Page 1

Troubleshooting

HVAC systems

with the Fluke 233 True-rms

Remote Display Multimeter

Application Note

I heard audible gasps from the

assembled maintenance techs at

a large university in the southeastern United States when I

showed them how I used my

new Fluke 233 True-rms Remote

Display Multimeter.

Of all the great Fluke products

I have seen and used, this one

has the potential to revolutionize the troubleshooting of HVAC

systems.

The HVAC industry has a bad

habit of locating mechanical

devices where they are very

hard to gain access to, including

on rooftops, in crawl spaces and

above ceilings. These mechanical units often have controls

located inside the building on

interior walls or inside control

panels. Speaking for myself, I

am not getting any younger, so

it is not as easy for me to climb

up and down ladders repeatedly

to check multiple readings in

different locations.

Using standard multimeters,

people like me must somehow

be in two places at the same

time in order to check the unit

operation in both places. The

Fluke 233 True-rms Remote

Display Multimeter has a detachable display that allows the

technician to locate the meter,

probes and accessories on the

electrical device being checked,

then detach the remote display

to permit viewing of the values

at another location, such as a

controller. When combined with

the features present in these

meters, quick troubleshooting of

HVAC system problems becomes

easier. Some common examples

are as follows:

1. Remote voltage measurement

and troubleshooting.

2. Remote continuity measurement to check wiring

integrity.

3. Remote temperature readings

while at a thermostat.

4. Remote min/max voltage

quality troubleshooting.

5. Control system sensor reading

calibration.

Here are troubleshooting scenarios for each of these examples:

1. Remote voltage measurement and troubleshooting.

An HVAC technician receives

a too-hot complaint from a

residence. Upon arrival, he

determines the unit is not

running. The tech desires

to test the operation of the

contactor while adjusting the

thermostat into the cooling

mode. He turns off the unit at

the thermostat and connects

the meter probes at the load

side of the contactor. Then he

detaches the remote display

and takes it inside the home.

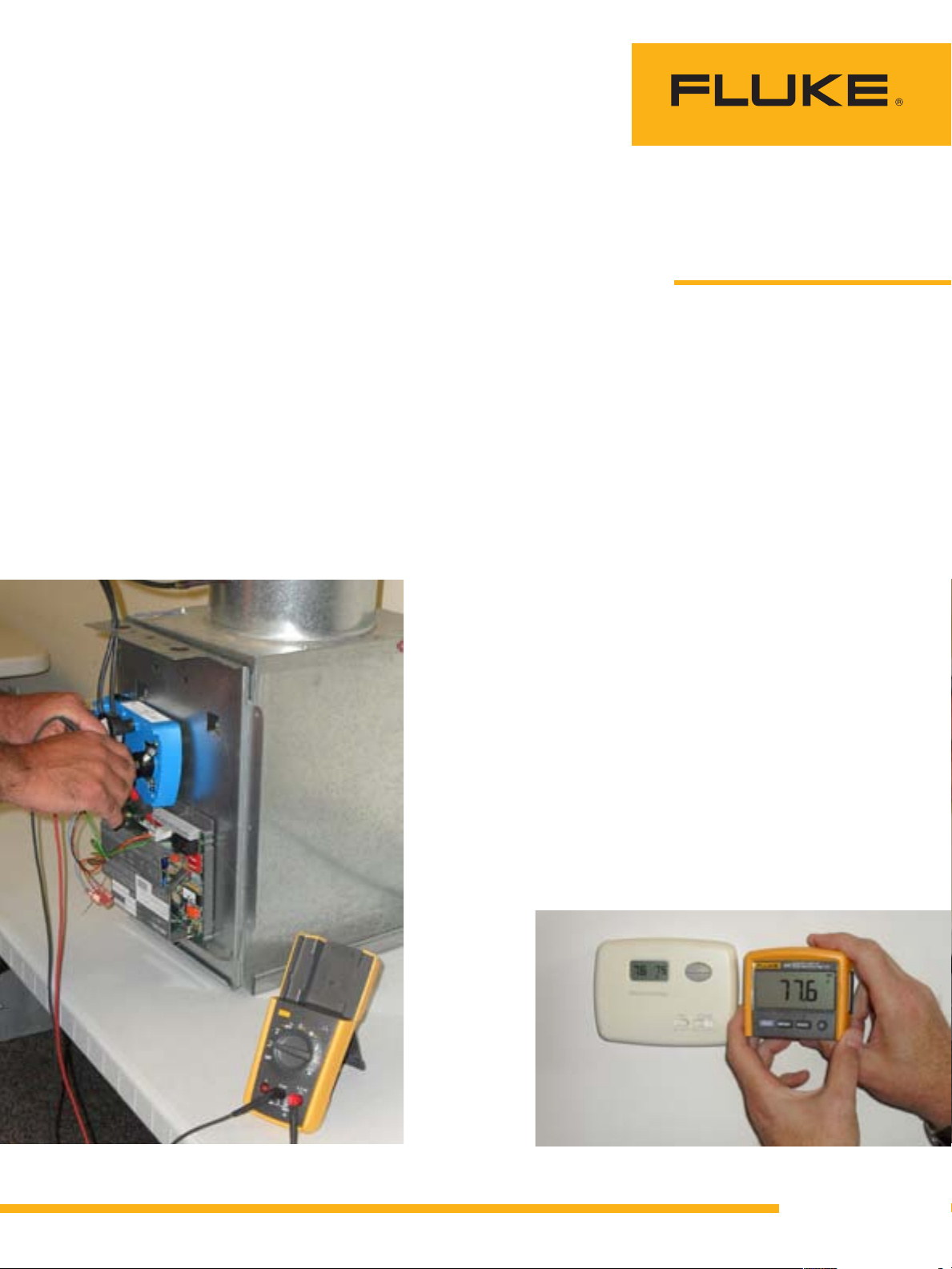

The main section of the 233 meter stays in place while the technician uses the detachable display to check results elsewhere.

A technician can compare the results on the 233’s detachable display to

the reading on a remote thermostat.

F r o m t h e F l u k e D i g i t a l L i b r a r y @ w w w . f l u k e . c o m / l i b r a r y

Page 2

He places the system switch

at the thermostat baseplate

into the cooling mode. The

voltage reading is zero, indicating that the contactor did

not engage. He inserts the

remote display into the meter

and does further checks at

the contactor, which he then

determines has failed. The

tech replaces the contactor

and puts the system back into

service.

2. Remote continuity measurement to check wiring

integrity. A tech is called

into a medical office building

due to a too-cold complaint.

The unit does not operate at

all, regardless of any adjustments at the thermostat. The

building owner tells the tech

that an electrician had been

doing some unrelated work

in a junction box close to

the unit. The tech decides to

check control continuity at

the HVAC unit. He disconnects and locks out/tags out

the power. Then he connects

the 233 meter probes at the

thermostat heating wiring.

The tech removes the remote

display and takes it indoors.

He switches the unit into the

heating mode and the meter

does not beep (beeping indicates continuity). He removes

the junction box cover and

discovers that the thermostat

wires were inadvertently

cut. He repairs the wires and

checks the system again. This

time the continuity function

beeps when he places the

thermostat into the heating

mode. He removes the 233

meter, removes the lockout/

tagout and turns on the

power. The unit then operates

normally.

3. Remote temperature readings while at a thermostat.

A tech wants to check the

discharge air temperature

of a unit while working on

the unit thermostat. In the

past this was difficult, but

the 233 meter now makes

it easier. The tech plugs the

temperature probe into the

meter and inserts the probe

into the unit supply duct. He

detaches the remote display

from the meter and carries it

into the thermostat location.

From that location the tech

can make any adjustments

needed while checking both

the space temperature and

the supply air temperature at

the same time.

4. Remote min/max voltage

quality troubleshooting.

One of the most difficult

problems to catch on a unit

is a momentary voltage spike

at the unit. An HVAC tech

receives a complaint the unit

has shut down. A low voltage condition is suspected.

The tech places the 233

meter leads on the incoming power supply and then

selects the Min/Max function. He detaches the remote

display and carries it into the

thermostat location. While in

this mode the unit will beep

every time the unit reaches

a new min or max voltage

reading level. Over a period

of time the tech cycles the

unit on and off a number of

times. After a few minutes

of operation the unit beeps

and the tech records a low

voltage reading. The utility is

contacted and an intermittent

loose neutral wire is found. It

is corrected and the unit then

runs flawlessly.

5. Control system sensor read-

ing calibration. A controls

technician needs to check

a sensor reading at a DDC

Controller. The sensor is 0-10

VDC. The reading needs

to be checked against the

computer readout. The tech

connects the 233 meter leads

at the sensor terminals at the

controller. He detaches the

remote display and carries it

over to the computer workstation. The tech checks the

reading at the 233 display

against the known range of

The technician can leave the 233 meter connected to the controller

while he carries the detachable display to a computer workstation.

the sensor, and notes a difference. He checks the controller

software and finds that the

sensor has been defined as

the wrong type. The tech

performs a quick correction

and the voltage reading is

exactly what the computer

workstation indicates.

It is possible to come up with

many more scenarios like the

ones listed above. As you can

see, the Fluke 233 True-rms

Remote Display Multimeter is

incredibly useful in a whole

range of common troubleshooting scenarios encountered in

today’s buildings.

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2010 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 8/2010 3850205A A-EN-N

Modification of this document is not permitted

without written permission from Fluke Corporation.

®

2 Fluke Corporation Troubleshooting HVAC systems with the Fluke 233 True-rms Remote Display Multimeter

Loading...

Loading...