Page 1

®

150X Series

Insulation Testers

Calibration Manual

PN 2465477

November 2005, Rev. 1, 7/07

© 2005, 2007 Fluke Corporation, All rights reserved. Printed in USA

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

Page 3

Table of Contents

Title Page

Introduction........................................................................................................ 1

Safety Information ............................................................................................. 1

Contacting Fluke................................................................................................ 2

General Specifications ....................................................................................... 3

Electrical Specifications .................................................................................... 4

AC/DC Voltage Measurement....................................................................... 4

Earth-Bond Resistance Measurement............................................................ 4

Insulation Specifications ............................................................................... 4

Models 1507 and 1508 .............................................................................. 4

Model 1503 ............................................................................................... 5

EN61557 Specification (Models 1503 and 1507) ..................................... 5

EN61557 Influence Variables and Uncertainties

(Models 1503 and 1507) ........................................................................... 5

Insulation Resistance Maximum and Minimum Display Values

(Models 1503 and 1507) ........................................................................... 6

Earth-Bond Resistance Maximum Display Values

(Models 1503 and 1507) ........................................................................... 7

Basic Maintenance............................................................................................. 7

Cleaning......................................................................................................... 7

Testing the Batteries ...................................................................................... 7

Replacing the Batteries and/or Fuse .............................................................. 7

Testing the Display........................................................................................ 9

Backlight Test................................................................................................ 9

Keypad Test................................................................................................... 9

Disassembling and Reassembling the Tester..................................................... 9

Removing the Holster.................................................................................... 10

Removing the Battery Door........................................................................... 11

Opening the Bottom Case.............................................................................. 11

Removing the PCA........................................................................................ 11

Removing the LCD........................................................................................ 12

Replacing the LCD ........................................................................................ 13

Reassembling the Tester................................................................................ 14

Required Tools and Equipment ......................................................................... 15

Performance Tests.............................................................................................. 16

Testing the Voltage Function ........................................................................ 16

i

Page 4

150X Series

Calibration Manual

Discharge Circuit Test................................................................................... 17

Testing the Insulation Function ..................................................................... 17

Insulation Resistance Accuracy Tests ....................................................... 17

Insulation Function, External Sense.......................................................... 18

Source Voltage Accuracy Test, "R" Nominal ........................................... 18

Source Voltage Accuracy Test, Open Circuit ........................................... 19

I Nominal Test........................................................................................... 20

I Limit Test................................................................................................ 20

Testing the Ohm Function ............................................................................. 20

Earth Bond Resistance Accuracy Tests..................................................... 20

2-Ohm Output Current Test ...................................................................... 21

Open Circuit Voltage Test ........................................................................ 21

Calibration Adjustment...................................................................................... 22

Calibration Adjustment Counter.................................................................... 22

Calibration Adjustment Password ................................................................. 22

Changing the Password ............................................................................. 22

Restoring the Default Password ................................................................ 23

Keys Used in the Calibration Steps ............................................................... 24

Calibration Adjustment Procedure ................................................................ 24

Service and Parts................................................................................................ 26

ii

Page 5

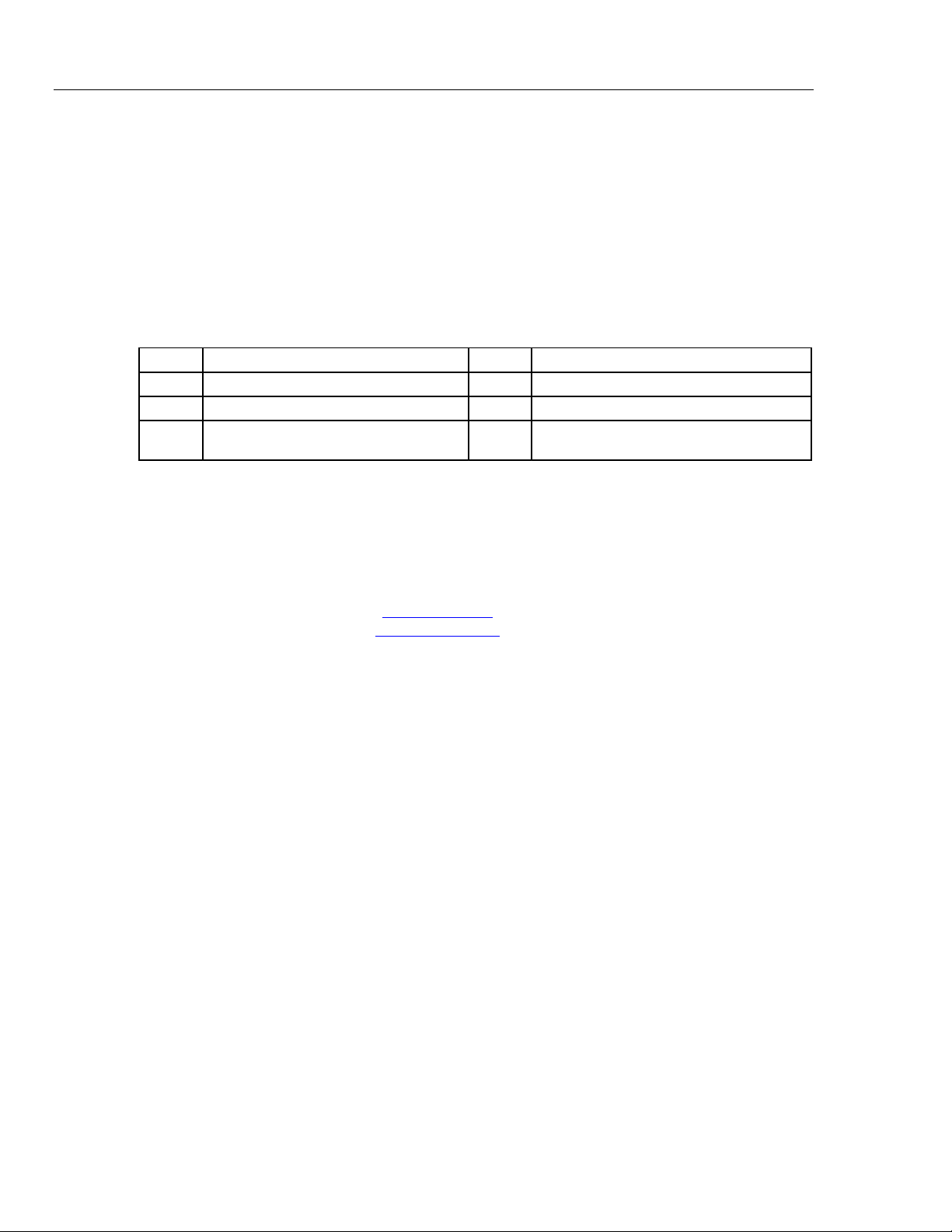

List of Tables

Table Title Page

1. Symbols.................................................................................................................. 2

2. Required Performance Test Equipment ................................................................. 15

3. Required Calibration Adjustment Equipment ........................................................ 15

4. Voltage Accuracy Tests ......................................................................................... 16

5. Insulation Resistance Accuracy Test...................................................................... 18

6. Source Voltage Accuracy Test, R-Nominal ........................................................... 19

7. Source Voltage Accuracy Test, Open Circuit ........................................................ 19

8. I Nominal Test/Limit Test...................................................................................... 20

9. Earth Bond Resistance Tests.................................................................................. 21

10. Calibration Adjustment Steps................................................................................. 25

11. Generic 150X Replacement Parts .......................................................................... 27

12. 1508 Specific Parts................................................................................................. 28

13. 1507 Specific Parts................................................................................................. 28

14. 1503 Specific Parts................................................................................................. 28

iii

Page 6

150X Series

Calibration Manual

iv

Page 7

List of Figures

Figure Title Page

1. Replacing the Fuse and Batteries ........................................................................... 8

2. Display Test ........................................................................................................... 9

3. Disassembling the Meter........................................................................................ 10

4. Insulation Terminal Clips....................................................................................... 12

5. Accessing the LCD ................................................................................................ 13

6. Restoring the Default Password ............................................................................. 23

7. 150X Replacement Parts ........................................................................................ 26

v

Page 8

150X Series

Calibration Manual

vi

Page 9

Introduction

The Fluke Models 1503, 1507, and 1508 are battery-powered insulation testers (hereafter,

Tester or UUT). These Testers meet CAT IV IEC 61010 standards. The IEC 61010

standard defines four measurement categories (CAT I to IV) based on the magnitude of

danger from transient impulses. CAT IV Testers protect against transients from the

primary supply level (overhead or underground utility service).

Although this manual contains calibration information for Models 1503, 1507, and 1508,

all illustrations and examples assume use of Model 1507. Table 1 provides a description

of all the symbols used in this manual.

The information provided in this manual includes the following:

• Warnings and Safety Information

• Specifications

• Basic Maintenance

• Performance Test Procedures

• Calibration Adjustment Procedure

• Replaceable Parts and Accessories

The information provided in this manual should only be used by qualified personnel. For

complete operating instructions and additional safety information, refer to the 1507/1503

Insulation Testers Users Manual or the 1508 Insulation Tester Users Manual.

Safety Information

To avoid possible electric shock or personal injury, follow these

guidelines:

• Use the Tester only as specified in this manual or the protection

provided by the Tester might be impaired.

• Do not use the Tester or test leads if they appear damaged, or if the

Tester is not operating properly. If in doubt, have the Tester serviced.

• Always use the proper terminal, switch position, and range for

measurements before connecting Tester to circuit under test.

• Verify the Tester’s operation by measuring a known voltage.

• Do not apply more than the rated voltage as marked on the Tester,

between the terminals or between any terminal and earth ground.

• Use caution with voltages above 30 V ac rms, 42 V ac peak, or 60 V dc.

These voltages pose a shock hazard.

• Replace the battery as soon as the low battery indicator (b) appears.

• Disconnect circuit power and discharge all high-voltage capacitors

before testing resistance, continuity, diodes, or capacitance.

• Do not use the Tester around explosive gas or vapor.

• When using the test leads, keep your fingers behind the finger guards.

• Remove test leads from the Tester before opening the Tester case or

battery door. Never operate the Tester with the cover removed or the

battery door open.

XWWarning

1

Page 10

150X Series

Calibration Manual

B AC (Alternating Current) J Earth Ground

F DC (Direct Current) I Fuse

X WARNING: risk of electric shock. T Double Insulated

b

Contacting Fluke

• Comply with local and national safety requirements when working in

hazardous locations.

• Use proper protective equipment, as required by local or national

authorities when working in hazardous areas.

• Avoid working alone.

• Use only the replacement fuse specified or the protection may be

impaired.

• Check the test leads for continuity before use. Do not use if the

readings are high or noisy.

Table 1. Symbols

Battery (Low battery when shown on

display.)

W Important information; see manual

To contact Fluke, call:

1-888-993-5853 in USA +81-3-3434-0181 in Japan

1-800-363-5853 in Canada +65-738-5655 in Singapore

+31-402-678-200 in Europe

Visit Fluke's web site at: www.fluke.com

Register your Tester at: register.fluke.com

+1-425-446-5500 from anywhere in the world

2

Page 11

Insulation Testers

General Specifications

General Specifications

Maximum Voltage Applied to any Terminal ... 600 V ac rms or dc

Storage Temperature........................................ −40 °C to 60 °C (−40 °F to 140 °F)

Operating Temperature ....................................−20 °C to 55 °C (−4 °F to 131 °F)

Temperature Coefficient .................................. 0.05 x (specified accuracy) per °C for temperatures < 18 °C or > 28 °C

Relative Humidity.............................................. Noncondensing

Vibration ............................................................Random, 2 g, 5-500 Hz per MIL-PRF-28800F, Class 2 instrument

Shock .................................................................1 meter drop per IEC 61010-1 2nd Edition (1 meter drop test, six sides,

Electromagnetic Compatibility ........................ In an RF field of 3 V/M, accuracy = specified accuracy (EN 61326-

Safety .................................................................Complies with ANSI/ISA 82.02.01 (61010-1) 2004, CAN/CSA-C22.2

Certifications

Batteries ............................................................ Four AA batteries (NEDA 15A or IEC LR6)

Battery Life ........................................................Insulation test use: Tester can perform at least 1000 insulation tests

Size..................................................................... 5.0 cm H x 10.0 cm W x 20.3 cm L (1.97 in H x 3.94 in W x 8.00 in L)

Weight ................................................................ 550 g (1.2 lb)

IP Rating ............................................................IP40

Altitude............................................................... Operating: 2000 m CAT IV 600 V, 3000 m CAT III 600 V

Over-Range Capability .....................................110% of range

Compliance to EN 61557 ..................................IEC61557-1, IEC61557-2, IEC61557-4, IEC61557-10

Model 1503 Accessories ..................................TL224 Leads

Model 1507 Accessories ..................................TL224 Leads

Model 1508 Accessories .................................. Lead Set PN 666602

..................................................... CSA per standard CSA/CAN C22.2 No. 61010.1-04; TUV per standard

(< 64 °F or > 82 °F)

0 % to 95 % @ 10 °C to 30 °C (50 °F to 86 °F)

0 % to 75 % @ 30 °C to 40 °C (86 °F to 104 °F)

0 % to 40 % @ 40 °C to 55 °C (104 °F to 131 °F)

oak floor)

1:1997).

NO. 61010-1-04, and IEC/EN 61010-1 2nd Edition for measurement

category IV 600 V (CAT IV)

IEC/EN 61010-1 2nd Edition

with fresh alkaline batteries at room temperature. These are standard

tests of 1000 V into 1 MΩ with a duty cycle of 5 seconds on and 25

seconds off. Resistance Measurements: Tester can perform at least

2500 earth-bond resistance measurements with fresh alkaline batteries

at room temperature. These are standard tests of 1 Ω with a duty cycle

of 5 seconds on and 25 seconds off.

Non Operating (Storage): 12,000 m

TP74 Probes

Clips PN 1958654 (red) and PN 1958646 (black)

Holster

TP74 Probes

Clips PN 1958654 (red) and PN 1958646 (black)

Holster

Remote Probe

Clips PN 1670641 (red) and PN 1670652 (black)

Holster

Remote Probe

3

Page 12

150X Series

Calibration Manual

Electrical Specifications

AC/DC Voltage Measurement

Accuracy

Input Impedance ............................................... 3 MΩ (nominal), <100 pF

Common Mode Rejection Ratio

(1 kΩ unbalanced) .............................................. > 60 dB at dc, 50 or 60 Hz

Overload Protection ......................................... 600 V rms or dc

Earth-Bond Resistance Measurement

[1] Accuracies apply from 0 to 100% of range.

Overload Protection .........................................2 V rms or dc

Open Circuit Test Voltage ................................ > 4.0 V, < 8 V

Short Circuit Current ........................................ > 200.0 mA

Range Resolution

600.0 V 0.1 V + (2 % + 3)

Range Resolution

20.00 Ω 0.01 Ω

200.0 Ω 0.1 Ω

2000 Ω 1 Ω

20.00 kΩ 0.01 kΩ

50 Hz to 400 Hz

± (% of Rdg + Digits)

Accuracy

+ (% of Rdg + Digits)

(1.5 % + 3)

+

[1]

Insulation Specifications

Measurement Range......................................... 0.01 MΩ to 10 GΩ models 1507 and 1508, 0.01 MΩ to 2000 MΩ model

Test Voltages .................................................... 50, 100, 250, 500, 1000 V models 1507 and 1508, 500 and 1000 V

Test Voltage Accuracy .....................................+ 20 %, - 0 %

Short-Circuit Test Current ............................... 1 mA nominal

Auto Discharge ................................................. Discharge time < 0.5 second for C = 1 μF or less

Live Circuit Detection ....................................... Inhibit test if terminal voltage > 30 V prior to initialization of test

Maximum Capacitive Load............................... Operable with up to 1 μF load

1503

model 1503

Models 1507 and 1508

Output Voltage Display Range Resolution Test Current

50 V

(0 % to + 20 %)

100 V

(0 % to + 20 %)

250 V

(0 % to + 20 %)

500 V

(0 % to + 20 %)

1000 V

(0 % to + 20 %)

0.01 to 20.00 MΩ 0.01 MΩ

20.0 to 50.0 MΩ 0.1 MΩ

0.01 to 20.00 MΩ 0.01 MΩ

20.0 to 100.0 MΩ 0.1 MΩ

0.01 to 20.00 MΩ 0.01 MΩ

20.0 to 200.0 MΩ 0.1 MΩ

0.01 to 20.00 MΩ 0.01 MΩ

20.0 to 200.0 MΩ 0.1 MΩ

200 to 500 MΩ 1 MΩ

0.1 to 200.0 MΩ 0.1 MΩ

200 to 2000 MΩ 1 MΩ

2.0 to 10.0 GΩ 0.1 GΩ

1 mA @ 50 kΩ ± (3 % + 5)

1 mA @ 100 kΩ ± (3 % + 5)

1 mA @ 250 kΩ ± (1.5 % + 5)

1 mA @ 500 kΩ ± (1.5 % + 5)

1 mA @ 1 MΩ

Accuracy

± (% of Rdg + Digits)

± (1.5 % + 5)

± (10 % + 3)

4

Page 13

Insulation Testers

Electrical Specifications

Model 1503

Output Voltage Display Range Resolution Test Current

500 V

(0 % to + 20 %)

1000 V

(0 % to + 20 %)

0.01 to 20.00 MΩ 0.01 MΩ

20.0 to 200.0 MΩ 0.1 MΩ

200 to 500 MΩ 1 MΩ

0.1 to 200.0 MΩ 0.1 MΩ

200 to 2000 MΩ 1 MΩ

1 mA @ 500 kΩ ± (2.0 % + 5)

1 mA @ 1 MΩ ± (2.0 % + 5)

Accuracy

± (% of Rdg + Digits)

EN61557 Specification (Models 1503 and 1507)

The following tables are a requirement for European labeling.

[1]

Measurement Intrinsic Uncertainty Operating Uncertainty

Volts

Earth-Bond Resistance

Insulation Resistance

[1] This specification comes from the standard and indicates the maximum amount allowable by the standard.

Depends on test voltage and range.

See Insulation Test specifications.

± (2.0 % + 3)

± (1.5 % + 3)

30 %

30 %

30 %

EN61557 Influence Variables and Uncertainties (Models 1503 and 1507)

Earth-Bond Resistance

Influence Variable

Supply Voltage E2 5 % 5 %

Temperature E3 5 % 5 %

[1] Specification confidence level 99 %.

Designation per EN61557

Uncertainty for Insulation

Resistance

1

Uncertainty for Earth-Bond

Resistance

[1]

5

Page 14

150X Series

Calibration Manual

The following tables can be used to determine the maximum or minimum display values considering maximum instrument

operating error per EN61557-1, 5.2.4.

Insulation Resistance Maximum and Minimum Display Values (Models 1503 and 1507)

Limit

Value

0.05 0.07 0.05 0.07 0.05 0.07 0.05 0.07

0.06 0.08 0.06 0.08 0.06 0.08 0.06 0.08

0.07 0.09 0.07 0.09 0.07 0.09 0.07 0.09

0.08 0.10 0.08 0.10 0.08 0.10 0.08 0.10

0.09 0.12 0.09 0.12 0.09 0.12 0.09 0.12

0.1 0.13 0.1 0.13 0.1 0.13 0.1 0.13 0.1 0.1

0.2 0.26 0.2 0.26 0.2 0.26 0.2 0.26 0.2 0.3

0.3 0.39 0.3 0.39 0.3 0.39 0.3 0.39 0.3 0.4

0.4 0.52 0.4 0.52 0.4 0.52 0.4 0.52 0.4 0.5

0.5 0.65 0.5 0.65 0.5 0.65 0.5 0.65 0.5 0.7

0.6 0.78 0.6 0.78 0.6 0.78 0.6 0.78 0.6 0.8

0.7 0.91 0.7 0.91 0.7 0.91 0.7 0.91 0.7 0.9

0.8 1.04 0.8 1.04 0.8 1.04 0.8 1.04 0.8 1.0

0.9 1.17 0.9 1.17 0.9 1.17 0.9 1.17 0.9 1.2

1.0 1.30 1.0 1.30 1.0 1.30 1.0 1.30 1.0 1.3

2.0 2.60 2.0 2.60 2.0 2.60 2.0 2.60 2.0 2.6

3.0 3.90 3.0 3.90 3.0 3.90 3.0 3.90 3.0 3.9

4.0 5.20 4.0 5.20 4.0 5.20 4.0 5.20 4.0 5.2

5.0 6.50 5.0 6.50 5.0 6.50 5.0 6.50 5.0 6.5

6.0 7.80 6.0 7.80 6.0 7.80 6.0 7.80 6.0 7.8

7.0 9.10 7.0 9.10 7.0 9.10 7.0 9.10 7.0 9.1

8.0 10.40 8.0 10.40 8.0 10.40 8.0 10.40 8.0 10.4

9.0 11.70 9.0 11.70 9.0 11.70 9.0 11.70 9.0 11.7

10.0 13.0 10.0 13.0 10.0 13.0 10.0 13.0 10.0 13.0

20.0 26.0 20.0 26.0 20.0 26.0 20.0 26.0 20.0 26.0

30.0 39.0 30.0 39.0 30.0 39.0 30.0 39.0 30.0 39.0

40.0 52.0 40.0 52.0 40.0 52.0 40.0 52.0 40.0 53.0

50 V 100 V 250 V 500 V 1000 V

Minimum

Display

Value

50.0 65.0 50.0 65.0 50.0 65.0 50.0 65.0

60.0 78.0 60.0 78.0 60.0 78.0 60.0 78.0

70.0 91.0 70.0 91.0 70.0 91.0 70.0 91.0

80.0 104.0 80.0 104.0 80.0 104.0 80.0 104.0

90.0 117.0 90.0 117.0 90.0 117.0 90.0 117.0

100.0 130.0 100.0 130.0 100.0 130.0

200.0 260.0 200.0 260.0

300.0 390.0 300.0 390.0

400.0 520.0 400.0 520.0

500.0 650.0

600.0 780.0

700.0 910.0

800.0 1040.0

900.0 1170.0

1000.0 1300.0

2000.0 2600.0

Limit

Value

Minimum

Display

Value

Limit

Value

Minimum

Display

Value

Limit

Value

Minimum

Display

Value

Limit

Value

Minimum

Display

Value

6

Page 15

Insulation Testers

Basic Maintenance

Earth-Bond Resistance Maximum Display Values (Models 1503 and 1507)

Limit Value

0.4 0.28 7.0 4.9 100.0 70.0

0.5 0.35 8.0 5.6 200.0 140.0

0.6 0.42 9.0 6.3 300.0 210.0

0.7 0.49 10.0 7.0 400.0 280.0

0.8 0.56 20.0 14.0 500.0 350.0

0.9 0.63 30.0 21.0 600.0 420.0

1.0 0.7 40.0 28.0 700.0 490.0

2.0 1.4 50.0 35.0 800.0 560.0

3.0 2.1 60.0 42.0 900.0 630.0

4.0 2.8 70.0 49.0 1000.0 700.0

5.0 3.5 80.0 56.0 2000.0 1400.0

6.0 4.2 90.0 63.0

Maximum

Display Value

Limit Value

Maximum

Display Value

Limit Value

Maximum

Display Value

Basic Maintenance

This basic maintenance section of the manual contains tests and procedures that require

no equipment other than the Tester and some consumables such as fuses and batteries.

Also, internal access is limited to the battery and fuse compartment.

Cleaning

When cleaning is necessary, wipe the Tester with a damp cloth and mild detergent. Do

not use abrasives or solvents. Dirt or moisture on the terminals can affect readings.

Testing the Batteries

XWWarning

To avoid electrical shock or personal injury, replace the

batteries as soon as the battery indicator (B) appears. A weak

battery can cause false readings.

The Tester continuously monitors battery voltage. If the low battery icon (B) appears

on the display, there is minimal battery life left. Before any performance test, check the

batteries and replace if necessary.

The following procedure tests the batteries under load:

1. Turn the rotary switch to the b position with no probes inserted.

2. Press the blue key to initiate the fully loaded battery test. The voltage function

display clears and the measured battery voltage is shown in the primary display

for two seconds, the voltage display then returns. The displayed voltage should

be within 5.5 to 6.2 V. If voltage is lower than 5.2 V, replace the batteries and

repeat the test.

Replacing the Batteries and/or Fuse

Replace the fuse and batteries as shown in Figure 1. Follow the steps below to replace the

batteries.

7

Page 16

150X Series

Calibration Manual

XWWarning

To avoid shock, injury, or damage to the Tester:

• To avoid false readings, which could lead to possible

electric shock or personal injury, replace the batteries as

soon as the battery indicator (B) appears.

• Use ONLY fuses with the amperage, interrupt, voltage,

and speed ratings specified.

• Turn the rotary switch to OFF and remove the test leads

from the terminals.

1. Remove the yellow boot from the Tester. Use the thumb-hole to press on the rear

of the Tester and peel the boot from the Tester.

2. Remove the battery door by using a standard screwdriver to turn the battery door

lock until the unlock symbol aligns with the arrow.

3. Lift the bottom of the battery door away from the Tester to access the fuse and

battery compartment.

4. Remove and replace the batteries and fuse as shown in Figure 1.

5. Replace the battery door and secure by turning the battery door lock until the

lock symbol (L)aligns with the arrow.

6. Position the bottom of the Tester in the bottom of the boot, and press the top of

the Tester firmly into the boot.

F315 mA 1000 V

Min interrupt rating

10000 A

Fuse, Fast, 315 mA, 1000 V, Min Interrupt Rating 10000 A Fluke PN 2279339

Battery, 1.5 V AA Alkaline, NEDA 15A, IEC LR6 Fluke PN 376756

ecz15f.eps

8

Figure 1. Replacing the Fuse and Batteries

Page 17

Insulation Testers

Disassembling and Reassembling the Tester

Testing the Display

Press and hold the blue key, and simultaneously turn the UUT on. Compare the display with the

example in Figure 2. Check all segments for clarity and contrast.

Figure 2. Display Test

Backlight Test

The display backlight is a toggle function controlled by the H key. Each press of

Hcauses the backlight to change states, on to off or off to on. To test the backlight:

1. Press the H key twice to verify that the toggle function is working.

2. Turn the backlight off.

Keypad Test

The keypad consists of six keys located above the rotary switch. To test the keypad:

1. Turn the rotary switch to

V and momentarily press each of the six keys. Each

press of an operational key will cause the Tester to beep. No beep in response to

a key press indicates a defective keypad.

2. Reset the Tester by turning it

OFF, and then to any other position.

Disassembling and Reassembling the Tester

This section of the manual provides instructions for disassembling and reassembling the

Tester. The instructions are limited to major replaceable assemblies and do not include

component-level detail. See Figure 3 for an exploded view of the major assemblies. Also,

the emphasis is placed on disassembly. However, when appropriate, an italicized entry at

the end of each disassembly procedure provides critical hints for reassembly.

bbw01f.eps

9

Page 18

150X Series

Calibration Manual

Holster

Battery Door

Case

Screws

Case

Bottom

Fuse

Plastic Shields

Red

Black

Figure 3. Disassembling the Tester

PCA Screws

PCA

Light-dispersing

Back Panel

Glass LCD

Display

Elastomeric

Strip

Gray Plastic

Bezel

Keypad

Case Top

ecz20f.eps

Removing the Holster

The standard Tester comes equipped with a snug-fitting yellow rubber holster. The

holster helps protect the Tester from rough handling and normally remains on the Tester.

The first step in disassembling the Tester is to remove the holster.

Use the following procedure to remove the holster:

1. Looking at the Tester, place your thumbs on the top corners of the holster and firmly

grasp the Tester.

2. Using both thumbs, push the holster up and over both corners of the Tester.

3. Continue pushing on the holster until both of its inside corners are resting on top of

the Tester.

4. Rest the heel of one hand behind the display, and place all four fingers of the same

hand along the upper front edge of the holster.

5. Firmly grasp the Tester with the other hand, and using your fingers, peel the holster

over the top of the Tester.

6. Slide the Tester up and out of the holster.

To install the holster, position the bottom of the Tester in the bottom of the

holster, and press the top of the instrument firmly into of the holster.

Note

10

Page 19

Insulation Testers

Disassembling and Reassembling the Tester

Removing the Battery Door

XWWarning

To avoid the risk of electrical shock, turn the rotary switch to

OFF, and remove the test leads from the front-panel terminals

before removing the battery cover.

With the boot removed, the next step in disassembling the Tester is to remove the battery

door. Use the following procedure to remove the door:

1. Locate the black slotted lock on the lower rear of the Tester.

2. Using a standard screwdriver, turn the battery-door lock until the unlock symbol

aligns with the arrow. The door is now unlocked.

3. Lift the bottom of the battery door away from the Tester. Removing the battery door

provides access to the fuse and battery compartment.

4. If necessary, remove and replace the batteries and fuse as shown in Figure 1.

Note

To install the battery door, slide the top of the door into position and secure

it by turning the battery door lock until the lock symbol (L) aligns with the

arrow.

Opening the Bottom Case

With the battery door removed, the next step in disassembling the Tester is to remove the

bottom case. Use the following procedure to remove the bottom case:

When removing the back cover, it is unnecessary to remove the fuse or the

batteries.

1. Locate the four Philips head screws on the bottom case (two are next to the batteries

and two are next to the fuse).

2. Using a Philips screwdriver, remove the four screws.

3. Separate the front and bottom cases at the fuse-end the Tester. Tilt the freed end of

the cover up, and lift it away from the top case.

To install the bottom case, first, position and press together the display-end

of the top and bottom cases. Before installing all four screws, press the

fuse-end of the covers together.

Removing the PCA

With the bottom case removed, the next step in disassembling the Tester is to remove the

printed circuit assembly (PCA). Refer to Figure 3 for the exploded part view and use the

following procedure to remove the PCA:

Note

Note

1. One Philips screw attaches the PCA to the top case. Locate the screw near the center

of the PCA, and remove it.

2. Two chrome plated springs on the PCA form an electrical connection (clip) to the

two recessed INSULATION(+) terminals on the top case. Break these connections by

carefully pulling each of the springs back and away from the terminals. See Figure 4.

11

Page 20

150X Series

Calibration Manual

Figure 4. Insulation Terminal Clips

eca18f.eps

3. With one hand over the PCA, roll the top case over (face up) and lift it away from the

PCA.

Two red and one black plastic shields are used to isolate the user from the

input terminals. With the PCA removed, these shields are loose and can fall

away from the PCA.

4. Remove and set aside all three shields for use during reassembly.

To avoid risk of electrical shock, make sure the plastic input

terminals are properly positioned on the PCA before attaching it

to the top case.

To install the PCA, proceed as follows:

1. With the PCA face-up, place all three plastic shields into position on the PCA.

2. Lower the top cover onto the PCA, and roll both parts over (PCA up).

3. Connect (snap) the chrome plated springs to the INSULATION terminals.

4. Install the screw that attaches the PCA to the top case.

Removing the LCD

With the PCA removed, the final step in disassembling the Tester is to remove the LCD

assembly from the PCA. Refer to Figure 5 and use the following procedure to remove the

LCD assembly:

Note

XWWarning

12

1. Remove the two screws from the display end of the PCA.

2. Hold the PCA face down with the fuse-end of the PCA toward you. Locate the

screw-hole near the center of the assembly. This hole is the one used to attach (with a

screw) the PCA to the top case.

Page 21

Insulation Testers

Disassembling and Reassembling the Tester

3. Locate the gray plastic tab just above and to the left of the hole. Using your

thumbnail, press the tab down and toward the display end of the PCA. This will

release the LCD assembly from the PCA.

WCaution

To avoid damaging the plastic guide pins on the LCD assembly,

keep the LCD assembly parallel to the PCA when separating the

two parts.

4. Without tilting the PCA, lift it straight up and away from the LCD assembly.

5. To keep loose parts from falling away from the LCD assembly, keep it face-down,

and set it in a safe place.

PCA Screws

Fuse

Replacing the LCD

The LCD assembly consists of four pieces as shown in Figure 5:

• Translucent light-dispersing back panel

• Flexible elastomeric conducting strip

• Plastic bezel for housing the assembly's components

• Glass LCD display

Figure 5. Accessing the LCD

PCA

Light-dispersing

Back Panel

Glass LCD

Display

Elastomeric

Strip

Gray Plastic

Bezel

ecz21f.eps

With the LCD assembly removed from the PCA, use the following procedure to replace

the LCD:

1. Lift the translucent light dispersing back panel from the plastic bezel.

2. Remove the pink and black elastomeric strip from its slot in the bezel.

13

Page 22

150X Series

Calibration Manual

3. Remove the old glass LCD display from the bezel.

Note

Make sure the new LCD display is clean (free of lint and fingerprints)

before placing it in position in the bezel.

4. Position the new glass LCD display in the bezel; the silver face should face the rear,

and the stepped portion of the glass should be directly under the elastomeric slot on

the bezel.

5. Drop the elastomeric strip into its slot on the bezel.

6. Position the translucent light-dispersing back panel over the silver side of the glass

LCD display. Make sure the guide pins on the light dispersing back panel are facing

up and that they are on the side opposite the elastomeric strip.

7. While holding the LCD assembly (face down) in one hand, position the PCA (fuse

side up) over the bezel; match the guide holes in the PCA with the plastic guide pins

on the bezel and the translucent light dispersing back panel. After the LCD assembly

is in position, lock it in place by pressing (below the display) the bezel against the

PCA; listen for the tab on the bezel to snap (lock) into position on the PCA.

8. Secure the PCA to the LCD assembly by installing the two screws that attach the

PCA to the bezel. These screws also ensure contact between the glass LCD display,

the elastomeric strip, and the PCA.

Reassembling the Tester

To reassemble the Tester, logically reverse the previous disassembly procedures. In the

process, make sure to re-establish all electrical connections; specifically, the elastomeric

strip for the LCD, the red and black plastic shields for the input terminals, and the two

spring contacts for the Insulation Test Probe. Also make sure all parts are correctly

aligned and positioned; do not force-fit any of the parts into position.

14

Page 23

Insulation Testers

Required Tools and Equipment

Required Tools and Equipment

Tables 2 and 3 list the required equipment used in the Performance Test and Calibration

Adjustments. If a recommended model is unavailable, use a substitute with equivalent or

better specifications.

Table 2. Required Performance Test Equipment

Equipment Required Characteristics Recommended Model

Calibrator AC Voltage Range: 0 – 600 V

Accuracy: ± 0.5 %

Frequency Range: 50 Hz – 400 Hz

Accuracy: ± 3 %

DC Voltage: 0 – 600 V

Accuracy: ± 0.5 %

Ω Range: 0 – 20 kΩ

Accuracy: ± 0.37 %

Insulation Resistance: 50 kΩ – 10 GΩ

Accuracy: ± 0.37 %

Meter Function DC Volts: 0 – 1500 V

Accuracy: ± 5 %

DC Current: 0 – 2 mA

Accuracy: ± 1 %

Ohm Meter Ω Range: 2000 – 3000 Ω Fluke 189

Table 3. Required Calibration Adjustment Equipment

Equipment Required Characteristics Recommended Model

Calibrator DC Voltage: 0 – 750 V

Accuracy: ± 5 %

DC Current: 0 – 2 mA

Accuracy: ± 0.37 %

Precision Resistor Resistor, Wirewound, 2 Ω k, ± 0.1 %, 1 W, 50 ppm IRC PN RWR89S2R00BR

Fluke 5320A/VLC

Fluke 5520A

15

Page 24

150X Series

Calibration Manual

Performance Tests

Testing the Voltage Function

The following series of tests comprise a performance test for verifying the accuracy of

the Tester (UUT) and its performance level. The performance test is recommended as an

acceptance test for incoming inspection and as a calibration procedure for periodically

ensuring the accuracy of the Tester. Fluke recommends running the performance test at

least once a year.

No adjustments are required during the performance test, and it is not necessary to open

the case. If the Tester does not pass all parts of the performance tests, repair and/or

calibration adjustment are required. A calibration adjustment procedure is given later in

this manual. If significant repairs are required, contact Fluke as described toward the

front of this manual. If user repairs are appropriate, refer to the list of user-replaceable

parts toward the end of this manual.

To verify the accuracy of the voltage measuring function, do the following:

1. Turn the UUT rotary switch to the

2. Connect the Fluke 5320A voltage output terminals to the

V function.

INSULATION and COM

terminals of the UUT.

3. Set the 5320A for the voltage output function (V).

4. Apply the input level for each step listed in Table 4.

5. Compare the reading on the UUT display with the Display Reading in Table 4.

6. If the display reading falls outside of the limits shown in Table 4, the Tester does

not meet specification.

Table 4. Voltage Accuracy Tests

Step Function Range Applied Input

1 3 V, 0 Hz 2.7 3.3

2 8 V, 0 Hz 7.5 8.5

3

4 50 V, 0 Hz 48.7 51.3

8 V, 400 Hz Display must show V ac

Display Reading

Low Limit High Limit

annunciator

16

5 100 V, 0 Hz 97.7 102.3

6 250 V, 0 Hz 244.7 255.3

7 500 V, 0 Hz 489.7 510.3

8 120 V, 60Hz 117.3 122.7

9 230 V, 50 Hz 225.1 234.9

10

V 600.0 V

600 V, 400 Hz 587.7 612.3

Page 25

Insulation Testers

Performance Tests

Discharge Circuit Test

The following Discharge Circuit Test is a safety related test that verifies input jack wiring

to the PCA, the RSOB contacts, RSOB PCA pads, and other active discharge components

on the PCA.

1. Place a Shorting Bar across the UUT

2. Set the UUT rotary switch to 1000 V, and press T.

3. Release the T key and remove the short from the UUT input terminals.

To avoid damage to the DMM, DO NOT press the UUT T key

during the following steps.

4. Connect the test DMM to the UUT

5. Set the test DMM to Ω function.

6. Verify that the test DMM reading is between 2000 and 3000 Ω.

Testing the Insulation Function

To avoid possible electric shock or personal injury, avoid

contact with the UUT when testing the insulation function.

Pressing the T key produces a potentially dangerous

voltage, at the UUT insulation output terminals, when the Tester

is in the Insulation function.

To avoid damage to the calibrator, do not attempt to use the

5500A, 5520A or other standard calibrator for the insulation

tests.

COM and INSULATION input terminals.

WCaution

INSULATION and COM terminals.

XWWarning

WCaution

WCaution

To avoid damage to the Fluke 5320A, make sure to select the

High Ohms function prior to pushing the UUT T key.

Insulation Resistance Accuracy Tests

To test the insulation resistance accuracy, complete the test steps in Table 5 using the

following procedure:

1. Connect the UUT

INSULATION and COM terminals to the Fluke 5320A High

Resistance output terminals.

2. Set the Fluke 5320A to the high resistance source function (H).

3. Turn the UUT rotary function switch to an

INSULATION function.

4. Select the UUT insulation voltage range per Table 5.

5. Apply the Fluke 5320A output called out in Table 5.

6. Press the UUT T key.

7. Verify that the UUT reading is within the display reading limits listed in

Table 5.

17

Page 26

150X Series

Calibration Manual

Table 5. Insulation Resistance Accuracy Test

Step

1 1000 V 9 GΩ N/A 7.8 to 10.2

2 1000 V 1.9 GΩ 1862 to 1938 N/A

3 1000 V 1 MΩ 0.5 to 1.5 0.5 to 1.5

4 1000 V 49 MΩ 47.5 to 50.5 47.8 to 50.2

5 1000 V 60 MΩ 58.3 to 61.7 58.6 to 61.4

6 500 V 500 kΩ 0.44 to 0.56 0.44 to 0.56

7 250 V 250 kΩ N/A 0.20 to 0.30

8 100 V 100 kΩ N/A 0.6 to 0.15

9 50 V 50 kΩ

Insulation

Voltage Range

Applied Display Units

MΩ

Display Reading Limits

1503 1507/1508

N/A 0.0 to 0.10

Insulation Function, External Sense

The following test verifies that the Tester will sense a voltage > 30 V when present on the

circuit under test.

1. Connect the UUT

INSULATION and COM output terminals to the Fluke 5320A

voltage output terminals.

2. Set the 5320A to the voltage output function (V).

3. Turn the UUT rotary function switch to an insulation function.

4. Apply 35 V, 50 Hz to the UUT.

5. Verify that the UUT displays > 30 V in the primary display, and the red LED

lightning bolt comes on.

Source Voltage Accuracy Test, "R" Nominal

Complete the test steps in Table 6 to verify source voltage of the insulation function

under load. If using the Fluke 5320A, use the high resistance function to verify source

voltage.

1. Connect the Fluke 5320A high resistance output terminals to the UUT

INSULATION and COM terminals.

2. Put the Fluke 5320A in the high resistance function (H).

3. Set the Fluke 5320A for the applied load shown in Table 6 for Steps 1-5.

4. Press T and verify that the UUT and Fluke 5320A voltage readings are

within the limits of Table 6. Record both of these readings.

5. Using the Fluke 5320A voltage reading as the reference, calculate the UUT

voltage reading error %, (5320A V - UUT V / 5320A V) x 100, and record for

later use.

18

Page 27

Insulation Testers

Table 6. Source Voltage Accuracy Test, R-Nominal

Performance Tests

Step UUT Function

1 Insulation 1000 V 1 MΩ 1000 V to 1200 V 1000 V to 1200 V

2 Insulation 500 V 500 k 500 V to 600 V 500 V to 600 V

Insulation

3

(1507/1508)

Insulation

4

(1507/1508)

5 Insulation

(1507/1508)

Tester

Range

250 V 250 kΩ 250 V to 300 V 250V to 300 V

100 V 100 kΩ 100 V to 120 V 100 V to 120 V

50 V 50 kΩ 50 V to 60 V 50 V to 60 V

Applied

Load

5320A Display

Reading

UUT Display

Reading

Source Voltage Accuracy Test, Open Circuit

The open circuit source voltage accuracy can be determined, by calculation, using the

UUT Voltage Reading Error % previously noted. Complete the following test to verify

the actual open circuit source voltage.

1. Remove test leads from the UUT terminals.

2. Set the UUT rotary function switch to an insulation test function.

3. Press T and record the UUT display reading for each step in

Table 7.

UUT Voltage

Reading Error %

4. Using the previously determined UUT Voltage Reading Error %, calculate the

actual open circuit output voltage for each voltage range. Verify that the

calculated value is within the limits shown in Table 7. The formula is Recorded

UUT Display Reading x UUT Voltage Reading Error % + Recorded UUT

Display Reading.

Table 7. Source Voltage Accuracy Test, Open Circuit

Step Function Range

1 Insulation 1000 V 1000 V to 1200 V

2 Insulation 500 V 500 V to 600 V

3

4

5

Insulation

(1507/1508)

Insulation

(1507/1508)

Insulation

(1507/1508)

250 V

100 V

50 V

Recorded UUT

Display Reading

Calculated UUT Output

Voltage Limits

250 V to 300 V

100 V to 120 V

50 V to 60 V

19

Page 28

150X Series

Calibration Manual

I Nominal Test

Step Function Range Applied Load 5320A Current Reading

1 Insulation 1000 V 1 MΩ

2 Insulation 500 V 500 kΩ

The following test verifies the UUT’s ability to maintain the nominal insulation test

current while loaded.

1. Connect the Fluke 5320A high resistance output terminals to the UUT

INSULATION and COM terminals.

2. Set the 5320A to the high resistance source function (H).

3. Set the 5320A for the Applied Load called out in Table 8 for Steps 1-5.

4. Press T and verify that the Fluke 5320A current reading is

> 1000.0 μA for steps 1-5.

Table 8. I Nominal Test/Limit Test

3

4

5

Insulation

(1507/1508)

Insulation

(1507/1508)

Insulation

(1507/1508)

250 V 250 kΩ

100 V 100 kΩ

50 V 50 kΩ > 1000.0 μA

I Limit Test

The following test verifies the UUT’s internal insulation function and current limit

operation.

1. Connect the Fluke 5320A high resistance output terminals to the UUT

INSULATION and COM terminals.

2. Set the Fluke 5320A to the high resistance source function (H) and 50 kΩ.

3. Set the UUT rotary switch to the 1000 V range.

4. Press and hold the T key.

5. The Fluke 5320A current reading should be <2000.0 μA.

Testing the Ohm Function

Earth Bond Resistance Accuracy Tests

To test earth bond resistance accuracy, complete the test steps in Table 9, using the

following procedure:

> 1000.0 μA

20

1. Connect the UUT

COM and Ω terminals to the Fluke 5320A low resistance

output terminals in a 4-wire configuration.

2. Set the Fluke 5320A to the low resistance source function (L).

3. Turn the UUT rotary function switch to the Ω function.

4. Apply the calibrator output listed in Table 9, Steps 1-3.

Page 29

Insulation Testers

Performance Tests

5. Press T, and verify that the UUT reading is within the display reading limits

shown in Table 9.

6. Connect the Fluke 5320A high resistance output terminals to the UUT

Ω terminals.

COM and

7. Set the Fluke 5320A to the high resistance source function (H).

8. Press T, and verify that the reading is within the display reading limits for

Table 9, Step 4.

Table 9. Earth Bond Resistance Tests

Step Tester Range Applied Display Units

1 20.00 Ω 2.0 Ω Ω 1.94 2.06

2 2000 Ω 810.0 Ω Ω 795 825

3 2000 Ω 990.0 Ω Ω 972 1008

4 20.00 kΩ 18.0 kΩ kΩ 17.70 18.30

Display Reading

Low Limit High Limit

2-Ohm Output Current Test

The following procedure verifies the minimum current for a 2-Ω Load in continuity

function:

1. Connect the Fluke 5320A low resistance output terminal to the UUT

COM and Ω

terminals.

2. Set the Fluke 5320A to the low resistance source function (L) and 2-Ω output.

3. Set the UUT rotary function switch to the Ω function.

4. Press the UUT T. The Fluke 5320A current reading should be > 200 mA.

Open Circuit Voltage Test

The following test confirms that the open circuit voltage for the UUT Ω function is

within limits.

1. Connect the Fluke 5320A

COM terminals observing correct polarity.

2. Set the Fluke 5320A to the M mode and dc volts.

3. Set the UUT rotary function switch to the

4. Press T and verify that the Fluke 5320A voltage reading is > 4.0 V but

< 8.0 V.

V and COM meter terminals directly to the UUT Ω and

Ω function.

21

Page 30

150X Series

Calibration Manual

Calibration Adjustment

Calibration Adjustment Counter

The Tester features closed-case calibration adjustment using known reference sources.

The Tester measures the applied reference source, calculates correction factors and stores

the correction factors in nonvolatile memory.

The following sections present the features and Tester function keys that are used during

the calibration adjustment procedure. Perform the calibration adjustment procedure

should the Tester fail any performance test listed earlier in this manual.

The Tester contains a calibration adjustment counter. The counter is incremented each

time a calibration adjustment procedure is completed. The value in the counter can be

recorded and used to show that no adjustments have been made during a calibration

cycle.

Use the following steps to view the Tester's calibration counter.

1. While holding down L, turn the rotary function switch from OFF to V. The

Tester displays CAL.

2. Press the blue key A once to see the calibration counter. For example n003.

3. Turn the rotary function switch to OFF.

Calibration Adjustment Password

Enter the correct four-key password to start the calibration adjustment procedure. The

password can be changed or reset to the default as described in the following paragraphs.

The default password is 1234.

Changing the Password

Use the following steps to change the Tester's password:

1. While holding down L, turn the rotary function switch from OFF to V. The

Tester displays CAL.

2. Press the blue key once to see the calibration counter.

3. Press the blue key again to start the password entry. The Tester displays ----.

4. The Tester’s keys represent the digits indicated below when entering or changing

the password:

Blue Key = 1

L = 2 C = 3 T = 4

5. Press the four keys to enter the old password. If changing the password for the

first time, press the blue key (1), L (2), C (3), T (4).

6. Press C to change the password. The Tester displays ---- if the old password is

correct. If the password is not correct, the Tester emits a double beep, displays

---- and the four key password must be entered again. Repeat step 4.

22

7. Press the four keys of the new password.

8. Press the blue key to store the new password.

Page 31

Insulation Testers

Calibration Adjustment

Restoring the Default Password

If you forget the calibration password, the default password (1234) can be restored using

the following steps.

XWWarning

To avoid electrical shock or personal injury, remove the test

leads and any input signal before removing the Tester's bottom

case.

1. Remove the back case from the UUT. Leave the PCA in the top case.

2. Apply 6.0 V across the battery contact pads (J8) + and − on the PCA.

See Figure 6.

3. Short across the Cal keypad (S8) on the back of the PCA. See Figure 6.

4. Turn the rotary knob from

OFF to V. The UUT will beep and display CAL. The

default password is now restored.

5. Remove the 6.0 V supply, turn the rotary switch to

on the UUT.

Cal Keypad

OFF, and install the back case

Battery Pads

Figure 6. Restoring the Default Password

23

ecz17f.eps

Page 32

150X Series

Calibration Manual

Keys Used in the Calibration Steps

Calibration Adjustment Procedure

The Tester keys behave as follows when you perform the calibration adjustment

procedure:

T stores the calibration value and advances to the next step.

H ignores the calibration value and advances to the next step. This key is also

used to exit the calibration function after the calibration adjustment sequence

is complete.

Use the following steps to make calibration adjustments to the Tester. If the Tester is

turned off before completion of the adjustment procedure, the calibration constants are

not changed.

1. Remove batteries from UUT battery compartment. Connect a + 5.0 V lab supply

to the + and − battery terminals.

2. While holding down L, turn the rotary function switch from OFF to VAC.

The Tester displays CAL.

3. Press the blue button once to see the calibration counter.

4. Press blue button again to start the password entry. ---- appears on the display.

5. Press four keys to enter the password.

6. Press the blue button to go to the first calibration step. The Tester displays C-01 if

the password is correct. If the password is not correct, the Tester emits a double

beep, displays ---- and the password must be entered again. Repeat step 4.

7. Using Table 10, apply the input value listed for each calibration adjustment step.

For each step, position the rotary function switch and apply the input to the

terminals as indicated in Table 10.

8. After each input value is applied, press T to accept the value and proceed to

the next step (C-02 and so forth).

Note

After pressing T, wait until the step number advances before changing

the calibrator source or turning the Tester rotary function switch. If the

Tester rotary function switch is not in the correct position, or if the

measured value is not within the anticipated range of the input value, the

Tester emits a double beep and will not continue to the next step. Some

adjustment steps take longer to execute than others (10 to 15 seconds). For

these steps, the Tester will beep when the step is complete. Not all steps

have this feature.

9. After the final step, the display shows End to indicate that the calibration

adjustment is complete. Press C to go to meter mode.

24

Note

Set the calibrator to standby prior to changing the function switch position

and or after completing adjustment of each function. If the calibration

adjustment procedure is not completed correctly, the Tester will not operate

correctly.

Page 33

Insulation Testers

Table 10. Calibration Adjustment Steps

Switch Position Input Terminal Adjustment Step Input Value

C-01 0m A, 0 Hz

Calibration Adjustment

1000 V Insulation

+ : COM

− : A gnd (remote test

probe pin)

Continuity

+ : Volts Input

Volts

− : COM

+ : Continuity Input

Continuity

− : COM

1000 V Insulation None C-15

+: Continuity Input

Continuity

−: COM

C-02 15u A, 0 Hz

C-03 0.18 mA, 0 Hz

C-04 1.8 mA, 0 Hz

C-05 0.5 mA, 0 Hz

C-06 5.0 mA, 0 Hz

C-07 0.5 mA, 0 Hz

C-08 5.0 mA, 0 Hz

C-09 5.0 mA, 0 Hz

C-10 300 mA, 0 Hz

C-11 25.0 V, 0 Hz

C-12 750 V, 0 Hz

C-13 0.5 V, 0 Hz

C-14 5.0 V, 0 Hz

2.00 Ω (Use external

C-16

resistor, 0.1 %, 1 W,

50 PPM)

[1]

Any

[1] Must certify that this resistor is within 1.998 Ω to 2.002 Ω. This resistor should be mounted directly to the

Tester Ω and COM terminals to minimize lead resistance.

+: Battery + Terminal

C-18 + 5 V

−: Battery − Terminal

25

Page 34

150X Series

Calibration Manual

Service and Parts

User service is limited to replacing parts. Table 11 identifies the replacement parts used

by all models, Tables 12, 13, and 14 identify the replacement parts unique to each model.

Figure 7 shows the location of each part. To order replacement parts refer to Contacting

Fluke earlier in this manual.

MP40-43

H26-29

(4x)

MP9

(4x)

MP18

MP16

F1

MP11

MP12-13

(2x)

MP32

MP10

H30-32

(3x)

MP7

MP21

MP34

26

MP22-24

(3x)

MP15

MP19

MP20

MP6

Figure 7. 150X Replacement Parts

MP1

ecz19f.eps

Page 35

Insulation Testers

Table 11. Generic 150X Replacement Parts

Ref Des Description P/N Qty

MP4 102-406-003,PROBE CAP,GS-38 RED 1942029 1

MP6 FLUKE-15X7-8008,KNOB 2278007 1

MP7 FLUKE-15X7-8001,FLUKE-15X7-8001, BACKLIGHT 2168609 1

MP9 FLUKE-1508-8003-02,BOTTOM CASE 2388589 1

MP10 FLUKE-15X7-8009,HOUSING ASSY,RSOB 2278018 1

MP11 FLUKE-15X7-8010,DETENT SPRING 2278029 1

MP12-13 FLUKE-15X7-8011,INSULATOR,RECEPTACLE, RED 2278128 2

Service and Parts

MP15 FLUKE-15X7-8011-01,INSULATOR,RECEPTACLE,

BLACK

MP16 FLUKE-15X7-8012,TILT STAND 2278143 1

MP18 FLUKE-15X7-8014,HOLSTER 2278162 1

MP19 FLUKE-15X7-8016,BATTERY CONTACT,NEG 2281317 1

MP20 FLUKE-15X7-8017,BATTERY CONTACT,POS 2281321 1

MP21 LCD,TN,3.0V,TRANSFLECTIVE,1/4-DUTY,1/3-BIAS 2156884 1

MP22-24 FLUKE 89-4-8012 ,BATTERY CONTACT, DUAL 666435 3

MP40-43 BATTERY,PRIMARY,MNO2-

ZN,1.5V,2.24AH,15A,LR6,ALKALINE,AA,14X50MM,BULK

H26-29 SCREW,5-14,.750,PAN,PHILLIPS,STEEL,BLK

CHROMATE,THREAD FORMING

H30-32 SCREW,4-14,.312,PAN,PHILLIPS,STEEL,ZINC-

CLEAR,THD FORM,#3 HEAD

MP32 FLUKE 87-8004,CONTACT,PTF 822676 1

F1 W FUSE,315 MA,1000 V AC/DC,FAST,6.35 X 32 MM,BULK 2279339 1

MP44 FLUKE-165X-8008,PROBE,MULTIFUNCTIONAL 2000757 1

2278137 1

376756 4

832246 4

642931 3

MP34 CONNECTOR,ELASTOMERIC,.01IN CTR,.218 IN

HIGH,.090 IN THICK,2.43 IN LONG,BULK

2396462 1

27

Page 36

150X Series

Calibration Manual

Ref Des Description P/N Qty

MP1 FLUKE-1508-8004-01,CASE TOP,PAD XFER 2282457 1

MP2 FLUKE-1508-8005-03,BRACKET,MASK,PAD XFER 2282504 1

MP3 FLUKE-1508-8018,KEYPAD 2388514 1

MP5 FLUKE-1508-8007-02,DOOR,ACCESS 2388550 1

MP46 FLK 19-8014,TEST LEAD SET 666602 1

MP47 ALLIGATOR CLIP,600/1000V,2MM JACK,RED 1670641 1

MP48 ALLIGATOR CLIP,600/1000V,2MM JACK,BLACK 1670652 1

MP36 1508 USERS MANUAL (Chinese and English) 2416024 1

Ref Des Description P/N Qty

Table 12. 1508 Specific Parts

Table 13. 1507 Specific Parts

MP1 FLUKE-1507-8004-01,CASE TOP, PAD XFER 2282433

MP2 FLUKE-1507-8005-02,BRACKET,MASK,PAD XFER 2282491

MP3 FLUKE-1507-8018-01,KEYPAD 2388523

MP5 FLUKE-1507-8007-03,DOOR,ACCESS 2388561

MP46 TL224-4201,175-263-011 TEST LEADS RA2S 2070140

MP47 021-236-003,ALL.CLIP EX-LARGE RED IEC1010 1958654

MP48 021-236-001,ALL. CLIP EX-LARGE BLK IEC1010 1958646

MP49 PROBE,TEST,BANANA JACK,4MM TIP,RED W/CAP,

175-290-003

MP50 PROBE,PROBE,TEST,BANANA JACK,4MM TIP,BLACK

W/CAP,175-290-001

Table 14. 1503 Specific Parts

Ref Des Description P/N Qty

MP1 FLUKE-1503-8004-01,CASE TOP,PAD XFER 2282416

MP2 FLUKE-1503-8005-01,BRACKET,MASK,PAD XFER 2282484

MP3 FLUKE-1503-8018-02,KEYPAD 2388538

MP5 FLUKE-1503-8007-04,DOOR,ACCESS 2388577

2099044

2427138

1

1

1

1

1

1

1

1

1

1

1

1

1

28

Loading...

Loading...