Page 1

1551A Ex/1552A Ex

Intrinsically Safe

“Stik” Thermometer

The new “gold standard”

of industrial temperature

calibration

Page 2

Designed

to go where

you work

Finally, a digital substitute

for your mercury-in-glass

thermometers! Accurate

and repeatable to ± 0.05 °C

over its full range, the

1551A/1552A “Stik”

Thermometer is the new

“gold standard” of industrial

temperature calibration.

Whether working outdoors

in environments where

potentially explosive gases

may be present or on the

floor of a processing plant,

the intrinsically-safe, battery-

operated, portable reference

thermometer is designed to

go where you work.

Features at a glance

Accuracy of ± 0.05 °C (± 0.09 °F)

•

over full range

Intrinsically safe (ATEX and

•

IECEx compliant)

Two models to choose from

•

(-50 °C to 160 °C or -80 °C to 300 °C)

User-configurable temperature

•

trend/stability indicator

2 2

Display temperature in °C or °F

•

Optional data logging to internal memory

•

300-hour battery life

•

Percent battery-life and low-battery indicator

•

NVLAP-accredited, NIST-traceable calibration

•

included

Page 3

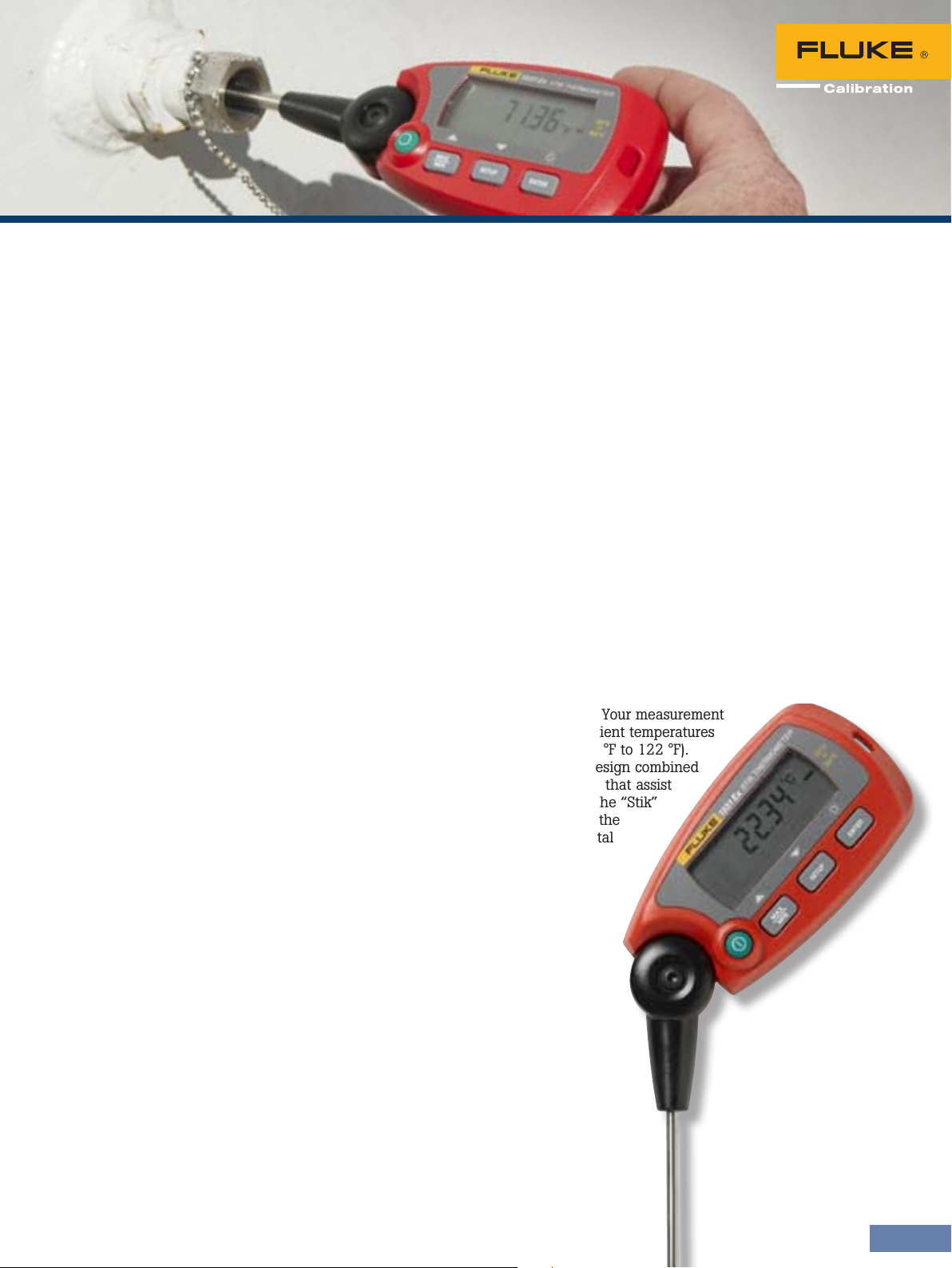

Thermometer probe and digital

readout combined into one unit

The stainless steel probe and digital readout are

fixed together and calibrated as a system. The

accuracy specification is easy to understand since

it includes all uncertainty components, including

drift, for up to one year

display rotates 90° making it easy to read from

any angle. A user-configurable stability/trend

indicator lets you know when your temperature is

stable enough to record an accurate measurement.

A user-settable auto-off function extends typical

battery life to three hundred hours. A low-battery

indicator and stop-measure function prevent

erroneous measurements from being made due to

low battery life. A simple three-point calibration

function allows you to easily and accurately

calibrate the “Stik” Thermometer. Data logging to

internal memory of up to 10,000 time-stamped

measurements is optionally available.

1

. The large backlit LCD

Why calibrate process

temperature sensors?

Because temperature greatly effects the

accuracy of a volumetric measurement, process

manufacturers of chemical, pharmaceutical, food or

petroleum products require accurate temperature

measurements—especially for processes where

quality or custody transfer are regulated by

government agencies. Since all temperature

sensors are subject to drift with time, regular

calibration or verification against a reliable

reference thermometer is required. Finding a

reference thermometer that is accurate, repeatable

and robust, however, can be challenging.

What’s wrong with my

reference thermometer?

Industrial reference thermometers available

on the market today, such as mercury-in-glass

thermometers (or “ASTM thermometers”) and

portable electronic thermometers are useful, but

both come with inherent problems. Although

accurate and repeatable, mercury thermometers are

fragile. The risk of a mercury spill poses potential

hazards to the environment and to the health of

personnel. Many of the United States and European

Union countries have already banned their use in

industrial applications. Some organizations have

replaced their mercury thermometers with more

durable portable electronic thermometers, only to

discover that the RTD probes lack the repeatability

and dependability required of a legitimate

reference thermometer.

The best alternative to

mercury thermometers

The Fluke “Stik” Thermometer is accurate, stable

and durable, making it the best alternative to

mercury thermometers and existing electronic

thermometers. The thin-film RTD sensor

incorporates the same characteristics of other

premium reference thermometers designed by

Hart Scientific, but it is more robust and less

susceptible to drift. Accuracy and repeatability,

however, are not sacrificed for improved durability.

Using a glass-stem mercury- or spirit-filled

thermometer at different immersion depths, or

at significantly different ambient temperatures

from which it was calibrated, may require the

application of emergent-stem corrections that can

be tedious but necessary to calculate an accurate

measurement. This isn’t required with the “Stik”

Thermometer. The sensor of the 1551A Ex

requires a minimum immersion depth of only

7 cm (2.8 in), with no appreciable effect on the

measured temperature due to heat loss through

stem conduction.

Some digital thermometers can become less

accurate when used outside a narrow range of

ambient temperatures. This isn’t the case for

the “Stik” Thermometer. Your measurement

remains accurate in ambient temperatures

from -10 °C to 50 °C (14 °F to 122 °F).

With a superior probe design combined

with electronic functions that assist

accurate measurement, the “Stik”

Thermometer surpasses the

capabilities of other digital

thermometers and is

the perfect substitute

for your mercury

thermometers.

1

In order to minimize sensor

drift, the probe should

always be protected

from mechanical shock.

3

Page 4

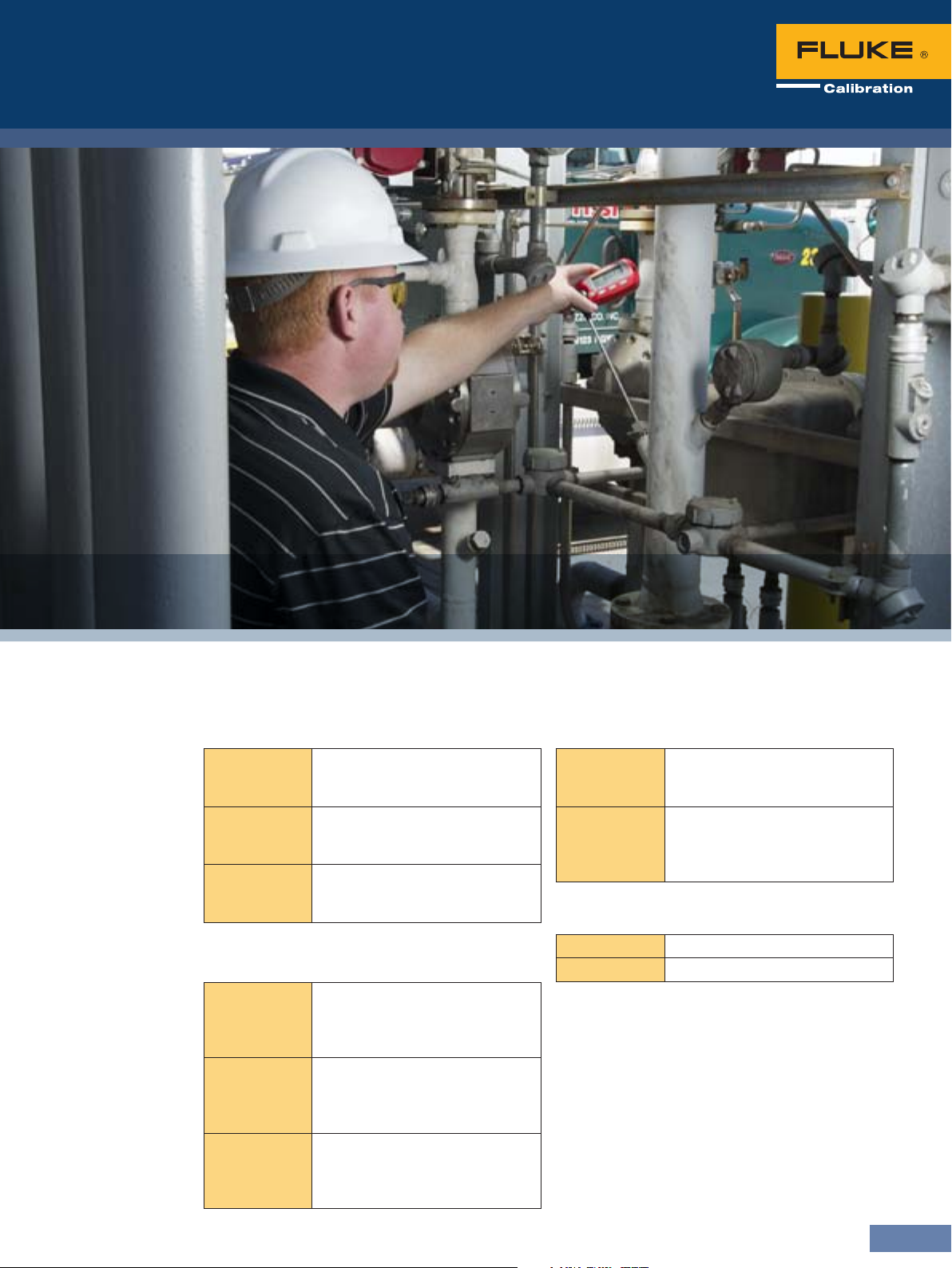

Easy-to-use,

one-handed

menu navigation

7 8

6

1

2

543

The digital display and probe

1

are fixed together as a system.

The hinge allows the display

to rotate 90° to easily view the

measurement from any angle.

Easily power up with the press

2

of a button and after a short selftest, start making measurements

within seconds. The power key is

slightly recessed inside the plastic

molded case to protect against

accidental power off.

Max/Min/Trend/Up key allows you

3

to see the maximum or minimum

temperature since the most recent

power up. The trend function tells

you the positive or negative rate

of temperature change in degrees

per minute.

The Setup/Down key lets you step

4

through submenus and adjust

field values down.

The Enter/Backlight key allows

5

you to accept changes while in

the setup menus or turn on the

backlight.

User-selectable resolution

6

(0.1, 0.01, 0.001)

7

Temperature displayed in °C or °F.

The stability/trend indicator tells

8

you if your temperature source

is trending upward or downward

(pictured trending up). A flat

bar indicates that the

temperature source and

thermometer are stable within

the user-selected stability window

(0.01, 0.1, 1.0, 10.0).

4

4

Page 5

Five reasons to replace mercury thermometers

1. Since the “Stik” Thermometer does not

contain mercury, it is not subject

to government-imposed bans.

Government agencies worldwide have

either banned or are seeking to ban

the use and transportation of industrial

mercury thermometers—this seems to

be a growing trend.

2. The stainless steel probe sheath of the

“Stik” Thermometer is far more robust

than the glass stem of a mercury

thermometer and better suited for

industrial environments. And since the

“Stik” thermometer does not contain

mercury, the risk of an accidental

mercury spill is eliminated.

3. When considering cost of ownership,

a digital thermometer is less expensive

than a mercury thermometer. With

a mercury thermometer, you either

invest in equipment or you hire out to

clean up after a mercury spill.

4. Mercury thermometers cannot be

adjusted after calibration. The actual

temperature must be calculated by

applying corrections to the measured

temperature. This costs time and is

susceptible to calculation error. A

digital thermometer does the math

for you—the displayed temperature

accurately represents the actual

measured temperature.

5. Emergent-stem corrections may

also be required if the mercury

thermometer is not used under the

same conditions under which it was

calibrated. A digital thermometer

doesn’t require that you match

calibration conditions to achieve

an accurate measurement. You’re

only required to meet the minimum

immersion requirements—which is

only 7 cm (2.8 in) in the case of

the 1551A Ex.

5

5

Page 6

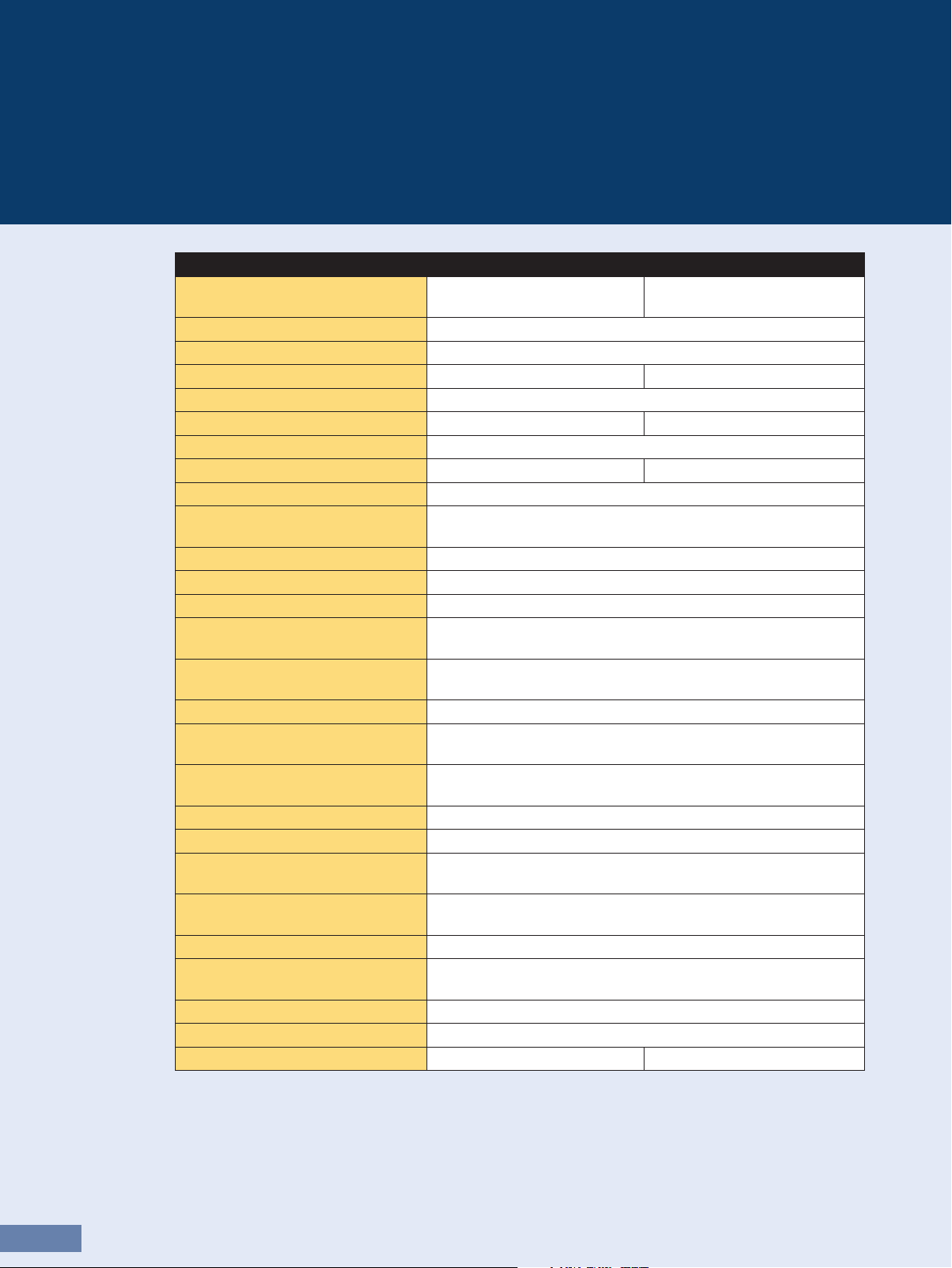

1551A Ex/1552A Ex Specications

Specifications 1551A Ex 1552A Ex

Temperature range -50 °C to 160 °C

(-58 °F to 320 °F)

Accuracy (1 year) ± 0.05 °C (± 0.09 °F)

Display units °C, °F

Sensor type 100 Ω thin-film RTD 100 Ω wire-wound PRT

Probe temperature coefficient 0.00385 Ω/Ω/°C nominal

Sensor length ≤ 10 mm ≤ 30 mm

Sensor position (from sheath tip) 3 mm (0.1 in)

Minimum immersion depth

1

7 cm (2.8 in) 12 cm (4.8 in)

Probe sheath material SST

Response time 4.8 mm diameter probe (3/16 in): 14 seconds

6.35 mm diameter probe (1/4 in): 21 seconds

Probe hysteresis ± 0.01 °C

Temperature resolution Selectable: 0.1, 0.01, 0.001 (default 0.01)

Sample rate Selectable: 0.5 seconds, 1 seconds, 2 seconds (default 1 seconds)

Operating temperature range

-10 °C to 50 °C (14 °F to 122 °F)

readout

Storage temperature -20 °C to 60 °C (-4 °F to 140 °F)

0 % to 95 % RH, non-condensing

2

Optional data logging

Logging intervals

Up to 10,000 time-stamped readings stored to internal memory

2

2 seconds, 5 seconds, 10 seconds, 30 seconds, or 60 seconds;

2 minutes, 5 minutes, 10 minutes, 30 minutes, or 60 minutes

Damping Moving average of the most recent 2 to 10 readings

(ON/OFF, 2, 5, 10)

Communications RS-232 stereo jack (access calibration parameters only)

AC power None

DC power Three AAA batteries, typical battery life of 300 hours

without LCD backlight

EMC compliance EN61326:2006 Annex C; CISPR II

Edition 5.0-2009; Class “B”

Enclosure rating IP50

Electronics dimensions

(H x W x D)

114 mm x 57 mm x 25 mm

(4.5 in x 2.25 in x 1.0 in)

Weight 196 g (6.9 oz)

Calibration (included) NVLAP-accredited, NIST-traceable

Characterization CVD ITS-90

1

Per ASTM E 644

2

See ordering information for optional data logging configurations

-80 °C to 300 °C

( -112 °F to 572 °F)

6

6

Page 7

Ordering information

1551A Ex

1551A-9 Thermometer, Fixed RTD,

-50 °C to 160 °C,

4.8 mm x 229 mm (3/16 in x 9 in)

1551A-12 Thermometer, Fixed RTD,

-50 °C to 160 °C,

6.35 mm x 305 mm (1/4 in x 12 in)

1551A-20 Thermometer, Fixed RTD,

-50 °C to 160 °C,

6.35 mm x 508 mm (1/4 in x 20 in)

1551A Ex Datalogging options

1551A-9-DL Thermometer, Fixed RTD,

-50 °C to 160 °C,

4.8 mm x 229 mm (3/16 in x 9 in)

with Datalog

1551A-12-DL Thermometer, Fixed RTD,

-50 °C to 160 °C,

6.35 mm x 305 mm (1/4 in x 12 in)

with Datalog

1551A-20-DL Thermometer, Fixed RTD,

-50 °C to 160 °C,

6.35 mm x 508 mm (1/4 in x 20 in)

with Datalog

1552A Ex

1552A-12 Thermometer, Fixed PRT,

-80 °C to 300 °C,

6.35 mm x 305 mm (1/4 in x 12 in)

1552A-12-DL Thermometer, Fixed PRT,

-80 °C to 300 °C,

6.35 mm x 305 mm (1/4 in x 12 in)

with Datalog

Accessories

1551-CASE Case, 1551-2, Carrying

1551-CBL Cable, RS-232 155X

Standard accessories include: NVLAP-accredited report

of calibration, User’s Guide on CD-ROM, three AAA batteries

Note: Model number appended with a -9, -12, -20

indicates probe sheath length in inches. All probe diameters

are 6.35 mm (1/4 in) with the exception of the 1551A-9,

which is 4.8 mm diameter (3/16 in).

7

7

Page 8

Fluke Calibration.

Precision, performance, confidence.

Fluke Calibration

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2010 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 11/2010 3947275A B-EN-N

Pub-ID 11698-eng

Modification of this document is not permitted

without written permission from Fluke Corporation.

™

2

Loading...

Loading...