Page 1

Fluke 192/196/199

ScopeMeter

Users Manual

4822 872 00983

October 2000, Rev.2, 2/ 01

© 2000 Fluke Corporation. All rights reserved. Printed in the Netherlands.

All product names are trademarks of their respective companies.

Page 2

Page 3

LIM ITED WARRANTY & LIM ITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and service. The warranty period is three years

and begins on the date of shipment. Parts, product repairs and services are warranted for 90 days. This warranty extends only to the original buyer or end-user

customer of a Fluke authorized reseller, and does not apply to fuses, disposable batteries or to any product which, in Fluke’s opinion, has been misused, altered,

neglected or damaged by accident or abnormal conditions of operation or handling. Fluke warrants that software will operate substantially in accordance with its

functional specifications for 90 days and that it has been properly recorded on non-defective media. Fluke does not warrant that software will be error free or

operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers only but have no authority to extend a greater or

different warranty on behalf of Fluke. Warranty support is available if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of repair/replacement parts when product purchased in one country

is submitted for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price, free of charge repair, or replacement of a defective product which is

returned to a Fluke authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center or send the product, with a description of the difficulty, postage and insurance

prepaid (FOB Destination), to the nearest Fluke authorized service center. Fluke assumes no risk for damage in transit. Following warranty repair, the product

will be re turned to Buyer, transportation prepaid (FOB Destination). If Fluke determines that the failure was caused by misuse, alteration, accident or abnormal

condition of operation or handling, Fluke will provide an estimate of repair costs and obtain authorization before commencing the work. Following repair, the

product will be returned to the B uyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO ANY IMP LIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR

ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER ARISING FROM BREACH

OF WARRANTY OR BASED ON CONTRACT, TORT, RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or consequential damages, the

limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court of competent

jurisdiction, such holding will not affect the validity or enforceability of any other provision.

Fluke Corporation, P.O. Box 9090, Everett, WA 98206-9090 USA, or

Fluke Industrial B.V., P.O. Box 90, 7600 AB, Almelo, The Netherlands

Page 4

SERVICE CENTERS

To locate an authoriz ed s ervice center, visit us on the W or ld Wide Web:

http://www.fluke.com

or call Fluke using any of the phone numbers list ed below:

+1-888-993-5853 in U.S .A. and Canada

+31-40-2675200 in Europe

+1-425-356-5500 fr om other countries

Page 5

Table of Contents

Chapter Title Page

Unpacking the Test Tool Kit...................................................................................... 2

Safety Infor m at ion: Read First .................................................................................. 4

1 Using The Scope.................................................................................................... 7

Powering the Test Tool............................................................................................. 7

Resetting the Test Tool............................................................................................ 8

Navigating a Menu ................................................................................................... 9

Hiding Key Labels and Menus .................................................................................. 10

Input Connections .................................................................................................... 10

Making Scope Connections...................................................................................... 11

Displaying an Unknown Signal with Connect-and-View™.......................................... 12

Making Automatic Scope Measurements .................................................................. 13

Freezing the Screen................................................................................................. 14

Using Average, Persistence and Glitch Capture........................................................ 15

Acquiring Waveforms............................................................................................... 18

Analyzing Waveforms............................................................................................... 20

i

Page 6

Fluke 192/196/199

Users Manual

2 Using The Multimeter.............................................................................................. 21

Making Meter Connections........................................................................................ 21

Making Multimeter Measurements............................................................................. 22

Freezing the Readings .............................................................................................. 25

Selecting Auto/Manual Ranges.................................................................................. 25

Making Relative Measurements................................................................................. 26

3 Using The Recorder Functions............................................................................... 27

Opening the Recorder Main Menu............................................................................. 27

Plotting Measurements Ov er Time ( Tr endPlot™)....................................................... 28

Recording Scope Waveforms In Deep Memory ( Scope Record™)............................. 31

Analyzing a TrendPlot or Scope Record .................................................................... 34

4 Using Replay, Zoom and Cursor s .......................................................................... 35

Replaying the 100 Most Recent Scope Screens ........................................................ 35

Zooming in on a Waveform....................................................................................... 38

Making Cursor Measurements................................................................................... 40

5 Triggering on W avef or m s ....................................................................................... 43

Setting Trigger Level and Slope................................................................................. 44

Using Trigger Delay or Pre-trigger............................................................................. 45

Automatic Trigger Options......................................................................................... 46

Triggering on Edges.................................................................................................. 47

Triggering on External Waveform s ............................................................................ 50

Triggering on Video Signals....................................................................................... 51

Triggering on Pulses ................................................................................................. 53

ii

Page 7

Contents (continued)

6 Using Memory, PC and Printer .............................................................................. 57

Saving and Recalling................................................................................................ 57

Documenting Screens .............................................................................................. 61

7 Tips......................................................................................................................... 65

Using the Standard Accessories............................................................................... 65

Using the Independently Floating Isolated Input s ...................................................... 68

Using the Tilt Stand.................................................................................................. 70

Resetting the Test Tool............................................................................................ 70

Suppressing Key Labels and Menu’s........................................................................ 70

Changing the Information Language ......................................................................... 71

Adjusting the Contrast and Brightness ...................................................................... 71

Changing Date and Time.......................................................................................... 72

Saving Battery Life................................................................................................... 73

Changing the Auto Set Options................................................................................. 74

8 Maintai ni ng t he Test Tool ...................................................................................... 75

Cleaning the Test Tool.............................................................................................. 75

Storing the Test Tool................................................................................................ 75

Charging the Batteries.............................................................................................. 76

Extending Battery Oper at ion Time ............................................................................ 77

Replacing the NiMH Battery Pack BP190.................................................................. 78

Calibrating the Voltage Probes ................................................................................. 78

Displaying Calibration Information............................................................................. 80

Parts and Accessories.............................................................................................. 80

Troubleshooting........................................................................................................ 85

iii

Page 8

Fluke 192/196/199

Users Manual

9 Specifications ......................................................................................................... 87

Introduction............................................................................................................... 87

Dual Input Oscillosc ope............................................................................................. 88

Automatic Scope Measurements............................................................................... 90

Meter........................................................................................................................ 94

DMM Measurements on M et er I nput s........................................................................ 94

Recorder................................................................................................................... 96

Zoom, Replay and Cursors........................................................................................ 97

Miscellaneous........................................................................................................... 97

Environmental........................................................................................................... 99

Safety....................................................................................................................... 100

10:1 Probe................................................................................................................ 101

Electromagnetic Immunit y ......................................................................................... 103

Index

iv

Page 9

Unpacking the Test Tool Kit

Declaration of Conformity

for

Fluke 192/196/199

®

ScopeMeter

Manufacturer

Fluke Industrial B.V.

7602 EA Almelo

The Netherlands

Statement of Confor m i ty

Based on test results using appropriate standar ds,

the product is in conformity with

Electromagnet ic Compatibility Directive 89/336/EEC

Low Voltage Directive 73/23/EEC

test tools

Lelyweg 1

Sample tests

Standards used:

EN 61010.1 (1993)

Safety Requirements for Electr ical Equipment f or

Measurement, Contr ol, and Labor at or y Use

EN-IEC61326-1 (1997)

Electrical equipment for

measurements and laborator y

use -EMC requirements-

The tests have been perform ed in a

typical configuration.

This Conformity is indicated by the symbol

i.e. “Conformité Europ éenne”.

,

1

Page 10

Fluke 192/196/199

13

Users Manual

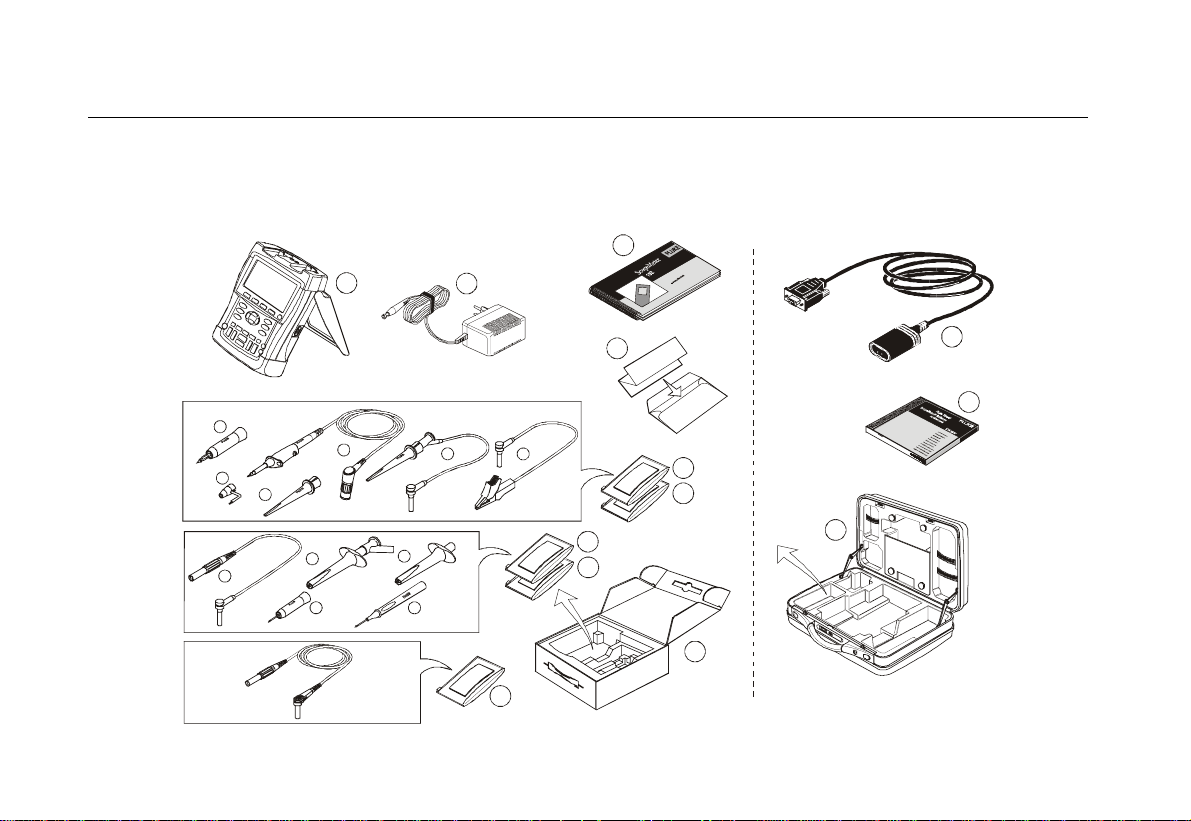

Unpacking the Test Tool Kit

The following items are included in your test tool kit:

1

(2x)

e

(1x)

f

(2x)

b

(2x)

e

(2x)

a

(2x)

d

(2x)

a

(2x)

b

2

(2x)

c

(2x)

(2x)

c

Note

When new, the rechargeable NiMH batter y is not

fully charged. See Chapter 8.

8

T

C

U

D

O

R

P

9

R

E

T

E

D

M

R

E

A

P

C

O

N

C

O

S

I

T

E

A

K

R

U

T

L

F

S

I

G

E

R

(2x)

d

3

4

6

7

10

5

11

12

Figure 1. ScopeMet er Test Tool Ki t

2

Page 11

Unpacking the Test Tool Kit

# Description

1 ScopeMeter Test Tool

2 Battery Charger (country dependent)

3 10:1 Voltage Probe Set (red)

10: 1 Voltage Pr obe ( r ed)

a)

Hook Clip for Probe Tip (r ed)

b)

Ground Lead with Hook Clip (red)

c)

G r ound Lead with M ini Alligator Clip (black)

d)

4- m m Test Pr obe f or Pr obe Tip (r ed)

e)

Ground Spring for Probe Tip (black)

f)

4 10:1 Voltage Probe Set (gray)

10: 1 Voltage Probe ( gr ay)

a)

Hook Clip for Probe Tip (gr ay)

b)

Ground Lead with Hook Clip (gray)

c)

G r ound Lead with M ini Alligator Clip (black)

d)

4- m m Test Pr obe f or Probe Tip ( gr ay)

e)

5 Test Leads (red and black)

6 Accessory Set (only for Fluke 196 and 199)

2- m m Test Pr obe f or Pr obe Tip (r ed)

a)

I ndus t r ial Alligator for Pr obe Tip ( r ed)

b)

2-mm Test Probe for Banana Jack (red)

c)

I ndus t r ial Alligator for Banana Jack ( r ed)

d)

G r ound Lead with 4- m m Banana Jack

e)

(black)

# Description

7 Accessory Set (only for Fluke 196 and 199)

2- m m Test Pr obe f or Probe Tip ( gr ay)

a)

I ndust r ial Alligator for Probe Tip (gr ay)

b)

2-mm Test Probe for Banana Jack (gray)

c)

I ndust r ial Alligator for Banana Jack (gr ay)

d)

G r ound Lead with 4- m m Banana Jack

e)

(black)

8 Users Manual (this book)

9 Product Registration Card with Envelope

10 Shipment box (basic version only)

Fluke 192-S, 196-S and 199-S versions include also the

following items:

# Description

11 Optically Isolated RS-232 Adapter/Cable

12 FlukeView® ScopeMeter® Software for

Windows

®

13 Hard Case

3

Page 12

Fluke 192/196/199

Users Manual

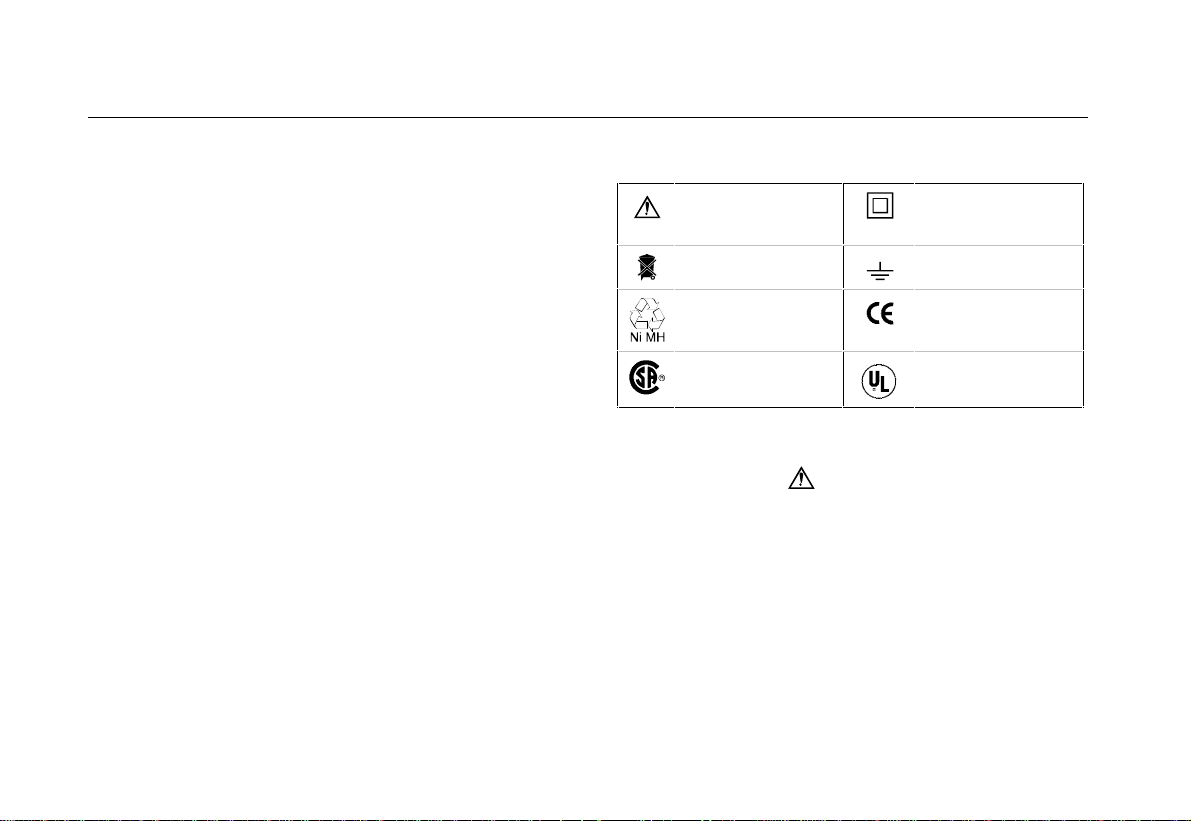

Safety Information: Read First

Carefully read the following safety inform at ion befor e

using the test tool.

Specific warning and caution statements, where t hey

apply, appear throughout t he m anual.

A “Warning” identi fies conditions and

actions that pose hazard(s ) t o t he user.

A “Caution” identifies conditions and act ions

that may damage the test t ool.

The following international symbols are used on the test

tool and in this manual:

See explanation in

manual

Disposal information Earth

Recycling

information

Safety Approval Safety Approval

Double Insulation

(Protectio n Class)

Conformité

Européenne

Warning

To avoid electrical shock or fire, use only t he

Fluke power supply, M odel BC190 (Bat t er y

Charger / Power Adapter).

4

Page 13

Safety Infor m at ion: Read First

Warning

To avoid electrical shock or fire if a test tool

input is connected t o m ore than 42 V peak (30

Vrms) or on circuits of more than 4800 VA:

• Use only insulated voltage pr obes and t est

leads (and adapters) supplied with t he t est

tool, or equivalents as specified i n t he

accessory list, see Chapter 8.

• Before use, inspect voltage pr obes, test

leads and accessories for mechanical

damage and replace when damaged.

• Remove all probes, test l eads and

accessories that are not in use.

• Always connect the battery char ger f i r st t o

the ac outlet befor e connect ing it to the test

tool.

• Do not connect the ground spring to

voltages higher than 42 V peak ( 30 Vrm s)

from earth ground.

• Do not apply voltages that di f f er m or e t han

600 V from earth ground t o any input when

measuring in a CAT III environment.

Do not apply voltages that di f f e r m or e t han

1000 V from earth ground t o any input when

measuring in a CAT II envi r onm ent .

• Do not apply voltages that di f f er m or e t han

600 V from each other t o t he i solated inputs

when measuring in a CAT III environment.

Do not apply voltages that di f f e r m or e t han

1000 V from each other t o t he i solated inputs

when measuring in a CAT II environment.

• Do not apply input voltages above t he r at i ng

of the instrume nt . Use caut i on w hen using

1:1 test leads because the pr obe t i p voltage

will be directly transmitted to the test tool.

• Do not use expos e d metal BNC or banana

plug connectors.

• Do not insert metal obj ects into connectors.

• Always use the test tool only in the manner

specified.

Voltage ratings that are mentioned in the warnings, are

given as limits for “working voltage”. They repr esent

V ac rms (50-60 Hz) for ac sinewave applications and as

V dc for dc applications.

Overvoltage Category III refers to distribution level and

fixed installation circuits inside a building.

Overvoltage Category II r ef er s t o local level, which is

applicable for appliances and portable equipment.

5

Page 14

Fluke 192/196/199

Users Manual

The terms ‘Isolated’ or ‘Electrically floating’ are used in

this manual to indicate a measurement in which the t est

tool input BNC or banana jack is connected to a voltage

different fr om ear t h gr ound.

The isolated input connectors have no exposed metal and

are fully insulated to protect against electr ical shock.

The red and gray BNC jacks, and the red and black

4-mm banana jacks can independently be connected to a

voltage above earth ground for isolated ( elect r ically

floating) measurement s and ar e r at ed up t o 1000 Vr m s

CAT II and 600 Vrms CAT III above earth ground.

If Safety F eat ures are Impaired

Use of the test tool i n a m anner not speci f ied may

impair the pr ot ect ion provided by the equipment .

Before use, inspect the test leads for m echanical damage

and replace damaged test leads!

Whenever it is likely that safety has been impaired, t he

test tool must be tur ned off and disconnected from t he

line power. The matter should then be r ef er r ed to

qualified personnel. Safety is likely to be impaired if, for

example, the test t ool fails to per f or m the intended

measurements or shows visible damage.

6

Page 15

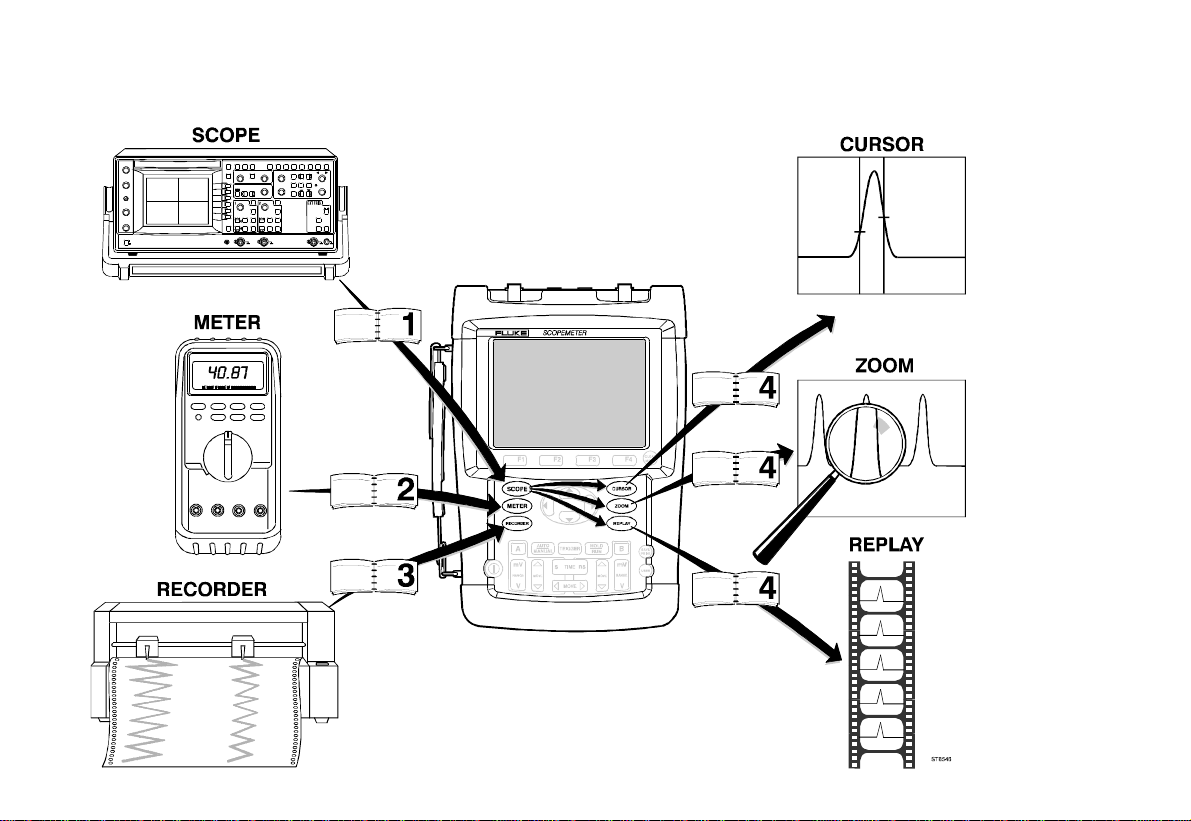

About this Chapter

This chapter provides a step-by-st ep intr oduction to the

scope functions of the test t ool. The int r oduct ion does not

cover all of the capabilit ies of the scope functions but

gives basic examples to show how to use the menus and

perform basic operations.

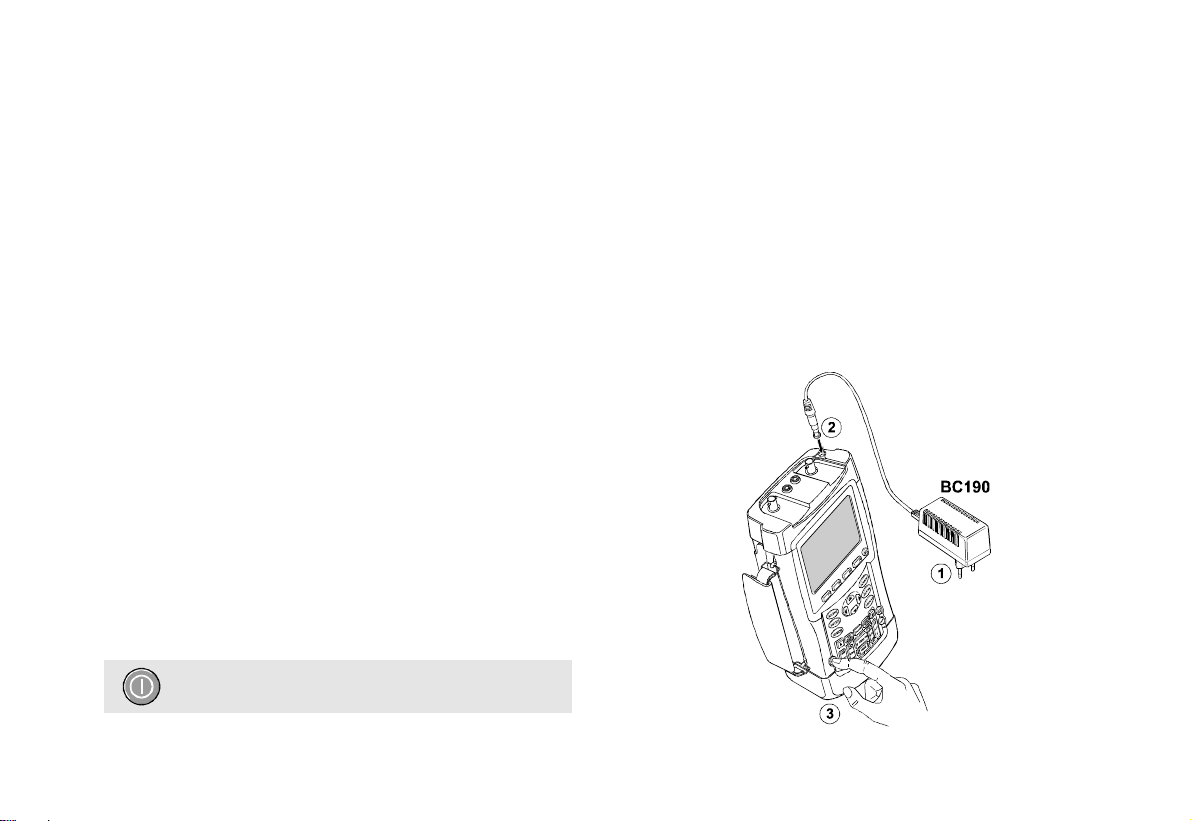

Powering the Test Tool

Follow the procedure (steps 1 through 3) in Figure 2 to

power the test tool fr om a st andar d ac out let .

See Chapter 8 for instructions on using batt er y power.

Turn the test tool on with the on/ off key.

Chapter 1

Using The Scope

The test tool powers up in its last setup configurat ion.

Figure 2. Powering the Test Tool

7

Page 16

Fluke 192/196/199

Users Manual

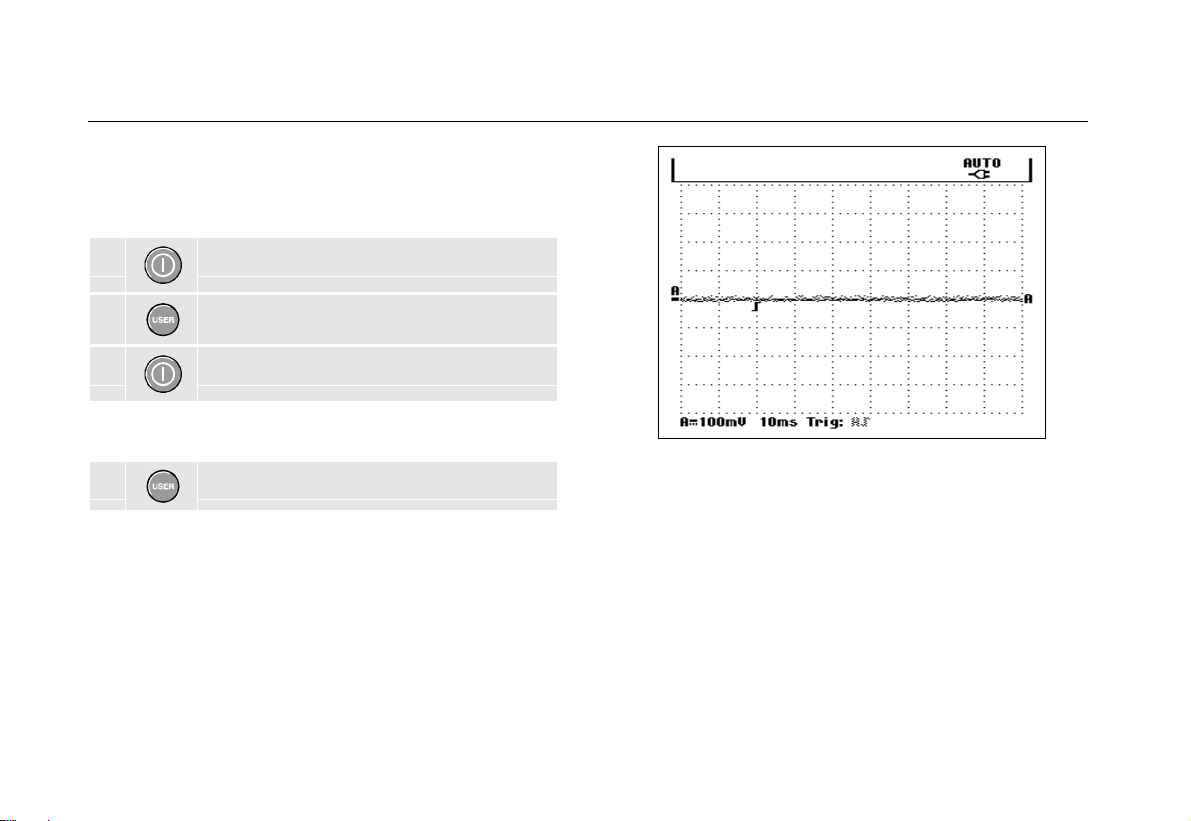

Resetting the Test Tool

If you want to reset the test tool to the factory settings, do

the following:

1 Turn the test tool off.

2 Press and hold.

3 Press and release.

The test tool turns on, and you should hear a double

beep, indicating the reset was successful.

4 Release.

Now look at the display; you will see a screen that looks

like Figure 3.

Figure 3. The Screen After Reset

8

Page 17

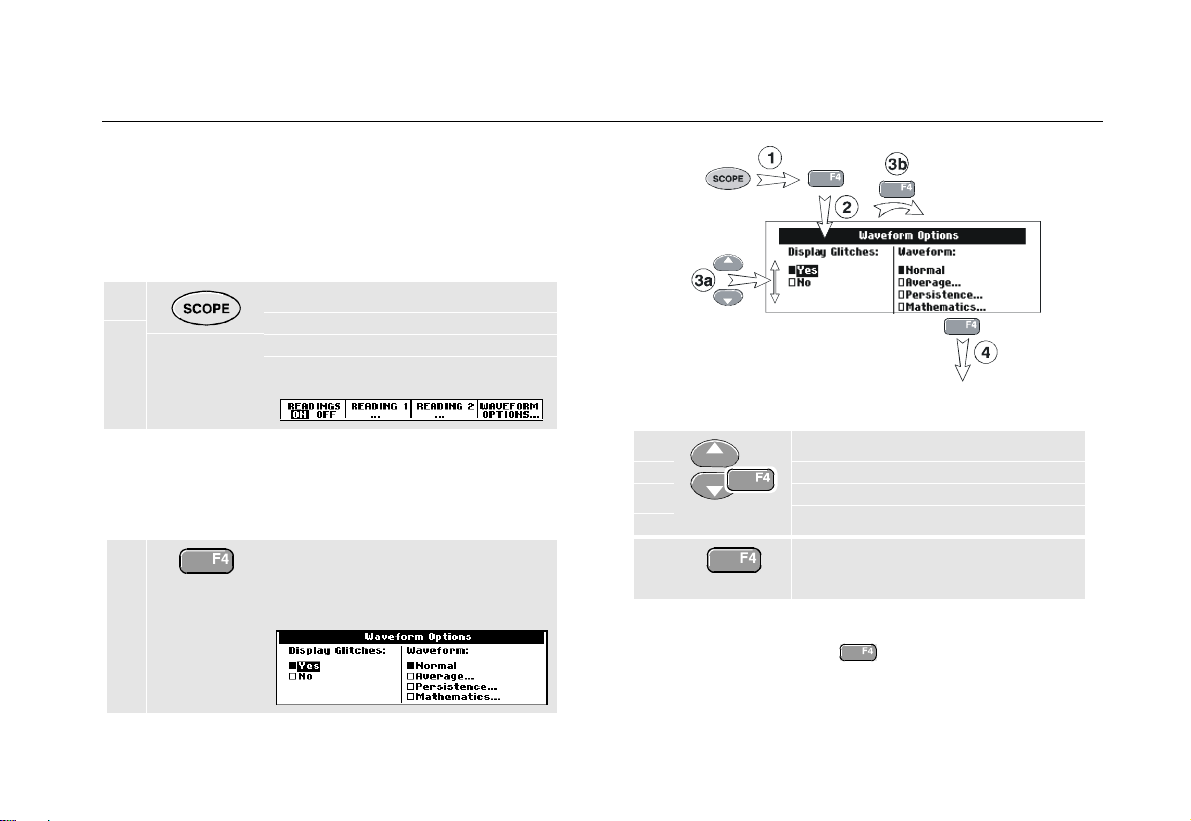

Navigating a Menu

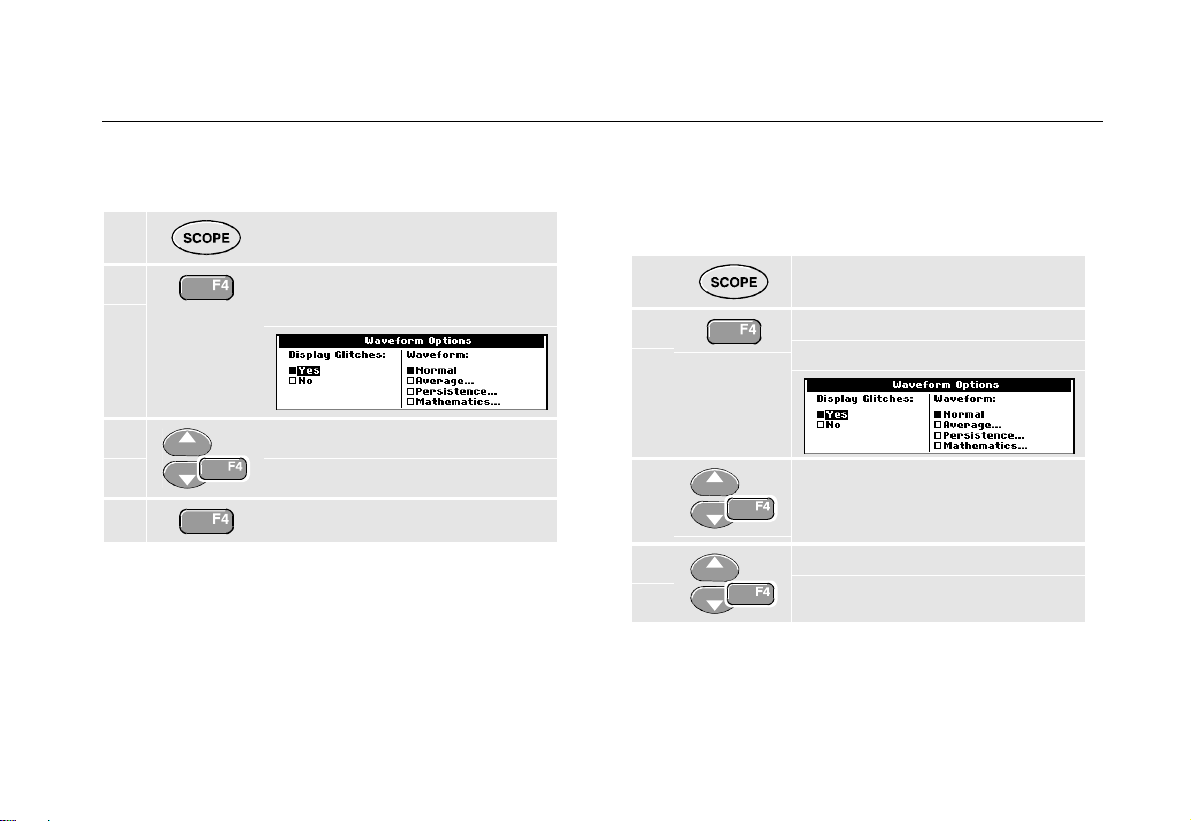

The following example shows how to use the test tool’s

menus to select a function. Subsequently f ollow steps

1 through 4 to open the scope menu and t o choose an

item.

1 Press the SCOPE key to display

the labels that define the present

use for the four blue f unct ion

keys at the bottom of t he scr een.

Using The Scope

Navigating a Menu

Figure 4. Basic Navigation

1

Note

To hide the labels for full screen view, press the

SCOPE key again. This toggling enables you to

check the labels without affecting your sett ings.

2 Open the Waveform Options

menu. This menu is displayed at

the bottom of t he scr een.

3a

3b

4 Press the ENTER key until you exit

Repeatedly pressing

through a menu without changing the settings.

Use the blue arrow keys to

highlight the item.

Press the blue ENTER key to

accept the selection.

the menu.

Note

lets you to step

9

Page 18

Fluke 192/196/199

Users Manual

Hiding Key Labels and Menus

You can hide a menu or key label at any time:

Hide any key label or menu.

To display menus or key labels, press one of the yellow

menu keys, e.g. the

SCOPE key.

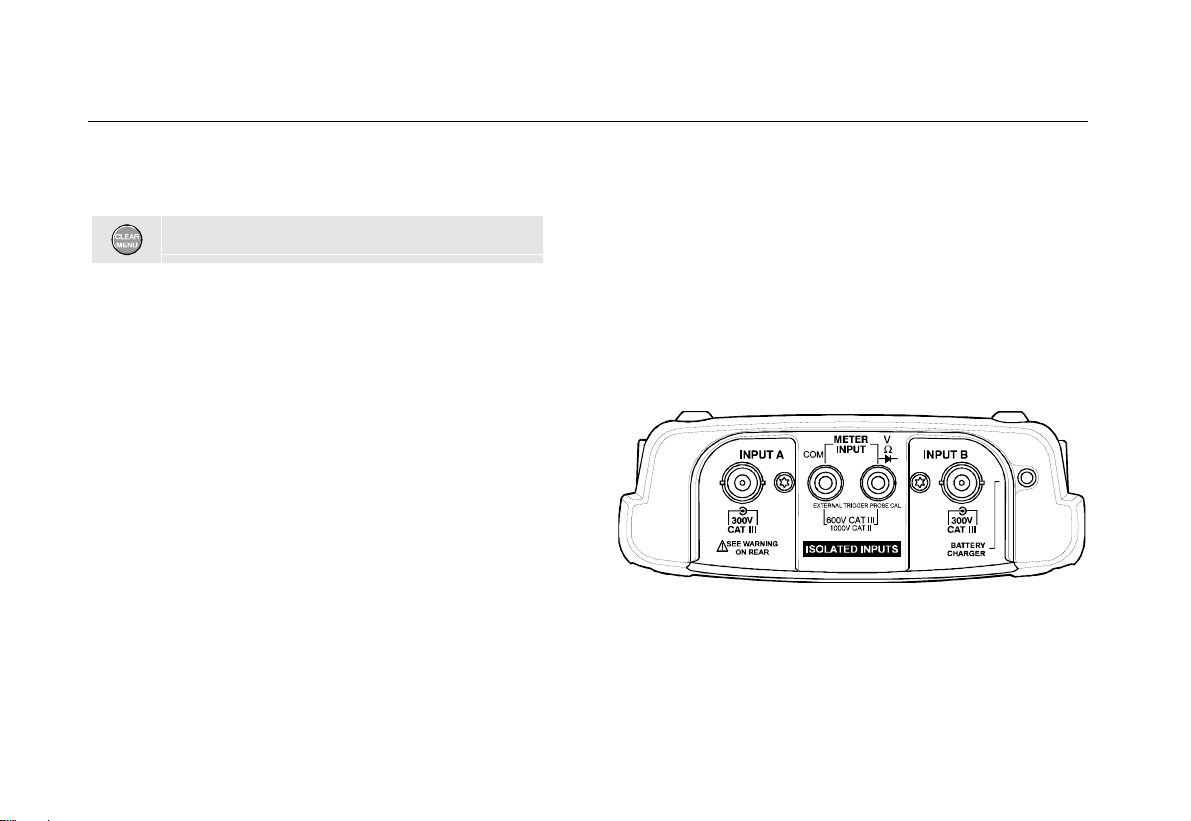

Input Connections

Look at the top of the test tool. The test t ool has f our

signal inputs: two safety BNC jack inputs (red input A and

gray input B) and two safety 4-m m banana jack inputs

(red and black). Use the two BNC jack inputs for scope

measurements, and t he t wo banana jack inputs for m et er

measurements.

Isolated input architectur e allows independent floating

measurements with each input.

Figure 5. Measurem ent Connect i ons

10

Page 19

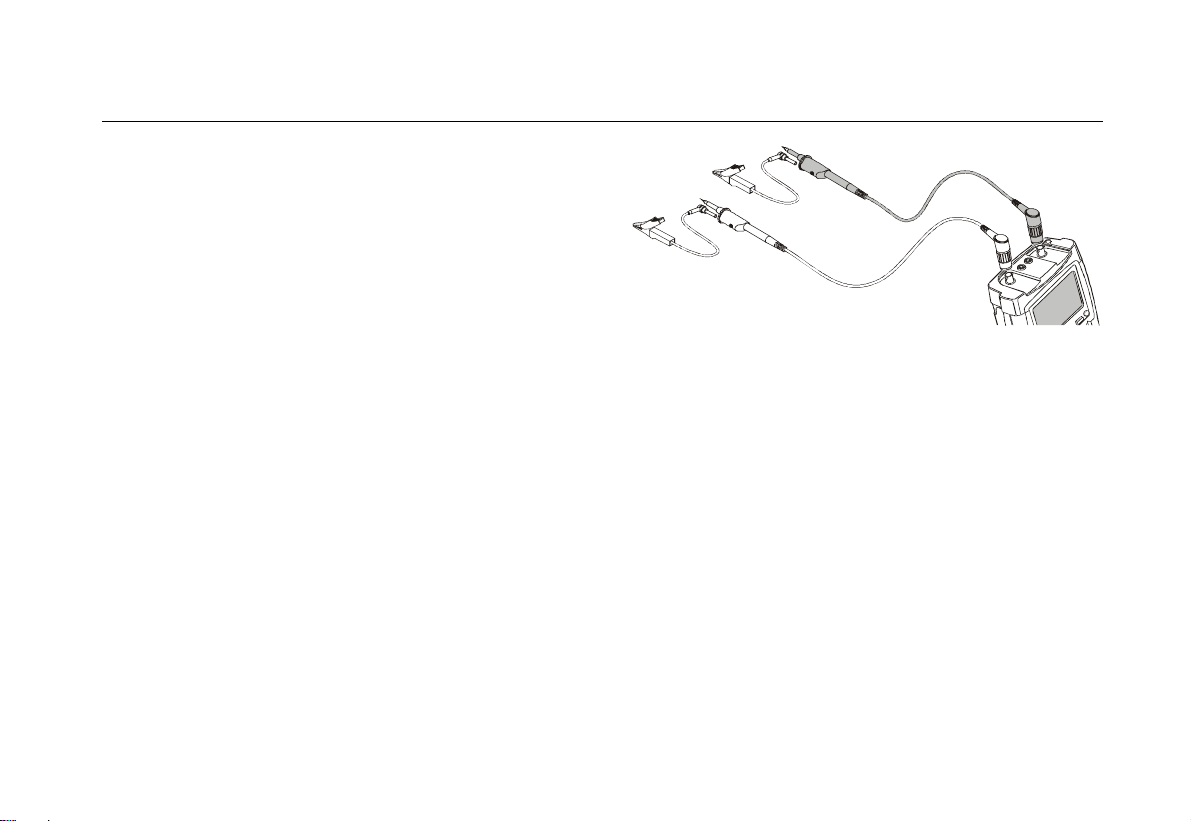

Making Scope Connections

To make dual input scope measurements, connect the

red voltage probe to input A, and t he gr ay voltage pr obe

to input B. Connect the short gr ound leads of each

voltage probe to its own ref er ence pot ential. (See Figure

6.)

Using The Scope

Making Scope Connections

1

Note

To maximally benefit from having independently

isolated floating inputs and to avoid problems

caused by improper use, read Chapter 7: “ Tips”.

Figure 6. Scope Connections

11

Page 20

Fluke 192/196/199

Users Manual

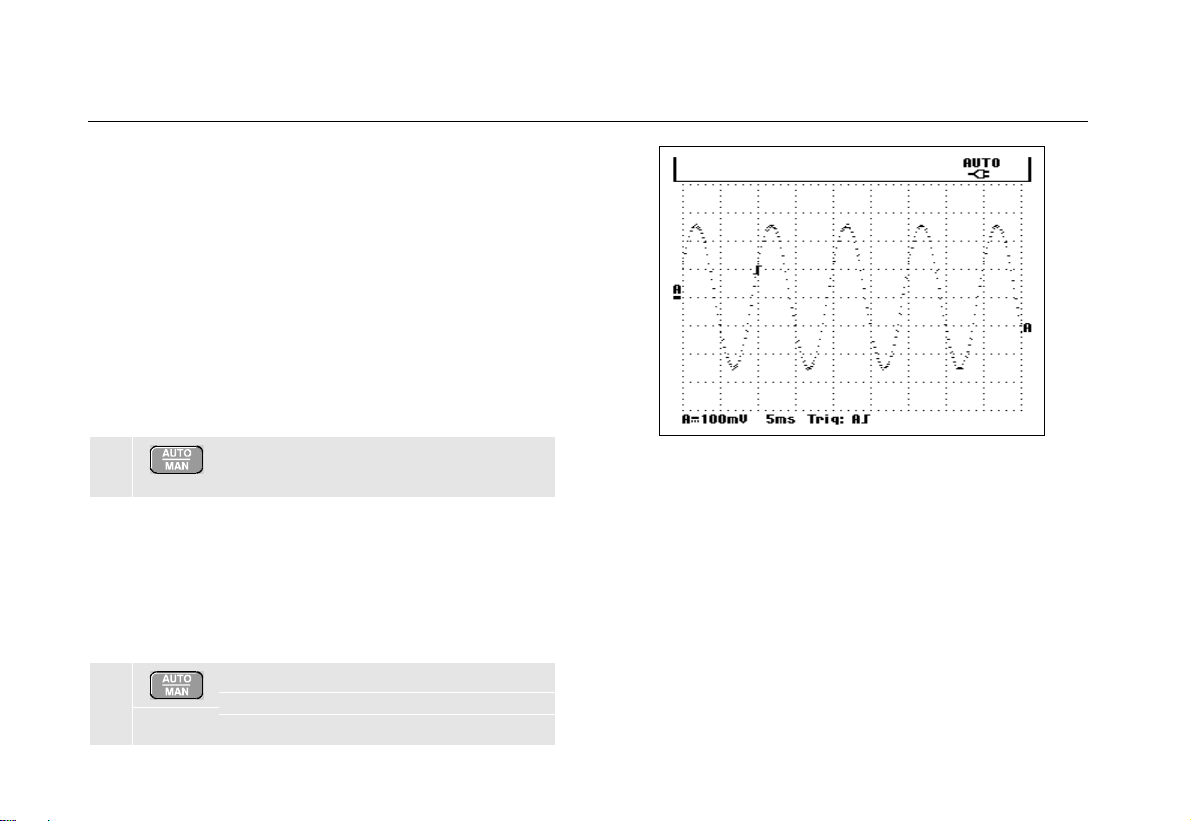

Displaying an Unknown Signal with

Connect-and-View™

The Connect-and-View feature lets the test tool display

complex, unknown signals automatically. This function

optimizes the position, range, t ime base, and triggering

and assures a stable display of virtually any waveform. If

the signal changes, the setup is automat ically adjusted to

maintain the best display result. This featur e is especially

useful for quickly checking several signals.

To enable the Connect-and-View feature, do the

following:

1 Perform an Auto Set . AUTO appears at

the top right of t he scr een.

The bottom line shows the range, the time base, and the

trigger informat ion.

The waveform identifier (A) is visible on the bottom r ight

side of the screen, as shown in Figure 7. The input A zero

) at the left side of t he scr een ident ifies the gr ound

icon (

-

level of the waveform.

Figure 7. The Screen After an Aut o Set

Use the light-gray

bottom of the keypad t o change t he view of t he wavef or m

manually.

RANGE, TIME and MOVE keys at the

2 Press a second time to select the

manual range again. MANUAL appears

at the top right of t he scr een.

12

Page 21

Using The Scope

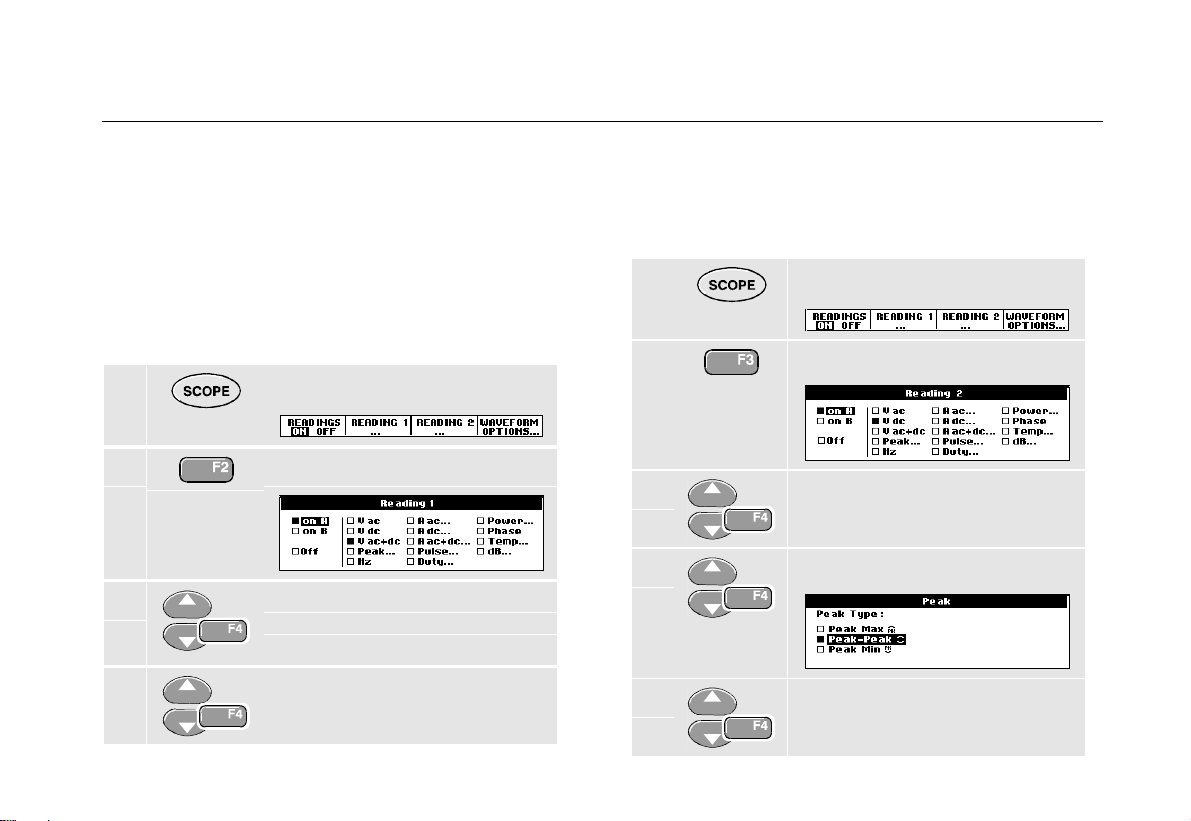

Making Automatic Scope Measurements

1

Making Automatic Scope Measurements

The test tool offer s a wide range of aut om at ic scope

measurements. You can display two numeric readings:

EADING 1 and READING 2. These readings are selectable

R

independently, and the measurement s can be done on

the input A or input B waveform

To choose a frequency measurement f or input A, do t he

following:

1 Display the SCOPE key labels.

2 Open the Reading 1 menu.

3 Select on A. Observe that the

highlight jumps to the present

measurement.

4 Select the Hz measurement.

Observe that the t op lef t of the screen displays the Hz

measurement. ( See Figure 8. )

To choose also a Peak-Peak measurement for Input B as

second reading, do the following:

1 Display the SCOPE key labels.

2

3

4

5

Open the Reading 2 menu.

Select on B. The highlight jumps

to the measurement s f ield.

Open the PEAK menu.

Select the Peak-Peak

measurement.

13

Page 22

Fluke 192/196/199

Users Manual

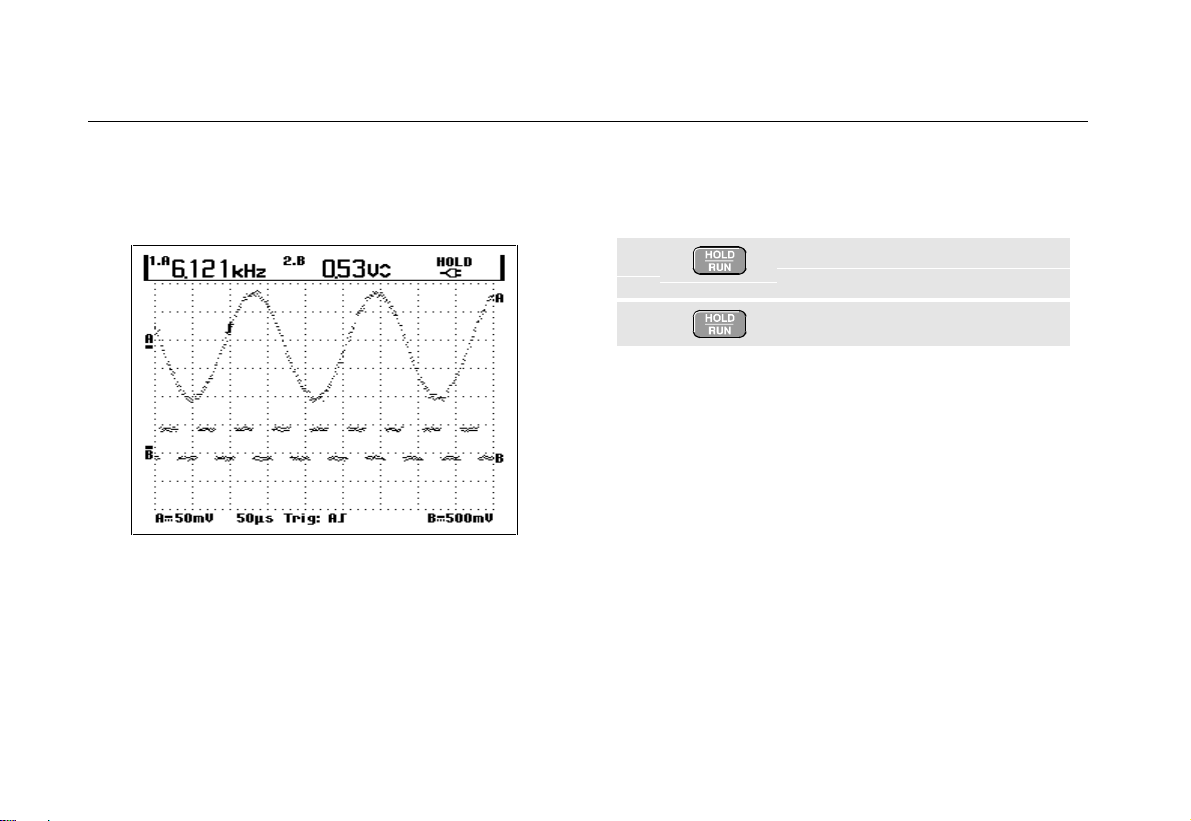

Figure 8 shows an example of the screen. Note that the

Peak-Peak reading for input B appears next to t he input A

frequency reading at the top of the screen.

Figure 8. Hz and V peak-peak as Scope Readings

Freezing the Screen

You can freeze the screen (all readings and waveforms)

at any time.

1 Freeze the screen. HOLD appears

at the right of t he r eading area.

2 Resume your measurement.

14

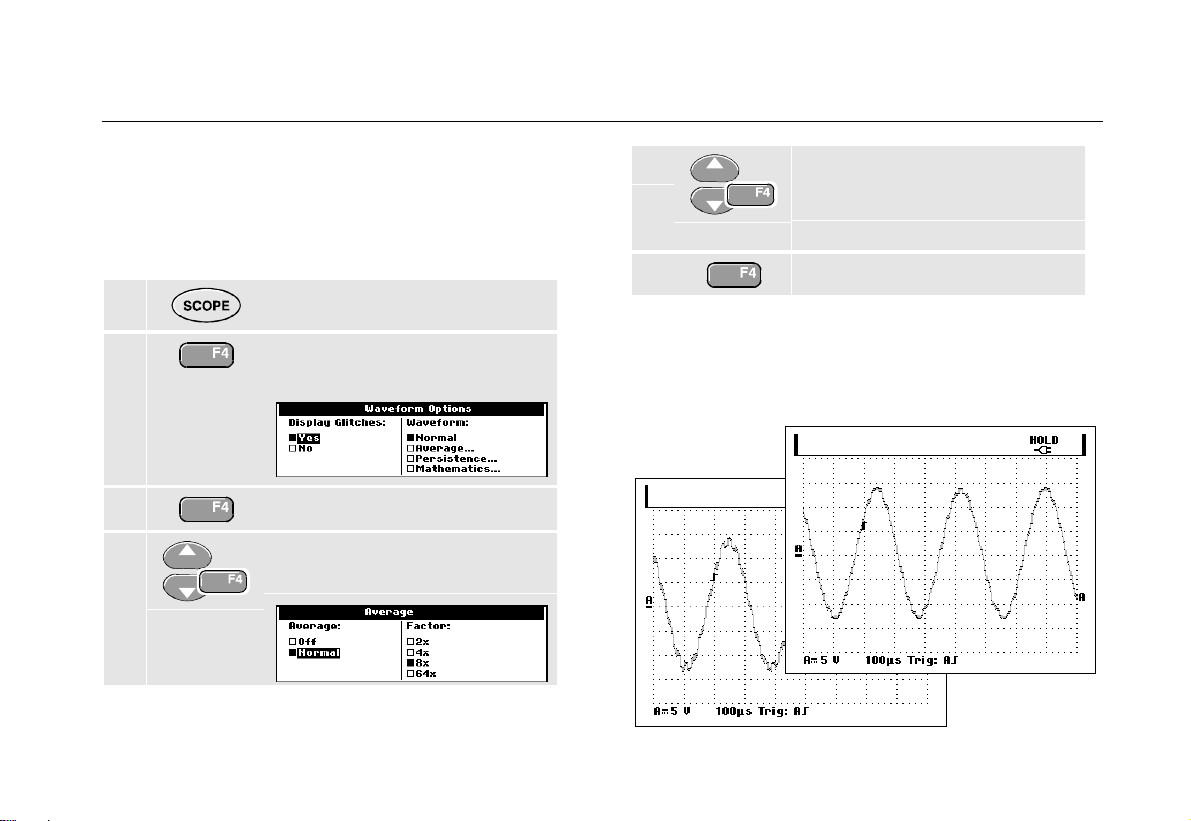

Page 23

Using The Scope

Using Average, Persistence and Glitch Capture

1

Using Average, Persistence and Glitch

Capture

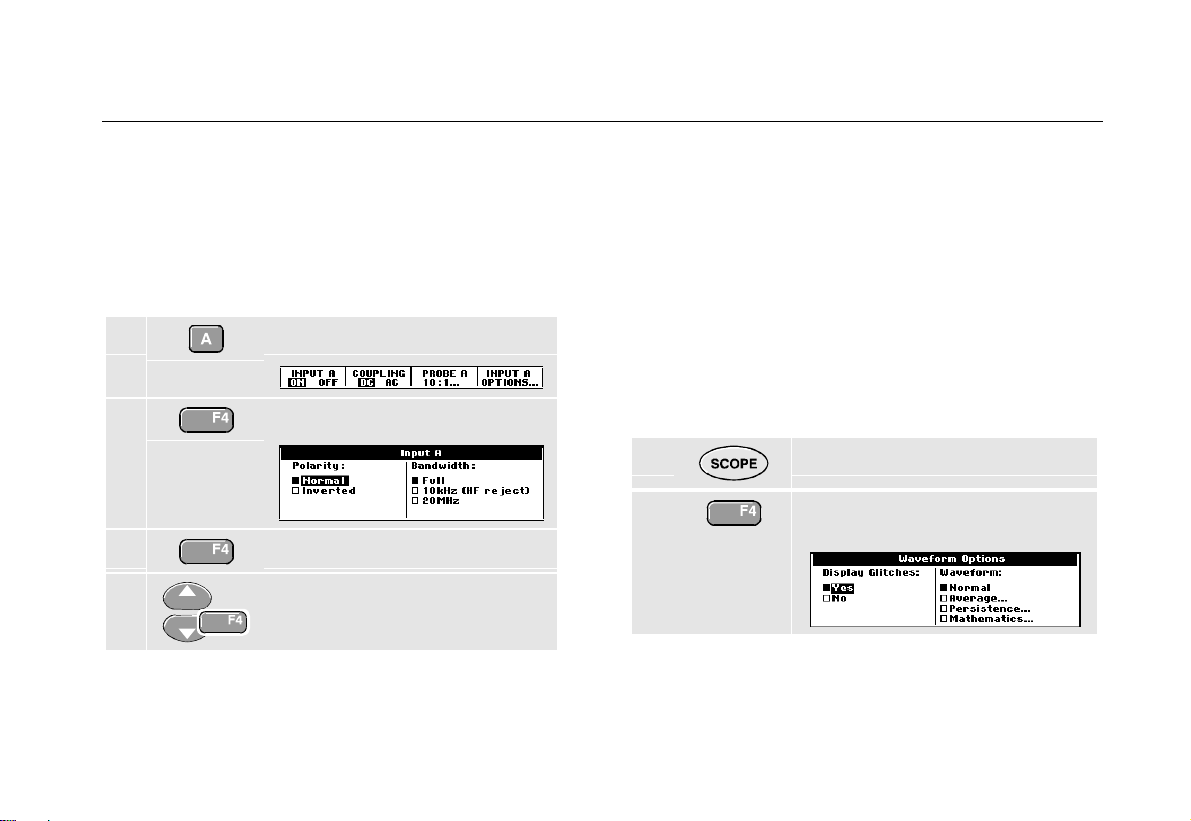

Using Average f or Smooth ing Waveforms

To smooth the waveform, do the following:

1 Display the SCOPE key labels.

2 Open the Waveform Options

menu.

3 Jump to Waveform:

4 Select Average... to open the

Average menu

5 Select Normal, jump to Factor:

and select Average 8x.This

averages the outcomes of 8

acquisitions.

6 Exit the menu.

You can use the average functions to suppress r andom

or uncorrelated noise in the waveform without loss of

bandwidth. Waveform samples with and without

smoothing are shown in Figure 9.

Figure 9. Smoothi ng a W avef or m

15

Page 24

Fluke 192/196/199

Users Manual

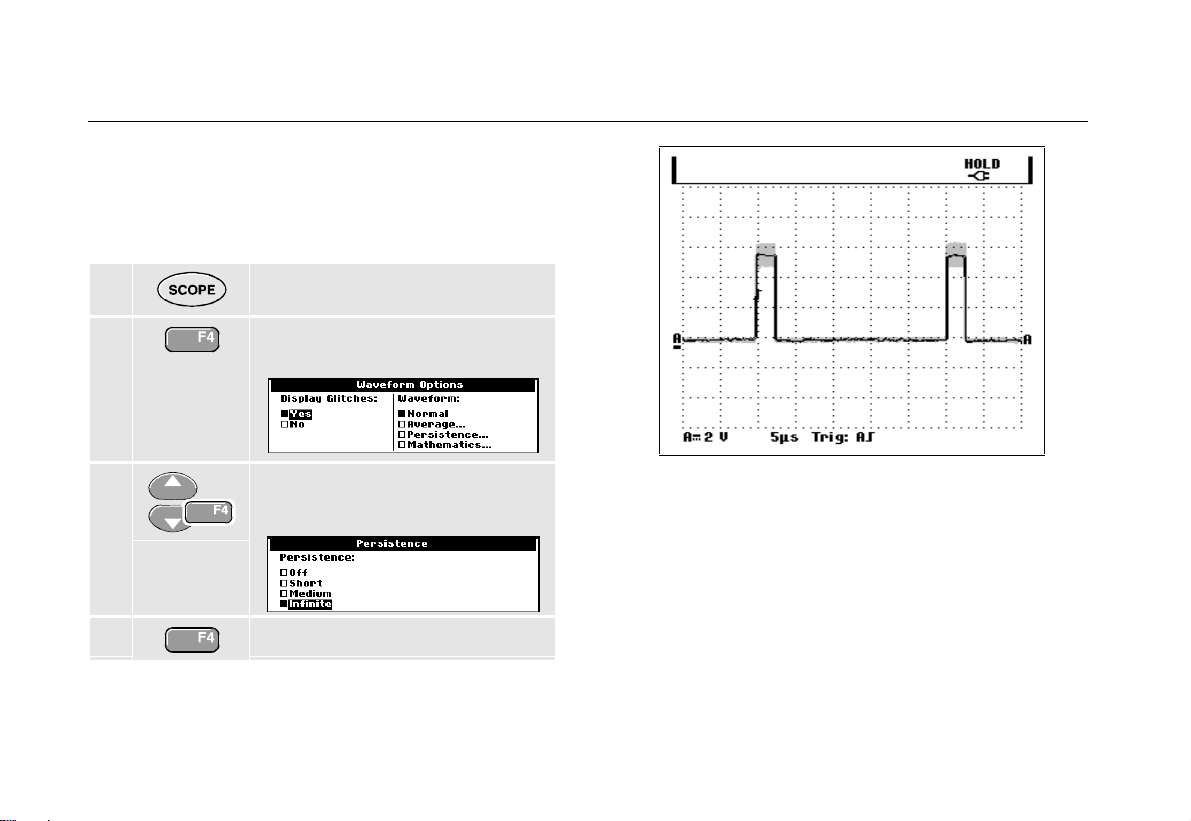

Using Persi st ence to Display Waveforms

When persistence is selected, the test t ool displays the

upper and lower boundaries of dynamic waveforms.

1 Display the SCOPE key labels.

2 Open the Waveform Options

menu.

3 Jump to Waveform: and Select

Persistence , t hen select Infinite.

4 Start monitoring the wavef or m .

16

Figure 10. Using Persi st ence t o Di spl ay W avef or m

Variations

Observe that the fluctuating portion of the wavefor m

appears in gray on the screen. See Figure 10.

You can use persistence to observe variations in time or

amplitude of input waveforms over t im e.

Page 25

Using The Scope

Using Average, Persistence and Glitch Capture

1

Displaying Gli t ches

To capture glitches on a waveform, do t he following:

1 Display the SCOPE key labels.

2 Open the Waveform Options

menu.

3 Select Di spl ay G litches: Yes

4 Exit the menu.

You can use this function to display events (glitches or

other asynchronous waveforms) of 50 ns ( nanoseconds)

or wider, or you can display HF modulated waveforms.

Suppressing High Frequency No ise

Switching Display Glit ches to No will suppress the high

frequency noise on a wavef or m . Averaging will suppress

the noise even more.

1 Display the SCOPE key labels.

2 Open the Waveform Options

menu.

3 Select Display G litches: No,

then select Average: to open t he

Average menu

4 Select Average: Normal, and

Factor : 8x

Tip

Glitch capture and average do not af f ect

bandwidth. Further noise suppression is possible

with bandwidth limiting filters. See Chapter 1:

“Working with Noisy Wav e forms”.

17

Page 26

Fluke 192/196/199

Users Manual

Acquiring Waveforms

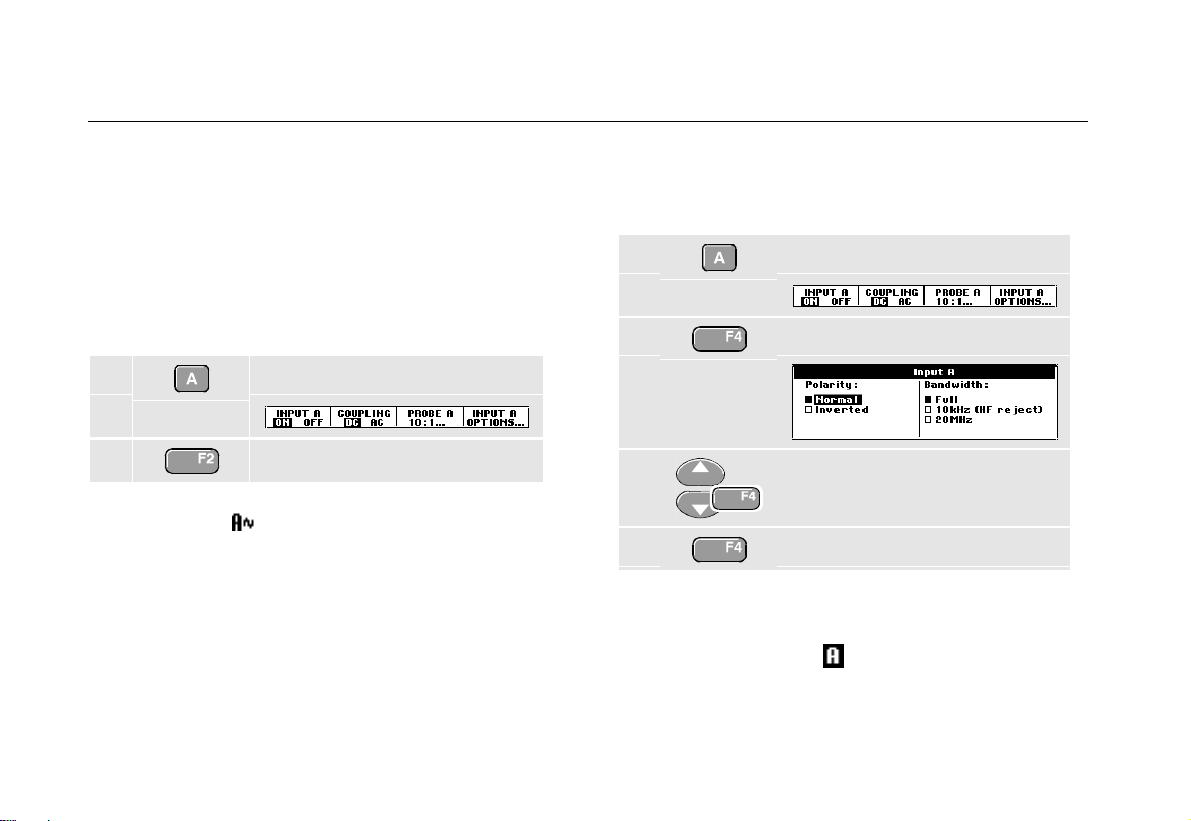

Selecting AC-Coupling

After a reset, the test tool is dc-coupled so that ac and dc

voltages appear on the screen.

Use ac-coupling when you wish to observe a small ac

signal that rides on a dc signal. To select ac-coupling, do

the following:

1 Display the INPUT A key labels.

2 Highlight AC.

Observe that the bot tom left of the screen displays the

ac-coupling icon:

.

Reversing th e P olarity of the Displayed

Waveform

To invert the input A waveform, do t he f ollowing:

1 Display the INPUT A key labels.

2 Open the Input A menu.

3 Select Inverted and accept

inverted waveform display.

4 Exit the menu.

For example, a negative-going waveform is displayed as

positive-going waveform which may provide a more

meaningful view. An inverted display is identified by an

inversed trace identifier (

) at the right of t he wavefor m.

18

Page 27

Using The Scope

Acquiring Waveforms

1

Working with Noisy Waveforms

To suppress high frequency noise on waveforms, you can

limit the working bandwidth to 10 kHz or 20 MHz. This

function smoothes the displayed waveform. For the same

reason, it improves tr iggering on the wavef or m .

To choose HF reject, do the following:

1 Display the INPUT A key labels.

2 Open the Input A menu.

3 Jump to Bandwidth.

4 Select 10kHz (HF reject) to

accept the bandwidth limitation.

Tip

To suppress noise without loss of bandwidth,

use the average function or turn off Display

Glitches.

Using Wavef orm Mathemati cs Functions

When adding (A+B), subtracting (A- B), or multiplying

(A*B) the input A and input B waveform, t he t est tool will

display the mathematical result waveform and t he input A

and input B waveforms.

A versus B provides a plot with input A on the vertical

axis and input B on the horizontal axis.

The Mathematics funct ions perf or m a point - t o- point

operation on waveforms A and B.

To use a Mathematics function, do t he following:

1 Display the SCOPE key labels.

2 Open the Waveform Options

menu.

19

Page 28

Fluke 192/196/199

Users Manual

3 Jump to Waveform: and Select

Mathematics... to open the

Mathematics menu.

4 Select Function: A+B, A-B, A*B

or A vs B.

5 Select a scale factor to fit the

mathematical result waveform onto

the display, and return.

The sensitivity range of the mathematical result is equal

to the sensitivity range of the least sensitive input divided

by the scale factor.

Analyzing Waveforms

You can use the analysis functions CURSOR, ZOOM and

REPLAY to perform detailed waveform analysis. These

functions are described in Chapter 4: “Us in g Cursors,

Zoom and Replay”.

20

Page 29

About this Chapter

This chapter provides a step-by-st ep intr oduction to the

multimeter funct ions of t he test tool (hereaft er called

“meter”). The introduction gives basic examples to show

how to use the menus and perform basic oper at ions.

Making Meter Connections

Use the two 4-mm safet y r ed ( ) and black (COM)

banana jack inputs for the Meter f unct ions.

(See Figure 11.)

Note

Typical use of the Meter test leads and

accessories is shown in Chapter 7.

Chapter 2

Using The Multimeter

Figure 11. Mete r Connect i ons

21

Page 30

Fluke 192/196/199

Users Manual

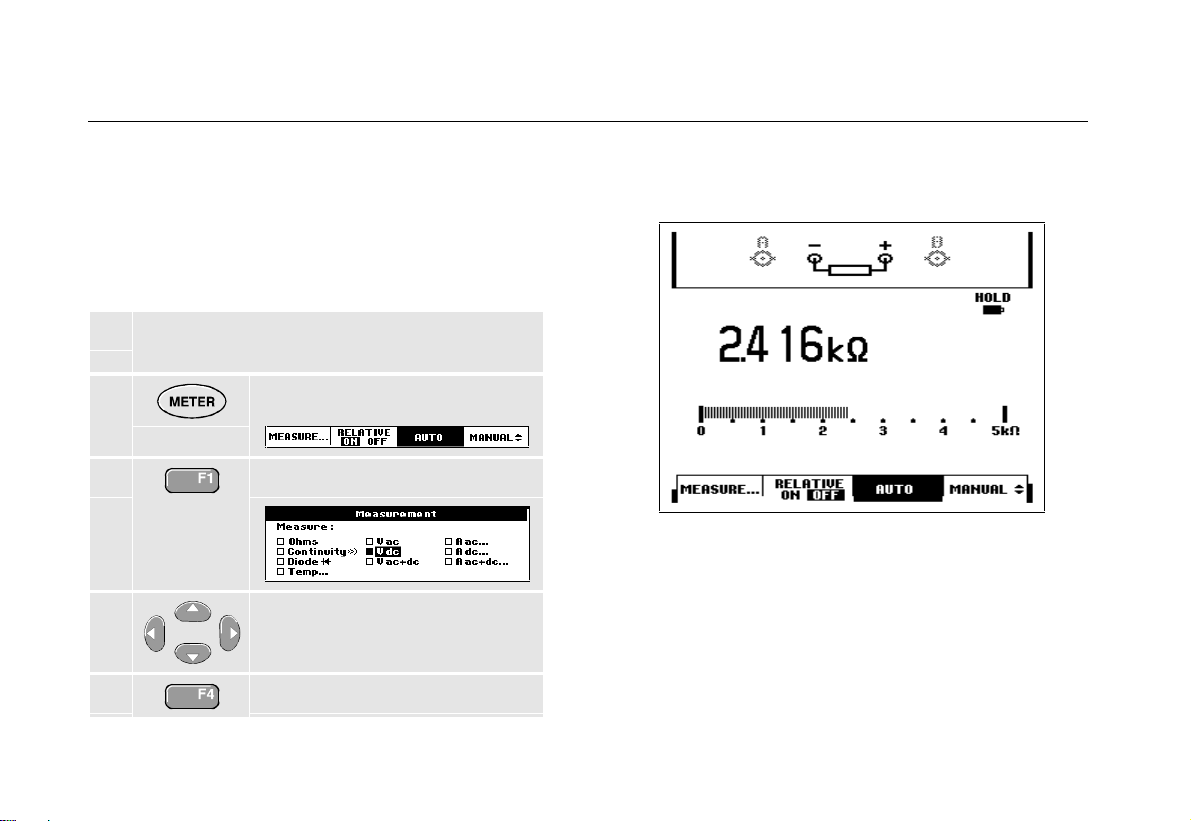

Making Multimeter Measurements

The screen displays the numeric readings of the

measurements on the m et er input.

Measuring Resistance Valu es

To measure a resistance, do the f ollowing:

1 Connect the red and black test leads from t he

4-mm banana jack inputs to the resistor .

The resistor value is displayed in ohms. Observe also

that the bargraph is displayed. ( See Figure 12. )

22

2

Display the METER key labels.

3

Open the Measurement menu.

Figure 12. Resistor Val ue Readings

4

Highlight Ohms.

5

Select Ohms measurement .

Page 31

Making a Cu rrent Measurement

You can measure current in both Scope mode and M eter

mode. Scope mode has the advantage of t wo wavefor m s

being displayed while you perform measurements.

Meter mode has the advant age of high m easur em ent

resolution.

The next example explains a typical current

measurement in Meter m ode.

Using The Multim et er

Making Multimeter Measur em ent s

Figure 13. Measurem ent Set up

2

Warning

Carefully read the instructions about t he

current probe you are usi ng.

To set up the test tool, do t he f ollowing:

1 Connect a current probe (e. g. i400, optional)

from the 4-m m banana jack output s to the

conductor to be measured.

Ensure that the red and black probe connect or s

correspond to the red and black banana jack

inputs. (See Figure 13.)

2

Display the METER key labels.

3 Open the Measurement menu.

4

5

Highlight A ac....

Open the Current Pr obe

submenu.

23

Page 32

Fluke 192/196/199

Users Manual

6

7

Now, you will see a screen like in Figur e 14.

Observe the sensitivity of the

current probe. Highlight the

corresponding sensitivity in the

menu, e.g. 10 mV/ A.

Accept the current measur em ent.

Figure 14. Ampere Measur em ent Readings

24

Page 33

Using The Multim et er

Freezing the Readings

2

Freezing the Readings

You can freeze the displayed readings at any time.

1 Freeze the screen. HOLD appears

at the top right of t he r eading

area.

2 Resume your measurement.

You can use this function to hold accurate readings for

later examination.

Note

For saving screens into memory, see Chapter 6.

Selecting Auto/Manual Ranges

To activate manual ranging, do the f ollowing during any

Meter measurem ent :

1 Activate manual ranging.

2 Increase or decrease the r ange.

Observe how the bargraph sensitivity changes.

Use manual ranging to set a fixed bargraph sensitivity

and decimal point.

3 Choose auto ranging again.

When in auto ranging, the bargraph sensit ivity and

decimal point are automatically adjusted while checking

different signals.

25

Page 34

Fluke 192/196/199

Users Manual

Making Relative Measurements

A relative measurement displays the present

measurement result r elative t o a def ined reference value.

The following example shows how to perform a relative

voltage measurement. Fir st obtain a reference value:

1 Display the METER key labels.

2 Measure a voltage to be used as

reference value.

3 Set RELATIVE to ON. (ON is

highlighted.)

This stores the reference value as ref er ence for

subsequent measurements. The st or ed r ef er ence value is

displayed in small digits at the bottom right side of the

screen after the word

4 Measure the voltage to be

REFERENCE.

compared to the ref er ence.

Observe that the m ain r eading is displayed as variations

from the ref er ence value. The act ual reading with its

bargraph is displayed beneath these readings. (See

Figure 15.)

Figure 15. Making a Rel at ive Measurement

You can use this feature when, for exam ple, you need to

monitor input activity (voltage, r esistance, temperature) in

relation to a known good value.

26

Page 35

About this Chapter

This chapter provides a step-by-st ep intr oduction to the

recorder functions of t he test tool. The introduction gives

examples to show how to use the menus and perfor m

basic operations.

Opening the Recorder Main Menu

First choose a measurement in scope or m et er m ode.

Now you can choose the recorder functions fr om t he

recorder main menu. To open t he m ain m enu, do t he

following:

Chapter 3

Using The Recorder Functions

1 Open the RECORDER main menu.

(See Figure 16.)

Figure 16. Recorder Main Menu

27

Page 36

Fluke 192/196/199

Users Manual

Plotting Measurements Over Time

(TrendPlot™)

Use the TrendPlot function to plot a gr aph of Scope or

Meter measurements as function of time.

Note

Because the navigations for the dual input

TrendPlot (Scope) and the single input TrendPlot

(Meter) ar e identical, only Tr endPlot ( Scope) is

explained in the next sections.

Starting a TrendPlot Function

To start plotting a graph of t he r eading over t ime, do the

following:

1 Apply a signal to the red BNC input A and turn

on Reading 1 in scope mode

2 Open the RECORDER main menu.

3 Highlight Trend Plot (Scope).

4 Start the TrendPlot r ecor ding.

The test tool continuously records the digital readings of

the input A measurements and displays these as a graph.

The TrendPlot graph rolls from right t o lef t like a paper

chart recorder.

Observe that the r ecor ded time from start appears at the

bottom of the scr een. The present reading appears on

top of the screen. ( See Figure 17. )

Note

When simultaneously TrendPlotting two

readings, the screen area is split into two

sections of four divisions each.

28

Page 37

Using The Recorder Functions

Plotting Measurements Ov er Time ( Tr endPlot™)

Displaying Recorded Dat a

When in normal view (NORMAL), only the nine most

recently recorded divisions are displayed on screen. All

previous recordings are stored in memor y.

VIEW ALL shows all data in memory:

7 Display an overview of the full

waveform.

Press repeatedly to toggle between normal view

NORMAL) and overview (VIEW ALL)

(

3

Figure 17. TrendPlot Readi ng

When the Scope is in automatic mode, aut omatic vertical

scaling is used to fit the TrendPlot graph on the scr een.

5 Set RECORDER to STOP to freeze

the recorder funct ion.

6 Set RECORDER to RUN to continue.

When the recorder mem or y is full, an aut omatic

compression algorithm is used to compress all samples

into half of the memory without loss of t r ansient s. The

other half of the r ecor der m em or y is f r ee again t o

continue recording.

29

Page 38

Fluke 192/196/199

Users Manual

Changing the Recorder Options

At the right bottom of t he display you can choose to

display the time elapsed from start and the actual time of

the day.

To change the time reference, pr oceed from step 6 as

follows:

7 Open the Recorder Options

menu.

8 Select Time of Day and jump to

the next field.

Now the recorded time and the curr ent time appear at the

bottom of the scr een.

The options Reading 1 and Reading 2 allow you to

select the scope readings to be recorded. ( Or one meter

measurement when in TrendPlot met er m ode. )

To continue without making further changes:

9 Close.

Turning Off the TrendPlot Display

10 Exit the recorder funct ion.

30

Page 39

Recording Scope Waveforms In Deep Memory ( Scope Record™)

Recording Scope Waveforms In Deep

Memory (Scope Record™)

The SCOPE RECORD function is a roll mode that logs one or

two long waveforms. This function can be used to m onit or

waveforms like motion control signals or the power-on

event of an Uninterruptable Power Supply (UPS). During

recording, fast tr ansients ar e captured. Because of the

deep memory, recor ding can be done for more than one

day. This function is similar to the roll mode in many

DSO’s but has deeper memory and bett er f unctionality.

Starting a Scope Record Function

1 Apply a signal to the red BNC input A.

Using The Recorder Functions

3

Figure 18. Recording Wavef or m s

2 From the Recorder main m enu,

highlight Scope Record.

3 Start the recor ding.

The waveform moves across the screen f r om r ight t o left

like a normal chart recorder. ( See Figure 18. )

Observe that the top of the screen displays the following:

• Time from start at the top of the scr een.

• The status at the bottom of the screen which

includes the time/div setting as well as the total

timespan that fits the memory.

Note

For accurate recordings it is advised to let the

instrument first warm up for five minutes.

31

Page 40

Fluke 192/196/199

Users Manual

Displaying Recorded Dat a

In Normal view, the samples that roll off t he scr een ar e

stored in deep memory. W hen t he m em or y is f ull,

recording continues by shifting the data in mem or y and

deleting the first samples out of m em or y.

In View All mode, the complete memory cont ent s ar e

displayed on the screen.

4 Press to toggle between VIEW ALL

(overview of all recorded

samples) and NORMAL view.

You can analyze the recorded waveforms using the

Cursors and Zoom functions. See Chapter 4: “Using

Replay, Zoom and Cursors”.

Using ScopeRecord in Single Sweep Mode

Use the recorder Single Sw eep function to automatically

stop recording when the deep memory is f ull.

Continue from step 3 of t he pr evious section:

4 Open the Recorder opti ons

menu.

5

6 Select Si ngl e Sw eep and accept

Jump to the Mode field.

(2x)

the recorder options.

32

Page 41

Recording Scope Waveforms In Deep Memory ( Scope Record™)

Using Scope Record in Triggered Single Sweep

Mode

To record, for exam ple, the power-on event of an

Uninterruptable Power Supply (UPS) it might be useful to

start recording on an exter nal t r igger signal. The next

example explains a typical triggered Single Sweep

recording.

To set up the test tool, cont inue f r om st ep 3 of t he

previous section:

4 Apply an Uninterruptable Power Supply signal

to the red BNC input A. Apply a start signal to

the red and black external trigger banana

inputs. (See Figure 19.)

5 Open the Recorder Options

menu.

6 Jump to Display Glitches.

7 Select Yes, then jump to Mode.

Using The Recorder Functions

3

Figure 19. Scope Record Single Sw eep

8 Select on EXT to open the

Start Single Sweep on Ext.

menu.

9 Select positive slope and jump to

Level.

10 Select 1. 2 V and accept all

recorder options.

33

Page 42

Fluke 192/196/199

Users Manual

The test tool starts r ecor ding aft er r eceiving the st ar t

signal. All samples are continuously saved in deep

memory until the mem or y is f ull. The last nine recor ded

divisions are displayed on the screen. Use View All to

display the full memory contents.

Note

To learn more about the Single Shot tr igger

function, see Chapter 5 “Tr iggering on

Waveforms”.

Figure 20. Trigger e d Si ngl e Sweep Recording

Analyzing a TrendPlot or Scope Record

From a Scope TrendPlot or Scope Record you can use

the analysis funct ions CURSO RS and ZO OM to perfo r m

detailed waveform analysis. These functions are

described in Chapter 4: “Using Replay, Zoom and

Cursors”.

34

Page 43

Chapter 4

Using Replay, Zoom and Cursors

About this Chapter

This chapter covers t he c apabilit ies of the analysis

functions Cursor, Zoom, and Replay. These functions

can be used with one or more of the prim ar y f unct ions

Scope, TrendPlot or Scope Record.

It is possible to combine two or three analysis functions.

A typical application using these functions follows:

• First replay the last screens to find t he scr een of

special int e rest.

• Then zoom in on the signal event.

• Finally, make measurements using the cursors.

Replaying the 100 Most Recent Scope

Screens

When you are in scope mode, the test t ool aut om at ically

stores the 100 most r ecent scr eens. When you pr ess the

HOLD key or the REPLAY key, the memory cont ent s ar e

frozen. Use the funct ions in the

in time” by stepping through the st or ed scr eens t o f ind t he

screen of your interest. This f eat ur e let s you capt ur e and

view signals even if you did not press

REPLAY menu to “ go back

HOLD.

35

Page 44

Fluke 192/196/199

Users Manual

Replaying Step-by-Step

To step through the last scope screens, do the following:

1 From scope mode, open the

REPLAY menu.

Observe that the trace is frozen

and that REPLAY appear s at t he

top of the screen (see Figur e 21) .

2 Step through the previous

screens.

Figure 21. Replaying a W avef or m

3 Step through the next screens.

Observe that the bottom of the wavefor m ar ea displays

the replay bar with a screen number and r elated t im e

stamp:

36

The replay bar represents all 100 stored screens in

memory. The

displayed on the screen (in this example:

icon represents the picture being

SCREEN -84). If

the bar is partly white, the m em or y is not com pletely f illed

with 100 screens.

From this point you can use the zoom and cur sor

functions to study the signal in more detail.

Page 45

Using Replay, Zoom and Cursors

Replaying the 100 Most Recent Scope Screens

4

Replaying Continuously

You can also replay the stored screens continuously, like

playing a video tape.

To replay continuously, do the following:

1 From Scope mode, open the

REPLAY menu.

Observe that the trace is frozen

and REPLAY appears at t he t op of

the screen.

2 Continuously replay the stored

screens in ascending order.

Wait until the screen with the signal event of interest

appears.

3 Stop the continuous replay.

Turning Off the Replay Function

4 Turn off REPLAY.

Capturin g 100 Intermit tents Auto mat ically

When you use the test tool in trigger ed m ode, 100

triggered screens are captur ed. This way you could use

Pulse Triggering to trigger and capture 100 int er m it t ent

glitches or you could use External Triggering to capture

100 UPS startups.

By combining the trigger possibilities with the capability of

capturing 100 screens for later r eplay, you can leave t he

test tool unattended t o capt ur e inter mittent signal

anomalies.

For triggering, see Chapter 5: “Tr igger ing on Wavef or m s ”.

37

Page 46

Fluke 192/196/199

Users Manual

Zooming in on a Waveform

To obtain a more detailed view of a waveform, you can

zoom in on a waveform using the

To zoom in on a waveform, do the f ollowing:

1 Display the ZOOM key labels.

Observe that the trace is frozen,

HOLD appears at the top of the

screen, and the waveform is

magnified.

ZOOM function.

Figure 22. Zooming in a Waveform

2 Enlarge (decrease the time/div)

or shrink (increase the time/div)

the waveform.

3 Scroll. A position bar displays the

position of the zoomed part in

relation to the total waveform.

Tip

Even when the key labels are not displayed at

the bottom of t he scr een, you can still use the

arrow keys to zoom in and out.

38

Observe that the bottom of the wavefor m ar ea displays

the zoom ratio, position bar, and time/div (see Figure 22).

The zoom range depends on the amount of dat a sam ples

stored in memory.

From this point you can use the cursor f unction for further

measurements on the wavefor m .

Page 47

Using Replay, Zoom and Cursors

Zooming in on a Waveform

4

Displaying the Zoomed Waveform

The VIEW ALL f eat ur e is usef ul when you quickly need to

see the complete waveform and t hen r et ur n t o t he

zoomed part.

4 Display the complete waveform.

Press repeatedly to toggle between the zoomed

part of the waveform and the complete waveform.

Turning Off the Zoom Function

5 Turn off the ZOOM function.

39

Page 48

Fluke 192/196/199

Users Manual

Making Cursor Measurements

Cursors allow you to make precise digital measurements

on waveforms. This can be done on live waveforms,

recorded waveforms, and on saved wavefor m s.

Using Horizontal Cursors on a W avef orm

To use the cursors for a voltage m easurement, do the

following:

1 From scope mode, display the

cursor key labels.

2 Press to highlight . Observe

that two horizontal cursors are

displayed.

3 Highlight the upper cursor.

4 Move the upper cursor t o t he

desired position on the screen.

5 Highlight the lower cursor.

6 Move the lower cursor to the

desired position on the screen.

Note

Even when the key labels are not displayed at

the bottom of t he s cr een, you still can use the

arrow keys. This allows full control of both

cursors while having full screen view.

Figure 23. Voltage M easur em ent with Cursors

The screen shows the voltage difference between t he t wo

cursors and the voltage at t he cur sor s. ( See Figure 23. )

Use horizontal cursors to measure the amplitude, high or

low value, or overshoot of a waveform.

40

Page 49

Using Vertical Cursors o n a Waveform

To use the cursors for a t ime m easurement, do the

following:

1 From scope mode, display the

cursor key labels.

2 Press to highlight . Observe

that two vertical cursors are

displayed. Markers (—) identify

the point where the cursors cross

the waveform.

Using Replay, Zoom and Cursors

Making Cursor Measurements

Figure 24. Time Measurement wi t h Cursor s

4

3 If necessary, choose the t r ace:

TRACE A ,B, or M (Mathem at ics).

4 Highlight the left cursor.

5 Move the left cursor to the

desired position on the

waveform.

6 Highlight the right cursor.

7 Move the right cursor to the

desired position on the

waveform.

The screen shows the time difference bet ween t he

cursors and the voltage differ ence bet ween t he t wo

markers. (See Figure 24. )

8 Turn off the cursor s.

41

Page 50

Fluke 192/196/199

Users Manual

Using Cursors on a A+B, A-B or A*B Waveform

Cursor measurements on a A*B wavefor m give a reading

in Watts if input A measures (m illi)Volts and input B

measur es (milli)Amp eres.

For other cursor m easur em ent s on a A+B, A- B or A*B

waveform no r eading will be available if the input A and

input B measurement unit are dif f er ent .

Making Ri se Time Measurements

To measure rise time, do t he f ollowing:

1 From scope mode, display the

cursor key labels.

2 Press to highlight (rise time).

Observe that two horizontal

cursors are displayed.

3 If only one trace is displayed,

select MANUAL or AUTO (this

automatically does steps 4 to 6).

For multiple traces select the

required trace A, B, or M ( if a

math function is active).

4 Move the upper cursor t o 100%

of the trace height. A mar k er is

shown at 90%.

5 Highlight the other cursor.

6 Move the lower cursor to 0% of

the trace height. A mar ker is

shown at 10%.

The reading shows the risetime from 10% - 90% of t he

trace amplitude.

Figure 25. Riseti m e M easur em ent

42

Page 51

Chapter 5

Triggering on Waveforms

About this Chapter

This chapter provides an introduction to t he t r igger

functions of the test t ool. Tr igger ing tells the t est tool

when to begin displaying the waveform. You can use

fully automatic triggering, t ake cont r ol of one or m or e

main trigger functions (sem i- aut om at ic t r iggering) , or you

can use dedicated trigger functions to capt ur e special

waveforms.

Following are some typical trigger applications:

• Use the Connect-and-View™ function to have full

automatic triggering and instant display of virt ually

any waveform.

• If the signal is unstable or has a very low frequency,

you can control the trigger level, slope, and t r igger

delay for a better view of the signal. ( See next

section.)

• For dedicated applications, use one of the four

manual trigger functions:

• Edge triggering

• External triggering

• Video triggering

• Pulse Width triggering

43

Page 52

Fluke 192/196/199

Users Manual

Setting Trigger Level and Slope

The Connect-and-View™ function enables hands-off

triggering to display complex unknown signals.

When your test tool is in manual range, do t he following:

Perform an auto set . AUTO appears

at the top right of t he scr een.

Automatic triggering assures a stable display of virtually

any signal.

From this point, you can take over t he basic t r igger

controls such as level, slope and delay. To optimize

trigger level and slope manually, do the following:

Figure 26. Screen with all Tri gger I nf or m ation

1 Display the TRIGGER key labels.

2 Trigger on either positive slope or

negative slope of the chosen

waveform.

3 Enable the arrow keys for manual

trigger level adjustment.

44

4 Adjust the trigger level.

Observe the trigger icon that indicates the trigger

position, trigger level, and slope.

At the bottom of t he scr een t he trigger parameters ar e

displayed. (See Figure 26.) For example,

means that input A is used as the tr igger sour ce with a

positive slope.

When no trigger is found, t he t r igger par ameters appear

in gray.

Page 53

Using Trigger Delay or Pre-trigger

You can begin to display the waveform some time befor e

or after the t r igger point has been det ected. Initially, you

have 2 divisions of pre-trigger view (negative delay).

To set the trigger delay, do t he f ollowing:

5 Hold down to adjust the trigger

delay.

Triggering on Wavef or m s

Using Trigger Delay or Pre-trigger

5

Observe that t he t r igger icon on the screen moves to

show the new trigger position. When the t r igger posit ion

moves left off of the screen, the trigger icon changes into

to indicate that you have selected a trigger delay.

Moving the trigger icon to the r ight on t he display gives

you a pre-trigger view.

In case of a trigger delay, t he st at us at the bottom of t he

screen will change. For exam ple:

This means that input A is used as the trigger sour ce with

a positive slope. The 500.0 ms indicates the (positive)

delay between trigger point and waveform display.

When no trigger is found, t he t r igger par ameters appear

in gray.

Figure 27. Trigger Del ay or Pr e- trigger View

Figure 27 shows an example of a trigger delay of 500 ms

(top) and an example of pre- t r igger view of 8 divisions

(bottom).

45

Page 54

Fluke 192/196/199

Users Manual

Automatic Trigger Options

In the trigger menu, settings for autom at ic t r iggering can

be changed as follows. (See also Chapter 1: “Displaying

an Unknown Signal with Connect-and-View”)

1 Display the TRIGGER key labels.

Note

The

TRIGGER key labels can differ depending on

the latest trigger f unct ion used.

2 Open the Trigger Options menu.

3 Open the Automati c Tr i gger

menu.

If the frequency r ange of the automatic triggering is set to

> 15 Hz, the Connect-and-View™ function responds

more quickly. The response is quicker because the test

tool is instructed not to analyze low frequency signal

components. However, when you measure f r equencies

lower than 15 Hz, the test tool must be inst r uct ed t o

analyze low frequency components for autom at ic

triggering:

4 Select > 1 HZ and r et ur n to the

measurement screen.

46

Page 55

Triggering on Wavef or m s

Triggering on Edges

5

Triggering on Edges

If the signal is instable or has a very low frequency, use

edge triggering to obtain full manual trigger cont r ol.

To trigger on rising edges of the input A waveform , do the

following:

1 Display the TRIGGER key labels.

2 Open the Trigger Options menu.

3 Open the Trigger on Edge menu.

When Free Run is selected, the test t ool updates t he

screen even if there are no tr iggers. A t r ace always

appears on the screen.

When On Trigger is selected, t he t est t ool needs a

trigger to display a waveform. Use t his mode if you want

to update the screen only when valid triggers occur.

When Single Shot is selected, the test tool waits for a

trigger. After r eceiving a tr igger, the waveform is

displayed and the instruments is set to HOLD.

In most cases it is advised to use the Free Run m ode:

4 Select Fr ee Run, jump to Noise

reject Filter.

5 Set Noise rej ect Fi lter to Off.

Observe that the key labels at t he bot tom of the screen

have adapted to allow further selection of specific edge

trigger settings:

47

Page 56

Fluke 192/196/199

Users Manual

Triggering on Noisy Waveforms

To reduce jitter on the screen when tr iggering on noisy

waveforms, you can use a noise rejection filter. Continue

from step 3 of t he pr evious example as f ollows:

4 Select On Trigger, jump to Noise

reject Filter.

5 Set Noise rej ect Fi lter to On.

Observe that the trigger gap has increased. This is

indicated by a taller trigger icon

.

Making a Single Acquisition

To catch single events, you can perform a si ngle shot

acquisition (one-time screen update). To set up t he test

tool for a single shot of the input A waveform, continue

from step 3 again:

4 Select Single Shot.

5 Accept the settings.

The word WAITING appears at the t op of t he scr een

indicating that the test t ool is waiting for a t r igger. As

soon as the test tool receives a tr igger, t he wavef or m is

displayed and the instrument is set to hold. This is

indicated by the word

HOLD at top of the scr een.

48

Page 57

The test tool will now have a sc r een lik e Figur e 28.

6 Arm the test tool f or a new single

shot.

Tip

The test tool stores all single shots in the replay

memory. Use the Replay funct ion to look at all

the stored single shots.

Triggering on Wavef or m s

Triggering on Edges

Figure 28. Making a Si ngle Shot Measurement

5

49

Page 58

Fluke 192/196/199

Users Manual

Triggering on External Waveforms

Use external triggering when you want to display

waveforms on inputs A and B while triggering on a third

signal. You can choose external triggering with automatic

triggering or with edge triggering.

1 Supply a signal to the red and black 4-mm

banana jack inputs. See Figure 29.

In this example you continue from t he Tr igger on Edges

example. To choose the external signal as trigger source,

continue as follows:

2 Display the TRIGGER (On Edges)

key labels.

3 Select Ext (external) edge tr igger.

Observe that the key labels at t he bot t om of the screen

have been adapted to allow selection of two different

external trigger levels: 0.12 V and 1.2 V:

50

Figure 29. External Tr iggering

4 Select 1.2V under the Ext LEVEL

label.

From this point the tr igger level is fixed and is compatible

with logic signals.

Page 59

Triggering on Video Signals

To trigger on a video signal, first select the st andar d of

the video signal you are going to measure:

1 Apply a video signal to the red input A.

2 Display the TRIGGER key labels.

3 Open the Trigger Options menu.

Triggering on Wavef or m s

Triggering on Video Signals

Figure 30. Measuri ng Interlaced Video Signals

5

4 Select Video on A to open the

Trigger on Video menu.

5 Select positive signal polarity for

video signals with negative going

sync pulses.

6

Trigger level and slope are now fixed.

Observe that the key labels at t he bot tom of the screen

have been changed to allow further selection of specific

video trigger settings:

Select the video standard and

return.

51

Page 60

Fluke 192/196/199

Users Manual

Triggering on Video Frames

Use FIELD 1 or FIELD 2 to trigger either on the first half

of the frame ( odd) or on the second half of the fram e

(even).

To trigger on the second half of t he frame, do the

following:

7 Choose FIELD 2.

The signal part of the even field is displayed on the

screen.

Triggering on Video Lines

Use ALL LINES to trigger on all line synchronization pulses

(horizontal synchronization).

7 Choose ALL LINES.

The signal of one line is displayed on the screen. The

screen is updated with the signal of the next line

immediately after the t est tool triggers on the horizontal

synchronization pulse.

To view a specific video line in more detail, you can select

the line number. For example, t o m easur e on video line

123, continue from step 5 as follows:

7 Enable video line selection.

8 Select number 123.

The signal of line 123 is displayed on the screen.

Observe that the st atus line now also shows the selected

line number. The screen is continuously updated with the

signal of line 123.

52

Page 61

Triggering on Pulses

Use pulse width triggering to isolate and display specific

pulses that you can qualify by time, such as glitches,

missing pulses, bursts or signal dropouts.

Detecting Narrow Pulses

To set the test tool t o t r igger on nar r ow positive pulses

shorter than 5 ms, do the following:

1 Apply a video signal to the red input A.

2 Display the TRIGGER key labels.

3 Open the Trigger Options menu.

Triggering on Wavef or m s

Triggering on Pulses

4 Select Pul se W idth on A... to

open the Trigger on Puls e

Width menu.

5 Select the positive pulse icon,

then jump to Condition.

6 Select <t, then jump to Update.

7 Select O n Tr igger.

The test tool is now prepared to t r igger on nar r ow pulses

only. Observe that t he t r igger key labels at t he bot tom of

the screen have been adapted to set t he pulse

conditions:

5

53

Page 62

Fluke 192/196/199

Users Manual

To set the pulse width to 5 ms, do t he f ollowing:

7 Enable the arrow keys to adjust

the pulse width.

8 Select 5 ms .

All narrow positive pulses shorter than 5 ms are now

displayed on the screen. (See Figure 31.)

Tip

The test tool stores all triggered scr eens in the

replay memory. For exam ple, if you set up your

triggering for glitches, you can captur e 100

glitches with time stamps. Use the

look at all the stored glitches.

REPLAY key to

Figure 31. Trigger ing on Narrow Glitches

54

Page 63

Triggering on Wavef or m s

Triggering on Pulses

5

Finding Missing Pulses

The next example covers finding missing pulses in a train

of positive pulses. In this example it is assumed that t he

pulses have a 100 ms distance between the rising edges.

If the time accidently increases to 200 m s, a pulse is

missing. To set the test t ool to t r igger on such m issing

pulses, let it trigger on gaps bigger than about 150 m s.

Do the following:

1 Display the TRIGGER key labels.

2 Open the Trigger Options menu.

3 Select Pulse Width on A... to

open the Trigger on Puls e

Width menu.

4 Select the positive pulse icon to

trigger on the gap between the

positive pulses, then jump to

Condition.

5 Select >t, then jump to Update.

6 Select O n Tr igger.

The test tool is now prepared to t r igger on pulse gaps.

Observe that t he t r igger m enu at the bottom of t he

screen has been adapted to set the pulse condition:

55

Page 64

Fluke 192/196/199

Users Manual

To set the pulse width to 150 ms, cont inue as follows:

7 Enable the arrow keys to adjust

the pulse width.

8 Select 150 ms.

Figure 32. Trigger ing on Missing Pulses

56

Page 65

Chapter 6

Using Memory, PC and Printer

About this Chapter

This chapter provides a step-by-st ep intr oduction to the

general functions of the test t ool t hat can be used in the

three main modes: Scope, M et er , or Recorder. You will

find information on printer and com puter communication

at the end of this chapter .

Saving and Recalling

You can:

• Save screens and setups to memory, and r ecall

them again from mem or y. The test tool has 10

screen and setup memories and 2 recor d and set up

memories.

• Recall screens and recordings to analyze or print the

screen image at a later date.

• Recall a setup to continue a measurement with the

recalled operating configuration.

57

Page 66

Fluke 192/196/199

Users Manual

Saving Screens with Associated Setups

To save a screen in memory location 10, do the f ollowing:

1 Display the SAVE/PRINT key labels.

From this point the screen is f r ozen unt il you hide the

SAVE/PRINT key labels again.

2 Open the Save menu.

Observe that free memory

locations are indicated by an open

square (p). Filled memory

locations are indicated by a solid

square (n).

3 Highlight SCREEN+SETUP location 10.

4 Save the actual screen.

Note

The two record+setup memor y locations st or e

more than what is just visible on the screen.

In TrendPlot or scope record m ode t he f ull

recording is saved. In scope mode you can save

all 100 replay screens in a single record+setup

memory location.

58

Page 67

Using Memory, PC and Pr inter

Saving and Recalling

6

Deleting S creens with Associated Setups

To delete all screens and associated setups, continue

from step 2 of t he pr evious example as f ollows:

3 Delete all saved screens and

setups.

To delete only one screen and setup, continue from st ep

2 of the previous example as follows:

3 Highlight SCREEN+SETUP location 5.

4 Delete the saved screen+setup of

memory location 5.

Recalling Screens wit h Associated S et ups

To recall screen+setup 2, do the following:

1 Display the SAVE/PRINT key labels.

2 Open the Recall menu.

3 Highlight SCREEN+SETUP location 2.

4 Use RECALL to recall the saved

screen.

Observe that the r ecalled waveform is displayed and that

HOLD appears on the screen. Fr om t his point you can use

cursors and zoom for analysis or you can print t he

recalled screen.

59

Page 68

Fluke 192/196/199

Users Manual

Recalling a Setup Configuration

To recall the setup configuration fr om m em or y 2, do the

following:

1 Display the SAVE/PRINT key labels.

2 Open the Recall menu.

3 Highlight SCREEN+SETUP location 2.

4 Use RECALL SETUP to recall the

saved setup.

Observe that RUN appears at the top right of the scr een.

From this point you continue in the new operating

configuration.

Viewin g Stored Screens

To scroll through the memories while looking at the

stored screens, do the f ollowing:

1 Display the SAVE/PRINT key labels.

2 Open the viewer.

3 Scroll through all stored screens.

Use this function to quickly find a stored screen.

60

Page 69

Using Memory, PC and Pr inter

Documenting Screens

6

Documenting Screens

With the FlukeView® software you can upload waveform

data and screen bitmaps to your PC or not ebook

computer for f ur t her pr ocessing. Pr inting can also be

done by connecting the test tool directly t o a pr inter .

Connecting to a Computer

To connect the test tool t o a PC or not ebook com put er

and use the FlukeView software for Windows

do the following:

l

Use the Optically Isolated RS-232 Adapter/Cable

(PM9080) to connect a computer to the OPTICAL

PORT of the test tool. ( See Figure 33. )

Figure 33. Connecting a Comput er

®

(SW90W),

Note

For information about installing and using the

FlukeView ScopeMeter software, see the

SW90W Users Manual.

A Software & Cable Carrying Case Kit is optionally

available as model number SCC190.

61

Page 70

Fluke 192/196/199

Users Manual

Connecting to a Printer

To print a screen directly to a printer , use one of the

following adapters:

l

The Optically Isolated RS-232 Adapter / Cable

(PM9080) to connect a serial print er t o t he O PTI CAL

PORT of the test tool. ( See Figure 34. )

l

The Print Adapter Cable (PAC91, optional) t o

connect a parallel printer to the O PTI CAL PORT of

the test tool. ( See Figure 35. )

Before printing, you must set up t he t est t ool f or a specific

printer.

Figure 34. Connecting a Serial Printer

62

Figure 35. Connecting a Par allel Print er

Page 71

Using Memory, PC and Pr inter

Documenting Screens

6

Setting up the Printing Configuration

This example demonstrates how to set up t he test tool for

printing on a postscript printer with a 9600 baud r at e:

1 Display the USER OPTIONS key

labels.

2 Open the User Opti ons m enu.

3 Open the Printer Setup submenu.

4 Select Postscript and jump to

Baud Rate.

5 Select a baud rate of 9600 and

return to norm al mode.

Whenever possible, choose the option Postscript when

printing screens. This option gives the best printing

results. Consult the manual that cam e with your pr inter to

find out whether it has Postscript pr inting possibilities.

Printing a Screen

To print the currently displayed screen, do the following:

1 Clear the menu if you do not want

to print it.

2 Display the SAVE/PRINT key labels.

3 Start printing.

A message appears at the bottom of the screen

indicating that the test tool is busy printing.

63

Page 72

Fluke 192/196/199

Users Manual

64

Page 73

Chapter 7

Tips

About this Chapter

This chapter gives you information and tips on how you

can make the best use of the t est tool.

Using the Standard Accessories

The following illustrations s how t he us e of t he s t andard

accessories such as voltage probes, test leads, and t he

various clips.

65

Page 74

Fluke 192/196/199

Users Manual

Figure 36. Probing Usi ng 2- m m Heavy Duty

Test Probes

Warning

To avoid electrical shock or fire, do not

connect the ground spring t o vol t ages higher

than 30 Vrms from ear th ground.

Figure 38. Heavy Duty Fixed Connecti ons f or Scope

Measurements Using I ndust r i a l Alligator Clips

Figure 37. HF Voltage Pr obe Connect i on Usi ng

Ground Spring

66

Figure 39. Elect ronic Connections for Scope

Measurements Using Hook Cli ps and Hook Clip

Grounding

Page 75

Tips

Using the Standard Accessories

7

Figure 40. Elect ronic Connections for Scope

Measurements Using Hook Cli ps and Alligator Clip

Grounding

Figure 41. Fixed El ect r oni c Connect i ons for Scope

Measurements wi th Fixed External Tri gger ing

Figure 42. Manual Probing for Meter M easur e me nt s

using 2-mm Test Pr obes

Figure 43. Heavy Duty Fixed Connecti ons f or M et e r

Measurements Using I ndust r i a l Alligator Clips

67

Page 76

Fluke 192/196/199

Users Manual

Using the Independently Floating

Isolated Inputs

You can use the independently floating isolated inputs to

measure signals that are independently floating f r om

each other.

Independently floating isolated inputs offer additional

safety and measur em ent c apabilit ies com pared to inputs

with common references or gr ounds.

Measuring Using In dependen t ly Floating

Isolated Inputs

The test tool has independently floating isolated inputs.

Each input section (A, B, External Trigger / DMM ) has it s

own signal input and its own reference input. The

reference input of each input sect ion is electrically

isolated from the ref er ence input s of t he ot her input

sections. The isolated input architecture m akes t he t est

tool about as versatile as having three independent

instruments. The advantages of having independently

floating isolated inputs are:

• It allows simultaneous measurement of

independently floating signals.