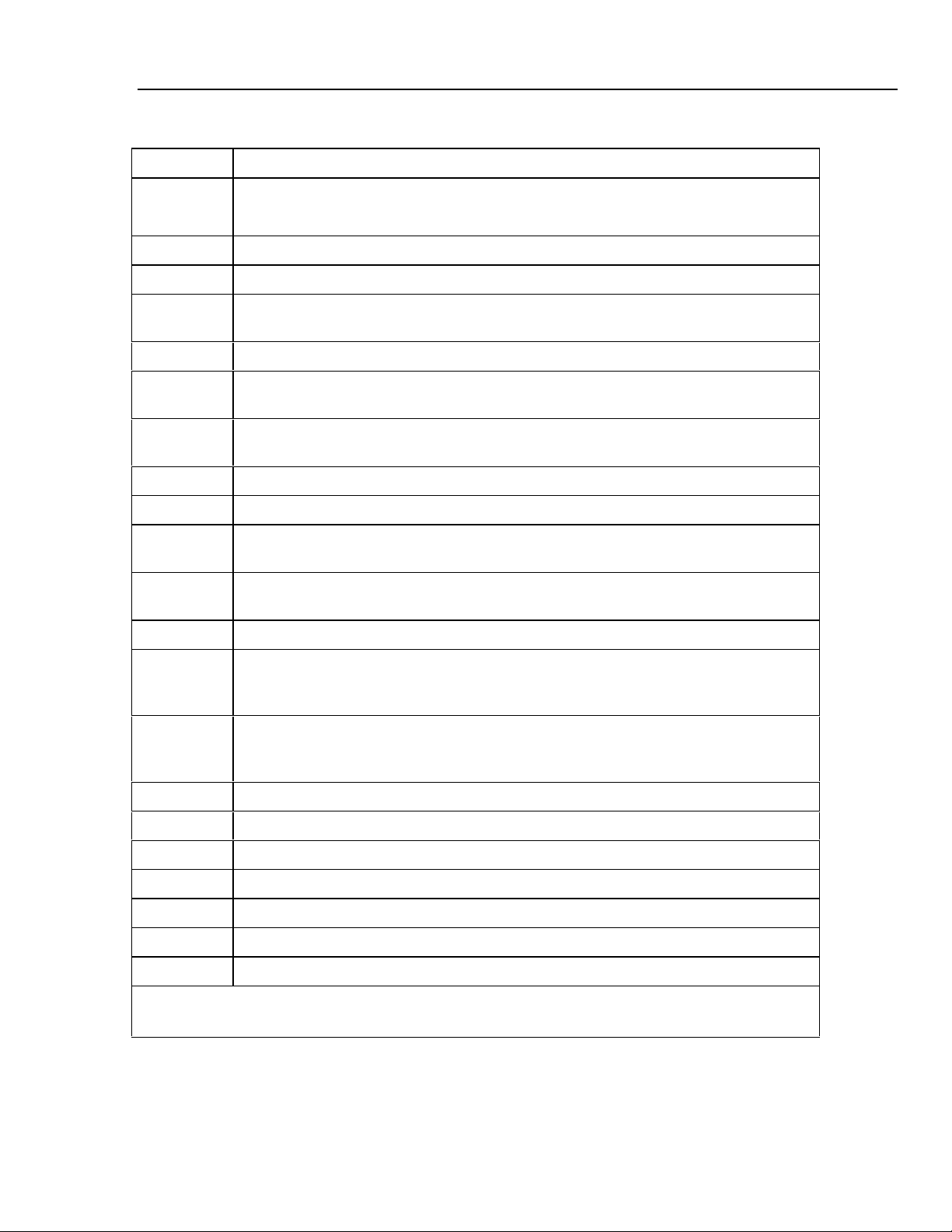

Table Title Page

1-1. Hydra Features.........................................................................................................1-6

1-2. Accessories............................................................................................................ 1-7

1-3. 2620A/2625A Specifications................................................................................. 1-8

1-4. 2635A Specifications............................................................................................. 1-20

2-1. Microprocessor Memory Map............................................................................... 2-11

2-2. Option Type Sensing ............................................................................................. 2-14

2-3. Programmable Input Threshold Levels ................................................................. 2-15

2-4. Analog Measurement Processor Pin Descriptions ................................................ 2-19

2-5. Function Relay States............................................................................................ 2-21

2-6. AC Volts Input Signal Dividers............................................................................. 2-25

2-7. Front Panel Switch Scanning................................................................................. 2-29

2-8. Display Initialization Modes ................................................................................. 2-32

2A-1. Microprocessor Interrupt Sources (2635A)........................................................... 2A-12

2A-2. Booting Microprocessor Memory Map (2635A)................................................... 2A-13

2A-3. Instrument Microprocessor Memory Map (2635A).............................................. 2A-13

2A-4. Analog Measurement Processor Pin Descriptions (2635A).................................. 2A-22

2A-5. Function Relay States (2635A).............................................................................. 2A-24

2A-6. AC Volts Input Signal Dividers (2635A).............................................................. 2A-28

2A-7. Front Panel Switch Scanning (2635A).................................................................. 2A-33

2A-8. Display Initialization Modes (2635A)................................................................... 2A-36

4-1. Recommended Test Equipment............................................................................. 4-3

4-2. Performance Tests (Voltage, Resistane, and Frequency)...................................... 4-5

4-3. Thermocouplt Information .................................................................................... 4-10

4-4. Performance Tests for Thermocouple Temperature Function............................... 4-10

4-5. Performance Tests for RTD Temperature Function (Resistance Source)............. 4-12

4-6. Performance Tests for RTD Temperature Function (DIN/IEC 751)..................... 4-13

4-7. Digital Input Values............................................................................................... 4-14

4-8. Calibration Mode Computer Interface Commands ............................................... 4-20

4-9. DC Volts Calibration............................................................................................. 4-23

4-10. AC Volts Calibration............................................................................................. 4-24

4-11. 4-Wire Ohms Calibration (Fixed Resistor) ........................................................... 4-27

4-12. 4-Wire Ohms Calibration (5700A)........................................................................ 4-28

4-13. Frequency Calibration ........................................................................................... 4-29

5-1. Error Codes............................................................................................................ 5-5

5-2. Preregulated Power Supplies................................................................................. 5-6

vii

Page 14

HYDRA

Service Manual

5-3. Power Supply Troubleshooting Guide................................................................... 5-13

5-4. DC Volts HI Troubleshooting ............................................................................... 5-17

5-5. AC Volts HI Troubleshooting ............................................................................... 5-18

5-6. Ohms Open-Circuit Voltage.................................................................................. 5-18

5-7. Ohms HI Troubleshooting..................................................................................... 5-18

5-8. Display Initialization ............................................................................................. 5-23

5-9. Calibration Faults (for software versions 5.4 and above)...................................... 5-27

5-10. Calibration Faults (for sotware versions lower than 5.4)...................................... 5-28

5A-1. Error Codes (2635A) ............................................................................................. 5A-5

5A-2. Preregulated Power Supplies (2635A) .................................................................. 5A-6

5A-3. Power Supply Troubleshooting Guide (2635A).................................................... 5A-13

5A-4. DC Volts HI Troubleshooting (2635A)................................................................. 5A-18

5A-5. AC Volts HI Troubleshooting (2635A)................................................................. 5A-18

5A-6. Ohms Open-Circuit Voltage (2635A) ................................................................... 5A-19

5A-7. Ohms HI Troubleshooting (2635A)....................................................................... 5A-19

5A-8. Display Initialization (2635A)............................................................................... 5A-26

5A-9. Calibration Faults (for software versions 5.4 and above) (2635A)....................... 5A-29

6-1. 2620A/2625A Final Assembly.............................................................................. 6-5

6-2. 2635A Final Assembly.......................................................................................... 6-11

6-3. 2620A/2625A A1 Main PCA ................................................................................ 6-17

6-4. 2635A A1 Main PCA ............................................................................................ 6-21

6-5. A2 Display PCA .................................................................................................... 6-25

6-6. A3 A/D Converter PCA......................................................................................... 6-27

6-7. A4 Analog Input PCA............................................................................................ 6-30

6-9. 2625A A6 Memory PCA....................................................................................... 6-34

6-10. 2635A A6 Memory Card I/F PCA......................................................................... 6-36

7-1. A5U1 Pin Differences............................................................................................ 7-3

7-2. IEEE-488 Transceiver Control.............................................................................. 7-5

viii

Page 15

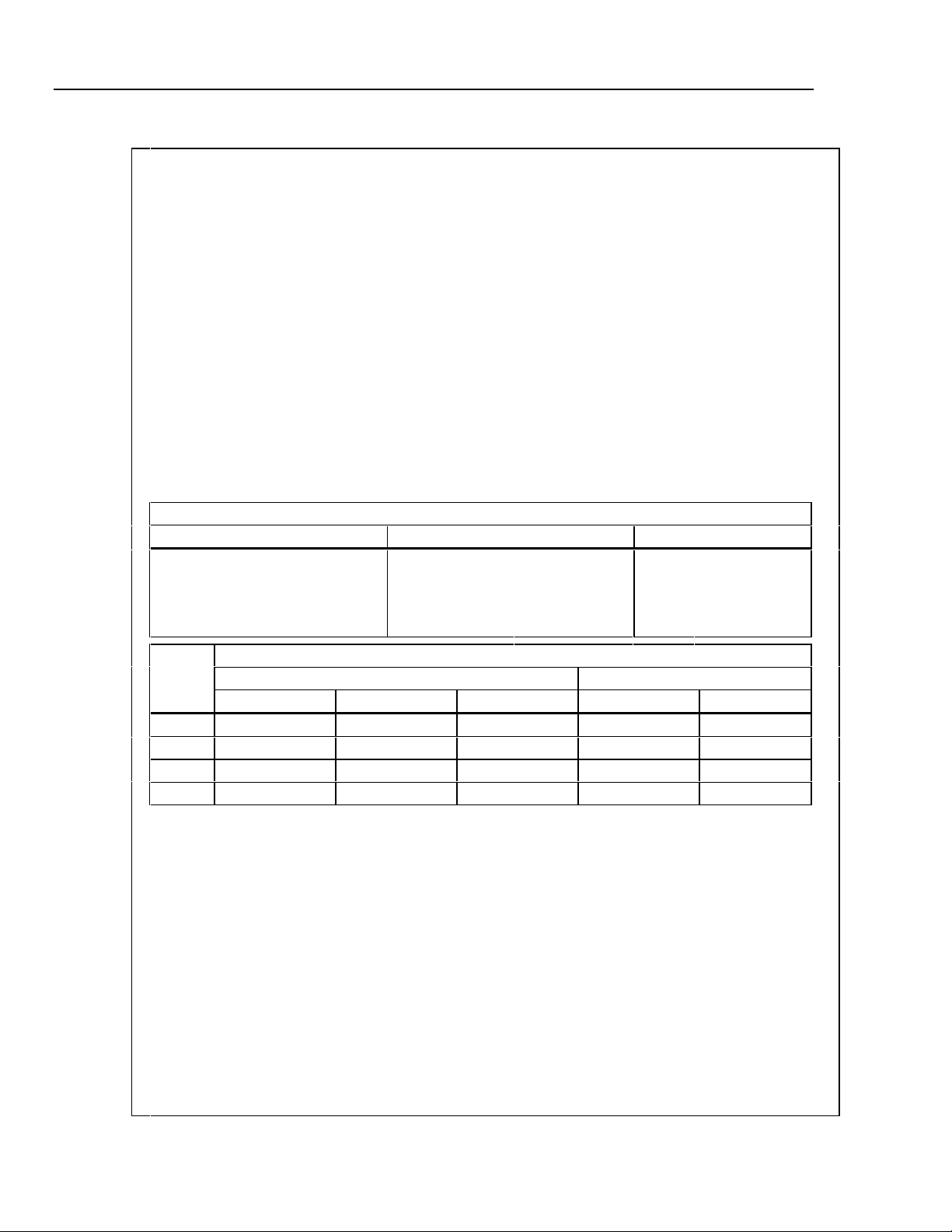

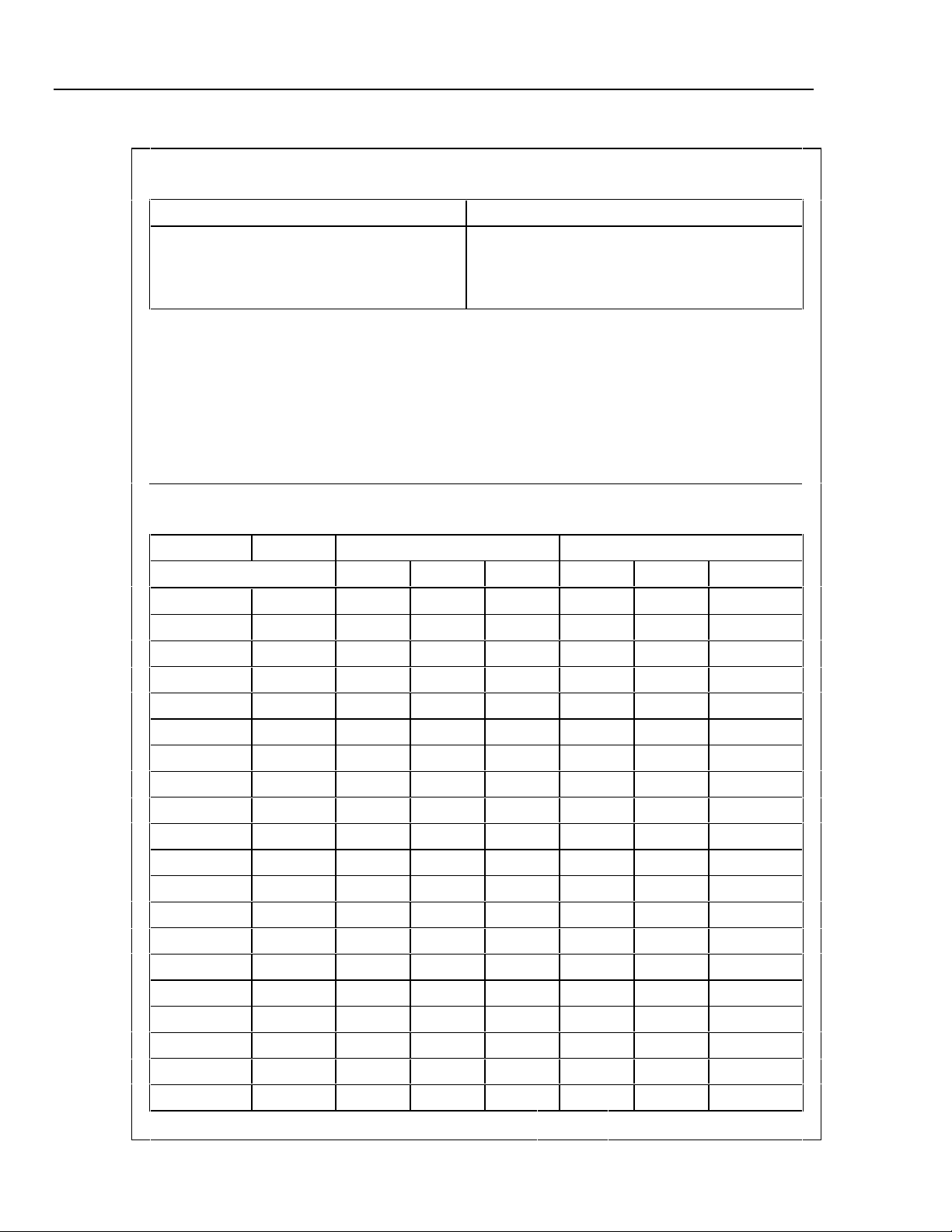

List of Figures

Figure Title Page

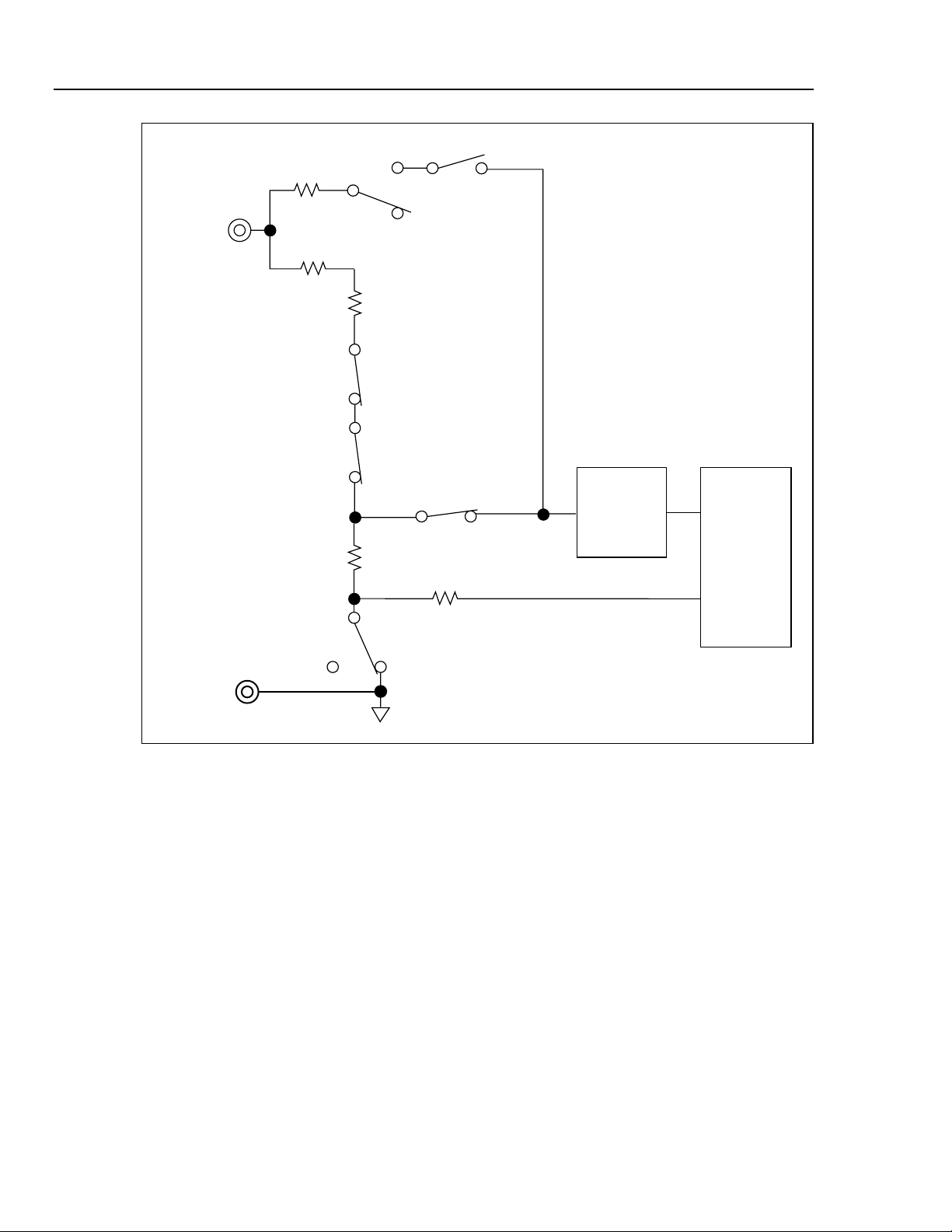

2-1. Interconnect Diagram ............................................................................................ 2-4

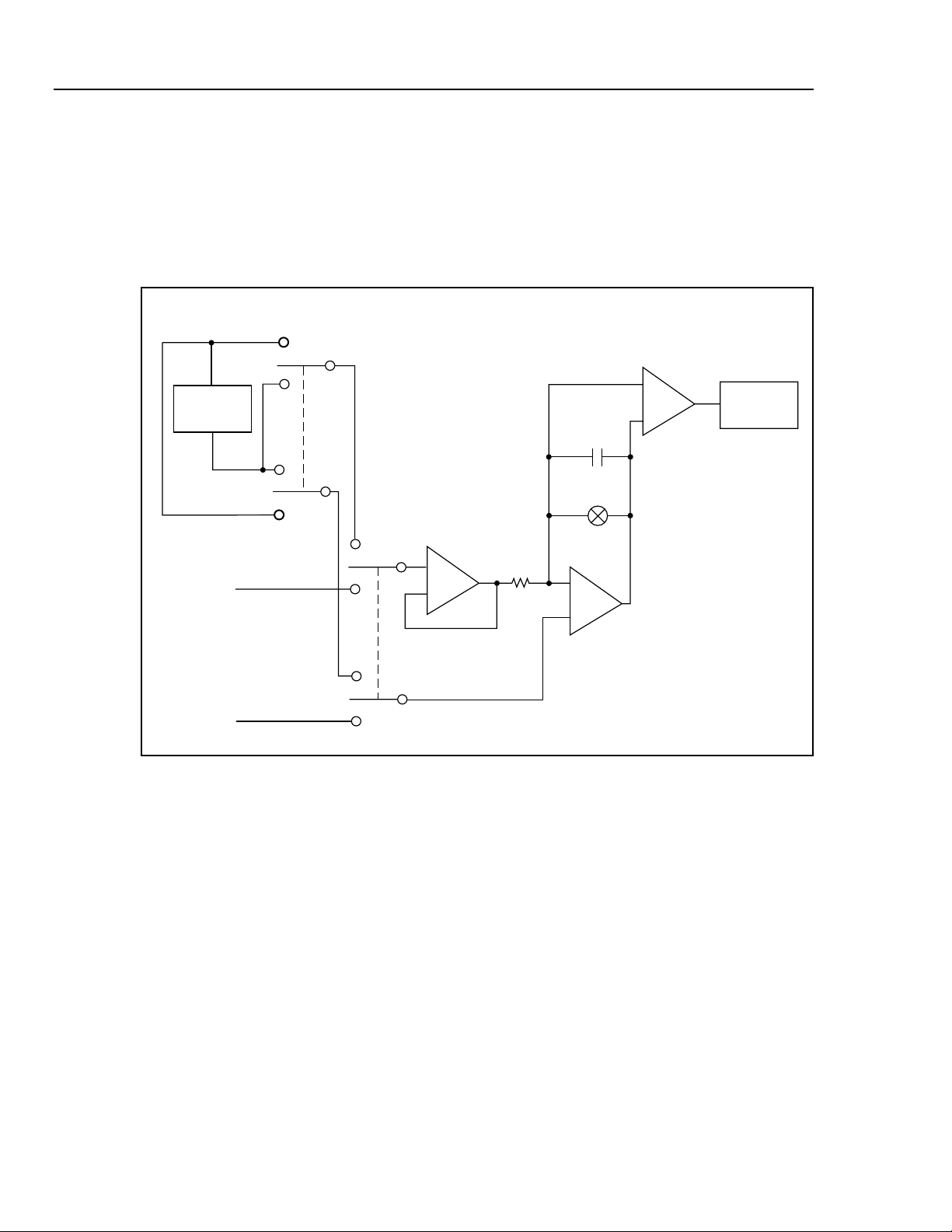

2-2. Overall Functional Block Diagram........................................................................ 2-5

2-3. Analog Simplified Schematic Diagram................................................................. 2-18

2-5. Ohms Simplified Schematic.................................................................................. 2-23

2-6. AC Buffer Simplified Schematic........................................................................... 2-24

2-7. A/D Converter Simplified Schematic.................................................................... 2-26

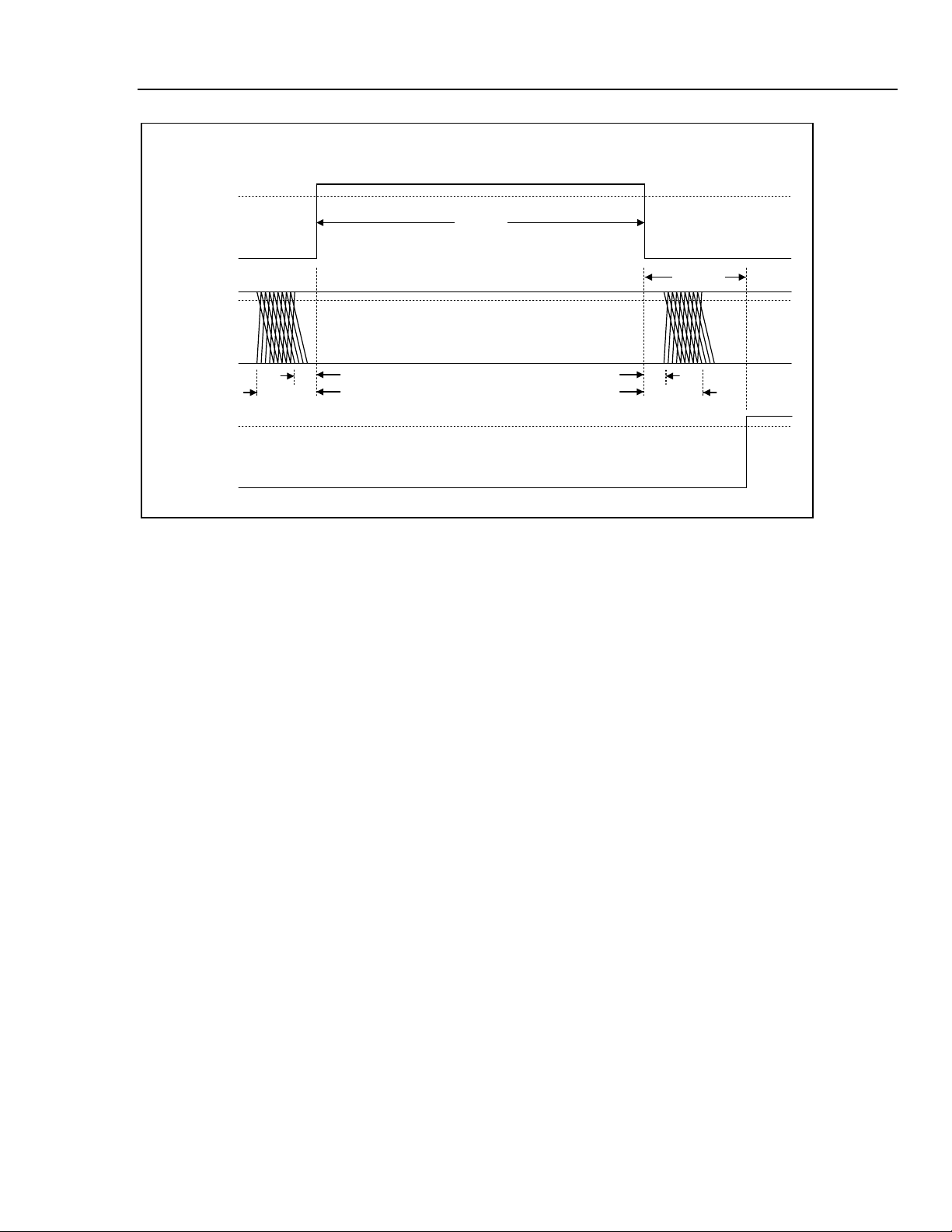

2-8. Command Byte Transfer Waveforms.................................................................... 2-31

2-9. Grid Control Signal Timing................................................................................... 2-32

2-10. Grid-Anode Timing Relationships ........................................................................ 2-33

2A-1. Interconnect Diagram (2635A).............................................................................. 2A-4

2A-2. Overall Functional Block Diagram (2635A)......................................................... 2A-5

2A-3. Analog Simplified SchematicDiagram (2635A)................................................... 2A-21

2A-4. DC Volts 300V Range Simplified Schematic (2635A)......................................... 2A-25

2A-5. Ohms Simplified Schematic (2635A).................................................................... 2A-26

2A-6. AC Buffer Simplified Schematic (2635A)............................................................ 2A-28

2A-7. A/D Converter Simplified Schematic (2635A)..................................................... 2A-30

2A-8. Command Byte Transfer Waveforms (2635A)..................................................... 2A-35

2A-9. Grid Control Signal Timing (2635A).................................................................... 2A-37

2A-10. Grid-Anode Timing Relationships (2635A).......................................................... 2A-37

3-1. Replacing the Line Fuse ........................................................................................ 3-5

3-3. Removing the Handle and Handle Mounting Brackets......................................... 3-8

3-3. Removing the Case................................................................................................ 3-8

3-5. 2635A Assembly Details....................................................................................... 3-10

3-5. 2620A and 2625A Assembly Details .................................................................... 3-10

4-1. Input Module ......................................................................................................... 4-8

4-2. 2T and 4T Connections.......................................................................................... 4-9

4-3. Dedicated Alarms Test .......................................................................................... 4-17

4-4. External Trigger Test............................................................................................. 4-18

4-5. 4-Terminal Connections to Decade Resistance Source......................................... 4-25

4-6. 4-Terminal Connections to the 5700A .................................................................. 4-26

5-1. Test Point Locator, Main PCA (A1)...................................................................... 5-7

5-2. 5-Volt Switching Supply ....................................................................................... 5-9

5-3. Inverter FET Drive Signals.................................................................................... 5-11

5-5. Test Points, A/D Converter PCA (A3, A3U9) ...................................................... 5-16

5-5. Test Points, A/D Converter PCA (A3, A3U9) ...................................................... 5-17

ix

Page 16

HYDRA

Service Manual

5-6. Integrator Output ................................................................................................... 5-17

5-7. Microprocessor Timing ......................................................................................... 5-20

5-8. Test Points, Display PCA (A2).............................................................................. 5-22

5-9. Display Controller to Microprocessor Signals...................................................... 5-23

5-10. Display Test Pattern #1.......................................................................................... 5-24

5-11. Display Test Pattern #2.......................................................................................... 5-24

5A-1. Test Point Locator, Main PCA (A1) (2635A)....................................................... 5A-7

5A-2. 5-Volt Switching Supply (2635A)......................................................................... 5A-10

5A-3. Inverter FET Drive Signals (2635A)..................................................................... 5A-11

5A-4. Test Points, A/D Converter PCA (A3, A3U8) (2635A)........................................ 5A-15

5A-5. Test Points, A/D Converter PCA (A3U9) (2635A)............................................... 5A-16

5A-5. Test Points, A/D Converter PCA (A3, A3U8) (2635A)........................................ 5A-16

5A-6. Integrator Output (2635A)..................................................................................... 5A-17

5A-7. Microprocessor Timing (2635A)........................................................................... 5A-23

5A-8. Test Points, Display PCA (A2) (2635A)............................................................... 5A-25

5A-9. Display Controller to Microprocessor Signals (2635A)........................................ 5A-26

5A-10. Display Test Pattern #1 (2635A)........................................................................... 5A-26

5A-11. Display Test Pattern #2 (2635A)........................................................................... 5A-26

6-1. 2620A/2625A Final Assembly.............................................................................. 6-7

6-2. 2635A Final Assembly.......................................................................................... 6-13

6-3. 2620A/2625A A1 Main PCA ................................................................................ 6-20

6-4. 2635A A1 Main PCA ............................................................................................ 6-24

6-5. A2 Display PCA .................................................................................................... 6-26

6-6. A3 A/D Converter PCA........................................................................................ 6-29

6-7. A4 Analog Input PCA............................................................................................ 6-31

6-8. A5 IEEE-488 Interface PCA (Option -05) ............................................................ 6-33

6-9. 2625A A6 Memory PCA....................................................................................... 6-35

6-10. 2635A A6 Memory Card I/F PCA......................................................................... 6-37

7-1. Installation ............................................................................................................. 7-6

8-1. A1 Main PCA (2620A/2625A).............................................................................. 8-3

8-2. A1 Main PCA (2635A).......................................................................................... 8-8

8-3. A2 Display PCA .................................................................................................... 8-14

8-4. A3 A/D Converter PCA......................................................................................... 8-16

8-5. A4 Analog Input PCA............................................................................................ 8-20

8-6. A5 (Option -05) IEEE-488 Interface PCA ............................................................ 8-22

8-7. A6 Memory PCA (2625A) .................................................................................... 8-24

8-8. A6 Memory Card I/F PCA (2635A)...................................................................... 8-26

x

Page 17

Chapter 1

Introduction and Specifications

Title Page

1-1. Introduction.......................................................................................... 1-3

1-2. Options and Accessories ...................................................................... 1-3

1-3. Operating Instructions.......................................................................... 1-3

1-4. Organization of the Service Manual..................................................... 1-4

1-5. Conventions.......................................................................................... 1-5

1-6. Specifications....................................................................................... 1-7

1-1

Page 18

HYDRA

Service Manual

1-2

Page 19

1-1. Introduction

Hydra measures analog inputs of dc and ac volts, thermocouple and RTD temperatures,

resistance, and frequency. It features 21 measurement input channels. In addition, it

contains eight digital input/output lines, one totalizing input, one external scan trigger

input, and four alarm output lines. Hydra is fully portable and can be ac or dc powered.

An RS-232 computer interface is standard. An optional IEEE-488 computer interface is

available for the Hydra Data Acquisition Unit (2620A) only.

The Hydra Data Logger (2625A) adds substantial measurement memory capabilities.

The RS-232 computer interface is standard, but IEEE-488 capability is not available for

the Hydra Data Logger.

The Hydra Data Bucket (2635A) adds more flexible storage for instrument setups and

measurement data by adding a PCMCIA memory card and interface. The amount of

storage can be easily changed by selecting a memory card of the appropriate size for the

job.

The Hydra instruments share many features and functions. The term "instrument" is used

to refer to all three instruments. The model number (2620A, 2625A, or 2635A) is used

when discussing features unique to one instrument.

The instrument is designed for bench-top, field service, and system applications. A dual

vacuum-fluorescent display uses combinations of alphanumeric characters and

descriptive annunciators to provide prompting and measurement information during

setup and operation modes.

Introduction and Specifications

Introduction

1

Some features provided by the instrument are listed in Table 1-1.

1-2. Options and Accessories

The following items can be installed either at the factory or in the field:

• Option 2620A-05K (IEEE-488 Interface Kit) consists of a printedcircuit assembly,

connecting cable, and mounting hardware. Thisfield-installable kit gives the 2620A

Hydra Data Acquisition UnitIEEE-488 interface capabilities. IEEE-488 computer

interfacecommands are virtually identical to RS-232 interface commands.

(The2625A and 2635A cannot be equipped with an IEEE-488 Interface.)

• Accessory 2620A-100 (Connector Kit).

The instrument can be mounted in a standard 19-inch rack panel on either the right-hand

or left-hand side using the Fluke M00-200-634 Rackmount Kit.

Accessories are listed in Table 1-2.

1-3. Operating Instructions

Full operating instructions are provided in the Hydra User Manual (2620A or 2625A)

and in the Hydra Data Bucket User Manual (2635A). Refer to the User Manual as

necessary during the maintenance and repair procedures presented in this Service

Manual.

1-3

Page 20

HYDRA

Service Manual

1-4. Organization of the Service Manual

This manual focuses on performance tests, calibration procedures, and component-level

repair of each of the instruments. To that end, manual sections are often interdependent;

effective troubleshooting may require not only reference to the troubleshooting

procedures in Section 5, but also some understanding of the detailed Theory of

Operation in Section 2 and some tracing of circuit operation in the Schematic Diagrams

presented in Section 8.

Often, scanning the table of contents will yield an appropriate place to start using the

manual. A comprehensive table of contents is presented at the front of the manual; local

tables of contents are also presented at the beginning of each chapter for ease of

reference. If you know the topic name, the index at the end of the manual is probably a

good place to start.

The following chapter descriptions serve to introduce the manual:

Chapter 1. Introduction and Specifications

Introduces the instrument, describing its features, options, and accessories. This chapter

also discusses use of the Service Manual and the various conventions used in describing

the circuitry. Finally, a complete set of specifications is presented.

Chapter 2. Theory of Operation (2620A and 2625A)

This chapter first categorizes these instrument’s circuitry into functional blocks, with a

description of each block’s role in overall operation. A detailed circuit description is then

given for each block. These descriptions explore operation to the component level and

fully support troubleshooting procedures defined in Chapter 5.

Chapter 2A. Theory of Operation (2635A)

This chapter first categorizes the instrument’s circuitry into functional blocks, with a

description of each block’s role in overall operation. A detailed circuit description is then

given for each block. These descriptions explore operation to the component level and

fully support troubleshooting procedures defined in Chapter 5A.

Chapter 3. General Maintenance

Provides maintenance information covering handling, cleaning, and fuse replacement.

Access and reassembly procedures are also explained in this chapter.

Chapter 4. Performance Testing and Calibration

This chapter provides performance verification procedures, which relate to the

specifications presented in Chapter 1. To maintain these specifications, a full calibration

procedure is also presented.

Chapter 5. Diagnostic Testing and Troubleshooting (2620A and 2625A)

The troubleshooting procedures presented in this chapter rely closely on both the Theory

of Operation presented in Chapter 2, the Schematic Diagrams shown in Chapter 8, and

the access information provided in Chapter 3.

1-4

Chapter 5A. Diagnostic Testing and Troubleshooting (2635A)

The troubleshooting procedures presented in this chapter rely closely on both the Theory

of Operation presented in Chapter 2A, the Schematic Diagrams shown in Chapter 8, and

the access information provided in Chapter 3.

Chapter 6. List of Replaceable Parts

Includes parts lists for all standard assemblies. Information on how and where to order

parts is also provided.

Page 21

Chapter 7. IEEE-488 Option (2620A only)

This chapter describes the IEEE-488 option. Included are specifications, theory of

operation, maintenance, and a list of replaceable parts. Schematic diagrams for this

option are included at the end of the overall Service Manual (Chapter 8).

Chapter 8. Schematic Diagrams

Includes schematic diagrams for all standard and optional assemblies. A list of

mnemonic definitions is also included to aid in identifying signal name abbreviations.

Chapter 9. HYDRA Starter Calibration Software

This chapter provides an extened tutorial that demostrates how to perform a series of

operations. These operations introduce you to the menu structure of the Starter with cal

software, explain what the menu items do, and teach you how to use them.

1-5. Conventions

Throughout the manual set, certain notational conventions are used. A summary of these

conventions follows:

• Instrument Reference

The Hydra Data Acquisition Unit (Model 2620A), the Hydra Data Logger(Model

2625A), and the Hydra Data Bucket (Model 2635A) share manyfeatures and

functions. The term Hydra refers to any of theseinstruments. The model number

(e.g., 2620A, 2625A, or 2635A) isused when features unique to one instrument are

being described.

• Printed Circuit Assembly

The term "pca" is used to represent a printed circuit board and itsattached parts.

• Signal Logic Polarity

On schematic diagrams, a signal name followed by a "*" is active (orasserted) low.

Signals not so marked are active high.

• Circuit Nodes

Individual pins or connections on a component are specified with adash (-) following

the assembly and component reference designators.For example, pin 19 of U30 on

assembly A1 would be A1U30-19.

• User Notation

For front panel operation,

XXXAn uppercase word or symbol without parentheses indicates a button to be

pressed by the user. Buttons can be pressed in four ways:

1. Press a single button to select a function or operation.

2. Press a combination of buttons, one after the other.

3. Press and hold down a button, then press another button.

4. Press multiple buttons simultaneously.

For computer interface operation,

XXX An uppercase word without parentheses identifies a command byname.

Introduction and Specifications

Conventions

1

<XXX> Angle brackets around all uppercase letters mean press the<XXX> key.

(xxx) When associated with a keyword, a lowercase word inparentheses

indicates an input required by the user.

1-5

Page 22

HYDRA

Service Manual

• Channel Scanning

• Channel Monitoring

• Channel Scanning and Monitoring

• Multi-Function Display

• Front-Panel Operation

• Measurement Input Function and Range

• Temperature Measurement

• Totalize Events on the Totalizing Input

• Alarms Limits and Digital Output Alarm Indication

• 4-Terminal Resistance Measurements (Ch. 1 .. 10)

• RS-232 Computer Interface Operation

• Measurement Rate Selection

• Nonvolatile Memory

• Features unique to the 2625A Data Logger.

• Features unique to the 2635A Data Bucket.

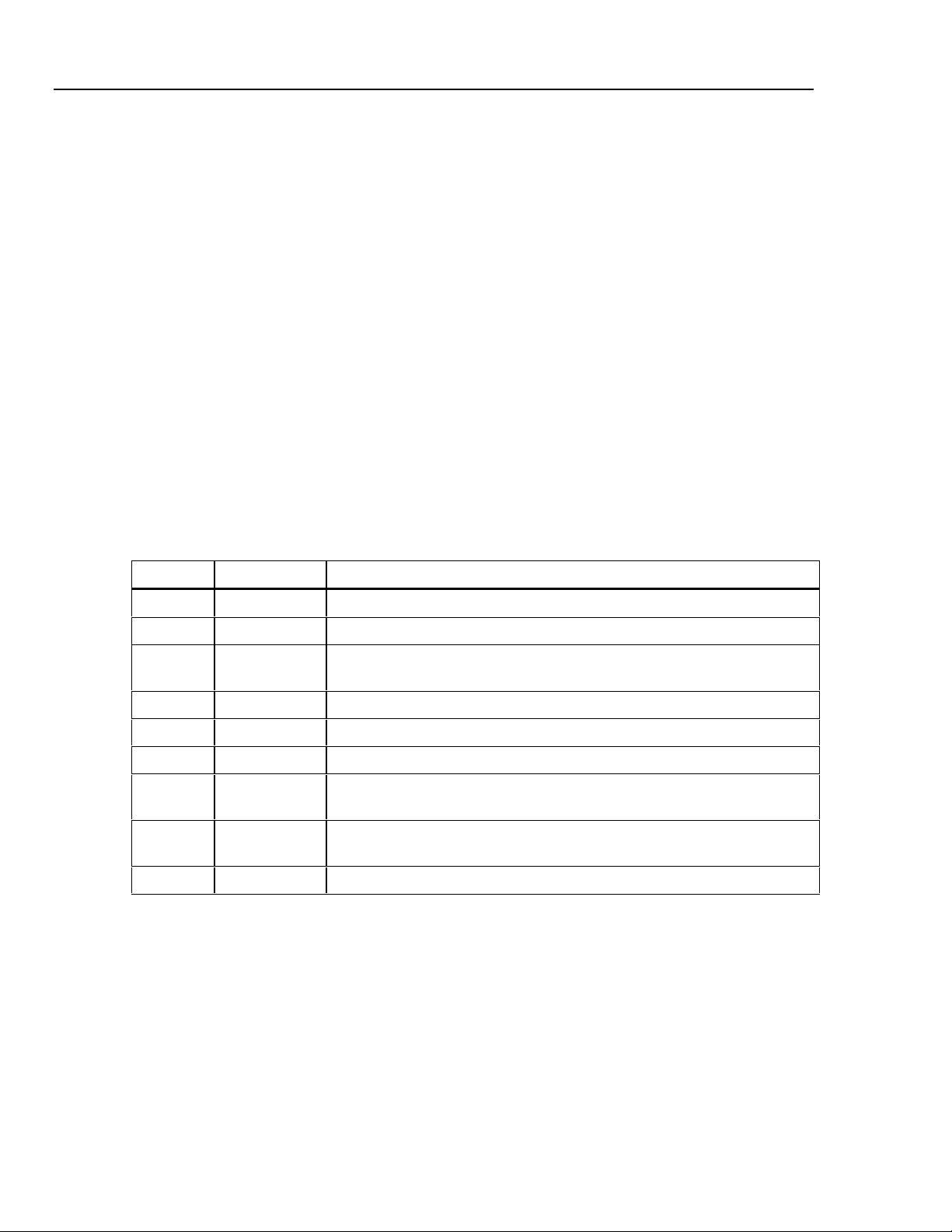

Table 1-1. Hydra Features

Can be continuous scanning, scanning at an interval time, single scans, or triggered (internal or external)

scans.

Make measurements on a single channel and view these measurements on the display.

View measurements made for the monitor channel while scanning of all active channels continues.

Left (numeric) display shows measurement readings; also used when setting numeric parameters.

Right (alphanumeric) display used for numeric entries, channel number selection and display, status

information, and operator prompts.

Almost all operations can be readily controlled with the buttons on the front panel.

Volts dc (VDC), volts ac (VAC), frequency (Hz), and resistance (Ω) inputs can be specified in a fixed

measurement range. Autoranging, which allows the instrument to use the measurement range providing

the optimum resolution, can also be selected.

Thermocouple types J, K, E, T, N, R, S, B, and Hoskins Engineering Co. type C are supported.Also,

DIN/IEC 751 (Pt 385) Platinum RTDs are supported.

Storage of minimum, maximum, and most recent measurements for all scanned channels.

Storage of Computer Interface setup, channel configurations, and calibration values.

Storage of measurement data: storage for 2047 scans of up to 21 channels, representing up to 42,987

readings.

Internal storage of measurement data for 100 scans of up to 21 channels, representing up to 2,100

readings.

Memory card storage of instrument setup configurations so that instrument may be quickly set up to do

different tasks.

Memory card storage of measurement data for up to 4,800 scans of 10 channels on a 256K-byte card or

up to 19,800 scans of 10 channels on a 1M-byte memory card.

Enhanced RS-232 interface with higher baud rates and hardware flow control using the Clear to Send

modem control signal.

1-6

Page 23

Table 1-2. Accessories

Model Description

Introduction and Specifications

Specifications

1

80i-410

80i-1010

80J-10 Current Shunt

2620A-05K Field-installable IEEE-488 Option kit (Hydra Data Acquisition Unit only.)

2620A-100 Extra I/O Connector Set: Includes Universal Input Module, Digital I/O and Alarm Output

262XA-801 Diconix(R) 80-column serial printer.

263XA-803 Memory Card Reader for IBM-PC or compatible personal computer. Card reader is external

263XA-804 256K-Byte Memory Card (2635A Data Bucket only). (This card is supplied with the

263XA-805 1M-Byte Memory Card (2635A Data Bucket only).

26XXA-901 Hydra Logger Applications Package (Version 3.0)

C40 Soft carrying case. Provides padded protection for the instrument. Includes a pocket for the

M00-200-634 Rackmount Kit. Provides standard 19-inch rack mounting for one instrument (right or left

PM 8922 Switchable X1, X10 passive probe.

Clamp-On DC/AC Current Probes

Connectors.

to the PC and connects to a PC parallel port (LPT1, LPT2, etc.). (2635A Data Bucket only).

instrument.)

manual and pouch for the line cord.

side.)

RS40 Shielded RS-232 terminal interface cable. Connects the instrument to any terminal or

printer with properly configured DTE connector (DB-25 socket), including an IBM PC(R),

IBM PC/XT(R) or IBM PS/2 (models 25, 30, 50, P60, 70, and 80).

RS41 Shielded RS-232 modem cable. Connects the instrument to a modem with properly

configured DB-25 male pin connector. Use an RS40 and an RS41 cable in series to

connect with an IBM PC/AT(R).

RS42 Shielded serial printer cable. Contact Fluke for list of compatible printers.

TL20 Industrial test lead set.

TL70A Test lead set (one set is supplied with the instrument).

Y8021 Shielded IEEE-488 one-meter (39.4 inches) cable, with plug and jack at each end.

Y8022 Shielded IEEE-488 two-meter (78.8 inches) cable, with plug and jack at each end.

Y8023 Shielded IEEE-488 four-meter (13 feet) cable, with plug and jack at each end.

Y9109 Binding post to BNC plug.

Footnote:

IBM PC, IBM PC/XT, and IBM PC/AT are registered trademarks of International Business Machines

1-6. Specifications

Table 1-3 contains the specifications for the 2620A and 2625A.

Table 1-4 contains the specifications for the 2635A.

1-7

Page 24

HYDRA

Service Manual

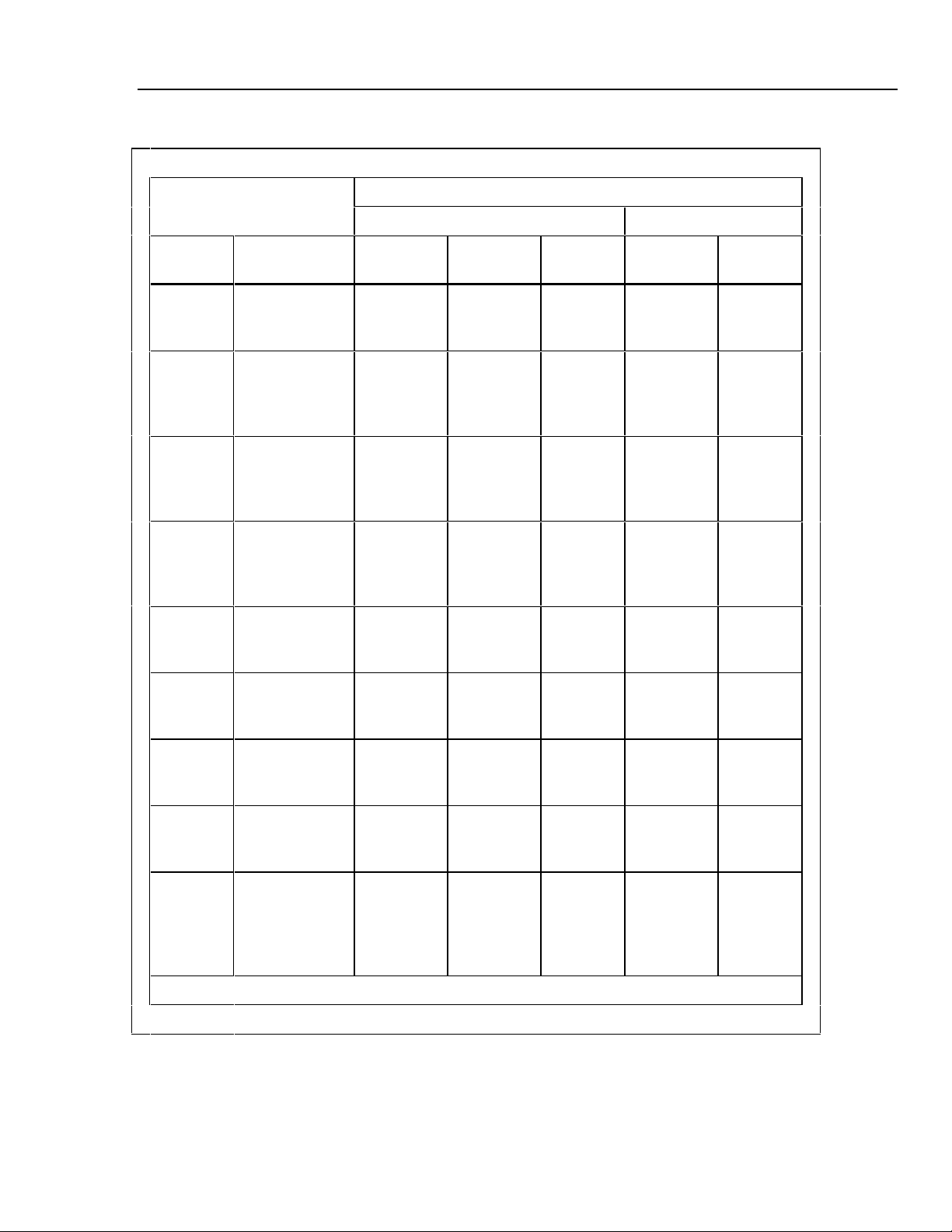

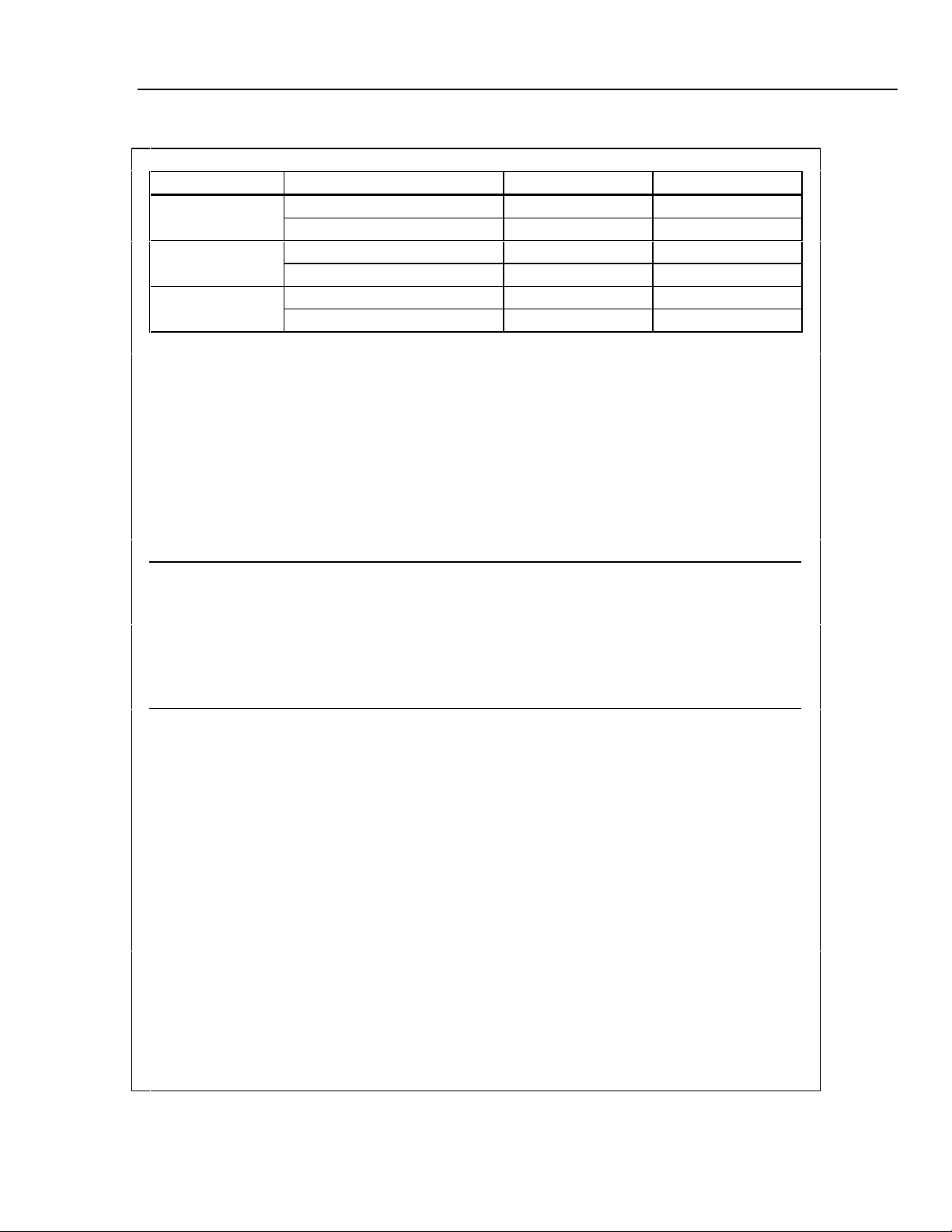

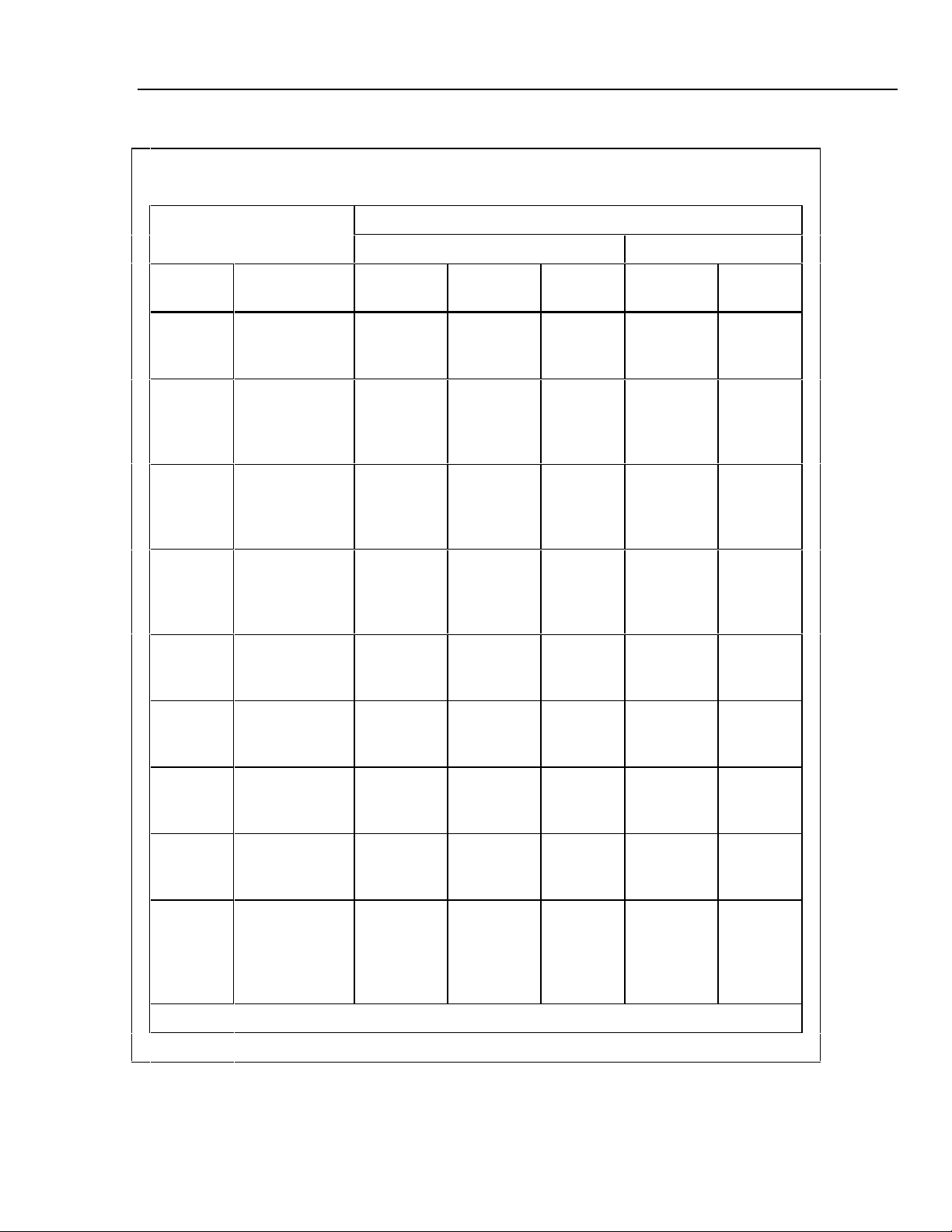

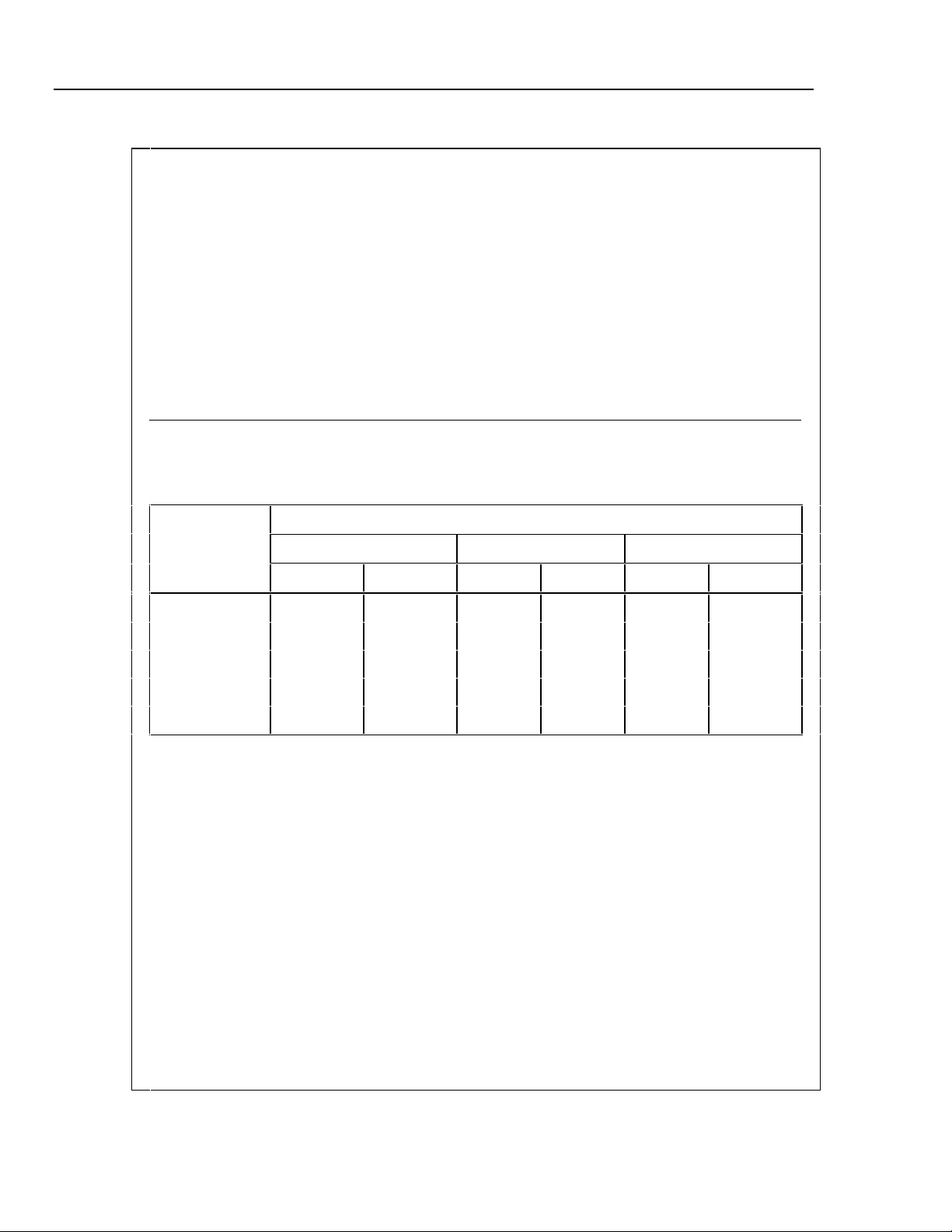

Table 1-3. 2620A/2625A Specifications

The instrument specifications presented here are applicable within the conditions listed in the

Environmental portion of this specification.

The specifications state total instrument accuracy following calibration, including:

• A/D errors

• Linearization conformity

• Initial calibration errors

• Isothermality errors

• Relay thermal emf’s

• Reference junction conformity

• Temperature coefficients

• Humidity errors

Sensor inaccuracies are not included in the accuracy figures.

Accuracies at Temperatures Other Than Specified

To determine typical accuracies at temperatures intermediate to those listed in the specification

tables, linearly interpolate between the applicable 0oC to 60oC and 18oC to 28oC accuracy

specifications.

Response Times

Refer to Typical Scanning Rate and Maximum Autoranging Time later in this table.

DC Voltage Inputs

Resolution

Range Slow Fast

300 mV 10 µV 0.1 mV

3V 0.1 mV 1 mV

30V 1 mV 10 mV

300V 10 mV 0.1V

Accuracy ±(% ±V)

Range 18°C to 28°C0°C to 60°C

90 Days, Slow 1 Year, Slow 1 Year, Fast 1 Year, Slow 1 Year, Fast

300 mV 0.026% + 20 µV 0.031% + 20 µV 0.047% + 0.2 mV 0.070% + 20 µV 0.087% + 0.2 mV

3V 0.028% + 0.2 mV 0.033% + 0.2 mV 0.050% + 2 mV 0.072% + 0.2 mV 0.089% + 2 mV

30V 0.024% + 2 mV 0.029% + 2 mV 0.046% + 20 mV 0.090% + 2 mV 0.107% + 20 mV

300V 0.023% + 20 mV 0.028% + 20 mV 0.045% + 0.2V 0.090% + 20 mV 0.107% + 0.2V

Input Impedance

100 MΩ minimum in parallel with 150 pF maximum for all ranges 3V and below 10 MΩ in parallel

with 100 pF maximum for the 30V and 300V ranges.

Normal Mode Rejection

53 dB minimum at 60 Hz ±0.1%, slow rate

47 dB minimum at 50 Hz ±0.1%, slow rate

Common Mode Rejection

120 dB minimum at dc, 1 kΩ imbalance, slow rate

120 dB minimum at 50 or 60 Hz ±0.1%, 1 kΩ imbalance, slow rate

Maximum Input

300V dc or ac rms on any range for channels 0, 1, and 11

150V dc or ac rms for channels 2 to 10 and 12 to 20

Voltage ratings between channels must not be exceeded

Crosstalk Rejection

Refer to "Crosstalk Rejection" at the end of this table.

1-8

Page 25

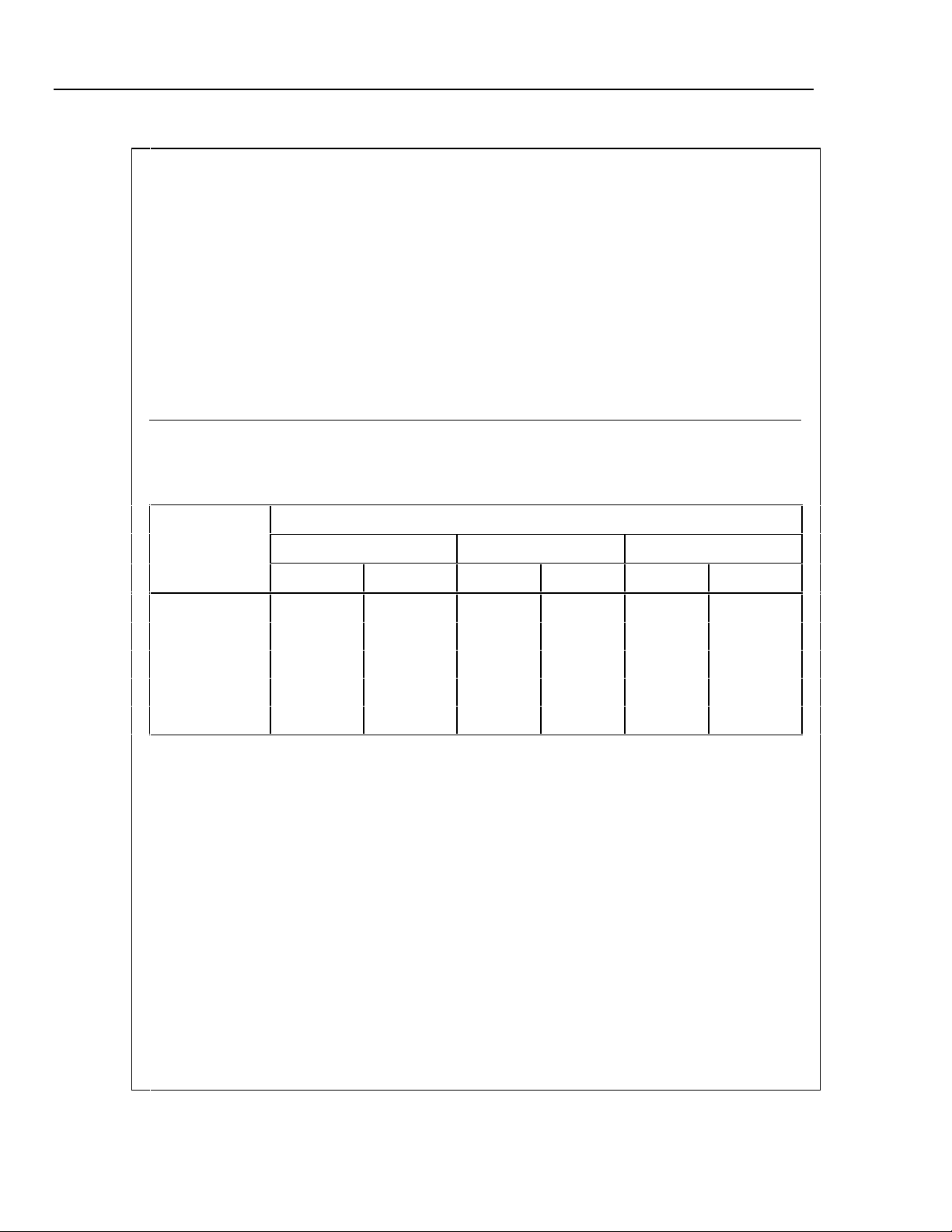

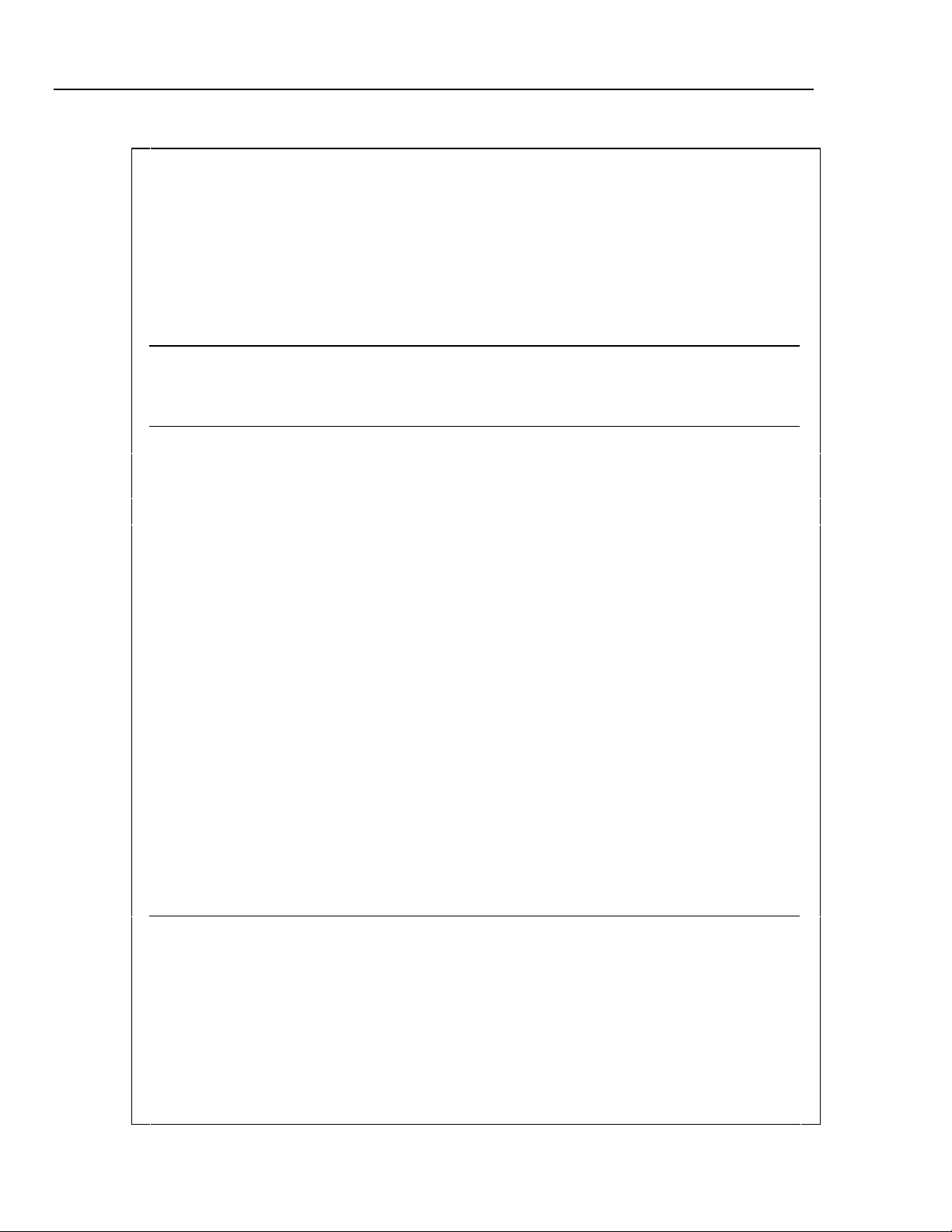

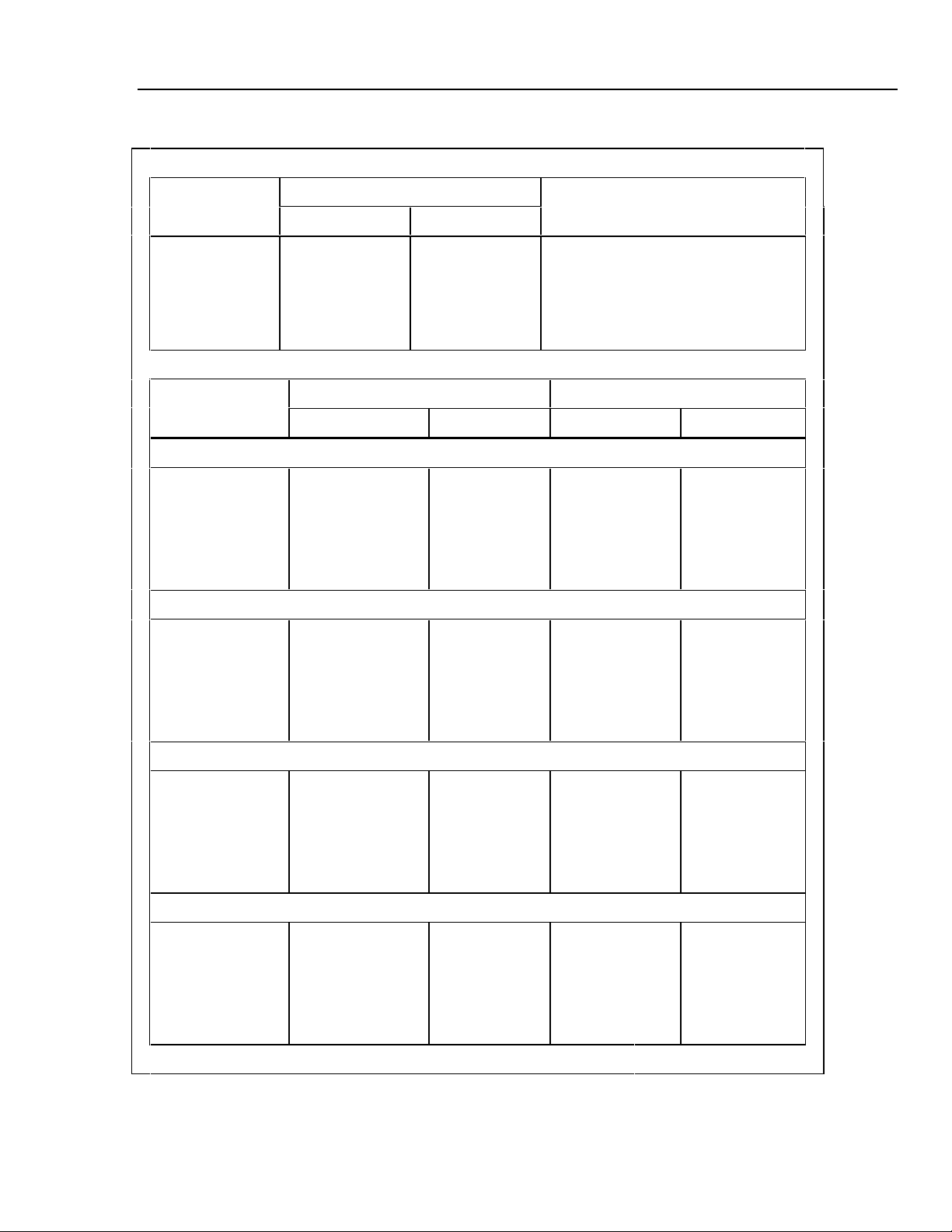

Thermocouple Inputs

Table 1-3. 2620A/2625A Specifications (cont)

Introduction and Specifications

Specifications

1

Thermocouple

Type

J

K

N

E

T

Temperature

(°C)

-100.00

0.00

760.00

-100.00

0.00

1000.00

1372.00

-100.00

0.00

400.00

1300.00

-100.00

0.00

500.00

1000.00

-150.00

0.00

400.00

90 Days

Slow

0.49

0.38

0.49

0.57

0.42

0.73

0.95

0.66

0.51

0.46

0.75

0.50

0.36

0.40

0.58

0.79

0.42

0.37

Accuracy (±°C)*

18°C to 28°C0°C to 60°C

1 Year

Slow

0.53

0.40

0.54

0.60

0.44

0.80

1.05

0.69

0.53

0.49

0.83

0.53

0.38

0.43

0.65

0.84

0.45

0.40

1 Year

Fast

1.00

0.77

0.97

1.20

0.88

1.46

1.89

1.48

1.14

0.99

1.53

0.99

0.72

0.77

1.11

1.66

0.89

0.74

1 Year

Slow

0.73

0.53

0.91

0.82

0.57

1.36

1.85

0.90

0.66

0.72

1.45

0.75

0.52

0.71

1.16

1.16

0.58

0.61

1 Year

Fast

1.22

0.91

1.35

1.43

1.02

2.03

2.70

1.70

1.29

1.23

2.16

1.22

0.86

1.05

1.63

1.99

1.04

0.97

250.00

R

S

B

C

* Sensor inaccuracies are not included.

1000.00

1767.00

250.00

1000.00

1767.00

600.00

1000.00

1820.00

0.00

500.00

1000.00

1850.00

2316.00

0.96

0.86

1.14

1.01

0.97

1.29

1.26

0.92

0.97

0.76

0.66

0.85

1.47

2.30

0.98

0.91

1.24

1.03

1.02

1.39

1.28

0.95

1.03

0.78

0.69

0.91

1.61

2.53

2.48

2.10

2.65

2.62

2.37

3.02

3.52

2.48

2.41

1.87

1.53

1.90

3.18

4.93

1.14

1.29

1.96

1.20

1.42

2.17

1.40

1.16

1.51

0.92

0.96

1.41

2.70

4.35

2.65

2.48

3.38

2.80

2.77

3.80

3.64

2.69

2.89

2.01

1.81

2.41

4.29

6.77

1-9

Page 26

HYDRA

Service Manual

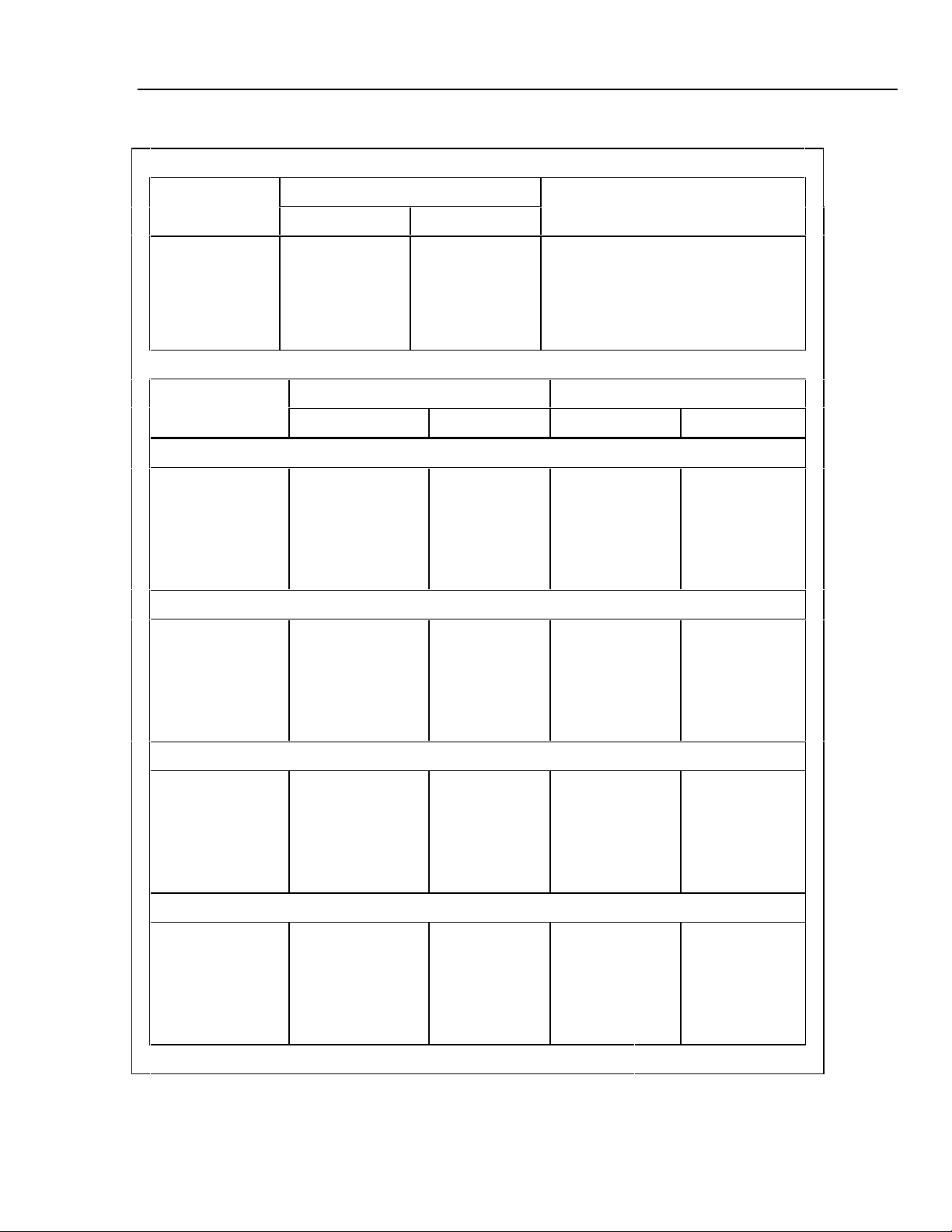

Table 1-3. 2620A/2625A Specifications (cont)

Thermocouple Inputs (cont)

Input Impedance

100 MΩ minimum in parallel with 150 pF maximum

Common Mode and Normal Mode Rejection

See Specifications, DC Voltage Inputs

Crosstalk Rejection

Refer to "Crosstalk Rejection" at the end of this table.

Open Thermocouple Detect

Small ac signal injection and detection scheme before each measurement detects greater than 1

to 4 kΩ as open. Performed on each channel unless defeated by computer command.

RTD Inputs

Type

DIN/IEC 751, 100Ω Platinum

RTD

Temperature Resolution 18°C to 28°C0°C to 60°C

(°C)

-200.00 0.02 0.01 0.08 0.49 0.12 0.54

0.00 0.02 0.01 0.21 0.67 0.50 0.96

100.00 0.02 0.01 0.27 0.75 0.69 1.17

300.00 0.02 0.01 0.41 0.92 1.10 1.60

600.00 0.02 0.01 0.65 1.21 1.77 2.33

2-Wire Accuracy

Not specified

Maximum Current Through Sensor

1 mA

Typical Full Scale Voltage

0.22V

Maximum Open Circuit Voltage

3.2V

Slow Fast Slow Fast Slow Fast

1 Year, 4-Wire Accuracy (±°C)

1-10

Maximum Sensor Temperature

600°C nominal

999.99°F is the maximum that can be displayed when using °F.

Crosstalk Rejection

Refer to "Crosstalk Rejection" at the end of this table.

Page 27

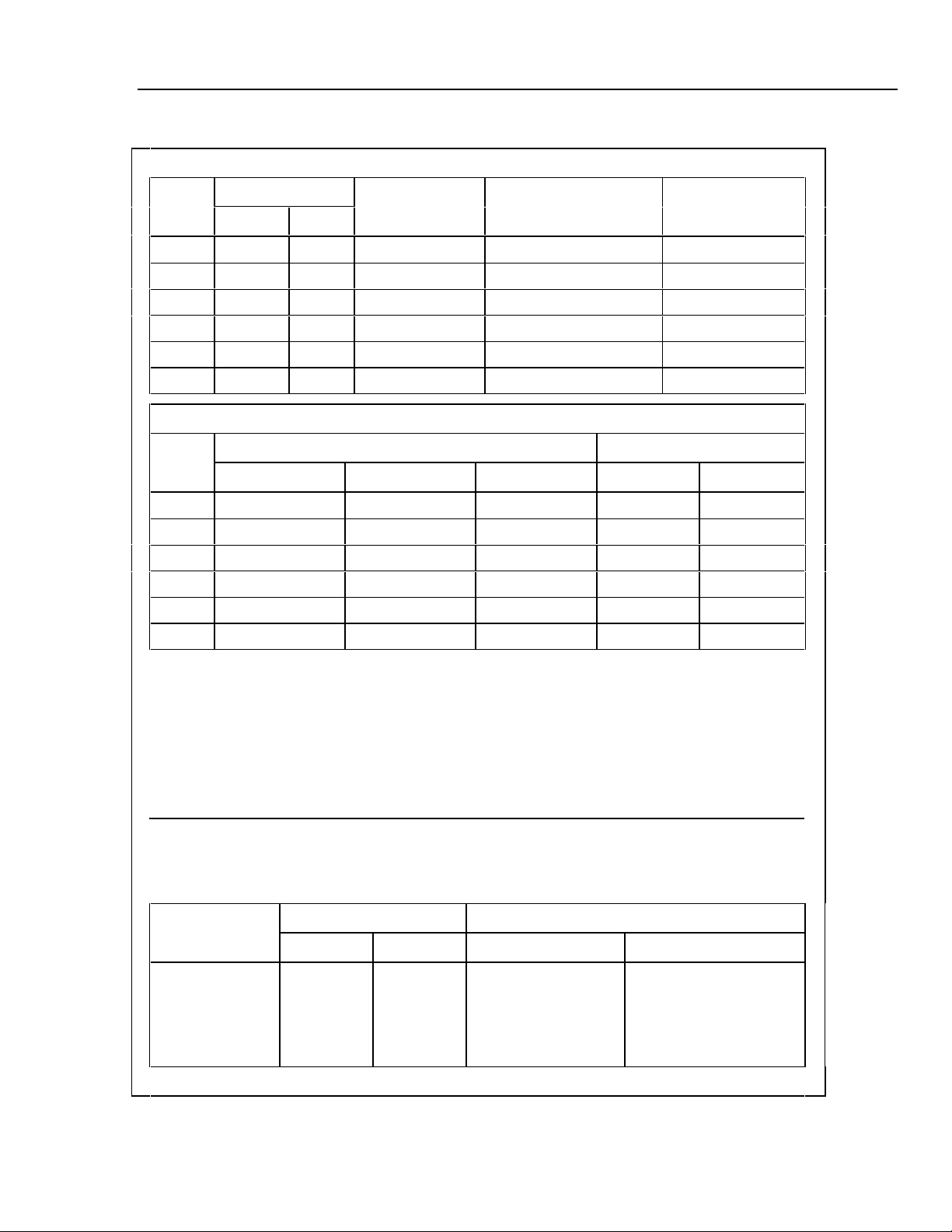

Table 1-3. 2620A/2625A Specifications (cont)

AC Voltage Inputs (True RMS AC Voltage, AC-Coupled Inputs)

Introduction and Specifications

Specifications

1

Range

300 mV 10 µV 100 µV 20 mV

3V 100 µV 1 mV 200 mV

30V 1 mV 10 mV 2V

300V 10 mV 100 mV 20V

1 Year Accuracy ±(%±V)

Frequency

300 mV Range

20 Hz - 50 Hz

50 Hz - 100 Hz

100 Hz - 10 kHz

10 kHz - 20 kHz

20 kHz - 50 kHz

50 kHz - 100 kHz

3V Range

20 Hz - 50 Hz

50 Hz - 100 Hz

100 Hz - 10 kHz

10 kHz - 20 kHz

20 kHz - 50 kHz

50 kHz - 100 kHz

1.43% + 0.25 mV

0.30% + 0.25 mV

0.17% + 0.25 mV

0.37% + 0.25 mV

1.9% + 0.30 mV

5.0% + 0.50 mV

1.42% + 2.5 mV

0.29% + 2.5 mV

0.14% + 2.5 mV

0.22% + 2.5 mV

0.6% + 3.0 mV

1.0% + 5.0 mV

Resolution

Slow Fast

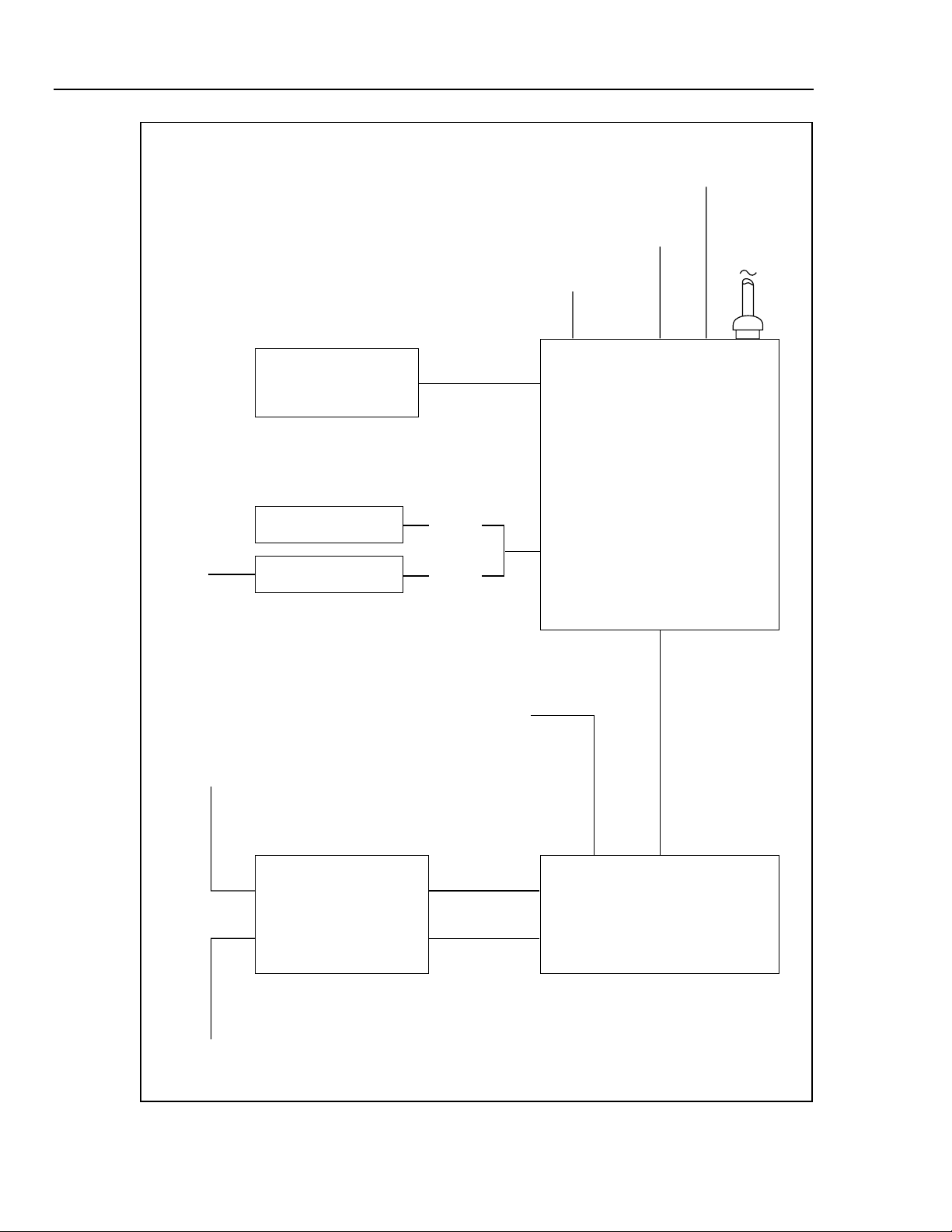

18°C to 28°C0°C to 60°C