Page 1

1745

Power Quality Logger

®

PN 2560366

April 2006 Rev.1, 7/06

© 2006 Fluke Corporation, All rights reserved.

All product names are trademarks of their respective companies.

Users Manual

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship

under normal use and service. The warranty period is two years and begins on the date of

shipment. Parts, product repairs, and services are warranted for 90 days. This warranty

extends only to the original buyer or end-user customer of a Fluke authorized reseller,

and does not apply to fuses, disposable batteries, or to any product which, in Fluke's

opinion, has been misused, altered, neglected, contaminated, or damaged by accident or

abnormal conditions of operation or handling. Fluke warrants that software will operate

substantially in accordance with its functional specifications for 90 days and that it has

been properly recorded on non-defective media. Fluke does not warrant that software will

be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to enduser customers only but have no authority to extend a greater or different warranty on

behalf of Fluke. Warranty support is available only if product is purchased through a Fluke

authorized sales outlet or Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for importation costs of repair/replacement parts when

product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price,

free of charge repair, or replacement of a defective product which is returned to a Fluke

authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain

return authorization information, then send the product to that service center, with a description of the difficulty, postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke determines that failure

was caused by neglect, misuse, contamination, alteration, accident, or abnormal condition

of operation or handling, including overvoltage failures caused by use outside the product’s specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair costs and obtain authorization before commencing the work.

Following repair, the product will be returned to the Buyer transportation prepaid and the

Buyer will be billed for the repair and return transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF

DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty,

or exclusion or limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is

held invalid or unenforceable by a court or other decision-maker of competent jurisdiction,

such holding will not affect the validity or enforceability of any other provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

Page 3

LIMITES DE GARANTIE ET DE RESPONSABILITE

La société Fluke garantit l’absence de vices de matériaux et de fabrication de ses

produits dans des conditions normales d’utilisation et d’entretien. La période de garantie

est de deux ans et prend effet à la date d’expédition. Les pièces, les réparations de

produit et les services sont garantis pendant une période de 90 jours. Cette garantie ne

s’applique qu’à l’acheteur d’origine ou à l’utilisateur final s’il est client d’un distributeur

agréé par Fluke, et ne s’applique pas aux fusibles, aux batteries/piles interchangeables

ni à aucun produit qui, de l’avis de Fluke, a été malmené, modifié, négligé, contaminé ou

endommagé par accident ou soumis à des conditions anormales d’utilisation et de manipulation. Fluke garantit que le logiciel fonctionnera en grande partie conformément à ses

spécifications fonctionnelles pendant une période de 90 jours et qu’il a été correctement

enregistré sur des supports non défectueux. Fluke ne garantit pas que le logiciel est

exempt d’erreurs ou qu’il fonctionnera sans interruption.

Les distributeurs agréés par Fluke appliqueront cette garantie à des produits vendus

neufs et qui n’ont pas servi, mais ne sont pas autorisés à offrir une garantie plus étendue

ou différente au nom de Fluke. Le support de garantie est offert uniquement si le produit a

été acquis par l’intermédiaire d’un point de vente agréé par Fluke ou bien si l’acheteur a

payé le prix international applicable. Fluke se réserve le droit de facturer à l’acheteur les

frais d’importation des pièces de réparation ou de remplacement si le produit acheté dans

un pays a été expédié dans un autre pays pour y être réparé.

L’obligation de garantie de Fluke est limitée, au choix de Fluke, au remboursement du

prix d’achat, ou à la réparation/remplacement gratuit d’un produit défectueux retourné

dans le délai de garantie à un centre de service agréé par Fluke.

Pour avoir recours au service de la garantie, mettez-vous en rapport avec le centre de

service agréé Fluke le plus proche pour recevoir les références d’autorisation de renvoi,

ou envoyez le produit, accompagné d’une description du problème, port et assurance

payés (franco lieu de destination), à ce centre de service. Fluke décline toute responsabilité en cas de dégradations survenues au cours du transport. Après la réparation sous

garantie, le produit est renvoyé à l’acheteur, frais de port payés d’avance (franco lieu

de destination). Si Fluke estime que le problème est le résultat d’une négligence, d’un

traitement abusif, d’une contamination, d’une modification, d’un accident ou de conditions

de fonctionnement ou de manipulation anormales, notamment de surtensions liées à

une utilisation du produit en dehors des spécifications nominales, ou de l’usure normale

des composants mécaniques, Fluke fournira un devis des frais de réparation et ne

commencera la réparation qu’après en avoir reçu l’autorisation. Après la réparation, le

produit est renvoyé à l’acheteur, en port payé (franco point d’expédition) et les frais de

réparation et de transport lui sont facturés.

LA PRESENTE GARANTIE EST EXCLUSIVE ET TIENT LIEU DE TOUTES AUTRES

GARANTIES, EXPRESSES OU IMPLICITES, Y COMPRIS, MAIS NON EXCLUSIVEMENT, TOUTE GARANTIE IMPLICITE DE VALEUR MARCHANDE OU D’ADEQUATION

A UN USAGE PARTICULIER. FLUKE NE POURRA ETRE TENU RESPONSABLE

D’AUCUN DOMMAGE PARTICULIER, INDIRECT, ACCIDENTEL OU CONSECUTIF, NI

D’AUCUN DEGAT OU PERTE, DE DONNEES NOTAMMENT, SUR UNE BASE

CONTRACTUELLE, EXTRA-CONTRACTUELLE OU AUTRE.

Etant donné que certaines juridictions n’admettent pas les limitations d’une condition

de garantie implicite, ni l’exclusion ou la limitation des dommages directs ou indirects, il

se peut que les limitations et les exclusions de cette garantie ne s’appliquent pas à

chaque acheteur. Si une disposition quelconque de cette garantie est jugée non valide ou

inapplicable par un tribunal ou un autre pouvoir décisionnel compétent, une telle décision

n’affectera en rien la validité ou le caractère exécutoire de toute autre disposition.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-0777

États-Unis

Fluke Europe B.V.

P.O. Box 1186

5602, boul. Eindhoven

Pays-Bas

Page 4

BESCHRÄNKTE GARANTIE UND HAFTUNGSBEGRENZUNG

Fluke gewährleistet, dass jedes Fluke-Produkt unter normalem Gebrauch und Service frei von

Material- und Fertigungsdefekten ist. Die Garantiedauer beträgt zwei Jahre ab Versanddatum.

Ersatzteile, Produktreparaturen und Servicearbeiten haben eine Garantie von 90 Tagen. Diese

Garantie wird ausschließlich dem Ersterwerber bzw. dem Endverbraucher, der das betreffende

Produkt von einer von Fluke autorisierten Verkaufsstelle erworben hat, geleistet und erstreckt sich

nicht auf Sicherungen, Einwegbatterien oder irgendwelche anderen Produkte, die nach dem

Ermessen von Fluke unsachgemäß verwendet, verändert, vernachlässigt, verunreinigt, durch

Unfälle beschädigt oder abnormalen Betriebsbedingungen oder einer unsachgemäßen

Handhabung ausgesetzt wurden. Fluke garantiert für einen Zeitraum von 90 Tagen, dass die

Software im Wesentlichen in Übereinstimmung mit den einschlägigen Funktionsbeschreibungen

funktioniert und dass diese Software auf fehlerfreien Datenträgern gespeichert wurde. Fluke

übernimmt jedoch keine Garantie dafür, dass die Software fehlerfrei ist und störungsfrei arbeitet.

Von Fluke autorisierte Verkaufsstellen dürfen diese Garantie ausschließlich für neue und nicht

benutzte, an Endverbraucher verkaufte Produkte leisten. Die Verkaufsstellen sind jedoch nicht dazu

berechtigt, diese Garantie im Namen von Fluke zu verlängern, auszudehnen oder in irgendeiner

anderen Weise abzuändern. Der Käufer hat nur dann das Recht, aus der Garantie abgeleitete

Unterstützungsleistungen in Anspruch zu nehmen, wenn das Produkt bei einer von Fluke

autorisierten Vertriebsstelle erworben oder der jeweils geltende internationale Preis gezahlt wurde.

Fluke behält sich das Recht vor, dem Käufer Einfuhrgebühren für Ersatzteile in Rechnung zu

stellen, falls der Käufer das Produkt nicht in dem Land zur Reparatur einsendet, in dem er das

Produkt ursprünglich erworben hat.

Die Garantieverpflichtung von Fluke beschränkt sich darauf, dass Fluke nach eigenem Ermessen

den Kaufpreis ersetzt oder aber das defekte Produkt unentgeltlich repariert oder austauscht, wenn

dieses Produkt innerhalb der Garantiefrist einem von Fluke autorisierten Servicezentrum zur

Reparatur übergeben wird.

Um die Garantieleistung in Anspruch zu nehmen, wenden Sie sich bitte an das nächstgelegene von

Fluke autorisierte Servicezentrum, um Rücknahmeinformationen zu erhalten, und senden Sie dann

das Produkt mit einer Beschreibung des Problems und unter Vorauszahlung von Fracht- und

Versicherungskosten (FOB-Bestimmungsort) an das nächstgelegene von Fluke autorisierte

Servicezentrum. Fluke übernimmt keine Haftung für Transportschäden. Im Anschluss an die

Reparatur wird das Produkt unter Vorauszahlung der Frachtkosten (Frachtfrei-Bestimmungsort) an

den Käufer zurückgesandt. Wenn Fluke feststellt, dass der Defekt auf Vernachlässigung,

unsachgemäße Handhabung, Verunreinigung, Veränderungen am Gerät, einen Unfall oder auf

anormale Betriebsbedingungen, einschließlich durch außerhalb der für das Produkt spezifizierten

Belastbarkeit verursachter Überspannungsfehler oder normaler Abnutzung mechanischer

Komponenten, zurückzuführen ist, wird Fluke dem Erwerber einen Voranschlag der

Reparaturkosten zukommen lassen und erst die Zustimmung des Erwerbers einholen, bevor die

Arbeiten in Angriff genommen werden. Nach der Reparatur wird das Produkt unter Vorauszahlung

der Frachtkosten an den Käufer zurückgeschickt, und es werden dem Käufer die Reparaturkosten

und die Versandkosten (Frachtfrei-Versandort) in Rechnung gestellt.

DIE VORSTEHENDEN GARANTIEBESTIMMUNGEN STE LLEN DEN E INZIGE N UND

ALLEINIGEN RECHTSANSPRUCH AUF SCHADENERS ATZ DES KÄUFE RS DAR UND GE LTEN

AUSSCHLIESSLICH UND AN STELLE ALLER A NDEREN VE RTRAG LICHEN ODER

GESETZLICHEN GEWÄHRLEISTUNGSPFLICHTEN, EINSCHLIESS LICH - JEDOCH N ICHT

DARAUF BESCHRÄNKT - DER GESETZLICHEN GEW ÄHRLE ISTUNG DER MARKT FÄHIGK EIT

UND DER EIGNUNG FÜR EINEN BESTIMMTEN Z WECK. FLUK E HAFTET NIC HT FÜR

SPEZIELLE, UNMITTELBARE, MITTELBARE, BEGLEIT- ODE R FOLGESCHÄDEN ODER

VERLUSTE, EINSCHLIESSLICH VERLUST VON DATEN, UN ABHÄNGIG VON DER URSAC HE

ODER THEORIE.

In einigen Ländern ist die Begrenzung einer gesetzlichen Gewährleistung und der Ausschluss oder

die Begrenzung von Begleit- oder Folgeschäden nicht zulässig, sodass die oben genannten

Einschränkungen und Ausschlüsse möglicherweise nicht für jeden Käufer gelten. Sollte eine Klausel

dieser Garantiebestimmungen von einem zuständigen Gericht oder einer anderen

Entscheidungsinstanz für unwirksam oder nicht durchsetzbar befunden werden, so bleiben die

Wirksamkeit oder Durchsetzbarkeit anderer Klauseln dieser Garantiebestimmungen von einem

solchen Spruch unberührt.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

USA

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

Niederlande

Page 5

GARANZIA LIMITATA E LIMITAZIONE DI RESPONSABILITÀ

Si garantisce che ogni prodotto Fluke è esente da difetti nei materiali e nella manodopera

per normali situazioni di uso. II periodo di garanzia è di due anni a decorrere dalla data di

spedizione. La garanzia sulle parti sostituite, sulle riparazioni e sugli interventi di

assistenza è di 90 giorni. La garanzia è valida solo per l’acquirente originale o l’utente

finale che abbia acquistato il prodotto presso un rivenditore Fluke autorizzato. Sono

esclusi i fusibili, le pile monouso e i prodotti che, a parere della Fluke, siano stati

adoperati in modo improprio, alterati, trascurati, contaminati o danneggiati in seguito a

incidente o condizioni anomale d’uso e maneggiamento. La Fluke garantisce che il

software funzionerà sostanzialmente secondo le specifiche per un periodo di 90 giorni e

che è stato registrato su supporti non difettosi. Non garantisce che il software sarà esente

da errori o che funzionerà senza interruzioni.

I rivenditori autorizzati Fluke estenderanno la garanzia sui prodotti nuovi o non usati

esclusivamente ai clienti finali, ma non potranno emettere una garanzia differente o più

completa a nome della Fluke. La garanzia è valida solo se il prodotto è stato acquistato

attraverso la rete commerciale Fluke o se I’acquirente ha pagato il prezzo internazionale

pertinente. La Fluke si riserva il diritto di fatturare all’acquirente i costi di importazione per

la riparazione/sostituzione delle parti nel caso in cui il prodotto acquistato in un Paese sia

sottoposto a riparazione in un altro.

L’obbligo di garanzia è limitato, a scelta della Fluke, al rimborso del prezzo d’acquisto,

alla riparazione gratuita o alla sostituzione di un prodotto difettoso che sia inviato ad un

centro di assistenza autorizzato Fluke entro il periodo di garanzia.

Per usufruire dell’assistenza in garanzia, rivolgersi al più vicino centro di assistenza

autorizzato Fluke per ottenere informazioni sull’autorizzazione alla restituzione, quindi

spedire il prodotto al centro di assistenza, allegando una descrizione del difetto, franco

destinatario e assicurato. La Fluke declina ogni responsabilità di danni durante il

trasporto. Una volta eseguite le riparazioni in garanzia, il prodotto sarà restituito

all’acquirente, franco destinatario. Se la Fluke stabilisce che il guasto è stato causato da

negligenza, uso improprio, contaminazione, alterazione, incidente o condizioni anomale di

uso o maneggiamento (comprese le sovratensioni causate dall’uso dello strumento oltre

la portata nominale e l’usura dei componenti meccanici dovuta all’uso normale dello

strumento), la Fluke darà una stima dei costi di riparazione e attenderà l’autorizzazione

dell’utente prima di procedere con la riparazione. A seguito della riparazione, il prodotto

sarà restituito all’acquirente con addebito delle spese di riparazione e di spedizione.

LA PRESENTE GARANZIA È L’UNICO ED ESCLUSIVO RICORSO DISPONIBILE

ALL’ACQUIRENTE ED È EMESSA IN SOSTITUZIONE DI OGNI ALTRA GARANZIA,

ESPRESSA O IMPLICITA, COMPRESA , MA NON LIMITATA A ESSA, QUALSIASI

GARANZIA IMPLICITA DI COMMERCIABILITÀ O DI IDONEITÀ PER SCOPI

PARTICOLARI. LA FLUKE NON SARÀ RESPONSABILE DI NESSUN DANNO O

PERDITA SPECIALI, INDIRETTI O ACCIDENTALI, DERIVANTI DA QUALUNQUE

CAUSA O TEORIA.

Poiché alcuni Paesi non consentono di limitare i termini di una garanzia implicita né

l’esclusione o la limitazione di danni accidentali o indiretti, le limitazioni e le esclusioni

della presente garanzia possono non valere per tutti gli acquirenti. Se una clausola

qualsiasi della presente garanzia non è ritenuta valida o attuabile dal tribunale o altro foro

competente, tale giudizio non avrà effetto sulla validità delle altre clausole.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

USA

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

Paesi Bassi

Page 6

GARANTIA LIMITADA E LIMITAÇÃO DE RESPONSABILIDADE

Todos os produtos da Fl uk e são garantidos contra defei tos de m at erial e d e mã o- de- ob ra ,

sob condições de uso e serviç o norm al. O perío do de gara nti a é de dois an os, a pa rtir da

data de remessa do produto. As peças, reparos do produto, e serviços são garantidos por

90 dias. Esta garantia aplica-se apenas ao comprador original, ou ao cliente usuário-final de

um revendedor autorizad o da F luke , e n ã o c obre fusíveis, baterias descartáveis, nem

qualquer produto que, na opinião da Fluke, tenha sido usado de forma inadequada,

alterado, contaminado, ou tenha sido danificado por acidente ou condições anormais de

operação ou manuseio. A Fluke gar ante que o so ftwa re fu ncio nará de ac ordo com as suas

especificações técnicas pelo per íod o de 90 dias , e que fo i grav ado de forma ad equ ada em

meio físico sem defeitos. A Fluk e não gar ante que o sof twar e não ap rese ntar á erros nem

que funcionará ininterruptamente.

Os revendedores Fluke autorizados devem conceder esta garantia somente para produtos

novos e não-usados, mas não estão autorizados a ampliá-la ou modificá-la de qualquer

forma em nome da Fluke. A ass ist ência técnica coberta pela garantia e st á d ispo nív e l se o

produto houver sido adquirido de uma loja autorizada da Fluke, ou se o Comprador tiver

pago o preço internacional aplicável. A Fluke reserva-se o direito de cobrar do Comprador

os custos de importação das peças de repos ição /r epar o nos casos em que o produ to tenha

sido comprado em um país e remetido para re paros em outr o país .

A obrigação da Fluke no tocante a esta garantia é limitada, a critério da Fluke, à

devolução da importância correspondente ao preço pago pelo produto, a consertos

gratuitos, ou à substituição de produto defeituoso que seja devolvido a um centro de

assistência técnica autorizado Fluke dentro do período coberto pela garantia.

Para obter serviços cobertos pela garantia, entre em contato com o centro de assistência

técnica autorizado Fluke mais próximo, ou remeta o produto, com uma descrição do

problema encontrado e com fret e e segur o pagos (FO B no des tino) , ao c entr o de

assistência técnica mais próximo. A Fluke não se responsabiliza por nenhum dano que

possa ocorrer durante o tra nspor te . A pós serem efetuados os serviços co ber t os pe la

garantia, o produto será remetido de volta ao Comprador, com frete pago (FOB no destino).

Se a Fluke constatar que a falha do produto foi causada por negligência, uso inadequado,

contaminação, alteraç ões, acidente, ou condiç ões anormais de operação o u m anuse io,

inclusive falhas devidas a sobrevoltagem ca usa das p e l o uso do pr o du t o fo ra d as f a ixas e

classificações especificadas, o u pelo d esg as te n orma l d e co mp on ent es mec â n icos , a Fluke

dará uma estimativa dos custos de repa ro, e obterá au torizaç ão do Co mprad or antes de

efetuar tais reparos. Após a realiza ção dos rep aros, o pr odut o será re met ido de volta ao

Comprador com frete pago, e este reembolsará a Fluke pelos custos do reparo e da

remessa (FOB no local de remessa).

ESTA GARANTIA É O ÚNICO E EX CL U SI VO R ECUR SO JUR ÍD ICO DO COMPRADOR,

E SUBSTITUI TODAS AS OUTRAS GARANTIAS, EXPRESSAS OU IMPLÍCITAS,

INCLUINDO, MAS NÃO SE LIMITANDO A, QUALQUER GARANTIA IMPLÍCITA DE

COMERCIABILIDADE OU ADEQU A ÇÃO PARA UM DETERMINADO FIM . A FL UK E N ÃO

SE RESPONSABILIZA POR NENHUM DANO OU PERDA, INCIDENTAL OU

CONSEQÜENTE, QUE POS S A O CORRER POR QUALQUER MO T I VO OU QUE SEJA

DECORRENTE DE QUALQUER CAUSA OU TEORIA JURÍDICA.

Como alguns estados ou p a íses nã o p er m it em a exc l usão ou lim it açã o d os t ermos de

garantias implícitas, nem de danos incidentais ou conseqüentes, esta limitação de

responsabilidade poderá não se aplicar ao seu caso. Se alguma provisão desta Garantia for

considerada inválida ou inexeqüível por algum tribunal ou outro órgão de jurisdição

competente, tal decisão judicial não afetará a validade ou exeqüibilidade de nenhuma

outra provisão.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090,

EUA

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

Holanda

Page 7

GARANTÍA LIMITADA Y LIMITACIÓN DE RESPONSABILIDAD

Todo producto de Fluke está garantizado contra defectos en los materiales y en la mano

de obra en condiciones normales de utilización y mantenimiento. El periodo de garantía es de tres

años y comienza en la fecha de despacho. Las piezas de repuesto, reparaciones y servicios están

garantizados por 90 días. Esta garantía se extiende sólo al comprador

original o al cliente usuario final de un revendedor autorizado por Fluke y no es válida para

fusibles, baterías desechables ni para ningún producto que, en opinión de Fluke, haya sido

utilizado incorrectamente, modificado, maltratado, contaminado, o sufrido daño accidental

o por condiciones anormales de funcionamiento o manipulación. Fluke garantiza que el

software funcionará substancialmente de acuerdo con sus especificaciones funcionales

durante 90 días y que ha sido grabado correctamente en un medio magnético sin defectos. Fluke

no garantiza que el software no contenga errores ni que operará permanentemente.

Los revendedores autorizados por Fluke podrán extender esta garantía solamente a los Compradores finales de productos nuevos y sin uso previo, pero carecen de autoridad para extender una

garantía mayor o diferente en nombre de Fluke. El soporte técnico en garantía está disponible sólo

si el producto se compró a través de un centro de distribución autorizado por Fluke o si el comprador pagó el precio internacional correspondiente. Cuando un producto comprado en un país sea

enviado a otro país para su reparación, Fluke se reserva el derecho de facturar al Comprador los

gastos de importación de las reparaciones/repuestos.

La obligación de Fluke de acuerdo con la garantía está limitada, a elección de Fluke, al

reembolso del precio de compra, la reparación gratuita o el reemplazo de un producto

defectuoso que sea devuelto a un centro de servicio autorizado de Fluke dentro del

período de garantía.

Para obtener servicio de garantía, póngase en contacto con el centro de servicio autorizado por

Fluke más cercano para obtener la información correspondiente a la autorización de la devolución,

después envíe el producto a ese centro de servicio, con una descripción del fallo, con los portes y

seguro prepagados (FOB destino). Fluke no se hace responsable de los daños ocurridos durante el

transporte. Después de la reparación de garantía, el producto se devolverá al Comprador con los

fletes ya pagados (FOB destino). Si Fluke determina que el problema fue debido a negligencia,

mala utilización, contaminación, modificación, accidente

o una condición anormal de funcionamiento o manipulación, incluidas las fallas por sobretensión

causadas por el uso fuera de los valores nominales especificados para el producto, o al desgaste

normal de los componentes mecánicos, Fluke preparará una estimación de los costes de reparación y obtendrá la debida autorización antes de comenzar el trabajo. Al concluir la reparación, el

producto se devolverá al Comprador con los fletes ya pagados, facturándosele la reparación y los

gastos de transporte (FOB en el sitio de despacho).

ESTA GARANTÍA ES EL ÚNICO Y EXCLUS IVO REC URS O DE L COMPRAD OR Y SUBST ITUYE

A TODAS LAS OTRAS GARANTÍAS, EXPRESAS O IMP LÍCITAS , INCLUYENDO , PERO S IN

LIMITARSE A, TODA GARANTÍA IMP LÍC ITA DE COMERCIABILIDAD O IDONEIDAD PARA UN

PROPÓSITO DETERMINADO. FLUKE NO SE RESPO NSABILIZA DE PÉ RDIDAS NI DAÑOS

ESPECIALES, INDIRECTOS, IMPREVISTOS O CONTINGENTES, INCLUIDA LA PÉRD IDA DE

DATOS, QUE SURJAN POR CUALQUIER TIPO DE CAUSA

O TEORÍA.

Como algunos países o estados no permiten la limitación de la duración de una garantía implícita ni

la exclusión ni limitación de los daños contingentes o resultantes, las limitaciones y exclusiones de

esta garantía pueden no regir para todos los Compradores. Si una cláusula de esta Garantía es

conceptuada no válida o inaplicable por un tribunal u otra instancia de jurisdicción competente, tal

concepto no afectará la validez o aplicabilidad de cualquier otra cláusula.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

EE.UU.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

Holanda

Page 8

有限担保和有限责任

Fluke 担保在正常使用和保养的情况下,其产品没有材料和工艺上的缺陷。

两年的担保期间由产品发货之日算起。部件、产品修理和服务的担保期限为

90 天。 本担保仅限于 Fluke 授权零售商的原购买人或最终用户,并且不适用

于一次性电池、电缆接头、电缆绝缘转换接头或 Fluke 认为由于误用、改装、

疏忽、污染及意外或异常操作或处理引起的任何产品损坏。Fluke 担保软件能

依照功能规格正常运行 90 天,并且软件是记录在无缺陷的媒介上。Fluke 并不

担保软件毫无错误或在运行中不会中断。

Fluke 授权的零售商应仅对最终用户就新的和未使用的产品提供本担保,但

无权代表Fluke 公司提供额外或不同的担保。 只有通过 Fluke 授权的销售店购

买的产品或者买方已经按适用的国际价格付款才能享受 Fluke 的担保支持。

在一国购买的产品需在他国修理时,Fluke 有权向买方要求负担重大修理/零

件更换费用。

Fluke 的担保为有限责任,由 Fluke 决定是否退还购买金额、免费修理或更换

在担保期间退还 Fluke 授权服务中心的故障产品。

如需要保修服务,请与您就近的 Fluke 授权服务中心联系,获得退还授权信息;

然后将产品寄至服务中心,并附上产品问题描述,同时预付运费和保险费(目的

地离岸价格)。Fluke 不承担运送途中发生的损坏。在保修之后,产品将被寄

回给买方并提前支付运输费(目的地交货)。 如果Fluke 认定产品故障是由于疏

忽、误用、污染、修改、意外或不当操作或处理状况而产生,包括未在产品规定

的额定值下使用引起的过压故障;或是由于机件日常使用损耗,则 Fluke 会估算

修理费用,在获得买方同意后再进行修理。在修理之后,产品将被寄回给买方并

预付运输费;买方将收到修理和返程运输费用(寄发地交货)的帐单。

本担保为买方唯一能获得的全部补偿内容,并且取代所有其它明示或隐含的担

保,包括但不限于适销性或满足特殊目的任何隐含担保。FLUKE 对任何特殊、

间接、偶发或后续的损坏或损失概不负责,包括由于任何原因或推理引起的数据

丢失。

由于某些国家或州不允许对隐含担保的期限加以限制、或者排除和限制意外或后

续损坏,本担保的限制和排除责任条款可能并不对每一个买方都适用。如果本担

保的某些条款被法院或其它具有适当管辖权的裁决机构判定为无效或不可执行,

则此类判决将不影响任何其它条款的有效性或可执行性。

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Page 9

Table of Contents

Title Page

Introduction .......................................................................................... 1

Information and PC Software CD..................................................... 1

Logger Power Supply ....................................................................... 2

Logging Functions ............................................................................ 2

Symbols ............................................................................................ 4

Safety Instructions ................................................................................ 4

Qualified Personnel........................................................................... 6

Standard Equipment and Optional Accessories ................................ 6

Features............................................................................................. 8

Power Network Configurations ........................................................ 11

Working with Logged Data............................................................... 11

Using the 1745 Power Quality Logger.................................................. 12

About Logging Jobs.......................................................................... 12

Preparing the Logger for Use............................................................ 13

Test Leads - Markings .................................................................. 15

Connecting Current Probes ........................................................... 15

Logging with Voltage Converters................................................. 15

Connecting the Logger...................................................................... 16

Connections in 3-Phase 4-Wire (Wye) Systems ........................... 19

Connections in 3-Phase 3-Wire (Delta) Systems .......................... 20

Connections for Single-Phase Logging......................................... 21

Connections for Medium Voltage Networks................................. 22

Logging............................................................................................. 24

Completing the Logging Job......................................................... 24

Evaluating the Logged Data.............................................................. 25

Methods of Logging.......................................................................... 25

Voltage Ranges................................................................................. 26

Signal Sampling............................................................................ 27

Resolution Accuracy......................................................................... 27

Voltage Variations ............................................................................ 27

Averaging Period .............................................................................. 28

Min/Max Values ........................................................................... 29

Voltage Interruptions .................................................................... 30

Voltage Dips and Swells............................................................... 31

Voltage Harmonics ........................................................................... 31

i

Page 10

1745

Users Manual

Current Harmonics ........................................................................... 32

Power ............................................................................................... 37

Measurement Theory............................................................................ 38

Maintenance ......................................................................................... 42

Lithium Battery ................................................................................ 42

Disposal............................................................................................ 42

Technical Specifications....................................................................... 43

Logging Parameters – Overview ...................................................... 43

General Specifications...................................................................... 48

Logging Function Parameters........................................................... 50

PQ Log PC Application Software ........................................................ 52

Index

Mains Signaling............................................................................ 32

THD V – In Function A................................................................ 33

Calculation of THD in Measuring Function P.............................. 34

Flicker .......................................................................................... 35

Unbalance..................................................................................... 36

Frequency..................................................................................... 36

Current Logging ........................................................................... 36

Logging Function A ..................................................................... 36

Crest Factor (CF).......................................................................... 36

Maximum Number of Intervals for Logging Funtion P................ 44

General Information ..................................................................... 44

Environmental Specifications....................................................... 45

EMC ............................................................................................. 45

Power Supply ............................................................................... 45

Measurement ................................................................................ 46

Input Voltage................................................................................ 46

Current Input with Flexi Set......................................................... 47

Current Input for Clamp ............................................................... 47

RMS Logging Slow Voltage Variations....................................... 48

Current Logging Values ............................................................... 48

Events Dips, Swells, Interruptions................................................ 48

Flicker .......................................................................................... 48

Power P, S, |P| .............................................................................. 49

Harmonics (Logging Function A Only)........................................ 49

Statistics ....................................................................................... 49

Logging Values ............................................................................ 50

Applications ................................................................................. 51

Live Reading (Online Test).......................................................... 53

ASCII Export................................................................................ 54

Timeplot Diagram ........................................................................ 55

UNIPEDE DISDIP Table............................................................. 56

Cumulative Frequency – Harmonics ............................................ 56

ii

Page 11

List of Tables

Table Title Page

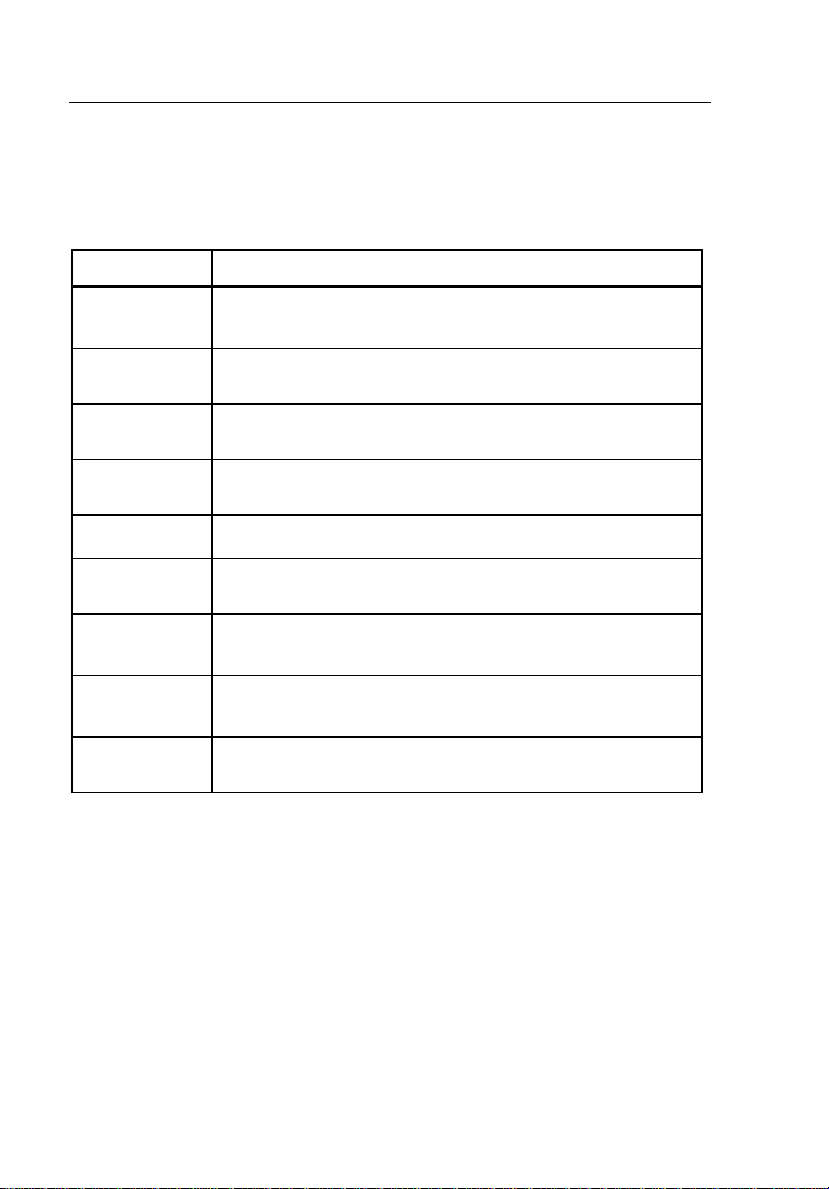

1. Symbols.............................................................................................. 4

2. Standard Equipment........................................................................... 7

3. Optional Accessories.......................................................................... 7

4. 1745 Power Quality Logger - Controls and Indicators....................... 9

5. Test Leads - Markings........................................................................ 15

6. Measuring Ranges.............................................................................. 26

7. Logging Parameters - Overview......................................................... 43

iii

Page 12

1745

Users Manual

iv

Page 13

List of Figures

Figure Title Page

1. 1745 Power Quality Logger ............................................................... 3

2. 1745 Power Quality Logger - Front View.......................................... 8

3. Supplying Operating Power to the Logger......................................... 14

4. Logging in a 3-Phase 4-Wire System................................................. 19

5. Logging in a 3-Phase 3-Wire (Delta) System..................................... 20

6. Single-Phase Logging ........................................................................ 21

7. Measuring 3 Phase Voltages in a 3-Wire (Delta)

System with Three Voltage Converters.............................................. 22

8. Two-Element Delta Connections ....................................................... 23

9. Basic Logger Setup Parameters.......................................................... 26

10. Measuring Voltage Variations............................................................ 28

11. Logging Min and Max Values............................................................ 29

12. Voltage Interruption........................................................................... 30

13. Voltage Dips and Swells .................................................................... 31

14. Measuring Flicker Values .................................................................. 35

15. Live Reading (Online Test)................................................................ 53

16. ASCII Export ..................................................................................... 54

17. Timeplot Diagram .............................................................................. 55

18. UNIPEDE DISDIP Table................................................................... 56

19. Cumulative Frequency - For Voltage and Current Harmonics ........... 56

v

Page 14

1745

Users Manual

vi

Page 15

1745

Power Quality Logger

Introduction

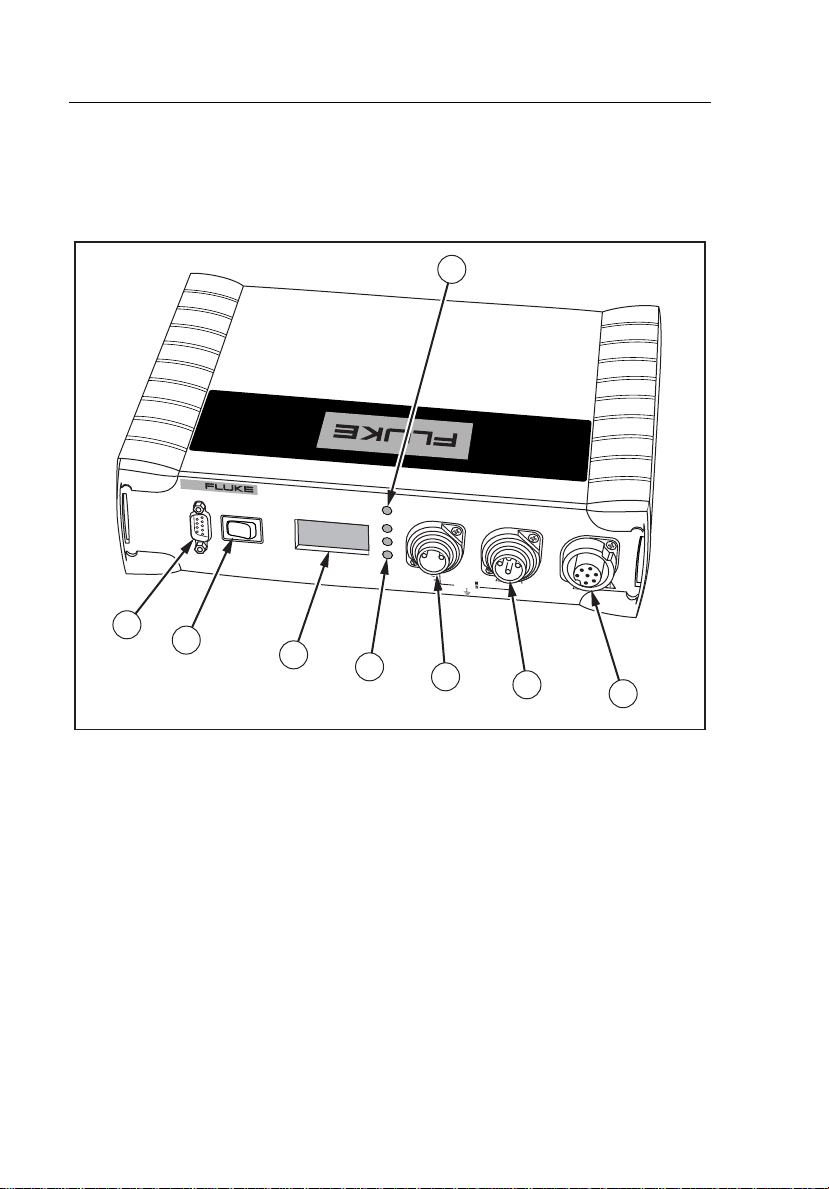

The Fluke 1745 Power Quality Logger, see Figure 1, is a sophisticated, easyto-use, electrical power-recording device for the electrician or power-quality

specialist.

Note

This manual also refers to the 1745 Power Quality Logger simply as

“the Logger”.

The Logger conatins an automatically charged 8-hour UPS (uninterruptable

power supply) battery for long-term voltage interruption ride-through, and an

LCD status display to provide confidence in setup before you leave the Logger

in place to collect data.

You can power the logger in parallel with the test leads or through an outlet.

Adapter cords for both methods of power in the Logger are included as

standard equipment.

You’ll prepare the Logger for use with the included PQ Log software. You can

then connect the Logger to an electrical power-distribution network to log a

variety of power parameters, recorded as sequential averaged values over an

averaging period you can define. The Logger can measure up to three voltages

and four currents simultaneously.

Information and PC Software CD

The CD included with the Logger contains the PQ Log application software for

Windows, along with users manuals in multiple languages.

The PQ Log software prepares the Logger for use, and downloads data from

the Logger to a connected PC.You can then view the logged data in graphical

and tabular form, export it to a spreadsheet, or create reports for printing. For

details and instructions, see the PQ Log Users Manual on the CD.

1

Page 16

1745

Users Manual

Logger Power Supply

The Logger does not include a power switch, but turns on automatically

whenever its power supply leads are connected to a voltage in its allowed

range. You can plug the Logger’s power supply leads into a standard wall

outlet (using the included adapter cord), or you can connect them directly to

the power network under test (in parallel with the test leads) if there is no

convenient wall outlet (only if the voltage at the test leads is below 660V

RMS.)

Logging Functions

The Logger monitors power quality and locates disturbances in low and

medium voltage distribution networks. It measures up to 3 voltages and

4 currents. Logged values are saved in your choice of sequential averaging

periods. You graphically or numerically evaluated measured values with PQ

Log.

The Logger has two types of logging functions: logging function A

(Advanced) and logging function P (Power). Function A is the full set of

parameters, and function P provides logging capability optimized for load

studies and basic power logging. Function P contains every parameter in

Function A except voltage and current harmonics and interharmonics.

Logging function P allows longer logging periods because it does not save

harmonics values.

2

Page 17

Power Quality Logger

Introduction

Logging function parameters:

• RMS Voltage of each phase (average, min, max)

• RMS Current of each phase and neutral (average, min, max)

• Voltage events (dips, swells, interruptions)

• Power (kW, kVA, kVAR, Power PF, Power tangent)

• Energy, total energy

• Flicker (Pst, Plt)

• Voltage THD

• Current THD

• Current CF

• Voltage harmonics to the 50

th

(not in P function)

• Voltage interharmonics (not in P function)

• Mains signalling voltage

• Unbalance

• Frequency

1745

P

O

WER QU

ALITY LOGGER

LOGGING S

T

A

TUS

SUPPL

Y INPUT

V

O

L

TA

L

1

A

L

B

2

L

C

3

660V MAX

8

8

-

660V

10

0

-

350

V

4

5

-

65

H

z

5VA

GE INPUT

CURRENT INPUT

830

V

60

0

V

C

48

AT

-

0V

L

/

L

30

0

V

C

A

T

10

MAX

V

-

L

N

RMS

M

A

X

/

egc001.eps

RS232

S

T

AR

T / ST

T

OP

Figure 1. 1745 Power Quality Logger

3

Page 18

1745

Users Manual

Symbols

Table 1 lists the symbols used on the instrument and in this manual.

Table 1. Symbols

Symbol Description

W

X

J

T

F

P

)

~

;

Important information. See the manual.

Hazardous voltage.

Earth ground.

Double insulation.

Direct Current (DC).

Conforms to European Union requirements

Canadian Standards Association is the certified body used

for testing compliance to safety standards.

Do not dispose of this product as unsorted municipal waste.

Contact Fluke or a qualified recycler for disposal.

Conforms to relevant Australian Standards.

Safety Instructions

Please read this section carefully. It will make you familiar with the most

important safety instructions for using the Logger.

Warnings identify conditions and actions that pose safety hazards to the

user and Cautions identify conditions and actions that can damage the

Logger.

4

Page 19

Power Quality Logger

Safety Instructions

W X Warnings

• To avoid electrical shock, do not connect any part of

the Logger to systems that have higher voltages to

ground (earth) than are marked on the Logger.

• Areas between the power company meter and the

source of the distribution system are characterized as

CAT IV areas. To avoid electrical shock or equipment

damage, never connect the Logger to power in CAT IV

areas if the voltage-to-earth ground is greater than

300 V.

• To avoid damaging the Logger, never connect its

voltage measuring inputs to phase-to-phase voltages

higher than 830 V.

• To avoid damaging the Logger, never connect the

power supply leads to voltages higher than 660 V-RMS

AC.

• The Logger is to be used and handled only by qualified

personnel (see page 8).

• Maintenance work on the Logger must be done only by

qualified service personnel.

• Use only the current probes specified in this manual. If

you use flexible current probes, wear suitable

protective gloves or work on de-energized conductors.

• Do not expose the Logger to moisture or humidity.

• To prevent electrical shock, always connect power

supply and voltage test leads to the Logger before

connecting to the load.

• All accessories must be approved for 600 V CAT III or

higher.

• Use the Logger only with its original standard

equipment or with approved optional accessories, as

listed in Table 2 and Table 3 in this manual.

5

Page 20

1745

Users Manual

• Connect clip-on current transformers and/or Flexi Set

to insulated live conductors only.

• If measuring sensors are to be connected to non-

insulated live conductors, additional personal

protective measures must be taken as required by local

government agencies.

WCaution

To avoid damage, use the 1745 Power Quality Logger, only

with the following nominal voltages:

• Single/3 phase, 4-wire (Wye) systems (P-N): 69 V to

480 V

• 3-phase-3-wire(Delta) systems (P-P): 120 V to 830 V

WX Warning

To avoid electrical shock, or damaging the Logger’s

internal protective circuitry weatherproof seal, do not open

the Logger.

Qualified Personnel

The following qualifications are required for using the Logger safely:

• Trained and authorized to switch on/off, ground (earth), and mark

power distribution circuits and devices in accordance with electrical

engineering safety standards.

• Trained or instructed in safety engineering standards for maintaining

and using appropriate safety equipment.

• Trained in first aid.

Standard Equipment and Optional Accessories

Table 2 lists the standard equipment for the 1745 Power Quality Logger and

Table 3 lists optional accessories.

6

Page 21

Power Quality Logger

Safety Instructions

Table 2. Standard Equipment

Equipment Model/Part

Number

Power Quality Logger 1745

International IEC Power Plug Adapter Set 2441372

RS232 Cable, Red, Null-Modem 2540511

Shielded 4-Phase Flexi Set (15 A/150 A/1500 A/3000 A) FS17XX

Dolphin Clip, Black (4x) 2540726

Color Coding Wire Clips WC17XX

Soft Case 2715509

English Users Manual 2560366

CD with Users Manual (English, German, French, Spanish,

Portuguese, Simplified Chinese, Italian), and PQ Log

software (same languages as the manual)

Power cord adapter for parallel connection to test leads 2651702

Power cord 2715492

USB Adapter 2539565

Table 3. Optional Accessories

Description Accessory

3-Phase Flexi Set MBX 3FLEX

3-Phase 1 A/10 A micro CT EPO405A

C425 Hardcase 2654865

Permlink Software for Modem E631820090

3-Phase Voltage Leads 2645854

2583507

Inspect the contents of the shipping box for completeness and damage. Report

any damage, to the shipper.

7

Page 22

1745

Users Manual

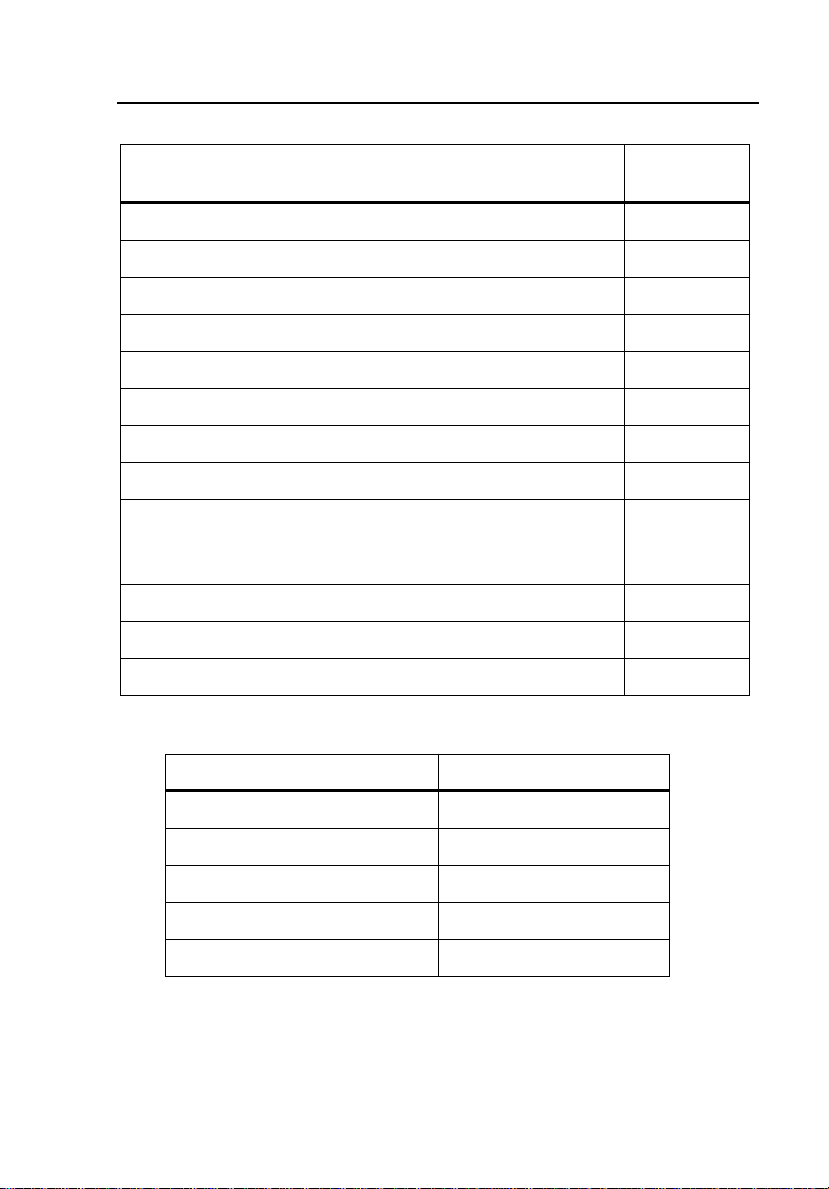

Features

This section introduces the Logger’s controls, indicators and other features.

Refer to Figure 2 and Table 4.

7

1745

P

O

WER QUALITY LOGGER

LO

G

GING

S

T

S

T

AR

T / S

T

T

O

P

RS232

6

2

3

Figure 2. 1745 Power Quality Logger - Front View

ATUS

SUPPL

Y INPUT

V

O

L

TA

L

1

A

L

B

2

L

C

3

660V MAX

8

8

-

660V

10

0

-

350

V

4

5

-

65

H

z

5VA

8

1

GE INPUT

CURRENT INPUT

830

V

60

0

V

C

48

AT

-

0V

L

/

L

30

0

V

C

A

T

10

MAX

V

-

L

N

4

R

M

S

M

A

X

/

5

egc002.eps

8

Page 23

Power Quality Logger

Safety Instructions

Table 4. 1745 Power Quality Logger - Controls and Indicators

Item Name Description

Connector for

1

Logger power

supply.

This is where the power cord attaches to the

Logger. The power cord connects in parallel

to any two test leads as long as the voltage

is below 660 V absolute maximum.

Whenever there is any risk that voltage

could be higher, connect the power cord to a

wall outlet using the appropriate

international power plug (supplied).

Power supply voltage range: 88-660 V AC or

100-350 VDC, 50 Hz / 60 Hz, 600 V CAT III.

START/STOP switch The START/STOP button is used to start or

2

LCD status display Shows measured input values to provide

3

end switch-operated logging sessions.

confidence in proper setup and test lead

connections. Every 3 seconds, the display

changes to the next set of readings in the

following sequence:

1. The three voltage levels

2. The main three phase currents

3. Neutral current and real-time clock

4. Active (true) power on each phase

The cycle repeats continuously. Make sure

the readings look reasonable before leaving

the Logger to collect data.

Power supply leads

4

and 3-phase plus

neutral voltage test

leads

Fixed installed voltage input cables for L1 or

A, L2 or B, L3 or C, N.

The highest permissible nominal voltage is

830 V in a 3-wire network with Delta

connection.

In a 4-wire network with Wye connection,

the highest permissible nominal voltage is

480 V.

When using PTs and CTs for measuring

voltage and current in a medium-voltage

network, refer to the IEC 60044 international

standard for guidelines.

9

Page 24

1745

Users Manual

Table 4. 1745 Power Quality Logger - Controls and Indicators (cont)

Item Name Description

Connector for Flexi

5

Set or current

clamps

RS232 interface port The serial RS232 interface is used to

6

Logging Status LED

7

8 Channel LEDs The logging channel LEDs indicate

Flexi sets or current clamps are detected

automatically at power-up. If you change the

current probe type, be sure to remove and

restore power so the Logger will detect the

new current probe.

Nominal ranges for the Flexi Set are 15 A,

150 A, 1500 A, and 3000 A AC. Nominal

input for current clamps is 0.5 V.

communicate with a PC. The Logger is

connected to the PC’s serial port (or a

modem for remote communication) using

the interface cable. Use a USB adapter if

necessary.

Yellow blinking = Logging job not set up yet,

or waiting for start time or START button.

Green blinking = logging is in progress

Steady green = Logging session is finished.

Data are ready to upload to a PC.

whether the applied voltages are within the

nominal range set using the PQ Log

software.

Red = Overload

Green = OK

Yellow = Underload

(There is no detection for the current input)

10

Page 25

Power Quality Logger

Safety Instructions

Power Network Configurations

You can set up the Logger to work with several power network configurations

(listed below). You make these settings using PQ Log software while

connected to the Logger using the interface cable. See the PQ Log Users

Manual for details.

• Delta system

• Delta 2 element system (2 voltage/current transformer)

• Wye (Star) system

• Single phase

• Split single phase

Working with Logged Data

See the PQ Log manual for full details. Logged data can be evaluated using the

PQ Log software to provide the following:

• Amount, date/time, and duration of quick and slow voltage variations

• Half-cycle: 10 ms-extreme values for 50 Hz (8.3 ms at 60 Hz) MIN

and MAX for each measuring interval

• Depth and duration of voltage dips

• Correlation between peak current and voltage dips

• 95 %-flicker values according to EN50160

• Number and duration of interruptions

• Compliance of harmonic levels with defined limits

• Mean and peak values of phase currents

• Value of neutral conductor current

• Current total harmonic distortion (THD) of phase and neutral

conductor currents

• Profile of active, reactive, and apparent power versus time

• Monitoring of power factor (PF) and information about effectiveness

of compensation systems

• Graphical representations of logging data and statistics

11

Page 26

1745

Users Manual

Using the 1745 Power Quality Logger

This section explains how to operate the 1745 Power Quality Logger. You

should also refer to the PQ Log Users Manual to become familiar with the

software you use to prepare the Logger for use and download logged data.

A typical logging session includes four steps:

1. Preparing the Logger for use with the PQ Log software.

2. Installing the Logger at the logging site.

3. Leaving the Logger to collect data for a period.

4. Downloading and evaluating the logged data.

These steps are described in the following pages.

About Logging Jobs

Logging jobs are defined using the PQ Log software, and transferred to the

Logger over the RS-232 cable. Each job contains the following information:

• Logging function P or A

• Measuring period, defined by start and end times

• Time activated, switch or immediate job

• Nominal voltage

• Power type (wye, delta, etc.)

• Averaging period length

• Logging time period

• Interharmonics and signaling voltages

• Limit values for events

• Memory model for events: circular (first-in/first-out, continuous), or

linear (quit logging when logging period is finished)

• Logging of current - neutral wire

• Optional converter ratios for current and voltage if using potential

transformers (PTs) and current transformers (CTs) at a mediumvoltage network site

12

Page 27

Power Quality Logger

Using the 1745 Power Quality Logger

Preparing the Logger for Use

Prepare the 1745 Logger for use with PQ Log software as follows (see

Figure 3):

1. Connect the Logger to line power. Use the power supply cables to

connect to an outlet, or to the test leads phase and neutral for Wye

configurations, or any two-phase leads for delta.

W Caution

If you are powering the Logger in parallel with the test

leads, and the voltage under test at the Logger power

supply connections could be greater than 660 V RMS AC,

plug the power supply leads into an outlet instead.

Otherwise, you could damage the Logger.

2. Connect the RS232 interface cable to the serial port of your PC. Use a

USB adapter if your PC does not have a serial port.

3. Run the PQ Log software as described in the PQ Log Users Manual.

4. Set up the Logging job and transfer the settings to the Logger.

13

Page 28

1745

Users Manual

Power in Parallel

with Test Leads

1

7

4

5

P

O

WER

QUALITY LOGGER

LOGG

ING S

T

S

T

ART / STOP

T

RS232

ATUS

Power

Supply

Leads

S

U

P

P

L

Y

IN

P

U

T

V

L

L

L

O

1

A

2

B

3

C

6

6

0

V

M

A

X

8

8

-6

6

0

V

1

0

0

-

3

5

0V

8

3

0

V

6

00

4

5

V

-

6

C

5

AT

Hz

-

L

5VA

3

0

0

V

C

A

T

Voltage

Test Leads

Power from Wall Outlet

1

7

45

P

O

WER

QUALITY LOGGER

LOGGING S

T

S

T

AR

T

T

/ ST

L

T

A

G

E

I

N

P

U

T

C

U

R

R

E

N

T

I

N

P

U

T

4

8

0V

/

L

10

M

V

A

R

X

-

M

L

S

N

M

AX

R

S232

Power Supply

Leads

ATUS

O

P

S

U

P

P

L

Y

I

N

P

U

T

V

O

L

TAGE

I

N

P

U

L

1

A

L

2

B

L

3

C

6

8

1

4

5VA

T

C

U

R

R

E

N

T

I

N

P

U

6

0

V

M

A

X

8

-

6

6

0

V

0

0

-

3

5

0

V

8

3

0

V

6

00

5

V

-

6

C

5

AT

Hz

3

0

0

V

C

A

T

T

4

8

-

0V

L

/

L

1

0

M

V

A

R

X

-

M

L

S

N

M

AX

Voltage

Test Leads

14

Max 660 V

Figure 3. Supplying Operating Power to the Logger

egc031.eps

Page 29

Power Quality Logger

Using the 1745 Power Quality Logger

Test Leads - Markings

The 1745 Logger includes detachable labeled test leads for voltage terminals

L1 or A, L2 or B, L3 or C, and N. Another detachable set of leads provides

operating power to the Logger. The Flexi Set or current clamp sets are

connected by a seven-pin plug to the Logger A connector. Color coding clips

are provided for your convenience.

Table 5 shows the test leads and markings of the Logger.

Table 5. Test Leads - Markings

Test Leads Markings

Phase L1 or A L1 / A

Phase L2 or B L2 / B

Phase L3 or C L3 / C

Neutral wire N N

Connecting Current Probes

Connect current clamps and Flexi Set probes so that current will flow in the

direction marked by arrows on the probes. Current must flow from the energy

generator to the energy consumer (the load) in order to maintain a positive

active power. Orient the Flexi probe so that the arrow points towards the load.

(The polarization of the test lead for neutral conductor current is not

significant, because the phase angle of the neutral conductor current is not

evaluated.)

Logging with Voltage Converters

The 1745 Logger includes an adjustable convertor ratio that enables it to be

used with voltage convertors (potential transformers, or PTs).

Note

When logging with voltage convertors, make sure the power supply

cables are not connected in parallel to the voltage test leads, or the

Logger’s power consumption can reduce accuracy.

The convertor ratio is defined using the PQ Log software.

15

Page 30

1745

Users Manual

Connecting the Logger

W X Warnings

• To avoid electrical shock, do not connect any part of

the Logger to systems that have higher voltages to

ground (earth) than are marked on the Logger.

• Areas between the power company meter and the

source of the distribution system are characterized as

CAT IV areas. To avoid electrical shock or equipment

damage, never connect the Logger to power in CAT IV

areas if the voltage-to-earth ground is greater than

300 V.

• To avoid damaging the Logger, never connect its

voltage measuring inputs to phase-to-phase voltages

higher than 830 V.

• To avoid damaging the Logger, never connect the

power supply leads to voltages higher than 660 V RMS

AC.

• The Logger is to be used and handled only by qualified

personnel (see page 6).

• Maintenance work on the Logger must be done only by

qualified service personnel.

• Use only the current probes specified in this manual. If

you use flexible current probes, wear suitable

protective gloves or work on de-energized conductors.

• Do not expose the Logger to moisture or humidity.

• To prevent electrical shock, always connect power

supply and voltage test leads to the Logger before

connecting to the load.

• All accessories must be approved for 600 V CAT III or

higher.

16

Page 31

Power Quality Logger

Using the 1745 Power Quality Logger

• Use the Logger only with its original standard

equipment or with approved optional accessories as

listed in Table 2 and Table 3 in this manual.

• Connect clip-on current transformers and/or Flexi Set

to insulated live conductors only.

• If measuring sensors are to be connected to non-

insulated live conductiors, additional personal

protective measures must be taken as required by local

government agencies.

WCaution

To avoid damage, use the 1745 Power Quality Logger only

with the following nominal voltages:

Single/3-phase 4-wire (Wye) systems (P-N): 69 V to 480 V

3-phase-3-wire (Delta) systems (P-P): 120 V to 830 V

WX Warning

To avoid electrical shock, or damaging the Logger’s

internal protective circuitry or weatherproof seal, do not

open the Logger.

17

Page 32

1745

Users Manual

Connect the Logger as follows.

Note

∆- (delta) or Υ- (wye) measurements.

The 1745 Logger is prepared for logging in Delta, Delta 2 Element,

Wye (Star), single and split phase. Please note the different types of

connection and configuration in the PQ Log software.

1. Connect all required measuring leads.

2. If you want to supply the Logger from an outlet use the supplied

power cord and plug adapter. The power supply leads can also be

connected in parallel to the voltage test leads, but the voltage is

limited to 660 V RMS AC.

3. Connect the current clamp set or Flexi Set to the Logger.

4. Connect the current sensor to the conductor under test.

5. Connect the dolphin clips to the test leads. For 3-phase, 4-wire

systems, connect the N-test lead first, and then the other phases.

18

Page 33

Power Quality Logger

Using the 1745 Power Quality Logger

Connections in 3-Phase 4-Wire (Wye) Systems

Figure 4 shows the connections for logging 3-phase 4-wire (Wye) systems:

17

45

POWER

QU

ALITY LOGGER

LO

G

GIN

G S

T

A

T

U

S

OP

S

U

P

P

L

Y

I

N

P

U

T

V

O

L

T

A

G

E

IN

P

U

L

1

A

L

2

B

L

3

C

6

6

8

8

1

0

4

5

5VA

T

C

U

R

R

E

N

T

I

N

P

U

0

V

M

A

X

6

6

0V

0

3

5

0

V

8

3

0

6

00V

6

C

5

AT

H

z

3

0

0

V

C

A

T

T

V

4

8

-

0

L

/

V

L

10

M

V

A

R

X

-

M

L

S

N

M

A

X

/

Power Supply

S

T

A

R

T / ST

T

R

S

23

2

L1 L2

L3

N

Figure 4. Logging in a 3-Phase 4-Wire (Wye) System

egc003.eps

19

Page 34

1745

Users Manual

Connections in 3-Phase 3-Wire (Delta) Systems

Figure 5 shows the connections for logging 3-phase 3-wire (Delta) systems.

The test lead “N” can be left open or connected to ground potential.

1745

P

OWER QU

ALITY LOGGER

LOGGING S

T

A

S

T

A

R

T / ST

T

RS232

Power Supply

TUS

O

P

SU

PP

L

Y IN

PU

T

V

O

L

T

A

G

E IN

P

L

1

A

L

B

2

L

C

3

UT

C

U

R

RE

N

T IN

PU

6

6

0

V

M

A

X

8

8

6

6

0

V

1

0

0

3

5

0

V

8

3

0

6

0

4

0

5

V

6

C

5H

A

T

z

5VA

3

0

0

V

C

A

T

T

V

4

8

-

0

L

/

V

L

10

M

V

A

R

X

-

M

L

S

N

M

A

X

/

L1 L2

L3

N

egc004.eps

Figure 5. Logging in a 3-Phase 3-Wire (Delta) System

20

Page 35

Power Quality Logger

Using the 1745 Power Quality Logger

Connections for Single-Phase Logging

Figure 6 shows the connections for logging single-phase logging systems:

17

45

POWER

QU

ALITY LOGGER

LO

G

GIN

G S

T

A

T

U

S

T

A

R

T / ST

T

R

S

23

2

Power Supply

S

OP

S

U

P

P

L

Y

I

N

P

U

T

V

O

L

T

A

G

E

IN

P

U

L

1

A

L

2

B

L

3

C

6

6

8

8

1

0

4

5

5VA

T

C

U

R

R

E

N

T

I

N

P

U

0

V

M

A

X

6

6

0V

0

3

5

0

V

8

3

0

6

00V

6

C

5

AT

H

z

3

0

0

V

C

A

T

T

V

4

8

-

0

L

/

V

L

10

M

V

A

R

X

-

M

L

S

N

M

A

X

/

L1

N

L3

L2

Figure 6. Single-Phase Logging

egc005.eps

21

Page 36

1745

Users Manual

Connections for Medium Voltage Networks

In a 3-phase 3-wire (Delta) system with three separate voltage converters and

three current transformers, the Logger can measure phase-phase (P-P, Delta) or

phase - N (P-N, Wye). See Figure 7.

1

7

4

5

POWER

QU

ALITY LOGGER

LO

G

G

IN

G

S

T

A

T

US

OP

S

U

P

P

L

Y

IN

P

U

T

V

O

L

T

A

G

E

IN

P

U

L

1

A

L

2

B

L

3

C

6

6

8

1

4

5

T

C

U

R

R

E

N

T

IN

P

U

0

V

M

A

X

8

6

6

0V

00

3

5

0

V

8

3

0

6

00V

5

6

C

5

A

H

T

z

V

3

A

0

0

V

C

A

T

T

V

4

8

-

0

L

/

V

L

1

0

M

V

A

R

X

-

M

L

S

N

M

A

X

/

L1

Power Supply

L1

L2

S

T

A

R

T / ST

T

RS

232

L2

L3

L1

L2

L3

N

L3

Figure 7. Measuring 3 Phase Voltages in a 3-Wire (Delta) System with

Three Voltage Converters

22

egc006.eps

Page 37

Power Quality Logger

Using the 1745 Power Quality Logger

Figure 9 shows the connections for two-element Delta (Aron or Blondel)

metering connections.

1

7

4

5

POWER

QU

ALITY LOGGER

LO

G

G

ING

S

T

A

TU

S

T

A

R

T

T

/ ST

RS

232

S

OP

S

U

P

P

L

Y

IN

P

U

T

V

O

L

T

A

G

E

I

N

P

U

L

1

A

L

B

2

L

3

C

6

6

8

8

1

00

4

5

5V

T

C

U

R

R

E

N

T

IN

P

U

0

V

M

A

X

6

6

0V

3

5

0

V

8

3

0

6

00V

6

C

5

A

H

T

z

3

A

0

0

V

C

A

T

T

V

4

8

-

0

L

/

V

L

10

M

V

A

R

X

-

M

L

S

N

M

A

X

/

Power Supply

L1

L2

L3

L3

L2, N

L1

egc009.eps

Figure 8. Two-Element Delta Connections

23

Page 38

1745

Users Manual

Logging

When the Logger is connected and ready, you can perform three types of

logging:

Switch-activated job: The status LED is blinking. Press the

START/STOP button once. As soon as the job is active, the LED is

on continuously. If needed, the job can be cancelled after running for

at least one minute, and restarted later.

Time-activated job: The Logger starts logging as soon as the pre-

programmed start time is reached and stops at the defined end time.

Immediate job: The Logger starts logging as soon as power is on.

Note the following about logging jobs:

1. The connection can be verified with the LCD (voltage, current,

power). If all three LEDs are lit continuously, the voltage connections

and signal levels are within nominal range. For details, see Table 4 in

the Features section.

2. The Logging job status is indicated by the status LED. For details, see

Table 4 in the Features section.

Completing the Logging Job

1. Terminate the job as follows:

• For switch activated jobs: At the end of the logging period,

stop the logging job by pressing the START/STOP button.

• For time activated and immediate jobs: Stop the job in PQ

Log with the icon, or with menu Logger/Stop logging

Note

Make sure the logging job is stopped with the START/STOP button

(switch activated jobs) or PQ Log (time activated jobs) before the

terst leads or power supply leads are removed. Otherwise, the Logger

will record a voltage interruption.

Only switch-activated jobs can be aborted. Time activated jobs are

terminated only when the programmed measuring time has elapsed.

24

Page 39

Power Quality Logger

Using the 1745 Power Quality Logger

2. Remove the test leads of the three phases. Be sure to remove the

measuring cable of the neutral wire last.

3. Remove the current probes.

Evaluating the Logged Data

You’ll use PQ Log to evaluate the logged data. Data can be read out during

logging as well as at the end.

1. Connect the Logger to line power.

2. Connect the RS232 interface cable to your PC’s serial port, then to the

Logger.

3. Start the PQ Log software.

4. Use PQ Log to transfer the data from the Logger to the PC.

5. Once the data is transferred, remove the RS232 interface cable and

operating power from the Logger.

6. Evaluate the data using PQ Log.

For details, refer to the PQ Log manual.

Methods of Logging

The following section describes methods of logging using the 1745 Logger.

25

Page 40

1745

Users Manual

Voltage Ranges

The software calculates the correct measuring range depending on the nominal

voltage (20 % overflow with C

Table 6 shows the measuring ranges of the Logger and Figure 9 shows the

selection for input ranges during job processing.

Connection Nominal Voltages (Wye/Delta) Max. Input Voltage

Wye/Delta 69 V / 120 V 115 V / 200 V 230 V / 400 V 480 V / 830 V

= 1.4).

F

Table 6. Measuring Ranges

Phase/Neutral

3-phase 4 wire

Phase/Phase

3-phase 3 wire

69 V ~, +20 % 115 V ~, +20 % 230 V ~, +20 % 480 V ~, +20 %

120 V ~, +20 % 200 V ~, +20 % 400 V ~, +20 % 830 V ~, +20 %

egb015.bmp

Figure 9. Basic Logger Setup Parameters

26

Page 41

Power Quality Logger

Using the 1745 Power Quality Logger

Signal Sampling

Input signals (up to three voltages and four currents) are filtered with an antialiasing filter and digitized with a 16-bit A/D converter. The sampling rate is

10.24 kHz. All parameters are calculated from this data.

Resolution Accuracy

Resolution and accuracy depend on the logging parameter. For details see

“Technical Specifications”.

Voltage Variations

The interval value of the voltage is defined as the mean value of the RMS

values over the interval length defined in PQ Log.

27

Page 42

1745

Users Manual

Averaging Period

Averaging period can be set in PQ Log to the following:

• 1, 3, 5, 10, or 30 seconds

• 1, 5, 10, 15, or 60 minutes

Figure 10 shows the measuring voltage variations of the Logger.

1 Interval

V

N

28

Measuring period

Figure 10. Measuring Voltage Variations

Time

egb016.eps

Page 43

Power Quality Logger

Using the 1745 Power Quality Logger

Min/Max Values

Logging detects the highest and lowest voltage RMS values and the highest

current RMS value during the test interval, using a minimum resolution of

10 ms.

The response time can be set in PQ Log to the following:

0.5, or 1 line power period

200 ms

1, 3, or 5 seconds.

Figure 11 shows the logging min and max values of the Logger.

U

Max. Value

Min. Value

t

Measuring Interval

Figure 11. Logging Min and Max Values

29

egb017.eps

Page 44

1745

Users Manual

Voltage Interruptions

The Logger records two types of interruptions:

• All measured RMS values of input voltages that are < 1 % of the

nominal voltage. This threshold can be adjusted in PQ Log.

• Interruptions > 1 half-cycle

The start time and duration of each interruption are registered. See Figure 12.

110% Vn

100% Vn

90% Vn

1%

Vn

30

Duration

Figure 12. Voltage Interruption

Time

egb018.eps

Page 45

Power Quality Logger

Using the 1745 Power Quality Logger

Voltage Dips and Swells

If the voltage passes the upper limit (VN + 10 %) or lower limit (VN - 10 %),

the event is registered as a voltage swell or dip respectively (thresholds are

adjustable in PQ Log).

The duration, time and extreme value of the dip or swell is also recorded. See

Figure 13.

Height

110% Vn

100% Vn

90% Vn

Depth

Duration

Figure 13. Voltage Dips and Swells

Duration

Time

egb019.eps

Voltage Harmonics