Page 1

1760

®

Power Quality Recorder

Users Manual

June 2006 Rev. 2, 5/10

© 2006-2010 Fluke Corporation, All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is two years and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

11/99

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Table of Contents

Chapter Title Page

1 Introduction ......................................................................................... 1-1

About this Manual.................................................................................. 1-3

Symbols................................................................................................. 1-3

CAT Identification .................................................................................. 1-4

Safety Instructions................................................................................. 1-4

Safety Instructions on Device Housing.................................................. 1-7

Mains Connection.............................................................................. 1-7

Input Voltage – Measuring Inputs...................................................... 1-8

Servicing and Maintenance ............................................................... 1-8

Design and Functions............................................................................ 1-8

Mains Connection and Interfaces ...................................................... 1-8

Functional Description ....................................................................... 1-10

Basic Measurements............................................................................. 1-18

Measurement Types.......................................................................... 1-18

Measurements................................................................................... 1-19

2 Getting Started .................................................................................... 2-1

Delivered Items ..................................................................................... 2-3

Setup ..................................................................................................... 2-4

Installation ......................................................................................... 2-4

Switching the Device On ................................................................... 2-4

Switching the Device Off ................................................................... 2-4

Simple Measurement - Function Check ................................................ 2-4

Transport and Storage .......................................................................... 2-9

Transport ........................................................................................... 2-9

Storage .............................................................................................. 2-9

3 Operation ............................................................................................. 3-1

Connections to Measuring Circuits........................................................ 3-3

Connecting Sequence ....................................................................... 3-3

Connection Diagrams ........................................................................ 3-4

1-Phase Measurement .................................................................. 3-4

3-Wire Network with Two Current Sensors (ARON2 Method)....... 3-5

3-Wire Network with Two Current Sensors (ARON2 Method,

Open Delta Method) ...................................................................... 3-7

i

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

1760

Users Manual

4-Wire Network: 3-Wattmeter Method ........................................... 3-8

Four-Wire Network: Three-Wattmeter Method with N Conductor

Voltage and N Conductor Current ................................................. 3-9

Two Star-Connected Voltage Systems.......................................... 3-11

Two Voltage Systems in Delta Configuration ................................ 3-12

Methods of Measurement/Formulas...................................................... 3-13

Parameter Aggregation ..................................................................... 3-13

Calculation of Power Parameters ...................................................... 3-14

Aggregations 200 ms and higher................................................... 3-14

Real power .................................................................................... 3-14

Apparent power ............................................................................. 3-15

Reactive power.............................................................................. 3-15

Power factor .................................................................................. 3-16

Displacement power factor cos φ .................................................. 3-16

Half and full cycle aggregations......................................................... 3-17

Real power .................................................................................... 3-17

Apparent power ............................................................................. 3-18

Reactive power.............................................................................. 3-18

Power factor .................................................................................. 3-18

Events and Flicker ............................................................................. 3-18

Harmonics and Interharmonics Parameters ...................................... 3-19

Signaling Voltage............................................................................... 3-22

Unbalance, Overdeviation, Underdeviation ....................................... 3-22

Current Unbalance ........................................................................ 3-23

Overdeviation and Underdeviation ................................................ 3-24

4 Maintenance......................................................................................... 4-1

Introduction............................................................................................ 4-3

Maintenance of Battery Package........................................................... 4-3

Cleaning ................................................................................................ 4-3

Replacement of Battery Pack................................................................ 4-4

Decommissioning and Disposal ............................................................ 4-4

Shutting Down ................................................................................... 4-4

Recycling and Disposal ..................................................................... 4-5

Warranty................................................................................................ 4-5

Recalibration ......................................................................................... 4-5

5 Specifications ...................................................................................... 5-1

General Specifications .......................................................................... 5-3

6 Options and Accessories ................................................................... 6-1

Instruments............................................................................................ 6-3

Accessories ........................................................................................... 6-3

Standard Voltage Probes for AC and DC .......................................... 6-4

Flexible Current Probes for AC.......................................................... 6-5

Current Probes for AC Currents ........................................................ 6-5

Shunt Resistors for AC and DC Currents .......................................... 6-6

Other Accessories ............................................................................. 6-6

Current Clamp 1 A/10 A AC .............................................................. 6-6

Current Clamp 5 A/50 A AC .............................................................. 6-10

Current Clamp 20 A/200 A AC .......................................................... 6-14

Flexi Current Sensor 100 A/500 A..................................................... 6-17

Flexi Current Sensor 200 A/1000 A................................................... 6-21

ii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

Flexi Current Sensor 3000 A/6000 A................................................. 6-24

GPS-Time Synchronization Module Option........................................... 6-27

Contents (continued)

iii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

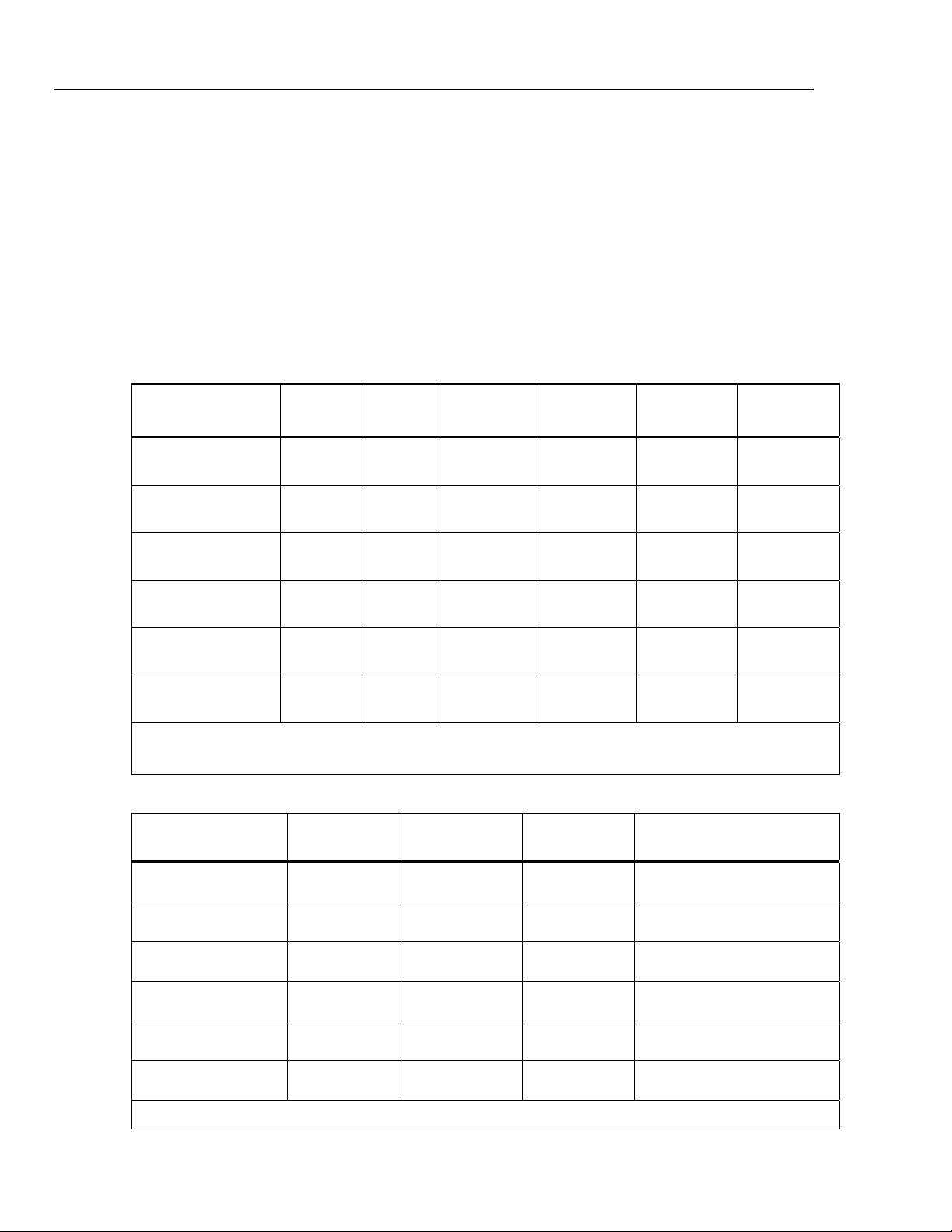

List of Tables

Table Title Page

1-1. Symbols..................................................................................................... 1-3

1-2. Controls and Indicators ............................................................................. 1-9

3-1. Symbols in the Connection Diagrams ....................................................... 3-4

3-2. Parameter Aggregation Matrix .................................................................. 3-25

v

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

List of Figures

Figure Title Page

1-1. CAT ........................................................................................................... 1-4

1-2. Instrument Labels...................................................................................... 1-7

1-3. Top View ................................................................................................... 1-8

1-4. Front View ................................................................................................. 1-9

2-1. Communication Cables ............................................................................. 2-3

3-1. Circuit Diagram: 1-Phase Measurement ................................................... 3-4

3-2. Circuit Diagram: 3-Wire Network (Aron 2)................................................. 3-6

3-3. Circuit Diagram: Aron 2 Method/Open Delta Method................................ 3-7

3-4. Circuit Diagram: 4-Wire Network (Wye Connection) ................................. 3-8

3-5. Circuit Diagram: 4-Wire ............................................................................. 3-10

3-6. Circuit Diagram: 2 Voltage System with Neutral ....................................... 3-11

3-7. Circuit Diagram: 2 Voltage System in Delta Connection ........................... 3-12

vii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

Chapter 1

Introduction

Title Page

About this Manual ............................................................................................... 1-3

Symbols ............................................................................................................... 1-3

CAT Identification............................................................................................... 1-4

Safety Instructions ............................................................................................... 1-4

Safety Instructions on Device Housing................................................................ 1-7

Mains Connection............................................................................................ 1-7

Input Voltage – Measuring Inputs................................................................... 1-8

Servicing and Maintenance ............................................................................. 1-8

Design and Functions........................................................................................... 1-8

Mains Connection and Interfaces .................................................................... 1-8

Functional Description .................................................................................... 1-10

Basic Measurements ............................................................................................ 1-18

Measurement Types......................................................................................... 1-18

Measurements.................................................................................................. 1-19

1-1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

Introduction

About this Manual 1

About this Manual

This manual consists of several chapters.

• Introduction

• Getting Started

• Operation

• Maintenance

• Specifications

• Options and Accessories

Symbols

Table 1-1 shows the symbols used on the instrument and/or in this manual.

Table 1-1. Symbols

Symbol Description

X Hazardous voltage. Risk of electric shock.

W Important information. See manual.

- Do not apply around or remove from HAZARDOUS LIVE conductors.

J Earth ground.

T Double insulation.

B AC (Alternating Current)

F DC (Direct Current).

P Conforms to requirements of European Union.

)

~

Canadian Standards Association is the certified body used for testing

compliance to safety standards.

Do not dispose of this product as unsorted municipal waste. Go to Fluke’s

website for recycling information.

; Conforms to relevant Australian Standards.

CAT II

CAT III

IEC Overvoltage Category/Measurement Category II equipment is designed

to be protected against transients from socket outlets and similar points.

IEC Overvoltage Category III equipment is designed to protect against

transients in installations, such as distribution panels, feeders and short

branch circuits, and lighting systems in large buildings.

IEC Overvoltage Category IV equipment is designed to protect against

CAT IV

transients from the primary supply level, such as an electricity meter or an

overhead or underground utility service.

1-3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

1760

Users Manual

CAT Identification

Figure 1-1 shows an example to identify the locations of different measurement

categories (CAT).

Safety Instructions

The design and manufacture of the device conform to the latest state of technology and

the safety standards laid down in EN/IEC 61010-1:2001 (2

there is a risk of injury to persons and damage of property.

Please read this section carefully. It will familiarize you with important safety

instructions for handling your 1760 Power Quality Recorder. In this manual a

identifies conditions and actions that pose hazard(s) to the user. A Caution identifies

conditions and actions that may damage the Recorder.

The 1760 Power Quality Recorder is referred to as ‘Recorder’ throughout

the manual.

To avoid electric shock or personal injury:

• The Power Quality Recorder must only be used and

handled by qualified personnel.

Figure 1-1. CAT

Note

XW Warnings

nd

ed.). If used improperly,

Warning

1_1.bmp

• Maintenance work must be done only by qualified service

personnel.

• Use only specified voltage and current probes. If you use

flexible current probes, wear suitable protective gloves or

work on de-energized conductors.

• Protect the Recorder against wetness and humidity.

• Do not hold the Current Clamp anywhere beyond the tactile

barrier.

• To prevent electrical shock, always connect current probe

test leads to the Recorder before connecting to the load.

1-4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Introduction

• To avoid electrical shock, do not connect the voltage

measuring or power supply input to systems with higher

voltages to ground (earth) than is marked on the Recorder.

• To avoid damage to the Recorder, never connect the

voltage measuring inputs to phase-to-phase voltages

higher than defined on the voltage sensors.

• To avoid damage to the Recorder, never connect the power

supply voltage inputs to phase-to-phase voltages.

• Use only the provided original or specified accessories.

• Use these accessories only in the specified overvoltage

category areas.

• Current transformers should not be applied or removed

from HAZARDOUS LIVE conductors without using highvoltage gloves.

• Flexi-probes should not be applied to or removed from

hazardous live conductors.

• Use the clamps only on insulated conductors, max. 600 V

rms or dc to ground.

Safety Instructions 1

• The power company side of the revenue power meter is

considered a CAT IV area. To avoid electrical shock or

damage to the equipment, never supply the Recorder from

the power in this area.

• Additional personal protective measures as required by

local government agencies must be taken if the measuring

sensors are installed on live conductors.

• Avoid connection from multiple channels to the same

phase.

Protection Class

This device is assigned to protection class I according to IEC 61140 and is equipped with

a protective earth connector.

Qualified Personnel

The device may only be operated by suitably qualified personnel. The adequate

qualifications required are:

• Trained and authorized to switch on/off, ground (earth) and mark the power

distribution circuits and devices in accordance with the safety standards of

electrical engineering

• Training or instruction in accordance with the standards of the safety engineering

in maintenance and use of appropriate safety equipment

• Training in first aid

Safe Operation

For safe operation of the Recorder:

• Ensure that all persons using the device have read and fully understood the

operating manual and safety instructions.

1-5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

1760

Users Manual

• The device may only be used under certain ambient conditions. Ensure that the

actual ambient conditions conform to the admissible conditions laid down in

Chapter 5, General Specifications.

• During the operation, ensure that the circulation of air around the instrument is

possible in order to prevent the accumulation of heat inside the housing.

• Always comply with the instructions in Chapter 2, Transport and Storage.

Proper Usage

Do not use the device for any other purpose other than measuring of voltages and

currents that are within the measuring ranges and categories, including voltage to earth as

laid down in Chapter 5, General Specifications.

Improper use shall void all warranty.

Electrical Connections

• Ensure that the power and connecting cables used with the device are in proper

working order.

• Ensure that the protective earth connector of the power lead and the housing

earth connector are connected according to the instructions to the low-resistance

unit earth cable.

• Ensure that the power and connecting cables as well as all accessories used in

conjunction with the device are in proper working order and clean.

• Install the device in such a way that its power cable is accessible at all times and

can easily be disconnected. If this is not applicable a two pole circuit breaker

with a nominal current must be installed in the power supply lines.

Risks During Operation

For connection work, do not work on your own but in teams of at least two persons.

Do not use the device if the housing or an operating element is damaged.

Ensure that the connected devices work properly.

Measurement sensors must not be connected to unfused circuits.

Connectors with locking mechanism have to be locked firmly.

Maintenance and Repairs

Do not open the housing.

Do not carry out any repairs and replace any component parts of the device other than the

replaceable battery.

Damaged connecting and power leads must be repaired or replaced by an authorized

service technician.

Authorized, specialized technicians may only repair damaged or defective devices.

Accessories

Only use the accessories supplied with the device or specifically available as optional

equipment for your model.

Ensure that any third-party accessories used in conjunction with the device conform to

IEC 61010-031/-2-032 standard and are suitable for respective measuring voltage range.

1-6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

Introduction

Safety Instructions on Device Housing 1

Device Shutdown

If you detect any damage to the housing, controls, power cable, connecting leads or

connected devices, immediately disconnect the measuring inputs of the unit and then

from the power supply.

If you are in doubt as regards the safe operation of the device, immediately shutdown the

unit and the respective accessories, secure them against inadvertent switching on and

bring them to an authorized service agent.

Safety Instructions on Device Housing

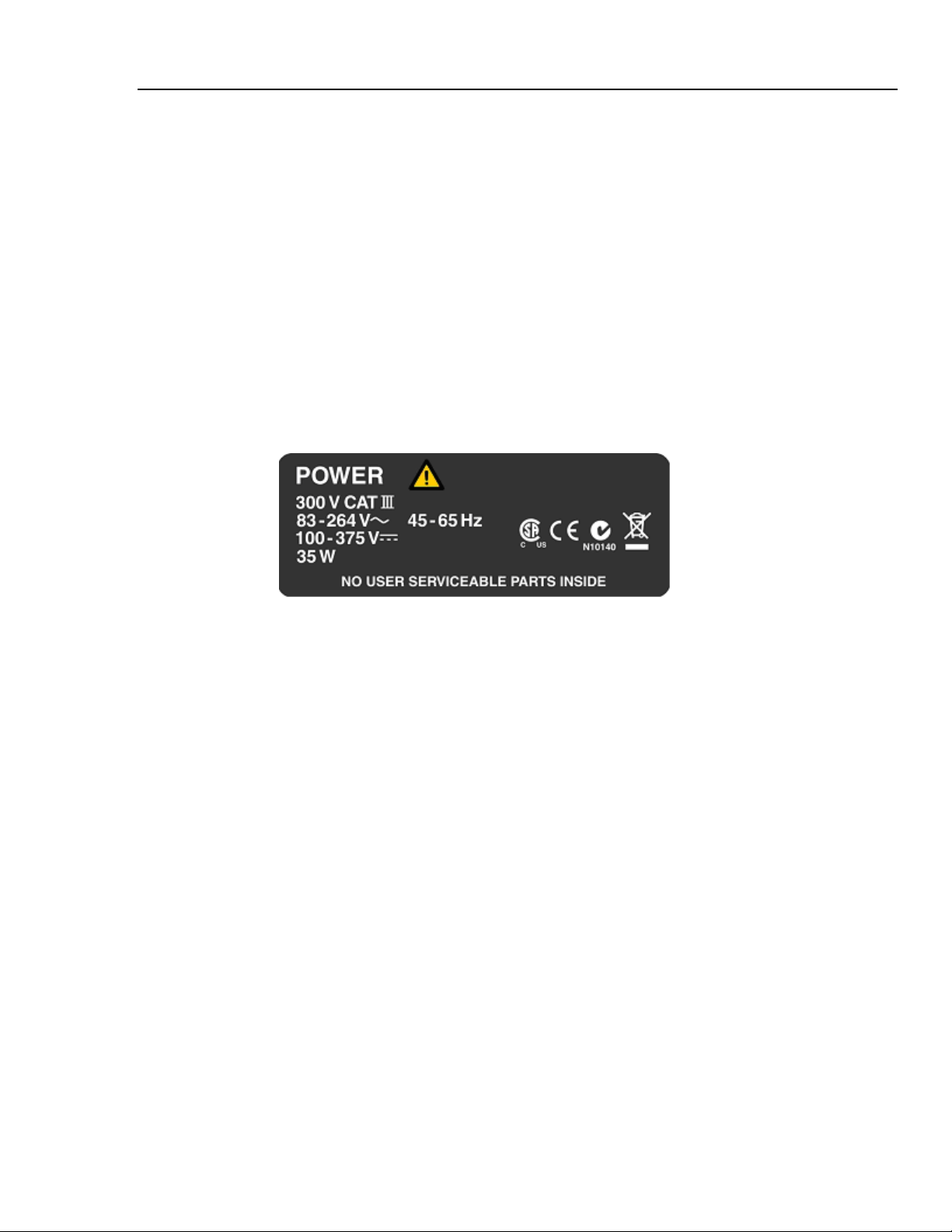

Mains Connection

The mains connection must conform to the ranges/values as inscribed on the instrument

labels.

Figure 1-2 shows the instrument labels.

Figure 1-2. Instrument Labels

schild-mains.wmf

schild-akku.wmf

1-7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

1760

J

Users Manual

Risk of voltage peaks in higher categories. Connect the supply

cable of the device only to sections CAT I, II or III of the supply

system (Refer to the ‘Functional Description’ section) the

voltage to earth may not exceed 300 V.

Input Voltage – Measuring Inputs

The measurement category (refer to Functional Description section) and the max. voltage

to earth of the sensors has to conform to the power supply system (See the inscription and

the technical specifications of the accessories).

Servicing and Maintenance

• Do not remove the cover

• Refer servicing to qualified personnel

• The user can replace the accumulator package (Refer to Chapter 4, Maintenance)

Design and Functions

This section provides an overview of the terminals, ports and interfaces of the Recorder,

as well as a list of displays and operating devices and a brief introduction to the basic

functions of the unit.

XW

Warning

Mains Connection and Interfaces

Figure 1-3 and Figure 1-4 show the top view and front view of the Recorder respectively.

11

Figure 1-3. Top View

grafikview.eps

1-8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

Introduction

Design and Functions 1

Figure 1-4. Front View

grafikview2.eps

Table 1-2 shows the controls and indicators of the Recorder.

Table 1-2. Controls and Indicators

Sl No. Description

A

B

C

D

E

F

G

H

I

J

K

1-9

Mains connection.

Mains switch.

LED indicators.

Ethernet connector

USB connectors type A.

COM1 – serial port (RS232).

Feature connector (GPS, DCF 77, COM2, alarms, etc).

Measurement input connectors.

Compact Flash card slot.

Compact Flash eject button and LED

Reset button.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

1760

Users Manual

Note

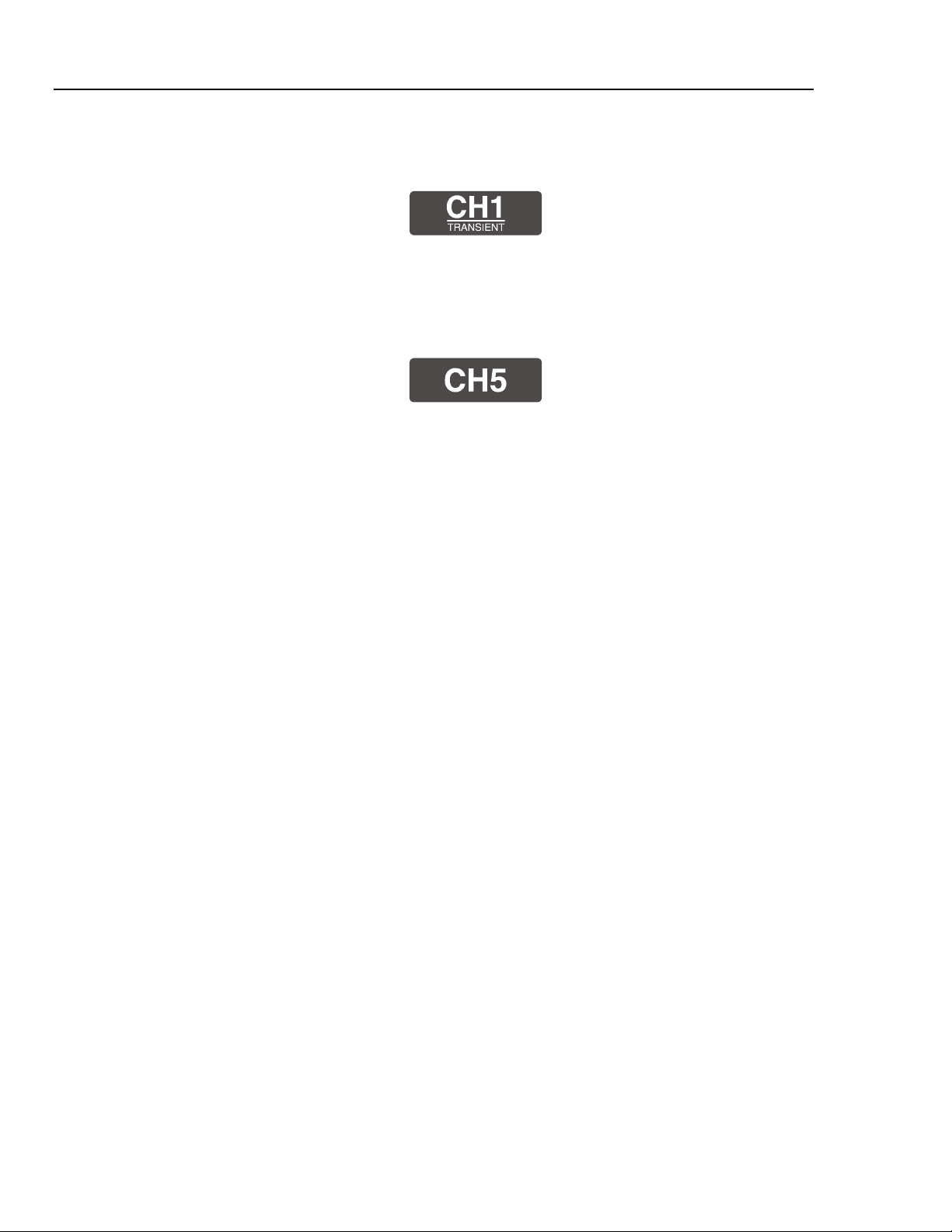

Channels ‘CH1’ to ‘CH4’ are labeled:

The text TRANSIENT indicates that these channels can be equipped with a

fast transient option.

Channels ‘CH5’ to ‘CH8’ cannot be used for fast transient recordings and

are labeled like this:

Functional Description

A Mains Connector

Connect the device to 83 V – 264 V AC-47 Hz – 65 Hz or 100 V – 375 V DC, power

consumption approx. 30 W.

Connect the supply cable of the device only to sections CAT I, II or III of

the supply system the voltage to earth may not exceed 300 V.

B Mains Switch

Activate the mains switch to switch the device on or off.

Note

Schild CH1.wmf

schild ch5.wmf

1-10

Note

The switch is secured by a mechanical feature against inadvertent

activation. Lift the knob slightly before moving it to the other position.

Instrument can be turned on only if the mains power supply is connected

and the supply voltage is within the specified range.

If the mains switch is in position I the instrument is turned on automatically

as soon as an appropriate supply voltage is applied to the mains connector.

If there is no mains supply and the battery pack capacity is too low the

instrument is turned off automatically.

Rebooting the Instrument

To reboot the instrument:

1. Set the mains switch to the 0-position.

2. Wait until all LEDs are off.

3. Connect instrument to mains and set the mains switch to the I-Position.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

Introduction

Design and Functions 1

Note

If the Reset button is held down while rebooting the instrument, the

Recorder’s stored data will be erased. This may be useful when the

Recorder memory is full and may help to resolve connection problems.

C LED Indicators

LEDs in the field Power:

Overview

Condition LED POWER LED UPS

Instrument boot Green OFF

Mains is on, battery is not charged

Mains is on, battery is charged

Battery operation

Green

Green

OFF

Green, yellow, or red according to

capacity

Slowly Flashing Green, yellow, or

red according to capacity

Green, yellow, or red according to

capacity

led-schild gesamt.wmf

led-power.wmf

Battery discharge mode

Instrument shutdown

OFF

Green, flashing

Flashing alternately

Flashing Green, yellow, or red,

Memory LEDs show “decreasing”

yellow flashlight

Flashing Green, yellow, or red

according to capacity

1-11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

1760

Users Manual

Details

These LEDs provide information about the power supply:

LED POWER:

• Continuously green: Instrument is supplied from mains

• OFF: Supply from battery package

LED UPS:

Indicates charging state of the UPS battery package:

• Green: Battery is charged with 80 % to 100 % of nominal capacity

• Yellow: Capacity is between 30 % and 80 %, mains independent operation is

possible for more than 3 minutes

• Red: Capacity is between 25 % and 30 % of nominal capacity. Mains

independent operation is possible for less than 3 minutes

• Flashing: During charging the LED is flashing red, yellow, or green

corresponding to charging state and turns to continuous green light when

charging is complete

LED RECORDING STATUS:

This indicator gives information about the recording status of the measurement campaign.

Condition LED RECORDING STATUS

Instrument is not yet initialized for a measurement

campaign

Measurement initialization is in progress, Instrument is

not yet ready for recording data

Measurement campaign has been initialized, but not yet

started

Measurement campaign is active, data are recorded Green, flashing slowly

Measurement campaign is active, data are recorded, but

some memory portions are full, i. e. some virtual

instruments do not record any more

Measurement campaign finished, no further campaign is

programmed, data ready for upload to the PC, Instrument

does not record data any more

In case of error Red

OFF

green, flashing rapidly

Green

Yellow, flashing slowly

Yellow

LEDs Time Sync:

led-timesync.wmf

1-12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

Introduction

Design and Functions 1

These indicators provide information about the time synchronization of the Instrument.

LED PULSE:

This LED indicates the reception of sync pulses. If Instrument is synchronized correctly

the LED is green and flashes yellow for each pulse detected.

If external pulses are used without GPS time information the LED is off and flashes red

for each detected sync pulse (to enable this, the “Pulse” protocol must be selected in the

“Time Synchronization Configuration” in the PQ Analyze software).

LED DATA:

• Green: The Recorder is configured for time synchronization (Service menu), a

time synchronization adaptor (GPS or DCF77) is connected, and the received

time information is valid.

• Yellow: The Recorder is configured for time synchronization; a time

synchronization adaptor is connected, but the received time information is not

correct. Possible reasons: No satellites or time source found or adaptor still

synchronizing after power on.

• Red: The Recorder is configured for time synchronization, but no time

synchronization adaptor is connected or it is not working properly.

• Off: The recorder is not configured for time synchronization.

LEDs for Data Transfer and Storage:

LED DATA TRANSFER:

The DATA TRANSFER LED indicates data transfer via external interfaces or to the

Compact Flash card.

• Off: No connection between PQ Analyze software and Recorder exists.

• Green: Connection between PQ Analyze software and Recorder established.

• Flashing yellow: data are written to the internal CF-card, external CF-card, USB

memory stick or data transfer via any of the interfaces (USB, RS232, or Ethernet)

LEDs MEMORY LEVEL:

The row of MEMORY LEVEL LEDs indicates the amount of free/occupied

measurement data memory on the Compact Flash card.

led-data.wmf

Occupied blocks are indicated by lit LEDs, 5 on the left side are green, 3 on the right side

are red to indicate that the memory is soon full.

During a forced battery discharge these LEDs are flashing yellow, the number of LEDs

lit represents the remaining capacity in minutes.

1-13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

1760

Users Manual

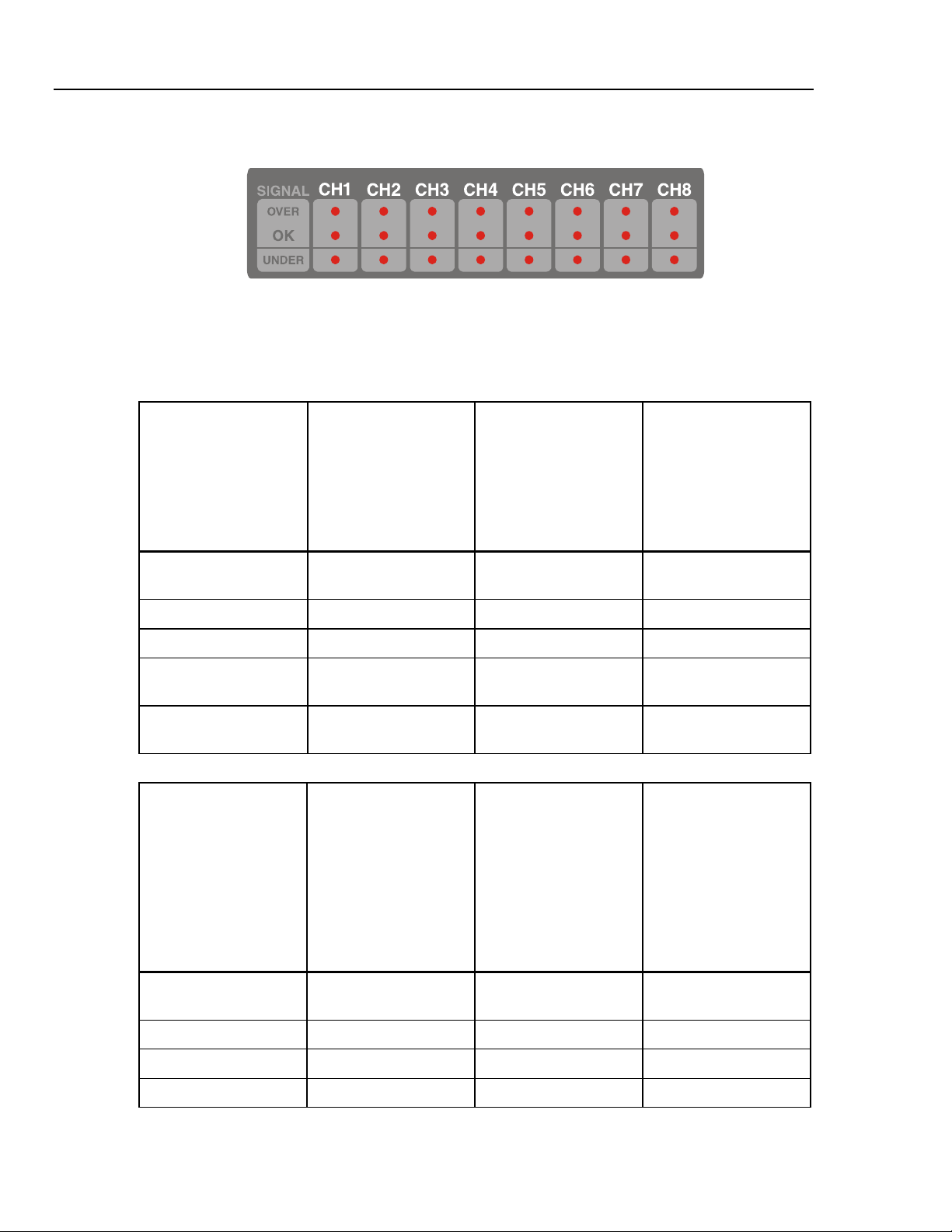

LEDs CH1 to CH8:

led-kanäle.wmf

Three LEDs are assigned to each of the eight input channels of the Recorder. The

indicators refer to half cycle or full circle rms values of the input signal (depending on the

configuration).

The following information is provided in case a valid sensor is detected.

Condition

Signal within nominal

range

Signal too low (dip) Yellow Off Off

Signal too high (swell) Off Off Yellow

Over range (ADCoverflow

Phase sequence wrong Off

LED UNDER

Off Green Off

Off Off Flashing red

LED OK

LEDs blinking in

sequence L3-L2-L1

LED OVER

Off

The following information is provided in case no valid sensor is detected:

Condition

LED UNDER

LED OK

LED OVER

Signal within nominal

range

Signal too low Yellow Red Off

Signal too high Off Red Yellow

Over range Off Red Flashing red

Off Red Off

1-14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

Introduction

Note

The LED OK is red if no valid sensor can be detected.

The limits for ‘Signal too low’ and ‘Signal too high’ are equal to the

thresholds for voltage dips and voltage swells (e.g.

For current inputs ‘Signal too low’ is indicated for half cycle or full cycle

rms values below 10 % of the sensor range as configured in the “Hardware

Settings” panel (if sensor is set to “Auto” the “Signal too low” indication

is deactivated).

‘Over range’ is indicated if the input signal is outside the valid

measurement range.

The phase voltages UL1, UL2, and UL3 of a three-phase system are monitored with the

symmetrical components (zero, positive and negative system). If the negative system

exceeds an upper threshold a wrong phase sequence condition is indicated (e.g. two lines

interchanged); the associated LEDs are flashing in sequence L3-L2-L1.

±

10 % of Un).

Design and Functions 1

XW Warning

The LEDs do not indicate whether there is voltage. Do not rely

on the LEDs to find out whether the device under test is live or

not.

D Ethernet port

Used for connection of the Recorder to an Ethernet port of a PC, or to an Ethernet

network (LAN). For a connection to an Ethernet network use the supplied Ethernet cable.

For direct connection of the instrument to a PC use the cross-linked Ethernet cable (with

the red plug).

E 2 USB connectors

The USB type A connectors for connection of a USB memory device, USB version V2.0

is supported.

USB connectors have the following function:

• USB stick support for storing of measurement data (same as external CF card).

CF card LED behaviour during USB copy process:

• copy process started --> flashing LED

• copy process finished and all data copied --> LED goes off

• copy process finished but not all data could be copied --> LED is turned on statically

• on error --> fast flashing LED for approx. 3 seconds then statically on

USB stick must not be pulled out while CF card LED is flashing. This can

cause permanent damage to the storage media. Only remove CF card /

USB stick while CF card LED is OFF or statically ON. Do not use CF card

or data connection at the same time.

Note

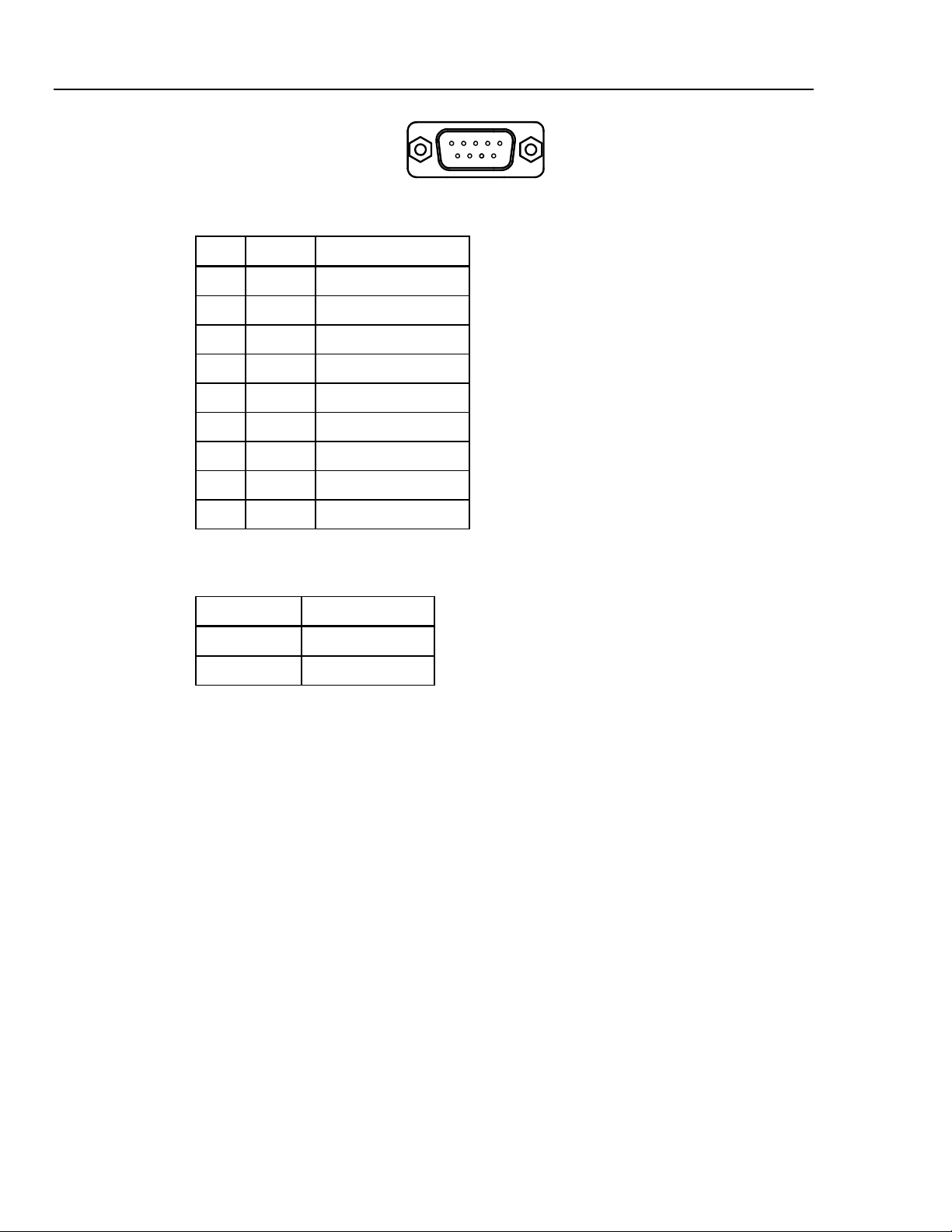

F Serial port COM1 (RS232)

Serial port for connection of the device to the serial port of a PC.

The default settings are 57.600 Baud, 8 data bits, 1 stop bit, no parity.

1-15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

1760

Users Manual

Pin assignment:

Pin Signal Description

1 DCD Data Carrier Detect

2 RxD Receive Data

3 TxD Transmit Data

4 DTR Data Terminal Ready

5 GND Ground

6 DSR Data Set Ready

7 RTS Request To Send

8 CTS Clear To Send

9 RI Ring Indicator

G Feature connector

Specification of outputs / inputs:

1

69

5

com_stecker.wmf

Condition Voltage level

Low (inactive) 0 - 0.8 V

High (active) 2.5 - 5 V

Maximum load current: 5 mA.

1-16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

Introduction

Design and Functions 1

stecker lpt.wmf

Pin assignment:

Pin Signal Description

1 +15 V Power supply voltage, max. 300 mA

2 TxD Output, Transmit Data COM2

3 RxD Input, Receive Data COM2

4 RTS Output, Request to send COM2

5 CTS Input, Clear to Send COM2

6 Service Output, internal use

7 GND Signal ground

8 Service Output, internal use

9 Watchdog Pulse Output, CPU watch dog signal

10 O1 Alarm output, reset with input RES 1

11 O2 Alarm output, reset with input RES 1

12 O3 Alarm output, reset with input RES 2

13 O4 Alarm output, reset with input RES 2

14 +5 V Power supply voltage

15 GPS PPS+ Input for GPS time synchronization

16 GPS PPS − Input for GPS time synchronization

17 GPS Transmit+ Input for GPS time synchronization

18 GPS Transmit- Input for GPS time synchronization

19-23 Service Output, internal use

24 RES1 Reset input for alarm outputs O1, O2

25 RES2 Reset input for alarm outputs O3, O4

H Measurement Channels

Plugs for 8 isolated measurement channels. Connect only original accessories such as

voltage and current sensors (clamps, Flexi Set, shunt resistors, etc.). The plug is secured

by means of a bayonet mechanism.

Note

Inputs that are not in use must be covered with the supplied protective caps

to prevent pollution.

When analyzing transients with 500 kHz transient option or 10 MHz

transient option, the potential to earth/ground is measured.

1-17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

1760

Users Manual

I J Compact Flash Card

Replaceable Compact Flash card for storage of measurement data. J Compact Flash

eject button and LED. Do not operate when data transfer is active (LED indicates

activity).

CF card LED behaviour during CF copy process:

• CF card inserted and detected --> short flashing (double pulses)

• copy process started --> flashing LED

• copy process finished and all data copied --> LED goes off

• copy process finished but not all data could be copied --> LED is turned on

statically

• on error --> fast flashing LED for approx. 3 seconds then statically on

Notes

• CF card must not be pulled out while CF card LED is flashing.

This can cause permanent damage to the storage media. Only

remove CF card / USB stick while CF card LED is OFF or

statically ON. Do not use USB stick or data connection at the same

time.

• Stored data can be erased by holding down the Reset Button K

while switching on (booting) the instrument. This may be useful

when the memory is full and may also resolve connectivity issues.

Basic Measurements

The Instrument offers all functions necessary to perform network analysis, quality

assurance evaluations and location of disturbance sources. A large compact flash data

memory provides a method of effecting long-term recordings. All data is saved even

without connection of the instrument to an evaluation computer. No information will be

lost. The recordings are the basis for detailed evaluations and analyze to assess

disturbances and the mains voltage quality. The instrument records and provides

historical event data, which protective relays or protective switches have induced and

how the resources have performed.

Measurement Types

The instrument combines many different measurement types, also referred to as “virtual

instruments”:

• Digital recording of measured data (data logger)

• Power measuring device (recording of load profiles)

• Recording of power frequency

• Power Quality Analyzer (including statistical evaluation)

• Fast transient recorder (optional)

• Ripple control signal analyzer

• Harmonics analyzer

• Voltage disturbances analyzer (events)

1-18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

Introduction

Measurements

The following measurements can be made:

• rms values of voltage and current as well as power values with programmable

averaging time

• Oscilloscope data (instantaneous value, sensing value)

• Powerful and versatile triggering engine

• Load and energy measurements

• Analysis of voltage and current harmonics

• Analysis of voltage and current interharmonics

• Fast transient analysis

• Signaling voltage, ripple control signal analysis

• Mains voltage quality analysis as per EN 50160

Basic Measurements 1

1-19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

Chapter 2

Getting Started

Title Page

Delivered Items.................................................................................................... 2-3

Setup .................................................................................................................... 2-4

Installation ....................................................................................................... 2-4

Switching the Device On................................................................................. 2-4

Switching the Device Off ................................................................................ 2-4

Simple Measurement - Function Check............................................................... 2-4

Transport and Storage.......................................................................................... 2-9

Transport ......................................................................................................... 2-9

Storage............................................................................................................. 2-9

2-1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

Getting Started

Delivered Items 2

Delivered Items

Before commencing work with the device, check the delivery to ensure that it is complete,

using the following list and the delivery specifications.

• 1 Power Quality Recorder Instrument

• 1 Getting Started manual

• CD-ROM with PQ Analyze application software, manuals, data sheets, and demo

data

• 1 power cord for mains connection

• 1 main connection adapter set

• 1 crosslink RS232 connection cable

• 1 Ethernet cable for direct PC connection

• 1 Ethernet cable for network connection

Optional:

• 4 voltage sensors

• 4 Flexi current sensors

• Carrying bag

• GPS receiver module

Figure 2-1 shows the communication cables.

Figure 2-1. Communication Cables

2-3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

ph_interfacecables.bmp

Page 28

1760

Users Manual

Setup

Installation

Follow the safety instructions regarding the ambient conditions and location of the

installation.

XW Warning

First connect the device with the mains cable and compatible

adapter to the power supply network. Observe the

specifications on the device type plate.

The device is connected to mains power, and a number of

internal components are live with dangerous voltage levels. To

remain safe during the operation, the device must be equipped

with a low-resistance connection to the earth. Therefore, check

the mains socket and its wiring.

Connect the supply cable of the device only to the sections

CAT I, II or III of the supply system. The voltage to earth may

not exceed 300 V.

Switching the Device On

Switch on the power supply to the device (lift switching knob B slightly and move to

position ‘I’). The LED POWER is lit. After approx. 40 seconds of booting, the device is

ready for the operation.

Switching the Device Off

Lift switching knob B slightly and move to position ‘0’. The LED POWER goes off

after closing all the internal data files.

Note

The instrument can be only switched off after the boot process is finished

(duration is approx. 40 seconds).

Simple Measurement - Function Check

The procedure below allows users to familiarize themselves with the measuring functions

of the instrument, while testing all basic device functions.

Installation: Install the instruments SW PQ Analyze, see Reference Manual PQ

Analyze.

Connect device: Connect instrument to mains and switch on.

Connect your computer and the recorder via the red Ethernet cable

for direct connection. Wait for a short time (see the 1760 Reference

Manual, “Direct Peer to Peer Communication over Crossover

Ethernet Cable”.

Connect the device channels as described in the “Connections to

Measuring Circuits”.

2-4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

Getting Started

Simple Measurement - Function Check 2

Communication: Start PQ Analyze

2_1.bmp

2_2.bmp

2-5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

1760

Users Manual

In the “Live Modes” section press “Setup”.

2_3.bmp

In the “Search Devices” dialog press “Search”.

Select your instrument in the list and press “Connect”.

2_4.bmp

After successful connection, you see a green light in the lower right corner next to status

information about the instrument.

2_5.bmp

2-6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

Getting Started

Simple Measurement - Function Check 2

Initialization: The “Settings” window is the starting point for all measurement

configurations. For now accept the default settings and press “Initialize”

2_6.bmp

Choose a name or accept the default one. Press OK.

2_7.bmp

Wait while measurement is initialized.

2_8.bmp

2_9.bmp

Press “OK” and watch the “RECORDING STATUS” LED on the instrument. It should

start flashing slowly indicating the active measurement.

Close the “Settings” window.

2-7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

1760

Users Manual

Measure: Select menu “Transfer > Live Mode”.

Press “Oscilloscope”

2_10.bmp

Select all channels that you want to have displayed and press the “Timeplot” icon.

2_11.bmp

2_12.bmp

If everything works correctly you will see an oscilloscope like recording of the signals

supplied to the input channels. All connections and sensors are working properly.

2_13.bmp

For detailed instructions, refer to the Reference Manual PQ Analyze.

2-8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

Getting Started

Next steps: For transferring the measured data from the device to the PC and for

evaluating the data according to your requirements see Reference Manual PQ

Analyze.

Transport and Storage 2

Transport and Storage

Transport

• Transport the device only in its original packaging

• Keep the operating manual supplied with the device for future reference

• Protect the device during the transport against heat and moisture. Do not exceed

the temperature range of −20 °C to +60 °C and a maximum humidity of 85 %

• Protect the device against impacts and loads

Storage

• Keep the original packaging, as it might be required at a later stage for transport

purposes or to return the device for repairs. Only the original packaging

guarantees the proper protection against mechanical impacts

• Store the device in a dry room; the temperature range of −20 °C to +60 °C and a

maximum humidity of 85 % may not be exceeded

Keep the operating manual supplied with the device for future reference

• Protect the device against direct sunlight, heat, moisture and mechanical impacts.

2-9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

Chapter 3

Operation

Title Page

Connections to Measuring Circuits...................................................................... 3-3

Connecting Sequence ...................................................................................... 3-3

Connection Diagrams ...................................................................................... 3-4

1-Phase Measurement ................................................................................. 3-4

3-Wire Network with Two Current Sensors (ARON2 Method) ................. 3-5

3-Wire Network with Two Current Sensors (ARON2 Method,

Open Delta Method).................................................................................... 3-7

4-Wire Network: 3-Wattmeter Method....................................................... 3-8

Four-Wire Network: Three-Wattmeter Method with N Conductor

Voltage and N Conductor Current .............................................................. 3-9

Two Star-Connected Voltage Systems........................................................ 3-11

Two Voltage Systems in Delta Configuration ............................................ 3-12

Methods of Measurement/Formulas .................................................................... 3-13

Parameter Aggregation.................................................................................... 3-13

Calculation of Power Parameters .................................................................... 3-14

Aggregations 200 ms and higher................................................................. 3-14

Real power .................................................................................................. 3-14

Apparent power........................................................................................... 3-15

Reactive power............................................................................................ 3-15

Power factor ................................................................................................ 3-16

Displacement power factor cos φ................................................................ 3-16

Half and full cycle aggregations...................................................................... 3-17

Real power .................................................................................................. 3-17

Apparent power........................................................................................... 3-18

Reactive power............................................................................................ 3-18

Power factor ................................................................................................ 3-18

Events and Flicker ........................................................................................... 3-18

Harmonics and Interharmonics Parameters..................................................... 3-19

Signaling Voltage ............................................................................................ 3-22

Unbalance, Overdeviation, Underdeviation .................................................... 3-22

Current Unbalance ...................................................................................... 3-23

Overdeviation and Underdeviation ............................................................. 3-24

3-1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

Operation

Connections to Measuring Circuits 3

Connections to Measuring Circuits

XW Warning

By connecting the unit to circuits, the terminals and certain

parts inside the device are live. Utilization of leads and

accessories that do not fulfill the relevant safety standards

could lead to serious injury or death from electric shock.

In order to ensure safe operation:

First connect the device to protective earth and to the power

supply.

Open the circuit before establishing a connection to the device.

Prior to connecting the circuits, ensure that the maximum

measuring voltage and the max. voltage to earth do not exceed

and the category of distribution system corresponds with the

inscription of the sensor ‘or’ meet the country specific standard.

Connecting Sequence

When connecting a circuit to Instrument, for safety reasons, proceed in the sequence

outlined below:

1. Check the standard mains socket for a proper protective earth connection.

Connect the instrument to the power supply socket. The PQ Recorder is now

connected to the protective earth (Safety Class 1 equipment).

2. Connect the measuring circuit as shown in the connection diagrams.

3. Switch on the Recorder.

4. Ensure that the direction of the energy flow is correct (load flow direction).

3-3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

1760

Users Manual

Connection Diagrams

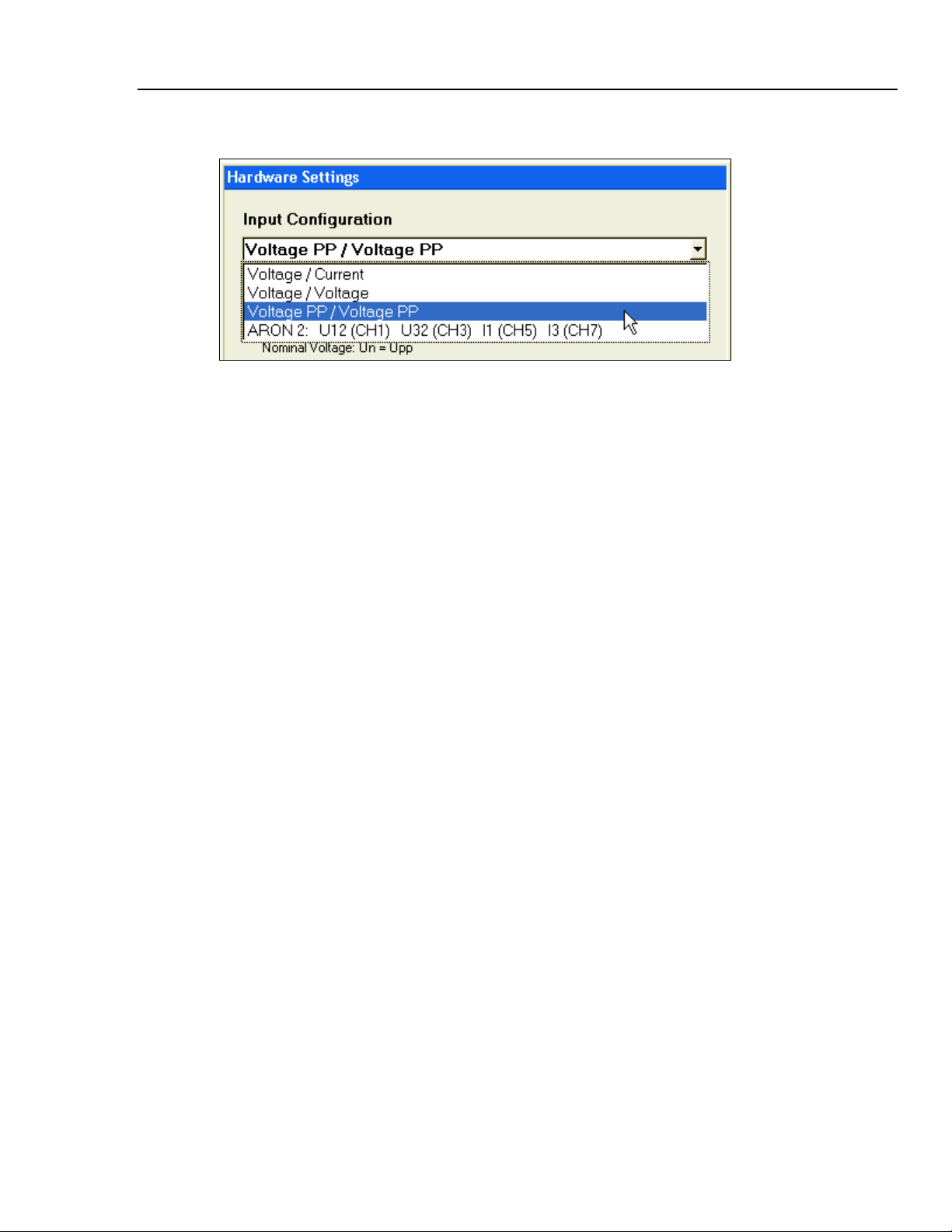

The measuring circuit is selected by means of the File > New / Hardware Settings menu

of the PQ Analyze software. Connect the sensors in load flow direction (observe arrows).

Table 3-1. Symbols in the Connection Diagrams

Symbol Meaning

Connect the Flexi current sensors in the right

direction.

The arrow on the Flexi must show from the network

to the load.

Red connector.

Black connector.

Use channel ‘CH4’ as control channel for triggering on external signals.

Fast voltage transients are always measured between the red plug of the

voltage sensor and the device ground (earth, protective conductor).

Please, note that the voltage sensors with a rated range of

equipped with the fast transient function (if the transient option is installed).

1-Phase Measurement

Figure 3-1 shows the circuit diagram for 1-phase measurement.

L1

Mains

L2

Note

Note

>

100 V are

L1

L3

PEN

Load

Fluke 1760

Figure 3-1. Circuit Diagram: 1-Phase Measurement

1wattm1.eps

3-4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

Operation

Connections to Measuring Circuits 3

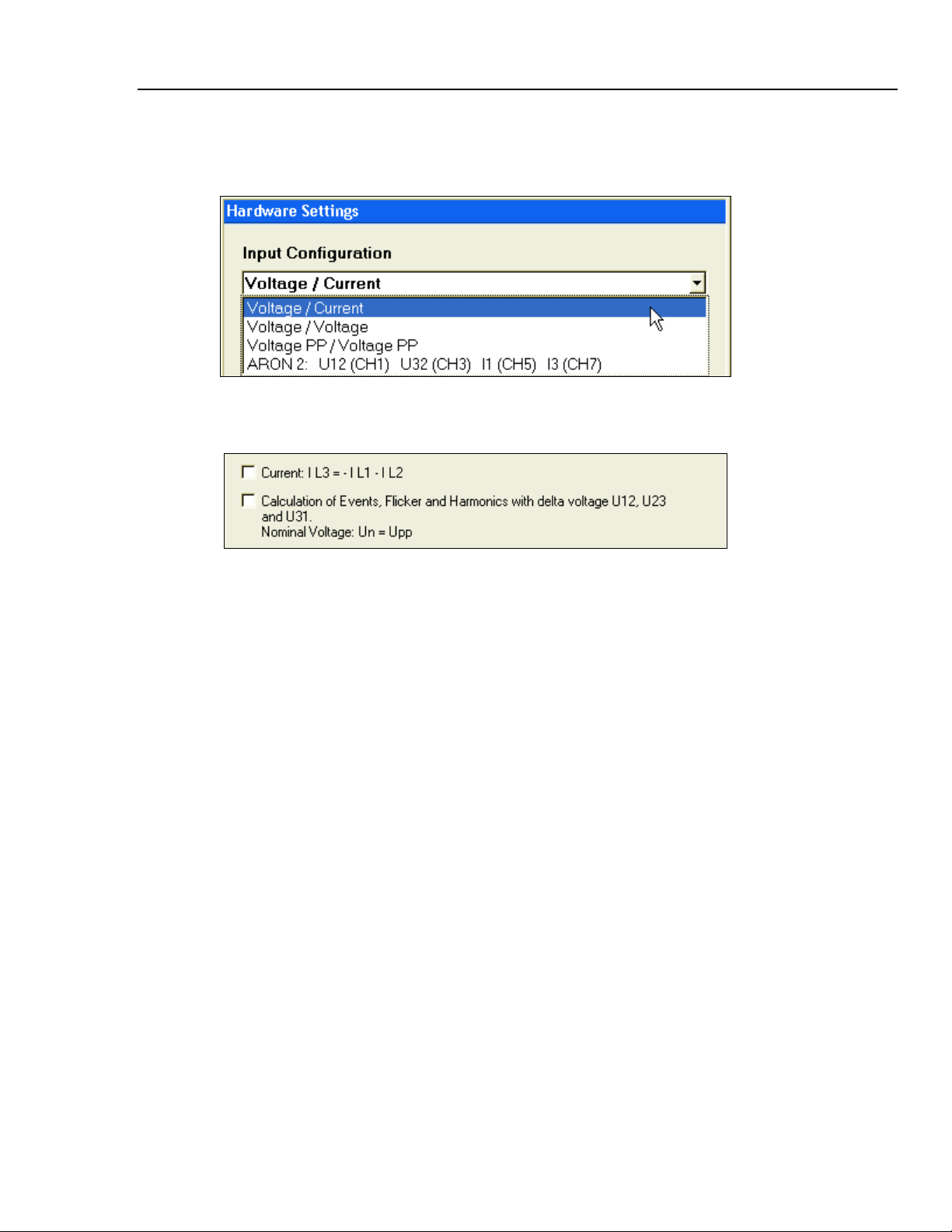

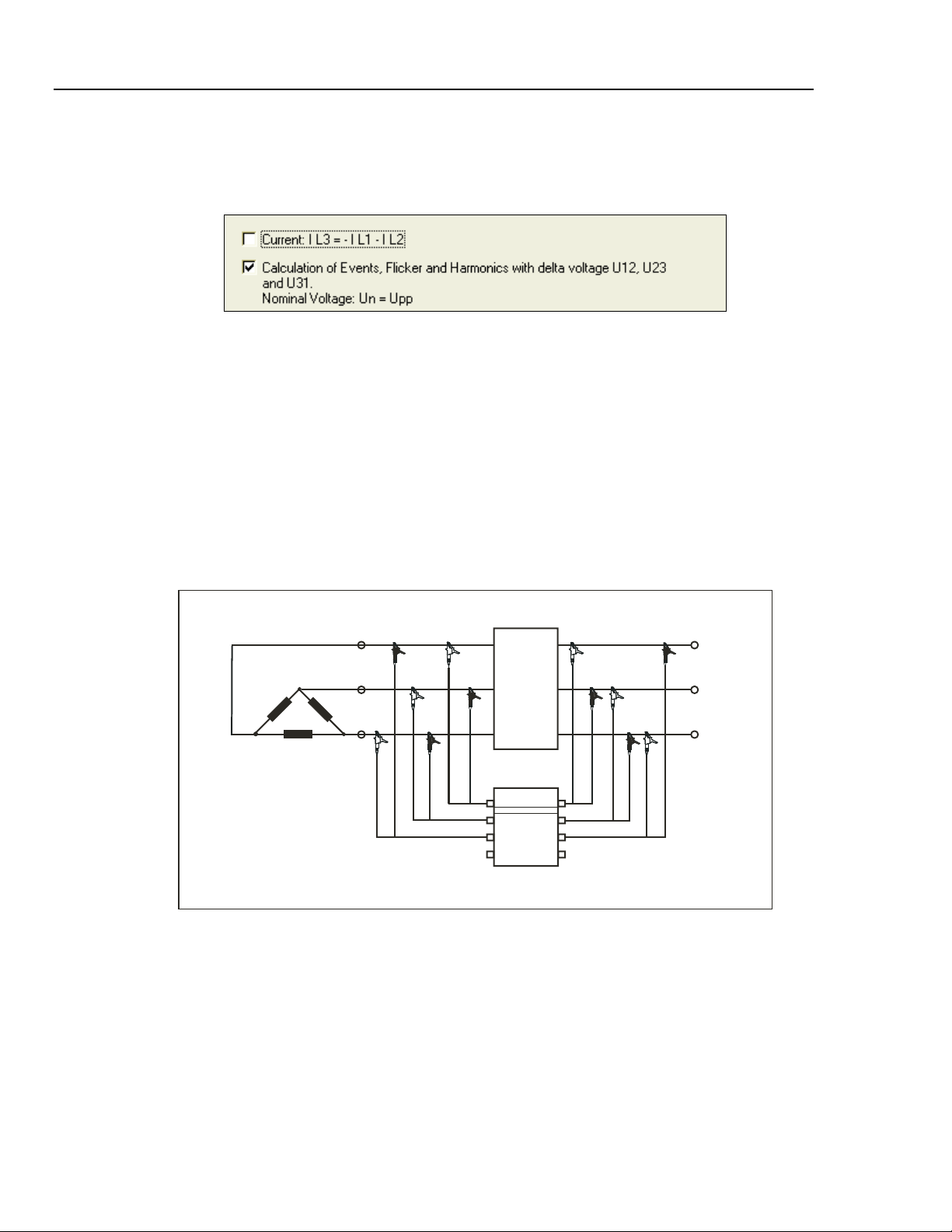

Associated PC software settings:

Connection to Single-Phase 2-Wire Network:

messsystem1 u-i.bmp

and

The option Calculation of Events, Flicker, and Harmonics with delta voltage U12, U23

and U31 for the phase-to-phase voltages is not of relevance here.

Note

All 8 channels are measured. Please keep this in mind when assessing the

power quality according to EN 50160.

To avoid false triggering, please switch channels that are not connected to

“OFF” in the “Hardware Settings” configuration panel.

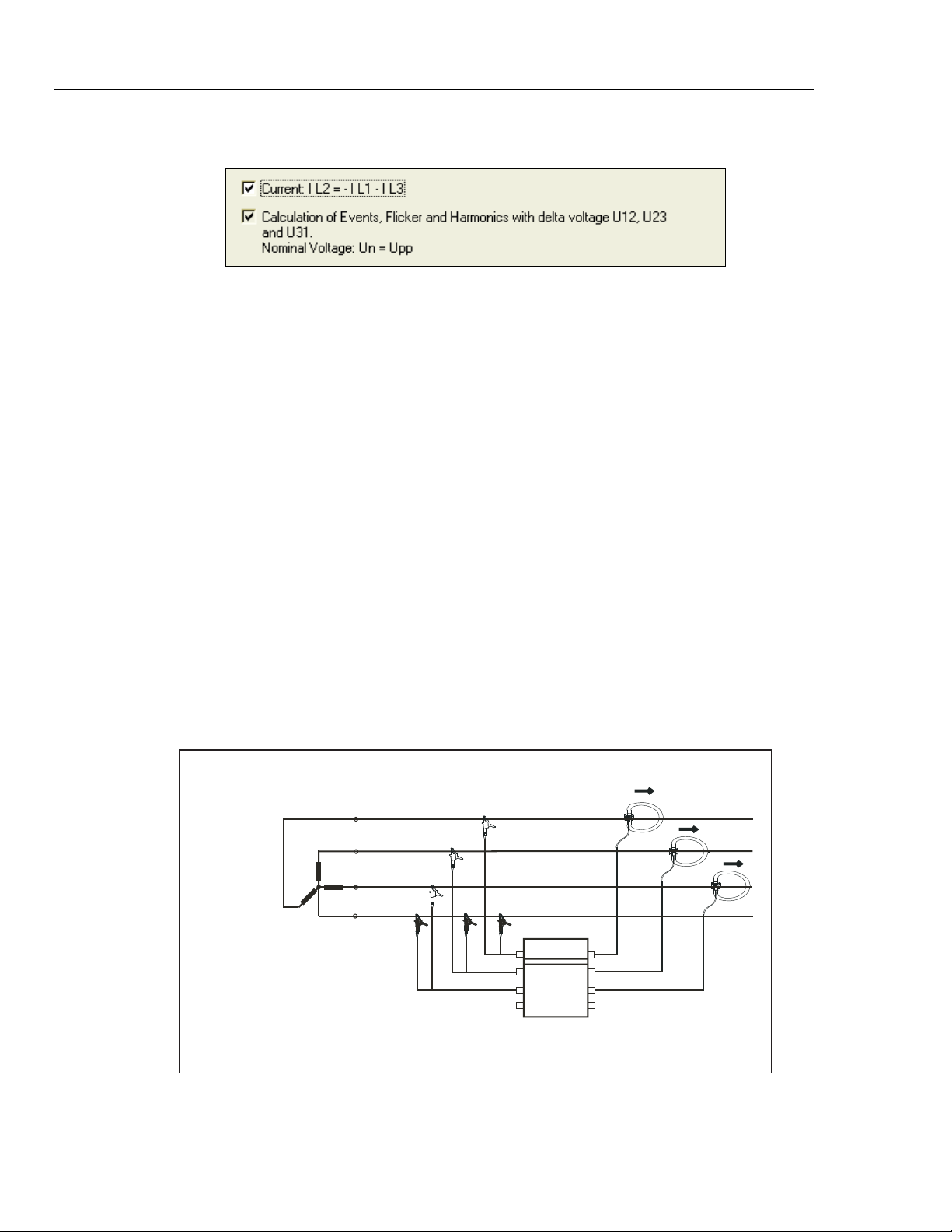

3-Wire Network with Two Current Sensors (ARON2 Method)

Conventional two-wattmeter method with current sensors on phases L1 and L3.

The device calculates IL2 = -IL1 – IL3. Two phase-to-phase voltages (U12 U32) are

measured. The third phase-to-phase voltage (U23) is calculated. The recorder then

transforms this delta system into a virtual Wye system by calculating virtual phase

voltages. This virtual Wye system is in turn used to calculate the power values of all three

phases as well as the total power. This method is applicable only if I1 + I2 + I3 =0, i.e. if

there is no neutral conductor.

Figure 3-2 shows the circuit diagram for 3-wire network (Aron 2).

messsystem1 u-i-1.bmp

3-5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

1760

Users Manual

Load Transformer

CH5 = I1

CH1 = U12

CH2 = U23

CH3 = U32

CH7 = I3

Fluke 1760

Figure 3-2. Circuit Diagram: 3-Wire Network (Aron 2)

Note

The voltage sensor at channel CH2 denoted with dotted lines is only

required for transient measurements; for current, voltage power

measurements, no sensor is required at CH2.

2wattm1-aron2.eps

Associated Device Software Settings:

messsystem5 aron2.bmp

Check the respective option.

messsystem5 aron2-1.bmp

If the option IL2 = -IL1 - IL3 is checked, the current IL2 is calculated. If this option is not

checked, the current IL2 is measured by means of a sensor at phase L2 (Instrument

channel CH6).

Note

The nominal voltage has to be entered as a phase-phase voltage in the

dialogue Nominal-Limit values (i.e. 400 V in a 230 V P-N-system).

3-6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

Operation

Connections to Measuring Circuits 3

3-Wire Network with Two Current Sensors (ARON2 Method, Open Delta Method)

The conventional two-wattmeter method with current sensors at phases L1 and L3 is

frequently used in the medium voltage networks with built-in current and voltage

converters.

The device calculates IL2 = -IL1 - IL3. Two phase-to-phase voltages (U12, U32) are

measured. The third phase-to-phase voltage (U23) is calculated. The recorder then

transforms this delta system into a virtual Wye system by calculating virtual phase

voltages. This virtual Wye system is in turn used to calculate the power values of all three

phases as well as the total power. This method is only applicable, if I1+I2+I3 = 0, i.e. if

there is no neutral conductor.

Figure 3-3 shows the circuit diagram for 3-wire network with 2 current sensors (Aron

method), open delta method.

L1

L1

L2

L2

L3

CH1 = U12

CH3 = U32

L3

Figure 3-3. Circuit Diagram: Aron 2 Method/Open Delta Method

Fluke 1760

CH5 = I1

CH7 = I3

v-schaltung-3.eps

Associated PC Software Settings:

messsystem5 aron2.bmp

3-7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

1760

Users Manual

Check the respective option.

messsystem5 aron2-1.bmp

If option IL2 = -IL1 - IL3 is checked, the current IL2 is calculated. If this option is not

checked, the current IL2 is measured by means of a sensor connected to phase L2

(Instrument channel CH6).

The option Calculation of Events, Flicker, and Harmonics with delta voltage U12, U23

and U31 is automatically on and cannot be deactivated.

Note

The nominal voltage has to be entered as a phase-phase voltage in the

dialogue Nominal-Limit values (i.e. 400 V in a 230 V P-N-system).

Enter the applicable transformation ratios for the current and voltage

converters in the ‘Hardware Settings’ dialog.

As conventional current converters have an output current of 1 A or 5 A AC

respectively at rated current, we recommend using current probes rather

than flexible current sensors, as they provide better resolution and linearity

at low currents.

4-Wire Network: 3-Wattmeter Method

This is the standard measurement configuration for three-phase networks with 3 voltage

and 3 current sensors.

Figure 3-4 shows the circuit diagram for 4-wire network (Wye connection).

Network

L1

L2

L3

PEN

LoadTransformer

Fluke 1760

Figure 3-4. Circuit Diagram: 4-Wire Network (Wye Connection)

3-8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

3wattm1.eps

Page 41

Operation

Connections to Measuring Circuits 3

Associated PC Software Settings:

messsystem1 u-i.bmp

If required, you have the option to determine events, Flicker and Harmonics, of the

phase-to-phase voltages.

Check the respective option.

Note

If this option (calculation) is checked, you must enter the phase-to-phase

voltage as the rated voltage V

in ‘Settings – Nominal / Limit values’ (e.g.

N

400 V in the 230 V P-N network).

Four-Wire Network: Three-Wattmeter Method with N Conductor Voltage and N Conductor Current

This is the standard measurement configuration for three-phase networks with 4 voltage

and 4 current sensors.

Figure 3-5 shows the circuit diagram for 4-wire network (3-wattmeter method) with Nconductor voltage and N-conductor current.

messsystem1 u-i-1.bmp

messsystem1 u-i-2.bmp

3-9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

1760

Users Manual

Transformer

Associated PC Software Settings:

PEN

L1

L2

L3

Fluke 1760

Figure 3-5. Circuit Diagram: 4-Wire

PE

L1

L2

L3

N

Load

3wattm2.eps

messsystem1 u-i-0.bmp

If required, you have the option to determine events, Flicker and Harmonics, of the

phase-to-phase voltages.

Check the respective option.

messsystem1 u-i-2.bmp

3-10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

Operation

Connections to Measuring Circuits 3

Note

If this option (Calculation) is checked, you have to enter the phase-to-phase

voltage as the rated voltage V

in ‘Settings – Nominal / Limit Values’ (e.g.

N

400 V in the 230 V P-N network).

Two Star-Connected Voltage Systems

With this method, you can determine two phase voltages and the respective N conductor

voltages in two star connected three-phase systems.

Figure 3-6 shows the circuit diagram for 2-voltage system with neutral.

Mains

L1

L1

L2

L3

PEN

Figure 3-6. Circuit Diagram: 2 Voltage System with Neutral

Associated PC Software Settings:

Fluke 1760

L2

L3

N

PE

System-U-U-Stern.eps

messsystem2.bmp

Note

The power quality assessment according to EN50160 can be performed for

the phase voltages of system 1 and system 2 respectively; the preset limit

values apply to both evaluations.

3-11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

1760

Users Manual

If required, you have the option to determine events, Flicker and Harmonics, of the

phase-to-phase voltages.

Check the respective option.

Note

If this option (Calculation) is checked, you have to enter the phase-to-phase

voltage as the rated voltage V

in ‘Settings – Nominal / Limit Values’ (e.g.

N

400 V in the 230 V P-N network).

Two Voltage Systems in Delta Configuration

This method is used to measure 3 phase-to-phase voltages in two delta-configured threephase systems. Channels CH4 and CH8 can be used for other parameters.

messsystem1 u-i-2.bmp

Figure 3-7 shows the circuit diagram for 2-voltage system in Delta connection.

Mains

L1

L2

L3

Fluke 1760

Figure 3-7. Circuit Diagram: 2 Voltage System in Delta Connection

Load

L1

L2

L3

system u-u dreieck.eps

3-12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 45

Operation

Methods of Measurement/Formulas 3

Associated PC Software Settings:

messsystem4.bmp

Note

The power quality assessment according to EN50160 can be performed for

the phase-to-phase voltages of system 1 and system 2 respectively; the

preset limit values apply to both evaluations.

We have to enter the phase-to-phase voltage as the rated voltage V

‘Settings – Nominal/Limit Values’ (e.g. 400 V in the 230 V P-N network).

Methods of Measurement/Formulas

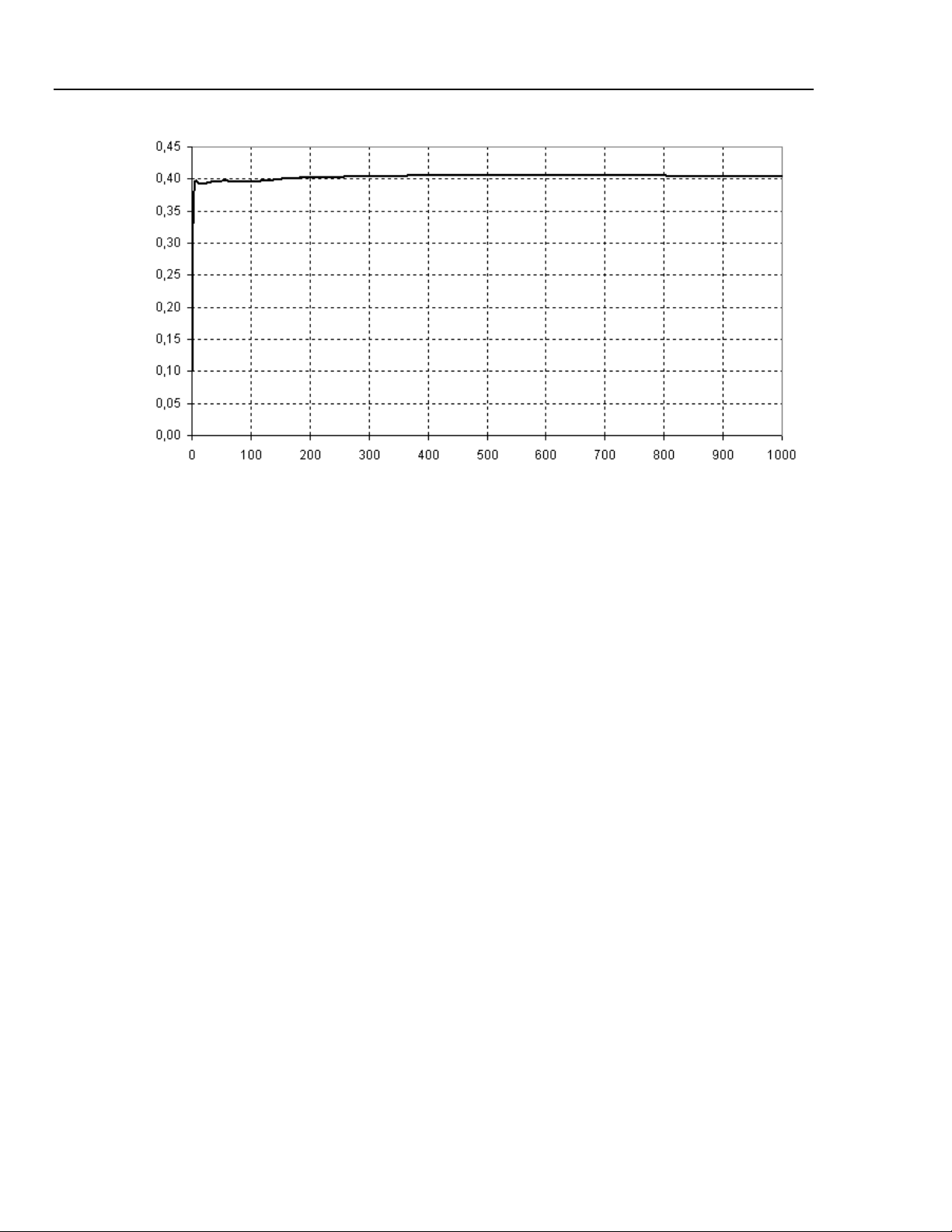

Parameter Aggregation

Signal Sampling

The device samples measurement signals at a nominal frequency of 10.24 kHz at nominal

power frequencies of 50 Hz and 60 Hz respectively.

The sampling frequency is synchronized to the power frequency on the reference channel

CH1, the signal level has to be at least 10 % of the input range. The required PLL (Phase

Locked Loop) is realized in the firmware of the instrument.

The synchronization range is according to IEC 61000-4-30 class A:

• Range for 50 Hz systems: 50 Hz ±15 % (42.5 Hz - 57.5 Hz)

• Range for 60 Hz systems: 60 Hz ±15 % (51 Hz - 69 Hz)

• Resolution: 16 ppm

Aggregations

The time aggregation2:02:05 PM of the measurement values is according to IEC 610004-30 class A, section 4.5 based on 10/12 cycle values (10 cycles for 50 Hz and 12 cycles

for 60 Hz nominal frequency).

N

in

The following time aggregations are available:

• Half cycle, full cycle updated every half cycle, 200 ms (precisely: 10/12 cycle

values), 3 s (precisely: 150/180 cycles), 10 minutes, 2 hours, Free interval ( ≥ 10

seconds)

• Half cycle and full cycle values are based on the zero crossings of the

fundamental

3-13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 46

1760

Users Manual

• The 10/12 cycle values are aggregated from 2.048 samples synchronized to the

power frequency

• The 3s (150/180 cycles)-intervals are derived from 15 consecutive 10/12 cycle

intervals

• The 10 minute and free interval values are based on the synchronized 10/12 cycle

values

• 2 hours interval is aggregated from 12 – ten minute intervals

• The 10 minute values are synchronized to the absolute time (e.g. via GPS time

sync option)

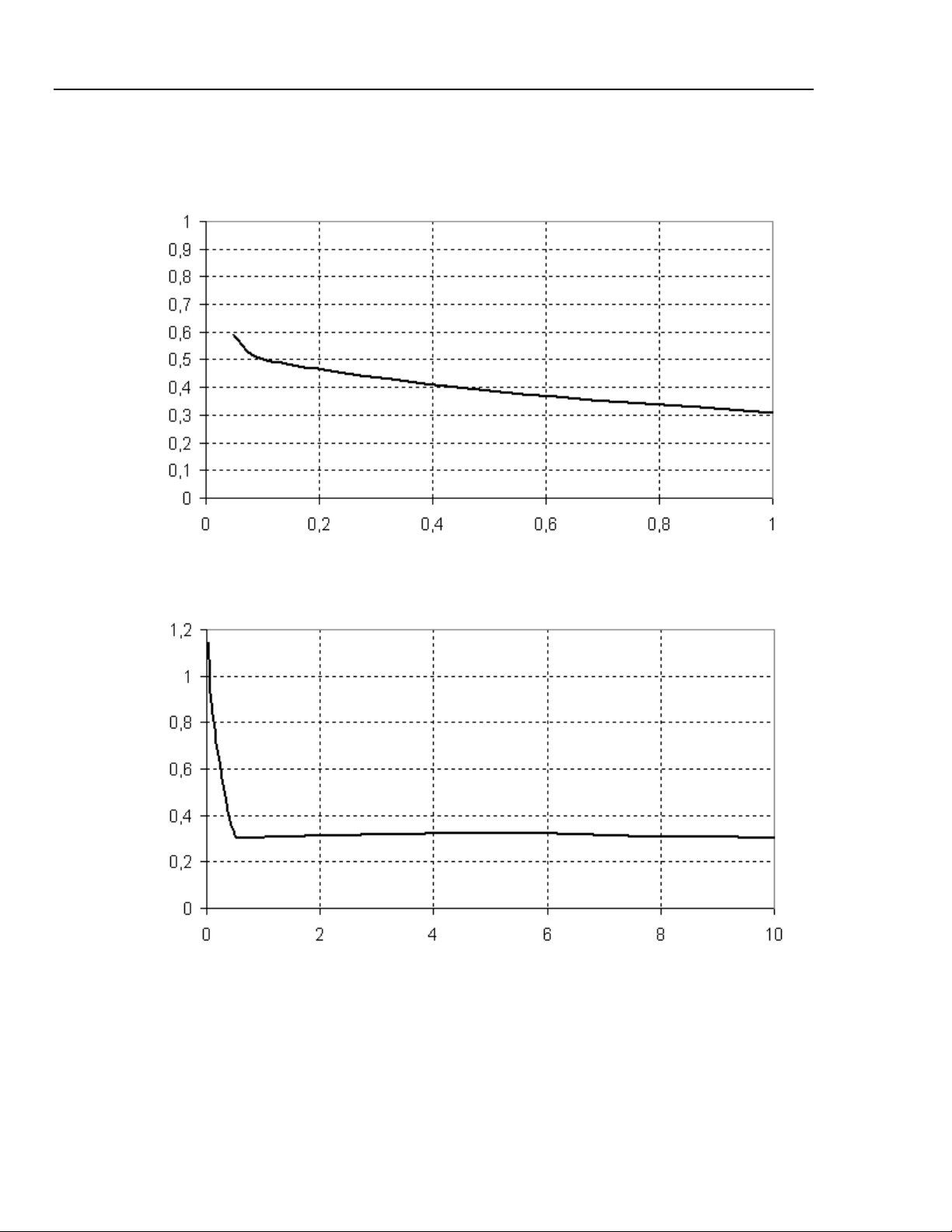

Power Frequency

For 10 s frequency values, the sample data are filtered by a 2

cut-off frequency is 50 Hz for 50 Hz nominal frequency and 60 Hz for 60 Hz nominal

frequency). Based on the filtered signal whole periods within 10 s intervals (taken from

the internal real time clock) are counted by detecting the zero crossings. The frequency is

calculated by dividing the number of whole periods by the duration of this number of

whole periods. The time interval is derived from the timestamps generated by the

hardware of the first and the last sample within the block of whole periods. A special

calculation method is used for the frequency measurement related to the 10 ms and 20 ms

(half/full cycle) rms values. The measured frequency is the sync frequency of the PLL

which is refreshed every 200 ms (based on the FFT evaluation).

nd

order IIR filter (the 3 dB

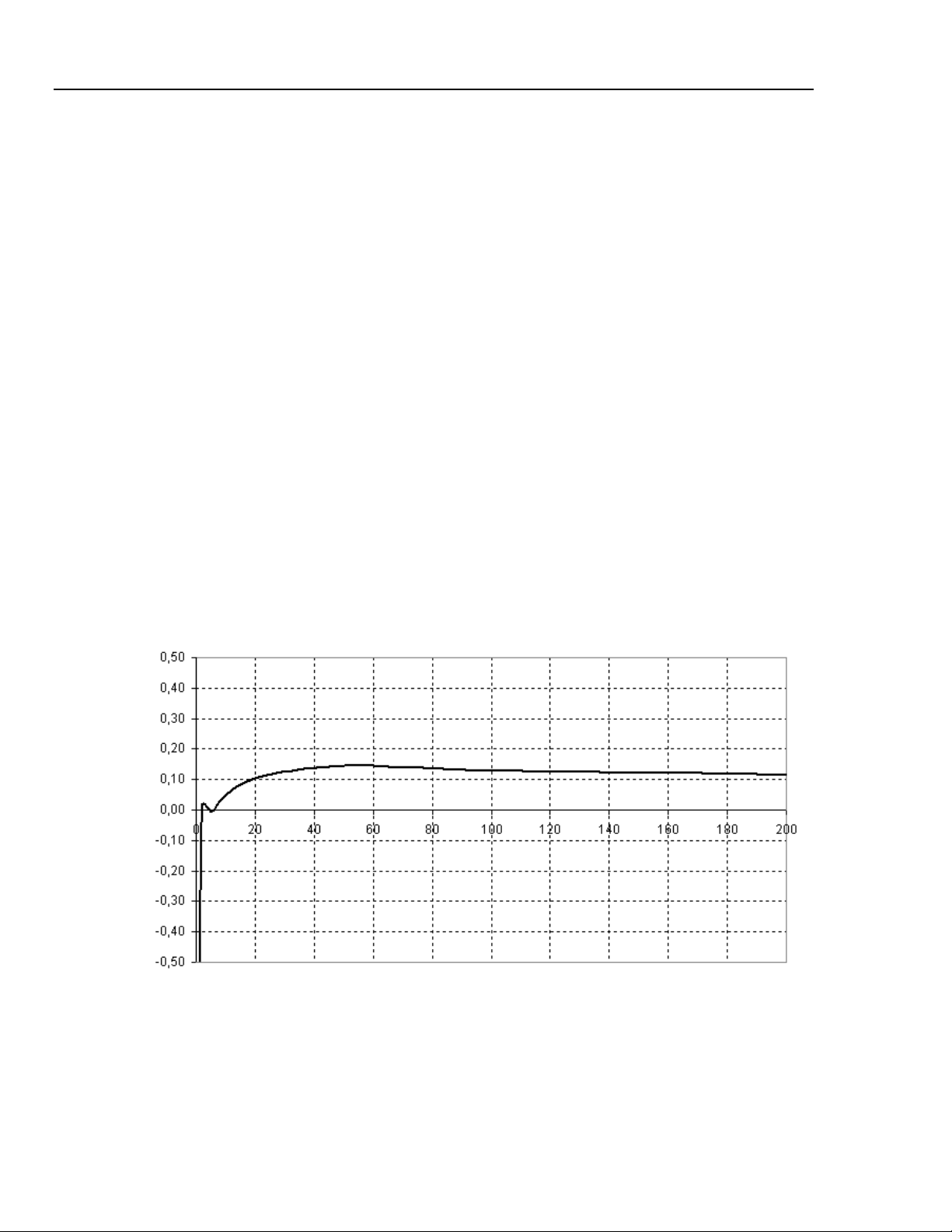

Voltage, Current rms Values, Min-/Max-Values

Half cycle rms is synchronized with the zero crossings of the fundamental component.

The fundamental component zero crossing is calculated from 200 ms FFT. Half cycle rms

is available as real half cycle rms and/or as full cycle rms, updated every half cycle.

The extreme values (Min-, Max-values) are derived from the half cycle rms values or full

cycle rms values updated every half cycle (whatever is configured in the “Nominal and

Limit Values” settings panel in PQ Analyze.

The interval values are averaged squared over the respective time interval.

FFT – Fast Fourier Transformation

FFT is calculated using an algorithm which is optimized for real input and complex

output with 2.048 points. As long as the PLL controlling the sampling frequency is

locked, no window function is applied. If locking cannot be established, a Hanning

window is used. The FFT is caclulated over 200 ms intervals and therefore results in a

frequency spectrum of 1024 5 Hz bins (DC to 5115 Hz).

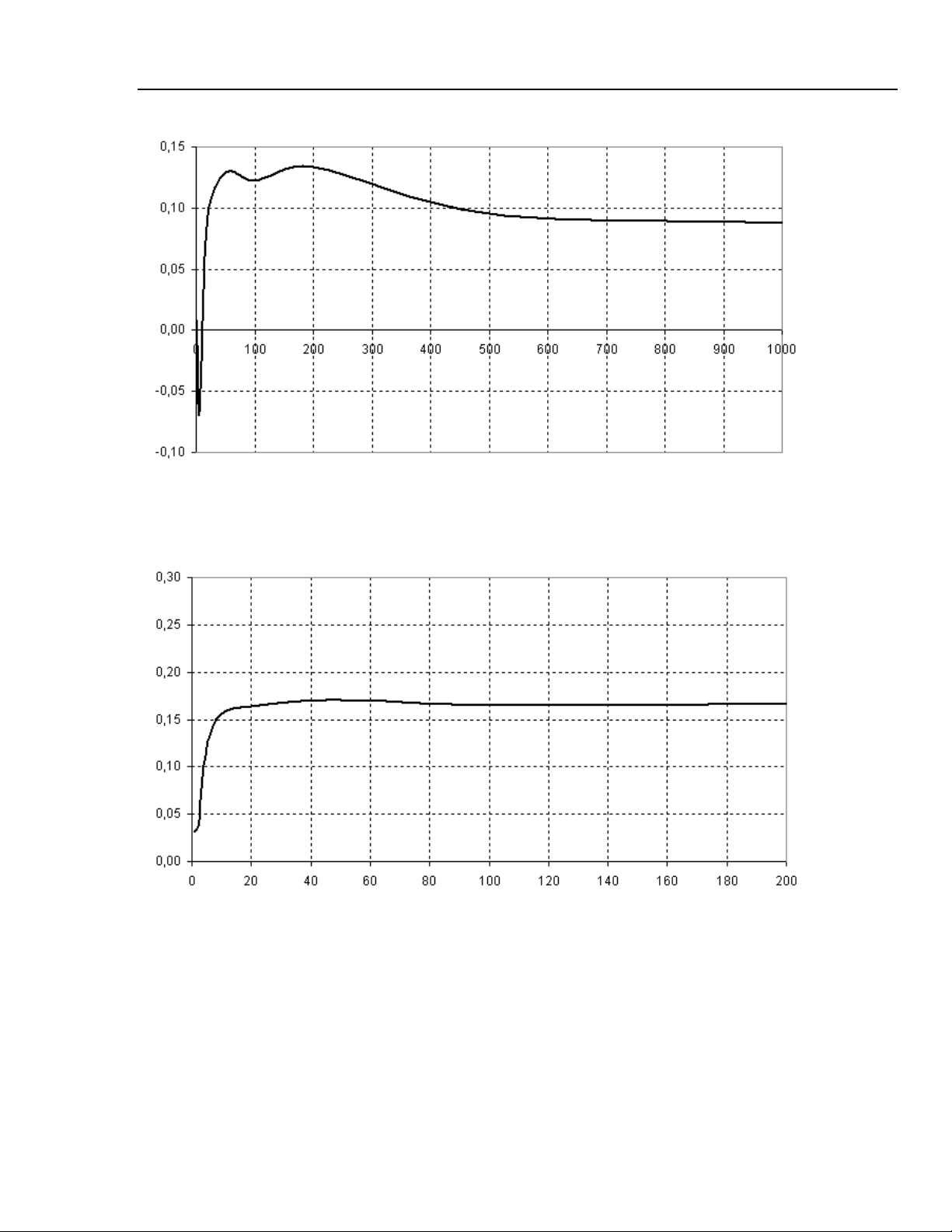

Calculation of Power Parameters

Two different sets of power parameter calculations are used. One for aggregations of

200ms and higher the other one for half and full cycle aggregations.

Aggregations 200 ms and higher

Real power

Real power

1023

∑

3-14

Find Quality Products Online at: sales@GlobalTestSupply.com

i

P is derived from the results of the FFT calculations of voltage and current.

⋅⋅=

cos

IUP

=

0

ϕ

iii

www.GlobalTestSupply.com

Page 47

Operation

ϕ

Methods of Measurement/Formulas 3

where

U rms value of the voltage bin with the frequency i⋅5 Hz

i

I rms value of the current bin with the frequency i⋅5 Hz

i

phase angle difference between voltage and current of the frequency i⋅5 Hz

i

The 3-phase real power sum is calculated as

PPPP ++=

321 LLLsum

Apparent power

Apparent power

S is calculated by multiplying rms values of voltage and current of the

given aggregation.

IUS ⋅=

The 3-phase apparent power sum is calculated as

Reactive power

The harmonic reactive power

of voltage and current. The index h in

component is derived from the harmonics (FFT) calculation.

1023

∑

=

i

Because every frequency component of the calculation has a sign,

other reactive power components are unsigned (always positive) by definition.

The 3-phase harmonic reactive power sum is calculated as

The total reactive power

tot

0

⋅⋅=

sin

IUQ

22

PSQ

−=

SSSS ++=

321 LLLsum

Q is also derived from the results of the FFT calculations

h

ϕ

iiih

QQQQ ++=

321 LhLhLhsumh

Q is calculated by

tot

Q indicates that the calculated reactive power

h

Q is also signed. All

h

The 3-phase total reactive power sum is calculated as

QQQQ ++=

321 LtotLtotLtotsumtot

The remaining reactive power component

Q (d stands for distortion) contains the rest of

d

the reactive power phenomena (mainly distortion reactive power and modulation reactive

power, the first originating e.g. from power converters with highly non sinusoidal current

waveforms, the latter from pulsating loads).

3-15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 48

1760

Users Manual

The 3-phase distortion reactive power sum is calculated as

Please note that the quadratic terms in the

Power factor

For the power factor one of two different formulas can be selected by the user through the

“Options > Power Factor” menu in PQ Analyze.

Formula 1: The sign is taken from the reactive harmonic power therefore giving an

indication about inductive or capacitive characteristic of the load.

PF ⋅=

22

QQQ −=

htotd

QQQQ ++=

321 LdLdLdsumd

Q calculation means that

d

22

QQQ −≠

sumhsumtotsumd

P

Q

h

Q

S

h

Formula 2: The sign is taken from the real power therefore giving the power flow

direction (motor / generator characteristic of the load).

P

PF =

S

The 3-phase power factor sum is calculated as

PF ⋅=

sum

Displacement power factor cos φ

The cos φ is most commonly referred to as the power factor of the fundamental

component. More general there is a cos φ for every harmonic frequency component.

When you select the harmonics analysis in the main analysis window in PQ Analyze you

can display the cos φ for all harmonics including the fundamental.

Harmonics analysis parameter group:

The formula used for calculating the cos φ is:

ϕ

Q

P

sum

S

sum

=

i

Q

sumh

or

sumh

⎛

⎜

arctancoscos

⎜

⎝

⎛

Q

⎜

⎜

P

⎝

PF =

sum

⎞

⎞

i

⎟

⎟

⎟

⎟

i

⎠

⎠

P

sum

S

sum

3-16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 49

Operation

P

where

P Real power of harmonic order i

i

Q Reactive power of harmonic order i

i

For historic reasons the cos φ parameter is also included in the V-I-P parameter group:

Calculation formula:

Methods of Measurement/Formulas 3

ϕ

where

⎛

⎜

=

⎜

⎝

⎛

Q

h

⎜

arctancoscos

⎜

P

⎝

P Real power

Q Harmonic reactive power

h

If you want to display the displacement power factor of the fundamental

component select the harmonics analysis parameter group and choose the

fundamental component in the drop-down list of available parameters.

Half and full cycle aggregations

Real power

Real power

the time domain.

n

∑

i

=

1

P

=

is calculated by directly multiplying the samples of voltage and current in

iiiu

⋅

)()(

n

⎞

⎞

⎟

⎟

⎟

⎟

⎠

⎠

Note

where