Page 1

Fluke 19xB-19xC-2x5C

ScopeMeter

models 192B,196B,199B,192C,196C,199C,215C,225C

Service Manual

PN 4822 872 05391

September 2002, rev.2, Oct.09

© 2002-2009 Fluke Corporation, All rights reserved.

All product names are trademarks of their respective companies.

Page 2

PLACING ORDERS AND GETTING ASSISTANCE

To locate an authorized service center, visit us on the World Wide Web:

http://www.fluke.com

or call Fluke using any of the phone numbers listed below:

+1-888-993-5853 in U.S.A. and Canada

+31-40-2675200 in Europe

+1-425-446-5500 from other countries

Page 3

Table of Contents

Chapter Title Page

1 Safety Instructions............................................................................... 1-1

1.1 Introduction..................................................................................................1-3

1.2 Safety Precautions........................................................................................1-3

1.3 Caution and Warning Statements.................................................................1-3

1.4 Symbols .......................................................................................................1-3

1.5 Impaired Safety............................................................................................1-4

1.6 General Safety Information..........................................................................1-4

2 Characteristics.....................................................................................2-1

3 List of Replaceable Parts .................................................................... 3-1

3.1 Introduction..................................................................................................3-3

3.2 How to Obtain Parts.....................................................................................3-3

3.3 Final Assembly Parts ...................................................................................3-4

3.4 Main PCA Unit Parts ...................................................................................3-6

3.5 Accessories ..................................................................................................3-8

4 Performance Verification .................................................................... 4-1

4.1 Introduction..................................................................................................4-3

4.2 Equipment Required For Verification .........................................................4-3

4.3 General Instructions.....................................................................................4-3

4.4 Operating Instructions..................................................................................4-4

4.4.1 Resetting the test tool ...........................................................................4-4

4.4.2 Navigating through menu’s ..................................................................4-4

4.4.3 Creating Test Tool Setup1....................................................................4-5

4.5 Display and Backlight Test..........................................................................4-5

4.6 Scope Input A&B Tests ...............................................................................4-7

4.6.1 Input A&B Vertical Accuracy Test ......................................................4-7

4.6.2 Input A&B DC Voltage Accuracy Test................................................4-9

4.6.3 Input A&B AC Voltage Accuracy Test (LF) .......................................4-11

4.6.4 Input A & B AC Coupled Lower Frequency Test...............................4-12

4.6.5 Input A and B Peak Measurements Test..............................................4-13

4.6.6 Input A&B Frequency Measurement Accuracy Test ...........................4-14

4.6.7 Input A&B Phase Measurements Test..................................................4-15

4.6.8 Time Base Test .....................................................................................4-16

4.6.9 Input A Trigger Sensitivity Test...........................................................4-17

4.6.10 Input A AC Voltage Accuracy (HF) & Bandwidth Test ....................4-19

4.6.11 Input B Trigger Sensitivity Test .........................................................4-20

4.6.12 Input B AC Voltage Accuracy (HF) & Bandwidth Test ....................4-21

4.6.13 Video test using the Video Pattern Generator ....................................4-22

i

Page 4

Fluke 19xB-19xC-2x5C

Service Manual

4.7 External Trigger Level Test .........................................................................4-27

4.8 Meter (DMM) Tests.....................................................................................4-28

4.9 Probe Calibration Generator Test ................................................................4-32

5 Calibration Adjustment ....................................................................... 5-1

5.1 General.........................................................................................................5-3

5.2 Calibration Procedure Steps.........................................................................5-4

5.3 Starting the Calibration................................................................................5-4

5.4 Contrast Calibration Adjustment .................................................................5-6

5.5 Warming Up & Pre-Calibration...................................................................5-7

5.6 Final Calibration ..........................................................................................5-8

5.6.9 Calculate Gain...........................................................................................5-17

5.7 Save Calibration Data and Exit....................................................................5-17

5.8 Probe Calibration .........................................................................................5-19

4.6.14 Video test using SC600 Scope Calibration Option ............................4-24

4.8.1 Meter DC Voltage Accuracy Test ........................................................4-28

4.8.2 Meter AC Voltage Accuracy & Frequency Response Test .................4-29

4.8.3 Continuity Function Test......................................................................4-30

4.8.4 Diode Test Function Test .....................................................................4-30

4.8.5 Ohms Measurements Test.....................................................................4-30

5.1.1 Introduction ..........................................................................................5-3

5.1.2 Calibration number and date.................................................................5-3

5.1.3 General Instructions..............................................................................5-3

5.1.4 Equipment Required For Calibration ...................................................5-4

5.6.1 Input A LF-HF Gain.............................................................................5-8

5.6.2 Input B LF-HF Gain .............................................................................5-9

5.6.3 Input A&B LF-HF Gain .......................................................................5-11

5.6.4 Input A&B Position.............................................................................5-12

5.6.5 Input A&B Volt Gain ...........................................................................5-13

5.6.6 DMM Volt Gain ...................................................................................5-14

5.6.7 Input A& B, and DMM Zero................................................................5-15

5.6.8 DMM Ohm Gain ..................................................................................5-16

6 Disassembling the Test Tool.............................................................. 6-1

6.1. Introduction.................................................................................................6-3

6.2. Disassembly & Reassembly Procedures .....................................................6-3

6.2.1 Required Tools .....................................................................................6-3

6.2.2 Removing the Tilt Stand & Hang Strap................................................6-3

6.2.3 Replacing the Side-Strap, Changing the Side-Strap Position...............6-3

6.2.4 Opening the Test Tool, Removing the Battery.....................................6-3

6.2.5 Removing the Main PCA Unit and the Fan..........................................6-5

6.2.6 Removing the Display Assembly .........................................................6-6

6.2.7 Replacing the LCD Window/Decal......................................................6-7

6.2.8 Removing the Keypad and Keypad Foil...............................................6-7

6.2.9 Disassembling the Main PCA Unit.......................................................6-7

6.2.10 Reassembling the Main PCA Unit......................................................6-8

6.2.11 Reassembling the Test Tool ...............................................................6-9

ii

Page 5

List of Tables

Table Title Page

3-1.Final Assembly Parts...................................................................................3-4

3-2.Main PCA Unit Parts...................................................................................3-6

3-3.Standard Accessories...................................................................................3-8

3-5.Optional Accessories ...................................................................................3-9

4-1.Vertical Accuracy Verification Points.........................................................4-8

4-2. Volts DC Measurement Verification Points...............................................4-10

4-4.Input A&B AC Input Coupling Verification Points....................................4-13

4-5.Volts Peak Measurement Verification Points..............................................4-14

4-6.Input A&B Frequency Measurement Accuracy Test ..................................4-15

4-7.Phase Measurement Verification Points......................................................4-16

4-8.Input A Trigger Sensitivity Test Points.......................................................4-18

4-9.HF AC Voltage Verification Points.............................................................4-19

4-11.HF AC Voltage Verification Points...........................................................4-21

4-12.Meter Volts dc Measurement Verification Points .....................................4-28

4-13.Meter Volts AC Measurement Verification Points....................................4-29

4-14.Resistance Measurement Verification Points ............................................4-31

5-1.Input A HF-LF Gain Calibration Points ......................................................5-9

5-2.Input B LF-HF Gain Calibration Points ......................................................5-10

5-3.Input A&B Gain Calibration Points ............................................................5-12

5-4.Input A&B Gain Calibration Points ............................................................5-14

5-5.DMM Gain Calibration Points ....................................................................5-15

5-6.Ohm Gain Calibration Points ......................................................................5-17

iii

Page 6

Fluke 19xB-19xC-2x5C

Service Manual

iv

Page 7

List of Figures

Figure Title Page

3-1.Final Assembly Details................................................................................3-5

3-2. Main PCA Unit...........................................................................................3-7

3-3.Rubber Spacer on Shielding Box Assy........................................................3-7

4-1.Menu item selection.....................................................................................4-4

4-2. Display Test Pattern ...................................................................................4-6

4-3.Test Tool Input A&B to 5500 Normal Output ............................................4-7

4-4.5500 Scope Output to Test Tool Input A&B...............................................4-14

4-5.5500A Scope Output to Test Tool Input A..................................................4-16

4-7.5500A Scope Output to Test Tool Input B..................................................4-20

4-8.Test Tool Input A to TV Signal Generator..................................................4-22

4-9.Trace for PAL/SECAM line 622 .................................................................4-23

4-10.Trace for NTSC line 525 ...........................................................................4-23

4-11.Trace for PAL/SECAM line 310 ...............................................................4-23

4-12.Trace for NTSC line 262 ...........................................................................4-23

4-13.Test Tool Input A to TV Signal Generator Inverted..................................4-24

4-14.Trace for PAL/SECAM line 310 Negative Video.....................................4-24

4-15.Trace for NTSC line 262 Negative Video .................................................4-24

4-16.Test Tool Input A to TV Signal Generator................................................4-25

4-17.SC600 Marker Pulse..................................................................................4-26

4-18.Test Tool Meter/Ext Input to 5500A Normal Output................................4-27

4-19.Test Tool Input A to 5500A Normal Output 4-Wire.................................4-31

5-1.Version & Calibration Data.........................................................................5-3

5-2.Display Test Pattern ....................................................................................5-7

5-3.5500A SCOPE Output to Test Tool Input A...............................................5-8

5-4.5500A SCOPE Output to Test Tool Input B ...............................................5-10

5-5.Test tool Input A&B to 5500 Scope Output ................................................5-11

5-6.Test tool Input A&B to 5500 Normal Output..............................................5-13

5-7.5500A NORMAL Output to Test Tool Banana Input.................................5-15

5-8.Four-wire Ohms calibration connections.....................................................5-16

5-9.10:1 Probe Calibration Connection .............................................................5-19

5-10.10:1 Probe Calibration...............................................................................5-19

6-1.Loosen 2 Input Cover Screws......................................................................6-4

6-2.Loosen 2 Bottom Holster Screws ................................................................6-4

6-3.Opening the Test Tool .................................................................................6-4

6-4.Removing the Battery Pack .........................................................................6-4

6-5.Final Assembly Details................................................................................6-5

6-6.Flex Cable Connectors ................................................................................6-6

6-7.PCA Unit Assembly ....................................................................................6-8

v

Page 8

Page 9

Chapter 1

Safety Instructions

Title Page

1.1 Introduction.................................................................................................. 1-3

1.2 Safety Precautions........................................................................................ 1-3

1.3 Caution and Warning Statements................................................................. 1-3

1.4 Symbols ....................................................................................................... 1-3

1.5 Impaired Safety............................................................................................ 1-4

1.6 General Safety Information.......................................................................... 1-4

1-1

Page 10

Page 11

Safety Instructions

1.1 Introduction 1

1.1 Introduction

Read these pages carefully before beginning to install and use the test tool.

The following paragraphs contain information, cautions and warnings which must be

followed to ensure safe operation and to keep the test tool in a safe condition.

Warning

Servicing described in this manual is to be done only by

qualified service personnel. To avoid electrical shock, do not

service the test tool unless you are qualified to do so.

1.2 Safety Precautions

For the correct and safe use of this test tool it is essential that both operating and service

personnel follow generally accepted safety procedures in addition to the safety

precautions specified in this manual. Specific warning and caution statements, where they

apply, will be found throughout the manual. Where necessary, the warning and caution

statements and/or symbols are marked on the test tool.

1.3 Caution and Warning Statements

Caution

Used to indicate correct operating or maintenance procedures

to prevent damage to or destruction of the equipment or other

property.

Warning

Calls attention to a potential danger that requires correct

procedures or practices to prevent personal injury.

1.4 Symbols

The following symbols are used on the test tool, in the Users Manual, in this Service

Manual, or on spare parts for this test tool.

See explanation in Users Manual

Live voltage

Static sensitive components

(black/yellow).

Do not dispose of this product

as unsorted municipal waste. Go to

Fluke's website for recycling

information.

DOUBLE INSULATION (Protection

Class)

Earth Ground

Recycling information

Conformité Européenne

Safety Approval

1-3

Safety Approval

Page 12

Fluke 19xB-19xC-2x5C

Service Manual

1.5 Impaired Safety

Whenever it is likely that safety has been impaired, the test tool must be turned off and

disconnected from line power. The matter should then be referred to qualified

technicians. Safety is likely to be impaired if, for example, the test tool fails to perform

the intended measurements or shows visible damage.

1.6 General Safety Information

Removing the test tool covers or removing parts, except those

to which access can be gained by hand, is likely to expose live

parts and accessible terminals which can be dangerous to life.

The test tool shall be disconnected from all voltage sources before it is opened.

Capacitors inside the test tool can hold their charge even if the test tool has been

separated from all voltage sources.

When servicing the test tool, use only specified replacement parts.

Warning

1-4

Page 13

Chapter 2

Characteristics

For the specifications please refer to the ScopeMeter test tool Users

Manual Chapter “Specifications”.

2-1

Page 14

2-2

Page 15

Chapter 3

List of Replaceable Parts

Title Page

3.1 Introduction..................................................................................................3-3

3.2 How to Obtain Parts.....................................................................................3-3

3.3 Final Assembly Parts ...................................................................................3-4

3.4 Main PCA Unit Parts ...................................................................................3-6

3.5 Accessories ..................................................................................................3-8

3-1

Page 16

Page 17

List of Replaceable Parts

3.1 Introduction 3

3.1 Introduction

This chapter contains an illustrated list of replaceable parts for the ScopeMeter test tool.

Parts are listed by assembly; alphabetized by item number. Each assembly is

accompanied by an illustration showing the location of each part and its item number.

The parts list gives the following information:

• Item number

• Description

• Ordering code

3.2 How to Obtain Parts

Contact an authorized Fluke service center.

To locate an authorized service center refer to the second page of this manual (back of the

title page).

In the event that the part ordered has been replaced by a new or improved part, the

replacement will be accompanied by an explanatory note and installation instructions, if

necessary.

To ensure prompt delivery of the correct part, include the following information when

you place an order:

• Instrument model (for example Fluke-196C), 12 digit instrument code (9444 ... ....),

and serial number (DM.......). The items are printed on the type plate on the bottom

cover.

• Ordering code

• Item number

• Description

• Quantity

3-3

Page 18

Fluke 19xB-19xC-2x5C

Service Manual

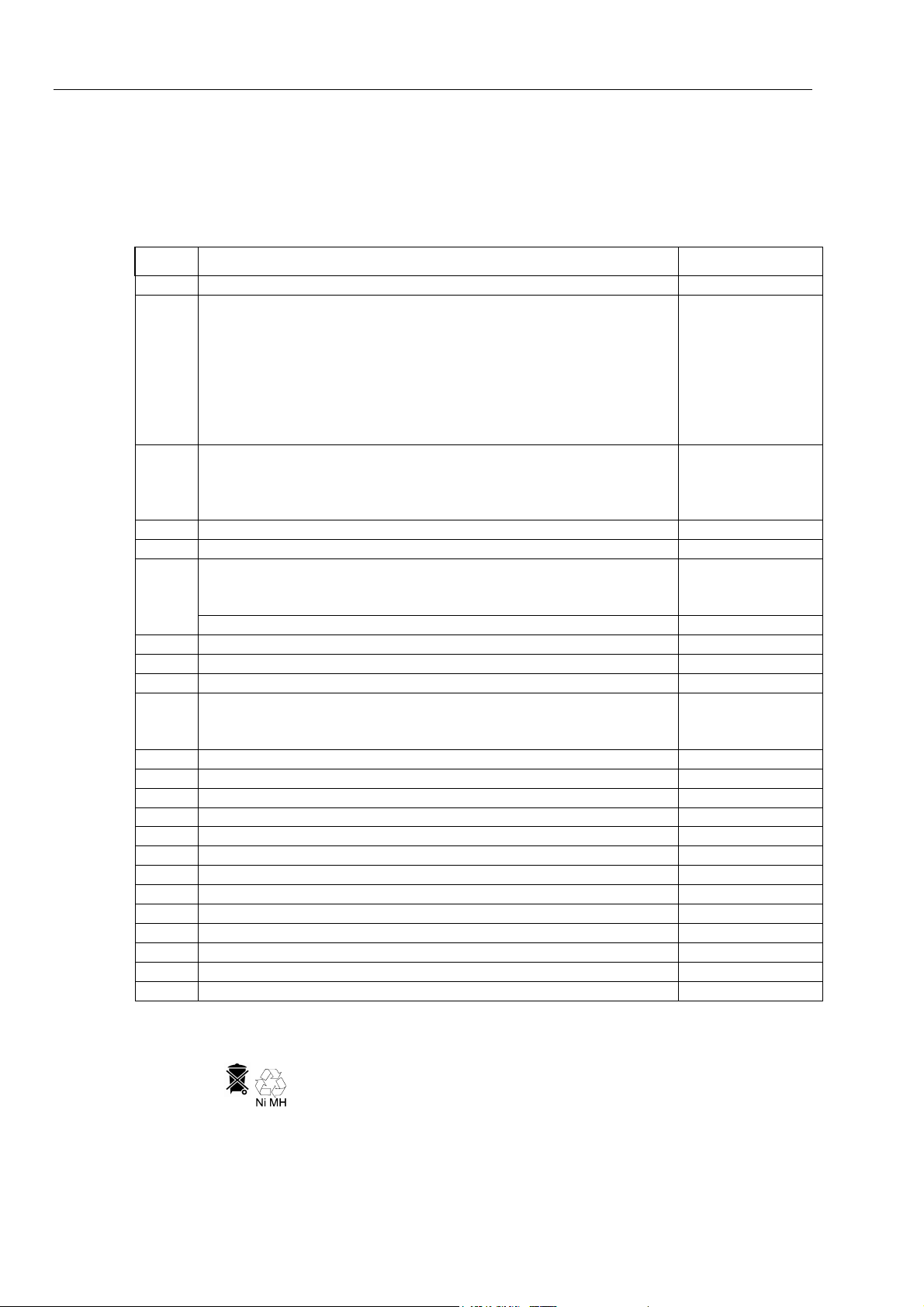

3.3 Final Assembly Parts

See Table 3-1 and Figure 3-1 for the Final Assembly parts.

Item Description Ordering Code

1 Top case assembly (without LCD, without window/decal) 1638248

2 Display window/decal Fluke 192B

Display window/decal Fluke 192C

Display window/decal Fluke 196B

Display window/decal Fluke 196C

Display window/decal Fluke 199B

Display window/decal Fluke 199C

Display window/decal Fluke 215C

Display window/decal Fluke 225C

3 + 4 Keypad set (includes large & small keypad) 19x

(Lowest yellow key = RECORDER)

Keypad set (includes large & small keypad) 2x5

(Lowest yellow key = ANALYZE)

5 Keypad foil 1642199

6 Keypad support assembly 1638253

7 Display unit Color Fluke 192C, 196C, 199C, 215C, 225C

Display unit B/W Fluke 192B, 196B, 199B

Remark: The Display unit does not include the flat cable

Flat cable for display unit (both versions) 2042596

8 Display mounting frame assy 1668063

9 Input cover (including screws) 1285765

10 EJOT Pt screw 1284966

11 Main PCA unit; The Main PCA is only available to Fluke Service Centers

due to the programming that is necessary after installation.

12 Hang strap 1286041

13 Bottom case assembly (see note 2 below) 1285783

14 Combi-screw Torx M3x10 (screw + split spring) 1285046

15 Strap 1285923

16 Strap holder 1285938

17 Tilt stand (bail) 1285945

18 Combi-screw Torx M3x10 (screw + flat washer) 1285079

19 Bottom holster 1285752

20 Combi-screw Torx M3x10 (screw + flat washer) 1285079

21 Battery Pack (see note 3 below) BP190

22 Spacer M2.5x3 for Fan 1638770

23 Fan Assy 1638294

24 Screw M2.5x12, countersunk Torx for Fan 1639787

Table 3-1. Final Assembly Parts

2042440

3402263

2042457

2042478

2042469

2042484

3402256

3402239

1638180

3402242

1638230

2042528

-

3-4

Note

The test tool contains a NiMH battery (item 21). Do not mix

with the solid wastestream. Spent batteries should be disposed

of by a qualified recycler or hazardous materials handler.

Page 19

List of Replaceable Parts

(2x)

3

4

5

6

7

3.3 Final Assembly Parts 3

1

2

9

21

20

(2x)

19

24

23

22

(2x)

(2x)

14

(2x)

18

Figure 3-1. Final Assembly Details

17

16

13

ST8738

10

11

12

15

8

(4x)

st8738.wmf

3-5

Page 20

Fluke 19xB-19xC-2x5C

Service Manual

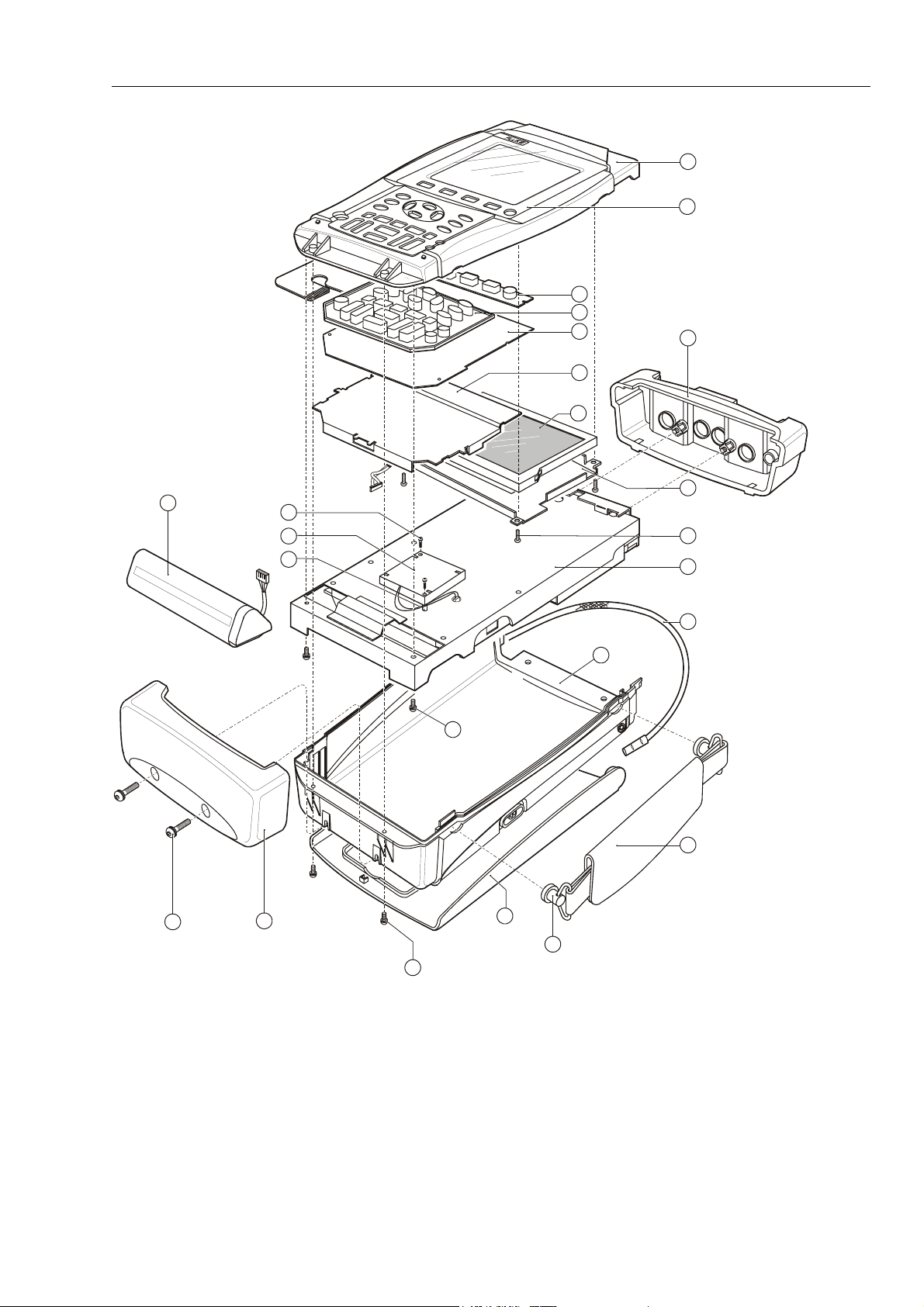

3.4 Main PCA Unit Parts

See Table 3-2 and Figure 3-2 for the main PCA Unit parts.

Item Description Ordering Code

1 Shielding box assy (includes rubber spacer, see fig. 8-5) 1665767

2 Insulation foil 1285961

3 PT-Screw K35x8 1284975

4 Input connector unit 1285977

5 Sealing ring for power connector 1286052

6 Input attenuator shielding:

7 Screw Torx M3x20 1285101

8 Shielding cover 1286034

9 Combi-screw Torx M3x10 (screw + split spring) 1285046

10 Hexagonal spacer M3x16.5 1285199

Table 3-2. Main PCA Unit Parts

- METER channel top

- METER channel bottom

- SCOPE channel A top

- SCOPE channel B top

- SCOPE channel A&B bottom

1285989

1285992

1286007

1286018

1286029

Note

The Scope channel A and B input attenuator top shieldings are provided with a

plate spring. The spring end is provided with heat conducting tape; it contacts

the C-ASIC’s N1000 and N1200, and transports the heat from the C-ASIC to the

shielding.

Do not bend the springs, keep the tape on the spring end free of dust, and put the

shielding on the correct position.

3-6

Page 21

List of Replaceable Parts

3.4 Main PCA Unit Parts 3

Figure 3-2. Main PCA Unit

Figure 3-3. Rubber Spacer on Shielding Box Assy

ST8676.wmf

rubber-spacer-16gray.jpg

3-7

Page 22

Fluke 19xB-19xC-2x5C

Service Manual

3.5 Accessories

Battery Charger, available models:

Universal Europe 230 V, 50 and 60 Hz

North America 120 V, 50 and 60 Hz

United Kingdom 240 V, 50 and 60 Hz

Japan 100 V, 50 and 60 Hz

Australia 240 V, 50 and 60 Hz

Universal 115 V/230 V, 50 and 60 Hz

The universal adapter is standard equipped with a plug EN60320-2.2G. For

connection to the mains outlet use a line plug that complies with National

Standards. The 230V rating of the BC190/808 is not for use in North America.

Voltage Probe Set (Red), designed for use with the Fluke ScopeMeter 190 series

test tool. The set includes the following items (not available separately):

• 10:1 Voltage Probe (red)

• 4-mm Test Probe for Probe Tip (red)

• Hook Clip for Probe Tip (red)

• Ground Lead with Hook Clip (red)

• Ground Lead with Mini Alligator Clip (black)

• Ground Spring for Probe Tip (black)

Voltage Probe Set (Gray), designed for use with the Fluke ScopeMeter 190 series

test tool. The set includes the following items (not available separately):

• 10:1 Voltage Probe (gray)

• 4-mm Test Probe for Probe Tip (gray)

• Hook Clip for Probe Tip (gray)

• Ground Lead with Hook Clip (gray)

• Ground Lead with Mini Alligator Clip (black)

Test Lead Set TL75

Accessory Set (Red)

The set includes the following items (not available separately):

• Industrial Alligator for Probe Tip (red)

• 2-mm Test Probefor Probe Tip (red)

• Industrial Alligator for Banana Jack (red)

• 2-mm Test Probe for Banana Jack (red)

• Ground Lead with 4-mm Banana Jack (black)

Accessory Set (Gray)

The set includes the following items (not available separately):

• Industrial Alligator for Probe Tip (gray)

• 2-mm Test Probe for Probe Tip (gray)

• Industrial Alligator for Banana Jack (gray)

• 2-mm Test Probe for Banana Jack (gray)

• Ground Lead with 4-mm Banana Jack (black)

Replacement Set for Voltage Probe VP200

The set includes the following items (not available separately):

• 2x , 4-mm Test Probe for Probe Tip (red and gray)

• 3x , Hook Clip for Probe Tip (2 red, 1 gray)

• 2x , Ground Lead with Hook Clip (red and gray)

• 2x , Ground Lead with Mini Alligator Clip (black)

• 5x Ground Spring for Probe Tip (black)

Table 3-3. Standard Accessories

Item Ordering Code

BC190/801

BC190/813

BC190/804

BC190/806

BC190/807

BC190/808

VP210-R

See Note below

VP210-G

See Note below

AS200-R

AS200-G

RS200

3-8

Page 23

List of Replaceable Parts

3.5 Accessories 3

Note:

From May 2007 the VPS200 probe sets have been replaced with the

VPS210 probe sets. The specifications of the VPS210 and the VPS200

probes are identical. The AS200 accessory sets can be used for the VP200

as well as for the VPS210 probe sets.

Table 3-4. Optional Accessories

Item Ordering Code

Software & Cable Carrying Case Kit

Set contains the following parts:

• Optically Isolated USB Cable

• Hard Carrying Case

• FlukeView™ ScopeMeter Software for Windows®

Optically Isolated RS-232 Adapter/Cable PM9080

Optically Isolated USB Cable OC4USB

Hard Case C190

Soft Case C195

Current Shunt 4-20 mA CS20MA

Print Adapter Cable for Parallel Printers PAC91

Bus Health Test Adapter (for Fluke 215C-225C) BHT190

SCC190

OC4USB

C190

SW90W

3-9

Page 24

Fluke 19xB-19xC-2x5C

Service Manual

3-10

Page 25

Chapter 4

Performance Verification

Title Page

4.1 Introduction.................................................................................................. 4-3

4.2 Equipment Required For Verification ......................................................... 4-3

4.3 General Instructions..................................................................................... 4-3

4.4 Operating Instructions.................................................................................. 4-4

4.4.1 Resetting the test tool ........................................................................... 4-4

4.4.2 Navigating through menu’s .................................................................. 4-4

4.4.3 Creating Test Tool Setup1.................................................................... 4-5

4.5 Display and Backlight Test.......................................................................... 4-5

4.6 Scope Input A&B Tests ............................................................................... 4-7

4.6.1 Input A&B Vertical Accuracy Test ...................................................... 4-7

4.6.2 Input A&B DC Voltage Accuracy Test................................................ 4-9

4.6.3 Input A&B AC Voltage Accuracy Test (LF) ....................................... 4-11

4.6.4 Input A & B AC Coupled Lower Frequency Test............................... 4-12

4.6.5 Input A and B Peak Measurements Test.............................................. 4-13

4.6.6 Input A&B Frequency Measurement Accuracy Test ........................... 4-14

4.6.7 Input A&B Phase Measurements Test.................................................. 4-15

4.6.8 Time Base Test ..................................................................................... 4-16

4.6.9 Input A Trigger Sensitivity Test........................................................... 4-17

4.6.10 Input A AC Voltage Accuracy (HF) & Bandwidth Test .................... 4-19

4.6.11 Input B Trigger Sensitivity Test ......................................................... 4-20

4.6.12 Input B AC Voltage Accuracy (HF) & Bandwidth Test .................... 4-21

4.6.13 Video test using the Video Pattern Generator .................................... 4-22

4.6.14 Video test using SC600 Scope Calibration Option ............................ 4-24

4.7 External Trigger Level Test ......................................................................... 4-27

4.8 Meter (DMM) Tests..................................................................................... 4-28

4.8.1 Meter DC Voltage Accuracy Test ........................................................ 4-28

4.8.2 Meter AC Voltage Accuracy & Frequency Response Test ................. 4-29

4.8.3 Continuity Function Test...................................................................... 4-30

4.8.4 Diode Test Function Test ..................................................................... 4-30

4.8.5 Ohms Measurements Test .................................................................... 4-30

4.9 Probe Calibration Generator Test ................................................................ 4-32

4-1

Page 26

Fluke 19xB-19xC-2x5C

Service Manual

4-2

Page 27

Performance Verification

4.1 Introduction 4

4.1 Introduction

Warning

Procedures in this chapter should be performed by qualified

service personnel only. To avoid electrical shock, do not

perform any servicing unless you are qualified to do so.

The ScopeMeter® test tool (referred to as test tool) should be calibrated and in operating

condition when you receive it.

The following performance tests are provided to ensure that the test tool is in a proper

operating condition. If the test tool fails any of the performance tests, calibration

adjustment (see Chapter 5) and/or repair is necessary.

The Performance Verification Procedure is based on the specifications, see Chapter 2 of

this Service Manual. The values given here are valid for ambient temperatures between

18 °C and 28 °C.

The Performance Verification Procedure is a quick way to check most of the test tool’s

specifications. Because of the highly integrated design of the test tool, it is not always

necessary to check all features separately.

4.2 Equipment Required For Verification

The primary source instrument used in the verification procedures is the Fluke 5500A. If

a 5500A is not available, you can substitute another calibrator as long as it meets the

minimum test requirements.

• Fluke 5500A Multi Product Calibrator, including SC300 or SC600 Oscilloscope

Calibration Option.

• Stackable Test Leads (4x), supplied with the 5500A.

• 50Ω Coax Cables (2x), Fluke PM9091 (1.5m) or PM9092 (0.5m).

• Male BNC to Dual Female BNC adapter (1x), Fluke PM9093/001

• 50Ω feed through termination, Fluke PM9585.

• Dual Banana Plug to Female BNC Adapter (1x), Fluke PM9081/001.

• Dual Banana Jack to Male BNC Adapter (1x), Fluke PM9082/001.

• TV Signal Generator, Philips PM5418, NOT required if SC600 Oscilloscope

Calibration Option is used.

• 75Ω Coax cable (1x), Fluke PM9075.

• 75Ω Feed through termination (1x), ITT-Pomona model 4119-75.

4.3 General Instructions

Follow these general instructions for all tests:

• For all tests, power the test tool with the BC190 power adapter/battery charger. The

battery pack must be installed.

• Allow the 5500A to satisfy its specified warm-up period.

• For each test point , wait for the 5500A to settle.

• Allow the test tool a minimum of 30 minutes to warm up.

• One division on the LCD consists of 25 pixels ( 1 pixel = 0.04 division).

4-3

Page 28

Fluke 19xB-19xC-2x5C

Service Manual

4.4 Operating Instructions

4.4.1 Resetting the test tool

Proceed as follows to reset the test tool:

• Press

• Press and hold

• Press and release

to turn the test tool off.

.

to turn the test tool on.

• Wait until the test tool has beeped twice, and then release

has beeped twice, the RESET was successful.

4.4.2 Navigating through menu’s

During verification you must open menus, and to choose items from the menu.

Proceed as follows to make choices in a menu :

• Reset the test tool

• Open a menu, for example press

as showed in Figure 4-1 will be opened.

Active functions are marked by

If more than one menu groups are available, they will be separated by a vertical line.

The menu you opened indicates that

shows the result of a V ac+dc measurement (

• Press

• Press

or to highlight the function to be selected.

(ENTER) to confirm the selection.

The active function in the next menu group will be highlighted now. If the

confirmation was made in the last (most right) menu group, the menu will be closed.

, then press (READING 1). The menu

,inactive functions by .

READING 1 (that is the upper left reading)

V ac+dc ) on Input A ( on A ).

.. When the test tool

4-4

Figure 4-1. Menu item selection

ws-read1.bmp

Page 29

Performance Verification

4.5 Display and Backlight Test 4

4.4.3 Creating Test Tool Setup1

Before starting the verification procedure you must define a standard test tool setup,

called SETUP 1. During verification you will be asked to recall this setup. This defines

the initial test tool setup for each verification.

Proceed as follows to create SETUP1:

1. Reset the test tool. Input A is ON, Input B is OFF now.

2. Press

3. Press

. The inverse text indicates the actual settings.

(toggle key) to select INPUT B ON. The Input B trace will become

visible.

4. Press

5. Select

6. Press

7. Press

8. Select

9. Press

10. Press

11. Press

12. Press

13. Press

Glitch Detect: Off | Average: Off | Waveform: NORMAL

14. Press

to change the PROBE B setting.

Probe Type: Voltage | Attenuation: 1:1 .

. The inverse text indicates the actual settings.

to change the PROBE A setting.

Probe Type: Voltage | Attenuation: 1:1 .

to select READINGS ON

READING 1 , and select on A | V dc

READING 2 , and select on B | V dc

WAVEFORM OPTIONS and select

to select MANUAL ranging (MANUAL in upper left of screen)

15. Press

16. Press

17. Using

18. Press

19. Press

SAVE...

and select SCREEN+SETUP 1 (or 1).

SAVE to save the actual test tool settings in setup memory 1.

to leave the HOLD mode.

4.5 Display and Backlight Test

Proceed as follows to test the display and the backlight:

1. Press

2. Remove the BC190 adapter power, and verify that the backlight is dimmed.

3. Apply the BC190 adapter power and verify that the backlight brightness increases.

4. Press and hold

4-5

to turn the test tool on.

(USER), then press and release (CLEAR MENU)

Page 30

Fluke 19xB-19xC-2x5C

Service Manual

The test tool shows the calibration menu in the bottom of the display.

• Do not press

• Pressing

5. Press

The test tool shows

6. Press

PREVIOUS three times.

CALIBRATE .The test tool shows a dark display; the test pattern as

now! If you did, turn the test tool off and on, and start at 4.

will toggle the menu on-off.

Contrast (CL 0100):

shown in Figure 4-2 may be not visible or hardly visible.

Observe the display closely, and verify that the display shows no abnormalities, as

for example very light pixels or lines.

Figure 4-2. Display Test Pattern

7. Press .

The test pattern is removed; the test tool shows

Contrast (CL 0100):

8. Press

9. Press

again to do the next step Contrast (CL 0110):

CALIBRATE

The test tool shows the display test pattern shown in Figure 4-2, at default contrast.

Observe the display closely, and verify that the display shows no abnormalities. Also

verify that the contrast of the upper left and upper right square of the test pattern is

equal.

10. Press

The test pattern is removed; the test tool shows

11. Press

12. Press

.

Contrast (CL 0110):

again to do the next step Contrast (CL 0120):

CALIBRATE

The test tool shows a light display; the test pattern as shown in Figure 4-2 may not be

visible or hardly visible.

Observe the display closely, and verify that the display shows no abnormalities.

13. Turn the test tool OFF and ON to exit the calibration menu and to return to the

normal operating mode.

If the maximum, minimum, or default display contrast is not OK, then you can set these

items without performing a complete calibration adjustment; refer to Section 5 for

detailed information.

4-6

Page 31

Performance Verification

4.6 Scope Input A&B Tests 4

4.6 Scope Input A&B Tests

4.6.1 Input A&B Vertical Accuracy Test

WARNING

Dangerous voltages will be present on the calibration source

and connecting cables during the following steps. Ensure that

the calibrator is in standby mode before making any connection

between the calibrator and the test tool.

Proceed as follows:

1. Connect the test tool to the 5500A as shown in Figure 4-3.

Figure 4-3. Test Tool Input A&B to 5500 Normal Output

al55ab.bmp

2. Select the following test tool setup:

• Recall the created SETUP 1 (see section 4.4.3): press

select

• Press

Bandwidth:

• Press

Bandwidth:

• Press

SCREEN+SETUP 1 , press

, press INPUT A OPTIONS... , and select Polarity Normal |

10 kHz (HF reject)

, press INPUT B OPTIONS... , and select Polarity Normal |

10 kHz (HF reject)

to clear the softkey menu, and to see the full screen.

RECALL SETUP .

,

RECALL ,

Note:

The 10 kHz bandwidth limiter rejects calibrator noise. It does not affect the gain

accuracy at a 50 Hz input signal

3. Using

change the time base to select manual time base ranging, and lock the

time base on 10 ms/div.

4-7

Page 32

Fluke 19xB-19xC-2x5C

Service Manual

4. Using and move the Input A ground level (indicated by the zero icon in

the left margin) to the center grid line.

5. Using

and move the Input B ground level (indicated by the zero icon in

the left margin) to the grid line one division below the center grid line.

6. Using

and set the Input A and B sensitivity range to the first test point in

Table 4-1.

7. Set the 5500A to source the appropriate initial ac voltage.

8. Adjust the 5500A output voltage until the displayed Input A trace amplitude is 6

divisions.

9. Observe the 5500A output voltage and check to see if it is within the range shown

under the appropriate column.

10. Adjust the 5500A output voltage until the displayed Input B trace amplitude is 6

divisions.

11. Observe the 5500A output voltage and check to see if it is within the range shown

under the appropriate column.

12. Continue through the test points.

13. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

Table 4-1. Vertical Accuracy Verification Points

Range Initial 5500A Setting,

V ac, sine, 50 Hz

Allowable 5500A output for trace amplitude of

6 divisions

2 mV/div 1) 4.243 mV 4.081 to 4.405

5 mV/div 10.606 mV 10.247 to 10.966

10 mV/div 21.213 mV 20.495 to 21.932

20 mV/div 42.426 mV 40.990 to 43.862

50 mV/div 106.06 mV 102.475 to 109.657

100 mV/div 212.13 mV 204.950 to 219.314

200 mV/div 424.26 mV 409.90 to 438.62

500 mV/div 1.0607 V 1.02475 to 1.09657

1 V/div 2.1213 V 2.04950 to 2.19314

2 V/div 4.2426 V 4.0990 to 4.3862

5 V/div 10.606 V 10.2475 to 10.9657

10 V/div 21.213 V 20.4950 to 21.9314

20 V/div 42.426 V 40.990 to 43.862

50 V/div 106.06 V 102.47 to 109.65

100 V/div 212.13 V 204.95 to 219.31

1)

C versions only

4-8

Page 33

Performance Verification

4.6 Scope Input A&B Tests 4

Note

The vertical accuracy test can also be done with dc voltage. This method is

advised for automatic verification using the Fluke Met/Cal Metrology

Software. For each sensitivity range you must proceed as follows:

1. Apply a +3 divisions voltage, and adjust the voltage until the trace is at

+3 divisions. Write down the applied voltage V1

2. Apply a -3 divisions voltage, and adjust the voltage until the trace is at

-3 divisions. Write down the applied voltage V2

3. Verify that V1-V2 = 6 x range

±

(1.5% + 0.04 x range).:

Example for range 10 mV/div. (range/div figure doubles because 2

measurements V1 and V2 are done for one accuracy check):

±

The allowed V1 - V2 = 60 mV

= 60 mV

(0.015 x 60 + 0.08 x 10)

±

(0.9 + 0.8) = 60 mV ± 1.7 mV

4.6.2 Input A&B DC Voltage Accuracy Test

WARNING

Dangerous voltages will be present on the calibration source

and connecting cables during the following steps. Ensure that

the calibrator is in standby mode before making any connection

between the calibrator and the test tool.

Proceed as follows to verify the automatic dc voltage scope measurement:

1. Connect the test tool to the 5500A as for the previous test (see Figure 4-3).

2. Select the following test tool setup:

• Recall the created SETUP 1 (see section 4.4.3): press

select

SCREEN+SETUP 1 , press RECALL SETUP .

• Press

• Select

• Press

, then press INPUT A OPTIONS ...

Polarity: Normal | Bandwidth: 10 kHz (HF Reject)

, then press INPUT B OPTIONS ...

, RECALL ,

• Select Polarity: Normal | Bandwidth: 10 kHz (HF Reject)

• Press

3. Using

to clear the softkey menu, and to see the full 8 divisions screen.

change the time base to select manual time base ranging, and lock the

time base on 10 ms/div.

4. Using

and move the Input A and B ground level (zero icon in the left

margin) approximately to the center grid line.

5. Using

and select manual vertical ranging and set the Input A and B

sensitivity range to the first test point in Table 4-2.

The sensitivity ranges are indicated in the left and right lower display edge.

6. Set the 5500A to source the appropriate dc voltage.

7. Observe the readings (

1.A and 2.B) and check to see if it is within the range shown

under the appropriate column.

Due to calibrator noise, occasionally OL (overload) can be shown.

8. Continue through the test points.

9. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

4-9

Page 34

Fluke 19xB-19xC-2x5C

Service Manual

2 mV/div 1) +6.0 mV +4.9 to +7.1

10 mV/div +30.0 mV +29.1 to +30.9

20 mV/div +60.0 mV +58.6 to +61.4

50 mV/div +150 mV +143 to +157

100 mV/div +300 mV +291 to +309

Table 4-2. Volts DC Measurement Verification Points

Range 5500A output V dc Input A&B Reading

-6.0 mV -4.9 to -7.1

5 mV/div +15.0 mV +14.3 to +15.7

-15.0 mV -14.3 to -15.7

-30.0 mV -29.1 to -30.9

-60.0 mV -58.6 to -61.4

-150 mV -143 to -157

-300 mV -291 to -309

200 mV/div +600 mV +586 to +614

-600 mV -586 to -614

500 mV/div +1.50 V +1.43 to +1.57

-1.50 V -1.43 to -1.57

1 V/div +3.00 V +2.91 to +3.09

-3.00 V -2.91 to -3.09

2 V/div +6.00 V +5.86 to +6.14

-6.00 V -5.86 to -6.14

5 V/div +15.0 V +14.3 to +15.7

-15.0 V -14.3 to -15.7

10 V/div +30.0 V +29.1 to +30.9

-30.0 V -29.1 to -30.9

20 V/div +60.0 V +58.6 to +61.4

-60.0 V -58.6 to -61.4

50 V/div +150 V +143 to +157

4-10

100 V/div +300 V +291 to +309

1)

C versions only.

-150 V -143 to -157

-300 V -291 to -309

Page 35

Performance Verification

4.6 Scope Input A&B Tests 4

4.6.3 Input A&B AC Voltage Accuracy Test (LF)

This procedure tests the Volts ac accuracy with dc coupled inputs up to 50 kHz. The

high frequencies are tested in sections 4.6.10 and 4.6.12.

Warning

Dangerous voltages will be present on the calibration source

and connecting cables during the following steps. Ensure that

the calibrator is in standby mode before making any connection

between the calibrator and the test tool.

Proceed as follows to test the Input A and B automatic scope ac Voltage measurement

accuracy:

1. Connect the test tool to the 5500A as for the previous test (see Figure 4-3).

2. Select the following test tool setup:

• Recall the created SETUP 1 (see section 4.4.3): press

SCREEN+SETUP 1 , press RECALL SETUP .

select

• Press

• Select

• Press

• Select

• Press

• Press

• Press

• Press

3. Using

, then press INPUT A OPTIONS ...

Polarity: Normal | Bandwidth: 20 MHz

, then press INPUT B OPTIONS ...

Polarity: Normal | Bandwidth: 20 MHz

READING 1 , and select on A | V ac.

READING 2 , and select on B | V ac.

to clear the softkey menu, and to see the full screen.

change the time base to select manual time base ranging. Lock the

, RECALL ,

time base on 20 μs/div for the 20 kHz signals, and on 10 ms/div for the 60 Hz signal.

4. Using

5. Using

and move the Input A and B ground level (indicated by the zero icon

in the left margin) to the center grid line.

and select manual vertical ranging, and set the Input A and B

sensitivity range to the first test point in Table 4-3.

The sensitivity ranges are indicated in the left and right lower display edge in gray.

6. Set the 5500A to source the appropriate ac voltage.

7. Observe the readings (

1.A and 2.B) and check to see if it is within the range shown

under the appropriate column.

8. Continue through the test points.

9. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

4-11

Page 36

Fluke 19xB-19xC-2x5C

Service Manual

Table 4-3. Volts AC Measurement Verification Points

Range 5500A output Input A&B Reading

V ac Frequency

2 mV/div 1) (Select 10 ms/div)

Set input A&B Bandwidth 10 kHz

to prevent OL due to calibrator

noise: see step 2.

5 mV/div (Select 20 μs/div).

Set input A&B Bandwidth 20 MHz

10 mV/div 20 mV 20 kHz 18.0 mV to 22.0 mV

20 mV/div 40 mV 20 kHz 37.5 mV to 42.5 mV

50 mV/div 100 mV 20 kHz 96.0 mV to 104.0 mV

100 mV/div 200 mV 20 kHz 180 mV to 220 mV

200 mV/div 400 mV 20 kHz 375 mV to 425 mV

500 mV/div (Select 10 ms/div) 900 mV 60 Hz 877 mV to 923 mV

500 mV/div (Select 20 μs/div) 900 mV 20 kHz 863 mV to 937 mV

1 V/div 2 V 20 kHz 1.80 V to 2.20 V

2 V/div 4 V 20 kHz 3.75 V to 4.25 V

5 V/div 9 V 20 kHz 8.63 V to 9.37 V

10 V/div 20 V 20 kHz 18.0 V to 22.0 V

4 mV 60 Hz 3.0 mV to 5.0 mV

10 mV 20 kHz 8.3 mV to 11.7 mV

20 V/div 40 V 20 kHz 37.5 V to 42.5 V

50 V/div 90 V 20 kHz 86.3 V to 93.7 V

100 V/div 200 V 20 kHz 180 V to 220 V

1)

C versions only

4.6.4 Input A & B AC Coupled Lower Frequency Test

Proceed as follows to test the ac coupled input low frequency accuracy:

1. Connect the test tool to the 5500A as for the previous test (see Figure 4-3).

2. Select the following test tool setup:

• Recall the created SETUP 1 (see section 4.4.3): press

select

SCREEN+SETUP 1 , press RECALL SETUP .

• Press

• Press

• Press

• Press

• Press

READING 1 , and select on A | V ac.

READING 2 , and select on B | V ac.

, then using select COUPLING AC

, then using select COUPLING AC

, RECALL ,

4-12

Page 37

Performance Verification

4.6 Scope Input A&B Tests 4

• Press to clear the softkey menu, and to see the full screen.

3. Using

change the time base to select manual time base ranging, and lock the

time base on 50 ms/div.

4. Using

5. Using

and move the Input A and B ground level (indicated by the zero icon

in the left margin) to the center grid line.

and select manual vertical ranging, and set the Input A and B

sensitivity range to 500 mV.

6. Set the 5500A to source the appropriate ac voltage and frequency, according to

Table 4-4.

7. Observe the readings (

1.A and 2.B) and check to see if it is within the range shown

under the appropriate column.

8. Continue through the test points.

9. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

Table 4-4. Input A&B AC Input Coupling Verification Points

5500A output, V rms 5500A Frequency Reading 1.A and 1.B

900 mV 60 Hz 873 mV to 927 mV

900 mV 5 Hz >630 mV

4.6.5 Input A and B Peak Measurements Test

WARNING

Dangerous voltages will be present on the calibration source

and connecting cables during the following steps. Ensure that

the calibrator is in standby mode before making any connection

between the calibrator and the test tool.

Proceed as follows to test the Peak measurement accuracy:

1. Connect the test tool to the 5500A as for the previous test (see Figure 4-3).

2. Select the following test tool setup:

• Recall the created SETUP 1 (see section 4.4.3): press

select

SCREEN+SETUP 1 , press RECALL SETUP .

• Press

• Press

Select

• Press

Select

• Press

READING 1 , and select on A | Peak.

Peak-Peak from the Peak menu.

READING 2 , and select on B | Peak.

Peak-Peak from the Peak menu.

to clear the softkey menu, and to see the full screen.

, RECALL ,

3. Using

change the time base to select manual time base ranging, and lock the

time base on 1 ms/div.

4-13

Page 38

Fluke 19xB-19xC-2x5C

Service Manual

4. Using and move the Input A and B ground level (indicated by the zero icon

in the left margin) to the center grid line.

5. Using

and select manual vertical ranging, and set the Input A and B

sensitivity range to 100 mV.

6. Set the 5500A to source the appropriate ac voltage and frequency, according to

Table 4-5.

7. Observe the readings (

1.A and 2.B) and check to see if it is within the range shown

under the appropriate column.

8. Continue through the test points.

9. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

Table 4-5. Volts Peak Measurement Verification Points

5500A output, Vrms (sine) 5500A Frequency Reading A-B

212.13 mV (0.6 V pp) 1 kHz 0.56 to 0.64

4.6.6 Input A&B Frequency Measurement Accuracy Test

Proceed as follows to test the frequency measurement accuracy:

1. Connect the test tool to the 5500A as shown in Figure 4-4. Do NOT use 50 Ω

terminations!

4-14

Figure 4-4. 5500 Scope Output to Test Tool Input A&B

2. Select the following test tool setup:

• Recall the created SETUP 1 (see section 4.4.3): press

select

SCREEN+SETUP 1 , press RECALL SETUP .

• Press

al55scab.bmp

, RECALL ,

Page 39

Performance Verification

4.6 Scope Input A&B Tests 4

• Press READING 1 , and select on A | Hz.

• Press

3. Using

4. Using

READING 2 , and select on B | Hz.

and select range 100 mV/div for A and B.

select the required time base setting.

5. Set the 5500A to source a sine wave according to the first test point in Table 4-6.

As no 50Ω termination is applied, the 5500 leveled sine wave output amplitude will

be twice the set value.

6. Observe the readings (

1.A and 2.B) and check to see if it is within the range shown

under the appropriate column.

7. Continue through the test points.

8. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

Table 4-6. Input A&B Frequency Measurement Accuracy Test

Model Time base 5500A-SC... MODE Voltage Frequency Input A&B Reading

all 20 ms/div wavegen, sine 600 mVpp 16 Hz 15.90 to 16.10

192B-C 20 ns/div levsine 300 mVpp 60 MHz 59.68 to 60.32

196B-C, 215C 20 ns/div levsine 300 mVpp 100 MHz 99.3 to 100.7

199B-C, 225C 20 ns/div levsine 300 mVpp 200 MHz 198.8 to 201.2

Note

Duty Cycle and Pulse Width measurements are based on the same

principles as Frequency measurements. Therefore the Duty Cycle and

Pulse Width measurement function will not be verified separately.

4.6.7 Input A&B Phase Measurements Test

Proceed as follows to test the phase measurement accuracy:

1. Connect the test tool to the 5500A as for the previous test (see Figure 4-4).

2. Select the following test tool setup:

• Recall the created SETUP 1 (see section 4.4.3): press

select

SCREEN+SETUP 1 , press RECALL SETUP .

• Press

• Press

• Press

3. Using

and select range 100 mV/div for A and B.

4. Using

5. Set the 5500A to source a sine wave according to the first test point in Table 4-6.

As no 50Ω termination is applied, the 5500 leveled sine wave output amplitude will

be twice the set value.

READING 1 , and select on A | Phase.

READING 2 , and select on B | Phase.

select the required time base setting.

, RECALL ,

4-15

Page 40

Fluke 19xB-19xC-2x5C

Service Manual

6. Observe the reading 1.A and 2.B and check to see if they are not outside the range

7. Continue through the test points.

8. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

Time base 5500A-SC... MODE Frequency Voltage Input A&B Reading ...Deg

20 ms/div wavegen, sine, 1 MΩ 10 Hz 600 mVpp -2 to +2

200 ns/div levsine 1 MHz 300 mVpp -2 to +2

20 ns/div levsine 10 MHz 300 mVpp -3 to +3

4.6.8 Time Base Test

Proceed as follows to test the time base accuracy:

1. Connect the test tool to the 5500A as shown in Figure 4-5.

shown under the appropriate column.

Table 4-7. Phase Measurement Verification Points

4-16

Figure 4-5. 5500A Scope Output to Test Tool Input A

2. Set the 5500A to source a 8 ms time marker (MODE marker).

3. Select the following test tool setup:

• Reset the test tool

• Using

and select manual vertical ranging, and set the Input A sensitivity

range to 5V (probe A is 10:1, so input sensitivity is 500 mV/div).

• Using

change the time base to select manual time base ranging, and lock

the time base on 10 ms/div).

• Using

move the trace to the left. After moving the trace 2 divisions, the

trigger delay time with respect to the first vertical grid line will be indicated in

al55sca.bmp

Page 41

Performance Verification

4.6 Scope Input A&B Tests 4

the center of the display bottom.

Adjust the trigger delay time to 8.000 ms (

A →| 8.00 ms )

• Using

4. Using

set the time base on 10 μs/div.

move the trace to the right until the indicated trigger delay is

7.990 ms.

5. Examine the rising edge of the time marker pulse at the height of the trigger level

indicator top. Verify that the rising edge is at the second grid line from the left. The

allowed deviation is ±3 pixels, see Figure 4-6.

6. Select the following test tool setup:

• Using

change the time base to select manual time base ranging, and lock

the time base on 10 ms/div).

• Using

A 800.0 μs).

(

• Using

move the trace to adjust the trigger delay time to 800.0 μs

set the time base on 1 μs/div.

7. Set the 5500A to source a 0.8 ms time marker (MODE marker).

8. Using

move the trace to the right until the indicated trigger delay is

799.0 μs.

9. Examine the rising edge of the time marker pulse at the vertical height of the trigger

level indicator top. Verify that the rising edge is at the second grid line from the left.

The allowed deviation is ±3 pixels, see Figure 4-6.

Figure 4-6. Time Base Verification

190c-tb1.bmp

4.6.9 Input A Trigger Sensitivity Test

Proceed as follows to test the Input A trigger sensitivity:

1. Connect the test tool to the 5500A as for the previous test (see Figure 4-5).

2. Select the following test tool setup:

• Reset the test tool

4-17

Page 42

Fluke 19xB-19xC-2x5C

Service Manual

• Using and change the sensitivity range to select manual sensitivity

ranging, and lock the Input A sensitivity range on 2 V/div.

3. Using

select the time base indicated under the second column of Table 4-8.

4. Set the 5500A to source the leveled sine wave for the appropriate test tool model.

5. Adjust the 5500A output voltage until the displayed trace has the trigger amplitude

indicated under the last column of Table 4-8.

6. Verify that the signal is well triggered.

If it is not, press

, then using enable the up/down arrow keys for manual

Trigger Level adjustment. Adjust the trigger level and verify that the signal will be

triggered now. The trigger level is indicated by the trigger icon (

).

7. Continue through the test points.

8. When you are finished, set the 5500A to Standby.

Table 4-8. Input A Trigger Sensitivity Test Points

UUT UUT 5500A SC... MODE levsin UUT

Model Time base Initial Input Voltage Frequency Trigger Amplitude

ALL 200 ns/div 100 mV pp 5 MHz 0.5 div

192B-C 10 ns/div 400 mV pp 60 MHz 1 div

10 ns/div 800 mV pp 100 MHz 2 div

196B-C, 215C 10 ns/div 400 mV pp 100 MHz 1 div

10 ns/div 800 mV pp 150 MHz 2 div

199B-C, 225C 10 ns/div 400 mV pp 200 MHz 1 div

10 ns/div 800 mV pp 250 MHz 2 div

4-18

Page 43

Performance Verification

4.6 Scope Input A&B Tests 4

4.6.10 Input A AC Voltage Accuracy (HF) & Bandwidth Test

Proceed as follows to test the Input A high frequency automatic scope ac voltage

measurement accuracy, and the bandwidth:

1. Connect the test tool to the 5500A as for the previous test (see Figure 4-5).

2. Select the following test tool setup:

• Recall the created SETUP 1 (see section 4.4.3): press

select

SCREEN+SETUP 1 , press RECALL SETUP .

• Press

• Press

• Using

, then press READING 1 , and select on A | V ac.

to select autoranging (AUTO in upper right LCD edge)

and change the sensitivity range to select manual sensitivity

ranging, and lock the Input A sensitivity range on 500 mV/div. (

, RECALL ,

AUTO in upper

right LCD edge disappears)

3. Set the 5500A to source a sine wave, to the first test point in Table 4-9.

4. Observe the Input A reading and check to see if it is within the range shown under

the appropriate column.

5. Continue through the test points.

6. When you are finished, set the 5500A to Standby.

Table 4-9. HF AC Voltage Verification Points

UUT 5500A SC... MODE levsin UUT

Model Voltage Frequency Reading A

all 2.545 Vpp 1 MHz 835 mV to 965 mV

all 2.545 Vpp 25 MHz 790 mV to 1.010 V

192B-C 2.545 Vpp 60 MHz >630 mV

196B-C, 215C 2.545 Vpp 100 MHz >630 mV

199B-C, 225C 2.545 Vpp 200 MHz >630 mV

4-19

Page 44

Fluke 19xB-19xC-2x5C

Service Manual

4.6.11 Input B Trigger Sensitivity Test

Proceed as follows to test the Input B trigger sensitivity:

1. Connect the test tool to the 5500A as shown in Figure 4-7.

Figure 4-7. 5500A Scope Output to Test Tool Input B

al55scb.bmp

2. Select the following test tool setup:

• Reset the test tool

• Press

• Press

• Using

• Press

• Using

and use to turn Input B on.

and use to turn Input A off.

move the Input B trace zero to the center grid line.

and use to select Input B as trigger source.

and change the sensitivity range to select manual sensitivity

ranging, and lock the Input B sensitivity range on 2 V/div.

3. Using

select the time base indicated under the first column of Table 4-10.

4. Set the 5500A to source the leveled sine wave given in the first row of Table 4-10.

5. Adjust the 5500A output voltage until the displayed trace has the amplitude indicated

under the appropriate column of Table 4-10.

6. Verify that the signal is well triggered.

If it is not, press

, then using enable the up/down arrow keys for manual

Trigger Level adjustment. Adjust the trigger level and verify that the signal will be

triggered now. The trigger level is indicated by the trigger icon (

).

4-20

7. Continue through the test points.

8. When you are finished, set the 5500A to Standby.

Page 45

Performance Verification

Table 4-10. Input B Trigger Sensitivity Test Points

UUT UUT 5500A SC... MODE levsin UUT

Model Time base Initial Input Voltage Frequency Trigger Amplitude

ALL 200 ns/div 100 mV pp 5 MHz 0.5 div

192B-C 10 ns/div 400 mV pp 60 MHz 1 div

10 ns/div 800 mV pp 100 MHz 2 div

196B-C, 215C 10 ns/div 400 mV pp 100 MHz 1 div

10 ns/div 800 mV pp 150 MHz 2 div

199B-C, 225C 10 ns/div 400 mV pp 200 MHz 1 div

10 ns/div 800 mV pp 250 MHz 2 div

4.6 Scope Input A&B Tests 4

4.6.12 Input B AC Voltage Accuracy (HF) & Bandwidth Test

Proceed as follows to test the Input B high frequency automatic scope ac voltage

measurement accuracy, and the bandwidth:

1. Connect the test tool to the 5500A as for the previous test (see Figure 4-7).

2. Select the following test tool setup:

• Recall the created SETUP 1 (see section 4.4.3): press

select

SCREEN+SETUP 1 , press RECALL SETUP .

• Press

• Press

• Using

, then press READING 2 , and select on B | V ac.

to select autoranging (AUTO in upper right LCD edge)

and change the sensitivity range to select manual sensitivity

, RECALL ,

ranging, and lock the Input B sensitivity range on 500 mV/div.

3. Set the 5500A to source a sine wave, to the first test point in Table 4-11.

4. Observe the Input B reading and check to see if it is within the range shown under

the appropriate column of table 4-11.

5. Continue through the test points.

6. When you are finished, set the 5500A to Standby.

Table 4-11. HF AC Voltage Verification Points

UUT 5500A SC... MODE levsin UUT

Model Voltage Frequency Reading B

all 2.545 Vpp 1 MHz 835 mV to 965 mV

all 2.545 Vpp 25 MHz 790 mV to 1.010 V

192B-C 2.545 Vpp 60 MHz >630 mV

196B-C, 215C 2.545 Vpp 100 MHz >630 mV

199B-C, 225C 2.545 Vpp 200 MHz >630 mV

4-21

Page 46

Fluke 19xB-19xC-2x5C

Service Manual

4.6.13 Video test using the Video Pattern Generator

You can skip this test if you do the test 4.6.14 Video test using the SC600 Scope

Calibration option

Only one of the systems NTSC, PAL, PALplus, or SECAM has to be verified.

Proceed as follows:

1. Connect the test tool to the TV Signal Generator as shown in Figure 4-8.

Figure 4-8. Test Tool Input A to TV Signal Generator

2. Select the following test tool setup:

• Reset the test tool

• Press

• Choose

Polarity: POSITIVE | PAL ( or NTSC PALplus SECAM )

• Press

• Press

• Using

, then press to open the Trigger Options menu.

VIDEO on A... , then from the shown opened menu choose

to select ALL LINES

to enable the arrow keys for selecting the video line number.

select line number:

⇒ 622 for PAL, PALplus, or SECAM

⇒ 525 for NTSC.

• Using

and set the Input A sensitivity to 2 V/div (the actual probe setting

is 10:1).

• Using

select the time base to 20 μs/div.

3. Set the TV Signal Generator to source a signal with the following properties:

• the system selected in step 2

• gray scale

al-tv-a.bmp

4-22

Page 47

Performance Verification

4.6 Scope Input A&B Tests 4

• sync pulse amplitude > 0.7 div.

• chroma amplitude zero.

4. Observe the trace, and check to see if the test tool triggers on line number:

⇒ 622 for PAL or SECAM, see Figure 4-9

⇒ 525 for NTSC, see Figure 4-10.

Figure 4-9. Trace for PAL/SECAM line 622

Figure 4-10. Trace for NTSC line 525

5. Using select line number:

⇒ 310 for PAL or SECAM

⇒ 262 for NTSC

6. Observe the trace, and check to see if the test tool triggers on:

⇒ line number 310 for PAL or SECAM, see Figure 4-11.

⇒ line number 262 for NTSC, see Figure 4-12.

Figure 4-11. Trace for PAL/SECAM line 310

Figure 4-12. Trace for NTSC line 262

7. Apply the inverted TV Signal Generator signal to the test tool.

Invert the signal by using a Banana Plug to BNC adapter (Fluke PM9081/001) and a

Banana Jack to BNC adapter (Fluke PM9082/001), as shown in Figure 4-13.

4-23

Page 48

Fluke 19xB-19xC-2x5C

Service Manual

Figure 4-13. Test Tool Input A to TV Signal Generator Inverted

al-tv-ai.bmp

8. Select the following test tool setup:

• Press

• Choose

Polarity: NEGATIVE | PAL ( or NTSC PALplus SECAM )

9. Using

to open the Trigger Options menu.

VIDEO on A... , then from the shown opened menu choose

select line number 310 (PAL or SECAM) or 262 (NTSC)

10. Observe the trace, and check to see if the test tool triggers on line number 310 (PAL

or SECAM, see Figure 4-14), or line number 262 (NTSC, see Figure 4-15).

Figure 4-14. Trace for PAL/SECAM line 310

Negative Video

Figure 4-15. Trace for NTSC line 262 Negative

Video

4-24

4.6.14 Video test using SC600 Scope Calibration Option

You can skip this test if you did test 4.6.13 Video test using the Video Pattern

Generator.

Only one of the systems NTSC, PAL, PALplus, or SECAM has to be verified.

Page 49

Performance Verification

4.6 Scope Input A&B Tests 4

Proceed as follows:

1. Connect the test tool to the calibrator as shown in Figure 4-16.

al55sca.bmp

Figure 4-16. Test Tool Input A to TV Signal Generator

2. Select the following test tool setup:

• Reset the test tool

• Press

• Choose

Polarity: POSITIVE | PAL ( or NTSC PALplus SECAM )

• Press

• Press

• Using

, then press to open the Trigger Options menu.

VIDEO on A... , then from the shown opened menu choose

to select ALL LINES

to enable the arrow keys for selecting the video line number.

select line number:

⇒ 622 for PAL, PALplus, or SECAM

⇒ 525 for NTSC.

• Using

and set the Input A sensitivity to 2 V/div (the actual probe setting

is 10:1).

• Using

select the time base to 20 μs/div.

3. Set the calibrator to mode video with amplitude +100%. Set format and marker line

number to :

⇒ PAL 622 (even), for PAL and PALplus

⇒ SECAM 622 (even), for SECAM

⇒ NTSC 262 even, for NTSC.

4. Observe the trace, and check to see if the test tool triggers on the negative pulse

before the marker pulse (see Figure 17).

4-25

Page 50

Fluke 19xB-19xC-2x5C

Service Manual

5. Using select test tool line number:

6. Set the calibrator format and marker line number to :

7. Observe the trace, and check to see if the test tool triggers on the negative pulse

8. Select the following test tool setup:

⇒ 310 for PAL, PALplus or SECAM

⇒ 262 for NTSC

⇒ PAL 310 (odd), for PAL and PALplus

⇒ SECAM 310 (odd), for SECAM

⇒ NTSC 262 odd, for NTSC.

before the marker.

• Press

• Choose

Polarity: NEGATIVE | PAL ( or NTSC PALplus SECAM )

to open the Trigger Options menu.

VIDEO on A... , then from the shown opened menu choose

9. Set the calibrator video trigger output signal to -100%

10. Using

select line number 310 (PAL, PALplus or SECAM) or 262 (NTSC)

11. Set the calibrator format and marker line number to :

⇒ PAL 310 (odd), for PAL and PALplus

⇒ SECAM 310 (odd), for SECAM

⇒ NTSC 262 odd, for NTSC.

12. Observe the trace, and check to see if the test tool triggers on the positive pulse

before the marker.

4-26

Figure 4-17. SC600 Marker Pulse

video-sc600.bmp

Page 51

Performance Verification

4.7 External Trigger Level Test 4

4.7 External Trigger Level Test

Proceed as follows:

1. Connect the test tool to the 5500A as shown in Figure 4-18.

Figure 4-18. Test Tool Meter/Ext Input to 5500A Normal Output

al55ex2w.bmp

2. Select the following test tool setup:

• Reset the test tool

• Press

• Using

⇒ Select

⇒ Select

• Using

• Using

• Using

select the TRIGGER OPTIONS... menu

On Edges... from the TRIGGER OPTIONS menu

Update: Single Shot | Noise reject Filter: On

EDGE TRIG select Ext .

SLOPE select positive slope triggering (trigger icon ).

Ext LEVEL select 1.2 V

3. Set the 5500A to source 0.4V dc.

4. Verify that no trace is shown on the test tool display, and that the status line at the

display top shows

trace, and status

SINGLE MANUAL or SINGLE WAITING. If the display shows the

SINGLE HOLD then press to re-arm the test tool for a trigger.

5. Set the 5500A to source 1.7 V

6. Verify that the test tool is triggered by checking that the trace becomes visible.

To repeat the test, start at step 3.

7. Set the 5500A to Standby.

4-27

Page 52

Fluke 19xB-19xC-2x5C

Service Manual

4.8 Meter (DMM) Tests

4.8.1 Meter DC Voltage Accuracy Test

Dangerous voltages will be present on the calibration source

and connecting cables during the following steps. Ensure that

the calibrator is in standby mode before making any connection

between the calibrator and the test tool.

Proceed as follows to test the meter dc voltage measurement accuracy:

1. Connect the test tool to the 5500A as for the previous test (see Figure 4-18).

2. Select the following test tool setup:

WARNING

• Press

(this key will toggle the menu bar on and off if the test tool is

already in the meter mode)

• Press

• Press

to open the Measurement menu, and select V dc

to select MANUAL ranging; use to select the ranges.

3. Set the range to the first test point in Table 4-12.

4. Set the 5500A to source the appropriate dc voltage.

5. Observe the reading and check to see if it is within the range shown under the

appropriate column.

6. Continue through the test points.

7. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

Table 4-12. Meter Volts dc Measurement Verification Points

Range 5500A output V dc Meter Reading

500.0 mV + 500 mV 497.0 to 503.0

- 500 mV -497.0 to -503.0

0 mV -0.5 to +0.5

5.000 V + 5.000 V 4.970 to 5.030

4-28

- 5.000 V -4.970 to -5.030

50.00 V + 50.00 V 49.70 to 50.30

- 50.00 V -49.70 to -50.30

500.0 V + 500.0 V 497.0 to 503.0

- 500.0 V -497.0 to -503.0

1100 V + 1000 V 0.990 to 1.010

- 1000 V -0.990 to -1.010

Page 53

Performance Verification

4.8 Meter (DMM) Tests 4

4.8.2 Meter AC Voltage Accuracy & Frequency Response Test

Warning

Dangerous voltages will be present on the calibration source

and connecting cables during the following steps. Ensure that

the calibrator is in standby mode before making any connection

between the calibrator and the test tool.

Proceed as follows to test the ac voltage measurement accuracy:

1. Connect the test tool to the 5500A as for the previous test (see Figure 4-18).

2. Select the following test tool setup:

• Press

• Press

• Press

to open the Measurement menu, and select V ac

to select MANUAL ranging; use to select the ranges

3. Set the range to the first test point in Table 4-13.

4. Set the 5500A to source the appropriate ac voltage.

5. Observe the reading and check to see if it is within the range shown under the

appropriate column.

6. Continue through the test points.

7. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

Table 4-13. Meter Volts AC Measurement Verification Points

Range 5500A output V ac Frequency Meter Reading

500.0 mV 500.0 mV 60 Hz 494.0 to 506.0

1 kHz 486.0 to 514.0

10 kHz >350.0

5.000 V 5.000 V 60 Hz 4.940 to 5.060

1 kHz 4.860 to 5.140

10 kHz >3.500

50.00 V 50.00 V 60 Hz 49.40 to 50.60

1 kHz 48.60 to 51.40

10 kHz >35.00

500.0 V 500.0 V 60 Hz 494.0 to 506.0

1 kHz 486.0 to 514.0

10 kHz >350.0

1100 V (1.1 kV) 1000 V 60 Hz 0.980 to 1.020

1 kHz 0.960 to 1.040

10 kHz > 0.700

4-29

Page 54

Fluke 19xB-19xC-2x5C

Service Manual